Ingersoll-Rand 302 SERIES Installation And Operation Manual

INGERSOLL RAND

302 SERIES

VARIABLE FREQUENCY DRIVE

INSTALLATION AND OPERATION MANUAL

More Than Air. Answers.

Online answers: http://www.air.irco.com

Before installing or starting this unit for the first time, this

manual should be studied carefully to obtain a working

knowledge of the unit and/or the duties to be performed

while operating and maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY D ATA and

should be kept with the unit at all times.

C.C.N. : 23046360

REV. C

DATE: DECEMBER 2009

2

TABLE OF CONTENTS

TABLE OF CONTENTS ................................................... 2

SECTION 1 — INTRODUCTION ..................................... 3

SECTION 2 — SAFETY .................................................. 3

SAFETY PRECAUTIONS ....................................................... 3

SHIPMENT INSPECTION / PRE-INSTALLATION CHECK ............... 3

LIFTING .......................................................................... 3

INSTALLATION ................................................................. 3

MECHANICAL INSTALLATION .............................................. 3

OPERATION .................................................................... 4

MAINTENANCE AND REPAIR .............................................. 4

INGERSOLL RAND 302 SERIES VFD WARNINGS AND

PRECAUTIONS ................................................................. 4

WARNING AGAINST UNINTENDED START ............................. 5

SECTION 3 — CONTROL FEATURES AND FUNCTIONS .. 6

STANDARD FEATURES AND FUNCTIONALITY .......................... 6

SECTION 4 — INSTALLATION ..................................... 10

SECTION 5 — DISPLAY AND MENU OPERATION ........ 18

SECTION 6 — COMMISSIONING ................................ 25

PHYSICAL CHECKS .......................................................... 25

RESISTANCE CHECKS ....................................................... 25

KEYPAD OPERATIONS ..................................................... 25

POWER-UP CHECKS ....................................................... 25

INTELLISYS SETUP ........................................................... 25

SECTION 7 — FAULT CODES ...................................... 31

WARNINGS / ALARM MESSAGES ...................................... 31

SECTION 8 — PART LIST ............................................ 39

SECTION 9 — TECHNICAL DATA ................................. 40

SECTION 10 — WIRING DIAGRAM ............................. 46

Refer to Section Indicated

Note

Important or Caution, Safety

3

SECTION 1 — INTRODUCTION

The purpose of this manual is to provide instructions

needed to install, operate, and maintain the IngersollRand rotary screw air compressor with the Ingersoll Rand

302 Series Variable Frequency Drive (VFD). The

Operators/Instruction Manual supplied with the

compressor and this Instruction Manual supplied with the

Ingersoll Rand 302 Series VFD should be referenced for

more detailed instructions regarding each of these

components.

The Ingersoll Rand 302 Series VFD will maintain a

constant pressure in compressed air systems by

adjusting the compressor motor’s speed to match the

compressed air usage. Depending on the application and

air demand profile, the Ingersoll Rand 302 Series VFD

system can achieve 25-35% energy savings. Smooth

start-up, reduced machine cyc l ing, lower noise, and

monitoring energy parameters are other benefits from an

Ingersoll-Rand compressor equipped with Ingersoll Rand

302 Series VFD.

SECTION 2 — SAFETY

SAFETY PRECAUTIONS

WARNING: Risk of Danger

WARNING: Risk of Electric Shock

WARNING: Risk of High Pressure

WARNING: Consult Manual

• Before installing or operating the Ingersoll Rand

302 Series VFD, take time to carefully read all

the instructions contained in this manual, all

compressor manuals, and all manuals of any

other peripheral devices that may be installed or

connected to the unit.

• Electricity and compressed air have the

potential to cause severe personal injury or

property damage.

• The operator should use common sense and

good working practices while operating and

maintaining this system. All applicable codes

should be strictly adhered to.

• Maintenance must be performed by adequately

qualified personnel that are equipped with the

proper tools.

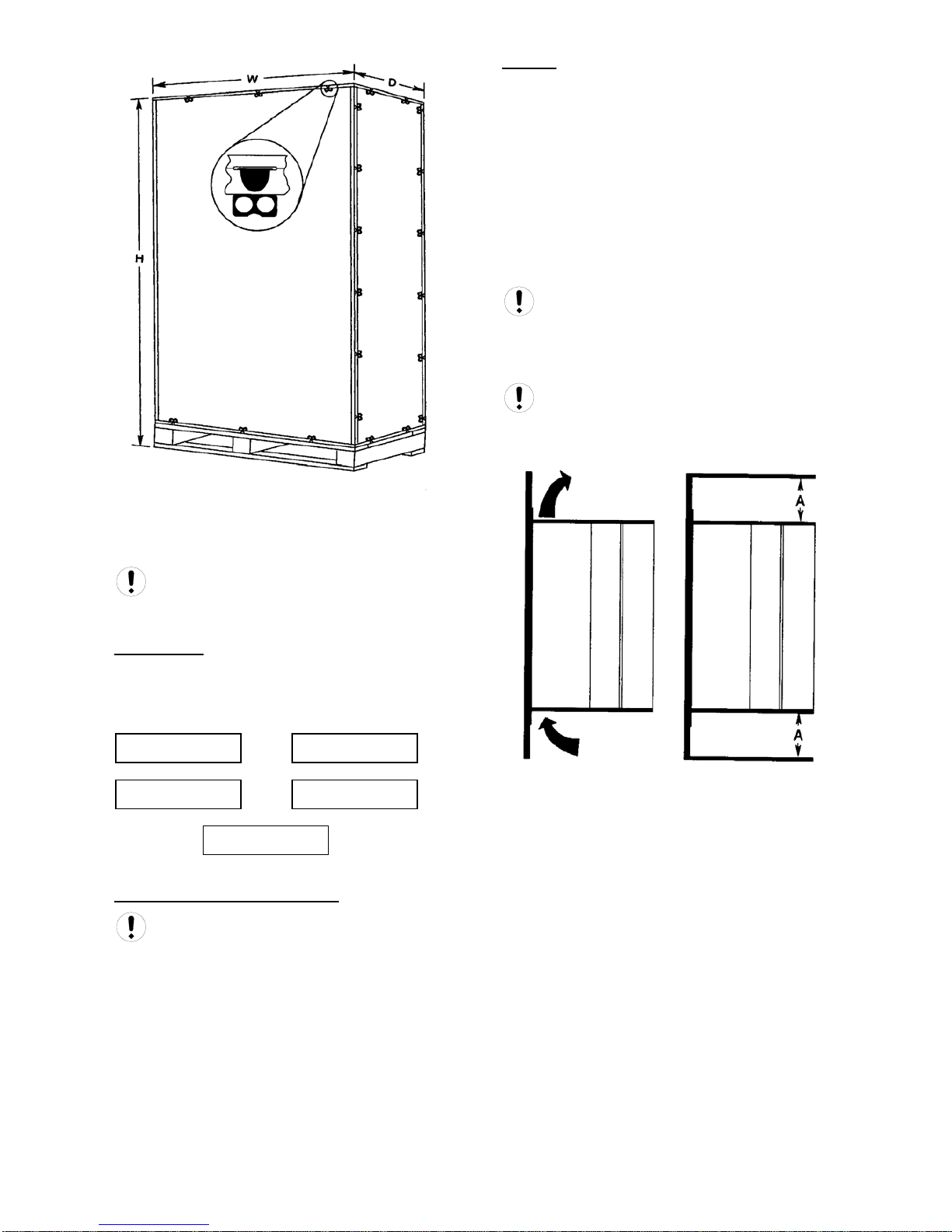

SHIPMENT INSPECTION / PREINSTALLATION CHECK

• The crating should be inspected for shipping

damage after the unit has arrived.

• Before unpacking the frequency converter it is

recommended that it is located as close as

possible to the final installation site. Remove the

box and handle the frequency converter on the

pallet, as long as possible.

LIFTING

• Always lift the frequency converter in the

dedicated lifting eyes. Use a bar to avoid

bending the lifting holes of the frequency

converter.

INSTALLATION

• Installation work must only be carried out by a

competent person under qualified supervision.

• A fused isolation switch must be fitted between

the main power supply and the Ingersoll Rand

302 Series VFD.

• The Ingersoll Rand 302 Series VFD should be

mounted in such a location as to allow

operational and maintenance acces s without

obstruction or hazard and to allow clear visibility

of indicators at all times.

• If raised platforms are required to provide

access to the Ingersoll Rand 302 Series VFD,

they must not interfere with normal operation or

obstruct access. Platforms and stairs should be

of grid or plate construction with safety rails on

all open sides.

MECHANICAL INSTALLATION

• Preparation of the mechanical installation of the

frequency converter must be done carefully to

ensure a proper result and to avoid additional

work during installation. Start taking a close look

at the mechanical drawings at the end of this

instruction to become familiar with the space

demands.

• To perform the mechanical installation the

following tools are needed:

o Drill with 10 or 12 mm drill

o Tape measure

o Wrench with relevant metric sockets (7-17

mm)

o Extensions to wrench

o Sheet metal punch for conduits or cable

glands in IP 21/Nema 1 and IP 54 units

o Lifting bar to lift the unit (rod or tube max. Ø

25 mm (1 inch), able to lift minimum 400 kg

(880 lbs)).

o Crane or other lifting aid to place the

frequency converter in position

o A Torx T50 tool is needed to install the E1

in IP21 and IP54 enclosure types.

4

• Space: Ensure proper space above and below

the frequency converter to allow airflow and

cable access. In addition space in front of the

unit must be considered to enable opening of

the door of the panel.

• Wire access: Ensure that proper cable access is

present including necessary bending allowance.

As the IP00 enclosure is open to the bottom

cables must be fixed to the back panel of the

enclosure where the frequency converter is

mounted, i.e. by using cable clamps.

o All cable lugs/ shoes must mount within the

width of the terminal bus bar

OPERATION

• The Ingersoll Rand 302 Series VFD must onl y

be operated by competent personnel under

qualified supervision.

• Never remove or tamper with safety devices,

guards or insulation materials fitted to the

Ingersoll Rand 302 Series VFD.

• The Ingersoll Rand 302 Series VFD must onl y

be operated at the supply voltage and frequency

for which it is designed.

• When main power is switched on, lethal

voltages are present in the electrical circuits and

extreme caution must be exercised whenever it

is necessary to carry out any work on the unit.

• Do not open access panels or touch electrical

components while voltage is applied unless it is

necessary for measurements, tests or

adjustments. Such work should be carried out

only by a qualified electrician equipped with the

correct tools and wearing appropriate protection

against electrical hazards.

• All air compressors and/or other equipment

connected to the unit should have a warning

sign attached stating “THIS UNIT MAY START

WITHOUT WARNING” next to the display panel.

• If an air compressor and/or other equipment

connected to the unit is to be started remotely,

attach two warning signs to the equipment

stating “THIS UNIT CAN BE STARTED

REMOTELY”. Attach one sign in a prominent

location on the outside of the equipment, and

the other sign inside the equipment control

compartment.

MAINTENANCE AND REPAIR

• Maintenance, repairs or modifications must only

be carried out by competent personnel under

qualified supervision.

• If replacement parts are required, use only

genuine parts from the original equipment

manufacturer, or an alternative approved

source.

• Carry out the following operati ons before

opening or removing any access panels or

carrying out any work on the Ingersoll Rand 302

Series VFD:

i. Isolate the Ingersoll Rand 302 Series

VFD from the main electrical power

supply. Lock the isolator in the “OFF”

position and remove the fuses.

ii. Attach labels to the isolator switch and

to the unit stating “WORK IN

PROGRESS - DO NOT APPLY

VOLTAGE”. Do not switch on electrical

power or attempt to start the CX Box if

such a warning label is attached.

• Make sure that all instructions concerning

operation and maintenance are strictly followed

and that the complete unit, with all accessories

and safety devices, is kept in good working

order.

• The accuracy of sensor devices must be

checked on a regular basis. They must be

calibrated when acceptable tolerances are

exceeded. Always ensure any pressur e withi n

the compressed air system is safely vented to

atmosphere before attempting to remove or

install a sensor device.

• The Ingersoll Rand 302 Series VFD must onl y

be cleaned with a damp cloth, using mild

detergents if necessary. Avoid the use of any

substances containing corrosive acids or alkalis.

• Do not paint the control faceplate or obscure

any indicators, controls, instru ctio ns or

warnings

.

INGERSOLL RAND 302 SERIES VFD

WARNINGS AND PRECAUTIONS

• The frequency converter DC link capacitors

remain charged after power has been

disconnected. To avoid electrical shock hazard,

disconnect the frequency converter from the

mains before carrying out maintenance. Before

doing service on the frequency converter wait at

least the amount of time indicated below:

o 380 - 500 V 90 - 200 kW 20 minutes

250 - 800 kW 40 minutes

o 525 - 690 V 37 - 315 kW 20 minutes

355 - 1200 kW 30 minutes

• The Stop/Reset key on the local control panel of

the Ingersoll Rand 302 Series VFD DOES NOT

disconnect the equipment from the AC line. DO

NOT use the Stop/Reset key as a safety switch.

• The installer must supply correct protective

grounding of the equipment. The user must be

protected against supply voltage, and the motor

must be protected against ove rload in

accordance with National Electric Code and

local codes.

• To avoid potential shock hazard when servicing

a motor or Ingersoll Rand 302 Series VFD ,

remove all power to all drives with wiring that

shares any conduit to be worked on. If that is

not possible, remove power to the drive and

ground the motor wires at the drive. When the

work has been completed, remove the grounds

before reapplying power to the drive. In general,

a conduit should not contain unshielded power

conductors for more than three PWM operated

motors.

5

• The earth leakage current from the frequency

converter exceeds 3.5 mA. To ensure that the

earth cable has a good mechanical connection

to the earth connection (terminal 95), the cable

cross section must be at least 10 mm

2

or 2 rated

earth wires terminated separately.

• The Electronic Thermal Relay (ETR) in UL/cUL

listed VFDs provides class 20 motor overload

protection in accordance with the NEC in a

single motor applications when parameter 1-40

is set for "TRIP" and parameter 1-24 is set for

the nominal motor rated (nameplate) current.

Protection against motor overload is NOT

included in the factory setting. If this function is

desired, set parameter to 1-40 to data value

ETR trip or data value ETR warning.

ETR function is initialized at 1.16 x rated motor

current.

WARNING AGAINST UNINTENDED

START

• The motor can be brought to a stop by means of

digital commands, bus commands, references

or a local stop, while the Ingersoll Rand 302

Series VFD is connected to the AC line. These

stop functions are NOT sufficient to ensure that

no unintended start occurs and should NOT be

used for personal safety considerations.

• While parameters are being changed, the motor

may start. Consequently, the Stop/Reset button

must be enabled (Parameter 0-41) after which

data can be modified. When the drive is in local

stop the LCP will be flashing. Parameter 0-41

will be changed later during the startup

procedure.

• A motor that has been stopped may start if

faults occur in the electronics of the Ingersoll

Rand 302 Series VFD or if a temporary overload

or a fault in the AC line supply or the motor

connection clears.

WARNING: The Ingersoll Rand 302 Series VFD contains dangerous voltages when connected to line

voltage. After disconnecting from the line wait at least 15 minutes before touching any electrical components. Also make

sure that other voltage inputs have been disconnected, such as external 24 VDC, load-sharing (linkage of DC intermediate

circuit), as well as the motor connection for kinetic back-up. Only a competent electrician should carry out the electrical

installation. Improper installation of the motor or the Ingersoll Rand 302 Series VFD may cause equipment fail ur e, seri ous

injury or death. Follow this manual and National

WARNING: Electrostatic Discharge (ESD) Precaution. Many electronic components are sensitive to static

electricity. Voltages are so low that they cannot be felt, seen or heard, can reduce the life, affect performance, or completely

destroy sensitive electronic components. When performing service, proper ESD equipment should be used to prevent

possible damage from occurring.

WARNING: It is the responsibility of the user or the person installing the Ingersoll Rand 302 Series VFD to

provide proper grounding, as well as motor overload and branch circuit protection according to the National Electrical Code

and local codes.

6

SECTION 3 — CONTROL FEATURES AND FUNCTIONS

STANDARD FEATURES AND

FUNCTIONALITY

The Ingersoll Rand 302 drive is an external device that is

wired to the compressor’s motors through the starter

panel. The Intellisys controller on the compressor still

starts and stops the compressor, while the Ingersoll Rand

302 Series VFD’s controller varies the compressor’s

motor speed to regulate constant system pressure. The

Ingersoll Rand 302 Series VFD operates in two different

setups:

1) In Setup 1, the Ingersoll Rand 302 Series VFD runs at

constant minimum speed and the compressor is

unloaded.

2) In Setup 2, the Ingersoll Rand 302 Series VFD

regulates a constant pressure and the compressor is

loaded.

The Intellisys controller logic determines which setup the

Ingersoll Rand 302 Series VFD operates.

See Intellisys and Ingersoll Rand 302 Series VFD

Controllers Interface Logic Diagram

As always, the Intellisy s contr o ller, set to On / Off Line

mode, will load and unload the compressor, depending

on the system pressure relative to the pressure band

limits. The Ingersoll Rand 302 Series VFD, however, tries

to keep the system pressure within the pressure band as

long as possible.

When the system pressure rises above the target

pressure, the drive will slow the compressor’s motors so

that the compressor supplies less air to the system and

allows the pressure to fall. Likewise, when the system

pressure falls, the drive increases the compressor’s

motor speed so that the compressor supplies more air to

the system.

The compressor with the Ingersoll Rand 302 Series VFD

will only load and unload at minimu m spee d, unle ss the

system pressure swings outside the Intellisys pressure

band faster than the drive can react. When the system

pressure rises above the Off Line pressure setpoint, the

blowdown valve opens and the inlet valve closes to

unload the compressor. The load relay, 2CR,

simultaneously opens to switch the drive to Setup 1

(constant, minimum speed).

Conversely, when the system pressure falls below the On

Line pressure setpoint, the blowdown valve closes and

the inlet valve opens to load the compressor. The load

relay, 2CR, simultaneously closes to swit ch the drive to

Setup 2 (pressure regulation).

Even with the Ingersoll Rand 302 Series VFD wired to

the compressor, the Start button on the Intellisys

controller initiates the full-voltage or star-delta starters.

When the 1M contactor closes, the start relay, 1CR,

closes to start the Ingersoll Rand 302 Series VFD. On

air-cooled, SSR units, the contactors have no power

flowing through them. However, the 1M contactor does

provide power to the constant-speed fan (for a watercooled unit) and the oil pump (on Sierra units only). After

the Start process is completed, the compressor will

automatically load and the Ingersoll Rand 302 Series

VFD will try to regulate the pressure.

On SSR air cooled units, the Ingersoll Rand 302 Series

VFD controls the main drive motor and the cooling fan

motor.

On SSR water cooled units, the Ingersoll Rand 302

Series VFD controls the main drive motor. The small

enclosure fan motor gets its power from the compressor

starter.

On Sierra units, the air cooled and water cooled units are

configured the same as the SSR units, except the

externally driven oil pump gets its power from the

compressor starter.

7

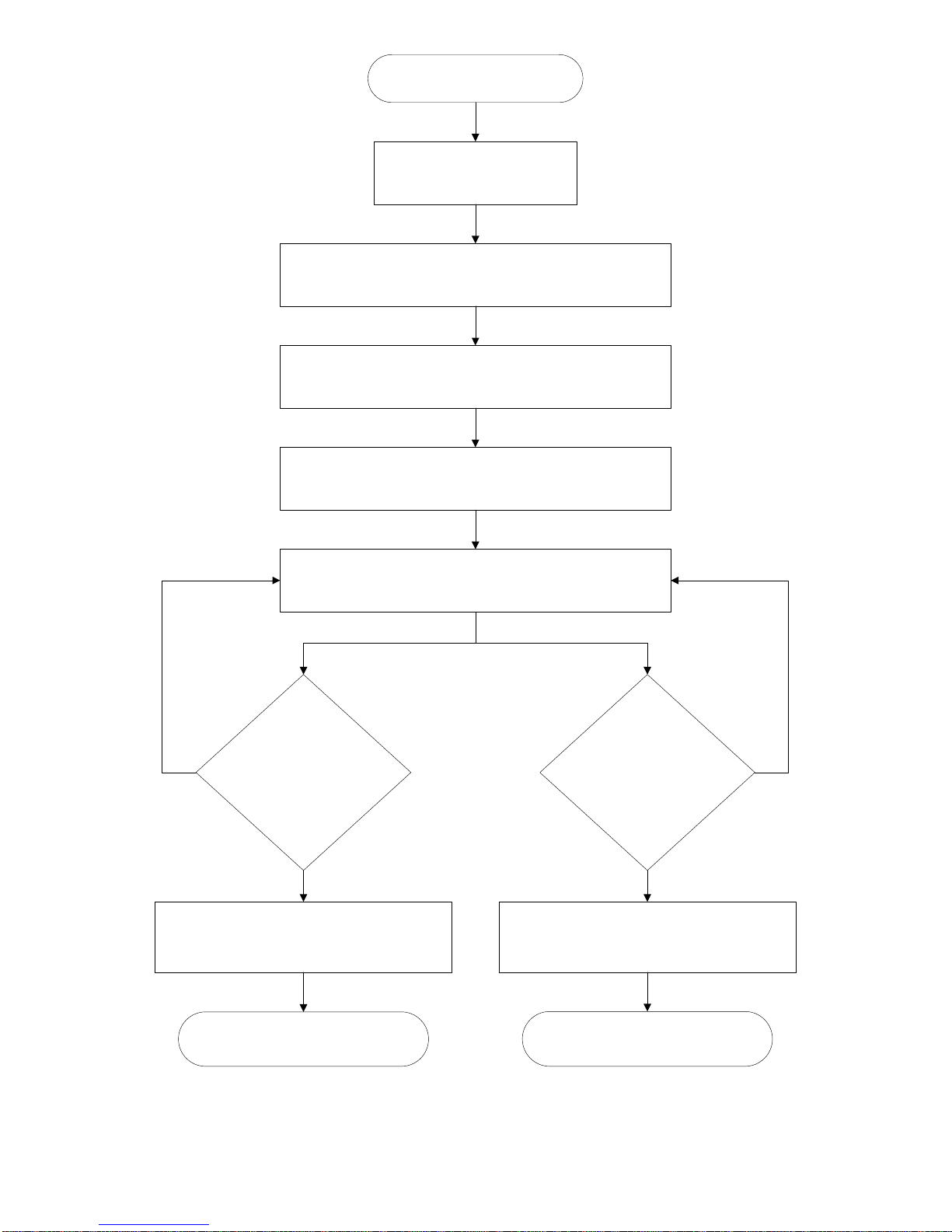

Power at VFD & Compressor

VFD Closes 3CR Relay

Press “START” on Compressor

The Intellisys Closes 1CR Relay to “START” the VFD. The

Compressor begins to run Unloaded with the VFD in SETUP 1

The Intellisys loads the Compressor and closes 2CR Relay

switching to SETUP 2. Variable Speed and Flow operation

continues until the Intellisys Unloads the Compressor.

The Intellisys Unloads the Compressor, opening 2CR Relay.

This switches the VFD to SETUP 1. The Compressor slows

down to minimum speed for the duration of the Unload cycle.

The Compressor continues to cycle between Load and Unload

(2CR Relay closing/opening) until one of the following

happens:

Has the Intellisys

decided the Unload time

has been long enough

to shut the

Compressor off?

Has the VFD Faulted

for any reason?

(I.E.: High Current,

Loss of Phase, etc.)

The Intellisys shuts down the Compressor and

Opens 1CR Relay, stopping the VFD power to

the motor.

The VFD Drive opens 3CR Relay telling the

Intellisys to Stop the Compressor immediately,

similar to the Compressor “Emergency Stop”

button being pressed.

The Compressor and the VFD are

stopped in “Stand-by” mode awaiting a

Start signal.

The Compressor and VFD Stop, both

flashing alarms.

INTELLISYS AND Ingersoll Rand 302 Series VFD CONTROLLERS INTERFACE LOGIC DIAGRAM

8

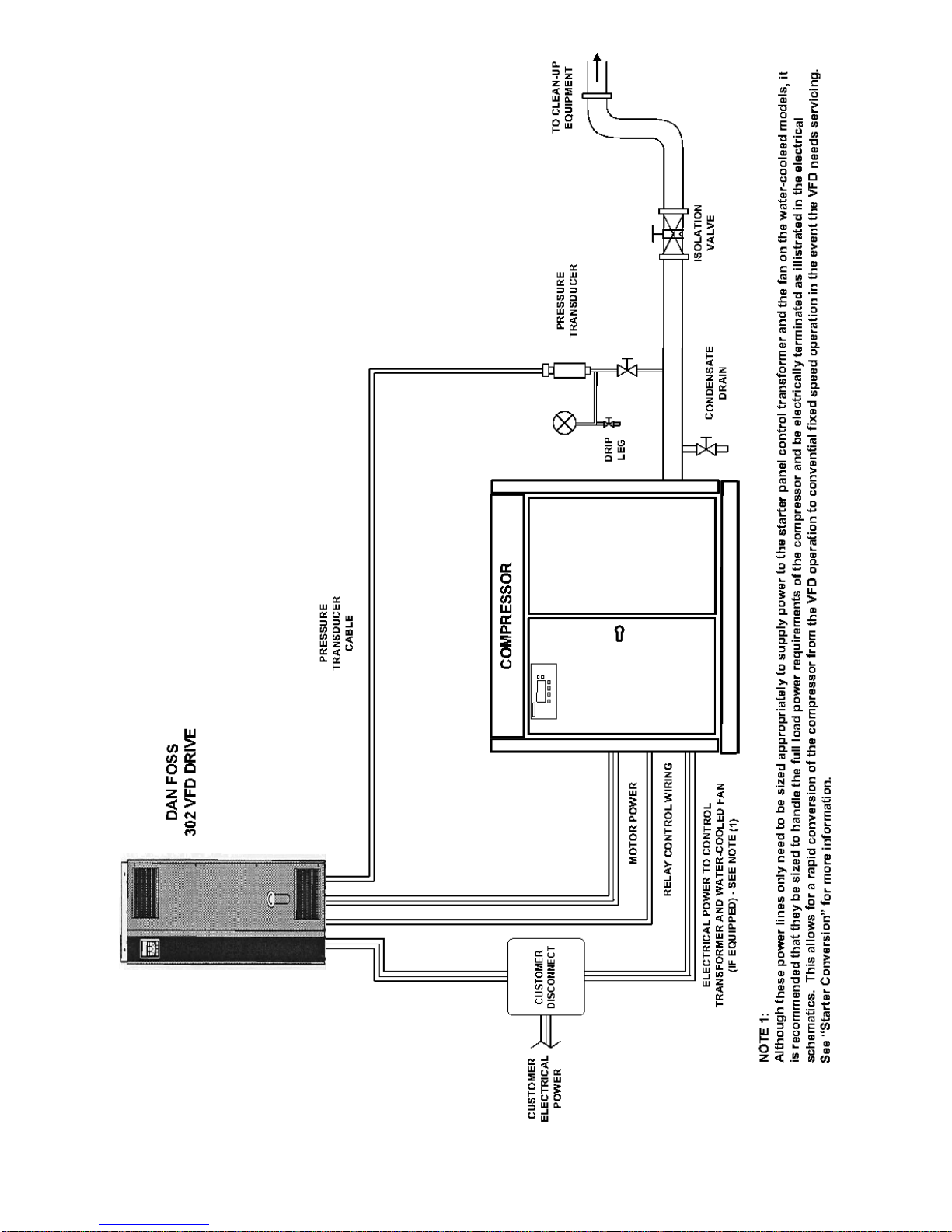

RECOMMENDED INGERSOLL RAND 302 SERIE S VFD AND COMPRESSOR SYSTEM INSTALLATION

9

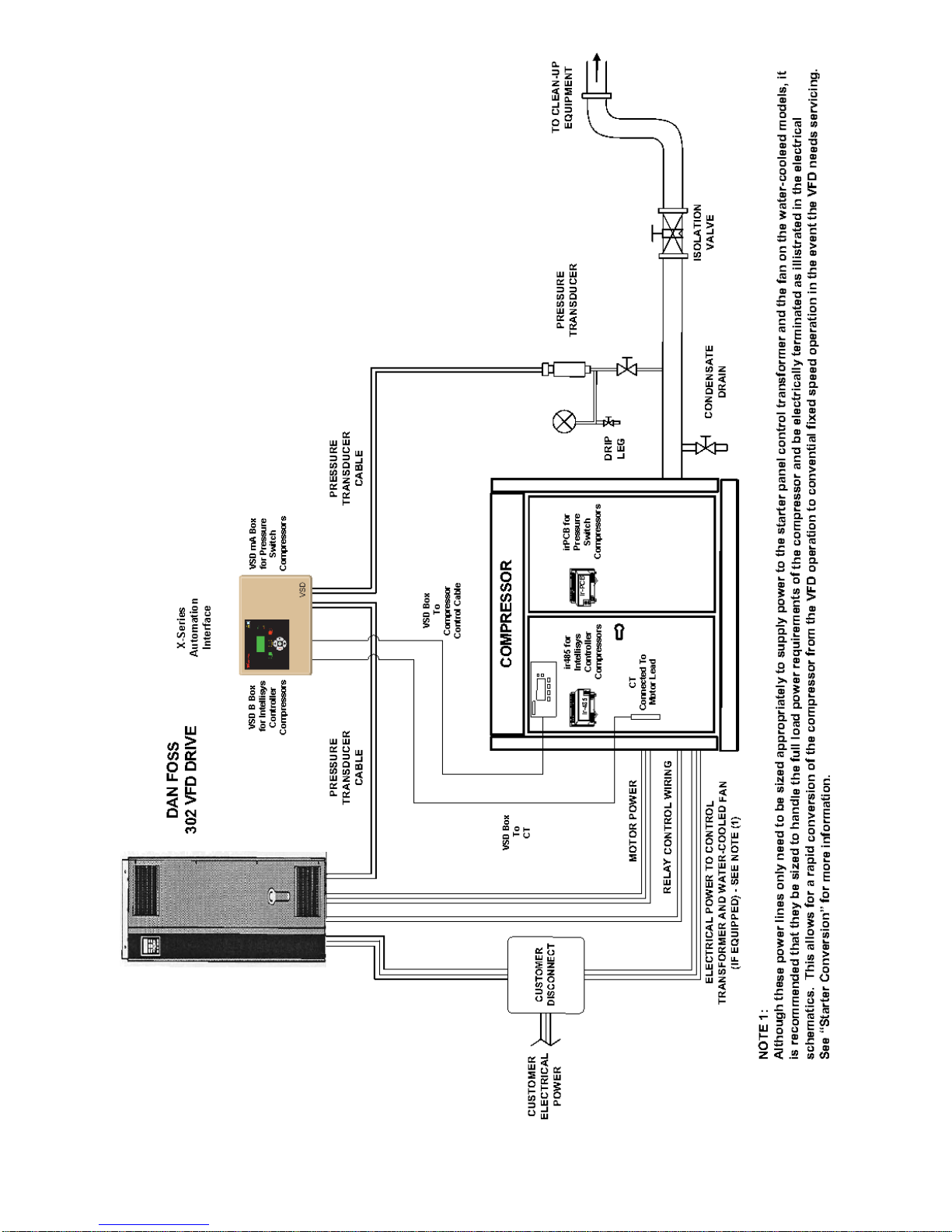

RECOMMENDED INGERSOLL RAND 302 SERIE S V FD AND COMPRESSOR SYSTEM INSTALLATION

WITH X-SERIES INTERFACE

10

SECTION 4 — INSTALLATION

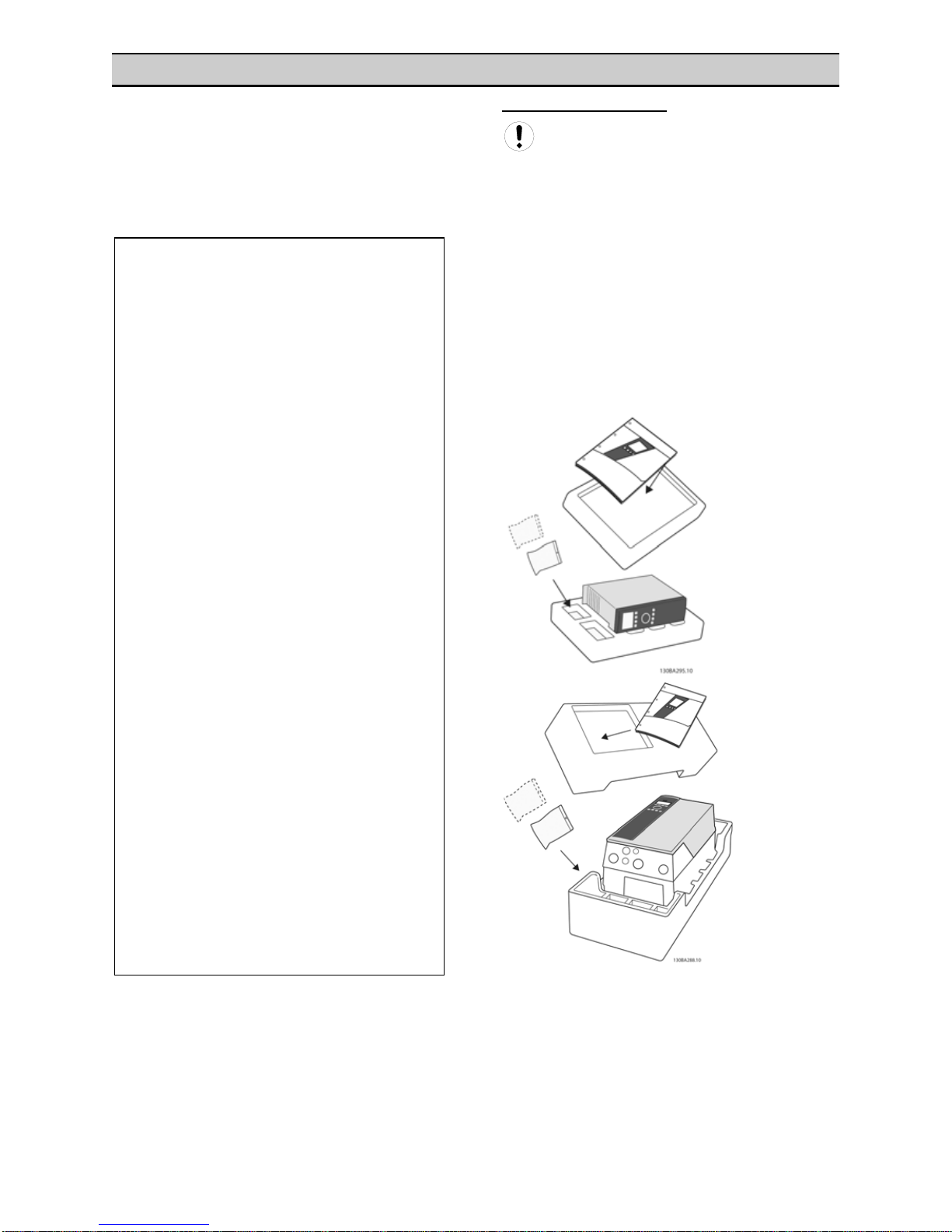

When you receive the Ingersoll Rand 302 Series VFD,

inspect it closely. Any indication of careless handling by

the carrier should be noted on the delivery receipt,

especially if the Ingersoll Rand 302 Series VFD will not

be immediately uncrated. Obtaining the delivery person’s

signed agreement to any noted damages will facilitate

any future insurance c laims.

Uncrating and Handling

It is recommended that installation and

commissioning be carried out by an authorized and

trained product supplier.”

To lessen the possibility of damage, it is recommended

that the crated Ingersoll Ra nd 302 Series VFD be located

as close to the final installation site as possible. If the

Ingersoll Rand 302 Series VFD is not to be installed

immediately, the following storage temperatures need to

be observed: –13°F to +150°F (-25°C to +65°C).

Door and ceiling clearances must be considered when

moving and installing the drive.

A qualified person with a forklift or other similar lifting

device will be needed to remove the drive from the crate.

When unpacking the frequency converter, ensure that the

unit is undamaged and complete.

IMPORTANT

READ THIS

LOST OR DAMAGED GOODS

THOROUGHLY INSPECT THIS SHIPMENT

IMMEDIATELY UPON ARRIVAL

OUR RESPONSIBILITY FOR THIS SHIPMENT

CEASED WHEN THE CARRIER SIGNED

If goods are received short or in damaged condition,

it is important that you notify the carrier and insist on

a notation of the loss or damage across the face of

the freight bill. Otherwise no claim can be enforced

against the transportation company.

If concealed loss or damage is discovered, notify

your carrier at once and request an inspection. This

is absolutely necessary. Unless you do this the

carrier will not entertain any claim for loss or

damage. The agent will make an inspection and

grant a concealed damage notation. If you give the

transportation company a clear receipt for goods

that have been damaged or lost in transit, you do so

at your own risk and expense.

WE, AT INGERSOLL RAND, ARE WILLING TO

ASSIST YOU IN EVERY POSSIBLE MANNER TO

COLLECT CLAIMS FOR LOSS OR DAMAGE, BUT

THE WILLINGNESS ON OUR PART DOES NOT

MAKE US RESPONSIBLE FOR COLLECTION OF

CLAIMS OR REPLACEMENT OF MATERIAL. THE

ACTUAL FILING AND PROCESSING OF THE

CLAIM IS YOUR RESPONSIBILITY.

Ingersoll-Rand Company

Davidson, North Carolina

APDDG-99-79

11

To open the crate: Pry up the metal locking tabs that

secure the top panel of the crate, this will allow access to

the lifting rings on the top of the drive.

See General Arrangement drawings in the VSD

Interconnect Guide for dimensions, weight, and

installation information.

Environment

The area selected for the location of the Ingersoll Rand

302 Series VFD should be free of dust, chemicals, metal

filings, paint fumes and overspray.

Dimensions: NEMA1 & NEMA 12

See General Arrangement drawings in the VSD

Interconnect Guide for dimensions, weight, and

installation information.

Cooling

The Ingersoll Rand 302 Ingersoll Rand 302 Series VFD is

cooled by means of air circulation. For the cooling air to

escape from the unit a minimum clearance must be left

above and below the unit.

The Ingersoll Rand 302 Ingersoll Rand 302 Series VFD

must be installed vertically.

To avoid overheating the unit, the ambient temperature is

not to exceed 115°F (46°C) and the mean temperature is

not to exceed 104°F (40°C). If the ambient temperature is

in the range of 115°F to 131°F (46°C to 55°C), there is a

possibility of a reduction of the service life of the Ingersoll

Rand 302 Series VFD .

For proper cooling, mount the Ingersoll Rand 302

Series VFD against a flat surface, such as a wall or a

piece of sheet metal.

Top and Bottom Free Space

See General Arrangement drawings in the VSD

Interconnect Guide for Air Space requirements.

DUST CHEMICALS

PAINT SPRAY

METAL FILINGS

OVERSPRAY

12

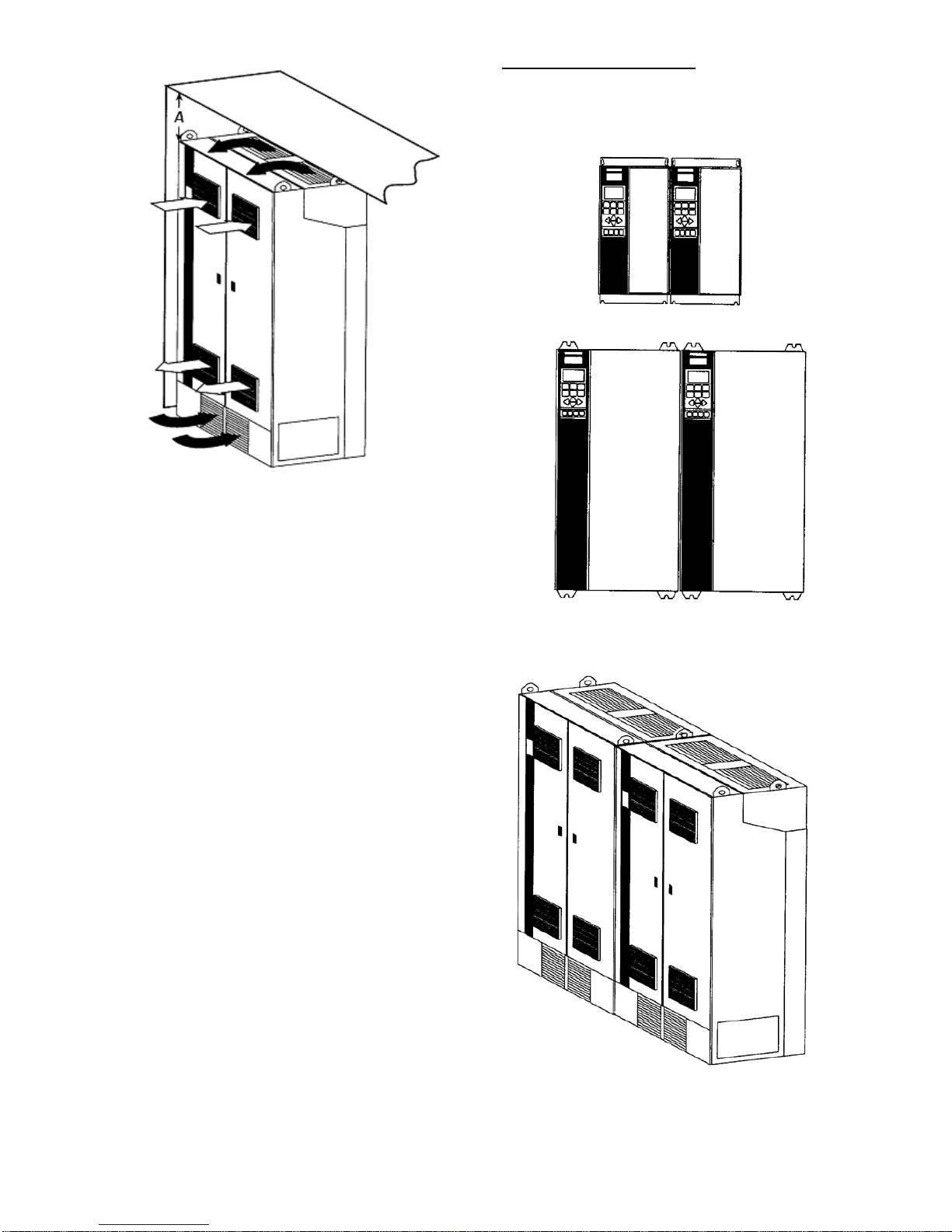

Side by Side Free Air Space

The Ingersoll Rand 302 Series VFD does not require free

air space between drives.

13

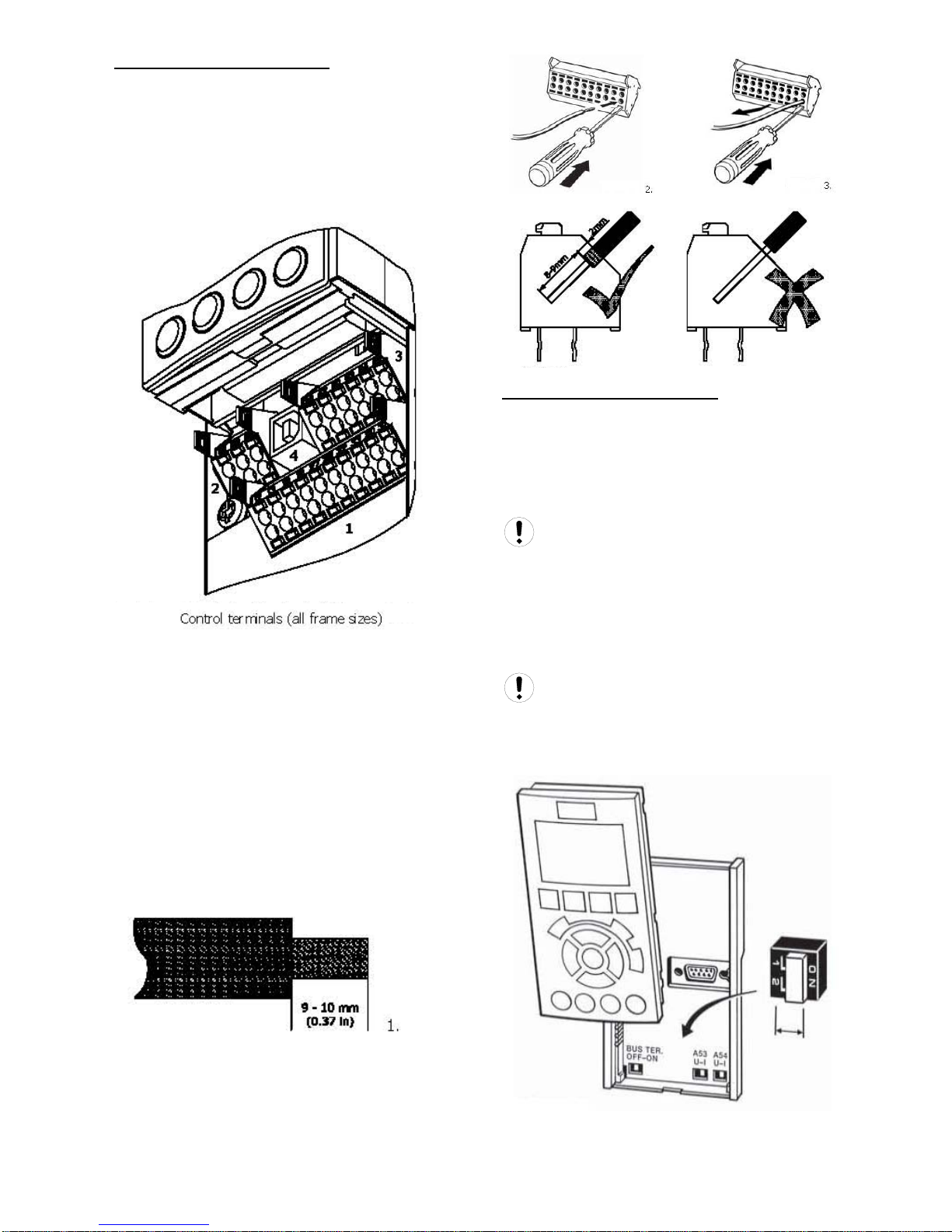

Terminal and Switch Locations

Control Terminals, Ingersoll Rand 302 Series VFD

Drawing reference numbers:

1. 10 pole plug digital I/O.

2. 3 pole plug RS485 Bus.

3. 6 pole analog I/O.

4. USB Connection.

To mount the cable to the terminal:

1. Strip insulation of 9-10 mm

2. Insert a screwdriver1) in the square hole.

3. Insert the cable in the adjacent circular hole.

4. Remove the screw driver. The cable is now

mounted to the terminal.

To remove the cable from the terminal:

1. Insert a screwdriver (1) in the square hole.

2. Pull out the cable.

(1)Max. 0.4 x 2.5 mm

.

Switches S201, S202, and S801

Switches S201 (A53) and S202 (A54) are used to select

a current (0-20 mA) or a voltage (-10 to 10 V)

configuration of the anal og inp ut termin als 53 and 54

respectively.

Switch S801 (BUS TER.) can be used to enable

termination on the RS-485 port (terminals 68 and 69).

See Power Wiring Diagram in the VSD

Interconnect Guide for all electrical terminals.

Default setting:

• S201 (A53) = OFF (voltage input)

• S202 (A54) = OFF (voltage input)

• S801 (Bus termination) = OFF

When changing the function of S201, S202 or

S801 be careful not to use force for the switch over. It is

recommended to remove the LCP fixture (cradle) when

operating the switches. The switches must not be

operated with power on the frequency converter.

14

Ingersoll Rand 302 Series VFD Electrical

Installation

The voltage of the Ingersoll Rand 302 Series VFD is

dangerous when the unit is connected to the AC line.

Incorrect installation of the motor or Ingersoll Rand 302

Ingersoll Rand 302 Series VFD may lead to material

damage or serious injury or death. Follow the instructions

in this manual and comply to National El ectr ica l Codes

(NEC) and local codes and safety guidelines.

DO NOT touch the electrical components of the

Ingersoll Rand 302 Series VFD for at least 15 minutes

after the AC line has been disconnected.

To avoid potential shock hazard when servicing a motor

or variable frequency drives, remove all power to all

drives having wiring that shares any conduit to be worked

on. If that is not possible, remove power to the drive and

ground the motor wires at the drive. When the work has

been completed, remove the grounds before reapplying

power to the drive.

In general, a conduit should not contain unshielded

power conductors for more than three PWM operated

motors.

It is the responsibility of the user or installer to

ensure correct grounding, branch circuit and motor

protection in accordance with the NEC and local codes

Connection of AC Line

Connect the three AC line phases to L1 (91), L2 (92), and

L3 (93) of the terminal block labeled Mains.

See Power Wiring Diagrams in the VSD

Interconnect Guide

To minimize electrical noise, install the drive within

100 feet (30 meters) of compressor.

To avoid electrical noise, do not route high-voltage

motor wires and low-voltage control wires through the

same conduit.

For proper safety, wire compressor and drive to a

common ground.

Schematics

The following table lists the electrical schematics that

illustrate the proper way to wire the Ingersoll Rand 302

Series VFD to the compressor. Locate t he corr e ct

schematic for the corresponding compressor and refer to

the Wiring Schematics section in this manual. The three

control relays, pressure transd ucer, and con tac t or (Si erra

only) should be wired per the proper schematic.

See Compressor Schematics in the VSD

Interconnect Guide

Safety Grounding

Please note that the Inger s oll Rand 302 Series VFD has

a high leakage current and must be grounded

appropriately for safety reasons. Use the ground

terminals (refer to the terminal drawings) which enable

reinforced grounding.

All national and local safety codes must be

observed.

See Power Wiring Diagrams in the VSD

Interconnect Guide

Motor Connection

The power cables from the Ingersoll Rand 302 Series

VFD connect to the motor terminal block located at the

bottom of the compressor’s starter box. The compressor

and fan motors’ leads are connected to the other side of

this block.

The power cables from the compressor/Ingersoll Rand

302 Series VFD system’s main disconnect (DIS1) to the

top of the compressor’s starter contactors sho uld be

sized for the full amp rating of the machine. This setup

allows for the compressor to be quickly converted from

variable speed to constant speed control should the

Ingersoll Rand 302 Series VFD need servicing.

See Power Wiring Diagrams in the VSD

Interconnect Guide

Loading...

Loading...