Page 1

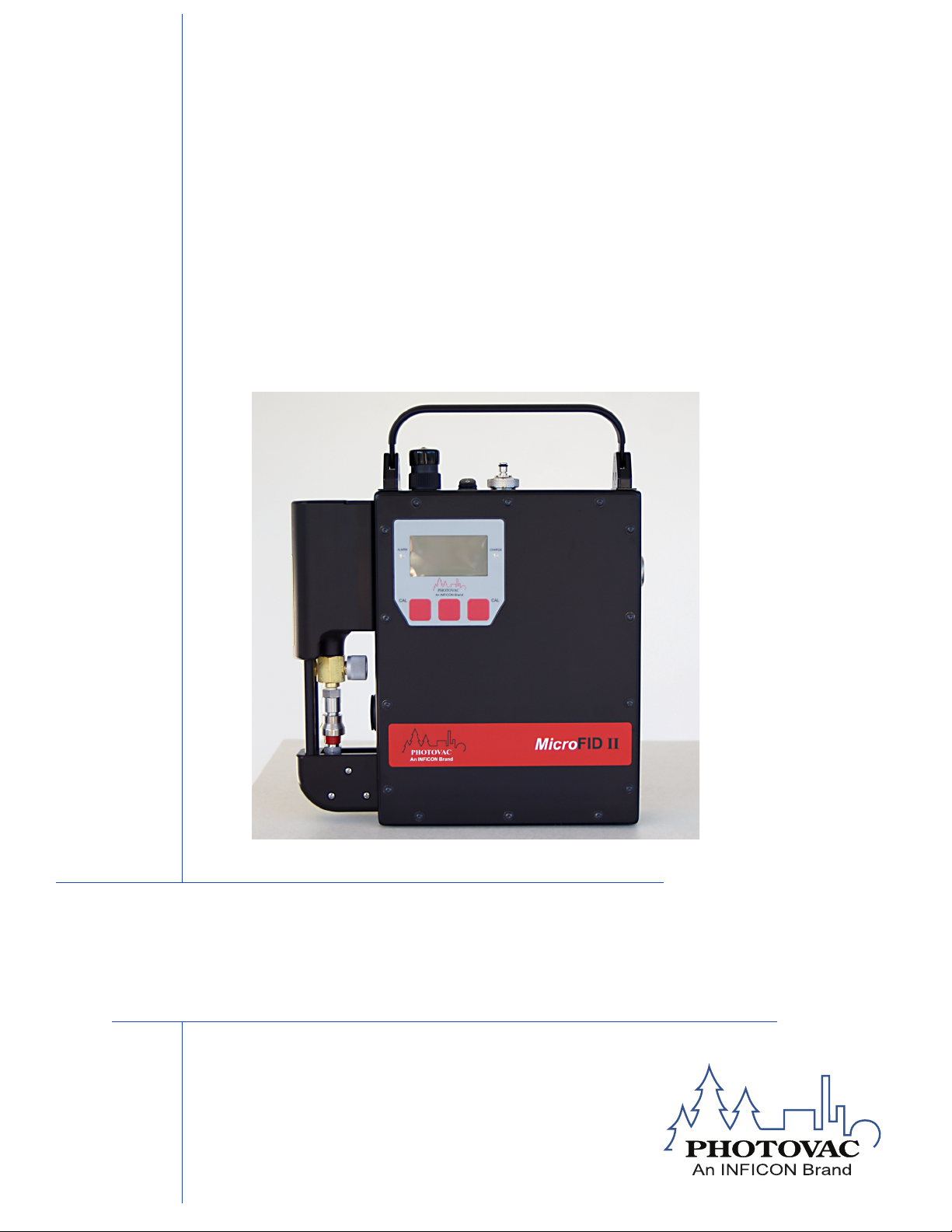

OPERATING MANUAL

MicroFID

Flame Ionization Detector

IPN 074-579-P1A

™

II

Page 2

Warning: Limitation of Liability

The ultimate responsibility of the consequences of use of toxic compounds rests with the user. INFICON’s

role is as a supplier of instrumentation to assist in the early detection of hazardous conditions involving

such compounds.

It is vitally important to ensure that the MicroFID II is maintained in accordance with INFICON’s

instructions and that proper calibration is regularly performed.

MicroFID II service should be performed only by INFICON, Inc., or an authorized INFICON repair center.

Unauthorized service may void the Intrinsic Safety Certifications.

As with any complex device, the MicroFID II is subject to failure and, while INFICON has taken, and

continues to take, all possible precautions to (a) reduce the possibility of failure, and (b) warn the user in

the event of failure, circumstances may occasionally occur in which there is a failure despite such

precautions on INFICON’s part. INFICON regrets that it cannot accept liability for damages of any kind

caused as a result of either failure of the user to follow instructions or of the MicroFID II to perform.

074-579-P1A 2

Page 3

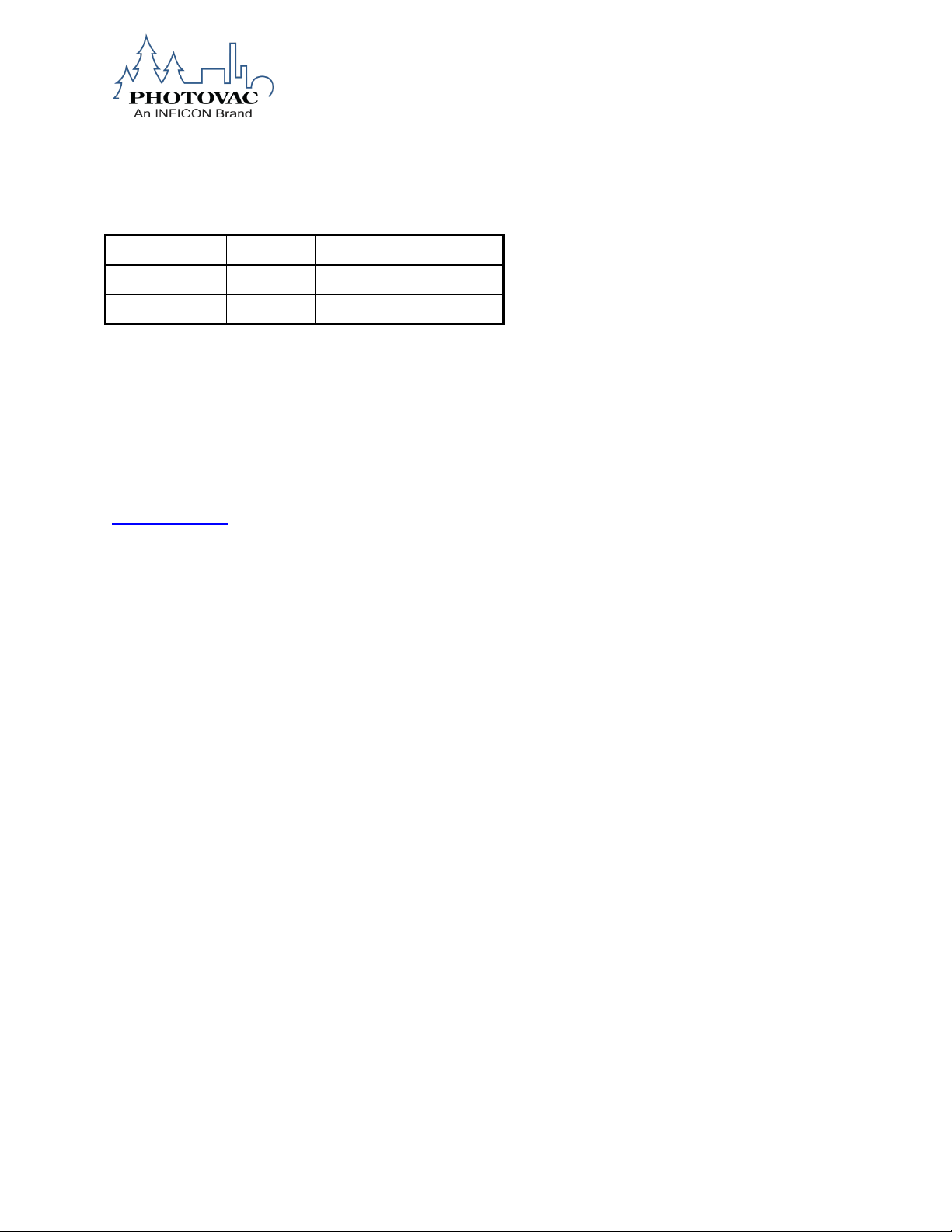

Part Number

Release

Publication Date

MN201103

A

6 September 2011

074-579-P1

A

16 October 2012

Release History

Customer Service

INFICON

Two Technology Place

East Syracuse, NY 13057 USA

315-434-1100

www.inficon.com

Notices

The information contained in this document is subject to change without notice. INFICON makes no

warranty of any kind with regard to the material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

INFICON shall not be liable for errors contained herein for incidental or consequential damages in

connection with furnishing, performance or use of this material.

Copyright © 2012 by INFICON

MicroFID IITM is a Trademark of INFICON

Windows® is a Registered Trademark of Microsoft Corporation

Bluetooth® is a registered Trademark of Bluetooth SIG, Inc.

Tedlar® and Teflon® are Registered Trademarks of E.I. du Pont de Nemours & Company, Inc.

A component of this device is licensed under U.S. Patent No. 7,369,945 B2

074-579-P1A 3

Page 4

Table of Contents

FOR YOUR SAFETY ............................................................................................................................ 7

NOTICES AND WARNINGS .............................................................................................................. 8

FCC Warning ............................................................................................................................................... 8

MicroFID II Intrinsic Safety Notice ............................................................................................................. 8

DECLARATION OF CONFORMITY ........................................................................................................... 11

1. INTRODUCTION ............................................................................................................................. 13

About this Manual ..................................................................................................................................... 13

UNPACKING THE MicroFID II ................................................................................................................... 14

WARNINGS AND SAFETY PRACTICES .................................................................................................. 14

Excessive Heat and Cold ........................................................................................................................ 14

Flame Ionization Detector Operation ...................................................................................................... 15

Detector Response ................................................................................................................................. 16

Support Equipment and Consumables ................................................................................................... 16

Compressed Gases ................................................................................................................................ 16

Regulators for Compressed Gases ......................................................................................................... 17

Hydrogen Gas ......................................................................................................................................... 17

Calibration Gas ....................................................................................................................................... 18

Oxygen Concentration Limits .................................................................................................................. 18

Flammable Gases ................................................................................................................................... 18

ACCESSORIES .......................................................................................................................................... 19

Computer ................................................................................................................................................. 19

Gas Sampling Bag .................................................................................................................................. 19

Charcoal Filters ....................................................................................................................................... 19

2. USING THE MICROFID II ............................................................................................................. 21

MicroFID II Feature Layout ....................................................................................................................... 21

Filling the Hydrogen Fuel Cylinder ......................................................................................................... 25

Attaching the Telescoping Probe to the MicroFID II ............................................................................. 33

Basic Operating Instructions ................................................................................................................... 33

Calibration.................................................................................................................................................. 34

Data Communication ................................................................................................................................ 34

Response Factors for Gases and Vapors ............................................................................................... 34

To use the response factors:................................................................................................................... 34

Preparing for Field Operation .................................................................................................................. 35

Field Check List ....................................................................................................................................... 35

Operational Check List ............................................................................................................................ 36

074-579-P1A 4

Page 5

3. USER FUNCTIONS ....................................................................................................................... 37

Display ........................................................................................................................................................ 37

Graphic Display ....................................................................................................................................... 37

Keys ............................................................................................................................................................ 41

Fixed ON/OFF Key .................................................................................................................................. 41

Soft Keys ................................................................................................................................................. 41

Beginning Operation ................................................................................................................................. 41

Turning on the MicroFID II ...................................................................................................................... 41

Default Display ........................................................................................................................................ 41

Numeric Value, Duration, Time and Date Entry ...................................................................................... 42

System Alerts and Alarms ....................................................................................................................... 43

User Interface – Basic Menu .................................................................................................................... 44

Passcode.................................................................................................................................................... 44

User Modes ................................................................................................................................................ 44

Location Mode Display ............................................................................................................................. 45

Interval Mode ............................................................................................................................................. 45

Method 21 Mode .................................................................................................................................... 46

Logging Off .............................................................................................................................................. 48

Data Logging ............................................................................................................................................. 48

Interval Mode - Data Logging .................................................................................................................. 49

MicroFID II Setup Functions ..................................................................................................................... 52

Pump ....................................................................................................................................................... 52

Backlight .................................................................................................................................................. 53

User Mode ............................................................................................................................................... 53

Date Format ............................................................................................................................................ 55

Password ................................................................................................................................................. 55

Language – Note: This feature is not yet available. ................................................................................ 55

Units ........................................................................................................................................................ 55

Real Time Data ....................................................................................................................................... 55

Alternative Calibration with Gas Bag ...................................................................................................... 61

Calibrating the MicroFID II (General) ....................................................................................................... 63

TARE selection .......................................................................................................................................... 71

4. WIRELESS COMMUNICATION ................................................................................................ 71

Wireless Communication Range ............................................................................................................. 71

Pairing ........................................................................................................................................................ 71

Enabling Blue Tooth Communication ..................................................................................................... 72

074-579-P1A 5

Page 6

5. ROUTINE MAINTENANCE ........................................................................................................ 74

Maintenance Intervals ............................................................................................................................... 74

Battery Charging ....................................................................................................................................... 74

Maintenance of the Flame Ionization Detector ....................................................................................... 75

Replacing Inlet Filter ................................................................................................................................. 75

Replacing the Sintered Filter (Exhaust Filter) ........................................................................................ 76

Calibration.................................................................................................................................................. 76

Maintenance Schedule Table ................................................................................................................... 77

Waste Electrical and Electronic Equipment (WEEE) ............................................................................. 77

7. TROUBLE SHOOTING ................................................................................................................. 78

General Information .................................................................................................................................. 78

MicroFID II Fault Messages ...................................................................................................................... 78

MicroFID II Troubleshooting .................................................................................................................... 80

8. APPENDICES ................................................................................................................................. 84

Monitoring Software ................................................................................................................................. 85

MicroFID II Telescoping Probe Holder Installation Guide ..................................................................... 86

MicroFID II Shoulder Strap Adaptor Kit Installation Guide ................................................................... 87

Warranty ..................................................................................................................................................... 88

Contacting INFICON .................................................................................................................................. 89

074-579-P1A 6

Page 7

For Your Safety

Strictly follow the Instructions for Use

Any use of this instrument requires a full understanding and strict adherence to these instructions.

The instrument is only to be used for the purposes specified in this manual.

Maintenance

The MicroFID II must be inspected and serviced by trained service personnel at regular intervals.

Repair of the MicroFID II may only be carried out by INFICON factory authorized service personnel.

Only authentic INFICON spare parts may be used for maintenance. Review the chapter “Maintenance

Intervals.”

Use in areas subject to explosion hazards

The MicroFID II has been tested and approved according to EMI and intrinsic safety requirements defined

by the US (FCC Pt. 15 and UL 913 5th edition). Declarations of conformity are found on page 11.

Modifications of components or the use of faulty or incomplete parts is not permitted. When making

repairs to equipment or components of this type, Intrinsic Safety Certifications may be violated if the

MicroFID II is serviced by individuals or organizations that are not INFICON factory certified for repair

services.

Liability

The liability for the proper functioning of the MicroFID II is irrevocably transferred to the owner or operator

to the extent that the instrument is improperly serviced or repaired by personnel not employed or

authorized by INFICON, or if the MicroFID II is used in a manner not conforming to its intended use.

INFICON cannot be held responsible for damage caused by non-compliance with the recommendations

given above.

The warranty and liability limitations provisions of the terms of sale and delivery of INFICON, are likewise

not modified by the recommendations given above.

Copyright Information

This document contains proprietary information that is protected by copyright. All rights are reserved. No

part of this publication may be reproduced in any form whatsoever or translated into any language without

the prior written permission of INFICON.

Trademarks

Registered names, trademarks, etc. used in this document, even when not specifically marked as such,

are protected by law.

074-579-P1A 7

Page 8

Notices and Warnings

FCC Warning

This equipment has been tested and found to comply with the limits for a Class B Digital Device, pursuant

to Subpart B, Class B of Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at their expense.

MicroFID II Intrinsic Safety Notice

THE MicroFID II IS CLASSIFIED FOR USE IN CLASS I, DIVISION 1, GROUPS A, B, C, D HAZARDOUS

LOCATIONS. T4 (135°C) RATING.

The MicroFID II has been listed by Intertek, Inc., to comply with Underwriters Laboratories® Inc. UL® 913

Standard for Intrinsically Safe Apparatus and Associated Apparatus for use in Class I, Division 1, Groups

A, B, C, D Hazardous (Classified) Locations.

MicroFID II Safety Label

NOTE: The MicroFID II and MicroFID II are based on the same platform and contain the same

components. The terms may be used interchangeably throughout this manual.

074-579-P1A 8

Page 9

WARNING

If there is any indication of physical damage to the MicroFID II after it has

been dropped, the unit must be checked out by a service technician to

ensure instrument integrity.

.

WARNING

Do not use any other accessories with the MicroFID II in a hazardous

location

Substitution of components may affect the safety rating.

THE MicroFID II IS NOT INTENDED TO DETECT COMBUSTIBLE LEVELS OF GASES.

THE MicroFID II IS CLASSIFIED FOR USE IN ATMOSPHERES CONTAINING COMBUSTIBLE LEVELS

OF GASES.

CAUTION

To reduce the risk of fire or injury to persons, read and follow these instructions:

1. All calibration, maintenance and servicing of this device, including battery charging, must be

performed in a safe area away from hazardous locations. Disconnect all power before servicing.

2. There are no operator replaceable parts for the MicroFID II except the exhaust frit, and sample

inlet filter.

3. There are no operator serviceable parts inside the MicroFID II.

WARNING

1. Do not dispose of the battery pack in a fire. The cells may explode. The battery pack must be

disposed of properly. Check with local codes for possible special disposal instructions.

2. Do not open or mutilate the battery pack. If the MicroFID II is used in a manner not specified,

the protection provided by the MicroFID II may be impaired.

3. Exercise care in handling battery packs in order not to short the terminals with conducting

materials such as rings, bracelets and keys. The battery or conductor may overheat and

cause burns.

4. Do not defeat proper polarity orientation between the battery pack and battery charger.

5. Charge the battery pack using the AC battery charger provided with or identified for use with

this product only in accordance with the instructions and limitations specified in this manual.

To charge the battery, use only the Universal Battery Charger Part No. A1201221. When

using the battery charger, do not block access to the mains outlet in use with adapter. The

074-579-P1A 9

AC battery charger is not to be used in a hazardous area.

Page 10

WARNING

Do not open the MicroFID II housings to access the internal components.

This action will invalidate the Intrinsic Safety rating for these products

WARNING

1. All calibration, maintenance and servicing of this device, including battery charging, must be

performed in a safe area away from hazardous locations.

2. Disconnect all power before servicing.

3. Do not open the MicroFID II exhaust frit when the unit is operating.

074-579-P1A 10

Page 11

DECLARATION OF CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market accordingly.

It has been constructed in accordance with good engineering practice in safety matters in force in the

Community and does not endanger the safety of persons, domestic animals or property when properly

installed and maintained and used in applications for which it was made.

In addition, this is to certify that this equipment has also been designed and manufactured, having regard

to the state of the art, to ensure compliance with the Protection Requirements of EMC directive

2004/108/EC.

A Technical Documentation File is also available for review by competent authorities and will be

maintained for a period of ten years after the date on which the equipment was last manufactured. In

addition to this file, technical, installation, maintenance and application information concerning this

equipment can also be found in the Operating Manual(s) for this product or product family.

Equipment Description: MicroFID II, MicroFID II, SiteFID.

Applicable Directives: 2006/95/EC (LVD)

1999/5/EC (R&TTE / EMC)

2004/108/EC (General EMC)

2011/65/EC (RoHS)

Applicable Standards:

Safety: UL 913, Fifth Edition; Dated February 21, 1997; with Revisions through

and including February 24, 1997, UL Standard for Safety for Intrinsically

Safe Apparatus and Associated Apparatus for Use in Class I, II, and III,

Division 1, Hazardous (Classified) Locations

ANSI/UL 1203-2006; Fourth Edition; Dated September 15, 2006,

UL Standard for Safety for Explosion-Proof and Dust-Ignition-Proof

Electrical Equipment for Use in Hazardous (Classified) Locations

ANSI/UL 61010-1-2008; Second Edition; Dated July 12, 2004,

(UL Standard for Safety for Electrical Equipment for Measurement,

Control and Laboratory Use)

Emissions: EN 61326-1:2006: FCC 47 CFR Part 15 Subpart B

(Radiated & Conducted Emissions)

Class B: Emissions per Table 3

(EMC – Measurement, Control & Laboratory Equipment)

074-579-P1A 11

Page 12

Countries

Restrictions

France

Outdoor use limited to 10mW e.i.r.p. within the band

2454 to 2483.5 MHz.

Italy

If used outside of own premises, general

authorization is required.

Luxembourg

General authorization is required for public service.

Romania

On a secondary basis. Individual license required.

Austria, Denmark, Finland,

Germany, Greece, Iceland,

Ireland, Liechtenstein,

Luxembourg, The Netherlands,

Norway, Portugal, Spain,

Sweden, Switzerland, The

United Kingdom

None

RoHS: INFICON hereby declares that the above mentioned products are

assigned to the classification of Category 9, Industrial Test and

Measurement Equipment, it is exempt from the RoHS directive pursuant

to Article 4, paragraph 4, section e), until 22 July 2017.

Immunity: EN 61000-4-5:1995+A1:1998+A2:2001

Electro Static Discharge (+4kV Contact discharge, + 8kV Air discharge)

EN61000-4-4:2004

Radiated RF Susceptibility (80-270 MHz @ 3 V/m, 1kHz AM 80%

Modulation)

Wireless Restrictions:

CE Implementation Date: May 15, 2012

Authorized Representative:

Name: Stephen Chabot

Title: Vice President of Operations and Quality

Done at East Syracuse, NY USA

On 13 August 2012

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE

DIRECTED, IN WRITING, TO THE VICE-PRESIDENT OF OPERATIONS AT THE ABOVE ADDRESS.

074-579-P1A 12

Page 13

WARNING

A warning indicates an operation that could cause personal injury if

precautions are not followed.

CAUTION

A caution indicates an operation that could cause damage to the

instrument if precautions are not followed.

NOTE

A note indicates significant information.

1. INTRODUCTION

About this Manual

This manual provides detailed instructions for the setup, operation and maintenance of the MicroFID II

Portable Flame Ionization Detector.

NOTE: The MicroFID II and MicroFID II are based on the same platform and contain the same

components. The terms may be used interchangeably throughout this manual.

Before unpacking the instrument, please read the Warnings and Safety Practices. This section

describes possible hazards that may injure the user, damage the instrument or compromise its operation.

Some general safety information is also provided.

The MicroFID II manual uses a few conventions for key names on the keypad and for text that is shown

on the display.

UPPERCASE Key names are denoted by uppercase text. An ARROW key is the

collective name for the UP ARROW and DOWN ARROW keys.

“Display Text” Text that appears on the MicroFID II display is in quotation marks.

<Angle Brackets> Computer keyboard names are denoted by angle brackets, e.g. <Ctrl>.

FID Text that must be typed in using the computer keyboard is shown in

italics.

In the User Manual text various warnings and notes are displayed, including:

074-579-P1A 13

Page 14

WARNING

The MicroFID II only measures the concentration of airborne gases and

vapors that can be ionized by a flame ionization detector.

The MicroFID II automatically displays and can record the concentration

values.

The reading displayed represents the total concentration of all flame

ionizable chemicals present in the sample. The MicroFID II can display

concentration values in ppm and ppb.

WARNING

Do not expose the instrument to intense sunlight for prolonged periods.

Exposure to excessive heat may result in erroneous readings.

At low temperatures, water vapor, a by-product of the hydrogen flame, may

condense at the exhaust port. At sub-zero temperatures the water vapor

will freeze and obstruct the exhaust port. If the exhaust port becomes

obstructed, pump operation will be inhibited. Flame out may also result.

UNPACKING THE MicroFID II

The following accessories are included with your MicroFID II:

MicroFID II Instrument CD Manual

70 Liter hydrogen cylinder

MicroFID II Multi-Tool

Universal Battery Charger with Line Cord

Replacement Fluoropore Membrane Filters for Sample Inlet

Ensure all of these accessories have been included with the instrument. If any items are missing or

damaged, contact INFICON immediately.

WARNINGS AND SAFETY PRACTICES

Please read this section before operating the MicroFID II.

Throughout this manual notes are provided to inform you of the limitations of usage for the MicroFID II.

Intended Use

Excessive Heat and Cold

074-579-P1A 14

Page 15

Electrometer

Repeller Electrode

(Jet +75 Volts)

Collector Electrode

Sample In

Exhaust Out

Flame Arrestor

Flame Arrestor

Microprocessor

Combustion Chamber

Glow PlugThermocouple

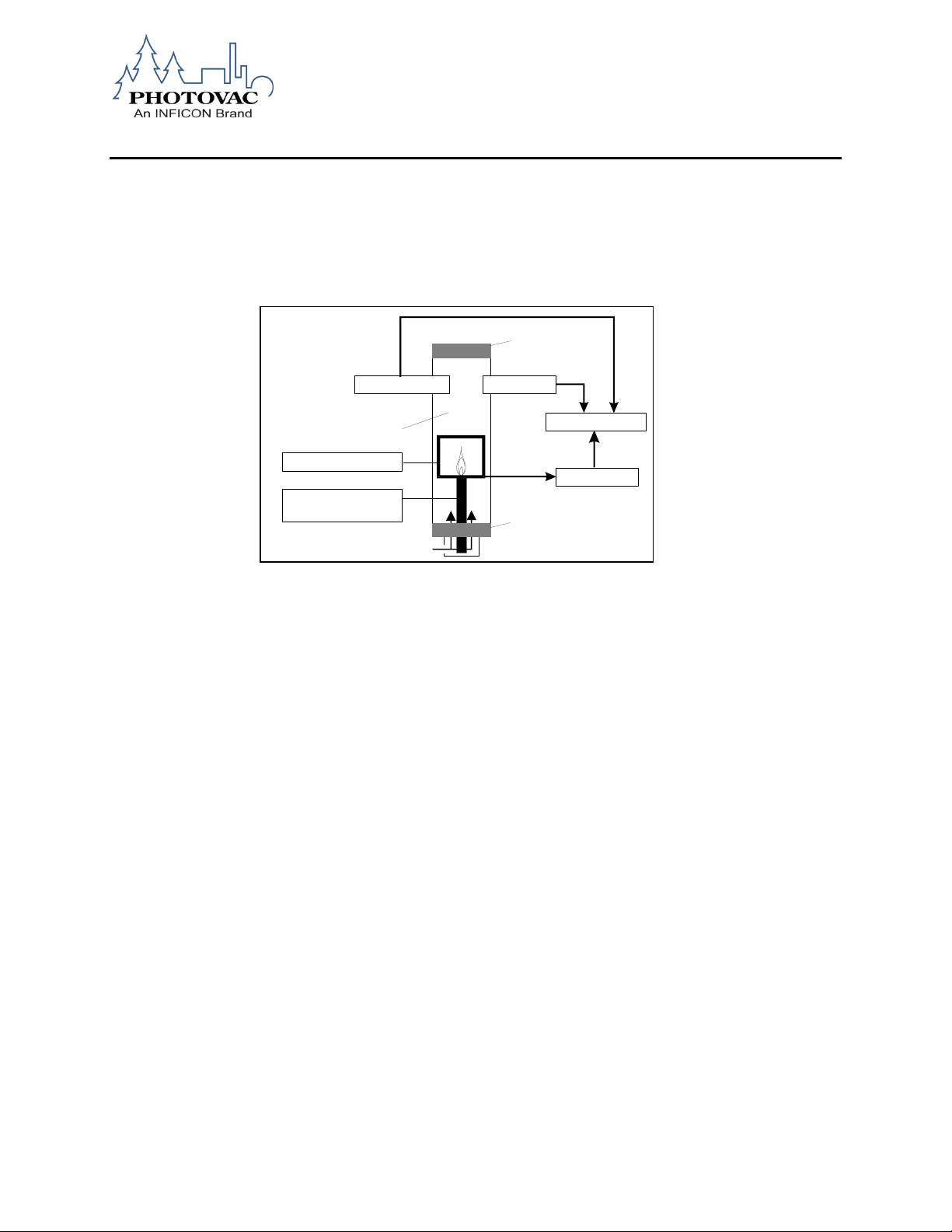

Flame Ionization Detector Operation

The MicroFID II uses a flame ionization detector for the measurement of combustible organic compounds

in air at parts-per million levels. The permanent air gases (argon, carbon dioxide, nitrogen, oxygen, water

vapor, etc.) are not ionized by the flame.

When the MicroFID II is flamed on, the internal pump draws air in through the MicroFID II inlet. This

sample air provides the oxygen necessary for combustion in the hydrogen fed flame.

Figure 1. Flame Ionization Detector

When the proper ratio of hydrogen to air is present in the combustion chamber, the flame is started

automatically with a glow plug. A thermocouple is used to monitor the status of the flame.

When the sample passes through the flame, the combustible organic compounds in the sample will be

ionized. After the compounds have been ionized by the flame, the ionized particles are subjected to a

continuous electric field between the repeller electrode at the jet (+75V) and the collector electrode.

The ions move in the electric field, generating a current, which is proportional to the concentration of the

ionized molecules in the ionization chamber. An electrometer circuit converts the current to a voltage that

is then fed to the microprocessor.

After the sample passes through the flame and has become ionized, it is vented from the detector through

a flame arrestor. The flame arrestor prevents the flame from igniting any flammable gases present in the

sampling location.

074-579-P1A 15

Page 16

Display and

I/O Connector

Keypad

Microprocessor

Power

Supply

Electrical Connections

Sample Flow

Pump

Sample

In

Inlet

Filter

Flame Ionization

Detector

Detector

Out

Figure 2. Block Diagram

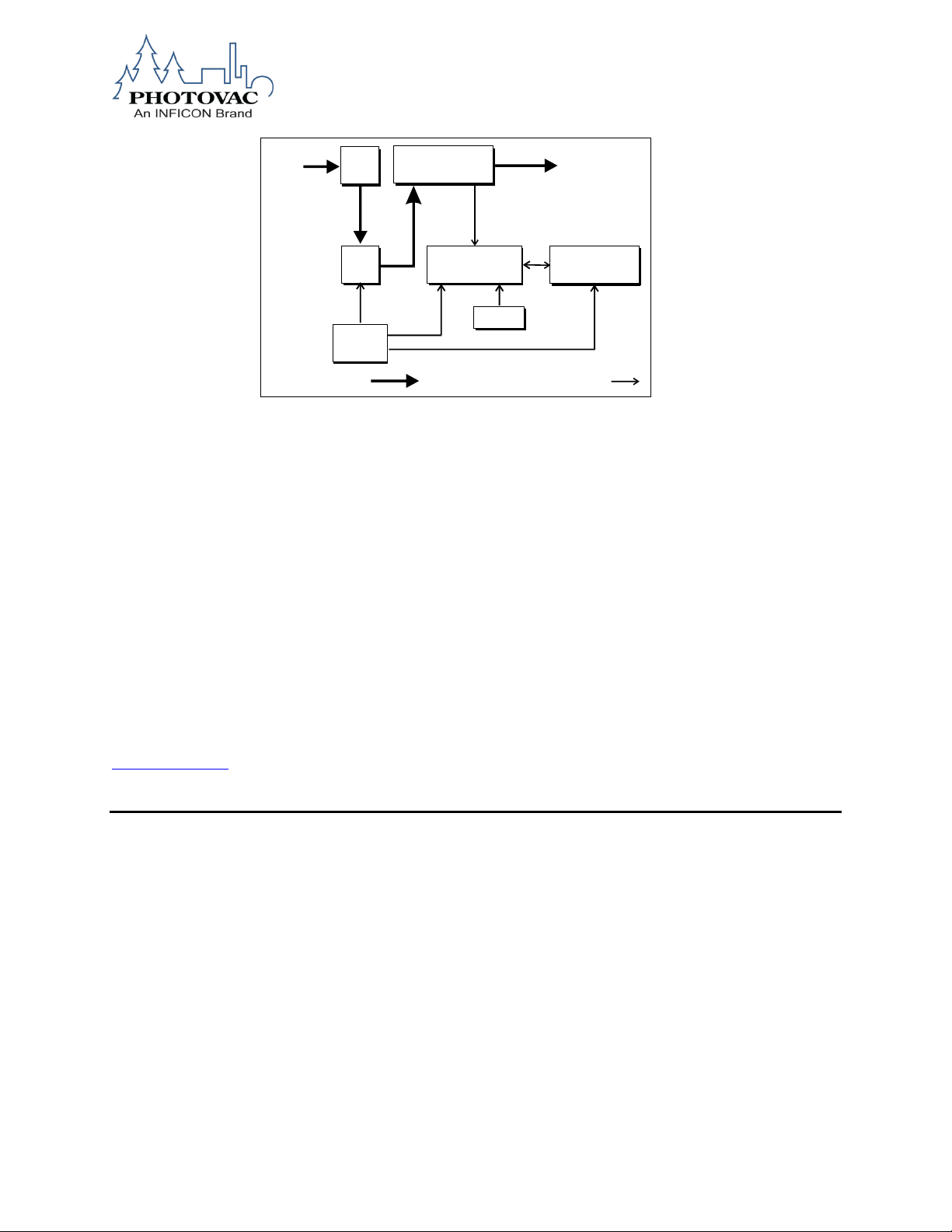

Detector Response

The MicroFID II is strictly an organic compound detector. It does not respond to inorganic compounds.

The MicroFID II’s sensitivity is highly dependent on chemical structure and bonding characteristics. The

combustion efficiency of a compound determines its sensitivity.

Simple saturated hydrocarbons (methane, ethane etc.) possess high combustion efficiencies and are

among the compounds that produce the highest MicroFID II response. Organic fuels (acetylene, refined

petroleum products), burn easily and are also extremely well detected.

The presence of substituted functional groups (amino, hydroxyl, halogens) on a simple hydrocarbon

reduces its combustion efficiency and thus MicroFID II’s sensitivity to the compounds methanol and

chloromethane, for example, are detectable with the MicroFID II but not as well as methane. A greater

number of carbon atoms can offset this loss of sensitivity due to substitution. For example, the MicroFID II

is more sensitive to n-butanol than it is to methanol.

NOTE: The FID Response Factors Technical Note is maintained on the INFICON web site:

www.inficon.com.

Support Equipment and Consumables

Compressed Gases

Cylinders of compressed gas, such as hydrogen and calibration gas, must be handled with extreme care.

When using the calibration gas bag adapter, take care not to kink or stress the tubing. For safety, the

hydrogen and calibration gas cylinders must be secured before use.

Please observe the following handling procedures:

Do not mutilate cylinders.

Do not expose the cylinders to direct sunlight.

Do not heat the cylinders. The cylinders may rupture at high temperatures.

Use only the specified regulator for the calibration gas. Confirm regulator type and material with

your specialty gas supplier.

Use only the MicroFID II Hydrogen Filling Station for the hydrogen cylinder, Part No. A1201222.

074-579-P1A 16

Page 17

WARNING

Hydrogen gas is a fire and explosion hazard when exposed to heat or

flame. The lower explosive limit (LEL) is 4%. The lower explosive limit is

the minimum concentration of gas or vapor in air that will ignite in the

presence of a source of heat or sparks.

Refer to the Material Safety Data Sheet (MSDS) before handling this gas.

The MSDS will be provided by the gas supplier when the gas is ordered.

Always secure cylinders before removing the cylinder valve protection cap.

Do not drag or roll cylinders. Use a cylinder hand truck to move large cylinders.

Wear safety glasses when working with compressed gases.

Store cylinders in an upright position.

Do not store cylinders in a hazardous location.

Store cylinders away from possible sources of ignition.

Keep regulators and related equipment in the same gas service. Do not change service or adapt

equipment without consulting your gas supplier.

Refer to local shipping regulations for hydrogen supply cylinder shipping instructions.

Regulators for Compressed Gases

When connecting a regulator to a large cylinder:

Ensure the cylinder valve and regulator connection match.

Ensure the regulator construction materials are compatible with the gas, and that the cylinder

pressure gauge will withstand the cylinder pressure.

Never use the regulator as a shut-off valve. Close the cylinder valve when it is not in use.

Do not subject the regulator to an inlet pressure greater than recommended.

Do not move or detach the regulator when it is pressurized or when it is in use.

Before connection, ensure the gas cylinder valve and the regulator CGA connection are clean.

Turn the pressure control valve on the cylinder all the way out (close the cylinder). Turn the

regulator outlet to off. Open the gas cylinder valve slowly and check for leaks. Adjust the delivery

pressure and then open the regulator outlet valve.

Hydrogen Gas

The MicroFID II detector uses a hydrogen flame to ionize samples and produce Total Volatile Organic

Compound (TVOC) readings. The quality and purity of the Hydrogen gas is very important to the

accuracy of the detector.

074-579-P1A 17

Page 18

You must obtain a tank of hydrogen from which you can fill the internal cylinder. When ordering hydrogen,

specify ultra-high purity hydrogen, 99.999% pure. This grade of hydrogen is also referred to as Grade 5 or

Ultra zero grade. The hydrogen must have less than 0.1 ppm hydrocarbon contamination.

You can obtain the hydrogen in various size cylinders and pressures. Specify a tank with no more than

2400 psig (16547 kPa).

The hydrogen cylinder must also have CGA 350, male outlet.

The MicroFID II Hydrogen Filling Station Part No.A1201222 is required to fill the MicroFID II hydrogen fuel

cylinder. You cannot fill the MicroFID II hydrogen cylinder without the MicroFID II hydrogen filling station.

Calibration Gas

Adequate ventilation must be provided when the MicroFID II is being calibrated.

If compound threshold limit values (TLV) are exceeded, you should use a gas bag for sampling and

calibration.

To determine the TLV of the compounds contained in the calibration gas, refer to the Material Safety Data

Sheet (MSDS) supplied with your calibration gas cylinder.

Oxygen Concentration Limits

A minimum of 17% oxygen is required to start the hydrogen flame. The oxygen is supplied from the

sample as it is drawn in by the pump. A minimum of 10% oxygen is required to maintain the hydrogen

flame. An oxygen deficiency will reduce the height of the flame or cause the flame to be extinguished and

may affect the displayed reading.

If the MicroFID II is used in a highly contaminated area where it is possible that the oxygen content is

below 10%, watch for indications of reduced flame height such as lowered detection limits or a flame out

fault.

Flammable Gases

High concentrations of flammable gases (gases within their flammable range) can act as an additional

fuel source. When this happens, the flame height may increase beyond the confines of the combustion

chamber. The hydrogen supply will then be cut off and the flame will go out.

Flame out may also occur when the concentration of sample gas is so great that it causes an oxygen

deficiency. This may occur when sampling enclosed or confined spaces where vapors and gases cannot

escape. Watch for indications of increased flame height such as erratic readings or sudden high

concentrations followed by a flame out fault.

074-579-P1A 18

Page 19

WARNING

The MicroFID II is not classified for use in hazardous locations with nonintrinsically safe rated computers.

ACCESSORIES

Computer

The MicroFID II will send information stored in its logged memory or will continuously stream data to a

computer or PDA via Bluetooth wireless communication. This feature may be used if you need to prepare

reports based on the MicroFID II recorded data.

Information prepared on a PC such as “routing or tag information” may be uploaded to the MicroFID II via

Bluetooth as well.

Gas Sampling Bag

A gas sampling bag can be used for calibration of the MicroFID II. If you are unsure of the quality of

ambient air you should use an additional gas bag filled with zero air. Connect the sample bag to the inlet

fitting with the gas bag adapter. See Calibration section for more information.

One sampling bag is included in the MicroFID II calibration kit Part No. MX396011. Additional gas bags

are also available (Part No. MX396017).

Charcoal Filters

A charcoal filter (Part No.MX396022, package of 10) may be connected to the MicroFID II during

calibration and sampling to provide clean air to the MicroFID II. The filter will remove hydrocarbon

contamination from room air to provide zero grade air to the MicroFID II.

NOTE: The charcoal filter does not filter methane or ethane. If these compounds are present, you should

use a gas bag with a supply of commercial zero air for calibration purposes.

074-579-P1A 19

Page 20

1/4" Nut

Connect

to MicroFID

Charcoal Filter

Front Ferrule

Back Ferrule

To connect a charcoal filter:

1. Load the Teflon ferrules into the nut. The nut and ferrules are supplied with the filter. See

Figure 3.

2. Connect the nut to the MicroFID II inlet. Do not tighten the nut.

CAUTION: Over-tightening the Teflon ferrules will result in damage to the ferrules.

3. Remove the charcoal filter from its plastic bag and insert it into the nut. Finger-tighten the nut

onto the inlet. If the filter is not secure, ensure you have inserted the tube stub far enough into

nut. Do not over-tighten the fitting.

Figure 3 Connecting the Charcoal Filter

The charcoal filter will remove hydrocarbon contaminants for up to 4000 ppm hours. This means that the

filter will be good for 1 hour removing 4000 ppm of hydrocarbon contaminants or will last for 4 hours

removing 1000 ppm. The exact time will be determined by the operating environment. You will notice an

increased hydrocarbon background when the filter requires replacement.

To replace the charcoal filter:

1. Loosen the nut on the MicroFID II inlet.

2. Remove the used filter.

3. Insert the new charcoal filter into the nut and finger-tighten the nut onto the inlet. Do not over-

tighten the fitting.

4. When the charcoal filter is not in use, place it in its plastic bag and store it in a clean, dry place.

074-579-P1A 20

Page 21

Hydrogen Fuel

Cylinder

Retention Plate

Handle

Inlet

On/Off

Switch

AC Charging

Connector Cap

Digital Display

and Soft Keys

Hydrogen Fuel

Cylinder

Alarm Speaker

Exhaust Frit

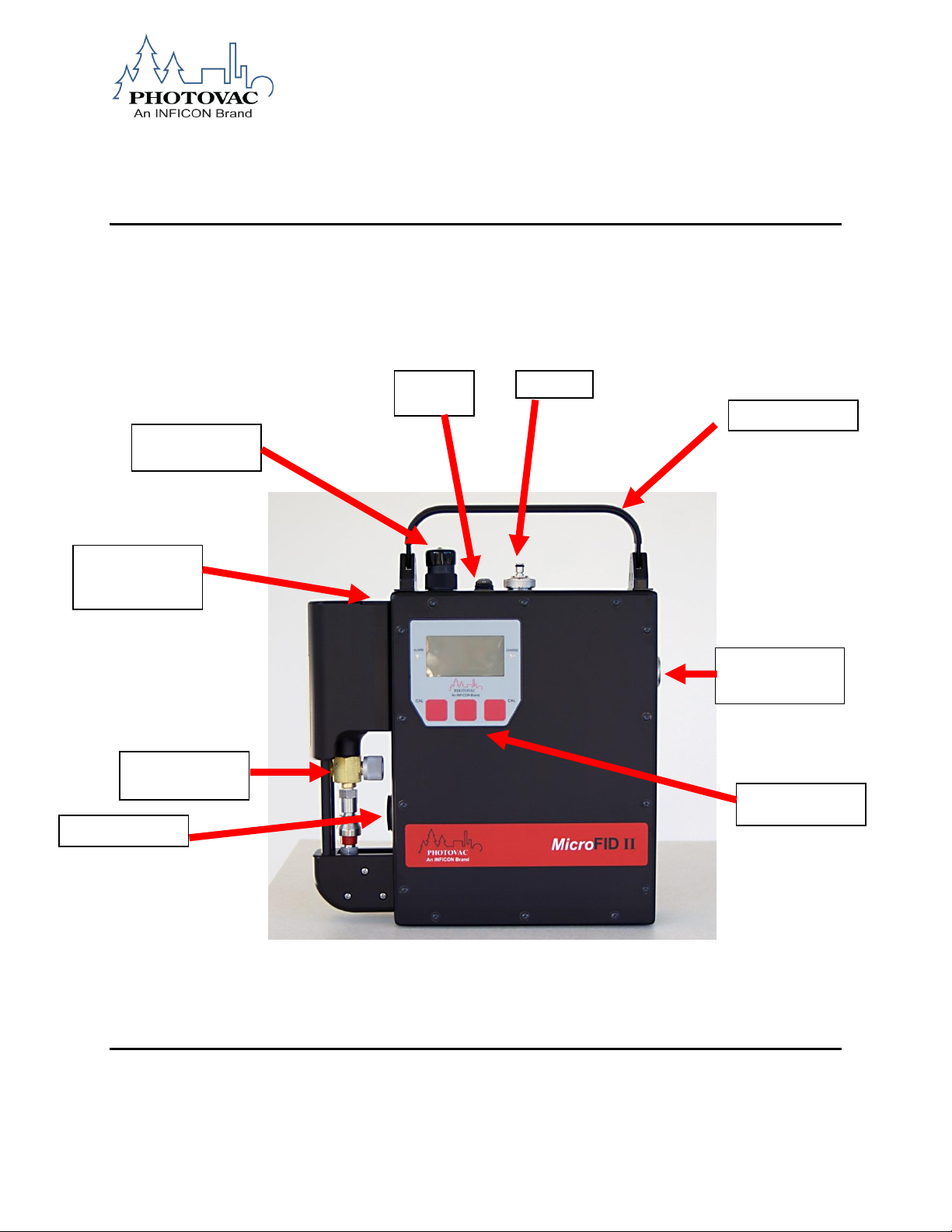

2. USING THE MicroFID II

MicroFID II Feature Layout

The photograph below shows the basic layout of the MicroFID II Version components. The MicroFID II is

also supplied with an optional telescoping probe that can be removed from its holder for access to hard to

reach spaces.

NOTE: The cover must be attached for the MicroFID II to operate and to maintain the intrinsic safety

rating.

074-579-P1A 21

Page 22

MicroFID II with probe in probe

holder position

MicroFID II with probe in

telescoping position

Using the MicroFID II Battery Charger

READ THESE INSTRUCTIONS BEFORE USING THE CHARGER

The MicroFID II battery charger is only designed for indoor use

and should not come into contact with water or dust. In order to

avoid overheating, the charger should not be covered when it is

in use.

The charger is turned on by connecting it to the mains socket.

Disconnecting it from the mains socket turns the charger off. If

the charger is equipped with a mains cord, verify that the cord

has not been damaged. If the cord is damaged, the charger

must not be used.

The charger contains dangerous voltages and the cover should not be removed.

CHARGER FUNCTIONALITY

This charger is a fast charger for NiMH batteries. The charger will automatically charge the battery at a

fast rate, and then charge to a slow rate near the end of the cycle. This prevents over-charging.

CAUTION: Do not charge batteries at too high or too low temperatures. Charge only in areas between

38-110°F (3-43°C).

074-579-P1A 22

Page 23

LED

MODE

Orange

Battery not connected

Orange

Battery initialization & analysis

Red

Fast Charge

Green with intermittent orange flash

Top-off charge

Green

Trickle charge

Alternating red-green

Error

HOW TO USE THE CHARGER

The Charger is started by connecting the battery pack to the charger. Once connected, the indicator LED

will start Orange, for the Initialization and Analysis Phase, before switching to Red for the Fast Charge

Phase. When the batteries are fully charged, the charger will go into a top-off charge mode before it goes

over to trickle charge mode. During top-off charge, the LED will be Green with short intermittent Orange

light. When the top-off charge is completed, the charger will go into trickle charge mode and the LED will

be Green. The charge current is now reduced to a safe level, which allows the charger to stay connected

to the NiMH batteries without damaging the battery. If the battery voltage is far below normal, the charger

will cut off the fast charge current and go to trickle charge mode. The LED will then indicate ‘error’ by

flickering Green and Red light. If the mains is turned off, the charger will reset and start a new charge

cycle if the mains is turned on again. If new batteries are to be connected, the charger must idle for

approximately 15 seconds to make sure all parameters in the microprocessor have been reset. The LED

changing to Orange light shows this and a new charge cycle can begin.

.

CHARGE CYCLE AND LED INDICATIONS

With mains connected, the LED will be orange the first 5-7 seconds, and will be orange when the

initialization and analysis starts. If a battery is connected, the actual charging will start a few seconds later

when the LED changes to red.

CAUTION: Use only Battery Charger P/N 1201221 to charge the MicroFID II.

074-579-P1A 23

Table 1. Battery Charger Indications

Page 24

To Charge the Battery

1. To charge the MicroFID II battery, unscrew the cover for the charging connector cap.

2. Connect the charge adapter to the MicroFID II charging connector.

3. When the battery charge indicates there is a full charge to the battery, disconnect the charge

adapter from the MicroFID II charging connector

4. Install the charging connector cap to the charging connector.

074-579-P1A 24

Page 25

NOTE: The MicroFID II will not operate without the charging connector cap in place.

NOTE: The MicroFID II will not operate with the AC Adapter plugged into the MicroFID II.

Repeat Charging with an AC Charger

If the AC charger has been plugged into an electrical outlet and has been used to charge a FID, and

another charging operation is to be performed, please remove the charger from the unit and wait until the

status LED on the charger changes from either green or red to orange before plugging it into the second

unit.

NOTE: The status change will take up to 15 seconds and the orange LED indicates that the unit

is ready to start a new charge cycle.

CAUTION: If the AC charger is not properly reset according to the above instructions, it is

possible that the AC charger will remain in trickle charge mode and the FID battery will not

receive a full charge. This will limit the FID’s operating time and may cause problems in lighting

the FID flame due to low voltage.

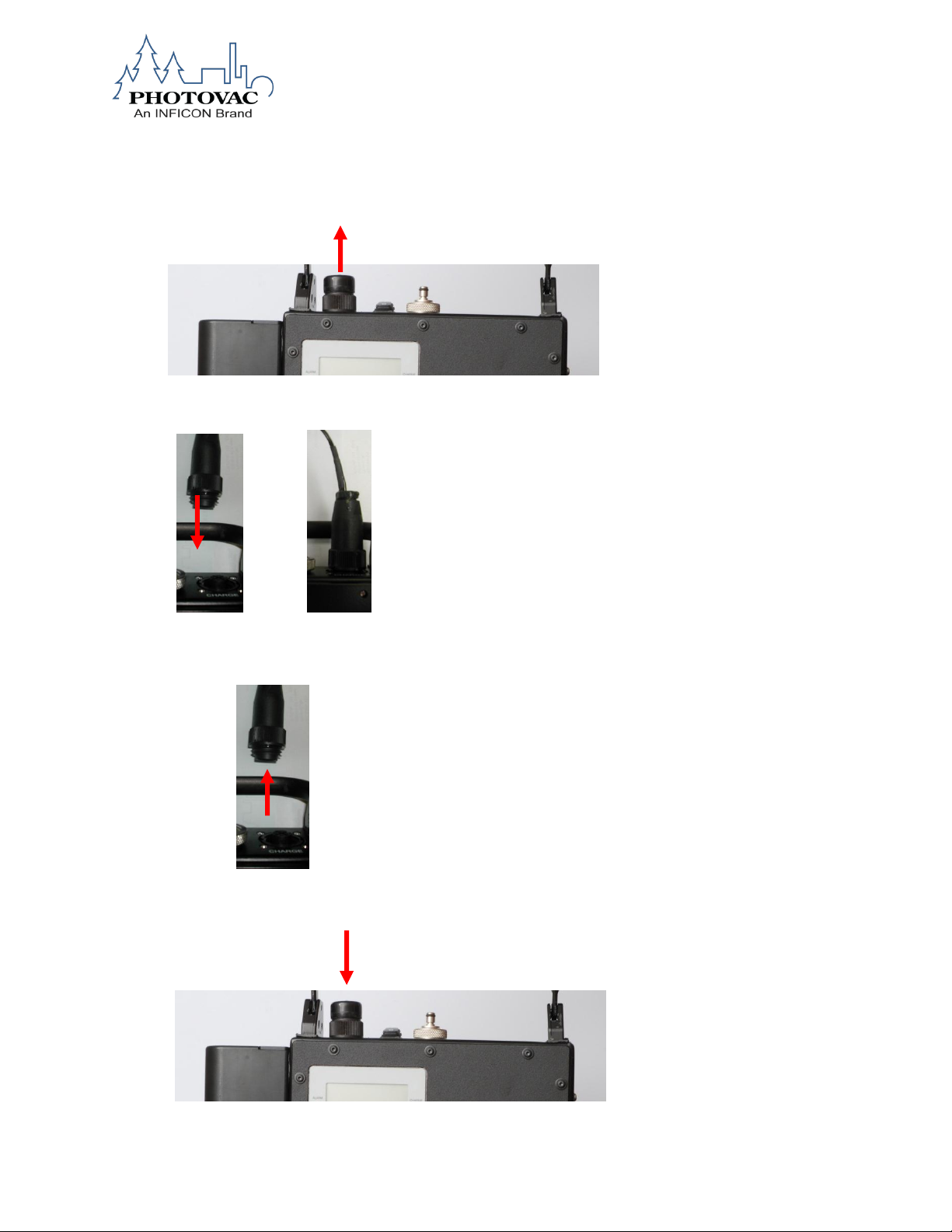

Filling the Hydrogen Fuel Cylinder

The MicroFID II hydrogen fuel cylinder is a metal hydride design that requires relatively low hydrogen

pressure to fill it.

Figure 7. MicroFID II Hydrogen Cylinder

074-579-P1A 25

Page 26

WARNING

Hydrogen storage on the metal oxide is an Exothermic Reaction. The

cylinder may become hot during the initial fill. Care must be taken to avoid

injury.

WARNING

DO NOT attempt to fill the hydrogen cylinder without a refill adapter..

The hydrogen fuel cylinder (see Figure 7), when full, will provide the MicroFID II with up to 70 hours of

continuous operation in a single fill. To fill the hydrogen fuel cylinder, the MicroFID II hydrogen filling

station Part No. A1201222 is required (see Figure 8). The hydrogen fill station is outfitted with a CGA 350

adaptor for use with a high pressure hydrogen cylinder that contains at least 99.999% pure grade

hydrogen (also known as ultra high purity hydrogen).

CAUTION: H2S, SO2, Cl2, and CO are contaminating substances for the cylinder alloy. Do not expose the

cylinder interior to these substances.

CAUTION: Lower grades of hydrogen will damage the fuel cell with impurities and decrease the overall

longevity of the fuel cell. Ensure the hydrogen is ultra high purity.

CAUTION: Do not modify or alter the hydrogen cylinder or fittings.

The Hydrogen Filling Station (Part No.A1201222) consists of an adapter fitting with a left-handed thread

for cylinder attachment, an output valve and a hydrogen fuel cylinder quick connect. The Hydrogen Filling

Station delivers a fixed 260 psi to the hydrogen fuel cylinder. The output valve is positioned to deliver gas

from the cylinder to the hydrogen fuel cylinder. Additionally, in the final stages of filling the hydrogen fuel

cylinder, the output valve is used to release gas held in the quick connect after filling.

The MicroFID II Hydrogen Fuel Cylinder is composed of metal hydride material. The process of filling this

cylinder involves the low pressure adsorption of hydrogen on the metal hydride surface, rather than the

high pressure filling process for conventional hydrogen cylinders. Table 2 illustrates the charge time

versus fill time for the MicroFID II hydrogen cylinder.

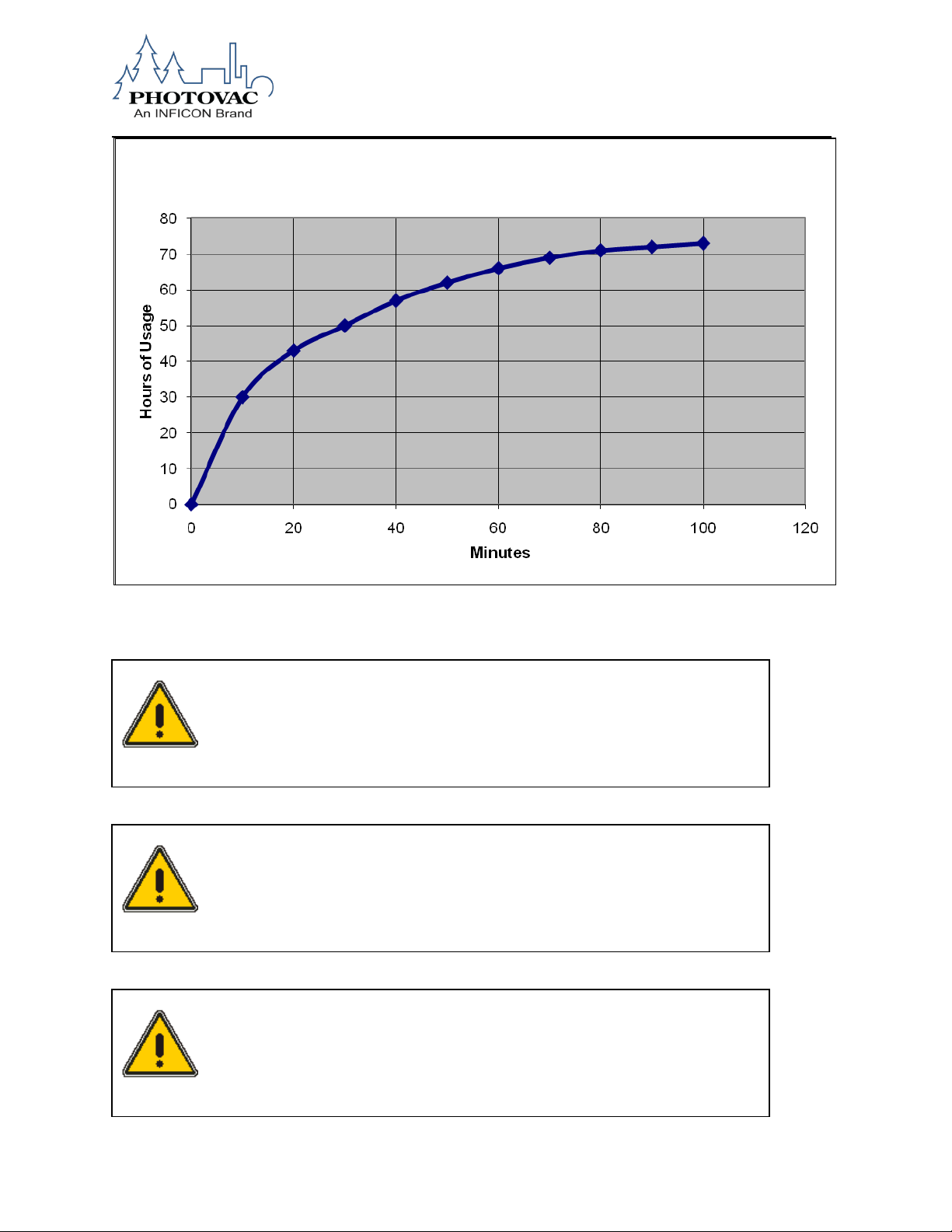

A 5 minute charge provides 10 hours of usage. Other charge times versus usage are as follows:

5 minutes 10 hours of use

10 minutes 30 hours of use

30 minutes 50 hours of use

60 minutes 65 hours of use

The hydrogen fuel cylinder is over 85% full after one hour. Thereafter, the cylinder charges more slowly

up to the full 70+ hours.

074-579-P1A 26

Page 27

WARNING

Use only the MicroFID II Hydrogen Fill Station p/n A1201222 to fill the

hydrogen cylinder. Use of any other filling device will void the warranty.

WARNING

The regulator pressure is set at the factory Do not adjust the regulator on the

hydrogen filling station. Adjustment of the hydrogen filling station regulator

will void the warranty.

WARNING

Do not exceed 260 psi when filling the MicroFID II Hydrogen Cylinder. The

fuel cells in the hydrogen cylinder will be damaged and will void the

warranty.

MicroFID II Hydrogen Cylinder Charge Chart

Table 2. Charging Time and Usage Time

074-579-P1A 27

Page 28

WARNING: FIXED REGULATOR, DO

NOT ATTEMPT TO ADJUST

Output Valve

Attach Hydrogen Fuel

Cylinder Here

Hydrogen Cylinder

on/off valve

CAUTION: When filling the MicroFID II Hydrogen Cylinder, ensure that the hydrogen cylinder on/off valve

is completely open in the counterclockwise position.

Figure 8. Hydrogen fuel cylinder on/off valve

074-579-P1A 28

Figure 9. Hydrogen Fuel Cylinder Filling Station

Page 29

WARNING

Hydrogen gas is a fire and explosion hazard when exposed to heat or flame.

The lower explosive limit is 4%

WARNING

DO NOT Use an open flame to test for leaks!

WARNING

DO NOT fill the hydrogen cylinder in a hazardous location.

NOTE: Read through this section before filling the hydrogen fuel cylinder.

Store the hydrogen supply tank in a well ventilated area, well away from heat or possible ignition sources.

Directions for Attaching the Hydrogen Filling Station to the Hydrogen Supply Tank

1. Connect the hydrogen fuel cylinder filling station to the tank of hydrogen. Hydrogen is supplied with a

CGA 350 cylinder valve outlet. The filling station is supplied with the matching fitting for ease of

connection. The threads of the adaptor will tighten counterclockwise.

NOTE: Do not force the connection. Do not use Teflon tape with CGA fittings. In general, these fittings

are designed for metal to metal sealing.

Do not use adapters to connect one CGA fitting to another type of CGA fitting. If the refill adapter does

not match the outlet on your hydrogen tank, contact INFICON.

2. Tighten the hydrogen cylinder filling station onto the tank with a wrench. Do not over tighten.

074-579-P1A 29

Page 30

Filling Position

Venting Position

Filling the Hydrogen Fuel Cylinder

1. Rotate the output valve to point toward the main cylinder of hydrogen (Filling Position)

Figure 9. Output Valve

2. Attach the MicroFID II hydrogen fuel cylinder to the quick connect mate on the hydrogen filling station

(see Figures 8 and 10).

3. Open the on/off valve on the hydrogen fuel cylinder. See Figure 8.

4. Open the valve on the hydrogen supply tank.

5. Allow the unit to fill for the amount of usage time required as per the above chart.

NOTE: The hydrogen fuel cylinder will become warm during the filling process and will be warm to the

touch. Once the fuel cells are full, the cylinder will begin to cool down and become room temperature.

Hydrogen cylinders that are only partly depleted of hydrogen may take less time to fill.

6. Close the valve on the main cylinder of hydrogen

7. Rotate the output valve to point away from the main cylinder of hydrogen, (Venting Position)

8. Wait approximately 5 seconds, and then rotate the output valve once again toward the main cylinder of

hydrogen. (Filling Position)

9. Disconnect the full hydrogen fuel cylinder from the quick connect on the filling station by holding the

release ring of the hydrogen fuel cylinder with one hand and holding the red release ring with the other.

Push up the hydrogen fuel cylinder release ring and the hydrogen fuel cylinder will be separated from the

hydrogen fill station. The hydrogen fuel cylinder will be cool to the touch when it is remove from the

hydrogen fill station. With time, the hydrogen fuel cylinder will become room temperature.

10. Ensure the main hydrogen supply tank valve is closed.

11. If the hydrogen cylinder will not be used immediately after the filling process is complete, close the

hydrogen cylinder by turning the on/off valve completely clockwise.

074-579-P1A 30

Page 31

Hydrogen

Tank

Valve

Warning: Do not

adjust this

regulator

Output

Valve

Red release

ring

Hydrogen fuel

cylinder

release ring

Figure 10. Hydrogen Fuel Cylinder Connected to Filling Station

074-579-P1A 31

Page 32

Hydrogen Fuel Cylinder

Retention Plate

Hydrogen

Fuel Cylinder

Holder

MicroFID II

Hydrogen

Fuel Inlet

Installing the Hydrogen Fuel Cylinder in the MicroFID II_____________________________

1. If the hydrogen fuel cylinder retention plate is installed on the MicroFID II, remove it and

set it aside.

2. Insert the hydrogen fuel cylinder into the hydrogen

fuel cylinder holder.

3. Guide the hydrogen fuel inlet into the MicroFID II

hydrogen fuel inlet.

4. Push the hydrogen fuel cylinder until you hear a

distinct click.

5. Attach the hydrogen fuel cylinder retention plate

with the two set screws.

074-579-P1A 32

Page 33

WARNING

The hydrogen fuel cylinder retention plate MUST be installed on the

MicroFID II to retain the intrinsic safety rating.

I

o

6. Open the hydrogen fuel cylinder on/off valve if monitoring is to be started.

Attaching the Telescoping Probe to the MicroFID II

1.. The Telescoping Probe has a knurled nut fitting. Simply screw in the knurled nut into the

MicroFID II inlet.

Basic Operating Instructions

The following steps should be followed to operate the basic functions of the MicroFID II.

1. Ensure that the MicroFID II battery has been fully charged.

2. Attach the hydrogen cylinder to the left side of MicroFID II instrument body. The cylinder slides through

an open holder, and the swage connector engages the cylinder with the instrument. A distinct click will be

heard when this occurs.

3. Install the hydrogen cylinder holding plate with the two screws that are attached.

4. Turn on the hydrogen fuel cylinder on/off valve (see Figure 8) by rotating the knob counter-clockwise.

Wait a few minutes for the hydrogen fuel to flow to the MicroFID II detector.

5. Turn on the MicroFID II using the “OFF /ON” power switch on the top right of MicroFID

II instrument body. On is the symbol” l” and off is the symbol “o”.

6. The display screen on the probe will show the “Top Level Menu” depicted in the

Section: User Menu Functions.

7. The MicroFID II body display has three red soft keys (see Figure 6) that operate all

menu functions facilitating single handed use of the instrument.

074-579-P1A 33

Page 34

8. The MicroFID II will automatically start with “MicroFID II Setup” on the main display. Simply press the

middle red soft key (“meas”) to initiate the “Flame ON Procedure.” After a few moments, measurements in

ppm should be shown on the display, and the flame icon should be present.

9. The calibration function is initiated by pressing both the left and right soft keys at the same time.

NOTE: See Calibration section immediately following these steps for a full discussion on the calibration

process.

10. To turn off the MicroFID II, follow the steps shown on the Shut Down MicroFID II Menu, Figure 15 in

Chapter 3 User Functions.”

Calibration

The MicroFID II must be calibrated in order to display concentration in ppm units equivalent to the

calibration gas. See the section on calibration starting on page 59 for a full description of calibration

procedures for the MicroFID II. The MicroFID II must be operated in an upright position during calibration.

Data Communication

The MicroFID II links to external devices via Bluetooth. This wireless technology is used as the

communication link to external PC’s used for uploading information to the MicroFID II and for

downloading measurement data collected during the process of field monitoring activity. It can also

communicate with external PDA’s which may be used for Method 21 LDAR monitoring

Refer to Chapter 4 for more information regarding Bluetooth communication set-up and operation.

Response Factors for Gases and Vapors

To use the response factors:

1. Press the CAL key and enter the response factor for the specific compound.

2. Calibrate the MicroFID II with zero air and 500 ppm methane as described in the section on

calibration

3. Expose the MicroFID II to the sample. The displayed reading is the approximate concentration

of the specific compound.

The response factors on the INFICON web site serve as a guide to concentrations measured by the

MicroFID II.

NOTE: It does not matter which Cal Memory is selected or which response factor is entered, MicroFID

II’s response is not specific to any one compound. The displayed reading represents the total

concentration of all ionizable compounds in the sample.

074-579-P1A 34

Page 35

Calibration kit(s) (Part No. MX396011)

Tank(s) of calibration gas (Part No. MX396028)

Spare gas bag for zero air (Part No. MX396017)

Gas bag adapter for zero air (Part No. MX396010)

Supply of commercial zero air

Charcoal filters (Part No. MX396022, pkg. 10)

Spare inlet filters (Part No. MX396015, pkg. 25)

MicroFID II Operating Manual (Part No. 074-579-P1)

Battery charger (Part No.A1201221)

Hydrogen Filling Station (Part No. A1201222)

Hydrogen fuel (Part No. MX754112)

Computer or PDA

Preparing for Field Operation

Field Check List

The following items should be carried into the field to reduce or eliminate instrument down time. If you will

be in the field for a single 8-10 hour day, you should include the following accessories:

Table 3. Check List for Field Operation

If you will be in the field for more than one day you should include the following additional items:

Table 4. Additional Field Items

074-579-P1A 35

Page 36

Operational Check List

Before beginning field work, set up and calibrate the MicroFID II for your particular application. Ensure the

instrument is in working order before heading into the field.

To prepare the MicroFID II for field work

1. You should not transport the MicroFID II with the hydrogen fuel cylinder attached to the

MicroFID II. Remove the hydrogen fuel cylinder from the MicroFID II and package it individually

for transport.

2. Press the SETUP key and ensure the correct date and time are entered.

3. Program and calibrate all the Cal Memories you will be using. After calibration is complete,

sample the bag of calibration gas and the bag of zero air to ensure the MicroFID II has been

calibrated correctly.

4. If you are using an averaging interval, you may also want to delete all events from the

datalogger to avoid confusion between different days’ data and to avoid running out of space in

the datalogger.

5. If you are performing Method 21 monitoring, ensure you have programmed and

calibrated all the Cal Memories. You must also program your monitoring schedule.

074-579-P1A 36

Page 37

Soft

Keys

Calibration

gas used

Hours of

hydrogen

usage

remaining

Battery

status

Flame-on

icon

Charging

light

Alarm

light

Time

Menu

Bar

3. USER FUNCTIONS

Display

The MicroFID II has a graphic display for reporting detected concentrations and to guide you through

configuration options. All functions of the MicroFID II will be reported on the display.

Graphic Display

The MicroFID II uses an 8 line graphic display. The display will always be used for reporting

detected concentration. In order to accommodate the range of concentrations the MicroFID II can

detect, the meter reading will be reported using one of three resolutions. A resolution of 0.01

ppm will be used for concentrations below 10 ppm, a resolution of 0.1 ppm will be used for

concentrations between 10 ppm and 999.9 ppm, and a resolution of 1 ppm will be used above

1000 ppm.

Figure 11. MicroFID II Display

074-579-P1A 37

Page 38

main menu

Data log

Menu

Download log to

Edit log interval

Verify BlueTooth

continue

Clear data log?

Yes or No

Enter New interval mode

Logging time (0-000 secs)

Sends logged data to

connection

Yes clears data log

No leaves data intact

Figure 13. Data Log Options Menu

View Menu

MicroFID II Setup

Data Log Options

Shutdown MicroFID II

meas

select

Menu Function Displays

Figure 12. The MicroFID II Main Menu Display

The display reports instantaneous concentrations at all times when the flame is on. There are

four User modes: Logging Off, Interval, Location, and Method 21. In all four modes, the display

will report instantaneous concentrations.

The MicroFID II is designed for ease of use with a logically organized internal menu

structure/user interface.

The four submenus for the MicroFID II are expanded in Figures 13, 14, 15, and 16.

The MicroFID II has three soft keys, and they are located under the graphic LCD display. Each

display screen will always show the available functions of the soft keys.

Options

connection between

MicroFID II and the

PC. Hit ‘next’ to

PCD

Clear data log

the PC via BlueTooth

074-579-P1A 38

Page 39

MicroFID II Setup Menu

Audio ON

Audio OFF

Pump ON

Pump OFF

Method 21

Interval

Optional Air ON

Optional Air

OFF

Backlight ON

Backlight OFF

Edit Current Date

Edit Current Time

DD/MM/YYYY

MM/DD/YYYY

Enter New 4

digit password

English

PPM

PPB

RT Output ON

RT Output OFF

Compound 1

Compound 7

Hexane Cal

Propane Cal

FW Boot Load

Diag Monitor

Turn Flame ON

Audio Control Menu

Pump

Optional Air

Backlight

User Mode

Clock

Date Format

Password

Language

Units

Real Time Data

Compound

Selection

Select Cal Gas

Service Diagnostics

Audio ON

Audio OFF

Turn Pump ON

Turn Pump OFF

Turn Optional Air ON

Turn Optional Air OFF

Turns display Backlight ON

Turns display Backlight OFF

Measures in Meth 21 mode

Measures in interval mode

Edit date mm/dd/yy

Edit time of day hh:mm

Commands MicroFID to

send data via Bluetooth

Display in parts per

Display in parts per billion

Other languages to be

added at later date

Change current

password

US date mm/dd/yy

Intl date dd/mm/yy

Performs selected diagnostic

problems

Methane Callib Gas is used

Hexane Calib Gas is used

Selects Compound Gas and

active meas

Edit H2 Timer

Enter 2 digit H2

time in hours

Sets time remaining for H2

tank

Figure 14. MicroFID II Setup Menu

Logging Off

Location

Measures w/no logging

Measures in location mode

million

074-579-P1A 39

to

Methane Cal

Signal Test

Glowplug Test

Hydrogen

Range

associated Response

Factor, Alarm level for

Propane Calib Gas is used

routine to help troubleshoot

Page 40

Shut Down

MicroFID II

Shut down in

soft key to continue

Shutdown Complete

Turn MicroFID II OFF

View

Menu

List Tag Strings

Sample Log Data

Tag Description 1

Tag description “n”:

Provides Read-only

number, etc.

Provides Read-only

3 09:51 32.6

Provides the user

selected Tag

Serial #: A123

Key Audio: OFF

process Press ‘next’

Turn Valves OFF

Figure 15. Shut Down MicroFID II Menu

Setup Configuration

Figure 16. View Menu

Tag description 2

…

description of the

MicroFID current

parameter setup,

SW version, serial

view of the current

data log, example:

1 09:49 14.5

2 09:50 22.9

with a way to view

and/or edit the

SW Ver: 1.01

Battery: 9.79 volts

Pump Curr: 1.79 mA

Flame State: ON

Calib Gas: Methane

Air Option: OFF

Log Type: Int

Log Inter: 2 secs

Language: English

Units: PPM

074-579-P1A 40

Page 41

main menu

View Menu

MicroFID II Setup

Data Log Options

Shutdown MicroFID II

select

Keys

Fixed ON/OFF Key

The ON/OFF key is used to both power on to the MicroFID II and to power off the MicroFID II.

To turn on the MicroFID II, press the ON/OFF key. To turn off the power, press the ON/OFF

key. It is recommended that the Shutdown MicroFID II option in the Main Menu be used to

ensure proper shutdown before pressing the OFF key.

Soft Keys

Three soft keys are located directly below the display. Each of these soft keys has varying

functions for configuring the MicroFID II, editing the data, and controlling the display. Since only

three soft keys are available, each function is broken down into a path. Maps, showing each

path and the resulting functions, are shown in Figures 13, 14, 15, and 16.

Beginning Operation

Turning on the MicroFID II

1. Turn the MicroFID II on by pressing the ON/OFF key. See Figure 5 for the location of

the ON/OFF key.

2. The MicroFID II will display the instrument’s software version number. Next, the

MicroFID II will proceed to the Main menu display.

3. For maximum accuracy and stability, allow the MicroFID II to warm-up for 20 minutes

prior to calibration.

Default Display

The MicroFID II always starts in the Main menu after start up. The unit’s setup will be restored to

the previous entries at the time it was powered down. The Up and Down arrows (soft key 1 and

3) provide a way for the user to choose from the 4 main options: (MicroFID II Setup, Data Log

Options, Shutdown MicroFID II, and View Menu). The Measure function (soft key 2) provides a

way for the user to start or return to TVOC measuring mode.

Figure 17. Main Menu Display

074-579-P1A 41

Page 42

enter password

Enter 4 digit code to access Setup menu

1111

done

Numeric Value, Duration, Time and Date Entry

In cases where the system requires the user to enter a number, duration, time, or date, the

following mechanism is used. The number of digits to be entered depends on the type of value

being entered. In some cases, units may be specified (e.g., ppm or hh:mm); in others there may

be no units. Upon entering a value entry screen, see Figure 18, a bar icon below the left most

digit highlights it as the active digit. The up (middle soft key) and down (left soft key) arrows are

used to increase/decrease the digit. The bar icon is moved to the next digit to the right using the

right soft key. The ‘done’ soft key (probe trigger key or soft keys 2 and 3 simultaneously) is

pressed once the user has finished entering the value and the new value is stored into memory.

No cancel option is available to the user. If a user decides against editing, then simply pressing

the done key (probe trigger) will exit with no changes to the current value.

Figure 7: Edit Mode Display

Figure 18. Numeric Value Display

Instrument Status

The instrument status is shown on the left of the first line, lower left of the last line, or with

various message screens that will display the status of the MicroFID II. Each status has a

priority assigned to it. If more than one status is in effect, then the status with the highest priority

is displayed until the condition is corrected or until the option is turned off. Table 5 is a list of the

possible system alerts.

074-579-P1A 42

Page 43

MicroFID II Display

Description

Flame Icon with line

through it

Flame has been extinguished and

needs to be relit

TVOC high level

alarm screen

TVOC concentration alarm

exceeded set value for selected

compound

Low Battery Icon

Low battery

Pump Error

Pump fault

Displayed value

blinking ON and

OFF

TVOC concentration over

instrument operating range

TVOC Display Max

Err

TVOC concentration over

instrument operating range

Hi Chamber temp

Chamber temperature too high

Recommend H2 Fill

Hydrogen cylinder has 10 hours of

use remaining

H2 Critically Low!

Hydrogen Cylinder has 5 hours of

use remaining

Sending log data to

the PC

Instrument sending log data to PC

Cal Zero Error

Zero value too high during

calibration

Span Gas Error

Span gas too low during

calibration

System Alerts and Alarms

While operating the instrument, system alerts can occur. To accurately identify the source of the

alarm, each type of alarm has been given a unique status.

In addition to the status, the MicroFID II also has an audio alarm and an alarm LED. A soft key

is used for acknowledging alarms and is named “Accept”. To clear the alarm, press the “Accept”

key. Once acknowledged, the alarm indicators are cleared. The alarm status will remain until the

alarm condition clears.

The MicroFID II updates the instantaneous concentration once every second. Following every

update, the instantaneous concentration is compared to the selected compounds high alarm

level, and if exceeded, an alarm is triggered.

During calibration, all alarms are disabled. Once the calibration is complete, the alarms are reenabled.

074-579-P1A 43

Table 5. System Alerts

Page 44

enter password

Enter 4 digit code to access Setup menu

1111

done

User Interface – Basic Menu

The MicroFID II is designed for ease of use with a logically organized internal menu

structure/user interface. The MicroFID II’s Main Menu options are shown in Figures 13, 14, 15,

and 16.

The MicroFID II has three soft keys under the graphic LCD display which always show available

functions of the soft keys in any screen.

Passcode

The MicroFID II allows setup data to be saved and accessed only through the use of a

password.

Figure 19. Enter Password Display

When the MicroFID II Setup menu is selected, the next display will ask for the operator to enter

a 4 digit code to access the Setup menu. The default passcode is 1111

User Modes

The four User Modes of the MicroFID II can be selected in the MicroFID II Setup menu by

selecting the User Mode option (See MicroFID II Setup). The MicroFID II’s default User mode is

the Interval mode with a default interval of 15 seconds. The user can select any one of the four

options:

Location

Interval

Logging Off

The MicroFID II can power up in the Interval, Location, Method 21, or Logging Off User Mode

depending on the mode that was set by the previous user prior to power down. While the user is

in one of these four modes, the resolution of the display changes with the magnitude of the

reading. A resolution of 0.01 ppm will be used for concentrations below 10 ppm, a resolution of

0.1 ppm will be used for concentrations between 10 ppm and 999.9 ppm, and a resolution of 1

ppm will be used above 1000 ppm.

Each of the four modes is described in the following sections.

074-579-P1A 44

Page 45

1/02/09 location

1/02/09 meas

35.7 ppm

Location Route Description

CAL: Meth

45.6 ppm

CAL: Meth

sample

Location Mode

Figure 20. Location Mode Display

Location mode is identified by the 20 character Location string on the line below the current

TVOC value being displayed. Location mode will continuously display the instantaneous

concentration of total volatile compounds. Location mode also allows the user to manually

location and log readings. Location mode allows the user to datalog a reading by pressing the

accept key (soft keys 2 and 3 together).

Location strings are loaded into the MicroFID II via a PC using the INFICON ProComm

software. In Location mode, the soft keys are CANCEL, EDIT, and MENU.

CANCEL exits Location user mode and returns to the default Interval user mode.

EDIT selects “Modify Location numb”, “Edit current Location”, or “Insert new Location”.

MENU selects the MicroFID II’s Main menu.

Interval Mode

Figure 21. Interval Mode Display

Interval displays the instantaneous readings. Interval mode also automatically stores these

readings in the MicroFID II’s memory at a preset interval selected by the user. In Interval mode,

the soft keys are STATUS, VIEW, and MENU.

STATUS displays a read-only version of the important setup parameters.

VIEW displays a read-only view of the current data log.

MENU returns to the MicroFID II’s Main menu while continuing to measure in the

background.

074-579-P1A 45

Page 46

1/02/09 method 21

1/02/09 method 21

1.72 ppm

Valve 12YJ5

H47

start

1.72 ppm

Valve 12YJ5

H47

Method 21 Mode

This section describes Method 21 setup if the user chooses to perform Method 21 readings

without a PDA.

The Method 21 user mode displays the current detected concentration. The reading is updated

once a second. The MicroFID II can also store the maximum background and maximum

component concentrations for a selected component. At the end of every interval, one entry is

placed in the log.

To enter the Method 21 logging mode, the MicroFID II Setup menu must be entered. After

entering the 4 digit pass code, scroll down to the User Mode entry and press the select mode on

the display. Then, scroll down to Meth 21 log mode and press the select mode on the display.

Hit the back soft key to return to the main menu and press the "meas" soft key to start taking

measurements in the Method 21 logging format.

Figure 22. Method 21 Mode Background - Start

The first Method 21 screen is shown in Figure 22. The purpose of this step is to take a

BACKGROUND reading. When the user is ready to begin measuring a BACKGROUND value

simply press the ‘start’ soft key. The screen will change to that shown in Figure 23.

Figure 23. Method 21 Mode Background - Stop

Figure 23. Method 21 Mode Component - Backround

074-579-P1A 46

Page 47

1/02/09 method 21

1/02/09 method 21

view meth 21

54.3 ppm

Valve 12YJ5

H47

54.9 ppm

Valve 12YJ5

COMPONENT

Corrected: 52.6 ppm

Leak Def: 100 ppm

When the user has a valid BACKGROUND reading on the display, simply press the ‘stop’ soft

key. The maximum value measured between ‘start’ and ‘stop’ will be saved into the log

associated with the current Method 21 tag. The screen will change to that shown in Figure 24.

Figure 24. Method 21 Mode Component - Start

Now that the Background value has been successfully logged, the COMPONENT value must be