Page 1

Sensistor ISH2000

HYDROGEN LEAK DETECTOR

Technical Reference Manual

Publication: INFICON AB - nipa60e1-a (1202) - All information can be modified without prior notice

Page 2

General content

A 100 Introduction to the Sensistor ISH2000 series ................................................ 5

A 300 Sensor Technologies working principle ......................................................... 6

A 400 Testing methods .......................................................................................... 7

A 401 About Hydrogen .......................................................................................... 9

A 600 Options ..................................................................................................... 10

A 700 Sensistor ISH2000 Components ................................................................. 11

A 701 Spare parts and accessories ........................................................................ 17

A 800 Sensistor ISH2000 - Technical specifications ............................................... 22

A 900 Dimensions ................................................................................................ 25

B 100 Safety instructions ...................................................................................... 29

B 110 Supplies and storage .................................................................................. 30

B 210 Connecting the detector to the installation ................................................ 31

B 300 Controlling the detector with the I/O interface ........................................... 33

B 310 Controlling the detector with a PC computer through the RS 232 interface 37

B 320 Connecting the detector directly to a printer or another device .................. 40

C 100 Getting started with the leak detector ....................................................... 45

C 200 Control panel ............................................................................................ 46

C 201 Menu system ............................................................................................. 48

C 210 Password ................................................................................................... 54

C 211 Operation of the leak detector ................................................................... 55

C 300 Calibration of the leak detector ................................................................. 57

C 304 Correlation value ....................................................................................... 62

C 305 Reference values settings ........................................................................... 63

C 410 Headphones .............................................................................................. 64

C 500 Factory configuration of the leak detector parameters ............................... 65

C 570 Date - Time - Language - Unit .................................................................... 67

C 580 Service mode och debug mode .................................................................. 68

D 100 Preventive maintenance ............................................................................. 73

D 200 General troubleshooting guide .................................................................. 74

D 300 Reference leak trouble guide ..................................................................... 76

E 100 Maintenance operations introduction ......................................................... 79

E 120 Sending the leak detection for repair to a service center ............................. 80

E 130 Functional verification ................................................................................ 81

E 140 Service menu .............................................................................................. 84

E 160 Software and documentation evolution ...................................................... 85

E 230 Sensistor ISH2000 Main board .................................................................... 86

E 410 Instrument maintenance ............................................................................. 88

E 411 Probe maintenance .................................................................................... 99

F 100 Service ...................................................................................................... 103

F 110 Disposal of product when taken out of service .......................................... 104

F 800 Tools ........................................................................................................ 105

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 2

Page 3

EN- 3 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 4

Introduction

A

Sensistor ISH2000 Technical Reference Manual

Detailed content

A 100 Introduction to the Sensistor ISH2000 series

A 300 Sensor Technologies working principle

A 400 Testing methods

A 600 Options

A 700 Accessories

A 800 Sensistor ISH2000 - Technical specifications

A 900 Dimensions

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 4

Page 5

Sensistor ISH2000

A 100

A 100 Introduction to the Sensistor ISH2000 series

Sensistor ISH2000 can be purchased in one of three versions. A desktop model

(Sensistor ISH2000), a battery operated model (Sensistor ISH2000C), and a

panel mount model (Sensistor ISH2000P).

Figure A-1: Sensistor ISH2000

Sensistor ISH2000 is equipped with a number of powerful functions making it

very easy to integrate in a semi or fully automatic test system. The functions

range from output of all necessary status signals and printer/communication

port to an advanced Active Probe Control system (APC). This makes the detector capable of controlling advanced sample collecting devices down to simple

test fixtures.

Sensistor ISH2000C

Sensistor ISH2000P

Figure A-2: Sensistor ISH2000C

The battery operated model, Sensistor ISH2000C, has all the Sensistor ISH2000

features apart from the APC system. This means that only passive probes (for

example Hand Probe P50) can be used. The battery, a Li-ion battery at 14.8 V,

can not support the current required to operate external probes. Sensistor

ISH2000C will operate for 14 hours on a fully charged battery with screensaver

and mute function. One hour charging will give about one hour of operating

time.

Figure A-3: Sensistor ISH2000P

The panel mount model, Sensistor ISH2000P, has identical features of the Sensistor ISH2000.The difference is that the Sensistor ISH2000 can be installed in

EN- 5 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 6

A 300

the operator’s panel or any other flat surface. Also it operates on +24 VDC.

Mounting brackets and a panel rubber seal are delivered with the detector.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 6

Page 7

Sensor Technology

A 400

A 300 Sensor Technologies working principle

The Sensistor ISH2000 leak detector is using SENSISTOR sensor technology

inside. SENSISTOR sensor technology uses an extremely sensitive hydrogen gas

sensor based on a microelectronic field effect transistor (MOS-FET).

The gas sensitivity appears when hydrogen absorbs into the sensor through a

metal alloy (metal hydride) layer.

Only hydrogen can diffuse into the metal and this makes the sensors practically

insensitive to other substances that do not contain free hydrogen molecules.

The signals from the sensors are processed by a microprocessor which also controls the sensor temperature with high accuracy, and other sensor diagnostics in

order to ensure perfect functionality. It also automatically compensates for

background gas.

EN- 7 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 8

To Detect leaks

A 400

A 400 Testing methods

If all you wish to do is to detect the presence of a leak, that is, find out whether

there is a leak or not, then use the Detection Mode (or use the detection bar in

Combined Mode). The definition of Leak/No Leak will then simply be "A leak is

a leak when it can be detected by the detector, set to a specific sensitivity".

To set up:

The operation in Detection Mode is not quantitative. The audio and visual sig-

nal will increase and decrease with the gas concentration. Therefore, there is no

actual calibration to be done, but rather a setting of the sensitivity to a desired

level.

A typical set-up procedure for Detection Mode is:

• Set up a reference leak which corresponds to the smallest leak you wish to

detect.

• Put the probe close to the reference leak and note approximately what reaction you get (no reaction, small, medium, high, full scale) within the first few

seconds.

• Set the sensitivity. This can be done permanently under the menu Detection

Mode Settings or temporarily as a Direct Sensitivity Adjustment on the display

(unless you have set this function to OFF under the Detection Mode Settings

menu).

There is also an Auto ranging function which can be selected under the Detection Mode Settings menu.

Note: If the Detection Mode is used and the alarm function is required to be

activated at a particular calibrated level, then the unit must be calibrated in

accordance with the instructions, see "Calibrate the leak detector" on page 17.

The reason for this is that the alarm is based on the Analysis Mode when the

Detection Mode is displayed.

To Locate Leaks

Note: The Detection Mode (or use the detection bar in Combined Mode) is

used to locate leaks. This mode is semi-quantitative, that is, it gives an audio

and visual signal which increases as a leak is approached (a higher gas concentration) and decreases as you move the probe away from the leak. It does not

display figures. In this mode of operation leaks can easily be detected using a

sensitivity which can be preset.

Leaks can be located very accurately, even when there are other leaks nearby. If,

for example, you are trying to locate a leak on a product and the product has a

major leak, then you will get an audio signal as soon as the probe is placed

close to the product.

When the probe is moved around and over the product, the signal will increase

as the probe approaches the leak. If the signal goes out of scale, simply reduce

the sensitivity setting to bring the signal within the scale. Working with the sensitivity setting this way you will be able to locate multiple leaks that are in close

proximity to each other.

Note: Working inside a confined space such as, for example, a cabinet or a narrow passage on a combustion engine there is a risk that the background concentration accumulates to levels close to the upper detection limit of the

detector. In such case it will not be possible to locate leaks as easily as in open

spaces.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 8

Page 9

To Quantify Leaks

A 401

Hint: It is good practice to detect a leak, locate it, and immediately remove the

probe to avoid saturation. The probe is not damaged by the exposure but it will

recover more slowly. After excessive exposure it will be less sensitive for a short

period of time.

The Analysis Mode (or use the analysis figures in Combined Mode) is used for

measuring the size of a leak (or the concentration of a gas sample). To be able

to do this measurement and obtain correct values, the instrument must first be

calibrated using the calibration function.

In the Analysis Mode the detector determines the gas concentration from the

change, as the probe goes from being exposed to background to being

exposed to a certain gas concentration. The detector does not continuously

monitor the gas concentration but takes just one reading instead. Another suitable alternative name for this mode could be Sampling Mode. It is important to

keep this in mind when using the detector in this mode.

In Analysis Mode the probe should be moved directly from a background situation to the test point. The size of the leak in PPM, or any other selected units, is

shown on the display. The probe can and should be removed from the measuring point as the measured value steadies and remains on the display. The period

during which the measured value is displayed can be adjusted in the Analysis

Mode Settings menu.

EN- 9 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 10

A 600

A 401 About Hydrogen

When pure hydrogen gas is released in air its flammability range spans from 4%

to 75% of hydrogen in air. Below 4% there is insufficient chemical energy available for a flame to occur. Above 75% hydrogen there is not enough oxygen left

to support a flame. When, for example, a mixture of less than 5.5 % hydrogen

in nitrogen mixes with air there is not sufficient energy to support a flame, irrespective of the ratio of air-to-gas. When a mixture of more than 5.5 % hydrogen in nitrogen is released into air there is a region of ratios of air-to-gas where

the mixture is flammable. When, for example, a mixture of 10% hydrogen in

nitrogen mixes with air there is still very little energy available. Only in exceptional circumstances can a flame be self-supporting. However, such mixtures

cannot detonate.

Hydrogen can be stored and transported as either a gas a cryogenic liquid.

The tracer gas is standard welding gas of industry quality, easy to obtain at low

cost. The generic name is Forming Gas.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 10

Page 11

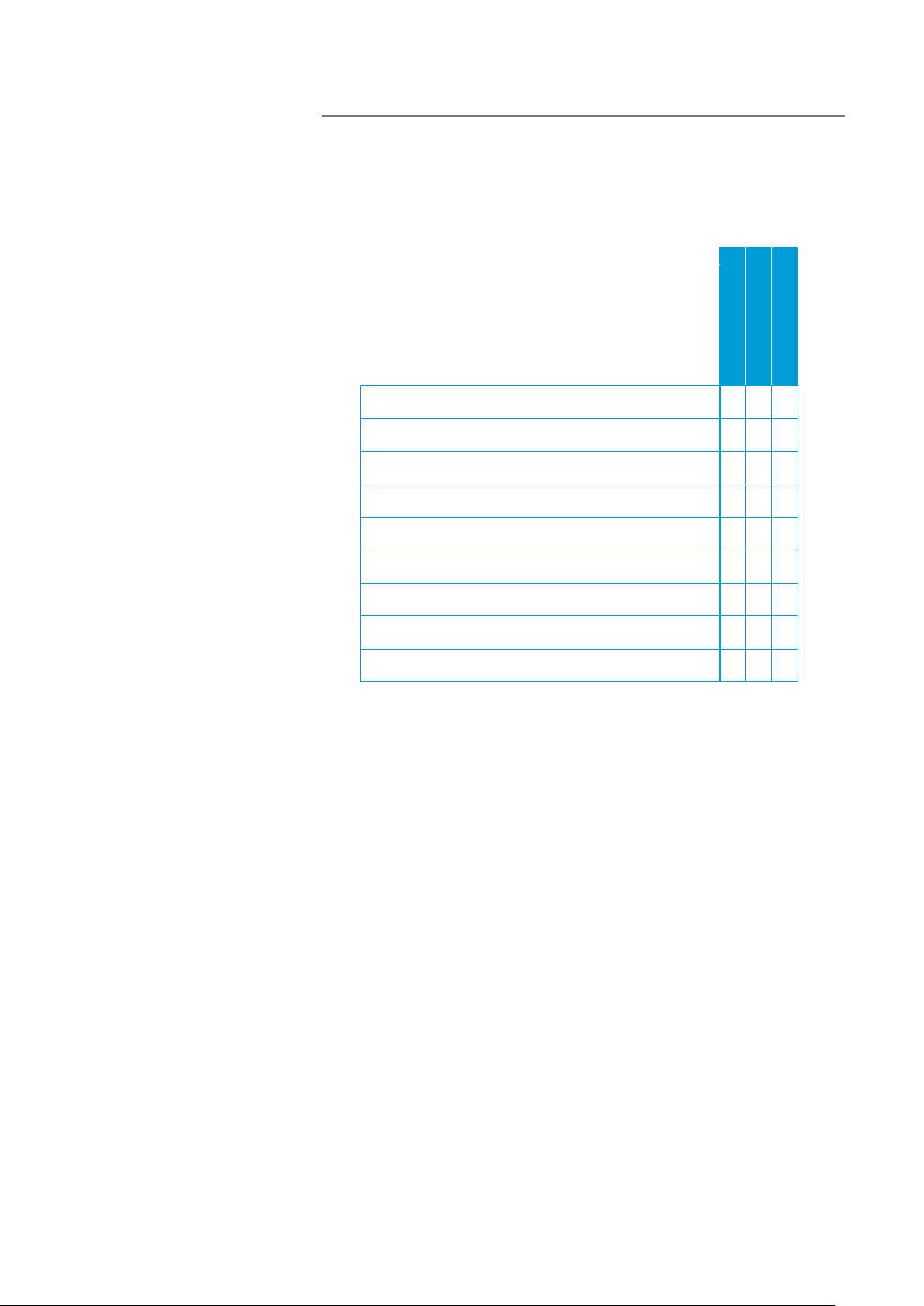

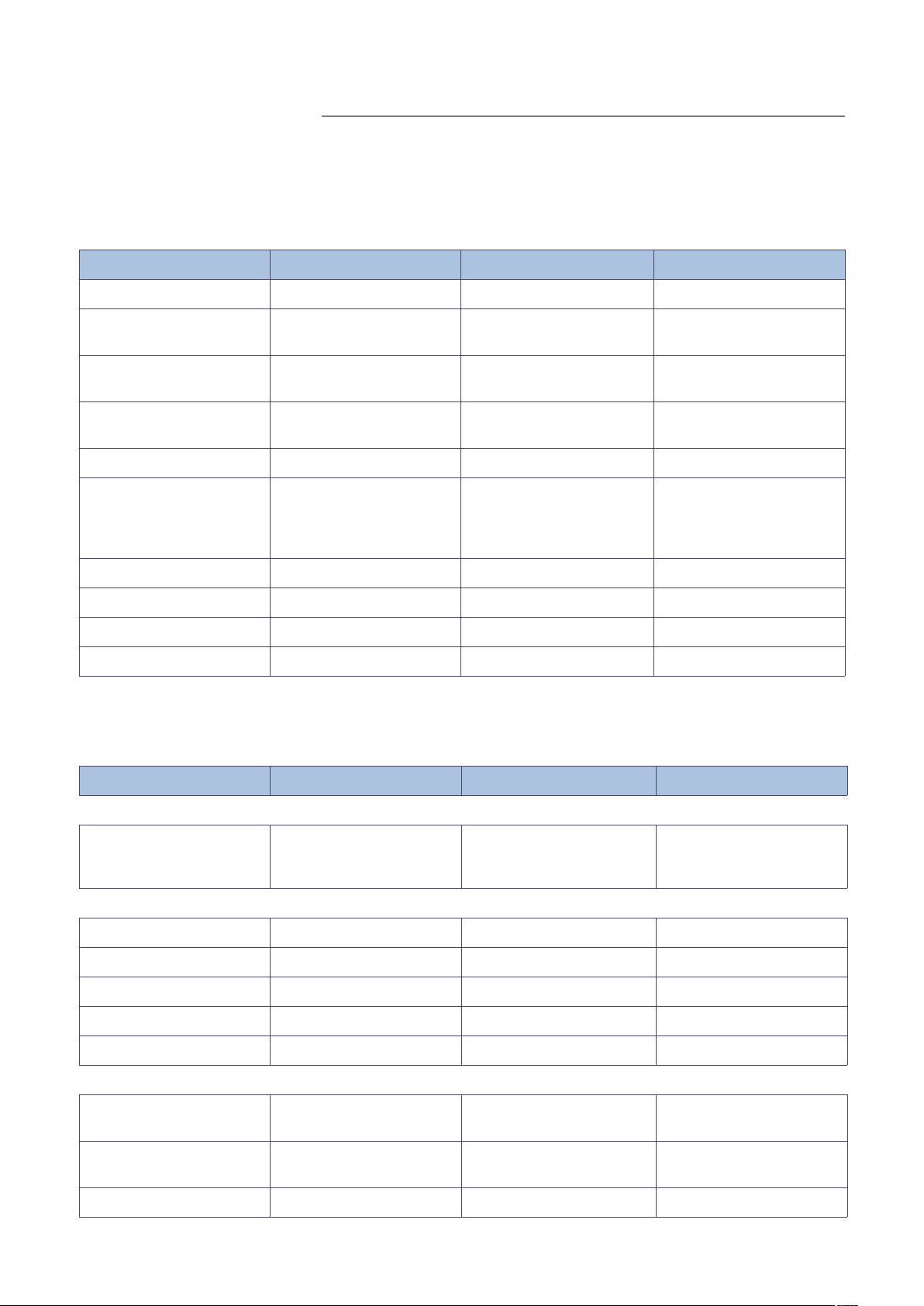

A 600 Options

Which options for which model?

A 700

Sensistor ISH2000

Sensistor ISH2000 C

Table model t

Portable model t

Panel model t

Hand probe P50 tt

3 m C21 cable tt

Sensistor ISH2000 P

Power supply cable t

Battery recharger

Cary case

Probe control port

t

t

t

t

EN- 11 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 12

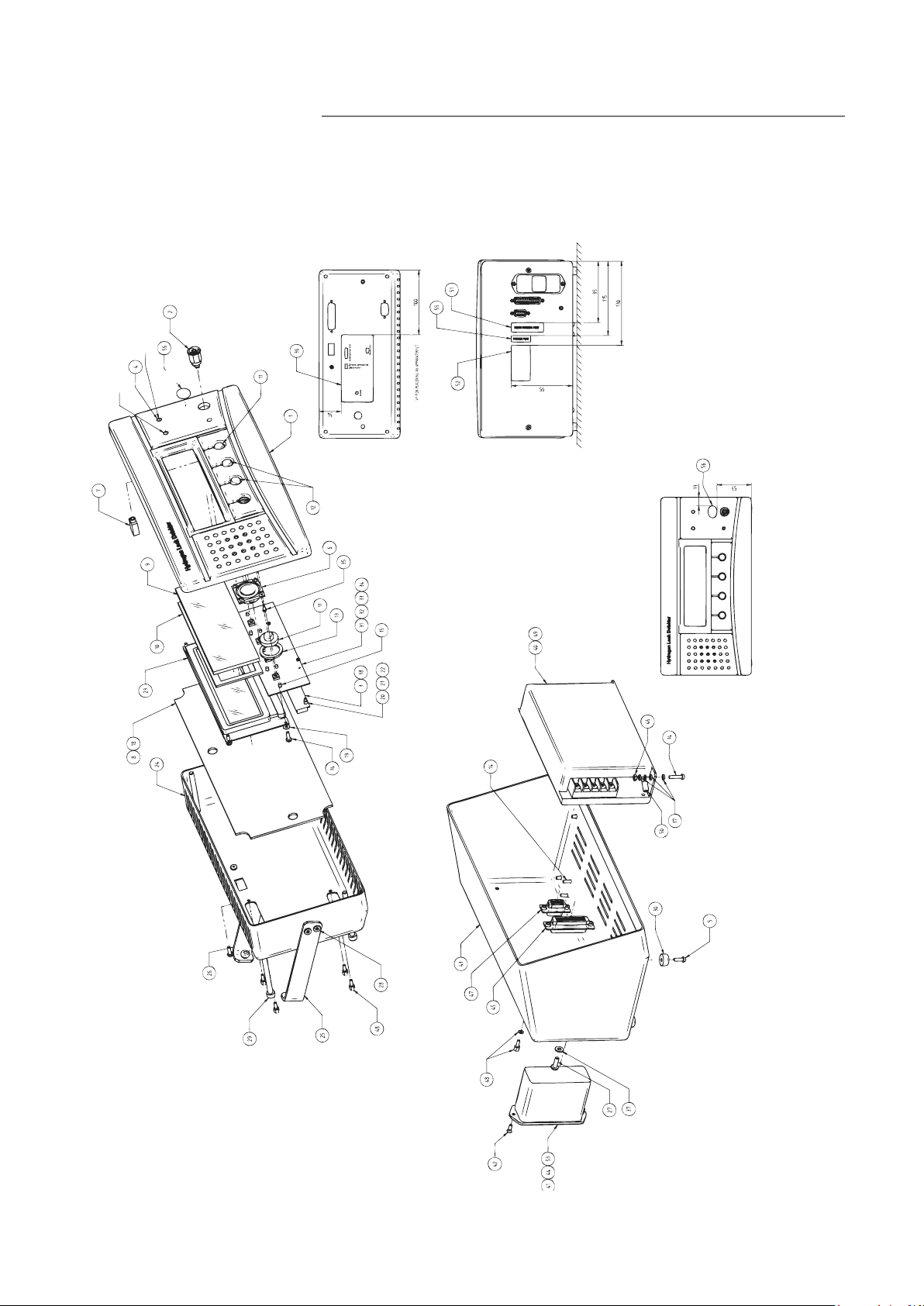

Sensistor ISH2000

A 700

A 700 Sensistor ISH2000 Components

Green diode

Red diode

Green diode

Red diode

Figure A-4: Sensistor ISH2000 components

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 12

Page 13

A 700

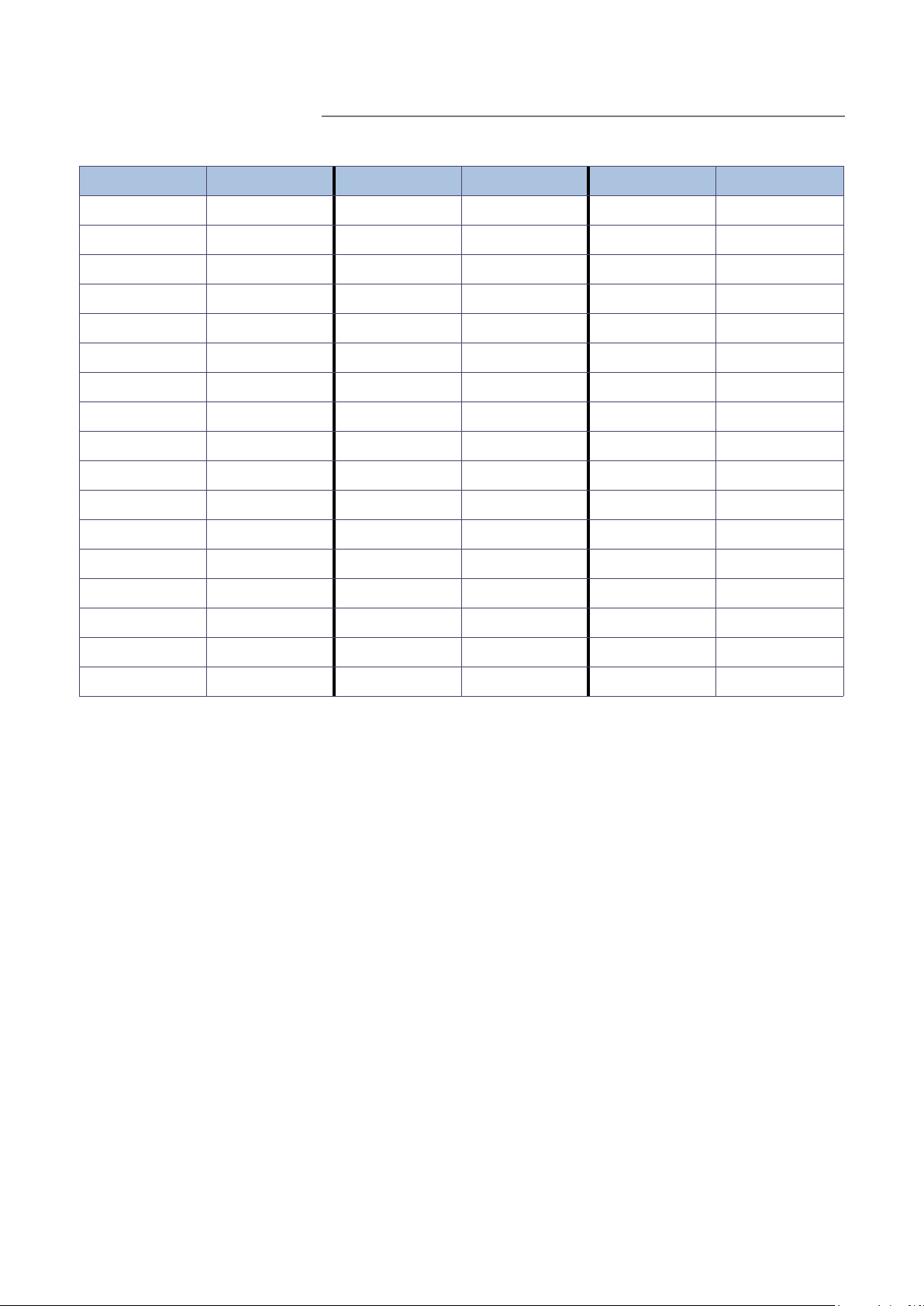

Sensistor ISH2000 components according to Figure A-4: on page 12.

Position P/N Position P/N Position P/N

1 598-170 21 591-493 41 591-812

2 591-770 22 591-499 42 591-607

3 591-496 23 591-494 43 598-167

4 591-771 24 598-166 44 591-578

5 591-533 25 591-502 45 591-774

6 591-773 26 591-503 46 591-013

7 591-779 27 591-487 47 591-777

8 591-780 28 591-488 48 591-538

9 598-121 29 591-490 49 591-781

10 591-501 30 591-786 50 591-772

11 591-500 31 591-497 51 598-177

12 591-515 32 591-796 52 591-809

13 598-043 33 591-797 53 591-577

14 591-791 34 591-798 54 591-317

15 591-790 35 591-787 55 598-173

17 591-775 36 598-174 56 591-810

18 591-778 37 591-266 57 591-017

19 591-532 38 591-527 58 591-142

20 591-492 40 591-482

EN- 13 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 14

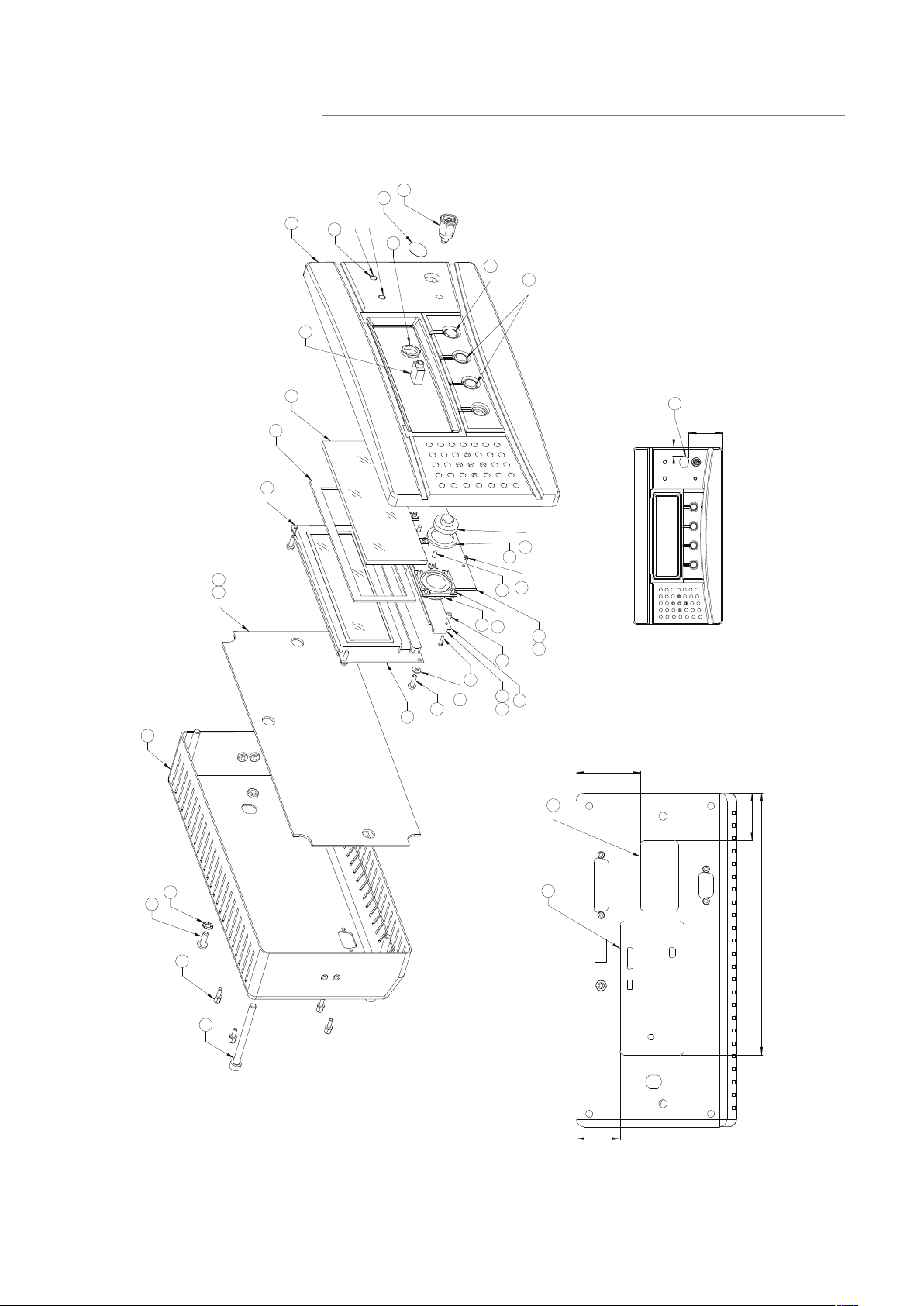

Sensistor ISH2000C

Green diode

Red diode

Green diode

Red diode

A 700

Figure A-5: Sensistor ISH2000C components

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 14

Page 15

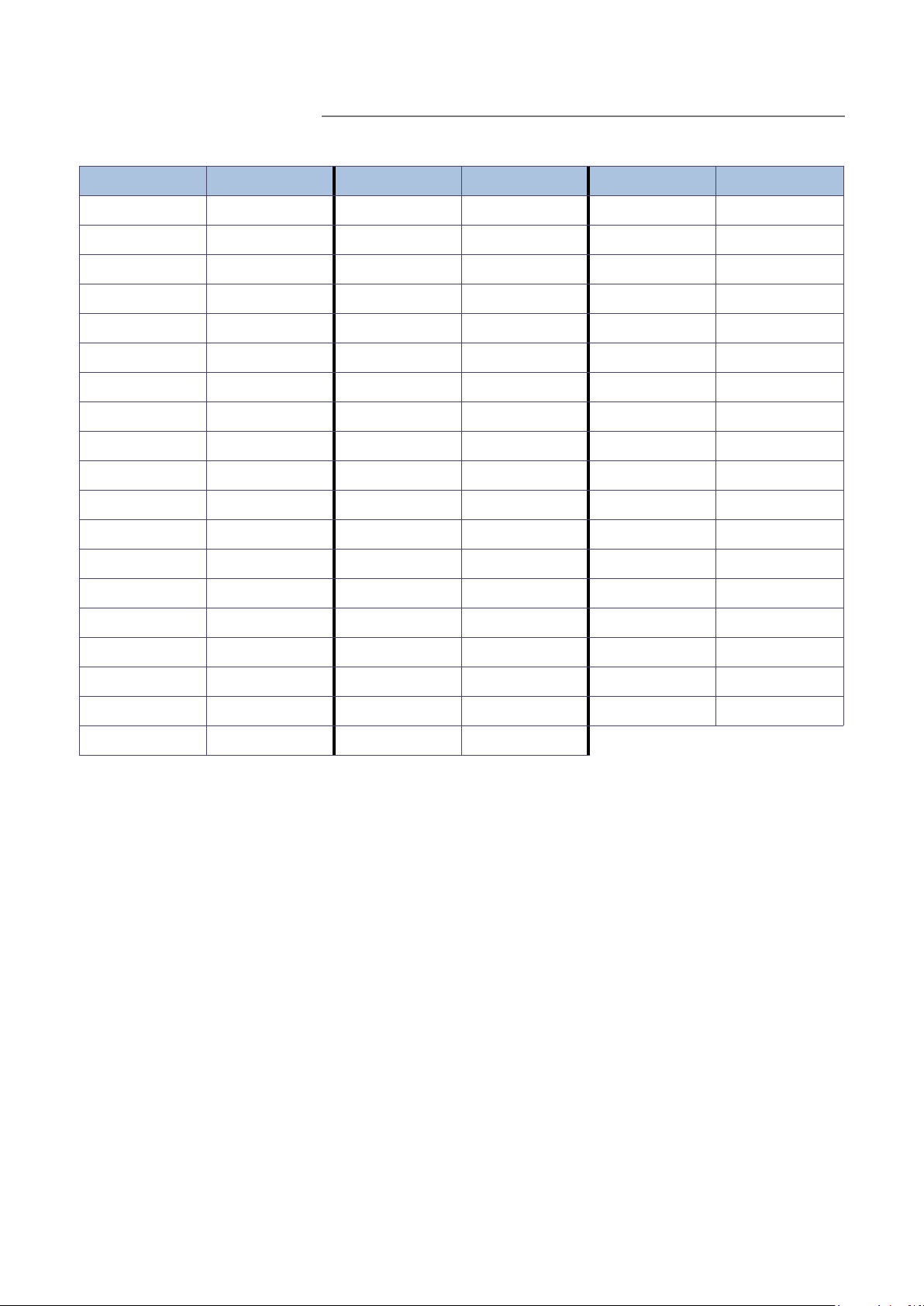

A 700

Sensistor ISH2000C components according to Figure A-5: on page 14.

Position P/N Position P/N Position P/N

1 598-170 19 591-532 36 598-174

2 591-770 20 591-492 37 591-266

3 591-498 21 591-493 38 591-527

4 591-771 22 591-499 39 598-178

5 591-533 23 591-494 40 591-782

6 591-773 24 598-166 41 591-328

7 591-779 25 591-502 42 591-452

8 591-780 26 591-503 43 591-806

9 598-121 27 591-298 44 591-327

10 591-501 28 591-488 45 598-172

11 591-500 29 591-490 46 591-538

12 591-515 30 591-786 48 591-785

13 598-043 31 591-497 49 591-807

14 591-791 32 591-796 50 598-173

15 591-790 33 591-797 51 591-777

17 591-775 34 591-798 52 591-810

18 591-778 35 591-787 53 591-810

EN- 15 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 16

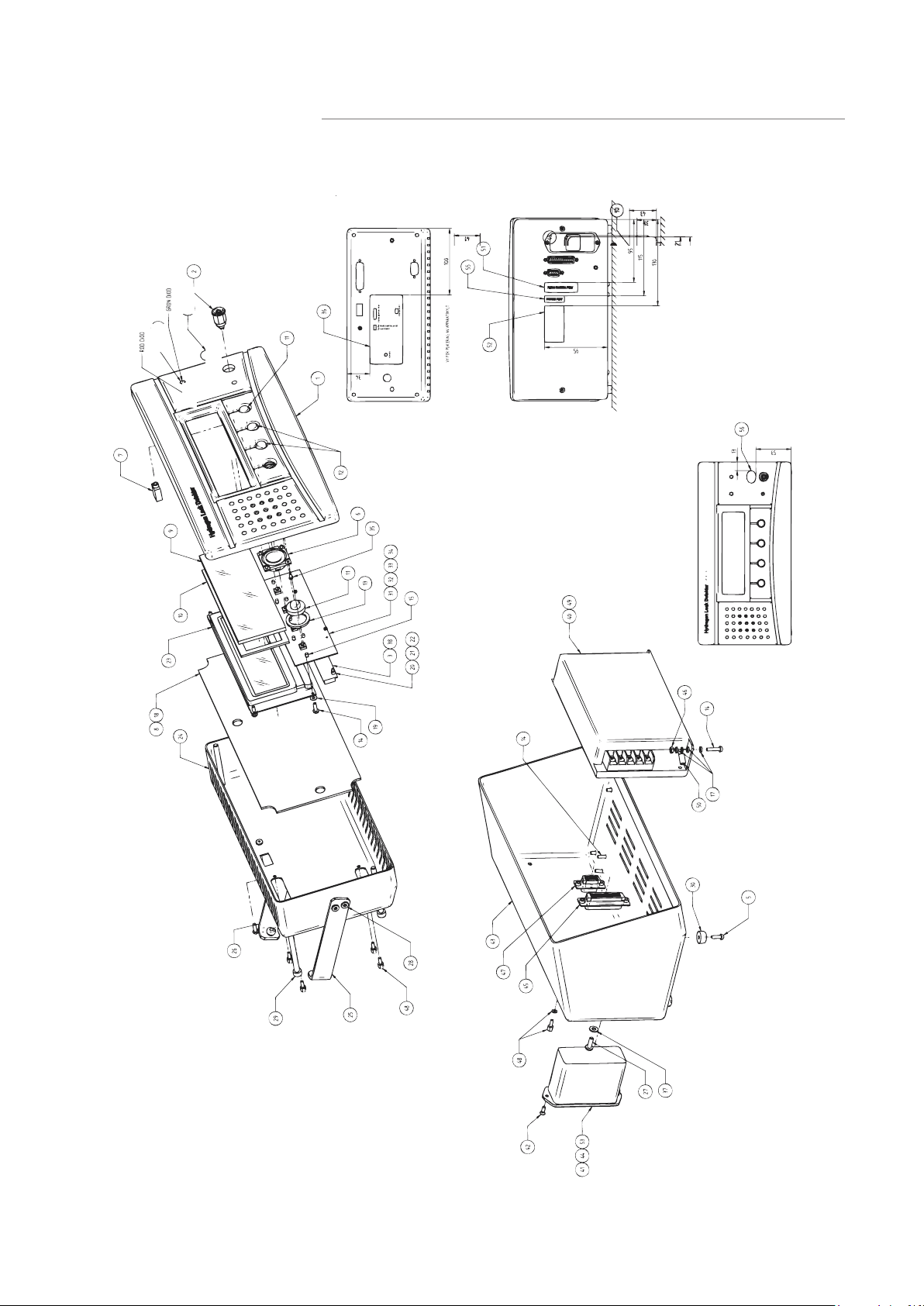

Sensistor ISH2000P

J

2

J

A 700

66,6

HQOL

(MWRO)|UULWQLQJ

Red diode

Green diode

ZP/K

'ZPE/K

$QPlUNQLQ

JlOOHU

66,62

5LWQLQJVQXPPHU

1HWWRGLPHQVLRQ0DWHULDO

,QJnUSnVPVW

6NDOD

3

/lFNV|NDUH+Y3DQHOPRGHOO

%HQlPQLQJ

3URMHNW1DPQ

091130091130091130

3(+(

*RGN

3(+(

*UDQVN

%HQlPQLQJ

(&*

.RQVWU

AC:?E6CA@CE

AC@364@?EC@=A@CE

4

5

E

?

@

=

C

#

%

G

@

4

6

@

3

C

A

4

:

5

>

?

#

%

2

G

D6?D@C

2ULJLQDOIRUPDW $

Figure A-6: Sensistor ISH2000P components

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 16

Page 17

A 701

Sensistor ISH2000P components according to Figure A-6: on page 16.

Position P/N Position P/N Position P/N

1 598-170 14 591-791 29 591-490.

2 591-770 15 591-790 31 591-497

3 591-498 16 591-808 32 591-796

4 591-771 18 591-778 33 591-797

6 591-773 19 591-532 34 591-798

7 591-779 20 591-492 35 591-787

8 591-780 21 591-493 36 598-174

9 598-121 22 591-499 37 591-538

10 591-501 23 591-494 38 591-527

11 591-500 24 598-166 39 591-810

12 591-515 25 591-776

13 598-043 26 591-298

EN- 17 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 18

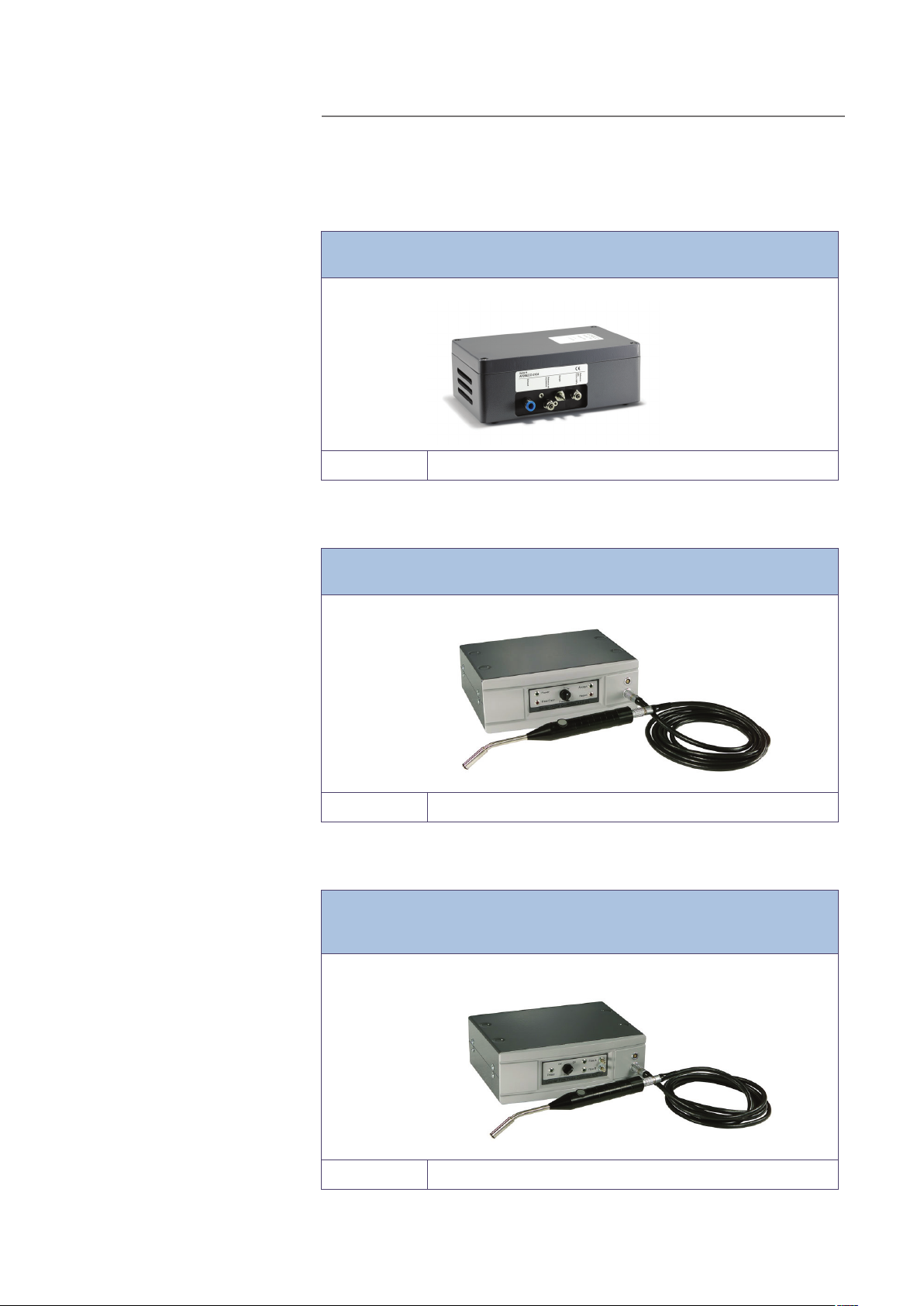

AP29ECO Sampling Probe

AP55 Sniffer Probe

A 701

A 701 Spare parts and accessories

For automatic leak testing of entire products or parts of products. Can also be used

for testing permeability of materials.

Part No: 590-035

AP57 Counter Flow Probe

For fast manual leak location in hard to-reach places. Active probe that sniffs the

sample air past the hydrogen sensor in the probe tip.

Part No: 590-550

For leak detection in enclosed spaces or in environments with a high background

level of tracer gas. An adjustable air flow from the probe tip provides a protective air

curtain against tracer gas in the surroundings.

Part No: 590-555

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 18

Page 19

P50 Hand Probes

A 701

Hand Probe P50 with rigid neck.

Part No: 590-780

With a flexible neck. Facilitates leak detection in hard-to-reach places.

Part No: 590-790

H65 Insert Sensor

Replaces the standard hand probe in automated tests.

Part No: 590-250

Probe Tip Protection Cap and filter

For Hand Probes P50 and P50-FLEX.

Part No: 591-273 (Probe Tip Protection Cap, set of 50)

590-625 (Probe Tip Protection Cap, set of 500)

591-234

EN- 19 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 20

A 701

Combox

C 21 Probe Cables

This page intentionally left blank

Probe adapter for AP29ECO, H65, AP55 and AP57.

Part No: 590-820

In various lengths for comfortable leak detection in every situation.

Part No: 590-161 (3m)

590-175 (6 m)

590-165 (9 m)

590-163 (4 m, spiral)

590-164 (6 m, spiral)

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 20

Page 21

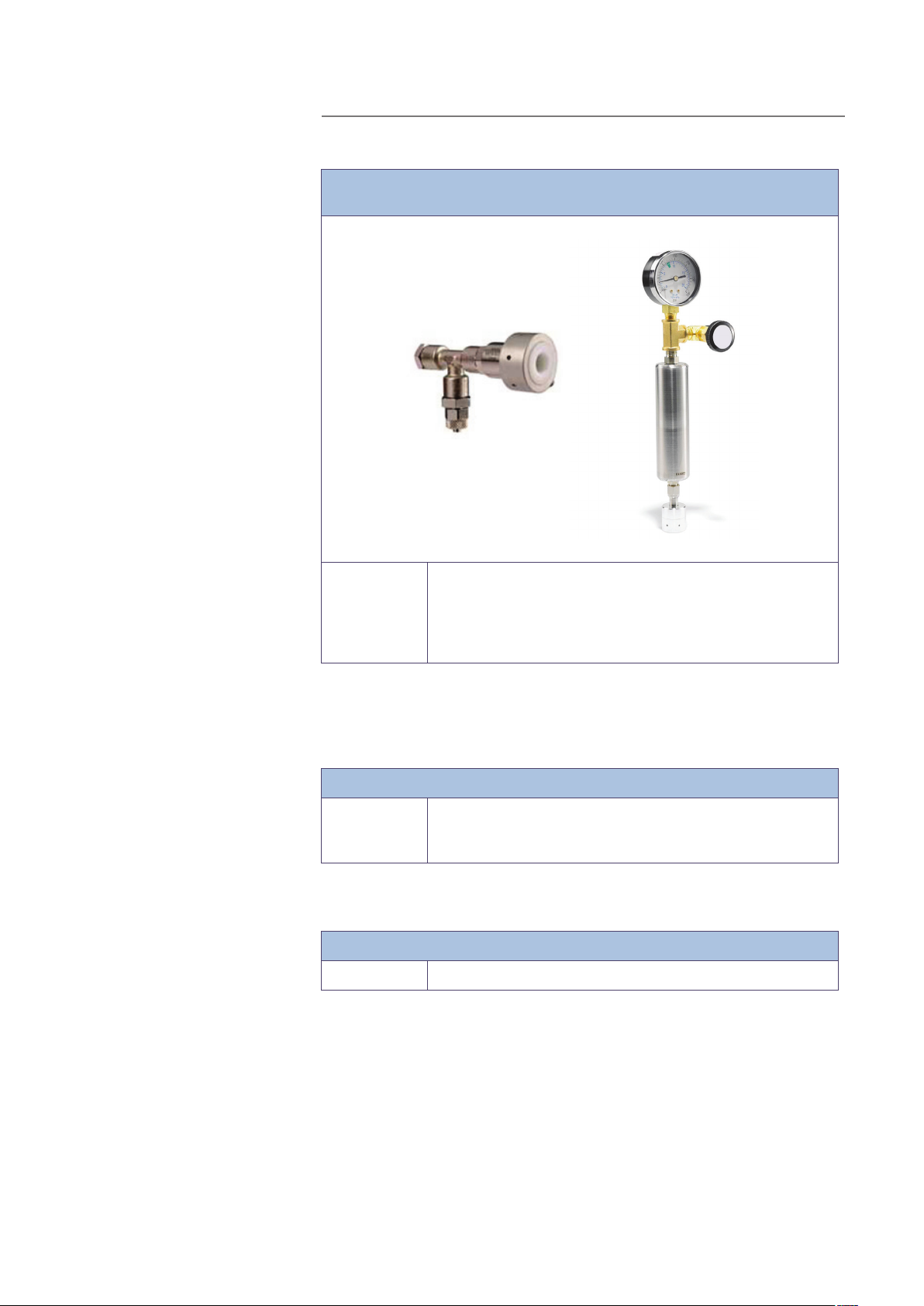

Reference Leaks

A 701

Large and small, with certificate, for calibration and function tests of the Sensistor

ISH2000.

Power cables

Fuse

Part No: 590-420 Type A 5x10

590-421 Type B 5x10

590-422 Type C 5x10

590-427 Type D 10 g/a R134a

590-429 Type G 3 g/a R134a

Power cables for Sensistor ISH2000

Part No: 591-146 (Power cable eu)

591-147 (Power cable uk)

591-853 (Power cable us)

2 A slow for Sensistor ISH2000

Part No: 591-578

-2

atm ml/s

-3

atm ml/s

-4

atm ml/s

EN- 21 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 22

Carrying case

Battery charger

A 800

For Sensistor ISH2000C

Part No: 591-329

For Sensistor ISH2000C

Part No: 591-795

Hand Probe sensor

Sensor, for sensor replacement on P50 Hand Probe.

Part No: 590-292

Mounting kit

For Sensistor ISH2000P inkluding Brackets and seals.

Part No: 590-810

Phoenix connector to Sensistor ISH2000P

For Sensistor ISH2000P, power connection.

Part No: 591-792

O-ring seal

For Sensistor ISH2000P.

Part No: 591-528

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 22

Page 23

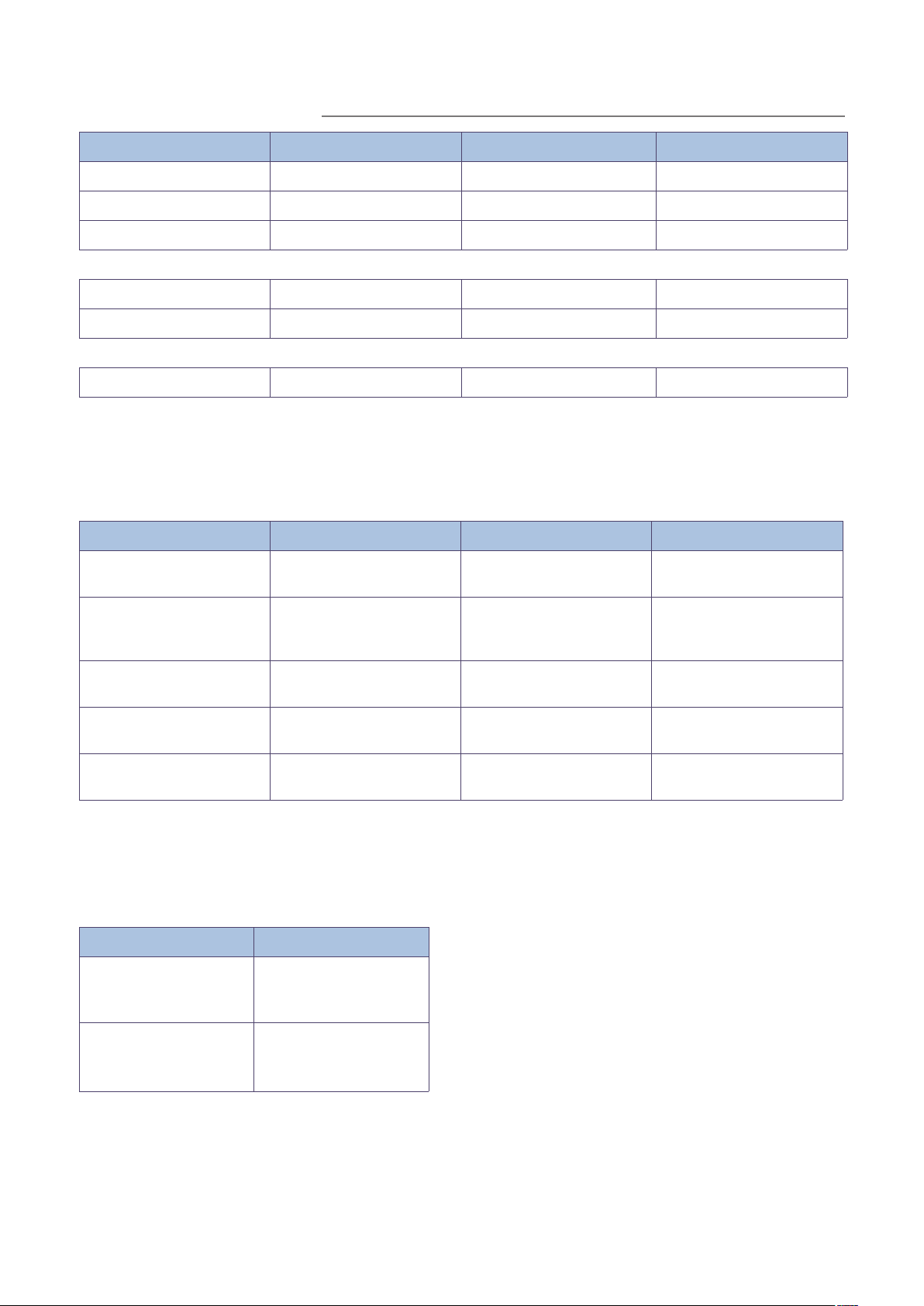

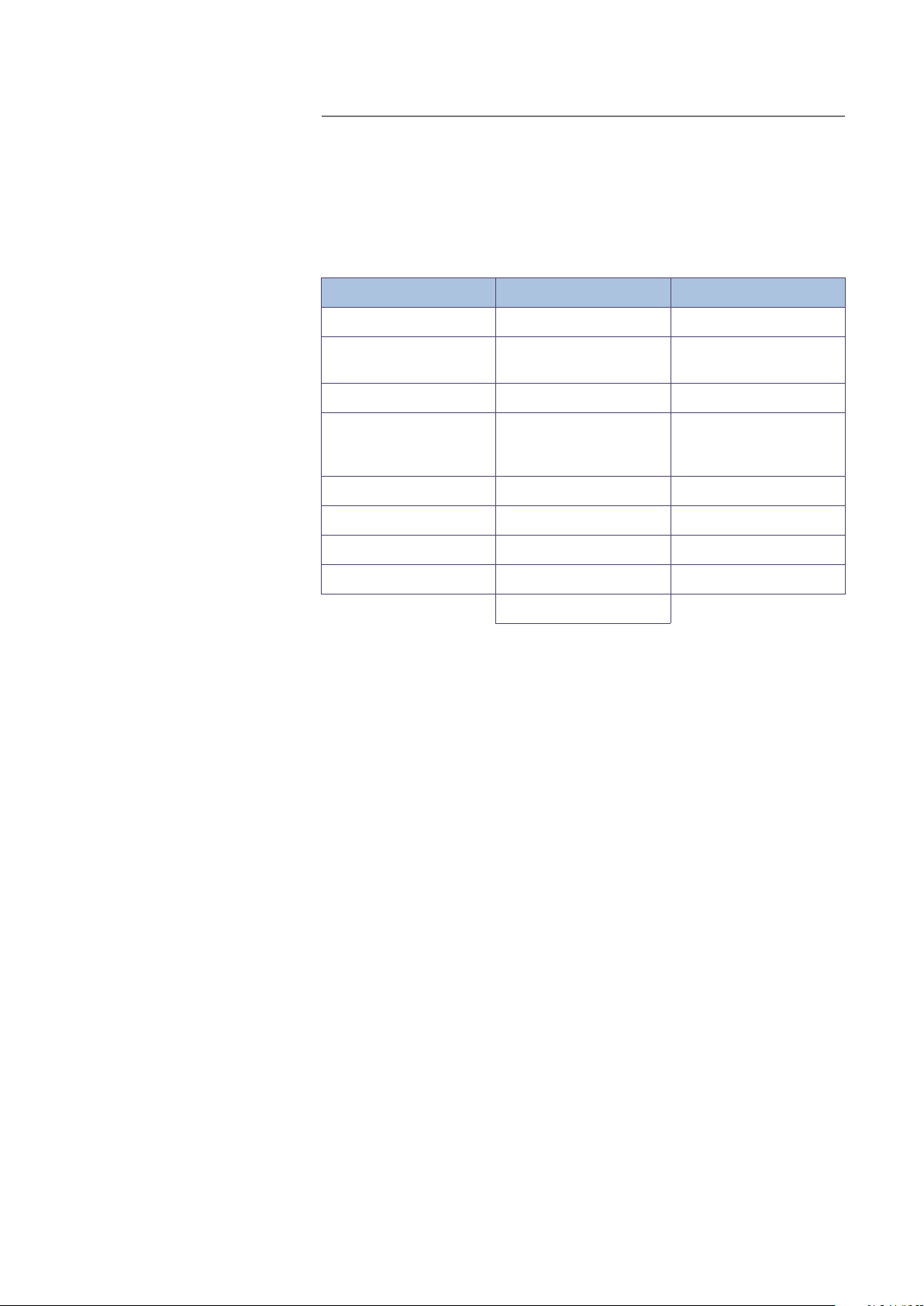

A 800 Sensistor ISH2000 - Technical specifications

Power supply specifications

Power Sensistor ISH2000 Sensistor ISH2000C Sensistor ISH2000P

AC mains voltage 100-240 V 50/60Hz. -

A 800

AC mains voltage to the

charger

AC mains current Typically 1 A (2 A pulse at

power on).

AC mains current to the

charger

Fuse 2 A slow/ 250 VAC. - -

Nominal battery voltage - 16.1 VDC (nominal). The unit

Operating time - 8 h -

Charging time - 6.5 h -

Power supply voltage - - 24 VDC

Power supply current - - 3 A max

100-240 V50/60 Hz -

-

Typically 300 mA -

will shutdown at approx.

12VDC, and will be operational at approx. 14VDC

Input and output connections

Type Sensistor ISH2000 Sensistor ISH2000C Sensistor ISH2000P

General

Power input connector AC input connector, IES 320. Charger input connector, 2.1

x 5.5 mm std. Positive centre.

Probe control port inputs

Minimum pulse length 40 ms - 40 ms

Input impedance 50k ohm - 50k ohm

Input maximum range -34 to +38 VDC - -34 to +38 VDC

Input high > 12.0 VDC - > 12.0 VDC

Input low < 8.0 VDC - < 8.0 VDC

Probe control port outputs

Output current max 0.5 A/output, max 2.5 A

total

Inductive loads External clamp diodes

recommended

Low stage voltage Max 1.5 VDC - Max 1.5 VDC

- max 0.5 A/output, max 2.5 A

- External clamp diodes rec-

4 pin Phoenix MC 1.5/5.81

Series Detachable screw terminal.

total

ommended

EN- 23 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 24

A 800

Type Sensistor ISH2000 Sensistor ISH2000C Sensistor ISH2000P

Short circuit protection Thermal and electronic - Thermal and electronic

Output high 22-24 VDC - > (Supply voltage – 2.5 VDC)

Output low < 1.5 VDC - < 1.5 VDC

Serial communication port

Connector 9-pol D-sub male 9-pol D-sub male 9-pol D-sub male

Standard RS232 RS232 RS232

Probe control/Status port

Connector 25-pin D-sub female 9-pin D-sub female -

Miscellaneous specifications

Misc Sensistor ISH2000 Sensistor ISH2000C Sensistor ISH2000P

Protection (IEC529) IP64 (front), IP32 (back) IP63 (in carrying case) IP64 (front), IP32

(back)

Net weight 3.9 kg (8.6 lb) 4.0 kg (8.8 lb)

4.9 kg (10.8) incl. case,

probe and charger

Overall dimensions 275 x 155 x 170 mm

(11 x 6 x 7 inches)

Environment

temperature

Environment

humidity

0-50°C 0-50°C 0-50°C

10-90% RH 10-90% RH 10-90% RH

275 x 190 x 170 mm

(11 x 7 x 7 inches)

1.8 kg (4.0 lb)

275 x 140 x 75 mm

(11 x 6 x 3 inches)

Gas sensing specification (In Detection Mode)

Selected unit Sensitivity

mbarl/s air (using 5% H2/

95% N

Tracer Gas)

as

2

1 x 10

-7

mbarl/s

g/a R143a (using 5% H

as

95% N

2

Tracer Gas)

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 24

/

0.02 g/a

2

Page 25

Gas sensing specification (In Analysis Mode)

A 900

Selected unit Sensitivity Measurement

range

ppm (H

mbarl/s air

(using 5% H

95% N

Tracer Gas)

g/a R143a (using

5% H

as Tracer Gas)

) 0.5 ppm 0.5 - 2000 ppm

2

as

2

/95% N

2

-7

/

2

2

5 x 10

0.2 g/a 0.2 - 8300 g/a Typ. ± 15% of reading

mbarl/s 5 x 10-7 - 4 x 10-2

(0.2%)

mbarl/s

Linearity Repeatability

Typ. ± 15% of reading

(within 0.1 - 10 x

calibration point in

range 0.5 - 100 ppm)

Typ. ± 15% of reading

(within 0.1 - 10 x

calibration point in

range 1 x 10

-

10

3

mbarl/s)

(within 0.1 - 10 x

calibration point in

range 0.2 - 420 g/a

-5

- 2 x

Typ. ± (10% of

reading + 0.3 ppm)

Typ. ± (10% of

reading + 3 x 10

mbarl/s)

Typ. ± (10% of

reading + 0.1 g/a)

-7

EN- 25 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 26

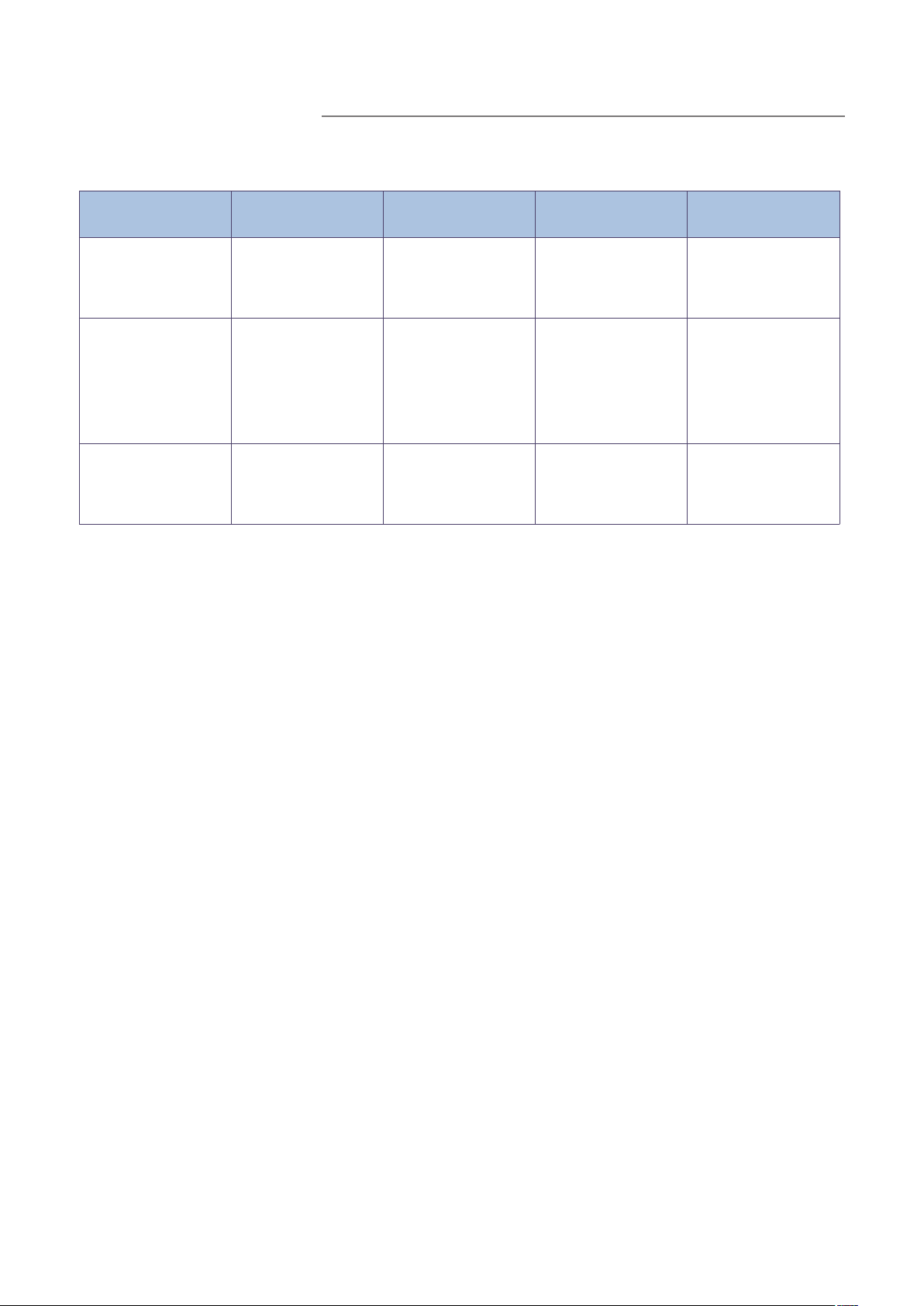

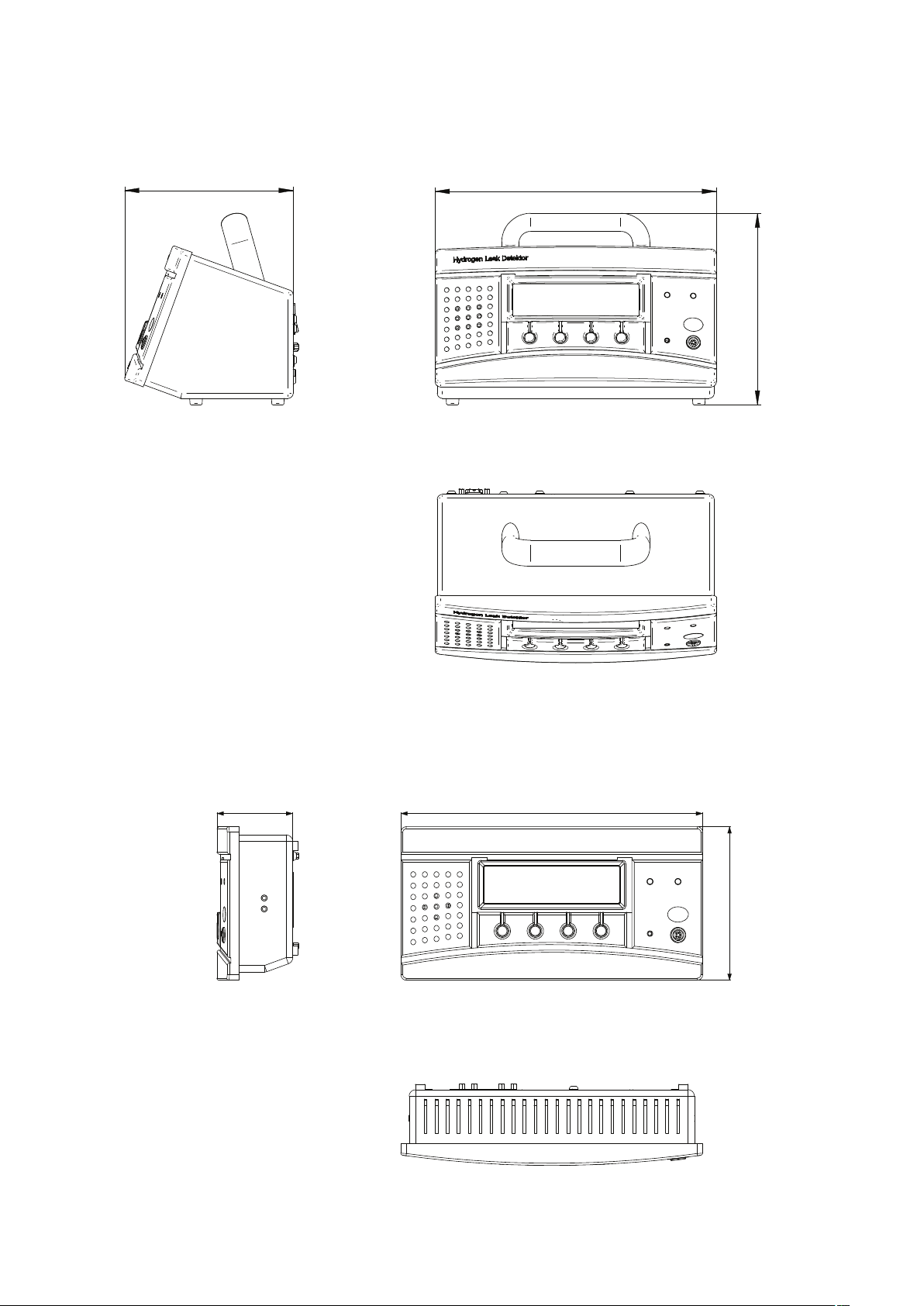

Sensistor ISH2000

A 900

A 900 Dimensions

165 / 0.54

275 / 0.9

156 / 0.51

Figure A-7: Sensistor ISH2000 dimensions

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 26

Page 27

Sensistor ISH2000C

This page intentionally left blank

165 / 0.54

275 / 0.9

188 /0.62

Sensistor ISH2000P

Figure A-8: Sensistor ISH2000C dimensions

Figure A-9: Sensistor ISH2000P dimensions

EN- 27 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 28

Installation

B

Sensistor ISH2000 Technical Reference Manual

Detailed content

B 100 Safety

B 110 Storage - transportation

B 210 Connecting the detector to the installation

B 300 Controlling the detector with the I/O interface

B 310 Controlling the detector with a PC computer through RS 232

B 310 Connecting the detector directly to a printer or another device

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 28

Page 29

B 100

B 100 Safety instructions

The normal risks associated with working with all compressed gases must be

considered.

Indicates a potentially hazardous situation which, if not avoided, could result in

property damage.

Indicates a potentially hazardous situation which, if not avoided, could result in

moderate or minor injury. It may also be used to alert against unsafe practices.

Indicates a potentially hazardous situation which, if not avoided, could result in death

or severe injury.

Indicates an imminently hazardous situation that, if not avoided, will result in death or

severe injury (extreme situations).

WARNING!

Pure hydrogen is a flammable gas. Only use readymade Hydrogen Tracer Gas of 5% Hydrogen in

Nitrogen. This is a standard industrial gas mixture

used in various industrial applications.

Note:

Whenever the word Hydrogen is used in

this manual it implies that the hydrogen gas is

safely mixed with Nitrogen in the proportions

- 95% N2.

5% H

2

Leak detector label

WARNING!

Since the tracer gas mix contains no oxygen,

releasing large amounts of gas in a confined space

may lead to asphyxiation.

WARNING!

Compressed gases contain a great deal of stored

energy. Always carefully secure gas bottles before

connecting pressure regulator. Never transport gas

bottle with the pressure regulator fitted.

Before connecting tracer gas: confirm that the connectors or test object is designed

for working at the test pressure.

WARNING!

Pressurising objects at too high pressures can result

in a burst object. This in turn can result in serious

injury or even death.

Never pressurise objects that have not previously

been burst tested or otherwise approved for the

chosen test pressure.

Located at the back of the Sensistor ISH2000, a label indicates the electrical

specifications of the leak detector and its serial number.

EN- 29 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 30

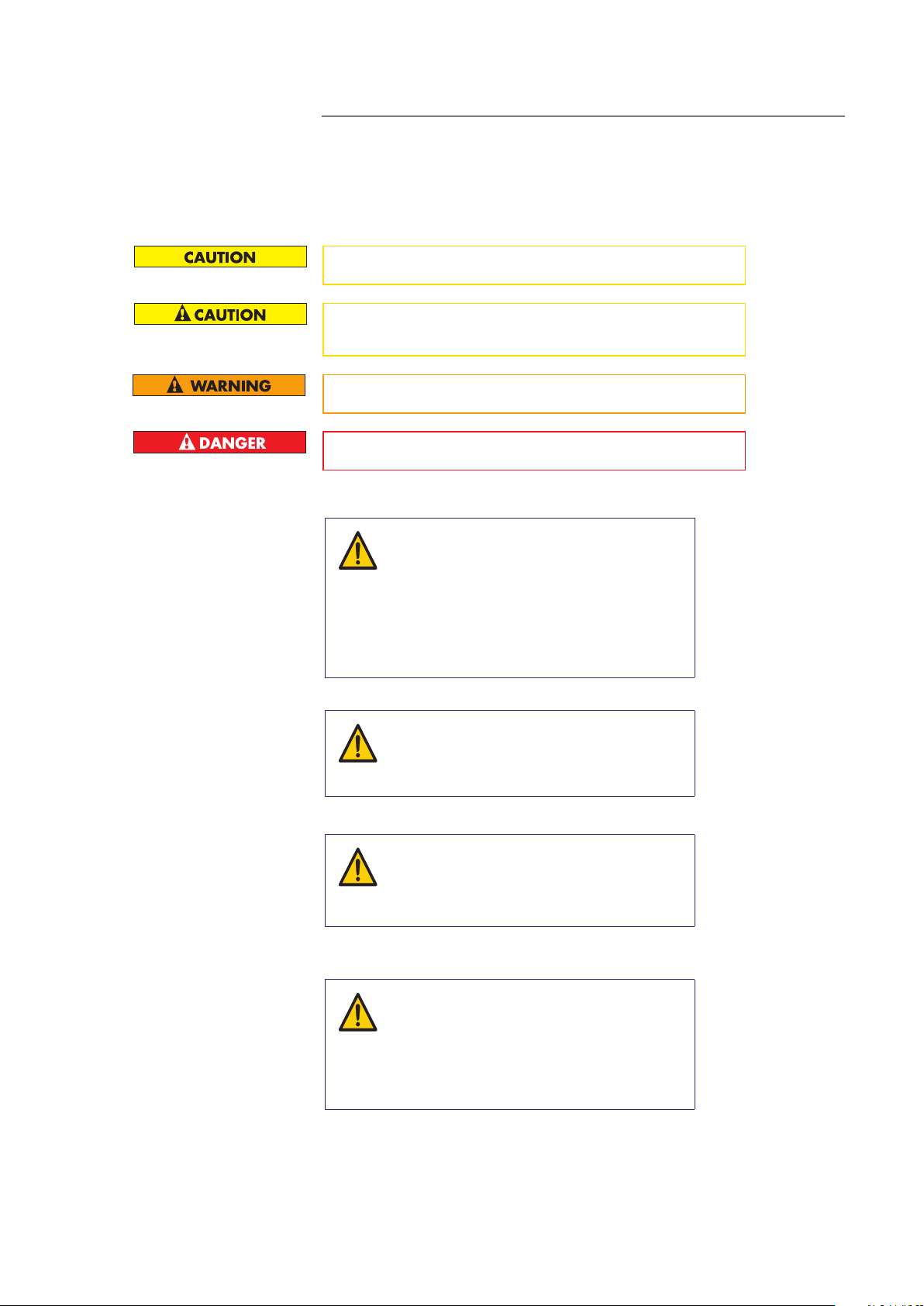

Supplies

B 110

B 110 Supplies and storage

The following parts are supplied with your detector:

Sensistor ISH2000 Sensistor ISH2000C Sensistor ISH2000P

Detector unit Detector unit Detector unit

Storage

Hand Probe P50.

Optional P50-Flex

Probe cable C21 Probe cable C21 Screws

Power cable (the power

cable is country specific

and may differ)

User manual User manual User manual

User manual CD User manual CD User manual CD

Product return form Product return form Product return form

Sample Kit Probe Tip Prot Sample Kit Probe Tip Prot Phoenix contact

For prolonged storage, factors such as temperature, humidity, saline atmosphere, etc. may damage the detector elements.

Please call your local representative for further information.

Hand Probe P50. Optional

P50-Flex

Battery charger (the battery charger are country

specific and may differ).

Case

Brackets

O-rings seal

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 30

Page 31

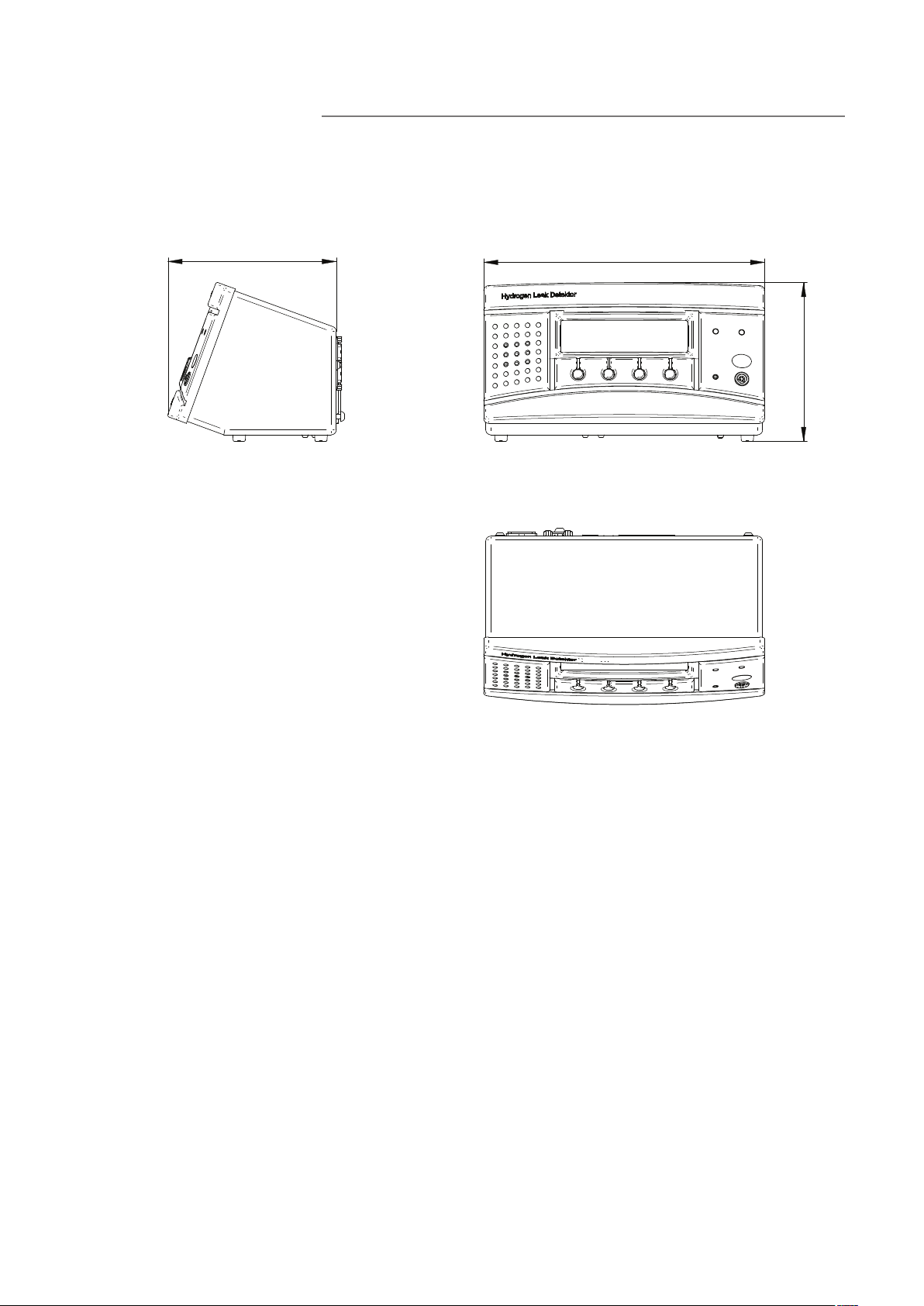

B 210 Connecting the detector to the installation

Ports and connections Sensistor ISH2000

Mounting plate screw hole

Probe control port

B 210

Power input

Printer port

Figure B-1: Sensistor ISH2000 back panel

Sensistor ISH2000 connections

Active Probe Control (APC) port.

See B 300.

Power switch

Fuse

Power input, 100-240 VAC

Printer connection, RS232 commands and APC driver installation.

Figure B-2: Sensistor ISH2000 connections

EN- 31 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 32

Sensistor ISH2000C connections

Battery charger

Figure B-3: Sensistor ISH200 C connections

B 210

Printer connection, RS232 commands and APC driver installation.

Sensistor ISH2000P connections

Power input, 24V

Probe

Active Probe Control (APC) port.

See B 300.

Printer connection, RS232 commands and APC driver installation.

Figure B-4: Sensistor ISH2000P connections

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 32

Page 33

I/O Interface

B 300

B 300 Controlling the detector with the I/O interface

The Sensistor ISH2000 is equipped with a parallel Probe Control port. This

Probe control port can be used for controlling active probes, feeding status signals to a supervising computer system, and for simple test fixture control.

Note: Battery operated model Sensistor ISH2000C does not have a Probe Control Port.

Pin configuration for the different detector models is described under Model

Specific Specifications below.

See "Sensistor ISH2000 Technical Specifications" on page page 23 for electrical specifications.

EN- 33 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 34

Probe Control Port Connector

The control port connector is a 25-pin female D-sub.

B 300

Pin Type Signal name

1 - GND

2 - GND

3 - GND

4 In In_0

5 In In_1

6 In In_2

7 In In_3

8 In In_4

9 Out CAL_CONF

10 Out OUT_6

11 - GND

12 - GND

13 - GND

14 OUT DET_ERROR

15 OUT LEAK_OUT

16 OUT DET_ON

17 OUT DET_SIGNAL

18 OUT DET_WAIT

19 OUT OUT_0

20 OUT OUT_1

21 OUT OUT_2

22 OUT OUT_3

23 OUT OUT_4

24 OUT OUT_5

25 OUT 24 VDC OUT

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 34

Page 35

Status signal patterns

B 300

Status signals for pin 14 - 18.

Figure B-5: Example screen

Where:

I/0 name on the screen Signal Name on the pins Function

Inputs 0 to 4 In_0 to In_4 Input signal

Outputs 0 to 6 Out_0 to Out_6 Output signal

Status O DET_ON When detector is on

Status W DET_WAIT High during warm-up

Status S DET_SIGNAL Gas detected / Sensor not

recovered

Status R LEAK_ALARM Leak above Reject Level

detected

Status C CAL_CONF Calibration preformed

and ok

Status E DET_ERROR High if Probe, Sensor or

Cable is broken

DET_ERROR will go high for a short time (1-5 seconds) when the detector is

switched on. It will go low when the sensor has been checked. In normal operation, DET_ERROR = HIGH means that there is a problem with the sensor,

probe, or cable.

DET_WAIT is high when instrument is in warm-up mode after switching on

power. Instrument will also go into warm-up if there is a temporary fault in the

sensor or sensor connection.

The timing of the status signals in relation to different events is described by the

following two examples:

• Example: Input signals issued to control the APC system should have a pulse

length of at least 40 ms.

• Example: Output signals switch with a cycle time of 20 ms (0.02 s). This is the

cycle time of the APC system.

Note: Not valid for battery operated version of Sensistor ISH2000.

EN- 35 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 36

DET_ERROR

DET_ON

DET_WAIT

DET_SIGNAL

LEAK_OUT

B 300

Status signal after power on

Power onPower off Warming up Detection or analysis

mode. No gas detected.

Figure B-6: Status signals after power on

Status signal when detecting a gas signal

Gas signal

Purge level

Reject level

Detector signal level

0 PPM

DET_SIGNAL

LEAK_OUT

PURGE_LEVEL Trigger

(APC)

Figure B-7: Status signals when detecting a gas signal

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 36

Page 37

B 310 Controlling the detector with a PC

computer through the RS 232 interface

RS 232 interface

The RS 232 interface makes it possible to control the leak detector with a PC

compatible computer: it is installed on all leak detectors.

Commands available for your leak detector

RS232 interface commands

Setting No printer PC printer Data output

Data rate 115200 baud 1200 baud 9600 baud

Data bits 8 8 8

B 310

Stop bits

Parity

Flow control

Common used functions

Command Header

Calibrate K

Measure M

Print Request N

Stop Measurement Q

Hand Probe R

Active Probe (Installed AP) S

Analysis Mode X

Detection Mode Z

Combined Mode Y

111

None None None

None None None

K = Calibration request

Starts calibration if the Sensistor ISH2000 has an active probe driver installed.

Sensistor ISH2000 answers with a "K" if an active driver containing a calibration routine was found and "F" if the calibration APC sequence not found. Calibration doesn’t start if Purge level is reached.

M = Measure Request

The active test cycle defined by the APC driver starts. “M” is returned if the

selected driver supports active test. “F” (failed) is returned otherwise.

N = Print Request

Returns current analysis value.

EN- 37 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 38

B 310

Q = Set APC in stand by, (stop a measurement)

Returns a “Q”.

R = Activates probe 0 (built in P50 driver)

Returns an “R”.

S = Activates probe 1 (Installed probe driver)

Returns an “S”.

X = Shift State to "Analysis Mode"

Returns nothing.

Z = Shift State to "Detection Mode"

Returns nothing.

Y = Shift State to “Combined Mode”

Return nothing.

Supported parameters

The following parameters can be downloaded to Sensistor ISH2000 in Analysis

and Detection mode.

Where: “Header” + “?” returns the a value from the instrument. This value is

presented as “A”, “B” and so on.

Parameter Header Data

Reject Level A n.nnE+nn

Correlation Value B n.nnE+nn

Analysis Unit C Text string (max 12 char-

acters)

Analysis Unit (Default list

unit**)

Timer A D nnn*

Timer B E nnn*

Timer C F nnn*

Timer D G nnn*

Purge Level H n.nnE+nn

Reference Value I n.nnE+nn

Reference Unit J Text string (max 12 char-

Reference Unit (Program

settings)

CUx x=1 to 10, 1=PPM, 2=CC/

S up to 10

acters)

JUx x=1 to 10, 1=PPM, 2=CC/

S up to 10

* entered as integer in 10’s of seconds, 1= 0.1s, 100 = 10s, 60000= 6000s

Default listed unit

PPM, cc/s, cc/min, SCCM, g/a, oz/yr, mbarl/s, mm3/s, mm3/min, Pa m3/s

Transfer of parameters

Send parameters one by one; send the specific header and then send the data

(for example “1.00E+01”). String must be ended with a carriage return character, chr13 (dec).

Example: “CPPM” or “C PPM”, Carriage Return (chr 13). This sets Reject Level

Rate Unit to “PPM”.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 38

Page 39

APC driver installation

B 310

Parameters can be sent in any order you like:

• If your data was received and correct, Sensistor ISH2000 immediately echoes

(sends back) the data.

• If you send a non existing header you will not receive anything.

• If the data could not be converted in the Sensistor ISH2000 you will receive

the string “CoEr”, (Conversion Error).

Note: Remember to use capitals for the header.

APC drivers are installed in the detector from a PC. All active probes need a

driver to be installed before they can be used.

Note: Battery operated model Sensistor ISH2000 does not incorporate the APC

feature.

For driver installation you will need the following:

• APC Driver software. (Delivered with the probe.)

• File transfer cable. (Delivered with the probe.)

• PC computer with Windows XP with .NET Framework 2.0 or later.

Refer to chapter “F 800” on page 105.

EN- 39 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 40

B 320 Connecting the detector directly to a printer or another device

For detailed information please refer to document RS 232 for leak detectors

users manual.

Printer port

The Sensistor ISH2000 is equipped with a serial printer port. This is the 9-pin Dtype connector. It is used for printer connection, RS232 commands and APC

driver installation.

Note: Always switch power off before disconnecting or connecting any cable.

Preparing the RS 232 link cable

Use INFICON cable, P/N: 103616, or make your own by following the pin connections specified below:

Use a Sub D9 pin, female connector (7 and 8 connections are necessary only if

RTS and CTS are used in an user software).

Connector pin configuration

B 320

Pin Signal Comment

1 Not used

2 RX Received data

3 TX Transmitted data

4 (DTR) Not used

5 SG Signal ground

6 (DSR) Not used

7 (RTS) Not used

8 (CTS) Not used

9 (RI) Not used

Only pin 2 (Received data), pin 3 (Transmitted data) and pin 5 (Signal ground)

are used.

CD

RxD

TxD

DTR

SG

DSR

D9 Female

RTS

CTS

RI

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

CD

RxD

TxD

DTR

SG

DSR

RTS

CTS

RI

D9 Female

Figure B-8: D9 Null modem cable wiring diagram

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 40

Page 41

Connecting the detector to a computer

For example, the user can communicate easily with the detector using the Terminal or Hyper Terminal program in Windows®.

Selectable printer types

Most PC-printers with serial interface can be connected to the 9-pin printer

port. Parallel (Centronics) interface printer can be used if connected through a

serial to parallel converter. The port can be set up for the following printer

types: PC Printer and Data Dump.

No printer

Printer output disabled. Incoming communication is enabled. Sensistor ISH2000

listens for incoming data but will not print/send test results.

PC printer (with serial interface)

The PC Printer option can be used to print data on most standard PC printer

with serial interface. Parallel interface printers can be used if connected through

a serial to parallel converter.

Note: The output format has been chosen to be as simple as possible to ensure

that most printers will accept it. Therefore, the printer output does not use any

flow control. This means that some printers may delay printing until the input

buffer is full or a pre-defined timeout has elapsed.

Figure B-9:

B 320

Setting Value

Data rate 1200 baud

Data bits 8

Stop bits 1

Parity None

Flow control None

Note: Due to the large variety of printers available on the market, INFICON

AB does not take responsibility for the operation of a particular type of printer.

Printed data

The detector can print the following information:

1 Date and Time for Power on of detector.

2 Time of print.

3 Value of all gas signals above the Reject Level.

4 Test result: “Accept” or “Reject”.

5 Value of signal obtained during active test.

6 Result of calibration: “OK” or “Calibration Not saved”, Date and Time,

Parameter settings.

Printing of the current value can also be requested by an RS232 command or

ordered manually by pressing PRINT.

EN- 41 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 42

Probe type determines information printed.

Probe type Data printed

Hand Probe P50 1, 2, 3, 4, 6

B 320

Counter Flow Hand Probe

AP57

Sniffer Hand Probe AP55 1, 2, 4, 5, 6

Sampling Units AP29 and

H28

APC driver with active test

(using MEAS flag)

APC driver not using

MEAS flag

1, 2, 3, 4, 6

1, 2, 4, 5, 6

1, 2, 4, 5, 6

1, 2, 3, 4, 6

Analysis data output

The Analysis Data Output option is intended for transferring test results to a

supervising computer system such as, for example, a PLC system.

Communication specifications.

Setting Value

Data rate 9600 baud

Data bits 8

Stop bits 1

Parity None

Flow control None

The data format for Analysis data output consists of nine ASCII characters.

Seven characters show the value in engineering format one character shows

the result of the test, and one character shows line feed (LF).

The character indicating the result of the test is one of the following.

Character Result of the test

A Accept. Previous test was below Reject Level alarm limit.

R Reject. Previous test was above Reject Level alarm limit.

P Rejected by Purging. Previous test was above purge limit

(and Reject level limit).

C Calibration approved. Previous cycle was calibration.

Calibration was approved.

F Calibration failed. Previous cycle was calibration.

E Test interrupted by “Error” that occurred during cycle

(probe or sensor error etc.).

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 42

Page 43

B 320

Example: 2.5E-04R (LF)

This example is a line feed (LF), R means that the test was above the Reject Level

alarm limit, and the value was 2.5E-04.

For passive probes (for example P50 and AP57*) data is printed when a signal is

detected above Reject Level or when the print button is pressed. Activate this

under Measure Button menu.

For active probes (e.g AP29) data is printed at end of measurement sequence.

Printing of the current value can also be requested by an RS232 command or

ordered manually by pressing PRINT.

* A custom APC program setting the MEAS flag prints as AP55/AP29 and an

APC program not using MEAS flag prints as P50.

Detection data output

The Detection Data Output option is intended for automated scanning of weld

seams etc.

Note: The Detection Data is expressed in arbitrary units. Detection Mode signal

is not affected by calibration!

Communication specifications.

Setting Value

Data rate 9600 baud

Data bits 8

Stop bits 1

Parity None

Flow control None

The data format for Detection data output contains of ten ASCII characters.

Nine characters show the value in engineering format, and one character shows

linefeed (LF).

The print time is 50Hz continuous streaming data.

EN- 43 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 44

Operation

C

Sensistor ISH2000 Technical Reference Manual

Detailed content

C 100 Getting started with the leak detector

C 110 Operating principle of the control panel

C 200 Control panel

C 201 Menu system

C 210 Password

C 211 Operation of the leak detector

C 300 Calibration of the leak detector

C 304 Correlation Value

C 305 Calibrated leak values programming

C 410 Headphone and loudspeaker

C 500 Factory configuration of the leak detector parameters

C 570 Date - Time - Language - Unit

C 580 Service mode och debug mode

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 44

Page 45

Starting up / switching off the leak detector

To familiarize oneself with the control panel

C 100

C 100 Getting started with the leak detector

1. Connect power.

2. Connect the probe.

3. Start the unit and wait approximately 1 minute.

4. Select probe in the menu.

Refer to C 211 “C 211 Operation of the leak detector” on page 55.

Refer to “C 200 Control panel” on page 46 for the control panel description.

EN- 45 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 46

Description

C 200

C 200 Control panel

Control push-buttons

Graphic interface

Earphone socket

Probe connector

LEDs

Figure C-1: Sensistor ISH2000 control panel

The display shows:

• indicator bar in Detection Mode and the figures in Analysis Mode.

• seven main menus. Their positions are indicated on a horizontal scale. Change

from one menu to another using the < and > buttons.

• main menus have submenus, which are also indicated by horizontal scales

and can be selected using the < and > buttons.

• scales for setting numeric values, languages, etc.

• messages.

Sensistor ISH2000C:

• A battery status indicator in the upper right corner, where 13.5 V indicates

discharged state and 16.0 V indicates that the battery is fully charged.

• six main menus. Their positions are indicated on a horizontal scale. Change

from one menu to another using the < and > buttons.

LEDs

The two LEDs indicate the status of the instrument as follows:

• Green flashing slowly, during warming up phase.

• Green fixed light indicates that instrument is ready and hydrogen signal is

below Reject Level limit.

• Red fixed light together with Reject on display means the instrument has

detected a leak larger than the set alarm limit. Red flashing rapidly, check message on screen. (See “Trouble-shooting” on page 74.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 46

Page 47

Push-buttons

Demo Mode

C 200

The functions of the push-buttons are shown at the lower edge of the display.

In this manual the buttons are numbered, from left to right, 1, 2, 3, and 4. The

push-buttons are used to:

• Change from one menu item to another using the < and > buttons.

• Press Enter to move down to the nearest submenu.

• Press Save to save the set value.

• Press Undo to restore the previously set value.

Press Esc to move up to the nearest higher level(s).

Demo Mode is a demonstration mode, special designed for seller. All APC drivers for standard probes and filler will be selectable. The seller can easily swap

between the different drivers and won't need to download them.

To set the Detector in Demo Mode:

• Select: Menu/General Settings/Change Password

• Enter "DEMO"

• Confirm New Password "DEMO"

Select driver under menu: APC Settings/Probe Type

The word "DEMO" will be shown at start up.

To turn Demo Mode off repeat the list above.

EN- 47 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 48

C 201

C 201 Menu system

The menu system is designed as a tree structure similar to that used in mobile

telephones. The display shows all the levels when browsing down through the

menus so that you can always see exactly where you are.

3

412

Figure C-2: Push-buttons

To enter the menus, press Menu (button 4). Press < and > (button 2 and button

3) to choose between main menus.

If no setting is made in a menu or its submenus within 60 seconds, the instru-

ment will revert to the Detection Mode/Analysis Mode.

The buttons may change functions in different menues. Always read the text,

just above the buttons in the display, for the button functions.

All changes in values are valid only when saved using the Save button (button

4).

Use the Undo button (button 1) to delete a change in value and revert to the

previous setting.

Use the Esc button (button 1) to browse backwards through the menus to the

start position Detection Mode/Analysis Mode/Combined Mode.

To change quickly from Detection Mode to Analysis Mode or vice versa, press

button 3 three times in succession.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 48

Page 49

Sensistor ISH2000 v. 6.0 Menu System

C 201

Measure Screen

Change Test

Mode

Analysis Mode

Detection Mode

Combined Mode

Calibration

Calibrate

Reference Value

Reference Unit

Calibration Time

Password

Protected

Calibration

Detection Mode

Settings

Senistivity

Auto Range

Direct Sensitivity

Adjustment

Auto Threshold

Reject indication

Audio Ready

Pulse

Analysis Settings

Reject Level

Correlation

Value

Analysis Unit

Multipoint

Analysis

Multipoint

Analysis Time

Min

Presentation

Time

Display

Threshold

Audio Threshold

APC Settings

Probe Type

APC Time A

APC Time B

APC Time C

APC Time D

Purge Level

Reset Signal

Display Settings

Contrast

Brightness

Invert Colors

Screen Save

Timeout

General Settings

Language

Measure/Print

Button

Probe Button

Probe Lamp

Change

Password

Audio Base

Frequency

Set Clock

Set Date

Service Settings

Show Password

System Reset

Detector Signal

Level

Trigg Level

Min Calibration

Time

Battery Mode

Number of

Significant Digits

Debug mode

Reject

Indications

Show Reject

Level

Audio Ready

Pulse

Figure C-3: Menu system

Printer Port

Info

Service Mode

EN- 49 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 50

Change test mode

Calibration

C 201

Choose the measuring method you will use in the menu Change Test Mode.

There are three different methods to choose:

• Analysis Mode

• Detection Mode

• Combined Mode

Figure C-4: Change test mode screen example

The instrument must be calibrated by using the integral calibration function to

ensure it displays the correct values in Analysis Mode/Combined Mode. After

calibration the instrument will show the correct measured values on the display.

The calibration parameters will be stored into the probe.

Detection mode settings

Analysis mode settings

Figure C-5: Calibration screen example

In Detection Mode, the signal is displayed in the form of a bar. The length of

the bar varies with the gas concentration.

Figure C-6: Detection mode screen example

In Analysis Mode the measured value is displayed in figures. The default unit is

in PPM but it is possible to choose other units, See .“C 500 Factory configuration of the leak detector parameters” on page 65

Figure C-7: Analysis mode screen example

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 50

Page 51

APC settings

C 201

APC is an abbreviation for Active Probe Control. The APC function is for the

control of an active probe that has a built-in alarm, valves or pumps via Probe

Control Port.

Different probes require controls therefore, it is possible to download different

drive routines for the instrument from a PC.

There is a possibility to adapt how to measure by adjusting the timers and Purge

Level.

Probe Type

Select the connected probe. Choose between “Hand Probe” and another

probe driver installed from the disc delivered with active probe (if ordered).

APC Time A-D

Adjustable timer used by the APC system. Select a APC timer and press “Enter”

to display specific use of this timer. APC timer can be used for general purposes

in a custom APC program.

Purge Level

Signal level controlling the Purge_Level APC Triggers. Standard probes that support active sampling use the Purge Level for fast interruption of sampling that

result in high gas signals.

Setting Purge Level equal to, or just above, Reject Level will give the fastest possible cycle times for those probes.

Quick purging also enhances signal repeatability.

Note: Purge level interrupts active sampling of APC probes. This means that

higher signals will be underestimated as the sensor is purged before full signal

has developed.

Reset Signal

Reset the sensor level in Analysis mode and Detection mode.

EN- 51 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 52

Display settings

General settings

C 201

This section describes the different display settings of the Sensistor ISH2000.

Contrast

Contrast level of display. Higher value gives higher contrast. The contrast may

need adjustment if ambient temperature changes.

Brightness

Brightness of the display lamp. A lower brightness value saves energy and prolonges the lamp.

Invert Colors

Change the black to white and white to black. Useful in a dark environment to

keep a high readability.

Screen Save Timeout

Display lamp will dim to half brightness if instrument is left idle for the number

of minutes set by this parameter. The screen save timeout can be set between 1

and 60 minutes, the function is deactivated if set to OFF. The display lamp will

return to the set brightness if any of the display buttons are pressed, if a gas

signal is detected or an instrument error is detected.

This part describes the general settings of the Sensistor ISH2000.

Language

The Sensistor ISH2000 user interface contains the following languages:

• English

• French

• German

• Italian

• Spanish

• Swedish

Measure/Print Button

Setting this parameter to ON displays Measure or Print above the button 1.

Measure will be displayed for an APC-Probe or Print for a Hand Probe. Pressing

Measure will initiate a sample cycle. Pressing Print will send the values from the

hand probe measurement to the printer port.

Probe Button

This is for setting the different functions with the probe button. These functions

are as follows:

• Toggle Mode-makes it possible to switch between Analysis mode and Detection mode.

• Zero detection signal-in Analysis mode and Detection mode.

• Measure/Print-makes it possible to initiate sample cycles or send the values

from the hand probe measurement to the printer port.

• Probe Lamp-makes it possible to turn on and off the Probe Lamp.

Probe Lamp

Makes it possible to have the Probe Lamp on even if the other Probe Button

function is chosen.

Change Password

The user password is a text string (max 12 alphanumerical characters) used to

lock critical parameters. Setting password to an empty string (no characters)

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 52

Page 53

C 201

means that no password is needed to modify the critical parameters. The

default is no password (“”).

Contact INFICON AB if you have lost your user password. If the Password Protected Calibration parameter is set to ON you will be prompted for a password

when starting a calibration.

Note: Setting Password Protected Calibration to ON has no effect if no password is set.

Note: APC controlled calibration can be started from the bus in both cases.

Audio Base Frequency

This sets the lowest audio base frequency tone in Search and Detection Mode.

Set Clock

Real time set as hh:mm:ss. Hours and minutes can be adjusted. Seconds will

automatically be set to 00 when hours and minutes have been set. Clock runs

even when detector is disconnected from the power supply.

Set Date

Real Time Clock date set as YY-MM-DD. Clock runs even when detector is disconnected from the power supply.

Printer Port

The Sensistor ISH2000 is equipped with a serial (RS232) printer port. See

“Printer port” on page 35.

Info

Contains information about software versions, Serial number, and Internet contact information.

Service settings

The Service Mode is reached by starting the instrument and at the same time

hold the right button down on the panel. After start a new main menu called

Service Settings will appear.

See “E 140 Service menu” on page 84

EN- 53 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 54

Change Password

C 210

C 210 Password

The user password is a text string (max 12 alphanumerical characters) used to

lock critical parameters. Setting password to an empty string (no characters)

means that no password is needed to modify the critical parameters. The

default is no password (“”).

Contact INFICON AB if you have lost your user password. If the Password Protected Calibration parameter is set to ON you will be prompted for a password

when starting a calibration.

Note: Setting Password Protected Calibration to ON has no effect if no password is set.

Note: APC controlled calibration can be started from the bus in both cases.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 54

Page 55

To detect leaks

C 211

C 211 Operation of the leak detector

Do not expose the probe to a hydrogen concentration higher than 0.1

% when the instrument is not put into operation, this might damage

or destroy the probe sensor.

When the instrument is put into operation the sensor withstands temporary exposure to hydrogen concentration up to 100%. Avoid long

exposures to high concentrations.

If all you wish to do is to detect the presence of a leak, that is, find out whether

there is a leak or not, then use the Detection Mode (or use the detection bar in

Combined Mode).

The definition of Leak/No Leak will then simply be "A leak is a leak when it can

be detected by the detector, set to a specific sensitivity".

To set up:

The operation in Detection Mode is not quantitative. The audio and visual sig-

nal will increase and decrease with the gas concentration. Therefore, there is no

actual calibration to be done, but rather a setting of the sensitivity to a desired

level.

A typical set-up procedure for Detection Mode is:

• Set up a reference leak which corresponds to the smallest leak you wish to

detect.

• Put the probe close to the reference leak and note approximately what reaction you get (no reaction, small, medium, high, full scale) within the first few

seconds.

• Set the sensitivity. This can be done permanently under the menu Detection

Mode Settings or temporarily as a Direct Sensitivity Adjustment on the display

(unless you have set this function to OFF under the Detection Mode Settings

menu).

There is also an Auto ranging function which can be selected under the Detec-

tion Mode Settings menu.

Note: If the Detection Mode is used and the alarm function is required to be

activated at a particular calibrated level, then the unit must be calibrated in

accordance with the instructions. The reason for this is that the alarm is based

on the Analysis Mode when the Detection Mode is displayed.

To locate leaks

Note: The Detection Mode (or use the detection bar in Combined Mode) is

used to locate leaks. This mode is semi-quantitative, that is, it gives an audio

and visual signal which increases as a leak is approached (a higher gas concentration) and decreases as you move the probe away from the leak. It does not

display figures. In this mode of operation leaks can easily be detected using a

sensitivity which can be preset.

Leaks can be located very accurately, even when there are other leaks nearby. If,

for example, you are trying to locate a leak on a product and the product has a

major leak, then you will get an audio signal as soon as the probe is placed

close to the product.

EN- 55 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 56

To quantify leaks

C 211

When the probe is moved around and over the product, the signal will increase

as the probe approaches the leak. If the signal goes out of scale, simply reduce

the sensitivity setting to bring the signal within the scale. Working with the sensitivity setting this way you will be able to locate multiple leaks that are in close

proximity to each other.

Note: Working inside a confined space such as, for example, a cabinet or a narrow passage on a combustion engine there is a risk that the background concentration accumulates to levels close to the upper detection limit of the

detector. In such case it will not be possible to locate leaks as easily as in open

spaces.

Hint: Do not expose the probe to more gas than is necessary, because it will

slowly saturate with time. It is good practice to detect a leak, locate it, and

immediately remove the probe to avoid saturation. The probe is not damaged

by the exposure but it will recover more slowly. After excessive exposure it will

be less sensitive for a short period of time.

The Analysis Mode (or use the analysis figures in Combined Mode) is used

for measuring the size of a leak (or the concentration of a gas sample). To be

able to do this measurement and obtain correct values, the instrument must

first be calibrated using the calibration function.

In the Analysis Mode the detector determines the gas concentration from the

change, as the probe goes from being exposed to background to being

exposed to a certain gas concentration. The detector does not continuously

monitor the gas concentration but takes just one reading instead. Another suitable alternative name for this mode could be Sampling Mode. It is important to

keep this in mind when using the detector in this mode.

In Analysis Mode the probe should be moved directly from a background situ-

ation to the test point. The size of the leak in PPM, or any other selected units,

is shown on the display. The probe can and should be removed from the measuring point as the measured value steadies and remains on the display. The

period during which the measured value is displayed can be adjusted in the

Analysis Mode Settings menu.

The leak detector operates in the range 0.5 - 2000 ppm H2 giving linearity

between 0.5 and 500 ppm. To obtain greatest accuracy over this range, follow

the calibration recommendation. See "Calibration of the leak detector" on

page page 57.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 56

Page 57

Introduction

Calibration reference

C 300

C 300 Calibration of the leak detector

The leak detector is the instrument and the probe together. This section consists

of step by step examples about how to calibrate the detector in the most comman cases.

The instrument must be calibrated by using the integrated calibration function

to make sure it displays the correct values in Analysis Mode. After calibration

the instrument will show the correct measured values on the display in Analy-

sis Mode and Combined Mode. The calibration parameters will be stored into

the probe.

There is a possibility to calibrate the detector by Reference Gas or Reference

Leak.

A Reference Gas contains a well-defined concentration of Hydrogen gas in ppm

mixed by air or some inert gas. A Certificate will normal follow the gas bottles.

Reference Gas can be ordered from local gas suppliers.

A Reference Leak is a well -defined gas leak, and should be feed by same gas as

using in the detection test and with a gas pressure that is defined in the Reference Leak certificate. Reference Leak can be ordered from the detector provider.

Choose a calibration reference size, as follows recommendations:

• Same or higher than the Reject Level (but maximum 10 times higher)

• In one of the following ranges:

- 5 to 1000 ppm H2

- 1x10-5 to 1x10-2 cc/s (mbarl/s) defined for air

- 3 to 300 g/a defined for R134a

Please contact the provider of the detector for help to select optimal calibration

reference for your application.

EN- 57 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 58

Calibration procedure

C 300

Before calibration, the Reference Value in the Calibration Menu must be set.

See “With reference gas” and “With reference leak” below.

When calibrating, expose the probe to the background air then do the following steps:

1. First Menu then Calibration/Calibrate/Enter.

2. Push the Start button or push the probe button.

3. Expose the probe for the reference gas/leak

The probe does not have to be exposed to the to the calibration gas during the

whole Calibration Time ( the time set in the Calibration Menu while the bar

is moving). The instrument only measures the change as the probe goes from

the background air to calibration gas.

While the calibration time bar is moving, the probe should be exposed to the

calibration gas or referenece leak. Then the display shows Detecting Gas and

gives sound signals. Save or repeat the calibration routine until you can save the

calibration. If the calibration is not saved, the instrument will revert to the previous value after one minute.

Note: You will need to repeat the calibation 2-3 times to get Calibration OK

after changing setup or probe.

• Allow at least 30 seconds between each calibration for best accuracy!

• If the message “No Gas or Unstable Signal” is displayed repeatedly - go back

to Detetion Mode and check functionality.

• If Repeat Calibration is displayed then this means that the measured value

devated more than 10% from the previous calibration. Repeat the calibration

procedure.

Also set the Analysis Unit to the same as the Reference Value. If you want to

use another unit you have to put a recalculation number into Correlation Value

which describes the relationship between the different units.

Calibration intervals

Low sensitivity warning

Calibration is a natural part of leak measurement and an important factor in

quality assurance. It is impossible to specify an exact requirement for the interval between the calibrations becase the applications for which the instrument is

used can vary considerably.

There will be some oxidation of the probe sensor, which reduces the sensitivity,

if the probe sensor:

• is not subjected to gas for a lengthly period or

• is exposed to a very small gas concentration (less than 10 PPM) with long

intervals between exposure.

If the instrument is subjected to a very large gas concentration over a long

period, a certain amount of insensitivity can occur directly afterwards. This saturation can make it difficult to detectvery small leaks. Therefore, make it a habit

of removingthe probe from the measurig point as soon as the measured value is

displayed. This gives the detector an opportunity to recover.

The Detector will warn if sensitivity of sensor is too low to safely detect a leak

equal to the set Reject Level limit. The warning can be ignored and calibration

updated but the CAL_CONF output will not be set.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 58

Page 59

Irregular reference warning

Sensor condition indicator

Calibration messages

C 300

The Detector will warn if the calibration signal is unreasonably high. This can

occur, for example, if 5% tracer gas mix has been used instead of proper reference gas or if the reference leak has an extra non-intentional leak. The warning

can be ignored and the calibration updated but the CAL_CONF output will not

be set.

The indicator bar extends in length when the sensor is detecting reference gas.

This indicator can be used for an early warning as to when a sensor replacement will be needed.

The length of the bar shows the condition of the sensor. The bar will become

shorter if the sensor has lost some in sensitivity. The scaling of the indicator is

not precise enough to say at exactly what length the sensor must be replaced.

You will learn when this happens for your particular application. The instrument

will also tell you in clear text when sensitivity is too low.

Message Explanation Remedy

Expose to background... Prepare the probe for

calibration by holding it

in hydrogen free

background.

Detecting gas Gas signal is detected. Normal operation, gas

Repeat calibration Calibration was not

within 20% of last.

Calibration OK Calibration was within

acceptable limit.

No gas or unstable signal. No gas signal or no stable

signal detected during

calibration.

Signal when reference gas

is shut off. Happens for

reference gas only.

Sensitivity too low for

Reject level

Sensitivity of sensor is too

low to guarantee correct

response to a gas flow or

concentration equal to

the Reject level. The most

likely reason is that sensor is too old.

-

exposure can be

interrupted.

Wait 30 s and calibrate

again.

Press Save (button 4) to

store calibration in

memory.

Check reference. Gas

valve may be shut.

Check that probe tip is

not clogged.

Background is higher

than reference gas

concentration. Improve

ventilation.

Check reference. Gas

valve may be shut.

Check that probe tip is

not clogged.

Check setting of Reject

Level.

Replace sensor if problem

remains.

EN- 59 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 60

Message Explanation Remedy

C 300

Reference Value

High signal! Check

reference!

Note: If calibration fails you can still use the instrument. Last valid calibration

parameters will be used. You should, however, check that the instrument reacts

to the reference.

Your reference should have a concentration or flow equal to or slightly above

what you want to measure. See the examples below for specific recommendations.

Example for reference gas:

• Reject Level is set at 8 PPM

• For good accuracy, use a reference gas between 8-80 ppm hydrogen.

• 8 PPM hydrogen in synthetic air will give best results.

Example for reference leak

• Reject Level level is set at 2.0E-4 atm. cc/s

• For best accuracy reference leak within 2.0E-4 - 2.0E-3 atm cc/s.

• A reference leak calibrated to 2.0E-4 atm. cc/s will give best accuracy.

Reference signal is abnormally high.

Check that reference gas

mix is not replaced with

tracer gas mix.

Check condition of reference.

Check that reference leak

connections has no leaks.

Reference Unit

Calibration Time

The Reference Unit is set in the Calibration menu. Select PPM, cc/s, cc/min,

SCCM, g/a, oz/yr, mbarl/s, mm3/min, Pa m3/s or Custom. When you select Custom you can enter any unit as long as it contains a maximun of 12 characters.

Calibration can be performed with:

• a known hydrogen concentration

• a known flow leak

The following characters can be used: Upper and lower case Roman letters, the

numbers ü, Å, Ä,Ö, å,ä,ö,%,/,(,),and - (dash).

Note: The space (““) is not supported. The leak rate unit string will be cut short

at the first space found.

The calibration time decides how long time the detector looks for a reference

signal before giving up. If the calibration is set to, for example, 6 seconds the

detector will record the maximum signal during 6 seconds after that the operator (or external hardware) orders a calibration.

It is very important that all delays in gas exposure as well as reaction time of

sensor are taken into consideration when setting the calibration time. Calibration will not be correct if the maximum signal comes after that the calibration

time has terminated.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 60

Page 61

Minimum calibration time

C 300

This parameter sets the lowest possible Calibration Time that can be set under

the Calibration menu. Default is 5 seconds.

Minimum calibration time should be set to safeguard so that the following two

requirements are fulfilled:

1 The hydrogen from the reference leak or gas line must reach the sensor

before end of calibration time.

2 The sensor must have time to reach its maximum signal before end of calibration time.

Setting Min Calibration Time too low will have the following effects:

• Calibration will fail if calibration time is set too low.

• Calibration might pass but be incorrect.

Setting a high Min Calibration Time will have the following effects:

• Calibration takes longer time than necessary.

• Calibration gas consumption is higher than necessary.

Note: Correct calibration is an essential parameter in quality testing. We, therefore, recommend that careful consideration is paid to setting an appropriate

Min Calibration Time. This will inhibit personnel, lacking detailed knowledge

about calibration, from jeopardising quality by setting a too short Calibration

Time.

Password protected calibration

If desired, the calibration can be set under the general password to prevent the

operator from calibrating by mistake. In this case you will have to enter the

password to start the calibration routine. Setting password protection on calibration is done in the General Settings menu. Note that you must also set a

password. The instrument is delivered with no password set.

EN- 61 Sensistor ISH2000 Technical Reference Manual (TRM)

Page 62

C 304

C 304 Correlation value

If you want to use another unit you have to put a recalculation number into

Correlation Value which describes the relationship between the different

units.

This might be necessary when you want to display Reject Level unit other than

the reference leak rate unit.

Useful also for correct the value when volume and time affect the measure

value result in accumulation test.

Example:

To use mbarl/s as an calibrate reference unit and mm3/s as a analysis Unit you

have to set a Correlation Valus to 1.00E-03.

Sensistor ISH2000 Technical Reference Manual (TRM) EN- 62

Page 63

C 305 Reference values settings

Reference value with reference leak

When measuring leak flow you will, in normal cases, calibrate the detector with

a reference leak.

Set the Reference Value equal to the calibrated flow of your reference leak.