Page 1

Translation of the original operating instructions

kina22en1-r, 1407

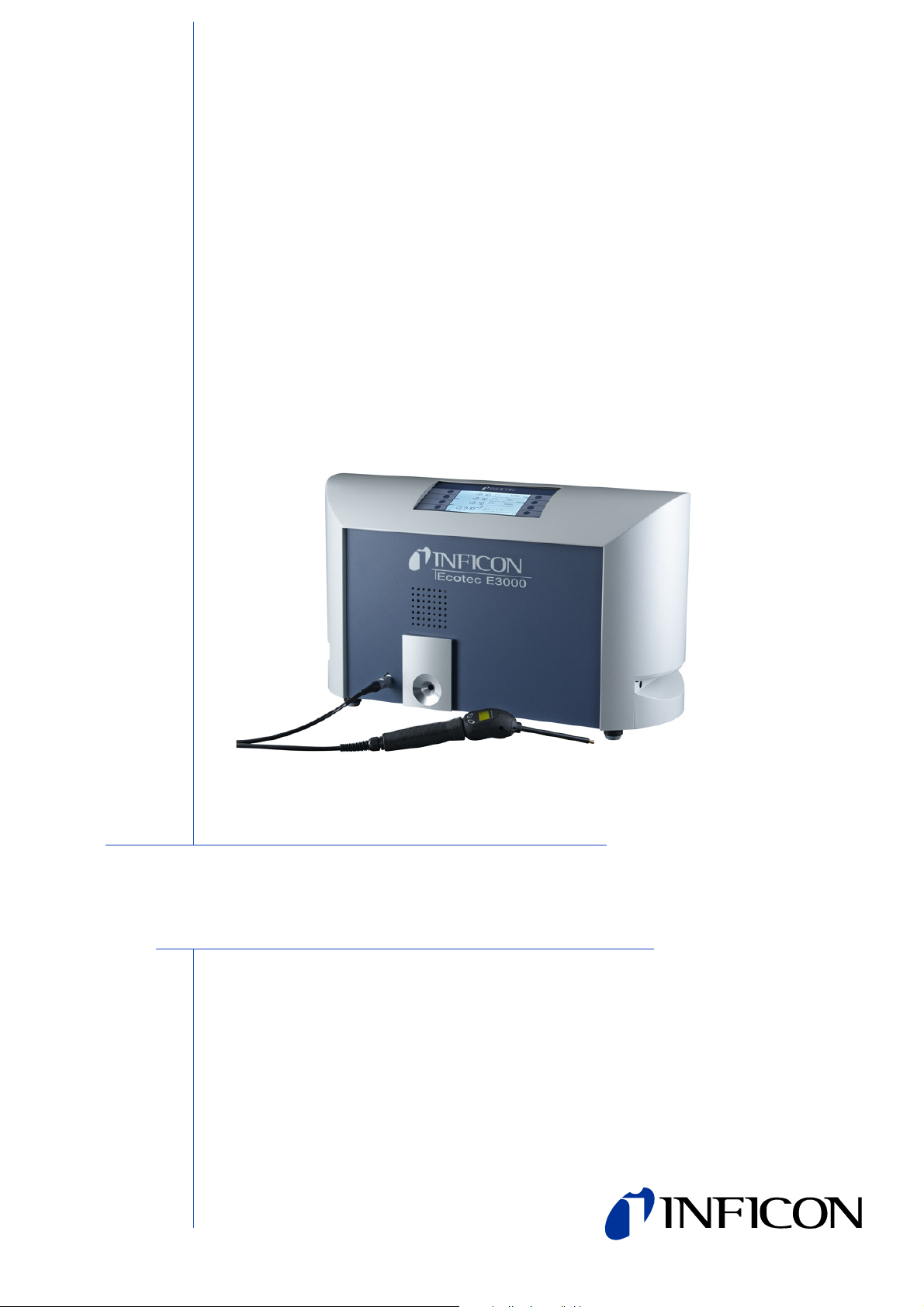

Ecotec E3000

Leak detector

Order no.:

530-001, 530-002

530-103, 530-104

from software version:

3.11

Page 2

Reprint, translation and duplication need to be approved in writing by INFICON GmbH.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

2

Page 3

Table of Contents

1 About this manual ........................................................................................................................................................ 5

1.1 Target group ................................................................................................................................................................... 5

1.2 Other applicable documents .................................................................................................................................... 5

1.3 Presentation of information ...................................................................................................................................... 5

1.3.1 Warnings ..........................................................................................................................................................................5

2 Safety ................................................................................................................................................................................. 7

2.1 Intended use ................................................................................................................................................................... 7

2.2 Owner requirements .................................................................................................................................................... 7

2.3 Operator requirements ............................................................................................................................................... 8

2.4 Dangers ............................................................................................................................................................................ 8

3 Shipment, transport, storage .................................................................................................................................... 9

4 Description ....................................................................................................................................................................11

4.1 Function and setup of the device .........................................................................................................................11

4.2 Main unit ........................................................................................................................................................................11

4.3 Sniffer line ......................................................................................................................................................................13

4.4 Technical data ...............................................................................................................................................................14

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

5 Installation .....................................................................................................................................................................17

5.1 Setup ...............................................................................................................................................................................17

5.2 Connecting the sniffer line ......................................................................................................................................18

5.2.1 Replacing the capillary filter of the sniffer probe ............................................................................................18

5.2.1.1 Replacing the plastic capillary filter with the metal capillary filter ...........................................................19

5.2.1.2 Replacing the metal capillary filter with the plastic capillary filter ...........................................................19

5.2.1.3 Water conservation sniffer probe mounting and remove ...........................................................................20

5.2.2 Attaching the sniffer lines holder ..........................................................................................................................21

5.3 Connecting the ECO-Check calibrated leak ......................................................................................................21

5.4 Connecting the external display unit to the Ecotec E3000RC ....................................................................21

5.5 Connecting to the power supply system ...........................................................................................................22

5.5.1 Connecting to a PC .....................................................................................................................................................22

5.5.2 Connecting with a PLC ..............................................................................................................................................22

6 Operation .......................................................................................................................................................................23

6.1 Start-up ...........................................................................................................................................................................23

6.2 Operating the device .................................................................................................................................................23

6.2.1 Display and keys ..........................................................................................................................................................23

6.2.1.1 Recurring function symbols ....................................................................................................................................24

6.2.2 Elements of the measurement view ....................................................................................................................25

6.2.3 Operating elements and display on the sniffer handle .................................................................................26

6.2.4 Special features of the Ecotec E3000RC ..............................................................................................................27

6.3 Settings before measurements ..............................................................................................................................28

6.3.1 Miscellaneous ...............................................................................................................................................................28

6.3.2 Audio settings ..............................................................................................................................................................29

6.3.3 Display settings ............................................................................................................................................................30

6.3.3.1 Gas display handle ......................................................................................................................................................31

Table of Contents 3

Page 4

6.3.4 Vacuum & access control ......................................................................................................................................... 31

6.3.5 Interfaces ....................................................................................................................................................................... 33

6.4 Settings for the measurements ............................................................................................................................. 34

6.4.1 Selecting the gas, changing gas parameters, activating measurement ................................................ 34

6.4.2 Calibration ..................................................................................................................................................................... 37

6.4.2.1 Internal calibration with ECO-Check ................................................................................................................... 38

6.4.2.2 External calibration with external calibrated leak .......................................................................................... 39

6.4.3 Gas equivalent to helium and hydrogen, settings for diluted gas ...........................................................40

6.4.4 Suppressing interfering gases (Sophisticated interfering gas suppression - IGS) .............................. 41

6.4.5 Setting a user-defined gas ...................................................................................................................................... 42

6.4.6 Measuring ..................................................................................................................................................................... 43

6.4.6.1 Calling up information on the measurement .................................................................................................. 45

6.4.7 Measuring with I•Guide ............................................................................................................................................ 45

6.4.7.1 Setting the I•Guide program .................................................................................................................................. 46

6.4.7.2 Starting the I•Guide program ................................................................................................................................. 47

6.5 Idle state (sleep) .......................................................................................................................................................... 50

6.6 Service ............................................................................................................................................................................ 50

6.7 Calling up information about the device ........................................................................................................... 50

6.8 Special features of individual gases ..................................................................................................................... 53

6.9 Switching off the device .......................................................................................................................................... 54

7 Warnings and error messages ............................................................................................................................... 55

8 Maintenance ................................................................................................................................................................ 63

8.1 Calling up and managing maintenance information .................................................................................... 63

8.2 Maintenance work ..................................................................................................................................................... 66

8.2.1 Replacing the air filter of the main unit .............................................................................................................. 68

8.2.2 Replacing the operating fluid reservoir .............................................................................................................. 69

8.2.3 Replacing mains fuses .............................................................................................................................................. 71

8.2.4 Replacing the filter inserts of the capillary filter and the water conservation tip ............................... 72

8.2.5 Replacing the sinter filter of the sniffer handle ............................................................................................... 73

9 Taking out of service ................................................................................................................................................. 75

9.1 Disposal of the Ecotec E3000 ................................................................................................................................. 75

9.2 Returning the Ecotec E3000 ................................................................................................................................... 75

10 Appendix ....................................................................................................................................................................... 77

10.1 Accessories .................................................................................................................................................................... 77

10.2 Gas library ..................................................................................................................................................................... 78

10.3 Menu tree ...................................................................................................................................................................... 85

10.4 CE-Declaration of Conformity ................................................................................................................................ 86

10.5 RoHS-Declaration of Conformity .......................................................................................................................... 87

Index ................................................................................................................................................................................ 89

4 Table of Contents

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 5

1 About this manual

This document applies to the software version stated on the cover page. Documents for

other software versions are available from our sales department.

1.1 Target group

These operating instructions are intended for the owner of the leak detection unit E3000

and for technically qualified personnel with experience in leak detection technology and

integration of leak detection devices in leak detection systems.

1.2 Other applicable documents

ECO-Check installation instructions, document no. liqa10

Interface description, document no. kins22

1.3 Presentation of information

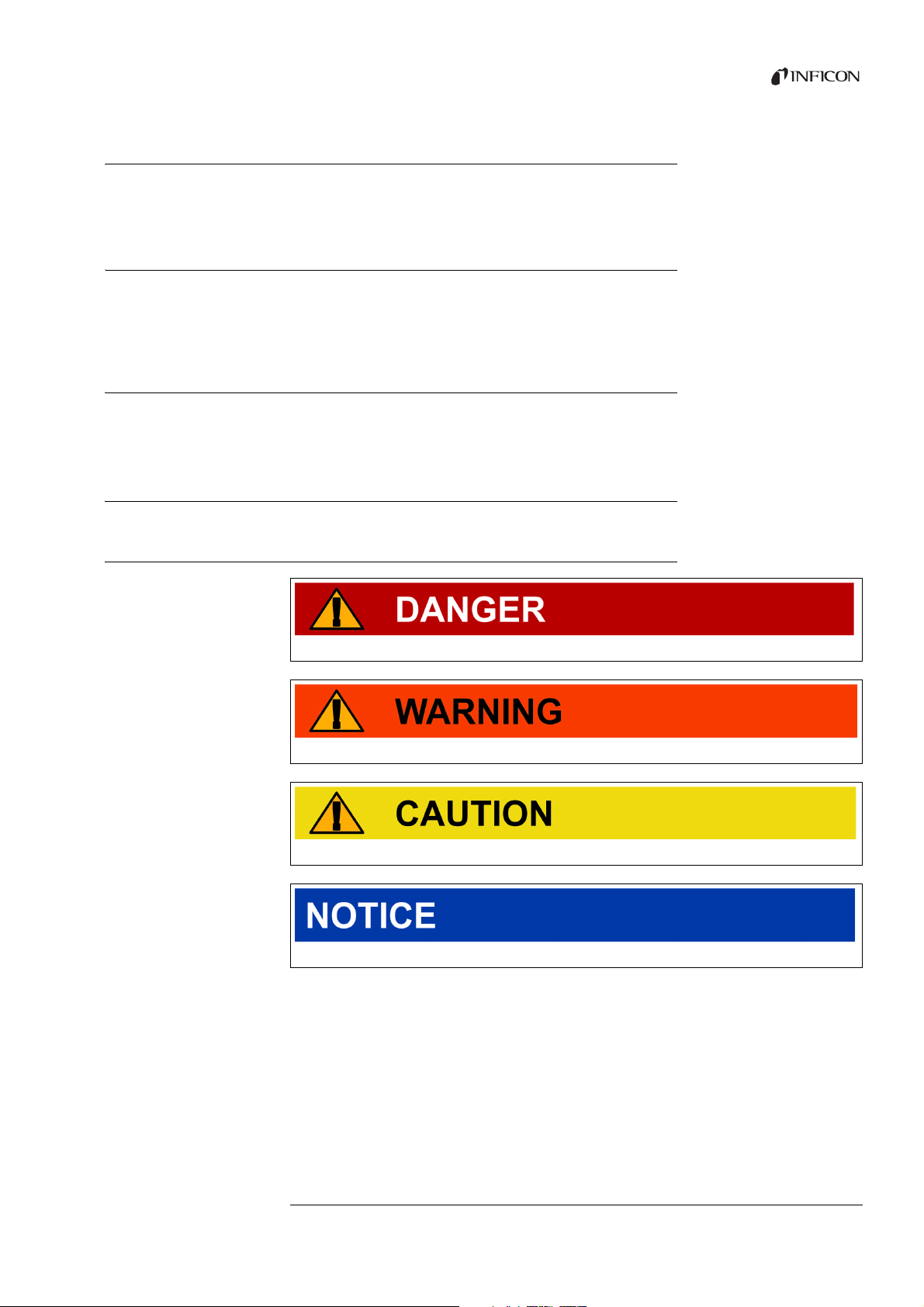

1.3.1 Warnings

Imminent threat of danger resulting in death or severe injuries

Dangerous situation potentially resulting in death or severe injuries

Dangerous situation resulting in minor injuries

Dangerous situation resulting in damage to property or the environment

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

1 About this manual 5

Page 6

6 1 About this manual

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 7

2Safety

2.1 Intended use

The device is a leak detector for sniffer leak detection. With the device you locate and

quantify leaks on test objects. The device sniffs for light gases, refrigerants and natural

gases.

The test objects must contain the gas under overpressure. The outsides of the test objects

are checked for escaping gas with a sniffer line (sniffing method).

The sniffer line is available as an accessory (see “10.1 Accessories”, page 77).

► You must install, operate and service the device only in compliance with these

► Adhere to the restrictions of use (see “4.4 Technical data”, page 14).

operating instructions.

Unauthorized use

► Do not suction in liquids with the device.

► Never hold the sniffer probe into liquids but sniff only for gases.

2.2 Owner requirements

Safety-conscious

operation

Personnel qualifications

► Operate the device only in technically perfect working order.

► Operate the device exclusively as specified, in a safety-conscious and hazard-conscious

manner and in compliance with these operating instructions.

► Fulfill the following regulations and monitor their compliance:

– Intended use

– Generally applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional provisions and regulations that are specific to the unit

► Use only original parts or parts approved by the manufacturer.

► Keep these operating instructions available at the equipment location.

► Allow only qualified technical staff to work with and on the device. The qualified

technical staff must have received training on the device.

► Allow personnel in training to work with and on the device only under the supervision

of trained qualified technical staff.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

► Make sure that the authorized personnel have read and understood the operating

instructions and all other applicable documents (see “1.2 Other applicable documents”,

page 5), especially the information on safety, maintenance and repairs, before starting

work.

► Define responsibilities, authorizations and supervision of personnel.

2Safety 7

Page 8

2.3 Operator requirements

► Read, observe and follow the information in these operating instructions and the

working instructions created by the owner, especially the safety instructions and

warnings.

► Carry out any work only based on the complete operating instructions.

► If you have questions regarding operation or maintenance that you cannot find

answers for in these instructions, please contact the INFICON customer service.

2.4 Dangers

The unit was built according to the state of the art and the recognized safety regulations.

Nevertheless, improper use can result in danger to life and limb of the operator or other

persons and damage to the unit and other property.

Dangers due to electric

power

Dangers due to liquids

and chemical

substances

The device is operated with electrical voltages of up to 265 V. Touching parts where

electric voltage is applied can result in death.

► Disconnect the device from the power supply prior to any installation and maintenance

work. Make sure that the electric power supply cannot be reconnected unauthorized.

Touching live parts with the sniffer probe can result in death.

► Before starting the leak test, disconnect electrically operated test objects from the

power supply. Make sure that the electric power supply cannot be reconnected

unauthorized.

The device contains electric components that can be damaged from high electric voltage.

► Before connecting the device to the power supply, make sure that the supply voltage

specified on the device is the same as the local power supply.

Liquids and chemical substances can damage the unit.

► Adhere to the restrictions of use (see “4.4 Technical data”, page 14).

► Do not suction in liquids with the device.

► Never try to find toxic, caustic, microbiological, explosive, radioactive or other harmful

substances with the device.

Hydrogen and air form a highly explosive mixture.

► Use the device only outside of explosive areas.

Dangers due to strong

light irradiation

8 2Safety

► You may not smoke. Do not subject the device to open fire and avoid sparking.

Exposure of the eyes to LED light can lead to lasting eye damage.

► Do not look into the LEDs of the sniffer handle from a short distance or for a longer

period of time.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 9

3 Shipment, transport, storage

Scope of delivery

Tra ns por t

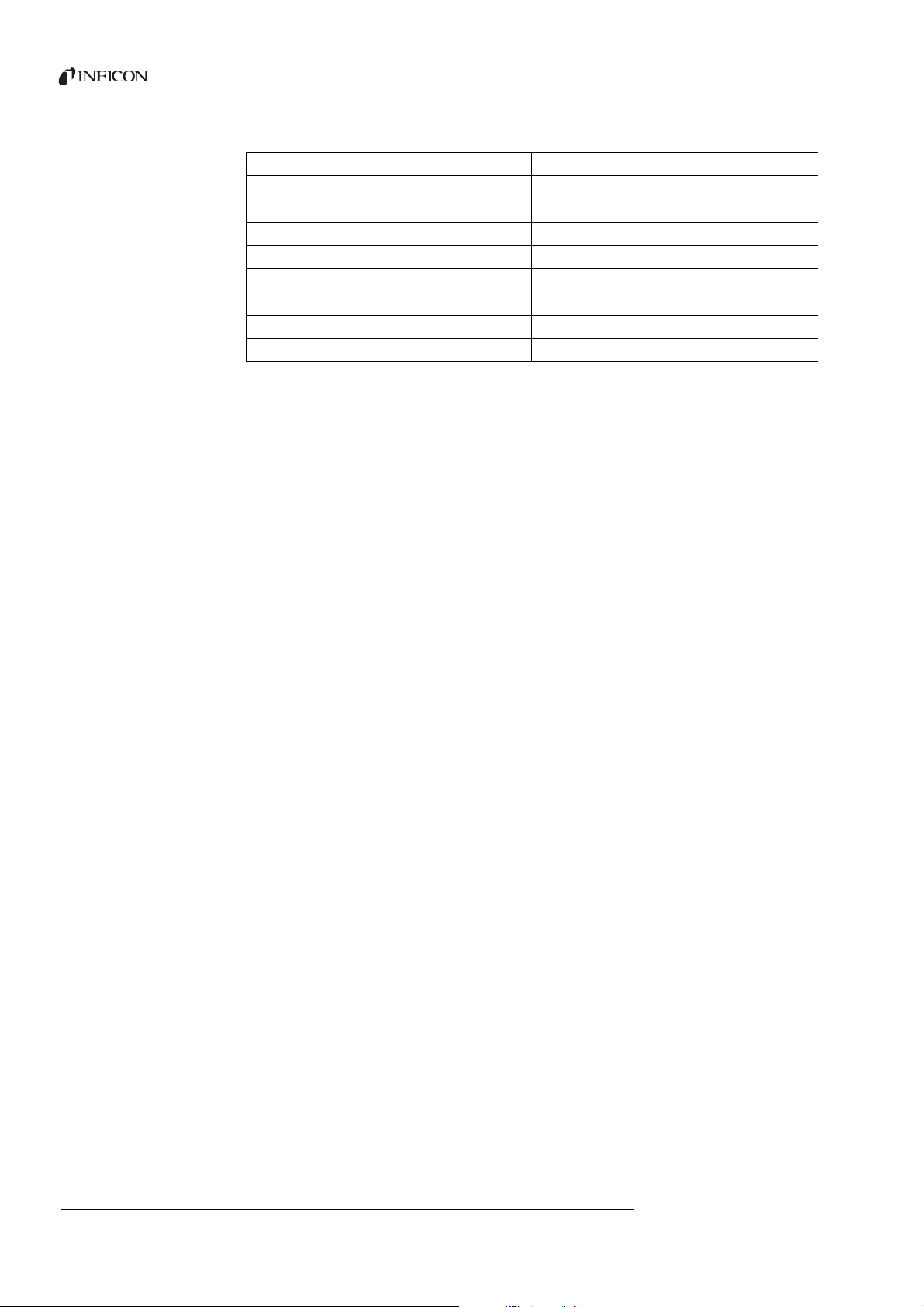

Table 1: Scope of delivery

Article Quantity

Ecotec E3000 (main unit) 1

Power supply cable, 3 m length 1

Fuses 30

Replacement air filter 1

8 mm Allen wrench 1

19 mm box wrench 1

Operating instructions 1

Interface description 1

► Check the scope of delivery of the product for completeness after receipt.

The following must be ordered separately:

sniffer lines with the desired length,

ECO-Check calibrated leak,

for device version E3000RC: display and connecting cable.

Accessory list: see “10.1 Accessories”, page 77

Damage from transport

Transport in unsuitable packaging material can damage the unit.

Parts inside the device can be damaged during transportation without transport

restraint.

► Store the original packaging.

► Transport the device only in the original packaging.

► Screw the transport restraint into the device floor before transportation, see

“5.1 Setup”, page 17.

Storage Store the device adhering to the specifications, see “4.4 Technical data”, page 14.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

3 Shipment, transport, storage 9

Page 10

10 3 Shipment, transport, storage

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 11

4 Description

a

c

b

d

b

e

4.1 Function and setup of the device

The Ecotec E3000 is comprised of main unit and sniffer line.

The Ecotec E3000 can verify and quantify gases sucked in by the sniffer line with the help

of a selective mass spectrometer.

Working in the Ecotec E3000:

a Quadrupol mass spectrometer as a detection system

a high vacuum pump system

an inlet system for the gas flow

electrical and electronic sub-assemblies for electrical supply and signal processing

The mass spectrometer works under high vacuum, i.e. the pressure in the mass

spectrometer must always be below 10

molecular pump with the help of a diaphragm pump.

4.2 Main unit

The main unit will be called “device” only in the following so long as this does not falsify

the meaning.

-4

mbar. This vacuum is created by the turbo

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Fig. 1: Front view

a Display

b Handles and ventilation openings

c Speaker

d ECO-Check calibrated leak

e Lemo plug-in connector for sniffer line

4Description 11

Page 12

Fig. 2: Rear view

a cbefd

90001054694

530-001 Ecotec E3000

g

Headphone

I/O Port

RS-232

Sicherungen / Fuses 2 x 4 AT

a

Headphone connection, 3.5 mm jack

b Inputs/outputs (I/O port)

c RS-232 connection

e Fuses behind cover

f Power supply

g Rating plate

d Mains plug

a Headphone connection, 3.5 mm jack

In order to better hear signals in a loud environment, you can connect head phones.

b Inputs/outputs (I/O port)

The I/O port enables communication with a PLC. Some functions of the Ecotec E3000 can

be controlled from the outside and measurement results and device states of the Ecotec

E3000 can be transmitted to the outside.

Relay changeover contacts allow monitoring of the trigger values and the operating status

of the Ecotec E3000. Please refer to the “Interface description Ecotec E3000” (doc. no.

kins22e1) for further information.

c RS-232 connection

A PC can read out all data and measurement results of the device and control the device

via the RS-232 connection. Please refer to the “Interface description Ecotec E3000” (doc.

no. kins22e1) for further information.

d Mains plug

The mains plug serves to switch the device on and off.

e Fuses behind cover

For information on replacing the fuses, see “8.2.3 Replacing mains fuses”, page 71.

f Power supply

For information on the power supply, see “4.4 Technical data”, page 14, as well as the

labeling on the power supply (rating plate).

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

12 4Description

Page 13

4.3 Sniffer line

90001054694

530-001 Ecotec E3000

a

b

c

a

c

b

e

d

g Rating plate

The rating plate contains the supply voltage specification and other information with

which the device can be clearly identified.

Fig. 3: Rating plate

a Supply voltage

b Serial number

c Production date

You need a sniffer line to operate the device. Sniffer lines are available in four lengths: 3 m,

5 m, 10 m and 15 m.

The sniffer line is made of a flexible tube (multi-function cable), a handle with controls

(sniffer handle) and a sniffer probe.

There is a special sniffer line for robotic applications (see “10.1 Accessories”, page 77).

Sniffer probe There are rigid and flexible sniffer probes with different lengths.

Sniffer handle display

and functions

The display on the sniffer handle shows current information on the measuring process.

You can operate functions frequently used during measurement with both buttons.

LEDs inserted in the handle illuminate the test area.

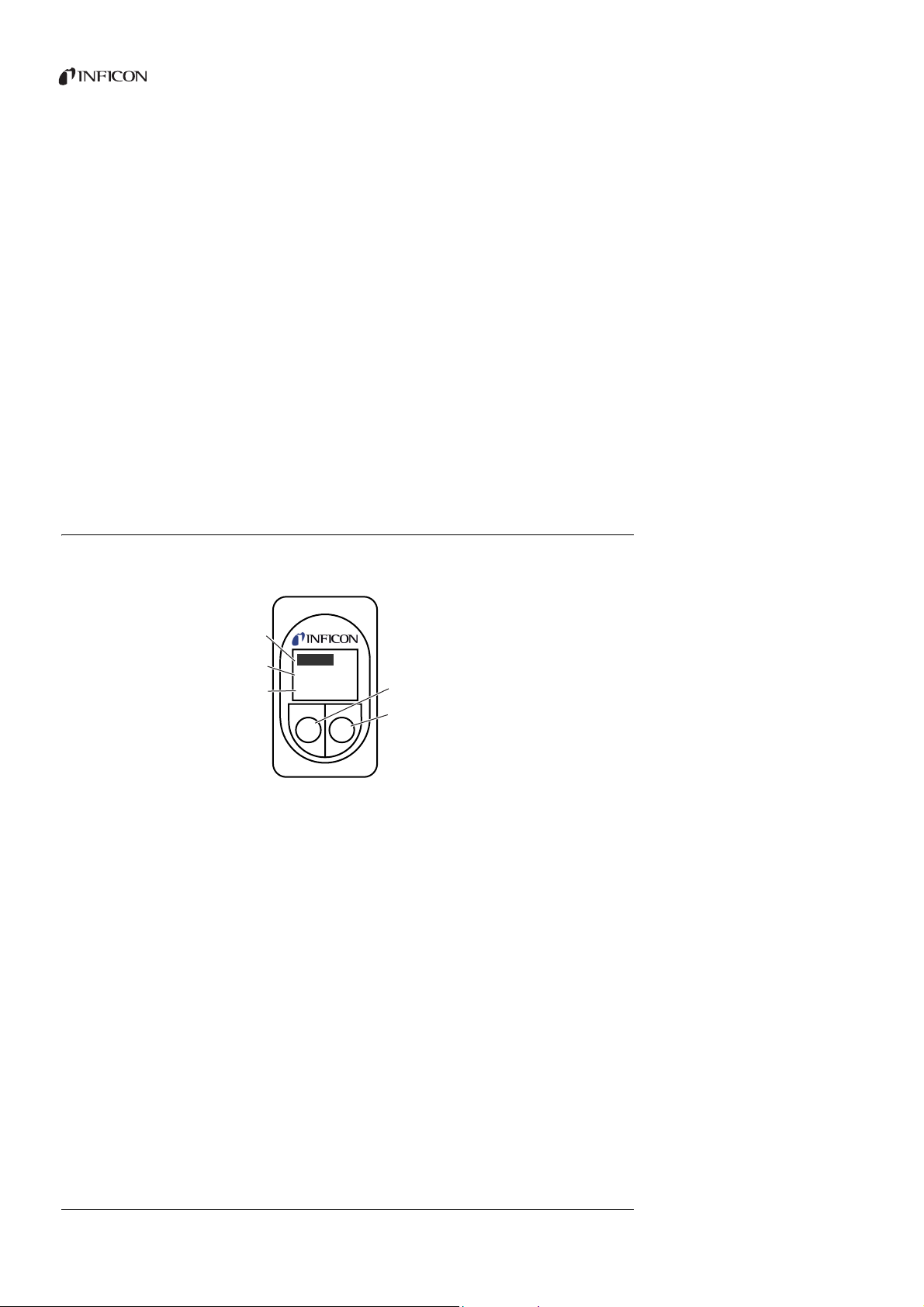

Fig. 4: Handle: display and functions

a Display

b ZERO adjustment

d Speaker (on the rear)

e I•Guide operation

c LEDs

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

4Description 13

Page 14

If the measuring value limit is exceeded, the display switches from green to red. You can

additionally set one speaker in the handle to output a signal and the LEDs in the handle to

flash or shine with maximum brightness, see “6.3 Settings before measurements”, page 28.

4.4 Technical data

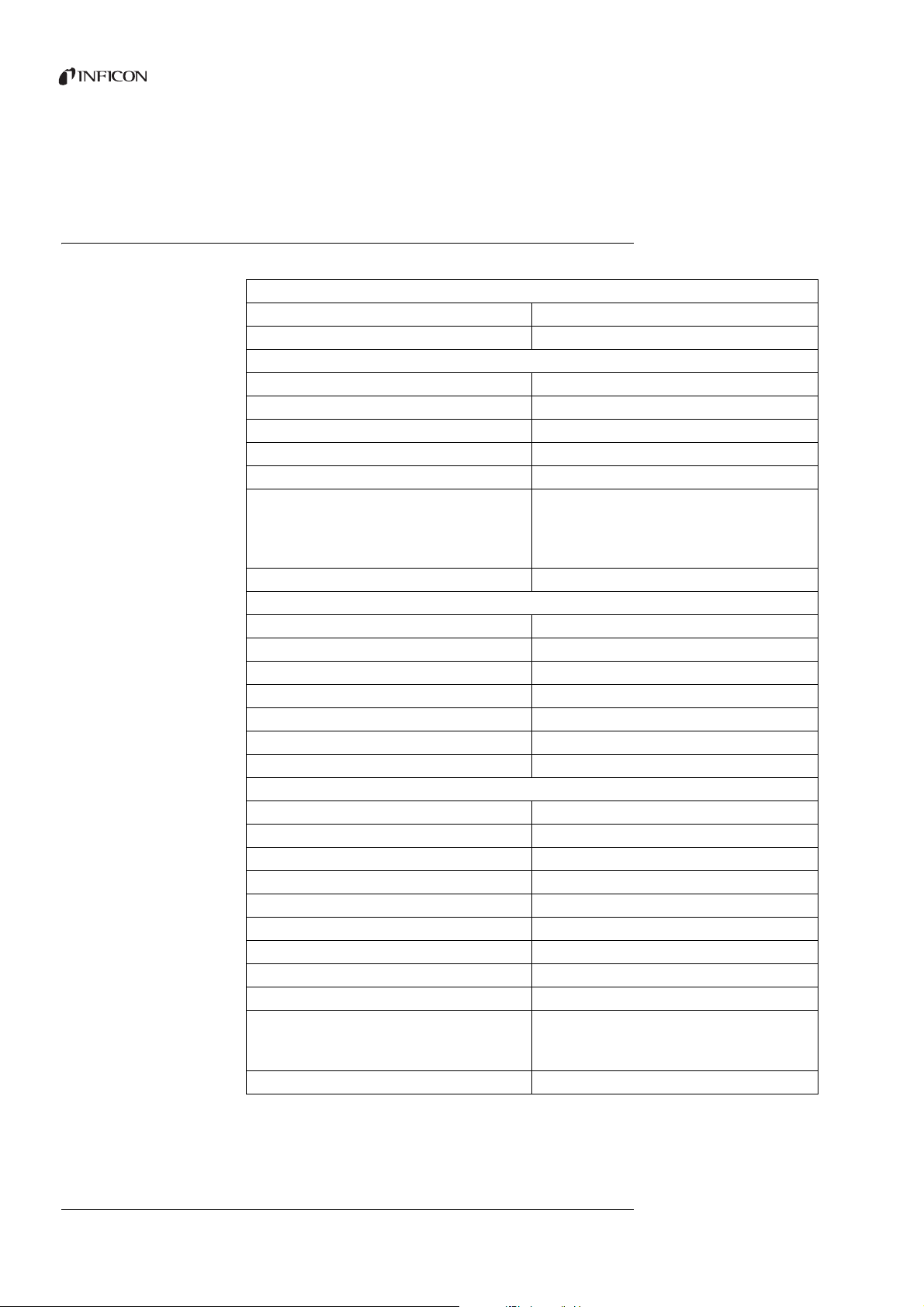

Table 2: Technical data

Mechanical data

Dimensions (W H D) 610 mm 370 mm 265 mm

Wei ght 34 kg

Ambient conditions

Permissible ambient temperature (during operation) 10 °C to 45 °C

Permissible storage temperature -20 °C to 60 °C

Max. relative humidity up to 31 °C 80 %

Max. relative humidity from 31 °C to 40 °C Linearly dropping from 80 % to 50 %

Max. relative humidity above 40 °C 50 %

Pollution degree II

Max. altitude above sea level 2000 m

Electrical data

Supply voltages and frequencies Country-specific, see rating plate on device rear

Power consumption 300 VA

Protection class IP 20

Overvoltage category II

Mains fuse 2 4 A slow-blow

Power supply cable 2.5 m

Noise level < 54 dBA

Physical data

Minimum detectable leak rate

Measurement range 6 decades

Detectable masses 2 to 200 amu

Mass spectrometer Quadrupol mass spectrometer

Ion source 2 cathodes

Time constant of the leak rate signal < 1 s

Gas flow through the capillary

Measured at 1 atm (1013 mbar) at sea level. The flow rate

changes with geographical height and barometric pressure.

Time until ready for operation < 2 min

(according to IEC 61010/part 1: “Usually, only nonconducting soiling may occur. However, temporary

conductivity caused by condensation is tolerable at times.“)

R134a 0.05 g/a (0.002 oz/yr)

R600a 0.05 g/a (0.002 oz/yr)

Helium < 1 10

-6

mbar l/s

120 to 200 sccm

14 4Description

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 15

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Table 2: Technical data (cont.)

Response time

3 m sniffer line 0.7 sec.

5 m sniffer line 0.9 sec.

10 m sniffer line 1.4 sec.

15 m sniffer line 3.0 sec.

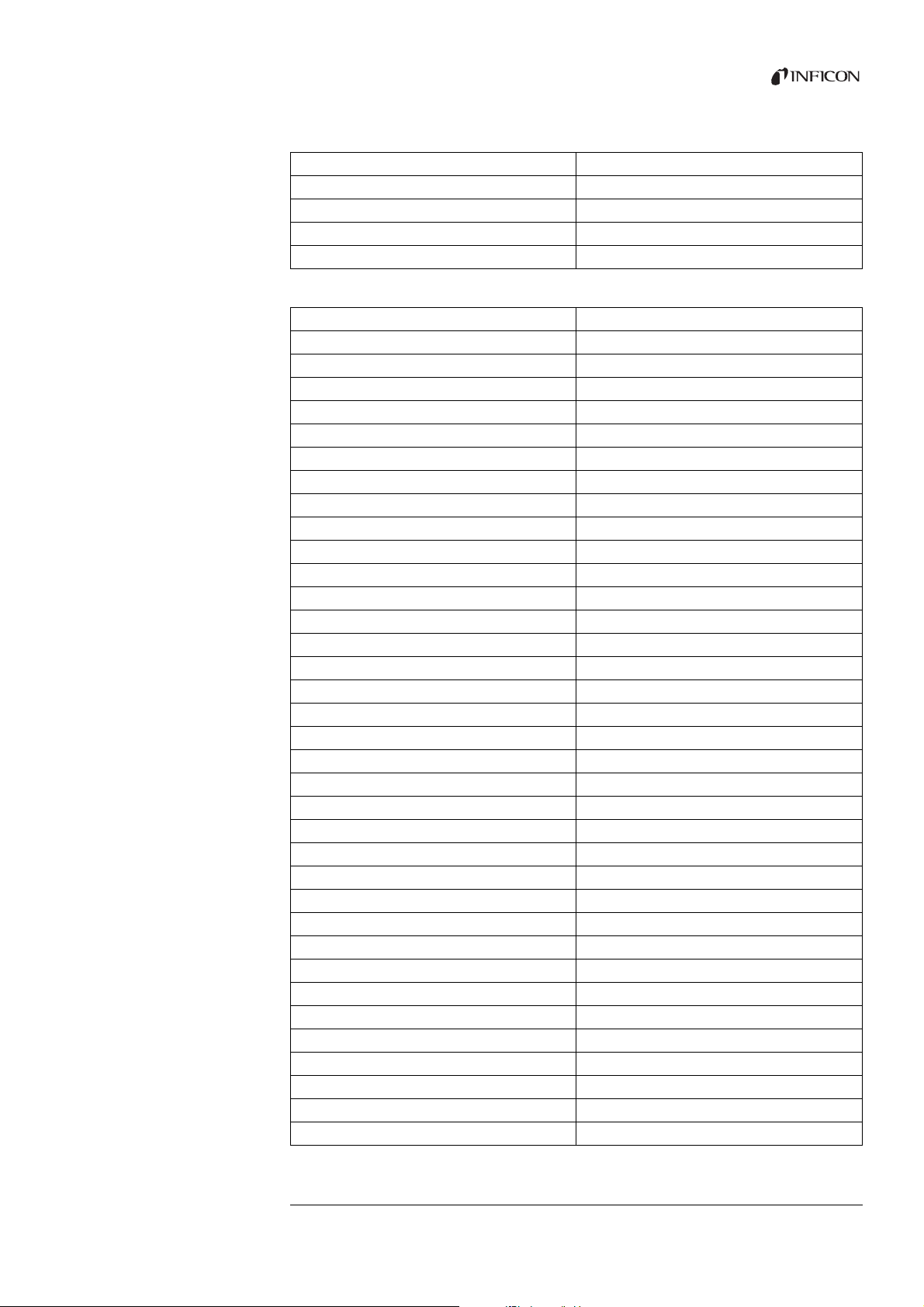

Table 3: Factory settings

Alarm profile Trigger alarm

Alarm delay Deactivated

Number of measuring points (I•Guide) 4

Functions Activated

Internal Activated

Recording output Auto

Baud rate and blank flange 9600 CR+LF

Pressure unit mbar

Flow rate

Lower limit 100 sccm

Upper limit 250 sccm

Sensitivity test Activated

Gas, definition Gas 1, gas 2, gas 3, gas 4, gas 5, gas 6

Device speaker Activated

Handle speaker Trigger value

Selecting a cathode A

I•Guide Deactivated

Calibration (cal), internal Activated

Contrast Not inverted, setting 30

Vol ume 2

Minimum volume 2

Leak rate, selected, highest Automatic

Leak rate filter I•Filter

Menu PIN Deactivated, 0000

Measuring time (I•Guide) 1 second

Measuring mass 69

Peak value Deactivated, 5 seconds

ECO-Check Activated

Relay outputs See interface description

RS-232 protocol ASCII

Sniffer probe, light Activated, Level 4

Sniffer probe, filter, maintenance 100 hours

Recorder, gas Auto

Scaling of the recorder Logarithmic

Language English

SPS outputs and inputs See interface description

4Description 15

Page 16

Table 3: Factory settings (cont.)

Control location Local and RS-232

Search threshold 90 %

Tri gge r va lue , su m (I •Gui de) 10 g/ a

Trigger and unit 4 g/a

Idle time (I•Guide) 3 seconds

Maintenance, sniffer probe filter 100 hours

Zero time 5 seconds

Zero key sniffer line Activated

ZERO key main unit Activated

16 4Description

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 17

5 Installation

5.1 Setup

Danger due to moisture and electricity

Moisture getting into the device can lead to personal injury from electric shocks and to

material damage from short circuits.

► Operate the Ecotec E3000 only in a dry environment.

► Operate the Ecotec E3000 away from sources of liquid and moisture.

Danger due to dropping heavy loads

The device is heavy and can damage persons and items through tilting or dropping.

► Place the device only on a sufficiently sturdy surface.

Material damage due to vibration.

Parts of the measurement technology rotate and must not be shaken. The parts continue

to rotate for several minutes after the device is shut down.

► Place the device only on a sturdy, vibration-free surface.

► The device must not be shaken during operation and at least five minutes after being

switched off.

Material damage due to an overheated device

The device heats up during operation and can overheat without sufficient ventilation.

► Please note the specifications, see page 14.

► Ensure sufficient ventilation especially on the ventilation openings on the left and

right of the device: free space on the side at least 20 cm, in front and in the rear at least

10 cm.

► Keep heat sources away from the device.

► Do not subject the device to direct sunlight.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

5Installation 17

Page 18

Material damage due to transport restraint that has not been removed

The transport restraint blocks the mechanical system in the device.

► Remove the transport restraint before the start-up.

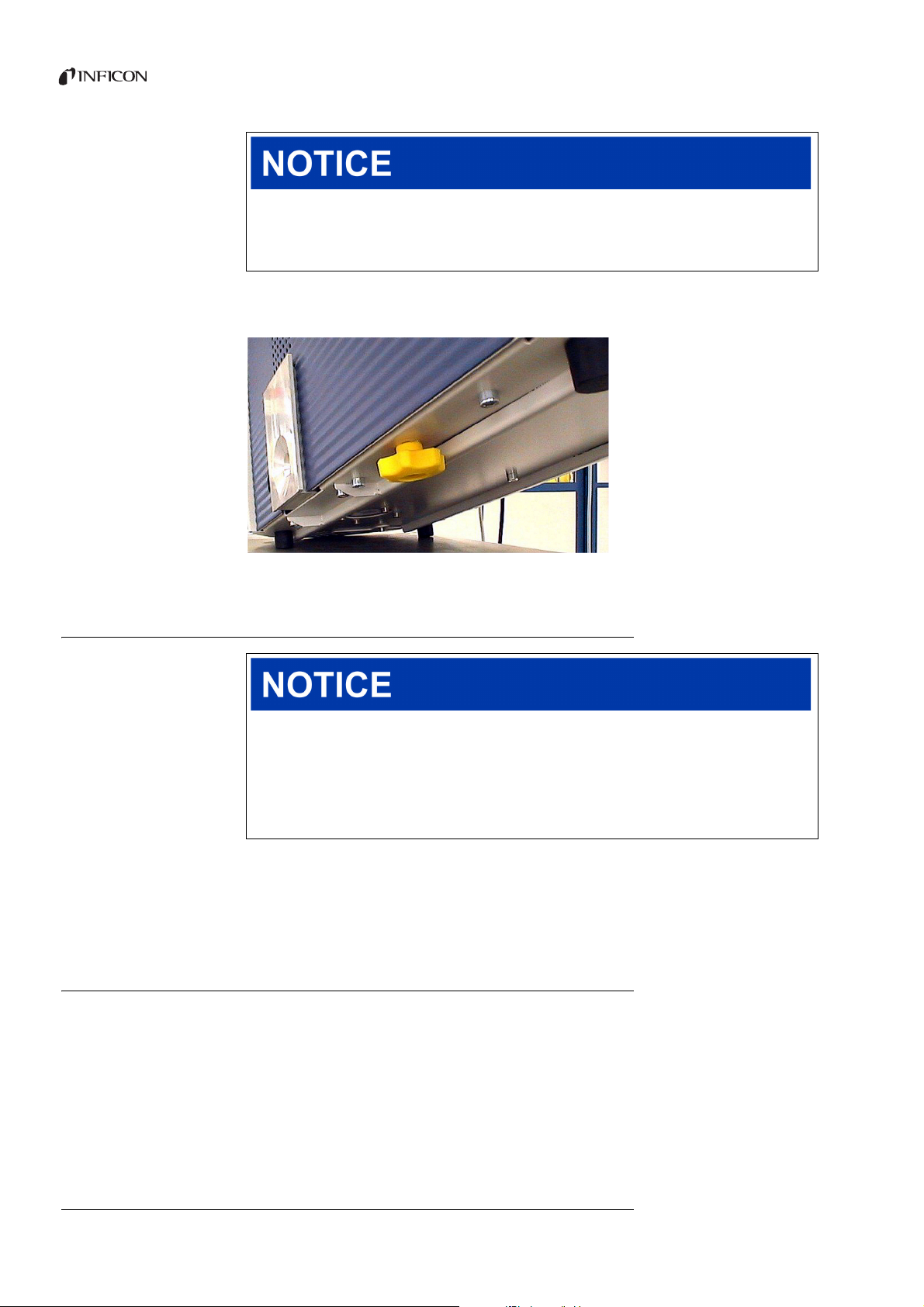

The transport restraint is on the bottom of the Ecotec E3000 and consists of a yellow star

screw.

Fig. 5: Unscrew the yellow transport restraint before the start-up

5.2 Connecting the sniffer line

Material damage due to a missing sniffer line

The device must not be operated without a connected sniffer line in order to avoid

overpressure in pump and measurement system.

► Connect the sniffer line before you start up the device.

► Do not replace the sniffer line while the device is in operation.

Align the red marking on the sniffer line plug with the red marking on the socket. Push the

sniffer line plug into the socket on the device until it locks into place.

Pull the grooved ring on the plug to release it. The ring opens the lock and you can pull out

the plug.

5.2.1 Replacing the capillary filter of the sniffer probe

The metal capillary filter is the standard filter. With the plastic capillary filter there is less

danger of scratching the surfaces to be sniffed. The water conservation tip is used if there

is a danger of suctioning in liquids.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

18 5Installation

Page 19

Fig. 6: Capillary filter

abc

d

a Sniffer probe end

b Plugwasher

c Metal capillary filter

d Plastic capillary filter

5.2.1.1 Replacing the plastic capillary filter with the metal capillary filter

1 Turn off the Ecotec E3000.

2 Unscrew the plastic capillary filter.

3 Insert the plugwasher, see fig. 6 on page 19.

4 Screw in the metal capillary filter on the sniffer probe end.

5 Calibrate the Ecotec E3000, see “6.4.2 Calibration”, page 37.

5.2.1.2 Replacing the metal capillary filter with the plastic capillary filter

If you want to switch from a capillary filter made of metal to a capillary filter made of

plastic, you have to the remove the plugwasher. The plugwasher sits on the steel capillary

in the sniffer probe.

1 Turn off the Ecotec E3000.

2 Unscrew the filter.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

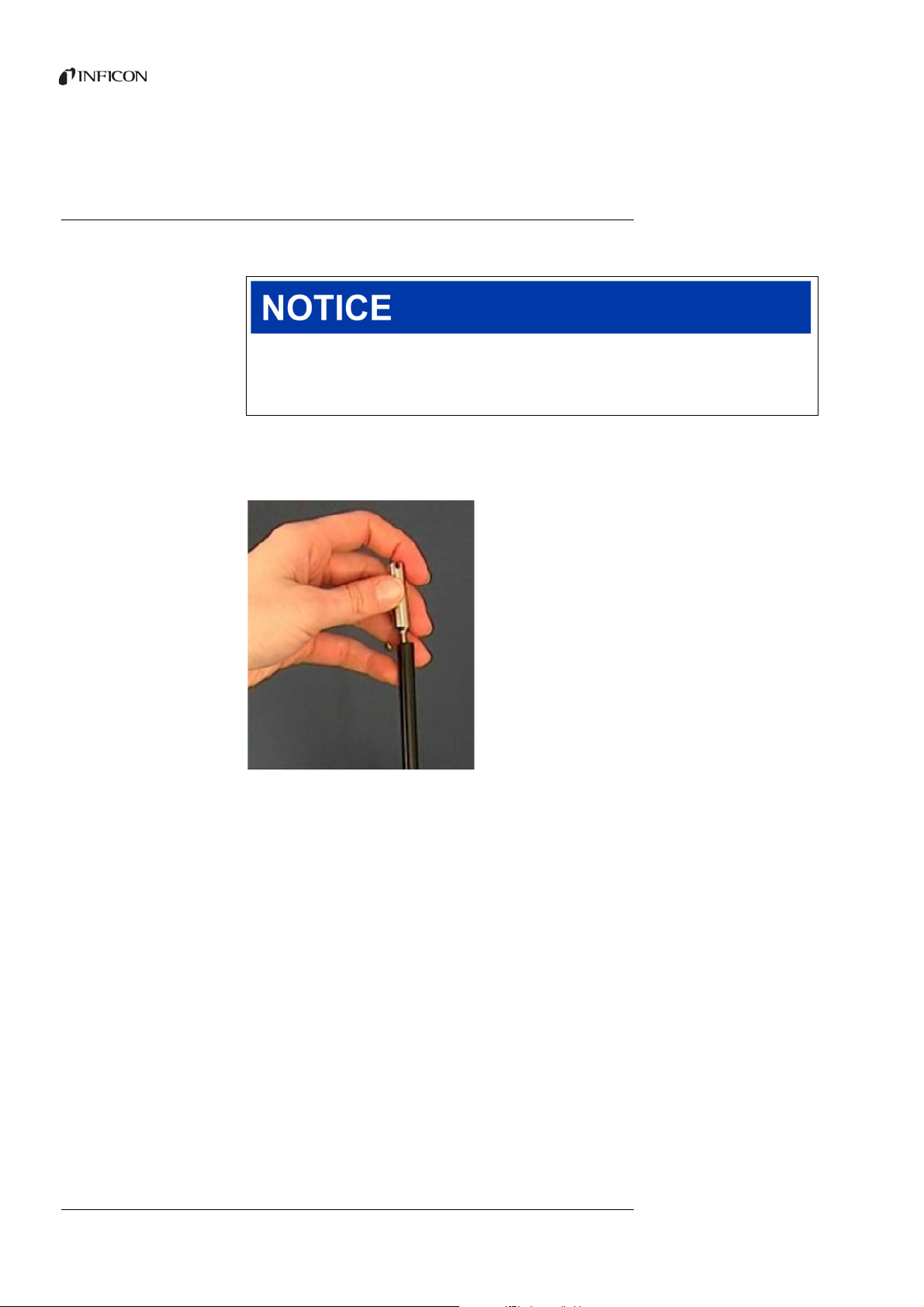

3 Unscrew the two cross-head screws in the sniffer probe flange and take out the sniffer

probe.

4 Push the capillary out of the plastic sheath a bit from the top with a narrow pin or a thin

needle (about 0.5 mm). Make sure that the sinter filter in the sniffer probe flange does

not get lost in doing so

5 Remove the plugwasher from the sniffer probe.

Fig. 7: Pushing out the capillary

6 Put the sinter filter back in and tighten the sniffer probe on the handle.

5Installation 19

Page 20

7 Screw the plastic capillary filter on the sniffer probe.

8 Calibrate the Ecotec E3000, see “6.4.2 Calibration”, page 37.

5.2.1.3 Water conservation sniffer probe mounting and remove

With the help of the water conservation sniffer probe, you can check test objects with low

surface moisture, e.g. condensation moisture, for tightness.

Short circuit hazard

Sucked in liquid can destroy the device.

► Do not suction in liquids with the device.

The water conservation sniffer probe is screwed onto the sniffer probe end like the metal

capillary filter. The small plugwasher must also be placed below the end, see

“5.2.1.2 Replacing the metal capillary filter with the plastic capillary filter”, page 19.

20 5Installation

Fig. 8: Tightening the water conservation sniffer probe

For renewed mounting of the plastic capillary filter, see “5.2.1.1 Replacing the plastic

capillary filter with the metal capillary filter”, page 19.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 21

5.2.2 Attaching the sniffer lines holder

A holder is available for the sniffer probe. The holder can be installed on the right or the

left of the device.

Fig. 9: Sniffer line holder mounting

The holder has two hooks that are inserted into two slits on the front panel of the device.

The holder is pulled to the front panel of the device with a magnet on its rear.

5.3 Connecting the ECO-Check calibrated leak

A built-in calibrated leak (ECO-Check) and different external calibrated leaks are available

as accessories available for the Ecotec E3000, see “10.1 Accessories”, page 77.

Please refer to the ECO-Check installation manual on how to connect the ECO-Check.

5.4 Connecting the external display unit to the Ecotec E3000RC

Connect the external display unit and the Ecotec E3000RC with the appropriate

connecting cable. Secure the plug on the socket by tightening the screws.

Fig. 10: The Ecotec E3000RC with external display unit as a table device (left), for rack mounting (right)

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

5Installation 21

Page 22

5.5 Connecting to the power supply system

The supply voltage of the Ecotec E3000 is specified on the labeling of the mains plug

(rating plate). The Ecotec E3000 cannot be switched for other supply voltages.

Danger due to incorrect supply voltage

Incorrect supply voltage can destroy the device and injure persons.

► Check whether the supply voltage specified on the Ecotec E3000 matches the supply

voltage available on site.

Connect the device to the electric power supply with the supplied power cable.

5.5.1 Connecting to a PC

The connection is made with a commercially available 9-pin SUB-D plug. Please refer to

the “Interface description Ecotec E3000” (doc. no. kins22e1) for further information on

data exchange.

5.5.2 Connecting with a PLC

The connection is made with a commercially available 25-pin SUB-D plug.

Please refer to the “Interface description Ecotec E3000” (doc. no. kins22e1) for further

information on data exchange.

22 5Installation

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 23

6Operation

Start screen in EN

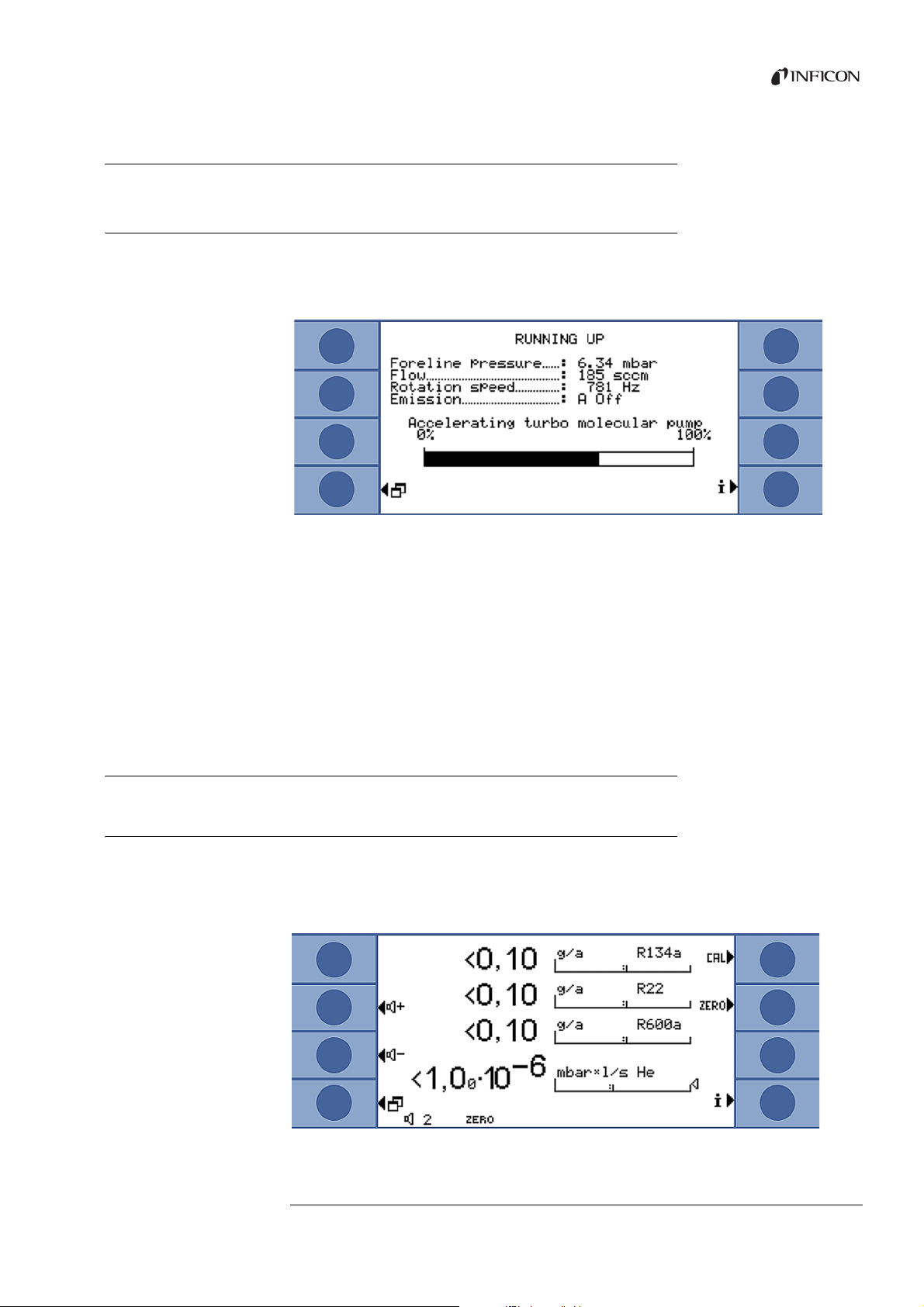

6.1 Start-up

Connect a sniffer line and switch on the device with the mains plug.

The Ecotec E3000 starts a self-test lasting several minutes. The display shows the headline

“Running up” and the individual steps of the self-test.

Fig. 11: The device runs up

After running up, the Ecotec E3000 already measures the gas concentration in the

environment. There is no separate start function. But you have to still calibrate the device

and make different settings for your intended measurement.

If the ECO-Check calibrated leak is not in the Ecotec E3000, an acoustic warning signal and

the warning 71 are output during the first start-up.

To stop the alarm quickly, press the key on the bottom right (labeled “OK“). If you are

working without the ECO-Check, you should deactivate the alarm permanently, see “ECO-

Check”, page 34.

6.2 Operating the device

6.2.1 Display and keys

All settings are made with the eight keys to the left and the right of the display. The

function allocations of the keys change depending on the current operating step. The

function allocation is shown directly next to the key which allows fast and purposeful

operation after a short learning period.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

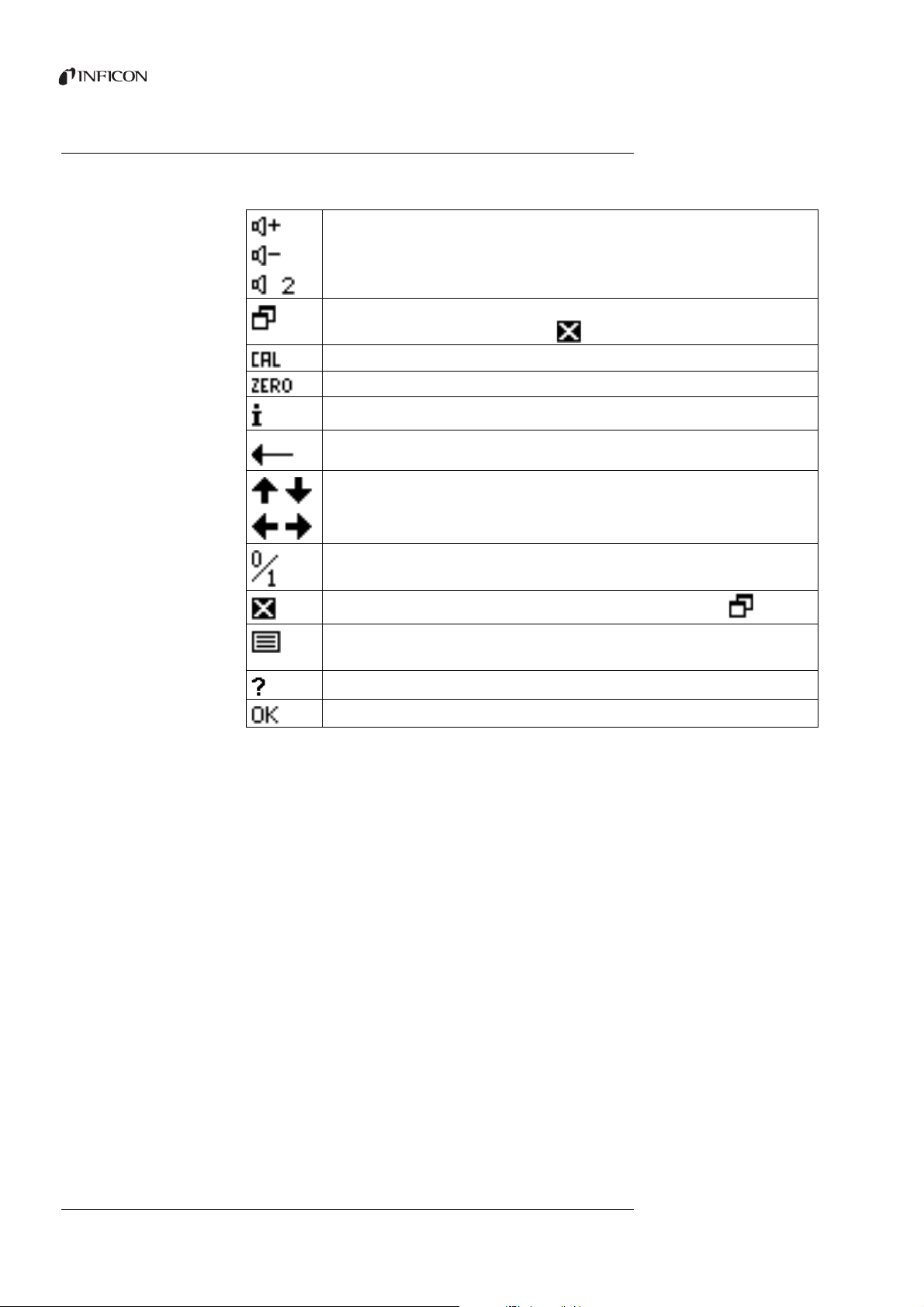

Fig. 12: Start display after the self-test

6Operation 23

Page 24

6.2.1.1 Recurring function symbols

Back

The keys are always assigned with the following functions and labeled with the shown

symbols.

Setting the volume for speakers and head phones.

Set volume: The set volume is displayed on the bottom edge of the display.

Value range: 0 (off) to 10 (max.)

– Calling the main menu.

– Calling a window again that was closed with .

Calling up calibration.

The lower edge of the display shows “Zero” if a zero point has been set since the device start-up.

Calling up information: software version, operating hours, serial number, date & time, alarm profile.

Back to last menu level.

Navigating in a list box.

Pressing the key assigns the allocation “0” to that key and “1” to an adjacent key. The same setting option

exists for the numbers “2/3”, “4/5”, “6/7”, and “8/9”.

Closing the window and calling up the measurement view. Back to the window with

– Calling up the list of gases.

– Measurement with I•Guide: calling up the list of I•Guide programs.

Calling up help for the current function.

Confirming an entry or selection.

24 6 Operation

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 25

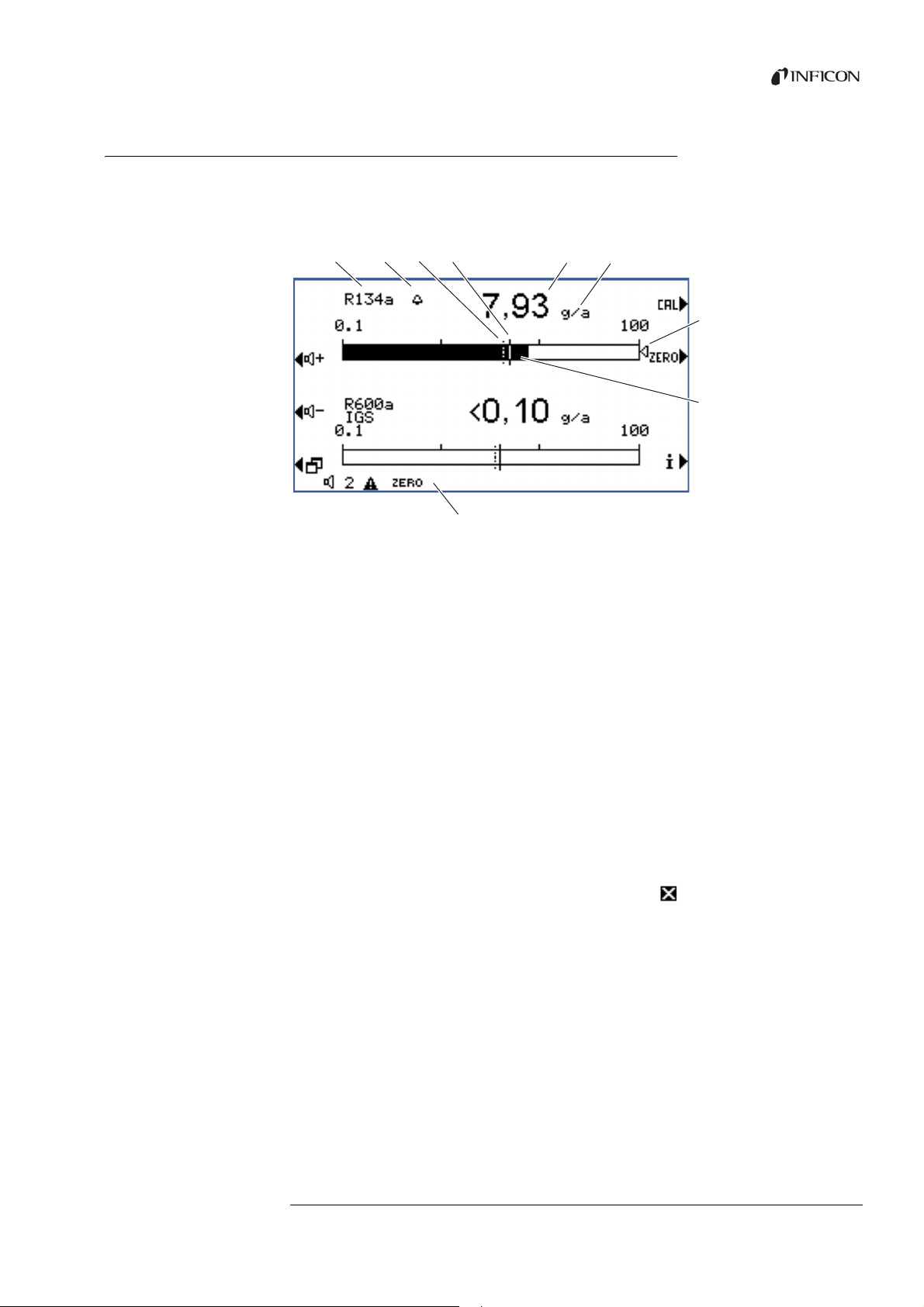

6.2.2 Elements of the measurement view

a b c d

g

e f

i

h

The measured leak rates are shown numerically and with logarithmically divided bar

graph displays.

The other elements of the measurement view are shown in the following figure.

Fig. 13: Elements of the measurement view

a

Gas

b Bell: search threshold exceeded; flashing bell:

trigger value exceeded

c Search threshold (broken line)

d Trigger value

e Numerical leak rate display

f Leak rate unit

g Marking arrow: marks the measurement

displayed on the sniffer handle

h Bar graph, logarithmic

i Status bar: symbols and text overlay provide

information about the device status

The two center keys on the left side of the display can be used to adjust the volume of the

alarm signal at any time. If one of the two keys is pressed, the device emits a sound with

the selected volume through the speaker and shows the setting with a bar graph in the

status line. The set value is also the first entry in the status line on the bottom of the display

and applies only to the speaker of the main unit. To adjust different alarm profiles, see

page 29.

Menu key

The key on the bottom left of the display has two functions:

Calling the main menu.

Returning you to the last window that was closed with .

Calibration key (CAL)

The key on the top right next to the display can be used to start a calibration of the Ecotec

E3000 with an external test leak at any time. Additional information on completing an

external calibration, see “6.4.2.2 External calibration with external calibrated leak”,

page 39.

ZERO key

Pressing the ZERO key briefly stores the currently displayed leak rate as zero point for all

selected refrigerants. Pressing the ZERO key for more than 2 seconds switches off the

ZERO function. The display ZERO disappears from the status line in this case. For more

information on the ZERO function, see “Zero”, page 31.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

6Operation 25

Page 26

Information key

a

b

c

d

e

2.0E-7

HE

Pressing the information key

the status of the Ecotec E3000. Details: see “6.4.6.1 Calling up information on the

measurement”, page 45.

Status line

Status information is displayed in the lower line of the measurement window. The set

volume for the alarm is displayed in the left of the line.

If the small speaker flashes, it indicates that the device speaker is switched off.

If the number flashes, it indicates that the alarm delay is switched on, see “Alarm delay”,

page 29

A small black triangle with an exclamation point next to it can indicate an active warning.

If the ZERO function is activated, the word “ZERO” follows in the status line.

If the first cathode (filament A) of the mass spectrometer has been consumed and the

Ecotec E3000 switches automatically to the second cathode (filament B), the display will

show “Fil. B” in the status line.

If you working with an activated IGS, “IGS” will be shown in the status line.

i (to the bottom right of the display) shows information on

6.2.3 Operating elements and display on the sniffer handle

The display of the sniffer handle shows the most important information for the current

measurement. Measurements can be controlled with the two keys.

26 6 Operation

Fig. 14: Operating elements and display on the sniffer handle

a Leak rate as bar graph

b Leak rate, numerical. Unit, as shown on the main unit

c Measured gas

d Left key, assigned “Zero”

e Right key, different assignments

The measured leak rate is shown as an increasing or decreasing bar. The second line shows

the leak rate as a numerical figure (with the same measurement unit as in the main

display). The third line shows the abbreviation for the measured gas.

Depending on the measurement, the display can also show something else, e.g. “Error” or

the number of a warning.

If you search for several gases simultaneously, you can switch between individual

measurement results with the right key. The right key can also be used to confirm

messages or states during a measurement cycle.

You can trigger the ZERO function with the left key, see “Zero”, page 31.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 27

The key can be deactivated to prevent accidental triggering: Press the key until you hear a

signal. The key is reactivated by pressing it longer.

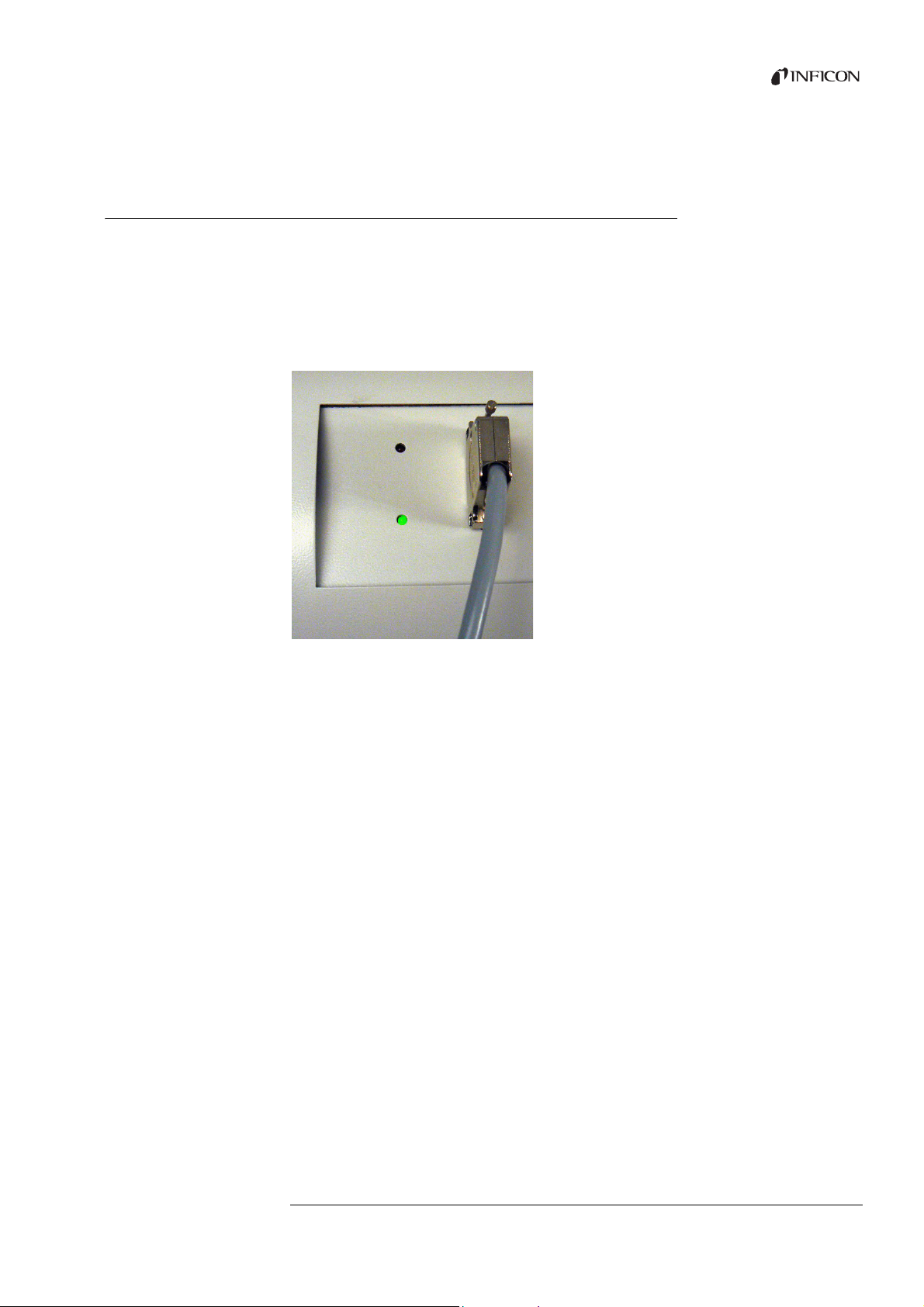

6.2.4 Special features of the Ecotec E3000RC

The Ecotec E3000RC has a connection panel for the external display unit instead of the

built-in display. Two LEDs (to the left of the plug) provide information on the status of the

Ecotec E3000RC, even if the external display unit is not connected.

The green LED shows that the Ecotec E3000RC is switched on. It has a steady green light if

an external display is connected and flashes if no external display can be detected.

The red LED flashes in case of an error message; a steady red light indicates a warning.

Fig. 15: Connection panel with LEDs

If no display unit is connected, you can confirm error messages and warnings by pressing

both keys on the sniffer line simultaneously.

The external display unit has four keys:

The menu key opens the main menu.

The current measured background value is set as zero point with the ZERO key, see

“Zero”, page 31.

The START / STOP keys do not have any function (the external display unit can also be

used with other leak detectors made by INFICON that require these keys).

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

6Operation 27

Page 28

6.3 Settings before measurements

Before the first measurements, you should make different device settings in the following

menus:

Miscellaneous

Display

Audio

Vacuum & access control

Interfaces (for control via interfaces and if you use an ECO-Check)

You can access the menus via the main menu

6.3.1 Miscellaneous

Language You can select one of the following languages:

English (factory setting)

German

French

Italian

Portuguese

Spanish

Japanese (Katakana)

Chinese (Mandarin, simplified Chinese)

To set the language to English temporarily, press keys two and six during the run-up of the

Ecotec. Call up the language setting after the run-up and set the required language.

Time & Date First page: internal date with the format DD.MM.YYYY

Second page (press key on the bottom right ) time with the format SS:MM.

Sniffer light Activate/deactivate light

Adjust brightness from 1 (min) to 6 (max)

Pressure unit atm

Tor r

Pa

mbar

Leak rate filter Auto

Fixed

I•Filter

The I•Filter is an intelligent filter algorithm that delivers the best results regarding

interference suppression and stability of the leak rate signal. It was especially developed

for the use in the Ecotec E3000.

Only in cases in which the older Ecotec II model was replaced with an Ecotec E3000 and

the Ecotec E3000 is used in a fixed test device can it be necessary to select the older filter

settings “Auto” or “Fixed”.

28 6 Operation

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 29

Alarm delay With very unstable surface conditions, it can be expedient to emit an acoustic alarm only

if the trigger value is exceeded for a specified period of time. If the function is activated,

the number indicating the volume of the device speaker flashes in the status bar.

Setting range: 0 to 9.9 seconds, in tenths of a second

Danger due to undetected leaks.

If the alarm delay is activated, there may be no acoustic alarm even though a leak is

detected.

► Please note the measurement display in the device and the handle.

► Deactivate the function when surface conditions are stable again.

Wake up If the Ecotec E3000 is in idle state (sleep), a time can be set for it to start automatically. This

way you can set the Ecotec up to run through its warm-up phase already before the shift

starts.

You can set a separate wake-up time exact to the minute for each day of the week.

To deactivate the wake up again, set the wake-up time to 00:00.

6.3.2 Audio settings

Beep sound You can switch off the signals that indicate the completion of specific functions.

Device speaker You can switch off the speaker installed in the main unit. This does not influence the

speaker connection.

Audio sniffer You can choose whether the speaker in the sniffer handle should signal the exceedance of

search threshold or trigger value.

You can also switch off the speaker completely.

Alarm profile You can assign one of three alarm profiles to the device speaker:

Pinpoint

Setpoint

Trigger/alarm

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

6Operation 29

Page 30

Table 4: Features of the alarm profiles

Alarm profile pinpoint Alarm profile setpoint Alarm profile trigger/alarm

Search value exceeded – Acoustic signal low frequency Acoustic signal low frequency

Trigger value exceeded – Acoustic signal high

Two-tone signal

frequency

Acoustic tracing of the

measurement result

< 1/10 trigger value: low frequency – –

>1/10 trigger value up to 10 trigger value:

rising frequency

> 10 trigger value: high frequency

Comment Recommended, for precise leak localization – Three different two-tone signals

available for selection.

This allows identification with a signal for

devices that are used together.

Volu me You can adjust the volume that cannot be set lower with the plus and minus keys next to

the display. This way you can prevent the acoustic signals from being switched off

accidentally during the measurement.

The adjustment applies to the speaker in the main unit and the head phones.

You can also set the current volume of speaker and head phones here.

Setting range: 0 to 15

Hearing damage from excessively loud signals

The volume of signals can exceed 85 dB(A).

► Keep away from the device if the volume has been set to high.

► Wear ear protection, when needed.

6.3.3 Display settings

In the menu “Settings > Display”, you can set the display details of the device display and

the display in the sniffer handle.

Contrast Increase or decrease the display contrast using the arrow buttons. Holding the button sc-

rolls through the values. The new setting takes immediate effect in the display.

► To adjust the contrast to the currently displayed menu, select “Automatic”.

► To display a dark background and the script in bright characters, select “Invert display”.

If the display is no longer legible because it is too dark or too bright, you can reset the

setting as follows:

1 Switch the device off and back on.

2 Press keys 3 and 7 during the run-up until the display can be recognized again.

3 Call up the window for the contrast setting and confirm the new value. The device will

otherwise use the old, unrecognizable setting after the next start-up.

30 6 Operation

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 31

The factory setting with black font on light background can be inverted. This causes the

a

display to emit less light overall.

Peak hold You can set if and how long the highest measured value is to be displayed additionally

below the current leak rate.

Setting range: 0 to 20 seconds.

Fig. 16: Measurement view with maximum value display

a Maximum value

6.3.3.1 Gas display handle

In the menu “Settings > Display > Gas display handle” you can define which gas is shown

in the display in the sniffer handle.

Automatic The display always shows the gas that the most of is measured currently. If a trigger value

is exceeded, this gas will be displayed.

Manual You can switch between gases with the right key on the handle.

Auto with hold You can switch to another gas with the right key on the handle. After the hold time has

elapsed, the display again shows the gas that the most of is measured currently.

Hold time The hold time can be set to 5, 10, 15, or 20 seconds.

6.3.4 Vacuum & access control

Zero The gas concentration contained in the measurement environment can be set as zero

point for measurement (background suppression). The function has the brief name “Zero”.

If the gas concentration drips after setting the zero point, a negative measured value

should be displayed. In order to avoid that, the zero point is revised downward if the

measured value is negative for the duration of the “Zero time”, see below.

The zero point is not automatically revised up (wards). It is therefore important to regularly

reset the zero point.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

The zero point can be set with the left key on the handle and with the key “Zero” in the

measurement view.

You can activate or deactivate the keys here in this menu. Deactivation prevents that the

function is triggered inadvertently and that an incorrect absolute measured value is thus

displayed.

6Operation 31

Page 32

The key on the sniffer line handle can also be activated or deactivated by pressing the key

longer.

Zero time Zero time is the time during which the leak rate must be negative so that the zero point

can be revised downward automatically. The best setting depends on your measurement

conditions (sampling speed, gas background, test specimen).

Setting range: 1 to 9.9 s

Flow limits To detect a leak on the 160-sccm capillary, an upper limit value is set. If the value is

exceeded, the system issues the warning “Capillary broken”. With longer exceedance,

device components are also switched off to protect them.

To detect a clogging of the 160-sccm capillary, a lower limit value is set. If the value is fallen

short of, the system issues warning “Changed flow!”. With a strong lower deviation, the

error message “Flow through capillary too low” is issued.

Possible settings range from 160 to 999 sccm or 0 to 160 sccm.

The closer the lower limit value is set to the actual flow rate, the more sensitive the Ecotec

E3000 reacts to a beginning clogging of the filter and the sniffer line.

Fig. 17: Setting flow limits

The flow through the sniffer line depends on the atmospheric pressure of the

environment. If you operate the device at great height, the flow rate through the sniffer

line can drop considerably, approx. 20 % per 1000 m height. Reset the flow limits

accordingly in this case.

Monitoring check The sensitivity check in the device ensures that the sensitivity of the Ecotec E3000 is always

sufficient. The entire gas flow from sniffer probe to sensor is monitored and the software

simultaneously checks whether the Ecotec E3000 can determine the correct signal

strength with it. The monitoring ensures that the Ecotec E3000 does not become

insensitive and that leaks are not detected without the user noticing. If the sensitivity is

reduced, the error message “Sensitivity too low” is issued. Recalibration can restore

sensitivity in this case, see “6.4.2 Calibration”, page 37. The error message is repeated every

15 seconds until calibration is started.

We urgently recommend leaving the monitoring switched on at all times. It should be

deactivated only for measurements in an argon-free environment because monitoring

requires the argon signal.

Calibration In the window “Calibration”, you can activate or deactivate external calibration. If

calibration is deactivated, you can calibrate only internally with a built-in ECO-Check

calibrated leak. The command “Cal” in the measurement window is no longer displayed.

This prevents a previously executed external calibration from being overwritten

accidentally. Details on calibration, see “6.4.2 Calibration”, page 37.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

32 6 Operation

Page 33

Changing the menu PIN You can protect access to the settings with a PIN.

To prevent entry errors, you have to enter the PIN twice. After confirmation with “OK”, the

main menu is displayed and the PIN is effective immediately.

To cancel protection again, enter “0000” as the new PIN (factory setting).

Fig. 18: Defining the menu PIN

6.3.5 Interfaces

In “Settings > Interfaces”, you enter the settings for the interfaces and for the ECO-Check.

Please refer to the interface description (kins22e1) for detailed information on interfaces.

Control location Local

RS-232

Local and RS-232

Recorder outputs >

Recorder output scale

Recorder outputs >

Recorder output gas

PLC Setup > Define PLC

inputs (outputs)

PLC setting > Baud rate

& End sign

Local: Only measurements can be read out via the RS-232 interface. They are not available

to control the device.

RS-232: The Ecotec E3000 is controlled almost exclusively via the interface. The display

serves only for a visual check. Some settings can be changed on the device. Please use the

protection via access PIN if all functions on the device are to be inaccessible, see

“Changing the menu PIN”, page 33.

Local and RS-232: The Ecotec E3000 can be controlled via interface and entries on the

device.

Linear

Logarithmic

The output is on channel 1 (pin 1 of the I/O connection).

Gas 1 to 4

Auto

You will assign different commands to the pins of the I/O connection here.

Baud rate 1200/2400/4800/9600/19200

End sign LF/CR/CR + LF

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

6Operation 33

Page 34

RS-232 protocol ASCII

Diagnosis

Printer Auto

Printer Manual

ECO-Check If you do not use an ECO-Check calibrated leak, you should choose “Deactivate” here.

Otherwise, warning 71 “No communication with ECO-Check” will be issued at every start

of the Ecotec E3000.

If you use an ECO-Check calibrated leak, you can set up a warning for the intended time of

use here: 14/30/60/90 days.

6.4 Settings for the measurements

With delivery, the data are programmed for the following gases and the measurement

results are shown below each other in the display:

R134a

R22

R600a

He

The gas selection can be changed at any time.

6.4.1 Selecting the gas, changing gas parameters, activating measurement

You can access the settings via the main menu

► Select “Measuring parameters”

Fig. 19: Gas information for the measurement

The display shows:

four gases

the respective mass position

the respective trigger value

the addition “Deactivated” if the associated gas is currently not searched for, see below.

34 6 Operation

You can also define your own gas with the key “Gas def.”, see “6.4.5 Setting a user-defined

gas”, page 42.

Press the key to the right of the gas whose parameters you want to change. The window

“Measuring param. gas …” will open.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 35

Fig. 20: Changing the settings for gas 1

With the keys up and down you select a setting. Pressing the key “change” on the bottom

right opens the associated settings menu.

Gas The gas to search for is displayed. You can open the gas library with “change” and choose

from approx. 100 gases there.

User-defined gases are displayed at the end of the list.

Fig. 21: The gas library

Status “Status” shows whether the search for this gas is activated or deactivated. You can change

the setting at any time. If the search for a gas is deactivated, it will also be displayed in the

window “Measuring parameters”.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

In the measurement window, the display of the measurement result for a deactivated gas

is dropped and the display is clearer.

Trigger and unit In the window “Trigger & unit”, you can set the trigger value with the keys on the left and

select the unit with the keys on the right.

Fig. 22: Setting trigger value and unit

6Operation 35

Page 36

The following table shows the adjustable units and the associated limits for the trigger

value.

Table 5: Trigger value according to unit

Unit Lower trigger value limit Upper trigger value limit

g/a 0.1 1000

oz/yr 0.004 100

ppm 1 999999

mbar l/s 2 10

Pa m3/s 2 10

atm cc/s 2 10

Torr l/s 2 10

-7

-8

-7

-7

9.9 10

9.9 10

9.9 10

9.9 10

-2

-3

-2

-2

Search & Limit (search

threshold and display

limit)

In the window “Search threshold display limit”, you can set the search threshold with the

keys on the left and select the factor for the lower display limit with the keys on the right.

The search threshold is a percentage of the trigger value and serves as an additional

warning level. Smaller leaks that are even below the trigger value can also be reported,

when needed, see “Alarm profile”, page 29.

The absolute value of the search threshold is calculated by the device and displayed.

Fig. 23: Setting display limit and search threshold

With the function “Display limit”, you can hide measurement results that are below the

expected leak rate. This makes the measurement view clearer especially in view of the

measurement bar because smaller measurement results are hidden.

You can define the lower display limit as a multiple of the lowest measurable leak rate (1 ,

2 , 5 , 10 , 20 , 50 , 100 ).

Internal calibration You can deactivate internal calibration. If it is deactivated, only the more precise external

calibration can be made for the gas, see “6.4.2 Calibration”, page 37.

Internal calibration is precluded from the start if the mass position of a gas is outside the

range from 40 to 105 amu.

Mass and position With the selection of a gas from the gas library, a standard mass position is automatically

selected for gas to be measured. If the device could respond to other substances in the

working environment for the leak test, we recommend selecting another mass position for

the verification of the required gas. You can find a list of all possible gases with their

normal and alternative mass positions in the Appendix, see page 78.

36 6 Operation

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 37

Fig. 24: Selection of another mass position

Below the selected mass is the information whether it is the preferred mass or not. In

addition, the molecular mass of the gas as well as the height of the peak in relation to the

highest peak for this gas are displayed. The standard factor is a measure of the sensitivity

of the device for the gas at the set mass position.

Cal. factor The calibration factor is displayed in this line.

Last cal. Based on this line, you can check when the last calibration took place.

Cal. method The line shows whether calibration was external or internal.

6.4.2 Calibration

The Ecotec E3000 can be calibrated most conveniently by adding an ECO-Check calibrated

leak. The ECO-Check can be integrated in the front panel of the device or set up at the

testing position. It compensates temperature fluctuation and thus enables the accuracy

required for calibration.

The ECO-Check calibrated leak includes R134a. It can be used for the calibration of gases

with a mass position from 40 to 105 amu because the Ecotec E3000 converts the

calibration result for the measurement of these gases.

You get the most accurate calibration with the external calibrated leak. The calibrated

leaks are valid for one gas each and temperature-insensitive.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

When to calibrate? The device should be calibrated daily and after every operator change. Calibration is

additionally required after the following events:

Sniffer line replacement

Sniffer line probe replacement

Switch between gases (if you calibrate with an external calibrated leak)

Filter replacement

Prompt for calibration by the system

6Operation 37

Page 38

6.4.2.1 Internal calibration with ECO-Check

Incorrect calibration because of operating temperature that is too low

Calibrating the device in the cold state can deliver incorrect measurement results.

► The device must have been switched on for at least 60 minutes before calibration for

hydrogen measurement.

► The device must have been switched on for at least 20 minutes before calibration for

the measurement of all gases.

The ECO-Check must be installed; refer to installation manual of the ECO-Check.

Fig. 25: Built-in ECO-Check calibrated leak

If a gas measurement cannot be calibrated with the ECO-Check because the gas mass

position is outside of 40 to 105 amu, the message “Int. calibration impossible” is displayed

for this gas subsequent to calibration.

If a gas was blocked for internal calibration in the menu “Settings gas”, the message “Gas

deactivated” (see “Internal calibration”, page 36) is displayed.

The Ecotec E3000 notices if you insert the sniffer tip in the opening of the calibrated leak

and starts calibration automatically. Messages subsequently guide you through the

calibration process.

A warning is displayed if the device has not be switched on for 20 minutes yet. Simply

confirm the warning and then continue with calibration if you know that the device has

reached operating temperature because it was switched off only briefly before calibration.

Otherwise remove the sniffer probe again and start calibration later.

After measuring and a short calculation period, the results of calibration are shown in the

display. The old and the new calibration factor as well as the old and the new relative peak

position are displayed.

In order to prevent that an earlier external and thus more accurate calibration is

accidentally overwritten, you have press the key “Confirm new values” to complete the

calibration.

1 Switch to measurement view.

2 Insert the sniffer tip in the opening of the ECO-Check until you feed some resistance.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

38 6 Operation

Page 39

3 Press the right key on the sniffer handle as soon as the display shows the line

“Calibration: Press right key”.

4 Remove the sniffer tip from the reference leak if the display shows the line “Remove

sniffer from cal-opening”.

5 Confirm the new values with the key on the bottom right.

Check calibration (Test

function)

If you insert the sniffer tip in the opening of the ECO-Check during measurement

operation, an examination of the calibration is started automatically (test function). The

device checks the measured value of the ECO-Check while the sniffer probe is inside the

opening of the calibrated leak. The operator is subsequently prompted to remove the

sniffer tip from the opening of the calibrated leak.

For gases released for internal calibration, either “Test o.k.” or “Recalibration required!” will

appear. For gases not activated for internal calibration, “Gas deactivated” will be displayed.

For gases that cannot be calibrated with the ECO-Check because of very high or very low

mass positions, “Gas spec. test not possible” is shown.

Press the key “OK” or the right key on the handle to return to measurement operation.

6.4.2.2 External calibration with external calibrated leak

For external calibration of the Ecotec E3000, we recommend calibrated leaks with leak

rates > 2 g/a. If background concentrations in the testing environment are clearly

increased, a calibrated leak with a higher leak rate is required.

External calibration is a semi-automatic process. Text messages in the display guide you

through the calibration process. Calibration can be stopped at any time with the key

“Cancel”.

Incorrect calibration because of operating temperature that is too low

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Calibrating the device in the cold state can deliver incorrect measurement results.

► The device must have been switched on for at least 60 minutes before calibration for

hydrogen measurement.

► The device must have been switched on for at least 20 minutes before calibration for

the measurement of all gases.

A warning is displayed if the device has not be switched on for 20 minutes yet. Simply

confirm the warning and then continue with calibration if you know that the device has

reached operating temperature because it was switched off only briefly before calibration.

Otherwise start calibration again later.

The gas measurement to be calibrated is generally activated. If you want to calibrate a

deactivated measurement, activate the gas in the menu “Measuring parameters”.

After measuring and a short calculation period, the results of calibration are shown in the

display. The old and the new calibration factor as well as the old and the new relative peak

position are displayed.

1 Switch to measurement view.

2 Press the key “Cal”. The list of gases currently set for measurement is displayed (up to

four gases).

3 Select the gas that the measurement is to be calibrated for.

6Operation 39

Page 40

4 Check whether the gas and the displayed leak rate match the data of the calibrated

leak. If the leak rate does not match, select “Leak rate change” and correct the value.

5 Select “Start”.

6 Hold the sniffer tip into the center of calibrated leak opening and follow the

instructions in the display.

If you have to wait until the air signal has stabilized then this can take up to 30 seconds

with a helium or hydrogen calibration.

7 Confirm the new values with the key on the bottom right.

6.4.3 Gas equivalent to helium and hydrogen, settings for diluted gas

If you are looking for helium or hydrogen, you can have also have the determined leak rate

for the gas equivalent displayed, e.g. as R134a.

If you have an equivalent set, all displays will show the original gas followed by the

equivalent in brackets. Example: He (R134a)

Proceed as follows to set a gas equivalent:

1 Select helium or hydrogen from the gas library.

2 Select the line “Status” in the window “Settings gas …” and press “Change”.

3 Select “Equivalent name” in the window that opens. The gas library will be displayed

again.

4 Select the equivalent name and confirm with “OK”.

Fig. 26: Example for a measurement view with helium as refrigerant equivalent

You can also take a different pressure and/or different concentration between original gas

and gas equivalent into consideration.

An internal conversion of the measurement result thus allows the Ecotec E3000 to

approximate the result of a leak pre-check close to the result of a main leak examination.

Enter the settings for concentration and pressure in the window “Settings gas … >

Status > Change > Equivalent settings”.

40 6 Operation

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 41

Fig. 27: Setting the parameters for gas equivalent and diluted gas

In this window, you can enter the helium or hydrogen filling pressure. You can enter the

pressure for the equivalent gas next to that.

The bottom right shows the correction factor of helium/Hydrogen based on the gas

equivalent. If a set of parameters that exceeds the limits of the Ecotec E3000 is entered, the

correction factor is displayed with inverted colors. In this case, adjust the parameter until

the correction factor display returns to normal.

On the bottom left, you can enter the value for the gas concentration. If you are looking

for diluted helium or hydrogen, you can take the dilution into consideration in this setting.

The leak rate for the undiluted gas is then displayed as the measured value.

Select “OK” when all parameters are set correctly.

Please note: If you are working with diluted gas, you have to select the original gas as gas

equivalent, i.e. gas and gas equivalent are identical.

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Switching off the gas

equivalent function

To switch off the gas equivalent setting, select the last entry from the gas library (Settings

gas … > Status > Change > Equivalent name).

Fig. 28: The last entry switches off the gas equivalent function

6.4.4 Suppressing interfering gases (Sophisticated interfering gas suppression - IGS)

IGS causes the findings of the interfering gases cyclopentane, isopentane as well as any

mixture thereof to be suppressed during the search for refrigerant R600a. Up to an

interfering gas concentration of 50 g/a, the error is only 1 % at most.

If I GS is activ at ed, on ly on e a dditio na l gas c an be ent er ed i n t he lis t o f sampl e g ases. If more

than two gases are activated for R600a when IGS is activated, the additional gases (starting

with the highest gas number from 1 to 4) will automatically be deactivated so that there

are only two gases left.

6Operation 41

Page 42

If R600a is measured with IGS and R134a is set as second gas, select mass position 83 for

R134a because malfunctions between propellant and R134a will occur otherwise.

IGS requires little maintenance. If repeated false alarms occur during the sniffing with IGS,

calibration must be set to interfering gases, see below.

Activating IGS 1 Select R600a as the gas to be searched for: “Measuring parameters > Gas... > Gas >

Change > R600a > OK”.

2 Switch to mass setting in the window “Measuring param. gas …”.

3 Browse the available mass positions until “IGS” is displayed in the line for the preferred

mass.

4 Confirm with “OK”.

Fig. 29: Selection of the IGS mode for R600a

IGS alignment The previous, actual calibration is carried out with an external test leak as it is with other

gases. For the additional IGS alignment, you need a cyclopentane test leak and an

isopentane test leak, available as “Calibration set for IGS mode”.

The Ecotec E3000 recognizes errors you make in the gas sequence during the alignment

and notifies you with a flashing gas display.

1 Activate IGS, see above.

2 Select “Cal” in the measurement window.

3 Select the gas R600a in the window “Select gas”. The entry should be expanded with

IGS.

4 Select “IGS alignment” in the window “Start external calibration” and follow the

instructions on the display.

5 Confirm the calibration with “OK”.

6.4.5 Setting a user-defined gas

You can save the settings for six individual gases.

► In the main menu, select “Measuring parameters > Gas def.”, then one entry and

“Change”.

42 6 Operation

Translation of the original operating instructions Ecotec E3000, kina22en1- r, 1407

Page 43

Fig. 30: Settings for a user-defined gas

You can switch between settings with the arrow keys and open a settings window by

pressing the “change” key.

User library no. Shows the number of the gas definition to be edited currently.

Name You have to enter a name for the gas to be defined.