Page 1

IDEAL INDUSTRIES INC.

TECHNICAL MANUAL

MODEL 61-096 Split Jaw Smart Meter

The Service Information provides the following information :

• Precautions and safety information

• Specifications

• Basic maintenance (cleaning, replacing the battery and fuses)

• Performance test procedures

• Calibration and calibration adjustment procedures

Form Number: TM61096

Revision: 2. Date: Nov 2010

Form Number TM61096 Rev 2 Nov 2010

Page 2

TABLE OF CONTENTS Page

Introduction

1

Precautions and Safety Information

1

Symbols

1

Safety

2

Specifications

3

General Specification

3

Voltage Specification

4

Resistance & Continuity Specification

4

Current Specification

4

Physical and environment characteristics

5

Certification and compliance

5

Required Equipment

6

Basic Maintenance

7

Opening the Meter Case

7

Replacing the Battery

7

Performance Tests

8

Testing the Voltage Function

8

Testing the Resistance Function

9

Testing the AC Current Function

10

Calibration

11

Calibrating DCV, ACV, Resistance, ACA Functions

11

Calibration Adjustment Points

12/13

Form Number TM61096 Rev 2 Nov 2010

i

Page 3

Introduction

Risk of electric shock

See instruction card

DC measurement

Equipment protected by double or reinforced

insulation

Battery

Earth

AC measurement

Conforms to EU directives

Warning

To avoid shock or injury, do not perform the verification tests or calibration procedures

described in the manual unless you are qualified to do so.

The information provided in this document is for the use of qualified personnel only.

Caution

The 61-096 contain parts that can be damaged by static discharge.

Follow the standard practices for handling static sensitive devices.

For additional information about IDEAL INDUSTRIES, INC. and its products, and services, visit

IDEAL INDUSTRIES, INC. web site at:

www.idealindustries.com

Precautions and Safety Information

Use the Meter only as described in the Service Manual. If you do not do so, the protection provided by the

Meter may be impaired. Read the “Safety Information” page before servicing this product.

In this manual, a Warning identifies conditions and actions that pose hazard (s) to the user; a Caution

identifies conditions and actions that may damage the Meter or the test instruments.

The Symbols

The symbols used on the Meter and in this manual are explained in Table 1.

Table A. The Symbols

Form Number TM61096 Rev 2 Nov 2010

1

Page 4

SAFETY

Review the following safety precautions to avoid injury and prevent damage to this product or products

connected to it. To avoid potential hazards, use the product only as specified.

CAUTION: These statements identify conditions or practices that could result in damage to the

equipment or other property.

WARNING: These statements identify conditions or practices that could result in personal injury or

loss of life.

Specific precautions

Do not operate without covers. To avoid personal injury, do not apply any voltage or current to the

product without covers in place.

Electric overload. Never apply a voltage to a connector on the product that is outside the range

specified for that connector.

Avoid electric shock. To avoid injury or loss of life, do not connect or disconnect probes or test leads

while they are connected to a voltage source.

Do not operate in wet/damp conditions. To avoid electric shock, do not operate this product in wet or

damp conditions.

2

Form Number TM61096 Rev 2 Nov 2010

Page 5

SPECIFICATIONS

Characteristics

Description

Display count

6000

Numeric update rate

5 times / sec

Polarity display

Automatic

Overrange display

“OL” is display

Low voltage indicator

is indicated

Automatic power-off time

Automatic backslit off = 30 minutes

Power source

Power 9V battery

Maximum input voltage

1000V CAT III between V and COM

Maximum floating voltage

1000V CAT III between any terminal and earth ground

V connector

V , V , Ω,

Temperature Coefficient

0.2×(Spec. Accuracy) / °C, <18°C or >28°C

Battery Life

180 hours typical (alkaline)

All specifications are warranted unless noted typical and apply to the 61-096

Stated accuracies are at 23°C±5°C at less than 80% relative humidity and without the battery indicator

displayed.

General specifications

3

Form Number TM61096 Rev 2 Nov 2010

Page 6

Measurement Characteristics

Function

Range

Accuracy

V

1.3V ~ 750.0V

±(1.5% reading + 3 digits)

50Hz ~ 500Hz

V

1.8V ~ 1000V

±(1% reading + 2 digits)

-0.6V ~ -1000V

±(1% reading + 4 digits)

Function

Range

Accuracy

Ω

0.0Ω ~ 99.9Ω

±(2% reading + 1Ω)

100Ω ~ 2000Ω

±(2% reading + 2 digits)

Function

Range

Accuracy

A

0.6A ~ 200.0A

±(1.8% reading + 3 digits)*

50Hz ~ 60Hz

Accuracy is ±(% reading + number of digits) at 23°C ± 5°C, less than 80% R.H.

DC / AC Volts

Overload protection: 750Vrms // 1000VDC

Max. Operation time: DT=30s for ≥ 30V

Input Impedance: ≥ 4K for input voltage up to 30V. Impedance increase with input voltage to 330KΩ at

1000V.

Resistance & Continuity

Overload protection: 750Vrms // 1000VDC

Max. Open Voltage: 1.5V

Continuity check: Internal sounds activates if the resistance of the circuit under test is less than 25Ω.

It will then turn off if the resistance is increased beyond 400Ω.

Operating temperature: 0°C ~ 40°C

AC Current

Overload protection: 400A

* ±(1.8% reading + 6 digits) ≤ 50A

Form Number TM61096 Rev 2 Nov 2010

4

Page 7

Physical and Environmental Characteristics

Characteristics

Description

Dimensions (W×H×L)

84mm×188mm×41mm

Weight (with battery)

230g

Environmental characteristics

Description

Temperature operating

0 to +50°C

Non-Operating

-20 to +60°C

Humidity (operating)

<80% R.H.

Altitude Operating

2,000M (6560 ft.)

Non-Operating

12,300M (40354 ft.)

Vibration & shock Operating

MIL-T-28800E TYPE II Class 5

2.66gRMS, 5 to 500 Hz, 3axes

(10 minutes each)

Indoor Use

Indoor Use

Safety

IEC 61010 and designed to meet UL 3111 specifications

Input rating

V / Ω: Category III 1000 Volts

Over voltage category

CAT III: Distribution level mains, fixed installation.

CAT II: Local level mains, appliances, portable equipment

CAT I: Signal level, special equipment or parts of equipment,

telecommunication, electronics.

Pollution Degree 2

Do not operate in environments where conductive

Pollutants may be present.

EC Declaration

of Conformity

Meets the intent of Directive 89/336/EEC for Electromagnetic

Compatibility and Low Voltage Directive 73/23/EEC for specifica tions as listed in the official Journal of the European Communites:

En 55011 Class A: Radiated and Conducted

Emissions.

En 50082-1 Immunity: IEC 801-2 Electrostatic Discharge

IEC 801-3 RF Radiated

En 61010-1 Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Certifications and compliances

Form Number TM61096 Rev 2 Nov 2010

5

Page 8

Required Equipment

Equipment

Required Characteristics

Recommended Model

Calibrator

AC Voltage Range: 0 ~ 750V AC

Accuracy: ±0.07% (Basic)

Frequency Range: 40 ~ 1KHz

Accuracy: ±2%

DC Voltage Range: 0 ~ 1000V DC

Accuracy: ±0.006% (Basic)

Current Range: 0 ~ 10A

Accuracy: AC (40Hz to 1KHz): ±0.08% (Basic)

Resistance Range: 1Ω ~ 100MΩ

Accuracy: ±0.03% (Basic)

1. Fluke 5700A Calibrator

2. 50 Turns Coil

Required equipment is listed in Table B. If the recommended models are not available, equipment with

equivalent specifications may be used.

Repairs or servicing should be performed only by qualified personnel.

Table B. Required Equipment

Form Number TM61096 Rev 2 Nov 2010

6

Page 9

Basic Maintenance

Warning

To avoid shock, remove the test leads and any input signals before opening the case or replacing the

battery.

Opening the Meter Case

Caution

To avoid unintentional shock circuit, always place the uncovered Meter assembly on a protective

surface. When the case of the Meter is open, circuit connections are exposed.

To open the Meter case, and do the following:

1. Disconnect test leads from any live source, push the button to OFF, and remove the test leads from

the front terminals.

2. Remove the battery door by using a flat-blade screwdriver to turn the battery door screws turn

counter-clockwise.

3. The case bottom is secured to the case top by two screws. Using a Phillips-had screwdriver, remove

the two screws.

Replacing the Battery

The Meter powered by 9V battery for 61-096

To replace the battery refer to Figure.

Form Number TM61096 Rev 2 Nov 2010

7

Page 10

Performance Tests

Step

Input

Frequency

Reading

1

3.0V

50Hz

2.7 to 3.3

2

3.0V

500Hz

2.7 to 3.3

3

30.0V

50Hz

29.3 to 30.8

4

30.0V

500Hz

29.3 to 30.8

5

300.0V

50Hz

295.2 to 304.8

6

300.0V

500Hz

295.2 to 304.8

7

600.0V

50Hz

590.7 to 609.3

8

600.0V

500Hz

590.7 to 609.3

The following performance tests verify the complete operability of the Meter and check the accuracy of

each Meter function against the Meter’s specifications.

Accuracy specifications are valid for a period of one year after calibration, when measured at an

operating temperature of 18°C to 28°C and a maximum of 80% relative humidity.

To perform the following tests, it is not necessary to open the case, no Adjustments are necessary,

merely make the required connections, apply the designated inputs, determine if the reading on the

Meter display falls within the acceptable range indicated.

If the Meter fails any of these tests, it needs calibration adjustment or repair.

Testing the voltage Function

To verify accuracy in the AC and DC voltage ranges, do the following:

1. Push the button to start your meter.

2. Connect the Calibrator to the VΩ and COM inputs on the Meter.

3. Set the Calibrator for the voltage and frequency from step 1 to 8 in Table 1.

4. Compare the reading on the Meter display with the display reading shown in Table 1.

5. If the display reading falls outside of the range shown in Table 1, the Meter does not meet

specification.

Table 1 AC Voltage Test:

8

Form Number TM61096 Rev 2 Nov 2010

Page 11

6. Set the calibration for the voltage from step 1 to 8 in Table 2.

Step

Input

Reading

1

3.0V

2.8 to 3.2

2

-3.0V

-2.6 to -3.4

3

30.0V

29.5 to 30.5

4

-30.0V

-29.3 to -30.7

5

600.0V

593.8 to 606.2

6

-600.0V

-593.6 to -606.4

7

900.0V

890.8 to 909.2

8

-900.0V

-890.6 to -909.4

Step

Source

Reading

1

50.0Ω

48.9 to 51.1

2

500Ω

488 to 512

3

800Ω

782 to 818

4

1200Ω

1174 to 1226

5

1500Ω

1468 to 1532

6

2000Ω

1958 to 2042

7. Compare the reading on the Meter display with the display reading shown in Table 2.

8. If the display reading falls outside of the range shown in Table 2, the meter does not meet

specification.

Table 2 DC Voltage Test:

Testing the Resistance Function

To verify the accuracy of the resistance function, do the following:

1. Connect the calibrator to VΩ and COM on the Meter.

2. Push the button to start your Meter.

3. Apply the inputs for step 1-6 in Table 3.

4. Compare the Meter display readings to the display readings in Table 3.

5. If the display reading falls outside of the range shown in Table 3, the Meter does not meet

specification.

Table 3 Resistance Test:

Continuity check: Internal sounds activates if the resistance of the circuit under test is less the 25Ω. It

will then turn off if the resistance is increased beyond 400Ω

9

Form Number TM61096 Rev 2 Nov 2010

Page 12

Testing the AC Current Function

Step

Source

Frequency

Reading

1

100A

50Hz

97.9 to 102.1

2

100A

60Hz

97.9 to 102.1

3

200A

50Hz

196.1 to 203.9

4

200A

60Hz

196.1 to 203.9

To verify the accuracy of AC current measurement functions, do the following:

1. Open jaw of the meter around the suitable wire or conductor.

2. Push the button to start your meter.

3. Apply the inputs for steps 1-4 in Table 4.

4. For each input, compare the readings on the Meter display to the reading in Table 4.

5. If the display reading falls outside of the range shown in the Table 4, the meter does not meet

specification.

Table 4 AC Current Test:

10

Form Number TM61096 Rev 2 Nov 2010

Page 13

CALIBRATION PROCEDURE

Recalibrate your meter:

It is recommended that the meter may be calibrated once year. Use the following procedure to calibrate the

clamp meter.

1. Perform calibration at an ambient temperature and relative humidity (23°C±2°C and R.H.≤80%). Allow

instrument to sit at this temperature for at least thirty minutes.

2. Disconnect the test leads from any circuit under test and turn off meter.

3. Loosen the screws from the battery cover, remove battery cover and pull the battery out of battery box

with battery still connected.

4. Loosen the two screws from the bottom case.

5. Lift the bottom case.

(A) DCV Calibration (Adjust VR15)

1. Press Hold button of the meter to power on.

2. Set the output of calibrator for DCV 100V and connect to V and COM test probes.

3. Using a small flat-tip screwdriver adjust the potentiometer VR15 until display reads 100.1V~100.2V.

4. Disconnect the output terminals of DCV calibrator.

(B) Resistance Calibration (Adjust VR13 & VR14)

1. Set the output of calibrator for resistance 1KΩ and connect to V and COM test probes.

2. Using a small flat-tip screwdriver adjust the potentiometer VR13 until display reads 1005Ω~1006Ω.

3. Set the output of calibrator for resistance 100Ω and connect to V and COM test probes.

4. Using a small flat-tip screwdriver adjust the potentiometer VR14 until buzzer sounds and check 400Ω

buzzer don’t sounds.

5. Disconnect the output terminals of resistance calibrator.

(C) ACV Calibration (Adjust VR16& VR1)

1. Set the output of ACV calibrator for ACV 70V 60Hz and connect to V and COM test probes.

2. Using a small flat-tip screwdriver adjusts the potentiometer VR16 until display reads 70.0V±1d.

3. Set the output of ACV calibrator for ACV 200V 60Hz and connect to V and COM test probes.

4. Using a small flat-tip screwdriver adjusts the potentiometer VR1 until display reads 199.8V±1d.

5. Disconnect the ACV calibrator from the meter.

(D) ACA Calibration (Adjust VR17 & VR12)

1. Flow the current of ACA 100.0A 60Hz around the suitable wire or conductor.

2. Using a small flat-tip screwdriver adjusts the potentiometer VR17 until display reads 99.8A.

3. Flow the current of ACA 300.0A 60Hz around the suitable wire or conductor.

4. Position the clamp around the wire or conductor, release clamp trigger to make sure that the clamp is

entirely closed.

5. Using a small flat-tip screwdriver adjusts the potentiometer VR12 until display reads 300.0A.

6. Remove the meter away from the wire or conductor.

11

Form Number TM61096 Rev 2 Nov 2010

Page 14

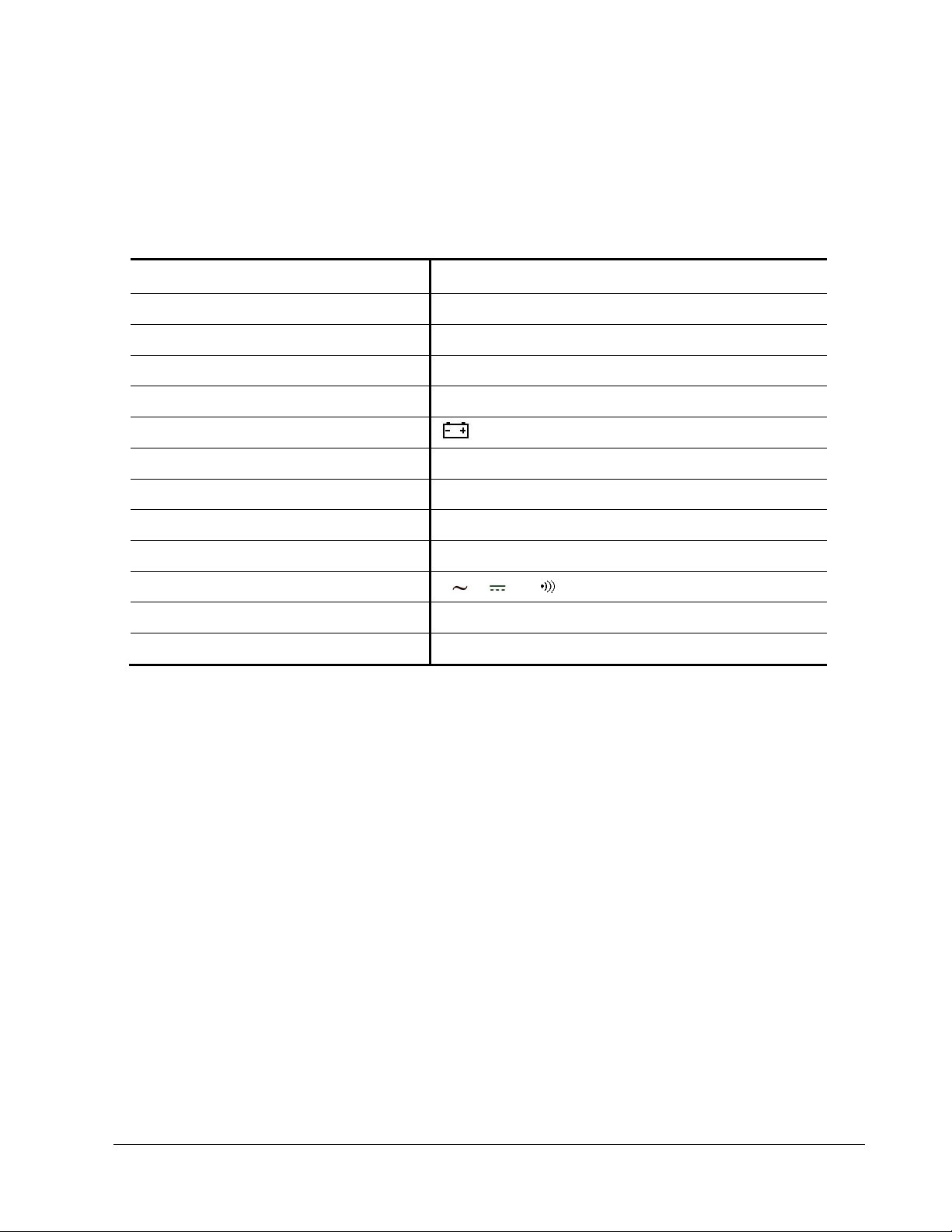

VR13

VR12

VR15

VR17

VR16

VR14

Figure 1 61-096

Calibration

Adjustment Points

12

Form Number TM61096 Rev 2 Nov 2010

Page 15

VR1

Figure 2 61-096 Calibration Adjustment Points

13

Form Number TM61096 Rev 2 Nov 2010

Loading...

Loading...