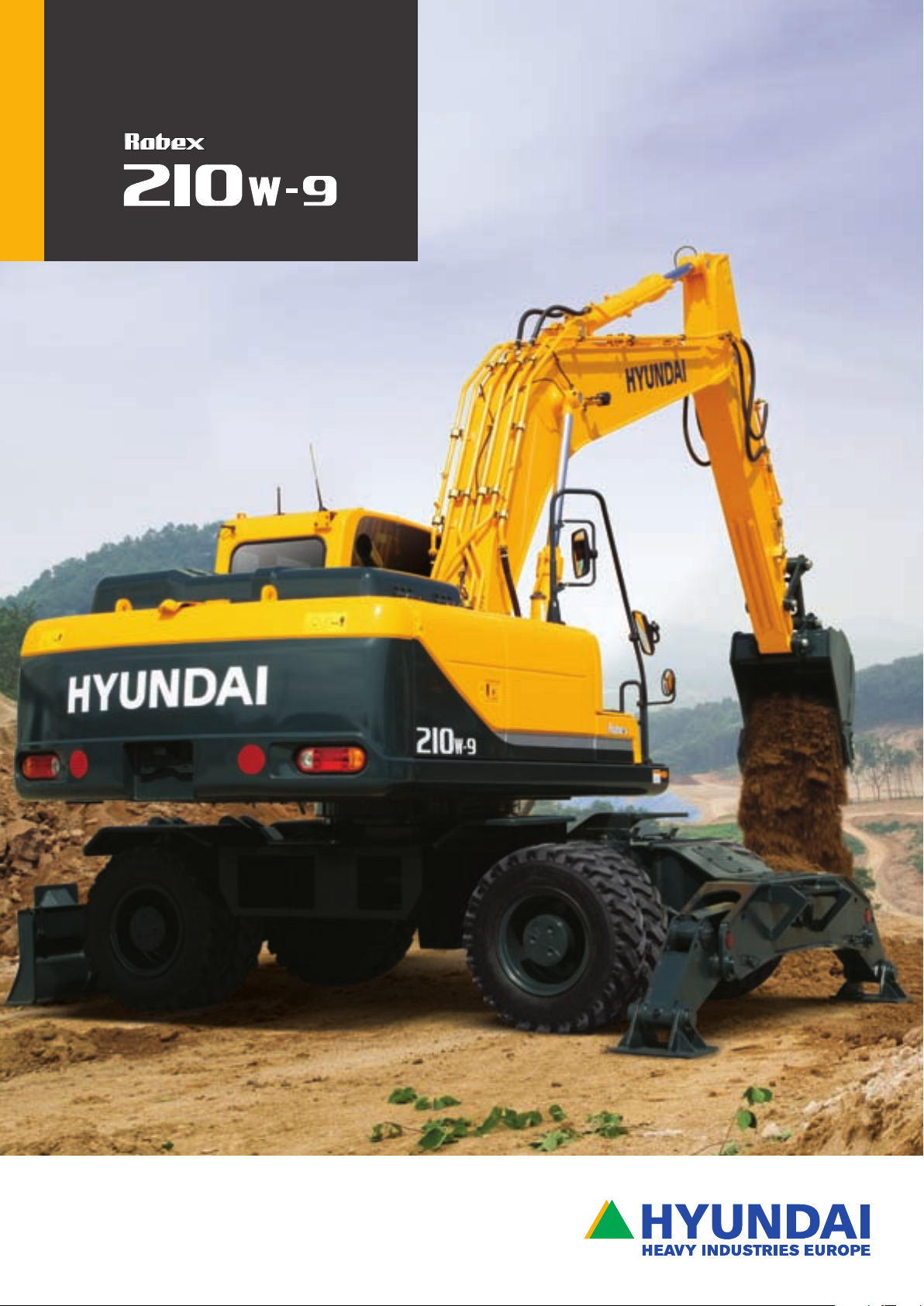

We build a better future

Equipped with Tier 3 Engine

*Photo may include optional equipment.

Pleasure works

An operator, who takes pleasure in his work, does a better job. That is why

we at Hyundai Heavy Industries do everything we can to make that happen.

We merged operator preference, fast precision and lasting performance into

a quality product. Hyundai 9 series earthmoving equipment simply makes time

fly, makes pleasure work!

*Photo may include optional equipment.

Machine Walk-Around

General performance

Heavy duty frame with two speed powershift transmission.

Heavy duty drive line and axles.

Front axle oscillation +/- 7 degrees with automatic ram lock.

Wet disc brakes in wheel hubs (front & rear).

Automatic parking brake - spring applied, hydraulically released.

Engine Technology

Powerfull and reliable, fuel efficient Cummins Tier III QSB6.7 engine.

Electronical controlled, clean and efficient combustion.

Low noise / Auto engine overheat prevention / Anti-restart function.

Hydraulic System Improvements

New patented hydraulic system for maximum controllability / Improved main control valve for higher efficiency

and smoother operation / Auto boom vs. swing priority for maximum speed / Auto power boost for extra power

/ Improved arm & boom regeneration for higher speed and better efficiency.

Pump Compartment

Powerful and reliable axial piston pumps, designed by Kawasaki.

Compact solenoid block to control: 2 speed travel, power boost, boom priority, safety lock, arm-in regeneration

control and swing logic valve control.

Well accessible fuel, engine oil and case drain filters.

New Design Steering Column

Slim steering column with adjustments for your operators’ preference (telescopic 60 mm, tilting 30°).

Enhanced Operators’ Cabin

Improved visibility

Enlarged cab with improved visibility / See-through sunroof for visibility and ventilation.

Large right-side window, for better visibility on foot of boom.

All windows consist of safety glass.

Roll-up type sun visor for operators’ convenience / Reduced front window seam for improved operator view.

Rigid Cabin Construction

New steel tube construction for increased operator safety, higher protection and better durability.

New front window mechanism designed with spring assist.

Improved Seat & Console

Ergonomic joysticks equipped with auxiliary buttons for attachment use.

Standard mechanic suspension with heater or optional air suspension.

New joystick consoles - adjustable in height.

Adjustable arm rests - for optimum comfort.

Advanced 7” Color Cluster

New color LCD-display with digital gauges for hydraulic oil temperature, coolant temperature and fuel level.

Toggle switch makes it easier to tune your machine and to check diagnostics. A new developed rear-view camera

is integrated into the cluster.

3 power modes : Power / Standard / Economy, 3 work modes : Digging / Breaker / Crusher, User mode for saving

operators’ preferences.

Enhanced self-diagnostic features with remote access through the Hi-Mate system.

One pump flow or two pump flow summation for optional attachment, selectable through the cluster /

Anti-theft system with password entry.

Boom speed and arm regeneration can be adjusted through the cluster.

Auto power boost in Power-mode - activated through the cluster.

Air conditioning and heater with automatic climate control.

Hi-Mate (Remote Management System) enables machine owners to follow-up machine performance, to verify

machine location and to access diagnostic information on a distance through any internet connection.

Preference

An operator, who sets his machine to his needs, takes pleasure in his work.

9 Series respects operator preference with regards to comfort, ease-of-use and

controllability. The dashboard cluster with 7 inch screen and toggle switch is the

preference nerve centre.

*Photo may include optional equipment.

Spacious Cabin with Excellent Visibility

The spacious cabin is ergonomically designed with low noise levels and high visibility. Special

attention was paid to create a clear, open and convenient interior with excellent visibility in all

directions. This well balanced operators’ environment put the operator in the perfect position

to work safely and securely.

Operator Comfort

be adjusted together and independent from each other. Improved telescopic and tilt

functions of the steering wheel provides operators better access and higher comfort.

A fully automatic, high capacity air conditioning system

maintains a constant temperature.

In a 9 series cabin you can adjust the seat, console

and armrests to suit your preferred comfort

level. Seat and console position and height can

Stressless

Work is stressful enough; your working environment should be stressless. Hyundai’s 9 series provides improved cabin

interior, additional space and a comfortable seat to minimize the stress of the operator. A powerful climate control

system provides the operator with his preferred air temperature. An advanced audio system with CD player, AM/FM

stereo and MP3 capabilities, plus remote controls is installed to listen to your preferred music favorites. Operators

can even call while operating with the hands-free mobile phone feature.

Easy to Use Cluster

The advanced cluster with 7 inch wide color LCD screen and toggle switch allows the

operator to select his personal machine preferences. Power and work mode selection, self

diagnostics, optional rear-view camera, maintenance check lists, start-up machine security

and video functions are integrated into the cluster to make the machine more versatile

and the operator more productive.

Precision

An operator, who feels his machine respond smoothly, takes pleasure in

his work. 9 Series delivers fast precision by combining smoother hydraulics

with wider view and less stress. The innovative Posi-Nega hydraulic system

combines straightforward technology with superior response.

*Photo may include optional equipment.

Computer Aided Power

The advanced CAPO (Computer Aided Power Optimization) system tunes engine and pump power to

optimum levels. Multiple mode selections are implemented for specifi c applications, maintaining high

performance while reducing fuel consumption.

Additional features include auto deceleration and power boost.

The LCD-display monitors engine speed, coolant and hydraulic oil temperature and through the selfdiagnostic capability, it displays current error codes. Operators can set their own preferences for boom or

swing priority, power mode selection and optional work tools at the touch of a button.

Power Mode

Work Mode

User Mode

Three unique power modes provide the operator with custom engine power,

attachment speed and fuel economy.

Power-mode maximizes machine speed and power for maximum productivity.

Standard-mode provides a reduced, fi xed rpm for optimum performance

and improved fuel economy.

Economy-mode provides precise fl ow and engine power based on load

conditions, for maximum fuel effi ciency and controllability.

Through the different work modes, the operator can select general

digging, single-acting attachments like a hydraulic breaker or double-acting

attachments like a crusher. Flow settings can be preset in the cluster.

Some jobs require more precise machine settings; some operators prefer

different machine settings. Using the User-mode, the operator can customize

engine speed, pump output, idle speed and other machine settings according

to personal preferences.

Hydraulic System Improvements

Auto Boom vs. Swing Priority

This smart function adapts the ideal hydraulic fl ow balance

for the boom and swing operation for your application. The

advanced CAPO system monitors the hydraulic operations and

adjusts the balance to maximize performance and productivity.

To achieve optimum precision, Hyundai

redesigned the hydraulic system to provide the

operator with super fi ne touch and top level

controllability. Spool valves in the control valve

are engineered to provide more precise fl ow to

each function with less effort.

Improved hydraulic valves, variable volume piston

pumps, fi ne-touch pilot controls and enhanced

travel functions make any operator look like

a smooth operator. Newly improved features

include arm and boom regeneration, enhanced

control valve technology and innovative auto

boom and swing priority for best performances

in any application.

Performance

An operator, who can rely on his machine, takes pleasure in his work.

9 Series stands for lasting performance in strength, speed and reliability.

The Auto boom-swing priority results into faster movements and

shorter cycle times.

*Photo may include optional equipment.

Structural Strength

The 9 series cabin structure is designed with slimmer but

stronger tubing for more safety and better visibility. Lowstress and high-strength steel is welded to form a strong

and stable lower frame. Structural durability is analyzed

and tested by FEM-analysis (Finite Elements Method) and

long-term durability tests.

Independent Outriggers

The R210W-9 can be equipped with four independent outriggers

or two independent outriggers and a dozer blade. Each outrigger

or dozer blade is controlled by a switch and the dozer lever.

Outriggers and dozer blades are equipped with cylinder guards for

additional protection.

Travel System

Cruise control system facilitates driving longer distances at a fi xed

speed. An auto ram lock system can be activated to improve

stability and operating safety.

A creep speed travel system improves maneuverability and fi ne

control. An optional forward / reverse travel pedal allows the

operator to change travel direction in work mode without releasing

the joysticks.

Cruise control system Auto ram lock system Creep speed travel system

CUMMINS QSB 6.7 Engine

With 6-cylinders, turbo charger and intercooler, the

Cummins QSB6.7 diesel engine is built for power,

economy and reliability. This engine meets TIER 3 / EU

stage IIIa emission regulations.

Profi tability

An owner, who knows his machine saves money, takes pleasure in owning it.

9 Series excavators contribute to your business as a time, fuel, spare-part and

cost saving earthmoving solution. The Remote Management System allows

machine owners to track, monitor and manage at a distance.

*Photo may include optional equipment.

Hi-mate (Remote Management System)

Hi-mate, Hyundai’s newly developed remote management

system, using GPS-satellite technology, provides our

customers with the highest level of service and product

support. Hi-mate enables machine owners to follow-up

machine performance, to verify machine location and to

access diagnostic information on a distance through any

internet connection.

Fuel Economy

9 series excavators are developed to do more work with less fuel.

Implemented innovations like the variable speed fan clutch, overload

prevention control, three-stage auto decel system and the new

economy mode, are helping to save fuel and reduce the impact on

the environment.

hour

5,000

4,000

3,000

2,000

1,000

200

2,000 hour

1,000 hour

250 hour

7A Model 9 Model

Filter Hydraulic Oil

7A Model 9 Model

5,000 hour

Easy Access

Access from ground to fi lters, lube fi ttings, fuses, drains and machine

computer components, combined with wide open compartments

makes servicing the 9-series a pleasure for your mechanics.

Extended Life Components

New long-life bushings are designed for extended lube intervals

(250 hrs). Wear-resistant polymer shims reduce noise and reduce wear

of bushings. Extended-life hydraulic fi lters last up to 1,000 hrs and

new long-life hydraulic oil need only be changed every 5,000 hrs.

2,000 (6’ 7”)

975 (2,150)

130.4 [141.6]

13,300 [14,440]

29,320 [31,830]

149.1 [161.8]

15,200 [16,500]

33,510 [36,380]

144.2 [156.5]

14,700 [15,960]

32,410 [35,190]

151.0 [164.0]

15,400 [16,720]

33,950 [36,860]

130.4 [141.6]

13,300 [14,440]

29,320 [31,830]

149.1 [161.8]

15,200 [16,500]

33,510 [36,380]

119.6 [129.9]

12,200 [13,250]

26,900 [29,210]

125.5 [136.3]

12,800 [13,900]

28,220 [30,640]

130.4 [141.6]

13,300 [14,440]

29,320 [31,830]

149.1 [161.8]

15,200 [16,500]

33,510 [36,380]

102.0 [110.7]

10,400 [11,290]

22,930 [24,900]

106.9 [116.1]

10,900 [11,830]

24,030 [26,090]

2,400 (7’ 10”)

1,045 (2,300)

5,650 (18’ 6”)

1,790 (3,950)

2,920 (9’ 7”)

1,095 (2,410)

SAE

kN

kgf

lbf

ISO

kN

kgf

lbf

SAE

kN

kgf

lbf

ISOkNkgf

lbf

0.51 (0.67)

0.80 (1.05)

0.87 (1.14)

0.92 (1.20)

1.10 (1.44)

1.20 (1.57)

1.34 (1.75)

0.74 (0.97)

0.90 (1.18)

1.05 (1.37)

0.87 (1.14)

0.75 (0.98)

0.45 (0.59)

0.70 (0.92)

0.75 (0.98)

0.80 (1.05)

0.96 (1.26)

1.00 (1.31)

1.15 (1.50)

0.65 (0.85)

0.80 (1.05)

0.92 (1.20)

0.75 (0.98)

0.65 (0.85)

700 (27.6)

1,000 (39.4)

1,090 (42.9)

1,150 (45.3)

1,320 (52.0)

1,400 (55.1)

1,550 (61.0)

985 (38.8)

1,070 (42.1)

1,290 (50.8)

1,140 (44.9)

1,790 (70.5)

820 (32.3)

1,120 (44.1)

1,210 (47.6)

1,270 (50.0)

1,440 (56.7)

1,520 (59.8)

1,670 (65.7)

-

-

-

-

-

570 (1,260)

700 (1,540)

740 (1,630)

770 (1,700)

830 (1,830)

850 (1,870)

920 (2,030)

770 (1,700)

810 (1,790)

890 (1,960)

900 (1,980)

880 (1,940)

0.51 (0.67)

0.80 (1.05)

0.92 (1.20)

1.10 (1.44)

1.20 (1.57)

1.34 (1.75)

0.74 (0.97)

0.87 (1.14)

0.75 (0.98)

Specifications

ENGINE

MODEL CUMMINS QSB 6.7

Watercooled, 4 cycle Diesel,

Type

J1995 (gross) 176 HP (131 kW) at 1,900 rpm

Rated

flywheel

horse power

Max. torque 81.4 kgf.m (589 lbf.ft) at 1,400 rpm

Bore x stroke 107 x 124 mm (4.2” x 4.9”)

Piston displacement 6,700 cc (409 in

Batteries 2 x 12 V x 100 AH

Starting motor 24V - 4.5kW

Alternator 24V - 70Amp

SAE

J1349 (net) 165 HP (123 kW) at 1,900 rpm

6271/1 (gross) 178 PS (131 kW) at 1,900 rpm

DIN

6271/1 (net) 167 PS (123 kW) at 1,900 rpm

6-cylinders in line, direct injection

Turbocharged, intercooler,

low emission

3

)

AXLES & WHEELS

Full floating front axle is supported by center pin for ocillation. It can be locked by

oscillation lock cylinders. Rear axle is fixed on the lower chassis.

SWING SYSTEM

STEERING SYSTEM

Hydraulically actuated, orbitrol type steering system actuates on front

wheels through the steering cylinders.

HYDRAULIC SYSTEM

MAIN PUMP

Type Two variable displacement piston pumps

Max. flow 2 X 222 L /min (58.6 US gpm / 48.8 UK gpm)

Pilot pump Gear pump

Cross-sensing and fuel saving pump system

HYDRAULIC MOTORS

Travel

Swing Axial piston motor with automatic brake

Two speed axial piston motor

with brake valve and parking brake

RELIEF VALVE SETTING

Implement circuits 350 kgf/cm2 (4,980 psi)

Travel 380 kgf/cm

Power boost (boom, arm, bucket) 380 kgf/cm

Swing circuit 265 kgf/cm

Pilot circuit 40 kgf/cm

Service valve Installed

2

(5,400 psi)

2

(5,400 psi)

2

(3,770 psi)

2

(570 psi)

HYDRAULIC CYLINDERS

Boom : 2-120 x 1,290 mm (4.7” x 50.8”)

No. of cylinderbore x stroke

Arm : 1-140 x 1,510 mm (5.5” x 59.4”)

Bucket : 1-125 x 1,055 mm (4.9” x 41.5”)

Blade : 2-120 x 226 mm (4.7” x 8.9”)

Outrigger : 2-130 x 427 mm (5.1” x 16.8”)

DRIVES & BRAKES

4-wheel hydrostatic drive. Constant mesh, helical gear transmission provides 2 forward

and reverse travel speeds.

Max. drawbar pull 11,100 kgf (24,470 lbf)

Travel speed

Gradeability 31.5° (61 %)

Parking brake : Independent dual brake, front and rear axle full hydraulic power brake.

- Spring released and hydraulic applied wet type multiple disk brake.

- Transmission is automatically locked at neutral position for parking.

1st 8.5 km/h (5.3 mph)

2nd 35 km/h (21.7 mph)

COOLANT & LUBRICANT CAPACITY

UNDERCARRIAGE

Reinforced box-section frame is all-welded, low-stress.

Dozer blade and outriggers are available. A bolt-on design.

OPERATING WEIGHT (APPROXIMATE)

Operating weight, including 5.65 m (18’ 6”) boom, 2.92 m (9’ 7”) arm, SAE heaped

0.80 m

the standard equipment.

Tires 10.00 - 20-16PR, Dual (tube type)

(optional) 10.00 - 20, Dual (solid type)

Swing motor Axial piston motor

Swing reduction Planetary gear reduction

Swing circuit lubrication Grease-bathed

Swing brake Multi wet disc (pin lock type)

Swing speed 10.3 rpm

Min. turning radius 6,690 mm (21’ 11”)

Re-filling liter US gal UK gal

Fuel tank 310.0 81.9 68.2

Engine coolant 35.0 9.2 7.7

Engine oil 24 6.3 5.3

Swing device - gear oil 5 1.3 1.1

Axle

Hydraulic system (including tank) 340.0 89.8 74.8

Hydraulic tank 165.0 43.6 36.3

Dozer blade

Outrigger

3

(front) 14.6 3.9 3.2

(rear) 18.1 4.8 4.0

A very useful addition for leveling and

back filling or clean-up work.

Indicated for max. operation stabillity

when digging and lifting. Can be mounted

on the front or the rear.

(1.05 yd3) backhoe bucket, lubricant, coolant, full fuel tank, hydraulic tank and

MAJOR COMPONENT WEIGHT

Upperstructure 8,950 kg (19,730 lb)

Counterweight 3,400 kg (7,500 lb)

Mono boom (with arm cylinder) 1,790 kg (3,950 lb)

OPERATING WEIGHT

Front outriggers and rear blade 20,500 kg (45,200 lb)

Front and rear outriggers 20,600 kg (45,400 lb)

Front blade and rear outriggers 20,900 kg (46,100 lb)

CONTROL

Pilot pressure operated joysticks and pedals with provide almost effortless and

fatigueless operation.

Pilot control

Engine throttle Electric, Dial type

Lights

Two joysticks with one safety lever

(LH): Swing and arm, (RH): Boom and bucket (ISO)

Two lights mounted on the boom, one under the

battery box and one under the cabin.

2,000 (6’ 7”)

975 (2,150)

130.4 [141.6]

13,300 [14,440]

29,320 [31,830]

149.1 [161.8]

15,200 [16,500]

33,510 [36,380]

144.2 [156.5]

14,700 [15,960]

32,410 [35,190]

151.0 [164.0]

15,400 [16,720]

33,950 [36,860]

130.4 [141.6]

13,300 [14,440]

29,320 [31,830]

149.1 [161.8]

15,200 [16,500]

33,510 [36,380]

119.6 [129.9]

12,200 [13,250]

26,900 [29,210]

125.5 [136.3]

12,800 [13,900]

28,220 [30,640]

130.4 [141.6]

13,300 [14,440]

29,320 [31,830]

149.1 [161.8]

15,200 [16,500]

33,510 [36,380]

102.0 [110.7]

10,400 [11,290]

22,930 [24,900]

106.9 [116.1]

10,900 [11,830]

24,030 [26,090]

2,400 (7’ 10”)

1,045 (2,300)

5,650 (18’ 6”)

1,790 (3,950)

2,920 (9’ 7”)

1,095 (2,410)

SAE

kN

kgf

lbf

ISO

kN

kgf

lbf

SAE

kN

kgf

lbf

ISOkNkgf

lbf

0.51 (0.67)

0.80 (1.05)

0.87 (1.14)

0.92 (1.20)

1.10 (1.44)

1.20 (1.57)

1.34 (1.75)

0.74 (0.97)

0.90 (1.18)

1.05 (1.37)

0.87 (1.14)

0.75 (0.98)

0.45 (0.59)

0.70 (0.92)

0.75 (0.98)

0.80 (1.05)

0.96 (1.26)

1.00 (1.31)

1.15 (1.50)

0.65 (0.85)

0.80 (1.05)

0.92 (1.20)

0.75 (0.98)

0.65 (0.85)

700 (27.6)

1,000 (39.4)

1,090 (42.9)

1,150 (45.3)

1,320 (52.0)

1,400 (55.1)

1,550 (61.0)

985 (38.8)

1,070 (42.1)

1,290 (50.8)

1,140 (44.9)

1,790 (70.5)

820 (32.3)

1,120 (44.1)

1,210 (47.6)

1,270 (50.0)

1,440 (56.7)

1,520 (59.8)

1,670 (65.7)

-

-

-

-

-

570 (1,260)

700 (1,540)

740 (1,630)

770 (1,700)

830 (1,830)

850 (1,870)

920 (2,030)

770 (1,700)

810 (1,790)

890 (1,960)

900 (1,980)

880 (1,940)

0.51 (0.67)

0.80 (1.05)

0.92 (1.20)

1.10 (1.44)

1.20 (1.57)

1.34 (1.75)

0.74 (0.97)

0.87 (1.14)

0.75 (0.98)

BUCKETS

All buckets are welded with high-strength steel

SAE heaped m

SAE heaped CECE heaped

Heavy-duty bucket

Slope finishing bucket

Heavy duty Rock-bucket

3

(yd3)

Capacity m3 (yd3)

Width mm (in)

Without

side cutters

With

side cutters

Weight

kg (lb)

Recommendation m (ft.in)

5.65 (18’ 6”) Boom

2.0 (6’ 7”) Arm 2.92 (9’ 7”) Arm2.4 (7’ 10”) Arm

Applicable for materials with density of 2,000 kg/m

Applicable for materials with density of 1,600 kg/m

Applicable for materials with density of 1,100 kg/m

3

(3,370 lb/yd3) or less

3

(2,700 lb/yd3) or less

3

(1,850 lb/yd3) or less

ATTACHMENT

Booms and arms are welded with a low-stress, full-box section design. 5.65 m (18’ 6”) boom and 2.0 m (6’ 7”); 2.4 m (7’ 10”) & 2.92 m (9’ 7”) arms are available.

DIGGING FORCE

Boom

Arm

Bucket

digging

force

Arm

crowd

force

Note: Boom weight includes arm cylinder, piping, and pin

Arm weight includes bucket cylinder, linkage, and pin

Length mm (ft.in)

Weight kg (lb)

Length mm (ft.in)

Weight kg (lb)

Remarks

[ ]:

Power

Boost

A

A’

B

B’

C

DEF

2,000

(6’ 7”)

2,400

(7’ 10”)

2,920

(9’ 7”)

9,110

(29’ 11”)

9,480

(31’ 1”)

9,960

(32’ 8”)

8,870

(29’ 1”)

9,260

(30’ 5”)

9,750

(32’ 0”)

5,480

(18’ 0”)

5,880

(19’ 3”)

6,380

(20’ 11”)

5,240

(17’ 2”)

5,670

(18’ 7”)

6,210

(20’ 4”)

4,970

(16’ 4”)

5,440

(17’ 10”)

5,990

(19’ 8”)

9,500

(31’ 2”)

9,730

(31’ 11”)

10,000

(32’ 10”)

6,670

(21’ 11”)

6,900

(22’ 8”)

7,160

(23’ 6”)

3,700

(12’ 2”)

3,620

(11’ 11”)

3,580

(11’ 9”)

5,650 (18’ 6”)

D

E

B

C

B'

A

A'

F

8ft

Q

P

A

J

I

C

F

G

D, D’

B

K

L

H

M

E

O

N

2,800 (9’ 2”)

1,874 (6’ 2”)

1,305 (4’ 3”)

2,800 (9’ 2”)

2,765 (9’ 1”)

2,530 (8’ 4”)

3,180 (10’ 5”)

345 (1’ 2”)

2,490 (8’ 2”)

445 (1’ 6”)

125 (4.9”)

610 (2’ 0”)

2,490 (8’ 2”)

1,220 (4’ 0”)

120 (4.7”)

3,770 (12’ 4”)

2,000 (6’ 7”)

9,680 (31’ 9”)

3,350 (10’ 12”)

9,630 (31’ 7”)

3,530 (11’ 7”)

2,400 (7’ 10”)

9,570 (31’ 5”)

3,240 (10’ 8”)

9,550 (31’ 4”)

3,460 (11’ 4”)

5,650 (18’ 6”)

2,920 (9’ 7”)

9,500 (31’ 2”)

3,150 (10’ 4”)

9,520 (31’ 3”)

3,440 (11’ 3”)

A

BCD

D’

E

F

G

H

I

J

K

L

MNO

P

Q

Dimensions & Working Ranges

DIMENSIONS R210W-9

Wheel base

Tread

Ground clearance of counterweight

Tail swing radius

Rear-end length

Overall width of upperstructure

Overall height of cap

Min. ground clearance

Overall width of lower structure

Ground clearance of blade up

Depth of blade down

Height of blade

Width of blade

Ground clearance of outrigger up

Depth of outrigger down

Overall width of outrigger

Boom length

Arm length

Shipping length of boom

Shipping height of boom

Traveling length of boom

Traveling height of boom

mm (ft . in)

WORKING RANGES R210W-9

mm (ft . in)

Boom length

Arm length

Max. digging

reach

Max. digging

reach on ground

Max. digging

depth

Max. digging

depth (8’ level)

Max. vertical wall

digging depth

Max. digging

height

Max. dumping

height

Min. swing radius

Lifting Capacities

R210W-9

Boom : 5.65 m (18’ 6”) / Arm : 2.40 m (7’ 10”) / Bucket : 0.80 m3 (1.05 yd3) SAE heaped / Front outrigger and rear dozer blade down and 3,400 kg (7,500 lb) counterweight

Load point

height

m (ft)

7.5 m

(25 ft)

6.0 m

(20 ft)

4.5 m

(15 ft)

3.0 m

(10 ft)

1.5 m

(5 ft)

Ground

Line

-1.5 m

(-5 ft)

-3.0 m

(-10 ft)

-4.5 m

(-15 ft)

Boom : 5.65 m (18’ 6”) / Arm : 2.40 m (7’ 10”) / Bucket : 0.80 m

7.5 m

(25 ft)

6.0 m

(20 ft)

4.5 m

(15 ft)

3.0 m

(10 ft)

1.5 m

(5 ft)

Ground

Line

-1.5 m

(-5 ft)

-3.0 m

(-10 ft)

-4.5 m

(-15 ft)

1. Lifting capacity is based on SAE J1097, ISO 10567.

2. Lifting capacity of the Robex Series does not exceed 75% of the tipping load with

the machine on firm, level ground or 87% of full hydraulic capacity.

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

Load point

height

m (ft)

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

1.5 m (5 ft)

*10680

*23550

*15190

*33490

1.5 m (5 ft)

*10680

*23550

*15190

*33490

*10680

*23550

*15190

*33490

*10680

*23550

*15190

*33490

3.0 m (10 ft)

*9840

*21690

*14730

*32470

270

*13

*29260

*10270

*22640

3.0 m (10 ft)

*9840

*21690

*14730

*32470

*13270

*29260

*10270

*22640

*9840

*21690

14050

30970

*13270

*29260

*10270

*22640

3

(1.05 yd3) SAE heaped / Front outrigger and rear dozer blade up and 3,400 kg (7,500 lb) counterweight

6700

14770

6770

14930

6960

15340

7350

16200

Load radius At max. reach

4.5 m (15 ft)

*5500

*12130

*7330

*16160

*8950

*19730

*9780

*21560

*9850

*21720

*9140

*20150

*7070

*15590

*5500

*12130

*7330

*16160

8100

17860

7850

17310

7800

17200

7900

17420

*7070

*15590

*5500

*12130

*7330

*16160

6970

15370

6720

14820

6680

14730

6780

14950

*7070

*15590

Load radius At max. reach

4.5 m (15 ft)

4770

10520

4220

9300

3780

8330

3570

7870

3530

7780

3620

7980

3880

8550

6.0 m (20 ft)

*4150

*9150

*4710

*10380

*5550

*12240

*6390

*14090

*6980

*15390

*7130

*15720

*6600

*14550

*4150

*9150

*4710

*10380

5400

11900

5140

11330

4970

10960

4920

10850

499

11000

3. The load point is a hook located on the back of the bucket.

4. (*) indicates the load limited by hydraulic capacity.

*4150

*9150

*4710

*10380

10360

6.0 m (20 ft)

0

4700

4450

9810

4290

9460

4230

9330

4300

9480

3110

6860

2930

6460

2690

5930

2470

5450

2320

5110

2270

5000

2330

5140

Rating over-front

7.5 m (25 ft)

*4390

*9680

*4760

*10490

*5180

*11420

*5480

*12080

3840

8470

3730

8220

3600

7940

3520

7760

3350

7390

3230

7120

3110

6860

3030

6680

7.5 m (25 ft)

1900

4190

1800

3970

1690

3730

1610

3550

Rating over-side or 360 degrees

Capacity Reach

m (ft )

*3810

*8400

*3910

*8620

*4050

*8930

*4230

*9330

*4430

*9770

*4640

*10230

*4830

*10650

*4870

*10740

*3810

*8400

3310

7300

2890

6370

2700

5950

2680

5910

2840

6260

3270

7210

4290

9460

3690

8140

2890

6370

2500

5510

2320

5110

2300

5070

2440

5380

2820

6220

3730

8220

Capacity Reach

2180

4810

1630

3590

1350

2980

1220

2690

1200

50

26

1280

2820

1520

3350

2080

4590

7.34

(24.1)

8.31

(27.3)

8.87

(29.1)

9.10

(29.9)

9.05

(29.7)

8.70

(28.5)

8.00

(26.2)

6.84

(22.4)

m (ft )

7.34

(24.1)

8.31

(27.3)

8.87

(29.1)

9.10

(29.9)

9.05

(29.7)

8.70

(28.5)

8.00

(26.2)

6.84

(22.4)

Lifting Capacities

R210W-9

Boom : 5.65 m (18’ 6”) / Arm : 2.92 m (9’ 7”) / Bucket : 0.80 m3 (1.05 yd3) SAE heaped / 4 outrigger down and 3,400 kg (7,500 lb) counterweight

Load point

height

m (ft)

9.0 m

(30 ft)

7.5 m

(25 ft)

6.0 m

(20 ft)

4.5 m

(15 ft)

3.0 m

(10 ft)

1.5 m

(5 ft)

Ground

Line

-1.5 m

(-5 ft)

-3.0 m

(-10 ft)

-4.5 m

(-15 ft)

Boom : 5.65 m (18’ 6”) / Arm : 2.92 m (9’ 7”) / Bucket : 0.80 m

9.0 m

(30 ft)

7.5 m

(25 ft)

6.0 m

(20 ft)

4.5 m

(15 ft)

3.0 m

(10 ft)

1.5 m

(5 ft)

Ground

Line

-1.5 m

(-5 ft)

-3.0 m

(-10 ft)

-4.5 m

(-15 ft)

1. Lifting capacity is based on SAE J1097, ISO 10567.

2. Lifting capacity of the Robex Series does not exceed 75% of the tipping load with

the machine on firm, level ground or 87% of full hydraulic capacity.

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

Load point

height

m (ft)

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

1.5 m (5 ft)

*9470

*20880

*12940

*28530

1.5 m (5 ft)

*9470

*20880

*12940

*28530

*9470

*20880

*12940

*28530

*9470

*20880

*12940

*28530

3.0 m (10 ft)

*10720

*23630

*8900

*19620

*10210

*22510

*13480

*29720

*14070

*31020

*11670

*25730

3.0 m (10 ft)

*10720

*23630

*8900

*19620

*10210

*22510

*13480

*29720

*14070

*31020

*11670

*25730

*10720

*23630

*8900

*19620

*10210

*22510

*13480

*29720

*14070

*31020

*11670

*25730

3

(1.05 yd3) SAE heaped / 4 outrigger up and 3,400 kg (7,500 lb) counterweight

7970

17570

6830

15060

6570

14480

6590

14530

6740

14860

7050

15540

Load radius At max. reach

4.5 m (15 ft)

*6550

*1444

*8350

*18410

*9470

*20880

*9820

*21650

*9430

*20790

*7990

*17610

*6550

*14440

8180

18030

7830

17260

7710

17000

7760

17110

7980

17590

*6550

*14440

0

*8350

*18410

8490

18720

8360

18430

8410

18540

*7990

*1761

Load radius At max. reach

4.5 m (15 ft)

4340

9570

3840

8470

3550

7830

3450

7610

3790

7690

3670

8090

6.0 m (20 ft)

*4210

*9280

*5090

*11220

*6020

*13270

*6730

*14840

*7060

*15560

*6830

*15060

0

*4210

*9280

*5090

*11220

5160

11380

4950

10910

4850

10690

4870

10740

3. The load point is a hook located on the back of the bucket.

4. (*) indicates the load limited by hydraulic capacity.

*4210

*9280

*5090

11220

5510

12150

5290

11660

5190

11440

5220

11510

6.0 m (20 ft)

2990

6590

2730

6020

2470

5450

2290

5050

2200

4850

2220

4890

Rating over-front

7.5 m (25 ft)

*2690

*5930

*3980

*8770

*4410

*9720

*4900

*10800

*5300

*11680

*5440

*11990

*2690

*5930

3880

8550

3740

8250

3590

7910

3480

7670

3440

7580

*2690

*5930

*3980

*8770

3970

8750

3820

8420

3710

8180

3660

8070

7.5 m (25 ft)

2010

4430

1930

4250

1810

3990

1670

3680

1570

3460

1530

3370

Rating over-side or 360 degrees

Capacity Reach

m (ft )

*341

*7520

*3470

*7650

*3580

*7890

*3720

*8200

*3890

*8580

*4080

*8990

*4290

*9460

*4500

*9920

*4640

*10230

*3410

*7520

*3470

*7650

2970

6550

2610

5750

2450

5400

2420

5340

2550

5620

2880

6350

3630

8000

*3410

0

*7520

*3470

*7650

3140

6920

2770

6110

2600

5730

2570

5670

2710

5970

3060

6750

3860

8510

Capacity Reach

2840

6260

1870

4120

1420

3130

1190

2620

1070

2360

1040

2290

1100

2430

1290

2840

1700

3750

6.52

(21.4)

7.96

(26.1)

8.85

(29.0)

9.37

(30.7)

9.59

(31.5)

9.54

(31.3)

9.21

(30.2)

8.56

(28.1)

50

7.

(24.6)

m (ft )

6.52

(21.4)

7.96

(26.1)

8.85

(29.0)

9.37

(30.7)

9.59

(31.5)

9.54

(31.3)

9.21

(30.2)

8.56

(28.1)

7.50

(24.6)

Lifting CapacitiesLifting Capacities

R210W-9

Boom : 5.65 m (18’ 6”) / Arm : 2.92 m (9’ 7”) / Bucket : 0.80 m3 (1.05 yd3) SAE heaped / Front outrigger and rear dozer blade down and 3,400 kg (7,500 lb) counterweight

Load point

height

m (ft)

9.0 m

(30 ft)

7.5 m

(25 ft)

6.0 m

(20 ft)

4.5 m

(15 ft)

3.0 m

(10 ft)

1.5 m

(5 ft)

Ground

Line

-1.5 m

(-5 ft)

-3.0 m

(-10 ft)

-4.5 m

(-15 ft)

Boom : 5.65 m (18’ 6”) / Arm : 2.92 m (9’ 7”) / Bucket : 0.80 m

9.0 m

(30 ft)

7.5 m

(25 ft)

6.0 m

(20 ft)

4.5 m

(15 ft)

3.0 m

(10 ft)

1.5 m

(5 ft)

Ground

Line

-1.5 m

(-5 ft)

-3.0 m

(-10 ft)

-4.5 m

(-15 ft)

1. Lifting capacity is based on SAE J1097, ISO 10567.

2. Lifting capacity of the Robex Series does not exceed 75% of the tipping load with

the machine on firm, level ground or 87% of full hydraulic capacity.

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

Load point

height

m (ft)

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

1.5 m (5 ft)

*9470

*20880

*12940

*28530

1.5 m (5 ft)

*9470

*20880

*12940

*28530

*9470

*20880

*12940

*28530

70

*94

*20880

*12940

*28530

3.0 m (10 ft)

*10720

*23630

*8900

*19620

*10210

*22510

*13480

*29720

*14070

*31020

*11670

*25730

3.0 m (10 ft)

*10720

*23630

*8900

*19620

*10210

*22510

*13480

*29720

*14070

*31020

*11670

*25730

*10720

*23630

*8900

*19620

*10210

*22510

*13480

*29720

14020

30910

*11670

*25730

3

(1.05 yd3) SAE heaped / Front outrigger and rear dozer blade up and 3,400 kg (7,500 lb) counterweight

7970

17570

6830

15060

6570

14480

6590

14530

6740

14860

7050

15540

Load radius At max. reach

4.5 m (15 ft)

*6550

*14440

*8350

*18410

*9470

*20880

*9820

*21650

*9430

*20790

*7990

*17610

*6550

*14440

8180

18030

7830

17260

7710

17000

7760

17110

7980

17590

*6550

*14440

7040

15520

6700

14770

6590

14530

6640

14640

6850

15100

Load radius At max. reach

4.5 m (15 ft)

4340

9570

3840

8470

3550

7830

3450

7610

3490

7690

3670

8090

6.0 m (20 ft)

*4210

*9280

*5090

*11220

*6020

*13270

*6730

*14840

*70

*15560

*6830

*15060

*4210

*9280

*5090

*11220

5160

11380

4950

10910

4850

10690

4870

10740

3. The load point is a hook located on the back of the bucket.

4. (*) indicates the load limited by hydraulic capacity.

*4210

*9280

10470

60

6.0 m (20 ft)

4750

4460

9830

4260

9390

4160

9170

4190

9240

2990

6590

2730

6020

2470

5450

2290

5050

2200

4850

2220

4890

Rating over-front

7.5 m (25 ft)

*2690

*5930

*3980

*8770

*4410

*9720

*4900

*10800

*5300

*11680

*5440

*11990

*2690

*5930

3880

8550

3740

8250

3590

7910

3480

7670

3440

7580

*2690

*5930

3380

7450

3250

7170

3100

6830

2990

6590

2950

6500

7.5 m (25 ft)

2010

4430

1930

4250

1810

3990

1670

3680

1570

3460

1530

3370

Rating over-side or 360 degrees

Capacity Reach

m (ft )

*3410

*7520

*3470

*7650

*3580

*7890

*3720

*8200

*3890

*8580

*4080

*8990

*4290

*9460

*4500

*9920

*4640

*10230

*3410

*7520

*3470

*7650

2970

65

2610

5750

2450

5400

2420

5340

2550

5620

2880

6350

3630

8000

*3410

*7520

3210

7080

2580

5690

2250

4960

2090

4610

2070

4560

2180

4810

2470

5450

3130

6900

Capacity Reach

2840

6260

1870

4120

1420

3130

50

1190

2620

1070

2360

1040

2290

1100

2430

1290

2840

1700

3750

(21.4)

(26.1)

(29.0)

(30.7)

(31.5)

(31.3)

(30.2)

(28.1)

(24.6)

m (ft )

(21.4)

(26.1)

(29.0)

(30.7)

(31.5)

(31.3)

(30.2)

(28.1)

(24.6)

6.52

7.96

8.85

9.37

9.59

9.54

9.21

8.56

7.50

6.52

7.96

8.85

9.37

9.59

9.54

9.21

8.56

7.50

Notes

NotesNotes

STANDARD EQUIPMENT

ISO Standard cabin

All-weather steel cabin with 360° visibility

Safety glass windows

Rise-up type windshield wiper

Sliding fold-in front window

Sliding side window

One key fits all lockable doors

Hot & cool box

Storage compartment & ashtray

Transparent cabin roof-cover

CD/MP3 Player with AUX-input

Handsfree mobile phone system with USB-charging device

Sun visor

Computer aided power optimization (New CAPO) system

3-power modes, 3-work modes, User mode

Auto & one-touch deceleration system

Auto warm-up system

Overheat prevention system

Automatic temperature control

Air conditioner & heater

Defroster

Self-diagnostics system

Starting Aid (air grid heater) for cold weather

Centralized monitoring

LCD-display

Engine speed or trip meter

Clock

Gauges

- Fuel level gauge

- Engine coolant temperature gauge

- Hyd. oil temperature gauge

Warning lamps

- Engine warning

- Overload

- Communication error

- Low battery

- Air filter clogging

Indicators

- Max power

- Low speed/High speed

- Fuel warmer

- Auto deceleration

Door and cab locks, one key

Two outside rearview mirrors

Fully adjustable suspension seat with seat belt

Adjustable joysticks

Console box height adjust system

Two front working lights

Electric horn

Batteries (2 x 12 V x 100 AH)

Battery master switch

Removable clean-out screen for cooler

Automatic swing brake

Removable reservoir tank

Fuel pre-filter with fuel warmer

Boom holding system

Arm holding system

Counterweight (3,400 kg; 7,500 lb)

Accumulator for lowering work equipment

Lower frame under cover

Viscous fan clutch

Dual tires (10.00-20-16PR)

Travel alarm

OPTIONAL EQUIPMENT

Fuel filler pump (50 L/min)

Beacon lamp

Safety lock valve for boom cylinder with overload warning device

Safety lock valve for arm cylinder

Single-acting piping kit (breaker, etc.)

Double-acting piping kit (clamshell, etc.)

Quick coupler

12 volt power outlet (24V DC to 12V DC converter)

Boom

Mono Boom: 5.65 m; 18’ 6”

2pc Boom: 5.65 m; 18’ 6”

Arm

Extra Short arm (2.0 m; 6’ 7”)

Short arm (2.4 m; 7’ 10”)

Buckets

Temperature control

Cabin FOPS/FOG (ISO/DIS 10262)

Cabin roof-steel cover

Wire net - Cabin front guard

Cabin lights

Rain guard – Front window

Undercarriage

Additional cover under lower frame

Tool kit

Operator suit

Rearview camera

Seat

Dual tires - solid (10.00 - 20)

Fenders

Pattern change valve (2 patterns)

Hi-mate (Remote Management System)

2 Way Travel pedal

3

0.51 m

0.80 m3; 1.05 yd

0.87 m3; 1.14 yd

0.92 m3; 1.20 yd

1.10 m3; 1.44 yd

1.20 m3; 1.57 yd

1.34 m3; 1.75 yd

0.74 m3; 0.97 yd3 (Heavy-duty bucket)

0.90 m

1.05 m

0.87 m

0.75 m

3

; 0.67 yd

3

3

3

3

3

3

3

; 1.18 yd3 (Heavy-duty bucket)

3

; 1.37 yd3 (Heavy-duty bucket)

3

; 1.14 yd3 (Heavy-duty bucket)

3

; 0.98 yd3 (Slope finishing bucket)

Air conditioner only

Heater only

FOPS (Falling Object Protective Structure)

FOG (Falling Object Guard)

Front and rear outriggers

Front blade and rear outriggers

Adjustable air suspension

Adjustable air suspension with heater

Mechanical suspension with heater

Standard and optional equipment may vary. Contact your Hyundai dealer for more information. The machine may vary according to international standards.

All imperial measurements rounded off to the nearest pound or inch.

PLEASE CONTACT

www.hyundai.eu EN - 2010.7 Rev 0

Loading...

Loading...