Page 1

CONTENTS

SAFETY HINTS

SPECIFICATIONS

CONTROL DEVICES

OPERATION

TRANSPORTATION

MAINTENANCE

TROUBLESHOOTING GUIDE

HYDRAULIC BREAKER AND QUICK CLAMP

INDEX

CONTENTS

Foreword

Before servicing this machine

EC regulation approved

Table to enter S/No and distribution

Safety labels

Machine data plate

Guide (direction, S/No, symbol)

SAFETY HINTS

1. Before operating the machine

2. During operating the machine

3. During maintenance

4. Parking

SPECIFICATIONS

1. Major components

2. Specifications

3. Working range

4. Weight

5. Lifting capacities

6. Bucket selection guide

7. Undercarriage

8. Specification for major components

9. Recommended oils

-----------------------------------------------------------

---------------------------

------------------------------------

---------------------

------------------------------------------------------

--------------------------------------------

------------------------

--------------------

--------------------

-----------------------------------

--------------------------------------------------------

-------------------------------------

--------------------------------------------

-------------------------------------------

-------------------------------------------------------

----------------------------------------

-------------------------------

-------------------------------------------

-----------

------------------------------------

0-1

0-2

0-3

0-4

0-5

0-18

0-19

1-1

1-6

1-13

1-16

2-1

2-2

2-5

2-7

2-8

2-12

2-13

2-15

2-18

6. Traveling of the machine

7. Efficient working method

8. Operation in the special work sites

9. Normal operation of excavator

10. Attachment lowering

11. Storage

12. RCV lever operating pattern

13. Switching hydraulic attachment circuit

TRANSPORTATION

1. Preparation for transportation

2. Dimension and weight

3. Loading the machine

4. Fixing the machine

5. Loading and unloading by crane

MAINTENANCE

1. Instruction

2. Tightening torque

3. Fuel, coolant and lubricants

4. Maintenance check list

5. Maintenance chart

6. Service instruction

7. Electrical system

8. Air conditioner and heater

-----------------------------------------------------

-------------------------------------------------

---------------------------------------

----------------------------

---------------------------

-------------

-------------------

----------------------------------

-----------------------

--------

--------------------

-------------------------------

---------------------------------

------------------------------------

----------------

---------------------------------------

-----------------------

------------------------------

------------------------------------

-------------------------------------

--------------------------

4-21

4-24

4-28

4-30

4-31

4-32

4-34

4-35

5-1

5-2

5-5

5-7

5-8

6-1

6-6

6-9

6-11

6-16

6-18

6-39

6-42

CONTROL DEVICES

1. Cab devices

2. Cluster

3. Switches

4. Levers and pedals

5. Air conditioner and heater

6. Others

OPERATION

1. Suggestion for new machine

2. Check before starting the engine

3. Starting and stop the engine

4. Mode selection system

5. Operation of the working device

-----------------------------------------------

-------------------------------------------------------

----------------------------------------------------

-------------------------------------

-------------------------

--------------------------------------------------------

----------------------

----------------------

------------------------------

-----------------

3-1

3-2

3-34

3-38

3-41

3-48

4-1

---------------

4-2

4-3

4-10

4-20

TROUBLESHOOTING GUIDE

1. Engine

2. Electrical system

3. Others

HYDRAULIC BREAKER AND QUICK CLAMP

1. Selecting hydraulic breaker

2. Circuit configuration

3. Maintenance

4. Precaution while operating the breaker

5. Quick clamp

INDEX

------------------------------------------------------

---------------------------------------

-------------------------------------------------------

------------------------

-----------------------------------

---------------------------------------------

----------------------------------------------

------------------------------------------------------------

7-1

7-2

7-3

8-1

8-2

8-3

------

8-4

8-6

9-1

Page 2

Read

understand

Inspect

follow

safety hints

genuine Hyundai spare parts

FOREWORD

FOREWORD

This manual contains a number of instructions and safety recommendations regarding driving, handling, lubrication, maintenance, inspection and adjustment of the excavator.

The manual is to promote safety maintenance and enhance machine performance.

Keep this manual handy and have all personnel read it periodically.

If you sell the machine, be sure to give this manual to the new owners.

This machine complies with EC directive "2006/42/EC".

1.

Read and

This operator's manual may contain attachments and optional equipment that are not available in

your area. Please consult your local Hyundai distributor for those items you require.

Improper operation and maintenance of this machine can be hazardous and could result in serious

injury or death.

Some actions involved in operation and maintenance of the machine can cause a serious accident,

if they are not done in a manner described in this manual.

The procedures and precautions given in this manual apply only to intended uses of the machine.

If you use your machine for any unintended uses that are not specifically prohibited, you must be

sure that it is safe for you and others. In no event should you or others engage in prohibited uses

of actions as described in this manual.

understand this manual before operating the machine.

2.

Inspect the jobsite and

ating the machine.

3. Use

Continuing improvements in the design of this machine can lead to changes in detail which may not

be reflected in this manual. Consult Hyundai or your Hyundai distributor for the latest available information for your machine or for questions regarding information in this manual.

genuine Hyundai spare parts for the replacement of parts.

We expressly point out that Hyundai will not accept any responsibility for defects resulting from nongenuine parts or non workmanlike repair.

In such cases Hyundai cannot assume liability for any damage.

follow the safety recommendations in the

safety hints section before oper-

0-1

Page 3

BEFORE SERVICING THIS MACHINE

How to adjust the language of cluster (cluster type 1)

BEFORE SERVICING THIS MACHINE

It is the responsibility of the owner and all service and maintenance personnel to avoid accidents and

serious injury by keeping this machine properly maintained.

It also is the responsibility of the owner and all service and maintenance personnel to avoid accidents

and serious injury while servicing the machine.

No one should service or attempt to repair this machine without proper training and supervision.

All service and maintenance personnel should be thoroughly familiar with the procedures and precau-

tions contained in this manual.

All personnel also must be aware of any federal, state, provincial or local laws or regulations covering

the use and service of construction equipment.

The procedures in this manual do not supersede any requirements imposed by federal, state, provin-

cial or local laws.

Hyundai can not anticipate every possible circumstance or environment in which this machine may be

used and serviced.

All personnel must remain alert to potential hazards.

Work within your level of training and skill.

Ask your supervisor if you are uncertain about a particular task. Do not try to do too much too fast.

Use your common sense.

How to adjust the language of cluster (cluster type 1)

※

User can select preferable language and all displays are changed the selected language.

Press Press Press Press

Please refer to the page 3-20 for the cluster.

※

0-2

Page 4

EC REGULATION APPROVED

EC REGULATION APPROVED

·

Noise level (EN474-1 : 2006 and 2000/14/EC) are as followings.

WA : 100

L

L

PA : 71

·

The value of vibrations transmitted by the operator's seat are lower than standard value of (EN474-1

: 2006 and 2002/44/EC)

dB

(EU only)

dB

0-3

Page 5

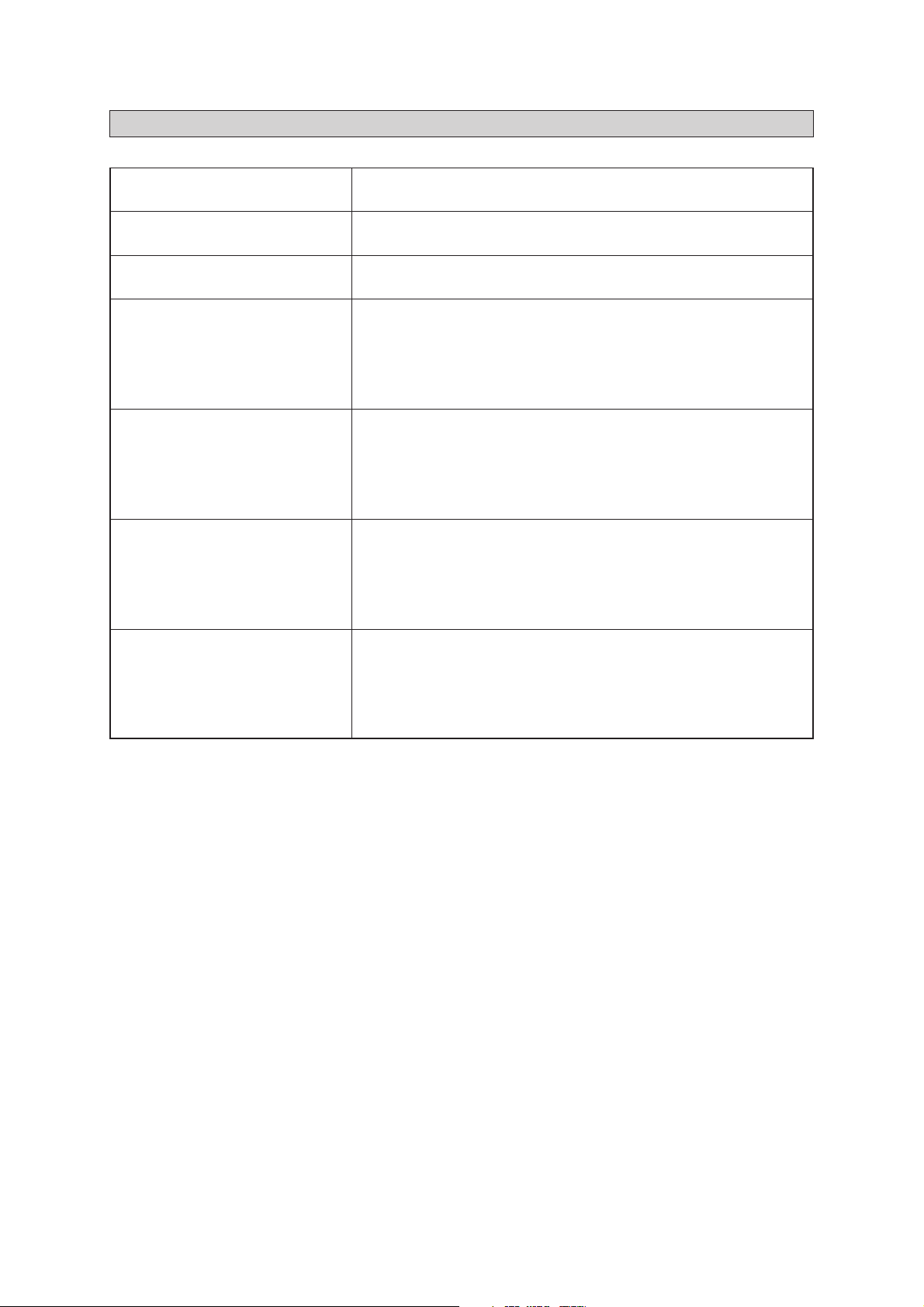

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

Machine Serial No.

Engine Serial No.

Manufacturing year

Manufacturer

Address

Distributor for U.S.A

Address

Distributor for Europe

Address

Dealer

Address

Hyundai Heavy Industries co., Ltd.

1000, Bangeojinsunhwan-doro, Dong-Ku,

Ulsan 682-792, Korea

Hyundai Heavy Industries U.S.A, Inc

6100 Atlantic Boulevard Norcross

GA 30071

U.S.A

Hyundai Heavy Industries Europe N. V.

Vossendal 11

2240 Geel

Belgium

0-4

Page 6

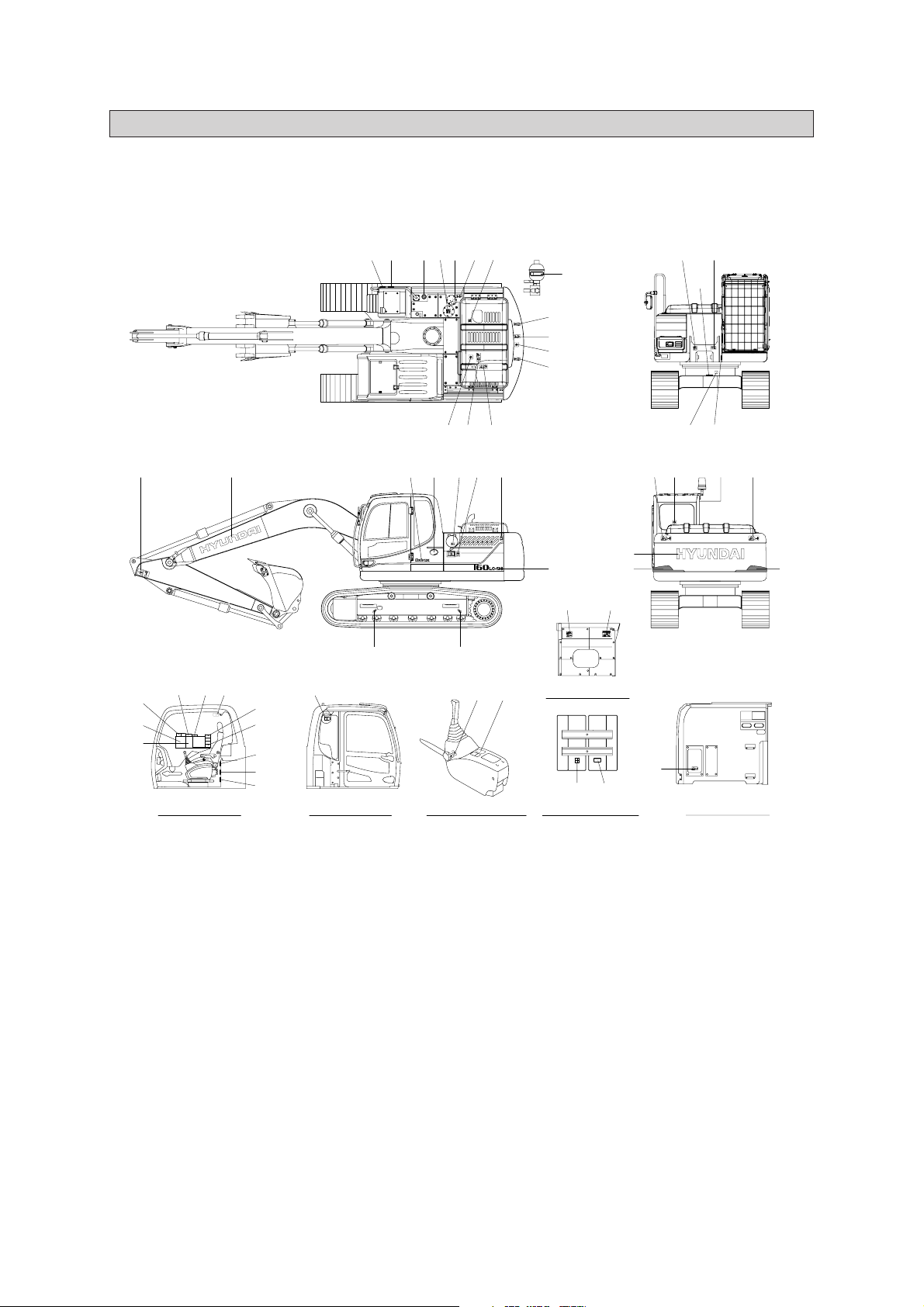

SAFETY LABELS

1. LOCATION

SAFETY LABELS

1. LOCATION

Always keep these labels clean. If they are lost or damage, attach them again or replace them with

a new label.

37

19

35

34

CAB INSIDE-RH

41

51

50

2

39

43

10

39

16

10

3

15

13

1

14

27

6

1212

26

45

PUMP SCREEN

5

38

BATTERY COVER

9

30

42

7

46

316

36

47

11

49

23

SCREEN PLATE

9

42

4

48

17

29

t

e

k

c

u

B

22

32

20

21

24

52

22

CAB INSIDE-LH

8

16

1828

LH CONSOLE BOX

1 Air cleaner filter

2 Turbocharger cover

3 Radiator cap

4 Fueling

5 Battery accident

6 High pressure hose

7 Hydraulic oil level

8 Hydraulic oil lub

9 Keep clear-rear

10 Lifting eye

11 Name plate

12 Slinging ideogram

13 Keep clear-side

14 Stay fix

15 Shearing-engine hood

16

No step-engine hood and CWT

17 Transporting

18 Low emission engine

19 Control ideogram

20

Ref operator manual-cab RH pillar

21 Hammer

22 Safety front window

23 Alternate exit

24 Air conditioner filter

26 Safety lever

27 Model name

28 Logo (ROBEX)

29 Trade mark (boom)

30 Trade mark (CWT)

31 Reduction gear grease

32 Clamp-locking

34 Service instruction

0-5

1609S0SL01

35 Lifting chart

36 Tie

37 Keep clear-Boom/arm

38 Electric welding

39 Falling

41 Turbocharger

42 Reflecting

43 Accumulator

45 Control ideogram-dozer

46 RCV lever pattern

47 Swing bearing

48 Battery position

49 Beacon lamp

50 Fuel shut off

51 Water separator

52 MCU connector

Page 7

2. DESCRIPTION

AIR CLEANER FILTER

Periodic and proper inspection, cleaning

and change of elements prolong engine

life time and maintain the good performance of engine.

1)

TURBOCHARGER COVER

Do not touch turbocharger or it may

cause severe burn.

2)

RADIATOR CAP

Never open the filler cap while engine

running or at high coolant temperature.

3)

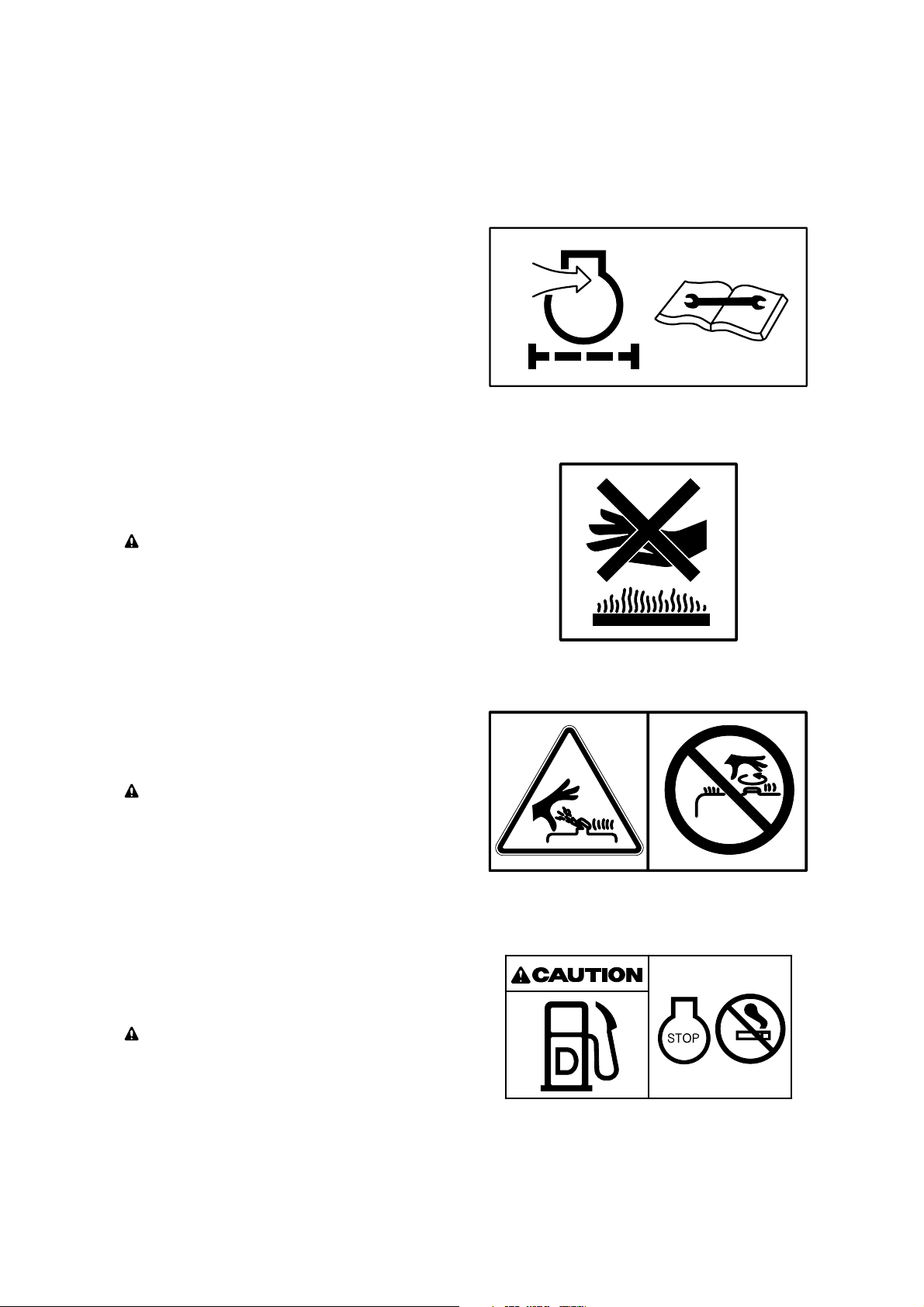

FUELING

Stop the engine when refueling. All

lights or flames shall be kept at a safe

distance while refueling.

4)

2. DESCRIPTION

There are several specific warning labels on this machine please become familiarized with all warning labels.

Replace any safety label that is damaged, or missing.

1)

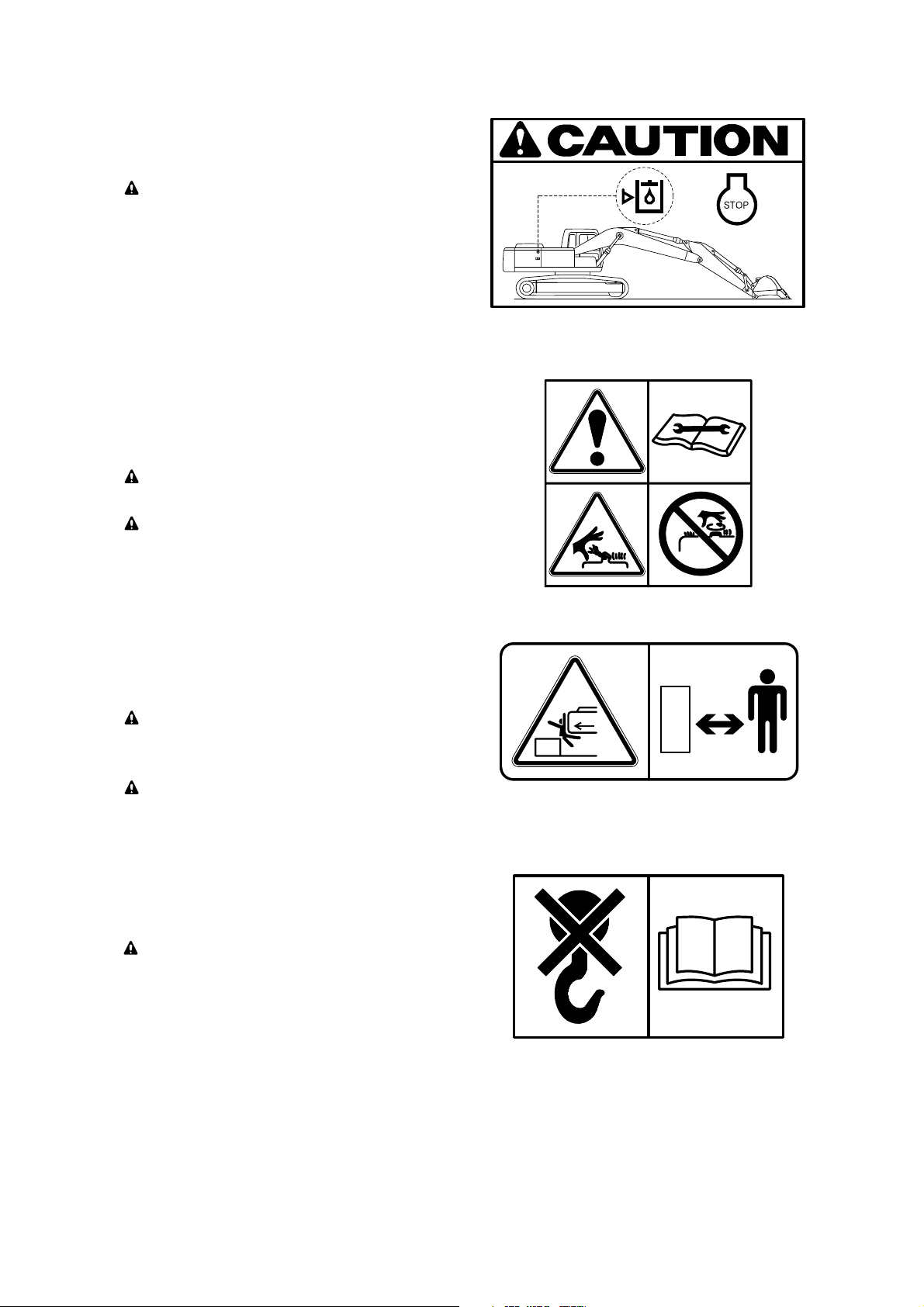

AIR CLEANER FILTER (item 1)

This warning label is positioned on the air

cleaner cover.

※

Periodic and proper inspection, cleaning

and change of elements prolong engine

life time and maintain the good performance of engine.

TURBOCHARGER COVER (item 2)

2)

This warning label is positioned on the turbocharger cover.

Do not touch turbocharger or it may

cause severe burn.

21070FW01

RADIATOR CAP (item 3)

3)

This warning label is positioned on the radiator.

Never open the filler cap while engine

running or at high coolant temperature.

FUELING (item 4)

4)

This warning label is positioned on the fuel

filler neck.

Stop the engine when refueling. All

lights or flames shall be kept at a safe

distance while refueling.

21070FW02

14070FW03

0-6

21070FW04

Page 8

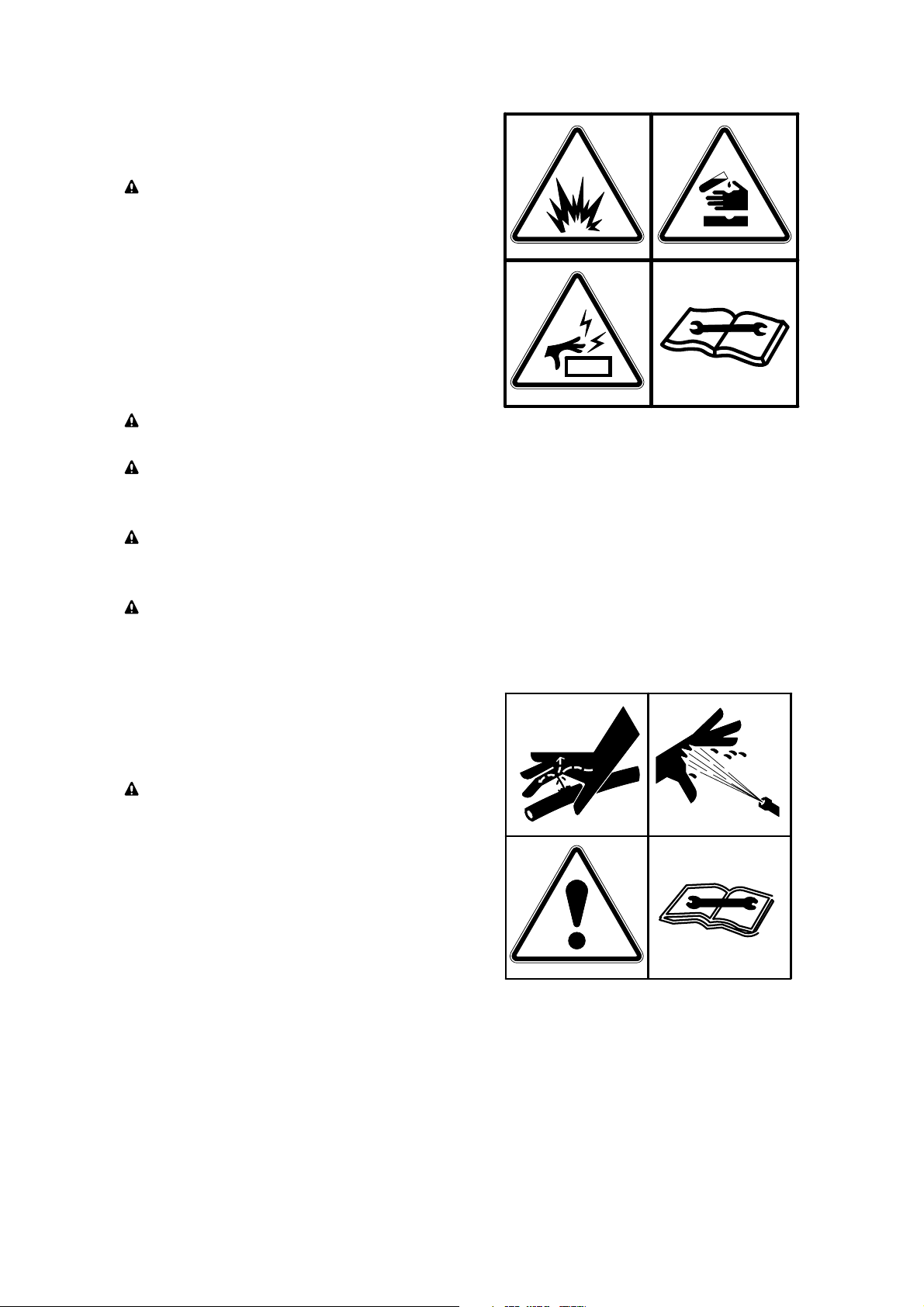

BATTERY ACCIDENT

Electrolyte containing sulfuric acid cause

severe burns. Avoid being in contact with

skin, eyes or clothes. In the event of

accident flush with sufficient water, call a

physician immediately.

Maintain the electrolyte at the recommended level.

With electrolyte at proper level, less

space may cause the gases to be accumulated in the battery.

Extinguish all smoking materials and

open flames before checking the battery.

Do not use matches, lighters or torches

as a light source near the battery for the

probable presence of explosive gas.

Do not allow unauthorized personnel to

change the battery or to use booster

cables.

For safety from electric shock, do not battery terminal with a wet hand.

5)

HIGH PRESSURE HOSE

Escaping fluid under pressure can penetrate the skin causing serious injury.

Study the service manual before service

job.

6)

BATTERY ACCIDENT (item 5)

5)

This warning label is positioned on the battery cover.

Electrolyte containing sulfuric acid cause

severe burns. Avoid being in contact with

skin, eyes or clothes. In the event of

accident flush with sufficient water, call a

physician immediately.

※

Maintain the electrolyte at the recommended level.

With electrolyte at proper level, less

space may cause the gases to be accumulated in the battery.

Extinguish all smoking materials and

open flames before checking the battery.

Do not use matches, lighters or torches

as a light source near the battery for the

probable presence of explosive gas.

Do not allow unauthorized personnel to

change the battery or to use booster

cables.

For safety from electric shock, do not battery terminal with a wet hand.

36070FW05

HIGH PRESSURE HOSE (item 6)

6)

These warning labels are positioned in the

front of upper frame and on the screen

plate.

Escaping fluid under pressure can penetrate the skin causing serious injury.

※

Study the service manual before service

job.

14070FW29

0-7

Page 9

LIFTING EYE

Do not lift the machine by using lifting

eyes on the counterweight or the lifting

eyes may be subject to overload causing

its breaking and possible personal injury.

See page 5-8 for proper lifting method of

the machine.

10)

HYDRAULIC OIL LUBRICATION

Do not mix with different brand oils.

Never open the filler cap while high temperature.

Loosen the cap slowly and release internal pressure completely.

8)

KEEP CLEAR-REAR

To prevent serious personal injury or

death keep clear or machine swing radius.

Do not deface of remove this label from

the machine.

9)

HYDRAULIC OIL LEVEL

Place the bucket on the ground whenever

servicing the hydraulic system.

Check oil level on the level gauge.

Refill the recommended hydraulic oil up

to specified level if necessary.

7)

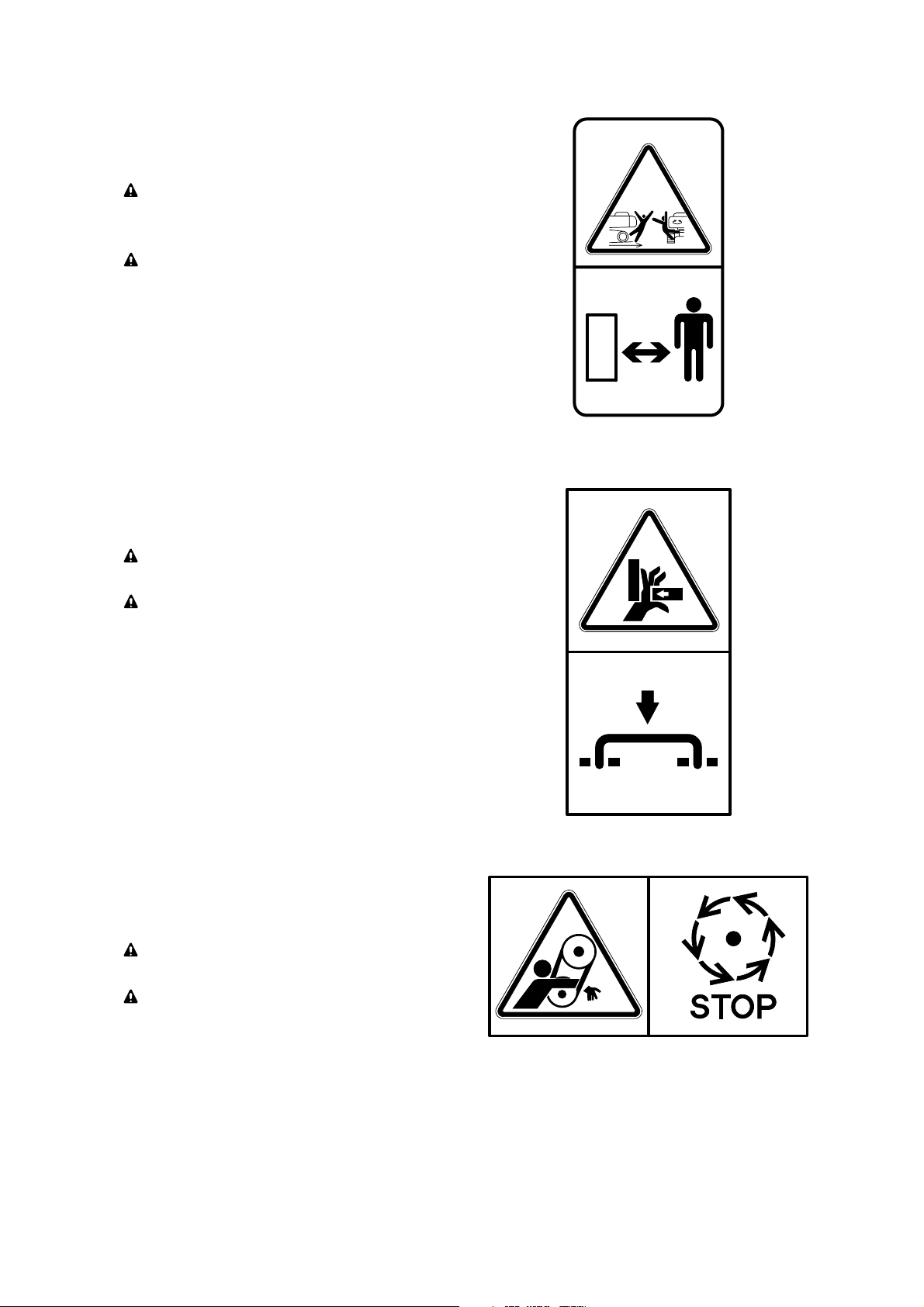

HYDRAULIC OIL LEVEL (item 7)

7)

This warning label is positioned on the

screen plate.

Place the bucket on the ground whenever

servicing the hydraulic system.

※

Check oil level on the level gauge.

※

Refill the recommended hydraulic oil up

to specified level if necessary.

HYDRAULIC OIL LUBRICATION (item 8)

8)

This warning label is positioned on the top

of the hydraulic tank.

※

Do not mix with different brand oils.

Never open the filler cap while high temperature.

Loosen the cap slowly and release internal pressure completely.

21070FW07

KEEP CLEAR-REAR (item 9)

9)

This warning label is positioned on the rear

of counterweight.

To prevent serious personal injury or

death keep clear or machine swing radius.

Do not deface of remove this label from

the machine.

LIFTING EYE (item 10)

10)

This warning label is positioned on the

counterweight.

Do not lift the machine by using lifting

eyes on the counterweight or the lifting

eyes may be subject to overload causing

its breaking and possible personal injury.

※

See page 5-8 for proper lifting method of

the machine.

14070FW08

21090FW09

21070FW10

0-8

Page 10

SHEARING-ENGINE HOOD

Don't open the engine hood during the

engine's running.

Don't touch exhaust pipe or it may cause

severe burn.

KEEP CLEAR-SIDE

To prevent serious personal injury or

death keep clear of machine swing radius.

Do not deface or remove this label from

the machine.

STAY FIX

Be sure to support the stay when the

door needs to be opened.

Be careful that the opened door may be

closed by the external or natural force

like strong wind.

13)

11)

12)

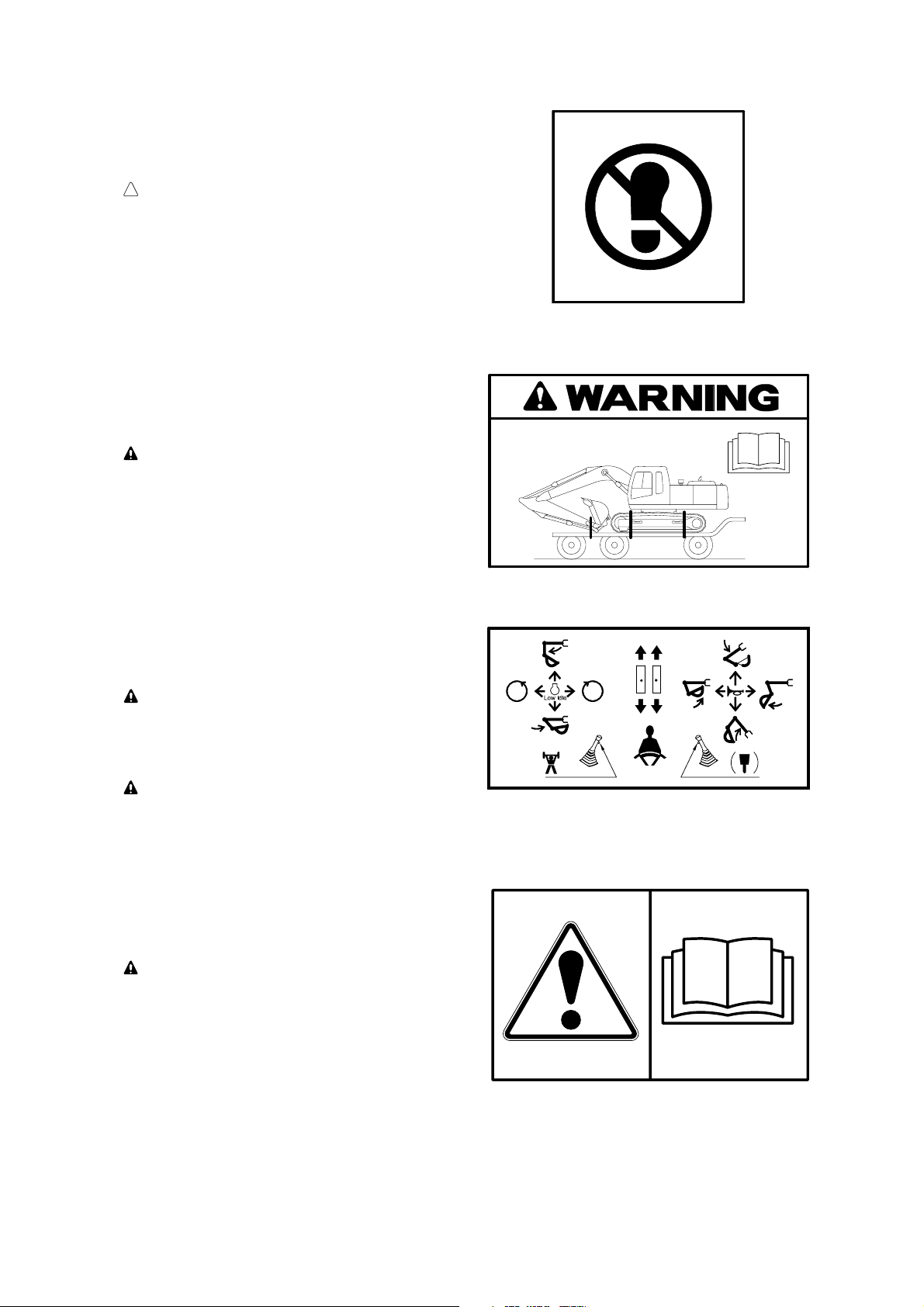

KEEP CLEAR-SIDE (item 13)

11)

This warning label is positioned on the LH

side cover.

To prevent serious personal injury or

death keep clear of machine swing radius.

Do not deface or remove this label from

the machine.

STAY FIX (item 14)

12)

This warning label is positioned on the both

side cover.

Be sure to support the stay when the

door needs to be opened.

Be careful that the opened door may be

closed by the external or natural force

like strong wind.

21070FW13

SHEARING-ENGINE HOOD (item 15)

13)

This warning label is positioned on the

engine hood.

Don't open the engine hood during the

engine's running.

Don't touch exhaust pipe or it may cause

severe burn.

21070FW14

21070FW15

0-9

Page 11

REF OPERATOR MANUAL

Study the operator's manual before starting and operating machine.

TRANSPORTING

Study the operator's manual before

transporting the machine, if provided and

tie down arm and track to the carrier with

lashing wire.

See page 5-7 for details.

CONTROL IDEOGRAM

Check the machine control pattern for

conformance to pattern on this label. If

not, change label to match patte rn

before operating machine.

Failure to do so could result in injury or

death.

See page 4-20 for details.

NO STEP-ENGINE HOOD/CWT

Do not step on the engine hood and

counterweight.

17)

14)

15)

16)

14)

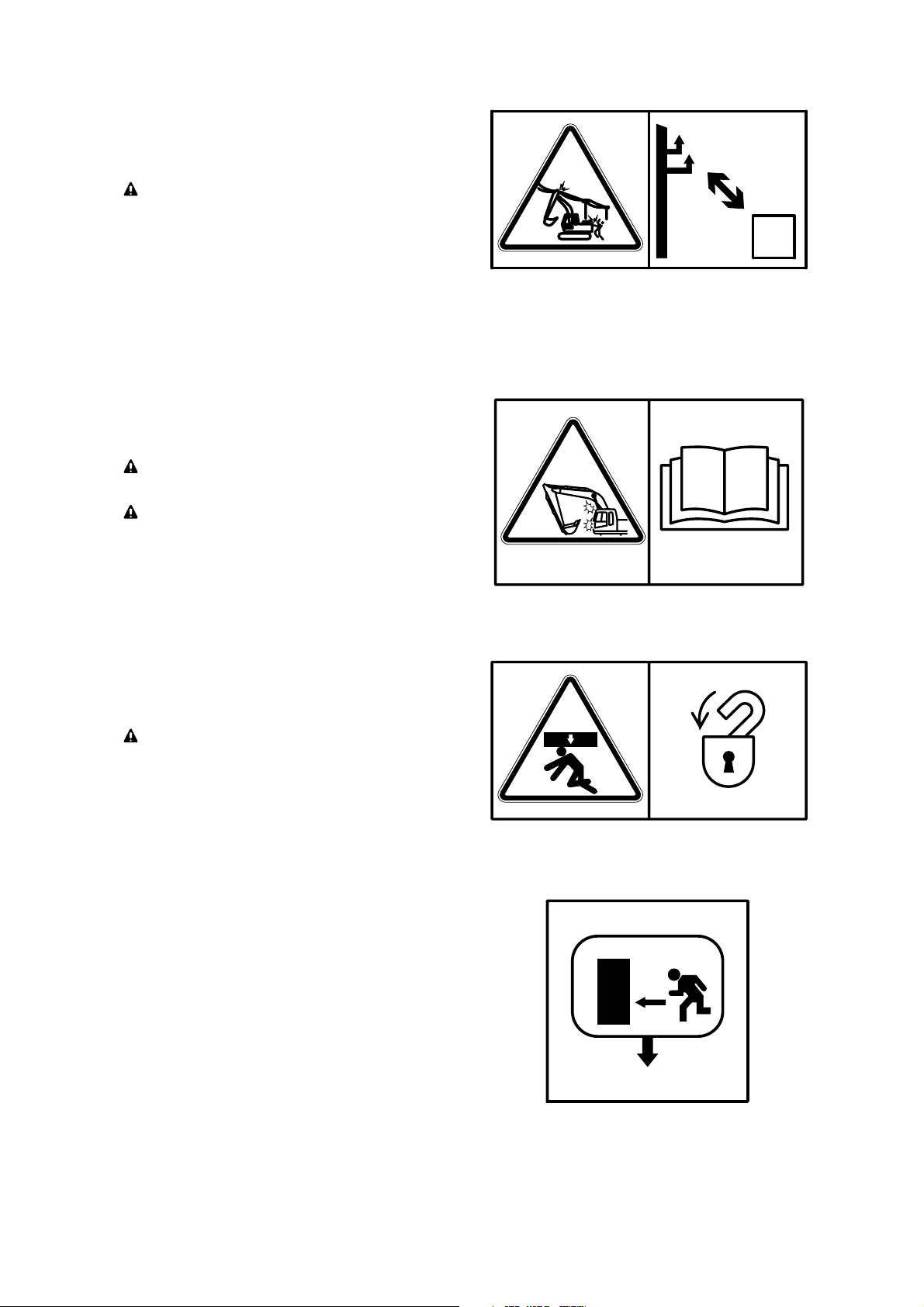

NO STEP-ENGINE HOOD/CWT (item 16)

These warning labels are positioned on the

engine hood and counterweight.

Do not step on the engine hood and

counterweight.

TRANSPORTING (item 17)

15)

This warning label is positioned right side

of upper frame.

Study the operator's manual before

transporting the machine, if provided and

tie down arm and track to the carrier with

lashing wire.

See page 5-7 for details.

21070FW16

CONTROL IDEOGRAM (item 19)

16)

This warning label is positioned in right

window of the cab.

Check the machine control pattern for

conformance to pattern on this label. If

not, change label to match pattern

before operating machine.

Failure to do so could result in injury or

death.

See page 4-20 for details.

REF OPERATOR MANUAL (item 20)

17)

This warning label is positioned on the right

side window of the cab.

Study the operator's manual before starting and operating machine.

14070FW17

36070FW19

0-10

21070FW22

Page 12

MAX HEIGHT

Serious injury or death can result from

contact with electric lines.

An electric shock being received by

merely coming into the vicinity of an

electric lines, the minimum distance

should be kept considering the supply

voltage as page 1-7.

INTERFERENCE

Be careful to operate machine equipped

with quick clamp or extensions.

Bucket may hit cab or boom, boom cylinders when it reached vicinity of them.

18)

19)

ALTERNATE EXIT

The rear window serves us an alternate

exit.

To remove rear window, pull the ring and

push out the glass.

SAFETY FRONT WINDOW

Be careful that the front window may be

promptly closed.

21

20)

MAX HEIGHT (item 20)

18)

This warning label is positioned on the right

side window of the cab.

Serious injury or death can result from

contact with electric lines.

An electric shock being received by

merely coming into the vicinity of an

electric lines, the minimum distance

should be kept considering the supply

voltage as page 1-7.

INTERFERENCE (item 20)

19)

This warning label is positioned on the

right side window of the cab.

Be careful to operate machine equipped

with quick clamp or extensions.

Bucket may hit cab or boom, boom cylinders when it reached vicinity of them.

21070FW23

SAFETY FRONT WINDOW (item 22)

20)

This warning label is positioned on the both

side window of the cab.

Be careful that the front window may be

promptly closed.

ALTERNATE EXIT (item 23)

21)

This warning label is positioned on the

inside of rear window.

※

The rear window serves us an alternate

exit.

※

To remove rear window, pull the ring and

push out the glass.

21090FW62

21070FW24

0-11

21070FW25

Page 13

AIR CONDITIONER FILTER

Periodic and proper inspection, cleaning

and change of filter prolong air conditioner life time and maintain good performance.

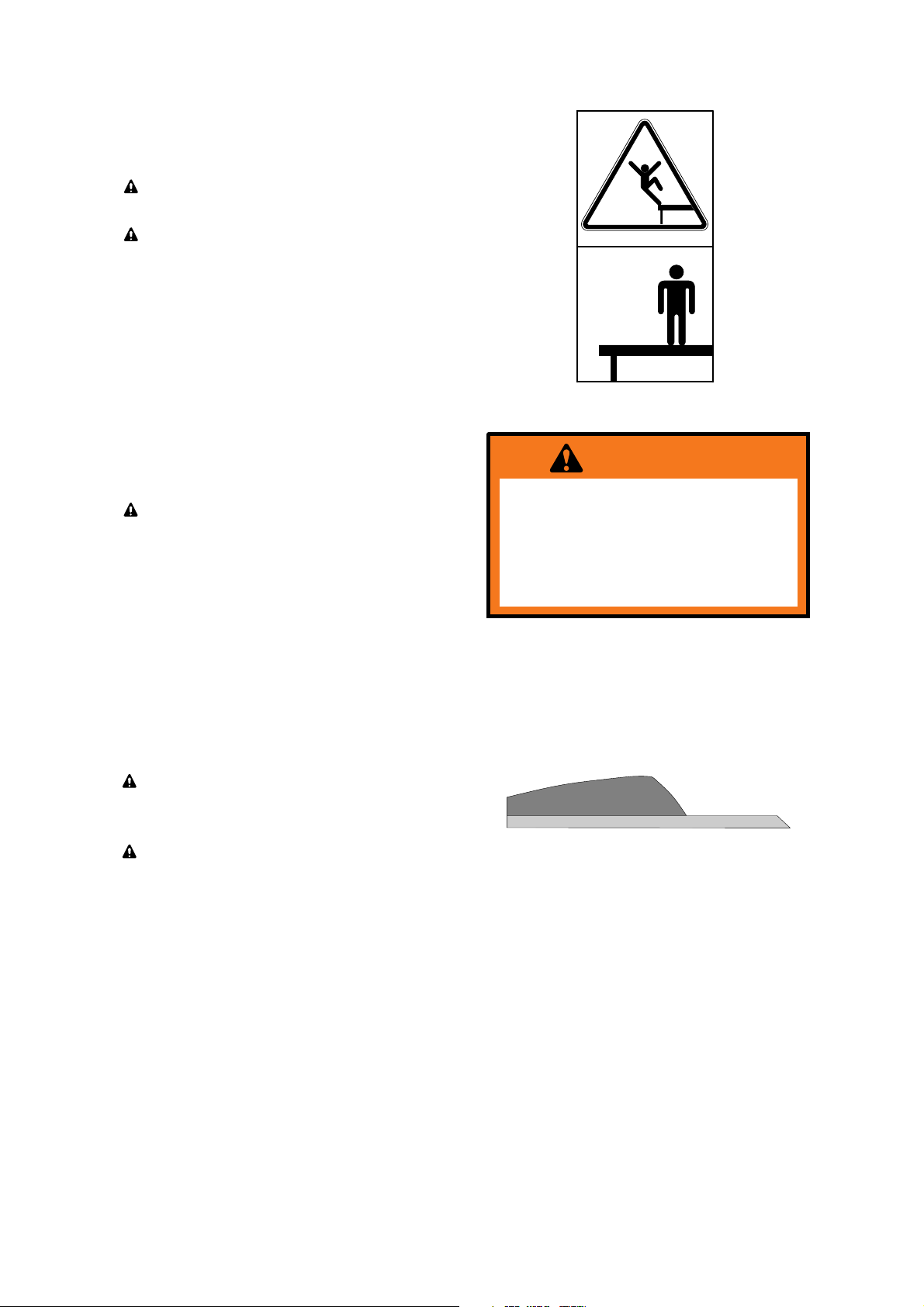

SAFETY LEVER

Before you get off the machine be sure

to place the safety lever LOCKED position.

22)

23)

REDUCTION GEAR GREASE

Grease is under high pressure.

Grease coming out of the grease plug

under pressure can penetrate the body

causing injury or death.

CLAMP-LOCKING

Serious injury or death can result from

dropping bucket.

Operating the machine with quick clamp

switch unlocked or without safety pin of

moving hook can cause the bucket to

drop off.

24)

25)

AIR CONDITIONER FILTER (item 24)

22)

This warning label is positioned on the air

conditioner cover.

※

Periodic and proper inspection, cleaning

and change of filter prolong air conditioner life time and maintain good performance.

SAFETY LEVER (item 26)

23)

This warning label is positioned on the

cover of the safety lever.

Before you get off the machine be sure

to place the safety lever LOCKED position.

21070FW26

REDUCTION GEAR GREASE (item 31)

24)

This warning label is positioned in the front

of upper frame.

Grease is under high pressure.

Grease coming out of the grease plug

under pressure can penetrate the body

causing injury or death.

CLAMP-LOCKING (item 32)

25)

This warning label is positioned on the right

side window of cab.

Serious injury or death can result from

dropping bucket.

Operating the machine with quick clamp

switch unlocked or without safety pin of

moving hook can cause the bucket to

drop off.

30007A1FW07A

21070FW35

14070FW60

0-12

Page 14

TIE

Make sure no personal are standing

close to the tow rope.

See page 4-23 for detail.

KEEP CLEAR-BOOM/ARM

Serious injury or death can result from

falling of the attachment.

To prevent serious injury or death, keep

clear the underneath of attachment.

26)

27)

ELECTRIC WELDING

Before carrying out any electric welding

on this machine, follow the below procedure.

See page 6-41 for detail.

28)

TIE (item 36)

26)

This warning label is positioned on the

lower frame.

Make sure no personal are standing

close to the tow rope.

See page 4-23 for detail.

KEEP CLEAR-BOOM/ARM (item 37)

27)

This warning label is positioned on both

side of the arm.

Serious injury or death can result from

falling of the attachment.

To prevent serious injury or death, keep

clear the underneath of attachment.

4507A0FW02

ELECTRIC WELDING (item 38)

28)

This warning label is positioned on the battery cover.

Before carrying out any electric welding

on this machine, follow the below procedure.

Pull the connector out of all electric con-

trol units.

-

Connector the ground lead of the welding equipment as close to the welding

point as possible.

※

See page 6-41 for detail.

14070FW31

W A R N I N G

·Before carrying out any electric welding on this

machine

- Pull the connectors out of all electronic control

units.

- Connect the ground lead of the welding equipment

as close to the welding point as possible.

·Read the instructions in operator's manual for

details.

7807AFW20

0-13

Page 15

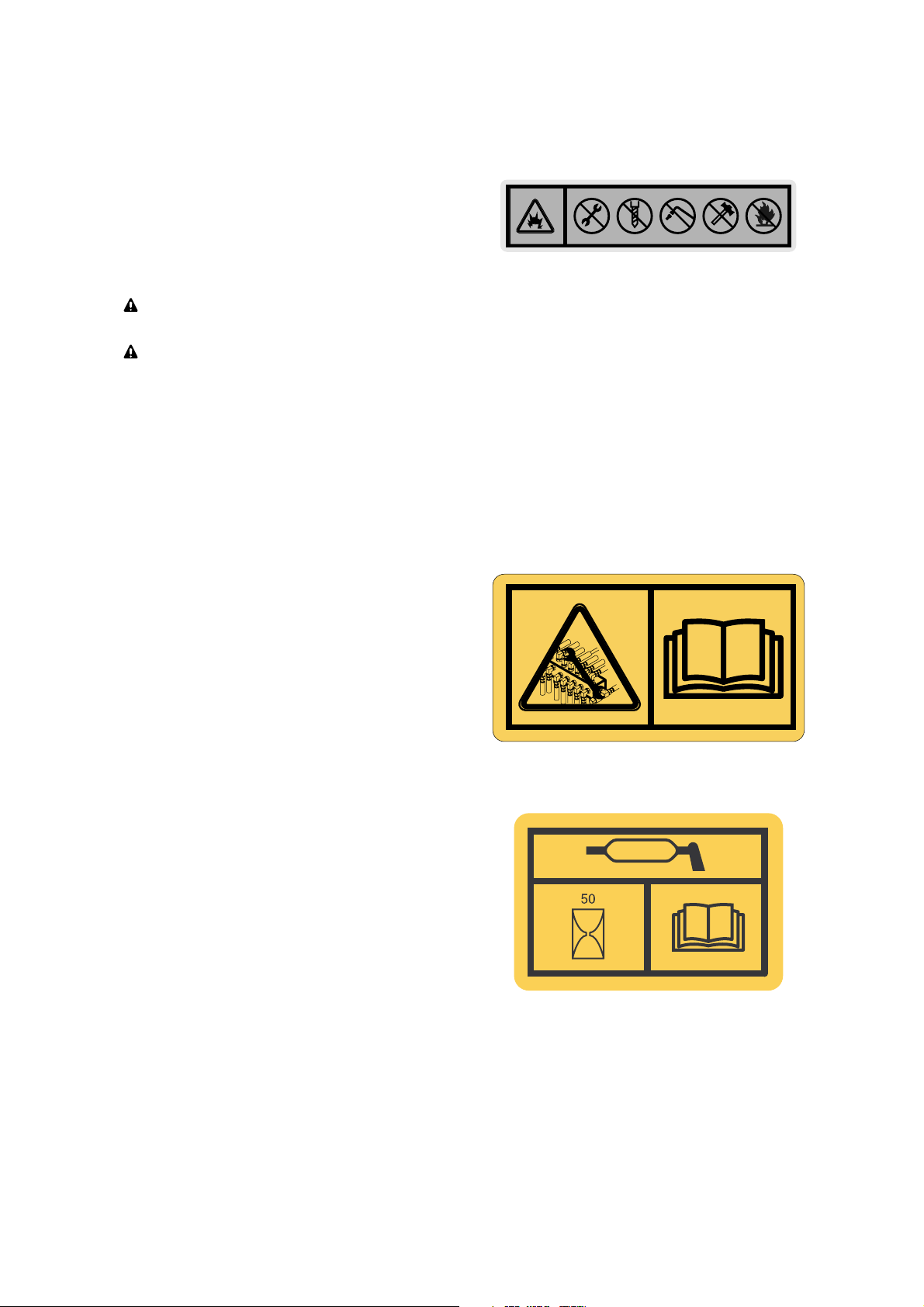

TURBOCHARGER

In order to prevent turbocharger failure,

please allow more than 5 minutes' cool

down period (no load low idle operation)

before shutting the engine off.

REFLECTING

To prevent serious personal injury or

death keep clear of machine swing radius.

Do not deface or remove this label from

the machine.

30)

31)

FALLING

Falling is one of the major cause of personal injury.

Be careful of slippery conditions on the

platforms, steps and handrails when

standing on the machine.

29)

FALLING (item 39)

29)

These warning labels are positioned on the

top of the hydraulic tank and counterweight.

Falling is one of the major cause of personal injury.

Be careful of slippery conditions on the

platforms, steps and handrails when

standing on the machine.

TURBOCHARGER (item 41)

30)

This warning label is positioned on the right

window of the cab.

In order to prevent turbocharger failure,

please allow more than 5 minutes' cool

down period (no load low idle operation)

before shutting the engine off.

14070FW30

C A U T I O N

In order to prevent turbocharger failure,

please allow more than 5 minutes' cool

down period(no load low idle operation)

before shutting the engine off.

REFLECTING (item 42)

31)

This warning label is positioned on the rear

of counterweight.

To prevent serious personal injury or

death keep clear of machine swing radius.

Do not deface or remove this label from

the machine.

7807AFW20

21090FW70

0-14

Page 16

ACCUMULATOR

The accumulator is filled with high-pressure nitrogen gas, and it is extremely

dangerous if it is handled in the wrong

way. Always observe the following precautions.

Never make any hole in the accumulator

expose it to flame or fire.

Do not weld anything to the accumulator.

When carrying out disassembly or maintenance of the accumulator, or when disposing of the accumulator, it is necessary to release the gas from the accumulator. A special air bleed valve is necessary for this operation, so please contact your Hyundai distributor.

32)

SWING BEARING

See page 6-32 for details.

34)

RCV LEVER PATTERN

See page 4-34 for details.

33)

ACCUMULATOR (item 43)

32)

This warning label is positioned on the

accumulator of the solenoid valve.

※

The accumulator is filled with high-pressure nitrogen gas, and it is extremely

dangerous if it is handled in the wrong

way. Always observe the following precautions.

Never make any hole in the accumulator

expose it to flame or fire.

Do not weld anything to the accumulator.

※

When carrying out disassembly or maintenance of the accumulator, or when disposing of the accumulator, it is necessary to release the gas from the accumulator. A special air bleed valve is necessary for this operation, so please contact your Hyundai distributor.

1107A0FW46

RCV LEVER PATTERN (item 46)

33)

This warning label is positioned on the

screen plate.

※

See page 4-34 for details.

SWING BEARING (item 47)

34)

This warning label is positioned in the front

of swing ring gear.

※

See page 6-32 for details.

14W90FW47

38090FW02

0-15

Page 17

BATTERY POSITION

35)

BEACON LAMP

Make sure the beacon lamp maintains a

vertical position.

A horizontal position can result in a

decrease in life time of the lamp due to

the infiltration of foreign substances such

as dust or water.

While the machine transfer, the beacon lamp

is easy to break. In that case, change the

position of the lamp to the horizontal.

36)

FUEL SHUT OFF

Fill only the hydraulic oil.

Do not fill the diesel fuel.

37)

WATER SEPARATOR

In order to protect high pressure fuel

system, please drain water in water

separator before starting the engine.

38)

35)

BATTERY POSITION (item 48)

This warning label is positioned right side of

tool box.

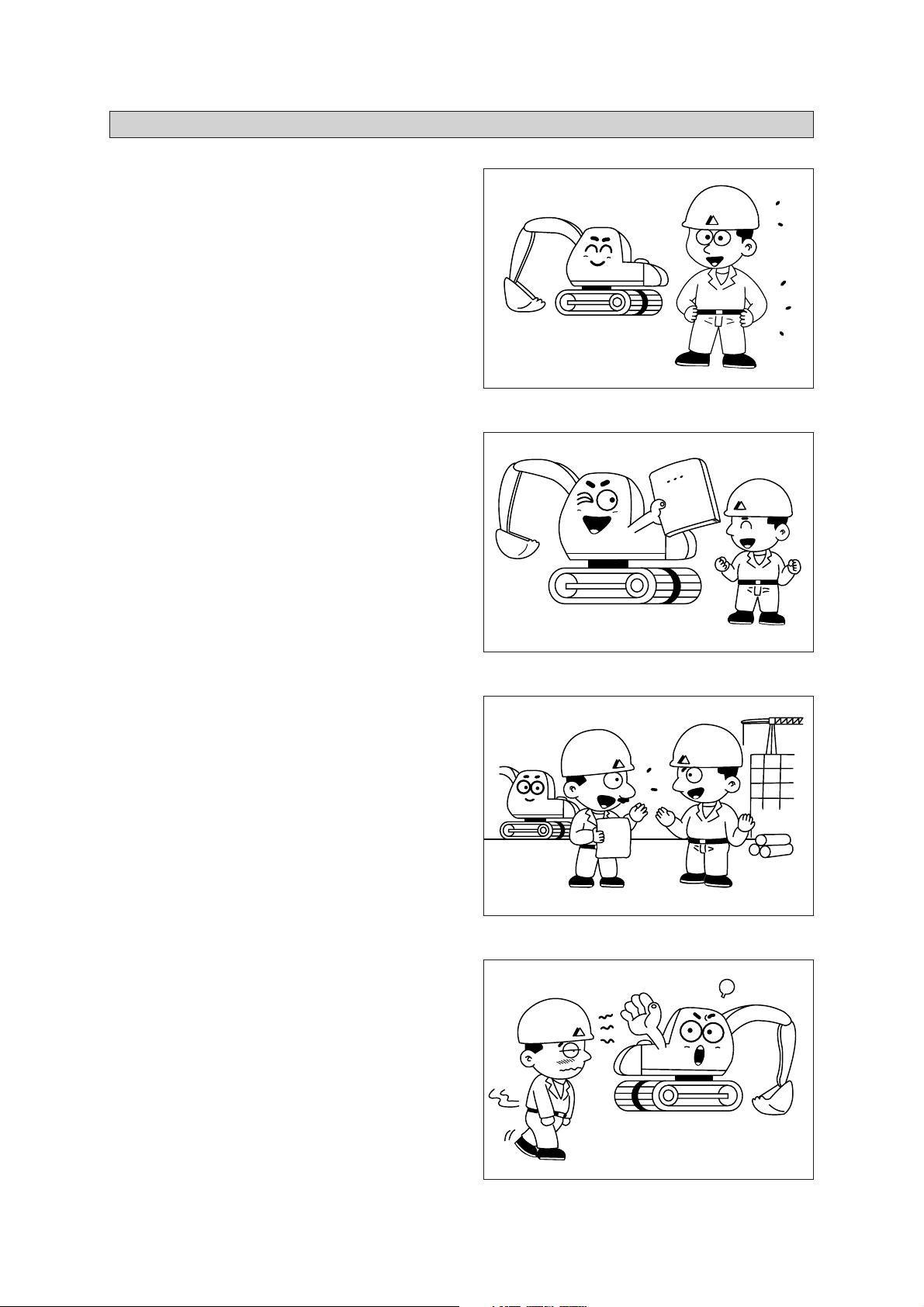

BEACON LAMP (item 49)

36)

This warning label is positioned on the right

outside of the cabin.

※

Make sure the beacon lamp maintains a

vertical position.

A horizontal position can result in a

decrease in life time of the lamp due to

the infiltration of foreign substances such

as dust or water.

While the machine transfer, the beacon lamp

※

is easy to break. In that case, change the

position of the lamp to the horizontal.

38090FW03

140Z90FW49

FUEL SHUT OFF (item 50)

37)

This warning label is positioned on the left

side of the hydraulic tank.

※

Fill only the hydraulic oil.

※

Do not fill the diesel fuel.

WATER SEPARATOR (item 51)

38)

This warning label is positioned in right window of the cab.

In order to protect high pressure fuel

system, please drain water in water

separator before starting the engine.

140WH90FW51

In order to protect high pressure fuel system,

please drain water in water separator before

starting the engine.

210N90FW50

0-16

Page 18

MCU CONNECTOR

MCU communicates the machine data with

Laptop computer through RS232 service

socket.

See page 3-60 for details.

39)

39)

MCU CONNECTOR (item 52)

This warning label is positioned on the low

cover of the air conditioner in the cab.

※

MCU communicates the machine data with

Laptop computer through RS232 service

socket.

See page 3-60 for details.

※

1409S0FW52

0-17

Page 19

MACHINE DATA PLATE

MACHINE DATA PLATE

1000, BANGEOJINSUNHWAN-DORO, DONG-GU, ULSAN 682-792, KOREA

EQUIPMENT

1

2

MODEL

SERIAL-NUMBER

3

DO NOT DEFACE OR REMOVE THIS PLATE

OPERATING WEIGHT

ENGINE POWER(PS/KW/rpm)

1

4

2

5

3

1000, BANGEOJINSUNHWAN-DORO, DONG-GU, ULSAN 682-792, KOREA

EQUIPMENT

MODEL

SERIAL-NUMBER

DO NOT DEFACE OR REMOVE THIS PLATE

OPERATING WEIGHT

ENGINE POWER(PS/KW/rpm)

MFG. YEAR

FOR EU ONLY

1 Equipment

2 Model name

The machine serial number assigned to this particular machine and should be used when request-

※

3 Serial number

4 Operating weight

5 Engine power

6 Manufacturing year

ing information or ordering service parts for this machine from your authorized HYUNDAI dealer.

The machine serial number is also stamped on the frame.

4

5

6

21090FW10

0-18

Page 20

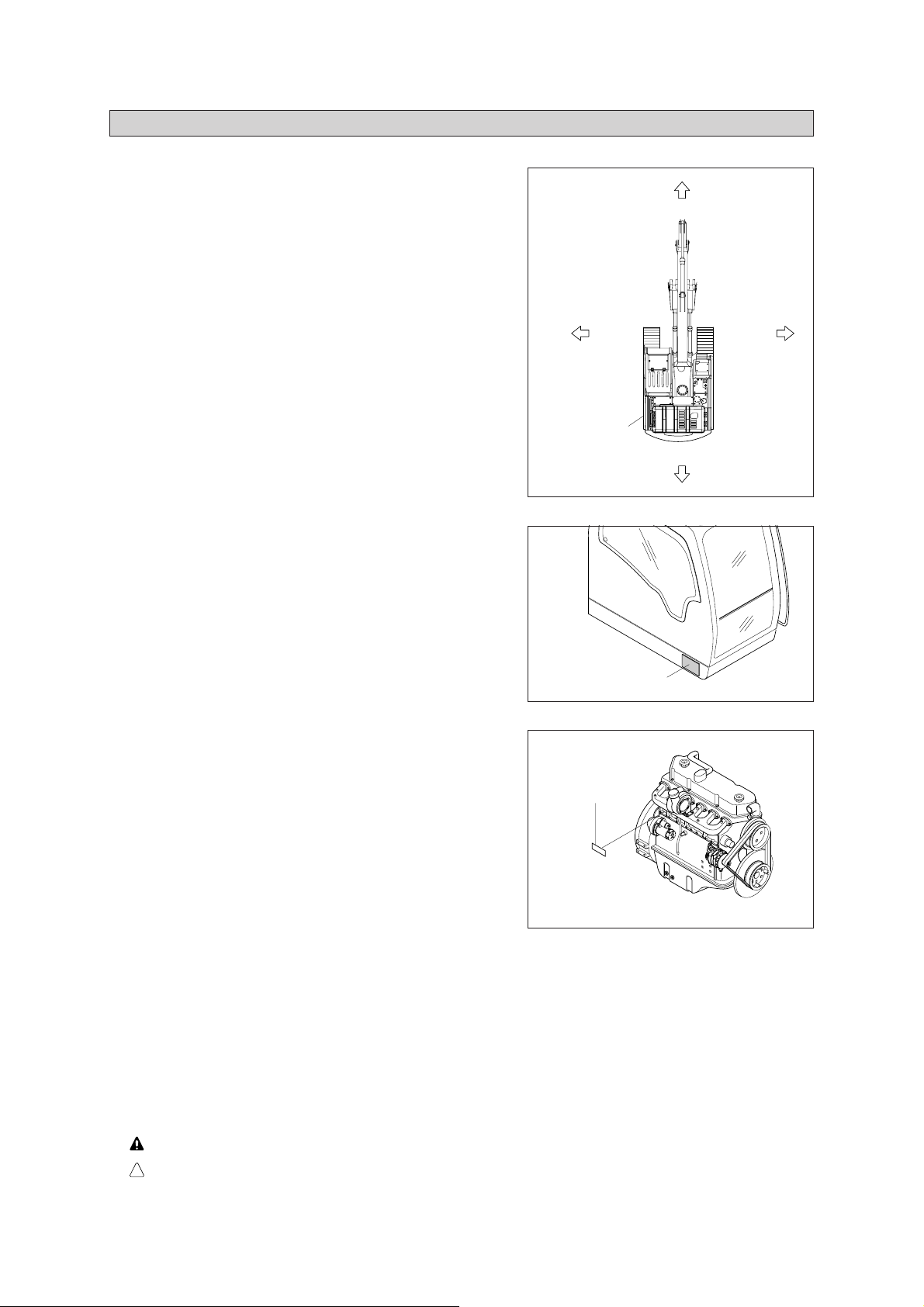

GUIDE

1. DIRECTION

2. SERIAL NUMBER

MACHINE SERIAL NUMBER

4. SYMBOLS

Important safety hint.

It indicates matters which can cause the great loss on the machine or the surroundings.

It indicates the useful information for operator.

1)

ENGINE SERIAL NUMBER

2)

3.

INTENDED USE

GUIDE

1. DIRECTION

The direction of this manual indicate forward, back-

ward, right and left on the standard of operator

when the travel motor is in the rear and machine is

on the traveling direction.

2. SERIAL NUMBER

Inform following when you order parts or the

machine is out of order.

1)

MACHINE SERIAL NUMBER

The numbers are located below the right window

of the operator's cab.

Forward

Travel motor

Backward

Machine serial No.

RightLeft

16090SG01

21090SN02

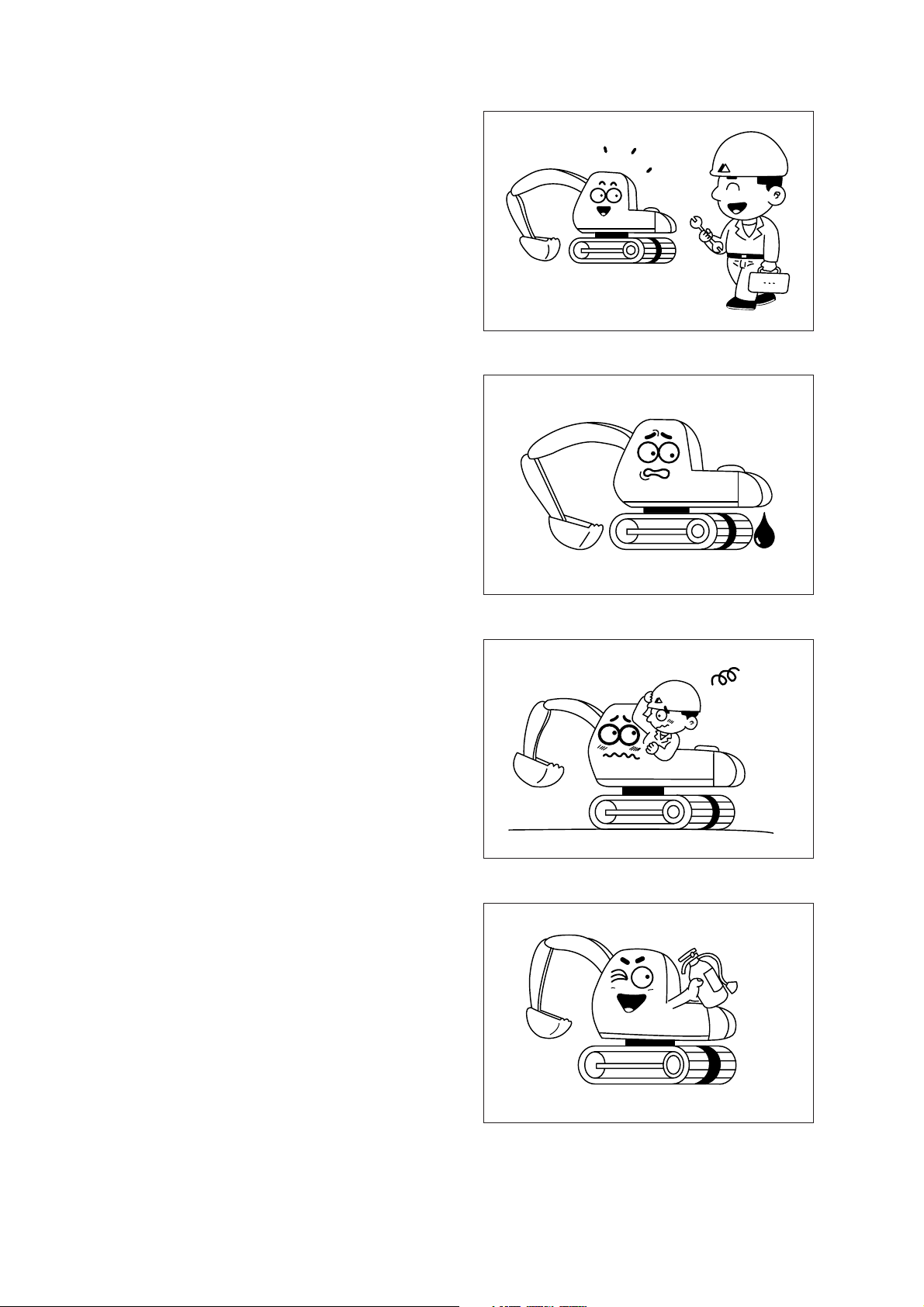

ENGINE SERIAL NUMBER

2)

The numbers are located on the engine name

plate.

3.

INTENDED USE

Engine serial No.

This machine is designed to be used mainly for the following work.

- Digging work

- Loading work

- Smoothing work

- Ditching work

※

Please refer to the section 4 (efficient working method) further details.

4. SYMBOLS

Important safety hint.

It indicates matters which can cause the great loss on the machine or the surroundings.

17W9S0SN01

※

It indicates the useful information for operator.

0-19

Page 21

1. BEFORE OPERATING THE MACHINE

SAFETY HINTS

1. BEFORE OPERATING THE MACHINE

Think-safety first.

In special situation, wear protective clothing

including a safety helmet, safety shoes, gloves,

safety glasses and ear protection as required by

the job condition.

Almost every accident is caused by disregarding the simple and fundamental safety

hints.

Be sure to understand thoroughly all about the

operator's manual before operating the

machine.

Proper care is your responsibility.

SAFETY HINTS

13031SH01

Fully understand the details and process of the

construction before starting the work.

If you find anything dangerous on the job,

consult with the job supervisor for the preventive measures before operating the machine.

Do not operate when tired, or after drinking

alcoholic beverages or any type of drugs.

13031SH02

13031SH03

1-1

13031SH05

Page 22

Check daily according to the operation manual.

Repair the damaged parts and tighten the loosened bolts.

Check for leakage of engine oil, hydraulic oil,

fuel and coolant.

Keep machine clean, clean machine regularly.

13031SH05

Do not operate the machine if it requires repairs.

Operate after complete repair.

Be prepared if a fire starts.

Keep a fire extinguisher handy and emergency

numbers for a fire department near your telephone.

13031SH06

13031SH07

1-2

13031SH08

Page 23

PROTEC TIO N AGAINS T FALLI NG OR

FLYING OBJECTS

UNAUTHORIZED MODIFICATION

PREPARE FOR EMERGENCY

PROTECTION AGAINST FALLING OR

FLYING OBJECTS

If there is any danger of falling or flying objects

hitting the operator, install protective guards in

place to protect the operator as required for

each particular situation.

Be sure to close the front window before commencing work.

Make sure to keep all persons other than operator outside the range of falling or flying objects.

In case you need top guard, front guard and

FOPS (falling object protective structure),

please contact Hyundai distributor in Europe.

UNAUTHORIZED MODIFICATION

Any modification made without authorization

from Hyundai can create hazards.

Top guard

Front guard

21091SH01

Before making a modification, consult your

Hyundai distributor. Hyundai will not be responsible for any injury or damage caused by any

unauthorized modification.

PREPARE FOR EMERGENCY

Only in case of emergency, use the installed

hammer for breaking the windshield of the cab,

and then exit carefully.

Be sure you know the phone numbers of persons you should contact in case of an emergency.

Hammer

1-3

21091SH02

Page 24

ROTATING BEACON

PRECAUTIONS FOR ATTACHMENTS

SAFETY RULES

Only

ROTATING BEACON

When you operate a machine on a road or

beside a road, a rotating beacon is required to

avoid any traffic accident.

Please contact your Hyundai distributor to install

it.

PRECAUTIONS FOR ATTACHMENTS

When installing and using an optional attachment, read the instruction manual for the attachment and the information related to attachments

in this manual.

Do not use attachments that are not authorized

by Hyundai or your Hyundai distributor. Use of

unauthorized attachments could create a safety

problem and adversely affect the proper operation and useful life of the machine.

Beacon

21091SH03

Any injuries, accidents, product failures resulting

from the use of unauthorized attachments are

not the responsibility of Hyundai.

The stability of this machine is enough to be

used for general work. When you operate this

machine, allow for the lifting capacity tables. If

you want to use other special applications (not

covered in this manual), you have to attach

additional counterweight or be cautious while

running the machine.

SAFETY RULES

Only trained and authorized personnel can

operate and maintain the machine.

Follow all safety rules, precautions and instructions when operating or performing maintenance on the machine.

When working with another operator or a person on worksite traffic duty, be sure all personnel understand all hand signals that are to be

used.

1-4

Page 25

SAFETY FEATURES

Never

Always

MACHINE CONTROL PATTERN

CALIFORNIA PROPOSITION 65

The wrong loading method can result in serious bodily injury or death.

SAFETY FEATURES

Be sure all guards and covers are in their proper position. Have guards and covers repaired if

damaged.

Use safety features such as safety lock and

seat belts properly.

Never remove any safety features.

Always

keep them in good operating condition.

Improper use of safety features could result in

serious bodily injury or death.

MACHINE CONTROL PATTERN

Check machine control pattern for conformance

to pattern on label in cab.

If not, change label to match pattern before

operating machine.

Failure to do so could result in injury.

CALIFORNIA PROPOSITION 65

Diesel engine exhaust and some of its constituents are known to the State of California to

cause cancer, birth defects and other reproductive harm.

This product contains or emits chemicals known

to the State of California to cause cancer or

birth defects or other reproductive harm.

Battery posts, terminals and related accessories contain lead and lead compounds.

WASH HANDS AFTER HANDLING

WASH HANDS

AFTER HANDLING !

contain lead and lead compounds,chemicals known to the

State of California to cause cancer and reproductive harm.

: Battery posts, terminals and related accessories

13031SH55

Do not load the machine with the lifting eyes on

the counterweight.

The wrong loading method can result in serious bodily injury or death.

1-5

Page 26

2. DURING OPERATING THE MACHINE

2. DURING OPERATING THE MACHINE

Use the handle and footstep when getting on or

off the machine.

Do not jump on or off the machine.

Sound the horn to warn nearby personnel

before operating the machine.

Remove all the obstacles like frost on the window before operating the machine for the good

visibility.

13031SH09

Operate carefully to make sure all personnel or

obstacles are clear within the working range of

the machine.

Place safety guards if necessary.

When using the work equipment, pay attention

to job site.

13031SH10

13031SH11

1-6

13031SH12

Page 27

Provide proper ventilation when operating

engine in a closed area to avoid the danger of

exhaust gases.

Check the locations of underground gas

pipes or water line and secure the safety before

operation.

13031SH13

The operating near the electrical lines is very

dangerous.

Operate within safe working range permitted as

below.

Supply voltage

6.6

kV

33.0

kV

66.0

kV

154.0

kV

275.0

kV

Min safe separation

3m (10 ft)

4m (13 ft)

5

m

(16 ft)

m

(26 ft)

8

10m (33 ft)

If the machine touches the electric power lines,

keep sitting on the operator's seat and make

sure the personnel on the ground not to touch

the machine until turning off the electric current. Jump off the machine without contacting

the machine when you need to get off.

13031SH14

13031SH15

1-7

13031SH16

Page 28

Watch out for obstacles.

Be particularly careful to check the machine

clearance during the swing.

When using the machine as breaker or

working in a place where stones may fall down,

cab roof guard and head guard should be provided for proper protection.

13031SH17

Avoid operating on a cliff or soft ground as there

is danger of rolling over.

Make sure to get off easily as keeping the track

at a right angle and putting the travel motor into

the backward position when working on a cliff or

soft ground inevitably.

Operate for the lifting work considering the

capacity of machine, weight and width of the

load.

Be careful not to lift exceeding the machine

capacity as it can be the cause of machine

damage and safety accident.

13031SH18

13031SH19

1-8

13031SH20

Page 29

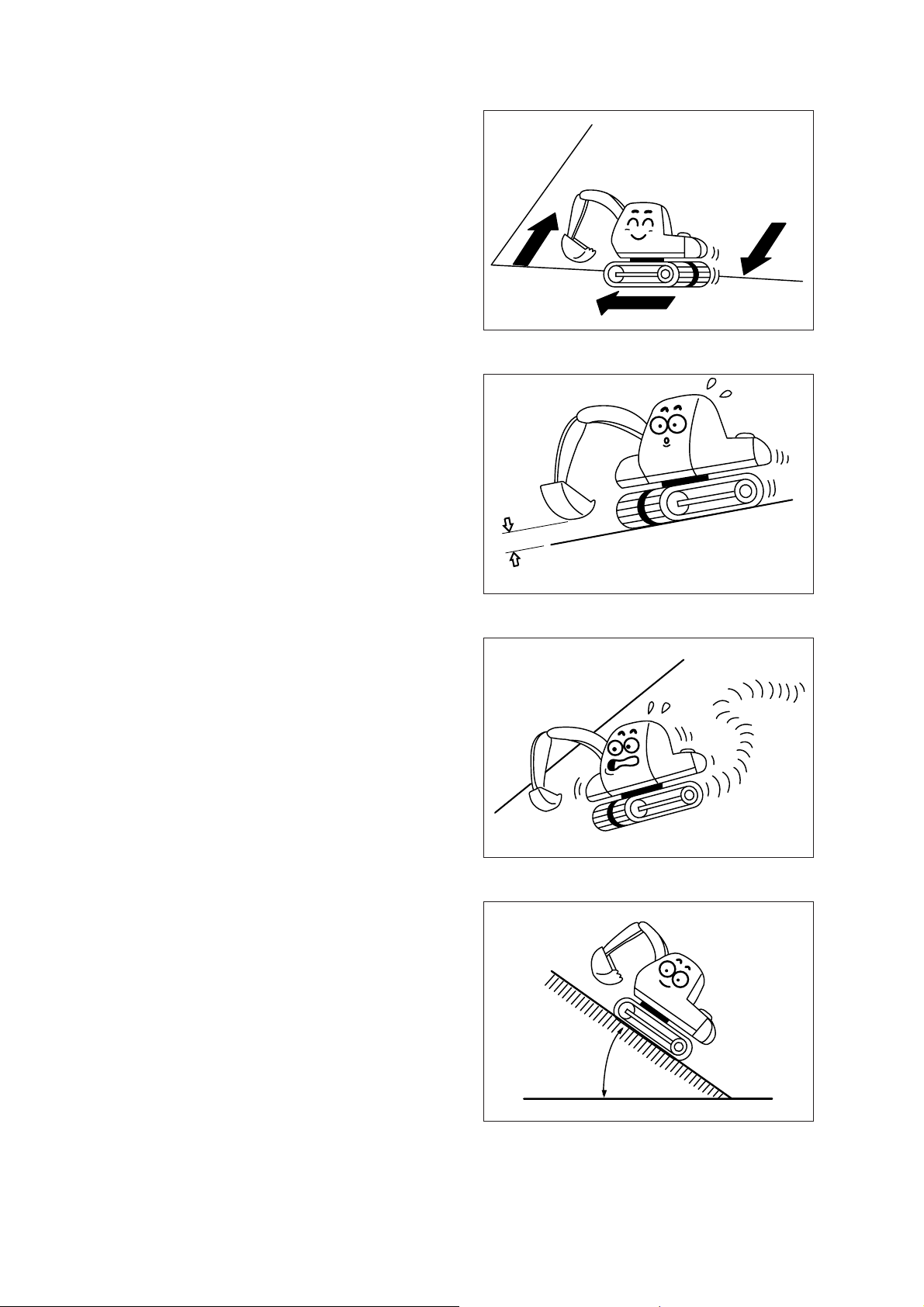

The operation on a slope is dangerous.

Avoid operating the machine on a slope of over

10 degree.

Operate the machine after making ground flat

when operation is required on a slope.

13031SH21

The swing on the slope can be danger of

rolling over.

Do not operate to swing the machine with the

bucket loaded on a slope since the machine

may lose its balance under such an instance.

Avoid parking and stopping on a slope.

Lower the bucket to the ground and block the

track when parking.

13031SH22

13031SH23

1-9

13031SH24

Page 30

Avoid traveling in a cross direction on a slope as

it can cause the danger of rolling over and sliding.

Traveling on a slope is dangerous.

Be sure to operate slowly when traveling down

a slope and maintain the bucket at a height of

20~30

cm

(1 ft) above the ground so that it can

be used as brake in an emergency.

13031SH25

Steering of the machine while traveling on a

slope is dangerous.

When an inevitable turning of direction is

required, turn on the flat and solid ground.

The engine angularity limits are 35 degree.

Do not operate by more than the engine limits

in any case.

20~30

cm

13031SH26

13031SH27

1-10

35。

13031SH28

Page 31

Before traveling the machine, sound the horn

to warn nearby personnel.

Operate forward and backward correctly with

confirming the location of the travel motor.

Slow down when traveling through obstacles or

uneven ground.

13031SH29

When working on soft ground, place mats or

wood boards on the ground to prevent the

machine sinking.

When operating in water or when crossing shallow, check the bed soil condition and depth and

flow speed of water, then proceed taking care

that water is not above carrier roller.

13031SH30

13031SH31

1-11

13031SH32

Page 32

MOUNTING AND DISMOUNTING

Never

Never

KEEP RIDERS OFF MACHINE

MOUNTING AND DISMOUNTING

Never jump on or off the machine.

Never get on or off

a moving machine.

When mounting or dismounting, always face the

machine and use the handrails, machine or track

frame steps, and track shoes. Additional track frame

step can be fitted for wider optional shoe. In this case

please contact your Hyundai distributor.

Do not hold any control levers when getting on or off

the machine.

Ensure safety by always maintaining at least threepoint contact of hands and feet with the handrails,

steps or track shoes.

Always remove any oil or mud from the handrails,

steps and track shoes. If they are damaged, repair

them and tighten any loose bolts.

If grasping the door handrail when mounting or dismounting or moving on the track, open and lock the

door securely in the open position. Otherwise, the

door may move suddenly, causing you to lose balance

and fall.

KEEP RIDERS OFF MACHINE

Riders on a machine are subject to injury such as

being struck objects and being thrown off the

machine.

Only allow the operator on the machine. Keep riders

off.

14071FW05/06

1-12

Page 33

3. DURING MAINTENANCE

3. DURING MAINTENANCE

Stop the engine immediately when the trouble

of the machine is found.

Inspect immediately the cause of trouble such

as vibration, overheating and trouble in the cluster then repair.

Park on a flat place and stop the engine for

inspecting and repairing. Properly TAG

machine is not operational. (remove start key)

Extreme care shall be taken during maintenance work. Parts may require additional safe

guard.

13031SH33

ON THE

INSPECTION

Do not remove the radiator cap from hot engine.

Open the cap after the engine cools, below 50

°C (122 °F) to prevent personal injury from heated coolant spray or steam.

Do not work below the machine.

Be sure to work with proper safety supports.

Do not depend on the hydraulic cylinders to

hold up the equipment and attachment.

13031SH34

13031SH35

1-13

13031SH36

Page 34

There is the danger of fire in fuel and oil.

Store in cool and dry area, away from any open

flames.

Do not touch exhaust pipe, or may cause

severe burn.

13031SH37

Do not open the engine hood and covers while

the engine is running.

Be careful of not hitting the edges when you

service engine.

13031SH38

13031SH39

1-14

13031SH40

Page 35

Be careful that the front window may be prompt-

HIGH PRESSURE GAS

LIFT EYES CAN FAIL

ly closed.

Be sure to support stay, when the side door

needs to be opened.

Be careful that the open side door may closed

by the external or natural force like strong wind.

The antislip protection should be replaced if

they have become worn or have been printed

over.

Be sure to free of oil, water and grease etc.

13031SH41

Be careful of not touching slip, fall down etc.,

when you work at the upper frame to service

engine and/or other component.

HIGH PRESSURE GAS

Contain high pressure gas.

To avoid explosion and personal injury, do not

expose to fire, do not weld, do not drill.

Relieve pressure before discharging.

13031SH42

13031SH43

21091SH08

LIFT EYES CAN FAIL

Lift eyes or tank can fail when lifting tank

taining fluids resulting in possible personal injury.

Drain tank of all fluids before lifting.

con-

1-15

Page 36

4. PARKING

4. PARKING

When leaving the machine after parking,

lower the bucket to the ground completely and

put the safety lever at parking position then

remove the key.

Lock the cab door.

Park the machine in the flat and safe place.

13031SH44

P

Hope you can work easily and safely

observing safety rules.

For safe operation, observe all safety rules.

13031SH45

13031SH46

1-16

Page 37

1. MAJOR COMPONENT

SPECIFICATIONS

R160LC-9S

1)

1. MAJOR COMPONENT

R160LC-9S

1)

SPECIFICATIONS

Tool box Fuel tank Hydraulic tank Main pump

Engine

Oil cooler

Radiator

Bucket cylinder

Side cutter

Tooth Turning joint Swing motor

Control link

Control rod

Bucket

Boom cylinderBoomArm cylinderArm

Idler

Carrier roller

Cab

Track

Track roller

Main control valve

Muffler

Travel motor

Sprocket

Counterweight

2-1

1609S2SP01

Page 38

2. SPECIFICATIONS

R160LC-9S

·

5.1 m (16' 9") BOOM and 2.6 m (8' 6") ARM

1)

2. SPECIFICATIONS

R160LC-9S

1)

5.1 m (16' 9") BOOM and 2.6 m (8' 6") ARM

I(I')

C

E

G

t

e

k

c

u

B

F

J

K

N

A

Description Unit Specification

Operating weight

Bucket capacity (SAE heaped), standard

Overall length A

kg (lb)

m3 (yd3)

17800 (39240)

0.70 (0.92)

8650 (28' 5")

Overall width, with 600 mm shoe B 2590 ( 8' 6")

D

H

M

B(L)

16092SP02

Overall height C 2990 ( 9' 10")

Superstructure width D 2475 ( 8' 1")

Overall height of cab E 2980 ( 9' 9")

Ground clearance of counterweight F 1055 ( 3' 6")

Engine cover height G 2315 ( 7' 7")

Minimum ground clearance H 460 ( 1' 6")

mm (ft-in)

Rear-end distance I 2480 ( 8' 2")

Rear-end swing radius I' 2530 ( 8' 4")

Distance between tumblers J 3170 (10' 5")

Undercarriage length K 3960 (13' 0")

Undercarriage width L 2590 ( 8' 6")

Track gauge M 1990 ( 6' 6")

Track shoe width, standard N 600 (24")

Travel speed (low/high)

Swing speed

Gradeability

Ground pressure (600

mm

shoe)

km/hr (mph)

rpm

Degree (%

) 30 (58)

kgf/cm2(psi)

3.2/5.5 (2.0/3.4)

11.3

0.43 (6.11)

Max traction force

2-2

kg (lb)

17000 (37500)

Page 39

R160LC-9S

· 5.1 m (16' 9")

YDRAULIC ADJUSTABLE BOOM AND

2.6 m (8' 6") ARM

2)

R160LC-9S

2)

5.1 m (16' 9") H H

YDRAULIC ADJUSTABLE BOOM AND

2.6 m (8' 6") ARM

C

A

Description Unit Specification

Operating weight

Bucket capacity (SAE heaped), standard

Overall length A

mm

Overall width, with 600

shoe B 2590 ( 8' 6")

J

K

I(I')

kg (lb)

m3 (yd3)

D

E

G

F

H

M

N

B(L)

16092SP03

18290 (40320)

0.70 (0.92)

8610 ( 28' 3")

Overall height C 3060 ( 10' 0")

Superstructure width D 2475 ( 8' 1")

Overall height of cab E 2980 ( 9' 9")

Ground clearance of counterweight F 1055 ( 3' 6")

Engine cover height G 2315 ( 7' 7")

Minimum ground clearance H 460 ( 1' 6")

Rear-end distance I 2480 ( 10' 5")

Rear-end swing radius I' 2530 ( 8' 4")

Distance between tumblers J 3170 (10' 5")

Undercarriage length K 3960 (13' 0")

Undercarriage width L 2590 ( 8' 6")

Track gauge M 1990 ( 6' 6")

Track shoe width, standard N 600 (24")

Travel speed (low/high)

Swing speed

Gradeability

mm

Ground pressure (600

shoe)

mm (ft-in)

km/hr (mph)

rpm

Degree (%

kgf/cm2(psi)

) 30 (58)

3.2/5.5 (2.0/3.4)

11.3

0.44 (6.11)

Max traction force

2-3

kg (lb)

17000 (37500)

Page 40

C

R160LCD-9S

·

5.1 m (16' 9") BOOM and 2.6 m (8' 6") ARM

3)

R160LCD-9S

3)

5.1 m (16' 9") BOOM and 2.6 m (8' 6") ARM

I(I')

E

G

t

e

k

c

u

B

J

K

F

P

O

Q

N

A

Description Unit Specification

Operating weight

Bucket capacity (SAE heaped), standard

Overall length A

kg (lb)

m3 (yd3)

18800 (41450)

0.70 (0.92)

9100 (29' 10")

Overall width, with 600 mm shoe B 2590 ( 8' 6")

D

H

M

B(L)

16092SP04

Overall height C 2990 ( 9'10")

Superstructure width D 2475 ( 8' 1")

Overall height of cab E 2980 ( 9' 9")

Ground clearance of counterweight F 1055 ( 3' 6")

Engine cover height G 2315 ( 7' 7")

Minimum ground clearance H 460 ( 1' 6")

Rear-end distance I 2480 ( 8' 2")

mm (ft-in)

Rear-end swing radius I' 2530 ( 8' 4")

Distance between tumblers J 3170 (10' 5")

Undercarriage length K 3960 (13' 0")

Undercarriage width L 2590 ( 8' 6")

Track gauge M 1990 ( 6' 6")

Track shoe width, standard N 600 (24")

Height of blade O 640 (2' 1")

Ground clearance of blade up P 615 (2' 0")

Depth of blade down Q 675 (2' 3")

Travel speed (low/high)

km/hr (mph)

3.2/5.5 (2.0/3.4)

Swing speed

Gradeability

Ground pressure (600 mm shoe)

Max traction force

rpm

Degree (%

kgf/cm2(psi)

kg (lb)

11.3

) 30 (58)

0.46 (6.54)

17000 (37500)

2-4

Page 41

3. WORKING RANGE

5.1

BOOM

1)

3. WORKING RANGE

5.1 m (16' 9") MONO

1)

(16' 9") MONO

BOOM

D

E

B'

B

A

A'

F

C

Description

Max digging reach

Max digging reach on ground

Max digging depth

Max digging depth (8ft level)

Max vertical wall digging depth

Max digging height

Max dumping height

Min swing radius

Bucket digging force

Arm crowd force

8ft

2.2 m (7' 3") Arm 2.6 m (8' 6") Arm 3.1 m (10' 2") Arm

A

8690 mm (28' 6") 9020 mm (29' 7") 9450 mm (31' 0")

A'

8530 mm (28' 0") 8860 mm (29' 1") 9300 mm (30' 6")

B

5660 mm (18' 7") 6060 mm (19'11") 6560 mm (21' 6")

B'

5430 mm (17'10") 5850 mm (19' 2") 6370 mm(20'11")

C

5120 mm (16'10") 5380 mm (17' 8") 5710 mm(18' 9")

D

8750 mm (28' 8") 8840 mm (29' 0") 8980 mm (29' 6")

E

6110 mm (20' 1") 6220 mm (20' 5") 6390 mm (21' 0")

F

3180 mm (10' 5") 3170 mm (10' 5") 3170 mm (10' 5")

SAE

ISO

SAE

ISO

107.9 [117.2]

11000 [11940]

24250 [26330]

123.6 [134.2]

12600 [13680]

27780 [30160]

87.2 [94.7]

8890 [9650]

19600 [21280]

91.0 [98.8]

9280 [10080]

20460 [22210]

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

107.9 [117.2]

11000 [11940]

24250 [26330]

123.6 [134.2]

12600 [13680]

27780 [30160]

77.3 [83.9]

7880 [8560]

17370 [18860]

80.3 [87.2]

8190 [8890]

18060 [19600]

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

11000 [11940]

24250 [26330]

12600 [13680]

27780 [30160]

15500 [16830]

16050 [17430]

107.9 [117.2]

123.6 [134.2]

69.0 [74.9]

7030 [7630]

71.4 [77.5]

7280 [7900]

16092SP05

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

[ ] : Power boost

2-5

Page 42

5.1 m (16' 9")

YDRAULIC ADJUSTABLE BOOM

2)

2)

5.1 m (16' 9") H H

YDRAULIC ADJUSTABLE BOOM

A

A'

D

E

C

B'

B

F

Description

Max digging reach

Max digging reach on ground

Max digging depth

Max digging depth (8ft level)

Max vertical wall digging depth

Max digging height

Max dumping height

Min swing radius

Bucket digging force

Arm crowd force

[ ] : Power boost

A

A'

B

B'

C

D

E

F

SAE

ISO

SAE

ISO

8ft

2.2 m (7' 3") Arm 2.6 m (8' 6") Arm

8760 mm(28' 9") 9110 mm(29'11")

8590 mm(28' 2") 8950 mm(29' 4")

5430 mm(17' 10") 5830 mm(19' 2")

5330 mm(17' 6") 5730 mm(18'10")

4630 mm(15' 2") 4980 mm(16' 4")

9420 mm(30' 11") 9610 mm(31' 6")

6710 mm(22' 0") 6910 mm(22' 8")

3100 mm(10' 2") 2970 mm( 9' 9")

107.9 [117.2]

11000 [11940]

24250 [26330]

123.6 [134.2]

12600 [13680]

27780 [30160]

87.2 [94.7]

8890 [9650]

19600 [21280]

91.0 [98.8]

9280 [10080]

20460 [22210]

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

107.9 [117.2]

11000 [11940]

24250 [26330]

123.6 [134.2]

12600 [13680]

27780 [30160]

77.3 [83.9]

7880 [8560]

17370 [18860]

80.3 [87.2]

8190 [8890]

18060 [19600]

16092SP06

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

kN

kgf

lbf

2-6

Page 43

4. WEIGHT

4. WEIGHT

Item

Upper structure assembly 7880 17370

Main frame weld assembly 1440 3180

Engine assembly 440 970

Fan clutch assembly 45 100

Main pump assembly 100 220

Main control valve assembly 140 310

Swing motor assembly 250 550

Hydraulic oil tank assembly 165 360

Fuel tank assembly 130 290

Counterweight 2900 6390

Cab assembly 440 970

Lower chassis assembly 6900 15210 7900 17420

Track frame weld assembly 2100 4630 2080 4590

Swing bearing 260 570

Travel motor assembly 235 520

Turning joint 60 130

Track recoil spring 140 310

Idler 160 350

Carrier roller 20 45

Track roller 40 90

Track-chain assembly (600 mm standard triple grouser shoe) 1160 2560

Front attachment assembly (5.1 m boom, 2.6 m arm,

0.7

m3 SAE heaped bucket)

5.1 m boom assembly 1060 2340

2.6 m arm assembly 560 1240

0.7

m3 SAE heaped bucket

Boom cylinder assembly 155 340

Arm cylinder assembly 180 400

Bucket cylinder assembly 125 280

Bucket control link assembly 120 265

Dozer blade assembly - - 655 1445

Dozer blade cylinder assembly - - 66 146

R160LC-9S R160LCD-9S

kg lb kg lb

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

3020 6660

540 1190

←

←

←

←

←

←

←

←

2-7

Page 44

R160LC-9S

1)

5. LIFTING CAPACITIES

5. LIFTING CAPACITIES

R160LC-9S

1)

5.1 m (16' 9") boom, 2.6 m (8' 6") arm equipped with 0.70

(1)

(24") triple grouser shoe and 2900

kg

(6390 Ib) counterweight.

m3 (SAE heaped) bucket and 600 mm

·

: Rating over-front : Rating over-side or 360 degree

·

Load radius At max. reach

Load

point

height

7.5

mkg

25.0 ft)

(

6.0

mkg

20.0 ft)

(

4.5

mkg

15.0 ft)

(

3.0

mkg

10.0 ft)

(

1.5

mkg

5.0 ft)

(

Ground

Line

-

1.5

mkg

5.0 ft) lb*14750 *14750 *23520 16890 15500 8860 9790 5750 6810 4030 (25.2)

(-

-

3.0

mkg

10.0 ft)lb*21980 *21980 *22730 17150 *15410 8930 9850 5820 *8310 5180 (21.8)

(-

-4.5

mkg

(-

15.0 ft)

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

lb

*3040 *3040 *3380 2240 7.37

lb

lb

*7930 *7930 *5330 4770 *4320 2990 *2830 2020 2730 1630 8.48

lb

lb

kg

lb

*6690 *6690 *10670 7660 7030 4020 4440 2610 3090 1830 7.69

*9970 *9970 *10310 7780 *6990 4050 4470 2640 *3770 2350 6.64

lb

*17480 *17480 *11750 10520 *9520 6590 *6240 4450 6020 3590 (27.8)

*8090 8060 *6680 4380 4670 2820 3250 1940 2650 1560 8.53

*17840 17770 *14730 9660 10300 6220 7170 4280 5840 3440 (28.0)

*7880 7700 7150 4130 4520 2680 3190 1880 2750 1620 8.28

*17370 16980 15760 9110 9960 5910 7030 4140 6060 3570 (27.2)

*7500 *7500 *4980 4230

*16530 *16530 *10980 9330

*6700 *6700 *7450 4940 (24.2)

*3790 3150 3000 1820 8.11

*8360 6940 6610 4010 (26.6)

Capacity Reach

*3410 3190 6.11

*7520 7030 (20.0)

m (ft)

Note 1. Lifting capacity are based on SAE J1097 and ISO 10567.

2. Lifting capacity of the ROBEX series does not exceed 75

on firm, level ground or 87

%

of full hydraulic capacity.

%

of tipping load with the machine

3. The load point is a hook located on the back of the bucket.

4. *indicates load limited by hydraulic capacity.

2-8

Page 45

5.1 m (16' 9") hydraulic adjustable boom, 2.6 m (8' 6") arm equipped with 0.70

(2)

bucket and 600

mm

(24") triple grouser shoe and 2900 kg (6390 Ib) counterweight.

m3 (SAE heaped)

Load

point

height

6.0

mkg

20.0 ft)

(

4.5

mkg

15.0 ft)

(

3.0

mkg

10.0 ft)

(

1.5

mkg

5.0 ft)

(

Ground

Line

-

1.5

mkg

5.0 ft) lb*13290 *13290 *21960 16710 15520 8750 9810 5690 6720 3920 (25.5)

(-

-

3.0

mkg

10.0 ft)lb*20920 *20920 *21740 17040 *14860 8840 9900 5750 *7390 5050 (22.2)

(-

-4.5

mkg

(-

15.0 ft)

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

lb

lb

*4350 2980 *3250 2000 2680 1570 8.57

lb

*6980 *6980 *6660 4350 4690 2790 3260 1920 2610 1510 8.62

lb

kg

lb

*6030 *6030 *9960 7580 7040 3970 4450 2580 3050 1780 7.78

*9490 *9490 *9860 7730 *6740 4010 4490 2610 *3350 2290 6.76

lb

*15390 *15390 *14680 9590 10340 6150 7190 4230 5750 3330 (28.3)

*7040 *7040 7160 4080 4530 2650 3190 1850 2710 1570 8.37

*15520 *15520 15790 8990 9990 5840 7030 4080 5970 3460 (27.5)

*6840 *6840 *4560 4220

*15080 *15080 *10050 9300

*9590 6570 *7170 4410 5910 3460 (28.1)

Capacity Reach

*3450 2160 7.48

*7610 4760 (24.5)

2950 1760 8.20

6500 3880 (26.9)

m (ft)

Load radius At max. reach

2-9

Page 46

R160LCD-9S

2)

R160LCD-9S

2)

5.1 m (16' 9") boom, 2.6 m (8' 6") arm equipped with 0.7

(1)

kg

(24") triple grouser shoe and 2900

(6390 Ib) counterweight.

m3 (SAE heaped) bucket and 600 mm

·

: Rating over-front : Rating over-side or 360 degree

·

Load radius At max. reach

Load

point

height

7.5

mkg

25.0 ft)

(

6.0

mkg

20.0 ft)

(

4.5

mkg

15.0 ft)

(

3.0

mkg

10.0 ft)

(

1.5

mkg

5.0 ft)

(

Ground

Line

-

1.5

mkg

5.0 ft) lb*14750 *14750 *23520 17810 *16870 9390 10870 6130 7610 4300 (25.2)

(-

-

3.0

mkg

10.0 ft)lb*21980 *21980 *22730 18080 *15410 9440 *10800 6170 *8310 5510 (21.8)

(-

-4.5

mkg

(-

15.0 ft)

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

lb

*3040 *3040 *3380 2370 7.37

lb

lb

*7930 *7930 *5330 5000 *4320 3160 *2830 2140 3040 1730 8.48

lb

lb

kg

lb

*6690 *6690 *10670 8080 *7650 4260 4930 2780 3450 1950 7.69

*9970 *9970 *10310 8200 *6990 4280 *4900 2800 *3770 2500 6.64

lb

*17480 *17480 *11750 11020 *9520 6970 *6240 4720 6700 3810 (27.8)

*8090 *8090 *6680 4620 *4950 2980 3620 2070 2960 1670 8.53

*17840 *17840 *14730 10190 *10910 6570 7980 4560 6530 3680 (28.0)

*7880 *7880 *7520 4360 5010 2840 *3490 2010 3080 1730 8.28

*17370 *17370 *16580 9610 11050 6260 *7690 4430 6790 3810 (27.2)

*7500 *7500 *4980 4460

*16530 *16530 *10980 9830

*6700 *6700 *7450 5220 (24.2)

*3790 3310 3340 1940 8.11

*8360 7300 7360 4280 (26.6)

Capacity Reach

*3410 3350 6.11

*7520 7390 (20.0)

m (ft)

Note 1. Lifting capacity are based on SAE J1097 and ISO 10567.

2. Lifting capacity of the ROBEX series does not exceed 75

on firm, level ground or 87

%

of full hydraulic capacity.

%

of tipping load with the machine

3. The load point is a hook located on the back of the bucket.

4. *indicates load limited by hydraulic capacity.

2-10

Page 47

5.1 m (16' 9") hydraulic adjustable boom, 2.6 m (8' 6") arm equipped with 0.7

(2)

bucket and 600

mm

(24") triple grouser shoe and 2900 kg (6390 Ib) counterweight.

m3 (SAE heaped)

Load

point

height

6.0

mkg

20.0 ft)

(

4.5

mkg

15.0 ft)

(

3.0

mkg

10.0 ft)

(

1.5

mkg

5.0 ft)

(

Ground

Line

-

1.5

mkg

5.0 ft) lb*13290 *13290 *21960 17660 *16490 9280 10890 6040 7500 4190 (25.5)

(-

-

3.0

mkg

10.0 ft)lb*20920 *20920 *21740 17970 *14860 9370 *10360 6130 *7390 5360 (22.2)

(-

-4.5

mkg

(-

15.0 ft)

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

lb

lb

*4350 3150 *3250 2120 2990 1680 8.57

lb

*6980 *6980 *6660 4590 *4920 2960 3630 2040 2920 1620 8.62

lb

kg

lb

*6030 *6030 *9960 8010 *7480 4210 4940 2740 3400 1900 7.78

*9490 *9490 *9860 8150 *6740 4250 *4700 2780 *3350 2430 6.76

lb

*15390 *15390 *14680 10120 *10850 6530 8000 4500 6440 3570 (28.3)

*7040 *7040 *7420 4310 5020 2810 3560 1980 3030 1680 8.37

*15520 *15520 *16360 9500 11070 6190 7850 4370 6680 3700 (27.5)

*6840 *6840 *4560 4460

*15080 *15080 *10050 9830

*9590 6940 *7170 4670 6590 3700 (28.1)

Capacity Reach

*3450 2280 7.48

*7610 5030 (24.5)

3280 1870 8.20

7230 4120 (26.9)

m (ft)

Load radius At max. reach

2-11

Page 48

6. BUCKET SELECTION GUIDE

1)

GENERAL BUCKET

0.39

m3 SAE

heaped bucket

Capacity Width

SAE

heaped

CECE

heaped

0.50

m3 SAE

heaped bucket

Without

side cutter

0.64, ※0.70

With

side cutter

m3 SAE

heaped bucket

Weight

2.2 m arm

(7' 3")

0.89, 1.05

heaped bucket

Recommendation

5.1

m

(16' 9")

Mono boom

2.6 m arm

(8' 6")

m3 SAE

3.1 m arm

(10' 2")

◈0.69

m3 SAE

heaped bucket

5.1 m (16' 9")

Hyd adjustable boom

2.2 m arm

(7' 3")

2.6 m arm

(8' 6")

3

m

0.34

(0.44

0.44

(0.58

0.55

(0.72

0.60

(0.78

0.77

(1.01

0.90

(1.18

0.62

(0.81

m

yd3)

m

yd3)

m

yd3)

m

yd3)

m

yd3)

m

yd3)

m

yd3)

0.39

(0.51

yd3)

3

0.50

m

(0.65

yd3)

3

0.64

m

(0.84

yd3)

※0.70

(0.92

0.89

(1.16

1.05

(1.37

◈0.69

(0.90

◈

3

m

yd3)

3

m

yd3)

3

m

yd3)

3

m

yd3)

: Heavy duty bucket

※ : Standard bucket

3

3

3

3

3

3

3

mm

620

(24.4")

mm

760

(29.9")

mm

920

(36.2")

mm

990

(39.0")

mm

1220

(48.0")

mm

1400

(55.1")

mm

990

(39.0")

740

mm

(29.1")

880

mm

(34.6")

1040

mm

(40.9")

1110

mm

(43.7")

1340

mm

(52.8")

1520

mm

(59.8")

-

410 kg

(900 lb)

470

kg

(1040 lb)

510

kg

(1120 lb)

540

kg

(1190 lb)

610

kg

(1340 lb)

680

kg

(1500 lb)

700

kg

(1540 lb)

Applicable for materials with density of 2000

Applicable for materials with density of 1600

Applicable for materials with density of 1100

2-12

kg/m3 (3370

kg/m3 (2700

kg/m3 (1850

lb/yd3) or less

lb/yd3) or less

lb/yd3) or less

Page 49

TRACKS

TYPES OF SHOES

7. UNDERCARRIAGE

1)

2)

NUMBER OF ROLLERS AND SHOES ON EACH SIDE

3)

7. UNDERCARRIAGE

1)

TRACKS

X-leg type center frame is integrally welded with reinforced box-section track frames. The design

includes dry tracks, lubricated rollers, idlers, sprockets, hydraulic track adjusters with shock

absorbing springs and assembled track-type tractor shoes with triple grousers.

2)

TYPES OF SHOES

Triple grouser

Model Shapes

※

Shoe width

mm (in)

500 (20)

600 (24)

700 (28)

R160LC-9S

R160LCD-9S

※

: Standard

NUMBER OF ROLLERS AND SHOES ON EACH SIDE

3)

Operating weight

Ground pressure

Overall width

Shoe width

Operating weight

Ground pressure

Overall width

kg (lb)

kgf/cm2 (psi)

mm (ft-in)

mm (in)

kg (lb)

kgf/cm2 (psi)

mm (ft-in)

17550 (38690) 17800 (39240) 18050 (39790)

0.51 (7.25) 0.43 (6.11) 0.38 (5.40)

2490 (8' 2") 2590 (8' 6") 2690 (8' 10")

500 (20)

18550 (40900) 18800 (41450) 19050 (42000)

0.54 (7.68) 0.46 (6.54) 0.40 (5.69)

2490 (8' 2") 2590 (8' 6") 2690 (8' 10")

Item

Carrier rollers

Track rollers

Track shoes

※

600 (24)

Quantity

R160LC/LCD-9S

2 EA

7 EA

49 EA

700 (28)

2-13

Page 50

SELECTION OF TRACK SHOE

Method of selecting shoes

table

table

4)

Table 2

Table 1

4)

SELECTION OF TRACK SHOE

Suitable track shoes should be selected according to operating conditions.

Method of selecting shoes

Confirm the category from the list of applications in

table 2 2, then use

table 1 1 to select the shoe.

Wide shoes (Categories B) have limitations on applications. Before using wide shoes, check the

precautions, then investigate and study the operating conditions to confirm if these shoes are

suitable.

Select the narrowest shoe possible to meet the required flotation and ground pressure.

Application of wider shoes than recommendations will cause unexpected problem such as bending

of shoes, crack of link, breakage of pin, loosening of shoe bolts and the other various problems.

※

Table 1

Track shoe Specification Category

mm

triple grouser Standard A

600

500 mm triple grouser Option A

700 mm triple grouser Option B

※

Table 2

Category Applications Applications

Rocky ground,

A

B

river beds,

normal soil

Normal soil,

soft ground

Travel at low speed on rough ground with large obstacles such as

·

boulders or fallen trees

These shoes cannot be used on rough ground with large obstacles such

·

as boulders or fallen trees

Travel at high speed only on flat ground

·

Travel slowly at low speed if it is impossible to avoid going over obstacles

·

2-14

Page 51

8. SPECIFICATIONS FOR MAJOR COMPONENTS

ENGINE

MAIN PUMP

1)

2)

8. SPECIFICATIONS FOR MAJOR COMPONENTS

ENGINE

1)

Item Specification

Model Mitsubishi S6S-DT

Type 4-cycle turbocharged charge air cooled diesel engine

Cooling method Water cooling

Number of cylinders and arrangement 6 cylinders, in-line

Firing order 1-5-3-6-2-4

Combustion chamber type Direct injection type

Ý

Cylinder bore

stroke 94Ý120

mm

(3.70"Ý4.72")

Piston displacement 4996

Compression ratio 19.5 : 1

Rated gross horse power (SAE J1995) 126

Maximum torque 42.5

Engine oil quantity 16.5˶ (4.4 U.S.

Dry weight 355

High idling speed 2200

Low idling speed 950Ü100

Rated fuel consumption 169.3

Starting motor 24 V-5.0

Alternator 24 V-50

Battery 2Ý12 VÝ

MAIN PUMP

2)

Item Specification

cc

(305 cu in)

Hp

(94 kW) at 2100

kgfÂm

(307

kg

(780 lb)

Ü

50

rpm

rpm

g/HpÂhr

kW

A

100

lbfÂft

gal

)

at

2100 rpm

Ah

rpm

) at 1500

rpm

Type

Capacity

Maximum pressure

Rated oil flow

Rated speed

[ ] : Power boost

Variable displacement tandem axis piston pumps

2Ý80

cc/rev

350

kgf/cm2 (4980

2Ý160

2000

rpm

˶/min

psi

) [380

(42.3 U.S.

kgf/cm2 (5400

gpm

/ 35.2 U.K.

psi

gpm

2-15

)]

)

Page 52

TRAVEL MOTOR

GEAR PUMP

MAIN CONTROL VALVE

SWING MOTOR

6)

3)

4)

5)

GEAR PUMP

3)

Item

Type

Capacity

Maximum pressure 40

Rated oil flow

MAIN CONTROL VALVE