Hyundai R180NLC-9S, R160LC-9S Operating Manual

CONTENTS

SAFETY HINTS

SPECIFICATIONS

CONTROL DEVICES

OPERATION

TRANSPORTATION

MAINTENANCE

TROUBLESHOOTING GUIDE

HYDRAULIC BREAKER AND QUICK CLAMP

INDEX

CONTENTS

Foreword

Before servicing this machine

EC regulation approved

Table to enter S/No and distribution

Safety labels

Machine data plate

Guide (direction, S/No, symbol)

SAFETY HINTS

1. Before operating the machine

2. During operating the machine

3. During maintenance

4. Parking

SPECIFICATIONS

1. Major components

2. Specifications

3. Working range

4. Weight

5. Lifting capacities

6. Bucket selection guide

7. Undercarriage

8. Specification for major components

9. Recommended oils

-----------------------------------------------------------

---------------------------

------------------------------------

---------------------

------------------------------------------------------

--------------------------------------------

------------------------

--------------------

--------------------

-----------------------------------

--------------------------------------------------------

-------------------------------------

--------------------------------------------

-------------------------------------------

-------------------------------------------------------

----------------------------------------

-------------------------------

-------------------------------------------

-----------

------------------------------------

0-1

0-2

0-3

0-4

0-5

0-18

0-19

1-1

1-6

1-13

1-16

2-1

2-2

2-5

2-7

2-8

2-12

2-13

2-15

2-18

6. Traveling of the machine

7. Efficient working method

8. Operation in the special work sites

9. Normal operation of excavator

10. Attachment lowering

11. Storage

12. RCV lever operating pattern

13. Switching hydraulic attachment circuit

TRANSPORTATION

1. Preparation for transportation

2. Dimension and weight

3. Loading the machine

4. Fixing the machine

5. Loading and unloading by crane

MAINTENANCE

1. Instruction

2. Tightening torque

3. Fuel, coolant and lubricants

4. Maintenance check list

5. Maintenance chart

6. Service instruction

7. Electrical system

8. Air conditioner and heater

-----------------------------------------------------

-------------------------------------------------

---------------------------------------

----------------------------

---------------------------

-------------

-------------------

----------------------------------

-----------------------

--------

--------------------

-------------------------------

---------------------------------

------------------------------------

----------------

---------------------------------------

-----------------------

------------------------------

------------------------------------

-------------------------------------

--------------------------

4-21

4-24

4-28

4-30

4-31

4-32

4-34

4-35

5-1

5-2

5-5

5-7

5-8

6-1

6-6

6-9

6-11

6-16

6-18

6-39

6-42

CONTROL DEVICES

1. Cab devices

2. Cluster

3. Switches

4. Levers and pedals

5. Air conditioner and heater

6. Others

OPERATION

1. Suggestion for new machine

2. Check before starting the engine

3. Starting and stop the engine

4. Mode selection system

5. Operation of the working device

-----------------------------------------------

-------------------------------------------------------

----------------------------------------------------

-------------------------------------

-------------------------

--------------------------------------------------------

----------------------

----------------------

------------------------------

-----------------

3-1

3-2

3-34

3-38

3-41

3-48

4-1

---------------

4-2

4-3

4-10

4-20

TROUBLESHOOTING GUIDE

1. Engine

2. Electrical system

3. Others

HYDRAULIC BREAKER AND QUICK CLAMP

1. Selecting hydraulic breaker

2. Circuit configuration

3. Maintenance

4. Precaution while operating the breaker

5. Quick clamp

INDEX

------------------------------------------------------

---------------------------------------

-------------------------------------------------------

------------------------

-----------------------------------

---------------------------------------------

----------------------------------------------

------------------------------------------------------------

7-1

7-2

7-3

8-1

8-2

8-3

------

8-4

8-6

9-1

Read

understand

Inspect

follow

safety hints

genuine Hyundai spare parts

FOREWORD

FOREWORD

This manual contains a number of instructions and safety recommendations regarding driving, handling, lubrication, maintenance, inspection and adjustment of the excavator.

The manual is to promote safety maintenance and enhance machine performance.

Keep this manual handy and have all personnel read it periodically.

If you sell the machine, be sure to give this manual to the new owners.

This machine complies with EC directive "2006/42/EC".

1.

Read and

This operator's manual may contain attachments and optional equipment that are not available in

your area. Please consult your local Hyundai distributor for those items you require.

Improper operation and maintenance of this machine can be hazardous and could result in serious

injury or death.

Some actions involved in operation and maintenance of the machine can cause a serious accident,

if they are not done in a manner described in this manual.

The procedures and precautions given in this manual apply only to intended uses of the machine.

If you use your machine for any unintended uses that are not specifically prohibited, you must be

sure that it is safe for you and others. In no event should you or others engage in prohibited uses

of actions as described in this manual.

understand this manual before operating the machine.

2.

Inspect the jobsite and

ating the machine.

3. Use

Continuing improvements in the design of this machine can lead to changes in detail which may not

be reflected in this manual. Consult Hyundai or your Hyundai distributor for the latest available information for your machine or for questions regarding information in this manual.

genuine Hyundai spare parts for the replacement of parts.

We expressly point out that Hyundai will not accept any responsibility for defects resulting from nongenuine parts or non workmanlike repair.

In such cases Hyundai cannot assume liability for any damage.

follow the safety recommendations in the

safety hints section before oper-

0-1

BEFORE SERVICING THIS MACHINE

How to adjust the language of cluster (cluster type 1)

BEFORE SERVICING THIS MACHINE

It is the responsibility of the owner and all service and maintenance personnel to avoid accidents and

serious injury by keeping this machine properly maintained.

It also is the responsibility of the owner and all service and maintenance personnel to avoid accidents

and serious injury while servicing the machine.

No one should service or attempt to repair this machine without proper training and supervision.

All service and maintenance personnel should be thoroughly familiar with the procedures and precau-

tions contained in this manual.

All personnel also must be aware of any federal, state, provincial or local laws or regulations covering

the use and service of construction equipment.

The procedures in this manual do not supersede any requirements imposed by federal, state, provin-

cial or local laws.

Hyundai can not anticipate every possible circumstance or environment in which this machine may be

used and serviced.

All personnel must remain alert to potential hazards.

Work within your level of training and skill.

Ask your supervisor if you are uncertain about a particular task. Do not try to do too much too fast.

Use your common sense.

How to adjust the language of cluster (cluster type 1)

※

User can select preferable language and all displays are changed the selected language.

Press Press Press Press

Please refer to the page 3-20 for the cluster.

※

0-2

EC REGULATION APPROVED

EC REGULATION APPROVED

·

Noise level (EN474-1 : 2006 and 2000/14/EC) are as followings.

WA : 100

L

L

PA : 71

·

The value of vibrations transmitted by the operator's seat are lower than standard value of (EN474-1

: 2006 and 2002/44/EC)

dB

(EU only)

dB

0-3

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

Machine Serial No.

Engine Serial No.

Manufacturing year

Manufacturer

Address

Distributor for U.S.A

Address

Distributor for Europe

Address

Dealer

Address

Hyundai Heavy Industries co., Ltd.

1000, Bangeojinsunhwan-doro, Dong-Ku,

Ulsan 682-792, Korea

Hyundai Heavy Industries U.S.A, Inc

6100 Atlantic Boulevard Norcross

GA 30071

U.S.A

Hyundai Heavy Industries Europe N. V.

Vossendal 11

2240 Geel

Belgium

0-4

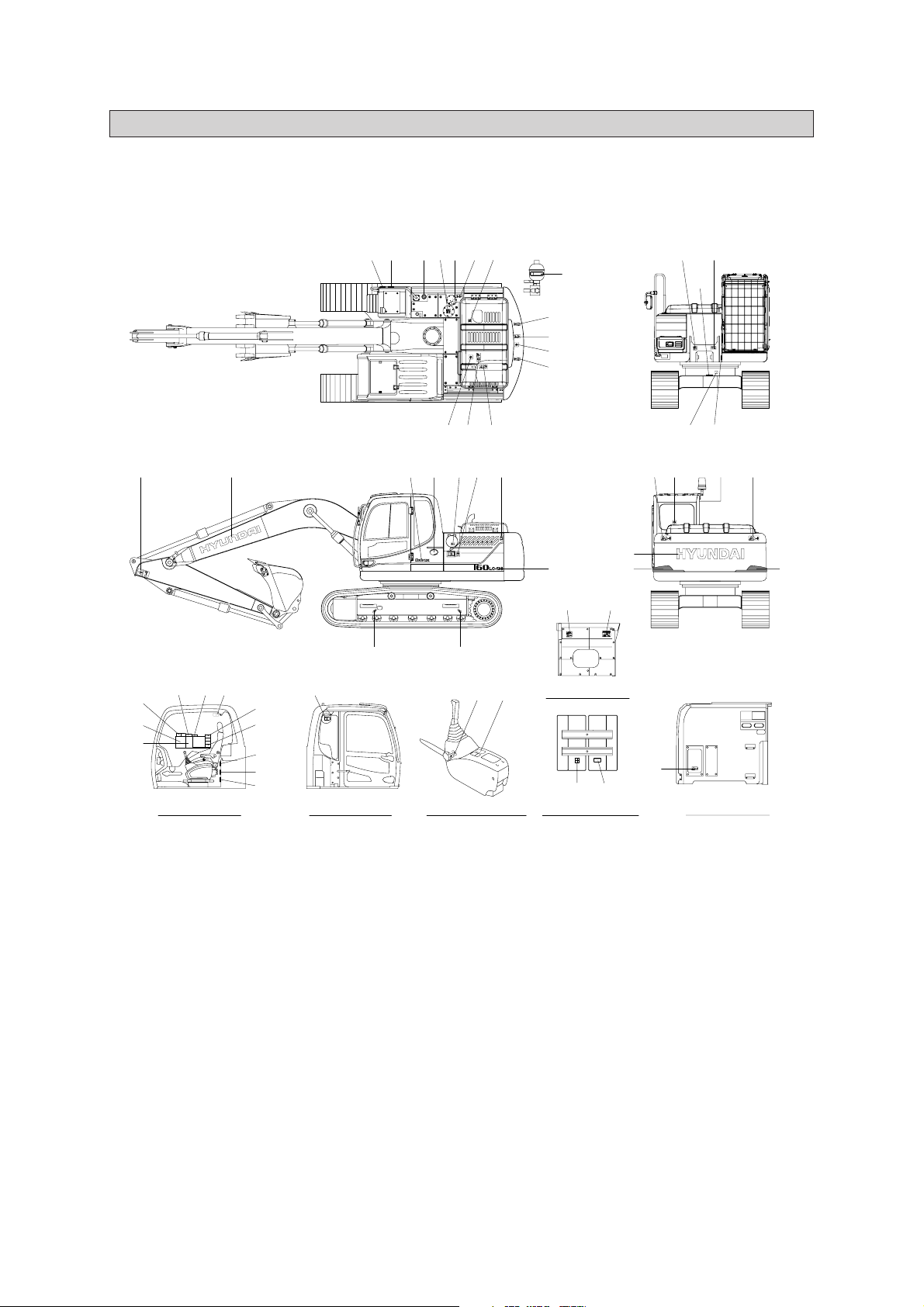

SAFETY LABELS

1. LOCATION

SAFETY LABELS

1. LOCATION

Always keep these labels clean. If they are lost or damage, attach them again or replace them with

a new label.

37

19

35

34

CAB INSIDE-RH

41

51

50

2

39

43

10

39

16

10

3

15

13

1

14

27

6

1212

26

45

PUMP SCREEN

5

38

BATTERY COVER

9

30

42

7

46

316

36

47

11

49

23

SCREEN PLATE

9

42

4

48

17

29

t

e

k

c

u

B

22

32

20

21

24

52

22

CAB INSIDE-LH

8

16

1828

LH CONSOLE BOX

1 Air cleaner filter

2 Turbocharger cover

3 Radiator cap

4 Fueling

5 Battery accident

6 High pressure hose

7 Hydraulic oil level

8 Hydraulic oil lub

9 Keep clear-rear

10 Lifting eye

11 Name plate

12 Slinging ideogram

13 Keep clear-side

14 Stay fix

15 Shearing-engine hood

16

No step-engine hood and CWT

17 Transporting

18 Low emission engine

19 Control ideogram

20

Ref operator manual-cab RH pillar

21 Hammer

22 Safety front window

23 Alternate exit

24 Air conditioner filter

26 Safety lever

27 Model name

28 Logo (ROBEX)

29 Trade mark (boom)

30 Trade mark (CWT)

31 Reduction gear grease

32 Clamp-locking

34 Service instruction

0-5

1609S0SL01

35 Lifting chart

36 Tie

37 Keep clear-Boom/arm

38 Electric welding

39 Falling

41 Turbocharger

42 Reflecting

43 Accumulator

45 Control ideogram-dozer

46 RCV lever pattern

47 Swing bearing

48 Battery position

49 Beacon lamp

50 Fuel shut off

51 Water separator

52 MCU connector

2. DESCRIPTION

AIR CLEANER FILTER

Periodic and proper inspection, cleaning

and change of elements prolong engine

life time and maintain the good performance of engine.

1)

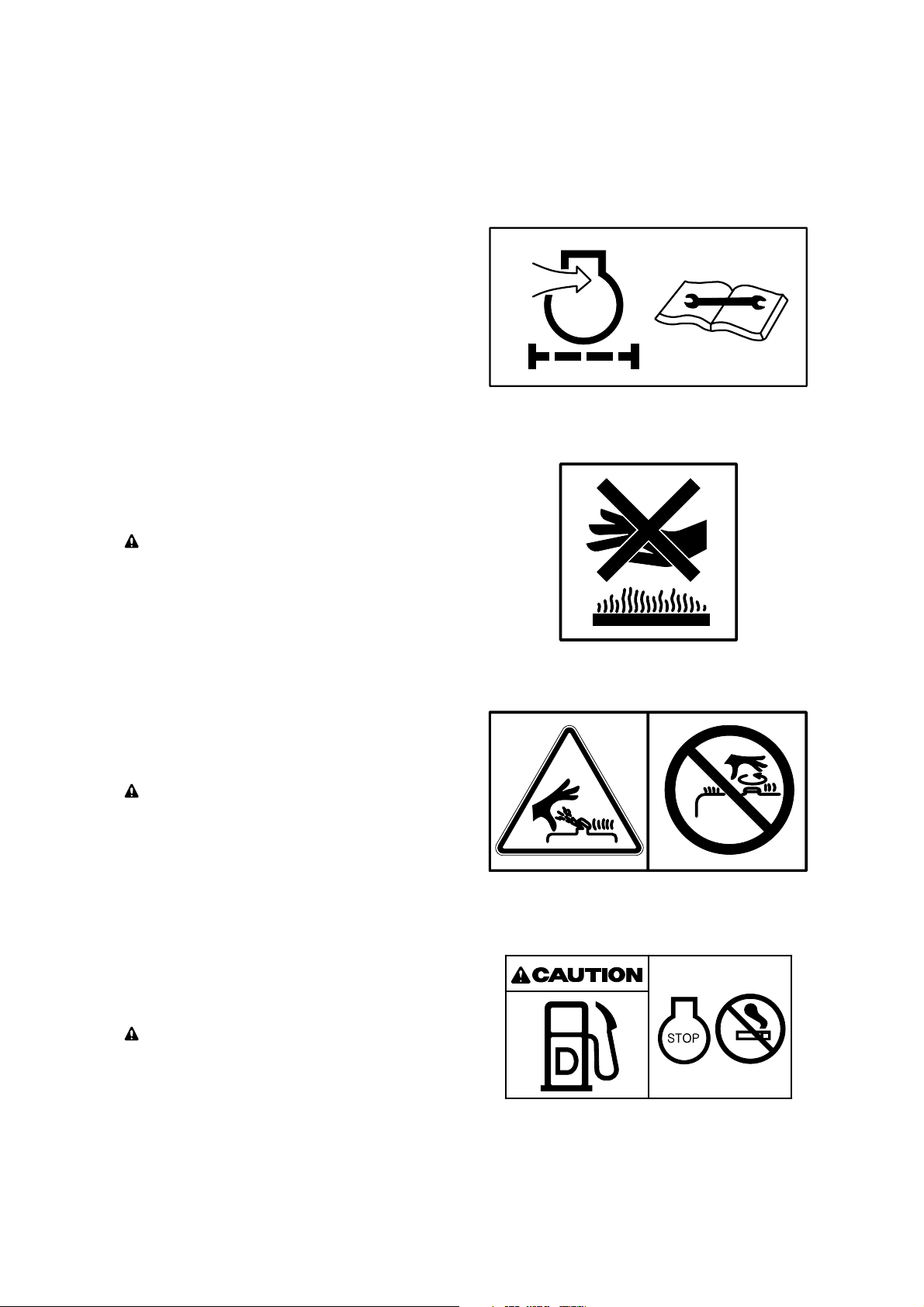

TURBOCHARGER COVER

Do not touch turbocharger or it may

cause severe burn.

2)

RADIATOR CAP

Never open the filler cap while engine

running or at high coolant temperature.

3)

FUELING

Stop the engine when refueling. All

lights or flames shall be kept at a safe

distance while refueling.

4)

2. DESCRIPTION

There are several specific warning labels on this machine please become familiarized with all warning labels.

Replace any safety label that is damaged, or missing.

1)

AIR CLEANER FILTER (item 1)

This warning label is positioned on the air

cleaner cover.

※

Periodic and proper inspection, cleaning

and change of elements prolong engine

life time and maintain the good performance of engine.

TURBOCHARGER COVER (item 2)

2)

This warning label is positioned on the turbocharger cover.

Do not touch turbocharger or it may

cause severe burn.

21070FW01

RADIATOR CAP (item 3)

3)

This warning label is positioned on the radiator.

Never open the filler cap while engine

running or at high coolant temperature.

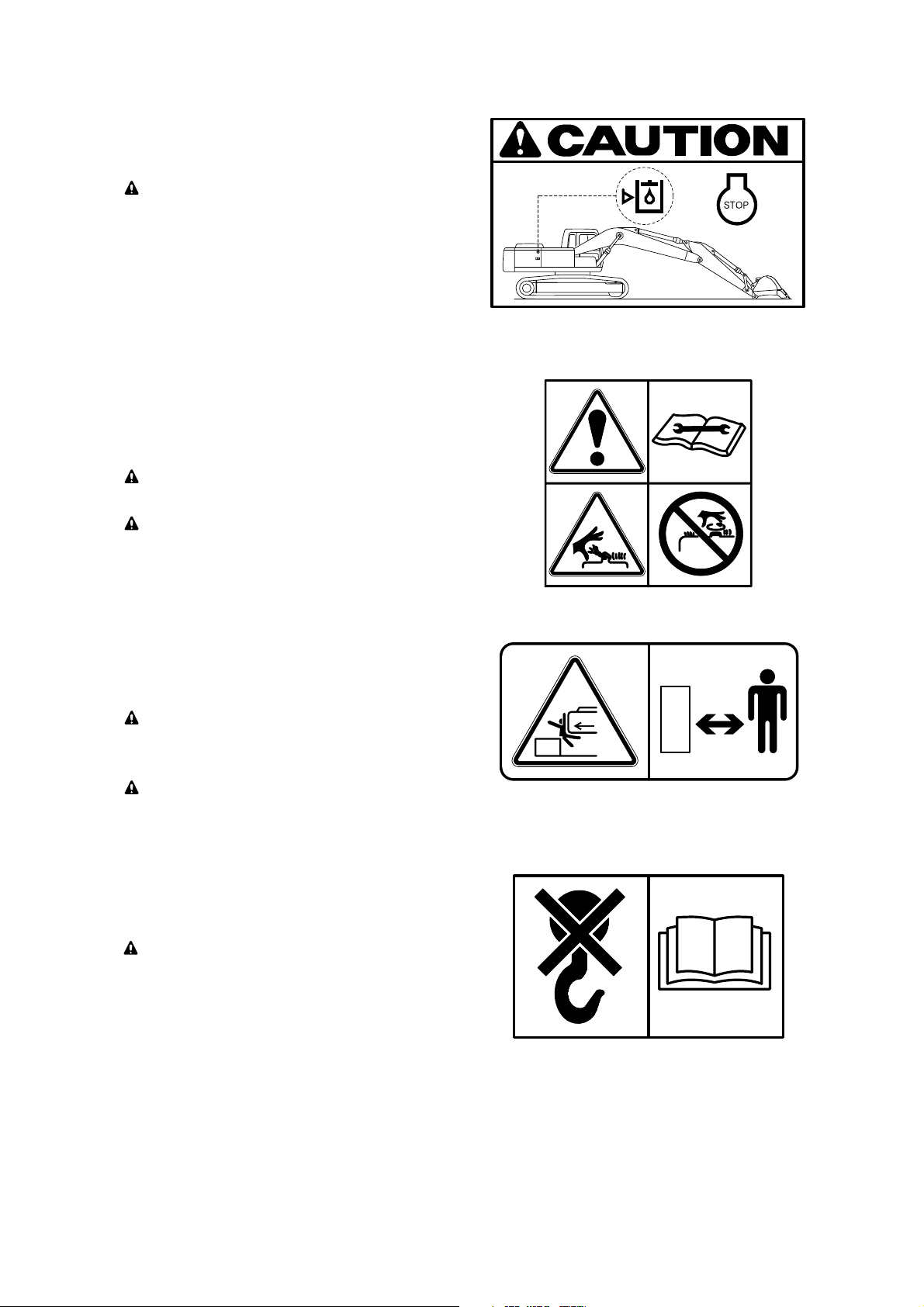

FUELING (item 4)

4)

This warning label is positioned on the fuel

filler neck.

Stop the engine when refueling. All

lights or flames shall be kept at a safe

distance while refueling.

21070FW02

14070FW03

0-6

21070FW04

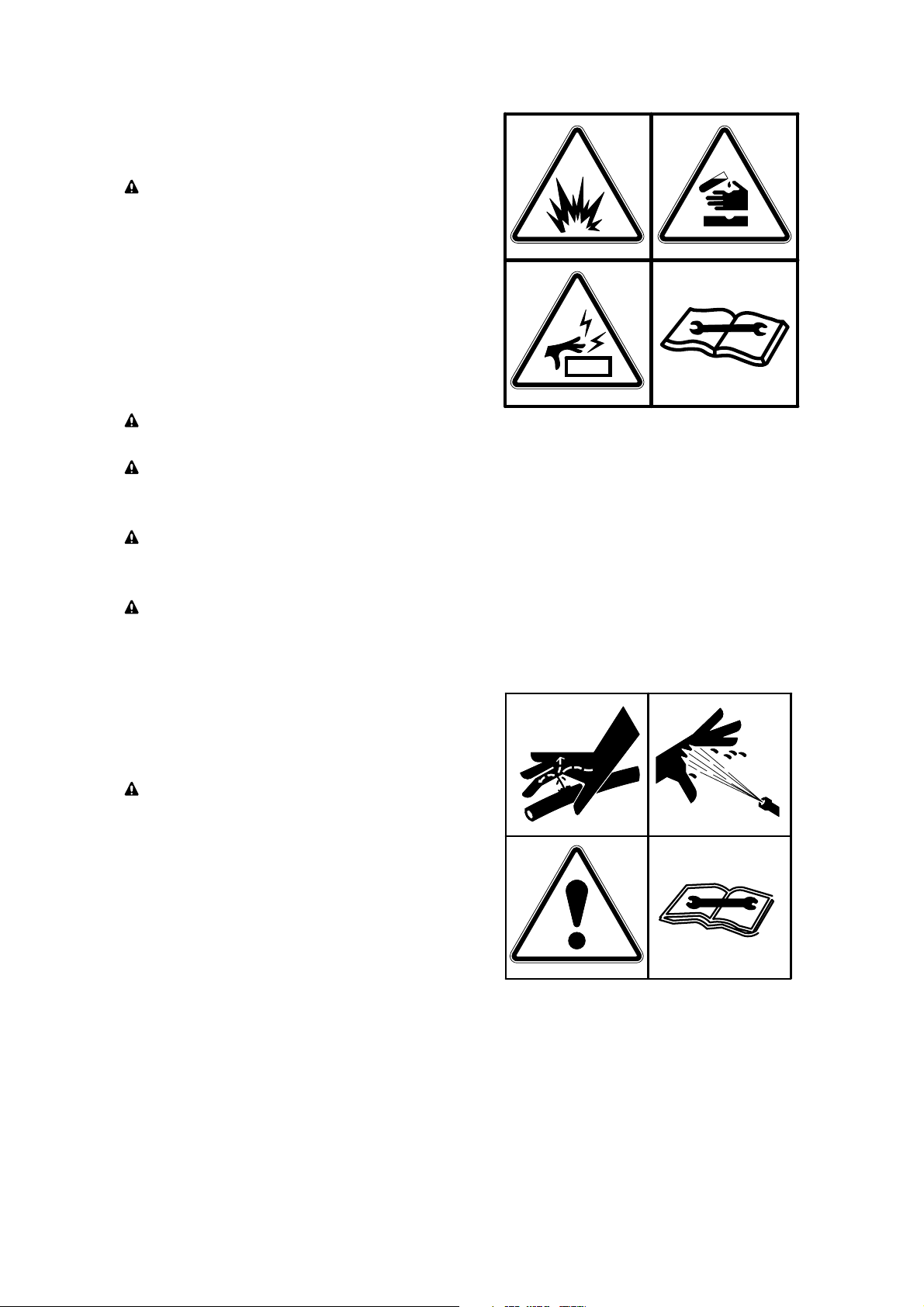

BATTERY ACCIDENT

Electrolyte containing sulfuric acid cause

severe burns. Avoid being in contact with

skin, eyes or clothes. In the event of

accident flush with sufficient water, call a

physician immediately.

Maintain the electrolyte at the recommended level.

With electrolyte at proper level, less

space may cause the gases to be accumulated in the battery.

Extinguish all smoking materials and

open flames before checking the battery.

Do not use matches, lighters or torches

as a light source near the battery for the

probable presence of explosive gas.

Do not allow unauthorized personnel to

change the battery or to use booster

cables.

For safety from electric shock, do not battery terminal with a wet hand.

5)

HIGH PRESSURE HOSE

Escaping fluid under pressure can penetrate the skin causing serious injury.

Study the service manual before service

job.

6)

BATTERY ACCIDENT (item 5)

5)

This warning label is positioned on the battery cover.

Electrolyte containing sulfuric acid cause

severe burns. Avoid being in contact with

skin, eyes or clothes. In the event of

accident flush with sufficient water, call a

physician immediately.

※

Maintain the electrolyte at the recommended level.

With electrolyte at proper level, less

space may cause the gases to be accumulated in the battery.

Extinguish all smoking materials and

open flames before checking the battery.

Do not use matches, lighters or torches

as a light source near the battery for the

probable presence of explosive gas.

Do not allow unauthorized personnel to

change the battery or to use booster

cables.

For safety from electric shock, do not battery terminal with a wet hand.

36070FW05

HIGH PRESSURE HOSE (item 6)

6)

These warning labels are positioned in the

front of upper frame and on the screen

plate.

Escaping fluid under pressure can penetrate the skin causing serious injury.

※

Study the service manual before service

job.

14070FW29

0-7

LIFTING EYE

Do not lift the machine by using lifting

eyes on the counterweight or the lifting

eyes may be subject to overload causing

its breaking and possible personal injury.

See page 5-8 for proper lifting method of

the machine.

10)

HYDRAULIC OIL LUBRICATION

Do not mix with different brand oils.

Never open the filler cap while high temperature.

Loosen the cap slowly and release internal pressure completely.

8)

KEEP CLEAR-REAR

To prevent serious personal injury or

death keep clear or machine swing radius.

Do not deface of remove this label from

the machine.

9)

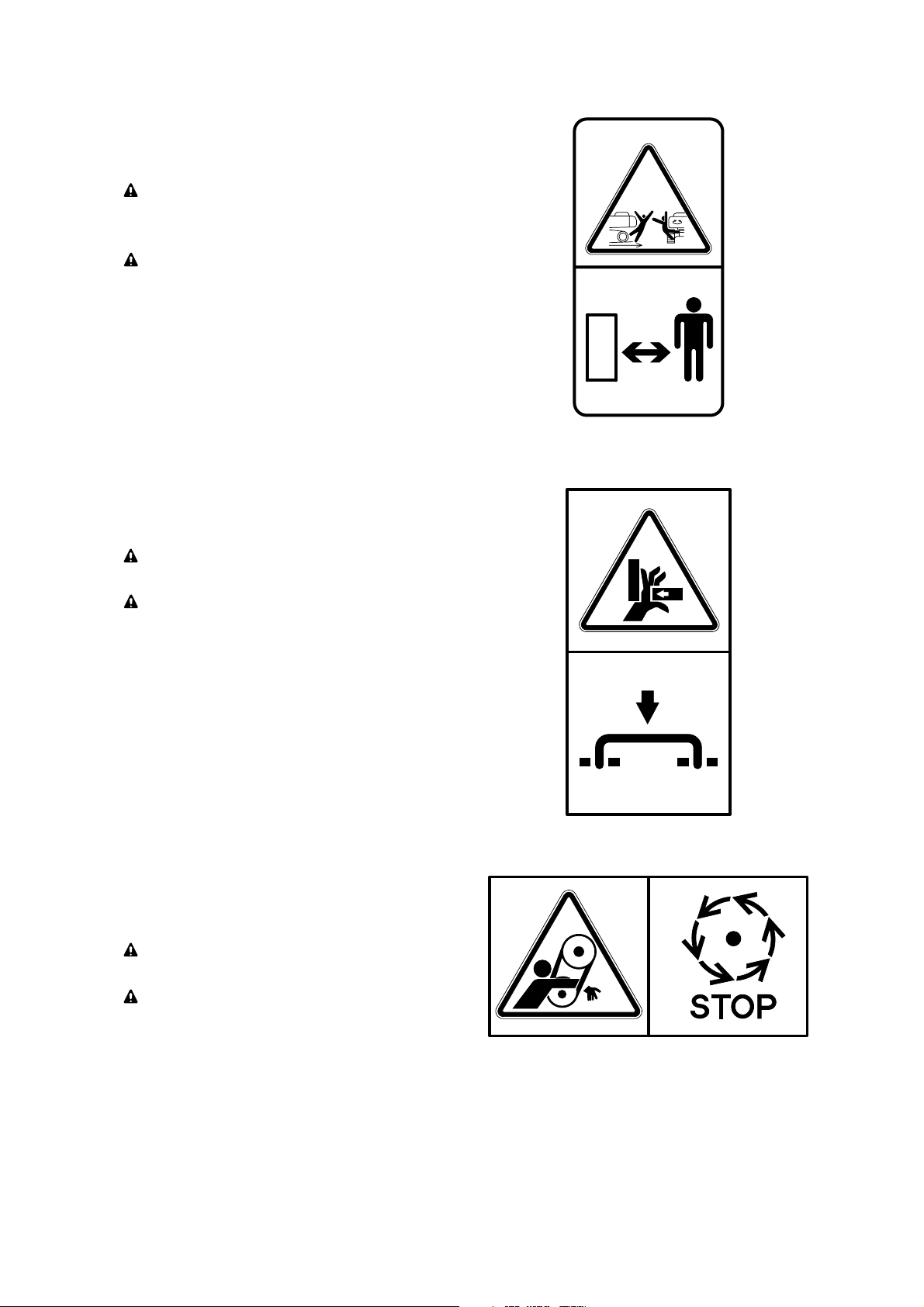

HYDRAULIC OIL LEVEL

Place the bucket on the ground whenever

servicing the hydraulic system.

Check oil level on the level gauge.

Refill the recommended hydraulic oil up

to specified level if necessary.

7)

HYDRAULIC OIL LEVEL (item 7)

7)

This warning label is positioned on the

screen plate.

Place the bucket on the ground whenever

servicing the hydraulic system.

※

Check oil level on the level gauge.

※

Refill the recommended hydraulic oil up

to specified level if necessary.

HYDRAULIC OIL LUBRICATION (item 8)

8)

This warning label is positioned on the top

of the hydraulic tank.

※

Do not mix with different brand oils.

Never open the filler cap while high temperature.

Loosen the cap slowly and release internal pressure completely.

21070FW07

KEEP CLEAR-REAR (item 9)

9)

This warning label is positioned on the rear

of counterweight.

To prevent serious personal injury or

death keep clear or machine swing radius.

Do not deface of remove this label from

the machine.

LIFTING EYE (item 10)

10)

This warning label is positioned on the

counterweight.

Do not lift the machine by using lifting

eyes on the counterweight or the lifting

eyes may be subject to overload causing

its breaking and possible personal injury.

※

See page 5-8 for proper lifting method of

the machine.

14070FW08

21090FW09

21070FW10

0-8

SHEARING-ENGINE HOOD

Don't open the engine hood during the

engine's running.

Don't touch exhaust pipe or it may cause

severe burn.

KEEP CLEAR-SIDE

To prevent serious personal injury or

death keep clear of machine swing radius.

Do not deface or remove this label from

the machine.

STAY FIX

Be sure to support the stay when the

door needs to be opened.

Be careful that the opened door may be

closed by the external or natural force

like strong wind.

13)

11)

12)

KEEP CLEAR-SIDE (item 13)

11)

This warning label is positioned on the LH

side cover.

To prevent serious personal injury or

death keep clear of machine swing radius.

Do not deface or remove this label from

the machine.

STAY FIX (item 14)

12)

This warning label is positioned on the both

side cover.

Be sure to support the stay when the

door needs to be opened.

Be careful that the opened door may be

closed by the external or natural force

like strong wind.

21070FW13

SHEARING-ENGINE HOOD (item 15)

13)

This warning label is positioned on the

engine hood.

Don't open the engine hood during the

engine's running.

Don't touch exhaust pipe or it may cause

severe burn.

21070FW14

21070FW15

0-9

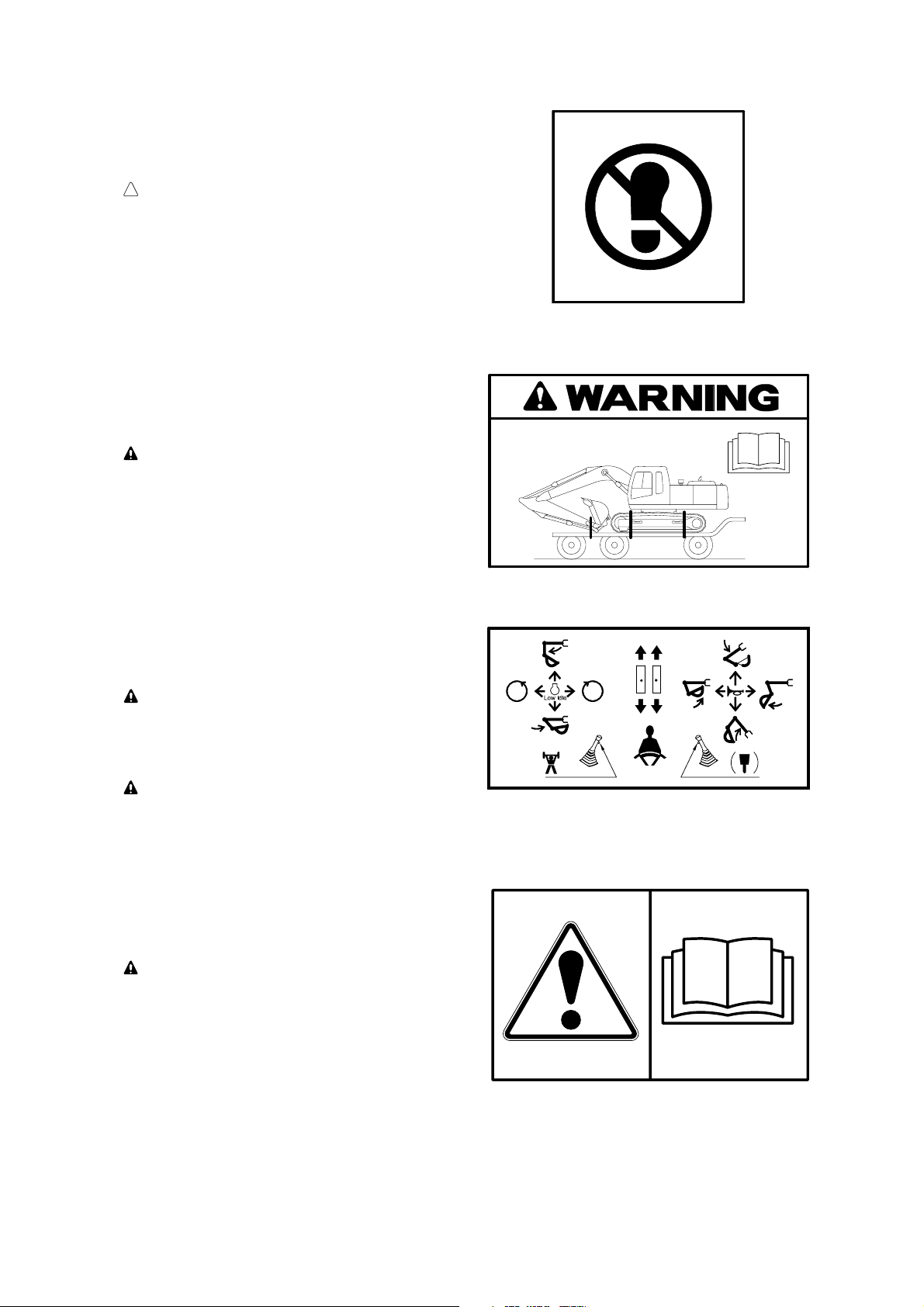

REF OPERATOR MANUAL

Study the operator's manual before starting and operating machine.

TRANSPORTING

Study the operator's manual before

transporting the machine, if provided and

tie down arm and track to the carrier with

lashing wire.

See page 5-7 for details.

CONTROL IDEOGRAM

Check the machine control pattern for

conformance to pattern on this label. If

not, change label to match patte rn

before operating machine.

Failure to do so could result in injury or

death.

See page 4-20 for details.

NO STEP-ENGINE HOOD/CWT

Do not step on the engine hood and

counterweight.

17)

14)

15)

16)

14)

NO STEP-ENGINE HOOD/CWT (item 16)

These warning labels are positioned on the

engine hood and counterweight.

Do not step on the engine hood and

counterweight.

TRANSPORTING (item 17)

15)

This warning label is positioned right side

of upper frame.

Study the operator's manual before

transporting the machine, if provided and

tie down arm and track to the carrier with

lashing wire.

See page 5-7 for details.

21070FW16

CONTROL IDEOGRAM (item 19)

16)

This warning label is positioned in right

window of the cab.

Check the machine control pattern for

conformance to pattern on this label. If

not, change label to match pattern

before operating machine.

Failure to do so could result in injury or

death.

See page 4-20 for details.

REF OPERATOR MANUAL (item 20)

17)

This warning label is positioned on the right

side window of the cab.

Study the operator's manual before starting and operating machine.

14070FW17

36070FW19

0-10

21070FW22

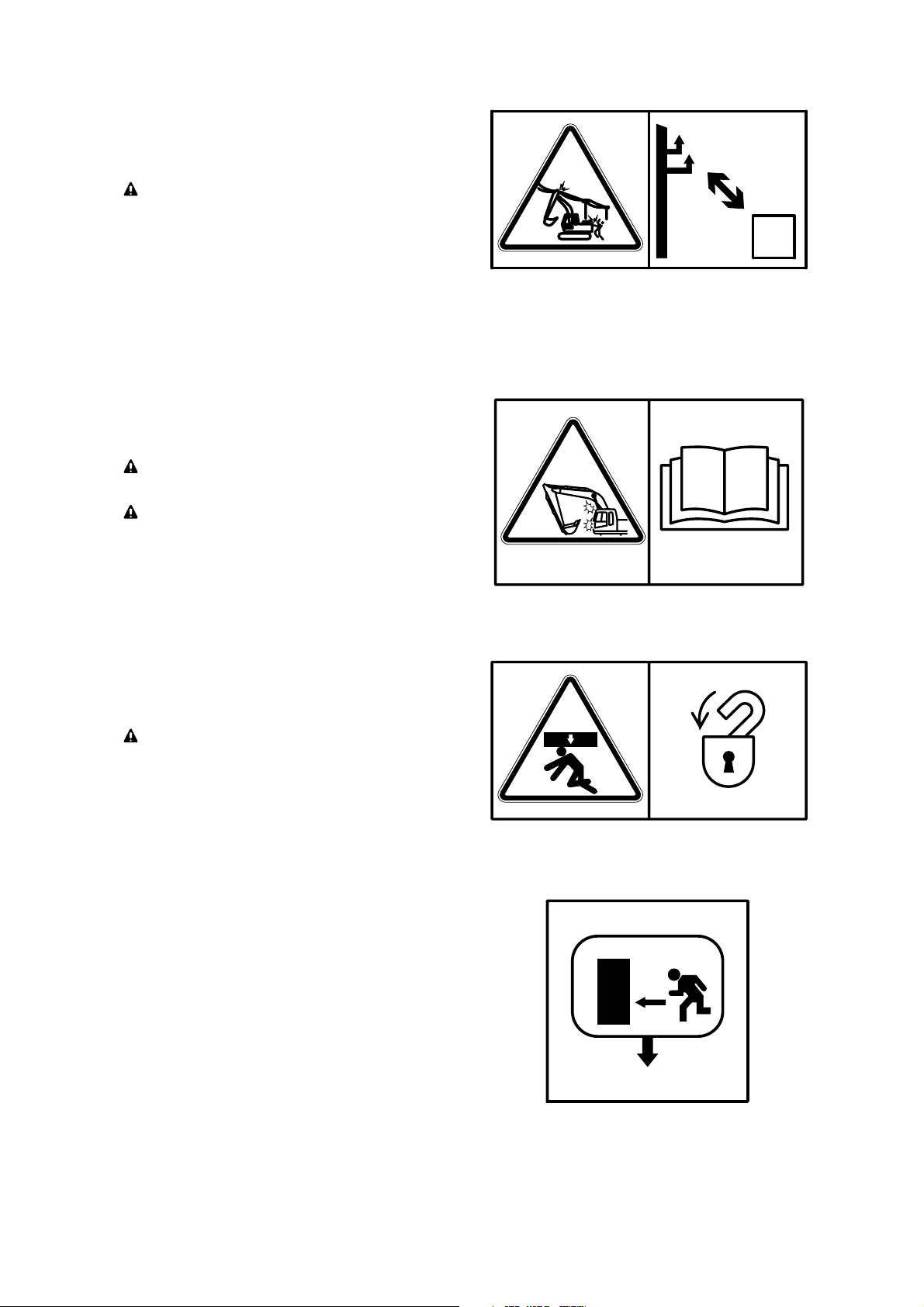

MAX HEIGHT

Serious injury or death can result from

contact with electric lines.

An electric shock being received by

merely coming into the vicinity of an

electric lines, the minimum distance

should be kept considering the supply

voltage as page 1-7.

INTERFERENCE

Be careful to operate machine equipped

with quick clamp or extensions.

Bucket may hit cab or boom, boom cylinders when it reached vicinity of them.

18)

19)

ALTERNATE EXIT

The rear window serves us an alternate

exit.

To remove rear window, pull the ring and

push out the glass.

SAFETY FRONT WINDOW

Be careful that the front window may be

promptly closed.

21

20)

MAX HEIGHT (item 20)

18)

This warning label is positioned on the right

side window of the cab.

Serious injury or death can result from

contact with electric lines.

An electric shock being received by

merely coming into the vicinity of an

electric lines, the minimum distance

should be kept considering the supply

voltage as page 1-7.

INTERFERENCE (item 20)

19)

This warning label is positioned on the

right side window of the cab.

Be careful to operate machine equipped

with quick clamp or extensions.

Bucket may hit cab or boom, boom cylinders when it reached vicinity of them.

21070FW23

SAFETY FRONT WINDOW (item 22)

20)

This warning label is positioned on the both

side window of the cab.

Be careful that the front window may be

promptly closed.

ALTERNATE EXIT (item 23)

21)

This warning label is positioned on the

inside of rear window.

※

The rear window serves us an alternate

exit.

※

To remove rear window, pull the ring and

push out the glass.

21090FW62

21070FW24

0-11

21070FW25

AIR CONDITIONER FILTER

Periodic and proper inspection, cleaning

and change of filter prolong air conditioner life time and maintain good performance.

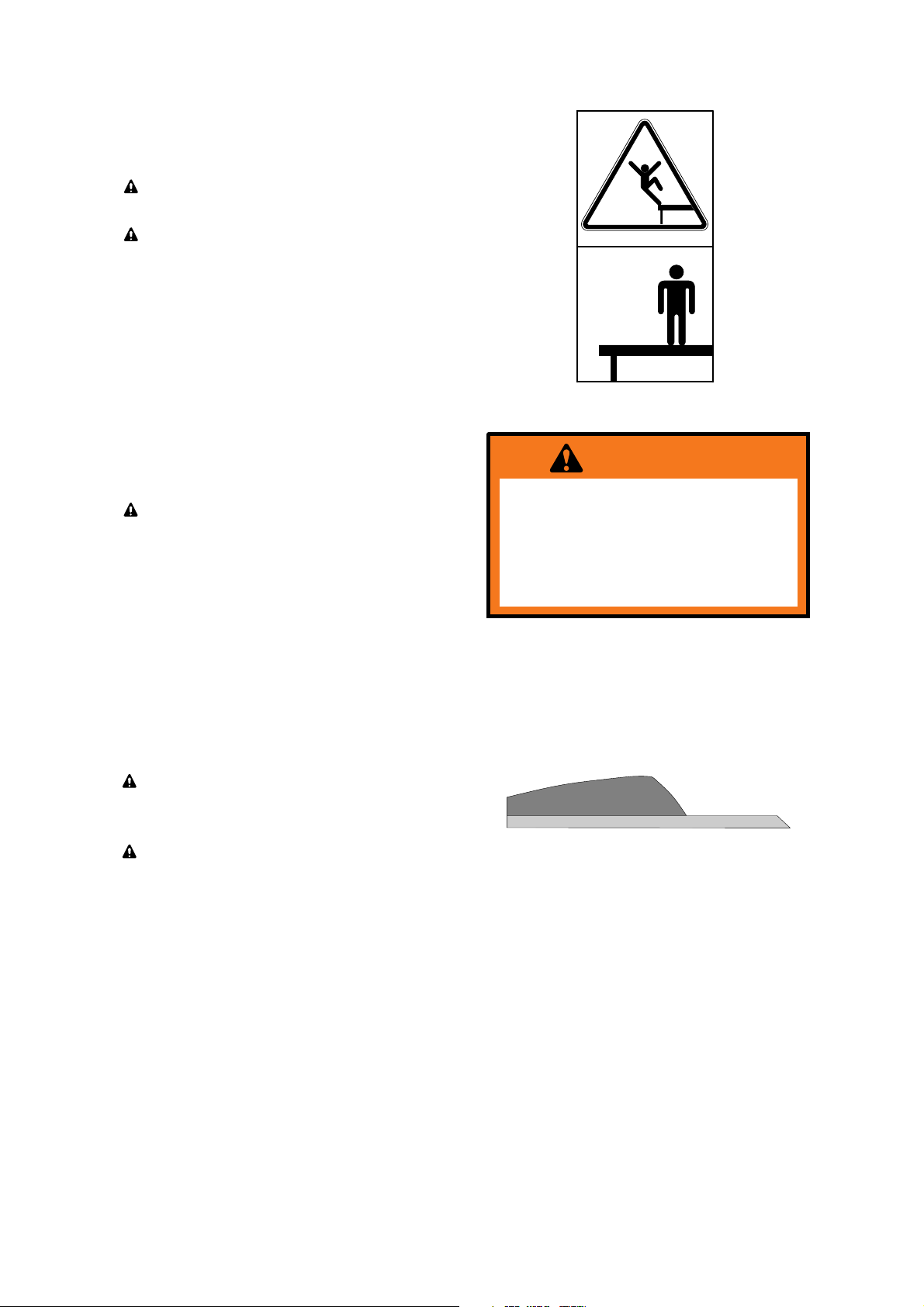

SAFETY LEVER

Before you get off the machine be sure

to place the safety lever LOCKED position.

22)

23)

REDUCTION GEAR GREASE

Grease is under high pressure.

Grease coming out of the grease plug

under pressure can penetrate the body

causing injury or death.

CLAMP-LOCKING

Serious injury or death can result from

dropping bucket.

Operating the machine with quick clamp

switch unlocked or without safety pin of

moving hook can cause the bucket to

drop off.

24)

25)

AIR CONDITIONER FILTER (item 24)

22)

This warning label is positioned on the air

conditioner cover.

※

Periodic and proper inspection, cleaning

and change of filter prolong air conditioner life time and maintain good performance.

SAFETY LEVER (item 26)

23)

This warning label is positioned on the

cover of the safety lever.

Before you get off the machine be sure

to place the safety lever LOCKED position.

21070FW26

REDUCTION GEAR GREASE (item 31)

24)

This warning label is positioned in the front

of upper frame.

Grease is under high pressure.

Grease coming out of the grease plug

under pressure can penetrate the body

causing injury or death.

CLAMP-LOCKING (item 32)

25)

This warning label is positioned on the right

side window of cab.

Serious injury or death can result from

dropping bucket.

Operating the machine with quick clamp

switch unlocked or without safety pin of

moving hook can cause the bucket to

drop off.

30007A1FW07A

21070FW35

14070FW60

0-12

TIE

Make sure no personal are standing

close to the tow rope.

See page 4-23 for detail.

KEEP CLEAR-BOOM/ARM

Serious injury or death can result from

falling of the attachment.

To prevent serious injury or death, keep

clear the underneath of attachment.

26)

27)

ELECTRIC WELDING

Before carrying out any electric welding

on this machine, follow the below procedure.

See page 6-41 for detail.

28)

TIE (item 36)

26)

This warning label is positioned on the

lower frame.

Make sure no personal are standing

close to the tow rope.

See page 4-23 for detail.

KEEP CLEAR-BOOM/ARM (item 37)

27)

This warning label is positioned on both

side of the arm.

Serious injury or death can result from

falling of the attachment.

To prevent serious injury or death, keep

clear the underneath of attachment.

4507A0FW02

ELECTRIC WELDING (item 38)

28)

This warning label is positioned on the battery cover.

Before carrying out any electric welding

on this machine, follow the below procedure.

Pull the connector out of all electric con-

trol units.

-

Connector the ground lead of the welding equipment as close to the welding

point as possible.

※

See page 6-41 for detail.

14070FW31

W A R N I N G

·Before carrying out any electric welding on this

machine

- Pull the connectors out of all electronic control

units.

- Connect the ground lead of the welding equipment

as close to the welding point as possible.

·Read the instructions in operator's manual for

details.

7807AFW20

0-13

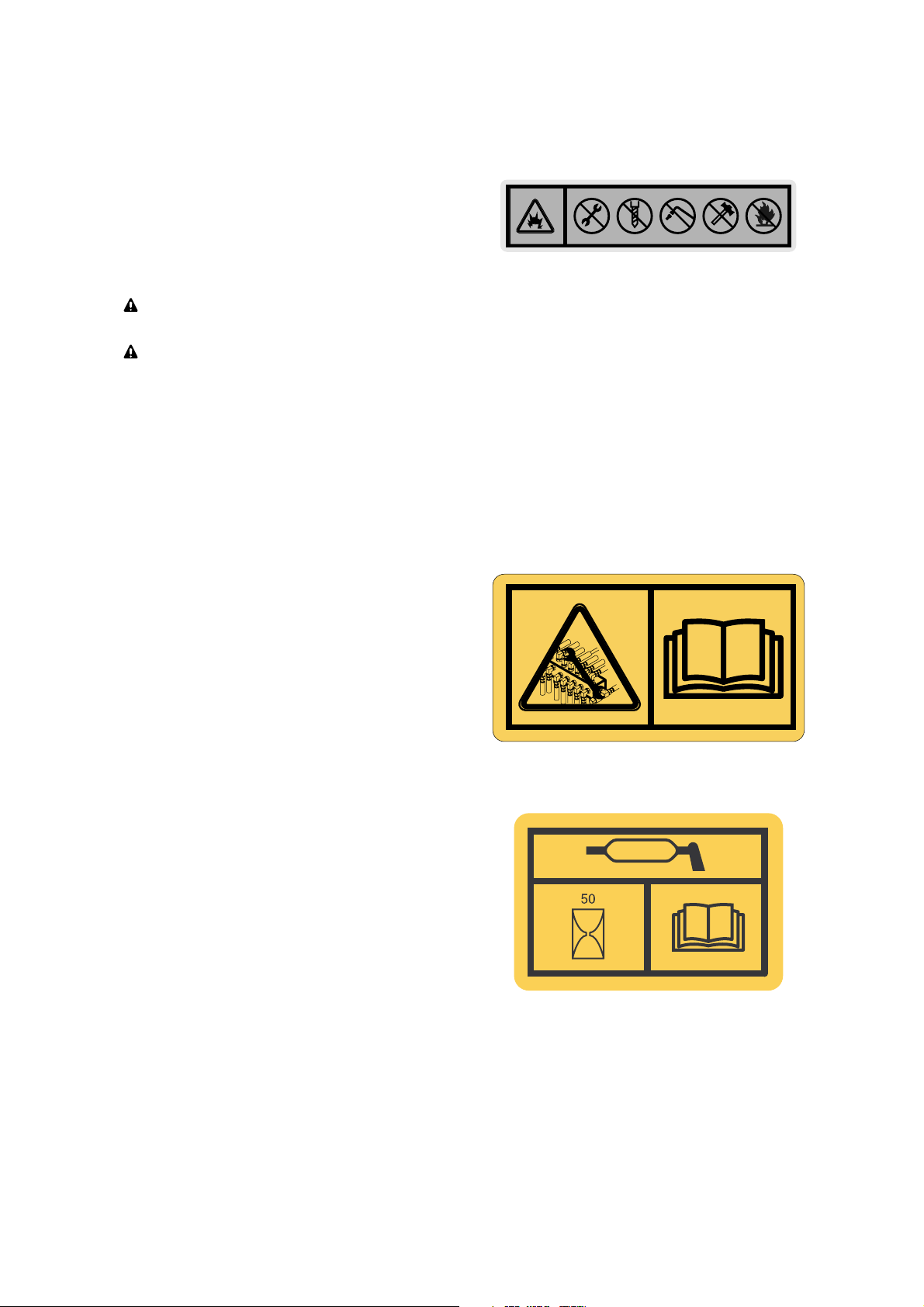

TURBOCHARGER

In order to prevent turbocharger failure,

please allow more than 5 minutes' cool

down period (no load low idle operation)

before shutting the engine off.

REFLECTING

To prevent serious personal injury or

death keep clear of machine swing radius.

Do not deface or remove this label from

the machine.

30)

31)

FALLING

Falling is one of the major cause of personal injury.

Be careful of slippery conditions on the

platforms, steps and handrails when

standing on the machine.

29)

FALLING (item 39)

29)

These warning labels are positioned on the

top of the hydraulic tank and counterweight.

Falling is one of the major cause of personal injury.

Be careful of slippery conditions on the

platforms, steps and handrails when

standing on the machine.

TURBOCHARGER (item 41)

30)

This warning label is positioned on the right

window of the cab.

In order to prevent turbocharger failure,

please allow more than 5 minutes' cool

down period (no load low idle operation)

before shutting the engine off.

14070FW30

C A U T I O N

In order to prevent turbocharger failure,

please allow more than 5 minutes' cool

down period(no load low idle operation)

before shutting the engine off.

REFLECTING (item 42)

31)

This warning label is positioned on the rear

of counterweight.

To prevent serious personal injury or

death keep clear of machine swing radius.

Do not deface or remove this label from

the machine.

7807AFW20

21090FW70

0-14

ACCUMULATOR

The accumulator is filled with high-pressure nitrogen gas, and it is extremely

dangerous if it is handled in the wrong

way. Always observe the following precautions.

Never make any hole in the accumulator

expose it to flame or fire.

Do not weld anything to the accumulator.

When carrying out disassembly or maintenance of the accumulator, or when disposing of the accumulator, it is necessary to release the gas from the accumulator. A special air bleed valve is necessary for this operation, so please contact your Hyundai distributor.

32)

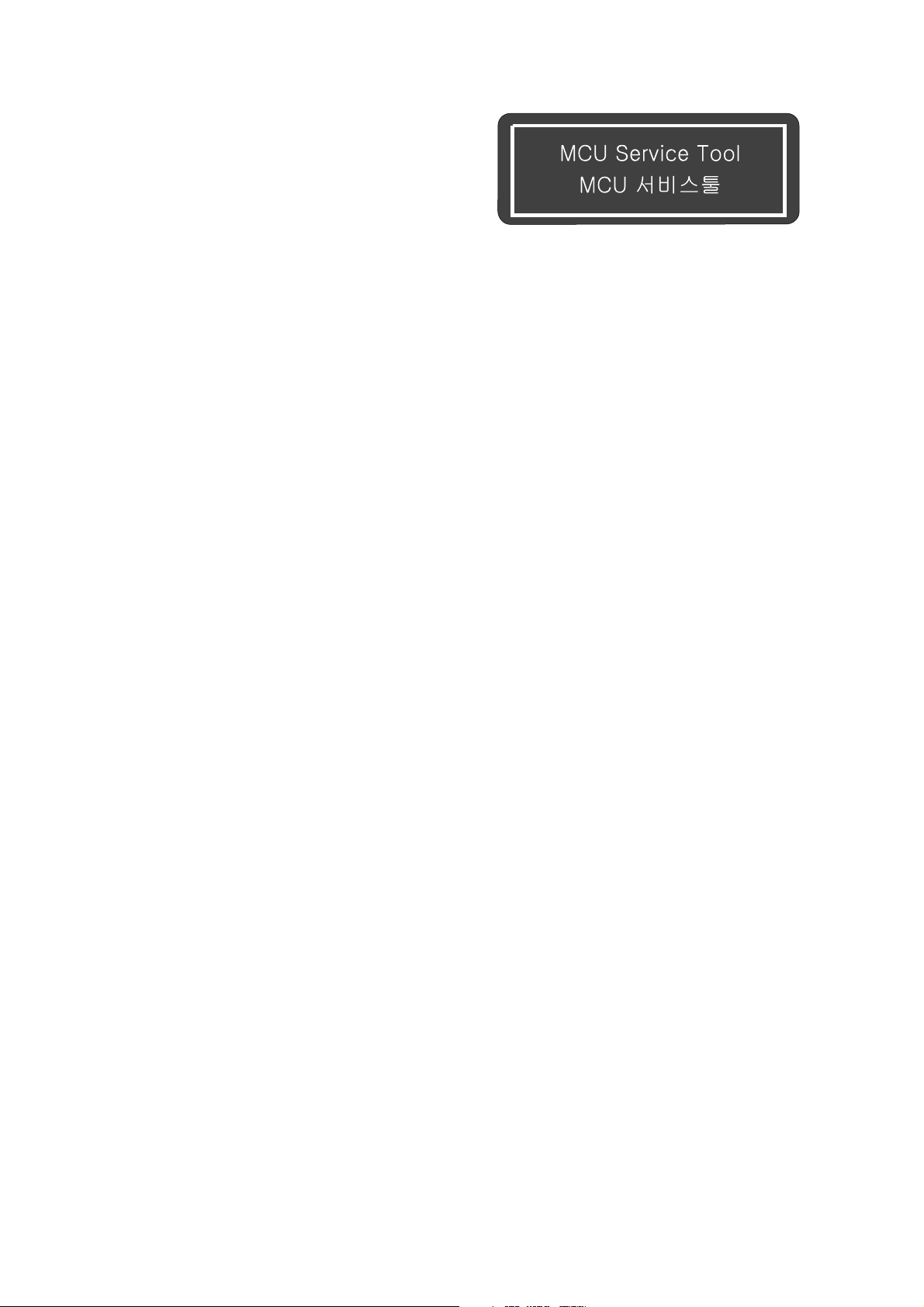

SWING BEARING

See page 6-32 for details.

34)

RCV LEVER PATTERN

See page 4-34 for details.

33)

ACCUMULATOR (item 43)

32)

This warning label is positioned on the

accumulator of the solenoid valve.

※

The accumulator is filled with high-pressure nitrogen gas, and it is extremely

dangerous if it is handled in the wrong

way. Always observe the following precautions.

Never make any hole in the accumulator

expose it to flame or fire.

Do not weld anything to the accumulator.

※

When carrying out disassembly or maintenance of the accumulator, or when disposing of the accumulator, it is necessary to release the gas from the accumulator. A special air bleed valve is necessary for this operation, so please contact your Hyundai distributor.

1107A0FW46

RCV LEVER PATTERN (item 46)

33)

This warning label is positioned on the

screen plate.

※

See page 4-34 for details.

SWING BEARING (item 47)

34)

This warning label is positioned in the front

of swing ring gear.

※

See page 6-32 for details.

14W90FW47

38090FW02

0-15

BATTERY POSITION

35)

BEACON LAMP

Make sure the beacon lamp maintains a

vertical position.

A horizontal position can result in a

decrease in life time of the lamp due to

the infiltration of foreign substances such

as dust or water.

While the machine transfer, the beacon lamp

is easy to break. In that case, change the

position of the lamp to the horizontal.

36)

FUEL SHUT OFF

Fill only the hydraulic oil.

Do not fill the diesel fuel.

37)

WATER SEPARATOR

In order to protect high pressure fuel

system, please drain water in water

separator before starting the engine.

38)

35)

BATTERY POSITION (item 48)

This warning label is positioned right side of

tool box.

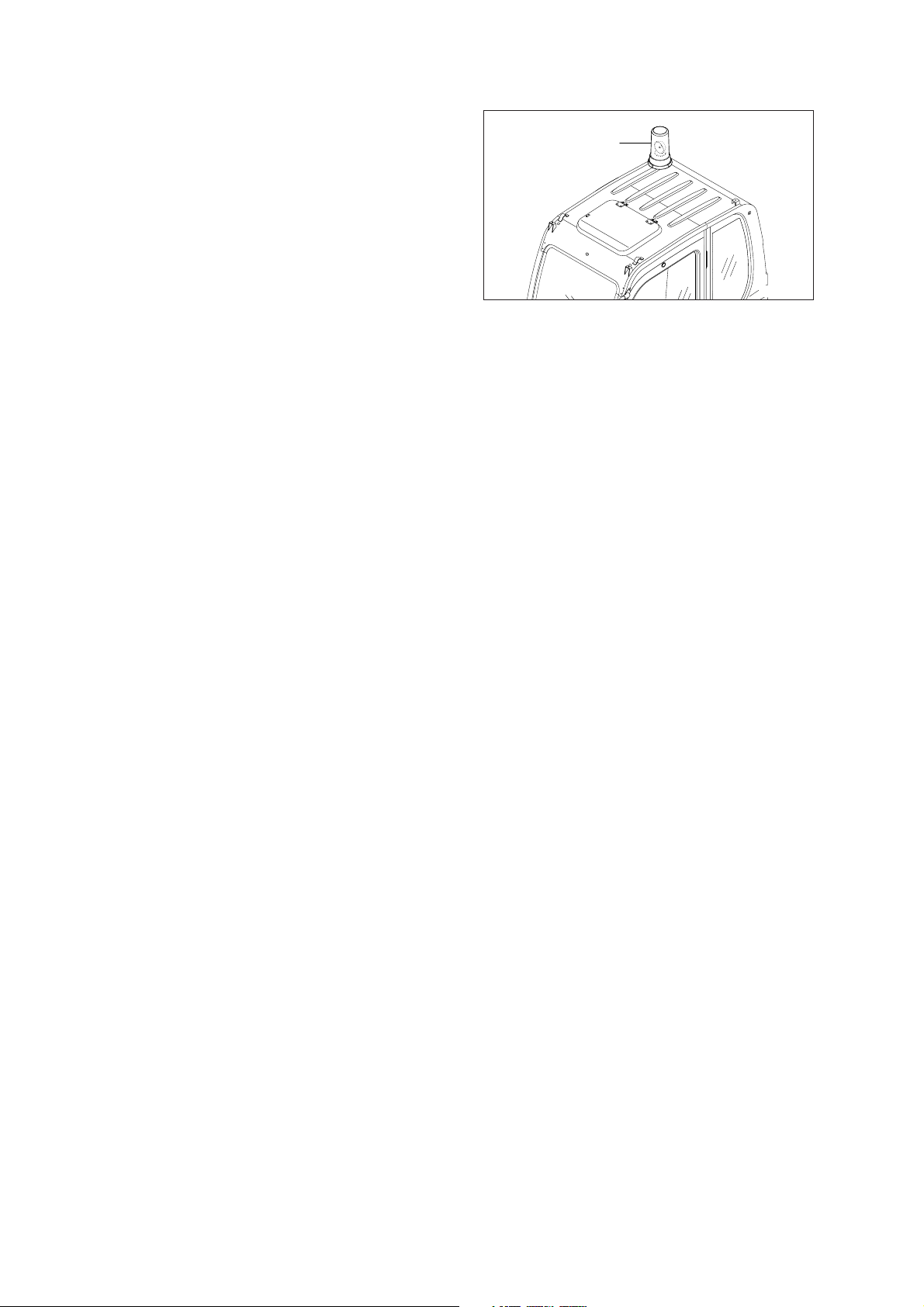

BEACON LAMP (item 49)

36)

This warning label is positioned on the right

outside of the cabin.

※

Make sure the beacon lamp maintains a

vertical position.

A horizontal position can result in a

decrease in life time of the lamp due to

the infiltration of foreign substances such

as dust or water.

While the machine transfer, the beacon lamp

※

is easy to break. In that case, change the

position of the lamp to the horizontal.

38090FW03

140Z90FW49

FUEL SHUT OFF (item 50)

37)

This warning label is positioned on the left

side of the hydraulic tank.

※

Fill only the hydraulic oil.

※

Do not fill the diesel fuel.

WATER SEPARATOR (item 51)

38)

This warning label is positioned in right window of the cab.

In order to protect high pressure fuel

system, please drain water in water

separator before starting the engine.

140WH90FW51

In order to protect high pressure fuel system,

please drain water in water separator before

starting the engine.

210N90FW50

0-16

MCU CONNECTOR

MCU communicates the machine data with

Laptop computer through RS232 service

socket.

See page 3-60 for details.

39)

39)

MCU CONNECTOR (item 52)

This warning label is positioned on the low

cover of the air conditioner in the cab.

※

MCU communicates the machine data with

Laptop computer through RS232 service

socket.

See page 3-60 for details.

※

1409S0FW52

0-17

MACHINE DATA PLATE

MACHINE DATA PLATE

1000, BANGEOJINSUNHWAN-DORO, DONG-GU, ULSAN 682-792, KOREA

EQUIPMENT

1

2

MODEL

SERIAL-NUMBER

3

DO NOT DEFACE OR REMOVE THIS PLATE

OPERATING WEIGHT

ENGINE POWER(PS/KW/rpm)

1

4

2

5

3

1000, BANGEOJINSUNHWAN-DORO, DONG-GU, ULSAN 682-792, KOREA

EQUIPMENT

MODEL

SERIAL-NUMBER

DO NOT DEFACE OR REMOVE THIS PLATE

OPERATING WEIGHT

ENGINE POWER(PS/KW/rpm)

MFG. YEAR

FOR EU ONLY

1 Equipment

2 Model name

The machine serial number assigned to this particular machine and should be used when request-

※

3 Serial number

4 Operating weight

5 Engine power

6 Manufacturing year

ing information or ordering service parts for this machine from your authorized HYUNDAI dealer.

The machine serial number is also stamped on the frame.

4

5

6

21090FW10

0-18

GUIDE

1. DIRECTION

2. SERIAL NUMBER

MACHINE SERIAL NUMBER

4. SYMBOLS

Important safety hint.

It indicates matters which can cause the great loss on the machine or the surroundings.

It indicates the useful information for operator.

1)

ENGINE SERIAL NUMBER

2)

3.

INTENDED USE

GUIDE

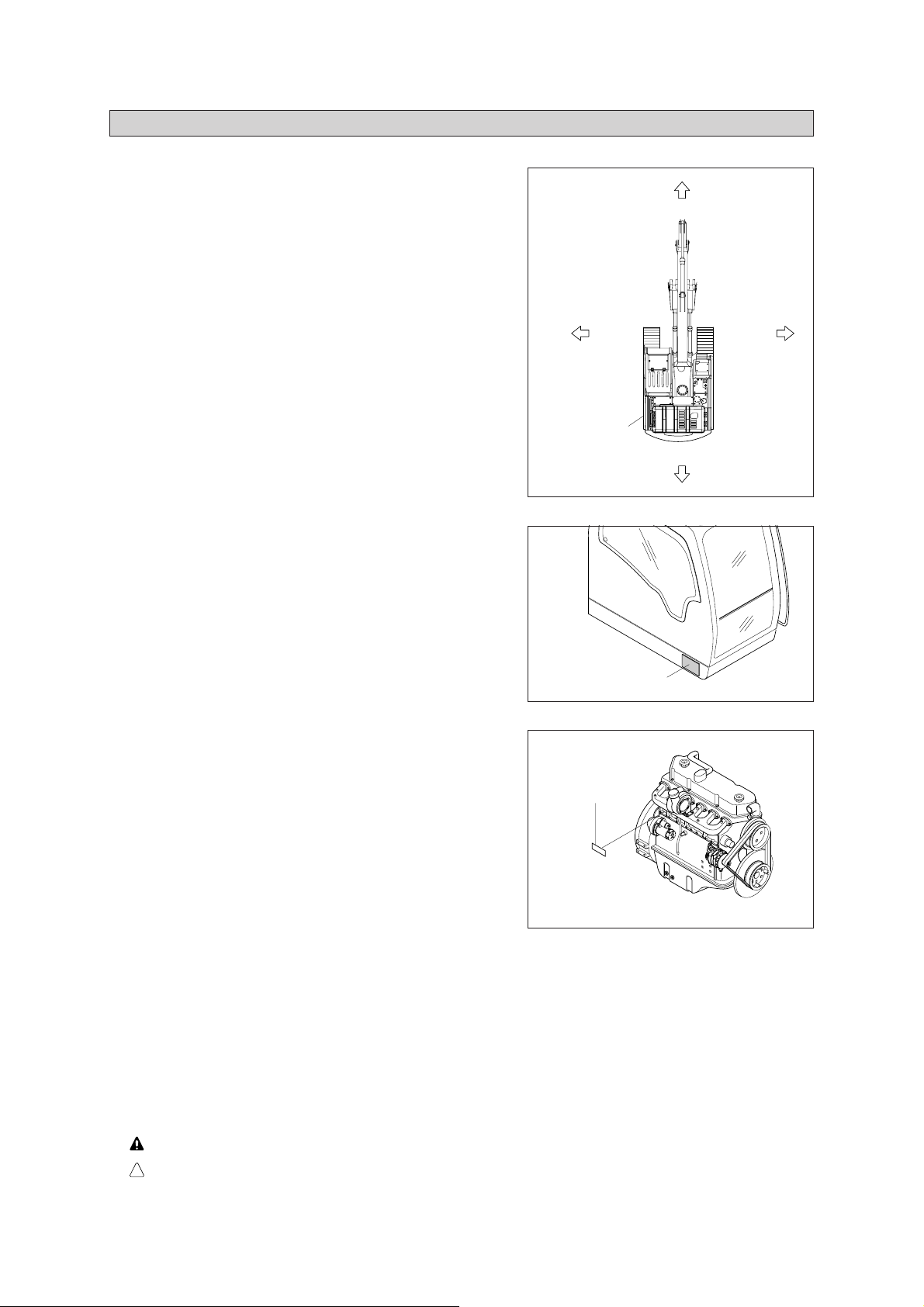

1. DIRECTION

The direction of this manual indicate forward, back-

ward, right and left on the standard of operator

when the travel motor is in the rear and machine is

on the traveling direction.

2. SERIAL NUMBER

Inform following when you order parts or the

machine is out of order.

1)

MACHINE SERIAL NUMBER

The numbers are located below the right window

of the operator's cab.

Forward

Travel motor

Backward

Machine serial No.

RightLeft

16090SG01

21090SN02

ENGINE SERIAL NUMBER

2)

The numbers are located on the engine name

plate.

3.

INTENDED USE

Engine serial No.

This machine is designed to be used mainly for the following work.

- Digging work

- Loading work

- Smoothing work

- Ditching work

※

Please refer to the section 4 (efficient working method) further details.

4. SYMBOLS

Important safety hint.

It indicates matters which can cause the great loss on the machine or the surroundings.

17W9S0SN01

※

It indicates the useful information for operator.

0-19

1. BEFORE OPERATING THE MACHINE

SAFETY HINTS

1. BEFORE OPERATING THE MACHINE

Think-safety first.

In special situation, wear protective clothing

including a safety helmet, safety shoes, gloves,

safety glasses and ear protection as required by

the job condition.

Almost every accident is caused by disregarding the simple and fundamental safety

hints.

Be sure to understand thoroughly all about the

operator's manual before operating the

machine.

Proper care is your responsibility.

SAFETY HINTS

13031SH01

Fully understand the details and process of the

construction before starting the work.

If you find anything dangerous on the job,

consult with the job supervisor for the preventive measures before operating the machine.

Do not operate when tired, or after drinking

alcoholic beverages or any type of drugs.

13031SH02

13031SH03

1-1

13031SH05

Check daily according to the operation manual.

Repair the damaged parts and tighten the loosened bolts.

Check for leakage of engine oil, hydraulic oil,

fuel and coolant.

Keep machine clean, clean machine regularly.

13031SH05

Do not operate the machine if it requires repairs.

Operate after complete repair.

Be prepared if a fire starts.

Keep a fire extinguisher handy and emergency

numbers for a fire department near your telephone.

13031SH06

13031SH07

1-2

13031SH08

PROTEC TIO N AGAINS T FALLI NG OR

FLYING OBJECTS

UNAUTHORIZED MODIFICATION

PREPARE FOR EMERGENCY

PROTECTION AGAINST FALLING OR

FLYING OBJECTS

If there is any danger of falling or flying objects

hitting the operator, install protective guards in

place to protect the operator as required for

each particular situation.

Be sure to close the front window before commencing work.

Make sure to keep all persons other than operator outside the range of falling or flying objects.

In case you need top guard, front guard and

FOPS (falling object protective structure),

please contact Hyundai distributor in Europe.

UNAUTHORIZED MODIFICATION

Any modification made without authorization

from Hyundai can create hazards.

Top guard

Front guard

21091SH01

Before making a modification, consult your

Hyundai distributor. Hyundai will not be responsible for any injury or damage caused by any

unauthorized modification.

PREPARE FOR EMERGENCY

Only in case of emergency, use the installed

hammer for breaking the windshield of the cab,

and then exit carefully.

Be sure you know the phone numbers of persons you should contact in case of an emergency.

Hammer

1-3

21091SH02

ROTATING BEACON

PRECAUTIONS FOR ATTACHMENTS

SAFETY RULES

Only

ROTATING BEACON

When you operate a machine on a road or

beside a road, a rotating beacon is required to

avoid any traffic accident.

Please contact your Hyundai distributor to install

it.

PRECAUTIONS FOR ATTACHMENTS

When installing and using an optional attachment, read the instruction manual for the attachment and the information related to attachments

in this manual.

Do not use attachments that are not authorized

by Hyundai or your Hyundai distributor. Use of

unauthorized attachments could create a safety

problem and adversely affect the proper operation and useful life of the machine.

Beacon

21091SH03

Any injuries, accidents, product failures resulting

from the use of unauthorized attachments are

not the responsibility of Hyundai.

The stability of this machine is enough to be

used for general work. When you operate this

machine, allow for the lifting capacity tables. If

you want to use other special applications (not

covered in this manual), you have to attach

additional counterweight or be cautious while

running the machine.

SAFETY RULES

Only trained and authorized personnel can

operate and maintain the machine.

Follow all safety rules, precautions and instructions when operating or performing maintenance on the machine.

When working with another operator or a person on worksite traffic duty, be sure all personnel understand all hand signals that are to be

used.

1-4

SAFETY FEATURES

Never

Always

MACHINE CONTROL PATTERN

CALIFORNIA PROPOSITION 65

The wrong loading method can result in serious bodily injury or death.

SAFETY FEATURES

Be sure all guards and covers are in their proper position. Have guards and covers repaired if

damaged.

Use safety features such as safety lock and

seat belts properly.

Never remove any safety features.

Always

keep them in good operating condition.

Improper use of safety features could result in

serious bodily injury or death.

MACHINE CONTROL PATTERN

Check machine control pattern for conformance

to pattern on label in cab.

If not, change label to match pattern before

operating machine.

Failure to do so could result in injury.

CALIFORNIA PROPOSITION 65

Diesel engine exhaust and some of its constituents are known to the State of California to

cause cancer, birth defects and other reproductive harm.

This product contains or emits chemicals known

to the State of California to cause cancer or

birth defects or other reproductive harm.

Battery posts, terminals and related accessories contain lead and lead compounds.

WASH HANDS AFTER HANDLING

WASH HANDS

AFTER HANDLING !

contain lead and lead compounds,chemicals known to the

State of California to cause cancer and reproductive harm.

: Battery posts, terminals and related accessories

13031SH55

Do not load the machine with the lifting eyes on

the counterweight.

The wrong loading method can result in serious bodily injury or death.

1-5

2. DURING OPERATING THE MACHINE

2. DURING OPERATING THE MACHINE

Use the handle and footstep when getting on or

off the machine.

Do not jump on or off the machine.

Sound the horn to warn nearby personnel

before operating the machine.

Remove all the obstacles like frost on the window before operating the machine for the good

visibility.

13031SH09

Operate carefully to make sure all personnel or

obstacles are clear within the working range of

the machine.

Place safety guards if necessary.

When using the work equipment, pay attention

to job site.

13031SH10

13031SH11

1-6

13031SH12

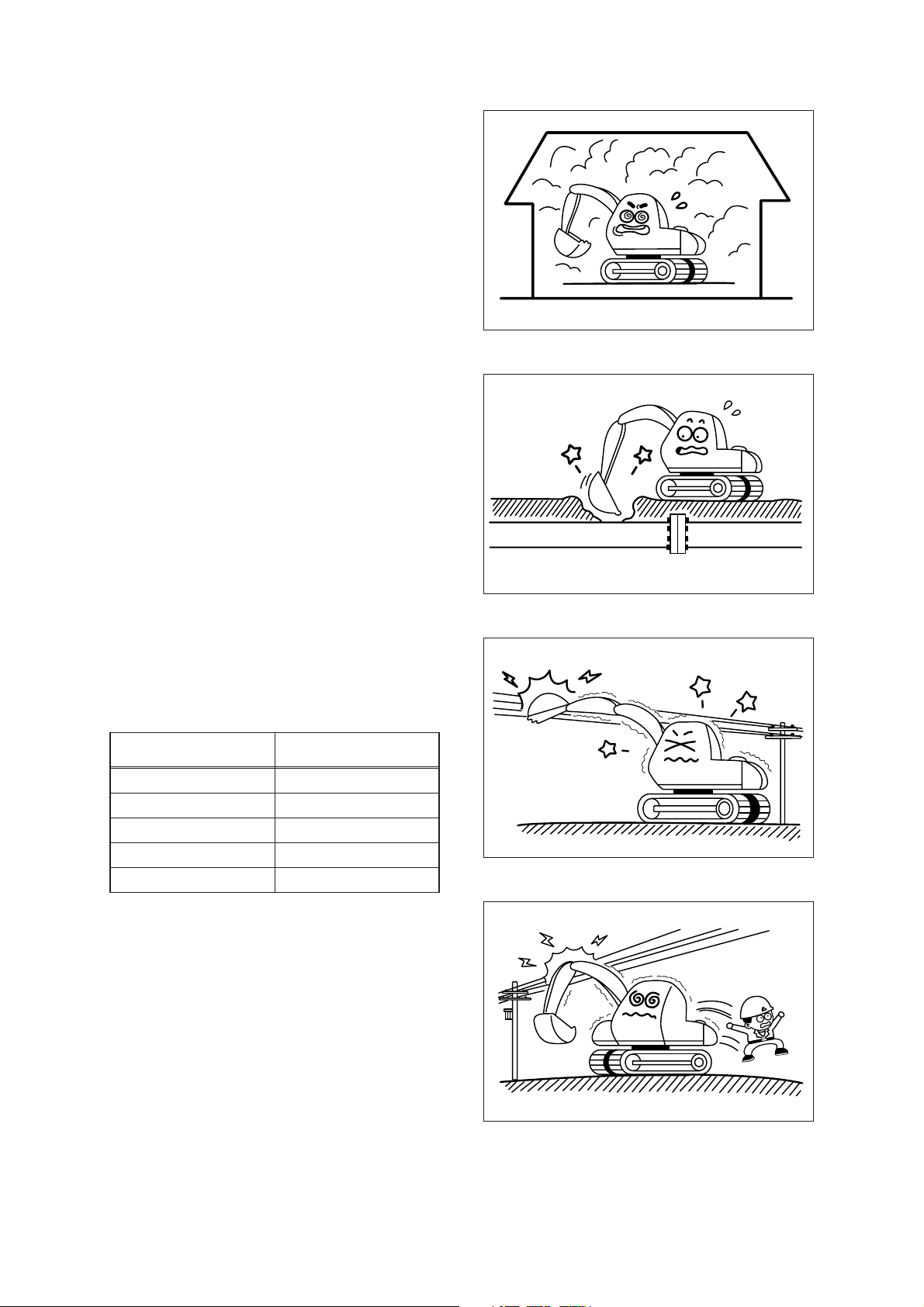

Provide proper ventilation when operating

engine in a closed area to avoid the danger of

exhaust gases.

Check the locations of underground gas

pipes or water line and secure the safety before

operation.

13031SH13

The operating near the electrical lines is very

dangerous.

Operate within safe working range permitted as

below.

Supply voltage

6.6

kV

33.0

kV

66.0

kV

154.0

kV

275.0

kV

Min safe separation

3m (10 ft)

4m (13 ft)

5

m

(16 ft)

m

(26 ft)

8

10m (33 ft)

If the machine touches the electric power lines,

keep sitting on the operator's seat and make

sure the personnel on the ground not to touch

the machine until turning off the electric current. Jump off the machine without contacting

the machine when you need to get off.

13031SH14

13031SH15

1-7

13031SH16

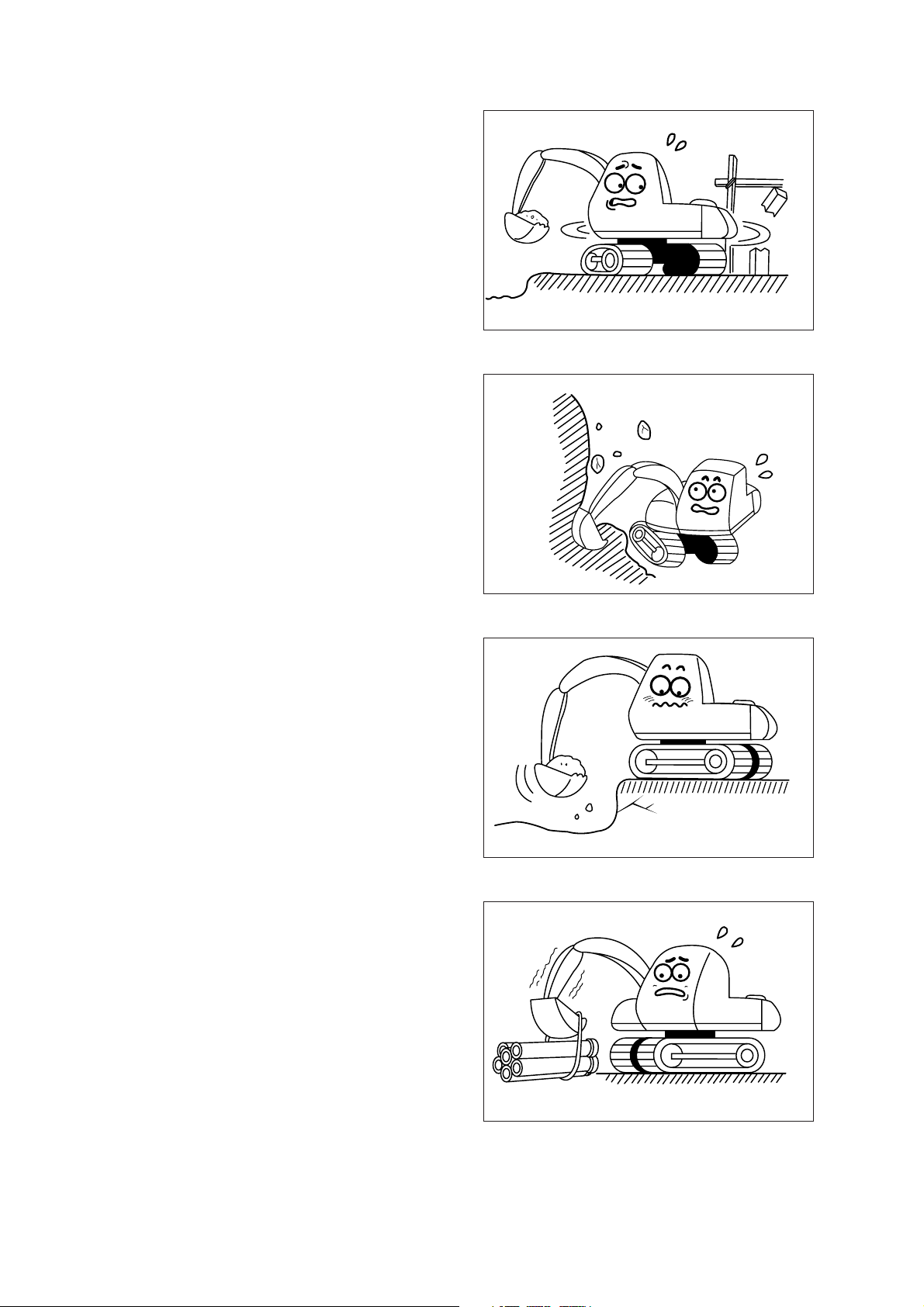

Watch out for obstacles.

Be particularly careful to check the machine

clearance during the swing.

When using the machine as breaker or

working in a place where stones may fall down,

cab roof guard and head guard should be provided for proper protection.

13031SH17

Avoid operating on a cliff or soft ground as there

is danger of rolling over.

Make sure to get off easily as keeping the track

at a right angle and putting the travel motor into

the backward position when working on a cliff or

soft ground inevitably.

Operate for the lifting work considering the

capacity of machine, weight and width of the

load.

Be careful not to lift exceeding the machine

capacity as it can be the cause of machine

damage and safety accident.

13031SH18

13031SH19

1-8

13031SH20

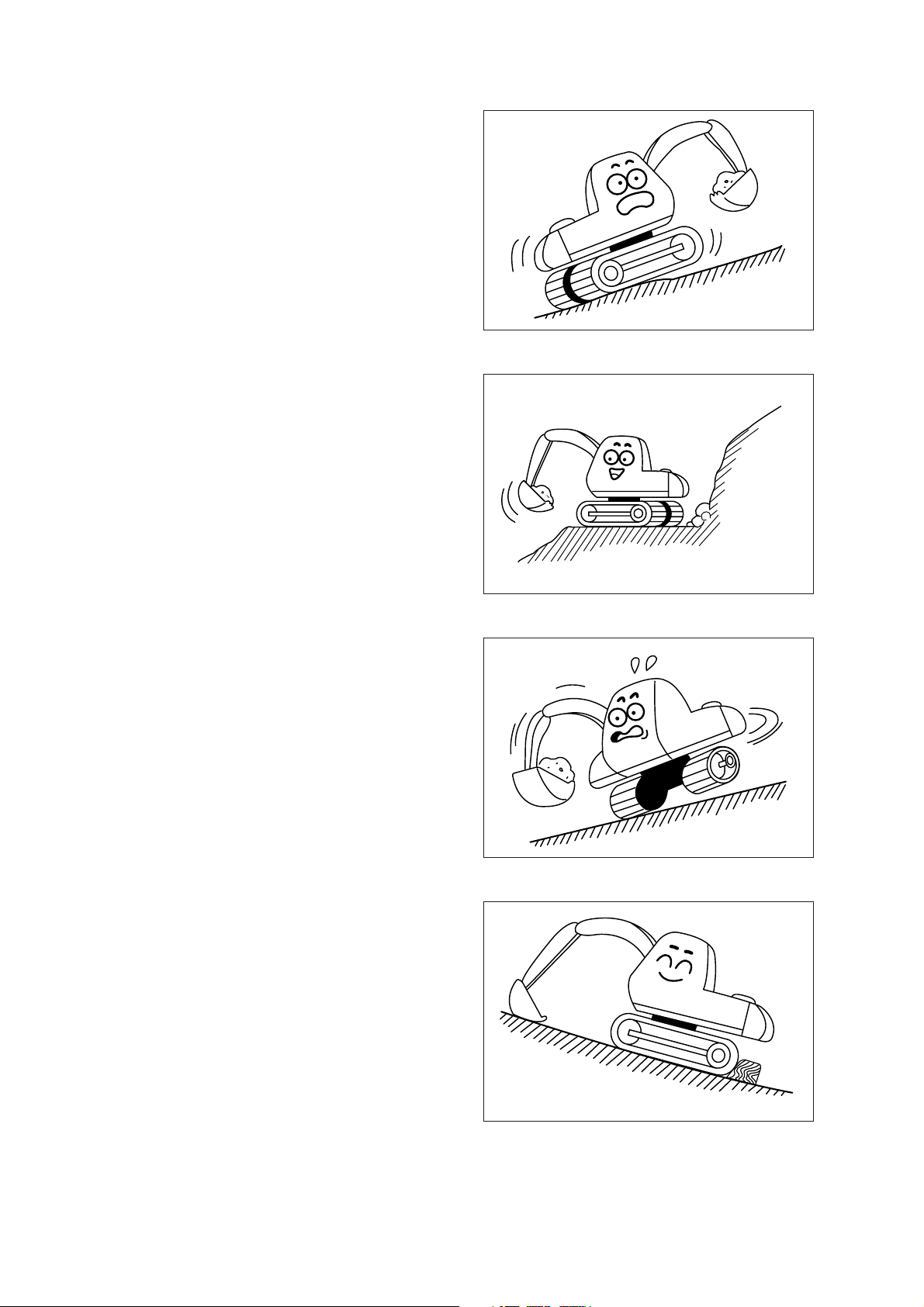

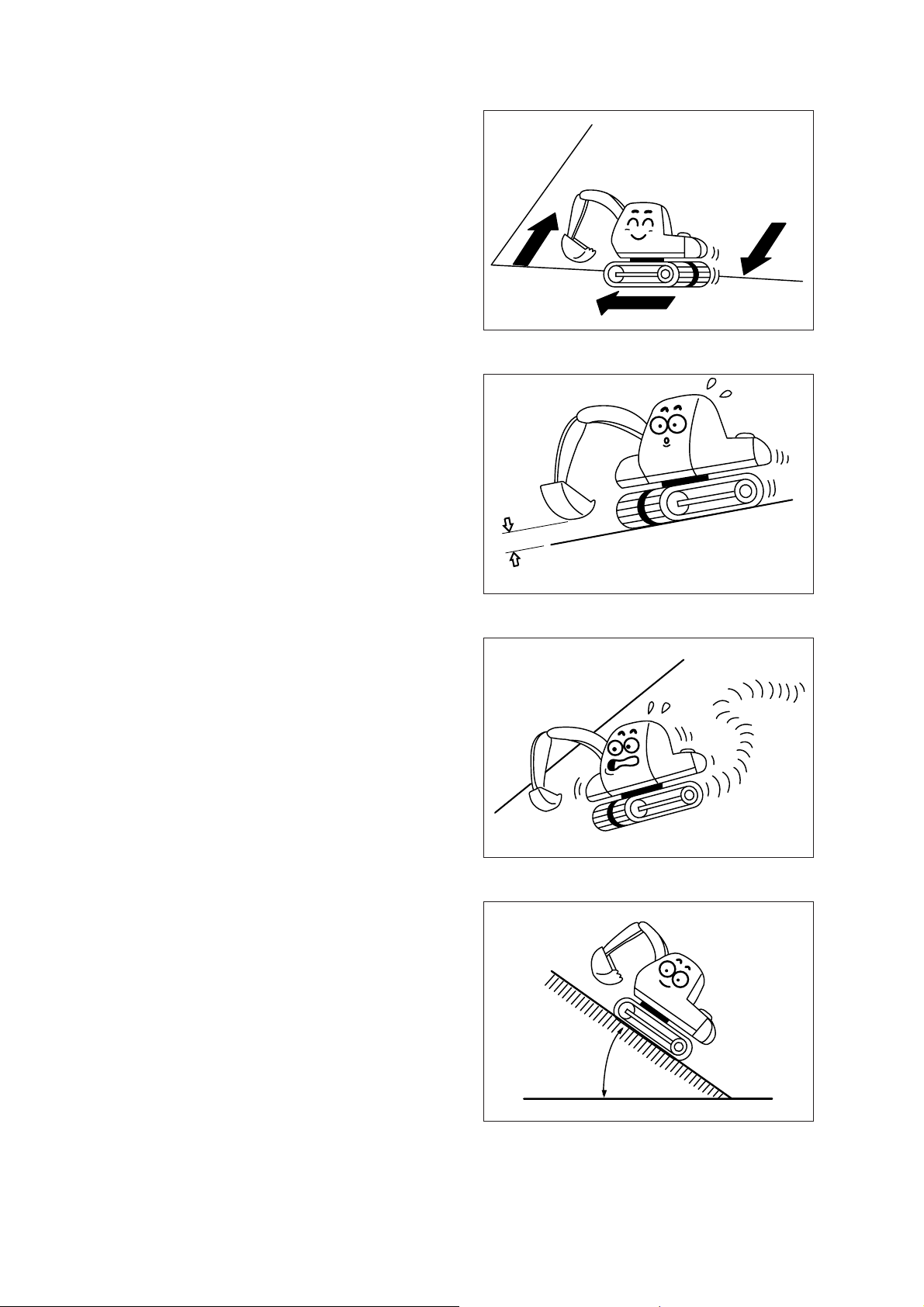

The operation on a slope is dangerous.

Avoid operating the machine on a slope of over

10 degree.

Operate the machine after making ground flat

when operation is required on a slope.

13031SH21

The swing on the slope can be danger of

rolling over.

Do not operate to swing the machine with the

bucket loaded on a slope since the machine

may lose its balance under such an instance.

Avoid parking and stopping on a slope.

Lower the bucket to the ground and block the

track when parking.

13031SH22

13031SH23

1-9

13031SH24

Avoid traveling in a cross direction on a slope as

it can cause the danger of rolling over and sliding.

Traveling on a slope is dangerous.

Be sure to operate slowly when traveling down

a slope and maintain the bucket at a height of

20~30

cm

(1 ft) above the ground so that it can

be used as brake in an emergency.

13031SH25

Steering of the machine while traveling on a

slope is dangerous.

When an inevitable turning of direction is

required, turn on the flat and solid ground.

The engine angularity limits are 35 degree.

Do not operate by more than the engine limits

in any case.

20~30

cm

13031SH26

13031SH27

1-10

35。

13031SH28

Loading...

Loading...