Page 1

60” 4-Way

Quadcycler Deck

Parts Manual

027292 Rev. 8/06

•••••••

Hustler Turf Equipment

•••••

P.O. Box 7000

•••

Hesston, Kansas

•

67062-2097

Page 2

Page 3

Chapter 1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Chapter 2 Contents

Deck Assembly - 925115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Deck Assembly - 923144, 923268, 924605 & 924613 . . . . . . . . . . 2-4

Deck Subassembly - 925115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Deck Subassembly - 923144, 923268, 924605 & 924613 . . . . . . . 2-8

Chapter 3 Contents

Gauge Arm Assembly - 469221 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

60” Quad Deck Gauge Wheel Kit - 320523. . . . . . . . . . . . . . . . . . . 3-3

Gauge Wheel Assembly - 307082 . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

60” Deck Heavy Duty Gauge Wheel Kit - 315606K . . . . . . . . . . . . 3-5

Gauge Arm Assembly - 466888 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Spindle Assembly - 506212 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Chapter 4 Contents

Gearbox Breakdown - 532861 (WSI) . . . . . . . . . . . . . . . . . . . . . . . 4-2

Gearbox Breakdown - 532861 (Agrigear) . . . . . . . . . . . . . . . . . . . . 4-3

Gearbox Breakdown - 532895 (WSI) . . . . . . . . . . . . . . . . . . . . . . . 4-4

Gearbox Breakdown - 532895 (Agrigear) . . . . . . . . . . . . . . . . . . . . 4-5

Table of Contents

Chapter 5 Contents

Decal Group - 925115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Decal Group - 924605 & 924613 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i-1

027292 8/06

Page 4

0272928/06

Page 5

Chapter 1

General Information

This Manual covers 60” 4-Way Mower Models: 923144, 923268, 924605, 924613 & 925115

Frequently Ordered Parts

PART NO. DESCRIPTON

027284 60" 3-WAY Deck Belt

Service Literature

PART NO. DESCRIPTION

027300 60” 4-Way Mower Owner’s Manual

374827 60” 4-Way Mower Assembly Instructions

Note: Parts painted blue are no longer available.

Note: When ordering parts, you

Always give the tractor model and serial number and the engine model and serial number to your parts and service representative.

Note: Items sold in bulk such as seals and hoses are sold by the foot.

Using this manual

Illustrations used were current at the time of printing, but subsequent production changes may cause your machine to

vary slightly in detail. Excel Industries, Inc. reserves the right to redesign and change the machine as deemed necessary, without notification. If a change has been made to your machine which is not reflected in this parts manual, see

your Hustler dealer for current information and parts.

must use the service part number as shown for each part, not the index number.

027292 8/06 1-1

Page 6

Hardware Description Codes & Abbreviations

The following codes are used throughout this parts manual. Refer to this list when ordering parts.

ABBREVIATION DESCRIPTION

CB Carriage Bolt

CE Clevis Pin

CP Cotter Pin

CS Cap Screw

CW Cup Washer

FDRW Fender Washer

FW Flat Washer

HX Hex Head

LW Lock Washer

MB Machine Bushing

MS Machine Screw

NT Nut

SC Self Tapping Cap Screw

SH Socket Head

SB Shoulder Bolt

SS Set Screw

OD Outside Diameter

ID Inside Diameter

Standard Torques

The following chart lists the standard torque values for the threaded fasteners found in this manual. Torque all cap

screws, nuts and set screws to these values unless a different torque is shown in the Notes section next to the fastener.

SIZE FT-LBS NM SIZE FT-LBS NM

.250 8.2 11.1 M3 1 1.3

.312 17 23 M4 2.2 3

.375 30 40 M5 4.5 6.1

.438 48 65 M6 7.7 10.4

.500 73 99 M8 18.5 25

.562 105 143 M10 37 50

.625 145 200 M12 64 87

.750 260 350 M16 160 215

.875 420 565 M20 320 435

1.00 625 850 M24 555 750

NOTE:

Lubricate all grease zerks.

1-2 027292 8/06

Page 7

Chapter 2 Contents

Deck Assembly - 925115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Deck Assembly - 923144, 923268, 924605 & 924613 . . . . . . . . . . . 2-4

Deck Subassembly - 925115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Deck Subassembly - 923144, 923368, 924605 & 924613 . . . . . . . . 2-8

027292 8/06 2-1

Page 8

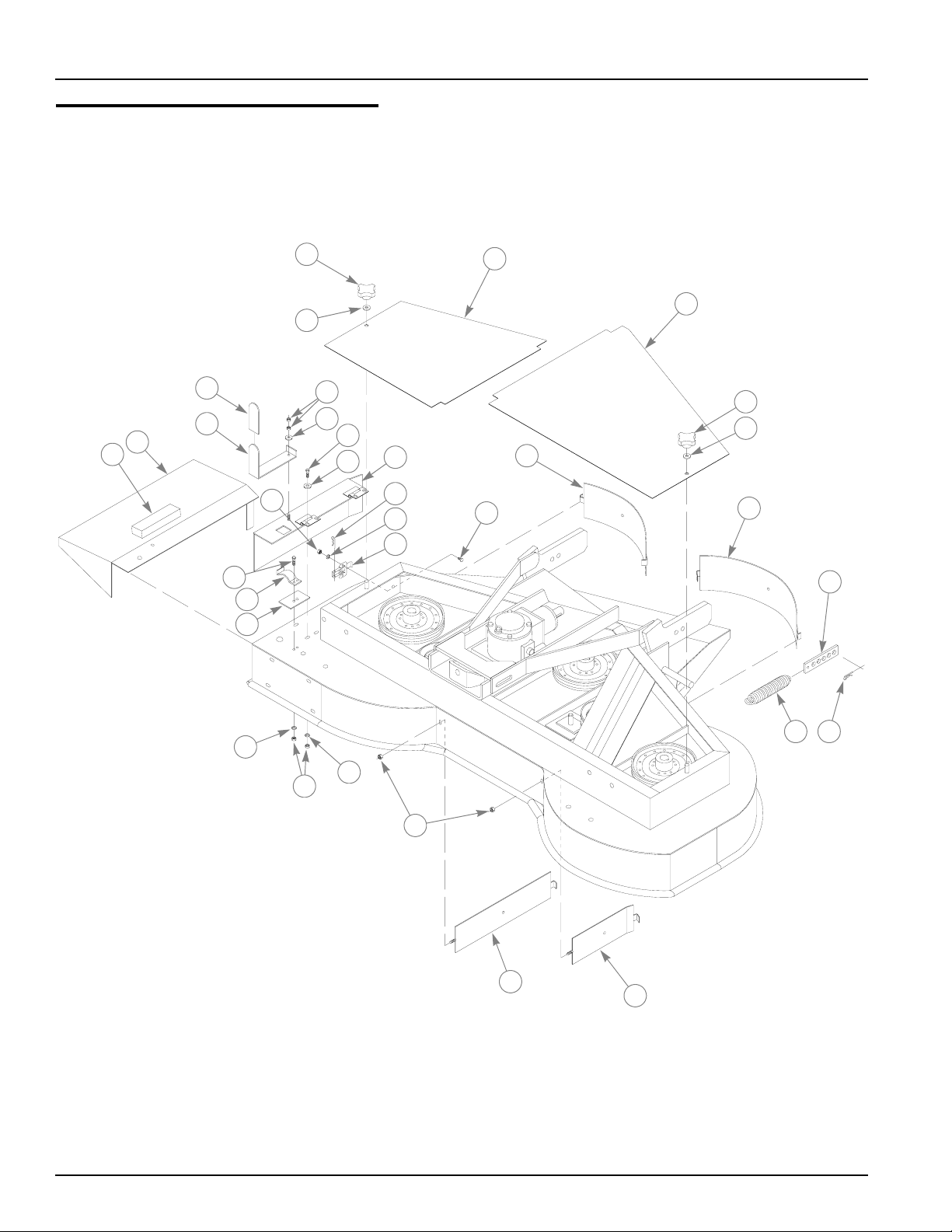

Deck Assembly - 925115

14

13

15

16

23

24

25

28

2

3

17

18

20

21

19

26

29

27

30

1

4

2

3

5

6

22

789

22

17

12

11

10

2-2 027292 8/06

Page 9

Deck Assembly - 925115

INDEX

PART NO. QTY. DESCRIPTION

NO.

1 306910 1 R/H DECK COVER 16 467258 1 HANDLE

2 075291 2 CLAMPING KNOB 17 024927 8 NT .25-20 HX G5 ZN

3 076547 2 FW .344 X .688 X .065 SAE ZN 18 017079 1 FW .250 X .560 X .040 SAE ZN

4 306928 1 L/H DECK COVER 19 474569 1 SIDE DISCHARGE COVER

5 474361 1 RIGHT REAR DISCHARGE DOOR 20 055939 4 CS .25-20 X .750 HX G5 ZN

6 474379 1 CENTER REAR DISCHARGE DOOR 21 089789 5 FW .266 X .750 X .060 ZN

7 011379 1 SPRING 22 017038 7 LW .250 MEDIUM SPRING ZN

8 370494 4 DECK SPRING STRAP 23 056077 2 CS .25-20 X 1.00 HX G5 ZN

9 023036 4 HP .148 X 2.690 ZN 24 287649 1 SIDE DISCHARGE CLIP

10 474460 1 L/H MULCHER BAFFLE 25 315465 1 CLIP PLATE

11 474478 1 R/H MULCHER BAFFLE 26 025320 2 HP .091 X 1.875 ZN

12 016816 2 NT .25-20 HX FL ZN 27 758821 2 OVER CENTER LATCH

13 474445 1 DEFLECTOR 28 035626 4 NT 10-24 HX ZN

14 259515 1 BUMPER 29 056176 4 LW #10 MEDIUM SPRING ZN

15 074559 1 GRIP 30 030437 4 MS 10-24 X .375 RD SL ZN

INDEX

NO.

PART NO. QTY. DESCRIPTION

NOTES:

027292 8/06 2-3

Page 10

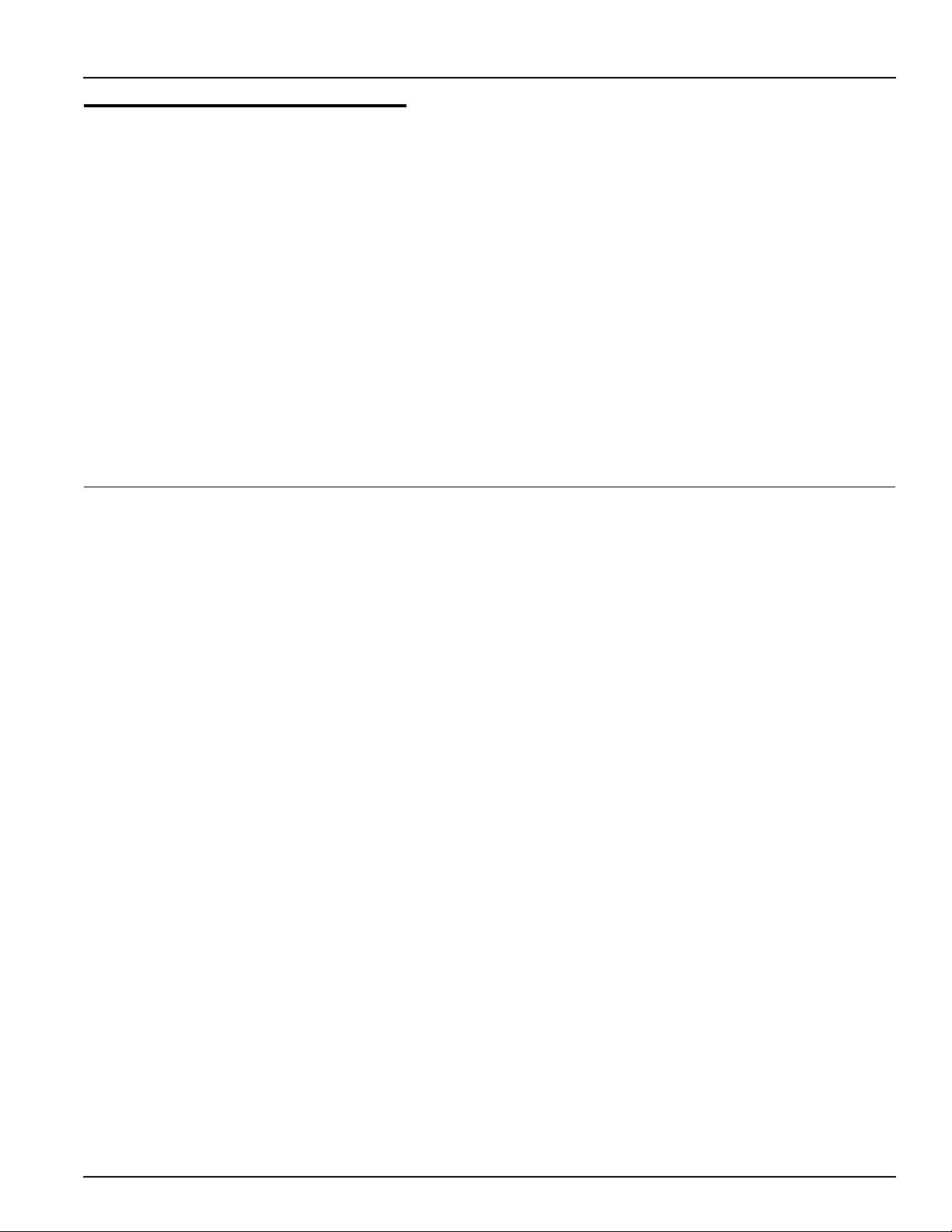

Deck Assembly - 923144, 923268, 924605 & 924613

23

24

25

26

27

28

29

25

32

31

14

15

18

16

19

24

30

33

34

17

2

39

40

20

3

21

42

22

35

2

3

4

35

36 38

3

1

2

4

3

4

37

41

43

44

13

45

5

6 7

9

8

10

12

2-4 027292 8/06

11

Page 11

Deck Assembly - 923144, 923268, 924605 & 924613

INDEX

PART NO. QTY. DESCRIPTION

NO.

1 474700 1 R/H DECK COVER 24 045765 4 FW 1.030 X 1.50 X .134 ZN

2 056077 5 CS .25-20 X 1.00 HX G5 ZN 25 469924 2 Gauge Wheel Spacer .25

3 017038 9 LW .250 MEDIUM SPRING ZN 26 469882 2 Gauge Wheel Spacer .50

4 089789 7 FW .266 X .750 X .060 ZN 27 015495 2 Grease Zerk

5 474692 1 L/H DECK COVER 28 018747 4 Bronze Bushing

6 474361 1 RIGHT REAR DISCHARGE DOOR 29 469916 4 Gauge Wheel Spacer 1”

7 474379 1 CENTER REAR DISCHARGE DOOR 30 469221 2 Gauge Wheel Assembly

8 011379 1 SPRING 31 474445 1 Deflector

9 370494 4 DECK SPRING STRAP 32 259515 1 Bumper

10 023036 4 HP .148 X 2.690 ZN 33 074559 1 Grip

11 474460 1 L/H MULCHER BAFFLE 34 467258 1 Handle

12 474478 1 R/H MULCHER BAFFLE 35 024927 8 NT .25-20 HX G5 ZN

13 016816 2 NT .25-20 HX FL ZN 36 017079 1 FW .250 x .560 x .040 SAE ZN

14 474486 2 GAUGE ARM 37 474569 1 Side Discharge Cover

15 036244 8 CS .375-16 X 1.00 HX G5 ZN 38 055939 4 CS .25-20 x .750 HX G5 ZN

16 017012 8 LW .375 MEDIUM SPRING ZN 39 287649 1 Side Discharge Clip

17 049346 8 FW .375 X .870 X .078 ZN 40 315465 1 Clip Plate

18 016527 4 CS .50-13 X 1.00 HX G5 ZN 41 025320 2 HP .091 x 1.875 ZN

19 017137 4 FW .560 X 1.370 X .109 SAE ZN 42 035626 4 NT 10-24 HX ZN

20 537225 2 TIE DOWN BRACKET 43 056176 4 LW #10 Medium Spring ZN

21 017046 4 LW .50 MEDIUM SPRING ZN 44 758821 2 Over Center Latch

22 008193 4 NT .50-13 HX G5 ZN 45 030437 4 MS 10-24 x .375 RD SL ZN

23 085985 2 HP .243 X 4.380 LG

INDEX

NO.

1

2

PART NO. QTY. DESCRIPTION

NOTES:

1. Supplied with item 14 but may be ordered separately.

2. See “Gauge Arm Assembly - 466888” on page 3-6 for breakdown.

027292 8/06 2-5

Page 12

Deck Subassembly - 925115

4

2

3

16

7

2

37

5

15

4

17

15

14

1

20

5

21

23

1

5

28

5

5

6

11

12

7

6

22

29

10

1

9

8

12

31

13

6

32

18

30

5

6

33

34

35

36

18

5

6

5

6

19

38

18

7

33

27

6

1

20

24

25

26

3

2-6 027292 8/06

Page 13

Deck Subassembly - 925115

8

INDEX

NO.

PART NO. QTY. DESCRIPTION

INDEX

5

PART NO. QTY. DESCRIPTION

NO.

1 533935 1 60” 4-WAY DECK ASSEMBLY 20 078378 6 CS .50-20 X 1.50 HX G5 ZN

2 074252 4 CS .50-13 X 1.50 HX G5 ZN 21 078386 3 FW .510 X 1.750 X .187 ZN

3 532861 1 GEARBOX 22 212076 3 KEY .250 X .250 X 1.50

4 474528 1 GEARBOX MOUNT 23 518316 3 DECK DRIVE PULLEY

5 017046 26 LW .50 MEDIUM SPRING ZN 24 506212 3 SPINDLE HOUSING ASSEMBLY

6 008193 12 NT .50-13 HX G5 ZN 25 712372 3 KEY .250 X .250 X .660

7 036715 2 WOODRUFF KEY 26 035808 3 BLADE SADDLE

8 467324 1 PULLEY 8” 27 076752 3 21” BLADE

9 042051 2 SS .375-16 X 1.00 SQ-HD ZN 28 016527 12 CS .50-13 X 1.00 HX G5 ZN

10 706168 2 NT .375-16 HX JAM G5 ZN 29 068759 4 CW .560 X 1.340 X .050 PN

11 041707 4 NT .437-14 HX G5 ZN 30 474544 1 IDLER ARM BRACKET

12 773259 8 FW .50 X 1.250 X .064/.104 SAE F436 ZN 31 263517 1 BEARING DISC

13 773242 4 CS .437-14 X 1.250 HX G5 ZN 32 078949 1 CS .50-13 X 2.00 G5 ZN

14 025601 1 CS .50-13 X 4.620 FULL TD ZN 33 475723 2 IDLER PULLEY

15 058875 2 MB .510 X .870 X .050 ZN 34 036384 1 IDLER SPRING

16 467126 1 ADJUSTER ARM 35 244384 1 IDLER CHAIN

17 028274 2 CB .50-13 X 1.50 FULL ZN 36 017277 1 CP .187D X 1.00 LG HML ZN

18 017137 8 FW .560 X 1.370 X .109 SAE ZN 37 061812 1 CS .50-13 X 3.50 HX G5 ZN

19 027284 1 DECK DRIVE BELT 38 469619 1 IDLER PULLEY BRACKET

NOTES:

1. Torque to 50-60 Ft. Lbs.

2. Item 8, pulley, must be in the same horizontal plane as the three item 23,

pulleys, within ±.03 tolerance.

3. Assemble item 24, spindle housing, so the grease zerk faces the front of

the deck.

4. Item 3, gearbox, to be filled to center of sight gauge upon installation

with Amoco 80W-90 or equivalent gear lube.

5. Tighten item 6, nut, to 20 Ft. Lbs. then loosen 1/4 turn.

6. Shaft and exposed end of bearings must be free of rust & wiped clean.

Coat entire shaft and exposed end of bearings with anti-seize.

7. To check for proper blade alignment, both ends of center blade must

align with both ends of outer blades. When blade tips are closest

together they must be within .20” vertically.

8. See “Spindle Assembly - 506212” on page 3-8 for breakdown

027292 8/06 2-7

Page 14

Deck Subassembly - 923144, 923268, 924605 & 924613

16

37

4

2 3

4

17

15

14

1

20

5

21

23

1

5

28

5

5

6

22

11

29

10

9

2

8

7

2

6

15

18

5

5

13

18

30

32

5

6

33

34

35

36

12

7

6

31

12

6

5

6

19

38

18

33

6

1

20

24

25

26

3

27

7

2-8 027292 8/06

Page 15

Deck Subassembly - 923144, 923268, 924605 & 924613

8

INDEX

NO.

PART NO. QTY. DESCRIPTION

INDEX

5

PART NO. QTY. DESCRIPTION

NO.

1 533935 1 60” 4-WAY DECK ASSEMBLY 20 078378 6 CS .50-20 X 1.50 HX G5 ZN

2 074252 4 CS .50-13 X 1.50 HX G5 ZN 21 078386 3 FW .510 X 1.750 X .187 ZN

3 532861 1 GEARBOX (MODEL 924605) 22 212076 3 KEY .250 X .250 X 1.50

532895 1 GEARBOX (MODEL 924613) 23 518316 3 DECK DRIVE PULLEY

4 474528 1 GEARBOX MOUNT 24 506212 3 SPINDLE HOUSING ASSEMBLY

5 017046 26 LW .50 MEDIUM SPRING ZN 25 712372 3 KEY .250 X .250 X .660

6 008193 12 NT .50-13 HX G5 ZN 26 035808 3 BLADE SADDLE

7 036715 2 WOODRUFF KEY 27 076752 3 21” BLADE

8 467324 1 PULLEY 8” 28 016527 12 CS .50-13 X 1.00 HX G5 ZN

9 042051 2 SS .375-16 X 1.00 SQ-HD ZN 29 068759 4 CW .560 X 1.340 X .050 PN

10 706168 2 NT .375-16 HX JAM G5 ZN 30 474544 1 IDLER ARM BRACKET

11 041707 4 NT .437-14 HX G5 ZN 31 263517 1 BEARING DISC

12 773259 8 FW .50 X 1.250 X .064/.104 SAE F436 ZN 32 078949 1 CS .50-13 X 2.00 G5 ZN

13 773242 4 CS .437-14 X 1.250 HX G5 ZN 33 475723 2 IDLER PULLEY

14 025601 1 CS .50-13 X 4.620 FULL TD ZN 34 036384 1 IDLER SPRING

15 058875 2 MB .510 X .870 X .050 ZN 35 244384 1 IDLER CHAIN

16 467126 1 ADJUSTER ARM 36 017277 1 CP .187D X 1.00 LG HML ZN

17 028274 2 CB .50-13 X 1.50 FULL ZN 37 061812 1 CS .50-13 X 3.50 HX G5 ZN

18 017137 8 FW .560 X 1.370 X .109 SAE ZN 38 469619 1 IDLER PULLEY BRACKET

19 027284 1 DECK DRIVE BELT

NOTES:

1. Torque to 50-60 Ft. Lbs.

2. Item 8, pulley, must be in the same horizontal plane as the three item 23,

pulleys, within ±.03 tolerance.

3. Assemble item 24, spindle housing, so the grease zerk faces the front of

the deck.

4. Item 3 gearbox to be filled to center of sight gauge upon installation with

Amoco 80W-90 or equivalent gear lube.

5. Tighten item 6, nut, to 20 Ft. Lbs. then loosen 1/4 turn.

6. Shaft and exposed end of bearings must be free of rust & wiped clean.

Coat entire shaft and exposed end of bearings with anti-seize.

7. To check for proper blade alignment, both ends of center blade must

align with both ends of outer blades. When blade tips are closest

together they must be within .20” vertically.

8. See “Spindle Assembly - 506212” on page 3-8 for breakdown.

027292 8/06 2-9

Page 16

2-10 027292 8/06

Page 17

Chapter 3 Contents

Gauge Arm Assembly - 469221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

60” Quad Deck Gauge Wheel Kit - 320523 . . . . . . . . . . . . . . . . . . . . 3-3

Gauge Wheel Assembly - 307082 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

60” Deck Heavy Duty Gauge Wheel Kit - 315606K . . . . . . . . . . . . . . 3-5

Gauge Arm Assembly - 466888. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Spindle Assembly - 249318 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

027292 8/06 3-1

Page 18

Gauge Arm Assembly - 469221

5

1

2

1

3

4

5

2

7

6

4

1

3

8

9

10

INDEX

PART NO. QTY. DESCRIPTION

NO.

1 469791 1 GAUGE WHEEL FORK 7 747402 1 TIRE

2 049148 1 OIL SEAL 8 048850 1 MACHINE BUSHING

3 049155 2 BEARING CONE 9 048868 1 NT .75-16 HX SL PN

4 049163 2 BEARING CUP 10 017244 1 CP .125D X 1.00 LG HML ZN

5 747410 1 WHEEL 11 049171 1 DUST CAP

6 019521 1 VALVE STEM 12 747428 1 TIRE & WHEEL ASS’Y

INDEX

NO.

PART NO. QTY. DESCRIPTION

(INCLUDES ITEMS 4-7)

NOTES:

1. Pack bearings thoroughly with grease before installing into wheel hub.

3

4

11

2. Fill wheel hub cavity between bearings approximately 2/3 full with grease.

3. To adjust wheel bearing, raise wheel off floor. Tighten item 9, nut, while

rotating the wheel until there is a slight bind to be sure all bearing surfaces

are in contact. Then back off nut 1/6-1/4 turn to nearest locking hose or

sufficiently to allow wheel to rotate freely within limits of .001-.010 (ref) end

play. Lock nut at this position by installing item 10, cotter pin.

4. Fill cap 3/4 full with grease then press into wheel hub.

5. Coat shaft end with light coat of grease.

3-2 027292 8/06

Page 19

60” Quad Deck Gauge Wheel Kit - 320523

5

6

7

60” 4-WAY DECK

10

11

12

13

14

1

15

16

8

4

9

3

2

1

12

17

11

18

INDEX

PART NO. QTY. DESCRIPTION

NO.

1 036244 8 CS .375-16 X 1.00 HX G5 ZN 10 085985 2 HP #19 WEST WIRE-HITCH ZN

2 017012 8 LW .375 MEDIUM SPRING ZN 11 045765 6 FW 1.030 X 1.50 X .134 ZN

3 049346 8 FW .375 X .870 X .078 ZN 12 469924 4 GAUGE WHEEL SPACER .25”

4 306977 2 GAUGE ARM 13 469882 2 GAUGE WHEEL SPACER .50”

5 077859 2 CS .50-13 X 3.250 HX G5 ZN 14 015495 2 GREASE FITTING

6 017137 4 FW .560 X 1.370 X .109 SAE ZN 15 018747 4 BRONZE BUSHING

7 481531 2 FRONT TIE DOWN 16 469916 4 GAUGE WHEEL SPACER 1.0”

8 017046 2 LW .50 MEDIUM SPRING ZN 17 082180 2 MB 1.00 X 1.50 X .049 PN

9 008193 2 NT .50-13 HX G5 ZN 18 307082 2 GAUGE WHEEL ASSEMBLY

2

NOTES:

1. Supplied with item 4 but may be ordered separately.

2. See “Gauge Wheel Assembly - 307082” on page 3-4 for breakdown.

027292 8/06 3-3

INDEX

NO.

PART NO. QTY. DESCRIPTION

Page 20

Gauge Wheel Assembly - 307082

2

3

1

4

2

3

6

5

INDEX

PART NO. QTY. DESCRIPTION

NO.

1 306936 1 11” GAUGE WHEEL ASSEMBLY 5 768044 1 TIRE & WHEEL ASSEMBLY 11 X 4-5

2 042630 1 CS .50-13 X 6.50 HX G5 ZN 6 017046 1 LW .50 MEDIUM SPRING ZN

3 004168 2 FW .50 X 1.060 X .090 SAE ZN 7 067918 1 NT .50-13 HX G8 ZN

4 306969 1 GAUGE WHEEL SPACER

INDEX

NO.

PART NO. QTY. DESCRIPTION

NOTES:

1. Torque to 75-85 Ft. Lbs.

1

7

2. After items 1 & 5 are assembled, apply grease to zerk until grease appears

at the end of the wheel hub.

3-4 027292 8/06

Page 21

60” Deck Heavy Duty Gauge Wheel Kit - 315606K

9

10

60” 4-WAY DECK

7

6

4

11

14

9

12

5

2

4

6

8

4

4

3

4

13

11

8

6

7

10

1

INDEX

NO.

1

PART NO. QTY. DESCRIPTION

1 466888 2 GAUGE ARM ASSEMBLY 8 036244 4 CS .375-16 X 1.00 HX G5 ZN

2 532887 2 GAUGE ARM MOUNT 9 074252 8 CS .50-13 X 1.50 HX G5 ZN

3 080655 4 CS .375-16 X 1.50 HX G5 ZN 10 017046 8 LW .50 MEDIUM SPRING ZN

4 712919 16 FW .406 X 1.00 X .120 HRD ZN 11 017137 4 FW .560 X 1.370 X .109 SAE ZN

5 315911 2 GAUGE ARM MOUNT BRACKET 12 537175 2 TIE DOWN BRACKET

6 017012 8 LW .375 MEDIUM SPRING ZN 13 008193 6 NT .50-13 HX G5 ZN

7 054502 4 NT .375-16 HX G5 ZN 14 315622 1 CLIP PLATE

INDEX

NO.

PART NO. QTY. DESCRIPTION

NOTES:

1. See “Gauge Arm Assembly - 466888” on page 3-6 for breakdown.

027292 8/06 3-5

Page 22

Gauge Arm Assembly - 466888

23

20

22

24

26

25

5

7

19

1

2

3

4

5

6

5

21

4

8

1

10

14

9

11

12

13

2

11

10

17

1

15

16

3

18

4

3-6 027292 8/06

Page 23

Gauge Arm Assembly - 466888

INDE

X NO

10 049155 2 BEARING 24 017277 1 CP .187 X 1.00 LG HML ZN

11 049163 2 BEARING CUP 25 068759 13 CW .560 X 1.340 X .050 PN

12 747410 1 GAUGE WHEEL 6 X 3.5 26 466672 1 LOCK PIN

13 019521 1 VALVE STEM 747428 TIRE & WHEEL ASSEMBLY (INCLUDES ITEMS 11-14)

14 747402 1 TIRE 13 X 5 X 6

PAR T

NO.

1 016527 1 CS .50-13 X 1.00 HX G5 ZN 15 048850 1 MACHINE BUSHING

2 017046 1 LW .50 MEDIUM SPRING ZN 16 048868 1 NT .75-16 HXSL PN

3 344267 1 FW .510 X 2.150 X .187 SPL ZN 17 011387 1 CP .125D X 1.250 LG HML ZN

4 082180 2 MB 1.00 X 1.50 X .049 PN 18 049171 1 DUST CUP

5 077123 2 BEARING 19 017350 1 SS .25-20 X .250 SH BO

6 310185 1 SPACER 20 466698 1 GAUGE WHEEL ARM HANDLE

7 532911 1 GAUGE WHEEL ARM 21 315226 1 HANDLE PIN

8 506428 1 GAUGE WHEEL FORK 22 466680 1 LOCK LINKAGE

9 049148 1 OIL SEAL 23 315234 1 LINKAGE PIN

QTY. DESCRIPTION

INDE

X NO

PART

NO.

QTY. DESCRIPTION

NOTES:

1. Pack wheel bearings thoroughly with grease before installing.

2. Fill wheel hub cavity between bearings approximately 2/3 full with grease.

3. To adjust wheel bearing, raise wheel off floor, tighten item 16, nut, while

rotating the wheel, until there is a slight bind to be sure all bearing surfaces

are in contact.Then back off nut 1/6-1/4 turn to nearest locking hole or

sufficiently to allow wheel to rotate freely within limits of .001-.010 (ref) end

play. Lock nut within limits of .001-.010 (ref) end play. Lock nut at this

position by installing cotter pin.

4. Fill cap 3/4 full with grease then press into wheel hub.

5. Do not fully spread item 24, cotter pin, for quicker adjustment of washers.

027292 8/06 3-7

Page 24

Spindle Assembly - 506212

1

2

3

INDEX

NO.

PART NO. QTY. DESCRIPTION

1 077123 2 BEARING

2 712364 1 SPINDLE SHAFT

4

1

INDEX

NO.

PART NO. QTY. DESCRIPTION

3 034843 1

4 012005 1

SPINDLE HOUSING

GREASE ZERK

NOTES:

3-8 027292 8/06

Page 25

Chapter 4 Contents

Gearbox Breakdown - 532861 (WSI). . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Gearbox Breakdown - 532861 (Agrigear) . . . . . . . . . . . . . . . . . . . . . 4-3

Gearbox Breakdown - 532895 (WSI). . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Gearbox Breakdown - 532895 (Agrigear) . . . . . . . . . . . . . . . . . . . . . 4-5

027292 8/06 4-1

Page 26

Gearbox Breakdown - 532861 (WSI)

WSI P/N TAG

1

2

3

4

24

23

5

6

7

8

11

9

10

6

5

12

13

16

17

14

19

6

5

2

15

1

22

9

18

20

21

11

INDEX

NO.

10 045567 1 CROSS SHAFT 20 045575 1 PINION HOUSING

11 045476 3 RETAINING RING 21 049106 1 BEARING CUP

12 045450 A/R SHIM .003 22 048991 1 BEARING CONE

PART NO. QTY. DESCRIPTION

1 036707 8 CS .312-18 X .875 HX G5 BO 13 1 CASE

2 017004 8 LW .312 MEDIUM SPRING ZN 14 035345 2 PLUG .25 NPT

3 036046 1 RELIEF VALVE 15 045658 1 SHAFT SEAL

4 046656 1 END PLATE 16 045518 A/R SHIM .003

5 045633 3 BEARING CUP 045500 A/R SHIM .005

6 045641 3 BEARING CONE 045492 A/R SHIM .02

7 045484 1 RING SEAL 17 045682 1 NT .625-18 HX NL

8 045534 1 R/H GEAR 18 017145 1 MB .620 X 1.120 X .080 PN

9 081752 2 WOODRUFF KEY 19 045526 1 L/H GEAR

045468 A/R SHIM .005 23 045559 1 PINION SHAFT

045443 A/R SHIM .02 24 045666 1 SHAFT SEAL

INDEX

NO.

PART NO. QTY. DESCRIPTION

NOTES:

4-2 027292 8/06

Page 27

Gearbox Breakdown - 532861 (Agrigear)

2

24

23

12

22

21

1

3

4

6

5

7

8

9

10

11

6

12

18

7

13

14

19

7

6

20

15

7

16

17

1

6

25

INDEX

NO.

10 034736 1 GEAR SHAFT 23 036657 2 SEAL CAP SHIM

11 036673 1 GEAR SHAFT SPACER 24 036541 1 CARRIER SEAL CAP

12 036624 2 SEAL 25 036723 4 MS 10-24 X .750 FT SH BO

13 036517 1 CASE

PART NO. QTY. DESCRIPTION

1 036707 8 CS .312-18 X .875 HX G5 BO 14 740829 1 SIGHT GLASS

2 036046 1 RELIEF VALVE 15 036665 2 SEAL CAP SHIM

3 036731 1 REDUCER BUSHING 16 036558 1 SEAL CAP

4 036525 1 BEARING CAP 17 019216 4 CS .25-20 X .750

5 036640 2 BEARING CAP SHIM 18 036632 2 CARRIER SHIM

6 036608 4 BEARING CUP 19 034751 1 PINION SHAFT (19 TEETH)

7 036616 4 BEARING CONE 20 036533 1 PINION CARRIER

8 034769 1 GEAR (25 TEETH) 21 036681 1 LOCK WASHER

9 036715 1 WOODRUFF KEY 22 036699 1 LOCK NUT

INDEX

NO.

PART NO. QTY. DESCRIPTION

NOTES:

027292 8/06 4-3

Page 28

Gearbox Breakdown - 532895 (WSI)

WSI P/N TAG

17

18

20

11

12

2

1

6

9

23

22

21

1

2

5

7

9

10

11

12

3

4

6

8

13

14

15

16

19

5

8

INDEX

NO.

10 046680 1 L/H GEAR 21 045575 1 PINION HOUSING

11 045641 2 BEARING CONE 22 045559 1 PINION SHAFT

12 045633 2 BEARING CUP 23 045666 1 SHAFT SEAL

13 045450 A/R SHIM .003

PART NO. QTY. DESCRIPTION

1 036707 8 CS .312-18 X .875 HX G5 BO 14 045583 1 CASE

2 017004 8 LW .312 MEDIUM SPRING ZN 15 740829 1 SIGHT GLASS

3 036046 1 RELIEF VALVE 16 045658 1 SHAFT SEAL

4 046656 1 END PLATE 17 045518 A/R SHIM .003

5 049106 2 BEARING CUP 045500 A/R SHIM .005

6 048991 2 BEARING CONE 045492 A/R SHIM .02

7 046672 1 CROSS SHAFT 18 045682 1 NT .625-18 HX NL

8 045476 3 RETAINING RING 19 017145 1 MB .620 X 1.120 X .08 PN

9 081752 2 WOODRUFF KEY 20 046698 1 R/H GEAR

045468 A/R SHIM .005

045443 A/R SHIM .01

INDEX

NO.

PART NO. QTY. DESCRIPTION

NOTES:

4-4 027292 8/06

Page 29

Gearbox Breakdown - 532895 (Agrigear)

24

12

21

1

4

2

3

6

7

8

5

9

10

11

7

6

12

13

18

14

19

7

6

15

20

6

7

16

17

1

22

23

25

INDEX

NO.

10 036715 1 KEY 23 036657 2 SEAL CAP SHIM

11 084939 1 SPIRAL BEVEL GEAR (25 TEETH) 24 036541 1 CARRIER SEAL CAP

12 036624 2 SEAL 25 036723 4 MS 10-24 X .750

13 036517 1 CASE

PART NO. QTY. DESCRIPTION

1 036707 8 CS .312-18 X .875 HX G5 BO 14 740829 1 SIGHT GLASS

2 036046 1 RELIEF VALVE 15 036665 2 SEAL CAP SHIM

3 036731 1 REDUCER BUSHING 16 036558 1 SEAL CAP

4 036525 1 BEARING CAP 17 055939 4 CS .25-20 X .750 HX G5 ZN

5 036640 2 BEARING CAP SHIM 18 036632 2 CARRIER SHIM

6 036608 4 BEARING CUP 19 084947 1 PINION SHAFT (19 TEETH)

7 036616 4 BEARING CONE 20 036533 1 PINION CARRIER

8 036673 1 SPACER 21 036681 1 LOCK WASHER

9 059543 1 GEAR SHAFT 22 036699 1 LOCK NUT

INDEX

NO.

PART NO. QTY. DESCRIPTION

NOTES:

027292 8/06 4-5

Page 30

4-6 027292 8/06

Page 31

Chapter 5 Contents

Decal Group - 925115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Decal Group - 923144 & 923268. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Decal Group - 924605 & 924613. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

027292 8/06 5-1

Page 32

Decal Group - 925115

1

2 3

4

6

5

7

2

11

10

9

8

2

INDEX

NO.

10 736769 1 60” 4-WAY DECK DECAL

11 727842 1 PTO SHAFT DECAL

12 757088K 1 DECAL KIT (INCLUDES ITEMS 1-12)

PART NO. QTY. DESCRIPTION

1 727420 1 DEFLECTOR POSITION DECAL

2 727438 3 WHIRLING BLADES DECAL

3 760637 1 MOWER DECK QUICK REFERENCE DECAL

4 727453 2 BELT & PULLEY DECAL

5 1 SERIAL NUMBER PLATE

6 741264 1 MADE IN U.S.A. DECAL

7 727917 1 PATENT NUMBER DECAL

8 251033 1 STEP TREAD

9 727636 1 LOGO DECAL

NOTES:

5-2 027292 8/06

Page 33

Decal Group - 923144 & 923268

1

2

3

42

5

6

7

9

11

10

8

9

INDEX

NO.

10 082479 1 3-WAY DECK DECAL

11 084202 1 ATTACHMENT DECAL

PART NO. QTY. DESCRIPTION

1 084046 1 DEFLECTOR POSITION DECAL

2 078675 2 BELT COVER DECAL

3 084194 1 DRIVE SHAFT DECAL

4 078444 1 DECK MAINTENANCE DECAL

5 081430 1 A.N.S.I. ATTACHMENT DECAL

6 084186 1 PATENT NUMBER DECAL

7 1 SERIAL NUMBER PLATE

8 251033 1 STEP TREAD

9 078428 2 BLADE CAUTION DECAL

NOTES:

027292 8/06 5-3

Page 34

Decal Group - 924605 & 924613

1

3

2

54

6

7

3

8

14

13

11

9

12

10

3

2

INDEX

NO.

10 251033 1 STEP TREAD

11 727636 1 LOGO DECAL

12 736769 1 60” 4-WAY DECK DECAL

13 737015 1 DECK STRIPE DECAL

14 727834 1 READ OWNER’S MANUAL DECAL

15 757088K 1 DECAL KIT (INCLUDES ITEMS 1-14)

PART NO. QTY. DESCRIPTION

1 727420 1 DEFLECTOR POSITION DECAL

2 751164 2 QUADCYCLER DECK DECAL

3 727438 3 WHIRLING BLADES DECAL

4 727842 1 PTO SHAFT DECAL

5 727453 2 BELT AND PULLEY DECAL

6 727172 1 MADE IN U.S.A. DECAL

7 1 SERIAL NUMBER PLATE

8 727917 1 PATENT NUMBER DECAL

9 727446 1 A.N.S.I. ATTACHMENT DECAL

736777 1 QUICK REFERENCE CARD (NOT SHOWN)

NOTES:

5-4 027292 8/06

Page 35

Numerical Index

Part Page

No. No.

Index

Numerics

008193 2-5, 2-7, 2-9, 3-3, 3-5

011379 2-3

011387 3-7

012005 3-8

015495 2-5

016527 2-5

016816 2-3

017004 4-2

017012 2-5

017038 2-3

017046 2-5

017079 2-3

017137 2-5

017145 4-2

017244 3-2

017277 2-7

017350 3-7

018747 2-5

019216 4-3

019521 3-2

023036 2-3

024927 2-3

025320 2-3

025601 2-7

027284 1-1

027300 1-1

028274 2-7

030437 2-3

034736 4-3

034751 4-3

034769 4-3

034843 3-8

035345 4-2

035626 2-3

035808 2-7

036046 4-2

036244 2-5

036384 2-7

036517 4-3

036525 4-3

036533 4-3

036541 4-3

036558 4-3

036608 4-3

036616 4-3

036624 4-3

036632 4-3

036640 4-3

036657 4-3

036665 4-3

, 2-5

, 3-3

, 2-7, 2-9, 3-7

, 2-5

, 4-4

, 3-3, 3-5

, 2-5

, 2-7, 2-9, 3-3,

3-4, 3-5, 3-7

, 2-5

, 2-7, 2-9, 3-3, 3-5

, 4-4

, 2-9, 3-7

, 3-3

, 3-7

, 2-5

, 2-5

, 2-5

, 2-9

, 2-7, 2-9

, 2-9

, 2-5

, 2-5

, 2-9

, 4-3, 4-4, 4-5

, 3-3, 3-5

, 2-9

, 4-5

, 4-5

, 4-5

, 4-5

, 4-5

, 4-5

, 4-5

, 4-5

, 4-5

, 4-5

, 4-5

, 4-5

Part Page

No. No.

036673 4-3

036681 4-3

036699 4-3

036707 4-2

036715 2-7

036723 4-3

036731 4-3

041707 2-7

042051 2-7

042630 3-4

045443 4-2

045450 4-2

045468 4-2

045476 4-2

045484 4-2

045492 4-2

045500 4-2

045518 4-2

045526 4-2

045534 4-2

045559 4-2

045567 4-2

045575 4-2

045583 4-4

045633 4-2

045641 4-2

045658 4-2

045666 4-2

045682 4-2

045765 2-5

046656 4-2

046672 4-4

046680 4-4

046698 4-4

048850 3-2

048868 3-2

048991 4-2

049106 4-2

049148 3-2

049155 3-2

049163 3-2

049171 3-2

049346 2-5

054502 3-5

055939 2-3

056077 2-3

056176 2-3

058875 2-7

059543 4-5

061812 2-7

067918 3-4

068759 2-7

, 4-5

, 4-5

, 4-5

, 4-3, 4-4, 4-5

, 2-9, 4-3, 4-5

, 4-5

, 4-5

, 2-9

, 2-9

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 4-4

, 3-3

, 4-4

, 3-7

, 3-7

, 4-4

, 4-4

, 3-7

, 3-7

, 3-7

, 3-7

, 3-3

, 2-5, 4-5

, 2-5

, 2-5

, 2-9

, 2-9

, 2-9, 3-7

Part Page

No. No.

074252 2-7

074559 2-3

075291 2-3

076547 2-3

076752 2-7

077123 3-7

077859 3-3

078378 2-7

078386 2-7

078428 5-3

078444 5-3

078675 5-3

078949 2-7

080655 3-5

081430 5-3

081752 4-2

082180 3-3

082479 5-3

084046 5-3

084186 5-3

084194 5-3

084202 5-3

084939 4-5

084947 4-5

085985 2-5

089789 2-3

212076 2-7

244384 2-7

251033 5-2

259515 2-3

263517 2-7

287649 2-3

306910 2-3

306928 2-3

306936 3-4

306969 3-4

306977 3-3

307082 3-3

310185 3-7

315226 3-7

315234 3-7

315465 2-3

315622 3-5

315911 3-5

344267 3-7

370494 2-3

374827 1-1

466672 3-7

466680 3-7

466698 3-7

466888 3-5

467126 2-7

, 2-9, 3-5

, 2-5

, 2-9

, 3-8

, 2-9

, 2-9

, 2-9

, 4-4

, 3-7

, 3-3

, 2-5

, 2-9

, 2-9

, 5-3, 5-4

, 2-5

, 2-9

, 2-5

, 2-5

, 2-5

, 2-9

027292 8/06 i-1

Page 36

Part Page

No. No.

Part Page

No. No.

Part Page

No. No.

467258 2-3, 2-5

467324 2-7

469221 2-5

469619 2-7

469791 3-2

469882 2-5

469916 2-5

469924 2-5

474361 2-3

474379 2-3

474445 2-3

474460 2-3

474478 2-3

474486 2-5

474528 2-7

474544 2-7

474569 2-3

474692 2-5

474700 2-5

475723 2-7

481531 3-3

506212 2-7

, 2-9

, 2-9

, 3-3

, 3-3

, 3-3

, 2-5

, 2-5

, 2-5

, 2-5

, 2-5

, 2-9

, 2-9

, 2-5

, 2-9

, 2-9

506428 3-7

518316 2-7

532861 2-7

532887 3-5

532895 2-9

532911 3-7

533935 2-7

537175 3-5

537225 2-5

706168 2-7

712364 3-8

712372 2-7

712919 3-5

727172 5-4

727420 5-2

727438 5-2

727446 5-4

727453 5-2

727636 5-2

727834 5-4

727842 5-2

727917 5-2

, 2-9

, 2-9

, 2-9

, 2-9

, 2-9

, 5-4

, 5-4

, 5-4

, 5-4

, 5-4

, 5-4

736769 5-2

736777 5-4

737015 5-4

740829 4-3

741264 5-2

747402 3-2

747410 3-2

747428 3-2

751164 5-4

757088K 5-2

758821 2-3

760637 5-2

768044 3-4

773242 2-7

773259 2-7

923144 1-1

923268 1-1

924605 1-1

924613 1-1

925115 1-1

, 5-4

, 4-4, 4-5

, 3-7

, 3-7

, 3-7

, 5-4

, 2-5

, 2-9

, 2-9

, 2-4

, 2-4

, 2-4

, 2-4

, 2-2

i-2 027292 8/06

Loading...

Loading...