For Husqvarna Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

TABLE OF CONTENTS

GENERAL INFORMATION....................................................SECTION 1

Model Plate, Parts Stock, Training Books, Bolt Torques,

Lubrication, Spark Plug, RPM Settings

TRACTOR BRAKE ADJUSTMENTS......................................SECTION 2

Lawn, Yard, And Garden Tractors

TRANSAXLES AND HYDRO INFORMATION ..................SECTION 3

Hydro Oil/Filter Change, Hydro Troubleshooting Charts

MOWER DECKS, BLADES, BAGGER INFORMATION ....SECTION 4

Deck Leveling, Deck Belts Replacing, Deck Safety Guards,

Deck Repairing And Service Tips, Blade Listing

1

2

3

4

BELT INFORMATION..............................................................SECTION 5

ELECTRICAL AND BATTERIES ............................................SECTION 6

Battery Testing And Charging, Troubleshooting Starter Circuits,

Electric Clutch Adjusting, Operator Presents System

TRACTOR FRAME AND STEERING....................................SECTION 7

Tractor Frame And Steering Repairs

ENGINE INFORMATION .......................................................SECTION 8

CRT TILLERS.............................................................................SECTION 9

5

6

7

8

9

SPECIALTY TOOLS AND TEST EQUIPMENT....................SECTION 10

Part No. 163578 - REV 4

www.mymowerparts.com

10

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

NOTES

4

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

FRIGIDAIRE HOME PRODUCTS

MODEL AND SERIAL NUMBER DECAL PLATE

HOW TO READ THE MODEL AND SERIAL DECAL PLATE

TO DETERMINE THE YEAR THE PRODUCT WAS PRODUCED

Model No., Serial Plate Location Model No., Serial Plate Location

1

OLD

(JULIAN DATE SYSTEM)

One white bar means the

product has one year warranty

CONFORMS TO ANSI B71.1-1990 SAFETY STANDARDS

MODEL NO. SERIAL NO.

917.255970

FOR SERVICE AND PARTS ALWAYS GIVE THE MODEL NO.

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 Made in U.S.A.

MODEL #

917.255970

{

{

MODEL #

SOURCE

3155S 001227

315 - Represents the

315th day of the

year.

5 - Last Digit of Year

1985

S - Plat Code

1227 - Number of Units

Produced

{

138037

NEW 1993

(CALANDER DATE SYSTEM)

Two white bars means the

product has two year warranty

CONFORMS TO ANSI B71.1-1990 SAFETY STANDARDS

MODEL NO. SERIAL NO.

917.255970

FOR SERVICE AND PARTS ALWAYS GIVE THE MODEL NO.

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 Made in U.S.A.

012793A - Calendar date of production

001765 - The last six (6) digits

012793A 001765

(January 27, 1993). The

Alpha character is Final

Assembly Line (A, B, C, D,

etc.

designate the number of the

units produced for a specific

model #. Each new unit will

start with 001001 and will

continue in consecutive

order.

{

138038

5

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

RECOMMENDED PARTS STOCK TRACTOR & TILLER

DIV. PLS. PART # DESCRIPTION DIV. PLS. PART # DESCRIPTION

O71 917 25034 44" STD Lift Blade O71 917 148698 Terminal Ring

O71 917 25036 38" STD Lift Blade O71 917 148763 Primary Deck Belt

O71 917 25321 42" STD Lift Blade O71 917 150280 Clutch Bolt Kit

O71 917 25741 38" STD Lift Blade O71 917 151785 Cam Roller Kit

O71 917 59904 Tube 5.3 / 4.5 X 6 O71 917 152443 46" Prem Mulch Blade

O71 917 65139 Valve Stem O71 917 153535 Pulley

O71 917 71208 Bushing O71 917 154963 PTO Switch

O71 917 127218 Link Front O71 917 155106 Bushing Kit

O71 917 128774 Man Housing 38/42 O71 917 155132 Hood Repair Kit

O71 917 129895 Bearing O71 917 156109 Belt Keeper Kit

O71 917 129963 Washer O71 917 157353 46" Blade Hi Lift

O71 917 130171 Trunion O71 917 157722 Screw

O71 917 130652 44" Prem Hi Lift Blade O71 917 158818 Primary Deck Belt

O71 917 130759 Latch O71 917 158913 Ignition Switch

O71 917 130794 Mandrel O71 917 160793 Bagger Latch

O71 917 130968 Deflector 42" O71 917 12000029 E-Ring

O71 917 130969 Primary Deck Belt O71 917 12000039 E-Ring

O71 917 131006 Ground Drive Belt O71 917 17490612 Screw

O71 917 131264 Primary Deck Belt O71 917 17580520 Bolt

O71 917 131290 Primary Deck Belt O71 917 71161010 Screw

O71 917 131340 Bolt shoulder O71 917 532124029 Lens

O71 917 131494 Flat Idler O71 917 532126938 Bumper

O71 917 131845 Brake Pad O71 917 532132800 Knob

O71 917 132673 Pin Clevis / Shear Pin O71 917 101342N Belt

O71 917 133957 Gauge Wheel O71 917 102403X Flat Idler

O71 917 134148 38" Mulch Blade O71 917 104239X Bearing

O71 917 134149 42" Mulch Blade O71 917 104418X 38"Cross Blade

O71 917 134998 38" Prem Mulch Blade O71 917 104445X Switch

O71 917 136321 Runner RH O71 917 1044R Washer

O71 917 136420 Mulch Cover O71 917 104757X Hub Cap

O71 917 136819 Mandrel O71 917 105709X Spring

O71 917 136874 Sector O71 917 106085X Ground Drive Belt

O71 917 136888 Baffle O71 917 106412X Belt

O71 917 137153 Ground Drive Belt O71 917 106578X Brake Mandrel

O71 917 137380 50" Prem Hi Lift Blade O71 917 106729X Ground Drive

O71 917 137553 Shaft 44/46/50 O71 917 106888X Brake Spring

O71 917 137644 Bolt shoulder O71 917 106909X Screw

O71 917 137646 Shaft Mandrel 38/42 O71 917 106932X Knob

O71 917 138255 Primary Deck Belt O71 917 106933X Knob

O71 917 138497 38" Hi Lift Blade O71 917 108597X Belt

O71 917 138498 42" Hi Lift Blade O71 917 108824X Fuse

O71 917 138971 42" Prem Hi Lift Blade O71 917 109310X Key Ignition

O71 917 139774 38" Prem Mulch Blade O71 917 109553X Switch

6

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

RECOMMENDED PARTS STOCK TRACTOR & TILLER

DIV. PLS. PART # DESCRIPTION DIV. PLS. PART # DESCRIPTION

O71 917 139775 42" Prem Mulch Blade O71 917 109808X Hood Latch

O71 917 139868 Arm Support O71 917 109816X Nyliner T

O71 917 140080 Bolt O71 917 110452X Push Nut

O71 917 140218 Ground Drive Belt O71 917 110485X Bearing

O71 917 140301 Ignition Switch O71 917 110883X Belt

O71 917 140403 Key Ignition O71 917 110884X Belt

O71 917 144200 Primary Deck Belt O71 917 120951X Brake Puck

O71 917 144959 Primary Deck Belt O71 917 120961X Brake Puck

O71 917 145960 Primary Deck Belt O71 917 121263X 38" High Lift

O71 917 145967 Belt O71 917 121687X Mandrel

O71 917 145956 Belt O71 917 121748X Washer

O71 917 146077 Bumper O71 917 121749X Washer

O71 917 146154 Solenoid Kit O71 917 121798X 50" STD Lift

O71 917 146525 Wing nut O71 917 123549X Fuel Cap

O71 917 146682 Spring O71 917 123713X Spring

O71 917 123796X Belt O71 502 91954 Bulb

O71 917 124035X Support O71 502 424285 Solenoid

O71 917 124035X Shaft O71 502 456246 30" Blade

O71 917 125907X Belt O71 502 492574 Housing

O71 917 126847X Bushing O71 502 54390E701 Blade

O71 917 126875X Rivet O71 502 91742E701 Blade

O71 917 2029J Weld Nut O71 502 91871E701 Blade 40"

O71 917 3366R Bearing O71 502 92117E701 Blade

O71 917 4921H Clip Retainer O71 536 330278 Blade

O71 917 4921H Retainer Ring O71 536 339093 Belt

O71 917 6266H Washer

O71 917 6554J Tine CRT

O71 917 6555J Tine CRT Spark Plugs

O71 917 6941R Belt O98 661 H10C H10C/216

O71 917 7152J Tube 18X 9.5— 8 O98 661 J17LM J17LM/245

O71 917 7631J Runner O98 661 PM-4 J19LM/458

O71 917 7662J Bulb O98 661 RC12YC PLUG

O71 917 8134H Tube 16 X 6.5 / 7.5 —8 O98 661 RJ12C RJ12C/308

O71 917 9040H Bearing Wheel O98 661 RJ12YC RJ12YC/85

O71 917 9180R Belt O98 661 RL86C L86C/RL86C

O71 O71 24101 Belt O98 661 DP26 RV154C

O71 O71 24102 Belt O98 661 N4C PLUG

O71 O71 24103 Belt O98 661 RJ19LM PLUG

O71 O71 24655 Blade Prem O98 661 RV17YC PLUG

O71 O71 24694 Belt

O71 O71 33500 Fuel Stabil Standard Parts

O71 O71 96145 Battery O98 980 STD365402Switch

O71 143 34279B Filter O98 980 STD624010Hitch Pin

O71 143 35403 Air Cleaner O98 980 STD560907PIN 8 PK

O71 143 35404 Filter

1

7

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

RECOMMENDED PARTS STOCK TRACTOR & TILLER

DIV. PLS. PART # DESCRIPTION DIV. PLS. PART # DESCRIPTION

O71 143 632633 Inlet Assy Recommended Supplies

O71 143 799021 Brake Pads *O92 192 730301 48 OZ. SAE 30 OIL

O71 247 736-0242 Washer *O92 192 25-357-06 10W30 Kohler Oil 32 OZ.

O71 500 222698 Key O92 192 144335 Tire Sealant 5 Gal Pail

O71 500 270843 Air Filter O92 192 100035 Pump for Tire Sealant

O71 500 271962 Air Filter *O92 Or buy oil Locally in bulk

O71 500 272403 Filter

O71 500 272490 Air Filter Recommended Tools

O71 500 280104 Gear Starter O92 150 DS-100 Deck Straightening tool

O71 500 291675 Seal Oil O92 150 19435 Starter Drive install tool

O71 500 394018 Cartridge O92 150 19436 Starter Drive tool for Briggs

O71 500 394019 Cartridge O92 150 25-761-18 Starter Drive tool for Kholer

O71 500 399806 Cartridge

O71 500 491588 Filter Service Kit for Current Service Flashes

O71 500 495878 Drive O71 917 158739 Debris Guard (SF71-364)

O71 500 496894 Air Filter O71 917 159258 Washer Kit (SF71-365)

O71 501 12-050-01 Oil Filter O71 917 139573 V Belt (SF71-366)

O71 501 12-083-05 Air Filter O71 917 159717 Belt Kit (SF71-378)

O71 501 12-083-08 Precleaner

O71 501 25-050-02 Fuel Filter Special 46" Blades for Bahia, Field or Pasture type Grass

O71 501 45-083-01 Precleaner O71 917 157033 46" Blade (SF71-390)

O71 501 45-083-02 Air Filter O71 917 159705 46" Bahia Blade (SF71-390)

O71 501 47-083-03 Filter

O71 501 52-050-02 Oil Filter Service Kits For High Volume Rough Service Markets

O71 502 54211 Adapter O71 917 137797 Frame Kit (SF71-243)

O71 502 55547 Flange O71 917 140342 Bushing Kit 96 Update Book

O71 502 91178 Pulley O71 917 149681 Kit Steering (SF71-297)

O71 502 91334 Bearing Wheel O71 917 149684 Kit Steering (SF71-297)

071 917 151786 Ring Kit

SEARS STEALTH HOOD TRACTOR MANUALS IN 1998

OMITTED THE HEADLIGHT SOCKET 71/917/163996

4152J

163996

8

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Cleaners and Lubricants

Sold in Case Lots Only

DIV. PLS PART # DESCRIPTION SIZE CASE SIZE

O92 192 81010C Multi-Purpose Cleaners & Degreaser 14oz can 12 cans

Biodegradable Citrus Force

O92 192 84010C Multi-Purpose Penetrant, Lubricant, Corrosion Preventive 15oz can 12 cans

& Moisture Displacer Fourway Force Case

O92 192 85010C Multi-Purpose White Lithium Grease Lithium Force 14oz can 12 cans

O92 192 87010C ‘Multi-Purpose Carburetor & Choke Cleaner Carb Force 15oz can 12 cans

O92 192 88010C ‘Multi-Purpose Battery Spray Protection Battery Protection 14oz can 12 cans

O92 192 89010C Contact Cleaners (Elec. Components) Refrigeration 14oz can 12 cans

O92 192 81410C Dry Teflon, Lubricant 10oz can 12 can

O92 192 82010C Multi-Purpose Cleaner and Degreaser Clean Force 32oz bottle12 bottles

O92 192 86010C Multi-Purpose Hand Cleaner and Skin Softener Hand Force 16oz bottle12 bottles

9

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

TECHNICAL TRAINING and SERVICE INFORMATION BOOKSTECHNICAL TRAINING and SERVICE INFORMATION BOOKS

TECHNICAL TRAINING and SERVICE INFORMATION BOOKS

1

Part NumberPart Number

Part Number

Part NumberPart Number

163578 Tractor & CRT Tiller Service Information Book

169291 1999 Craftsman & Wizzard Tractor, Mowers, Tiller Accessories

169418 1999 Craftsman & Wizard Tractor Wiring Schematics Book

168830 1999 Service Update Information Book

158222 1997 FHP Tractor Quick Reference Book

158223 1997 FHP Mowers / Tillers Quick Reference Book

158224 1997 FHP Tractor Wiring Schematics Book

168695 Deck Leveling Video

169287 Automatic Transmission/Drive System Video

139132 Electrical & Charging Systems Book

BLN-50432 HYDRO GEAR LT Hydro IHT Service & Repair Manual

BLN-50334 HYDRO GEAR GT Hydro 3010L Service & Repair Manual

99924-2041-01 KAWASAKI Engine Model FD590V 18HP Service Manual

TECHNICAL TRAINING and SERVICE INFORMATION BOOKSTECHNICAL TRAINING and SERVICE INFORMATION BOOKS

DescriptionDescription

Description

DescriptionDescription

from F.H.P. Source 917 order from D92/192

Book

Part NumberPart Number

Part Number

Part NumberPart Number

MS-8518 Troubleshooting Magnetron Ignition Systems (1985 Update)

MS-8798

MS-9152

MS-9557 Troubleshooting Carburetion Systems (1988 Update)

MS-9884

MS-2285 Carburetor Problem Solving Chart, page 10 (1991Update)

MS-2857 Troubleshooting Governor Systems (1993 Update)

MS-0279 Float Style Carburetor Leakage, page 27 (1994 Update)

MS-0575

MS-0981 Troubleshooting Carburetors (1996 Update)

MS-0709 OHV Gasket Chart

MS-0710 V-Twin OHV Gasket Chart

MS-2288 Alternator Chart

MS-3957 Air Filter Charts (2)

MS-3992 Handy Repair Check Chart

MS-5437 Single Cylinder L-Head Gasket Chart

MS-5441 Opposed Twin Gasket Chart

270962 Single Cylinder L-Head Engine MANUAL

271172 Opposed Twin Engine MANUAL

Part NumberPart Number

Part Number

Part NumberPart Number

692509 3 to 10 HP 4 Cycle "L" Head Engine MANUAL

691462A 8 to 18 HP Cast iron Engine MANUAL

691218 PEERLESS PowerTrain Components MANUAL

695244A 4 Cycle Overhead Valve Engines MANUAL

695907 Carburetor Troubleshooting Booklet

695590 4 Cycle Engine Failure Analysis Booklet

695933 Quick Reference Chart / Booklet

694862 Special Tools Booklet

DescriptionDescription

Description

DescriptionDescription

from BRIGGS & STRATTON Training & Ref. Mtl. (D92/192)

Quick Check, an Effective Troubleshooting Tool (1986 Update)

Systematically Troubleshooting Ignition, Carbureton and Compression

Troubleshooting Ignition, Starting, and Charging Systems (1991Update)

Troubleshooting - Ignition Tester, DC Shunt, Leakdown Tester (1995 Update)

DescriptionDescription

Description

DescriptionDescription

from TECUMSEH Source 143 Training & Ref. Mtl. order D92/192

Part NumberPart Number

Part Number

Part NumberPart Number

TP-2339 Command Single Cylinder CV11-CV16 Service Manual

TP-2450 Command Twin Cylinder CV18-CV25 Service Manual

TP-2289 Magnum Twin Cylinder MV18-MV20 Service Manual

TP-2131 Troubleshooting Flow Chart & Guidebook

ES-103 General Maintenance Video An Ounce of Prevention

ES-2007 Product Specifications; Sales Brochure on Models

TP-2372 Specifications & Tollerances Wallchart

ENS-967 Gaskets Wallchart

TP-2067 Air Cleaner Elements Wallchart

DescriptionDescription

Description

DescriptionDescription

from KOHLER Source 501 Training & Ref. Mti. order D92/192

10

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Blade Bolt / Mandrel Nut

Blade Bolt to 30-35 Ft. Lbs.

Mandrel Nut to 55-65 Ft.

IMPORTANT BOLT TORQUES

TRACTORS:

Electric Clutch Bolt

Grade 5 Bolt

Torque to 50 Ft. Lbs.

Mechanical Clutch Bolt

Grade 5 Bolt

Torque to 35 Ft. Lbs.

1

Engine Mounting Bolts

Grade 5 Bolts

Torque to 35 Ft. Lbs.

STANDARD TORQUE VALUES

BOLTS, SCREWS, NUTS, AND FASTENERS

ASSEMBLED INTO CAST IRON OR STEEL.

11

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

TECUMSEH ENGINES OEM PLUG# GAP STD PLUG# OIL GRADE OIL CAPACITY

3HP thru 6.2HP, L Head

and HTL Rotary RJ19LM .030 PM4 30W 20.OZ

5HP thru 6.6HP Hi Torque

w/Extruded Carb. RJ19LM .030 PM4 30W 27.OZ

4HP, 5HP, OHV Rotary 6HP

OHV Slant Horizontal RN4C .030 NONE 30W 20.OZ

8HP, 10HP Vertical L Head RJ17LM .030 NONE 30W 32.OZ

12HP, 12.5HP Vertical

w/Stationary Cooling Air

Inlet Screen RL86C .030 NONE 30W 32.OZ

12HP, 12.5HP, 16.5HP OHV

Vertical w/Rotating Cooling

Air Inlet Screen NC4 .030 NONE 30W 32.OZ

BRIGGS AND STRATTON

3HP, 3.5HP, Classic 4HP, 5HP,

Quantum RJ19LM .030 PM4 30W 20.OZ

5HP Horizontal L Head RJ19LM .030 PM4 30W 20.OZ

8HP Horizontal L Head RJ19LM .030 PM4 30W 44.OZ

12HP, 12.5HP, 13HP Singles Cyl. RJ19LM .030 PM4 30W 48.OZ

15HP, 15.5HP OHV RC12YC .030 NONE 30W 48.OZ

14HP, 16HP, 18HP, 19HP,

Opposed Twins RJ19LM .030 PM4 30W 48.OZ

20HP Opposed Twin w/Filter RJ19LM .030 PM4 30W 56.OZ

13HP, 14HP, 15HP, 16HP, 17HP

Vanguard Single OHV + Intek/V RC12YC .030 NONE 30W 56.OZ

14HP, 16HP, 18HP, 20HP, 22HP

Vanguard Twin OHV+ Intek/V RC12YC .030 NONE 30W 56.OZ

KOHLER ENGINES

CV 12.5HP, 14HP, 14.5HP,

15HP, 15.5HP RC12YC .040 NONE 10W30 64.OZ

CV 20.5HP, 22HP

22.5HP, 25HP RC12YC .030 NONE 10W30 64.OZ

M18HP, 20HP, MV18HP,

18.5HP, 19HP, 20HP RV17YC .035 NONE 30W 56.OZ

HONDA ENGINE

5HP GXV140 NGK Brand NGKBPR5ES .030 NONE 30W 20.OZ

ONAN ENGINES

20HP RS14YC .025 NONE 30W 56.OZ

KAWASAKI

18HP NGK BPMRGA .025 CJ8 10W30 70.OZ

NOTE: Make sure the correct engine spark plug is used with (correct reach and heat range), as the use of a incorrect

spark plug will cause damage to the customer engine.

Tractor 1992 and newer with vented decks 3350 RPM + or - 50 RPM

Tractor 1991 and older with standard decks 3550 RPM + or - 50 RPM

Tractor low RPM single cylinder 1800 RPM

Tractor low RPM twin cylinder 1400 RPM

Rotary mower high RPM 3200 fast

Rotary mower low RPM 2600 slow

12

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

MAINTENANCE (M/A) CHECK

1

Tractor / Riding Mowers

• Tune engine, Check: rpm engine speed ,charging system , ignition, spark plug, throttle & choke

controls, clean engine cooling fins, replace air filter, change oil, oil filter, and fuel filter.

• Check & adjust tires for proper inflation.

• Lubricate moving parts, steering, linkage, and grease all fittings.

• Test overall operation of equipment and ensure that all safety features are operating properly.

• Check electrical system and clean battery terminals.

• Sharpen or replace cutting blades.

• Check blade mounting bolt Torque with Torque wrench ( 30 to 35 ft lbs).

• Check and adjust brakes & do brake test. See brake adjustment section for brake test.

• Compliance check operator present system and blade brake system, blades stop within 5 seconds

when disengaged.

• Check belts & pulleys.

• Adjust guage wheels, (off of ground).

• Check deck rake and level.

Tillers

• Remove fuel from tank & bowl.

• Tune engine , Check: rpm engine speed, Ignition, carburetor, clean or replace air filter and change

oil.

• Lubricate moving parts, pivot point and cable.

• Inspect, adjust or replace as needed all belts and chains as applicable.

• Test overall operation of equipment and ensure that all safety features are fully operational.

Snow Throwers

• Tune engine , Check: rpm engine speed , Ignition system, carburetor, battery, replace spark plug

and change oil winter weight only.

• Lubricate moving parts: pivot point, cables, auger shaft, grease zerk, and chains.

• Inspect, adjust or replace (as needed) all drive belts, belt guides.

• Check manual starter and electric starter if so equipped.

• Check and adjust disk drive assembly and auger cable.

• Check chute control rod and deflector.

• Test overall operation of the snow thrower.

• Check for proper operation of all safety features.

POKE HOLE IN TOP

OF FILTER HERE.

PREVENT OIL FROM SPILLING ALL OVER THE

WHEN CHANGING FILTER. POKING A HOLE

IN THE TOP OF THE FILTER WILL VENT SYSTEM

AND ALLOW OIL TO DRAIN OUT THROUGH

ENGINE SUMP.

13

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

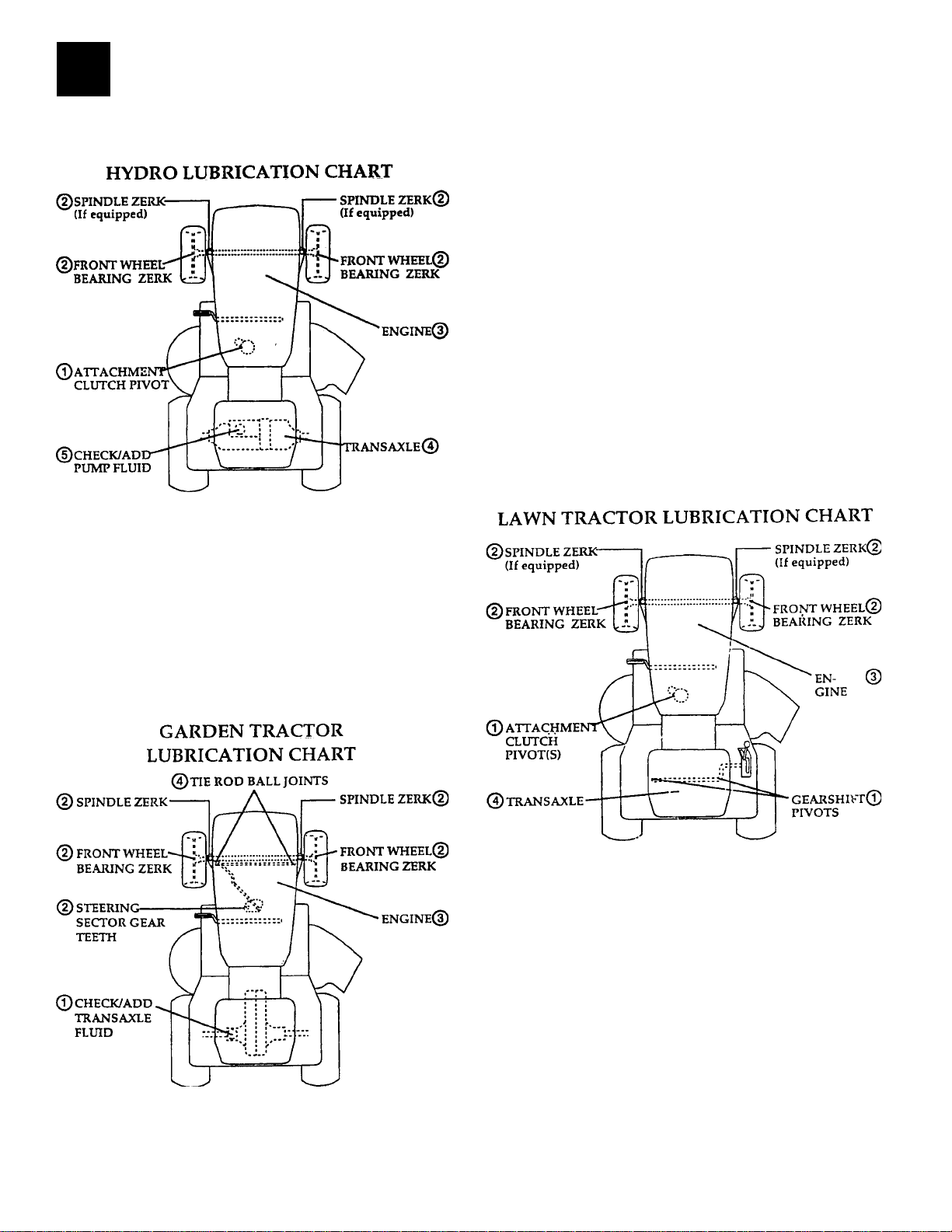

TRACTOR LUBRICATIONTRACTOR LUBRICATION

TRACTOR LUBRICATION

TRACTOR LUBRICATIONTRACTOR LUBRICATION

Important: do not oil or grease the pivot points which have special nylon bearings. Viscous

lubricants will attract dust and dirt that will shorten the life of the self-lubricating bearings. If you

feel they must be lubricated, use only a dry, powdered graphite type lubricant sparingly.

NOTE: HYDRO TRANSAXLE FLUID

Typically, a 20W-50 engine oil with an API

classification of SH/CD is recommended for

most normal operating conditions. In some

cases, such as northern climates where

temperatures commonly drop below 20°F it

may be necessary to perform seasonal oil and

filter changes to achieve the proper

performance levels expected from a hydrostatic

transmission. The recommended “winter” fluid

would then become a 10W-40 engine oil. An

alternative to seasonal fluid and filter changes

would be to use a synthetice engine oil such as

15W-50 Mobil 1. This choice offers not only

better cold weather performance, but also

improves high temperature protection over

both of the previously mentioned fluids. The

volume of fluid required to refill a transaxle is

approximately 2-1/2 quarts.

1. SAE 10W30 Motor Oil API-SG

2. General purpose grease

3. Refer to customer responsibilities "Engine"

section in owners manual.

4. Grease shell dorina type 0 20 oz.

5. SAE 20W50 Motor Oil API SG/CD

Lawn Tractor:

310-500, 310-650, 310-750 IHT Hydro

transmission holds approximately 80 oz.

20W50 motor oil.

Garden Tractor:

210-3010L GT Hydro transmission holds

approximately 60 oz. 20W50 motor oil or

10W40 or 15W50 Mobil 1 synthetic motor oil.

1. SAE 30 or 10W30 Motor oil API - SG

2. General purpose grease

3. Refer to customer responsibilities “Engine”

section in owner’s manual

4. Dana transaxle 16 oz. Shell dorina type 0

grease. Part number 120416X

1. SAE 30 Motor Oil API-SF/SG holds 128 oz.

2. General purpose grease.

3. Refer to customer responsibilities "Engine"

section.

4. Spray silicone lubricant (move boots to

lubricate)

www.mymowerparts.com

Peerless transaxle: 30 oz. Bentonite grease.

NOTE:NOTE:

NOTE: on transaxle with grease, only change or

NOTE:NOTE:

add grease when making repairs to the inside of

transaxle.

IMPORTANT:IMPORTANT:

IMPORTANT: do not oil or grease the Pivot

IMPORTANT:IMPORTANT:

points which have special nylon bearings.

Viscous lubricants will attract dust and dirt that

will shorten the life of the self-lubricating

bearings. If you feel they must be lubricated

use only a dry, powdered graphite type

lubricant sparingly.

14

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

SERVICE ORDER DOCUMENTATION

1

It’s important to always document the reason for failure on the service order. On an in-warranty

product, do not close the service orders as in-warranty, if the failure is due to customer abuse, neglect

or even accident. Verify and document as much information as possible about a service call on the

service order. Especially when a major component has been replaced, here are a few examples of

acceptable and not acceptable service orders.

1 - NOT ACCEPTABLE

A. Service Requested: Won’t Run

B. Tech Comments: Replaced Engine

2 - ACCEPTABLE

A. Service Requested: Won’t Run

B. Tech Comments: Found black, dirty oil in pump, connecting rod broken.

Customer abuse, changed engine, tested for safety compliance and charged customer.

C. Call closed as collect

3 - ACCEPTABLE

A. Service Requested: Won’t Run

B. Tech Comments: Found engine locked. Oil normal, no external causes found.

Internal component failed. Replaced engine and tested.

C. Call closed as in-warranty

Note: The cost of an engine replacement must be supported by what you have determined caused the

failure.

Engine Replacement

Other than catastrophic internal engine failures, ordering a replacement engine is not

always the solution. Many perfectly good engines have been received and inspected

at the Dallas Rebuilding facility. Before replacing an engine check the following items

first:

Complaint:

Noisy

• Disconnect belt(s), run engine with no load.

• If an engine is noisy, determine where noise is coming from. If engine runs normally but has a knock,

pull head(s) and check for carbon buildup.

High Oil Consumption

• Is it leaking or burning oil?

• Check integrity of all seals and gaskets (as described in the Troubleshooting section of this manual).

• Ensure breather is operating properly.

• Check condition of spark plug. An oil-fouled plug will indicate engine is burning oil.

• Check oil type, quality and quantity.

• Does the engine smoke? If so, is the smoke black, white or blue?

Won't Run / Locked Up

• Disconnect belt(s), run engine with no load.

• Check external causes.

• Check starter drive to ensure it is not jammed in the flywheel.

15

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

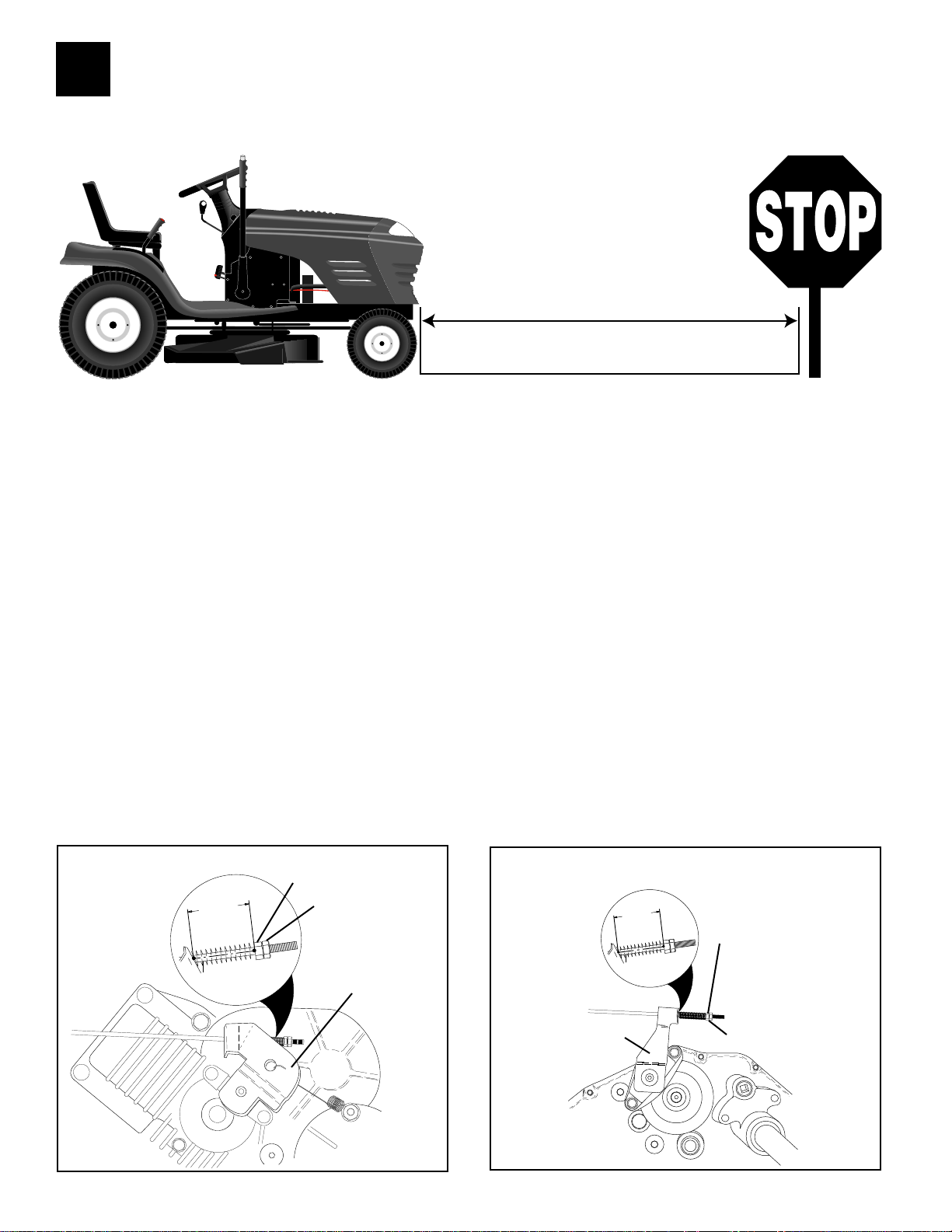

BRAKE ADJUSTMENTS

6 FEET

BRAKE TEST

A brake test should be performed whenever Service work is performed on a tractor. Tractor traveling at high speed in highest

gear must stop within 6 feet when the brakes are applied. If tractor requires more than 6 feet to stop, a brake adjustment

should be made before returning tractor to the customer.

TO ADJUST BRAKE

Your tractor is equipped with an adjustable brake system which is mounted on the side of the transaxle.

• Depress clutch/brake pedal and engage parking brake.

• Measure distance between brake operating arm and nut “A” on brake rod.

• If distance is other than dimension shown for your type tractor, loosen jam nut and turn nut “A”

until correct distance is reached. Retighten jam nut against nut “A”.

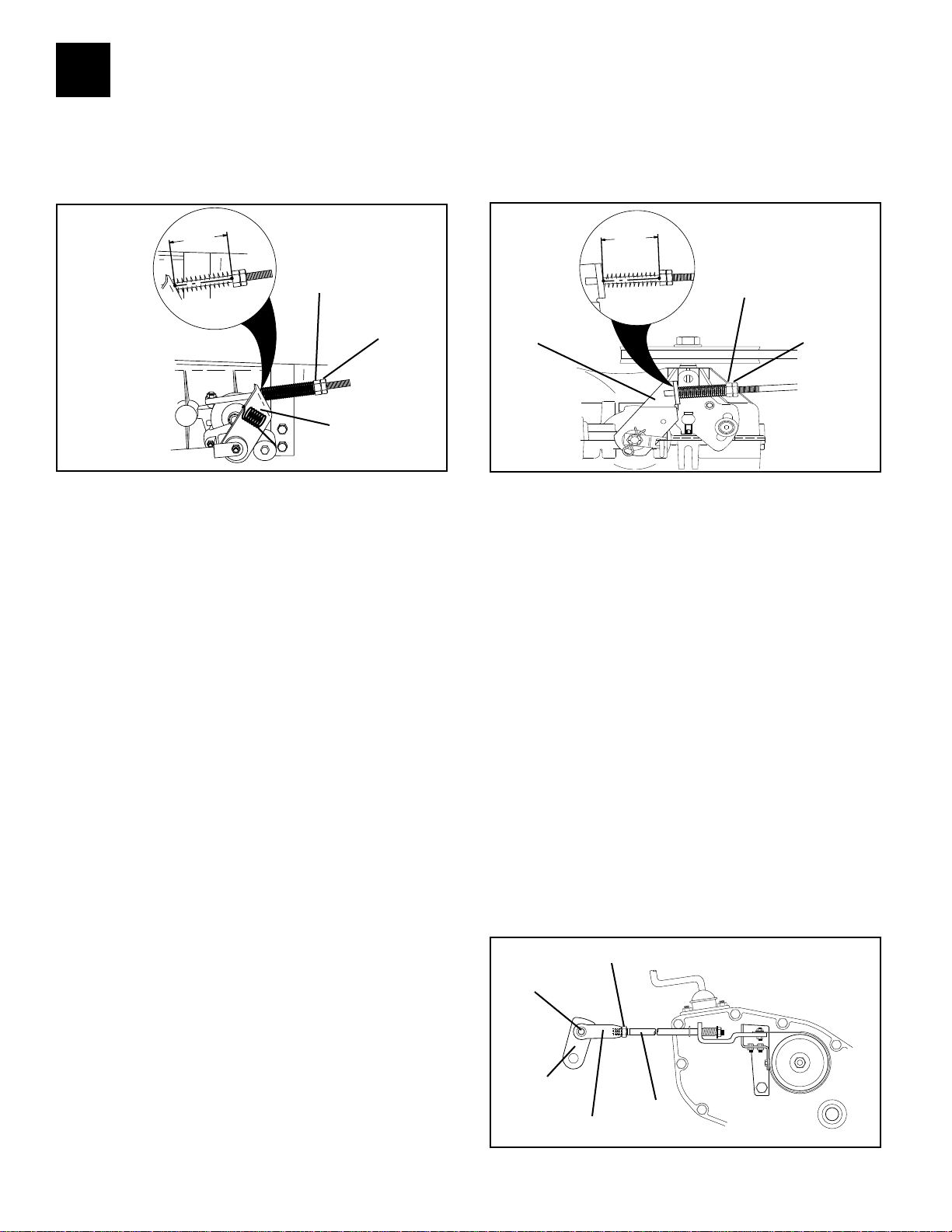

VGT HYDRO TRANSAXLE AYP DISC BRAKE TRANSAXLE

WITH PARKING BRAKE “ENGAGED”

NUT

“A”

1-1/2"

JAM

NUT

OPERATING

ARM

WITH PARKING BRAKE “ENGAGED”

1-3/4"

NUT

“A”

OPERATING

ARM

16

www.mymowerparts.com

JAM NUT

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

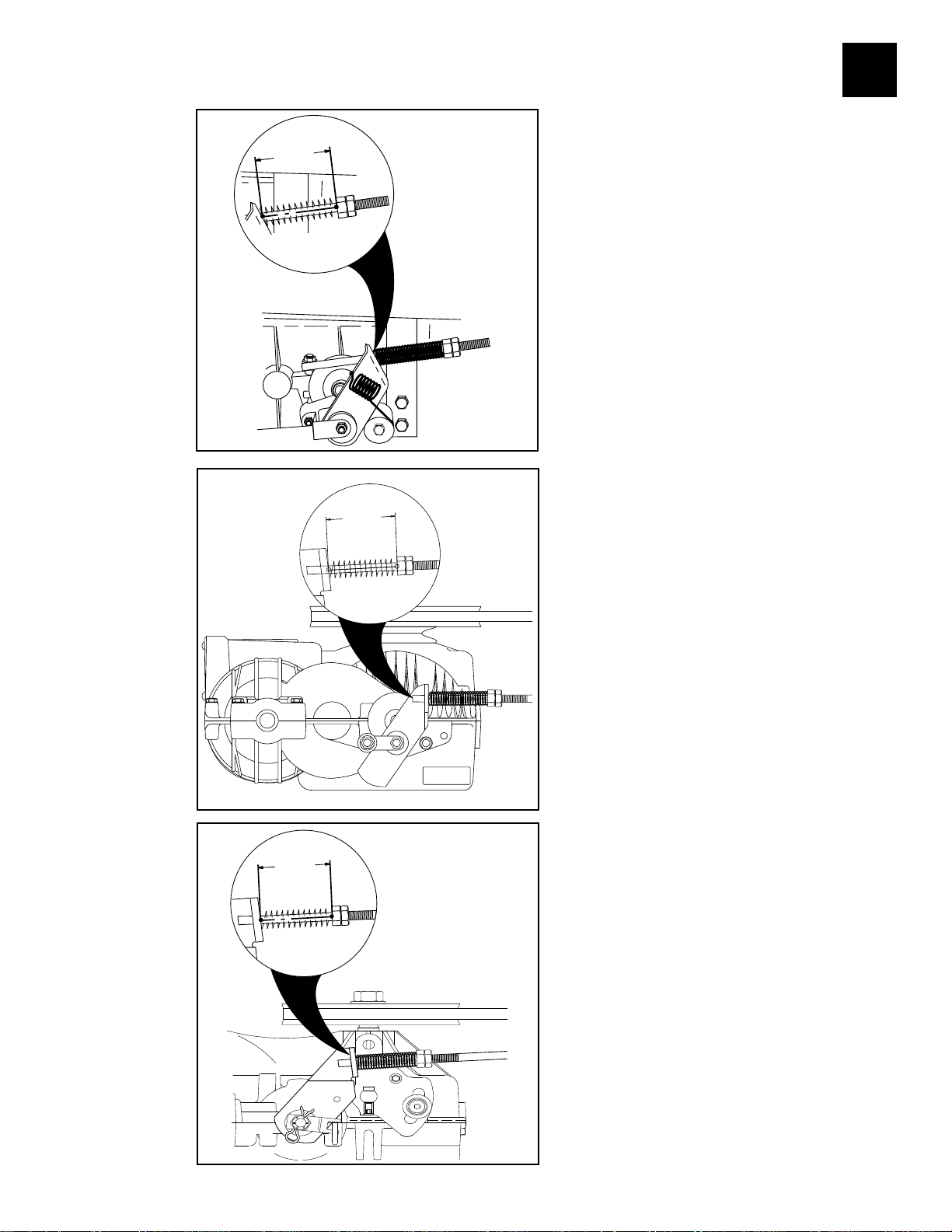

LAWN RIDER

1-1/2"

Brake adjustments

2

1-1/2"

PEERLESS HYDRO

Brake adjustments

1-1/2"

HYDRO GEAR 3000

Brake adjustments

17

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

BRAKE ADJUSTMENT

STEP-THRU LT/YT GEAR DRIVE

TRANSAXLES PEERLESS + DANA

SHOWN WITH

1-1/2"

PARKING BRAKE

"ENGAGED"

NUT "A"

JAM NUT

OPERATING

ARM

STEP-THRU LT/YT HYDROGEAR

0500/0650

SHOWN WITH

1-9/16"

OPERATING

ARM

PARKING BRAKE

"ENGAGED"

NUT "A"

JAM NUT

GT BRAKE BAUD BRAKE ADJUSTMENT

IMPORTANT: DO NOT OVER TIGHTEN BRAKE. WHEN DEPRESSING CLUTCH BRAKE PEDAL, THE MOTION DRIVE

BELT MUST STOP MOVING (DECLUTCH FROM ENGINE PULLEY) BEFORE BRAKE ENGAGES. IMPROPER

ADJUSTMENT WILL CAUSE HARD SHIFTING AND EXCESSIVE WEAR TO BRAKE LINING.

• Park and turn off the tractor on a level surface.

Place gear shift lever in neutral (N) position.

Disengage parking brake and be sure tractor

does not roll in either direction.

• Lower mower deck (if installed on tractor).

• Snap out access hole cover on left side of tractor

above footrest.

• Loosen jam nut at clevis which will allow brake

rod to be rotated.

• With pliers, from underside of frame, unscrew

brake rod from clevis four (4) to six (6) full turns.

• Start tractor with gear shift lever in neutral (N)

position.

• Slowly depress clutch/brake pedal to the point

where the motion drive belt stops moving. Hold

clutch/brake pedal in this position and engage

parking brake. If belt begins to move after engaging parking brake, reset parking brake by

depressing clutch/brake pedal slightly to next

notch on parking brake.

• Stop engine. Screw brake rod back into clevis

until clevis pin is against rear edge of slot in

brake arm. Do not over tighten (see “IMPORTANT” above).

• Tighten jam nut against clevis.

• Replace access hole cover.

• Road test tractor for proper stopping distance

and declutching as stated above. Readjust if

necessary. If proper adjustment cannot be

attained, replace brake band.

GT BAND BRAKE TRANSAXLE

JAM NUT

CLEVIS

PIN

BRAKE

ARM

CLEVIS

BRAKE

ROD

18

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

TRANSAXLES

3

WHAT YOU SHOULD CHECK BEFORE YOU REPLACE THE TRANSAXLE

Symptom: Hard Shifting / Transaxle locked up.

Eliminate all customer issues: Make sure customer is not shifting on the go or is trying to shift on

a hill. Shifting on the go will damage transaxle, shifting on a hill is incorrect due to the gear load.

Jerking is caused by clutch misuse. Do not replace transaxle, instruct customer how to use clutch.

Surging happens when a tractor goes down hill and momentarily picks up speed (this is normal).

Remember you cannot fix something on a transaxle that is normal (not broken).

1. Place tractor on level ground.

2. Remove drive belt from transaxle input pulley.

3. If transaxle shifts OK. Tractor has a belt guide out of adjustment or belt guide is missing.

4. Verify that both square axle keys are installed in each wheel hub.

5. Verify shift lever linkage is secure (all fasteners are tight).

6. Check brakes/clutch dwell setting for proper adjustment (verify brake return spring is installed).

7. If transaxle is still locked up you have a internal problem in the transaxle, repair or replace.

8. Note: 30% of all transaxles returned to the rebuild center have nothing wrong with them.

Set Parking Brake: Check the brake clearance it should be. 019"/.024" between the brake disc and

the outside friction puck while the brake lever contacts the brake jaw.

Compliance brake test: tractor on level ground at full speed in highest gear must stop within six (6)

feet or less. If unit fails, follow brake adjustment procedures on page 16, 17 and 18 of this manual.

BRAKE DISC

OUTSIDE FRICTION PACK

.019 BRAKE PUCK CLEARANCE

.024 WITH LEVER CONTACTING

BRAKE JAW BOSS

19

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

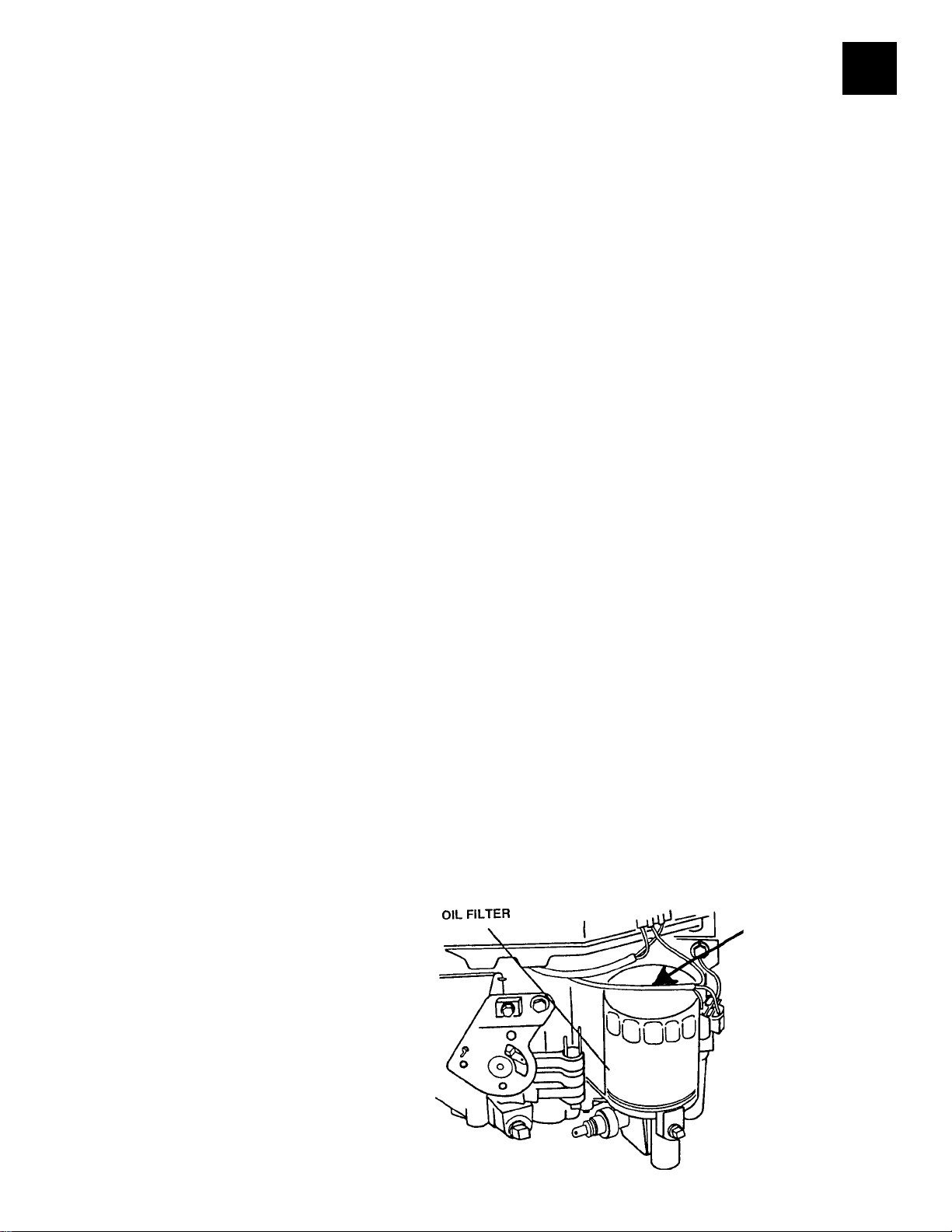

Oil and filter change should occur approximately every 200 hours of operation or when oil condition results in loss of power. More frequent oil and filter changes are recommended if operation

conditions are severe or adverse, such as pulling a plow or a tiller for an extended period, or

operating in very dusty conditions.

• Run tractor to heat up oil (Warm oil will drain more freely).

• Be sure tractor is on level surface and catch oil in a suitable container.

Lift tractor off the ground with lift at the drawbar of the tractor or block up tractor so the left rear

wheel is just off the ground and remove left rear tire (Be sure to keep tractor as level as possible).

(#1) Remove oil filter.

(#2) Remove hose from end of swivel fitting at oil drain location.

(#3) After oil has drained completely, replace hose end to swivel fitting and tighten securely

(#4) Put a small amount of oil on the filter rubber seal before installing. Install the new filter and

tighten 3/4 of one turn after the filter seal touches the filter mounting base, to prevent an air leak.

Order the proper replacement filter from AYP.

(#5) Remove oil level port plug.

(#6) Remove vent cap from end of oil fill tube and refill transaxle with about 45 ounces of 15w50

Synthetic Mobil one engine oil . Fill oil through the oil fill breather vent hose until just before the oil

starts to come out of the oil level port hole. Pour slowly do not overfill, let excess oil drain out of

oil level port hole.. Note the system holds 60 ounce of oil but you will only get out about 75%

during a oil change. About 25% of the oil will remain in the pump for a prime to restart the system

after the oil change.

(#7) Replace oil level plug and purge transaxle as follows:

• Engage parking brake and place freewheel control in “freewheel” position.

• Sit in seat, start engine and move throttle control to “slow” position.

• Put motion control lever in neutral (N) and slowly disengage clutch/brake pedal.

• Move motion control lever to full forward position and hold for five (5) seconds.

(#8) After purging the system of air andonce tractor has been running for one minute, the oil level

should be rechecked. Remove oil drain port hole plug and add 2 to 4 ounces or more oil if needed.

Reinstall oil drain port hole plug and the vent cap to oil fill tube. Refer to step#6.

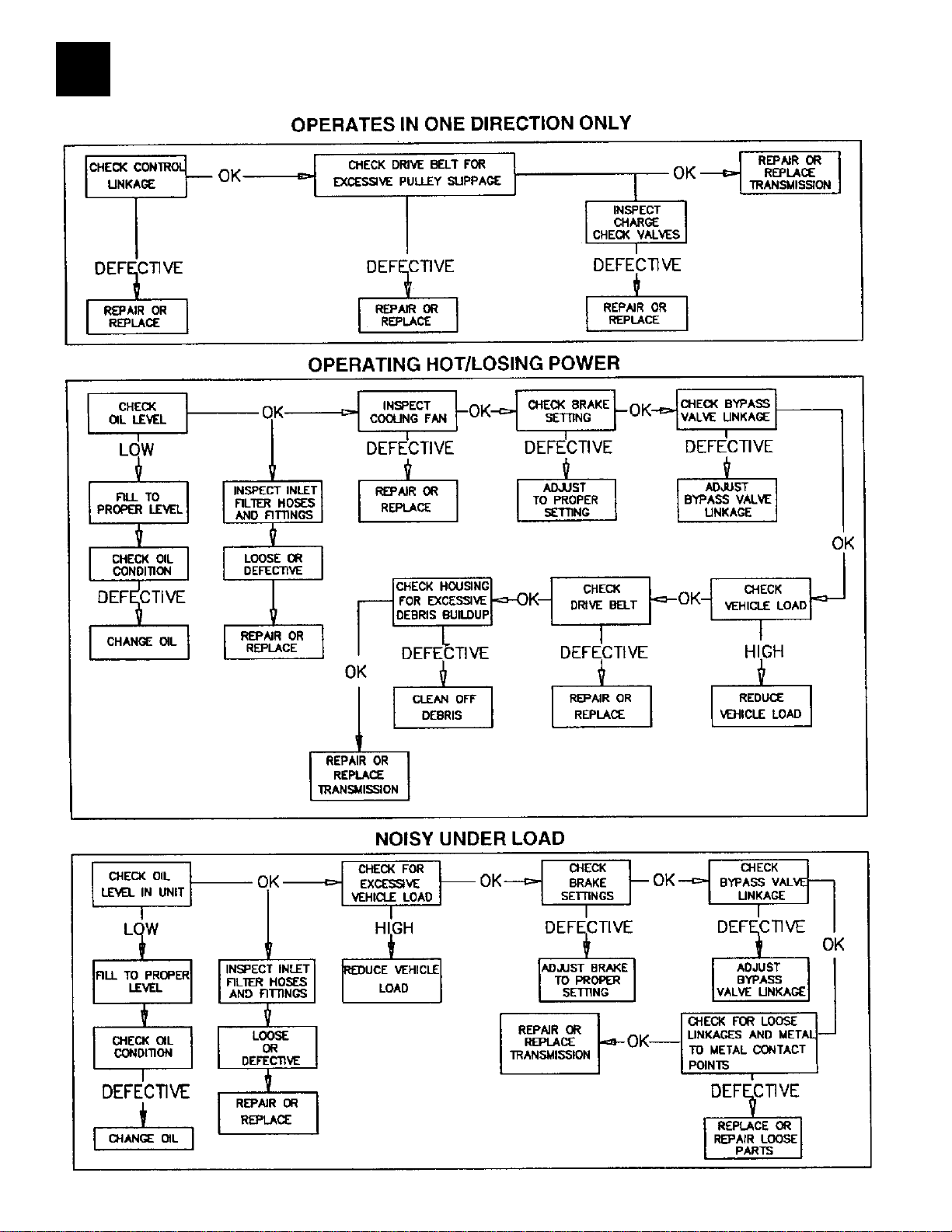

HYDRO TRANSAXLES - GT OIL/FILTER CHANGE

Move lever to full reverse position and hold for five (5) seconds.

Repeat this procedure three (3) times.

OIL LEVEL

LEFT SIDE VIEW RIGHT SIDE VIEW

PARKING BRAKE ARM

BREATHER

VENT / OIL FILL

TUBE

FREEWHEEL CONTROL

OIL DRAIN SWIVEL PLUG

20

(BYPASS VALVE)

www.mymowerparts.com

OIL FILTER

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

HYDRO TRANSAXLES - GT TROUBLESHOOTING

3

Symptom: Hydro Garden Tractor Won’t Drive.

Trouble shooting Cold starting for hydro (below 40 degrees F) after starting engine and before

driving , let the transmission warm up for (1) minute by placing the motion control lever in neutral

(N) position and releasing clutch/brake pedal.

1. Follow purge procedures described in step #7 on page 20 of this manual.

2. Place free wheel control in the drive position.

3. Check for proper installation and function of motion drive belt.

4. Verify that the axle engagement key is in place in both rear wheel hubs..

5. Verify motion control linkage is secure (all fastener are tight).

6. Verify proper oil level in transmission, remove oil level port plug and check oil level. Oil should

be at the bottom of the plug hole, but not running out.

7. Verify parking brake arm releases..

8. Test for system leaks ( fitting, hoses, seals, ect ) see test procedures.

PARKING BRAKE

The brake was factory set for specific running

clearance between the disc and pucks of 0.020".

Place a feeler gage between the disc and one puck,

if the clearance is not set properly remove the

cotter pin retaining the castle nut and set the correct clearance by adjusting the castle nut accordingly. Reinstall the cotter pin. Compliance brake

test: Check Brakes operation, tractor at full speed

in high gear must stop within six (6) feet or less

on level ground.

Test Procedure for System Leaks:

1. Remove vent from breather hose ( located at

the rear tractor on top of the hydro

transaxle).

2. Apply (5) to a maximum of (10) psi air pressure

to the hose.

3. If a leak is present, a puddle of oil should begin

to form under the transmission in less then (2)

minutes. Determine the origin of the leak.

4. If no leaks are found, change filter and oil.

5. If leak is found repair or replace defective

components.

6. Check level and top off with recommended oil.

7. Follow purge procedures as described in step #7

on previous page of this manual.

8. If tractor functions properly, check oil level and

top off with recommended oil if needed.

9. If tractor still won’t drive replace hydro/pump

(or) defective component) and follow

recommended start up purge procedures.

INSERT 0.020"

FEELER GAUGE

HERE

LEFT SIDE VIEW

PARKING BRAKE ARM

RIGHT SIDE VIEW

APPLY 5 TO 10 P.S.I. OF AIR

TO THE BREATHER HOSE

CHECK

FOR OIL

LEAKS IN

THESE

AREAS

(FITTINGS)

21

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

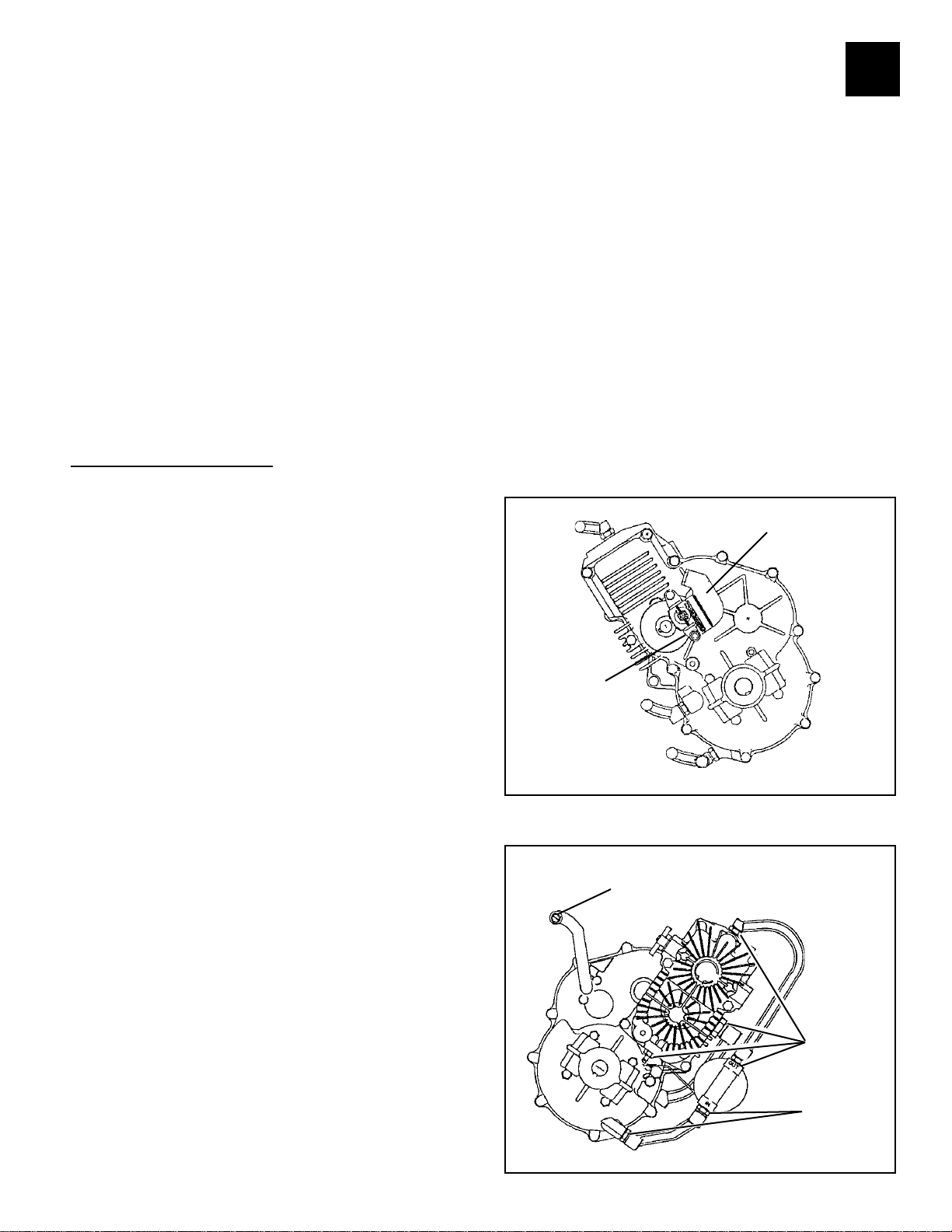

TROUBLESHOOTING CHART

GARDEN TRACTOR WITH HYDRO GEAR TRANSAXLE

22

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

HYDRO TRANSAXLES - LT REPLACEMENT

3

WHAT YOU SHOULD CHECK BEFORE YOU REPLACE THE TRANSAXLE

Symptom: Tractor has loss of drive. No forward / reverse motion.

1. Check to see that the freeweel control is “DISENGAGED” position.

2. Make sure the motion drive belt is not worn , damaged or broken.

3. Vehicle should be on level ground before performing adjustments.

4. Verify that square axle key are installed in each wheel hub.

5. Was air trapped in hydro transaxle during shipment? (PURGE TRANSAXLE.)

6. Adjust the neutral position. Make sure shift lever linkage is tight.

7. Does hydro transaxle have enough oil ? Check oil level and add if needed..

8. Check the parking brake setting.

Set Parking Brake :

1. Adjust the nut onto brake bolt until tight or until the brake arm will not move.

CAUTION! do not over tighten the nut or damage may occur to the brake assembly.

2. Back nut off 2/3 turn (4 to 5 flats); place a 0.030" feeler gauge between the two outer discs to set

air gap.

3. Reinstall the cotter pin or second new nylon insert locking nut to lock the brake setting.

Bolt without hole requires use of Spring and 2 Locknuts Bolt with hole requires the use of Spring and Cotter Pin

Place 0.030"

Feeler Gauge here

Back off nut 4 to 5 flats

(2/3 of one turn = 0.030")

23

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

HYDRO TRANSAXLES - TROUBLESHOOTING

SYMPTOM: TRANSAXLE NOISY

Note: The average Hydro-transaxle has a different sound level.

1. Check oil level as previously described, using a ruler for LT tractor and oil level port for GT.

2. Check cooling fan ( if applicable) for obstruction and/or broken fins, if fan blade is broken, re-

place, to keep the transaxle running at optimum performance keep the area clean. It’s recommended to use air to clean off debris. Although, using a garden hose (low pressure) with water is

acceptable as long as the transaxle is completely cooled down, for example clean with water before

the customer cuts the grass or after, as long as the tractor has sufficient time to cool down.

3. Check brake setting to ensure that it has the proper clearance and that the puck is not giving

resistance during freewheel. To check brake clearance; place a feeler gauge between the two outer

discs, if the clearance is out of range (.020"-.040" for LT tractor and .020"-.025" for GT tractors),

adjust the break retainer as needed to bring clearance into this range.

4. Check bypass valve linkage to insure that the bypass valve is fully opening and closing when the

actuator is activated.

5. Verify axle key is in place and in one piece.

HYDRO TRANSAXLES - LT TROUBLESHOOTING

SYMPTOM: ENGINE RUNS, TRACTOR WON’T DRIVE

1. Check bypass actuator to insure that it is in the “Drive” position.

2. Check belt integrity and that there is not excessive slippage on the input pulley. If the belt is

worn, dry rotten, broken, etc., replace and adjust.

3. Check oil level, the 310-0500 and 310-0750 holds approximately 80 ounces of 20W50 SG/CD

grade oil (or in cold weather 15W50 Mobil One synthetic oil is recommended) To check oil level:

remove vent hose and fitting. Put tape measure inside vent hole and measure oil level

On model 310-0500: the oil should be between 1.25" and 2.00" from top of housing.

On model 310-0650/0750: the oil should be between 1.00" and 1.75" from top of housing.

To add oil, remove vent hose and fitting. Add

oil until proper oil level for either type transaxle

is reached. Note: If oil level is found low, find

the cause of the problem, check the input seals,

bypass seals, and axle key. If needed, perform

the pressure test to find the leak.

4. If tractor still does not move, check shift

linkage to be sure the shift lever is fully actuated.

5. Check brake and verify that the brake is

adjusted properly and the tractor freewheels

when the transaxle is in the transport position.

TO ADD OIL: Remove breather hose and

fitting. Add oil until proper oil level for

transaxle type is reached.

BREATHER

HOSE

MEASURE

OIL LEVEL /

ADD OIL

HERE

RULER OR

TAPE MEASURE

24

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

HOW TO ADJUST MOTION CONTROL LEVER ON VST PEERLESS HYDRO

The motion control lever has been preset at the factory and adjustment should

not be necessary.

If for any reason the motion control lever will not hold its position while at a

selected speed, it may be adjusted as follows:

• Park tractor on a level surface. Stop tractor by turning key to "OFF" `

position and engage parking brake.

NOTE: Transmission should not be warm when making this adjustment.

Allow transmission to cool to airtemperature before making this adjustment.

To access the transmission adjustment, it will be necessary to remove the

battery and the battery box from tractor.

• Raise seat and open battery box door. Disconnect BLACK battery cable

first, then the RED cable.

• Remove battery and battery box from tractoras shown.

NOTE: When reinstalling battery box, ensure that battery acid drain tube is

routed toward the rear and is clear of the cooling fan.

• Locate the access plug underthe cooling fan. This plug and surrounding

area must be cleaned to prevent contamination of internal parts during

this procedure. Before removing the plug, pack a cloth in the housing

pocket to absorb excess oil.

• Using needle nose pliers, remove the access plug described above.

When the plug is removed, a small quantity of oii will flow out of the

transmission. This is normal and will not effect-transmission function.

• Insert a #30 torx or 5/32 alien wrench into the access hole and locate the

adjustment screw. Adjust the screw clockwise 1/4 turn at a time to

increase motion control effort. An effort of 15-18 Ibs. at the motion

control lever knob is nommal.

NOTE: If for any reason the effort to move the motion control lever becomes

too excessive, reverse the above procedure by turning the adjustment screw

counterclockwise 1/4 turn.

• Clean the access plug and insert it into position using the torx or alien

wrench.

• Clean spilled oil from transmission and

reinstall battery box and battery

into tractor. When connecting battery be

sure to connect the RED bat

tery cable first. Road test tractor after

adjustment and repeat procedure

if necessary.

ACCESS PLUG

WRENCH

BATTERY ACID

DRAIN TUBE

3

25

www.mymowerparts.com

COOLING FAN

HOUSING

POCKET

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

SECTION 11. VST TROUBLESHOOTING

The information on the following pages has been provided to help understand the internal operation of the VST. Do not use this information to attempt any internal repairs. Tecumseh's current

policy on hydrostatic transaxles that have internal failures is to replace the complete unit. This has

not changed. However, Tecumseh would like to provide a failure checklist to assist in making an

accurate evaluation of the complete tractor to eliminate any unnecessary replacements. Here is a list

of items to check and corrective actions to take.

To properly test the unit for power loss.

1. Allow the unit to cool before trying the following steps.

2. Put the shift lever in a position that is 1/2 of the travel distance from neutral to forward.

3. Place the tractor on a 17 degree grade.

4. Drive the tractor up the grade (without the mower deck engaged). The loss of power

experienced should be approximately 20%. This is considered normal. If the loss of power is

approximately 50%, this would be considered excessive.

5. Bring the unit to neutral, shift into forward and note the response. Care should be taken to

move the lever slowly to avoid an abrupt wheel lift.

To detemmine if the problem is with the hydro unit, all external problem possibilities must be

eliminated. Here are some potential problem areas.

1. Overheating: Heat can cause a breakdown in the viscosity of the oil which reduces the

pressure used to move the motor. Remove any grass, debris, or dirt buildup on the transaxle

cover and / or between the cooling fins and fan. Buildup of material will reduce the cooling

efficiency.

2. Belt slippage: A belt that is worn, stretched, or the wrong belt (too large or wide) can cause

belt slippage. This condition may have the same loss of power symptom as overheating.

Typically, the unit which has a slipping belt will exhibit a pulsatina type motion of the

mower. This can be verified visually by watching the beTt and pulley relationship. It the

belt is slipping, the belt will chatter or jump on the pulley. If the belt is good, a smooth

rotation will be seen. Replace the belt and inspect the pulley for damage.

26

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

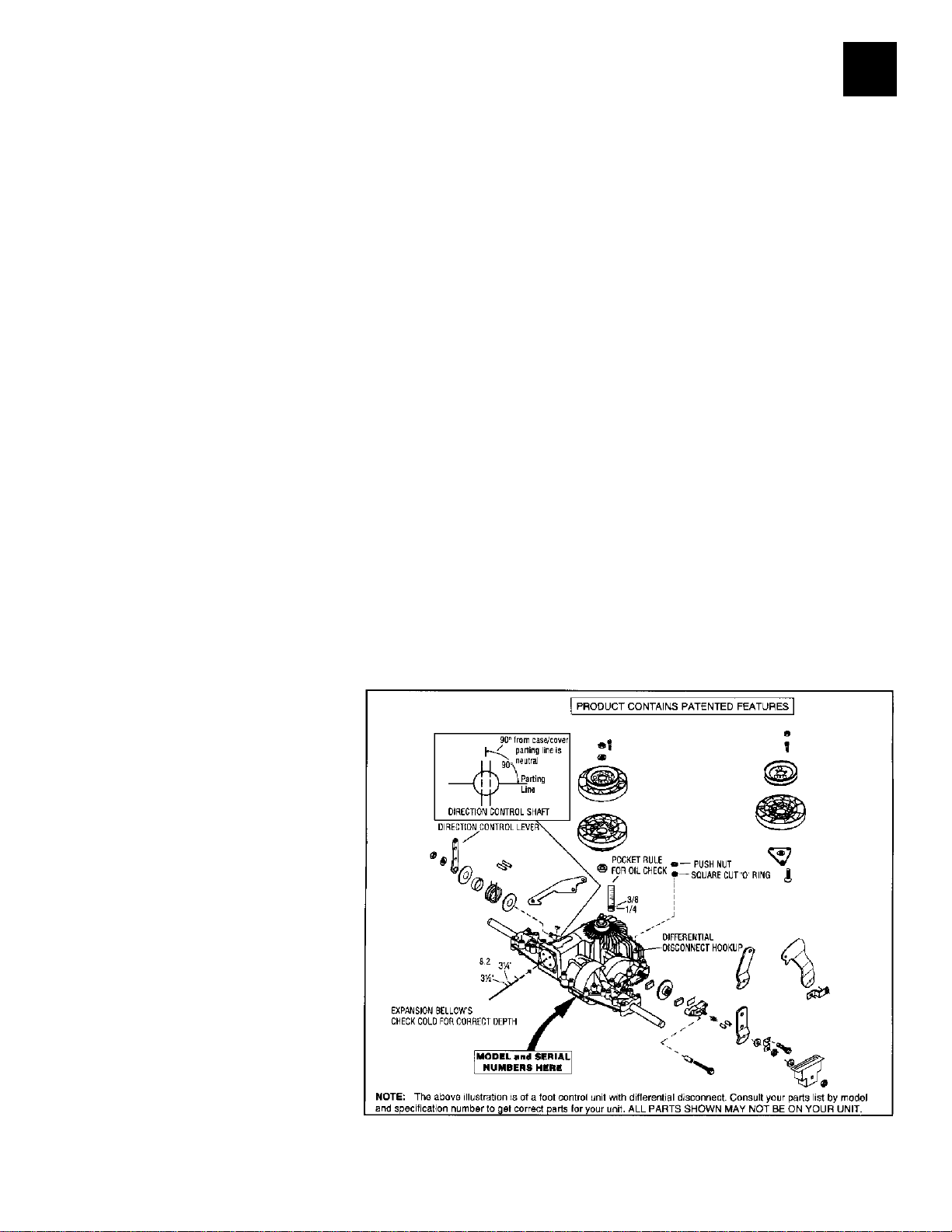

3. Leakage: The VST and 1800 Series have two oil reservoirs which can be checked for diagnostic

purposes. The first is the pump and motor expansion bellows, With a small diameter blunt or round

nose probe, check the bellows depth through the center vent hole. Proper depth from the edge of

that hole is 3-1/4 - 3-1/2 inches (8.25 - 8.9 cm).

The second chamber is for the output gears including the differential. FIRST make sure the tractor is

level, then remove the drain/fill plug. NOTE: Some units that do not have differential disconnect

will have two plugs. We recommend using only the primary plug. With a small pocket rule insert

until you touch bottom of case. You can then remove it and check for 1/4 - 3/8 inches (6.5 - 9.5 mm)

contact. This is full at its 8 oz. capacity of SAE EP 80W90 oil.

4. Low ground speed: If the linkage is not synchronized to absolute neutral, or the shift lever is not

properly fastened to the tapered control shaft, full forward travel may not be achieved. This may

cause a false reading and be misdiagnosed as a low power condition. This also could be caused by

the brake not releasing.

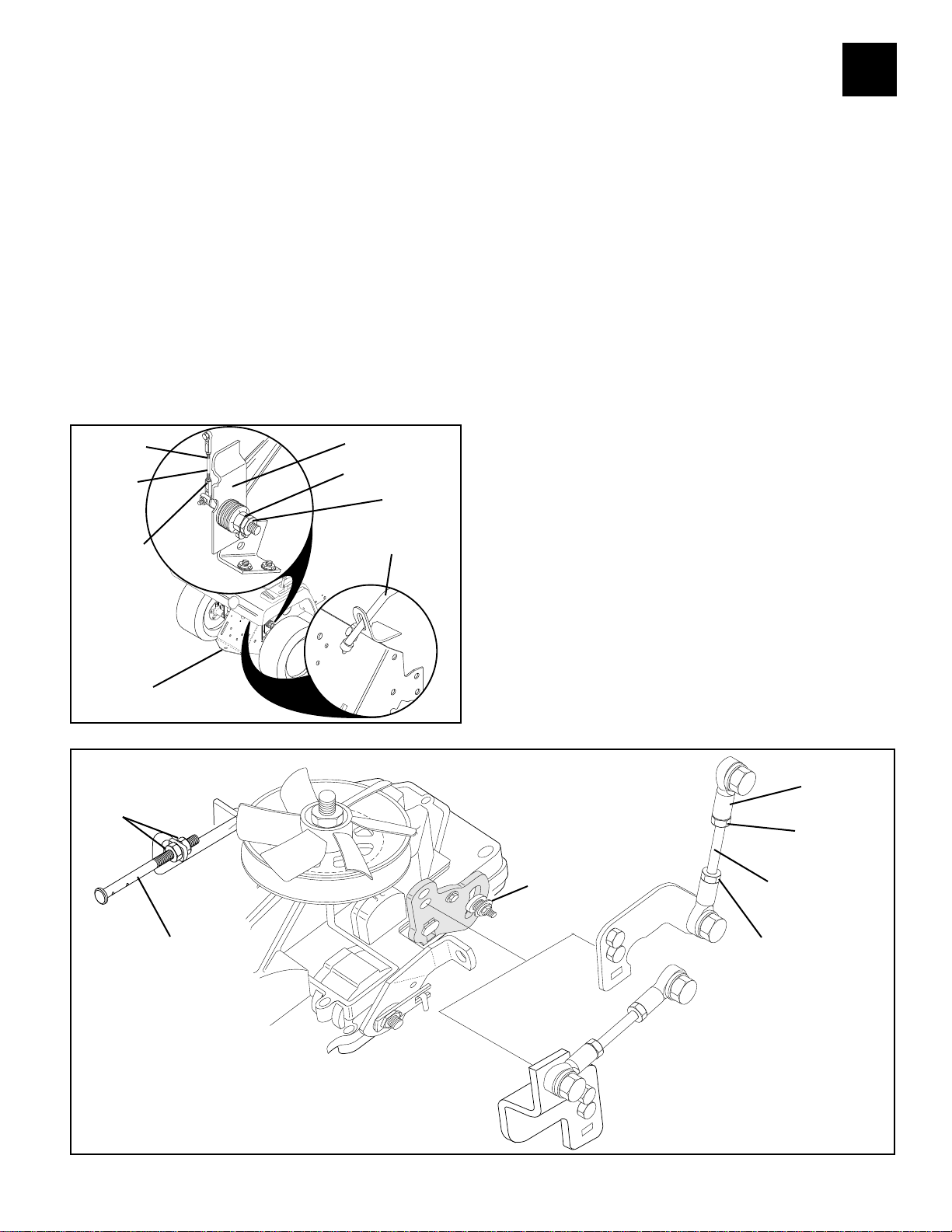

To detemmine absolute neutral, the hole in the tapered control shaft must face straight up and

down, at this point make sure the OEM linkage is in neutral. To properly fasten the control lever to

the shaft, torque the nut to 25-35 ft. Ibs. (34 - 48.3 NM) of torque with the shaft and the lever in

neutral.

When attaching the shifter arm to the shaft you must prevent any rotation during torquing. This

can be done by placing a long 5/16 bolt in the hole as shown in Illustration. Hold the bolt until the

tapers are locked and the nut torque is correct.

To make sure that the brake is not binding, drive the unit up a slight grade. Position the speed

control lever into neutral. The unit should coast backwards. If the unit does not coast back slowly,

the brake is not released from the brake disk. Adjust the brake linkage to release the brake completely when the foot pedal is released.

5. Hard to shift: Typically hard

to shift symptoms are not caused

by the hydrostatic unit. The shift

arm should move with relative

ease. Approximately 40-50 inch Ibs.

(4.48 - 5.6 NM) at the transaxle for

foot pedal units or 150-200 inch Ibs.

(16.8 - 22.4 NM) for hand operated

units. This varies depending on the

type of linkage. Binding may occur

in the linkage connections due to

rust or moisture. Lubricating these

connections and checking for bent

or damaged parts should resolve

hard shifting.

27

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

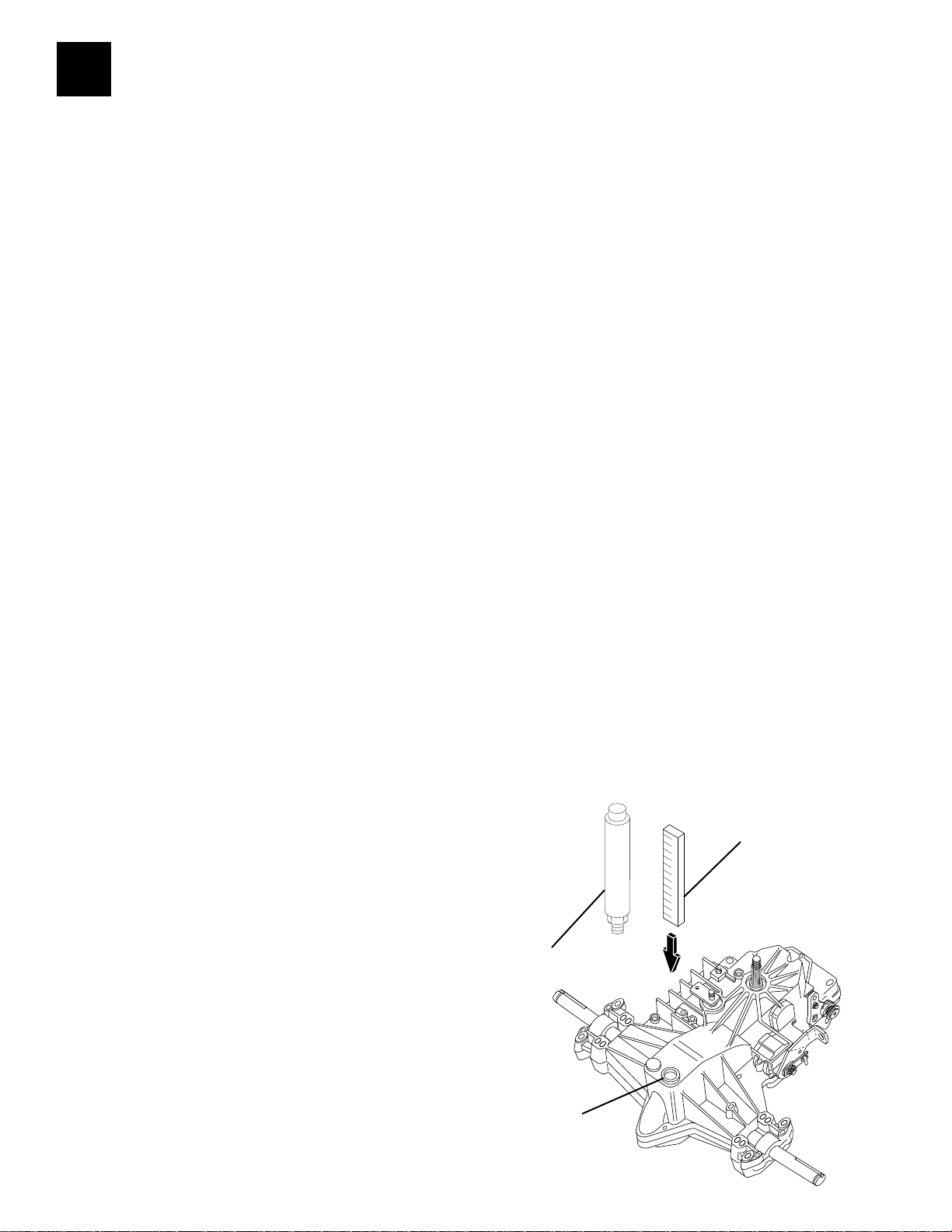

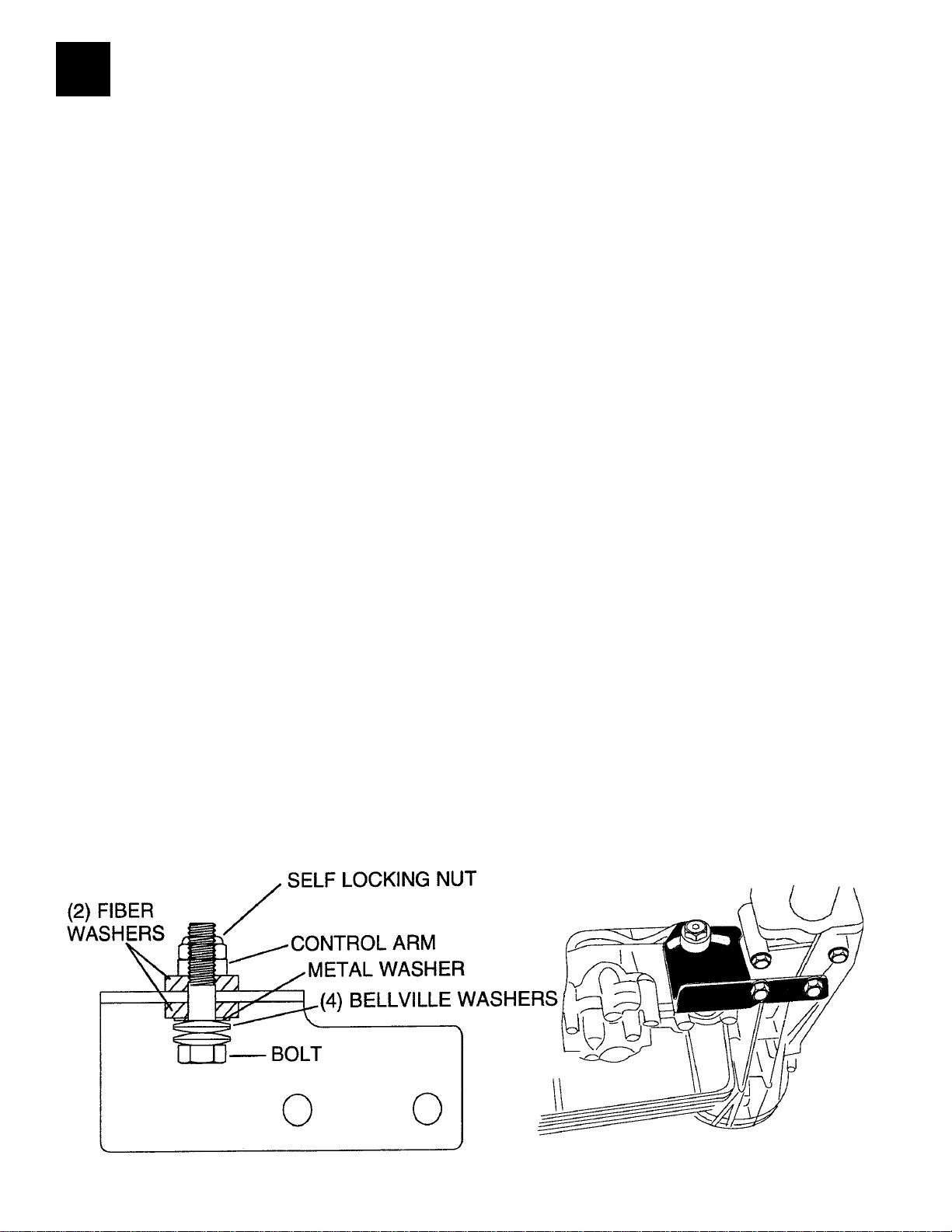

To install the friction pack kit first take these precautions. 1 ) Park the mower on a level surface. 2)

Make sure the parking brake has been set.

Raise the rear of the mower off of the ground and rest it on a stable support. Block the front wheels

to prevent the mower from rolling off the support. Remove the left rear wheel (in the operators

position) to expose the shifting linkage. Disconnect the turnbuckle shifting linkage at the pivot

point of the control arm and turn the control arm counter clockwise until it stops. To help accomplish this it may be necessary to place a 5/16 pin punch in the hole in the shifter shaft just behind

the control arm. Putting the punch in from the bottom side will provide increased leverage.

To mount the kit on the transaxle, angle the bracket so that it will clear the opening in the bracket

for the nut on the shifter shaft. Align the two bracket mounting holes up with the axle housing thru

holes. Fasten the bracket to the housing securing it with the two (2) 3/8" diameter self threading

bolts included in your kit.

FRICTION PACK KIT INSTALLATION 71/143 799026

Place the four (4) belleville washers on the remaining bolt so that the cupped sides face each other,

followed by a metal washer and a fiber washer. Place this assembly through the arced slot in the

bracket and the second fiber washer and the control arm securing the entire assembly with the

compression nut. Return the control arm to the neutral position and connect the shifting linkage.

Adjust the friction kit by using a torque wrench (beam style or needle style) on the shifter shaft nut.

The torque required to move the shaft should be between 150 - 200 inch pounds. If the shaft moves

at less then this setting tighten the nut on the friction kit accordingly or so that the shift lever stays

in position when driving up an incline. CAUTION: For safety reasons never operate equipment on

inclines greater then 15 deg rees .

28

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

HYDRO TRANSAXLES - ADJUSTMENT

TO ADJUST MOTION CONTROL LEVER

The motion control lever has been preset at the factory and

adjustment should not be necessary.

If for any reason the motion control lever will not hold its

position while at a selected speed, it may be adjusted

at the friction pack located on the right side of transmission.

• Park tractor on level surface. Stop tractor by turning

ignition key to “OFF” position, and engage parking

brake.

LT (See Fig. 2):

•Adjust motion control lever by tightening adjustment locknut one half (1/2) turn.

GT (See Fig. 1):

•Place motion control lever in neutral (N) position.

•While holding locknut, loosen jam nut.

•Tighten locknut 1/4 turn.

•While holding locknut, tighten jam nut securely.

JAM NUT

LINKAGE

CONNECTING ROD

JAM NUT

DRAWBAR

TURNBUCKLE/

LINKAGE

LOCKNUT

JAM NUT

FREEWHEEL

CONTROL ROD

NOTE: If for any reason the effort to move

the motion control lever becomes too excessive, reverse the

above adjustment procedure by loosening locknut 1/

4 to 1/2 turn.

Road test tractor after adjustment and repeat procedure if

necessary.

TO ADJUST NEUTRAL POSITION

The Neutral (N) position of the motion control lever has

been preset at the factory and adjustment should not

be necessary.

If your tractor tends to "creep" when the motion control

lever is in the neutral (N) position, adjust the neutral

lever position as follows.

LT (See Fig. 2):

•Sit on the tractor in the normal operators position.

Start the engine and disengage the parking brake so

that the foot pedal is in the full up position.

•Move the motion control lever until the tractor no

longer moves forward or backwards. Stop the engine

and remove the key.

•Loosen the jam nuts on balljoint shift linkage and

twist connecting rod clockwise or counterclockwise

until motion control lever falls into the neutral slot.

Tighten jam nuts and retest.

GT (See Fig. 1):

•Place motion control lever in neutral position.

•Locate turnbuckle/linkage at top right corner of draw-

bar and loosen jam nuts.

•Place concrete block under drawbar to lift rear wheels

off ground. Start engine and turn linkage connecting

rod clockwise or counterclockwise until the rear tires

stop turning.

•Stop the engine and remove the key. Tighten jam

nuts and retest for creeping with fastest engine rpm

from both forward and reverse.

3

ROD NUTS

(IF EQUIPPED)

FREEWHEEL

CONTROL

ROD

FIG. 1

FIG. 2

29

MODEL 0750

TRANSAXLE

ADJUSTMENT

LOCKNUT

BALLJOINT

SHIFT

LINKAGE

JAM NUT

CONNECTING LINK

JAM NUT

MODEL 0500

TRANSAXLE

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

3

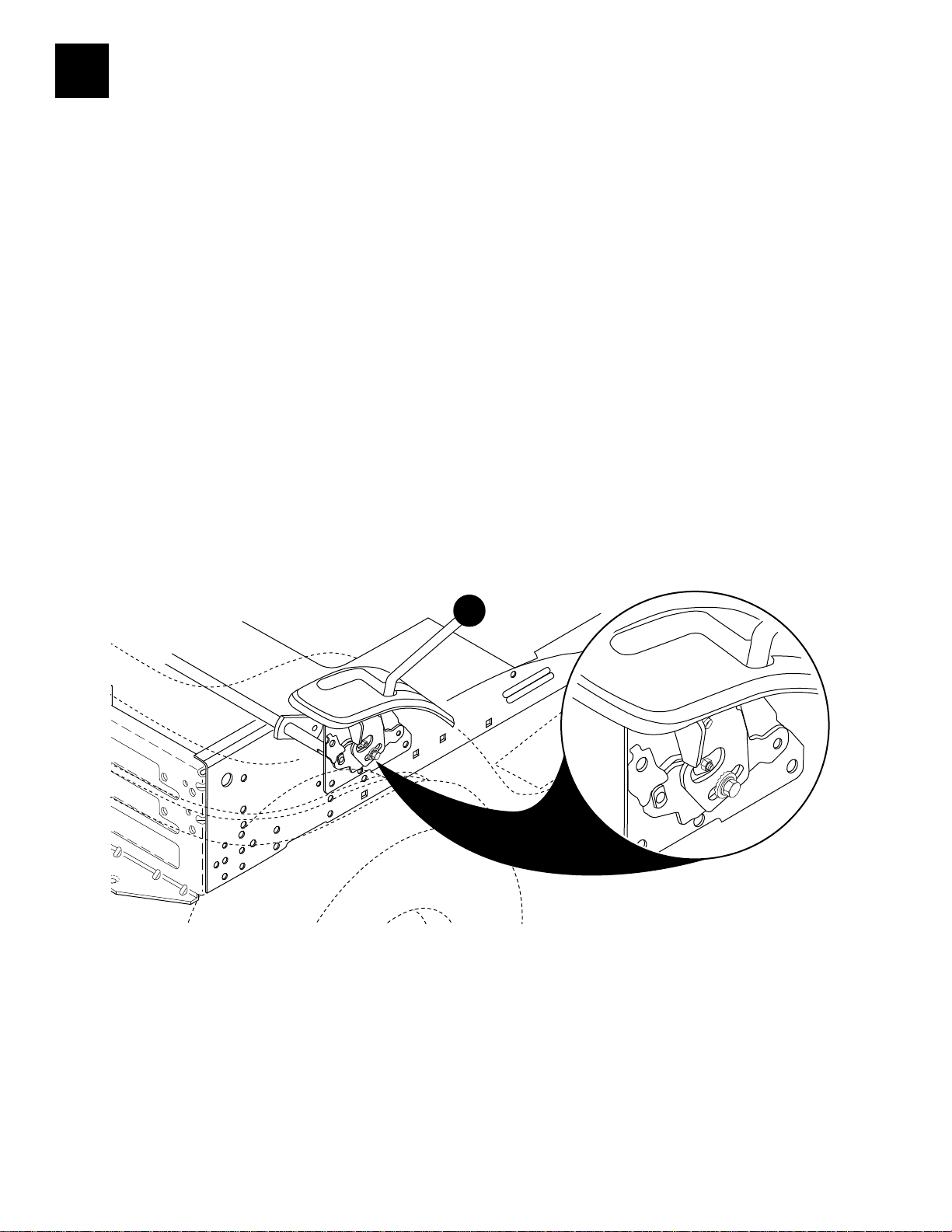

NEUTRAL ADJUSTMENT FOR AUTOMATIC DRIVE CONTROL LEVER

1. Place the tractor on a smooth paved level surface.

2. Loosen Adjustment Bolt in front of the right rear wheel, and lightly tighten using a 1/2" wrench.

3. Start Engine and move Lever until tractor does not move forward or backward.

Hold Control Lever in that position and do not move. Turn the engine off.

4. While holding the Control Lever to keep it from moving, loosen theAdjustment Bolt . Move the

Control Lever to the position indicated for Neutral on the fender. Tighten Adjustment Bolt

securely.

FINE TUNE THE NEUTRAL ADJUSTMENT ON AUTOMATIC DRIVE

1. Place the tractor on a smooth paved level surface.

2. Loosen the Adjustment Bolt using a 1/2" wrench. If the tractor is creeping forward, move the

Control Lever forward 1/4 to 1/2 inch. Move the Control Lever rearward 1/4 to 1/2 inch if the

tractor is creeping backwards. Tighten the Adjustment Bolt securely.

3. Start engine and test from both forward and reverse.

4. If tractor still creeps, repeat step # 2 until satisfied.

NOTE: If additional clearance is needed to get to adjustment bolt, move mower deck height to the

lowest position.

NEUTRAL ADJUSTMENT FOR GEAR DRIVE SHIFT LEVER

1. Place the tractor on a level surface.

2. With the engine off and the parking brake disengaged, push the tractor from behind while shifting

gears.When the tractor rear wheels move freely, the transaxle is in neutral. Leave in this position.

3. Loosen Adjustment Bolt in front of the right rear wheel,using a 1/2" wrench. Position the Lever

in the position indicated for Neutral.Tighten Adjustment Bolt securely.

NOTE: If additional clearance is needed to get to adjustment bolt, move mower deck height to the

lowest position.

30

www.mymowerparts.com

Loading...

Loading...