Husqvarna TE250R-310R 2012, TXC250R-310R 2012 Owner's manual

TE 250R - 310R 2013

TE 310R 2013 USA

TXC 250R - 310R 2013 USA

Manuale utente_Owner’s manual_Manuel d’utilisateur_Benutzerhandbuch_Manual del usuario

TE

TXC

TE 250R - 310R 2013

TE 310R 2013 USA

EN

EN

Ed. 06-2012 - Rev. 00

Unless specified, data and prescription are referred to all the models.

TXC 250R - 310R 2013 USA

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 1

TABLE OF CONTENTS

PRESENTATION

...................................................................... 3

IMPORTANT NOTICES

IDENTIFICATION DATA

CONTROL LOCATION (TE)........................................................6

CONTROL LOCATION (TXC)

TECHNICAL DATA

LUBRICATION TABLE, SUPPLIES

CONTROLS

........................................................................... 10

................................................................................ 28

RIDING

APPENDIX

............................................................................50

PRE-DELIVERY INSPECTION

ALPHABETICAL INDEX

............................................................. 3

............................................................ 5

......................................................7

...................................................................8

............................................... 9

................................................... 51

........................................................... 52

Page

PERIODIC MAINTENANCE -ADJUSTMENT .................. Appendix

•References to the “left” or “right” of the motorcycle are in

Note

the sense of a person facing forwards.

•Z: number of teeth

• A: Austria

AUS: Australia

B: Belgium

BR: Brazil

CDN: Canada

CH: Switzerland

D: Germany

E: Spain

F: France

A

FIN: Finland

GB: Great Britain

I: Italy

J: Japan

USA: United States of America

•Where not specified, all the data and the instructions are

referred to any and all Countries.

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 2

PRESENTATION

Welcome to the Husqvarna motorcycling Family!

Your new Husqvarna motorcycle is designed and manufactured to be the finest in its field.

The instructions in this book have been prepared to provide

a simple and understandable guide for your motorcycle’s

operation and care.

Follow the instructions carefully to obtain maximum performance and your personal motorcycling pleasure. Your

owner’s manual contains instructions for owner care and

maintenance.

The main work of repair or maintenance requires the attention of a skilled mechanic and the use of special tools

and equipment.

Your Husqvarna dealer has the facilities, experience and original parts necessary to properly render this valuable service.

This “Owner’s Manual” is part and parcel of the motorcycle, hence, this had to

remain with the motorcycle even when

sold to another user.

This motorcycle uses components designed thanks to systems and state of the art technologies which are thereafter

tested in competition.

In competition motorcycles, every detail is verified after each

race in order to always guarantee better performance. For

correct functioning of the vehicle, it is necessary to follow the

maintenance and control table found on Appendix A.

IMPORTANT NOTICES

1) The TXC models are guaranteed COMPETITION motorcycles exempt from functional

defects, the suggested maintenance table for

competition use is shown on Appendix A.

2) TE vehicles are STREET LEGAL motorcycles (with LIMITED POWER ENGINE); they are

guaranteed exempt from functional defects

and covered with legal guarantee, if the

STANDARD CONFIGURATION is maintained

and the suggested maintenance table, shown

on Appendix A is observed.

If TE vehicles are transformed in COMPETITION MOTORCYCLES (with FULL POWER ENGINE), the suggested maintenance table for

competition use is shown on Appendix A.

TXC

TE

MOTOCROSS

EN

ENDURO

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 3

IMPORTANT

The reference for recognition of the guarantee will be the MOTORCYCLE CONFIGURATION, as shown below:

A) STANDARD MOTORCYCLE, STREET LEGAL: with LIMITED

POWER ENGINE

B) COMPETITION MOTORCYCLE, RACING USE: with FULL POWER

ENGINE

This motorcycles was not designed for long

trips with the engine always at maximum

rpm as can occur whilst travelling on roads

or highways. Long trips at full throttle can

cause severe damage to the engine.

This motorcycles is setup for competition use

and therefore guarantees maximum performance with the rider alone. It is thereby

not recommended to use the vehicle on circuits or off-road with a passenger.

ALWAYS keep in mind that these motorcycles have been designed strictly for competition use, that is, for conditions of

usage very different from those presented on the road.

ALWAYS keep in mind that these motorcycles

have been designed strictly for competition

use, that is, for conditions of usage very different from those presented on the road.

In order to maintain the vehicle’s “Guarantee of Functionality”, the client must follow

the maintenance program indicated in the

user’s manual by carrying out maintenance

checks at authorized HUSQVARNA dealers.

The cost for substituting parts and for the

labour necessary in order to respect the

maintenance plan, is charged to the client.

NOTE: the guarantee is EXTINGUISHED in the

case where the motorcycle is rented.

Important Notice

Read this manual carefully and pay special attention to statements preceeded by the following words:

Warning*: Indicates a possibility of severe

personal injury or loss of life if instructions

are not followed.

Caution*: Indicates a possibility of personal

injury or equipment damage if instructions

are not followed.

Note*: Gives helpful information.

Parts Replacement

When parts replacement is required, use only Husqvarna ORIGINAL parts.

Warning*: After an upset, inspect the motorcycle carefully. Make sure that the throttle,

brake, clutch and all other systems are undamaged. Riding with a damaged motorcycle can lead to a serious crash.

Warning*: Never attempt to start or operate

your motorcycle unless you are wearing appropriate protective clothing. Always wear a

motorcycle helmet, motorcycle boots, gloves,

goggles and other appropriate protective

clothing.

Warning*: This motorcycle is a state of the

art competition bike. Do not attempt to start

or ride this motorcycle until you have received expert instruction and are in excellent

physical condition.

PRECAUTIONS FOR CHILDREN

WARNING

• Park the vehicle where it is unlikely to

be bumped into or damaged. Even slight or

involuntary bumps can cause the vehicle to

topple over, with subsequent risk of serious

harm to people or children.

• To prevent the vehicle from tipping over,

never park it on soft or uneven ground, nor

on asphalt strongly heated by the sun.

•Engine and exhaust pipes become very hot

during riding. Always park your motorcycle where people or children can not easily

reach these parts, in order to avoid serious

burns.

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 4

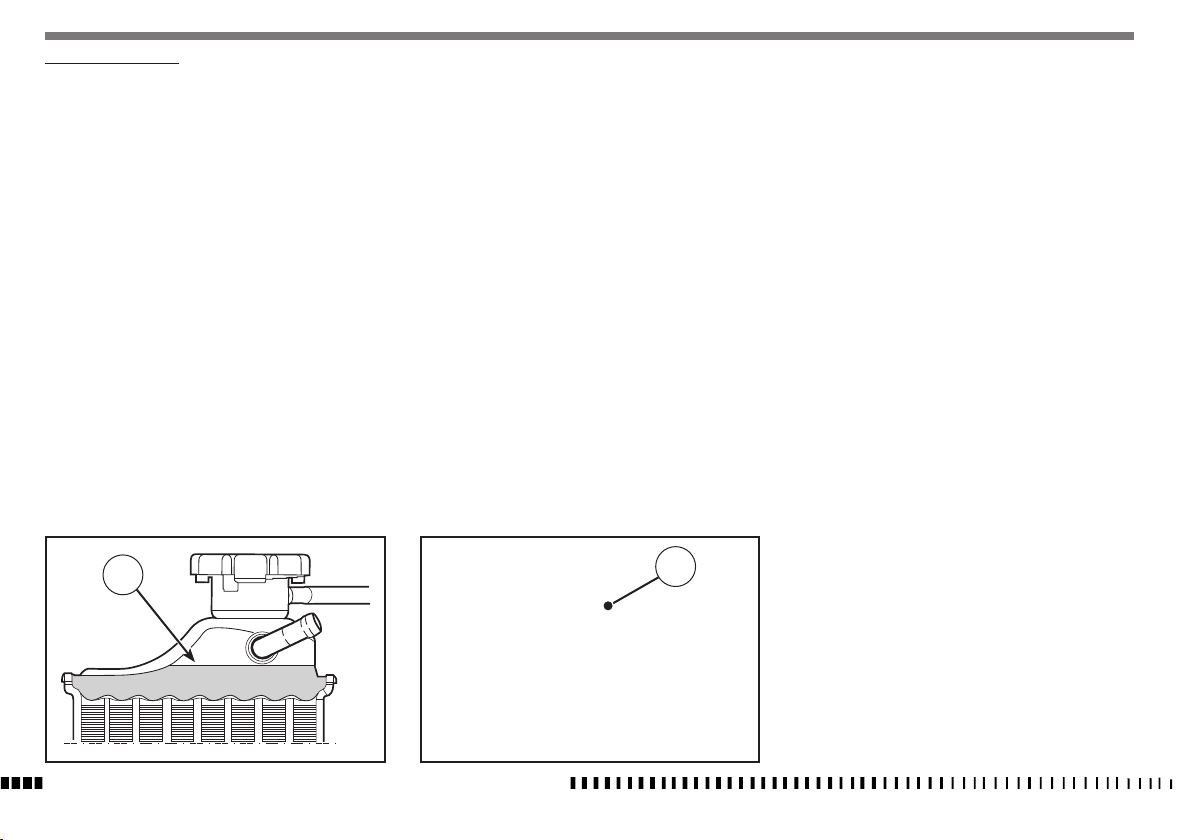

IDENTIFICATION DATA

The engine number is printed on the upper side of the engine

case, whereas the frame number is printed on the steering tube.

Always state the number stamped on the frame

(and write it on this booklet), when placing orders for spare

parts, or when asking for informations about your motorcicle.

TE 250

ZKHA300AADV000001

(l) (▲) (♦)

TXC 250 - USA

ZKHTX253#DV000001

EN

(l) (▲) (♦)

FRAME NUMBER

VEHICLE IDENTIFICATION NUMBER (V.I.N.)

The full 17 digit serial, or Vehicle Identification Number, is

stamped on the steering head tube (R.H. side).

(l) = Model designation

(▲) = Model Year (2013)

(♦) = Progressive no.

1. Frame serial number

2. Engine serial number

1

TE 310

ZKHA301AADV000001

TE 310 USA

ZKHKCEDG#DV000001

2

(l) (▲) (♦)

(l) (▲) (♦)

SPECIFICATIONS - OPERATION - MAINTENANCE

TXC 310 - USA

ZKHTX313#DV000001

(l) (▲) (♦)

EN - 5

11

12

13

14

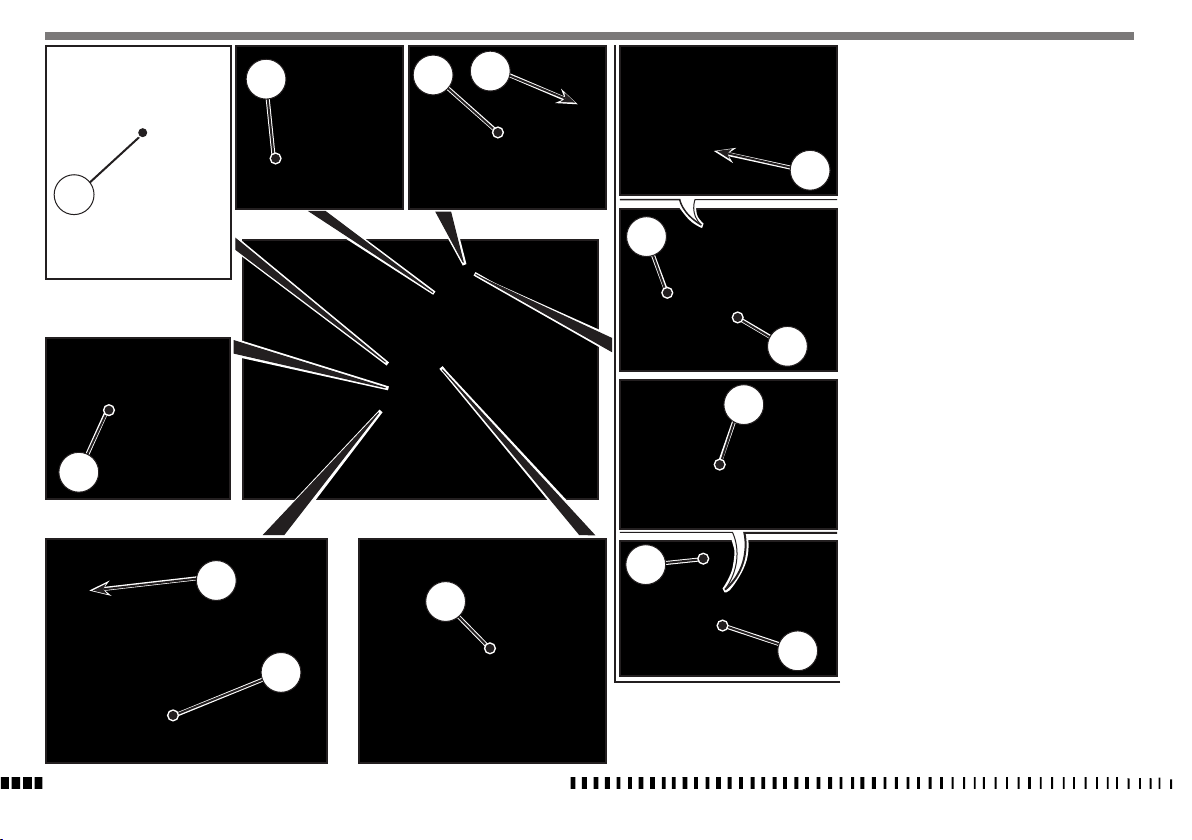

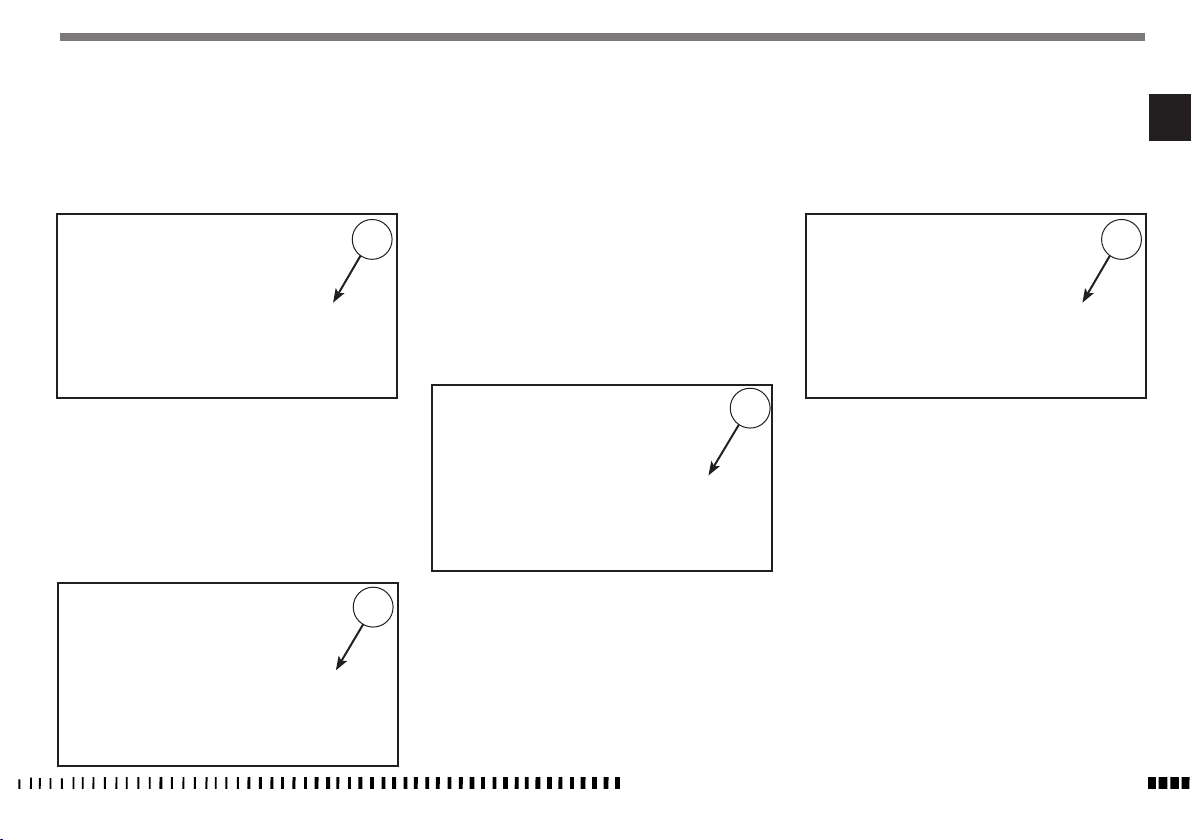

CONTROLS LOCATION (TE)

1. Front brake lever

2. Throttle twistgrip

3. Engine stop button

4. Engine start button

5. L.H. switch

6. Clutch control lever

4

7. Starting device

8. Gear shift pedal

2

1

9. Rear brake control pedal

10. Master cylinder

11. Kick start pedal

12. Fuel tank ller cap

13. Dashboard

14. FI Lamp - Operating failures

8

10

9

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 6

3

KEYS

Two keys are supplied with the motorcycle (one

of them is a spare key) to be used on steering

lock.

6

7

5

CONTROLS LOCATION (TXC)

1. Front brake lever

2. Throttle twistgrip

3. ENIGINE STOP button (engine stop)

4. Engine start button

5. Clutch control lever

6. Starting device (for cold start)

7. Fuel tank ller cap

8. Control panel

9. Gear shift pedal

10. Rear brake control pedal

11. Master cylinder

12. Kick start pedal

7

8

2

EN

1

12

3

4

11

6

10

9

SPECIFICATIONS - OPERATION - MAINTENANCE

5

EN - 7

TECHNICAL DATA

ENGINE

Type............................................single cylinder, 4 stroke

........................liquid, with electric fan on models

Cooling

TE-TXC 250

Bore ...............................................................3,11 in. (79 mm)

Stroke .....................................................2.00 in. (50,9 mm)

Displacement

Compression ratio

TE-TXC 310

................................15,22 cu. in. (249,5 cm

................................................. 13,6:1

3

Bore ............................................................ 3,23 in. (82 mm)

.......................................................2,26 in. (57,3 mm)

Stroke

Displacement

.............................. 18,46 cu. in. (302,44 cm

Compression ratio

.....................................................13:1

3

Starting................................................................ electric

TIMING SYSTEM

Type...............

4 titanium valves, controlled by twin finger

follower type camshafts, mixed chain/gear drive system

Valve clearance (with engine cold)

.............................................0,006 in. (0,15 mm)

Intake

...........................................0,008 in. (0,20 mm)

Exhaust

LUBRICATION

Type...wet crankcase, lobe pump and cartridge and mesh

filters

IGNITION

Type ...........Electronic, inductive discharge, with

adjustable advance (digital control)

Spark plug type

Spark plug gap

.........................................NGK CR9EIA-9

............... 0.031÷0,035 in. (0,8÷0,9 mm)

FUEL SYSTEM

Type......................................................Electronic injection feed

PRIMARY DRIVE

Drive pinion gear- Clutch ring gear

Transmission ratio

CLUTCH

)

Type...........oil bath multiple disc clutch, hydraulic control

............................................................ 3,176

............................Z 17- Z 54

TRANSMISSION

Type...........................................constant mesh gear type

Transmission ratio

)

............................................... 1,750 (z 28/16)

2nd gear

..............................................1,450 (z 29/26)

3rd gear

...............................................1,227 (z 27/22)

4th gear.

..............................................1,041 (z 25/24)

5 th gear.

...............................................0,884 (z 22/27)

6 th gear

............................................... 2,142 (z 30/14)

1st gear.

SECONDARY DRIVE

Transmission sprocket- Rear wheel sprocket

(TXC)

.........................................................................Z 13- Z 50

(TE)

...........................................................................Z 13- Z 40

Transmission ratio

(TXC)

...............................................................................3,846

(TE).

................................................................................ 3,076

FINAL RATIOS (TE)

1st gear

.....................................20,926

2nd gear

....................................17,096

3rd gear

....................................14,165

4th gear

.....................................11,987

5th gear

.....................................10,169

6th gear

......................................8,636

FINAL RATIOS (TXC)

1st gear

.....................................26,164

2nd gear

....................................21,376

3rd gear

....................................17,251

4th gear

.....................................14,987

5th gear

.....................................12,715

6th gear

.....................................10,797

FRAME

Type...............Steel single tube cradle (roud, rectangular,

ellipsoidal tubes); light alloy rear frame

FRONT SUSPENSION

Type ......”Upside-down” telescopic hydraulic front fork with

advanced axle (adjustable in compression and rebound stroke);

stanchions tubes Ø 1.89 in. (Ø 48 mm)

Legs axis stroke ................................. 11.8 in. (300 mm)

REAR SUSPENSION

Type......progressive with hydraulic single shock absorber

Wheel stroke

..................................... 11.6 in. (296 mm)

FRONT BRAKE

Type ... fixed disc Ø 10.23 in. (Ø 260 mm) “Wave” type with

hydraulic control and floating caliper

REAR BRAKE

Type.... floating disc,

Ø 9.45 in. (Ø 240 mm) “Wave” type

with hydraulic control and floating caliper

RIMS

Front

.......................................................in light alloy: 1,6x21”

Rear......................................................in light alloy: 2,15x18”

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 8

TIRES

Front . . . .

Rear (TE - TXC). . .

Rear (TE USA). . .

..............................90/90x21”

.......................120/90x18”

........................140/90x18”

Cold tire pressure

...........................0,9÷1,0 Kg/cm

front (*)

front (%) ................................1,1 Kg/cm

rear (*) ............................0,8÷0,9 Kg/cm

rear (%) ................................1,0 Kg/cm

(*) In case of racing use - (%) Road use

DIMENSION, WEIGHT, CAPACITY

Wheelbase ...................... 57.87 in. (1470 mm)

Overall length

...........................88.98 in. (2260 mm)

(TE)

..........................85.67 in. (2176 mm)

(TXC)

Overall width

2

2

Overall height

2

Saddle height

2

Minimum ground clearance

Kerb weight, without fuel

(TE )

250,22 lb. (113,5 kg) (310)

(TXC) .....................239,42 lb. (108,6 kg) (250)

240,52 lb. (109,1 kg) (310)

Fuel tank capacity .......................Imp. Gall. 1.87

U.S. Gall. 2.25

8,5 l

(Qt. reserve included 2.02 Imp. Qt./2.43 U.S. Qt. - 2,3 l)

Coolant capacity ......................0.79 Imp. Quarts

0.95 U.S. Quarts

900 cc

Transmission oil

Oil and oil filter replacement

U.S. Quarts 0.95

900 cc

Oil replacement .......................Imp. Quarts 0.75

U.S. Quarts 0.90

850 cc

.....................32.30 in. (820 mm)

...................50.79 in. (1290 mm)

...................... 37.4 in. (950 mm)

..........11.42 in. (290 mm)

....................... 249,12 lb. (113 kg) (250)

............Imp. Quarts 0.79,

TABLE FOR LUBRICATION, SUPPLIES

Engine, gearbox and primary drive lubricating oil

CASTROL POWER 1 RACING 10W-50

Engine coolant

CASTROL MOTORCYCLE COOLANT

Brake system fluid

CASTROL RESPONSE SUPER DOT 4

Clutch fluid

CASTROL RESPONSE SUPER DOT 4

Grease lubrication

CASTROL PASTE TA GREASE

Final drive chain lubrication

CASTROL CHAIN LUBE RACING

Front fork oil

Kayaba KHL15-11

Oil for rear shock absorber

CASTROL SYNTHETIC FORK OIL 5W

Electric contact protection

CASTROL METAL PARTS CLEANER

CASTROL MOTORCYCLE DWF

Fillers for radiator

AREXONS TURAFALLE LIQUIDO

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 9

CONTROLS

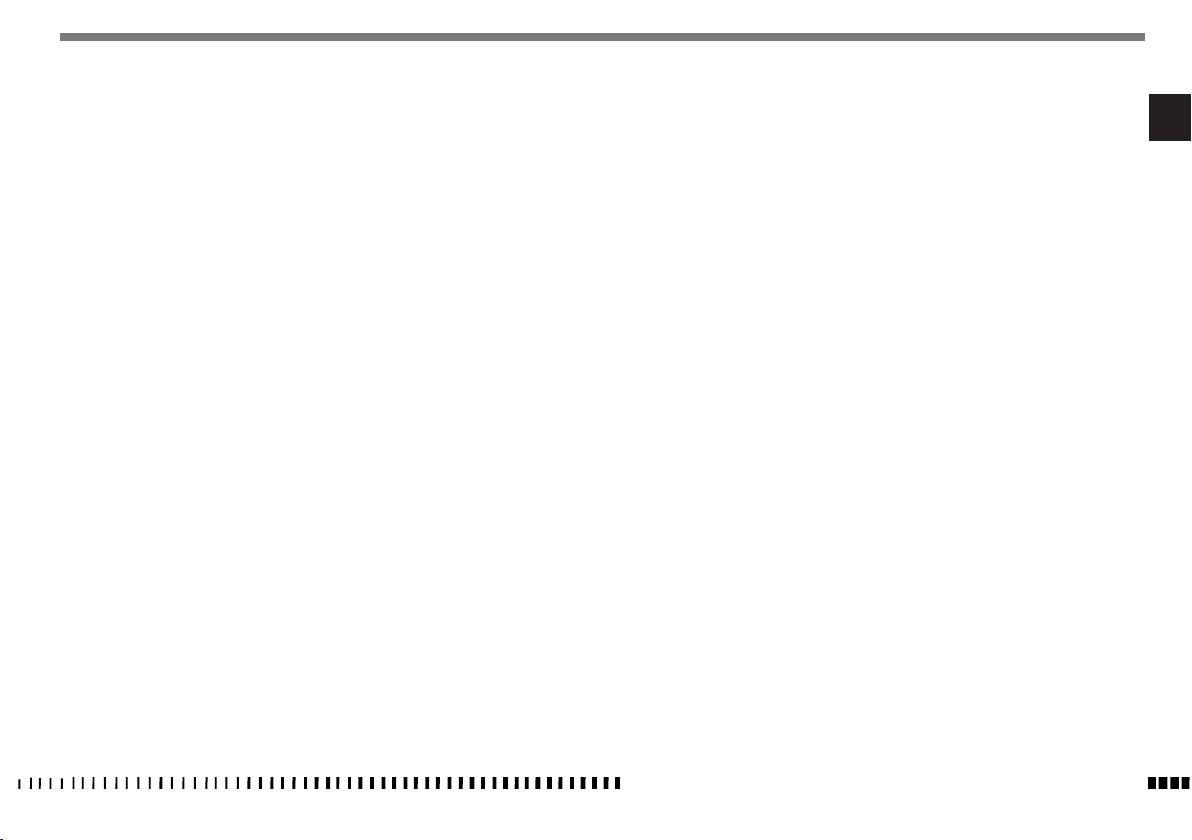

FUEL COCK

There is an ON-OFF fuel cock (1) on the right side of the

tank; make sure it is always on “ON” position.

There is a screw-type fuel cock (2) on the right side of the

tank; make sure it is always in its max. opening position.

On these models, the cocks operate only as by-passes;

ON-OFF cock has a fuel level sensor which sends the reserve indication to a light on the instrument panel (TE) or

on the control panel (TXC).

WARNING*: Be careful not to touch the hot

engine while operating the fuel valve.

SIDE STAND

These models have a side stand (1) on the left side of the motorcycle.

WARNING*: The stand is designed to support the weight of the MOTORCYCLE ONLY. Do

not sit on the motorcycle using the stand for

support as this could cause structural failure

to the stand and could cause serious bodily

injury.

WARNING*: The motorcycle MUST be set on

the side stand ONLY AFTER the rider has got

off the vehicle. Stand AUTOMATICALLY folds

back to rest position once the vehicle is vertical, no longer resting on the ground.

Periodically check the side stand (see “Periodical maintenance

card”); check that the springs are not damaged and that the

side stand freely moves. If the side stand is noisy, lubricate the

fastening pivot (A).

1

1

2

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 10

A

FUEL

Recommended fuel: premium grade unleaded fuel. (R.O.N. 96

÷ 98).

WARNING*: Gasoline is extremely flammable and can be explosive under certain conditions. Always stop the engine and do not

smoke or allow flames or sparks in the area

where the motorcycle is refueled or gasoline

is stored.

WARNING*: Do not overfill the tank. After refueling, make sure the tank cap (2) is closed

securely.

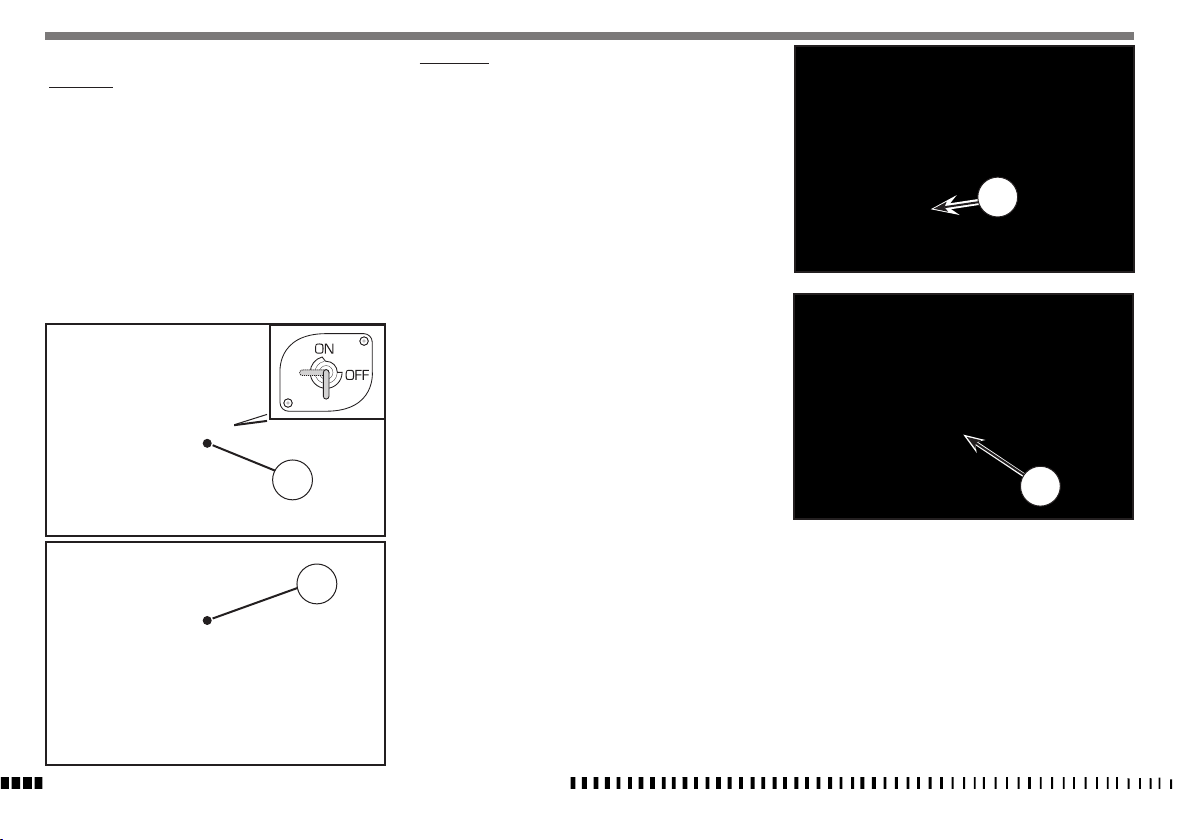

COLD START

The motorcycle is equipped with a knob (1) positioned on throttle body for cold start. Pull the knob towards the outside to activate the starter, and on the opposite direction to deactivate it.

1

EN

2

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 11

DIGITAL INSTRUMENT, WARNING LIGHTS (TE)

- The instrument functions are the following, as shown below.

1- SPEED (Km/h or mph) / ODO

The motorcycle is equipped with a digital instrument; on

the instrument are located 3 warning lights too: high beam,

blinkers and fuel reserve.

1- BLUE warning light “HIGH BEAM”

2- GREEN warning light “BLINKERS”

3- ORANGE warning light “Fuel reserve”

The dashboard is activated only after the engine has been

started.

NOTES

- Every time the engine is started, the dashboard shows the SW

version for the first 2 seconds; after the check routine, the

dashboard shows the last planned function.

- A few seconds after the engine has been turned off, the dashboard is deactivated.

- To select the instrument functions and to set to zero the

functions, use the SCROLL knob (A).

2

1

3

1- SPEED / ODO

2- SPEED / CLOCK

3- SPEED / TRIP

4- SPEED / CHRONO

5- SPEED /

HOUR COUNTER (H)

1- SPEED / ODO

.................

- SPEED: motorcycle speed- maximum value: 299 Km/h or 299

mph;

- ODO: odometer- maximum value: 99999 km;

To go from Km to Miles or from Miles to Km, visit the nearest

Husqvarna dealer.

A

A

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 12

2- SPEED / CLOCK

- SPEED:

motorcycle speedmaximum value

mph;

- CLOCK:

clock- Reading from 0:00 to 23:59:59;

To reset the clock, push the knob SCROLL (A) for more than 3

seconds in order to increase the hours; release the knob and

then, after 3 seconds, it is possible to increase the minutes;

: 299 Km/h o 299

A

3- SPEED / TRIP

- SPEED:

motorcycle speedmaximum value

- TRP:

distance- maximum value: 999.9 km (the data will be lost

after battery detachment).

To reset TRIP, push the SCROLL button (A) and hold for more

than 3 seconds.

: 299 Km/h o 299 mph

A

4- SPEED / CHRONO

- SPEED:

motorcycle speedmaximum value

mph;

-

LPT: miles/kilometers covered time;

-

Reading from 0:00 to 99:59:59 (the data will be lost after

battery detachment).

To activate the function LPT, push the knob SCROLL (A) for more

than 3 seconds.

- 1st step: function ON;

- 2nd step: stop to the counters;

- 3rd step: LPT reset;

- 4th step: function ON;

- 5th step: stop to the counters;

.............................

and so following

(LPT)

: 299 Km/h o 299

A

5- SPEED /

- SPEED:

mph;

- H: it indicates engine operating hours and minutes.

- Data will be lost after disconnecting the battery.

- To activate the function hour counter (H), push the SCROLL

button (A) and hold for more than 3 seconds.

HOUR COUNTER (H)

motorcycle speedmaximum value

: 299 Km/h o 299

A

EN

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 13

FI LAMP - OPERATING FAILURES (TE)

FI Lamp (1) is located on the side of the digital dashboard.

WARNING LIGHTS PANEL (TXC)

The motorcycle is tted with a small warning lights panel

with two warning lights:

1 - Red “FI LAMP” warning light (operating failures)

2 - Yellow warning light “FUEL RESERVE”

NOTE: FI LAMP - OPERATING FAILURES (TE - TXC)

IN THE EVENT OF ENGINE AND/OR INJECTION

SYSTEM MALFUNCTION, THE WARNING LIGHT

WILL START BLINKING, THUS COMMUNICATING

A FAILURE.

IF THE WARNING LIGHT TURNS ON, PAY ATTENTION NOT TO RUN THE ENGINE AT FULL THROTTLE AND CONTACT THE NEAREST HUSQVARNA

DEALER.

1

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 14

TE

TXC

1

2

THROTTLE CONTROL

The throttle knob (1), is located on the right hand side of the

handlebar. The position of the throttle control can be adjusted

by loosening the two fastenig screws (A).

CAUTION

Do not forget to tighten the screws (A) after

the adjustment.

FRONT BRAKE CONTROL

The brake control lever (2) is located on the right hand side of

the handlebar. The position of the throttle control can be adjusted by loosening the two fastenig screws (B).

CLUTCH CONTROL

The hydraulic clutch control lever (3) is located on the left-hand

side of the handlebar and is protected against dirt with a rubber guard.

The position of the clutch control on handlebar can be adjusted

by loosening the retaining screws (C).

CAUTION

Do not forget to tighten the screws after the

adjustment.

C

STEERING LOCK (TE)

The motorcycle is equipped with a steering lock (1) on the R.H.

side of the steering head tube.

To lock it, procede as follows:

turn the handlebar leftwards, place the key in lock and turn

counterclockwise. Push the key inwards (if necessary, turn to

and from). Turn the key clockwise and remove it from the lock.

To unlock the steering lock, reverse the above procedure.

EN

CAUTION

Do not forget to tighten the screws (B) after

the adjustment.

B

A

B

1

2

TXC

TXC

3

3

TE

1

C

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 15

ENGINE START BUTTON

The engine start button (1) is located on the handlebar righthand side.

A

B

1

L.H. HANDLEBAR COMMUTATOR (TE)

Controls:

- Headlamp (A)

1) Selection control High beam

Selection control Low beam

- Turn signals (B), (C)

2) Left turn signals (automatic return)

Right turn signals (automatic return)

To deactivate the turn signals, press the control lever after its

returning to center.

3)

Warning horn

4) Engine stop button.

EN - 16

.

SPECIFICATIONS - OPERATION - MAINTENANCE

4

3

1

C

2

REAR BRAKE CONTROL

The rear brake control (1) is placed on the right-hand side of

the motorcycle.

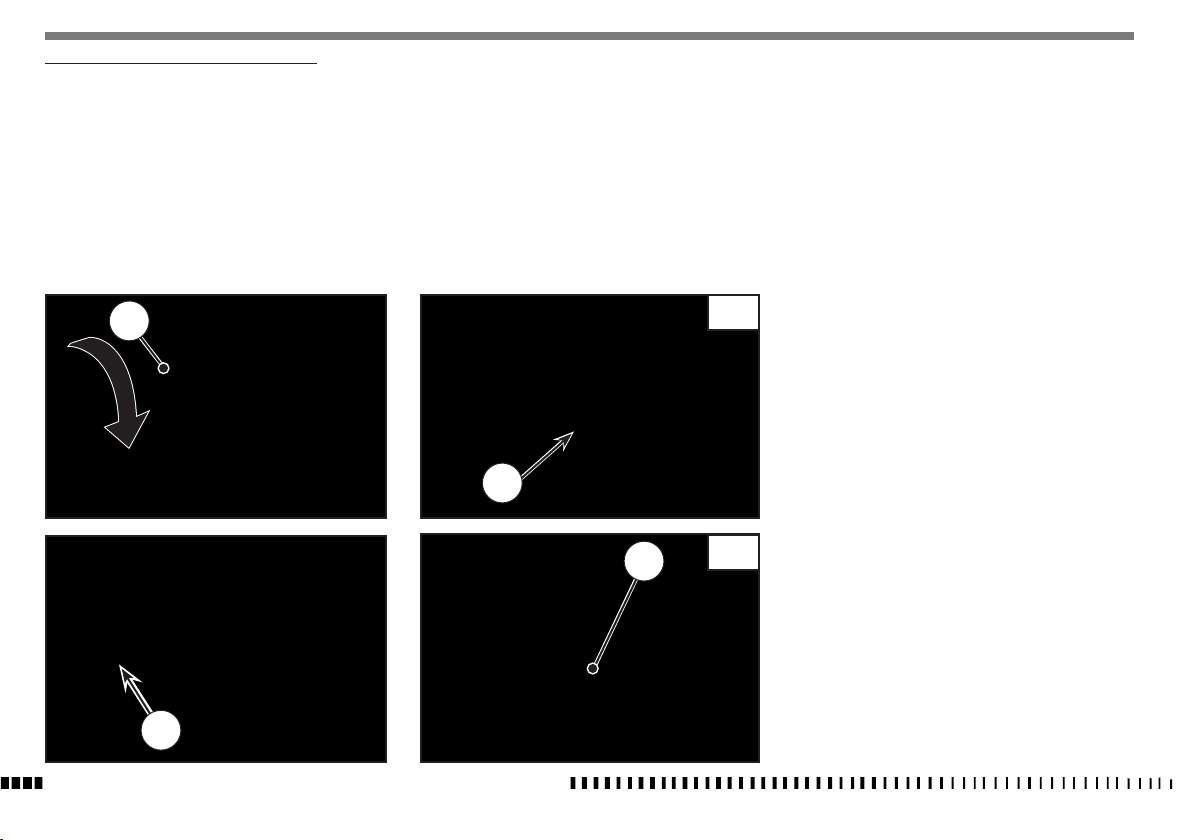

GEAR SHIFT CONTROL

The lever (1) is placed on the left-hand side of the engine. The

operator must release the lever after each gear change to allow

it to return to its central position before another gear

change can be made.

Neutral position (N) is between first (low) and second gears.

First gear is engaged by pushing the lever downwards; all the

other gears are engaged, by pushing the lever upwards.

The position of the gear shift lever on the shaft can be varied by:

- loosening screw;

- pulling lever out;

- placing lever in new position on the shaft when the operation

is over tighten the screw and then tightening the screw.

CAUTION*: Do not shift gears without disengaging the clutch and closing the throttle. The

engine could be damaged by overspeed and

shock.

N: Neutral

6

5

4

3

2

WARNING*: Do not downshift when traveling

at a speed that would force the engine to

overrev in the next lower gear, or cause the

rear wheel to lose traction.

EN

N

1

1

1

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 17

RIDING

BEFORE EVERY RIDE MAKE FOLLOWING CHECKS

WARNING!

Before each ride, to prevent accidents or failures during ride,

make sure to go through following list.

1. Check all fluids

A. Engine-transmission oil level

B. fuel level

C. coolant level

Make sure all caps are properly adjusted.

WARNING*: Don’t remove radiator cap when

hot!

Check all controls

2.

A. Throttle handgrip

B. Clutch lever

Make sure cables are not damaged and turn smoothly.

3. Check brakes

Look for brake fluid leaks and worn hoses. Check for proper

functioning.

Check suspensions

4.

Compress fork and rear suspensions. Look for oil leaks and

ensure proper functioning.

Check wheels

5.

Check spokes and look for worn bearings.

Check rims and tyres.

Check tyre pressure.

6. Check chain rollers and sprockets

Check wear on chain rollers and sprockets

Ensure chain is correctly adjusted and lubricated.

7. Check air filter and intake system

Check that air filter is clean

Check all rubber connections and clamps.

8. Check exhaust system

Check hook up, look for cracks

Check muffler.

9. Check torque

A. Spark plug

B. General check of torque

10. Check steering action

Check bearing play.

11. Check the electric system (TE).

Start the engine and check that the front and rear lamps, the

stop light, the turn signals the cluster warning lights and the

horn are working correctly.

WARNING*: Failure to perform these checks

every day before you ride may result in serous damage or a severe accident.

.

RUNNING IN

Before using the motorcycle for sporting activities run in the

engine for two hours at least to increase the life and the performance of the engine.

During the first half-hour of driving we advise keeping a low

speed and avoiding sudden accelerations. Never open the throttle fully.

Change the oil and carry out all the necessary maintenance operations. After the first half-hour of driving, lightly increase the

rev number, but never run the engine at full throttle. Never keep

low speeds when the high gears are inserted.

Slowly drive the motorcycle for two hours before using it for

sporting activities.

CHECKS DURING RUNNING

- SPOKE TENSION OF WHEELS;

- TIGHTENING OF WHEELS;

- FORK PIN TIGHTENING;

- CHAIN ADJUSTMENT;

- STEERING BEARING PLAY;

- HANDLEBAR TIGHTENING;

- ENGINE GRIP TO FRAME;

- SUCTION FITTING GRIP;

- HEAD AND CYLINDER NUTS GRIP;

OFTEN CHECK THE BATTERY CHARGE CONDITION

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 18

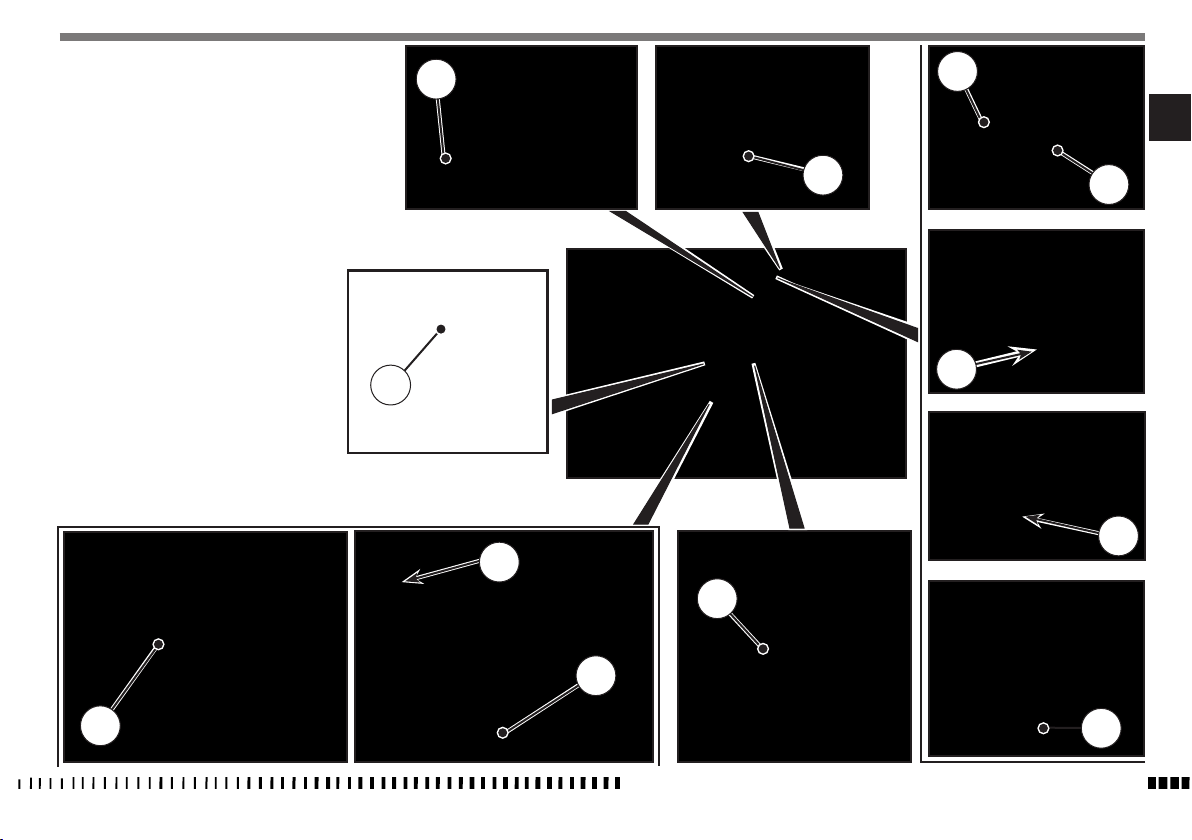

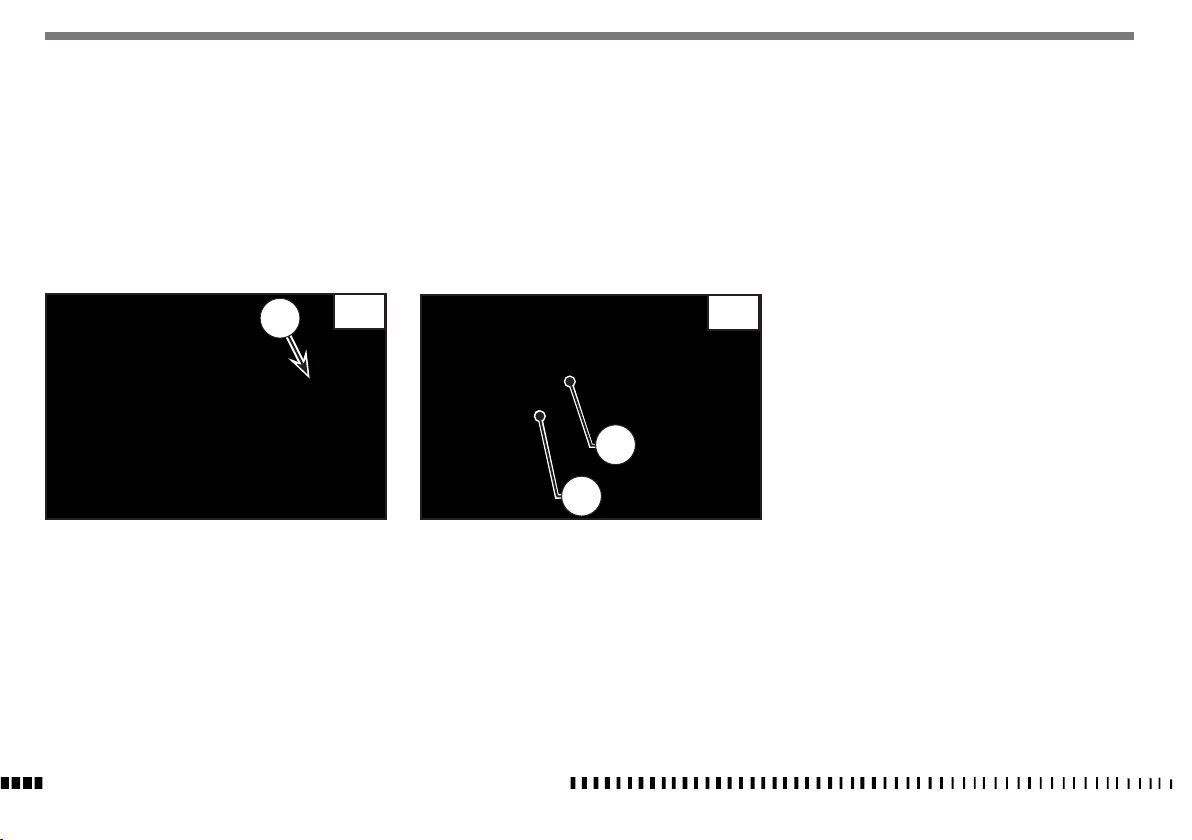

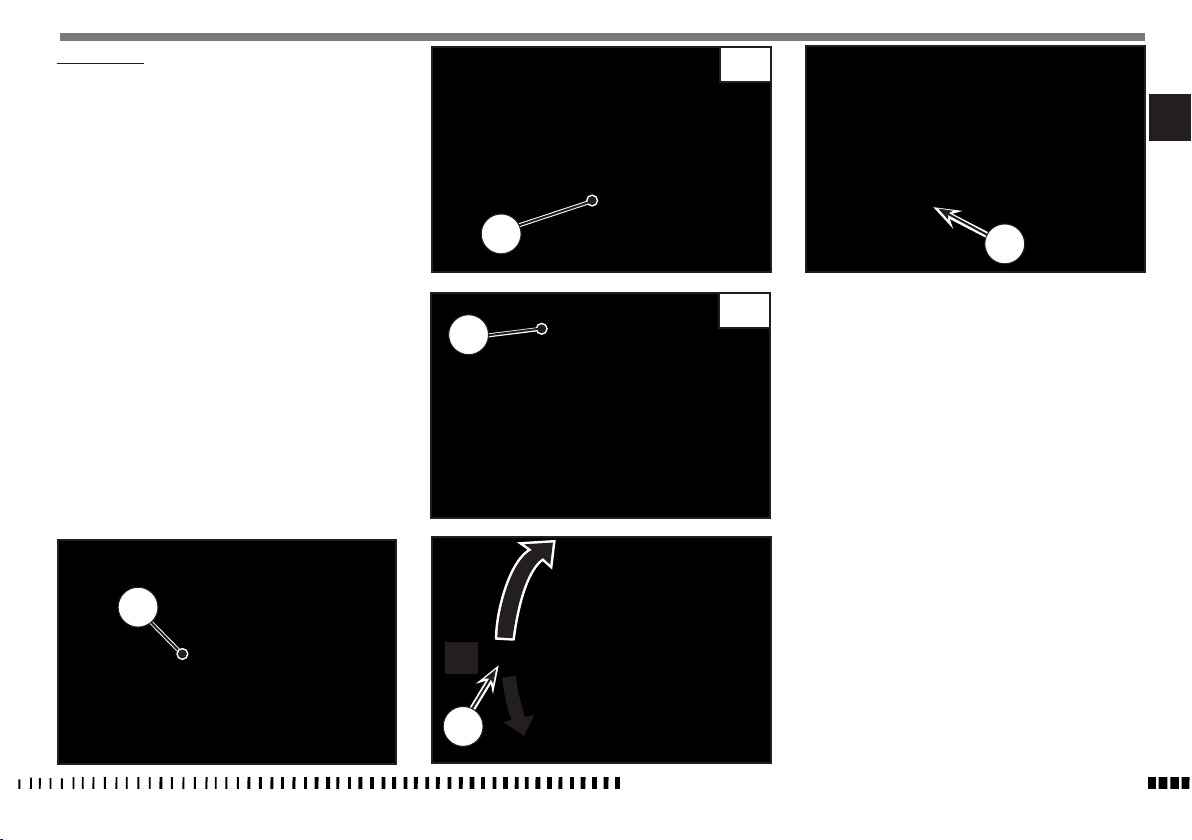

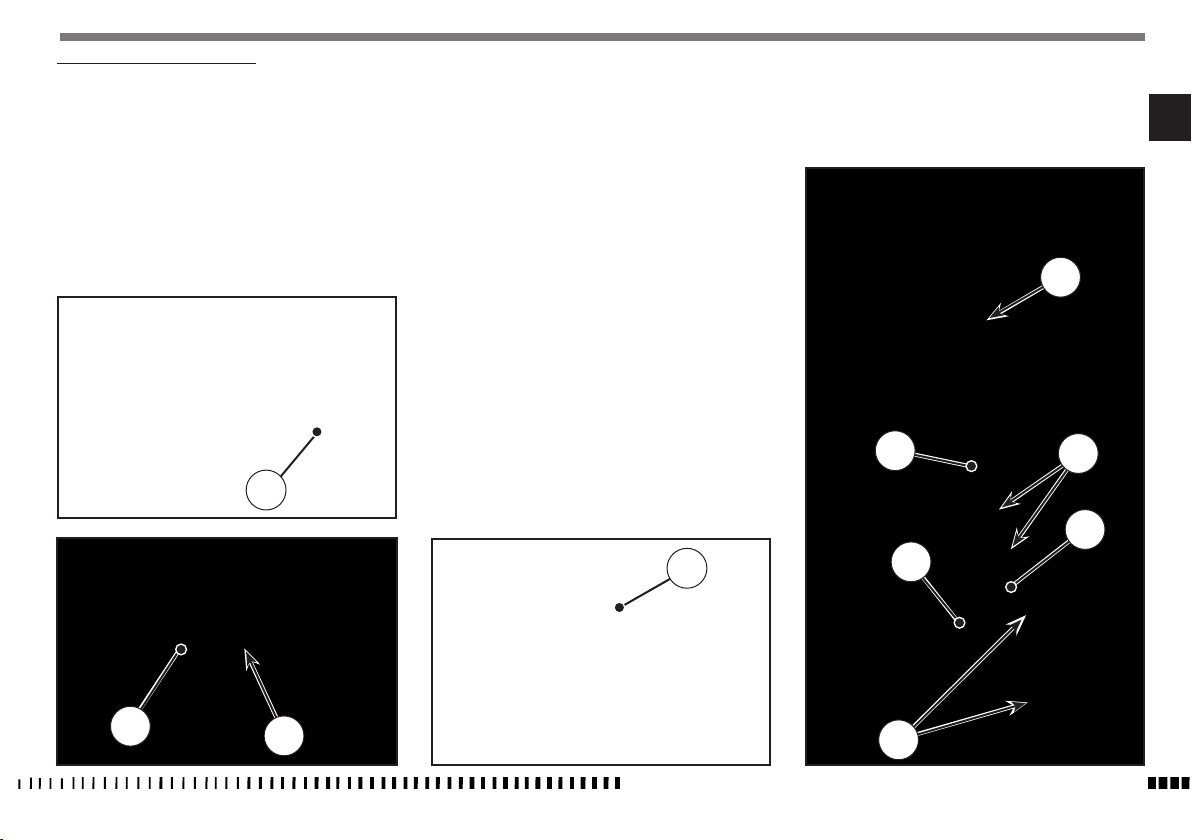

ENGINE START

With cold engine, as after a prolonged inactivity of the

motorcycle or in presence of a low external temperature,

proceed as follows:

1) pull knob (1) towards the outside;

2) pull clutch lever (2) and hold it in place;

3) shift gear pedal (3) to neutral position;

4) press start button (4);

5) release the clutch lever (2);

6) take starter knob (1) back to its initial position as soon as

engine stays idle.

When a cold engine has just been started, do not increase

revs, to ensure an adequate oil warm-up and circulation.

IMPORTANT

NEVER START WITH DISCONNECTED BATTERY.

IMPORTANT

DO NOT OPERATE THE THROTTLE CONTROL WHILE

STARTING-UP.

TXC

EN

2

4

TE

2

IMPORTANT NOTE IN CASE OF COLD STARTS AT

LOW TEMPERATURES

It is recommended to briefly warm-up the engine at idle until,

after having disengaged the starter, there is a normal response

from the engine when opening the throttle.

In this way the oil can reach all the surfaces needing lubrication

and the coolant will reach the necessary temperature for correct

engine function.Avoid overheating the engine.

6

5

1

4

3

2

N

1

Never accelerate the engine after a cold start.

WARNING*: Exhaust contains poisonous carbon monoxide gas. Never run the engine in a

closed garage or in a confined area.

IMPORTANT

3

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 19

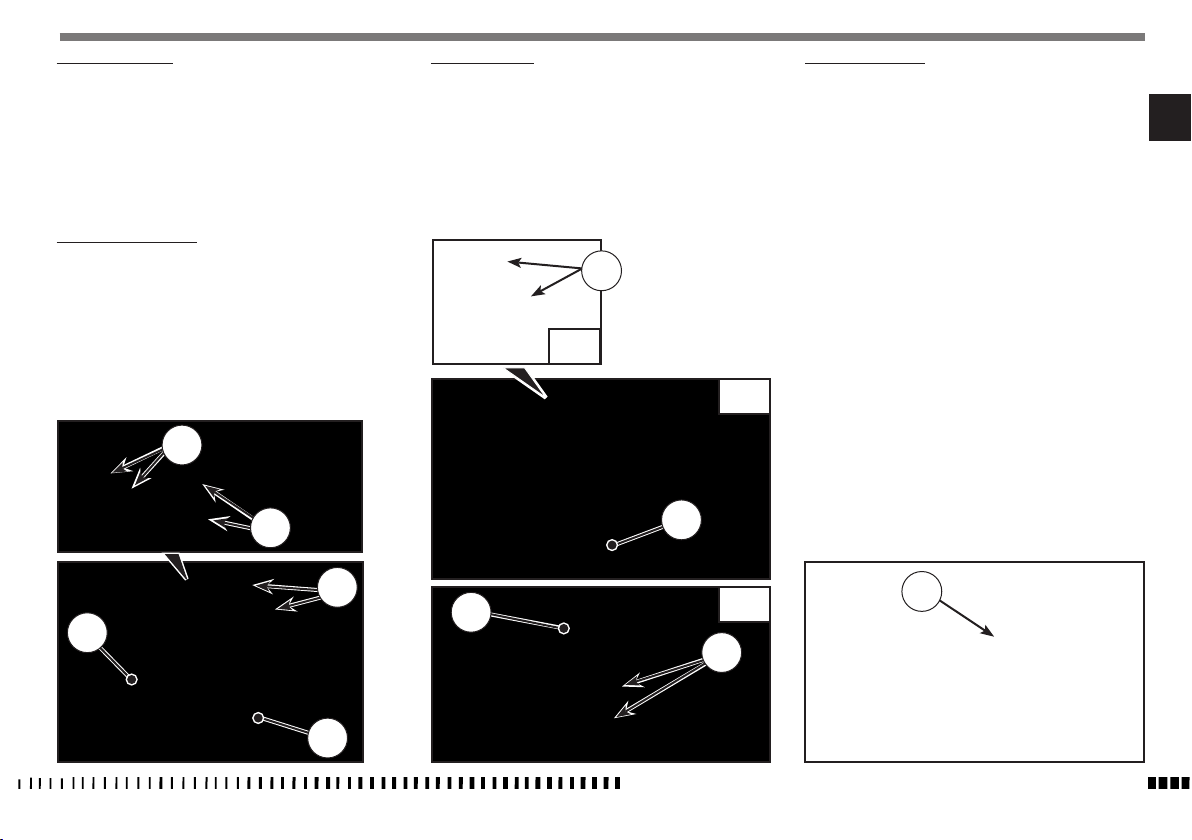

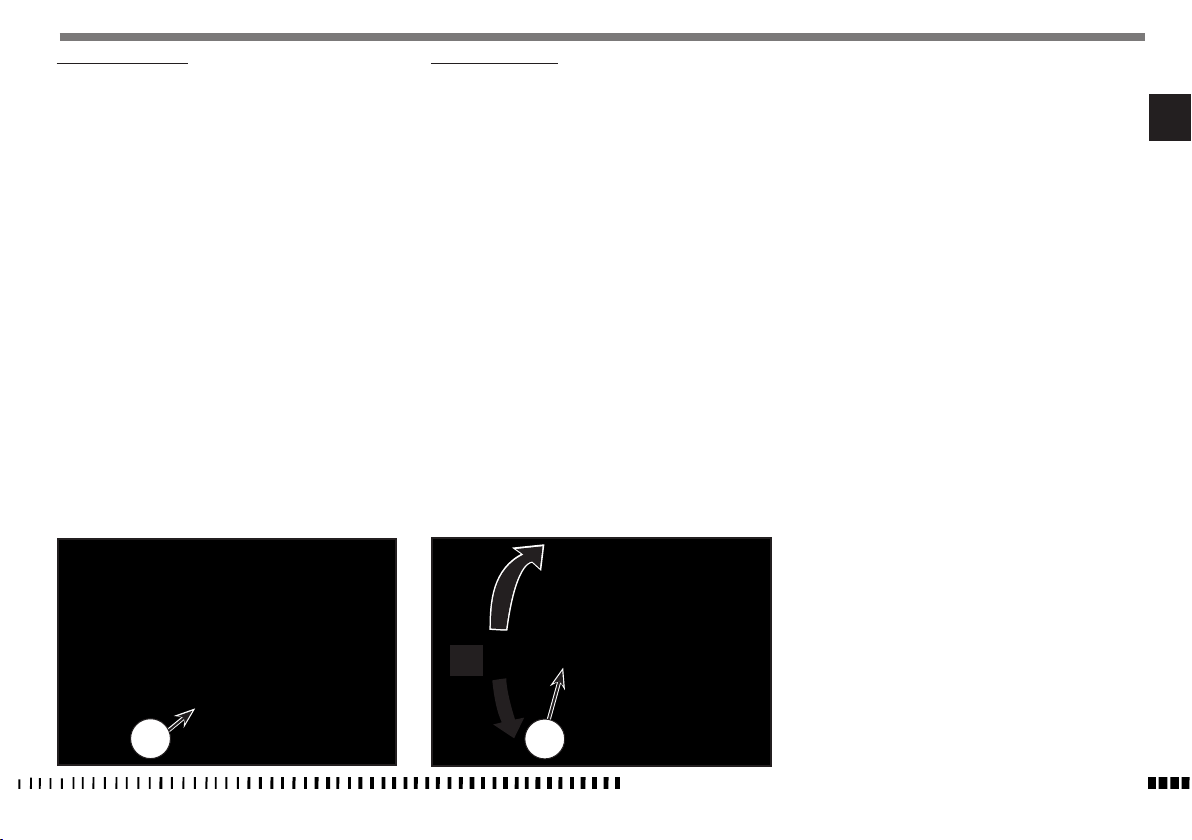

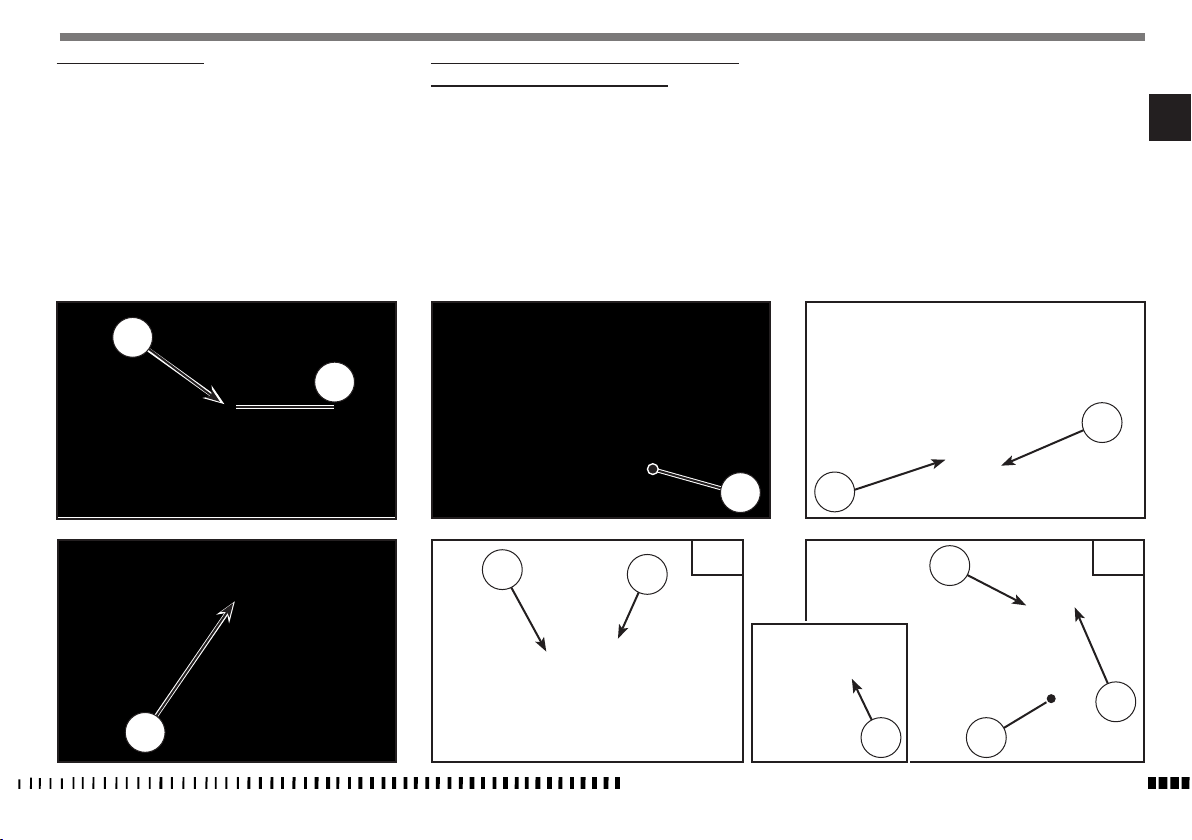

STOPPING THE MOTORCYCLE AND THE ENGINE

- Close the throttle (1) completely so that the engine will help slow

down the motorcycle.

- For normal braking, gradually apply both front and rear brakes

while down shifting (for maximum deceleration, apply the front

and rear brakes firmly).

- Before the motorcycle stops, pull the clutch lever and shift gear

lever (2) into neutral position.

1

- Press the engine stop button (3).

3

TXC

WARNING*: Independent use of the front or

rear brake may be advantageous under certain conditions. Use caution when using the

front brake, especially on slippery surfaces.

Improper use of the brakes can lead to a serious crash.

WARNING*:

or other malfunction that causes the engine to run uncontrollably, pull the clutch

lever IMMEDIATELY and press the engine

stop switch.

mal use of the brakes and steering while

holding the engine stop button down.

In the event of a stuck throttle

Control the motorcycle by nor-

2

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 20

3

TE

CHECKING THE OIL LEVEL

Keeping the motorbike level and in a vertical position, check the

oil level through the inspection (1) window on the right crankcase.

Make sure the level is in between the MIN and MAX notches.

To fill up, remove the filler cap (2).

Note*: Have this operation made with

warmed-up engine.

WARNING*: Be careful not to touch hot engine oil.

1

a

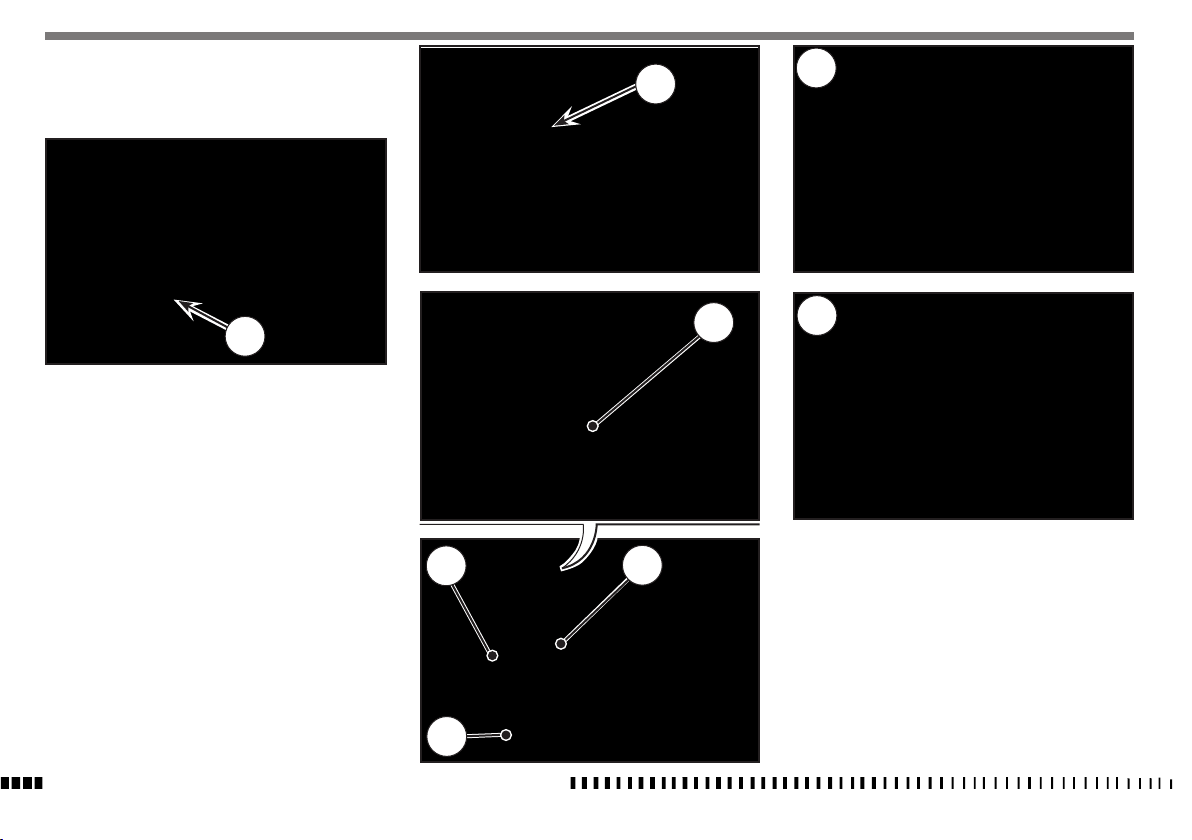

ENGINE OIL REPLACEMENT AND BAG FILTERS-FILTER

CARTRIDGE CLEANING OR REPLACEMENT

WARNING*: Be careful not to touch hot engine oil.

Drain the oil with WARM ENGINE; proceed as follows:

• remove oil filler cap (2);

• remove the engine lower guard (A);

• place an oil drain pan under the engine block;

TE - TXC 250

• Remove the oil drain cap (3), the mesh filter (4) and drain

the old oil;

TE - TXC 310

• loosen tie (3a) without disconnecting tube (3b);

• unscrew hose tail (3c), remove mesh filter (4) and drain the

used oil.

• Clean the mesh filter with benzine;

• in order to replace the filter cartridge (5), unscrew the three

fastening screws then the filter cartridge cover (6).

Once the oil filters have been cleaned-replaced, fit the parts

back in, in the opposite sequence to the disassembly, and pour

in the prescribed amount of oil, as listed in the LUBRICATION

TABLE.

5

EN

A

3

4

250

6

3c

310

3a

2

4

SPECIFICATIONS - OPERATION - MAINTENANCE

3b

EN - 21

COOLANT LEVEL CHECK

Check level (1) in right-hand radiator when engine is cold (place

the motorcycle so that it is perpendicular to the ground). The

coolant should be approximately 10 mm above cells and besides.

The radiator cap (A) is provided of two unlocking positions, the

first being for the previous pressure discharge in the cooling

system.

WARNING

Avoid removing radiator cap when engine

is hot, as coolant may spout out and cause

scalding.

NOTE

Difficulties may arise in eliminating coolant

from varnished surfaces. If this occurs, wash

off with water.

1

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 22

A

REPLACEMENT OF COOLING FLUID

Place a vessel on the L.H. side of the cylinder, under the Piping (1).

Remove the exhaust pipe (a). Loosen the pipe strap (2) of the piping (1), take the pipe off the fitting that secures it to the engine, then

SLOWLY open the R.H. radiator cap (3); slope the motorcycle on the left

side to drain the coolant easily in the vessel.

When finished, refit the hose (1), secure it with the clamp (2)

and refit the drain hose.

Pour the necessary quantity of coolant in the radiator then warm

up the engine in order to eliminate any possible air bubbles.

Periodically check the connecting hoses (see “Periodical maintenance card”): this will avoid coolant leakages and consequent

engine seizure: If hoses (A) show cracks, swelling or hardenings

due to sheats desiccation, their replacement shall be advisable.

Check the correct tightening of the clamps (B).

A: Piping

B: Clamps

EN

B

A

B

a

A

3

1

2

SPECIFICATIONS - OPERATION - MAINTENANCE

A

B

EN - 23

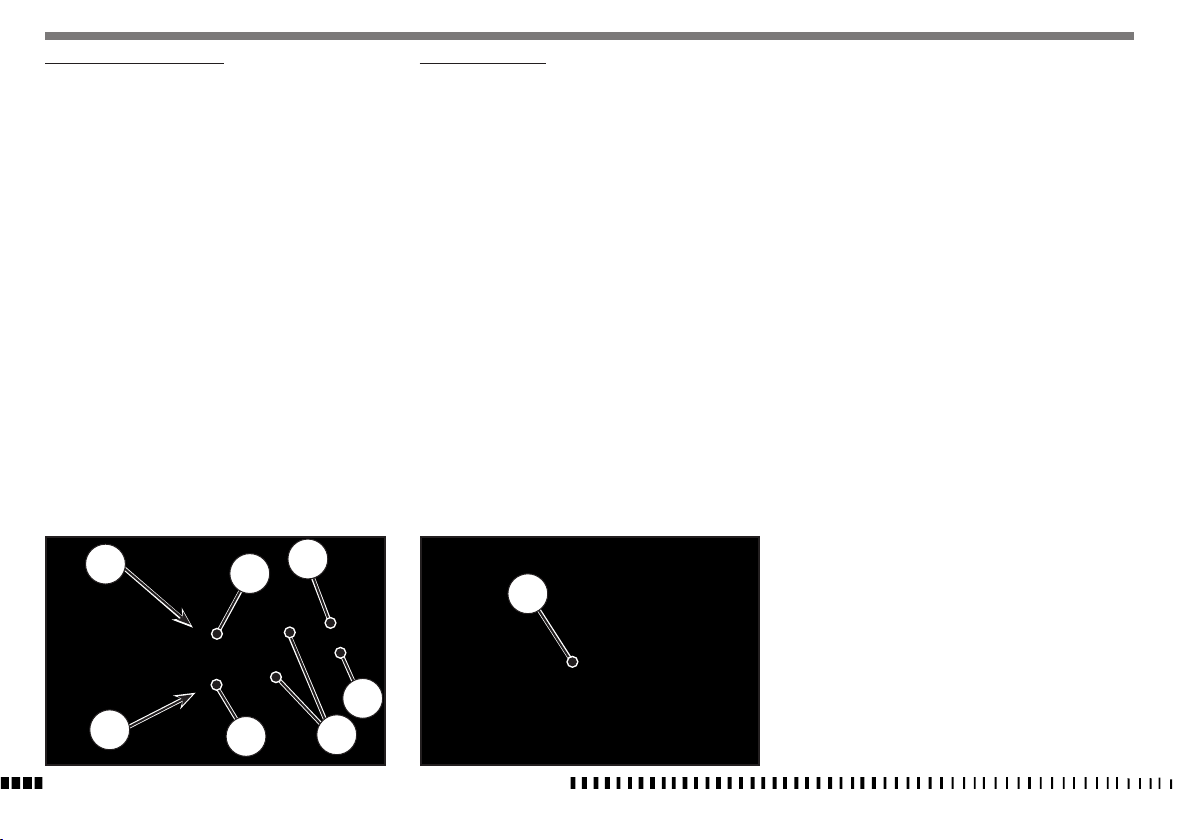

THROTTLE CABLE ADJUSTMENT

To check the correct adjustment of the throttle operate as follows:

- Remove rubber caps (1);

- by moving the opening cable (2) back and forth, check that

free play is 3 mm;

- by moving the closing cable (3) back and forth, check that free

play is 1 mm;

- if it does not happen, loosen the nut (4) and appropriately

turn the adjuster screw (5);

(loosen it to decrease clearance, tighten it to increase it);

- after adjustment block the nut (4).

WARNING*: Operation with damaged throttle cable could result in an unsafe riding condition.

WARNING*: Exhaust gas contains poisonous

carbon monoxide gas. Never run the engine

in a closed area or in a confined area.

ADJUSTING THE IDLE

Adjust the carburetor with warm engine and with the throttle

control in closed position. Proceed as follows:

- turn the knob (1) on the left side of the throttle body of about

34 clicks from the fully closed position, checking with the suitable device that revs are of about 1,950 RPM (turn clockwise

to increase the speed and counter clockwise to reduce it).

4

2

5

3

4

SPECIFICATIONS - OPERATION - MAINTENANCE

EN - 24

5

1

1

Loading...

Loading...