Page 1

Operator ′ s manual Manuel d’utilisation Manual de instrucciones

Saw attachment PA PA 1100

Accessoire de sciage PA PA 1100

Suplemento de sierra PA PA 1100

EEEEnnnngggglllliiiisssshh

GB FR ES

hh

Page 2

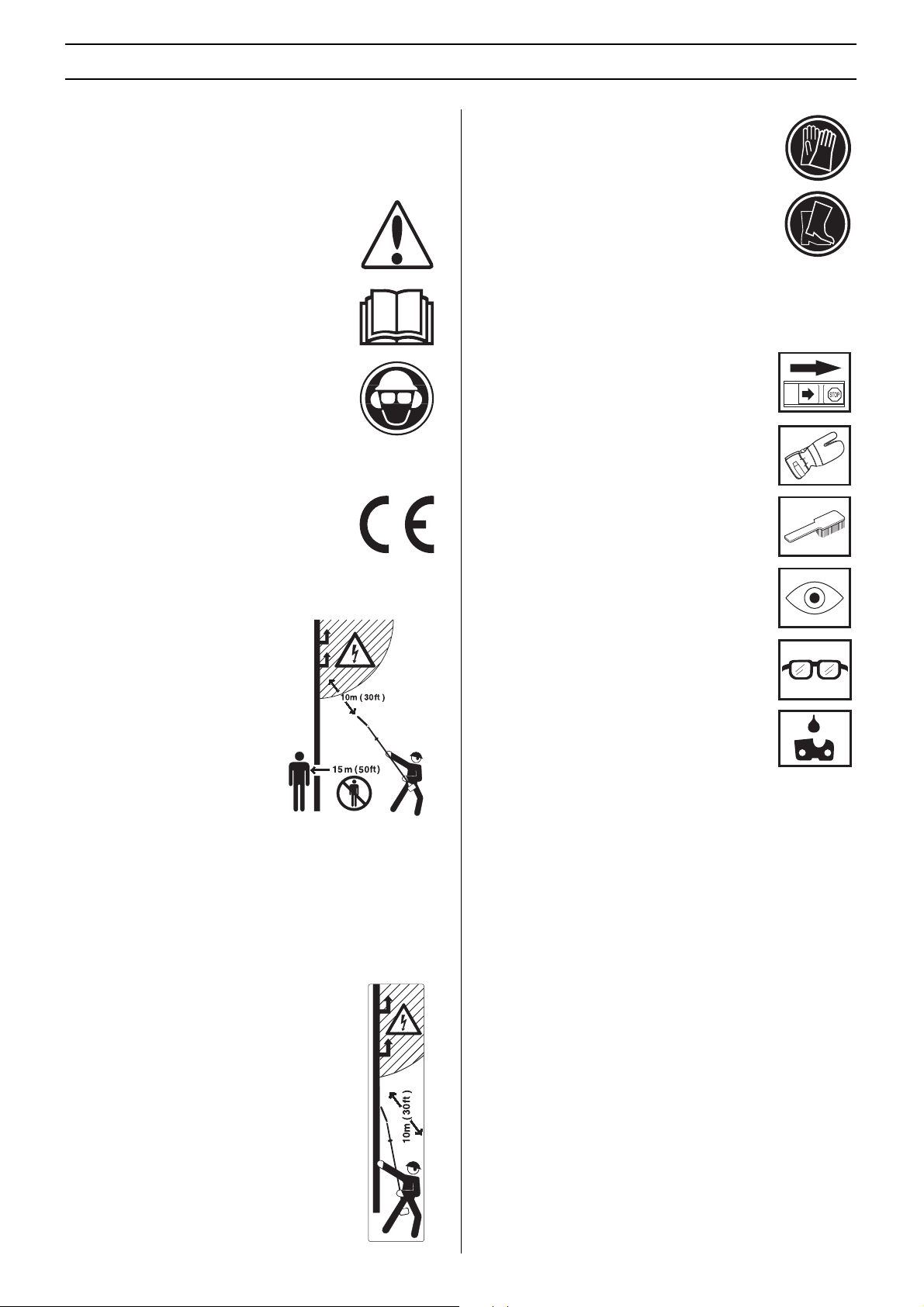

KEY TO SYMBOLS

Symbols

WARNING! The machine can be a dangerous

tool if used incorrectly or carelessly, which can

cause serious or fatal injury to the operator or

others.

Please read the operator’s manual carefully

and make sure you understand the

instructions before using the machine.

Always wear:

• A protective helmet where there is a risk of

falling objects

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with applicable

EC directives.

.

Always wear approved protective gloves.

Wear sturdy, non-slip boots.

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

Switch off the engine by moving the stop

switch to the STOP position before carrying

out any checks or maintenance.

Always wear approved protective gloves.

Regular cleaning is required.

Saw attachment with shaft PA 1100

This machine is not electrically

insulated. If the machine touches

or comes close to high-voltage

power lines it could lead to death

or serious bodily injury. Electricity

can jump from one point to

another by arcing. The higher the

voltage, the greater the distance

electricity can jump. Electricity

can also travel through branches

and other objects, especially if

they are wet. Always keep a

distance of at least 10 m between

the machine and high-voltage power lines and/or any objects

that are touching them. If have to work within this safe

distance you should always contact the relevant power

company to make sure the power is switched off before you

start work.

Saw attachment without shaft PA

This machine is not electrically insulated. If the

machine touches or comes close to highvoltage power lines it could lead to death or

serious bodily injury. Electricity can jump from

one point to another by arcing. The higher the

voltage, the greater the distance electricity can

jump. Electricity can also travel through

branches and other objects, especially if they

are wet. Always keep a distance of at least 10

m between the machine and high-voltage

power lines and/or any objects that are

touching them. If have to work within this safe

distance you should always contact the relevant

power company to make sure the power is

switched off before you start work.

Visual check.

Protective goggles or a visor must be worn.

Filling with chain oil and adjusting oil flow

2 –

English

Page 3

CONTENTS

Contents Note the following before starting:

KEY TO SYMBOLS

Symbols ....................................................................... 2

CONTENTS

Contents ...................................................................... 3

Note the following before starting: ................................ 3

SAFETY INSTRUCTIONS

Cutting equipment ........................................................ 4

Specification of bar and saw chain .............................. 4

Sharpening your chain and adjusting raker clearance . 5

Tensioning the chain .................................................... 6

Lubricating cutting equipment ...................................... 7

Checking wear on cutting equipment ........................... 8

Safety instructions for using a pruning saw ................. 8

WHAT IS WHAT?

What is what on the saw attachment? (Saw attachment

with shaft PA 1100)....................................................... 11

What is what on the saw attachment? (Saw attachment

without shaft PA)........................................................... 12

ASSEMBLY

Fitting the cutting head (Saw attachment with shaft PA

1100)............................................................................. 13

Fitting the cutting head (Saw attachment without shaft

PA) ................................................................................ 13

Fitting the bar and chain .............................................. 13

Fitting the hanging ring ................................................ 13

Adjusting the harness .................................................. 14

Filling with oil ................................................................ 14

Check before starting ................................................... 14

TECHNICAL DATA

Technical data .............................................................. 15

Bar and chain combinations ........................................ 15

EC-declaration of conformity ........................................ 16

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify the

design and appearance of products without prior notice.

Long-term exposure to noise can result in permanent hearing

impairment. So always use approved hearing protection.

Please read the operator’s manual carefully and make sure

you understand the instructions before using the machine.

These instructions supplement the instructions that were

included with the machine. For other procedures, please refer

to the operating instructions for the machine.

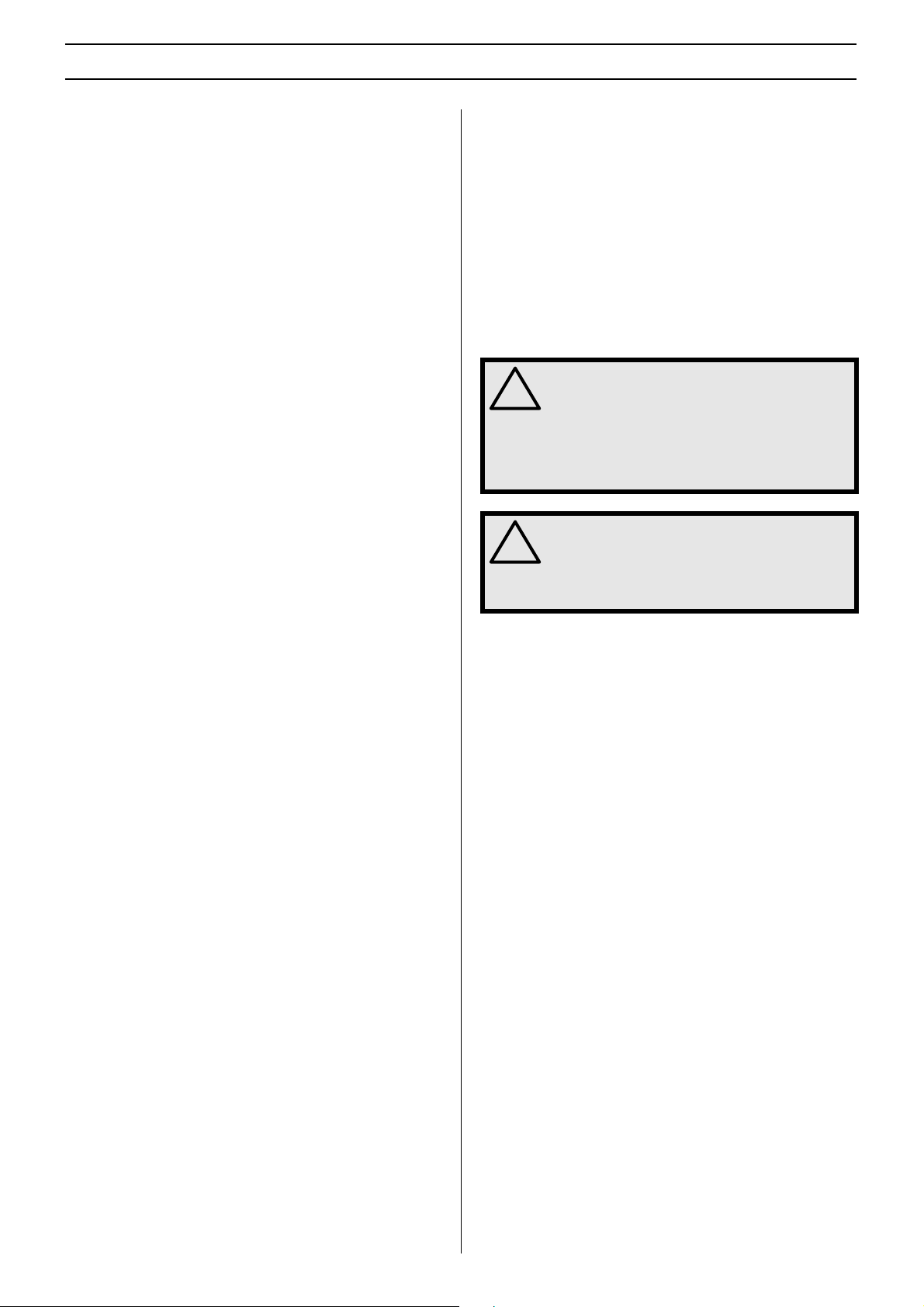

WARNING! Under no circumstances may the

design of the machine be modified without

!

the permission of the manufacturer. Always

use genuine accessories. Non-authorized

modifications and/or accessories can result

in serious personal injury or the death of the

operator or others.

WARNING! This accessory may only be used

together with the intended clearing saw/

!

trimmer, see under heading ”Approved

accessories” in chapter Technical data in the

machine’s Operator’s Manual.

The machine is only designed for cutting branches and twigs.

English

– 3

Page 4

SAFETY INSTRUCTIONS

Cutting equipment

This section describes how you can achieve maximum

clearing capacity and extend the life of the cutting attachment

through correct maintenance and using the right type of

cutting attachment.

Only use cutting equipment recommended by us! See

the Technical data section.

Keep the chain’s cutting teeth properly sharpened!

Follow our instructions and use the recommended file

gauge. A damaged or badly sharpened chain increases the

risk of accidents.

WARNING! Always stop the engine before

doing any work on the cutting attachment.

!

This continues to rotate even after the

throttle has been released. Ensure that the

cutting attachment has stopped completely

and disconnect the HT lead from the spark

plug before you start to work on it.

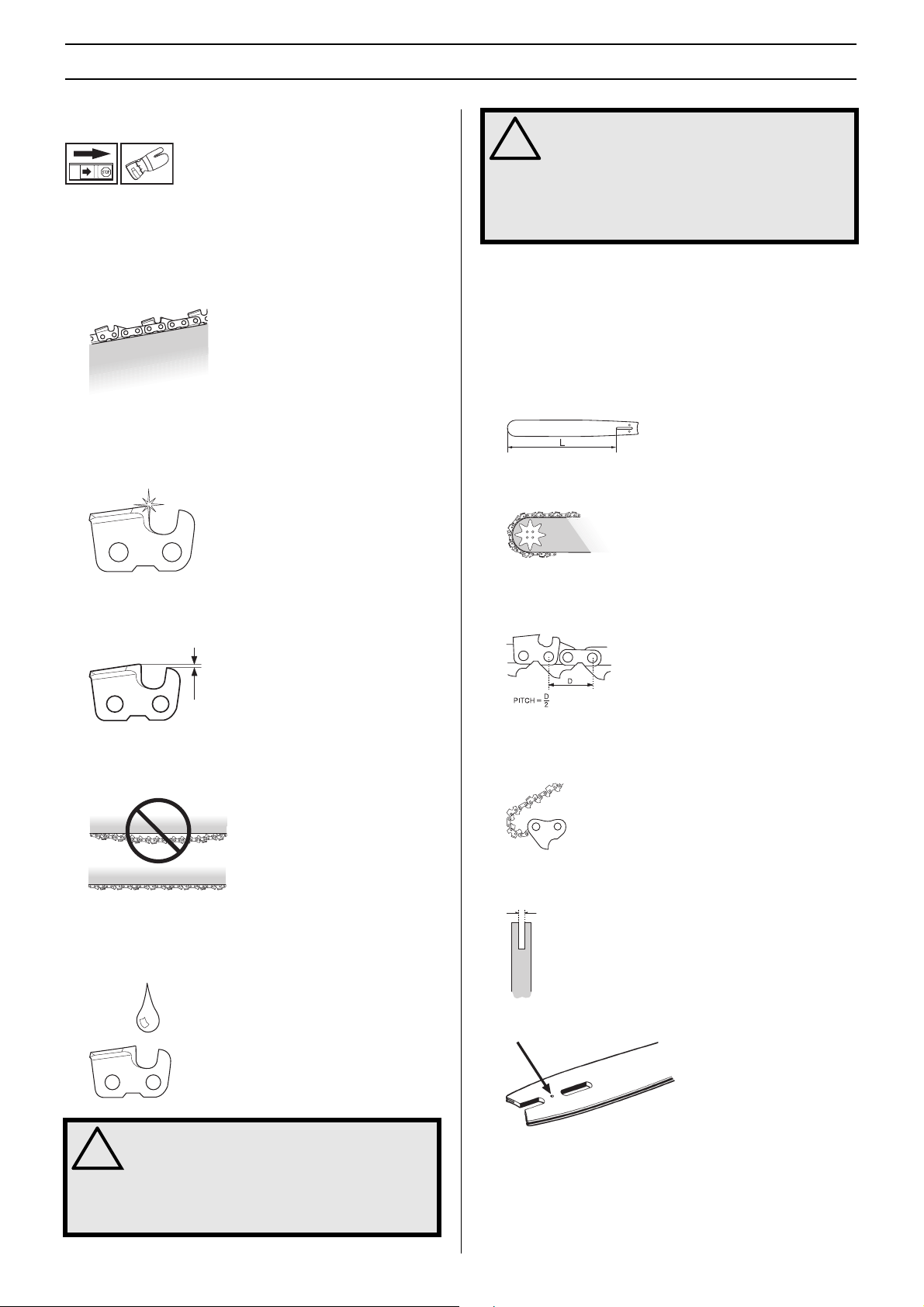

Specification of bar and saw chain

When the cutting attachment supplied with your machine has

to be replaced, because it is worn out or damaged, you must

only fit the types of bar and saw chain recommended by us.

Bar

• Length (inches/cm)

• Number of teeth on bar tip sprocket (T). Small number =

small tip radius = low risk of kickback.

Maintain the correct raker clearance! Follow our

instructions and use the recommended raker gauge. Too

large a clearance increases the risk of kickback.

Keep the chain properly tensioned! If the chain is slack it

is more likely to jump off and lead to increased wear on the

bar, chain and drive sprocket.

Keep cutting equipment well lubricated and properly

maintained! A poorly lubricated chain is more likely to break

and lead to increased wear on the bar, chain and drive

sprocket.

• Chain pitch (inches). The spacing between the drive links

of the chain must match the spacing of the teeth on the

bar tip sprocket and drive sprocket.

• Number of drive links. The number of drive links is

determined by the length of the bar, the chain pitch and

the number of teeth on the bar tip sprocket.

• Bar groove width (inches/mm). The groove in the bar must

match the width of the chain drive links.

• Saw chain oil hole and hole for chain tensioner pin.

4 –

!

English

WARNING! Never use a machine with faulty

safety equipment. The machine’s safety

equipment must be checked and maintained

as described in this section. If your machine

fails any of these checks contact your

service agent to get it repaired.

Page 5

1

5

SAFETY INSTRUCTIONS

Chain

• Saw chain pitch (inches). (The distance between three

drive links, divided by two.)

• Drive link width (mm/inches)

• Number of drive links.

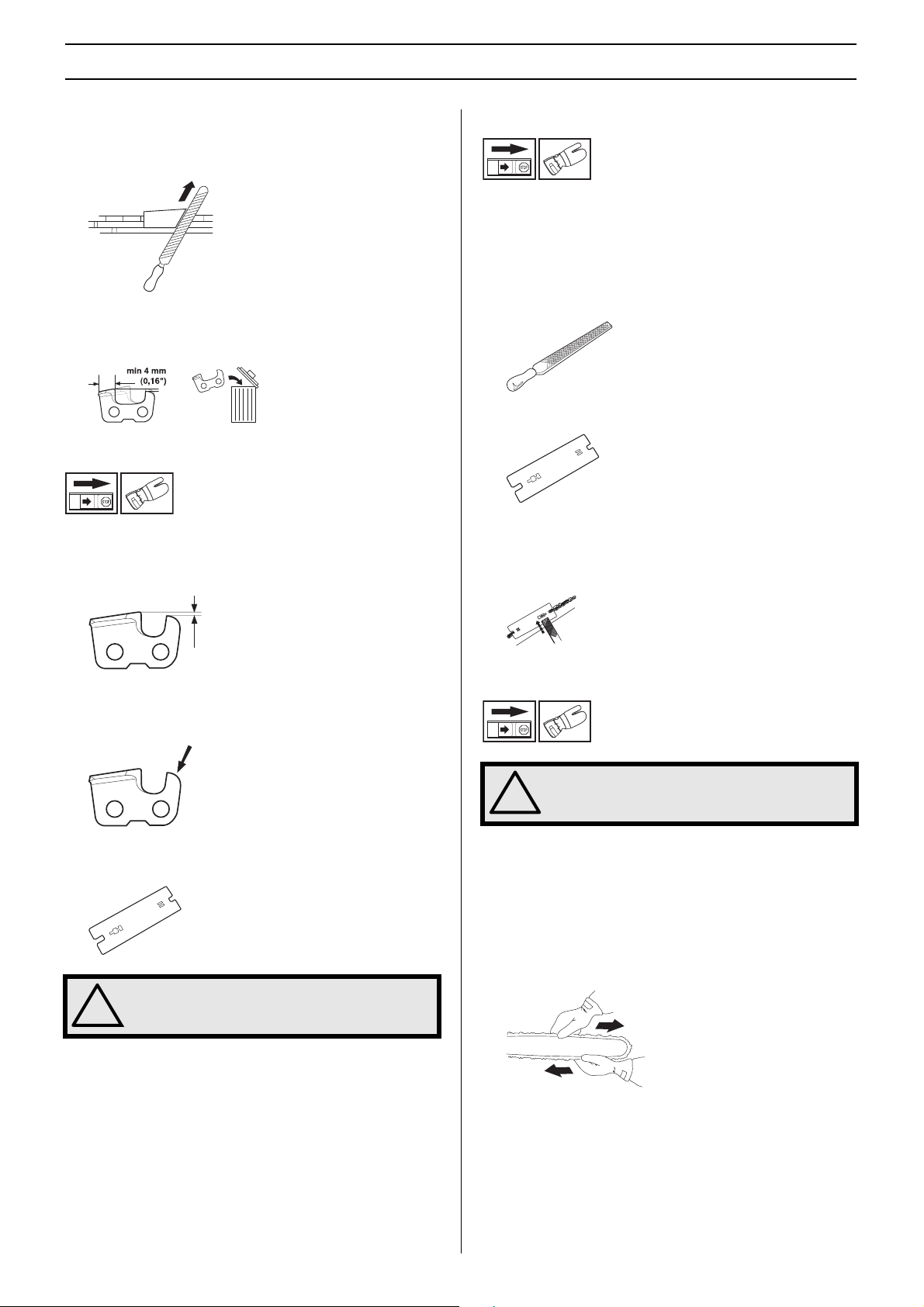

Sharpening your chain and

adjusting raker clearance

3 File position

4 Round file diameter

5 File depth

It is very difficult to sharpen a chain correctly without the right

equipment. We recommend that you use our file gauge. This

will help you obtain the maximum kickback reduction and

cutting performance from your chain.

WARNING! The risk of kickback is increased

with a badly sharpened chain!

!

General information on sharpening cutting

teeth

• Never use a blunt chain. When the chain is blunt you have

to exert more pressure to force the bar through the wood

and the cuttings will be very small. If the chain is very blunt

it will not produce any cuttings at all. Wood powder would

be the only result.

• A sharp chain eats its way through the wood and

produces long, thick cuttings.

The cutting part of the chain is called the cutting link and

this consists of a cutting tooth (A) and the raker lip (B). The

cutting depth is determined by the difference in height

between the two.

• When you sharpen a cutting tooth there are five important

factors to remember.

1 Filing angle

WARNING! The following faults will increase

the risk of kickback considerably:

!

File angle too large

Cutting angle too small

File diameter too small

Sharpening cutting teeth

• To sharpen cutting teeth you will need a round file and a

file gauge.

2 Cutting angle

• Check that the chain is correctly tensioned. A slack chain

will move sideways, making it more difficult to sharpen

correctly.

English

– 5

Page 6

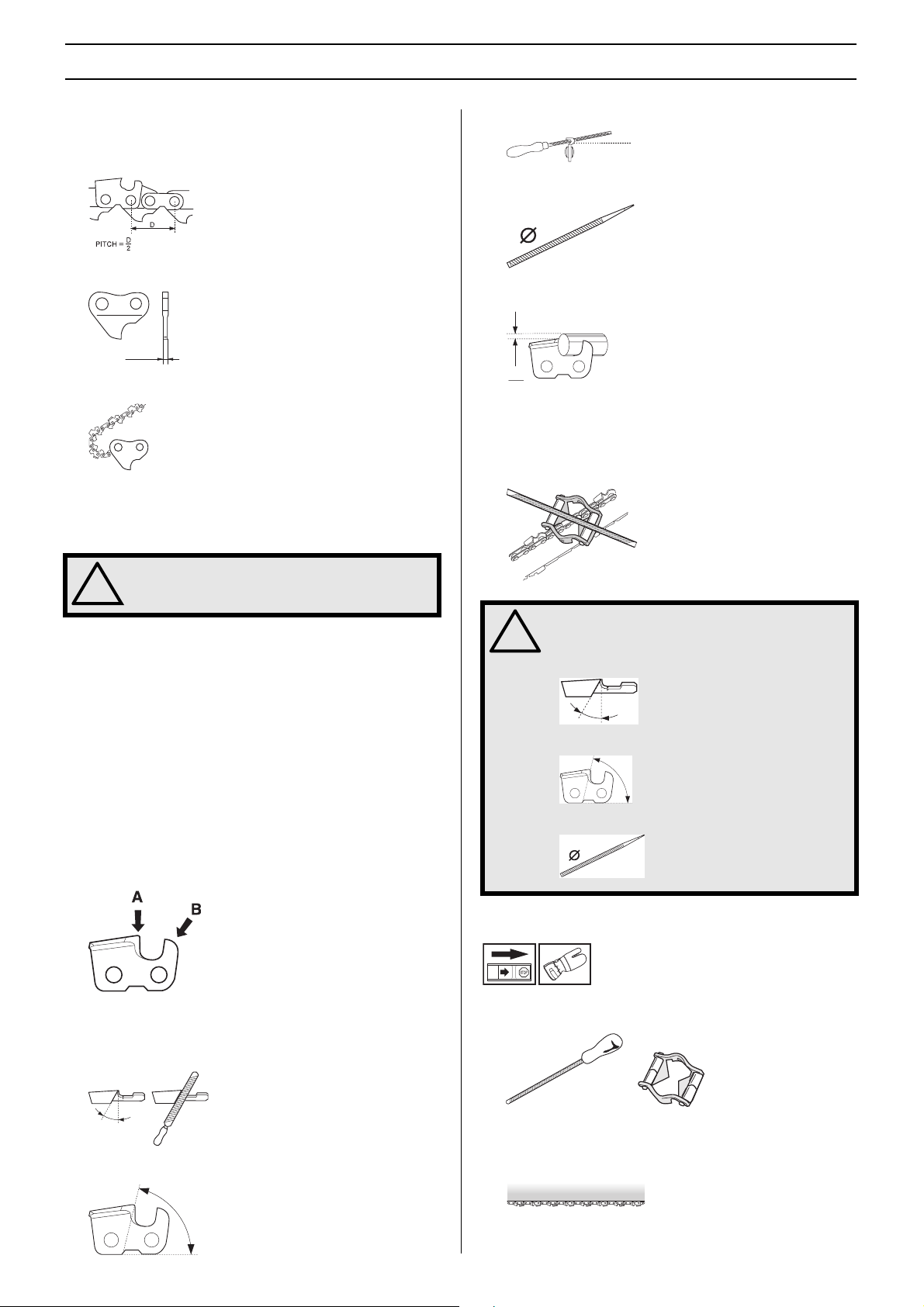

SAFETY INSTRUCTIONS

• Always file cutting teeth from the inside face outwards.

Reduce the pressure on the return stroke. File all the teeth

on one side of the bar first. Then turn the saw over and file

the remaining teeth from the other side.

• File all the teeth to the same length. When the length of

the cutting teeth is reduced to 4 mm (0.16") the chain is

worn out and should be replaced.

General advice on setting raker clearance

• When you sharpen the cutting teeth you reduce the raker

clearance (=cutting depth). To maintain optimal cutting

performance you must file back the raker lip to the

recommended height.

Setting the raker clearance

• Before setting the raker clearance the cutting teeth should

be newly sharpened. We recommend that you adjust the

raker clearance every third time you sharpen the chain.

NOTE! This recommendation assumes that the length of

the cutting teeth is not reduced excessively.

• To adjust the raker clearance you will need a flat file and a

raker gauge.

• Place the gauge over the raker lip.

• Place the file over the part of the lip that protrudes through

the gauge and file off the excess. The clearance is correct

when you no longer feel any resistance as you draw the

file over the gauge.

• On a low-kickback cutting link the front edge of the raker

lip is rounded. It is very important that you maintain this

radius or bevel when you adjust the raker clearance.

• We recommend that you use our raker gauge to achieve

the correct clearance and bevel on the raker lip.

WARNING! The risk of kickback is increased

if the raker clearance is too large!

!

Tensioning the chain

WARNING! A slack chain may jump off and

cause serious or even fatal injury.

!

• The more you use a chain the longer it becomes. It is

therefore important to adjust the chain regularly to take up

the slack.

• Check the chain tension every time you refuel. NOTE! A

new chain has a running-in period during which you

should check the tension more frequently.

• Tension the chain as tightly as possible, but not so tight

that you cannot pull it round freely by hand.

6 –

English

Page 7

SAFETY INSTRUCTIONS

1 Undo the bar nut.

2 Raise the tip of the bar and stretch the chain by tightening

the chain tensioning screw using the combination

spanner. Tighten the chain until it does not sag from the

underside of the bar.

Filling with chain oil

The oil pump is preset at the factory to meet most lubrication

requirements. A full oil tank will last about half as long as a full

tank of fuel. You should therefore check the level of oil in the

oil tank regularly to avoid damage to the saw chain and bar

that could occur due to lack of lubrication.

3 Use the combination spanner to tighten the blade nut

while holding up the tip of the bar. Check that you can pull

the saw chain round freely by hand.

Lubricating cutting equipment

WARNING! Poor lubrication of cutting

equipment may cause the chain to snap,

!

which could lead to serious, even fatal

injuries.

Chain oil

Checking chain lubrication

Check the chain lubrication each time you refuel.

Aim the tip of the bar at a light coloured surface about 20 cm

(8 inches) away. After 1 minute running at 3/4 throttle you

should see a distinct line of oil on the light surface.

Adjusting chain lubrication

When cutting dry or hard species of wood it may be

necessary to increase lubrication. Turn the adjuster screw

anticlockwise to increase the oil flow. Remember that this will

increase oil consumption, check the level in the oil tank

regularly. Turn the adjuster screw clockwise to decrease the

oil flow.

• Chain oil must demonstrate good adhesion to the chain

and also maintain its flow characteristics regardless of

whether it is warm summer or cold winter weather.

• As a chain saw manufacturer we have developed an

optimal chain oil which, with its vegetable oil base, is also

biodegradable. We recommend the use of our own oil for

both maximum chain life and to minimise environmental

damage.

• If our own chain oil is not available, standard chain oil is

recommended.

• In areas where oil specifically for lubrication of saw chains

is unavailable, ordinary EP 90 transmission oil may be

used.

• Never use waste oil! This is dangerous for yourself, the

machine and the environment.

What to do if lubrication does not work:

1 Check that the oil channel in the bar is not obstructed.

Clean if necessary.

English

– 7

Page 8

SAFETY INSTRUCTIONS

2 Check that the oil channel in the gear housing is clean.

Clean if necessary.

3 Check that the bar tip sprocket turns freely. If the chain

lubrication system is still not working after carrying out the

above checks you should contact your service workshop.

Checking wear on cutting

equipment

Chain

Check the chain daily for:

• Visible cracks in rivets and links.

Vibration damping system

Check regularly that the vibration damping element is free

from cracks. Check regularly the degree of wear to the rubber

dampers. Replace them if worn.

Bar

Check regularly:

• Whether there are burrs on the edges of the bar. Remove

these with a file if necessary.

• Whether the groove in the bar has become badly worn.

Replace the bar if necessary.

• Whether the chain is stiff.

• Whether rivets and links are badly worn.

We recommend you compare the existing chain with a new

chain to decide how badly the existing chain is worn.

When the length of the cutting teeth has worn down to only 4

mm the chain must be replaced.

Chain drive sprocket

Regularly check the degree of wear on the drive sprocket.

Replace if wear is excessive.

• Whether the tip of the bar is uneven or badly worn. If a

hollow forms on the underside of the bar tip this is due to

running with a slack chain.

To prolong the life of the bar you should turn it over daily.

WARNING! A faulty cutting attachment may

increase the risk of accidents.

!

Safety instructions for using a

pruning saw

WARNING! The machine can cause serious

personal injury. Read the safety instructions

!

carefully. Learn how to use the machine.

8 –

English

WARNING! Cutting tool. Do not touch the

tool without first switching off the engine.

!

CAUTION! Please read the operator’s manual carefully and

make sure you understand the instructions before using the

machine.

Page 9

SAFETY INSTRUCTIONS

Personal protection

• Always wear boots and other equipment described under

the heading Personal protective equipment in the

machine’s Operator’s Manual.

• Always wear working clothes and heavy-duty long

trousers.

• Never wear loose clothing or jewellery.

• Make sure your hair does not hang below shoulder level.

Safety instructions regarding the

surroundings

• Never allow children to use the machine.

• Ensure that no-one comes closer than 15 m while you are

working.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

• Never work from a ladder, stool or any other raised

position that is not fully secured.

• When the engine is switched off, keep your hands and feet

away from the cutting attachment until it has stopped

completely.

• Watch out for stumps of branches that can be thrown out

during cutting.

• Always lay the machine on the ground when you are not

using it.

• Check the working area for foreign objects such as

electricity cables, insects and animals, etc, or other

objects that could damage the cutting attachment, such

as metal items.

• If any foreign object is hit or if vibrations occur stop the

machine immediately. Disconnect the HT lead from the

spark plug. Check that the machine is not damaged.

Repair any damage.

• If anything gets caught up in the cutting attachment while

you are working, switch off the engine and let it stop

completely before cleaning the cutting attachment.

Safety instructions after completing work

• The transport guard should always be fitted to the cutting

attachment when the machine is not in use.

• Make sure the cutting attachment has stopped before

cleaning, carrying out repairs or an inspection.

Disconnect the HT lead from the spark plug.

• Always wear heavy-duty gloves when repairing the cutting

attachment. This is extremely sharp and can easily cause

cuts.

Safety instructions while working

• Always ensure you have a safe and stable working

position.

• Always use both hands to hold the machine. Hold the

machine at the side of your body.

• Use your right hand to control the throttle setting.

• Make sure that your hands and feet do not come near the

cutting attachment when the engine is running.

• Store the machine out of reach of children.

• Use only original spare parts for repairs.

Basic working techniques

• Hold the machine as close to your body as possible to get

the best balance.

• Make sure that the tip does not touch the ground.

• Do not rush the work, but work steadily until all the

branches have been cut back cleanly.

English

– 9

Page 10

SAFETY INSTRUCTIONS

• Always slow the engine to idle speed after each working

operation. Long periods at full throttle without any load on

the engine can lead to serious engine damage.

• Always work at full throttle.

• Let the engine drop back to idle speed between each cut.

Long periods at full throttle can cause serious damage to

the centrifugal clutch.

WARNING! Never stand directly underneath

a branch that is being cut. This could lead to

!

serious or even fatal personal injury.

Observe great care when working close to overhead power

lines. Falling branches can result in short-circuiting.

WARNING! Observe the applicable safety

regulations for work in the vicinity of

!

overhead power lines.

WARNING! This machine is not electrically

insulated. If the machine touches or comes

!

close to high-voltage power lines it could

lead to death or serious bodily injury.

Electricity can jump from one point to

another by arcing. The higher the voltage,

the greater the distance electricity can jump.

Electricity can also travel through branches

and other objects, especially if they are wet.

Always keep a distance of at least 10 m

between the machine and high-voltage

power lines and/or any objects that are

touching them. If have to work within this

safe distance you should always contact the

relevant power company to make sure the

power is switched off before you start work.

• Cut large branches in sections so that you have better

control over where they fall.

• Never cut through the swelling at the root of the branch as

this will slow down healing and increase the risk of fungal

attack!

• Use the stop at the base of the cutting head to provide

support during cutting. This will help prevent the cutting

attachment from ”jumping” on the branch.

• Make an initial cut on the underside of the branch before

cutting through the branch. This will prevent tearing of the

bark, which could lead to slow healing and cause

permanent damage to the tree. The cut should not be

deeper than 1/3 of the branch thickness to prevent

jamming. Keep the chain running while you withdraw the

cutting attachment from the branch to prevent it jamming.

WARNING! This machine has a long reach.

Make sure that no people or animals come

!

closer than 15 m when the machine is

running.

• Whenever possible position yourself so that you can make

the cut at right angles to the branch.

• Do not work with the shaft held straight out in front of you

(like a fishing rod) as this increases the apparent weight of

the cutting attachment.

• Use the harness to support the weight of the machine and

make it easier to handle.

• Make sure you have a firm footing and that you can work

without being hampered by branches, stones and trees.

WARNING! Never activate the throttle

without having the cutting attachment in full

!

view.

10 –

English

Page 11

WHAT IS WHAT?

12

10

11

9

8

4

7

13

14

11

2

1

3

6

5

15

What is what on the saw attachment? (Saw attachment with shaft PA 1100)

1 Bevel gear

2 Chain lubrication adjustment screw

3 Shaft (1100 mm)

4 Harness support hook

5 Protective guard for saw chain

6 Bar nut

7 Chain tensioning screw

8 Chain

9 Bar

10 Chain oil tank

11 Filling with chain oil

12 Operator ′ s manual

13 Transport guard

14 Combination spanner

15 Harness

English

– 11

Page 12

WHAT IS WHAT?

11

8

10

10

2

1

7

9

5

4

3

6

14

12

13

What is what on the saw attachment? (Saw attachment without shaft PA)

1 Bevel gear

2 Chain lubrication adjustment screw

3 Harness support hook

4 Protective guard for saw chain

5 Bar nut

6 Chain tensioning screw

7 Chain

8 Bar

9 Chain oil tank

10 Filling with chain oil

11 Operator′s manual

12 Transport guard

13 Combination spanner

14 Harness

12 – English

Page 13

ASSEMBLY

Fitting the cutting head

(Saw attachment with shaft PA 1100)

• Fit the cutting head on the shaft so that the screw (A) is

aligned with the hole in the shaft as shown.

B

A

• Tighten screw A.

• Tighten screw B.

CAUTION! Make sure that the drive shaft inside the shaft

engages with the cut-out in the cutting head.

Fitting the cutting head

(Saw attachment without shaft PA)

Fitting the bar and chain

• Unscrew the bar nut and remove the protective cover.

• Fit the bar over the bar bolt. Place the bar in its rearmost

position. Place the chain over the drive sprocket and in the

groove on the bar. Begin on the top side of the bar.

• Make sure that the edges of the cutting links are facing

forward on the top edge of the bar.

• Fit the cover and locate the chain adjuster pin (A) in the

hole in the bar. Check that the drive links of the chain fit

correctly on the drive sprocket (B) and that the chain is in

the groove in the bar (C). Tighten the bar nut finger-tight.

• Tension the chain by turning the chain tensioning screw

clockwise using the combination spanner. The chain

should be tensioned until it does not sag from the

underside of the bar.

• Remove the mitre gear from the shaft.

• Fit the cutting attachment to the shaft.

B

A

• Tighten screw A.

• Tighten screw B.

CAUTION! Make sure that the drive shaft inside the shaft

engages with the cut-out in the cutting head.

• The chain is correctly tensioned when it does not sag from

the underside of the bar, but can still be turned easily by

hand. Hold up the bar tip and tighten the bar nuts with the

combination spanner.

• When fitting a new chain, the chain tension has to be

checked frequently until the chain is run-in. Check the

chain tension regularly. A correctly tensioned chain

ensures good cutting performance and long life.

Fitting the hanging ring

Fit the hanging ring between the rear handle and the loop

handle. Position the hanging ring so that the machine is

balanced and comfortable to work with.

English – 13

Page 14

ASSEMBLY

Adjusting the harness

You should always use the harness with the machine to give

maximum control over the machine and reduce the risk of

fatigue in your arms and back.

• Put on the harness.

• Hook the machine onto the harness support hook.

• Adjust the length of the harness so that the support hook

is roughly level with your right hip.

Filling with oil

• Open the cap on top of the bar head

Check before starting

• Inspect the working area. Remove any objects that could

be thrown out.

• Check the cutting attachment. Never use blunt, cracked or

damaged equipment.

• Check that the machine is in perfect working order. Check

that all nuts and screws are tight.

• Make sure the chain is adequately lubricated. See

instructions under the heading Lubricating the cutting

attachment.

• Check that the cutting attachment always stops when the

engine is idling.

• Only use the machine for the purpose it was intended for.

• Make sure the handle and safety features are in order.

Never use a machine that has any parts missing or has

been modified in relation to the specification.

• Fill with Husqvarna saw chain oil.

• Refit the cap.

14 – English

Page 15

Technical data

TECHNICAL DATA

Technical data

Saw attachment without

shaft PA

Saw attachment with shaft

PA 1100

Lubrication system

Oil tank capacity, litre 0,22 0,22

Weight

Weight without fuel, cutting attachment and guard, kg 0,8 1,4

Noise levels

(see note 1)

Equivalent noise pressure level at the user’s ear, measured

according to EN ISO 11680-1, dB(A) 95 96

Equivalent noise power level at the user’s ear, measured

according to EN/ISO 11680-1 and ISO 10884, dB(A) 106 106

Vibration levels

Vibration levels on the handles, measured according to

EN/ISO 11680 m/s

2

When idling, rear/front handles: 1,0/3,0 1,2/2,3

At max. speed, rear/front handles: 5,5/3,6 6,0/5,5

Note 1: Equivalent sound pressure level is calculated as the time-weighted energy total for sound pressure levels under various

working conditions with the following time distribution: 1/2 idling and 1/2 max speed.

Bar and chain combinations

The following combinations are CE approved.

Bar Chain

Length, inches Pitch, inch

Max. no of teeth

on tip sprocket

10 3/8 7 T Husqvarna S 36/Oregon 91 VG

12 3/8 7 T

10 3/8 7 T Oregon 90SG

12 3/8 7 T

D

D

_

PITCH =

2

L

English – 15

Page 16

TECHNICAL DATA

EC-declaration of conformity

(Applies to Europe only)

We, Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel +46-36-146500, declare that this saw attachment from 2002’s serial

numbers and onwards (the year is clearly stated in plain text on the type plate, with subsequent serial number), complies with the

requirements of the COUNCIL’S DIRECTIVE:

of June 22, 1998 ”relating to machinery” 98/37/EC, annex IIA.

The following standards have been applied: EN 292-2, EN ISO 11680-1

Notified body: 0404, SMP Svensk Maskinprovning AB, Fyrisborgsgatan 3, SE-754 50 Uppsala, Sweden, has carried out EC type

examination in accordance with the machinery directive’s (98/37/EC) article 8, point 2c. The certificate for EC type examination in

accordance with annex VI, has number: 404/02/858

The supplied saw attachment conforms to the example that underwent EC type examination.

Huskvarna January 3, 2002

Bo Andréasson, Development manager

16 – English

Page 17

´®z+H8r¶0_¨

1140248-26

´®z+H8r¶0_¨

20

2004-02-05

Loading...

Loading...