Husqvarna P 520D, P 525D User Manual

Oper ator ′ s manual

P 520D

P 525D

Please r ead the operator’s manual carefully and make sure you

understand the instructions before using the machine.

EEEEnnnngggglllliiiisssshh

hh

2

ST

Dr

T

CONTENTS

Contents

CONTENTS

Contents ...................................................................... 2

Ser vice journal

Pre-deliv ery service ..................................................... 3

After the first 25 hours ................................................. 3

INTR ODUCTION

Dear Customer , ............................................................ 4

Driving and transport on public roads .......................... 4

Towing .......................................................................... 4

Use .............................................................................. 4

Good service ................................................................ 5

KEY TO SYMBOLS

Symbols ....................................................................... 6

WHA T IS WHAT?

Location of the controls ................................................ 7

SAFETY INSTR UCTIONS

Saf ety instructions ........................................................ 8

Driving on slopes ......................................................... 9

Children ....................................................................... 10

Maintenance ................................................................ 10

Transport ...................................................................... 11

PRESENT ATION

Presentation ................................................................. 12

Throttle trigger ............................................................. 12

Speed limiter ................................................................ 12

Counter ........................................................................ 12

Parking brake ............................................................... 12

Cutting unit ................................................................... 12

Lever for hydraulic lift of attachments ........................... 13

Seat ............................................................................. 14

Fueling ......................................................................... 14

Lights and power outlet ................................................ 14

Instrument panel .......................................................... 15

Bypass valves .............................................................. 15

ROPS (Roll Over Protective Structure) ........................ 16

Auxiliary lift system ...................................................... 16

ARTING ENGINE

Bef ore starting ............................................................. 17

Start the engine ........................................................... 17

Starting the engine with a weak battery ....................... 18

DRIVING

iving the Rider .......................................................... 19

Braking ......................................................................... 19

Stop the engine ............................................................ 19

Cutting tips .................................................................. 20

Maintenance

Maintenance schedule ................................................. 21

Cleaning ....................................................................... 22

Removing of the machine hoods ................................. 22

Checking the engine’s cooling air intake ...................... 22

Adjustment of pump and alternator belt ....................... 23

Change pump and alternator belt ................................ 23

Inspecting the muffler ................................................... 23

Adjusting the parking brake ......................................... 23

Replacement of fuel filter ............................................. 23

Cleaning the air filter .................................................... 24

Replacing the air filter .................................................. 24

Cleaning the engine and muffler .................................. 24

Check the safety system .............................................. 25

Replacing the light bulbs .............................................. 25

Main fuse ...................................................................... 25

Checking the tyre pressure .......................................... 25

Check the battery ......................................................... 26

The Cutting Unit Components ...................................... 26

Fitting the cutting head ................................................. 26

Removing the cutting unit ............................................. 27

Service position for the cutting unit .............................. 28

Placing in the service position ...................................... 28

Cutting height and tilt angle adjustment. ...................... 29

Replacing the cutting unit belts .................................... 30

Checking the blades ..................................................... 30

Removing the BioClip plug ........................................... 30

Adjustment of PTO belts .............................................. 31

Change PTO belts ........................................................ 31

Change coolant ............................................................ 32

Lubrication

Lubr ication schedule .................................................... 33

General ........................................................................ 33

Accessories .................................................................. 34

Pivot wheel bearings ................................................... 34

The cutting unit bevel gear ........................................... 34

Universal drive shaft joints ........................................... 34

Cutting unit bracket ...................................................... 34

Lift arm rear bearings ................................................... 34

Lift cylinder ................................................................... 34

The drive shaft front support bearing ........................... 35

The drive shaft rear support bearing ............................ 35

Steering cylinder .......................................................... 35

Joint bearing ................................................................. 35

Link brace ..................................................................... 35

Checking the engine’s oil level. .................................... 35

Changing the oil filter ................................................... 36

Check the hydraulic system oil level ............................. 36

Check the oil level in the transmission gearboxes ........ 37

Knobs for setting the cutting height .............................. 37

Driver seat .................................................................... 37

Lubricating the cables .................................................. 37

Throttle and choke cables, lever bearings .................... 37

Lubricate the parking brake wire .................................. 37

roubleshooting schedule

ELECTRICAL SYSTEM

Wir ing diagram ............................................................. 41

ELECTRICAL SYSTEM

Wir ing diagram ............................................................. 47

Stora ge

Winter stor age .............................................................. 53

Guard ........................................................................... 53

Service ......................................................................... 53

TECHNICAL D ATA

EC-declar ation of conformity ........................................ 55

–

English

1

1

Ser vice journal

Pre-deliver y service

Charge the battery for at least 4 hours at max. 3

amp.

2 Check coolant level and antifreeze.

3 Check and adjust tyre pressure (150 kPa, 1,5 bar,

21,8 PSI).

4 Make sure the correct amount of oil is in the

cutting unit's bevel gear.

5 Check that the right amount of oil is in the engine.

6 Check that there is oil in the transmission’s oil

tank.

7 Fit cutting unit.

8 Adjust cutting unit:

Adjust cutting unit so that rear edge is about 6-9

mm higher than front edge.

9 Lubricate the universal drive shaft with grease.

10 Connect battery.

11 Fill with fuel and start engine.

12 Check that machine does not move in neutral.

13 Check:

Forward drive.

Reverse drive.

Operation of blades.

Seat safety switch.

14 Tell customer about:

The requirement and advantages of servicing the

machine according to the service plan

Servicing and the influence of this journal on the

second-hand value of the machine.

The transmission guarantee is only valid if the

synchronisation of the front and rear wheels has

been checked and adjusted in compliance with

the service schedule. The system will be damaged if

synchronisation is not carried out.

At temperatures below 0 ° C, the machine must

be warmed up for at least 10 minutes for the

hydraulic oil and transmission to get hot.

Otherwise there is a risk of the transmission breaking

down thereby reducing the service life of the transmission.

Range of applications for BioClip.

Complete proof of sale etc.

Pre-delivery service carried out. No outstanding problems.

Certified:

______________________________________________

Date, mileage, stamp, signature

Safety switch for parking brake.

After the fi rst 25 hours

Change the engine oil and oil filter

2 Change the transmission oil and oil filter

3 Check the synchronisation between the front and

rear wheels.

English

– 3

4

T

INTR ODUCTION

Dear Customer ,

Thank y ou for choosing a Husqvarna Rider. Husqvarna Riders are built to a unique design with a front-mounted cutting unit and a

patented articulated steering. Riders are designed for maximum efficiency even in small or confined areas. The closely grouped

controls and pedal-operated hydrostatic transmission also contribute to the performance of this machine.

This operator’s manual is a valuable document. By following its instructions (on operation, service, maintenance, etc.) you will

significantly extend the life of the machine and even its second-hand value.

When you sell your Rider, make sure you pass on the operator’s manual to the new owner.

The last chapter in the operator’s manual consists of a Service Journal. Make sure that all service work and repairs are recorded.

A well-documented service history reduces the costs of seasonal maintenance and influences the second-hand value of the

machine. Bring the operator’s manual with the Rider when bringing it to a workshop for service procedures.

Driving and transpor t on public roads

Chec k the relevant road traffic regulations before driving the machine on a public road. If transporting the machine on another

vehicle always use approved securing devices and make sure that the machine is securely held.

owing

When y our machine is equipped with a hydrostatic transmission you should only tow the machine over short distances and at a

low speed, otherwise there is a risk of damaging the transmission.

The transmission must be disengaged when towing, see instructions under the heading Bypass valves.

Use

This r ide-on mower is designed to mow grass on open and level ground surfaces. In addition, there is a number of accessories

recommended by the manufacturer that broadens the application area. Please contact your dealer for more information about

which accessories are available. The machine may only be used with the equipment recommended by the manufacturer. All other

types of use are incorrect. Compliance with and strict adherence to the conditions of operation, service and repair as specified by

the manufacturer also constitute essential elements of the intended use.

IMPOR TANT INFORMATION The transmission guarantee is only valid if the synchronisation of the front and rear wheels has

been checked and adjusted in compliance with the service schedule. The system will be damaged if synchronisation is not

carried out.

This machine should be operated, serviced and repaired only by persons who are familiar with its particular characteristics and

who are acquainted with the relevant safety procedures.

Accident prevention regulations, all other generally recognised regulations on safety and occupational medicine, and all road traffic

regulations must be observed at all times.

Any arbitrary modifications carried out to this machine may relieve the manufacturer of liability for any resulting damage or injury.

–

English

INTR ODUCTION

Good ser vice

Husqv arna products are sold all over the world and ensures that you, the customer, get the best support and service. For example,

before this machine was delivered it was inspected and adjusted by your dealer. See the certificate in the Service Journal in this

manual.

When you need spare parts or advice on service issues, warranty terms, etc., contact:

This Operator’s Manual belongs to machine with

serial number:

On the machine's rating plate you will find the following information:

• The machines type designation.

• The manufacturer’s type number.

• The machine’s serial number.

State the type designation and serial number when ordering spare parts.

Engine Transmission

English

– 5

6

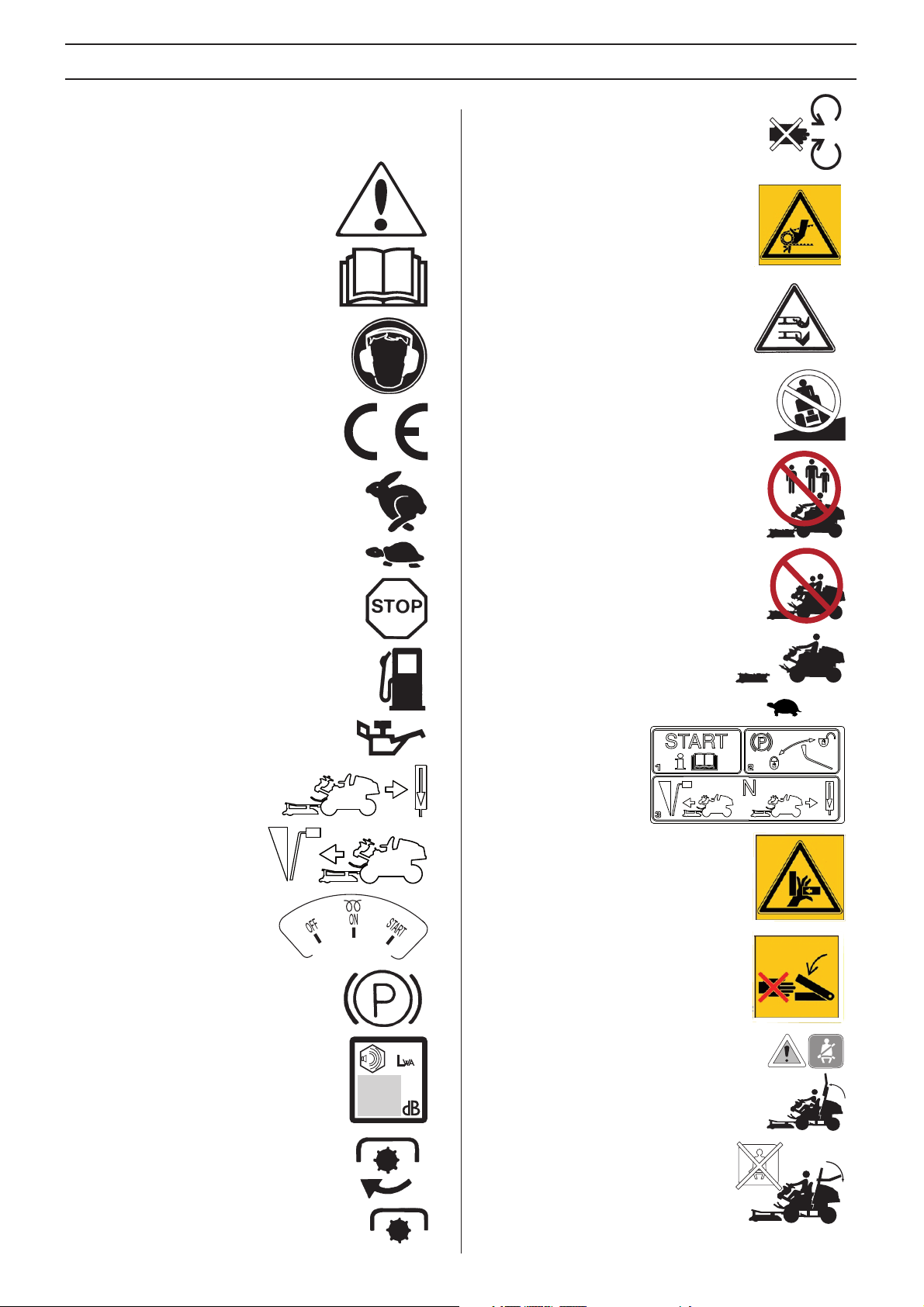

KEY T O SYMBOLS

Symbols

These symbols are on the machine and in the instr uctions.

WARNING! Careless or incorrect use can

result in serious or fatal injury to the

operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the machine.

Always wear:

• Approved hearing protection

This product is in accordance with

applicable EC directives.

Fast

Slow

Stop the engine.

Warning: rotating parts. Keep hands and feet

clear.

Watch your hands and other body parts

so they do not get caught and crushed

between the belt and belt pulley.

Rotary blades Keep hands and feet

away from under the hood when the

engine is running

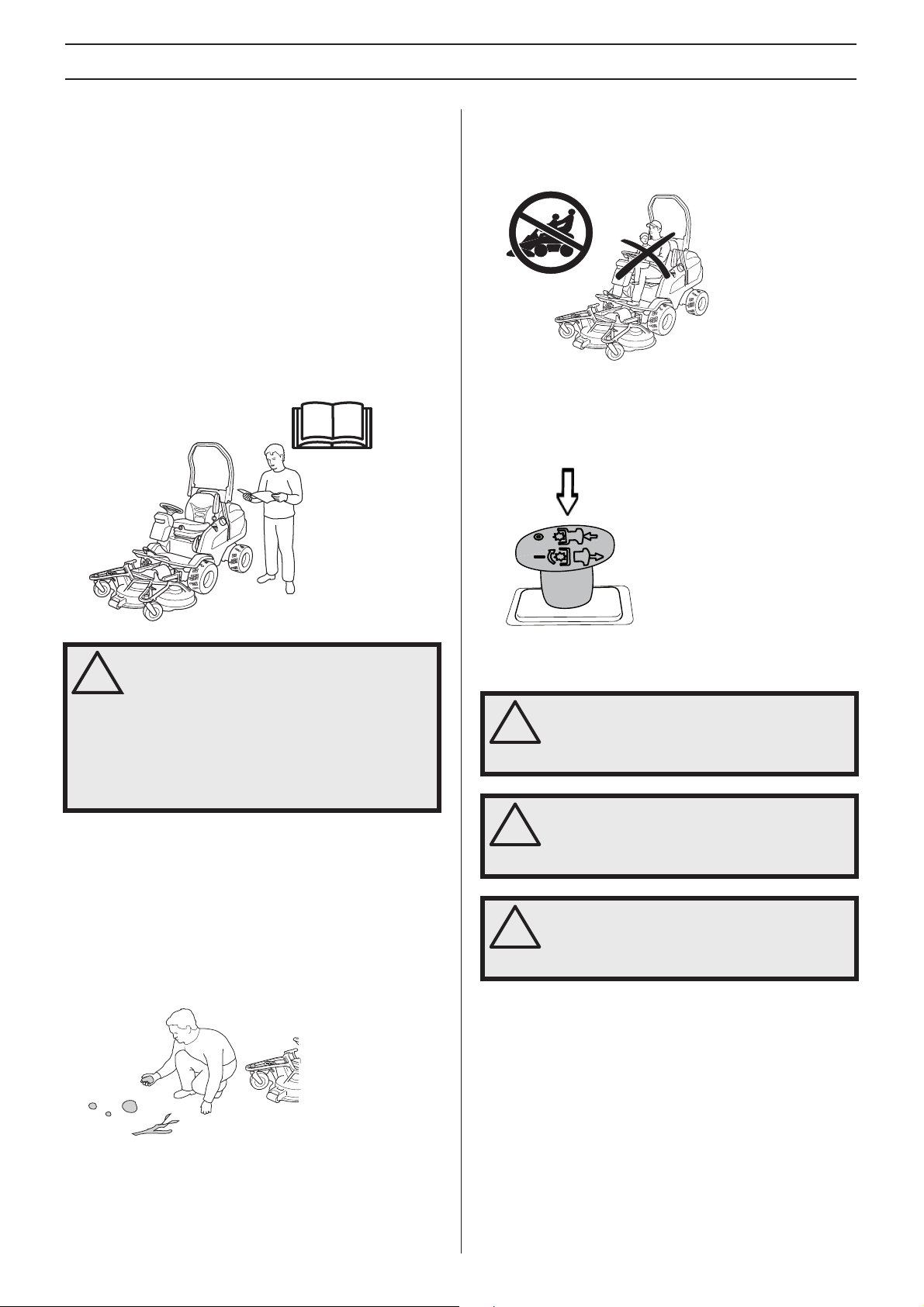

Never drive across a slope

Never use the machine if persons,

especially children, or animals, are in the

vicinity

Never carry passengers on the machine or

equipment

Fuel

Oil pressure

Backwards

Forwards

Ignition

Parking brake

Noise emission to the environment

according to the European Community’s

Directive. The machine’s emission is

specified in the Technical data chapter and

on the label.

Drive very slowly if no cutting unit is

fitted

Starting instructions

Risk of crush injuries!

Danger of crushing between the lift arms

and base plate.

If the frame is folded up, the safety belt

must be used.

Connecting the power take-off (PTO).

Disengaging the power take-off (PTO)

–

English

If the frame is folded down the safety

belt should NOT be used.

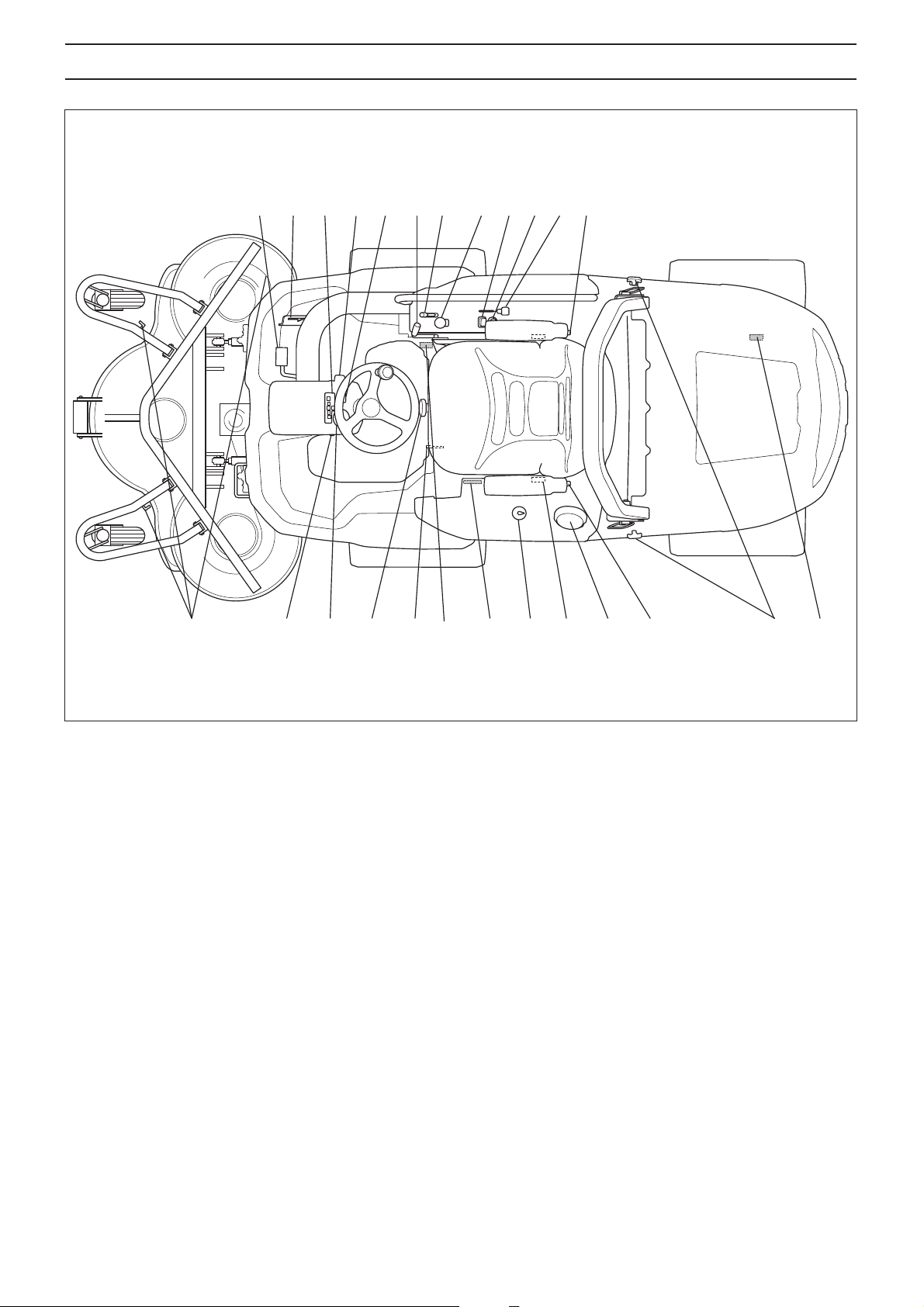

WHA T IS WHA T?

1

123456789101112

13

14

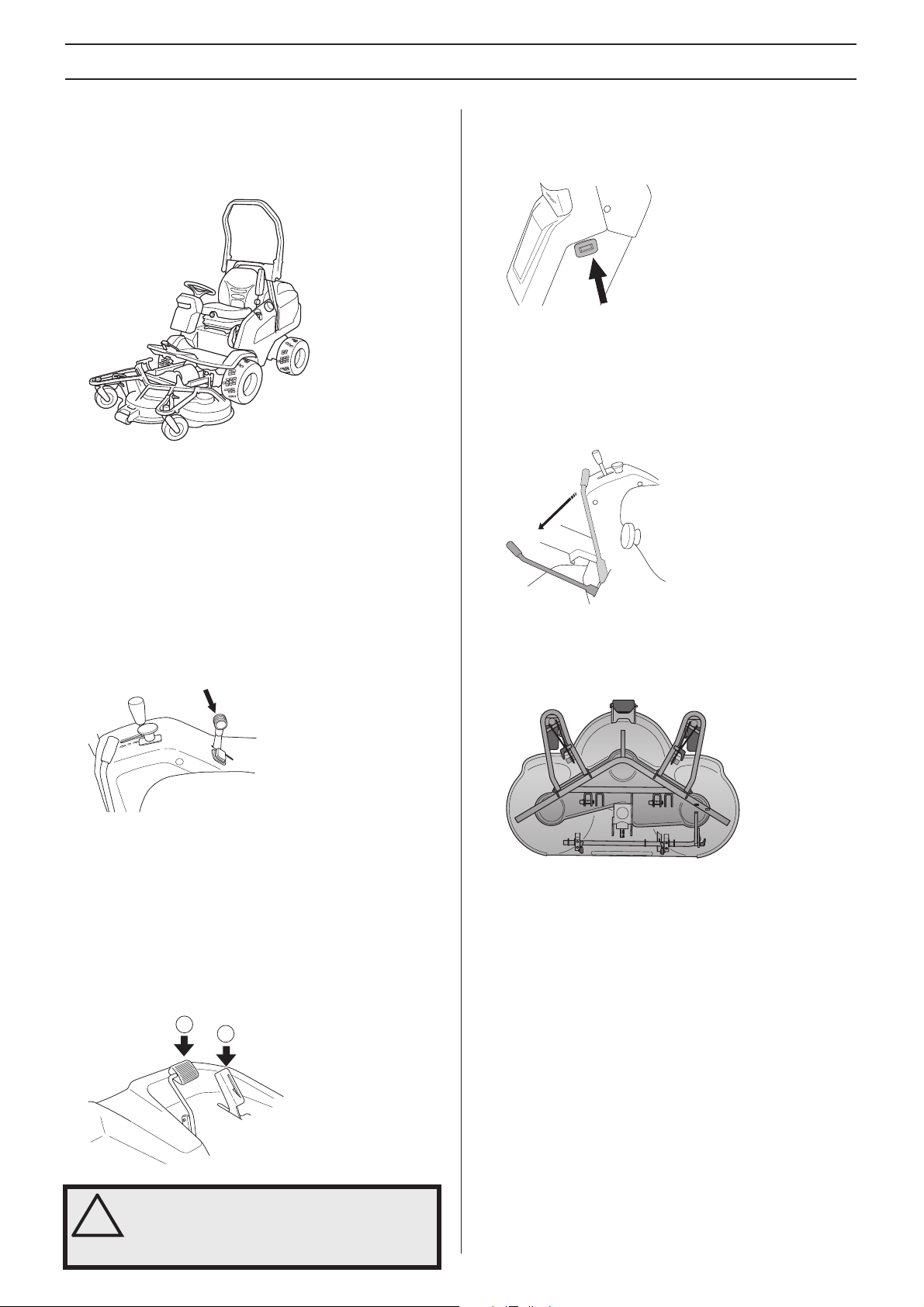

Location of the contr ols

Knob for seatback angle

2 Throttle trigger

3 Power outlet

4 Switch for the power outlet

5 Control for cutting unit drive

6 Lever for hydraulic lift of attachments

7 Parking brake

8 Switch for the lights

9 Ignition lock

10 Instrument panel

11 Speed limiter for reversing

12 Speed limiter for driving forward

13 Adjusting the cutting height

15

16 17

18

19

20

21

14 Counter

15 Temperature gauge

16 Knob for adjustment of the seat suspension

17 Lever for longitudinal seat adjustment

18 Bypass valve front axle

19 Product and serial number plate

20 Fuel gauge

21 Catch for lowering seat

22 Fuel cap

23 Knob for lumbar support

24 Cover lock

25 Bypass valve rear axle

22

23

24

25

English

– 7

SAFETY INSTR UCTIONS

8

•

•

W

W

W

W

Saf ety instructions

These instr uctions are for your safety. Read them carefully.

Insure y our Rider

Check the insurance coverage for your new Rider.

• Contact your insurance company.

• You should have fully comprehensive insurance including:

third party, fire, damage, theft and liability

General use

Read all the instructions in this operator’s manual and on

the machine before you start it. Ensure you understand

them and then observe them.

• Remember that the driver is responsible for dangers or

accidents.

• Never carry passengers. The machine is only intended to

be used by one person.

• Always look downwards and backwards before and while

reversing. Keep watch for both large and small obstacles.

• Slow before cornering.

• Switch off the blades when you are not mowing.

ARNING! This machine produces an

electromagnetic field during operation. This

!

field may under some circumstances

interfere with active or passive medical

implants. To reduce the risk of serious or

fatal injury, we recommend persons with

medical implants to consult their physician

and the medical implant manufacturer

before operating this machine.

• Learn how to use the machine and its controls safely and

learn to how to stop quickly. Also learn to recognize the

safety decals.

• Only allow the machine to be used by adults who are

familiar with its use.

• Make sure nobody else is in the vicinity of the machine

when you start the engine, engage the drive or drive off.

• Clear the area of objects such as stones, toys, wires, etc.

that may become caught in the blades and be thrown out.

• Look out for the ejector and do not direct it towards

anyone.

• Stop the engine and prevent it from starting before you

clean the cutting unit.

• Take care when rounding a fixed object, so that the blades

do not hit it. Never run the machine over foreign objects.

ARNING! This machine can sever hands

and feet as well as throw objects. Failure to

!

observe the safety instructions can result in

serious injuries.

ARNING! The inside of the muffler contain

chemicals that may be carcinogenic. Avoid

!

contact with these elements in the event of a

damaged muffler.

ARNING! The engine emits carbon

monoxide, which is a colourless, poisonous

!

gas. Do not use the machine in enclosed

spaces.

• Only use the machine in daylight or in other well-lit

conditions. Keep the machine at a safe distance from

holes or other irregularities in the ground. Pay attention to

other possible risks.

• Never use the machine if you are tired, if you have

consumed alcohol, or if you are taking other drugs or

medication that can affect your vision, judgement or coordination.

• Keep an eye on the traffic when working close to a road or

when crossing it.

• Never leave the machine unsupervised with the engine

running. Always stop the blades, apply the parking brake,

stop the engine and remove the keys before leaving the

machine.

–

English

SAFETY INSTR UCTIONS

•

Dr

•

W

Never allow children or other persons not trained in the

use of the machine to use or service it. Local laws may

regulate the age of the user.

ARNING! You must use approved personal

protective equipment whenever you use the

!

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

• Use hearing protection to minimise the risk of hearing

impairment.

This is what y ou do

Remove obstacles such as stones, branches, etc.

• Mow upwards and downwards, not sideways.

• Do not use the machine on ground that slopes more than

10 ° .

• Take extra care if any attachments are fitted that can

change the stability of the machine.

• Avoid starting or stopping on a slope. If the tyres start to

slip, stop the blades and drive slowly down the slope.

• Always drive smoothly and slowly on slopes.

• Always use ROPS (Rollover Protective Structure) and

seat belts when riding on slopes.

• Never wear loose-fitting clothing, jewellery or similar that

can get caught in moving parts.

• Never use the machine when barefoot. Always wear

protective shoes or protective boots, preferably with steel

toes.

• Make sure that you have first aid equipment close at hand

when using the machine.

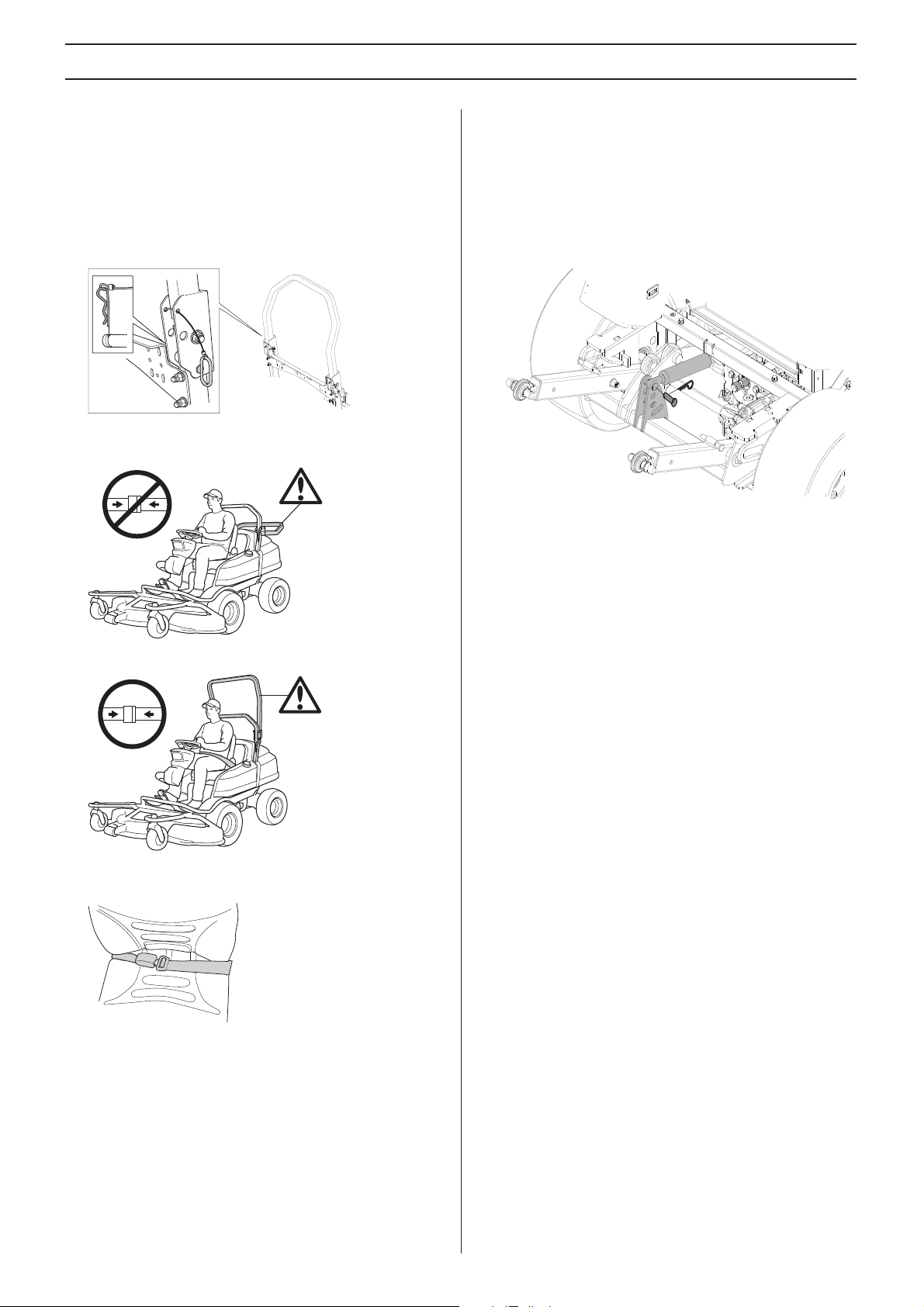

Driving on slopes

iving on slopes is one of the operations where the risk of

the driver losing control of the machine or of it overturning is

the greatest; this can result in serious injury or death. All

slopes demand extra care. If you cannot reverse up a slope or

if you feel unsure, do not mow it.

IMPORTANT INFORMATION

Do not drive down slopes with the unit raised.

• Do not make any sudden changes in speed or direction.

• Avoid unnecessary turns on slopes, if necessary, turn

slowly and gradually downwards if possible. Drive slowly.

Do not turn the wheel sharply.

• Watch out for and avoid driving over furrows, holes and

bumps. It is easier for the machine to overturn on uneven

ground. Tall grass can hide obstacles.

• Do not mow too close to edges, ditches or banks. The

machine can suddenly overturn if one wheel comes over

the edge of a steep slope or a ditch, or if an edge gives

way.

• Do not mow wet grass. It is slippery, and tyres can lose

their grip so that the machine skids.

• Do not try to stabilize the machine by putting your foot on

the ground.

• When cleaning the chassis, the machine may never be

driven near verges or ditches.

• When mowing, keep away from bushes and other objects.

• Follow the manufacturer’s recommendations regarding

wheel weights or counterbalance weights to increase

machine stability.

IMPORTANT INFORMATION

Some combinations of accessories require additional

counterweight at the rear Check with your dealer for the

right combination.

English

– 9

SAFETY INSTRUCTIONS

Children

• Serious accidents may occur if you fail to be on your guard

for children in the vicinity of the machine. Children are

often attracted to the machine and mowing. Never

assume that children will remain where you last saw them.

• Keep children away from the area to be mowed and under

close supervision by another adult.

• Keep an eye out and shut off the machine if children enter

the work area.

• Before and during reversing procedures, look behind you

and down for small children.

• Never allow children to ride along. They can fall off and

seriously injure themselves or be in the way for safe

manoeuvring of the machine.

• Never allow children to operate the machine.

• Be particularly careful near corners, bushes, trees or

other objects that block your view.

• Electrical shocks can cause injuries. Do not touch cables

when the engine is running. Do not test the ignition

system with your fingers.

WARNING! The engine and the exhaust

system become very hot during operation.

!

Risk of burn injuries if touched. When

mowing, keep away from bushes and other

materials in order to avoid a heating effect.

• If leaks arise in the fuel system, the engine must not be

started until the problem has been resolved.

• Store the machine and fuel in such a way that there is no

risk that leaking fuel or fumes can cause any damage.

• Check the fuel level before each use and leave space for

the fuel to expand, because the heat from the engine and

the sun may otherwise cause the fuel to expand and

overflow.

• Avoid overfilling. If you spill petrol on the machine, wipe up

the spill and wait until it has evaporated before starting the

engine. If you spill on your clothing, change your clothing.

• Allow the machine to cool before performing any actions

in the engine compartment.

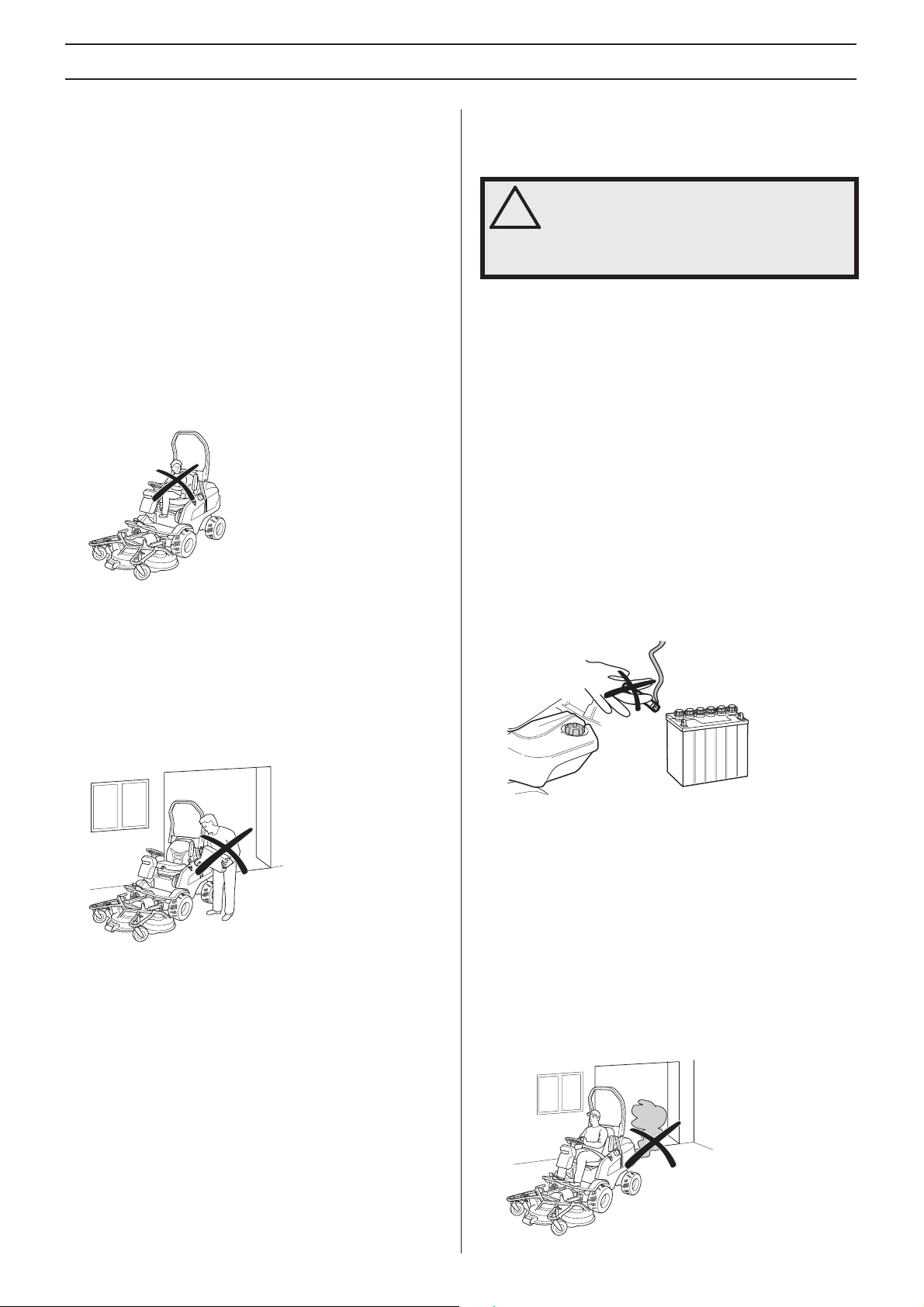

• Take care with battery maintenance. Explosive gases

form in the battery. Never perform maintenance on the

battery while smoking or in the vicinity of open flames or

sparks. This can cause the battery to explode and cause

serious injuries.

Maintenance

• Stop the engine. Prevent the engine from starting by

removing the ignition key before making any adjustments

or performing maintenance.

• Never fill the fuel tank indoors.

• Fuel and fuel vapour are poisonous and highly flammable.

Be especially careful when handling petrol and engine oil,

as carelessness can result in personal injury or fire.

• Only store fuel in containers approved for the purpose.

• Never remove the fuel cap and fill the fuel tank when the

engine is running.

• Allow the engine to cool before refuelling. Do not smoke.

Do not fill with fuel in the vicinity of sparks or naked

flames.

• Handle oil, oil filters, fuel and the battery carefully, of

environmental considerations. Follow the local recycling

requirements.

• Make sure all nuts and bolts are tightened correctly and

that the equipment is in good condition.

• Do not modify safety equipment. Check regularly to be

sure it works properly. The machine must not be driven if

protective plates, protective covers, safety switches or

other protective devices are not fitted or are defective.

• Observe the risk of injury caused by moving or hot parts if

the engine is started with the engine cover open or

protective cowlings removed.

• Never use the machine indoors or in spaces lacking

proper ventilation. Exhaust fumes contain carbon

monoxide, an odourless, poisonous and highly dangerous

gas.

10 – English

SAFETY INSTRUCTIONS

• Stop and inspect the equipment if you run over or into

anything. If necessary, make repairs before starting.

• Never make adjustments with the engine running.

• The machine is tested and approved only with the

equipment originally provided or recommended by the

manufacturer.

• The blades are sharp and can cause cuts. Wrap the

blades or wear protective gloves when handling them.

• Check regularly that the parking brake works. Adjust and

maintain as required.

• Reduce the risk of fire by removing grass, leaves and

other debris that may have fastened on the machine.

Allow the machine to cool before putting it in storage.

Transport

IMPORTANT INFORMATION

The parking brake is not sufficient to lock the machine

during transport. Ensure you secure the machine firmly to

the transporting vehicle.

• The machine is heavy and can cause serious crush

injuries. Take extra care when loading it onto or off a

vehicle or trailer.

• Use an approved trailer to transport the machine.

• To secure the machine on the trailer, two approved

tension belts and four wedge shaped wheel blocks should

be used.

Engage the parking brake and tie the tension belts around

the front and rear brackets.

Secure the machine by tensioning the belts towards the

back and the front of the trailer respectively.

Place the wheel blocks in front of and behind the rear

wheels.

• Check and observe local road traffic regulations before

transporting or driving the machine on roads.

English – 11

PRESENTATION

Presentation

Congratulations on your choice of an excellent quality product

that will give you great pleasure for many years. This

operator’s manual describes P 520D and P 525D.

P 520D and P 525D are equipped with hydraulic steering and

an equipment hoist.

The machines are equipped with four wheel drive.

The power transmission from the engine is handled by a

hydrostatic transmission, which allows variable variation of

the speed by using the pedals. One pedal for driving forward

and one for reverse.

Counter

The chronometer shows how many hours the engine has

been running.

Any time when the engine is not running but the ignition is

switched on is not registered. The last digit shows tenths of an

hour (6 minutes).

Parking brake

Operate the parking brake by moving the handle forwards.

Throttle trigger

The throttle control regulates the engine speed, and thereby

also the rotation speed of the blades.

To increase or reduce the engine speed the control is moved

forwards or backwards.

When driving the throttle control must be in the position for

maximum engine speed, work mode.

Speed limiter

The speed of the machine is steplessly regulated with two

pedals. Pedal (1) is used to drive forwards, and pedal (2) to

drive backwards.

1

2

Cutting unit

P 520D and P 525D can be equipped with two different cutting

units.

• Combi 132

• Combi 155

The Combi-unit, equipped with a BioClip-plug, finely chops

the cuttings to fertiliser. Without the BioClip-plug the unit

works in the same way as a rear ejection unit. The rear ejector

ejects the clippings behind the unit without finely chopping

them.

!

12 – English

WARNING! Make sure that branches do not

obstruct the pedals when mowing under

bushes. Otherwise there is a risk you may

lose control.

PRESENTATION

Adjusting the cutting height

The cutting height can be adjusted to seven different

positions.

Select the required cutting height (1-7) using the cutting

height adjusters. Set the knobs horizontally so that they do

not snag on bushes and the like.

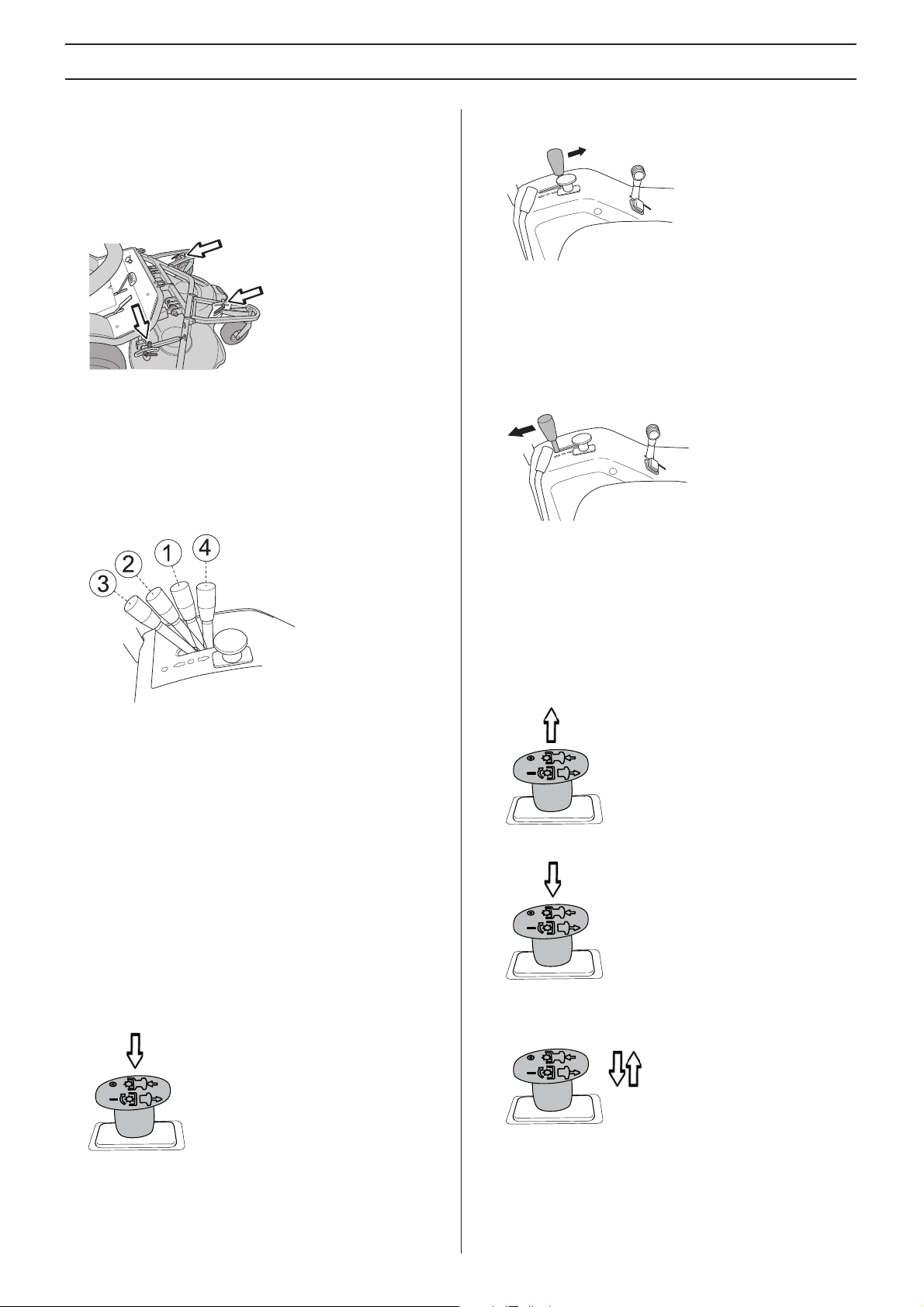

Lever for hydraulic lift of attachments

The lifting lever is used to put the cutting unit in either the

transport or mowing position when hydraulic pressure is

available.

The lever has four different positions.

Pull the lever backwards to engage the transport position. The

unit is then raised.

The cutting unit can be raised slightly with the blades rotating.

This is to facilitate the mowing of extremely tall grass or

uneven surfaces.

Lowering the Unit (Mowing Position)

Move the hydraulic lifting lever forwards to engage the cutting

position.

When cutting the lever should be set directly to the floating

position (3).

• Position 1 is the neutral position.

• Position 2 lowers the cutting unit with spring return to the

neutral position

• Position 3 is floating where the lever stops. The unit is

lowered to the automatically floating position, which

means that the cutting unit follows the contours of the

ground.

• Position 4 raises the cutting unit with spring return to

neutral position.

When cutting the lever should be set directly to the floating

position (3).

Lifting the Cutting Unit (Transport Position)

Stop the blades by pressing the stop button.

Controls for operating the cutting unit blades

The cutting unit can be started only when the driver is sitting

in the seat.

• Pull out the lever to engage the drive of the blades.

• Push in the lever to disengage the blades.

When the safety circuit has stopped the drive to the cutting

unit, the control must be pushed and pulled out again to start

the blades.

The safety circuit is triggered and the cutting unit is stopped

in the following cases:

• When the driver leaves the seat with the blades engaged.

There is a short delay to prevent stopping if the driver

bounces on the seat.

English – 13

PRESENTATION

Seat

The seat has a jointed attachment on the front edge and can

be tipped forward.

To fold the seat forward, the latch for the seat must be

operated.

WARNING! Take care so that hands are not

trapped or injured by the locking hooks

!

when the seat is folded back.

WARNING! Do not adjust seat settings while

driving. Risk of unsafe manoeuvring.

!

The seat can also be adjusted lengthways.

• When making adjustments, the lever under the front edge

of the seat is moved up, after which the seat can be moved

backwards or forwards to the desired position.

• The lumbar support is adjusted with the knob on the left

side of seat back .

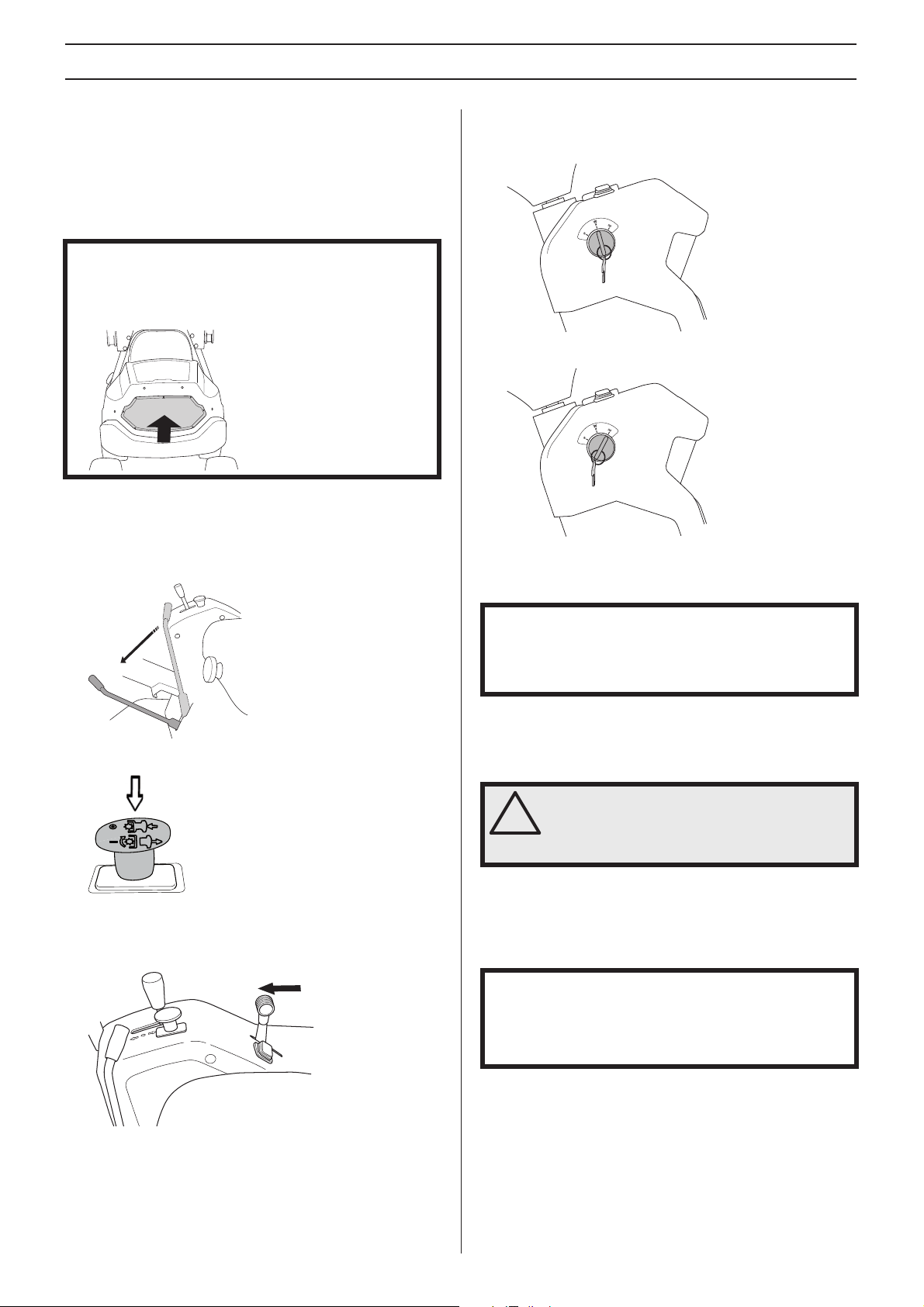

Fueling

The fuel level in the tank is shown by the gauge on top of the

tank.

Fill with diesel fuel. Petrol must not be used under any

circumstances. Use fuel with a cetane rating over 45. Max

RME mixing 5% in mineral oil-based fuels.

• The seat suspension can be adjusted to driver's weight.

The weight is adjusted by turning the knob under the front

edge of the seat .

On the sides of the backrest are two knobs:

• Seatback angle is adjusted with the knob on the right side.

WARNING! Diesel is highly flammable.

Exercise care and refuel outdoors (see

!

safety instructions).

The diesel engine injection system is very sensitive and can

be damaged by the slightest contamination. Observe the

greatest possible fuel cleanliness. Use only clean containers.

Clean the area around the fuel cap. Contamination in the tank

can cause operating problems.

If you have spilt fuel on yourself or your clothes, change your

clothes. Wash any part of your body that has come in contact

with fuel. Use soap and water.

Wipe up any spillage. Materials contaminated by fuel must be

moved to a safe location.

IMPORTANT!

Do not use the fuel tank as a support area.

Lights and power outlet

The lights are switched on and off using the switch on the

instrument panel.

14 – English

A seat heater or mobile phone charger are examples of

articles that can be connected to the power socket.

PRESENTATION

The power outlet is switched on and off using power switch on

the control panel.

The power outlet works even if the ignition is turned off. Do

not forget to disconnect the power outlet or remove the power

consumer when the machine is not in use.

The voltage is 12 V.

The power outlet is fuse protected by its own fuse. The fuse

for the power outlet is placed in the electrical connection box,

behind the side plate on the control panel.

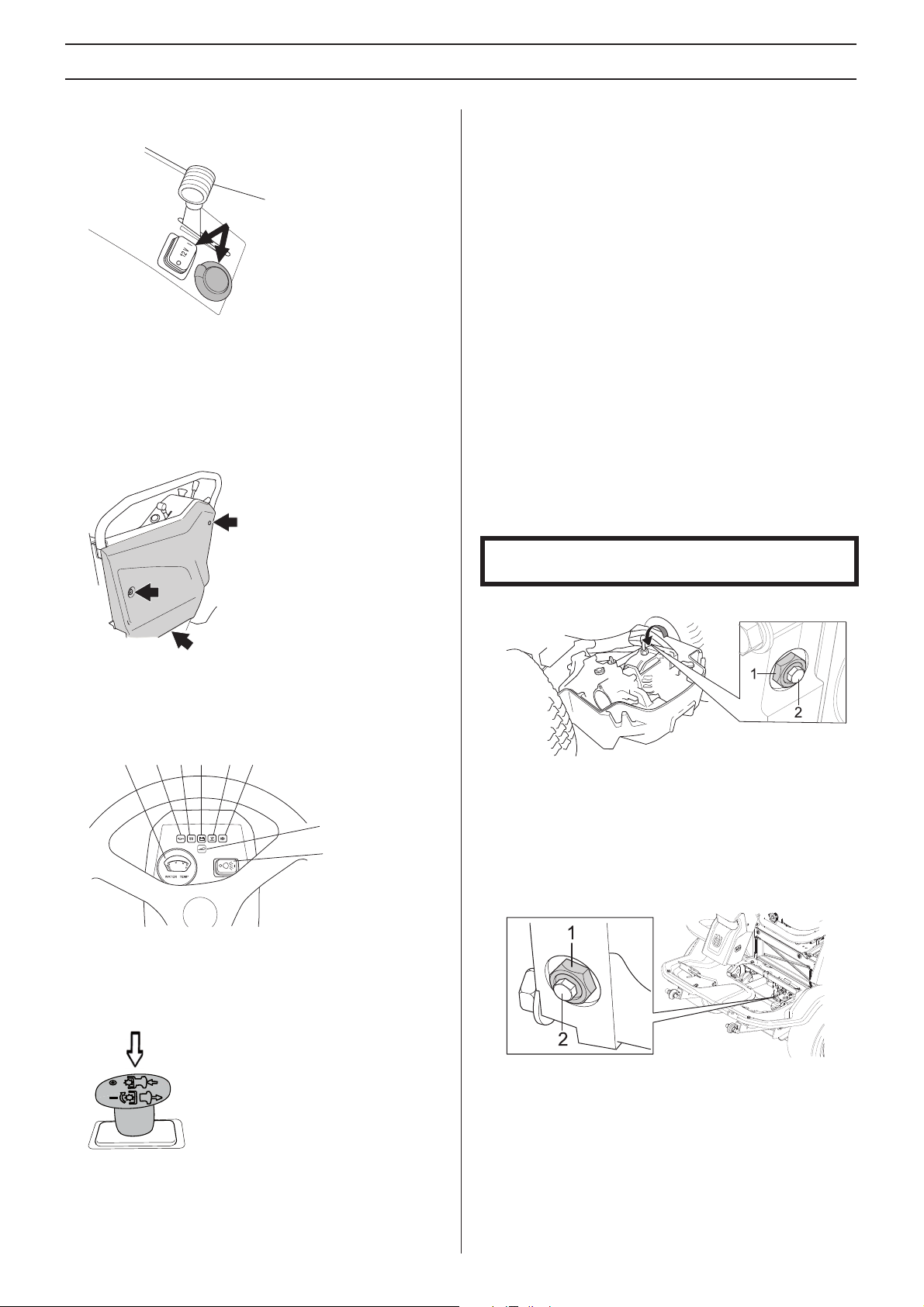

2 Oil pressure, check oil level and top up if necessary.

3 Ignition

4 Battery charging

5 Power transmission connected

6 Parking brake

7 Spotlight

8 Switch for the lights

Bypass valves

Hydraulic pressure must be released in order for the ride-on

mower to be moved when the engine is shutoff.

The hydraulic pressure is opened and closed with a bypass

valve.

If you try to drive the machine without hydraulic pressure, it

will not move. The drive on the axle is disengaged if one valve

is open.

The P 520D and theP 525D has two valves, one valve for the

front axle and one for the rear axle.

IMPORTANT! Always drive the machine with both valves

closed.

Instrument panel

The indicator lights are on the steering console under the

steering wheel.

123456

7

8

1 Temperature gauge for coolant. The engine is liquid

cooled. If overheating of the engine is indicated the first

action to take is to reduce the engine temperature by

running the engine at idle with no load. Turn off the power

transmission

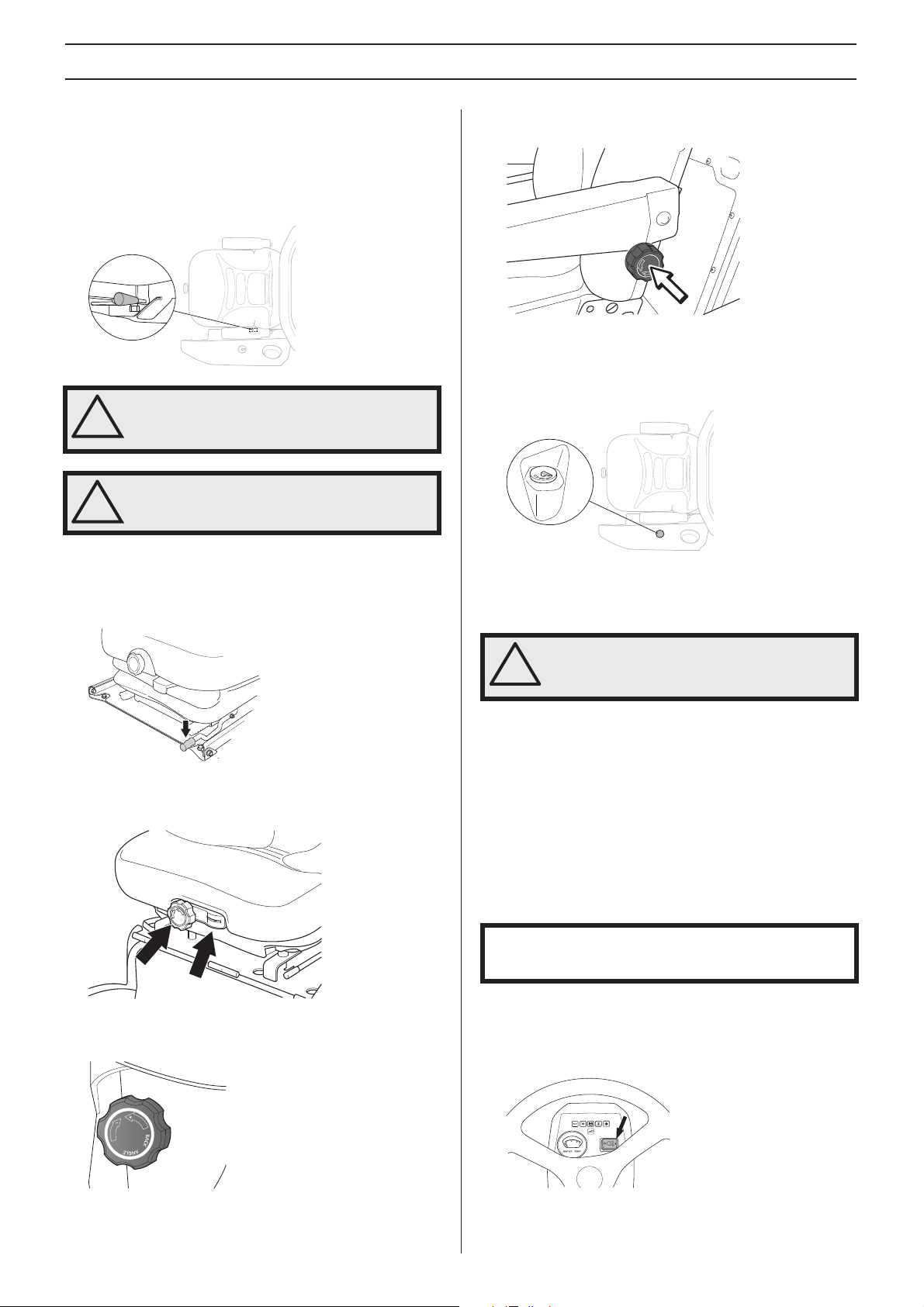

• Bypass valve rear axle

- The hydraulic pressure is released by opening the locking

nut (1) 1/4-1/2 turn anti-clockwise, then the bypass valve (2)

2 turns.

- The hydraulic pressure is switched on by closing the valve.

Close the valve nut (2) fully before tightening the locking nut

(1).

• Bypass valve front axle

Check coolant level and top up if necessary. Also check

that the radiator grill and radiator are clean and not

clogged. The grill is at the rear of the machine and on top

of the bonnet.

- The hydraulic pressure is released by opening the locking

nut (1) 1/4-1/2 turn anti-clockwise, then the bypass valve (2)

2 turns.

- The hydraulic pressure is switched on by closing the valve.

Close the valve nut (2) fully before tightening the locking nut

(1).

English – 15

PRESENTATION

ROPS (Roll Over Protective Structure)

ROPS is a protective frame that reduces the risk of injury in

the event of overturning. Use ROPS and a safety belt when

driving on slopes.

The frame can be folded down. Remove the two pins that hold

the frame and fold it backwards.

If the frame is folded down the safety belt should NOT be

used.

Auxiliary lift system

The auxiliary lift system transfers the weight of the cutting unit

pivot wheel to the machine's front wheel.

The effect of the auxiliary lift system can be adjusted by

moving the gas spring up or down.

Maximum effect is obtained when the gas spring is placed in

the top hole.

No effect is obtained in the slot at the bottom.

When using the cutting unit, the gas spring must be mounted

in the top hole.

If the frame is folded up, the safety belt must be used.

When the safety belt is not used, it must be wrapped around

the chair back and tightened.

16 – English

STARTING ENGINE

Before starting

• Read the safety instructions and information concerning

the placement of controls and functions before starting.

• Perform daily maintenance before starting as set out in

the Maintenance schedule.

IMPORTANT INFORMATION

The air intake grille in the engine cover must not be blocked

by, for example, clothing, leaves, grass or dirt. Impaired

cooling of the engine. Risk of major engine damage.

Start the engine

1 Ensure that the bypass valves are closed.

2 Apply the parking brake.

5 Turn the ignition key to the ignition position and hold it

there until the indicator light on the instrument panel goes

out.

6 Turn the ignition key to the start position.

7 When the engine starts release the ignition key

immediately back to neutral position.

3 Push the PTO switch down (blades off).

The engine will not start unless the parking brake is on

and the PTO switch is pressed

4 Move the throttle control to half throttle.

IMPORTANT INFORMATION

Do not run the starter for more than about 15 seconds at a

time. If the engine does not start, wait about 15 seconds

before trying again.

8 Set the required engine speed with the throttle control.

Let the engine run at moderate speed or half throttle for 35 minutes before subjecting it to heavy load.

WARNING! Never run the engine indoors, in

enclosed or poorly ventilated areas. The

!

exhaust fumes contain toxic carbon

monoxide.

Starting and driving when cold

If the engine fails to start due to the cold, repeat ignition and

attempt to re-start. Start gas or ether must not be used.

IMPORTANT! At temperatures below 0 ° C, the machine

must be warmed up for at least 10 minutes for the hydraulic

oil and transmission to get hot. Otherwise there is a risk of

the transmission breaking down thereby reducing the

service life of the transmission.

Winter fuel

When driving in very cold weather operating problems due to

paraffin precipitation can occur if you run on standard fuel. To

counteract this, winter fuel is sold in the climate areas

affected. In some regions, different fuel is sold in summer and

winter. Ask your fuel supplier and use only winter fuel below

0°C (+32°F).

English – 17

Loading...

Loading...