Page 1

HP StoreEver Enterprise Systems Library (ESL) G3 Tape Library

User Guide

HP Part Number: QN998-96133

Published: June 2014

Edition: 7

Page 2

© Copyright 2011, 2014 Hewlett-Packard Development

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

1 Library overview.......................................................................................11

Hardware and firmware differences..........................................................................................12

Library features......................................................................................................................13

Density.............................................................................................................................13

Centralized management....................................................................................................13

Proactive availability..........................................................................................................13

Data Path and Control Path Failover.....................................................................................13

Serviceability and reliability................................................................................................14

Host attachment.................................................................................................................14

Remote management..........................................................................................................14

Capacity on demand.........................................................................................................14

Control module......................................................................................................................14

Expansion modules.................................................................................................................15

High density expansion modules..............................................................................................17

Library management module....................................................................................................17

Management control blade (MCB).......................................................................................18

Robotics control unit (RCU)..................................................................................................18

Library motor drive (LMD) or library power control (LPC1)........................................................18

I/O Management units...........................................................................................................18

Control management blade (CMB).......................................................................................19

Ethernet expansion blade (EEB)...........................................................................................19

Picker (cartridge accessor).......................................................................................................19

Import/Export stations.............................................................................................................19

Extended I/E option...........................................................................................................19

Cartridges.............................................................................................................................20

Cartridge magazines..............................................................................................................20

Support for WORM................................................................................................................22

Tape drives............................................................................................................................22

LTO drives.........................................................................................................................22

Operator panel .....................................................................................................................23

Power system..........................................................................................................................23

Using the library demonstration mode.......................................................................................23

Starting demo mode...........................................................................................................24

Pausing demo mode...........................................................................................................24

Stopping demo mode.........................................................................................................24

2 Modifying the library configuration.............................................................25

Setup Wizard prerequisites......................................................................................................25

Accessing the Setup Wizard ...................................................................................................25

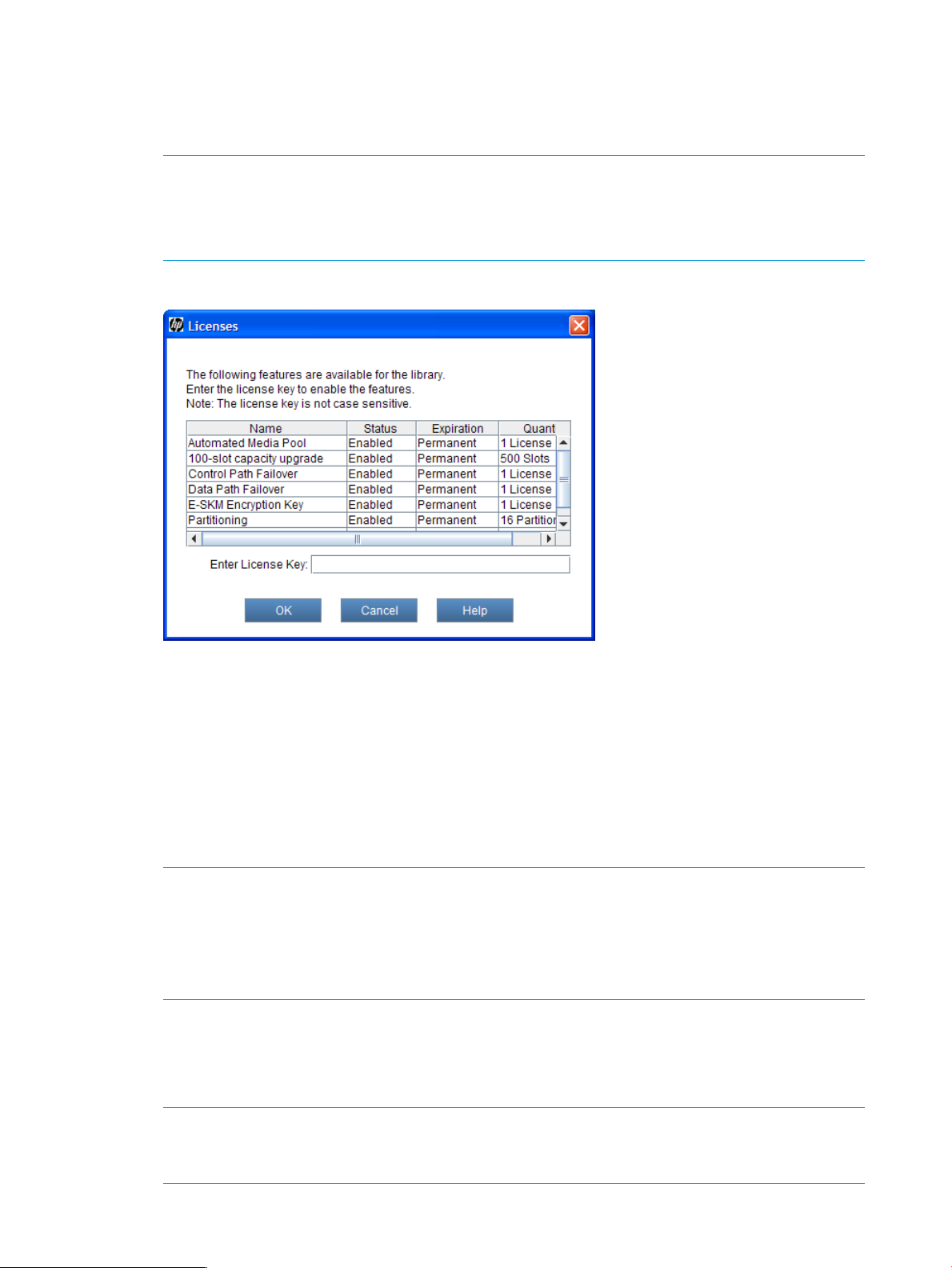

Entering License Keys..............................................................................................................25

Working with partitions...........................................................................................................27

Understanding partition media policy settings........................................................................27

Media domain..............................................................................................................27

Media type..................................................................................................................27

Media ID checking........................................................................................................28

Return media identifier...................................................................................................28

Returning media identifiers to hosts..................................................................................28

Working with library control paths.......................................................................................29

Creating partitions.............................................................................................................29

Creating partitions with the Setup Wizard........................................................................29

Creating partitions automatically.....................................................................................30

Creating partitions manually using Simple mode...............................................................30

Contents 3

Page 4

Creating partitions manually using Expert mode................................................................32

Modifying partitions...........................................................................................................35

Data Path Failover for partitions...........................................................................................37

Deleting partitions..............................................................................................................38

Selecting a partition control path.........................................................................................39

Control Path Failover for partitions........................................................................................40

Automated Media Pool (AMP).............................................................................................40

Enabling or disabling IPv6 and IPv4 network configuration..........................................................42

Setting up IPv4 network configuration...................................................................................42

Setting up IPv6 network configuration...................................................................................44

Setting the network configuration using the Setup Wizard.......................................................45

Configuring the host name using the Setup Wizard.....................................................................46

Specifying the date and time using the Setup Wizard..................................................................46

Specifying the date and time....................................................................................................46

Filling the library with cartridges (bulk loading)..........................................................................47

Setting up the network configuration.........................................................................................47

Changing internal IP network addressing...................................................................................48

Enabling Federal Information Processing Standards (FIPS)............................................................49

Configuring DNS....................................................................................................................50

Setting up network security......................................................................................................50

Setting up drives.....................................................................................................................51

Configuring e-mail..................................................................................................................51

Setting up or changing e-mail configuration..........................................................................52

Testing current e-mail configuration.......................................................................................53

Setting up e-mail notifications...................................................................................................53

Setting up media security notifications.......................................................................................56

Setting up advanced reporting options......................................................................................57

Saving report criteria templates............................................................................................58

Scheduling a new job........................................................................................................58

Editing scheduled jobs........................................................................................................60

Deleting scheduled jobs......................................................................................................61

Configuring drive cleaning.......................................................................................................61

Assigning cleaning magazines and importing cleaning media.................................................61

Exporting cleaning media...................................................................................................63

Unassigning a cleaning magazine.......................................................................................63

Registering SNMP traps...........................................................................................................64

Registering an application...................................................................................................64

Removing an application trap registration.............................................................................64

Using the secure manager configuration wizard..........................................................................65

Using the Host Configuration option.....................................................................................65

Using the Access Group Configuration option........................................................................66

Using the Host Access Configuration option...........................................................................68

Using LDAP............................................................................................................................68

LDAP server guidelines.......................................................................................................68

User and group access..................................................................................................68

OpenLDAP 2.4.............................................................................................................69

Configuring LDAP..............................................................................................................69

General tab..................................................................................................................69

Access tab...................................................................................................................69

Test tab........................................................................................................................70

Failure modes...............................................................................................................70

Configuring library behavioral settings......................................................................................71

Configuring screen saver preferences........................................................................................73

About the configuration record.................................................................................................74

Setting aisle lights...................................................................................................................74

4 Contents

Page 5

Clear the registered Command View TL management station........................................................75

Robot failover.........................................................................................................................75

3 Operating the library................................................................................76

Logging on and off.................................................................................................................76

Logging on from the OCP...................................................................................................76

Logging off from the OCP...................................................................................................76

Logging on from the Library Management Console (LMC) using a web browser.........................77

Software requirements...................................................................................................77

Accessing the LMC applet..............................................................................................77

Logging off from the LMC....................................................................................................78

Connecting to multiple libraries................................................................................................78

Using the indicator panel and OCP..........................................................................................78

Using the indicator panel........................................................................................................79

Accessing the Library Management Console (LMC).....................................................................80

Menus..............................................................................................................................81

Toolbar............................................................................................................................84

Reading the library information panel...................................................................................85

System status buttons..........................................................................................................86

Viewing details about events...............................................................................................87

Understanding location coordinates..........................................................................................88

Cartridge locations............................................................................................................88

Tape drive locations...........................................................................................................92

Viewing the physical library or a partition..................................................................................93

Using the View menu..........................................................................................................93

Using the Managed Views region of the LMC display.............................................................93

Changing the library state.......................................................................................................93

Taking the physical library or a partition online or offline........................................................93

Online and offline functionality............................................................................................94

Working with local user accounts.............................................................................................95

Creating local user accounts...............................................................................................95

Modifying local user accounts.............................................................................................97

Deleting local user accounts................................................................................................97

Viewing local user account permissions................................................................................98

User privileges and library/partition functions........................................................................98

Shutting down/rebooting the library.......................................................................................101

Library Access Wizard..........................................................................................................102

Aisle access....................................................................................................................103

Robot access...................................................................................................................103

Powering off the library.........................................................................................................104

Powering on the library.........................................................................................................104

Locking/Unlocking the I/E station...........................................................................................104

Using the library when robotics are not ready..........................................................................105

4 Monitoring the library.............................................................................107

Using Library Explorer...........................................................................................................107

Understanding the graphical display, frame view.................................................................110

Accessing library operations.............................................................................................110

Monitoring system components...............................................................................................110

Monitoring system status...................................................................................................110

Monitoring drive status.....................................................................................................112

Monitoring I/E station status..............................................................................................113

Monitoring slots status......................................................................................................114

Checking slot status.....................................................................................................115

Filtering slots by location..............................................................................................115

Monitoring media status...................................................................................................116

Contents 5

Page 6

Monitoring library configuration........................................................................................117

Working with the media usage report.................................................................................117

Monitoring sensor status...................................................................................................118

Accessing the sensor status dialog box...........................................................................118

Displaying cooling fan information................................................................................118

Displaying power supply information.............................................................................119

Displaying temperature information...............................................................................119

Displaying voltage information......................................................................................120

Displaying humidity information....................................................................................120

Saving and restoring library configuration...........................................................................120

Types of configuration image files..................................................................................121

When to save the library configuration..........................................................................121

Saving a remote restore image......................................................................................121

Saving a local rescue image.........................................................................................122

Restoring library configuration......................................................................................123

Rescuing library configuration.......................................................................................124

Reverting library configuration......................................................................................125

E-mailing or saving the configuration record........................................................................126

E-mailing the configuration record.................................................................................126

Saving the configuration record.....................................................................................126

Monitoring user status......................................................................................................127

Monitoring partitions status...............................................................................................128

Viewing partition status details...........................................................................................128

Monitoring key management.............................................................................................129

Creating support tickets.........................................................................................................129

E-mailing, saving, and printing status information......................................................................130

5 Maintaining the library...........................................................................132

Configuring and testing drives................................................................................................132

Viewing the Drives window...............................................................................................132

Viewing drive details........................................................................................................134

Emailing and saving support tickets....................................................................................135

Cleaning a drive..............................................................................................................136

Saving a report template.......................................................................................................137

Generating an Events Report.............................................................................................137

Generating a Tape Alert History Report..............................................................................138

Teaching the library (configuration and calibration)...................................................................138

Running configuration teach..............................................................................................138

Running calibration teach.................................................................................................139

Working with verification tests................................................................................................140

Verification test descriptions...............................................................................................141

Installation verification test............................................................................................141

Partial system tests.......................................................................................................141

Field replaceable unit operational tests...........................................................................141

Custom library alignment tests.......................................................................................141

Verification test functions...................................................................................................142

Library alignment test...................................................................................................142

Get/Put test................................................................................................................143

Accessor assembly test.................................................................................................143

Picker assembly test.....................................................................................................143

Drive sled assembly test...............................................................................................143

Scan barcode test.......................................................................................................143

I/E station assembly test...............................................................................................143

Scanner fiducial test....................................................................................................144

Tower assembly test.....................................................................................................144

6 Contents

Page 7

Initiating verification tests..................................................................................................144

Running the installation verification test..........................................................................144

Partial tests.................................................................................................................147

FRU operational tests...................................................................................................149

Running custom tests....................................................................................................151

Understanding the verification test inventory........................................................................152

Library inventory.........................................................................................................152

Drive inventory............................................................................................................153

Test results.......................................................................................................................153

Verification test graphical reports.......................................................................................154

Joint alignments..........................................................................................................154

Vertical alignments......................................................................................................154

Horizontal alignments..................................................................................................155

Calibration offsets.......................................................................................................155

Boundary/accessibility................................................................................................155

Get/Put.....................................................................................................................155

Scan fiducials.............................................................................................................156

Picker pivot/reach.......................................................................................................156

Verification test logs.........................................................................................................157

Viewing test logs.........................................................................................................157

Viewing graphical reports and text logs.........................................................................159

Emailing, saving, and printing test logs...............................................................................160

Using the partitions defragmentation tool.................................................................................160

Defragmenting partitions...................................................................................................161

Canceling defragmentation...............................................................................................163

Recovering after defragmentation is interrupted....................................................................163

Cycling library power.......................................................................................................163

Using Sift Sort......................................................................................................................163

Exporting media via Sift Sort.............................................................................................163

Capturing Sift Sort screen shot...........................................................................................165

Retrieving, emailing, and saving MIB files................................................................................165

Maintaining air filters............................................................................................................166

Configuring robot and power rail health checks........................................................................167

6 Working with cartridges and barcodes.....................................................168

Handling cartridges properly.................................................................................................168

Removing lodged cartridges...................................................................................................168

Write-protecting cartridges.....................................................................................................169

Barcode requirements...........................................................................................................169

Installing barcode labels........................................................................................................170

Using cleaning cartridges......................................................................................................171

Managing media.................................................................................................................171

Importing cartridges into partitions.....................................................................................172

Exporting cartridges from partitions....................................................................................173

Loading drives.................................................................................................................173

Unloading drives.............................................................................................................174

Moving media.................................................................................................................174

Inventory.........................................................................................................................175

7 Managing library firmware and software versions.......................................176

Updating library software......................................................................................................176

Accessing the update firmware wizard................................................................................176

Installing new library software...........................................................................................178

Downloading a new library software package.....................................................................178

Installing a new library software package...........................................................................179

Reinstalling current library software....................................................................................179

Contents 7

Page 8

Rolling back to the previous build package..........................................................................180

Updating drive firmware........................................................................................................181

Accessing the Update Drive Firmware window.....................................................................181

Downloading new drive firmware.......................................................................................182

Updating drive firmware using firmware images...................................................................183

Updating drive firmware using update tapes............................................................................184

8 Troubleshooting your library.....................................................................186

Is the access door closed?.....................................................................................................186

Testing the accessor..............................................................................................................186

Testing the scanner...............................................................................................................186

Testing the signals and sensors...............................................................................................187

Testing the picker..................................................................................................................187

Is a cartridge or drive having problems?..................................................................................188

How does the library report issues?........................................................................................188

Understanding indicators on system status buttons................................................................190

Understanding email notifications......................................................................................190

Working with events.............................................................................................................191

Event guidelines...............................................................................................................191

Displaying event lists........................................................................................................193

Using system status buttons to display event lists..............................................................194

Using the Events command or the Events button to display event lists.......................................195

Viewing event details............................................................................................................196

Viewing history event details.............................................................................................199

Viewing event details reports.............................................................................................200

Viewing repair pages.......................................................................................................202

Viewing tape alerts..........................................................................................................203

Creating a Tape Alert History report...................................................................................203

Emailing, saving, and printing event information..................................................................204

Running verification tests to determine issue resolution...........................................................205

Closing events.................................................................................................................206

Closing individual events..............................................................................................206

Closing multiple events................................................................................................206

Generating the Events report.............................................................................................206

Specifying Events report criteria.....................................................................................207

Printing or exporting a report to PDF..............................................................................208

Exporting a report to an email or a text file....................................................................209

Saving a report template..............................................................................................209

Interpreting LEDs...................................................................................................................209

Interpreting blade status LEDs............................................................................................209

Actions based on LED states.........................................................................................211

Interpreting drive status LEDs..............................................................................................212

Interpreting fibre port link LED............................................................................................213

Drive sled Fibre Channel link LED..................................................................................213

Interpreting MCB port LEDs...............................................................................................213

MCB Ethernet port LEDs...............................................................................................213

MCB Fibre Channel port LEDs.......................................................................................214

Interpreting LBX terminator LEDs.........................................................................................214

Interpreting power supply LEDs..........................................................................................215

Accessing Online Help .........................................................................................................216

9 Support and other resources....................................................................217

Contacting HP......................................................................................................................217

Subscription service..............................................................................................................217

Related information...............................................................................................................217

HP websites.........................................................................................................................218

8 Contents

Page 9

Typographic conventions.......................................................................................................218

Rack stability........................................................................................................................219

Customer self repair..............................................................................................................219

10 Documentation feedback.......................................................................220

A ESKM Management Solutions..................................................................221

Enabling the ESKM License Key..............................................................................................221

Configuring Encryption Key Management................................................................................221

Using Select Key Management Type...................................................................................221

Using Update Key Manager Configuration..........................................................................223

Using Update Key Manager Certificate...............................................................................223

B Using the Key Management Interoperability Protocol (KMIP) feature..............224

Key Managers.....................................................................................................................224

Operation...........................................................................................................................224

Licensing.............................................................................................................................224

KMIP Configuration...............................................................................................................224

Verifying the KMIP encryption feature is working.......................................................................229

Basic encryption..............................................................................................................229

Failover test.....................................................................................................................230

C Tape Alert listing....................................................................................231

D CLI Guide.............................................................................................234

Introduction..........................................................................................................................234

Accessing the CLI.................................................................................................................234

Paths...................................................................................................................................234

Global Commands...............................................................................................................235

help...............................................................................................................................235

home.............................................................................................................................235

exit................................................................................................................................235

up..................................................................................................................................235

Alphabetical List of Commands...............................................................................................236

Command Details.................................................................................................................237

clear station....................................................................................................................237

move media....................................................................................................................238

reboot drive....................................................................................................................239

reboot library..................................................................................................................240

restore system defaults......................................................................................................241

save support ticket............................................................................................................242

set network ipv4Address...................................................................................................243

set partition.....................................................................................................................244

show drive hostport..........................................................................................................245

show firmware revisions....................................................................................................246

show library configuration.................................................................................................247

show library sensors.........................................................................................................249

show library status...........................................................................................................251

show library time.............................................................................................................252

show media....................................................................................................................253

show network information.................................................................................................254

show partitions................................................................................................................255

E Frequently Asked Questions.....................................................................256

F Belarus Kazakhstan Russia marking...........................................................258

Turkey RoHS material content declaration.................................................................................258

Ukraine RoHS material content declaration..............................................................................258

Warranty information............................................................................................................258

Contents 9

Page 10

G Product Safety Statements.......................................................................260

Mechanical Locks.................................................................................................................260

Power Button on the Library Indicator Panel..............................................................................260

Glossary..................................................................................................261

Index.......................................................................................................263

10 Contents

Page 11

1 Library overview

The ESL G3 automates the retrieval, storage, and control of tape cartridges. Application software

on the host can use the library robotics to mount cartridges into tape drives and retrieve them

without operator intervention.

The library can be installed on a solid or raised floor. It has a standard 19-inch rack footprint and

can be placed in a standard server rack space. Because the library provides access by way of

the access and service doors, the library can be placed with either side against a wall or between

racks.

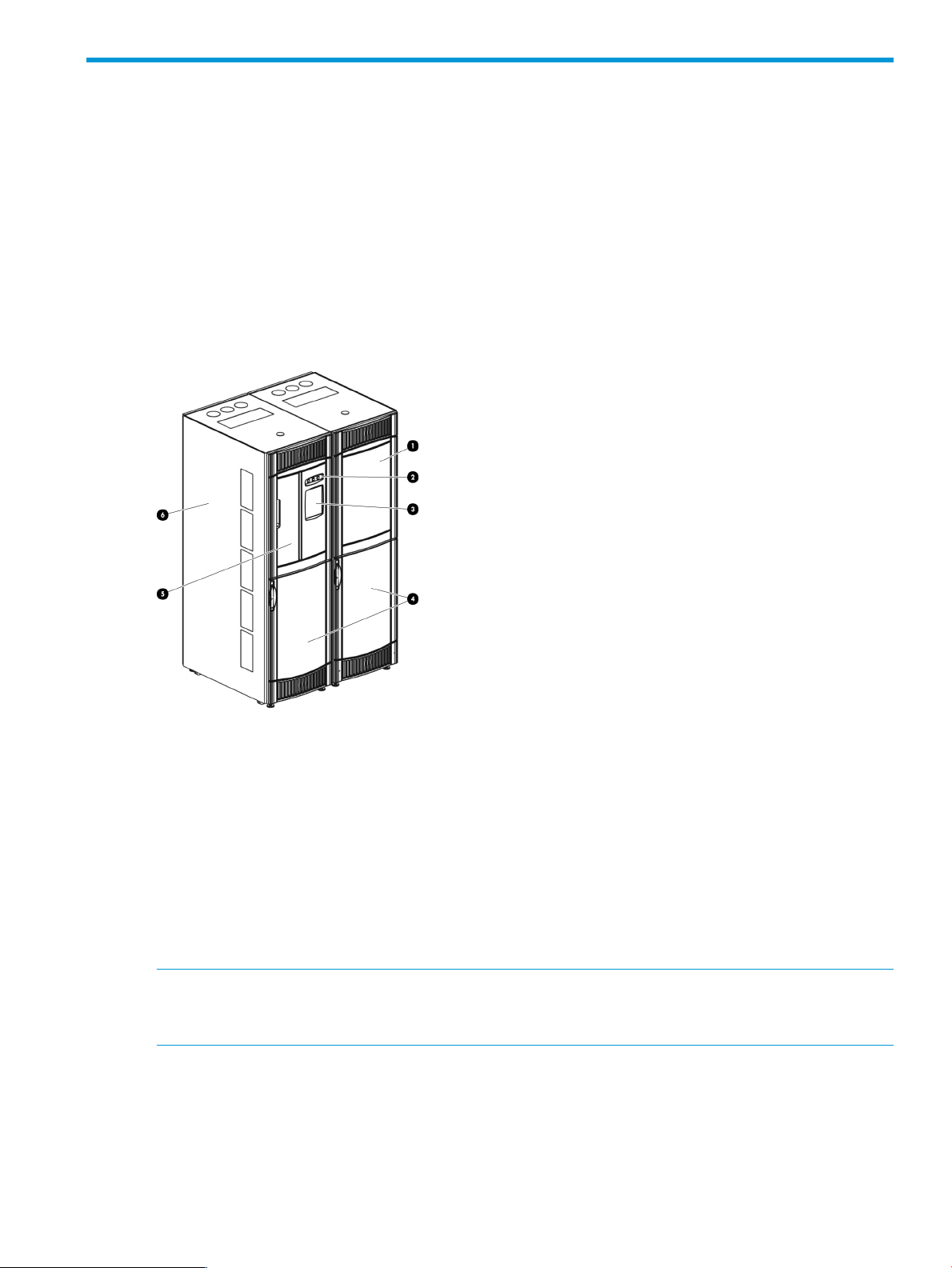

Figure 1 (page 11) shows a front view of the library, consisting of a control module and expansion

module.

Figure 1 Front view of a control module and expansion

2. Indicator panel1. Expansion module

4. Access doors3. Operator Control Panel (OCP)

6. Control module5. Import/Export station (I/E station)

The library is designed for ease of installation, configuration, and field upgrades.

The minimum library configuration of a single robot library consists of:

• One control module

• One left parking module

• One right parking module

NOTE: Expansion Modules are available in two types; standard Expansion Modules (EMs) and

High Density Expansion Modules (HDEMs). For more information, see “Expansion modules”

(page 15).

As your storage and tape drive requirements change, you can add additional Expansion Modules

to accommodate your needs.

The maximum library configuration is dependant on whether it is a single or dual robot library.

11

Page 12

A single robot library maximum configuration can accommodate:

• 1 control module

• 0 to 15 expansion modules

• 102 to 12,006 cartridges

• 1 to 192 tape drives

A dual library maximum configuration can accommodate:

• 1 control module

• 2 to 16 expansion modules

• 102 to 11,760 tape cartridges

• 1 to 192 tape drives

Hardware and firmware differences

Libraries shipped before June 2012 with Control Module SKU QQ007A are likely to be Hardware

Revision 1 (HW REV1). These libraries are characterized by:

• A multi-part accessor or picker

• An X-axis gear track system

• A Library Motor Drive (LMD) board in the Control Module

• Robot power via an umbilical cable along the floor of the library

• Removable calibration targets

• An accessor installed on the Y-rail

Libraries shipped after June 2012 with Control Module SKU QQ007B are likely to be Hardware

Revision 2 (HW REV 2) libraries. These libraries were introduced to support dual robot capability,

but all single robot libraries now use this architecture. HW REV 2 libraries are characterized by:

• A new one-piece robot

• An X-axis gear track system

• A Library Power Control (LPC1) board in the Control Module, replacing the LMD

• Robot power via a power rail system

• Calibration targets that are glued in place and in new locations

• A robot which is installed via a loader bracket

• Two new boards, the SPA and SCC, used to connect the Control Module to the left Parking

Module

A library's Hardware Revision can be identified on either the Library Management Console (LMC)

or through Library and Tape Tools (L&TT). On the LMC, the Hardware Revision is displayed

prominently on the main screen under the Status, Serial #, and Date.

NOTE: If there is no “HW Revision” text displayed on the LMC, this also indicates Hardware

Revision 1.

In L&TT, the Hardware Revision is displayed under Detailed Device Information→Device.

In this document, parts that are specific to one revision or the other are called out specifically. All

other parts are common between both library types.

12 Library overview

Page 13

Libraries shipped after May 2013 and running library firmware version 663H or later offer

additional features and configuration options, including:

• Support for HDEMs

• A new command-line interface (CLI)

• Anti-malware checks to make sure that firmware is certified by HP

• Active/Active robots, when dual robots are present

• More flexible drive placement among modules

• Two new boards, the MCB2.0 and RCU2.0, required to run firmware version 663H or later

NOTE: To enable these features, HW REV 2 libraries shipped between June 2012 and May

2013 require a Controller Board Upgrade Kit, purchased separately. HW REV 1 libraries, shipped

before June 2012, cannot access these features without first converting to the HW REV 2

architecture.

Library features

Density

The storage density of a library is dependent on several factors, including the type of expansion

modules utilized (standard or high density), the number of drives an expansion modules contains,

and I/E station usage. The maximum storage density of an EM is 758 cartridges (LTO) per square

meter. The maximum storage density of an HDEM is 1444 cartridges (LTO) per square meter. Each

module, also referred to as a frame, has two storage racks: one on the drive side and another on

the door side. A rack consists of up to 10 horizontal sections and three or four columns of

magazines, depending on the rack configuration. Each magazine, located at the intersection of

a particular section and a particular column, consists of six cartridge slots.

Centralized management

The Library Management Console (LMC) gives you a single point from which to view all library

components, including robotics, drives, storage, I/E stations, and network connectivity. You can

use this graphical user interface both locally from the library OCP and remotely from a remote

client. The LMC communicates with the LMC server that runs on the library. The LMC uses a simple

and intuitive graphical style that is secure and provides library managers with native partitioning

ability.

Proactive availability

The library can alert you about problems before they occur. The library also monitors its six major

subsystems (drives, power, robotics, cooling, connectivity, and control). You can configure the

library to send notifications of problems to one or more e-mail accounts. For more information

about the library monitoring and reporting capabilities see, “Maintaining the library” (page 132).

Data Path and Control Path Failover

For high availability on the Fibre Channel fabric, the ESL G3 tape library offers licensed failover

features for the drive data paths and the robot control paths. For both data path and control path

failover, basic and advanced failover modes are available.

Basic path failover uses library and drive firmware to create a new Fibre Channel path to a drive

or robot if the original path is lost. Most applications recognize the new path and some will

automatically retry commands after the original path is lost. Other applications may require user

intervention to begin using the new path.

Advanced path failover uses host drivers in conjunction with library and drive firmware to manage

multiple paths across multiple SANs, present a single drive or robot path to applications, and

Library features 13

Page 14

automatically transfer commands to the new path if the original path is lost. This transfer is invisible

to most applications, avoiding the need for user intervention.

IMPORTANT: Basic failover requires LTO-5 tape drives or later. Advanced failover requires LTO-6

drives or later, a supported host driver, and library firmware version 665H or later.

Serviceability and reliability

The library has extensive serviceability and reliability features. You can hot swap drives, power

supplies (in redundant power configurations only), fans, and many of the boards within the library.

Your backup system and data path are idle most of the time. When backups begin, the system is

used intensively at maximum bandwidth. The library provides you with notifications and a robust

event system that notifies you of any problems it identifies, enabling you to solve them before

backups begin. For more information about the library notification system, event system, and other

troubleshooting help, see “Troubleshooting your library” (page 186).

Host attachment

Requests issued from the host application result in cartridge movement in the library. The primary

requests issued are for mounting and dismounting cartridges in and out of the tape drives and for

importing and exporting cartridges in and out of the library. The library manages the physical

location. In addition to requesting cartridge movement in the library, the host application can use

the Fibre Channel (FC) command interface to obtain status information, configuration information,

and cartridge storage information from the library.

Tape drives are directly attached to host systems or to the SAN. The library robot control path is

presented through one or more tape drive ports, depending on Partitioning and Failover

configuration.

Remote management

The library can be managed locally or remotely using the LMC. Locally, the LMC appears on the

OCP on the front of the library. Remotely, the LMC is accessed through a client instance of the

LMC software on any computer on the network. For more information about access, see “Logging

on from the Library Management Console (LMC) using a web browser” (page 77). For more

information about the LMC, see “Accessing the Library Management Console (LMC)” (page 80).

The LMC provides additional monitoring of a SAN-attached library over the network to a

management server by using Simple Network Management Protocol (SNMP). This includes library

subsystem health and status information and early fault notification.

The library also supports the Common Information Model (CIM) server based on the Storage

Management Initiative Specification (SMI-S) on the MCB. A CIM client can use the CIM server to

monitor the SAN-attached library.

Capacity on demand

ESL G3 tape libraries can be purchased at starting points of 100, 300, 700, 1500, 3000, or

5000 cartridge slots enabled. Adding physical EMs/HDEMs does not automatically enable new

slots. Instead, slots are flexibly enabled for use in groups of approximately 100 through capacity

upgrade licenses.

Control module

All library configurations include the control module, which contains the following minimum

components (see Figure 2 (page 15)):

• Library management module (LMM)

• I/E station

14 Library overview

Page 15

• Tape drives

• Cartridge storage

• Operator panel

• Power system

• I/O Management Unit and Ethernet Expansion Blade (EEB)

Figure 2 Front and back view of the control module

Expansion modules

Expansion modules (also referred to as standard expansion modules or EMs) enable the library to

expand by adding space for tape drives, I/E stations, and cartridges. Each EM can add several

hundred LTO cartridge slots, depending on the number of tape drives installed and whether an

I/E station is installed. The library maximum configuration includes 15 EMs for a total of 16

modules. EMs can only be added to the right of the control module. See Figure 3 (page 16) and

Figure 4 (page 16).

NOTE: For libraries shipped before May 2013 and running a firmware version prior to 663H,

EMs in positions 9-12 are storage-only and do not contain I/E stations or drives.

For libraries shipped after May 2013 and running firmware version 663H or later, EMs can contain

I/E stations and drives throughout the library. Some restrictions apply, see “Import/Export stations”

(page 19) and “Tape drives” (page 22) for more information.

The EMs can accommodate the following components:

2. Control module front view1. Magazines and cartridge slots

4. I/E station3. Control module back view

6. I/O management unit5. Drive clusters

8. Power supplies7. Library management module

10. Accessor9. Picker

• I/O management unit (optional)

• Tape drives (optional)

• I/E station (optional)

Expansion modules 15

Page 16

• Cartridge storage

• AC power compartment (required only if drives are added)

If an EM contains only cartridges, all power is derived from the control module.

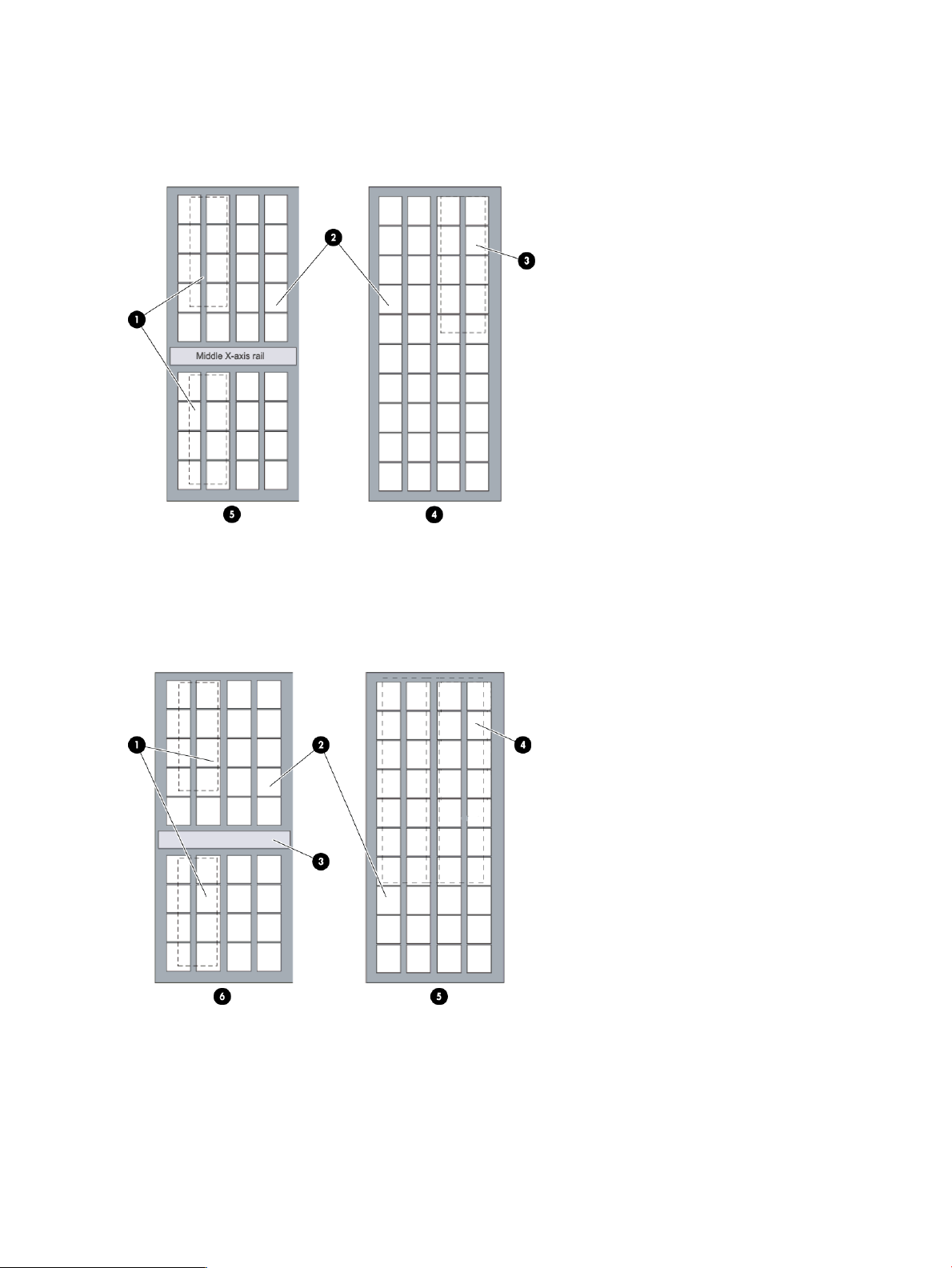

Figure 3 Expansion module with location of 24–slot I/E station

5. Drive side

Figure 4 EM with location of 72–slot I/E station

2. Cartridge magazines location1. Drive cluster (optional) location

4. Door side3. I/E station 24–slot (optional) location

An EM can have no I/E station, a 24–slot I/E station, or a 72–slot I/E station.

The 24–slot I/E station has a capacity of 24 LTO cartridges that are located in four removable

magazines.

16 Library overview

2. Magazines location1. Drive cluster (optional) location

4. 72–slot I/E station (optional) location3. Middle X-axis rail

6. Drive side5. Door side

Page 17

The 72–slot I/E station consists of two side-by-side 36–slot I/E stations that can operate as one

72–slot I/E station or can operate independently. Each 36–slot I/E station provides I/E capacity

of 36 LTO cartridges in six removable magazines.

NOTE: I/E stations are supported in all EMs, with the following exceptions in dual robot libraries:

• The left parking module cannot contain an I/E station.

• The last frame (also referred to as the right parking module) of a library cannot support a

72–slot I/E station.

High density expansion modules

High Density Expansion Modules (HDEMs) are storage-only modules that each contain a rotating

tower of storage magazines, allowing for a larger number of storage slots in the same footprint

as a standard expansion module. The HDEMs can only be added to the right of the control module.

NOTE: HDEMs are storage-only modules and do not contain drives. If you have a dual robot

library, HDEMs cannot be used as the left or right parking modules (the modules furthest left or

right).

HDEMs, in a dual robot library, can accommodate the following components:

• I/E station (optional)

• Cartridge storage

• Redundant power supply (optional)

NOTE: HDEMs are only available in HW Rev 2 libraries.

HDEMs are only supported in libraries that were purchased after May 2013 or libraries that have

been upgraded with the Controller Board Upgrade Kit, purchased separately.

Library management module

The library management module (LMM) controls and manages library hardware and software

components. It enables both SAN-connected hosts and users who access the library using the

operator panel to configure the library, obtain system status information, and perform various

library functions. The LMM contains the management control blade (MCB), the robotics control

unit (RCU), and the library motor drive (LMD) or Library Power Control (LPC1), as shown in

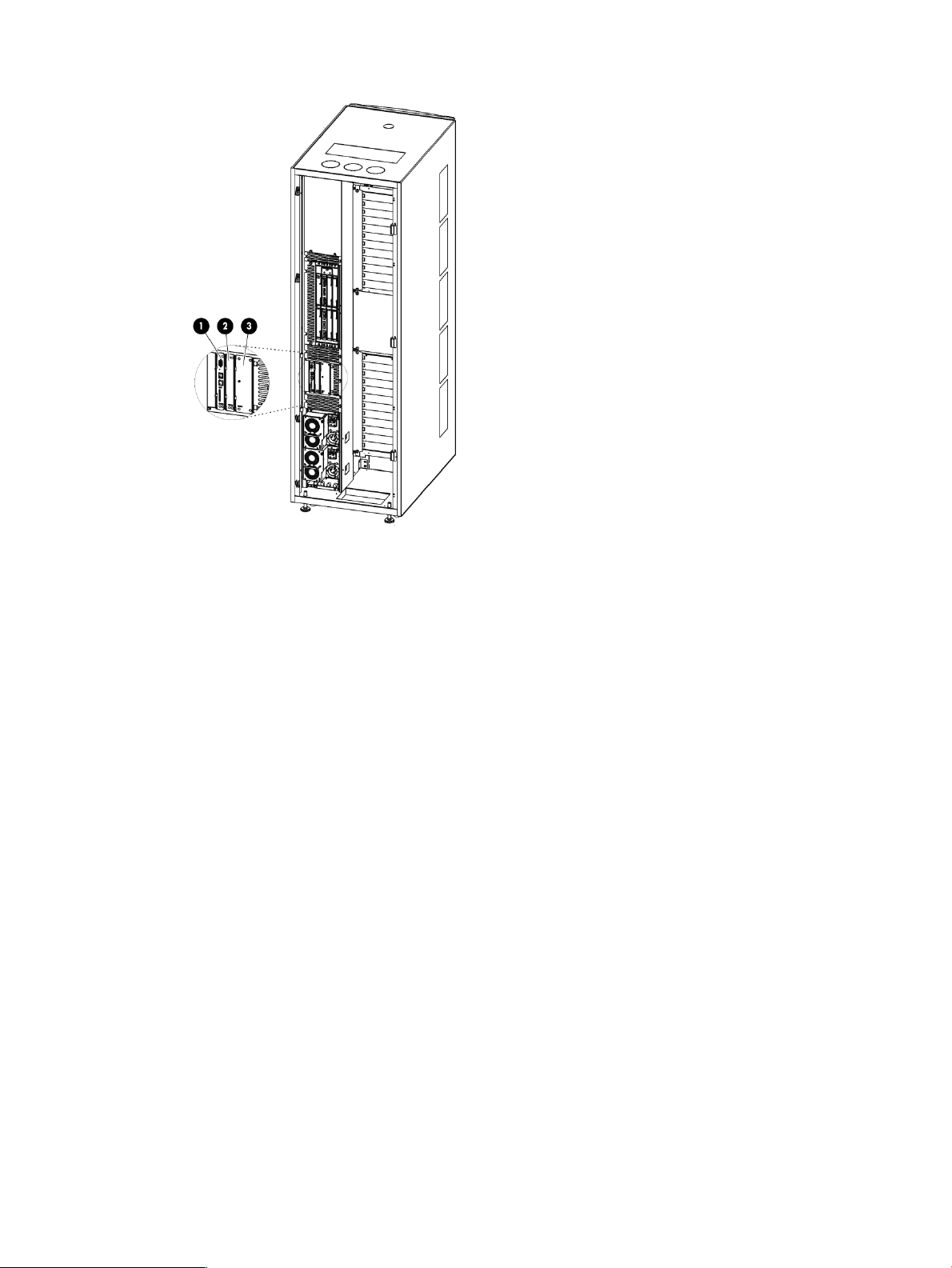

Figure 5 (page 18).

High density expansion modules 17

Page 18

Figure 5 Library management module boards

1. Management control blade

2. Robotics control unit

3. Library motor drive (LMD) or Library power control (LPC1)

Management control blade (MCB)

The MCB is the primary point of intelligent management in the library. The MCB stores firmware

and configuration data for itself as well as most other intelligent components in the library. It also

contains the LMC, which enables local or remote users or hosts to operate, configure, and monitor

the library. The MCB collects status information on other components in the library and issues

notifications when problems occur.

The MCB Version 2 also has two Ethernet ports, allowing the library to be on two different networks.

This provides both additional redundancy as well as greater configuration flexibility.

Robotics control unit (RCU)

The RCU provides robotics intelligence that controls accessor movements and functions, including

picker, pivot, and reach actions.

Library motor drive (LMD) or library power control (LPC1)

The LMD/LPC1 monitors wiring, fuses, and relays within the library. It regulates power levels and

performs other power-related functions, such as disabling robotics when a library door opens.

I/O Management units

The I/O management unit supports the control management blade (CMB) and the Ethernet Expansion

Blade (EEB).

18 Library overview

Page 19

Control management blade (CMB)

The CMB performs unit status monitoring, including power and I/O present conditions. The CMB

also enables you to update drive firmware without using a firmware update (FUP) tape.

Ethernet expansion blade (EEB)

The EEB provides Ethernet connectivity to each LTO drive for MCB-to-drive communication purposes

only. The EEB is not in the data path. This EEB provides a control path to the drive for commands

as well as facilitates taking drive logs and downloading drive firmware. Each EEB has 6 Ethernet

ports to allow attachment to 6 LTO drives. The EEB provides Ethernet connectivity to the library

internal Ethernet and should not be connected to an external Ethernet source.

Picker (cartridge accessor)

The picker moves cartridges between storage cells, tape drives, and I/E stations. A picker is used

to Get or Put cartridges in a storage cell or a tape drive slot. It moves along an X and Y axis and

can pivot 180 degrees. A barcode scanner on the picker assembly identifies cartridges located

in storage slots.

Import/Export stations

I/E stations enable you to import and export cartridges without interrupting normal library

operations. A 24–slot I/E station comes installed on the front of the control module. Optionally,

additional I/E stations can be added to both standard EMs and HDEMs in larger libraries. See

Figure 1 (page 11) and Figure 2 (page 15) to see the location of the I/E station.

Each 24-slot I/E station contains four removable magazines for a total of 24 LTO tape cartridges.

Each 72-slot I/E station contains twelve removable magazines for a total of 72 LTO tape cartridges.

NOTE: The I/E station cannot be configured as a storage location, but it can be part of a logical

division of library resources known as partitions. For information about partitions, see “Working

with partitions” (page 27).

A library I/E station configuration can accommodate one 24–slot I/E station in the control module

and up to seven 72–slot I/E stations, with a maximum of 528 I/E slots per library. The I/E station

placement options available in your library are dependent on the date of purchase and firmware

version installed on your library:

• Libraries shipped before May 2013 and running a firmware version prior to 663H, I/E stations

cannot be placed in EMs in positions 9–16.

• Libraries shipped after May 2013 and running firmware version 663H or later, I/E stations

can be placed in EMs throughout the library.

NOTE: If you have a dual robot library, the left parking module cannot contain an I/E station.

If you have a dual robot library, the last frame (also referred to as the right parking module) of a

library can support a 24–slot I/E station but cannot support a 72–slot I/E station.

Extended I/E option

The number of I/E slots in a library is usually associated with the number of I/E slots in an actual

physical I/E station, but this physical slot count might limit how many I/E slots are available to a

host application.

Extended I/E configurations remove such limitations by increasing the I/E slot count for a partition

with storage slots that will be reported to a host as I/E slots. Therefore, Extended I/E allows you

to configure partitions with I/E slots beyond the number of physical I/E slots configured in the

library. As a result, the host can export more media than previously allowed.

Picker (cartridge accessor) 19

Page 20

Keep in mind that as Extended I/E slots are used, less storage slots are available. You will need

to initiate the move/import operations of tape cartridges into the extended I/E area for host access.

Conversely, to move/export tape cartridges from Extended I/E area slots to the emptied physical

I/E Station slots, you need to initiate the move/export operation from the user interface for physical

access to the library.

NOTE: By default, the Extended I/E feature is disabled. Extended I/E can be enabled/disabled

from the Physical Library dialog box.

To configure a partition with Extended I/E segments, the user must use the Partition Wizard

(Setup→Partition→Configure). The Extended I/E feature is only available in Expert creation mode

or if you are modifying an existing partition. See “Creating partitions manually using Expert mode”

(page 32).

Extended I/E must be enabled before using it. When configuring Extended I/E:

• Ensure you have enough licensed slots (Capacity On Demand - COD) to accommodate the

• Ensure you have at least one physical I/E segment configured in the partition. The maximum

Cartridges

Cartridges are stored in magazines within the library, as shown in Figure 6 (page 20).

new Extended I/E slots, since the slots use the COD licensed slot count.

number of physical and Extended I/E slots per partition is 240.

Figure 6 Example of LTO cartridge insertion into a magazine

2. Magazine barcode1. LTO cartridge

4. Cartridge barcode location3. LTO magazine

Each cartridge has an operator-attached, machine-readable barcode label on it for identification

purposes. The library can dynamically support barcode labels that consist of up to thirteen characters

plus a two character media identifier, for a total maximum of fifteen characters. However, it is

always recommend that HP barcode labels are used, which are comprised of a six character

cartridge identifier followed by a two character media identifier, for a total of eight characters. .

For more information about tape cartridges, see “Tape drives” (page 22).

For additional barcode label specification information, see “Barcode requirements” (page 169).

Cartridge magazines

The cartridge magazine is a storage assembly that installs on the drive side or door side of the

control module, expansion module, or high density expansion module as shown in Figure 7

20 Library overview

Page 21

(page 21). It contains 6 cartridge slots and provides flexibility when adding storage cartridges to

a module.

See Table 1 (page 21) for cartridge capacities.

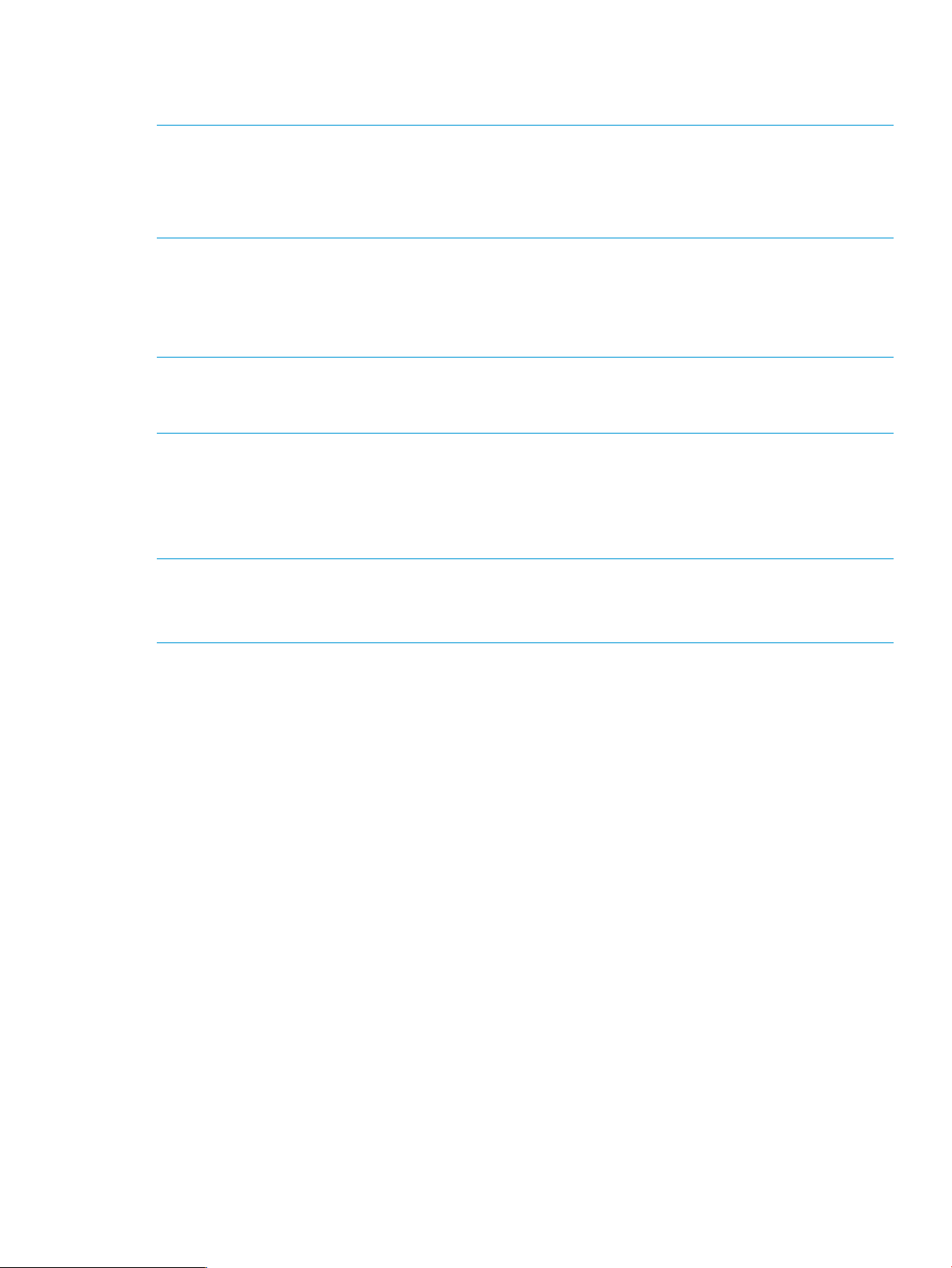

Figure 7 Magazine and drive locations in the control module (left) and on the control module access

door (right)

2. Upper drive cluster1. Lower drive cluster

4. Middle X-axis rail3. Cartridge magazines

6. I/E station cartridge magazines5. I/E station

8. Drive side7. Door side

10. Drives or cartridge magazines9. Lower drive ports

11. Upper drive ports

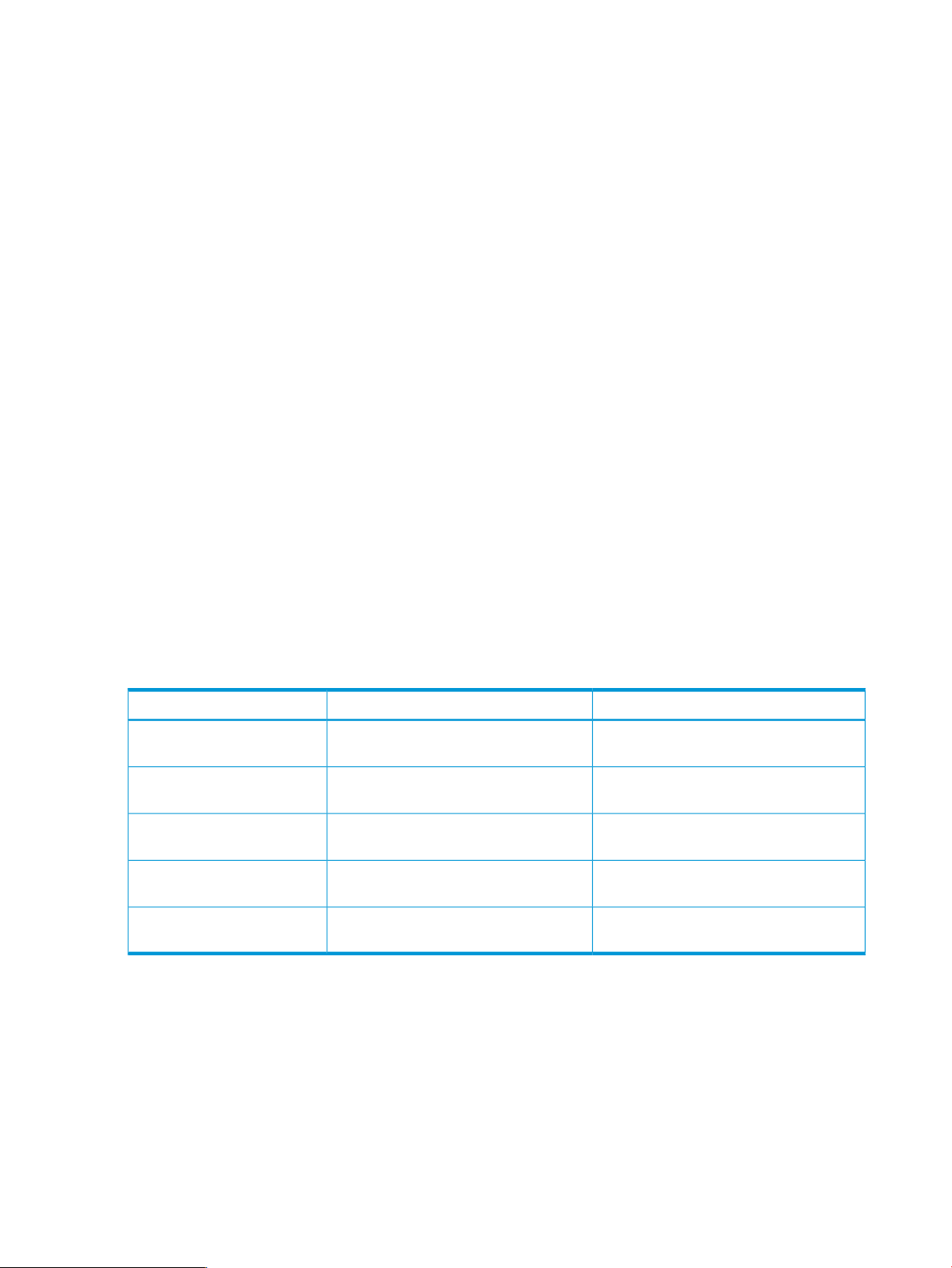

Table 1 Cartridge capacities in library modules

5

HDEM

Cartridge

Capacity

612 min /

780 max

4

Magazines

per HDEM

102 min /

130 max

3

EM

Cartridge

Capacity

192

min/456

max

Type of

cartridge

Cartridges

per

magazine

Magazines per

Control Module

Magazines

1

per EM

2

Control

Module

Cartridge

Capacity

44 min/50 max6LTO

32 min/76

max

264

min/300

max

1

The minimum is based on having 12 drives installed. The maximum is based on having one drive and one I/E station

installed.

2

The minimum is based on having an I/E station and 12 drives installed. The maximum is based on having no drives and

no I/E station installed.

3

The minimum is based on having 12 drives installed. The maximum is based on having one drive and one I/E station

installed.

4

The minimum is based on having an I/E station and 12 drives installed. The maximum is based on having no drives and

no I/E station installed.

5

The minimum is based on having no drives and a 72-slot I/E station installed. The maximum is based on having no drives

and no I/E stations installed.

5

Each magazine has a barcode label that the scanner reads for identification and inventory. An

optional, snap-on dust cover is available for the magazines. Magazines with the dust cover have

Cartridge magazines 21

Page 22

interlocked stacking that enables easier storage of the media when they are removed from the

library for external storage.

Support for WORM

The ESL G3 library supports WORM (write once, read many) technology in LTO-4 and later tape

drives.

WORM allows non-erasable data to be written once and provides extra data security by prohibiting

accidental data erasure.

Tape drives

Tape drives are enclosed in a universal drive sled. You can hot swap and hot add all supported

drives, regardless of type. The library supports HP LTO-4 and later FC Multi-mode tape drives.

The control module and expansion modules have upper and lower drive clusters. Each library must

have at least one tape drive. Each drive cluster can house up to six tape drives for a total of 12

drives. Additional drives can be added to standard EMs both consecutively and non-consecutively,

with a maximum of 192 drives per library, with current hardware and firmware.

NOTE: When you add drives, you lose storage slots.

For libraries shipped before May 2013 and running a library firmware version prior to 663H,

drives must be installed in bottom to top order in the CM, filling the module with 12 drives, before

any are added to the first EM. Additionally, the first EM must have all 12 drives installed in the

same order before adding any drives to the next EM..

For libraries shipped after May 2013 and running library firmware version 663H or later, drives

can be installed throughout the CM and EMs consecutively or non-consecutively, as long as the

control module contains at least one drive. However, drives should still be added to the CM and

any additional EMs in bottom to top order.

NOTE: The term drive cluster defines a grouping of up to six tape drives below or above the

middle X-axis rail.

Figure 7 (page 21) shows the locations of drives in the control module.

LTO drives

LTO drives are supported as shown in Table 2 (page 22).

Table 2 LTO drive and cartridge compatibility

All LTO cartridges are the same size, which means they use the same magazines in the library.

LTO drives can be directly attached to hosts but for full functionality they should be integrated in

a SAN.

LTO-6 CartridgeLTO-5 WORMLTO-5 CartridgeLTO-4 WORMLTO-4 Cartridge

Reads/WritesLTO-4 Drives

Many

Reads/WritesLTO-5 Drives

Many

Reads/WritesWrite Once, Read

Many

Reads/WritesReadsReadsLTO-6 Drives

Many

Not compatibleNot compatibleNot compatibleWrite Once, Read

Not compatibleWrite Once, Read

Reads/WritesWrite Once, Read

22 Library overview

Page 23

Operator panel

The operator panel is located on the front of the control module and consists of the indicator panel

and the OCP (see Figure 8 (page 23)). In the indicator panel, the buttons are for robot control and

power, and the indicators provide library status.

Figure 8 Operator panel

2. Power indicator/button1. Status indicator

4. Robotics enabled indicator/button3. OCP

The OCP is the library navigation point and provides access to the LMC. For more information

about the OCP and the LMC, see “Accessing the Library Management Console (LMC)” (page 80).

Power system

The library supports single and redundant power configurations. The single configuration has a

single AC line input and single DC power supply. The redundant configuration has dual AC line

input and dual DC power supplies. You can hot swap a power supply if you have a redundant

power supply. You can hot add a second power supply.