Page 1

HP StorageWorks XP10000 Disk Array

Site Prep Guide

This guide describes how to prepare your site for the HP StorageWorks XP10000 Disk Array.

Par t number: AE102-96004

second edition: (December 2005)

Page 2

Legal and notice information

© Copyright 2005 Hewlett-Packard Development Company, L.P., all rights reserved.

Confidential computer software. Valid license from HP required for possession, use or copying. Consistent with

FAR 12.211 and 12.212, Commercial Computer Software, Computer Software Documentation, and Technical

Data for Commercial Items are licensed to the U.S. Government under vendor’s standard commercial license.

The information contained herein is subject to change without notice. The only warranties for HP products

and services are set forth in the express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical

or editorial errors or omissions contained herein.

Intel, Itanium, Pentium, Intel Inside, and the Intel Inside logo are trademarks or registered trademarks of Intel

Corporation or its subsidiaries in the United States and other c ountries.

Microsoft, Windows, Windows XP, and Windows NT are U.S. registered trademarks of Microsoft Corporation.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

Java is a US trademark of Sun Microsystems, Inc.

Oracle is a registered US trademark of Oracle Corporation, Redwood City, California.

Linux is a U.S. registered trademark of Linus Torvalds.

UNIX is a registered trademark of The Open Group.

Printed in the US

HP StorageWorks XP10000 Disk Array Site Prep Guide

Page 3

Contents

Preface ......................... 6

Aboutthisguide................................ 6

Intendedaudience............................... 6

DiskArrays.................................. 6

RelatedDocumentation............................. 6

Documentconventionsandsymbols ....................... 7

Rackstability ................................. 8

HPtechnicalsupport.............................. 8

Subscriptionservice .............................. 8

OtherHPwebsites .............................. 9

1Siteprepteamandtasks................ 11

Thesiteprepteam.............................. 12

HPrepresentativeresponsibilities...................... 12

Customerresponsibilities ......................... 12

Sitepreptasks ............................... 13

Siteprepchecklist ............................ 14

Sitepreptimeallowances......................... 16

2Siterequirements ................... 17

Disk array physical specifications ....................... 18

Dimensionsandweights ......................... 20

Componentweights ........................... 21

Calculating the weight of your disk array configuration ............ 23

Weightcalculationexample........................ 24

Deliveryspacerequirements.......................... 25

Generalcomputerroomrequirements...................... 26

Preventingelectrostaticdischarge ..................... 27

Safetyrequirements ............................. 28

Firesafety ............................... 28

Equipmentservicinghazards ....................... 28

Electricalhazards ............................ 28

Spaceplanningrequirements ......................... 29

Thespaceplanningprocess........................ 29

Raised floorrequirements........................... 30

Estimating required floorloadrating .................... 31

Floorcovering.............................. 31

HP StorageWorks XP10000 Disk Array Site Prep Guide

3

Page 4

Floorclearanceandcutoutdimensions ................... 32

Primaryrackdimensionsandcablecutoutlocation............ 32

Calculatingclearances........................ 33

Primary and second rack clearance dimensions and cutouts . . . . . . . . 37

Environmentalrequirements.......................... 40

Altitude ................................ 40

Airconditioning............................. 40

Temperature specifications ........................ 41

Humidity specifications.......................... 42

Mechanical vibration specifications..................... 43

Shock specifications ........................... 43

Heat dissipation, power consumption, and air flow .............. 44

Acoustics................................ 46

Dustandpollutioncontrol......................... 47

Metallicparticulatecontamination ..................... 47

Datacommrequirements ........................... 48

Electricalrequirements ............................ 49

Linevoltage............................... 49

Branchcircuitbreakers.......................... 49

Single-phasebranchcircuitbreakers .................. 49

Frequency ............................... 49

Safetyanddedicatedground ....................... 49

Groundingrequirements ......................... 50

ACconnections ............................. 50

Powerlinetransients ........................... 51

Protection against sources of electrical interference . . . . . . . . . . . . . . 51

Uninterruptiblepowersupply(UPS)....................... 52

3Electricalspecifications................. 53

AClinevoltagerequirements ......................... 53

ACinputs................................ 54

NorthAmericanACpowercabling....................... 56

Branchcircuitrequirements ........................ 56

EuropeanACpowercabling ......................... 57

Europeanbranchcircuitrequirements.................... 57

ConnectingtheEuropeanpower-supplycables................ 58

4Deliveryandunpacking ................ 59

Checkingforshippingshortageanddamage .................. 60

Unpackingtheequipment........................... 60

Requiredpersonnel ........................... 60

Requiredtools.............................. 60

Packaging configurations......................... 61

Unpackingprocess............................ 61

Safetyprecautions.......................... 62

Removingpackagingmaterials .................... 63

4

Page 5

Glossary........................ 67

Index ......................... 75

HP StorageWorks XP10000 Disk Array Site Prep Guide

5

Page 6

Preface

About this guide

This guide provides information about preparing your site for installation of the XP10000

Disk Array.

Intended audience

This guide is intended for system administrators with knowledge of the host hardware,

the operating sy

stem, and RAID technology.

Disk Arrays

Unless otherwise noted, the term disk array refers to the XP10000 D isk Array.

Related Documentation

HP provides the

se related documents:

• HP StorageWorks XP10000 Disk Array Owner’s Guide

• HP StorageWorks Remote Web Console XP User Guide

• HP StorageWor

ks Command View XP Advanced Edition User Guide

• HP StorageWorks Disk Array XP Operating System Configuration Guide

To locate these documents, to learn more about HP software products, or to obtain

software updates, visit the HP web site: h

ttp://h18006.www1.hp.com/storage/

xparrays.h

tml.

6

Preface

Page 7

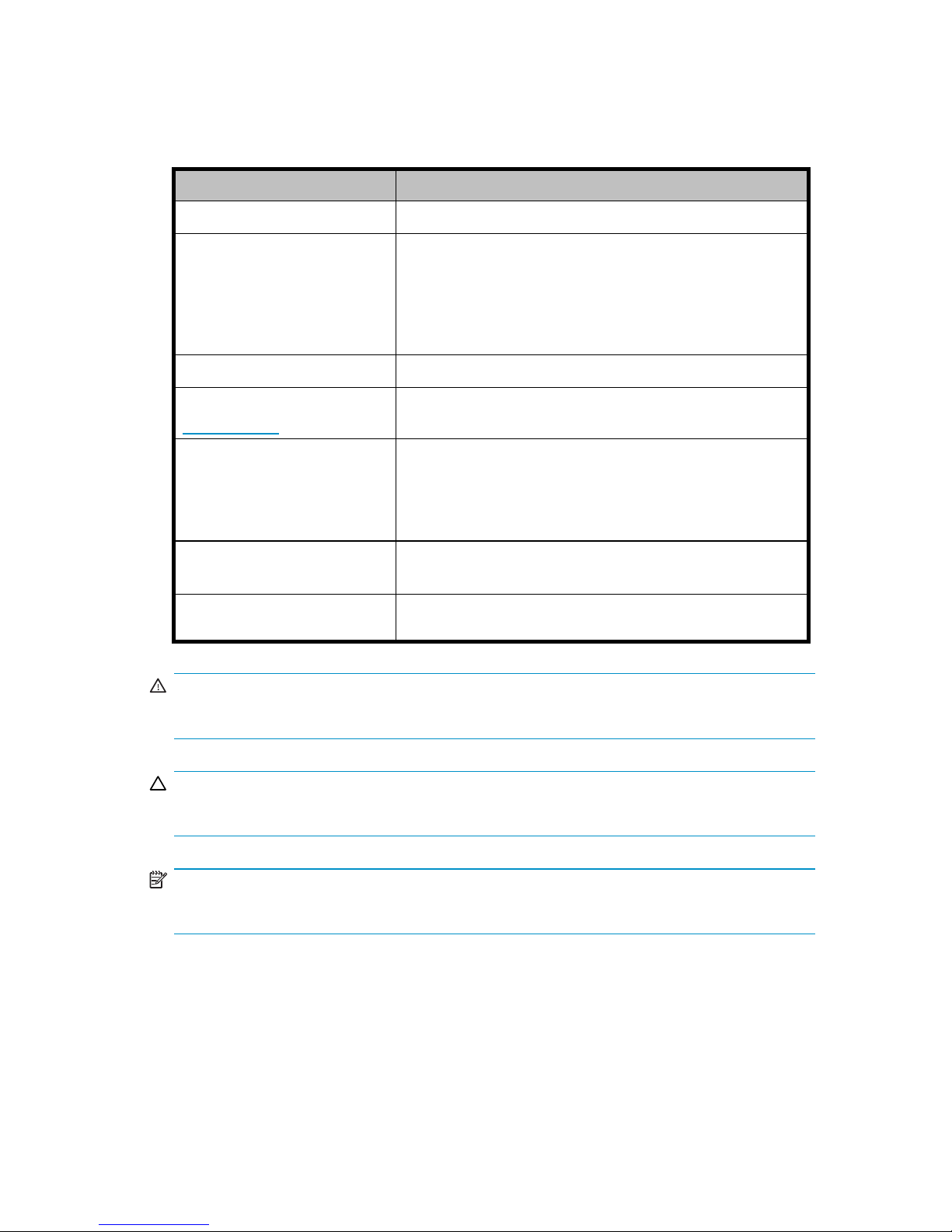

Document conventions and symbols

Convention

Element

Blue text

Cross-reference l

inks and email addresses

Bold

• Keys that are pre

ssed

• Text typed into a GUI element, such as a box

• GUI elements that are clicked or selected, such as

menu and list it

ems, buttons, tabs, and check boxes

• Literal values typed exactly as shown

Italics

Text emphasis and book titles

Blue, underlined:

w

ww.hp.com

Web site addresses

Monospace fo

nt

• File and directory names

• System outp

ut

• Code

• Commands, their arguments, and argument values

Monospace, italic

font

• Code variables

• Command v

ariables

Monospace, bold

font

Emphasized monospace text

WARNING!

Indicates that failure to follow directions could result in bodily harm or death.

CAUTION:

Indicates that failure to follow directions could result in damage to equipment or data.

NOTE:

Provides additional information.

HP StorageWorks XP10000 Disk Array Site Prep Guide

7

Page 8

Rack stability

Rack stability protects personnel and equipment.

WARNING!

To reduce the r

isk of personal injury or damage to equipment:

• Extend leveling jacks to the floor.

• Ensure that the full weight of the rack rests on the leveling jacks.

• Install sta

bilizing feet on the rack.

• In multiple-rack installations, fasten racks together securely.

• Extend only one rack component at a time. Racks can become unstable if more

than one co

mponent is extended.

HP technical support

Telephone numbers for worldwide technical support are listed on the HP support web

site: h

ttp://www.hp.com/support/.

Collect the following information before calling:

• Technical support registration number (if applicable)

• Product serial numbers

• Product model names and numbers

• Error messages

• Operating system type and revision level

• Detailed questions

For continuous quality improvement, calls may be recorded or monitored.

Subscription serv ice

HP strongly recommends that customers register online using the Subscriber’s choice web

site: h

ttp://ww w.hp.com/go/e-updates.

Subscribing to this service provides you with e-mail updates on the latest product

enhancements, newest driver versions, and firmware documentation updates as well as

instant access to numerous other product resources.

After subscribing, locate your products by selecting Business suppor t and then Storage

under Product Category.

8

Preface

Page 9

Other HP web sites

For additional information, see the following HP web sites:

•w

ww.hp.com

•www.hp.com/go/storage

•www.hp.com/service_locator

•www.docs.hp

.com

HP StorageWorks XP10000 Disk Array Site Prep Guide

9

Page 10

10

Preface

Page 11

1 Site prep team and tasks

The objective of a site preparation is to prepare your site for the successful and timely

installation of the HP XP10000 disk array. Proper site preparation is vital for the

reliability of the disk array.

Site prep involves a careful balance of equipment design criteria, site environmental

variables, your business needs, and your budget constraints.

In addition to this guide, other site prep resources may be available to you. The HP

service organization is committed to making sure you receive maximum benefitfromyour

disk array. HP representatives will guide and assist you throughout the site prep process.

HP StorageWorks XP10000 Disk Array Site Prep Guide

11

Page 12

Thesiteprepteam

The site prep team plans, schedules, and completes all tasks necessary to prepare your

site for succ

essful disk array installation.

The site prep team consists of HP representatives and you, the customer.

HP representative responsibilities

The HP team includes various HP representatives who have the training, knowledge,

experience, tools, and parts required to install and maintain XP disk arrays. This team:

• Helps you to determine and implement the site requirements for your specific

site and array configuration

• Coordinates all HP resources to ensure successful delivery and installation of

the disk array

Your HP SR is your primary point of contact with HP during the site preparation process.

Customer responsibilities

As part of

thesiteprepteam,yourresponsibilitiesincludeplanningandpreparing

asuitab

le environment for the disk array, and scheduling equipment delivery and

installation. However, HP representatives are available to help you throughout the site

prep process. Your internal site team may include personnel specializing in your site

comput

er room, such as your storage administrator and your site electrician.

12

Site prep team and tasks

Page 13

Site prep tasks

Contact your HP SR for assistance at any time during the site prep process.

1. If you have not printed a copy of this guide, HP recommends that you print at least

Chapter 2 and the “Site prep checklist”. Working from printed copies makes it

easier to use the tools provided and provides hard copy documents that you can

keep for you

rrecords.

2. Carefully review Chapter 2 to understand the site requirements for the disk array.

If you plan to connect additional external storage to the XP10000, be sure to

take the requirements of that storage into account. See the documentation for the

external

system.

3. Use the information, instructions, and tools in Chapter 2 to determine site

requirements for the specific disk array components you ordered.

4. On the si

te prep checklist, answer ea ch item “Yes” or “No” as it relates to your site.

The checklist includes references to the pages in this guide where you can find

more information on each item.

5. Checklist items that require a “Yes” answer are marked with asterisks (*). If you

answe

r “No” for any of these items, your site does not meet site requirements for the

disk array. Using the information in Chapter 2, correct the site environment so that

you can answer “Yes” for each of these items.

6. When your site meets all site requirements, contact your HP SR to coordinate

del

ivery of the disk array equipment.

7. If you choose to unpack the equipment cartons without HP supervision, follow the

instructions in Chapter 3.

8. Co

ntact the HP SR to schedule disk array installation and configuration.

HP StorageWorks XP10000 Disk Array Site Prep Guide

13

Page 14

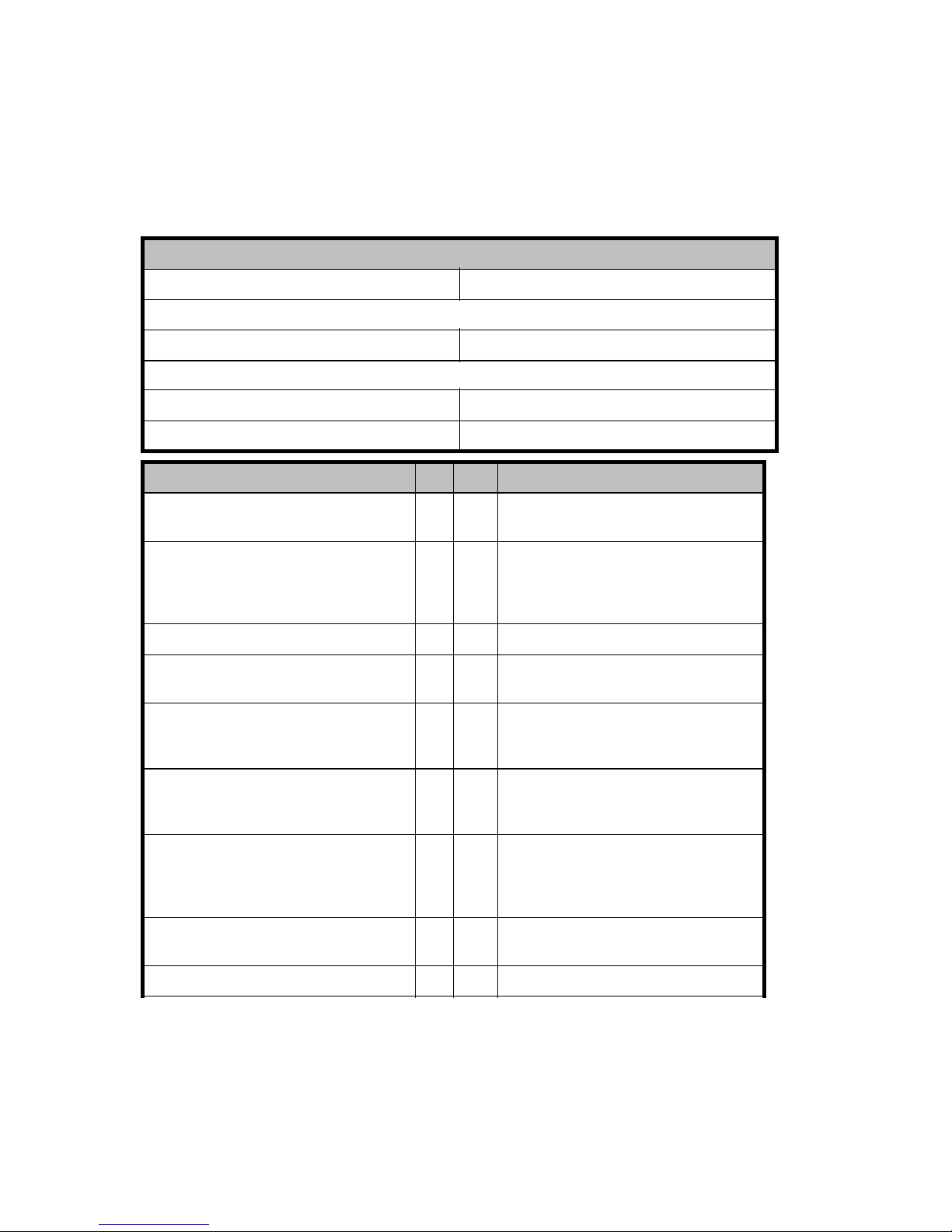

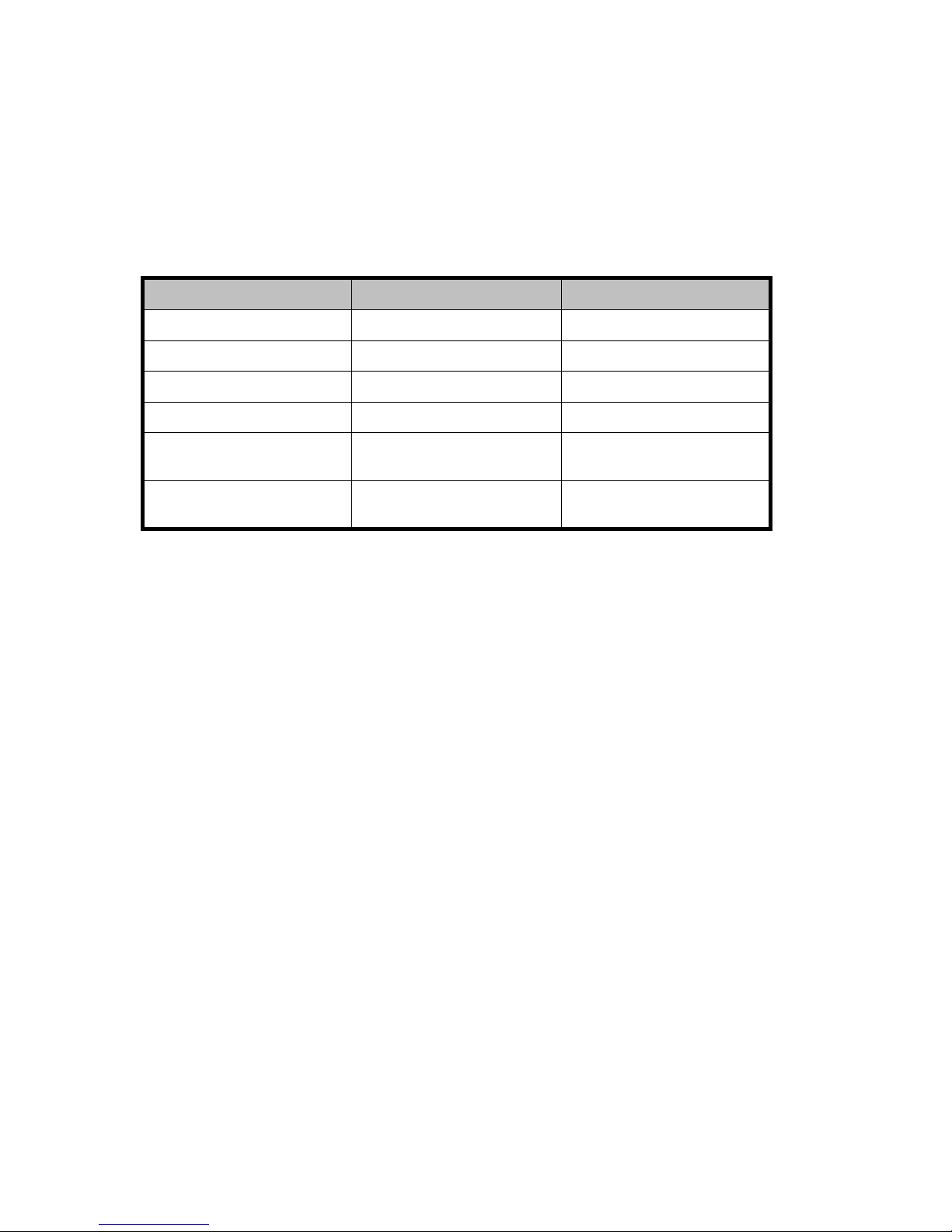

Site prep check

list

Checklist ite

ms that require a “Yes” answer a re marked with asterisks (*). The customer

summary information is included for the benefit of HP representatives, who will help

you complete the checklist.

Customer summary

Customer:

Date:

Address:

Contact:

Phone:

HP summary

HP SR:

Phone:

HP representative:

Phone:

Safety Yes No Reference

Is there a fire protection system in the

computer room?

Fire safety

Isthecomputerroomfreeofany

equipment servicing hazards (for

example, electrical or data cables

that obstruct access)?

Equipment servicing hazards

Is the exi

sting floor plan documented?

The space planning process

Has a new floor plan been developed

to include the new array?

The space planning process

Does the new floor plan include

adequate space for airflow and

servicing needs?

Floor clearance and cutout

dimensions

Does th

enewfloor plan include the

cleara

nce required for the floor’s load

ratin

g?

Floor clearance and cutout

dimensions

Is the computer room structurally

complete (walls, floor, air

conditioning system, and so

on)?

General computer room

requirementsAir conditioning

Is the raised floor adequate for the

equipment load?

Raised floor requirements

Is antistatic flooringormatsinstalled?

Pre

venting electrostatic discharge

14

Site prep team and tasks

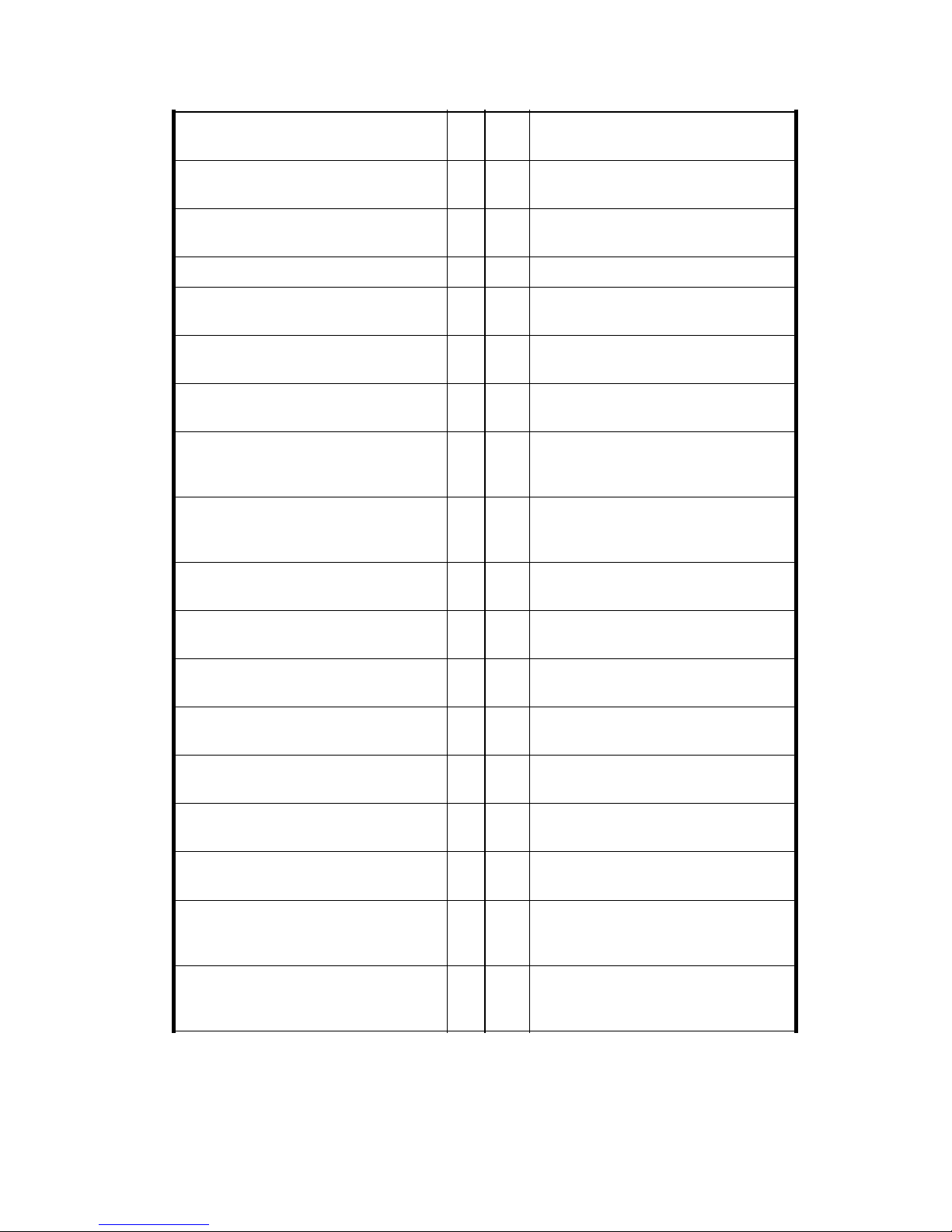

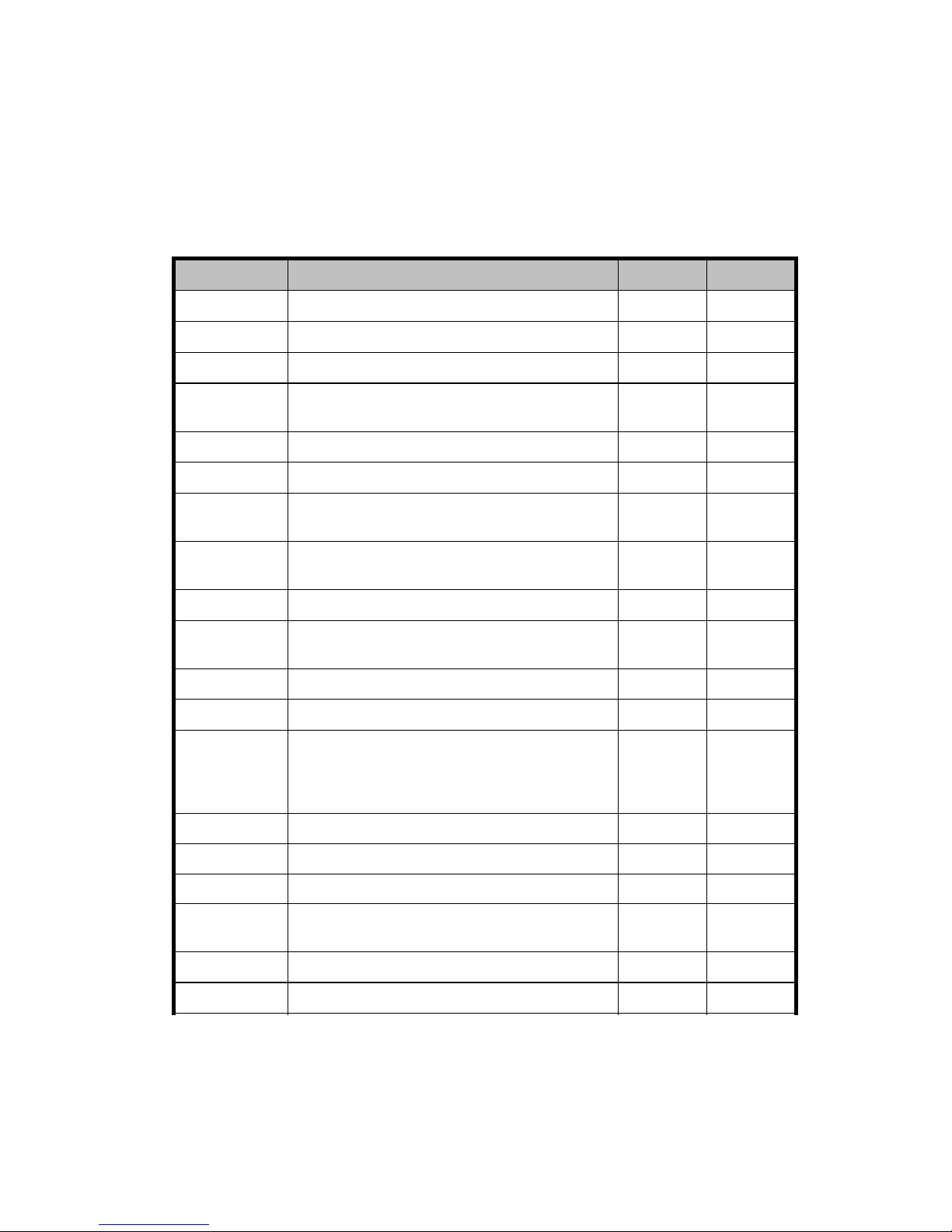

Page 15

Are there cutouts or channels for

cable routing?

Floor clearance and cutout

dimensions

Is there a dedicat

ed analog telephone

line for “phone home” configuration?

Data comm requirem

ents

Is a telephone line available for HP

representative use?

Data comm requirements

Is a private LAN available?

Data comm requirements

Can t he temperature be maintained

between 16× and 32× C?

Temperature spe

cifications

Can temperature changes be held to

less than 10× C per hour?

Temperature specifications

Can the humidity level be maintained

between 20% and 80%?

Humidity specifications

Is the compu

ter room protected

against dus

t, pollution, and metallic

particula

te contamination?

Dust and pol

lution controlMetallic

particulat

e contamination

Does the computer room support

other environmental considerations

(such as vibration and acoustics)?

Mechanical vibration

specificationsAcoustics

Are sufficient AC outlets, on different

lines, available for the equipment?

Electrical requirements

Does the

input voltage correspond to

the equipment specifications?

Electri

cal requirements

Are the input circuit breakers

adequate for equipment loads?

Electrical requirements

Does the input frequency correspond

to equipment specifications?

Electrical requirements

Is an appropriate uninterruptible

power supply (UPS) strategy in place?

Uninterruptible power supply (UPS)

If lightning arresters are

recommended, are they installed?

Protection against sources of

electrical interference

Have all sources of electrical

interference been corrected?

Protection against sources of

electrical interference

Doe

s the customer site have

ac

cess control (for example, do HP

re

presentatives need an escort)?

N/A

Does the computer room have

access control (for example, do HP

representatives need a security code)?

N/A

HP StorageWorks XP10000 Disk Array Site Prep Guide

15

Page 16

Are all floors, stairs, elevators,

stairwalkers, lifts, ramps, or ladders

needed to move the equipment

adequate to support its weight and

size?

Dimensions and weights

Will the equipment fitthroughall

doors and corrid

ors and in lifts?

Dimensions and w

eights

Doesthebuildinghavealoading

dock? Maximum access height is

_____m.

Dimensions and weights

Additional equipment N/A

For any additi

onal equipment

required (fo

r example, connectors,

receptacles

,cables,andany

equipment n

ot supplied by HP), is the

equipment o

nsiteandreadyforuse?

N/A

Site prep time allowances

The following site prep tasks may require several weeks:

• Acquiring required power connectors

• Arranging for an electrician

• Adding or modifying air conditioning systems

• Making building alterations

• Placing an order for data comm equipment

The time between placing an equipment order and actual delivery can vary. Contact

your HP representative to determine the best estimated delivery dates.

16

Site prep team and tasks

Page 17

2Siterequirements

Your site must meet the following requirements before HP can deliver and install the

disk array:

• General computer room requirements

• Safety requirements

• Raised floor requirements

• Environmental requirements

• Data comm requirements

• Electrical requirements

• Protection aga inst sources of electrical interference

• Uninterruptible power supply (UPS)

HP StorageWorks XP10000 Disk Array Site Prep Guide

17

Page 18

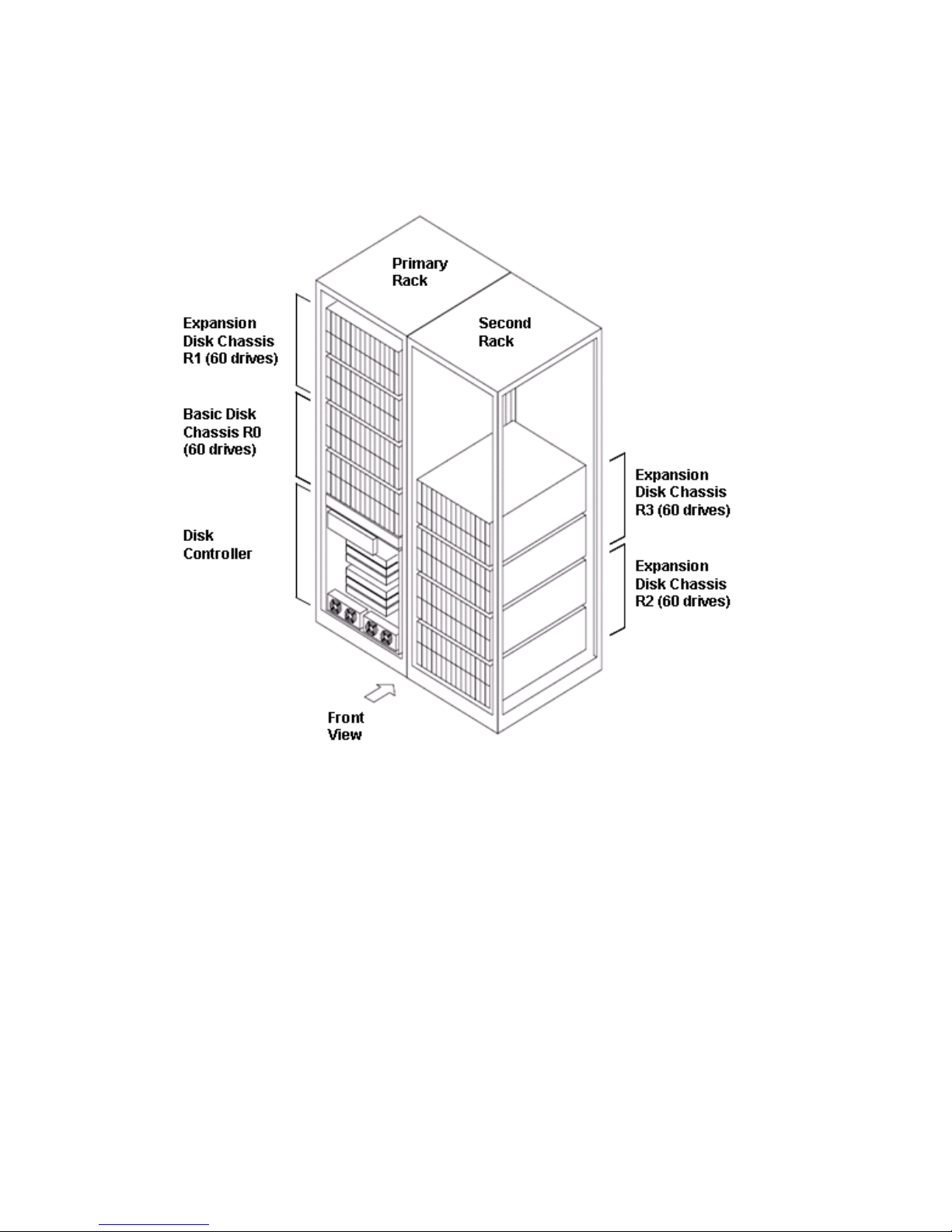

Disk array physical specifications

Use the information in this section to determine the total dimensions and weight for your

specificarrayconfiguration. You will need these values to complete other procedures

in this chapter.

The followin

g figure shows the disk array equipment racks.

Primary rack

In the basic configuration, the disk array consists of one primary 19-inch rack containing

the following:

• One disk con

troller with control panel and SVP blade PC

• One 60-disk chassis, consisting of two 30-drive HDU boxes

• Mix board with disk adapters and host ports

• Power supp

lies, power distribution units (PDUs), backup batteries, power cords,

and cabling

Primary rack expansion

You can exp

and the primary rack as follows:

• Add one 60-disk chassis containing two 30-drive HDU boxes to the top space of

the primary rack. This provides a total of 120 drives.

Second rack

After exp

anding the primary rack, you can add a second 19-inch rack with additional

disk uni

ts as follows:

• Addone60-diskchassistothesecondrackforatotalof180drives

• Add a second 60-disk chassis to the second rack for a total of 240 drives

Disk arr

ay basic storage includes disk chassis R0 in the primary rack. Add more disk

chassi

s in the order shown in the figure: R1, R2, R3.

18 Site requirements

Page 19

HP StorageWorks XP10000 Disk Array Site Prep Guide

19

Page 20

Dimensions and

weights

Use the packaged values when determining delivery space and loading requirements

and unpackaged values during space and floor load planning. In the USA and Canada,

most shipments use a special carrier process in which frames are shipped without

pallets, ramps, or cartons. In these cases, the packaged weight is the unpackaged

weight plus

23 kg (50 lb).

Rack specification

Unpackaged rack Packaged rack

Width 610 mm, 24.0 inches 950 mm, 37.4 inches

Depth 925 mm, 36.4 inches 1110 mm, 43.7 inches

Height 1920 mm, 75.6 inches 2030 mm, 79.9 inches

Weight, p

rimary rack, basic

335.5 kg,

740 lbs

448.5 kg,

989 lbs

Weight, primary rack,

maximum

577 kg, 1272 lbs 690 kg, 1521 lbs

Weight second rack,

maximum

47 3 kg, 1043 lbs 586 kg, 1292 lbs

20 Site requirements

Page 21

Component weig

hts

The following

table provides approximate weights of additional disk array components.

The number of d

isk drives is the m a in factor accounting for total weight of the disk

array. Actua

lweightofthearrayracksistheminimumrackweightplustheweightofall

additional components.

Product

Description

kg lb

AE006A

HP XP12000/100 00 16-port 2-Gb FC CHIP

5.0 11.0

AE007A

HP XP12000/10000 32-Port 2-Gb FC CHIP

5.8 12.8

AE008A

HP XP12000/

10000 FC SFP LW Transceiver

0.02

0.04

AE010A

XP12000/10000 32-port 4 Gbps FC SW

CHIP pair

5.9 13

AE013A

HP XP12000/10000 8-Port FICON SW CHIP

5.7

12.6

AE014A

HP XP12000/

10000 8-Port FICON LW CHIP

5.7

12.6

AE015A

XP12000/10000 16-port 1–2 Gbps FICON

SW CHIP pair

5.9 13

AE016A

XP12000/10000 16-port 1–2 Gbps FICON

LW C HIP pair

5.9 13

AE017A

HP XP12000

/10000 16-Port EXSA CHIP

5.4

11.9

AE018A

HP X P12000/10000 8-Port 1-Gb NAS SW

CHIP

6.5

14.3

AE025A

HP XP12000/10 000 4-GB Cache Memory

0.2

0.44

AE030A

HP XP1200

0/10000 1-GB Shared Memory

0.06 0.13

AE102A

HP XP10000 19" primary rack, disk

controller, base disk chassis for up to 60

HDDs, power supplies, base batteries for up to

12GB cache and up to 3GB Shared M emory

335.5

740

AE104B

HP XP10000 Disk Chassis

80.4

177

AE105B HP XP10

000 16-Port FC SW CHIP 8-Port ACP

5.0 11.0

AE110B

HP XP10000 Battery 8.0 17.6

AE115B

HP XP10000 Second Rack Disk Array Frame DKU

261

575

AE120A

HP XP

10000 73GB 15k rpm Array Group

4.4

9.7

AE120AS

HP XP10000 73GB 15k rpm Spare Disk

1.1

2.4

HP StorageWorks XP10000 Disk Array Site Prep Guide

21

Page 22

Product

Description

kg lb

AE121A

HP XP10000 146GB 10k rpm Array Group

4

8.8

AE121AS

HP XP10000 146GB 10k rpm Spare Dis k

1

2.2

AE122A

HP XP10000 146GB 15k rpm Array Group

4

8.8

AE122AS

HP XP10000 146GB 15k rpm Spare Dis k

1

2.2

AE123B

HP XP10000 300GB

10k rpm Array Group

4

8.8

AE123BS

HP XP10000 300GB 10k rpm Spare Disk

1

2.2

22 Site requirements

Page 23

Calculating the weight of your disk array configuration

The total weight of your array configuration includes the controller, the disk chassis, plus

the total of all disk drives in each cabinet and any optional components. Your site must

have adequate floor strength to suppor t the total weight of the array, from the delivery

area to the co

mputer room.

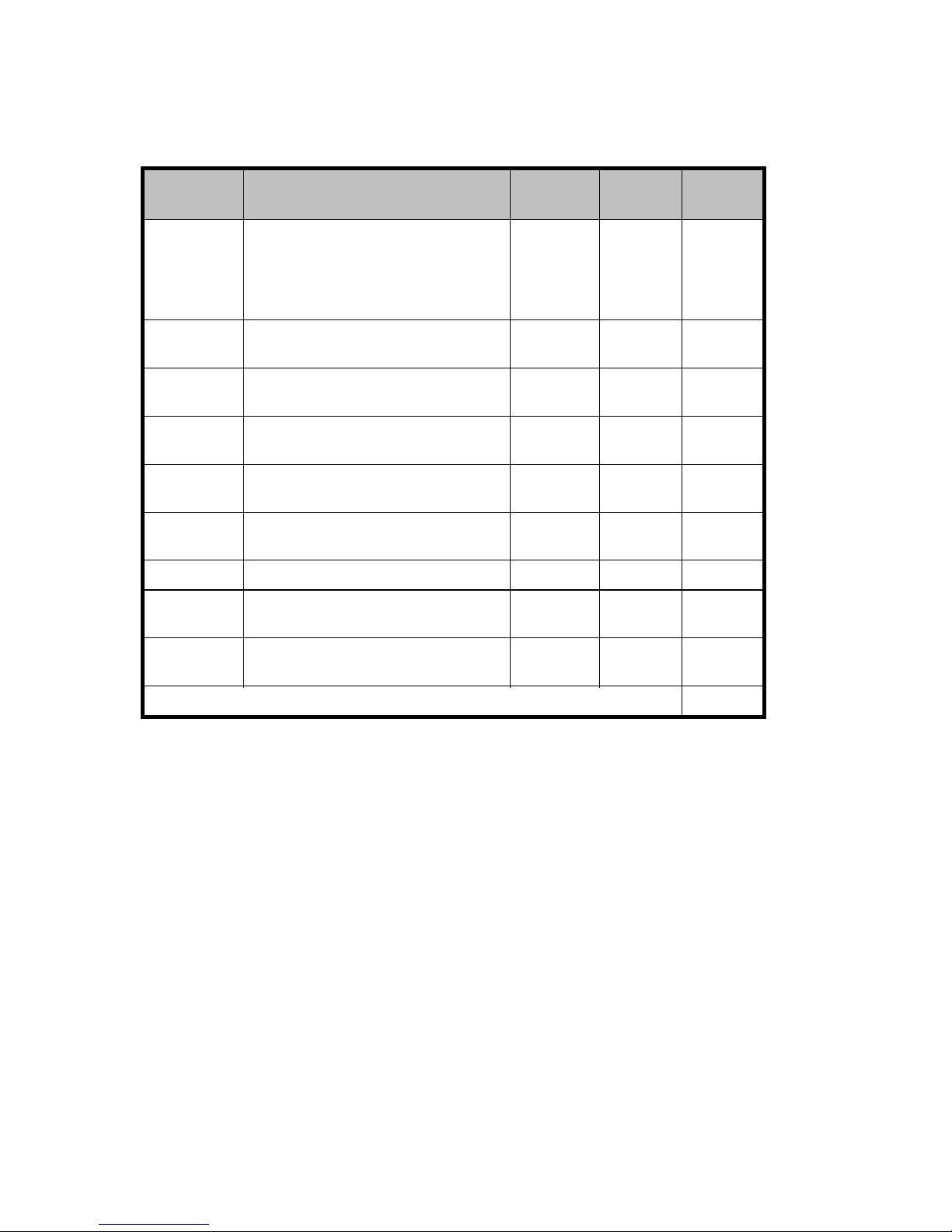

Fill in the following weight calculation worksheet to calculate the total weight of your

unpackaged array configuration, in your preferred units (kg or lb). Following the

worksheet is a completed example worksheet.

Use the calc

ulated total weight to estimate the required floor load rating for the computer

room as explained later in this chapter.

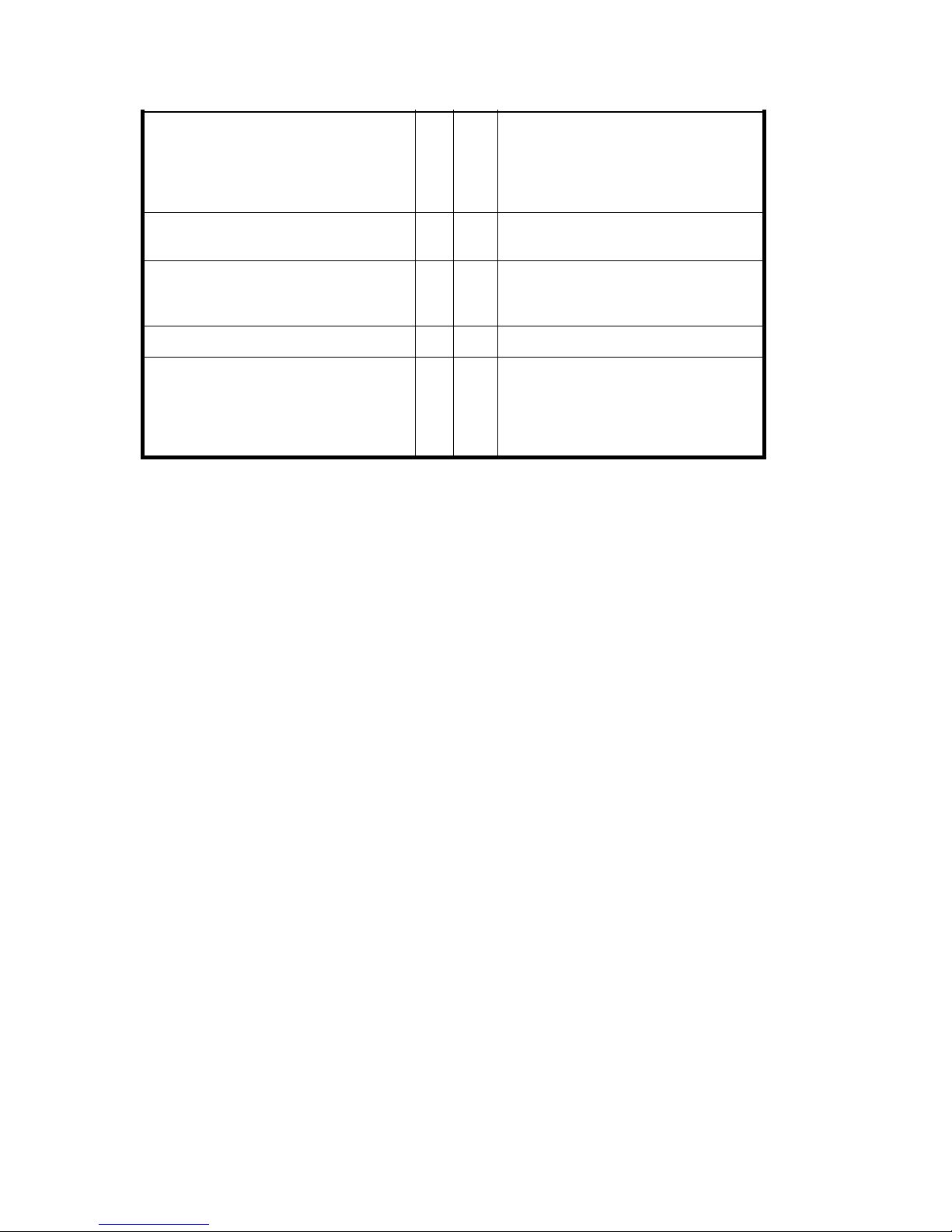

Part Number

Descriptio

n

Weight

Quantity

Total weigh

t

Total weight of your configuration

HP StorageWorks XP10000 Disk Array Site Prep Guide

23

Page 24

Weight calcula

tion example

Part

Number

Description

Weight

Quan-

tity

Total

weight

AE102A

HP XP10000 19" Primary Rack, disk

controller, base disk chassis for up

to 60 HDDs, power supplies, base

batteries for up to 12GB cache and

up to 3GB Shared Memory

740 x

1=

740 .0

AE007A

HP XP12000/10000 32-Port 2-Gb

FC CHIP

12.8 x

1=

12.8

AE025A

HP XP12000/10000 4-GB Cache

Memory

0.44 x

1=

0.4

AE030A

HP X P12 000/10000 1-GB Shared

Memory

0.13 x 3 =

0.4

AE104B

HP XP10 000 Disk Chassis (holds up

to 60 drives)

177.0 x

1=

177.0

AE105B HP XP100

00 16Port FC SW CHIP

8-Port

ACP

11.0 x

1=

11.0

AE110B

HP XP10000 Battery 17.6 x

1=

17.6

AE123B

HP XP10000 300GB 10k rpm Array

Group

8.8 x 28 =

246.4

AE123BS

HP XP1

0000 300GB 10k rpm Spare

Disk

2.2 x 8 = 17 .6

Total unpackaged weight of your configuration (rounded)

1223.2

24

Site requirements

Page 25

Delivery space requirements

The delivery area must provide enough space and floor strength to support the packaged

equipment cartons for the disk array. Refer to the packaged dimensions and weights

under the heading “Dimensions and weights.”

CAUTION:

Make sure tha

t your doorways and hallways provide enough clearance to move the

equipment s

afely from the delivery area to the computer room. Permanent obstructions

such as pillars or narrow doorways can cause equipment damage. If necessary, plan

for the removal of walls or doors.

CAUTION:

Make sure all floors, stairs, and elev ators you use when moving the disk arr ay to the

computer room can support the weight and size of the equipment. Failure to do so

could damage the equipment or your site.

HP StorageWorks XP10000 Disk Array Site Prep Guide

25

Page 26

General computer room requirements

The goal of a computer room is to maintain an ideal environment for computer

equipment, including XP disk arrays.

Make sure your computer room adheres to all national and local building codes for a

data center/computer room environment.

HP recommend

s that you follow these general guidelines:

• Locate the computer room away from exterior walls of the building to avoid the

heat gain from windows and exterior wall surfaces.

• When exterior windows are unavoidable, use windows that are double or tripled

glazed and

shaded to prevent direct sunlight from entering the computer room.

• Maintainthecomputerroomatapositivepressurerelativetothesurrounding

spaces to reduce introduction of contaminants.

• Install a vapor barrier around the entire computer room envelope

(floors/

walls/ceiling) to help keep moisture out of the room. This is especially

import

ant if your computer room is located underground.

• Caulk and vapor-seal all pipes and cables that penetrate the computer room

envelope.

26 Site requirements

Page 27

Preventing ele

ctrostatic discharge

Electrostatic discharge (ESD) can cause component damage, especially during servicing

operations.

Static charge

s occur when objects are separated or rubbed together. The voltage level

of a static ch

arge is determined by the following factors:

• Types of materials

• Relative humidity — low humidity tends to increase ESD voltage.

• Rate of chan

ge — a sta ndard air conditioner cools the air and lowers humidity.

The faster

the air is cooled and dried, the greater the likelihood of ESD.

• Separation — refers to the static discharge that can be generated when two

objects are separated. For example, printer paper is often stored in cool dry

conditions. If opened and used immediately, the act of removing the paper

from its box generates static.

Follow these precautions to minimize possible ESD-induced failures in your co mputer

room:

• Install c onductive flooring(conductiveadhesivemustbeusedwhenlayingtiles).

• Useconductivewaxifwaxedfloors are installed.

• Ensure

that all equipment and flooring are properly grounded and are at the

same ground potential.

• Useconductivetablesandchairs.

• Store

spare electric parts in antistatic containers.

• Use proper cooling equipment to reduce the risk of ESD by maintaining

recommended humidity level and airflow rates.

• Leave boxes of paper open in the computer room for several hours before use to

all

ow static to discharge gradually over time.

HP StorageWorks XP10000 Disk Array Site Prep Guide

27

Page 28

Safety requirements

When making decisions concerning site safety, your first concern should be the safety of

your personnel and then the safety of your equipment.

Fundamental safeguards for disk arrays should include a site well away from any

sources of potential damage.

If you have any qu estions on site safety, consult your HP representative, your insurance

carrier, an

d local building inspectors for safety recommendations.

Fire safety

Consult your insurance carrier and local fire department for fire safety suggestions. They

can analyze your existing fire control systems and advise you on any required changes.

If you are building a new site or making structural changes to an existing site, consult

your local b uild ing cod es for fire prevention and protection guidelines.

Equipment servicing hazards

Your staff and HP service personnel require safe access to the disk array. Running

electrical and data communication cables underneath your computer room’s raised floor

is the b

est way to ensure that they do not create a safety hazard.

Electrical hazards

The disk array equipment racks contain dangerous voltages. To prevent injury or death

from electric shock, refer all electrical installation and service to qualified personnel.

28 Site requirements

Page 29

Space planning requirements

Space planning involves making sure that your computer room:

• Is large enou

gh to hold the new array and other equipment and furniture

• Provides clearance around the array for service access and to ensure proper

weight distribution on the computer room’s floor

• Includes cor

rectly positioned floor cutouts for the array’s power and data c ables

The space planning process

1. Document your computer room’s existing floor plan, including locations of these

items:

a. Im movable objects, such as structural support columns

b. Walls

c. All equipment, furniture, cabinets, racks, data comm equipment, and systems

d. Floor cutouts

e. Electrical outlets

f. Interconnecting cables and power cords, including lengths

g. Floor vents

2. Developanewfloor plan that includes the locations of all of the above items

plus the disk array and any new items added to support it. Include flexibility to

accommodate additional equipment as your requirements increase.

3. Implem ent the new floor plan, leaving empty space where the array will be

installed. If the new floor plan requires construction changes, consult with local

contractors and your HP representatives.

HP StorageWorks XP10000 Disk Array Site Prep Guide

29

Page 30

Raised floor requirements

The computer room floor must be able to support the total weight of the equipment as

well as localized weight at each caster or foot of the equipment cabinets. A common

method of preparing an adequate floor for a computer room is to construct a raised

flooroverthebuildingfloor. A raised floor:

• Allows weight to be spread evenly across the floor

• Provides a

nunder-floor area for running interconnecting cables conveniently

and unobtrusively

• Allows optimum distribution of conditioned air

WARNING!

If metal is used in the construction of the raised floor, ensure that there is a common

ground co

nnection between the raised floor and main floor to avoid possible build

up of dif

ferent voltage potentials. Failure to comply can result in serious injury to

personnel and damage to equipment.

Requirements for raised floors:

• Raised floor access ramps must not exceed a 10 degree slope.

• Use a raised floorsystem(254to305mm,10to12inches)forthemost

favorable room air distribution system.

• Gridpanelsmustbeatleast450x450mm(17.72x17.72in).

• The floor must have a load rating between 300 and 500 kg per square meter

(553 to 921.7 lb per square yard, or 61.4 to 102.4 lb per square foot). The

maximum floor loading at any point is 500 kg (1102.3 lb) .

30 Site requirements

Page 31

Estimating required floor load rating

To estimate the load rating you need for your floor, consider the total weight of all

of these items:

• Thediskarray;seetheprecedingComponent weights

• Other equipm

ent

• Furniture such as desks, chairs, and storage cabinets

• Computer room personnel

• Moving equi

pment such as forklifts, dollies, and similar items

The lower t

he floor load rating, the more clearance is required around the array to

distribut

e the equipment weight correctly. If your computer room is too small to allow

for minim

um required clearance around the array, you may need to increase the floor

load rating. For more on required clearance, see Floor clearance and cutout dimensions

later in this chapter.

Floor covering

HP recommends the use of a tiled raised floor.

CAUTION:

HP strongly discourages the use of carpeting, including antistatic varieties, within 6.0 m

(20 ft.) of the disk array. Over time, carpeting may shed dust that can cause problems

with the disk array.

CAUTION:

If your computer room has carpeting, place static discharge mats so that personnel

must walk across them before touching any part of the array. Failure to comply with this

precaution can result in equipment damage through static discharge.

HP StorageWorks XP10000 Disk Array Site Prep Guide

31

Page 32

Floor clearanc

e and cutout dimensions

Figures on the following pages show the clearance dimensions, locations of floor cutouts,

and other dimensions for the primary and second racks.

Primary rack dimensions and c able cutout location

The following figure shows rack dimensions, clearances, and the cable cutout location.

The cutout may be off-center as long as it is within the area shown and corresponds

to the opening in the bottom of the cabinet to allow cables to pass through. See the

following pages for additional notes.

32 Site requirements

Page 33

Calculating cl

earances

The total floor c

learance required for the disk array includes:

• The actual space required by the equipment.

• Service clearance — the floor space required to access the disk array. Never

use this space

for storage.

• Additional space required to properly distribute the equipment weight on your

computer room’s raised floor. The amount of additional space required depends

on your floor load rating.

HP StorageWorks XP10000 Disk Array Site Prep Guide

33

Page 34

34

Site requirements

Page 35

Calculate primary rack clearance dimensions as follows:

• Clearance “a” is the space between the service clearance at the left side of

the array (100 mm minimum for installing the kickplate) and any other object,

such as a desk or wall.

• Clearance “b” is the space between the service clearance at the right side of the

array (100 mm for the kickplate) and any other object.

• Clearance “c” is the space between the service clearance at the front of the

array and any other object.

• Usethevalueof“c”andyourfloor load rating to determine the values for a

and b according to the following steps.

1. Determine how much space you can assign to clearance “c”. For maintenance

purposes, try to make “c” larger (1000 mm) rather than smaller (0 cm). The

smaller “c” is, the larger “a” and “b” must b e.

2. In the following floor loading table, findthecolumnfor“c”thatmostclosely

matches your value. If your “c” value is in between two table values, use the

larger table value. Then, find the row for your floor load rating. Where the

column and row intersect is the a+b value.

3. To determine clearance “a” and clearance “b”, divide the a+b value between

“a” and “b”. They do not need to be equal. For example, if the a +b value

from the table is 600 mm, then “a” can be 400 mm and “b” can be 200, or

both “a” and “b” can be 300.

4. Calculate clearances by filling in and adding the table columns below:

Left

(add down)

Right

(add down)

Front

(add down)

Back

(add down)

Clearance

values

a _________

b _________

c _________

Not applicable

Plus minimum

service

clearance

100 mm (3.94

in)

100 mm (3.94

in)

1000 mm (39.4

in)

1000 mm (39.4

in)

Equal

stotal

clea

rance

HP StorageWorks XP10000 Disk Array Site Prep Guide

35

Page 36

Primary rack cl

earance notes and floor loading

The following n

otes apply to preceding primary rack dimensional figures.

Note *1: Cleara

nce (a+b) depends on the floor load rating and clearance “c”. Required

clearances fo

rvariousfloor load ratings are shown below.

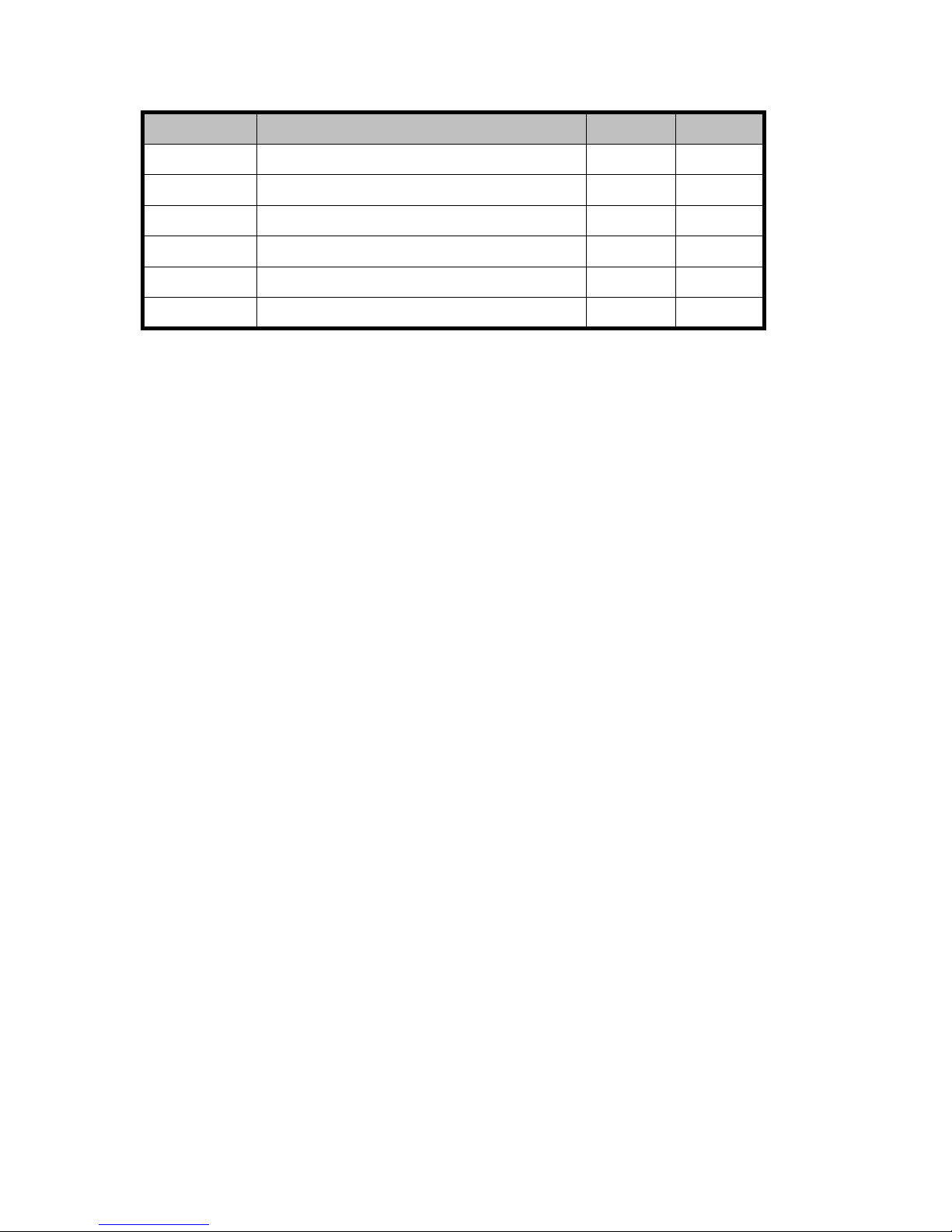

Required clearance (a + b) mm

Clearance (c) mm

Floorload

rating

(kg/mm2)

c = 0 c = 200 c = 400 c = 600 c = 1000

500 200 100 0.00 0.00 0.00

450

300 200 100 100 0.00

400 400

300 300 200 100

350 600 500

400 400

200

300 1000 800 700 600 500

Provide100mmofclearanceonbothsidesofthediskarraywhenthekickplatesareto

be attache

d after the disk array is installed. When disk arrays of the same type are to

be installed adjacent to each other, clearance between the arrays may be 100 mm.

Additional notes on primary rack floor loading and clearances:

• Decide actual clearances in consultation with the construction specialist

responsible for installation. They may vary depending on the size and layout of

the system and building conditions.

• When multiple disk arrays are arranged in a row, base your clearance values on

the requirements of the largest disk array.

• Generally, clearances (“c”) should be as large as allowable.

36 Site requirements

Page 37

Primary and sec

ond rack clearance dimensions and cutouts

The following fi

gures show floor clearance dimensions when two racks are installed.

See also the ta

ble and text following the figures for notes and details. Clearances

for two racks

are calculated and recorded in the preceding table in the same way as

asinglerack.

HP StorageWorks XP10000 Disk Array Site Prep Guide

37

Page 38

38 Site requirements

Page 39

Primary and sec

ond rack clearance notes and floor loading

The following e

xplanatory notes apply to the preceding floor clearance drawings for the

primary and second rack.

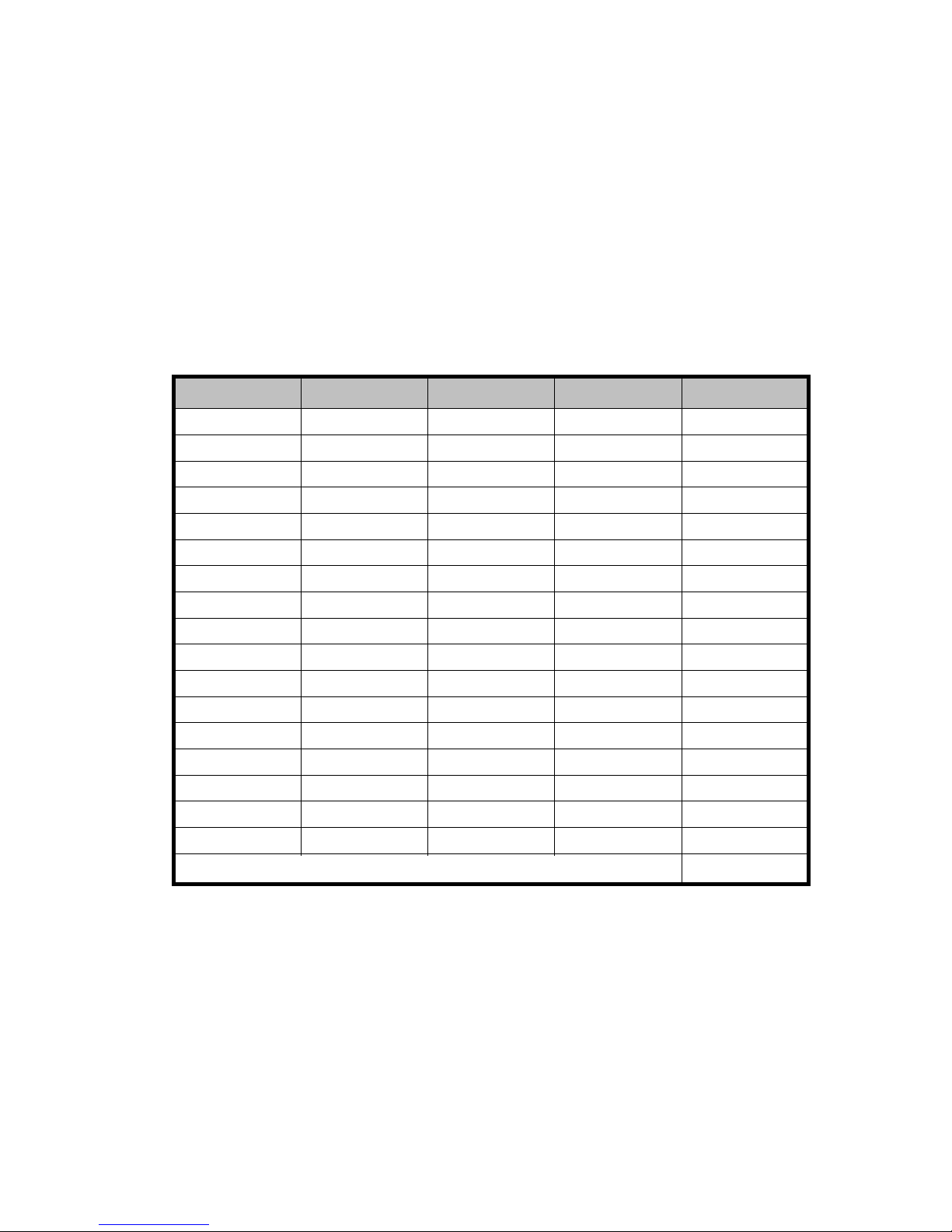

*1: Clearance (a+b) depends on the floor load rating and clearance “c”. Required

clearances for various floor load ratings are shown below.

*2: Clearance between racks must be at least 10 mm. If the kickplate is installed after

rack placeme

nt, allow 100 mm.

Required clearance ( a + b) mm

Clearance (c) mm

Floorload

rating

(kg/mm2)

c = 0 c = 200 c = 400 c = 600 c = 1000

500 100 0.00 0.00 0.00 0.00

450

300 200 0.00 0.00 0.00

400

600

400

300 200 0.00

3501000800600500200

300 1600 1300 1100 900 600

Addition

al primary and second rack floor loading and clearance notes:

• Decide actual clearances in consultation with the construction specialist

responsi

ble for installation. They may vary depending on the size and layout of

the system and building conditions.

• When multiple disk arrays are arranged in a row, b ase your clearance values on

the requirements of the largest disk array.

• Genera

lly, clearances (“c”) should be as large as allowable.

HP StorageWorks XP10000 Disk Array Site Prep Guide

39

Page 40

Environmental requirements

The environmental specifications for operating your dis k array must be satisfied before

installation.

Altitude

The maximum altitude for disk array operation is 3,000 meters. For nonoperational or

storage situations, the maximum altitude is 4,000 m eters.

Air conditioning

Use separate computer room air conditioning duct work. If it is not separate from the

rest of the building, it might be difficult to control cooling and air pressure levels. Duct

work seals are important for maintaining a balanced air conditioning system and high

static air pressure. Adequate cooling capacity means little if humidity levels increase

when the ducts are exposed to warm air, producing condensation. Condensation on

any disk

hardware can damage the components.

Any ques

tions regarding the adequacy of airflow construction should be referred to and

evalua

ted by a qualified structural engineer.

40

Site requirements

Page 41

Temperature specifications

Temperature range type Range

Recommended operating temperature range 21 to 24 degrees C

70 to 75 degrees F

Operating tem

perature

16 to 32 degree

sC

61 to 89 degree

sF

Nonoperating temperature range

–10 to +43 degrees C

14 to 109 degrees F

Shipping and storage temperature (product

packed in factory packing)

–25 to +60 degrees C

–13to+140degreesF

Temperatur

e shock immunity (maximum rate

of temperat

ure change)

10 degrees C

per hour

18 degrees F

per hour

HP StorageWorks XP10000 Disk Array Site Prep Guide

41

Page 42

Humidity specifications

Maintain proper humidity levels. High humidity levels cause galvanic actions to occur

between some dissimilar metals. This eventually causes a high resistance between

connections, leading to equipment failure.

Low humidity contributes to undesirably high levels of electrostatic charges. This

increases th

e electrostatic discharge (ESD) voltage potential. ESD can cause component

damage during servicing operations.

Low humidity levels are often the result of the facility heating system a nd occur during

the cold season. Most heating systems provide air with a low humidity level, unless the

system has a built-in humidifier.

You shou ld

not see any condensation in or around the disk array under any conditions.

There is no procedure for recovery from moisture condensation.

Humidity r

ange type

Nonconden

sing relative humid it y (RH)

Operating humidity range at 22 d e grees C

(71 degrees F)

20%to80%

Nonoperating humidity range

8% to 90%

Shipping and storage humidity range

(produ

ct packed in factory packing)

5% to 95%

Operating maximum wet bulb temperature 26 degrees C

79 degrees F

Nonoperating maximum wet bulb

temperature

27 degrees C

81 degrees F

Shipping and storage maximum wet bulb

temperature

29 degrees C

84 degrees F

42

Site requirements

Page 43

Mechanical vibration specifications

Continuous vi

bration can cause a slow degradation of mechanical parts and, when

severe, can cause data errors in disk drives. Mechanical connections such as printed

circuit assembly (PCA) conductors, cable connectors, and processor backplane wiring

can also be affected by vibrations. Vibration specifications apply to all three axes. For

vibration te

sting methods, see ASTM D999-91 Standard Methods for Vibration Testing

of Shipping

Containers.

Condition

Specification

Operating 0.25 mm, 5–10 Hz

0.05 G, 10–300 Hz

Nonoperating

2.5 mm, 5–10 Hz

0.5 G, 10–70 Hz

0.05 mm, 70–99 Hz

1.0 G, 99–300 Hz

Shipping and storage (product packed in

factory packing)

0.5G,15minutes(atfourmostsevere

resonances between 5–200 Hz)

Shock specifications

The following tables lists shock specifications. For horizontal shock testing methods,

see ASTM D5277-92 Standard Test Methods for Performing Programmed Horizontal

Impacts Using an Inclined Impact Tester. For vertical shock testing methods, see ASTM

D6055-96 Standard Test Methods for Mechanical H andling of Unitized Loads and

Large Shipping Cases and Crates.

Condition

Specification

Operat

ing

None

Nonoperating

8G,15ms

Shipping and storage (product packed in

factory packing)

Horizontal: Incline impact: 1.22 m/s

Vertical: Rotational edge: 0.1 m

HP StorageWorks XP10000 Disk Array Site Prep Guide

43

Page 44

Heat dissipation, power consumption, and air flow

The following table describes the heat dissipation and power consumption of the

XP10000 when loaded with the maximum number of disk drives.

Parameter

Primary Rack Second Rack Full array

Power consumption

(kVA)

4.

9

3.2 8.1

Heat dissipation

(kW)

4.6

3.0 7.6

BTUs per hour

15710 10246 25955

Kcal per ho

ur

39

59 2582 6541

Thetablebelowshowstheairflow requirements for the frames and disk chassis.

Product

No.

Description

Air flow

(cubic meters

per minute)

AE102A

HP X P1 0000 Disk Control Frame - DKC 15

AE104B

HP XP100

00 Disk Chassis

8

AE115B HP XP10000 Disk Array Frame 8

44

Site requirements

Page 45

The following table presents the power requirements and heat dissipation of individual

components.

Product

No.

Description

Heat output

(kW)

Power

consumption

(kVA)

AE102A

HP XP10000 Disk Control Frame - DKC 0.738 0.761

AE105B

HP XP10000 16Port FC SW CHIP

8-Port ACP 0.370 0.381

AE006A

HP XP12000 /1000

0 16-port 2-Gb FC

CHIP

0.287 0.296

AE007A

HP XP120 00/10000 32-Port 2-Gb FC

CHIP

0.382

0.394

AE010A

HP XP120 00/10000 32-Port 4-Gb FC

CHIP

0.382

0.394

AE013A

HP XP12000/10

000 8-Port FICON

SW CHIP

0.346

0.356

AE014A

HP XP12000/10000 8-Port FICON

LW CHIP

0.346

0.356

AE015A

HP XP12000/10000 1 6-Port FICON

SW CHIP

0.35 0.361

AE016A

HP XP12000/

10000 16-Port FICON

LW CHIP

0.35 0.361

AE017A

HP XP12000/10000 16-Port EXSA

CHIP

0.313 0.323

AE018A

HP XP12000/10 000 8-Port 1-Gb NAS

SW CHIP

0.446 0.46

AE025A

HP XP12000

/10000 4-GB Cache

Memory

0.014 0.014

AE030A

HP XP12000/10000 1-GB Shared

Memory

0.011 0.012

AE110B HP XP10000 Battery 0.044 0.045

AE104B

HP XP10000 Disk Chassis

0.100 0.103

AE115B HP XP10000 Disk Array Frame 0.100 0.103

AE120A

HP XP10000 73GB 15k rpm Array

Group

0.088 0.096

AE121

A

HP XP10

000 146GB 10k rpm Array

Group

0.092 0.1

HP StorageWorks XP10000 Disk Array Site Prep Guide

45

Page 46

Product

No.

Description

Heat output

(kW)

Power

consumption

(kVA)

AE122A

HP XP10000 146GB 15k rpm Array

Group

0.092 0.1

AE123B

HP XP10000 300GB 10k rpm Array

Group

0.092 0.1

AE120AS

HP XP10000 73GB 1

5k rpm Spare

Disk

0.022

0.024

AE121AS

HP XP10000 146GB 10k rpm Spare

Disk

0.023 0.025

AE122AS

HP XP10000 146GB 15k rpm Spare

Disk

0.023 0.025

AE123BS

HP XP10000 300GB 10k rpm Spare

Disk

0.023 0.025

Acoustics

The acoustic emission specification for the disk array is:

• 65 dB (A) so

und pressure, operator position (1 meter from the floor and surface

of the cabinet)

You can reduce the ambient noise level caused by equipment and air conditioning

blowers i

n your computer room by:

• Installing a dropped ceiling covered in commercial-grade, fire-resistant,

acoustic-rated, fiberglass ceiling tile

• Covering the walls in sound-deadening material

• Instal

ling foam rubber removable partitions

46

Site requirements

Page 47

Dust and pollut

ion control

Airborne contaminants and particles of a certain size and hardness can damage the

disk array. Some of the most common contaminants are dust, smoke, ash, eraser debris,

food crumbs, a

nd salty air.

Mechanical filters on the disk array protect it by trapping large dust particles. Smaller

particles can pass through some filters, and can eventually cause problems in mechanical

parts. Prevent sm all dust particles from entering the computer room by maintaining its

air conditioning system at a high static air p ressure level.

Your HP representative can help you determine if you need to be concerned about

airborne c

ontaminants.

Metallic particulate contamination

Metallic particulates can be especially harmful a round electronic equipment. This type

of contamination may enter the data center environment from a variety of sources,

including but not limited to raised floor tiles, worn air conditioning parts, heating

ducts, rotor brushes in vacuum cleaners, or printer component wear. Because metallic

particulates conduct electricity, they have an increased potential for creating short

circuits in electronic equipment.

Over time, very fine whiskers of pure metal can form on electroplated zinc, cadmium, or

tin surfaces. If these whiskers are disturbed, they m ay break off and become airborne,

possibly causing failures or operational interruptions. For over 50 years, the electronics

industry has been aware of the relatively rare but possible threat posed by metallic

particulate contamination. During recent years, a growing concern has developed in

computer rooms where these conductive contaminants are formed on the bottom of

some raised floor tiles.

Although this problem is relatively rare, it may be an issue within your computer room.

Since metallic contamination can cause permanent or intermittent failures on your

electronic equipment, HP strongly recommends that your site be evaluated for m etallic

particulate contamination before installation of electronic equipment.

HP StorageWorks XP10000 Disk Array Site Prep Guide

47

Page 48

Data comm requirements

Route data comm cables away from areas of high static electrical fields created by

power transformers and heavy foot traffic. Use shielded data comm cables that meet

approved industry standards to reduce the effects of external fields.

For the XP disk

array, you need:

Item

Description

A dedicated analog

phone line

Needed for the HP StorageWorks Continuous Track XP “phone

home” feature, if you plan to use it. An HP representative will

configure Continuous Track XP during installation. For more

information on Continuous Track XP, see the HP StorageWorks

XP10000 Disk Array Owner’s Guide.

A twisted pair (Cat 5)

cableAn available LAN

drop on your Intranet

Needed to connect the XP10000 to an available Ethernet

port on your p ublic LAN. To ensure network security, consult

with an HP representative and your network administrator

before selecting the appropriate location of your LAN drop.

Apublicvoicephoneline

near the disk array

Needed to allow your staff and HP representatives to

communicateinsideandoutsideyoursite.

48

Site requirements

Page 49

Electrical requirements

Line voltage

Linevoltage(AC)atthewallpoweroutletisafunctionofthelocalpowerutilityandyour

building power distribution network. Voltages outside of the operating range of the disk

array can cause intermittent system errors or a complete system shutdown. If required,

an HP representative and your electrician can determine the current line voltage and

make recommendations. See "

Chapter 3 Electrical specifications" for specificACline

voltage requirements.

Avoid the use of a line voltage conditioner.

Make sure that a power distribution unit (if used) provides the c orrect voltage to support

your entire system.

Branch circuit breakers

See "Chapter 3 Electrical specifications" for specific branch circuit requirements for

your pow

er situation.

Single-phase branch circuit breakers

The power cords supplied are specified for connection to a single-phase, 20-amp circuit.

Frequency

Usuall

y, AC line frequency is determined by your local power providers. In some cases,

electrical power is supplied by generators. Shifts in AC line frequency can cause system

errors. An HP representative can monitor the frequency of the input AC line power and

make recommendations, if necessary. The disk array requires that the line frequency be

withi

n 0.5 Hz of the rated line frequency (50 Hz or 60 Hz). See "

Chapter 3 Electrical

specifications" for more information.

Safety and dedicated ground

The primary reason for grounding electrical systems is safety. The safety ground is

required by the National Electric Code (USA) and most other local, regional, and

national codes. In addition to safety ground, HP requires that a dedicated (earth

reference) ground be installed as a common reference point for all system components.

Consult with an HP representative and your electrician to ensure that your electrical

system meets all lo cal and national safety codes.

HP StorageWorks XP10000 Disk Array Site Prep Guide

49

Page 50

Grounding requirements

Your site’s electrical subsystem must meet all of the following co nditions:

• Grounding as presc

ribed by your local country codes.

• An insulated grounding conductor that is identical in size and insulation material

and thickness to the ungrounded branch-circuit supply conductors. It should be

green, with or without yellow stripes, and is to be installed as a part of the

branch circuit t

hat supplies the unit or system. This means the ground conductor

must be run in the same conduit, armored cable, or other cable bundle as the

phase wires.

• The grounding c

onductor should be grounded to earth at the service equipment

or other accep

table building earth ground such as the building frames (in case

of a high-rise

steel-frame structure).

• IT-configured grounding systems are not certified for use with the disk array as

these grounding systems may not h ave solidly conductor-connected grounded

power systems and/or they may have resistive imp e dance inserted in ground

and/or neutral lines. The disk array requires a solidly conductor-connected

ground and

may require a separate neutral in the case of WYE or STAR

connectio

ns. For HP disk arrays, TN grounding systems are preferred.

AC connections

The disk array primary rack has four sepa rate connections to 200 VAC, single-phase,

20-amp power.

The second rack has two connections to AC power in the minimum configuration (four

recommended) and four connections to AC power in the maximum configuration. Power

requirements are 200 VAC, single-phase, 20-Amps.

When receptacles are used to connect disk array components to AC power, they must

include a dedicated ground connection that is insulated from the receptacle. It is

important that the receptacle box be g rounded with an additional ground connection

that is separate from the dedicated ground. The additional ground can be hard conduit.

Specific AC power cords and plugs are available to suit the power requirements and

receptacles in your location. You can specify the cords and plugs you need when you

order the HP XP10000 disk array. You are responsible for having the correct plugs and

receptacles installed by an electrician in compliance with local electrical requirements

and practices.

50 Site requirements

Page 51

CAUTION:

When installing the receptacles, the electrician must ensure that each receptacle has its

own neutral (if required) and ground. Using the same neutral/ground for more than one

circuit causes voltage loss and heat problems and can create a fi re hazard. A shared

neutral conductor that fails open-circuit can cause overvoltage damage to equipment.

See "Chapter 3 Ele ctrical specifications" for specific power requirements as well as plug

and receptacle pa rt numbers and ordering information.

Power line transients

Heavy electrical loads from nearby machinery or e quipment (for example, elevators or

electric welders) can cause intermittent system problems with sophisticated electronic

equipment, even if that equipment is on a separate circuit breaker. When faced with

these conditions, provide a separate, completely independent power panel with an

isolated ground an d circuit breaker coming directly from the main building power source

or secondary power source.

If necessary, an HP representative can measure your power line noise level and ma ke

appropriate recommendations concerning the use of line treatment devices.

Protection against sources of electrical interference

Protect the disk array from sources of electrical interference:

HP StorageWorks XP10000 Disk Array Site Prep Guide

51

Page 52

Potential source

Description

Wall outlets

Convenience power outlets for building maintenance equipment

(such as vacuum cleaners and floor buffers) must be wired from circuit

breakers on a power panel separate from the computer system panel.

The ground wires from these outlets must be connected to the normal

building distribution panel and not to the system ground.If a separate

power source and separate ground are not provided, operation of

janitorial equipment can induce electrical noise and cause abnormal

operation of the computer system. Your electrician can verify whether

maintenance outlets are on separate panels.

Lightning In geographical areas subject to lightning storms, it may by advisable

to install l

ightning protection for both personnel and computer

systems. The principles of lightning protection and personnel safety

areoutlinedindetailinthelightningprotectioncodecontainedinthe

National Fire Protection Association (NFPA) Handbook.

Electromagnetic

interference

The disk array is specifically d esigned to reduce its susceptibility to

radiated and conducted interference. Electromagnetic interference

can cause a variety of system problems. An HP representative can

advise you about the most common causes of electromagnetic

interference.

Uninterruptible power supply (UPS)

Most disk array units are installed in data centers where a UPS strategy is already in

place. However, if you are making your first large disk array purchase, you may need

a separate UPS solution.

CAUTION:

If you are planning or already have a site-wide UPS, HP recommends against using a

product UPS powered by a site-wide UPS for the XP10000.

Make sure your UPS satisfies the power requirements listed u n der Heat dissipation

and power consumption in this chapter and also under AC line voltage requirements

in Chapter 3.

52 Site requirements

Page 53

3Electricalspecifications

The detailed electrical specifications in this chapter are provided to help your site

electrician perform any necessary electrical work related to site prep.

AC line voltage r

equirements

The AC power requ

irements are essentially the same for both the primary and the

second racks. Each rack operates on 200 VAC nominal, 20 amps, 50 or 60 Hz,

single-phase power. An independent branch circuit and circuit breaker is required

for each AC input power cord.

The following

table lists specific power requirements.

Parameter

200

VAC

208

VAC

220

VAC

230

VAC

240

VAC

Minimum operating voltage

(VAC)

184

191 202 212 221

Maximum operating voltage

(VAC)

212 220 233

244 254

Rated line current per power

cord

16A 16A 16A 16A 16A

Number of power cords

44444

Recommended circuit breakers

20A 20A 20A 20A 20A

Number of c

ircuit breakers

44444

Important notes:

208 VAC is

60 Hz only. Rated line current per power cord is the maximum allowable

current under worst case conditions. This value applies to each individual power cord

and is specified in RMS amperes. For the second rack, four power cords and circuit

breaker

s are strongly recommended even though a minimum configuration containing

only one

expansion disk chassis requires only 2 power cords and 2 circuit breakers. If

a second expansion disk chassis is added to the second rack, four power cords and

four circuit breakers are required.

HP StorageWorks XP10000 Disk Array Site Prep Guide

53

Page 54

AC inputs

The disk array

primary rack has four separate connections to 200 VAC, single-phase,

20-amp power

. The AC power inputs to the primary rack are distributed to four power

distribution units (PDUs) as shown in the following figure. This provides fault tolerant

operation of the disk array. Each pair of AC inputs (00/10 and 01/11) must be

capable of supporting the entire current demand for the cabinet. Each PDU is fitted with

an IEC320-C20 inlet that fits the supplied input power cord, and four IEC320-C13

outlets th

at connect to the hardware inside the rack by means of supplied cables.

CAUTION:

The four PDU outputs shown in the figures a re for internal power connections to the

disk array only. Do not connect any other equipment to these outlets. Usin g the outlets

for any equipment other than the disk array may compromise disk array reliability

or availability .

Thesecondrackshowninthefollowingfigure has four connections to AC power. Power

requirements are 200 VAC, single-phase, 20-Amps.

54

Electrical specifications

Page 55

HP offers the following AC power cables and connectors, which you can order

individually (four each are required per primary or second rack):

• E7805A HP 4.5 m power cord w/NEMA L6-30P plug

• E7806A HP

4.5 m power cord with stripped ends

• E7808A HP 2 40 V power cord w/ IEC 309 plug, 4.5 m

• E7809A HP 240 V power cord w/ CEE7/7, 4.5 m

• E7810A H

P power cord for China

• E7811A HP power cord for Israel

• E7804A HP power cord, 4.5 m, C19/C20 Plug (jumper for UPS)

• E7798A

cord w/IEC 320-C20 connector and 2.5 m jumper for UPS

You can supply your own power cables as long as they meet a 20 amp rating, fitthe

IEC320-C20 PDU inlets, and me et lo cal codes.

HP StorageWorks XP10000 Disk Array Site Prep Guide

55

Page 56

NorthAmericanACpowercabling

The XP10000 racks each require 20-amp, single-phase 200 VAC power supplied by

four power cords with p lugs, four receptacles, and four main disconnect devices (circuit

breakers). If the second rack contains only one disk chassis, only two power cords and

breakers ar

e required, but four are required if you plan to add another disk chassis.

The XP10000 comes from the HP factory with the AC power cords and plugs you have

ordered. Plug types rated for 30 Amps are specified under the heading, AC inputs

earlier in this chapter. The opposite end of the power cord connects to the XP10000

power distribution unit input, which is a type IEC320 C20 connector.

Connect ea

ch AC power cable to a separate receptacle on a separate circuit breaker,

and connect each pair of power cords (the left pair and the right pair) to separate

distribution panels to ensure power fault tolerance.

CAUTION:

Do not apply power until instructed to do so by HP. An HP representative should be

present

whenever the disk array is being connected to a new power source.

Branch circuit requirements

To protect the disk array, your building must be wired correctly. Each supply ( “hot”)

conductor must be protected by a short-circuit protective device and by an overcurrent

protective device. The table listed under AC line voltage requirements provides

specifications for the overcurrent protective devices required for single-phase operation.

All protective devices must comply with national standards of the country where the

units are to be installed. If a protective device interrupts any supply conductor, it must

also interrupt all other supply conductors.

56

Electrical specifications

Page 57

European AC power cabling

The XP10000 racks each require 20-amp, single-phase 200 VAC power supplied by

four power cords with plugs, four receptacles, and four main disconnect devices (circuit

breakers). If the second rack contains only one disk chassis, only two power cords

and breaker

s are required, but four are recommended if you plan to add another disk

chassis later.

The XP10000 comes from the H P factory with the AC power cables and plugs or

stripped ends you have ordered. Plug types are specified under the heading, AC inputs.

The opposite end of the power cord connects to the XP10000 power distribution unit

(PDU) inp

ut, which is a type IEC 320-C20 connector.

European branch circuit requirements

To protect the disk array, your building must be wired correctly. Each supply (“hot”)

conductor must be protected by a short-circuit protective device and by an overcurrent

protective device. The table listed under AC line voltage requirements provides

specifications for the overcurrent protective devices required for single-phase operation.

All protective devices must comply with national standards of the country where the

units are to be installed. If a protective device interrupts any supply conductor, it must

also interrupt all other supply conductors.

Overcurrent protection is also required for the neutral conductor.

Your electrician should know the appropriate code requirements for your location/site

and wire power distribution to the XP10000 accordingly.

HP StorageWorks XP10000 Disk Array Site Prep Guide

57

Page 58

Connecting the

European power-supply cables

Connect each AC power cable to a separate receptacle on a separate circuit breaker,

and connect each pair of power cords (the left pair and the right pair) to separate

distribution panels to ensure power fault tolerance. Sing l e-phase power cable wiring is

showninthefigure below.

CAUTION:

Do not apply

power until instructed to do so by HP. An HP representative should be

present whenever the disk array is being connected to a new power source.

CAUTION:

Be sure to connect the power cords to the distribution panel as shown in the figure.

Improper wiring of the neutral conductor may cause damage to the disk array. To

reduce the risk of a wrong connection, use a plug and socket that are approved for

this disk array. It is your electrician’s responsibility to select and install the proper

plugs and receptacles.

WARNING!

High leakage current can occur between the power supply and the unit. To avoid

electrical shock, be sure to make the protecti ve earth connection before the supply

connections.

58

Electrical specifications

Page 59

4 Delivery and un packin g

The disk array equipment is shipped directly from HP. If the disk array is part of a system

order, HP coordinates shipment from all HP locations so that all of the equipment arrives

at your site at approximately the same time.

When your equipment ships, HP p rovides you with carrier information and an expected

delivery date. Factors beyond HP’s control can cause delivery delays. If you have not

received your equipm ent within two weeks of its shipment from HP, contact your HP SR,

who will trace your order and expedite delivery.

CAUTION:

Before delivery, make sure your site meets the requirements explained under the

heading, “Delivery space requirements”.

HP StorageWorks XP10000 Disk Array Site Prep Guide

59

Page 60

Checking for shipping shortage and damage

Upon delivery of each equipment shipment:

1. Check the carrier’s bill of lading to ensure that the items listed match the item s

delivered. Notify the carrier immediately if there are any discrepancies or missing

items.

2. Inspect all shipping containers for signs of damage, such as dents, scratches, cuts,

or water ma rks.

3. If you see an

y damage to the containers:

a. Note on the bill of lading that there is apparent damage, subject to inspection.

b. Arrange for the carrier’s representative and an HP representative to be present

when the item in question is unpacked.

c. Contact y

our HP representative, who will make sure any damaged components

are repl

aced, regardless of the circumstances and without waiting for any

claim settlements.

Unpacking the equipment

HP representatives will supervise the unpacking and moving of the disk array equipment.

It is your responsibility to provide the people, tools, and equipment necessary to perform

these tasks.

Requi

red personnel

HP re

commends that three physically able personnel be available to assist with

off-loading the disk array equipment from the pallet. Personnel must be knowledgeable

and experienced with the safe handling of large, heavy, and sensitive computer

equipment.

Required tools

• Claw hammer (if full packaging with wooden crate)

• Ratchet wrench or box-open end wrench sizes 11mm (7/16") and 19mm (3/4"),

or adjustable end wrench

• 6mm hex wrench

• Scissors or box knife to cut polyester banding

• Safety glasses

• Short stepladder (helpful, but not required)

60

Delivery and unpacking

Page 61

Packaging configurations

XP disk array cabinets are shipped in one of three standard packaging configurations:

• Environmental pack — consists of stretch wrap over corner protectors. No

special tools

or procedures are required to unpack shipments in this form. This

packaging is used for most shipments within the USA and Canada that are direct

from the factory to the customer. HP uses special carriers with a de dicated fleet

of trucks and specially trained personnel.

• Full packag

ing — consists of a pallet, wooden loading ramp, inner packaging,

and outer corrugated carton assembly.

• Full packaging with wooden crate — consists of full packaging encased in a

wooden cra

te.

Unpacking process

If you need to unpack the equipment without HP supervision, follow the instructions

in this section.

1. Following the steps “Removing packaging materials”, unpack the equipment cartons

outside of the computer room to avoid debris and possible contamination of the

computer room environment.

2. For software CDs, cables, and other installation hardware, leave the sealed cartons

or packages intact. HP representatives will unpack them when they install and

configure the disk array.

3. As you unpack the cartons, match the delivered items to the packing list (invoice) for

each carton. Contact your HP SR imm e diately if any items are missing or are not

the ones you ordered.

4. Move all equipment to the computer room before the installation date.

HP StorageWorks XP10000 Disk Array Site Prep Guide

61

Page 62

Safety precautions

CAUTION:

Be very careful when handling the equipment. Do not drop the equipment from a

height of more than 0.5 cm (0.2 in). Floor unevenness must be less than 1 cm (0.4 i n).

WARNING!

The equipme nt frames are very heavy. To avoid injury, use appropriate lifting tools

and have three people unpack and move the equipment.

CAUTION:

Anymovementoftheequipmentbyforkliftshouldbedonepriortounpacking. The

cartonassemblyprovidesthemostsecuresupportoftheequipmentduringmovement.

Transporting the equipment by forklift after the packaging carton has been removed is

not advisable.

CAUTION:

Equipment racks are top heavy

and contain very sensitive electronic and mechanical

components. Whenmovingonframecasters,therollingsurfacemustbeableto

support the equipment weight and must be free of surface conditions that could cause

shock or vibration to the cabinet contents. Avoid pushing the racks from behind

because they may tip over. Instead, pull the racks from the front to roll them. Be careful

when pulling the rack that it doesn’t tip toward you or fall on you, causing injury.

WARNING!

When using sharp objects or cutting tools, make sure that no part of your body lies in

the path of the blade bit or point.

CAUTION: