Page 1

Semiconductor Parameter Analyzer

User's Task Guide

Page 2

c

Copyright Hewlett-Packard

Company 1993 - 1995

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited, except as

allowed under the copyright laws.

HP Part Number

04155-90010

Printing History

First edition, February 1994

Second edition, December 1994

Third edition, November 1995

Printed in Japan

R

MS-DOS

is U.S. registered

trademark of Microsoft

Corporation.

Lotus 1-2-3 is U.S. registered

trademark of Lotus Development

Corporation.

PageMaker is a trademark of

Aldus Corporation.

Product Warranty

This Hewlett-Packard product is warranted against

defects in material and workmanship for a period of

one year from date of shipment. During the warranty

period, Hewlett-Packard will, at its option, either repair

or replace products which prove to be defective.

For warranty service or repair, this product must be

returned to a service facility designated by

Hewlett-Packard. Buyer shall prepay shipping charges

to Hewlett-Packard and Hewlett-Packard shall pay

shipping charges to return the product to Buyer

.

However, Buyer shall pay all shipping charges, duties,

and taxes for products returned to Hewlett-Packard

from another country.

Hewlett-Packard warrants that its software and

rmware designated by Hewlett-Packard for use with

an instrument will execute its programming

instructions when properly installed on that instrument.

Hewlett-Packard does not warrant that the operation

of the instrument, or software, or rmware will be

uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects

resulting from improper or inadequate maintenance by

Buyer, Buyer-supplied software or interfacing,

unauthorized modications or misuse, operation outside

of the environment specications for the products, or

improper site preparation or maintenance.

No other warranty is expressed or implied.

Hewlett-Packard specically disclaims the implied

warranties of merchantability and tness for a

particular purpose.

Exclusive Remedies

The remedies provided herein are the Buyer's sole and

exclusive remedies. Hewlett-Packard shall not be liable

for any direct, indirect, special, incidental, or

consequential damages, whether based on contract,

tort, or any other legal theory.

Assistance

Product maintenance agreements and other customer

assistance agreements are available for

Hewlett-Packard products.

For any assistance, contact your nearest

Hewlett-Packard Sales Oce.

Certication

Yokogawa-Hewlett-Packard, Ltd.

9-1, Takakura-Cho, Hachioji-Shi,

Tokyo, 192 Japan

Hewlett-Packard Company certies that this product

met its published specications at the time of shipment

[from the factory]. Hewlett-Packard further certies

that its calibration measurements are traceable to the

National Institute of Standards and Technology

(

NIST

), to the extent allowed by the Institute's

calibration facility, and to the calibration facilities of

other International Standards Organization members.

Page 3

Safety Summary

The following general safety precautions must be observed during all

phases of operation, service, and repair of this instrument. Failure to

comply with these precautions or with specic warnings elsewhere in

this manual may impair the protection provided by the equipment. In

addition it violates safety standards of design, manufacture, and intended

use of the instrument. Hewlett-Packard Company assumes no liability for

customer's failure to comply with these requirements.

NOTE

HP 4155A/4156A comply with INSTALLATION CATEGORY II and

POLLUTION DEGREE 2 dened in IEC 1010-1.

HP 4155A/4156A are INDOOR USE products.

GROUND THE INSTRUMENT

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not

install substitute parts or perform any unauthorized modication to

the instrument. Return the instrument to a Hewlett-Packard Sales

and Service Oce for services and repair to ensure that safety

features are maintained.

DANGEROUS PROCEDURE WARNINGS

Warnings, such as example below, precede potentially dangerous

procedures throughout this manual. Instructions contained in the

warnings must be followed.

WARNING

Dangerous voltages, capable of causing death, are present in this

instrument. Use extreme caution when handling, testing, and adjusting.

To minimize shock hazard, the instrument chassis and cabinet must

be connected to an electrical ground. The power terminal and the

power cable must meet International Electrotechnical Commission

(IEC) safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of ammable gases

or fumes. Operation of any electrical instrument in such an

environment constitutes a denite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Operation personnel must not remove instrument covers. Component

replacement and internal adjustments must be made b

y qualied

maintenance personnel. Do not replace components with power cable

connected. Under certain conditions, dangerous voltages may exist

even with the power cable removed. To avoid injuries, always

disconnect power and discharge circuits before touching them.

DO NOT SERVICE OR ADJUSTALONE

Do not attempt internal service or adjustment unless another person,

capable of rendering rst aid and resuscitation, is present.

Safety Symbols

The general denitions of safety symbols used on equipment or in

manuals are listed below.

Instruction manual symbol: the product will be marked

L

with this symbol when it is necessary for the user to

refer to the instruction manual in order to protect

against damage to the instrument.

Indicates dangerous voltage (terminals fed from the

interior by voltage exceeding 1000 volts must be so

marked).

Indicates earth (ground) terminal.

K

Frame or chassis terminal. A connection to the frame

(chassis) of the equipment which normally includes all

exposed metal structures.

A

F

Alternating current.

Direct current.

Page 4

ON (Supply).

OFF (Supply).

Herstellerbescheinigung

GEAUSCHEMISSION

WARNING

CAUTION

The warning sign denotes a hazard. It calls attention to

a procedure, practice, condition or the like, which, if

not correctly performed or adhered to, could result in

injury or death to personnel.

The caution sign denotes a hazard. It calls attention to

an operating procedure, practice, condition or the like,

which, if not correctly performed or adhered to, could

result in damage to or destruction of part or all of the

product.

Lpa<70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T.19

Manufacturer's Declaration

ACOUSTIC NOISE EMISSION

Lpa<70 dB

operator position

normal operation

per ISO 7779

Page 5

Page 6

Page 7

Page 8

Page 9

Introduction

HP 4155A/4156A is an electronic instrument for measuring and analyzing the

characteristics of semiconductor devices. This one instrument allows you to

perform

both

measurement

and

analysis of measurement results.

highly accurate measurements.

HP 4155A/4156A has four highly accurate source/monitor units (SMUs), two

voltage source units (VSUs), and two voltage measurement units (VMUs).

The HP 4156A is designed for Kelvin connections and has high-resolution

SMUs (HRSMUs), so HP 4156A is especially suited for low resistance and low

current measurements.You can measure voltage values with a resolution of

0.2V by using the dierential measurement mode of VMUs.

reliability testing.

HP 4155A/4156A can perform

stress

testing. That is, can force a specied dc

voltage or current for the specied duration.

Also, you can force ac stress by using pulse generator units (PGUs), which are

installed in HP 41501A SMU/Pulse Generator Expander. The HP 41501A is

attached to HP 4155A or HP 4156A, and can be equipped with a ground unit

(GNDU), high power SMU (HPSMU), two medium power SMUs (MPSMUs), or

two PGUs.

data storing and printing.

HP 4155A/4156A can print and store, in addition to performing measurement

and analysis.You can store measurement setup information, measurement

data, and instrument setting information on a 3.5-inch diskette inserted into

the disk drive of HP 4155A/4156A. And you can print the setting information

and measurement results on a plotter or printer that is connected to

HP 4155A/4156A.

remote control.

HP 4155A/4156A can be controlled by an external controller via HP-IB by

using remote control commands. These commands are based on Standard

Commands for Programmable Instruments (SCPI), so you can easily develop

measurement programs.

HP 4155A/4156A has internal HP Instrument BASIC, so you can develop and

execute measurement programs by using the HP 4155A/4156A only, without

using an external controller.

ix

Page 10

In This Manual

This manual gives step-by-step instructions for performing common HP

4155A/4156A tasks, and consists of the following chapters:

NOTE

If you have never used the HP 4155A/4156A or HP 4145A/B, read the HP 4155A/4156A

Guide

rst before reading this manual. The

Quick Start Guide

gives you an overview of the product

Quick Start

and a brief introduction, which is a good rst step for beginners.

Introducing the HP 4155A/4156A

This chapter is an overview of the HP 4155A/4156A.

Installation

This chapter describes how to install HP 4155A/4156A, accessories

, and

peripherals.

Making a Measurement

This chapter describes device connections, making a sweep measurement,

knob sweep measurement, and sampling measurement, and forcing stress.

Analyzing Measurement Results

This chapter describes how to analyze measurement results manually and

automatically.

Filer and Hardcopy

This chapter describes how to print or plot out measurement results or

measurement setups.

If You Have a Problem

This chapter provides problem-solving information that you may encounter.

Manual Changes Depending on ROM Version

Index

x

Page 11

Other Manuals.

Also the following manuals about HP 4155A/4156A are available:

User's Dictionary Reference

This manual is a dictionary reference for all parts and functions of the HP

4155A/4156A, and consists of the following chapters:

Measurement Units

Measurement Mode

Measurement Functions

Page Organization

Print/Plot Function

Data Variable and Analysis Function

Softkey Maps and External Keyboard

Specications

Accessories and Options

Manual Changes Depending on ROM Version

Index

Programmer's Guide

This manual provides information about controlling the HP 4155A/4156A

by remote command via HP-IB interface and HP Instrument B

ASIC, and

consists of the following chapters:

Using HP Instrument BASIC

Reference: HP Instrument BASIC

Getting Started on Programming the HP 4155A/4156A

HP 4155A/4156A SCPI Programming

Running HP 4145A/B Program Directly on HP 4155A/4156A

Sample Application Programs

Manual Chages Depending on ROM Version

HP-IB Command Reference

This manual is a complete reference of HP-IB commands

the following chapters:

SCPI Commands

HP 4145B Syntax Commands

Manual Changes Depending on ROM Version

Index

Quick Start Guide

, and consists of

xi

Page 12

This manual is mainly for beginners and provides brief instructions about

using HP 4155A/4156A.

Text Conventions.

The following text conventions are used in this manual:

4

Front-panel key

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Softkey

Screen Text

Italic

5

Represents a key physically located on HP 4155A/4156A

or external keyboard.

Represents a softkey that appears on screen of

HP 4155A/4156A.

Represents text that appears on screen of

HP 4155A/4156A.

Refers to a related document, or is used for emphasis

.

xii

Page 13

Contents

1. Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A . . . . . . . . . . . .

Conguration of HP 4155A/4156A and HP 41501A . .

Front View of HP 4155A/4156A . . . . . . . . . . .

Rear View of HP 4155A/4156A . . . . . . . . . . .

1-3

1-4

1-5

1-9

L

L

L

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Front and Rear View of HP 41501A . . . . . . . . .

L

. . . . . . . . . . . . . . . . . . . . .

An Overview of Functions . . . . . . . . . . . . . .

Operation and Control . . . . . . . . . . . . . . .

Measurements and Results Display . . . . . . . . .

Graphical Analysis . . . . . . . . . . . . . . . .

Data Storage . . . . . . . . . . . . . . . . . . .

Plotting and Printing . . . . . . . . . . . . . . .

2. Installation

L

. . . . . . . . . . . . . . . . . . . . .

Requirements . . . . . . . . . . . . . . . . . . . .

Power Requirements . . . . . . . . . . . . . . . .

Power Cable . . . . . . . . . . . . . . . . . . .

Ventilation Requirements . . . . . . . . . . . . . .

Operating Environment . . . . . . . . . . . . . .

Cleaning . . . . . . . . . . . . . . . . . . . . .

Setting up HP 4155A/4156A . . . . . . . . . . . . .

To Inspect HP 4155A/4156A and Accessories . . . . .

To Install HP 41501A SMU/Pulse Generator Expander

To Check HP 4155A/4156A Operation . . . . . . . .

Installing Accessories . . . . . . . . . . . . . . . .

To Install Connector Plate . . . . . . . . . . . . .

To Connect InterlockTerminal . . . . . . . . . . .

1-10

1-10

1-11

1-12

1-13

1-19

1-20

1-22

1-25

1-26

1-27

2-2

2-3

2-4

2-5

2-7

2-7

2-7

2-8

2-8

2-9

2-10

2-12

2-13

2-17

Contents-1

Page 14

Change 1

To Connect Connector Plate and DUT . . . . . . . .

To Install HP 16442A Test Fixture ........... 2-29

To Install HP 16441A R-Box . . . . . . . . . . . .

To Install HP 16440A SMU/Pulse Generator Selector .

To Connect HP 16440A Selector to HP 4155A/56A . .

3. Making a Measurement

Connection to Device Under Test (DUT) . . . . . . . .

To Mount a DUT on Test Fixture . . . . . . . . . .

To Make Connections to Reduce Leakage Current . . .

To Make Connections to Measure Low Resistance (For

HP 4156A Only) . . . . . . . . . . . . . . . .

Sweep Measurements . . . . . . . . . . . . . . . .

To Dene Sweep Measurement Units . . . . . . . . .

To Set up Primary Sweep Source . . . . . . . . . .

To Set up Secondary Sweep Source . . . . . . . . .

To Set up Synchronous Sweep Source . . . . . . . .

To Set up Constant Output . . . . . . . . . . . . .

To Set up SMU Pulsed Output . . . . . . . . . . .

To Set up PGU Pulsed Output . . . . . . . . . . .

To Output Same Value Before and After Measurements

To Dene a User Function . . . . . . . . . . . . .

To Set up Graphical Display of Measurement Results .

To Set up List Display of Measurement Results . . . .

To Execute or Stop Measurement . . . . . . . . . .

To Control R-Box . . . . . . . . . . . . . . . . .

Knob Sweep Measurements . . . . . . . . . . . . . .

To Execute Knob Sweep Measurement . . . . . . . .

To Stop Knob Sweep Measurement . . . . . . . . .

Sampling Measurements . . . . . . . . . . . . . . .

To Dene Sampling Measurement Units . . . . . . .

To Set up Sampling Parameters . . . . . . . . . . .

To Set up Constant Output . . . . . . . . . . . . .

To Dene Measurement Stop Conditions . . . . . . .

Stress Force . . . . . . . . . . . . . . . . . . . .

To Set up Stress Source Channels . . . . . . . . . .

To Set up Stress Condition/Timing . . . . . . . . .

To Set up AC (Pulse) Stress . . . . . . . . . . . .

To Set up DC Stress . . . . . . . . . . . . . . . .

ToForce Stress . . . . . . . . . . . . . . . . . .

To Control Selector for Switching SMU and PGU . . .

2-22

2-35

2-38

2-45

3-3

3-4

3-6

3-8

3-10

3-12

3-14

3-16

3-18

3-20

3-21

3-24

3-27

3-28

3-30

3-32

3-33

3-34

3-37

3-38

3-42

3-43

3-45

3-47

3-49

3-51

3-53

3-55

3-57

3-60

3-62

3-64

3-66

Contents-2

Page 15

4. Analyzing Measurement Results

Manual Analysis . . . . . . . . . . . . . . . . . .

To Specify a MeasurementPoint on Curve . . . . . .

To Specify between MeasurementPoints on Curve. . .

To DisplayorMove Cursor . . . . . . . . . . . . .

To Adjust Display Range to Measurement Curve

Automatically . . . . . . . . . . . . . . . . .

To Zo om the Display Range . . . . . . . . . . . .

To Center Display at Cursor Lo cation . . . . . . . .

To Draw Line through Two Sp ecied Points . . . . .

To Draw Line through Specied Point with Specied

Gradient . . . . . . . . . . . . . . . . . . .

To DrawTangent to Specied Point of Measurement

Curve. . . . . . . . . . . . . . . . . . . . .

To Draw Regression Line for Specied Region . . . . .

To Display and Select a Line . . . . . . . . . . . .

To Display Grid on the Graph . . . . . . . . . . .

To Change Data Variable on Graph . . . . . . . . .

To Change Range of X or Y Axis Scale .

. . . . . . .

To Change Variable Assigned to X, Y1, or Y2 Axis . .

ToOverlayanInternal Memory Measurement Curve

onto Plotting Area . . . . . . . . . . . . . . .

To Scroll the LIST Page . . . . . . . . . . . . . .

To DisplayorMove Marker on LIST Page . . . . . .

To Change Variables of LIST page . . . . . . . . . .

Automatic Analysis . . . . . . . . . . . . . . . . .

To Draw Line by Specifying TwoPoints . . . . . . .

To Draw Line by Specifying Gradient and One Point. .

To DrawTangent to Specied MeasurementPoint. . .

To Draw Regression Line by Sp ecifying TwoPoints . .

To Display Marker at Specied Point . . . . . . . .

Change 1

4-3

4-4

4-6

4-8

4-10

4-11

4-12

4-13

4-15

4-17

4-19

4-22

4-23

4-24

4-25

4-26

4-27

4-29

4-30

4-32

4-33

4-34

4-36

4-38

4-40

4-43

5. Filer

File Operations . . . . . . . . . . . . . . . . . . .

To List File Names Stored on Diskette . . . . . . . .

To Store Setup or Result Data onto Diskette . . . . .

To Store Setup or Result Data into Internal Memory . .

To Store Result Data in Spreadsheet Format . . . . .

To Load Setup or Result Data from Diskette . . . . .

To Load Setup or Result Data from Internal Memory .

To Rename a File on Diskette . . . . . . . . . . . .

5-3

5-5

5-7

5-9

5-11

5-13

5-16

5-18

Contents-3

Page 16

Change 1

To Remove a File from Diskette . . . . . . . . . . .

To Copy File on Diskette to Another Diskette ...... 5-21

To Copy Setup or Result Data from Internal Memory to

Diskette . . . . . . . . . . . . . . . . . . . .

To Initialize a Diskette . . . . . . . . . . . . . . .

To Backup a Diskette . . . . . . . . . . . . . . .

6. If You Have A Problem

When You Install the HP 4155A/4156A . . . . . . . .

If HP 4155A/4156A cannot be Powered on . . . . . .

If Measurement Units of HP 41501A are not Displayed

on the CHANNELS: CHANNEL DEFINITION Page

If External Keyboard do es not Work . . . . . . . . .

If Display Page do es not App ear after Applying P

If HP 16442A Test Fixture is not Stable . . . . . . .

When You Make A Measurement . . . . . . . . . . .

If Measured Value Oscillates when Measuring

High-Frequency Devices . . . . . . . . . . . . .

If Measured Value Oscillates when Measuring Negative

Resistance . . . . . . . . . . . . . . . . . . .

If Noise Aects the Measured Values . . . . . . . . .

If Measured Voltage has some Error when Forcing a

Large Current . . . . . . . . . . . . . . . . .

If Large Current Causes High Temperature (Thermal

Drift) . . . . . . . . . . . . . . . . . . . . .

If MeasurementTakes More Time than Specied . . .

If Measurement Damages the Device under Test . . . .

If You Get Unexpected Data when Performing Sampling

Measurement . . . . . . . . . . . . . . . . .

If Errors Occur . . . . . . . . . . . . . . . . . . .

If Errors Occur when You Perform Self-calibration or

Diagnostics . . . . . . . . . . . . . . . . . .

If an error o ccurs when you operate HP 4155A/4156A .

If a Measurement Data Status is Displayed. . . . . . .

ower .

5-19

5-23

5-24

5-26

6-4

6-5

6-6

6-7

6-7

6-7

6-8

6-9

6-10

6-12

6-13

6-13

6-14

6-14

6-15

6-16

6-17

6-25

6-40

7. Manual Changes Depending on ROM Version

Change 1 . . . . . . . . . . . . . . . . . . . . . .

Index

Contents-4

7-3

Page 17

Figures

1-1. Front View of HP 4155A/4156A . . . . . . . . . . . . . . 1-5

1-2. Rear View of HP 4155A/4156A .............. 1-9

1-3. Front and Rear View of HP 41501A . . . . . . . . . . . . 1-12

1-4. Rear View of HP 41501A Option 402 ........... 1-14

1-5. Rear View of HP 41501A Option 410 ........... 1-15

1-6. Rear View of HP 41501A Option 412 ........... 1-16

1-7. Rear View of HP 41501A Option 420 ........... 1-17

1-8. Rear View of HP 41501A Option 422 ........... 1-18

2-1. Power Cables . . . . . . . . . . . . . . . . . . . . . .

2-2. Dimensions of Connector Plate for HP 4155A

(HP Part Number: 04155-60006) . . . . . . . . . . . .

2-3. Dimensions of Connector Plate for HP 4156A

(HP Part Number: 04156-60002) . . . . . . . . . . . .

2-4. Dimensions of Connector Plate for HP 41501A

(HP Part Number: 41501-60004) . . . . . . . . . . . .

2-5. Dimensions of Interlock Switch (HP part number 3101-0302) .

2-6. Dimensions of Interlock Switch (HP part number 3101-3241) .

2-7. Dimensions of LED (HP part number 1450-0641) ...... 2-21

2-5

2-14

2-15

2-16

2-20

2-20

Tables

1-1. Conguration of HP 41501A ............... 1-4

2-1. Connectors on Connector Plate . . . . . . . . . . . . . .

Contents-5

2-15

Page 18

Contents

Page 19

1

Introducing the HP

4155A/4156A

Page 20

Introducing the HP 4155A/4156A

The HP 4155A semiconductor parameter analyzer and HP 4156A precision

semiconductor parameter analyzer are made for use in semiconductor

laboratories and factories. The HP 4155A/4156A can measure device

characteristics. The HP 4155A/4156A can do the following:

Perform measurements.

Graph the device characteristics.

Extract device parameters.

Perform go, no-go evaluation.

Perform reliability (stress test) evaluation.

The HP 4155A/4156A is easy to operate and can perform automatic graphical

analysis like the HP 4145B. In addition, the HP 4155A/4156A is also easy to

use in a system, which expands areas of application to quality assurance and

in-line monitoring.

In this chapter.

This chapter provides a view of front and rear panels of the HP 4155A/4156A

and its accessories, and briey describes the HP 4155A/4156A functions.

1-2

Page 21

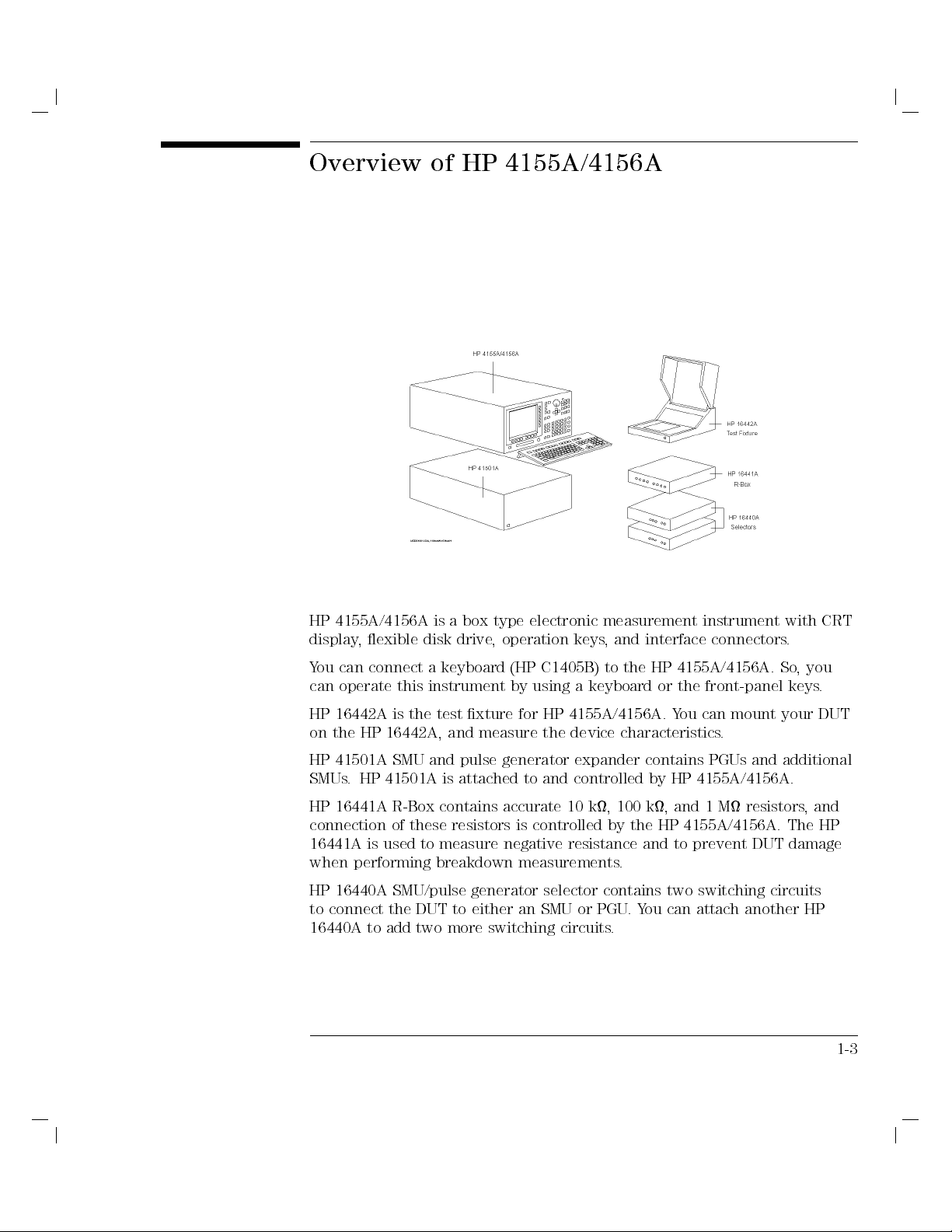

Overview of HP 4155A/4156A

HP 4155A/4156A is a box type electronic measurement instrument with CRT

display, exible disk drive, operation keys, and interface connectors.

You can connect a keyboard (HP C1405B) to the HP 4155A/4156A. So

can operate this instrument by using a keyboard or the front-panel keys

HP 16442A is the test xture for HP 4155A/4156A. Y

on the HP 16442A, and measure the device characteristics

HP 41501A SMU and pulse generator expander contains PGUs and additional

SMUs. HP 41501A is attached to and controlled by HP 4155A/4156A.

HP 16441A R-Box contains accurate 10 k, 100 k, and 1 M resistors, and

connection of these resistors is controlled by the HP 4155A/4156A. The HP

16441A is used to measure negative resistance and to prevent DUT damage

when performing breakdown measurements.

HP 16440A SMU/pulse generator selector contains two switching circuits

to connect the DUT to either an SMU or PGU.You can attach another HP

16440A to add two more switching circuits.

ou can mount your DUT

.

, you

.

1-3

Page 22

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

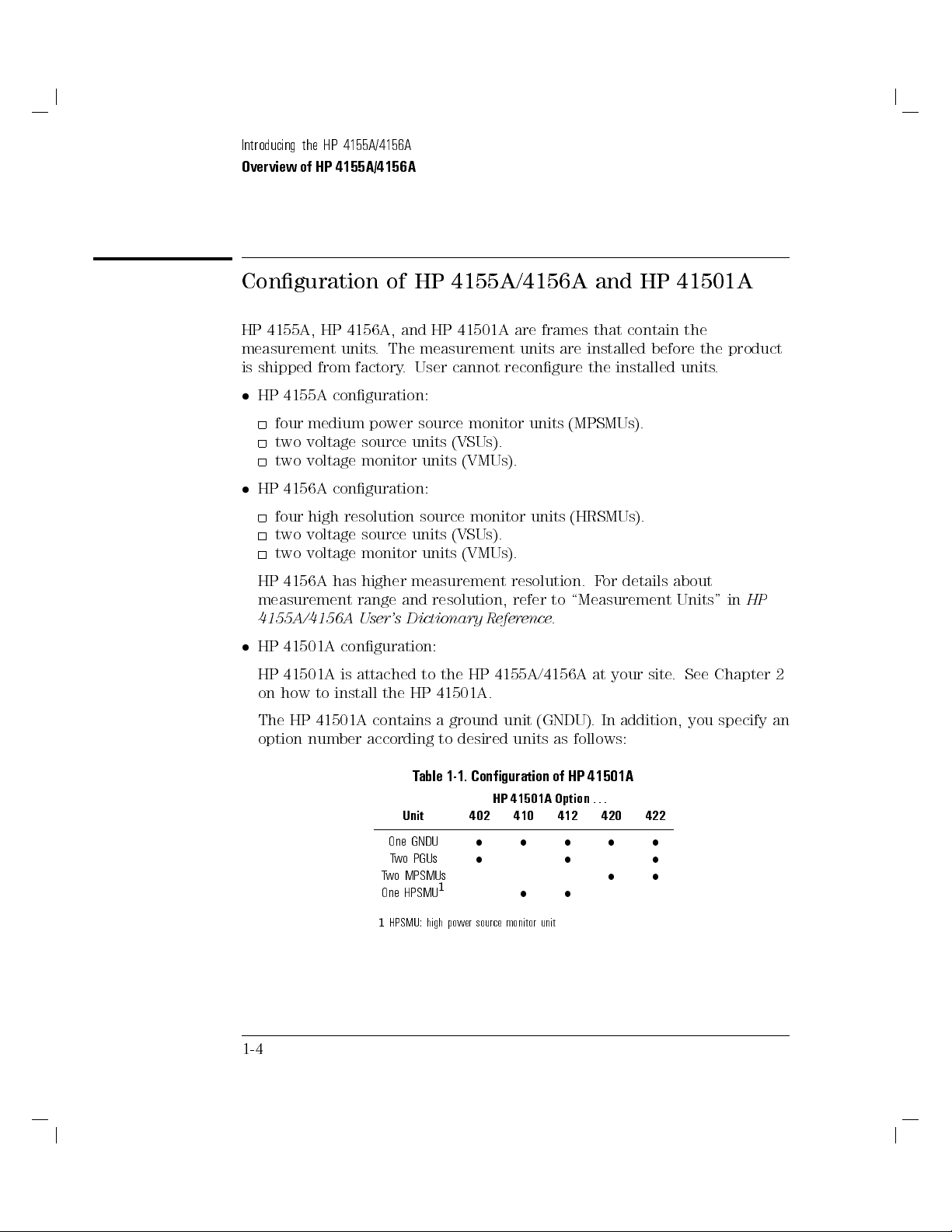

Conguration of HP 4155A/4156A and HP 41501A

HP 4155A, HP 4156A, and HP 41501A are frames that contain the

measurement units. The measurement units are installed before the product

is shipped from factory. User cannot recongure the installed units.

HP 4155A conguration:

four medium power source monitor units (MPSMUs).

two voltage source units (VSUs).

two voltage monitor units (VMUs).

HP 4156A conguration:

four high resolution source monitor units (HRSMUs).

two voltage source units (VSUs).

two voltage monitor units (VMUs).

HP 4156A has higher measurement resolution. For details about

measurement range and resolution, refer to \Measurement Units" in

4155A/4156A User's Dictionary Reference

.

HP

HP 41501A conguration:

HP 41501A is attached to the HP 4155A/4156A at your site

. See Chapter 2

on how to install the HP 41501A.

The HP 41501A contains a ground unit (GNDU). In addition, you specify an

option number according to desired units as follows:

Table 1-1. Conguration of HP 41501A

HP 41501A Option

Unit

One GNDU

Two PGUs

Two MPSMUs

One HPSMU

1

HPSMU: high power source monitor unit

402 410 412 420 422

1

...

1-4

Page 23

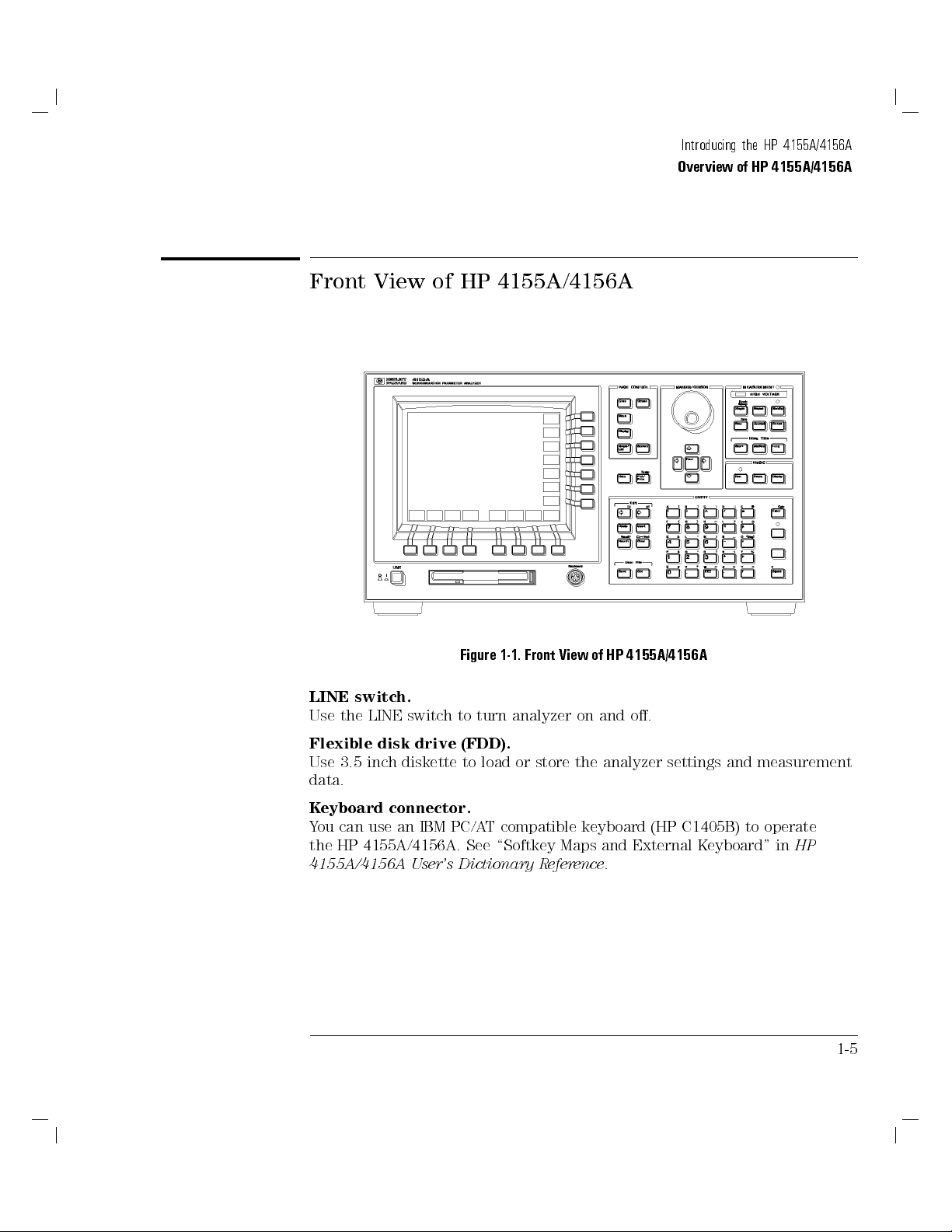

Front View of HP 4155A/4156A

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

Figure 1-1. Front View of HP 4155A/4156A

LINE switch.

Use the LINE switch to turn analyzer on and o.

Flexible disk drive (FDD).

Use 3.5 inch diskette to load or store the analyzer settings and measurement

data.

Keyboard connector.

You can use an IBM PC/AT compatible keyboard (HP C1405B) to operate

the HP 4155A/4156A. See \Softkey Maps and External K

4155A/4156A User's Dictionary Reference

.

eyboard" in

HP

1-5

Page 24

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

PAGE CONTROL key group.

Page Control keys are used to change the pages.

4

Chan

5

Moves to CHANNELS page group.You dene channels, user

functions, and user variables.

4

Meas

5

Moves to MEASURE page group.You set the output parameters,

measurement parameters, and so on.

4

Display

5

Moves to DISPLAY page group.You set the result display

format, auto analysis denitions, and so on.

4

Graph/List

5

Moves to GRAPH/LIST page group. This softkey toggles between

GRAPH and LIST pages.

4

Stress

5

Moves to STRESS page group.You dene the stress channels,

set the stress parameters, and monitor the stress forcing.

4

System

5

Moves to SYSTEM page group.You operate on diskette les,

set up plotting and printing environment, dene colors of the

display, and so on.

MARKER/CURSOR key group.

Rotary knob and arrow keys of the Marker/Cursor key group are used to

move the marker and cursor.

Rotary knob Moves the marker, or increases or decreases setup value.

4(5,4

4*5

4

Fast

)

, and

5

5

,

Moves eld pointer or cursor.

4

5

+

Moves the marker or cursor faster. When you rotate the rotary

knob or press the arrow keys with holding

4

5

key down, the

Fast

marker or cursor moves faster.

1-6

Page 25

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

MEASUREMENT key group.

Measurement keys control the measurement, stress, and integration time.

4

Single

5

Executes the measurement once, then returns to the idle state

(or standby state if standby is enabled for the channel) after the

measurement is nished. Measurement data is updated, so data

of previous measurement is lost. Pressing the green key, then

4

5

4

Repeat

key starts

Single

5

Starts and repeats the measurement continuously. Measurement

knob sweep

measurement.

data is updated, so data of previous measurement is lost. To

4

Append

stop the measurement, press

5

Executes the measurement once, then returns to idle state

4

Stop

5

key.

(or standby state if standby is enabled for the channel) after

measurement is nished. Measurement data is appended to data

of previous measurement.

4

Stop

5

Stops the measurement or stress. Standby enabled channels

return to standby state, and other channels return to idle state.

4

Standby

5

Toggles between the standby enabled (Standby indicator is lit)

and disabled states. If Standby indicator is lit, then

STBY ON

channels change to standby state (instead of idle state) when

measurement or stress nishes.

4

5

key has no aect on

Stop

standby state.

4

Stress

4

Short

4

Medium

and

5

5

,

4

Long

5

Forces the specied stress. The guide around this key prevents

you from accidently pressing the

4

Stress

5

key.

Sets the integration time to SHORT, MEDIUM, or LONG,

,

respectively.

5

MEASUREMENT indicator.

This indicator lights when HP 4155A/4156A is in the measurement state.

HIGH VOLTAGE indicator.

This indicator lights when a unit forces more than 40 V

.

Standby indicator.

This indicator lights when the HP 4155A/4156A is standby enabled, which

means that the channels that are standby enabled (

STBY ON

) will return to

the standby state after the measurement is nished.

1-7

Page 26

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

IBASIC key group.

IBASIC keys control the IBASIC program execution.

4

Run

5

Starts the IBASIC program that is in memory. The indicator is

on during program execution.

4

Pause

4

Display

5

5

Pauses the IBASIC program execution.

Toggles between the IBASIC screen and measurement screen.

Run indicator.

When an IBASIC program is running, this indicator lights.

ENTRY key group.

You enter or modify data such as output values, comments, and variable

names.

Character keys Are used to enter alphanumeric and special characters.

4

Enter

5

After you enter desired characters into the data entry

eld, press this key. The characters are entered at the

eld pointer location.

Also, you can use the green key to calculate the value of

the data entry eld. For example, if you press

greenkey

4

5

, the result (24) appears.

Enter

4

454*546

5

Blue key Changes entry mode to blue-key shift mode, and lights

the indicator. In this mode, you can enter the blue

characters that are printed above the keys. Pressing blue

key again changes to normal mode. Indicator turns o.

Green key Changes entry mode to green-key shift mode. This mode

is eective for the next pressed key, then changes back to

normal mode.

Edit keys Are used to edit the characters in the data entry eld.

User File keys Are used to operate quickly on a diskette le. Pressing

4

5

moves into the ler's SAVE function, and pressing

Save

4

5

moves into the ler's GET function.

Get

4

5

key.

Help

Pressing

4

Plot/Print

Pressing

your plotter, printer, or diskette le. If you press green key and

4

5

Help

5

key.

4

Plot/Print

displays the

5

prints the setup information and measurement results to

help

pages.

4

Plot/Print

5

,

the screen image is dumped to plotter, printer, or diskette le.

1-8

Page 27

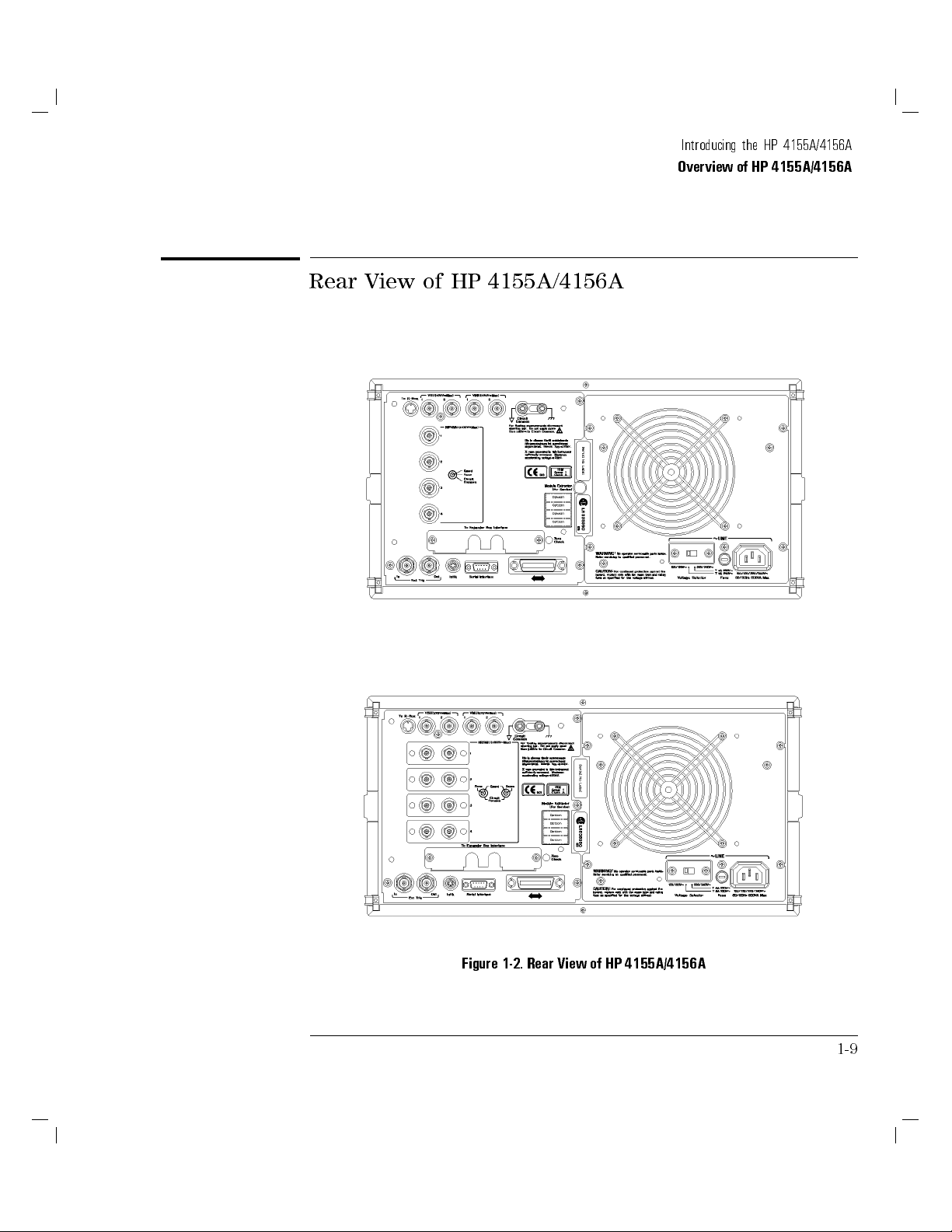

Rear View of HP 4155A/4156A

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

Figure 1-2. Rear View of HP 4155A/4156A

1-9

Page 28

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

To R-Box terminal.

\To R-Box" terminal is a 10-pin connector.To use R-Box, connect this

terminal to control terminal of HP 16441A R-Box.

VSU terminals.

VSU output terminals are BNC connectors.To use VSUs, connect these

terminals to VSU terminals of HP 16442A or connector plate.

VMU terminals.

VMU input terminals are BNC connectors.To use VMUs, connect these

terminals to VMU terminals of HP 16442A or connector plate.

L

WARNING

L

Circuit Common (

) and Frame ground ( ) terminals.

For oating measurement, remove the shorting bar (HP part number

5000-4206).

6

Do not oat the Circuit Common terminal at voltages greater than

42 V

referenced to frame ground. Failure to heed this warning may result in

damage to HP 4155A/4156A.

Serial number.

You need this

serial number

when using the telephone assistance program

(HP HelpLine).

Voltage selector.

Voltage selector must be in proper position. Line voltage and position are:

Line Voltage Position

90|132 Vac left

198|264 Vac right

Fuse.

Use the following fuse:

Line Fuse type HP part number

100/120 Vac UL/CSA T 8A, 250 Vac 2110-0383

220/240 Vac UL/CSA T 4A, 250 Vac 2110-0014

LINE input receptacle.

AC power cable is connected to this receptacle.

1-10

Page 29

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

SMU terminals.

HP 4155A has four triaxial connectors. HP 4156A has eight triaxial

connectors, and you can use Kelvin connections. When you use HP 16442A

test xture and Kelvin connections, up tp 3 SMUs can be connected to HP

16442A test xture.

To Expander Box Interface.

When you use HP 41501A, you insert the board for HP 41501A into this

interface.

Zero Check terminal.

Ground reference point of the HP 4155A/4156A.

Ext Trig terminals.

Two BNC connectors: one for trigger input, and one for trigger output.

L

WARNING

Intlk terminal.

Used in conjunction with interlock function of HP 4155A/4156A. If the Intlk

6

terminal is open, maximum SMU output is limited to

40 V. Be sure to

connect this terminal to HP 16442A test xture or connector plate before

performing measurement. If you use connector plate, you must install

interlock circuit. For details on how to install the interlock circuit, see \T

o

Connect Interlock Terminal" in Chapter 2.

Dangerous voltage of up to the maximum voltage of SMUs may be present

at force, guard, and sense terminals if the interlock terminal is shorted.

Serial Interface connector.

9-pin female connector for RS-232-C serial communication.

HP-IB connector.

Use HP 10833A/B/C/D HP-IB cable.

1-11

Page 30

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

Front and Rear View of HP 41501A

Figure 1-3. Front and Rear View of HP 41501A

LINE switch.

Use the LINE switch to turn HP 41501A on and o.

41501A before turning on the HP 4155A/4156A.

1-12

You must turn on the HP

Page 31

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

L

Fuse.

Use the following fuse:

Line Fuse type HP part number

100/120 Vac UL/CSA T 8A, 250 Vac 2110-0383

220/240 Vac UL/CSA T 4A, 250 Vac 2110-0014

Voltage Selector.

Voltage selector must be in proper position. Line voltage and position are:

Line Voltage Position

90|132 Vac left

198|264 Vac right

LINE input receptacle.

AC power cable is connected to this receptacle.

Serial number.

The HP 41501A has its own serial number.You need this

when using the telephone assistance program (HP HelpLine).

GNDU connector.

The GNDU connector is a triaxial connector: inner conductor is sense

conductor is force, and outer conductor is circuit common.

serial number

, middle

1-13

Page 32

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

Option 402

HP 41501A Option 402 has two PGUs.

Figure 1-4. Rear View of HP 41501A Option 402

PGU output terminals.

BNC connectors. Inner conductor is force and outer conductor is circuit

common.

Ext Pulse Generator Trig Out terminal.

Trigger pulses synchronized with PGU pulses are output. This trigger is

used to synchronize the PGU pulse outputs with external pulse generators

You

cannot

trigger, see \Measurement Functions" in

Reference

change the parameters of this trigger.For details about PGU

HP 4155A/4156A User's Dictionary

.

.

To SMU/Pulse Generator Selector Interface.

D-SUB 15-pin connector is used to control the HP 16440A SMU/pulse

generator selector.

1-14

Page 33

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

Option 410

HP 41501A Option 410 has one HPSMU.

Figure 1-5. Rear View of HP 41501A Option 410

HPSMU terminals.

There are two triaxial connectors for Kelvin connections: one is for force and

the other is for sense.

1-15

Page 34

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

Option 412

HP 41501A Option 412 has one HPSMU and two PGUs.

Figure 1-6. Rear View of HP 41501A Option 412

HPSMU terminals.

There are two triaxial connectors for Kelvin connections: one is for force and

the other is for sense.

PGU output terminals.

BNC connectors. Inner conductor is force and outer conductor is circuit

common.

Ext Pulse Generator Trig Out terminal.

Trigger pulses synchronized with PGU pulses are output. This trigger is

used to synchronize the PGU pulse outputs with external pulse generators

You

cannot

trigger, see \Measurement Functions" in

Reference

change the parameters of this trigger.For details about PGU

HP 4155A/4156A User's Dictionary

.

.

To SMU/Pulse Generator Selector Interface.

D-SUB 15-pin connector is used to control the HP 16440A SMU/pulse

generator selector.

1-16

Page 35

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

Option 420

HP 41501A Option 420 has two MPSMUs.

Figure 1-7. Rear View of HP 41501A Option 420

MPSMU terminals.

Two MPSMUs are installed and each MPSMU has a triaxial connector

these connectors are not designed for Kelvin connections.

. But

1-17

Page 36

Introducing the HP 4155A/4156A

Overview of HP 4155A/4156A

Option 422

HP 41501A Option 422 has two MPSMUs and two PGUs.

Figure 1-8. Rear View of HP 41501A Option 422

MPSMU terminals.

Two MPSMUs are installed and each MPSMU has a triaxial connector

connectors are not designed for Kelvin connections.

PGU output terminals.

BNC connectors. Inner conductor is force and outer conductor is circuit

common.

Ext Pulse Generator Trig Out terminal.

Trigger pulses synchronized with the PGU pulses are output. This trigger is

used to synchronize the PGU pulse outputs with external pulse generators

You

cannot

trigger, see \Measurement Functions" in

Reference

change the parameters of this trigger.For details about PGU

HP 4155A/4156A User's Dictionary

.

. These

.

To SMU/Pulse Generator Selector Interface.

D-SUB 15-pin connector is used to control the HP 16440A SMU/pulse

generator selector.

1-18

Page 37

An Overview of Functions

HP 4155A/4156A has the following useful functions.

Operation and control

Measurements and results display

Graphical analysis

Data storage

Plotting and printing

1-19

Page 38

Introducing the HP 4155A/4156A

An Overview of Functions

Operation and Control

You operate HP 4155A/4156A from the front-panel keys. Also, you can attach

a keyboard (HP C1405B) to HP 4155A/4156A, and operate it from keyboard.

See \Softkey Map and External Keyboard" in

Dictionary Reference

.

HP 4155A/4156A User's

HP 4155A/4156A is operated by a \form ll-in" method. That is

user-interface consists of setup and results pages, and you ll in elds

on appropriate pages to select a measurement mode, set measurement

parameters and conditions, set results display mode, and so on. After you

execute the measurement, measurement results are displayed on result pages.

When you operate from the front panel, the basic page ow is as follows:

1. channel denition

2. source setup

3. display setup

4. results display

Also, HP 4155A/4156A can be controlled via HP-IB by external controller,

such as an HP 9000 computer.To control HP 4155A/4156A, you create a

control (measurement) program by using a programming language such as HP

BASIC. The measurement program uses remote control commands of the HP

4155A/4156A. These are easy-to-understand commands based on Standard

Commands for Programmable Instruments (SCPI).

1-20

, the

Page 39

Introducing the HP 4155A/4156A

An Overview of Functions

The HP 4155A/4156A has a built-in HP Instrument B

environment. You can create a measurement program using IBASIC to control

the HP 4155A/4156A instead of using an external controller

the need for an external controller, so required working space is reduced.

When you develop measurement programs using the built-in HP Instrument

BASIC environment of the HP 4155A/4156A, you use the HP 4155A/56A

remote commands. See the HP 4155A/4156A

Command Reference

.

Programmer's Guide

ASIC (IBASIC)

. This eliminates

and

HP-IB

1-21

Page 40

Introducing the HP 4155A/4156A

An Overview of Functions

Measurements and Results Display

You set up the elds on the setup pages of HP 4155A/4156A, then perform

the measurement. After measurement, you can display the measurement

results on the GRAPHICS or LIST page.

Measurement.

The HP 4155A/4156A can perform two types of measurements: sweep

measurement and sampling measurement. These two types of measurements

cannot

be executed at the same time.

Sweep measurement

For sweep measurements, an SMU or a VSU can become a primary sweep

source, secondary sweep source, synchronous sweep source, or constant

source.

For example, you can perform sweep measurements to get an Ic-Vce curve

of a bipolar transistor as in the following example:

In the example above, a primary source (Vce) and a secondary source

(Ib) are dened. After primary sweep source nishes each sweep, the

secondary sweep source outputs the next value.

1-22

Page 41

Introducing the HP 4155A/4156A

An Overview of Functions

Sampling measurements

For sampling measurements, the source units output constant values, and

measurements are executed by each unit at the specied intervals.

For example, you can get an integration curve of an RC integrator by

sampling measurement as follows:

In the example above, measurements by the monitor unit start when the

source unit outputs the specied value.

1-23

Page 42

Introducing the HP 4155A/4156A

An Overview of Functions

Setup pages.

You set the measurement mode, parameters, and conditions by lling in the

blank elds on the appropriate pages.You can enter variable names for the

output and measurement values, and you can dene more complex variables

called user functions.For example, you can specify a variable name for the

forward current, such as \If", and refer to this variable on other pages

instead of the unit name.

Results display.

You can display measurement results on the screen in graphics or list style.

When measurement starts, the results page appears according to the display

setting information that you set. Of course, the HP 4155A/4156A plots or

displays the results as the measurement progresses

.You can also modify

the measurement parameters and conditions on the results page without

returning to the setup page.

Knob sweep.

For knob sweep measurement, you can vary the sweep range by rotating

the rotary knob. The knob sweep function is useful when you need to

quickly make a rough measurement of your DUT characteristics

.You only

need to dene the channel assignments, then you can start the knob sweep

measurement. You can also change parameters and conditions by using

secondary softkeys on the knob sweep page, and you can easily copy these

changes so that they will be used in the normal sweep mode

.

Stress.

HP 4155A/4156A can force stress to your DUT for a specied duration. Y

ou

can set the stress force parameters and channels independently from the

measurement channels. And the stress duration is controlled accurately.

You can force dc stress, and also ac stress because the HP 41501A can be

equipped with pulse generators.You can perform reliability evaluations by

repeating the stress-measurement cycle.

1-24

Page 43

Introducing the HP 4155A/4156A

An Overview of Functions

Graphical Analysis

You can analyze the measurement results graphically by using a marker and

two lines. The marker can move on the measurement curve only, so you can

read the measurement values by reading the marker coordinates.You can

draw up to two lines on plotting area by following methods:

Normal line: through two points that are specied by cursors.

Gradient line: through one point specied by cursor with specied

gradient.

Tangent line: tangent to point specied by marker on measurement

curve.

Regression line: regression line for area specied by two cursors.

X/Y intercept values and gradient of each line are automatically displayed, so

you can get values such as threshold voltage (Vth) and Early voltage (VA).

Also, you can setup the auto-analysis page to position marker and lines at

desired location automatically after measurement nishes.For example, you

can automatically nd threshold voltage (Vth) as follows:

1.

Vg versus

2.

Maximum

onpId

p

Id

@

@V g

curve.

curve, and Vg versus

p

Id

is found, and marker is moved to corresponding point

3. Tangent is drawn to marker on

p

Id

@

@V g

curve.

p

curve are drawn.

Id

4. X intercept value of this tangent is Vth.

1-25

Page 44

Introducing the HP 4155A/4156A

An Overview of Functions

Data Storage

The HP 4155A/4156A can store data on a 3.5-inch diskette.You can

store the measurement setup information, measurement data, and HP

4155A/4156A system setup information on the diskette.You can also easily

save measurement result data in MS-DOS

by using print/plot function. (For details, see \To Store Result Data in

Spreadsheet Format" in Chapter 5.)

Also, you can load information from the diskette to the HP 4155A/4156A.

R

ASCII format to your diskette

R

The allowable disk formats are MS-DOS

is the most popular disk format, which allows you to use the diskette in many

types of computers.

The HP 4155A/4156A is upwardly compatible with the HP 4145B

load setting information that was created by the HP 4145B.

You can also use internal memory for temporary data storage.You can save

up to four les in internal memory.You can quickly move information

between the internal memory and HP 4155A/4156A working memory.

1-26

and HP LIF. The MS-DOS

R

format

, so you can

Page 45

Introducing the HP 4155A/4156A

An Overview of Functions

Plotting and Printing

You can print setup data, measurement results, and screen images on a

plotter or printer that is connected to the HP 4155A/4156A. Setup data and

list results are printed as a list report, and the graphics results page is plotted

as a graphics report. You can also plot or print the screen image.

You can connect your plotter or printer to the HP 4155A/4156A via serial

interface or HP-IB interface. See Chapter 2 for information about installing

your plotter or printer.

Also, you can store setup data, measurement results, and screen images on

diskette les. The stored data les can be read by other computers

So you can create reports that include measurement curves or data by using

spreadsheet software such as Lotus

software such as PageMakerTM.For details about saving data in MS-DOS

ASCII format, refer to \To Store Result Data in Spreadsheet Format" in

Chapter 5.

R

1-2-3

R

or by using desktop publishing

.

R

1-27

Page 46

Introducing the HP 4155A/4156A

An Overview of Functions

Page 47

2

Installation

Page 48

Installation

This chapter describes requirements to install HP 4155A/4156A and the tasks

for installation, and is organized into the following four sections:

Requirements

Setting up HP 4155A/4156A

Installing Accessories

L

WARNING

The HP 4155A/4156A can force dangerous voltages (200 V for HPSMU

and 100 V for HRSMU and MPSMU) at the force

, guard, and sense

terminals.To prevent electric shock hazard, the following safety

precautions must be observed during the use of the HP 4155A/4156A.

Use a three-conductor ac power cable to connect cabinet (if used) and

HP 4155A/4156A to an electric ground (safety ground).

If you do not use HP 16442A Test Fixture, make sure to connect the

INTLK terminal to a switch that turns o when the shielding box access

door is opened.

Conrm periodically that INTLK function works normally.

Before touching the connections of the force, guard, and sense

terminals, turn the HP 4155A/4156A o and discharge any capacitors

whenever possible. If you do not turn the HP 4155A/4156A o,

complete

all

of the following items, regardless of any HP 4155A/4156A

settings.

Set the SMU output switches to o.

Conrm that HIGH VOLTAGE indicator is not lit.

Open the shielding box access door (open the INTLK terminal).

Discharge any capacitors if the capacitance is connected to an SMU

Warn workers around the HP 4155A/4156A about dangerous conditions.

,

.

2-2

Page 49

Requirements

This section describes the following requirements

Power requirements

Power cable

Ventilation requirements

Operating environment

2-3

Page 50

Installation

Requirements

Power Requirements

CAUTION

CAUTION

Before applying ac line power to the HP 4155A/4156A or HP 41501A, ensure

that the correct line fuse is installed in the fuse holder and the correct power

cable is used.

Line Voltage Fuse

Line Fuse Type HP Part Number

100/120 Vac UL/CSA T 8A, 250 V

ac 2110-0383

220/240 Vac UL/CSA T 4A, 250 Vac 2110-0014

Use only replacement fuses of the correct current rating and of the specied

type. Do not use repaired fuses, and do not short circuit the fuse holder

.

The HP 4155A/4156A can operate from any single-phase ac power source

supplying 100 { 120 V or 220 { 240 V in the frequency range from 50 to 60

Hz. The maximum power consumption is 600 VA for HP 4155A/4156A, and

450 VA for HP 41501A. For details, see \Specications" in

User's Dictionary Reference

.

HP 4155A/4156A

The line voltage selector switch is set at the factory for your area. But, you

had better check the voltage selector setting before applying ac line power

to the HP 4155A/4156A or HP 41501A. The line voltage selector switch is

located on the rear panel of the HP 4155A/4156A and HP 41501A.

2-4

Line Voltage Selector setting

Line Voltage Position

90-132 Vac left

198-264 Vac right

Page 51

Installation

Requirements

Power Cable

In accordance with international safety standards, this instrument is equipped

with a three-wire power cable. When connected to an appropriate ac power

outlet, this cable grounds the instrument frame. The type of power cable

shipped with each instrument depends on the country of destination. Refer to

Figure 2-1 for the part numbers of the power cables available.

Plug: BS 1363A, 250 V

Cable: HP 8120-1351

Plug: NZSS 198/AS C112, 250 V

Cable: HP 8120-1369

Plug: CEE-VII, 250 V

Cable: HP 8120-1689

Plug: NEMA 6-15P, 250 V,15A

Cable: HP 8120-0698

Plug: NEMA 5-15P, 125 V,15A

Cable: HP 8120-1378

Plug: SEV 1011.1959-24507 Type 12, 250 V

Cable: HP 8120-2104

Figure 2-1. Power Cables

2-5

Page 52

Installation

Requirements

Plug: DHCR 107, 220 V

Cable: HP 8120-2956

Plug: JIS C 8303, 125 V,15A

Cable: HP 8120-4753

Plug: SABS 164, 250 V

Cable: HP 8120-4211

WARNING

Power Cables (continued)

If the plug on the cable does not t the power outlet, or the cable is to be

attached to a terminal block, cut the cable at the plug end and re-wire it.

This work should be performed by a qualied electrician|all local electrical

codes being strictly observed.

The color coding used in the cable will depend on the cable supplied. If a

new plug is to be connected, it must meet local safety requirements and

include the following features:

Adequate load-carrying capacity (see table of \Specications" in

4155A/4156A User's Dictionary Reference

Ground connection.

Cable clamp.

).

HP

For protection from electrical shock, the power cable ground must not be

defeated.

2-6

Page 53

Installation

Requirements

Ventilation Requirements

The HP 4155A/4156A has one cooling fan, and HP 41501A has two cooling

fans.To ensure adequate airow, make sure that there is adequate clearance

around the cooling fans: 6 inches (150 mm) behind, 3 inches (70 mm) sides,

and 0.5 inch (12 mm) above and below.

If the airow is restricted, the internal operating temperature will be

higher, reducing the instrument's reliability or causing the instrument's

thermal-protection circuits to automatically switch o the instrument.

Operating Environment

The HP 4155A/4156A and HP 41501A must be operated within the following

environmental conditions:

Temperature: 5

Humidity: 15% to 80% RH at 40

Cleaning

To prevent electrical shock, never use a wet cloth when cleaning the

HP 4155A/4156A. Always use a slightly damp or dry cloth to clean HP

4155A/4156A.

Cto40C (41F to 104F)

C (104F)

2-7

Page 54

Setting up HP 4155A/4156A

This section describes what you do when you receive the HP 4155A/4156A

and accessories.

Briey, you must do the following:

1. Inspect HP 4155A/4156A and accessories.

2. Install HP 41501A with HP 4155A/4156A, if needed.

3. Check HP 4155A/4156A operation after supplying ac line power.

To satisfy the specications of HP 4155A/4156A and HP 41501A measurement

accuracy, perform calibration and adjustment every year.

To Inspect HP 4155A/4156A and Accessories

Inspect the following items when the HP 4155A/4156A and accessories arrive

at your site, and when you open the boxes that contain the HP 4155A/4156A

and accessories:

When the HP 4155A/4156A and accessories arrive at your site

unpacking any components, inspect all boxes for any signs of damage that

might have occurred during shipment such as:

Dents

Scratches

Cuts

Water marks

If you suspect damage, notify your local HP sales oce.

When you open the boxes that contain the HP 4155A/4156A and

accessories, check the components against the contents lists that are

attached to the boxes.

If anything is missing, notify your local HP sales oce.

2-8

, and before

Page 55

Setting up HP 4155A/4156A

To Install HP 41501A SMU/Pulse Generator Expander

1. Put the HP 41501A on your workbench. 2. Put the HP 4155A/4156A on the HP 41501A.

Installation

WARNING

3. Remove the blank panel labeled \To Expander Box

Interface" from the rear panel of the HP 4155A/4156A.

The HP 4155A/4156A together with the HP 41501A weighs about 40 kg

(88.4 lb). The HP 4155A/4156A is just placed on top of the HP 41501A

without attaching it securely.So, be very careful when handling.

4. Insert the interface board from the HP 41501A into the

HP 4155A/4156A, then attach it with the thumbscrews.

2-9

Page 56

Installation

Setting up HP 4155A/4156A

To Check HP 4155A/4156A Operation

1. Make sure that the line switches are set to o.

2. On the HP 4155A/4156A, make sure that the

is tied to frame ground terminal by shorting-bar. If not, a potential shock

hazard exists.

3. Connect the power cable between the HP 4155A/4156A and outlet at your

site. If the HP 41501A is also installed, connect the power cable between

the HP 41501A and the outlet.

4. If the HP 41501A is installed, press the LINE button to switch on.

5. Press the LINE button to switch on the HP 4155A/4156A. The initialization

screen appears on the CRT of the HP 4155A/4156A.

6. After initialization nishes, the CHANNELS: CHANNEL DEFINITION page

appears as follows:

Circuit Common

terminal

7. Make sure the units displayed in the UNIT column (on the CHANNELS:

CHANNEL DEFINITION page) match the units that are actually installed.

The following table shows the displayed units in the UNIT column:

2-10

Page 57

Setting up HP 4155A/4156A

HP 4155A HP 4156A HP 41501A

Installation

SMU1:MP

SMU2:MP

SMU3:MP

SMU4:MP

VSU1

VSU2

VMU1

VMU2

1

These are labeled on the rear panel of the HP 41501A.

SMU1:HR

SMU2:HR

SMU3:HR

SMU4:HR

VSU1

VSU2

VMU1

VMU2

GNDU

HPSMU Installed1MPSMU Installed1PGU Installed

SMU5:HP SMU5:MP

SMU6:MP

PGU1

PGU2

1

8. If HP 41501A units are not displayed in UNIT column, turn o the HP

4155A/56A and HP 41501A, then make sure that interface board of

HP 41501A is rmly inserted into HP 4155A/56A. Turn on HP 41501A,

then turn on HP 4155A/56A.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

9. Press

4

System

5

front-panel key, then select

N

MISCELLANEOUS

primary

softkey. Conrm that POWER LINE FREQUENCY eld is correct frequency

for your site. If not, select the correct secondary softkey.

If problems occur, see Chapter 6.

2-11

Page 58

Installing Accessories

This section describes how to install the HP 4155A/4156A and accessories at

your site. Refer to \Ventilation Requirements" when considering the proper

location at which to install the HP 4155A/4156A.

This section describes how:

To install connector plate

To connect interlock terminal

To install HP 16442A Test Fixture

To install HP 16441A R-Box

To install HP 16440A SMU/Pulse Generator Selector

To connect HP 16440A to HP 4155A/4156A

When you install a keyboard (HP C1405B), connect the connector of the

keyboard to the keyboard interface on the front-panel

HP 4155A/4156A. The HP 4155A/4156A recognizes the keyboard during the

power-on self-test.

before

switching on the

2-12

Page 59

Installation

Installing Accessories

To Install Connector Plate

1. Before installing connector plate, make sure that HP 4155A/4156A and

HP 41501A are turned o.

2. Create proper openings and screw holes on your shielding box that match

the size of connector plate. See Figure 2-2, Figure 2-3, or Figure 2-4 for

dimensions of the connector plates.

3. Attach the connector plates with screws, nuts, and washers.

4. To prevent electric shock, make sure to install interlock circuit. (See \T

Connect Interlock Terminal".)

5. Connect the furnished cables between the HP 4155A/4156A and connector

plates.

For details about connections between HP 4155A/4156A and the terminals

on the connector plates, refer to \To Install HP 16442A Test Fixture"in

this chapter. Connections to connector plate are similar to connections to

test xture.

The proper connector plates are furnished with HP 4155A, HP 4156A, and

HP 41501A.

The screws, nuts, and washers are not furnished. Each connector plate has

four screw holes (3.0 mm in diameter).

o

2-13

Page 60

Installation

Installing Accessories

If you do not use the HP 16442 test xture (for example, you use a wafer

prober or your own test xture), you need to perform measurements in a

shielding box because of the following:

To prevent the operator from receiving an electric shock from the output

voltage or current of the HP 4155A/4156A.

To minimize the eects of environmental noise and ambient light.

For details on how to connect terminals of connector plate and DUTs, refer to

\Connection to Device Under Test (DUT)" in Chapter 3.

2-14

Figure 2-2.

Dimensions of Connector Plate for HP 4155A

(HP Part Number: 04155-60006)

Page 61

Table 2-1. Connectors on Connector Plate

Connector HP Part Number

Triaxial 1250-1906

for SMU, GNDU

Coaxial (BNC) 1250-0083

for VSU, VMU, PGU

Interlock 1252-1419

Installation

Installing Accessories

Figure 2-3.

Dimensions of Connector Plate for HP 4156A

(HP Part Number: 04156-60002)

2-15

Page 62

Installation

Installing Accessories

Figure 2-4.

Dimensions of Connector Plate for HP 41501A

(HP Part Number: 41501-60004)

2-16

Page 63

Installation

Installing Accessories

To Connect Interlock Terminal

When you use a shielding box, you must install an interlock circuit to prevent

electric shock. When you use the HP 16442A test xture, you do

install an interlock circuit because the HP 16442A has a built-in interlock

circuit.

The upper part of the following shows the interlock circuit you need to make

in your shielding box, and the lower part shows the pin assignments of the

interlock connector on the connector plate.

not

have to

2-17

Page 64

Installation

Installing Accessories

interlock (Intlk) terminal.

To prevent an operator from receiving an electric shock from high voltage

(more than640 V), you connect the interlock (Intlk) terminal (of the

connector plate) to a switch that turns on when the shielding box door is

closed, and that turns o when the shielding box access door is opened. For

safety, use two switches in series.

If the door is open (the interlock terminals are open), the SMU cannot force

more than640 V. If the door is opened while the SMU output is more than

6

40 V, the HP 4155A/4156A immediately drops the outputs of all units to 0 V.

Conversely, if the door is closed (interlock terminals are shorted), this

function is disabled. So, you can force more than640 V.

WARNING

Dangerous voltages of up to the maximum voltage of SMUs may be

present at force, guard, and sense terminals when the interlock terminals

are shorted.

HP 16435A Interlock Cable Adapter.

If you already have a connector plate or test xture that has a BNC coaxial

connector for interlock (such as the HP 16088B test xture), you can use HP

16435A Interlock Cable Adapter to connect the test xture.

To connect:

1. Connect interlock (Intlk) terminal on the rear panel of the HP

4155A/4156A to the interlock cable adapter by using the following

interlock cable.

HP Part Number Description

04155-61613 Interlock cable 3 m

04155-61614 Interlock cable 1.5 m

2. Connect the interlock cable adapter to the connector plate or test xture

by using the coaxial cable furnished with HP 16435A.

2-18

Page 65

Installation

Installing Accessories

Warning Indicator on HP 16088B Test Fixture

The high voltage warning indicator on this test xture is designed only for HP 41423A High Voltage

Source/Monitor Unit for HP 4142B.

This warning indicator is not valid when you use the HP 16088B test xture with the HP

4155A/4156A by using HP 16435A interlock cable adapter.

LED terminal.

When more than640 V is forced from an SMU, the LED lights to indicate

high voltage output

recommended parts.

You can get the following parts from Hewlett-Packard:

.

HP Part Number Description

3101-3241 switch

3101-0302 switch

1450-0641 LED (V

2.1 V @ IF= 10 mA)

=

F

2-19

Page 66

Installation

Installing Accessories

Figure 2-5. Dimensions of Interlock Switch (HP part number 3101-0302)

2-20

Figure 2-6. Dimensions of Interlock Switch (HP part number 3101-3241)

Page 67

Figure 2-7. Dimensions of LED (HP part number 1450-0641)

ToPerform Interlock Circuit Test

To conrm that interlock circuit test, do as follows:

Installation

Installing Accessories

1. Connect the

2.

Press

4

System

Intlk

terminal of HP 4155A/4156A to your interlock circuit.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

front-panel key, then select

CALIB/DIAG

SYSTEM: SELF-CALIBRATION/DIAGNOSTICS page.

3.

In the CALIB/DIAG eld, select

4.

In the CATEGORY eld, select

5. Move pointer to the

NNNNNNNNNNNNNNNNNNNNNN

Select

N

EXECUTE

6.

403 (INT.) Interlock & LED

secondary softkey.

NNNNNNNNNNNNNN

DIAG

secondary softkey.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

I/O & PERIPH

7. Conrm the following:

LED turns on within 1 sec from when interlock circuit is shorted.

LED turns o within 1 sec from when interlock circuit is open.

NNNNNNNNNNNNN

8.

To stop the interlock test, select

N

STOP

secondary softkey.

primary softkey to display the

secondary softkey.

eld.

2-21

Page 68

Installation

Installing Accessories

To Connect Connector Plate and DUT

GNDU connections

CAUTION

Do not use the HP 16493C triaxial cable of the SMU to connect the GNDU to a

DUT. The GNDU can sink up to 1.6 A, and the maximum current rating of the

cable is 1 A.

Kelvin connections

Use a low-noise coaxial cable (part number: 8120-3674) from the

connector plate to DUT as shown in the following gure

eects of cable resistance, connect the sense line as close as possible to

the terminal of the DUT.

.To cancel the

2-22

Page 69

Installation

Installing Accessories

non-Kelvin connections

Short sense and force at the connector plate as shown. Use AWG

22 single-strand insulated wire (part number: 8150-2639) from the

connector plate to the DUT. Measurement results include the residual

resistance of the connection wire.

To easily connect GNDU for a measurement in which the accuracy is not

important, connect only force to the DUT, without shorting sense and

force.

2-23

Page 70

Installation

Installing Accessories

SMU connections

WARNING

CAUTION

The SMU forces dangerous voltages of up to6100 V (6200 V for HPSMU)

at the force, sense, and guard terminals.

To prevent electric shock, do not expose these lines.

Before turning the HP 4155A/4156A on, connect the Intlk terminal to a

switch that turns o when the shielding box access door is opened.

Before you touch connections of these terminals, turn HP 4155A/56A o,

disconnect power cable, and discharge any capacitors.

Never connect the guard terminal to any output, including circuit common,

chassis ground, or the guard terminal of any other unit. Doing so may result

in an emergency condition.

Kelvin connections

Use low-noise coaxial cable (part number: 8120-4461) from connector

plate to DUT as shown in following gure.To cancel eects of cable

resistance, connect sense line as close as possible to DUT terminal. T

prevent oscillations, do not use cables longer than 1.5 m. F

accurate current forcing and measurements while minimizing leakage,

surround all force and sense lines from SMU by a guard as far as

possible, and make cables stable by taping.

or highly

o

2-24

Page 71

Installation

Installing Accessories

non-Kelvin connections

Connections are shown in following gure. Measurement results include

residual resistance from the connection wire.To enable highly accurate

current forcing and measurements while minimizing leakage, surround all

force lines from SMU by a guard as far as possible.

2-25

Page 72

Installation

Installing Accessories

NOTE

When you make a connection by using low-noise coaxial cable (part number: 8120-4461), shave the

Conductive layer and the Insulator(clear) by knife so that the Center Conductor is insulated from the

Conductive layer. Refer to following gure.

2-26

Page 73

Installing Accessories

VSU and VMU connections

The following gure shows an example of a connection between VSU1,

VSU2, VMU1, or VMU2 and a DUT. Use AWG 24 single-strand insulated

wire (part number: 8150-0447) to connect the connector plate and the

DUT.

Installation

2-27

Page 74

Installation

Installing Accessories

PGU connections

Regardless of output impedance setting, use a low-noise coaxial cable (part

number: 8120-0102) from the connector plate to the DUT as shown in the

following gure. If you use HP 16440A selector, use a low-noise coaxial

cable (part number: 8120-4461).

2-28

Page 75

Installation

Installing Accessories

To Install HP 16442A Test Fixture

Before performing the following procedure, make sure that HP 4155A/4156A

and HP 41501A are turned o.

When you use HP 16442A test xture without HP 16441A R-Box or HP

16440A selector, you can make HP 16442A stable by using stabilizers as

shown in the following gure.

1. Put a stabilizer on both sides of test xture

.

2. Screw a athead screw into hole of each stabilizer.

2-29

Page 76

Installation

Installing Accessories

Connecting HP 4155A and HP 16442A test xture

WARNING

CAUTION

1. To prevent shock,

cable:

Intlk

be sure

to connect following by 3.0m or 1.5m Intlk

terminal (HP 4155A)

()

Intlk

terminal (HP 16442A)

2. Connect the following by using 3.0 m or 1.5 m coaxial cables:

VSU

terminals (HP 4155A)

()

VSU

terminals (HP 16442A)

3. Connect the following by using 3.0 m or 1.5 m coaxial cables:

VMU

terminals (HP 4155A)

()

VMU

terminals (HP 16442A)

4. Connect the following by using 3.0 m or 1.5 m triaxial cables:

MPSMU

terminals (HP 4155A)

()

SMU

terminals (HP 16442A)

MPSMUs force dangerous voltage of up to6100 V at the Force, Sense, and

Guard terminals.To prevent electric shock, do not expose these lines.

Never connect Guard terminal to any output, including circuit common, frame

ground, or other guard terminal. Doing so will damage SMU.

2-30

Page 77

Connecting HP 4156A and HP 16442A test xture

Installation

Installing Accessories

WARNING

CAUTION

1. To prevent shock,

cable:

Intlk

be sure

to connect following by 3.0m or 1.5m Intlk

terminal (HP 4156A)

()

Intlk

terminal (HP 16442A)

2. Connect the following by using 3.0 m or 1.5 m coaxial cables:

VSU

terminals (HP 4156A)

()

VSU

terminals (HP 16442A)

3. Connect the following by using 3.0 m or 1.5 m coaxial cables:

VMU

terminals (HP 4156A)

4. Connect the following by using 3.0 m or 1.5 m K

HRSMU

terminals (HP 4156A)

()

VMU

()

terminals (HP 16442A)

elvin triaxial cables:

SMU

terminals (HP 16442A)

HRSMUs force dangerous voltage of up to6100 V at the Force, Sense, and

Guard terminals.To prevent electric shock, do not expose these lines.

Never connect guard terminal to any output, including circuit common,

chassis ground, or other guard terminal. Doing so will damage SMU.

2-31

Page 78

Installation

Installing Accessories

Connecting HP 41501A and HP 16442A test xture

1. To prevent electric shock, make sure that

4155A/4156A is connected to

Intlk

terminal of HP 16442A.

Intlk

terminal of HP

2. Connect the following by using a 3.0 m or 1.5 m GNDU cable:

GNDU

3. If the HP 41501A is equipped with two PGUs

terminal (HP 41501A)

()

GNDU

terminal (HP 16442A)

, connect the following by

using 3.0 m or 1.5 m coaxial cables:

PGU

terminals (HP 41501A)

()

PGU

terminals (HP 16442A)

4. Do the following:

If the HP 41501A is equipped with two MPSMUs, connect the

following by using 3.0 m or 1.5 m triaxial cables:

MPSMU

terminals (HP 41501A)

()

SMU

terminals (HP 16442A)

If the HP 41501A is equipped with HPSMU, connect the following by

using 3.0 m or 1.5 m Kelvin triaxial cable:

HPSMU