HP Officejet Enterprise Color X555, Officejet Enterprise Color MFP X585 Repair Manual and Troubleshooting Manual

Page 1

Officejet Enterprise Color X555

Officejet Enterprise Color MFP X585

Repair Manual

c

a

p

s

l

o

c

k

A

s

h

i

f

t

S

D

Z

F

X

G

C

@

H

V

J

a

l

t

B

K

L

N

:

M

“

;

e

n

,

t

e

r

‘

?

.

a

l

t

s

h

i

f

t

/

www.hp.com/support/ojcolorX555

www.hp.com/support/ojcolorMFPX585

Page 2

Page 3

HP Officejet Enterprise Color X555 and MFP

X585 Series

Repair Manual

Page 4

Copyright and License

Trademark Credits

© 2014 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or

omissions contained herein.

Edition 1, 4/2014

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered trademarks

of Microsoft Corporation.

Page 5

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging the

product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal injury,

catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

Table of contents

1 Removal and replacement .............................................................................................................................. 1

Removal and replacement strategy ...................................................................................................................... 2

Electrostatic discharge ........................................................................................................................ 2

Required tools ..................................................................................................................................... 3

Types of screws ................................................................................................................................... 3

Service approach ................................................................................................................................................... 3

Before performing service .................................................................................................................. 3

After performing service ..................................................................................................................... 3

Post-service test ................................................................................................................................. 4

Removal and replacement procedures ................................................................................................................. 5

Customer replaceable parts ................................................................................................................ 5

Covers ................................................................................................................................................ 33

Main assemblies ................................................................................................................................ 44

2 Parts and diagrams ...................................................................................................................................... 63

Order parts by authorized service providers ...................................................................................................... 64

Order replacement parts ................................................................................................................... 64

Related documentation and software .............................................................................................. 64

Supplies part numbers ...................................................................................................................... 64

Customer self-repair parts ............................................................................................................... 65

How to use the parts lists and diagrams ............................................................................................................. 68

Assembly locations—X555 models .................................................................................................................... 69

Assembly locations—X585 models .................................................................................................................... 70

Covers, control panels, and doors—X555 models ............................................................................................. 72

Covers, control panels, and doors—X585 models ............................................................................................. 74

Internal assemblies—all models ........................................................................................................................ 76

Scanner/document feeder assembly—X585 models ........................................................................................ 80

Alphabetical parts list .......................................................................................................................................... 82

Numerical parts list ............................................................................................................................................. 86

Index ............................................................................................................................................................. 91

ENWW v

Page 8

vi ENWW

Page 9

List of tables

Table 2-1 Order parts, accessories, and supplies .............................................................................................................. 64

Table 2-2 Related documentation and software ............................................................................................................... 64

Table 2-3 Supplies part numbers ....................................................................................................................................... 64

Table 2-4 Product accessories ........................................................................................................................................... 65

Table 2-5 Customer self-repair parts ................................................................................................................................ 65

Table 2-6 Assembly locations—X555 models .................................................................................................................. 69

Table 2-7 Assembly locations—X585 models .................................................................................................................. 70

Table 2-8 Covers, control panels, and doors—X555 models ........................................................................................... 73

Table 2-9 Covers, control panels, and doors—X585 models ........................................................................................... 75

Table 2-10 Internal assemblies .......................................................................................................................................... 77

Table 2-11 Internal assemblies—print mechanism kit ..................................................................................................... 79

Table 2-12 Scanner/document feeder assembly—X585 models ..................................................................................... 81

Table 2-13 Alphabetical parts list ...................................................................................................................................... 82

Table 2-14 Numerical parts list .......................................................................................................................................... 86

ENWW vii

Page 10

viii ENWW

Page 11

List of figures

Figure 1-1 Remove Tray 2 .................................................................................................................................................... 5

Figure 1-2 Remove the ink collection unit (1 of 2) ............................................................................................................... 7

Figure 1-3 Remove the ink collection unit (2 of 2) ............................................................................................................... 7

Figure 1-4 Remove the output bin ....................................................................................................................................... 8

Figure 1-5 Remove the output bin flap ................................................................................................................................ 9

Figure 1-6 Remove the document-feeder roller (1 of 3) ................................................................................................... 10

Figure 1-7 Remove the document-feeder roller (2 of 3) ................................................................................................... 10

Figure 1-8 Remove the document-feeder roller (3 of 3) ................................................................................................... 11

Figure 1-9 Reinstall the document-feeder roller .............................................................................................................. 11

Figure 1-10 Remove the document-feeder separation pad spring (1 of 3) ...................................................................... 12

Figure 1-11 Remove the document-feeder separation pad spring (2 of 3) ...................................................................... 12

Figure 1-12 Remove the document feeder separation pad spring (3 of 3) ....................................................................... 13

Figure 1-13 Remove the document feeder white backing (1 of 3) .................................................................................... 14

Figure 1-14 Remove the document feeder white backing (2 of 3) .................................................................................... 14

Figure 1-15 Remove the document feeder white backing (3 of 3) .................................................................................... 15

Figure 1-16 Install a replacement document feeder white backing (1 of 6) ..................................................................... 15

Figure 1-17 Install a replacement document feeder white backing (2 of 6) ..................................................................... 16

Figure 1-18 Install a replacement document feeder white backing (3 of 6) ..................................................................... 16

Figure 1-19 Install a replacement document feeder white backing (4 of 6) ..................................................................... 17

Figure 1-20 Install a replacement document feeder white backing (5 of 6) ..................................................................... 17

Figure 1-21 Install a replacement document feeder white backing (6 of 6) ..................................................................... 18

Figure 1-22 Remove the background selector (1 of 4) ...................................................................................................... 19

Figure 1-23 Remove the background selector (2 of 4) ...................................................................................................... 19

Figure 1-24 Remove the background selector (3 of 4) ...................................................................................................... 20

Figure 1-25 Remove the background selector (4 of 4) ...................................................................................................... 20

Figure 1-26 Reinstall the background selector ................................................................................................................. 21

Figure 1-27 Remove the control panel — X555 models (1 of 4) ...................................................................................... 21

Figure 1-28 Remove the control panel — X555 models (2 of 4) ...................................................................................... 22

Figure 1-29 Remove the control panel — X555 models (3 of 4) ...................................................................................... 22

Figure 1-30 Remove the control panel — X555 models (4 of 4) ...................................................................................... 23

Figure 1-31 Remove the control panel — X585 models (1 of 4) ...................................................................................... 23

Figure 1-32 Remove the control panel — X585 models (2 of 4) ...................................................................................... 24

ENWW ix

Page 12

Figure 1-33 Remove the control panel — X585 models (3 of 4) ...................................................................................... 24

Figure 1-34 Remove the control panel — X585 models (4 of 4) ...................................................................................... 25

Figure 1-35 Remove the control panel keyboard — X585 Flow models (1 of 2) ............................................................. 25

Figure 1-36 Remove the control panel keyboard — X585 Flow models (2 of 2) ............................................................. 26

Figure 1-37 Remove the formatter PCA (1 of 3) ................................................................................................................ 27

Figure 1-38 Remove the formatter PCA (2 of 3) ................................................................................................................ 27

Figure 1-39 Remove the formatter PCA (3 of 3) ................................................................................................................ 28

Figure 1-40 Remove the fax PCA (1 of 2) ........................................................................................................................... 28

Figure 1-41 Remove the fax PCA (2 of 2) ........................................................................................................................... 29

Figure 1-42 Remove the SSD (1 of 2) ................................................................................................................................. 29

Figure 1-43 Remove the SSD (2 of 2) ................................................................................................................................. 30

Figure 1-44 Remove the HDD ............................................................................................................................................. 30

Figure 1-45 Remove the rear cover (1 of 2) ....................................................................................................................... 33

Figure 1-46 Remove the rear cover (2 of 2) ....................................................................................................................... 33

Figure 1-47 Remove left door (1 of 5) ................................................................................................................................ 34

Figure 1-48 Remove the left door (2 of 5) ......................................................................................................................... 34

Figure 1-49 Remove the left door (3 of 5) ......................................................................................................................... 35

Figure 1-50 Remove the left door (4 of 5) ......................................................................................................................... 35

Figure 1-51 Remove the left door (5 of 5) ......................................................................................................................... 36

Figure 1-52 Remove the left rear cover (1 of 2) ................................................................................................................ 36

Figure 1-53 Remove the left rear cover (2 of 2) ................................................................................................................ 37

Figure 1-54 Remove the left front cover (1 of 2) ............................................................................................................... 37

Figure 1-55 Remove the left front cover (2 of 2) ............................................................................................................... 38

Figure 1-56 Remove the top cover (1 of 4) ........................................................................................................................ 39

Figure 1-57 Remove the top cover (2 of 4) ........................................................................................................................ 39

Figure 1-58 Remove the top cover (3 of 4) ........................................................................................................................ 40

Figure 1-59 Remove the top cover (4 of 4) ........................................................................................................................ 40

Figure 1-60 Remove the top cover cap (1 of 2) ................................................................................................................. 41

Figure 1-61 Remove the top cover cap (2 of 2) ................................................................................................................. 41

Figure 1-62 Remove the front cover (1 of 2) ..................................................................................................................... 42

Figure 1-63 Remove the front cover (2 of 2) ..................................................................................................................... 42

Figure 1-64 Remove the right cover (1 of 2) ...................................................................................................................... 43

Figure 1-65 Remove the right cover (2 of 2) ...................................................................................................................... 43

Figure 1-66 Remove the document feeder mylar strip (1 of 4) ......................................................................................... 44

Figure 1-67 Remove the document feeder mylar strip (2 of 4) ......................................................................................... 44

Figure 1-68 Remove the document feeder mylar strip (3 of 4) ......................................................................................... 45

Figure 1-69 Remove the document feeder mylar strip (4 of 4) ......................................................................................... 45

Figure 1-70 Install a replacement document feeder mylar strip (1 of 2) ......................................................................... 46

Figure 1-71 Install a replacement document feeder mylar strip (2 of 2) ......................................................................... 46

Figure 1-72 Remove the document feeder (1 of 6) ........................................................................................................... 47

Figure 1-73 Remove the document feeder (2 of 6) ........................................................................................................... 47

x ENWW

Page 13

Figure 1-74 Remove the document feeder (3 of 6) ........................................................................................................... 48

Figure 1-75 Remove the document feeder (4 of 6) ........................................................................................................... 48

Figure 1-76 Remove the document feeder (5 of 6) ........................................................................................................... 49

Figure 1-77 Remove the document feeder (6 of 6) ........................................................................................................... 49

Figure 1-78 Remove the SCB (1 of 6) ................................................................................................................................. 50

Figure 1-79 Remove the SCB (2 of 6) ................................................................................................................................. 50

Figure 1-80 Remove the SCB (3 of 6) ................................................................................................................................. 51

Figure 1-81 Remove the SCB (4 of 6) ................................................................................................................................. 51

Figure 1-82 Remove the SCB (5 of 6) ................................................................................................................................. 52

Figure 1-83 Remove the SCB (6 of 6) ................................................................................................................................. 52

Figure 1-84 Remove the scanner (1 of 7) ........................................................................................................................... 53

Figure 1-85 Remove the scanner (2 of 7) ........................................................................................................................... 53

Figure 1-86 Remove the scanner (3 of 7) ........................................................................................................................... 54

Figure 1-87 Remove the scanner (4 of 7) ........................................................................................................................... 54

Figure 1-88 Remove the scanner (5 of 7) ........................................................................................................................... 55

Figure 1-89 Remove the scanner (6 of 7) ........................................................................................................................... 55

Figure 1-90 Remove the scanner (7 of 7) ........................................................................................................................... 56

Figure 1-91 Remove the power supply (1 of 3) ................................................................................................................. 56

Figure 1-92 Remove the power supply (2 of 3) ................................................................................................................. 57

Figure 1-93 Remove the power supply (3 of 3) ................................................................................................................. 57

Figure 2-1 Assembly locations—X555 models ................................................................................................................. 69

Figure 2-2 Assembly locations—X585 models ................................................................................................................. 70

Figure 2-3 Covers, control panels, and doors—X555 models .......................................................................................... 72

Figure 2-4 Covers, control panels, and doors—X585 models .......................................................................................... 74

Figure 2-5 Internal assemblies ........................................................................................................................................... 76

Figure 2-6 Internal assemblies—print mechanism kit ...................................................................................................... 78

Figure 2-7 Scanner/document feeder assembly—X585 models ..................................................................................... 80

ENWW xi

Page 14

xii ENWW

Page 15

1 Removal and replacement

●

Removal and replacement strategy

●

Service approach

●

Removal and replacement procedures

ENWW 1

Page 16

Removal and replacement strategy

WARNING! Turn the product off, wait 5 seconds, and then remove the power cord before attempting to

service the product. If this warning is not followed, severe injury can result, in addition to damage to the

product. The power must be on for certain functional checks during problem solving. However, the power

supply should be disconnected during parts removal.

The sheet-metal parts can have sharp edges. Be careful when handling sheet-metal parts.

CAUTION: Many repair operations will require you to flatten or straighten flex cables. However, where

possible, try to avoid doing so. You must make sure that all FFCs are fully seated in their connectors. Failure

to fully seat an FFC into a connector can cause a short circuit in a printed circuit-board assembly (PCA).

NOTE: To install a self-tapping screw, first turn it counterclockwise to align it with the existing thread

pattern, and then carefully turn it clockwise to tighten. Do not overtighten. If a self-tapping screw-hole

becomes stripped, repair the screw-hole or replace the affected assembly.

Throughout this chapter, the reinstallation process should follow the reverse order of the removal process

documented. Where necessary, the tasks include reinstallation tips to aid in the installation of replacement

parts.

Electrostatic discharge

CAUTION: Some parts are sensitive to electrostatic discharge (ESD). Look for the ESD reminder when

removing product parts. Always perform service work at an ESD-protected workstation or mat. If an ESD

workstation or mat is not available, ground yourself by touching the sheet-metal chassis before touching an

ESD-sensitive part.

Protect the ESD-sensitive parts by placing them in ESD pouches when they are out of the product.

2 Chapter 1 Removal and replacement ENWW

Page 17

Required tools

●

#T10 TORX driver with a magnetic tip and a 152 mm (6 in) shaft length

●

Small flatblade screwdriver

●

Needle-nose pliers

●

ESD mat (if one is available) or ESD strap

●

Penlight (optional)

Types of screws

WARNING! Make sure that components are replaced with the correct screw type. Using the incorrect screw

(for example, substituting a long screw for the correct shorter screw) can cause damage to the product or

interfere with product operation. Do not intermix screws that are removed from one component with the

screws that are removed from another component.

Service approach

CAUTION: When working on the product, do not pick up the unit by the output tray, which will detach under

the weight of the product.

Before performing service

●

Remove all paper from the product.

●

Turn off the power using the power button.

●

Unplug the power cable and interface cable or cables.

●

Remove the output bin.

●

Place the product on an ESD workstation or mat, or use an ESD strap (if one is available). If an ESD

workstation, mat, or strap is not available, ground yourself by touching the sheet-metal chassis before

touching an ESD-sensitive part.

●

Remove the ink cartridges.

●

Remove the Tray 2 cassette.

●

Remove the ink collection unit, which is located inside the left door.

NOTE: When removing the ink collection unit, avoid making direct contact with the black cylinder to

prevent ink smear on skin or clothes. Keep the ink collection unit level to avoid spilling any waste ink.

After performing service

●

Plug in the power cable.

●

Reinstall the output bin.

●

Reinstall the ink cartridges.

●

Reinstall the Tray 2 cassette.

ENWW Service approach 3

Page 18

●

Reinstall the ink collection unit.

●

Load paper in the product.

Post-service test

Perform the following test to verify that the repair or replacement was successful.

Print-quality test

1. Verify that you have completed the necessary reassembly steps.

2. Make sure that the tray contains clean, unmarked paper.

3. Attach the power cord and interface cable or interface cables, and then turn on the product.

4. Print a configuration page.

5. Print a print quality page, and then verify that there are no lines, streaks, banding, or other print quality

defects.

6. Send a print job from the host computer, and then verify that the output meets expectations.

7. Clean the outside of the product with a damp cloth.

4 Chapter 1 Removal and replacement ENWW

Page 19

Removal and replacement procedures

NOTE: Due to time constraints in producing this manual, the product might look slightly different than what

is depicted in the photographs in this section. Most changes will be cosmetic in nature and should not affect

the repair procedures.

Customer replaceable parts

CSR-A parts

CSR-A parts require no tools during installation.

Tray 2

▲

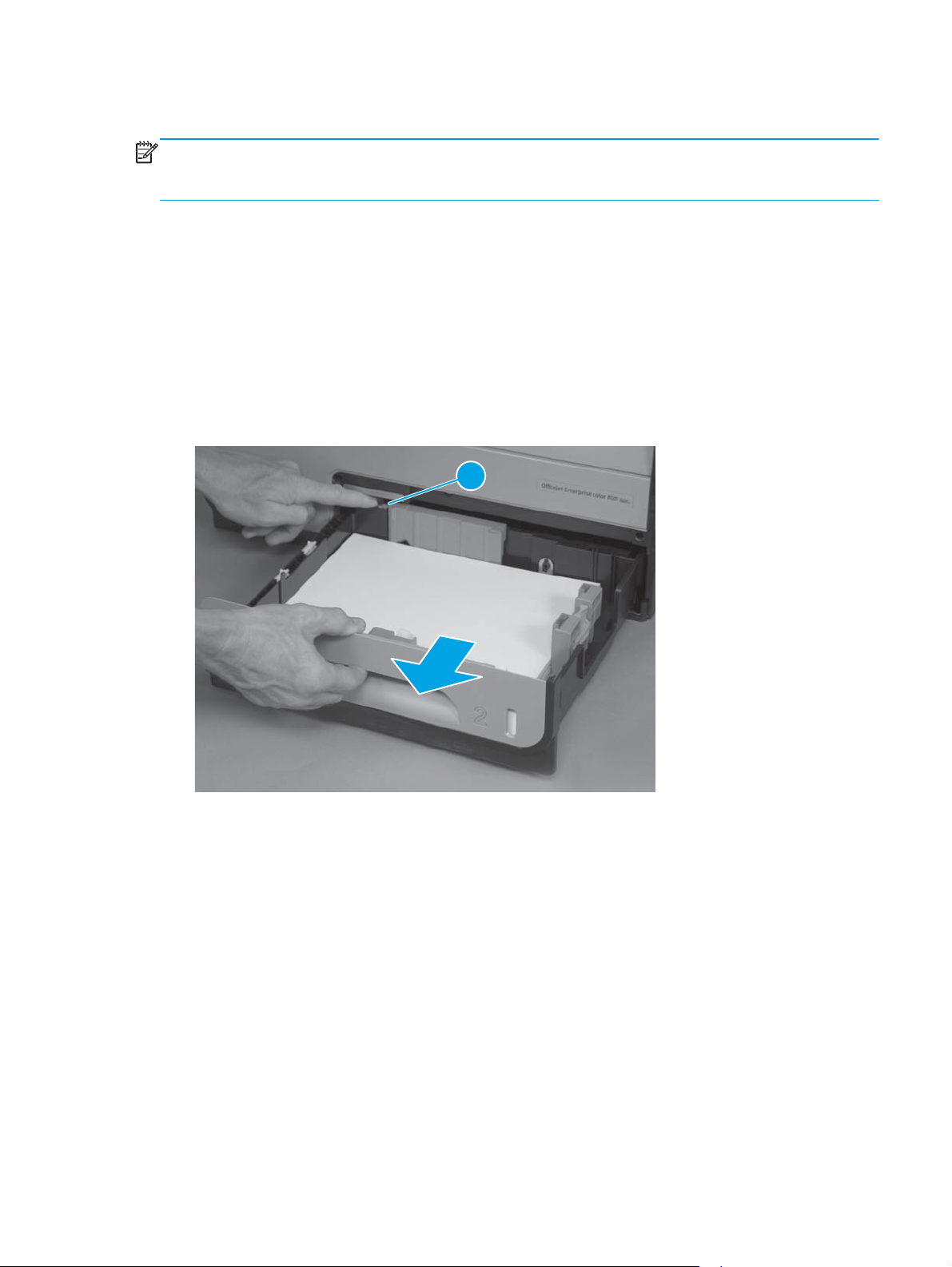

Pull out the tray, and then press the latch (callout 1) in left-rear corner of the tray to remove it from the

product.

Figure 1-1 Remove Tray 2

1

Ink cartridges

The product uses four colors and has a different ink cartridge for each color: yellow (Y), cyan (C), magenta

(M), and black (K).

ENWW Removal and replacement procedures 5

Page 20

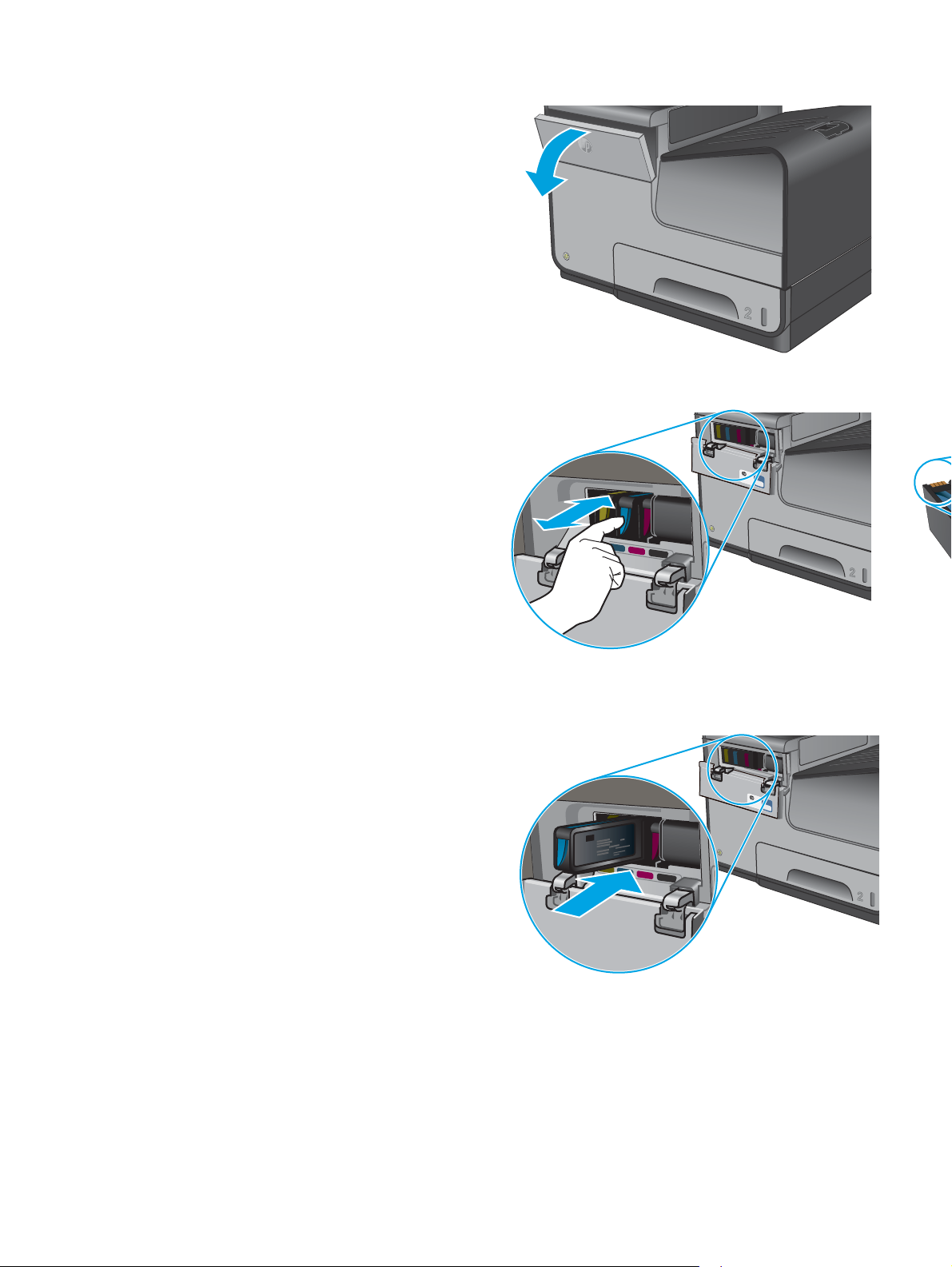

1. Open the ink cartridge door.

2. Push the old ink cartridge inward to unlock it, and

then pull the cartridge straight out to remove it.

CAUTION: When handling the new ink

cartridges, do not touch the gold-colored metal

contacts on the cartridges. Fingerprints on the

contacts can cause print-quality problems.

3. Insert the new ink cartridge into the product,

push the cartridge until it “clicks” into place, and

then close the ink cartridge door.

4. Place the old cartridge in the box. Refer to the

box for information about recycling used ink

cartridges.

6 Chapter 1 Removal and replacement ENWW

Page 21

Ink collection unit

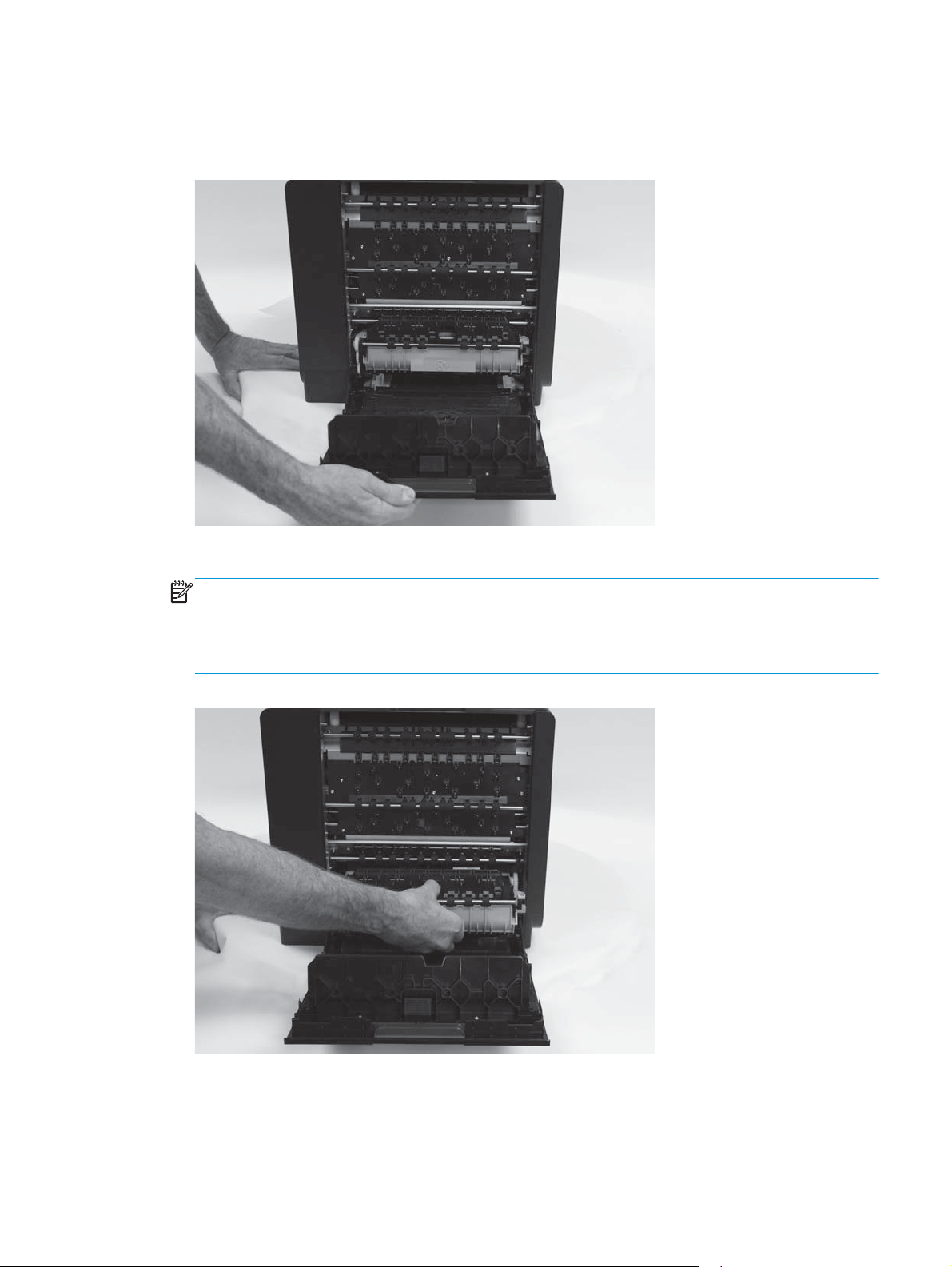

1. Open the left door.

Figure 1-2 Remove the ink collection unit (1 of 2)

2. Use the green hand-grip to pull the ink collection unit out of the product.

NOTE: When removing the ink collection unit, avoid making direct contact with the black cylinder to

prevent ink smear on skin or clothes. Keep the ink collection unit level to avoid spilling any waste ink.

Also, do not let the bottom of the ink collection unit touch or rest on the ribs on the left door, which can

damage them and might lead to media damage and jams.

Figure 1-3 Remove the ink collection unit (2 of 2)

ENWW Removal and replacement procedures 7

Page 22

Output bin

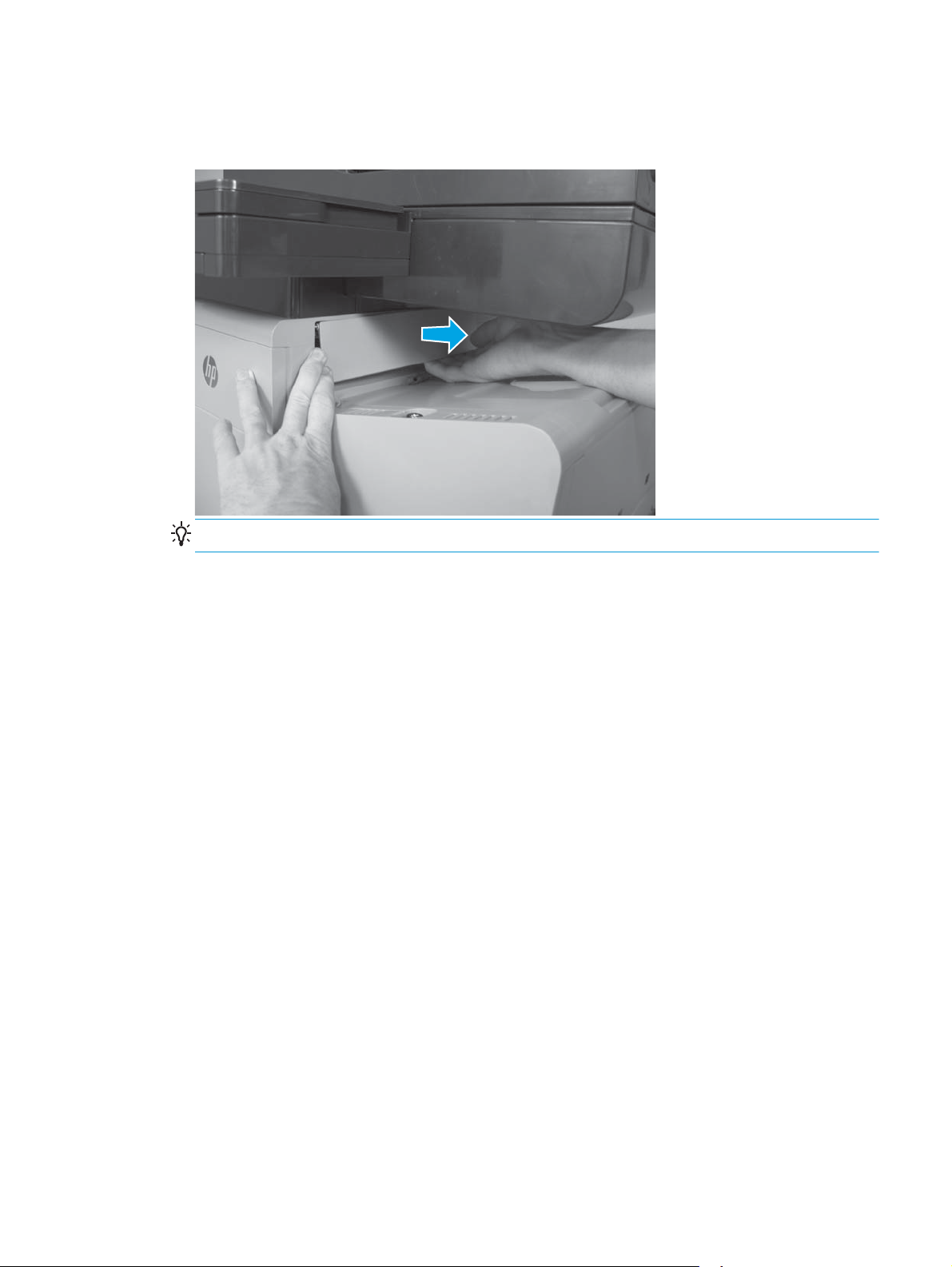

▲

Lift and unsnap the output bin tabs below the output flap, and then lift the output bin to remove it from

the product.

CAUTION: Do not tilt the assembly too far back, as it will damage tabs at bottom seam of the output

bin.

Figure 1-4 Remove the output bin

1

2

Output bin flap

1. Remove the output bin. See

Reinstallation tip Insert the tabs on the bottom edge first, and then snap the top edge into place.

Output bin on page 8.

8 Chapter 1 Removal and replacement ENWW

Page 23

2. Slightly open the output bin flap, flex the middle of the output bin flap, and then remove the flap by

pulling the right pin away from the product first.

Figure 1-5 Remove the output bin flap

Reinstallation tip Insert the left pin into the product first when reinstalling the flap.

ENWW Removal and replacement procedures 9

Page 24

Document feeder roller (X585 models)

CAUTION: If you are replacing the roller, do not touch the surface of the replacement roller. Skin oils

deposited on the roller might cause paper pickup problems.

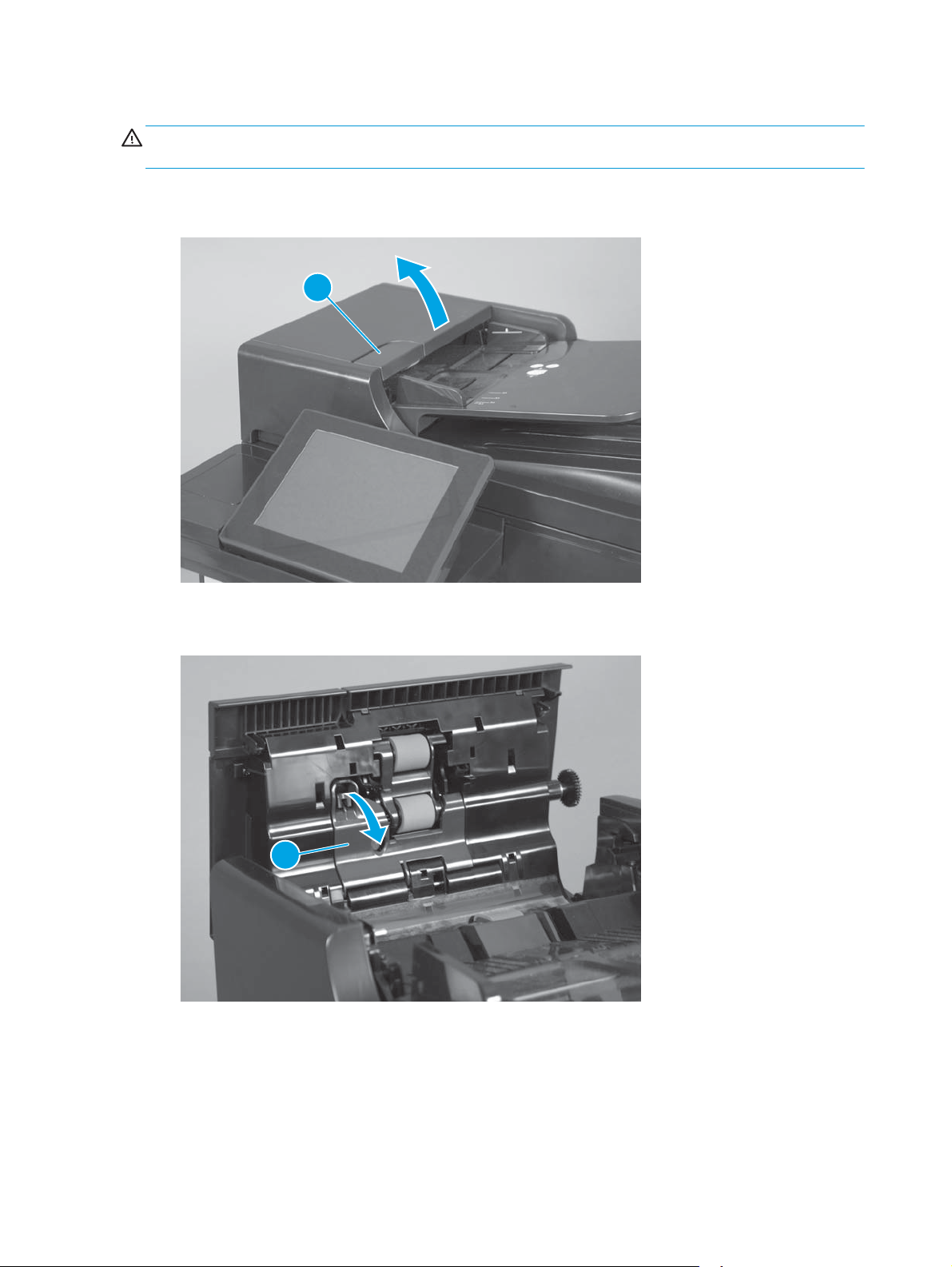

1. Pull the latch (callout 1) to open the document feeder door.

Figure 1-6 Remove the document-feeder roller (1 of 3)

1

2. Release one tab, and then open the access cover (callout 1).

Figure 1-7 Remove the document-feeder roller (2 of 3)

1

10 Chapter 1 Removal and replacement ENWW

Page 25

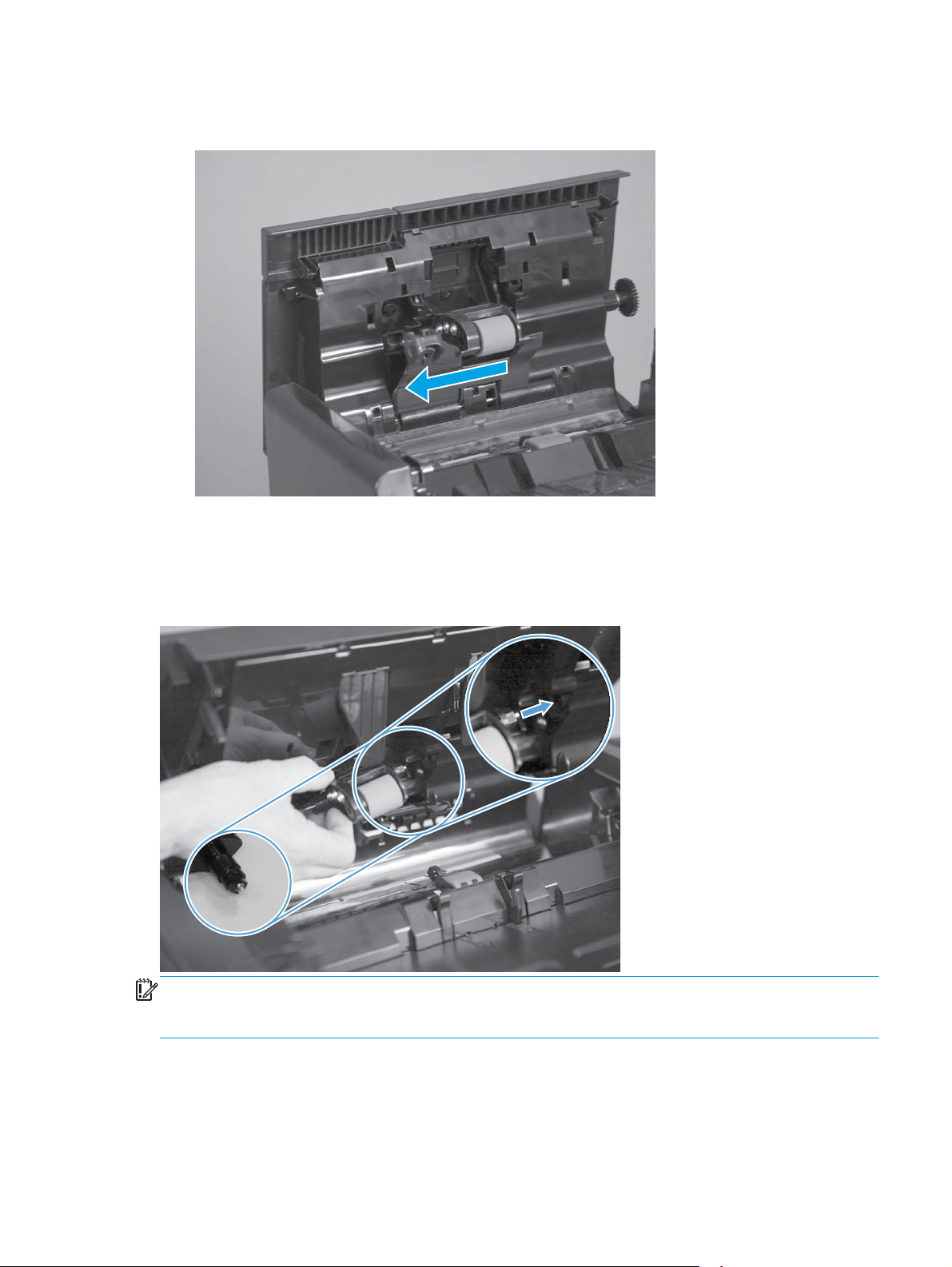

3. Slide the roller assembly left, and then lift it up and out of the product.

Figure 1-8 Remove the document-feeder roller (3 of 3)

Reinstall the document-feeder roller

The roller assembly is keyed. When reinstalling the roller assembly, position the hex-shaped fitting on the

shaft toward the rear of the product.

Figure 1-9 Reinstall the document-feeder roller

IMPORTANT: When the roller is reinstalled, the access door must be fully closed. When you close the door,

you should hear two audible clicks. If, after replacing the roller document feeder, a document feeder jam

message appears on the control panel display, make sure that the access door is fully closed.

ENWW Removal and replacement procedures 11

Page 26

Document feeder separation pad spring (X585 models)

CAUTION: Do not touch the surface of the separation pad. Skin oils deposited on the pad might cause paper

pickup problems.

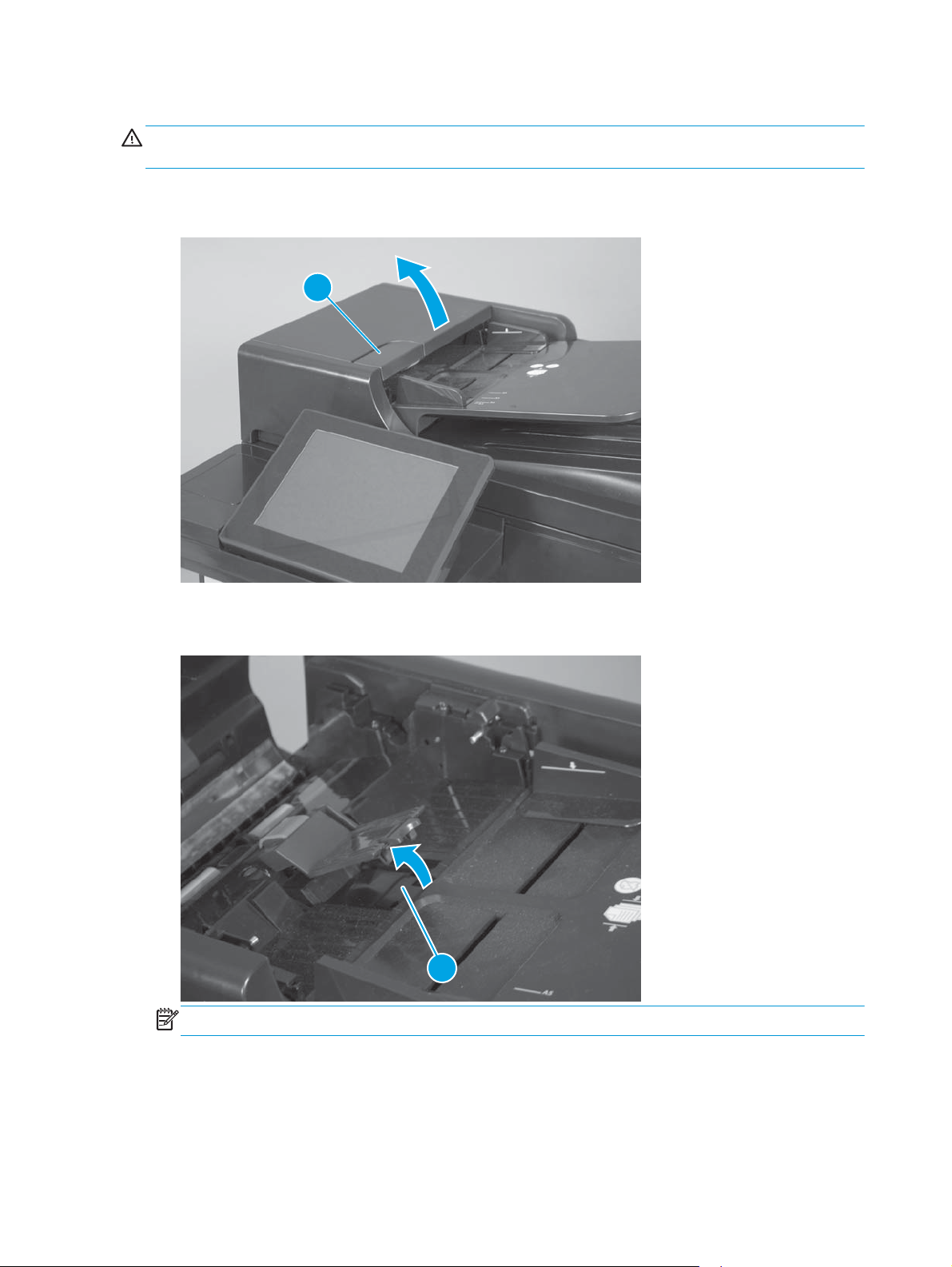

1. Pull the latch (callout 1) to open the document feeder door.

Figure 1-10 Remove the document-feeder separation pad spring (1 of 3)

1

2. Release one tab (callout 1) to open the separation pad assembly.

Figure 1-11 Remove the document-feeder separation pad spring (2 of 3)

1

NOTE: The separation pad assembly is spring-loaded and partially rises when the tab is released.

12 Chapter 1 Removal and replacement ENWW

Page 27

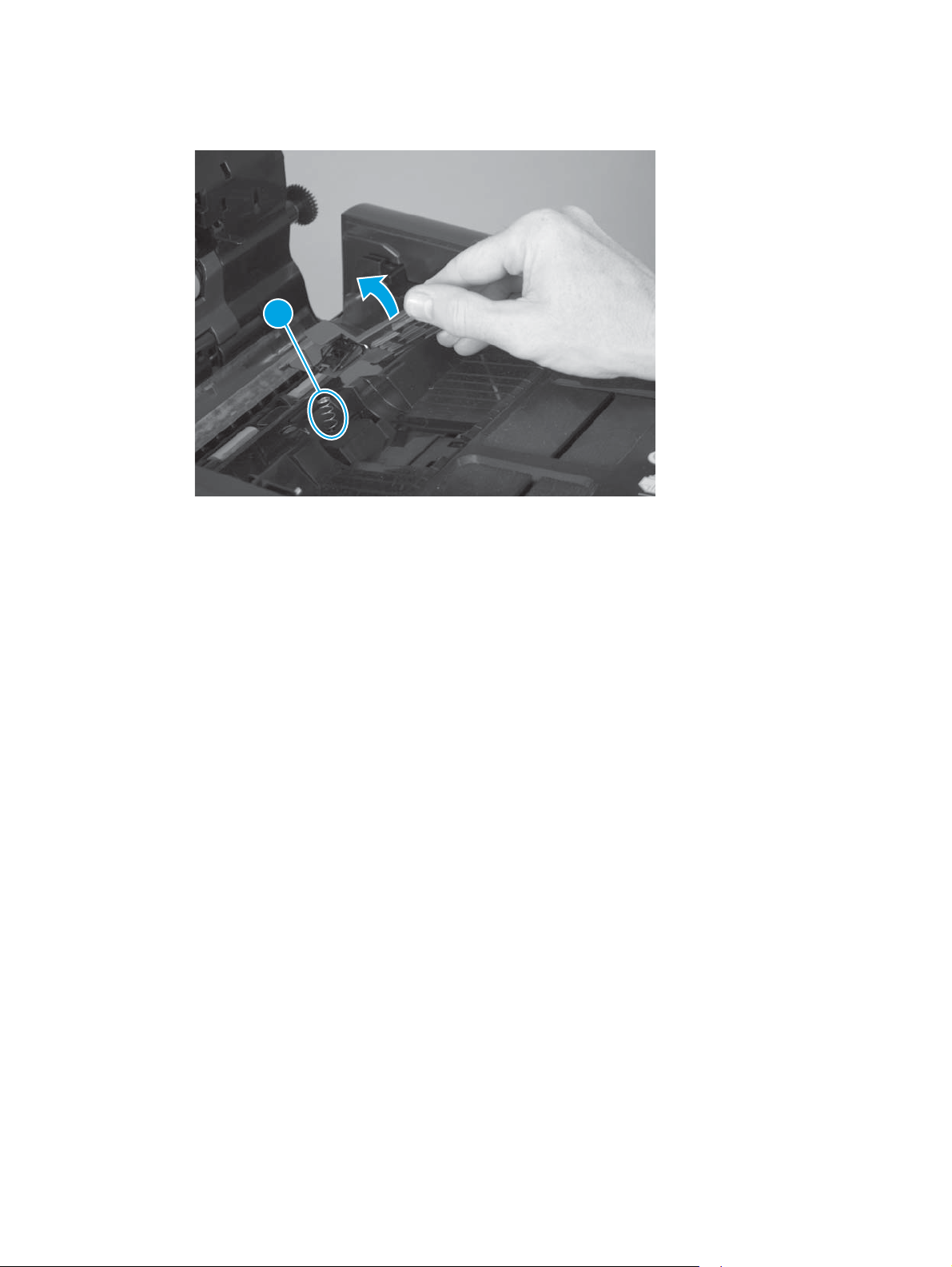

3. Lift the separation pad assembly up and away from the product, and then remove the spring (callout 1).

Figure 1-12 Remove the document feeder separation pad spring (3 of 3)

1

ENWW Removal and replacement procedures 13

Page 28

Document feeder white backing (X585 models)

1. Open the document feeder.

Figure 1-13 Remove the document feeder white backing (1 of 3)

2. Carefully remove the white backing.

Figure 1-14 Remove the document feeder white backing (2 of 3)

14 Chapter 1 Removal and replacement ENWW

Page 29

3. Remove any rubber stoppers that might still be attached to the document feeder.

Figure 1-15 Remove the document feeder white backing (3 of 3)

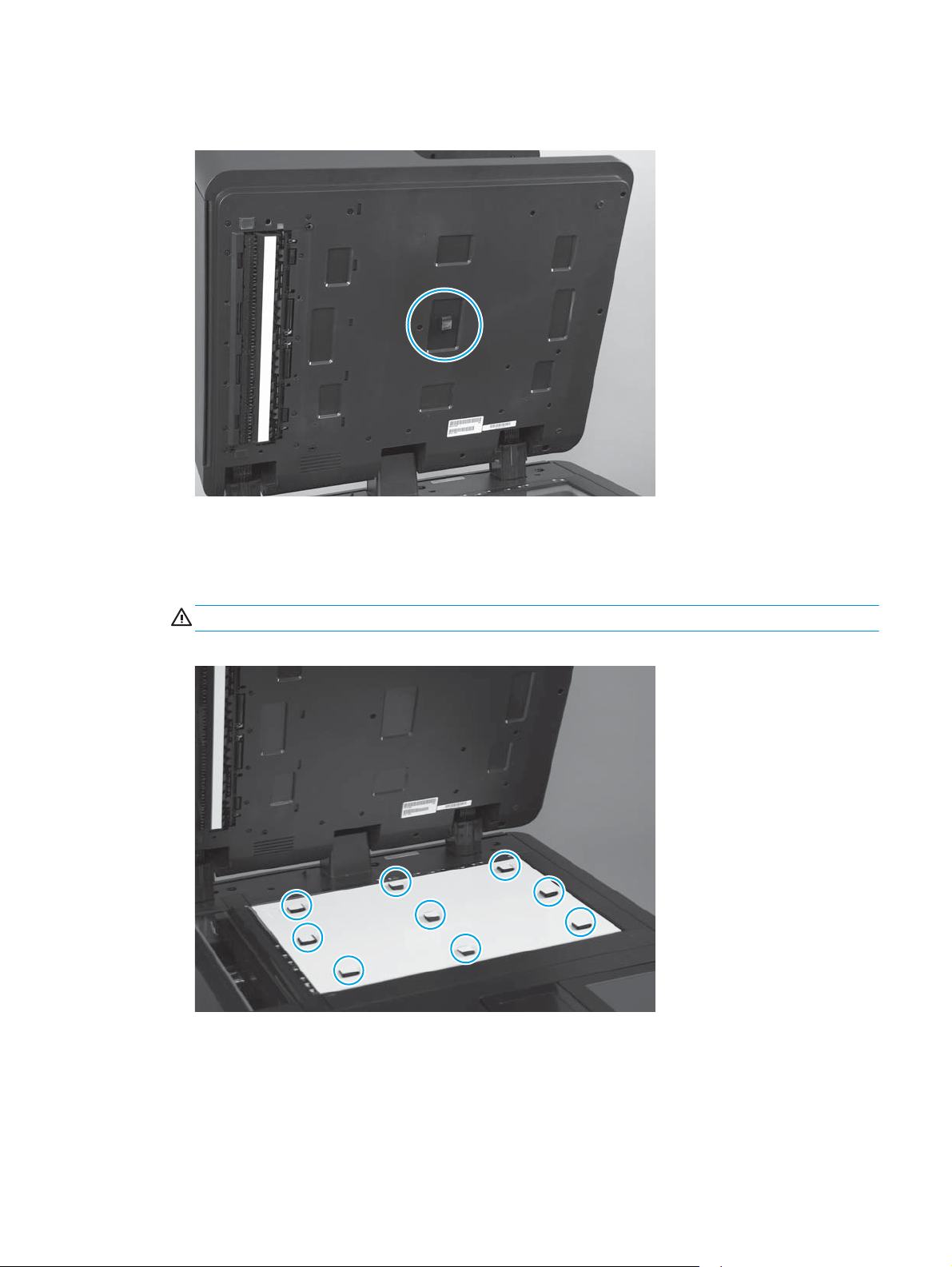

Install a replacement document feeder white backing

1. Position the replacement white backing on the scanner glass. Carefully remove the protective backing

from the rubber stoppers.

CAUTION: Do not touch the exposed adhesive.

Figure 1-16 Install a replacement document feeder white backing (1 of 6)

ENWW Removal and replacement procedures 15

Page 30

2. Make sure that the arrow on the replacement white backing is positioned in the upper-left corner of the

scanner glass.

Figure 1-17 Install a replacement document feeder white backing (2 of 6)

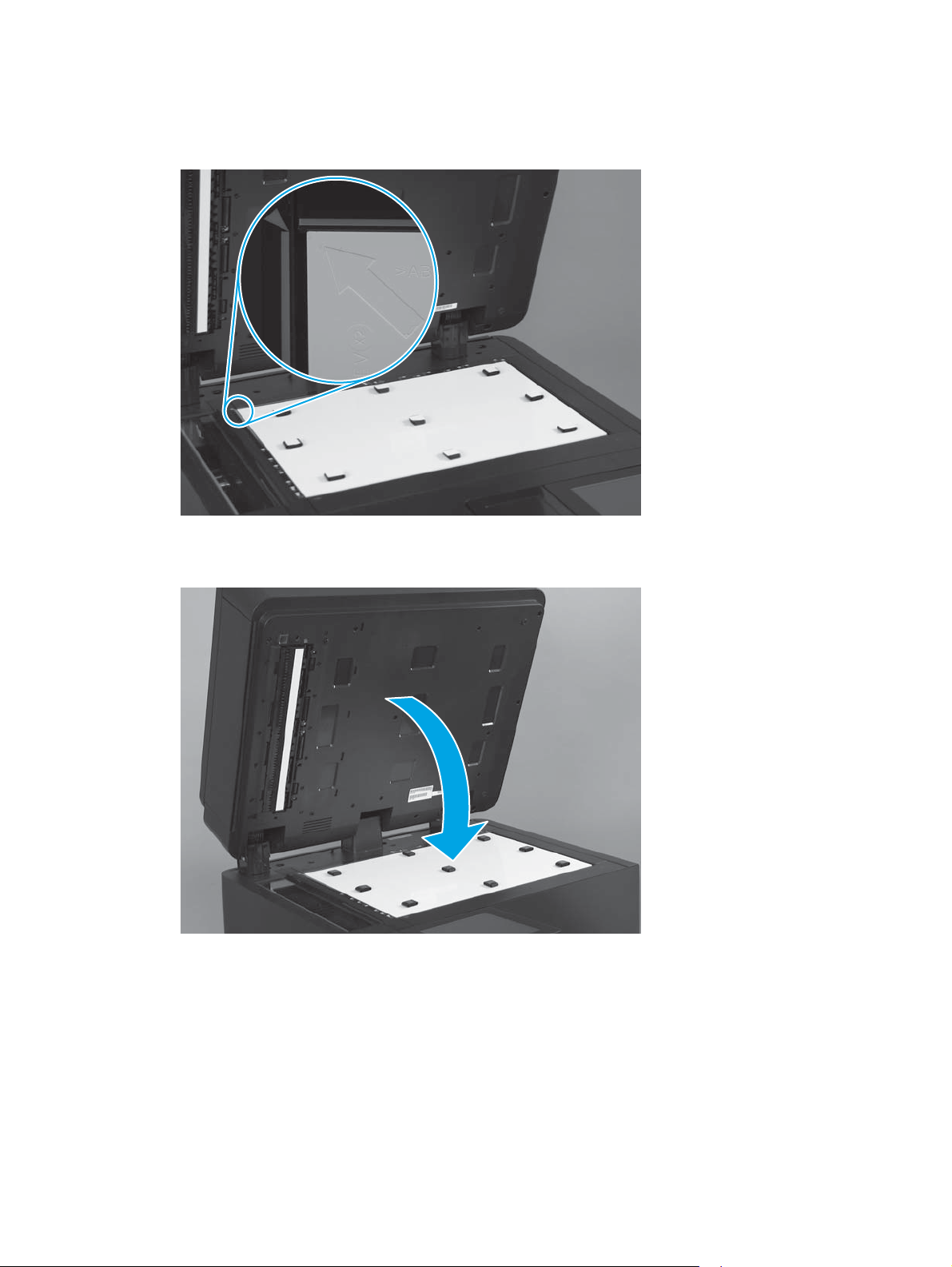

3. Completely close the document feeder.

Figure 1-18 Install a replacement document feeder white backing (3 of 6)

16 Chapter 1 Removal and replacement ENWW

Page 31

4. Firmly push down on the four corners of the document feeder to adhere the white backing to the

document feeder.

Figure 1-19 Install a replacement document feeder white backing (4 of 6)

5. Carefully open the document feeder.

Figure 1-20 Install a replacement document feeder white backing (5 of 6)

ENWW Removal and replacement procedures 17

Page 32

6. Firmly press on the white backing over the areas shown below to make sure that the rubber stoppers

are completely adhered to the document feeder.

Figure 1-21 Install a replacement document feeder white backing (6 of 6)

18 Chapter 1 Removal and replacement ENWW

Page 33

Background selector (X585 Flow models only)

1. Pull the latch (callout 1) to open the document feeder door.

Figure 1-22 Remove the background selector (1 of 4)

1

2. Lift the input tray up.

Figure 1-23 Remove the background selector (2 of 4)

ENWW Removal and replacement procedures 19

Page 34

3. Release two tabs (callout 1) on the selector.

Figure 1-24 Remove the background selector (3 of 4)

1

4. Slide the background selector away from the product to remove it.

Figure 1-25 Remove the background selector (4 of 4)

20 Chapter 1 Removal and replacement ENWW

Page 35

Reinstall the background selector

Push in on the background selector until the tabs snap into place.

NOTE: If jams occur after the assembly is installed, make sure that the assembly is fully seated.

Figure 1-26 Reinstall the background selector

Control panel (X555 models)

1. Tilt the control panel away from the product.

Figure 1-27 Remove the control panel — X555 models (1 of 4)

ENWW Removal and replacement procedures 21

Page 36

2. Remove the access cover behind the control panel.

Figure 1-28 Remove the control panel — X555 models (2 of 4)

3. Turn the lock lever counterclockwise to release it.

Figure 1-29 Remove the control panel — X555 models (3 of 4)

1

22 Chapter 1 Removal and replacement ENWW

Page 37

4. Lift the left end of the control panel up, and then disconnect three connectors (callout 1) and the ground

wire (callout 2).

Figure 1-30 Remove the control panel — X555 models (4 of 4)

Control panel (X585 models)

1

2

1. Tilt the control panel up, and then open and remove the access cover.

Figure 1-31 Remove the control panel — X585 models (1 of 4)

ENWW Removal and replacement procedures 23

Page 38

2. Disconnect two cables (callout 1).

NOTE: Flow models have a third cable, a flat, flexible cable (FFC) for the keyboard. You do not need to

detach this FFC.

Figure 1-32 Remove the control panel — X585 models (2 of 4)

1

3. Remove the thumbscrew (callout 1).

Figure 1-33 Remove the control panel — X585 models (3 of 4)

1

24 Chapter 1 Removal and replacement ENWW

Page 39

4. Slide the control panel to the left, and then carefully pull it away from the product to avoid damaging

the cables.

Figure 1-34 Remove the control panel — X585 models (4 of 4)

1

2

Remove the control panel keyboard (X585 Flow models only)

1. Remove the control panel. See

2. Disconnect the keyboard FFC (callout 1).

Figure 1-35 Remove the control panel keyboard — X585 Flow models (1 of 2)

Control panel (X585 models) on page 23.

1

ENWW Removal and replacement procedures 25

Page 40

3. Extend the keyboard, turn the control panel assembly over, and release two tabs (callout 1) to remove

the keyboard.

Figure 1-36 Remove the control panel keyboard — X585 Flow models (2 of 2)

1

26 Chapter 1 Removal and replacement ENWW

Page 41

CSR-B parts

CSR-B parts require tools during installation.

Formatter PCA

1. Remove the output bin. See

2. At the front of the product, disconnect the thumbscrew (callout 1), and then remove the formatter

cover from the product by lifting upward on it.

Figure 1-37 Remove the formatter PCA (1 of 3)

Output bin on page 8.

1

3. On the back of the product, disconnect two thumbscrews (callout 1).

Figure 1-38 Remove the formatter PCA (2 of 3)

1

ENWW Removal and replacement procedures 27

Page 42

4. At the front of the product, grab the formatter handle and pull the formatter out of the product.

Figure 1-39 Remove the formatter PCA (3 of 3)

Fax PCA (X585 fax models only)

1. Remove the formatter. See

2. On the formatter, remove one screw (callout 1) from the black fax card bracket, and then remove the

bracket.

Figure 1-40 Remove the fax PCA (1 of 2)

Formatter PCA on page 27.

1

28 Chapter 1 Removal and replacement ENWW

Page 43

3. Pull the fax PCA away from the formatter to disconnect the connector to the formatter.

Figure 1-41 Remove the fax PCA (2 of 2)

Solid state drive (SSD) (X555dn models only)

1. Remove the formatter. See

2. Locate the drive on the formatter, and then turn the lock tab (callout 1) counterclockwise.

Figure 1-42 Remove the SSD (1 of 2)

Formatter PCA on page 27.

1

ENWW Removal and replacement procedures 29

Page 44

3. Pull the lock tab out of the formatter, and then pull the SSD (callout 1) in the direction indicated to

disconnect it from the formatter.

NOTE: After replacing the SSD, you must reinstall the firmware. See Reinstall the product firmware

on page 31.

Figure 1-43 Remove the SSD (2 of 2)

1

Hard disk drive (HDD) (X555xh and all X585 models)

1. Remove the formatter. See

2. Locate the drive on the formatter, pull the latch tab (callout 1) toward the hard drive, and then move the

drive in the direction indicated to remove it from the formatter.

NOTE: After replacing the HDD, you must reinstall the firmware. See Reinstall the product firmware

on page 31.

Figure 1-44 Remove the HDD

Formatter PCA on page 27.

1

30 Chapter 1 Removal and replacement ENWW

Page 45

Reinstall the product firmware

NOTE: If you are installing a replacement HDD or SSM, use this procedure to install the product firmware on

the replacement drive.

If you are removing the HDD or SSM so that it can be installed on a replacement formatter, you can skip this

procedure.

1. Locate the product support Web site.

●

In the US:

◦

●

Outside the US:

a. Go to

b. Select your country/region.

c. Select Drivers & Downloads.

d. Enter the product name, and then click Go.

e. Select your product model.

2. Select Cross operating system (BIOS, Firmware, Diagnostics, etc.).

3. Locate the firmware download, and then select Download.

4. Copy the firmware upgrade file to the root directory of a USB flash drive. The firmware upgrade file has

a .bdl extension.

5. Insert the USB flash drive into the USB port on the product control panel, and then turn the product

power on.

6. The following message displays on the control panel: Error: 99.09.63 Incorrect Disk. Touch the OK

button to continue.

7. Wait for the Pre-Boot menu to appear on the control-panel display, and then touch the down arrow

button to scroll to 3 Administrator. Touch the OK button to select it.

www.hp.com/support/ojcolorX555 or www.hp.com/support/ojcolorMFPX585.

Go to

www.hp.com/support.

8. Touch the down arrow

9. Touch the down arrow

10. Touch the down arrow

11. The message Proceed with Requested Action displays. Touch the OK button to select it.

12. Touch the back

13. Touch the down arrow

14. Touch the down arrow

15. Touch the down arrow

ENWW Removal and replacement procedures 31

button to scroll to 6 Manage Disk. Touch the OK button to select it

button to scroll to + 6 Boot Device. Touch the OK button to select it.

button to scroll to 2 Erase / Unlock. Touch the OK button to select it

button to return to the Pre-Boot menu home screen.

button to scroll to 3 Administrator. Touch the OK button to select it.

button to scroll to 1 Download. Touch the OK button to select it.

button to scroll to 3 USB Thumbdrive. Touch the OK button to select it.

Page 46

16. Touch the down arrow button to scroll to the firmware upgrade file that you downloaded in step 4.

Touch the OK button to select it.

NOTE: If no .bdl files are listed, try saving the file to a different USB flash drive.

17. Wait while the file transfers. When the transfer is complete, the message Complete displays on the

screen.

18. Turn the product off, remove the USB flash drive, and then turn the product on. Wait for several minutes

while the product initializes.

32 Chapter 1 Removal and replacement ENWW

Page 47

Covers

Rear cover

1. Remove the following components.

●

Output bin. See

2. Remove one screw (callout 1) and one thumbscrew (callout 2).

Figure 1-45 Remove the rear cover (1 of 2)

Output bin on page 8.

1

3. Pull the cover to the right and remove it.

2

Left door

Figure 1-46 Remove the rear cover (2 of 2)

1. Lower the left door.

ENWW Removal and replacement procedures 33

Page 48

Figure 1-47 Remove left door (1 of 5)

2. Remove the ink collection unit.

Figure 1-48 Remove the left door (2 of 5)

34 Chapter 1 Removal and replacement ENWW

Page 49

3. Unhook each restraining strap by twisting the bottom end of the strap away from the door.

Figure 1-49 Remove the left door (3 of 5)

4. At the rear door hinge, the door is held in place by a retractable post. Insert a flat-blade screw driver

between the door hinge and the chassis to push the post (callout 1) toward the product rear, and then

pull that corner of the left door away from the product.

Figure 1-50 Remove the left door (4 of 5)

1

ENWW Removal and replacement procedures 35

Page 50

5. With the left end of the door free, remove the door.

Left rear cover

1. Remove the following components.

Figure 1-51 Remove the left door (5 of 5)

●

Ink collection unit. See

●

Left door. See

●

X555 models only: top cap. See

2. Remove two screws (callout 1).

Figure 1-52 Remove the left rear cover (1 of 2)

Left door on page 33.

Ink collection unit on page 7.

1

Top cover cap (X555 models only) on page 40.

36 Chapter 1 Removal and replacement ENWW

Page 51

3. Remove the cover by sliding the cover up 10 mm (0.4 in), and then rotating the cover away from the

product.

Figure 1-53 Remove the left rear cover (2 of 2)

NOTE: This cover can be very difficult to remove. You can use a flat-blade screwdriver to pry the

bottom edge of the cover away from the chassis.

Left front cover

1. Remove the following components:

●

●

2. Remove one screw (callout 1).

Figure 1-54 Remove the left front cover (1 of 2)

Left door. See

X555 models only: top cap. See

Left door on page 33.

Top cover cap (X555 models only) on page 40.

1

ENWW Removal and replacement procedures 37

Page 52

Top cover

3. Use a screwdriver to depress the tab (callout 1), and then remove the cover by sliding the it up 10 mm

(0.4 in), and then rotating the cover away from the product.

Figure 1-55 Remove the left front cover (2 of 2)

1

1. Remove the following components.

●

Rear cover. See

●

Left door. See

●

Left rear cover. See

●

Left front cover. See

●

Output bin flap. See

●

Control panel and control panel support. See

●

Scanner assembly. See

Rear cover on page 33.

Left door on page 33.

Left rear cover on page 36.

Left front cover on page 37.

Output bin flap on page 8.

Scanner assembly (X585 models only) on page 52.

Control panel (X585 models) on page 23.

38 Chapter 1 Removal and replacement ENWW

Page 53

2. Disconnect the control panel cable connectors (callout 1) from the main PCA.

Figure 1-56 Remove the top cover (1 of 4)

1

3. On the left side of the product, remove two screws (callout 1).

Figure 1-57 Remove the top cover (2 of 4)

1

ENWW Removal and replacement procedures 39

Page 54

4. Unthread the cables through the channel in the top cover.

NOTE: Unthread the cable with the 12-pin connector first, and then unthread the USB cable. Reverse

the procedure when reinstalling the cover. To pass the 12-pin connector through the top cover cable

channel, turn the connector sideways, parallel to the cable, and then pull it through the channel.

Figure 1-58 Remove the top cover (3 of 4)

5. X555 models: Lift the top cover to remove it.

X585 models: On the top cover, lift the left side part of the cover up and then slide the cover over the

scanner assembly support.

Figure 1-59 Remove the top cover (4 of 4)

1

2

Top cover cap (X555 models only)

1. Open the left door.

40 Chapter 1 Removal and replacement ENWW

Page 55

Figure 1-60 Remove the top cover cap (1 of 2)

2. Use a small, flat-blade screwdriver to loosen the top cover cap at three tab points (callout 1), and then

pull the cap from the product chassis.

Figure 1-61 Remove the top cover cap (2 of 2)

Front cover

1. Remove the following components:

●

Scanner assembly. See

●

Top cover. See

1

Scanner assembly (X585 models only) on page 52.

Top cover on page 38.

ENWW Removal and replacement procedures 41

Page 56

2. Remove one screw (callout 1).

Figure 1-62 Remove the front cover (1 of 2)

1

3. Remove the front cover.

NOTE: When removing the front cover, be aware that the power button (callout 1) has a cover that can

come loose when the front cover is removed.

Right cover

1. Remove the following components:

Figure 1-63 Remove the front cover (2 of 2)

1

●

Scanner assembly. See

Scanner assembly (X585 models only) on page 52.

●

Top cover. See

42 Chapter 1 Removal and replacement ENWW

Top cover on page 38.

Page 57

●

Front cover. See

Front cover on page 41.

●

Rear cover. See

2. Remove three screws (callout 1).

Figure 1-64 Remove the right cover (1 of 2)

Rear cover on page 33.

1

3. Remove the right cover from the product.

Figure 1-65 Remove the right cover (2 of 2)

ENWW Removal and replacement procedures 43

Page 58

Main assemblies

Document feeder mylar strip (X585 models)

1. Pull the latch (callout 1) to open the document feeder door.

Figure 1-66 Remove the document feeder mylar strip (1 of 4)

1

2. Locate the mylar strip.

Figure 1-67 Remove the document feeder mylar strip (2 of 4)

44 Chapter 1 Removal and replacement ENWW

Page 59

3. Carefully remove the mylar strip.

Figure 1-68 Remove the document feeder mylar strip (3 of 4)

4. Use your finger to remove any adhesive that remains after removing the mylar strip.

Figure 1-69 Remove the document feeder mylar strip (4 of 4)

Install a replacement document feeder mylar strip

Use the following guidelines when you install the replacement mylar strip:

1. Skin oils on the mylar strip can cause paper pickup problems. Wash your hands before handling the

replacement mylar strip.

2. When handling the replacement mylar strip, do not touch the adhesive portion of the strip.

ENWW Removal and replacement procedures 45

Page 60

3. Position the replacement mylar strip as shown, with the rounded corners on the strip facing the

document tray.

NOTE: Make sure that the adhesive side of the guide is face down.

Figure 1-70 Install a replacement document feeder mylar strip (1 of 2)

4. Press down firmly on the strip to adhere it to the product.

Figure 1-71 Install a replacement document feeder mylar strip (2 of 2)

Document feeder assembly (X585 models only)

1. At the back of the scanner assembly, use a Torx T10 screwdriver to remove two screws (callout 1) from

the scanner assembly back cover, and then pull the bottom of the cover away from the product to

remove the cover.

46 Chapter 1 Removal and replacement ENWW

Page 61

Figure 1-72 Remove the document feeder (1 of 6)

1

Reinstallation tip Line up the tabs on the bottom of the cover first, and then snap the rest of the

cover in place.

2. At the base of the document feeder hinges, use a Phillips screwdriver to remove two screws (callout 1).

Figure 1-73 Remove the document feeder (2 of 6)

1

ENWW Removal and replacement procedures 47

Page 62

3. Remove a cable clip screw (callout 1), two connectors (callout 2) on the scanner control board (SCB),

remove the ground wire screw (callout 3), and then remove one more screw (callout 4).

Figure 1-74 Remove the document feeder (3 of 6)

1

4

3

2

4. Remove one screw (callout 1), and then pull the SCB partially out of the product.

X585 Flow models only: Disconnect the flat flexible cable (callout 2).

Figure 1-75 Remove the document feeder (4 of 6)

1

2

48 Chapter 1 Removal and replacement ENWW

Page 63

5. X585 Flow models only: Unclip and remove the lower FFC ferrite (callout 1) from the assembly. This will

make it easier to install the document feeder.

Figure 1-76 Remove the document feeder (5 of 6)

1

6. Open the document feeder lid and tilt the assembly toward the back of the product as far as possible,

and then lift the document feeder up to remove it.

Figure 1-77 Remove the document feeder (6 of 6)

1

2

NOTE: If the document feeder is not tipped back as far as possible, it is difficult to remove.

Scanner control board (SCB) (X585 models only)

1. At the back of the scanner assembly, use a Torx T10 screwdriver to remove two screws (callout 1) from

the scanner assembly back cover, and then pull the bottom of the cover away from the product to

remove the cover.

ENWW Removal and replacement procedures 49

Page 64

Figure 1-78 Remove the SCB (1 of 6)

1

Reinstallation tip Line up the tabs on the bottom of the cover first, and then snap the rest of the

cover in place.

2. Remove a cable clip screw (callout 1), two connectors (callout 2) on the scanner control board (SCB),

remove the ground wire screw (callout 3), and then remove one more screw (callout 4).

Figure 1-79 Remove the SCB (2 of 6)

1

2

4

3

50 Chapter 1 Removal and replacement ENWW

Page 65

3. Remove one screw (callout 1), disconnect one connector (callout 2), and then pull the SCB partially out

of the product.

X585 Flow models only: Disconnect the flat flexible cable (callout 3).

Figure 1-80 Remove the SCB (3 of 6)

1

2

3

4. X585 Flow models only: Unclip and remove the lower FFC ferrite (callout 1) from the assembly. This will

make it easier to install the FFC.

NOTE: Unclip the ferrite by pulling it forward and rotating the back clips out first, then lift it up and

out.

Figure 1-81 Remove the SCB (4 of 6)

1

ENWW Removal and replacement procedures 51

Page 66

5. Disconnect two connectors (callout 1) and one FFC (callout 2).

Figure 1-82 Remove the SCB (5 of 6)

1 2

6. Pull the SCB away from the product to remove it.

Figure 1-83 Remove the SCB (6 of 6)

Scanner assembly (X585 models only)

1. Remove the following components:

●

Output bin. See

●

Document feeder. See

●

SCB. See

52 Chapter 1 Removal and replacement ENWW

Output bin on page 8.

Document feeder assembly (X585 models only) on page 46.

Scanner control board (SCB) (X585 models only) on page 49.

Page 67

●

Rear cover. See

Rear cover on page 33.

●

Control panel. See

2. Use a flat-blade screwdriver to remove the scanner base cover.

NOTE: This panel can be difficult to remove and might require some force to release it from the

scanner assembly. Reinstalling also requires some force to snap the cover in place.

Figure 1-84 Remove the scanner (1 of 7)

Control panel (X585 models) on page 23.

3. On the left side of the product, remove two screws (callout 1).

NOTE: The rear screw has a rubber plug over it. Use a flat-blade screwdriver to remove the plug to

access the screw.

Figure 1-85 Remove the scanner (2 of 7)

1

ENWW Removal and replacement procedures 53

Page 68

4. At the front of the product, inside the control panel support, remove two screws (callout 1), and then

pull the support away from the front of the unit.

Figure 1-86 Remove the scanner (3 of 7)

1

5. In the space where the control panel support was installed, remove one screw (callout 1).

Figure 1-87 Remove the scanner (4 of 7)

1

54 Chapter 1 Removal and replacement ENWW

Page 69

6. Unthread the two scanner cables.

Figure 1-88 Remove the scanner (5 of 7)

7. Move the scanner assembly toward the left side of the product.

Figure 1-89 Remove the scanner (6 of 7)

ENWW Removal and replacement procedures 55

Page 70

8. Lift the assembly to remove it.

Power supply

Figure 1-90 Remove the scanner (7 of 7)

CAUTION: Make sure that the power cable is disconnected from the product.

1. Remove the following components.

●

Output bin. See

●

Rear cover. See

2. Disconnect one connector (callout 1), and remove one screw (callout 2).

Figure 1-91 Remove the power supply (1 of 3)

Output bin on page 8.

Rear cover on page 33.

2

1

56 Chapter 1 Removal and replacement ENWW

Page 71

3. On the right side of the product, remove two screws (callout 1). Using a magnetic Torx T10 screwdriver

can be helpful when removing these screws.

Figure 1-92 Remove the power supply (2 of 3)

1

4. Slide the power supply out of the back side of the product.

Figure 1-93 Remove the power supply (3 of 3)

Print mechanism kits

Acclimation

Cold temperatures can affect the print mechanism

The print mechanism kit will not operate properly below 5° C (41° F). The product control panel will display an

error message.

ENWW Removal and replacement procedures 57

Page 72

Cold temperatures during kit storage or transportation might require extra time before installation to allow

the kit and ink cartridges to adjust to a warmer temperature (acclimation). Exposure to extended periods of

heat usually requires a minimal amount of acclimation time.

Exposure to extended periods of cold can cause condensation (moisture) to form on the parts when moved

into warmer areas. Condensation indicates the need for an acclimation period until the condensation

disappears. Exposure to extended cold (below 0° C (32° F)) can cause the ink inside the kit to freeze. The kit

and ink cartridges were designed to be exposed to freezing temperatures without being damaged. However,

if the ink is frozen and cannot flow properly during installation or during printing, errors might be reported on

the control panel or print quality might be poor, or possible damage will occur.

CAUTION: When unsure if the kit and ink cartridges need to be acclimated, always proceed as if they do

need to be acclimated. Acclimation will not damage these kits, but the failure to acclimate them can cause

errors or print quality issues, or possible damage can occur.

Acclimation process

1. Unpack the kit.

2. Open the doors or remove the covers, and pull out the input tray.

3. Leave the kit in the repair area until there is no visible condensation before proceeding with installation.

The print mechanism kit might need 2 to 4 hours to thaw depending on how frozen the shipping fluid is. The

shipping fluid is contained in the printbar, which is inside the print mechanism kit assembly.

The product might display error codes if there is an attempt to install a kit that is not acclimated completely.

Ink cartridge acclimation

Unpack the ink cartridges. It is important to remove the ink cartridges from their packaging and to separate

them to speed the acclimation process. The packaging will act as an insulation barrier and prevent frozen ink

from thawing quickly.

The ink cartridges might need 2 to 4 hours to thaw, depending on how frozen the ink is.

Move the ink cartridges into a warmer area and keep them separated to accelerate the thawing process.

Do not install ink cartridges that show visible condensation on the outside walls.

CAUTION: Check each ink cartridge’s electrical connection (gold colored contacts) for condensation before

installing them. Remove condensation by carefully blotting the electrical connections with a lint-free cloth.

To prevent damage, do not wipe or drag the cloth across the connections.

Installation notes

Keep the packaging

Do not destroy the box in which the new mechanism kit was shipped. You will use the box to return the

defective mechanism.

Necessary tools

This process requires the following tools:

58 Chapter 1 Removal and replacement ENWW

Page 73

●

Magnetized T10 Torx screwdriver

●

Magnetized Phillips no. 2 screwdriver

●

Small flat-blade screwdriver

Avoid cartridge issues

If the customer has activated the anti-theft feature on the ink cartridges, those cartridges must be installed

into the new mechanism after the initial purge and calibration – which uses the startup cartridges – but

before 15 pages are printed on the new mechanism.

Use the correct formatter

Do not power on the new mechanism with any formatter other than the formatter from the old mechanism.

Using another formatter will cause data loss and require another mechanism kit replacement.

Install the print mechanism kit (X555 models)

1. Remove the new mechanism kit from the box by lifting it out by the bag around it.

2. Remove all the blue shipping tape, and be sure to remove the cartridge shipping restraint in the ink

cartridge cavity.

NOTE: The shipping tape and restraint are reusable. Use the shipping tape and shipping restraint from

the new mechanism to prepare the old mechanism for shipping.

3. Install the startup cartridges included with the kit and load paper into Tray 2.

4. Turn off the old unit, and then disconnect the power cord and either the USB cable or the network cable.

5. From the old unit, remove the cartridges, and then insert the shipping cartridge restraint from the new

print mechanism into the old unit.

NOTE: You can re-use the old cartridges in the future but must use the startup cartridges sent with

the new kit for the setup initialization and calibration.

6. From the right side of the old product, remove the output bin. See Output bin on page 8.

7. From the rear of the old product, remove the rear cover. See

NOTE: In order to retain the model number, serial number, and regulatory information, the new kit

will contain a rear cover, but the rear cover from the failed unit needs to be moved to the new kit.

8. Remove the control panel. See Control panel (X555 models) on page 21.

9. Reverse the removal procedures above to attach the control panel to the new kit. Do not reinstall the

output bin or rear cover at this time.

10. From the front of the old product, loosen the thumbscrew on the formatter cover. Pull the cover

straight up to remove it.

11. From the rear of the old product, loosen the remaining thumbscrew on the formatter assembly. Use the

handle on the front of the product to pull the formatter assembly out of the product.

Rear cover on page 33.

12. Reverse the removal procedures to reinstall the formatter assembly in the new kit.

NOTE: Do not power on the new mechanism with any formatter other than the formatter from the old

unit. Using another formatter will cause data loss and require another product kit replacement.

ENWW Removal and replacement procedures 59

Page 74

13. From the rear of the old product, disconnect the power supply connector and remove one screw from

the power supply. See

14. From the right side of the product, remove two screws (use a magnetized T10 Torx screwdriver), and

pull the power supply straight out from the rear of the product.

15. Reverse the removal procedures to reinstall the power supply into the new unit.

NOTE: The new print mechanism includes a new power supply cable. Use this cable with the new print

mechanism, and return the old power supply cable with the defective unit.

16. Reinstall the formatter cover, rear cover, and output bin.

Reinstallation tip Reinstall the rear cover by inserting the right side tabs into the rear left cover, and

then snapping the remaining clips in place, moving to the left.

17. Reconnect the USB cable or the network cable, and then reconnect the power cord.

18. Turn on the product, and then allow it to initialize and calibrate. These processes will take

approximately 26 minutes. Make sure that Tray 2 contains paper.

NOTE: While the product is initializing, re-tape and box up the defective mechanism to be returned.

Install the print mechanism kit (X585 models)

1. Remove the new mechanism kit from the box by lifting it out by the bag around it.

Power supply on page 56.

2. Remove all the blue shipping tape, and be sure to remove the cartridge shipping restraint in the ink

cartridge cavity.

NOTE: The shipping tape and restraint are reusable. Use the shipping tape and shipping restraint from

the new mechanism to prepare the old mechanism for shipping.

3. Install the startup cartridges included with the kit and load paper into Tray 2.

4. Turn off the old unit, and then disconnect the power cord and either the USB cable or the network cable.

5. From the old unit, remove the cartridges, and then insert the shipping cartridge restraint from the new

print mechanism into the old unit.

NOTE: You can re-use the old cartridges in the future but must use the startup cartridges sent with

the new kit for the setup initialization and calibration.

6. From the right side of the old product, remove the output bin. See Output bin on page 8.

7. From the rear of the product, remove the rear cover. See

NOTE: In order to retain the model number, serial number, and regulatory information, the new mech

kit will contain a rear cover, but the rear cover from the failed unit needs to be moved to the new kit.

8. Remove the control panel. See Control panel (X585 models) on page 23.

NOTE: On models with the work flow keyboard, pull the keyboard out partly to provide more room to

remove the thumbscrew.

Rear cover on page 33.

60 Chapter 1 Removal and replacement ENWW

Page 75

9. From the front of the product, remove the two T10 Torx screws that secure the control panel support,

and then slide the support toward the front of the product to remove it.

NOTE: Hewlett-Packard recommends using a magnetic Torx driver to remove the control panel

support screws.

10. From the front of the product, remove the integrated scanner assembly retention screw. See Scanner

assembly (X585 models only) on page 52.

11. At the rear of the product, remove the two screws from the scanner assembly rear cover. Pull the

bottom of the cover away from the product to remove the rear scanner cover and chimney cover

assembly.

Reinstallation tip Align the lower retention hooks on the cover, and then snap the cover into place.

12. From the right side of the product, at the bottom of the scanner assembly, use a flat-blade screwdriver

to remove the scanner bottom cover. See

NOTE: Removing the cover requires a significant amount of force.

13. At the rear of the product, remove the power cable (the red and black cable) and the IPASS cable (the

red cables inside a black sheath).

●

On the power cable, depress the connector lock and lift the connector to unhook it. Remove the

cable from the cable stay. Pull the cable down through the channel.

Scanner assembly (X585 models only) on page 52.

●

On the IPASS cable, depress the connector lock to un-hook it. Pull the cable down through the

channel keeping the front of the connector facing the rear of the product to make it easier to pull

through the channel.

14. From the left side of the product, remove the two screws from the scanner.

NOTE: The rear screw has a rubber cover over it. Use a small flat-blade screwdriver to remove the

plug and gain access to the screw.

15. From the front of the product, slide the document feeder/scanner assembly toward the left side, and

then lift it to remove it.

16. The document feeder/scanner assembly now can be installed on the new kit. From the front of the new

kit, first align the cut out in the front of the assembly sheet metal with the control panel cable channel,

and then slide the assembly toward the right side to lock it into place.

17. Reverse the removal procedures above to attach the document feeder/scanner assembly and control

panel to the new kit. Do not reinstall the output bin, scanner bottom cover, or rear cover at this time.

18. From the front of the product, loosen the thumbscrew on the formatter cover. Pull the cover straight up

to remove it.

19. From the rear of the product, loosen the remaining thumbscrew on the formatter assembly. Use the

handle on the front of the product to pull the formatter assembly out of the product.

20. Reverse the removal procedures to reinstall the formatter assembly in the new kit.

NOTE: Do not power on the new mechanism with any formatter other than the formatter from the old

unit. Using another formatter will cause data loss and require another mechanism kit replacement.

ENWW Removal and replacement procedures 61

Page 76

21. From the rear of the product, disconnect the power supply connector and remove one screw from the

power supply. See

Power supply on page 56.

22. From the right side of the product, remove two screws (use a magnetized T10 Torx screwdriver), and

pull the power supply straight out from the rear of the old product.

23. Reverse the removal procedures to reinstall the power supply into the new unit.

NOTE: The new print mechanism includes a new power supply cable. Use this cable with the new print

mechanism, and return the old power supply cable with the defective unit.

24. Reinstall the formatter cover, the scanner base cover, the rear cover, and the output bin.

Reinstallation tip Reinstall the rear cover starting on the right side and snapping in the retaining clips

moving to the left.

25. Reconnect the USB cable or the network cable, and then reconnect the power cord.

26. Turn on the product, and then allow it to initialize and calibrate. These processes will take

approximately 26 minutes. Make sure that Tray 2 contains paper.

NOTE: While the product is initializing, re-tape and box up the defective mechanism to be returned.

62 Chapter 1 Removal and replacement ENWW

Page 77

2 Parts and diagrams

NOTE: In this chapter, part numbers are listed only for available replaceable parts.

●

Order parts by authorized service providers

●

How to use the parts lists and diagrams

●

Assembly locations—X555 models

●

Assembly locations—X585 models

●

Covers, control panels, and doors—X555 models

●

Covers, control panels, and doors—X585 models

●

Internal assemblies—all models

●

Scanner/document feeder assembly—X585 models

●

Alphabetical parts list

●

Numerical parts list

ENWW 63

Page 78

Order parts by authorized service providers

Order replacement parts

Table 2-1 Order parts, accessories, and supplies

Order supplies www.hp.com//go/suresupply.

Order genuine HP parts or accessories

Order through service or support providers Contact an HP-authorized service or support provider.

Order using the HP Embedded Web Server (EWS) To access, in a supported Web browser on your computer, enter the product IP

Related documentation and software

Table 2-2 Related documentation and software

Item Description Part number

HP Officejet Enterprise Color X555 User Guide Product user guide C2S11-90904

HP Officejet Enterprise Color MFP X585 User Guide B5L04-90904

HP Officejet Enterprise Color X555 and MFP X585 Repair Manual English repair manual (this

HP Officejet Enterprise Color X555 and MFP X585

Troubleshooting Manual

www.hp.com/buy/parts

address or host name in the address/URL field. The EWS contains a link to the

HP SureSupply Web site, which provides options for purchasing Original

HP supplies.

manual)

English troubleshooting

manual

Supplies part numbers

The following supplies are available for the product.

Table 2-3 Supplies part numbers

Item Part number Product number Cartridge number Type/size

Ink cartridges D8J10-67901 D8J10A HP 980A Standard-capacity black

D8J07-67901 D8J07A HP 980A Standard-capacity cyan

D8J09-67901 D8J09A HP 980A Standard-capacity yellow

D8J08-67901 D8J08A HP 980A Standard-capacity

ink cartridge with HP

Officejet pigment ink

ink cartridge with HP

Officejet pigment ink

ink cartridge with HP

Officejet pigment ink

magenta ink cartridge

with HP Officejet pigment

ink

64 Chapter 2 Parts and diagrams ENWW

Page 79

Table 2-3 Supplies part numbers (continued)

Item Part number Product number Cartridge number Type/size

Ink collection unit B5L04-67906 B5L09A HP Officejet Enterprise ink

Document feeder

roller maintenance

kit

(X585 models)

L2725-60002 L2718A Replacement rollers for

collection unit and duplex

module

X585 document feeder

NOTE: For information about the yield for the cartridges, see www.hp.com/go/pageyield. Actual yield

depends on specific use.

Some ink cartridges might not be available in all countries/regions.

The following accessories are available for the product.

Table 2-4 Product accessories

Item Part number Product number Description

Paper-handling

accessory

Paper tray cassette B5L04-67924 HP Officejet Enterprise 500-sheet paper tray cassette

B5L04-67923 B5L07A HP Officejet Enterprise 500-sheet feeder and paper

tray assembly (optional Tray 3)

(optional Tray 3)

Product cabinet and

stand

Network accessory J8029-61001 J8029A HP NFC/Wireless Direct Accessory

Fax accessory (X585

models only)

Wireless print server J8026-61001 J8026A USB wireless print server

USB cable 8121-0868 2-meter A-to-B cable

B5L04-67925 B5L08A HP Officejet Enterprise printer cabinet and stand

A2W77-67910 CC487A HP MFP Analog Fax Accessory 500

Customer self-repair parts

The following customer self-repair parts are available for the product.

Each kit includes parts and installation instructions. The customer self repair (CSR) level indicates the

expected difficulty the customer will experience when replacing this part:

●

A: Easy

●

B: More difficult

Table 2-5 Customer self-repair parts

Item Description CSR level Part number

Tray 2 cassette 500-sheet paper tray A B5L04-67911

ENWW Order parts by authorized service providers 65

Page 80

Table 2-5 Customer self-repair parts (continued)

Item Description CSR level Part number

Ink collection unit Waste ink collection unit and duplex module A B5L04-67906

Output bin Face-down output bin assembly A B5L04-67914

Eject assembly flap Output bin flap B B5L04-67913

Control panel assembly—X555

models

Control panel assembly—X585

models

Control panel keyboard

assembly, US English—X585

Flow models