2-139

MOTION SENSING

AND CONTROL

General Purpose Motion

Control ICs

Technical Data

HCTL-1100 Series

Description

The HCTL-1100 series is a high

performance, general purpose

motion control IC, fabricated in

HP CMOS technology. It frees the

host processor for other tasks by

performing all the time-intensive

functions of digital motion

control. The programmability of

all control parameters provides

maximum flexibility and quick

Features

• Low Power CMOS

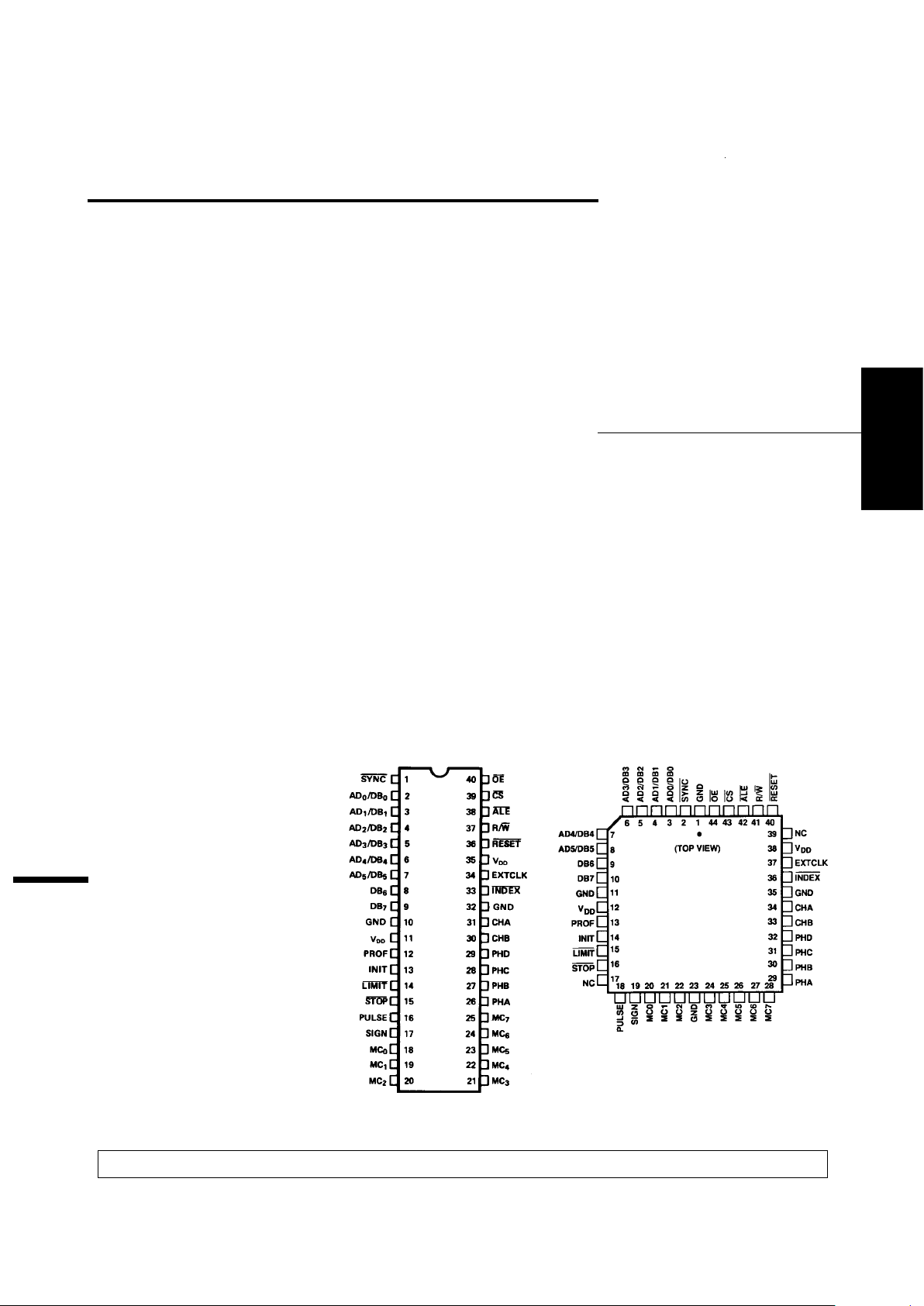

• PDIP and PLCC Versions

Available

• Enhanced Version of the

HCTL-1000

• DC, DC Brushless, and Step

Motor Control

• Position and Velocity

Control

• Programmable Digital Filter

and Commutator

• 8-Bit Parallel, and PWM

Motor Command Ports

• TTL Compatible

• SYNC Pin for Coordinating

Multiple HCTL-1100 ICs

• 100 kHz to 2 MHz Operation

• Encoder Input Port

design of control systems with a

minimum number of components.

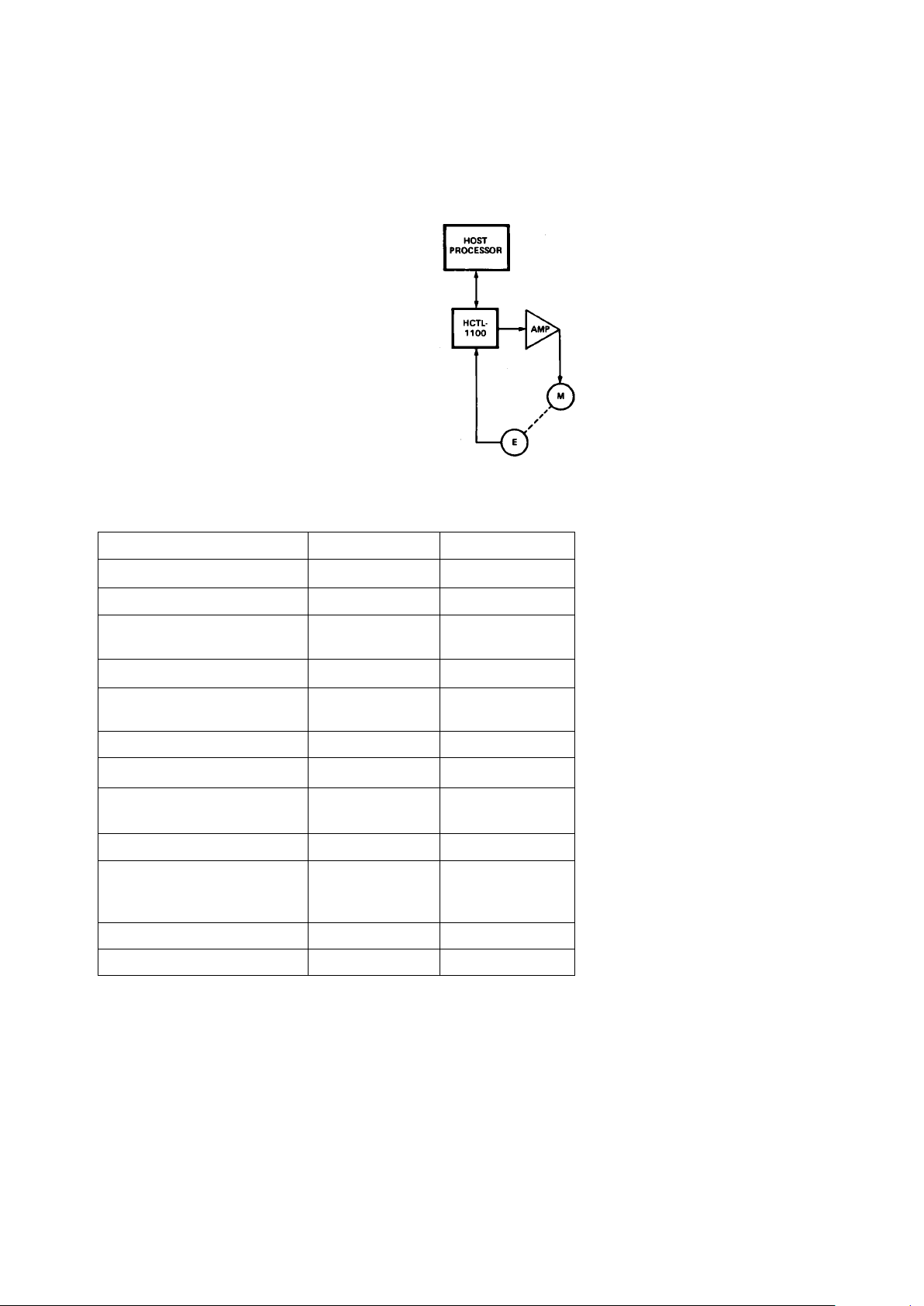

In addition to the HCTL-1100, the

complete control system consists

of a host processor to specify

commands, an amplifier, and a

motor with an incremental

encoder (such as the HP HEDS5XXX, -6XXX, -9XXX series). No

analog compensation or velocity

feedback is necessary.

Pinouts

ESD WARNING: NORMAL HANDLING PRECAUTIONS SHOULD BE TAKEN TO AVOID STATIC DISCHARGE.

H

5965-5893E

2-140

Applications

Typical applications for the

HCTL-1100 include printers,

medical instruments, material

handling machines, and industrial

automation.

HCTL-1100 vs.

HCTL-1000

The HCTL-1100 is designed to

replace the HCTL-1000. Some

differences exist, and some

enhancements have been added.

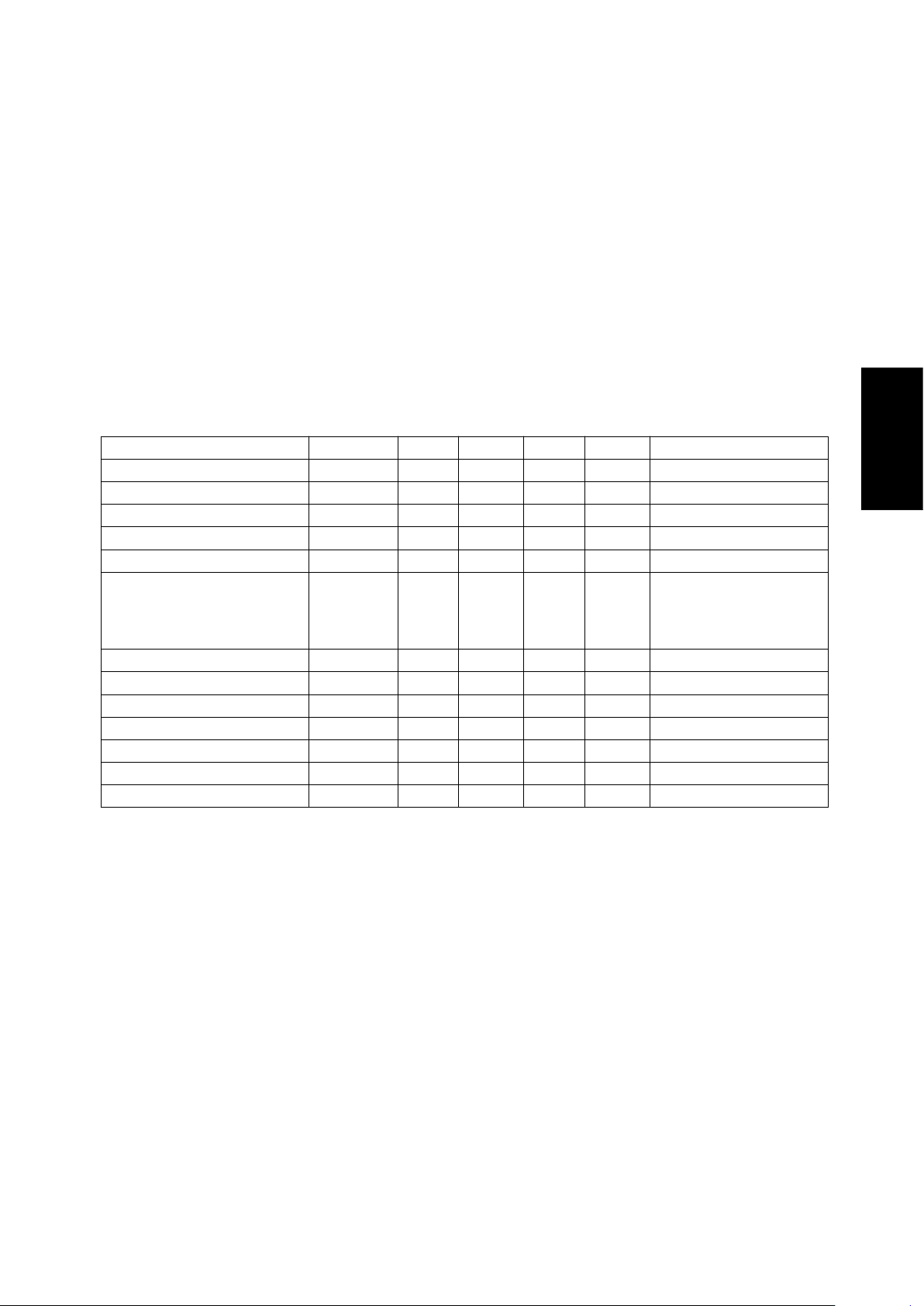

Comparison of HCTL-1100 and HCTL-1000

Description HCTL-1100 HCTL-1000

Max. Supply Current 30 mA 180 mA

Max. Power Dissipation 165 mW 950 mW

Max. Tri-State Output

Leakage Current 150 nA 10 µA

Operating Frequency 100 kHz-2 MHz 1 MHz-2 MHz

Operating Temperature

Range -20°C to +85°C0°C to 70°C

Storage Temperature Range -55°C to +125°C-40°C to +125°C

Synchronize 2 or More ICs Yes –

Preset Actual Position

Registers Yes –

Read Flag Register Yes –

Limit and Stop Pins Must be pulled Can be left

up to VDD if floating if not

not used. used.

Hard Reset Required Recommended

PLCC Package Available Yes –

System Block Diagram

2-141

MOTION SENSING

AND CONTROL

Theory of Operation

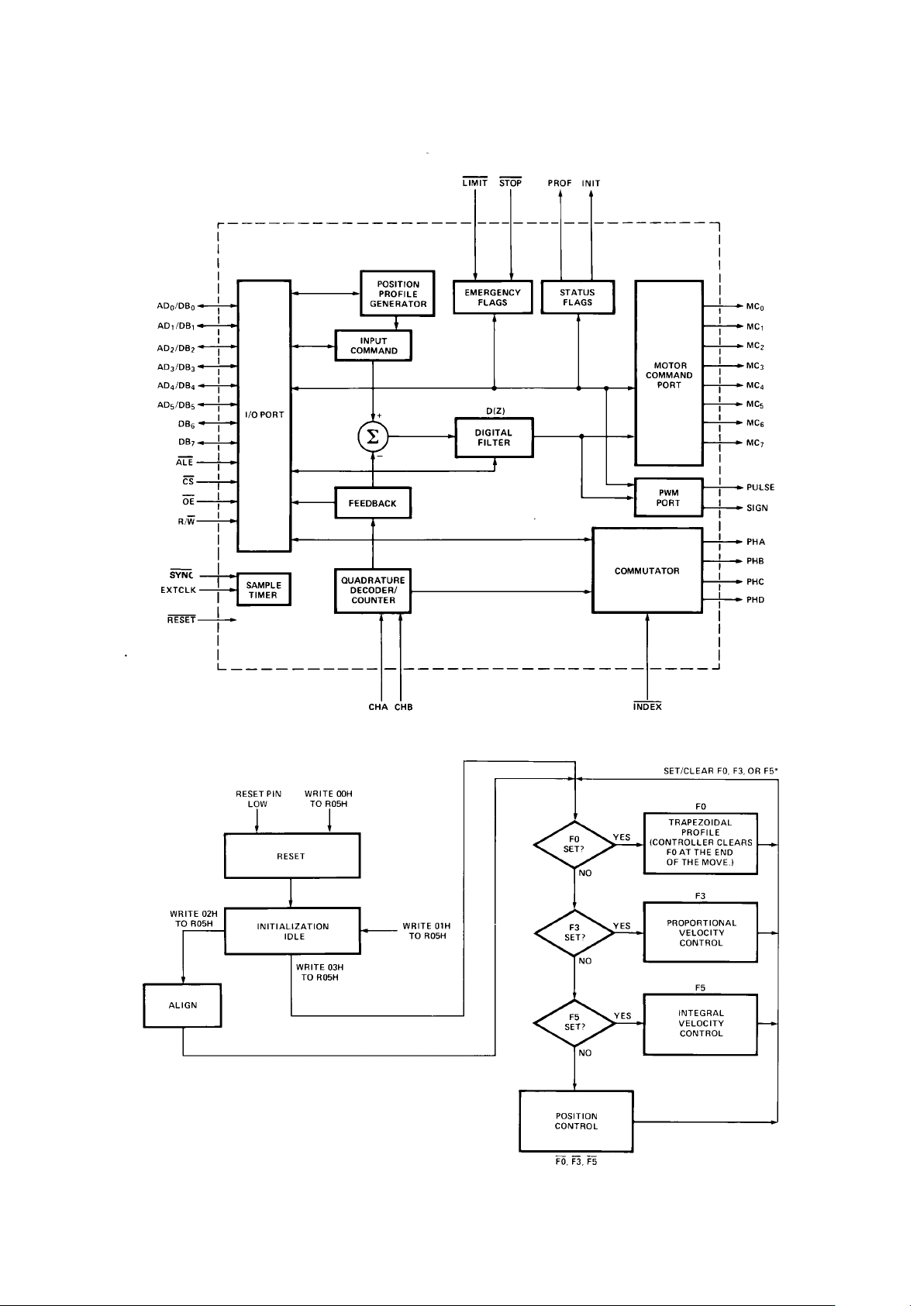

The HCTL-1100 is a general purpose motor controller which

provides position and velocity

control for DC, DC brushless and

stepper motors. The internal

block diagram of the HCTL-1100

is shown in Figure 1. The HCTL1100 receives its input commands

from a host processor and

position feedback from an

incremental encoder with quadrature output. An 8-bit bi-directional

multiplexed address/data bus

interfaces the HCTL-1100 to the

host processor. The encoder

The resident Position Profile

Generator calculates the necessary profiles for Trapezoidal Profile Control and Integral Velocity

Control. The HCTL-1100 compares the desired position (or

velocity) to the actual position (or

velocity) to compute compensated

motor commands using a programmable digital filter D(z). The

motor command is externally

available at the Motor Command

port as an 8-bit byte and at the

PWM port as a Pulse Width

Modulated (PWM) signal.

The HCTL-1100 has the capability

of providing electronic commutation for DC brushless and

stepper motors. Using the

encoder position information, the

motor phases are enabled in the

correct sequence. The commutator is fully programmable to

encompass most motor/encoder

combinations. In addition, phase

overlap and phase advance can be

programmed to improve torque

ripple and high speed performance. The HCTL-1100 contains a

number of flags including two

externally available flags, Profile

and Initialization, which allow the

user to see or check the status of

the controller. It also has two

emergency inputs, Limit and Stop,

which allow operation of the

HCTL-1100 to be interrupted

under emergency conditions.

The HCTL-1100 controller is a

digitally sampled data system.

While information from the host

processor is accepted asynchronously with respect to the

control functions, the motor

command is computed on a

discrete sample time basis. The

sample timer is programmable.

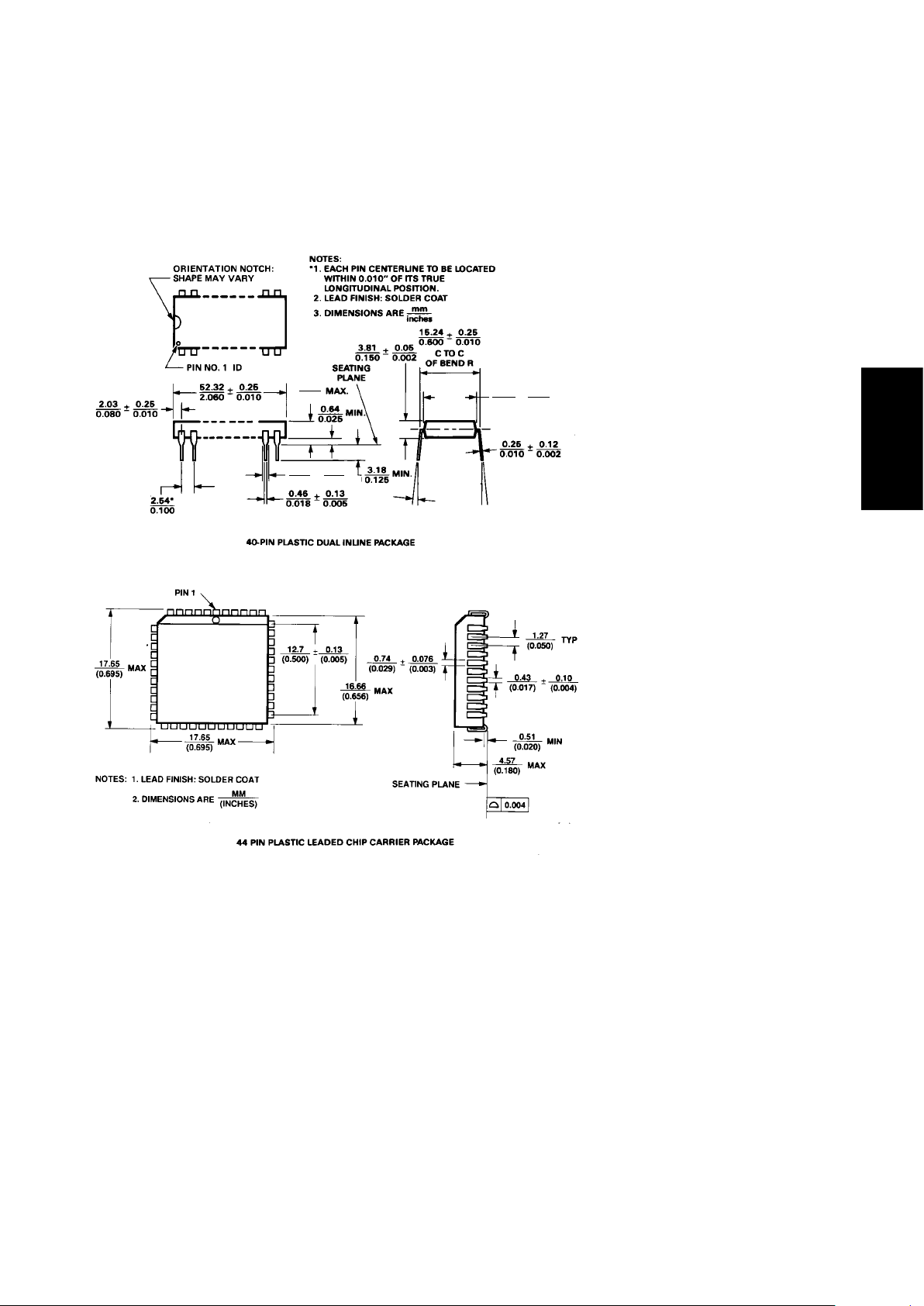

Package Dimensions

feedback is decoded into

quadrature counts and a 24-bit

counter keeps track of position.

The HCTL-1100 executes any one

of four control algorithms

selected by the user. The four

control modes are:

• Position Control

• Proportional Velocity Control

• Trapezoidal Profile Control for

point to point moves

• Integral Velocity Control with

continuous velocity profiling

using linear acceleration

4.83

0.190

1.27

0.050

±

0.15

0.006

0-15°

13.72

0.540

13.72

0.540

0.25

0.010

±

2-142

Figure 1. Internal Block Diagram.

Figure 2. Operating Mode Flowchart.

2-143

MOTION SENSING

AND CONTROL

Electrical Specifications

Absolute Maximum Ratings

Operating Temperature, T

A

...................................................................

-20°C to 85°C

Storage Temperature, T

S

......................................................................

-55°C to 125°C

Supply Voltage, V

DD

......................................................................................

-0.3 V to 7 V

Input Voltage, V

IN

.........................................................................

-0.3 V to VDD +0.3 V

Maximum Operating Clock Frequency, f

CLK

...............................................

2 MHz

DC Electrical Characteristics

VDD = 5 V ± 5%; TA = -20°C to +85°C

Parameter Symbol Min. Typ. Max. Units Test Conditions

Supply Voltage V

DD

4.75 5.00 5.25 V

Supply Current I

DD

15 30 mA

Input Leakage Current I

IN

10 100 nA VIN = 0.00 and 5.25 V

Input Pull-Up Current

SYNC PIN I

PU

- 40 ± 150 µAVIN = 0.00 V

Tristate Output Leakage I

OZ

10 -150 nA Sync, LIMIT, STOP

Current pin #35 (PDIP)

V

OUT

= -0.3 to 5.25 V

pin #38 (PLCC)

Input Low Voltage V

IL

-0.3 0.8 V

Input High Voltage V

IH

2.0 V

DD

V

Output Low Voltage V

OL

-0.3 0.4 V IOL = 2.2 mA

Output High Voltage V

OH

2.4 V

DD

VIOH = -200 µA

Power Dissipation P

D

75 165 mW

Input Capacitance C

IN

20 pF

Output Capacitance C

OUT

100 pF

2-144

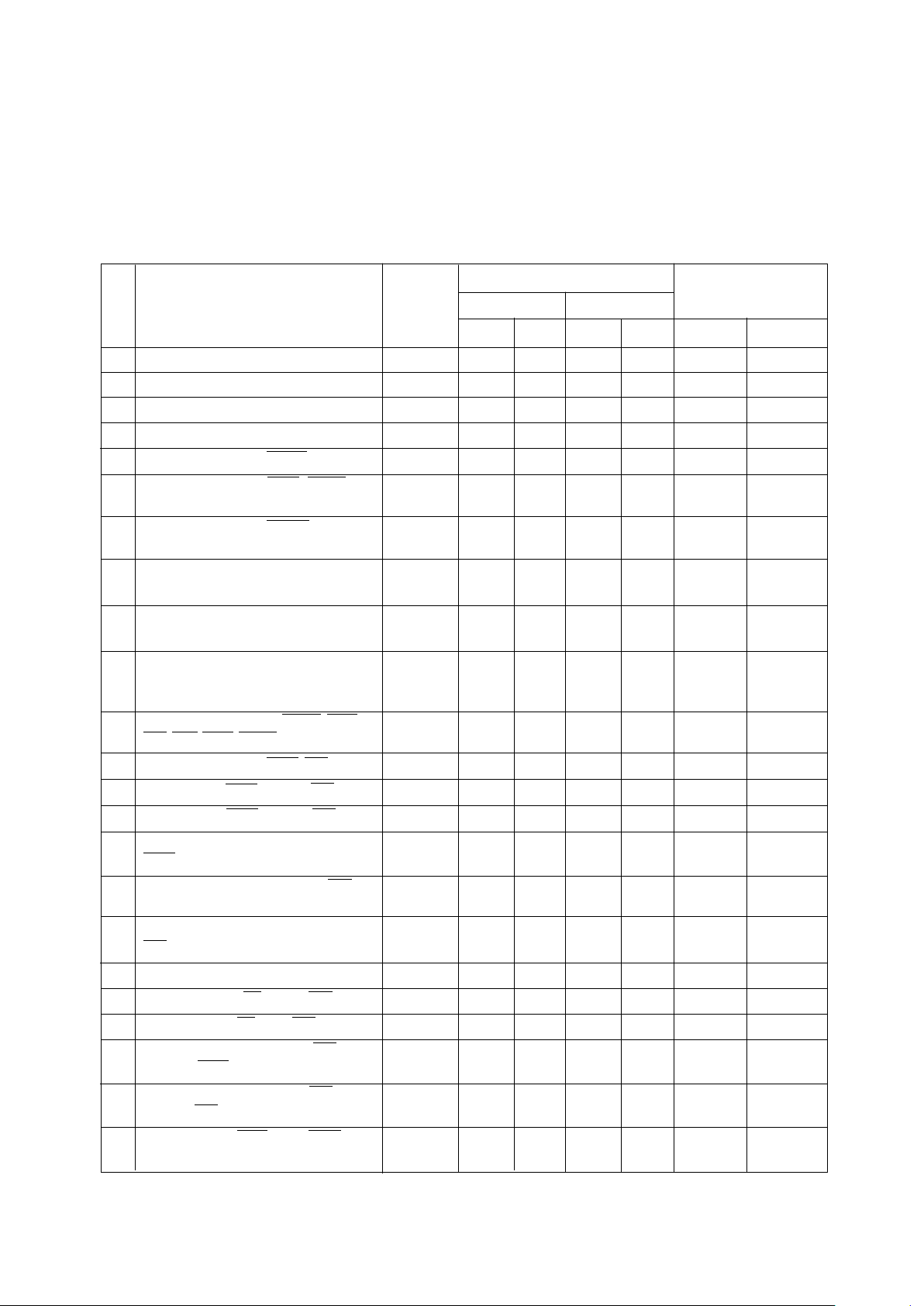

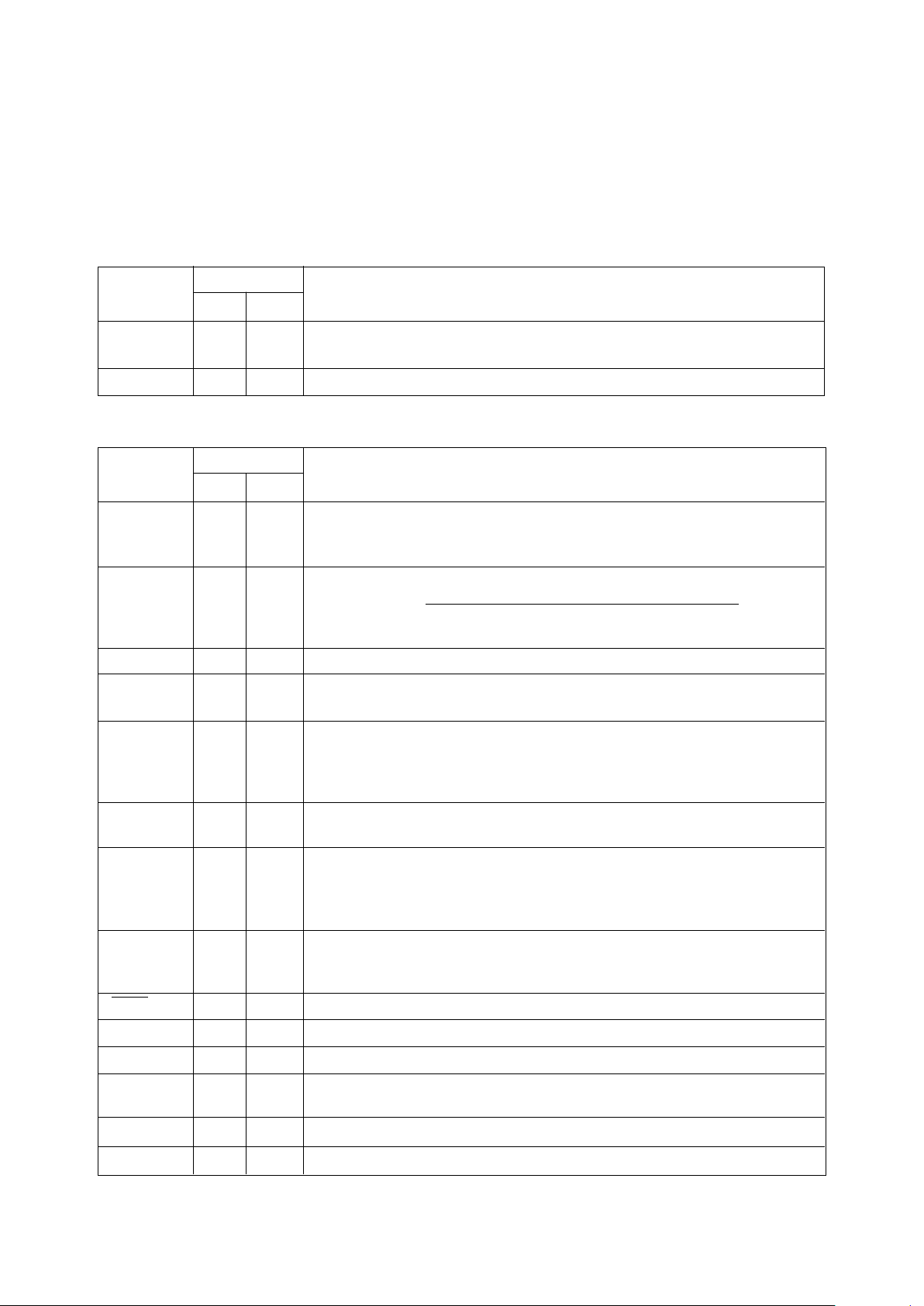

AC Electrical Characteristics

VDD = 5 V ± 5%; TA = -20°C to +85°C; Units = nsec

Clock Frequency

Formula*

2 MHz 1 MHz

ID

# Signal Symbol Min. Max. Min. Max. Min. Max.

1 Clock Period (clk) t

CPER

500 1000

2 Pulse Width, Clock High t

CPWH

230 300

3 Pulse Width, Clock Low t

CPWL

200 200 200

4 Clock Rise and Fall Time t

CR

50 50 50

5 Input Pulse Width Reset t

IRST

2500 5000 5 clk

6 Input Pulse Width Stop, Limit t

IP

600 1100 1 clk

+ 100 ns

7 Input Pulse Width Index, Index t

IX

1600 3100 3 clk

+ 100 ns

8 Input Pulse Width CHA, CHB t

IAB

1600 3100 3 clk

+ 100 ns

9 Delay CHA to CHB Transition t

AB

600 1100 1 clk

+ 100 ns

10 Input Rise/Fall Time CHA, CHB,

Index t

IABR

450 900 900 (clk

< 1 MHz)

11 Input Rise/Fall Time Reset, ALE,

CS, OE, Stop, Limit t

IR

50 50 50

12 Input Pulse Width ALE, CS t

IPW

80 80 80

13 Delay Time, ALE Fall to CS Fall t

AC

50 50 50

14 Delay Time, ALE Rise to CS Rise t

CA

50 50 50

15 Address Setup Time Before

ALE Rise t

ASR1

20 20 20

16 Address Setup Time Before CS t

ASR

20 20 20

Fall

17 Write Data Setup Time Before

CS Rise t

DSR

20 20 20

18 Address/Data Hold Time t

H

20 20 20

19 Setup Time, R/W Before CS Rise t

WCS

20 20 20

20 Hold Time, R/W After CS Rise t

WH

20 20 20

21 Delay Time, Write Cycle, CS

Rise to ALE Fall t

CSAL

1700 3400 3.4 clk

22 Delay Time, Read/Write, CS

Rise to CS Fall t

CSCS

1500 3000 3 clk

23 Write Cycle, ALE Fall to ALE

Fall For Next Write t

WC

1830 3530 3.7 clk

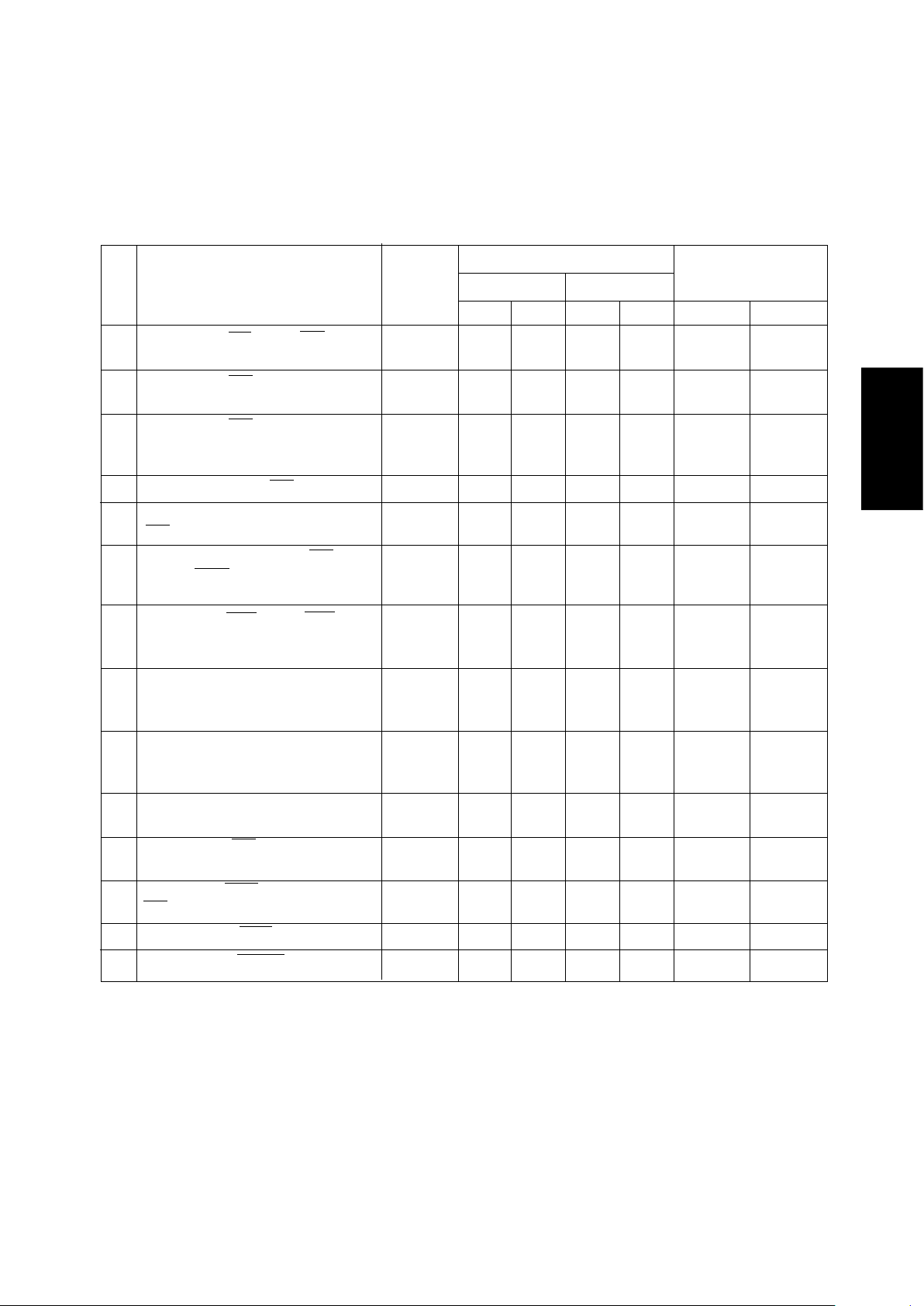

2-145

MOTION SENSING

AND CONTROL

Clock Frequency

Formula*

2 MHz 1 MHz

ID

# Signal Symbol Min. Max. Min. Max. Min. Max.

24 Delay Time, CS Rise to OE Fall t

CSOE

1700 3200 3 clk

+ 200 ns

25 Delay Time, OE Fall to Data

Bus Valid t

OEDB

100 100 100

26 Delay Time, CS Rise to Data

Bus Valid t

CSDB

1800 3300 3 clk

+ 300 ns

27 Input Pulse Width OE t

IPWOE

100 100 100

28 Hold Time, Data Held After

OE Rise t

DOEH

20 20 20

29 Delay Time, Read Cycle, CS

Rise to ALE Fall t

CSALR

1820 3320 3 clk

+ 320 ns

30 Read Cycle, ALE Fall to ALE

Fall For Next Read t

RC

1950 3450 3 clk

+ 450 ns

31 Output Pulse Width, PROF,

INIT, Pulse, Sign, PHA-PHD,

MC Port t

OF

500 1000 1 clk

32 Output Rise/Fall Time, PROF,

INIT, Pulse, Sign, PHA-PHD,

MC Port t

OR

20 150 20 150 20 150

33 Delay Time, Clock Rise to

Output Rise t

EP

20 300 20 300 20 300

34 Delay Time, CS Rising to MC

Port Valid t

CSMC

1600 3200 3.2 clk

35 Hold Time, ALE High After

CS Rise t

ALH

100 100 100

36 Pulse Width, ALE High t

ALPWH

100 100 100

37 Pulse Width, SYNC Low t

SYNC

9000 18000 18 clk

*General formula for determining AC characteristics for other clock frequencies (clk), between 100 kHz and 2 MHz.

AC Electrical Characteristics (continued).

2-146

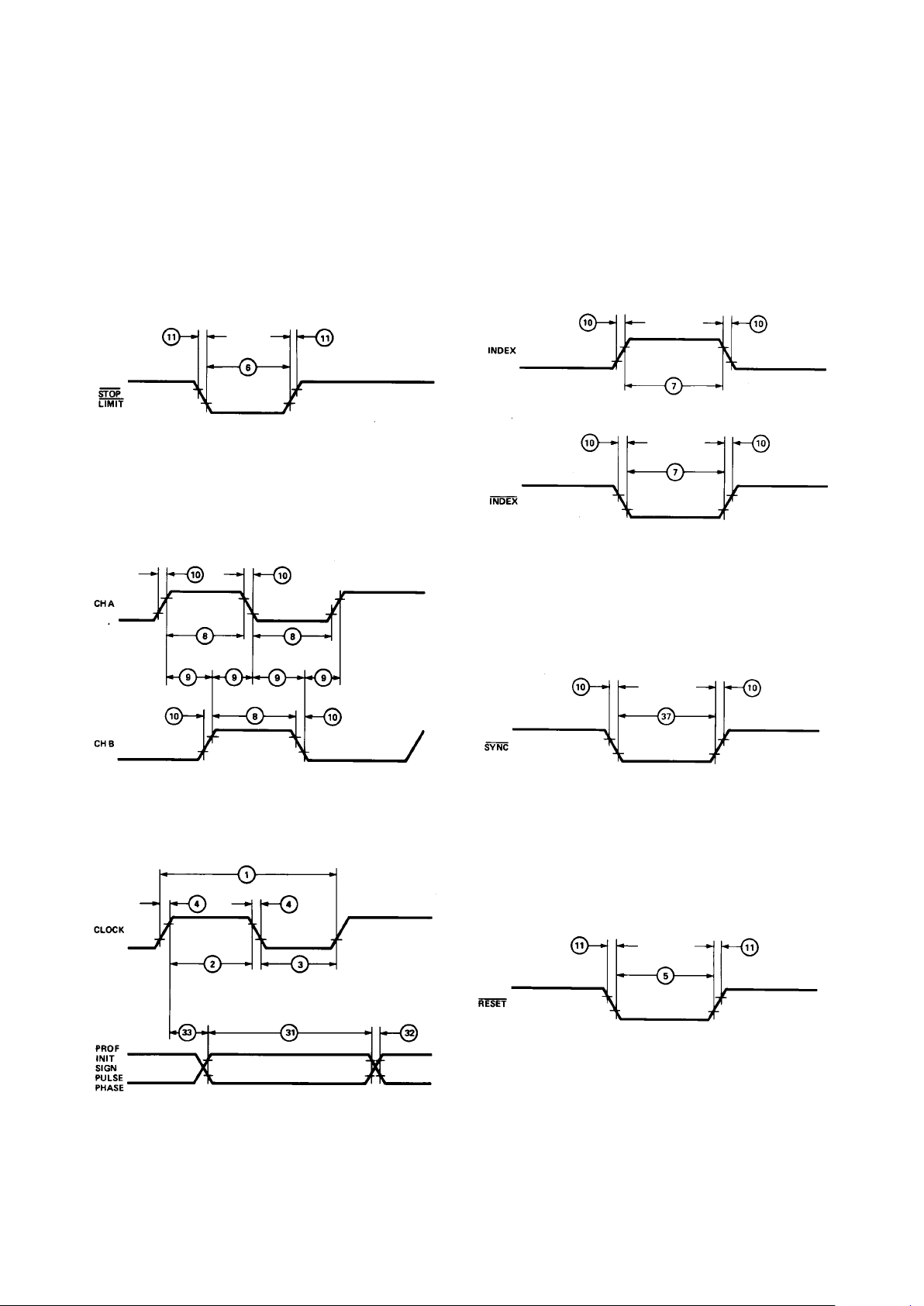

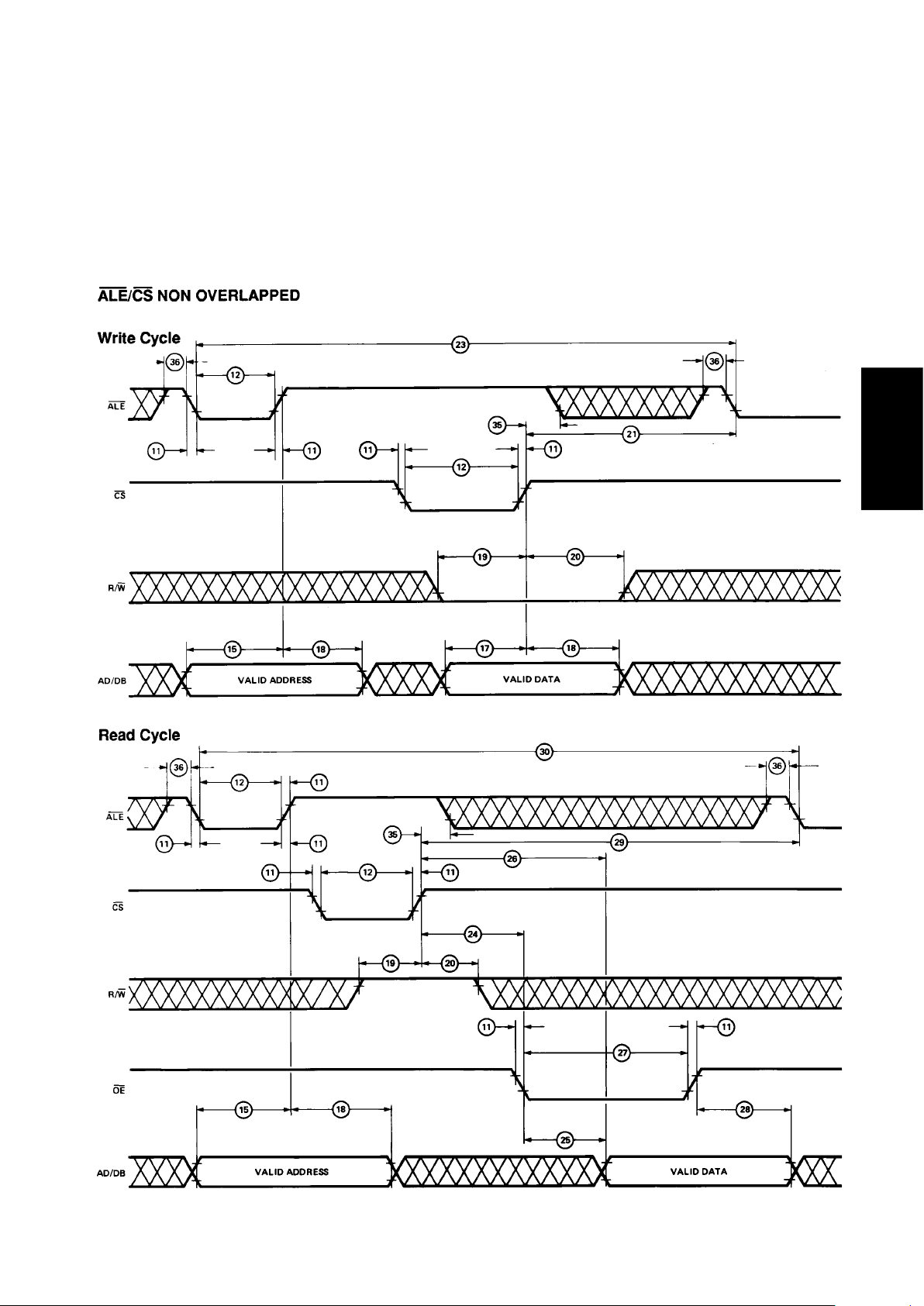

HCTL-1100 I/O Timing Diagrams

Input logic level values are the TTL Logic levels VIL = 0.8 V and VIH = 2.0 V. Output logic levels

are VOL = 0.4 V and VOH = 2.4 V.

2-147

MOTION SENSING

AND CONTROL

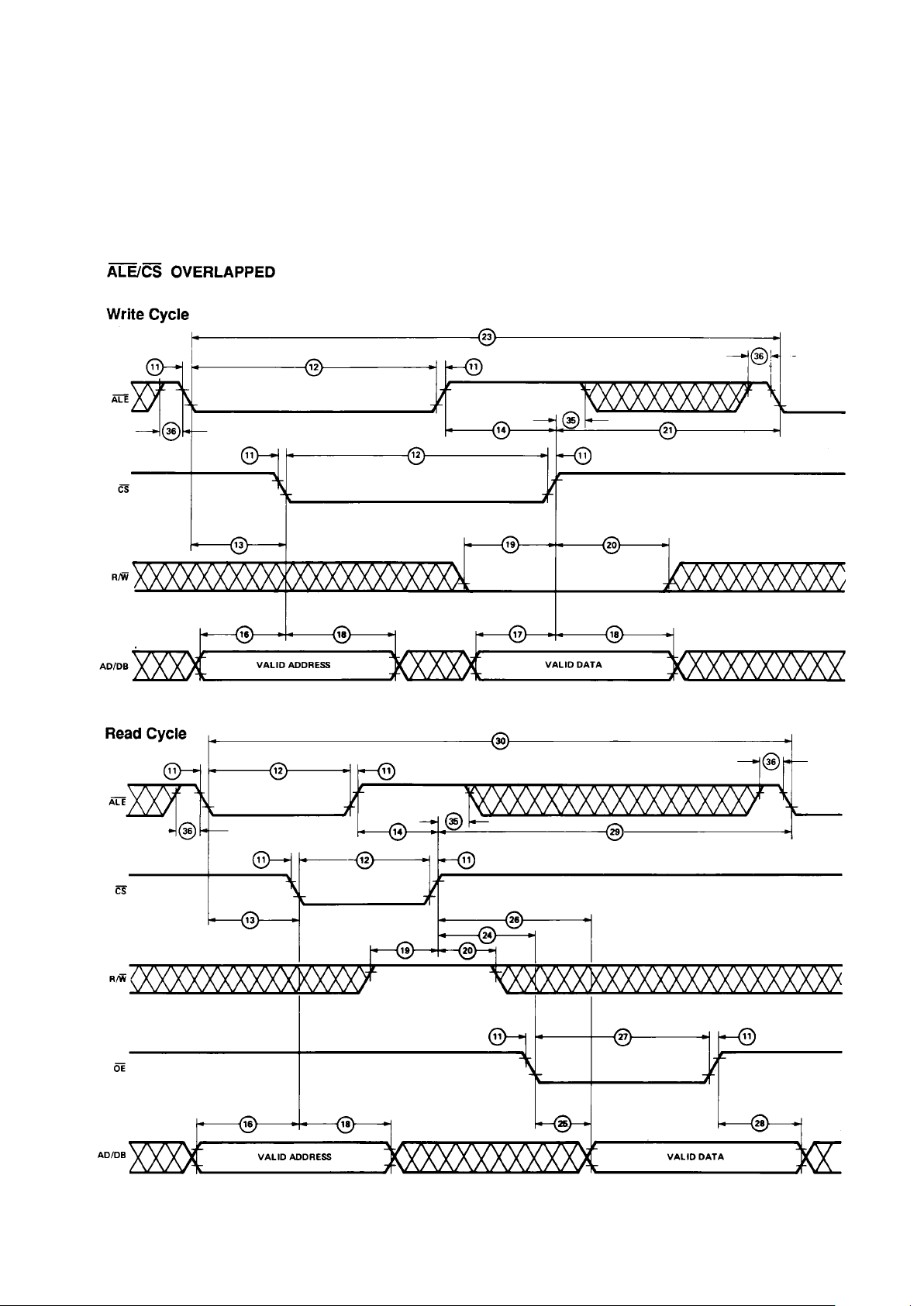

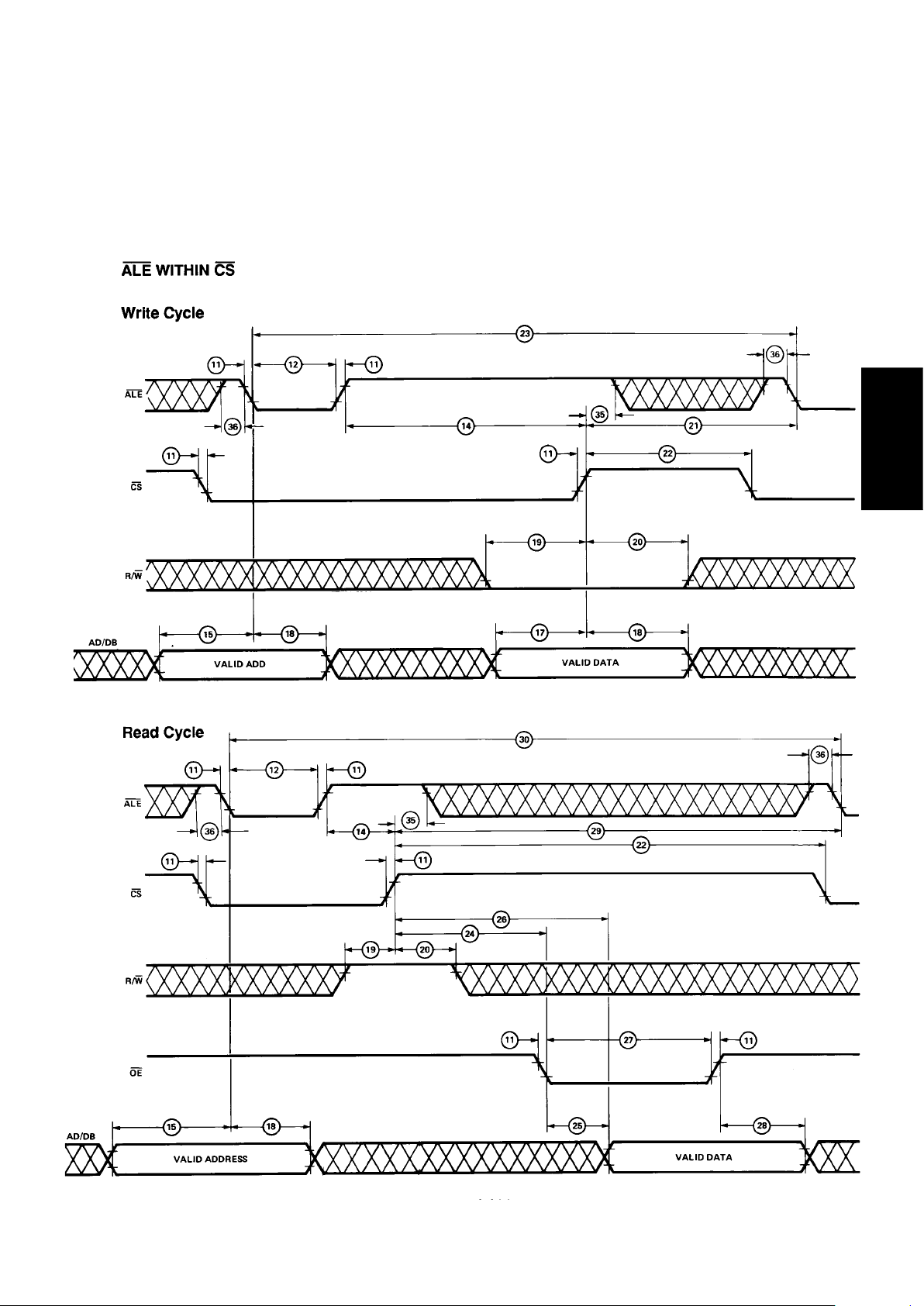

HCTL-1100 I/O Timing Diagrams

There are three different timing configurations which can be used to give the user flexibility to interface the

HCTL-1100 to most microprocessors. See the I/O interface section for more details.

2-148

HCTL-1100 I/O Timing Diagrams

2-149

MOTION SENSING

AND CONTROL

HCTL-1100 I/O Timing Diagrams

2-150

Pin Descriptions and Functions

Input/Output Pins

Pin Number

Symbol PDIP PLCC Description

AD0/DB0- 2-7 3-8 Address/Data Bus – Lower 6 bits of 8-bit I/O port which are

AD5/DB5 multiplexed between address and data.

DB6, DB7 8, 9 9, 10 Data bus – Upper 2 bits of 8-bit I/O port used for data only.

Input Signals

Pin Number

Symbol PDIP PLCC Description

CHA/CHB 31, 30 34, 33 Channel A, B – Input pins for position feedback from an incremental

shaft encoder. Two channels, A and B, 90 degrees out of phase are

required.

Index 33 36 Index Pulse – Input from the reference or index pulse of an incre-

mental encoder. Used only in conjunction with the Commutator. Either

a low or high true signal can be used with the Index pin. See Timing

Diagrams and Encoder Interface section for more detail.

R/W 37 41 Read/Write – Determines direction of data exchange for the I/O port.

ALE 38 42 Address Latch Enable – Enables lower 6 bits of external data bus into

internal address latch.

CS 39 43 Chip Select – Performs I/O operation dependent on status of R/W line.

For a Write, the external bus data is written into the internal

addressed location. For Read, data is read from an internal location

into an internal output latch.

OE 40 44 Output Enable – Enables the data in the internal output latch onto the

external data bus to complete a Read operation.

Limit 14 15 Limit Switch – An internal flag which when externally set, triggers an

unconditional branch to the Initialization/Idle mode before the next

control sample is executed. Motor Command is set to zero. Status of

the Limit flag is monitored in the Status register.

Stop 15 16 Stop Flag – An internal flag that is externally set. When flag is set

during Integral Velocity Control mode, the Motor Command is

decelerated to a stop.

Reset 36 40 Reset – A hard reset of internal circuitry and a branch to Reset mode.

ExtClk 34 37 External Clock

V

DD

11, 35 12, 38 Voltage Supply – Both VDD pins must be connected to a 5.0 volt supply.

GND 10, 32 1, 11, Circuit Ground

23, 35

SYNC 1 2 Used to synchronize multiple HCTL-1100 sample timers.

NC – 17, 39 Not connected. These pins should be left floating.

2-151

MOTION SENSING

AND CONTROL

Output Pins

Pin Number

Symbol PDIP PLCC Description

MC0-MC7 18-25 20-22, Motor Command Port – 8-bit output port which contains the digital

24-28 motor command adjusted for easy bipolar DAC interfacing. MC7 is

the most significant bit (MSB).

Pulse 16 18 Pulse – Pulse width modulated signal whose duty cycle is proportional

to the Motor Command magnitude. The frequency of the signal is

External Clock/100 and pulse width is resolved into 100 external clocks.

Sign 17 19 Sign – Gives the sign/direction of the pulse signal.

PHA-PHD 26-29 29-32 Phase A, B, C, D – Phase Enable outputs of the Commutator.

Prof 12 13 Profile Flag – Status flag which indicates that the controller is execut-

ing a profiled position move in the Trapezoidal Profile Control mode.

Init 13 14 Initialization/Idle Flag – Status flag which indicates that the controller

is in the Initialization/Idle mode.

Pin Functionality

SYNC Pin

The SYNC pin is used to synchronize two or more ICs. It is

only valid in the INIT/IDLE mode

(see Operating the HCTL-1100).

When this pin is pulled low, the

internal sample timer is cleared

and held to zero. When the level

on the pin is returned to high, the

internal sample timer instantly

starts counting down from the

programmed value.

Connecting all SYNC pins

together in the system and

pulsing the SYNC signal from the

host processor will synchronize

all controllers.

Limit Pin

This emergency-flag input is used

to disable the control modes of

the HCTL-1100. A low level on

this input pin causes the internal

Limit flag to be set. If this pin is

NOT used, it must be pulled up to

VDD. If it is not connected, the pin

could float low, and possibly

trigger a false emergency

condition.

The Limit flag, when set in any

control mode, causes the HCTL1100 to go into the Initialization/

Idle mode, clearing the Motor

Command and causing an immediate motor shutdown. When the

Limit flag is set, none of the three

control mode flags (F0, F3, or

F5) are cleared as the HCTL-1100

enters the Initialization/Idle mode.

The user should be aware that

these flags are still set before

commanding the HCTL-1100 to

re-enter one of the four control

modes from Initialization/Idle

mode.

In general, the user should clear

all control mode flags after the

limit pin has been pulled low,

then proceed.

Stop Pin

The Stop flag affects the HCTL1100 only in the Integral Velocity

Mode.

When a low level is present on

this emergency-flag input, the

internal stop flag is set. If this pin

is NOT used, it must be pulled up

to VDD. If it is not connected, the

pin could float low, and possibly

trigger a false emergency

condition.

When the STOP flag is set, the

system will come to a decelerated

stop and stay in this mode with a

command velocity of zero until

the Stop flag is cleared and a new

command velocity is specified.

Notes on Limit and Stop Flags

Stop and Limit flags are set by a

low level input at their respective

pins. The flags can only be

cleared when the input to the

corresponding pin goes high,

signifying that the emergency

condition has been corrected,

AND a write to the Status register

(R07H) is executed. That is, after

the emergency pin has been set

and cleared, the flag also must be

cleared by writing to R07H. Any

word that is written to R07H after

the emergency pin is set and

cleared will clear the emergency

flag. The lower four bits of that

word will also reconfigure the

Status register.

2-152

Encoder Input Pins (CHA,

CHB, INDEX)

The HCTL-1100 accepts TTL

compatible outputs from 2 and 3

channel incremental encoders

such as the HEDS-5XXX, 6XXX,

and 9XXX series encoders.

Channels A and B are internally

decoded into quadrature counts

which increment or decrement

the 24-bit position counter. For

example, a 500-count encoder is

decoded into 2000 quadrature

counts per revolution. The

position counter will be incremented when Channel B leads

Channel A. The Index channel is

used only for the Commutator and

its function is to serve as a

reference point for the internal

Ring Counter.

The HCTL-1100 employs an

internal 3-bit state delay filter to

remove any noise spikes from the

encoder inputs to the HCTL-1100.

This 3-bit state delay filter

requires the encoder inputs to

remain stable for three consecutive clock rising edges for an

encoder pulse to be considered

valid by the HCTL-1100’s actual

position counter (i.e., an encoder

pulse must remain at a logic level

high or low for three consecutive

clock rising edges for the HCTL1100’s actual position counter to

be incremented or decremented.)

The designer should therefore

generally avoid creating the

encoder pulses of less than 3

clock cycles.

The index signal of an encoder is

used in conjunction with the

Commutator. It resets the internal

ring counter which keeps track of

the rotor position so that no

cumulative errors are generated.

The Index pin of the HCTL-1100

also has a 3-bit filter on its input.

The Index pin is active low and

level transition sensitive. It

detects a valid high-to-low

transition and qualifies the low

input level through the 3-bit filter.

At this point, the Index signal is

internally detected by the

commutator logic. This type of

configuraiton allows an Index or

Index signal to be used to generate the reference mark for

commutator operation as long as

the AC specifications for the

Index signal are met.

Motor Command Port (MC0MC7)

The 8-bit Motor Command port

consists of register R08H whose

data goes directly to external pins

MC0-MC7. MC7 is the most

significant bit. R08H can be read

and written to, however, it should

be written to only during the

Initialization/Idle mode. During

any of the four Control modes,

the controller writes the motor

command into R08H.

This topic is further discussed in

the “Register Section” under

“Motor Command Register

R08H”.

Pulse Width Modulation

(PWM) Output Port (Pulse,

Sign)

The PWM port consists of the

Pulse and Sign pins. The PWM

port outputs the motor command

as a pulse width modulated signal

with the correct polarity. This

topic is further discussed in the

“Register Section” under “PWM

Motor Command Register R09H”.

Trapezoid Profile Pin (Prof)

The Trapezoid Profile Pin is

internally connected to software

flag bit 4 in the Status Register.

This flag is also represented by bit

0 in the Flag Register (R00H).

See the “Register Section” for

more information. Both the Pin

and the Flag indicate the status of

a trapezoid profile move. When

the HCTL-1100 begins a

trapezoid move, this flag is set by

the controller (a high level

appears on the pin), indicating

the move is in progress. When the

HCTL-1100 finishes the move,

this flag is cleared by the

controller.

Note that the instant the flag is

cleared may not be the same

instant the motor stops. The flag

indicates the completion of the

command profile, not the actual

profile. If the motor is stalled

during the move, or cannot

physically keep up with the move,

the flag will be cleared before the

move is finished.

INIT/IDLE Pin (INIT)

This pin indicates that the HCTL1100 is in the INIT/IDLE mode,

waiting to begin control. This pin

is internally connected to the

software flag bit 5 in the Status

Register R07H. This flag is also

represented by bit 1 in the Flag

Register (R00H) (See the

“Register Section” for more

information).

Commutator Pins (PHA-PHD)

These pins are connected only

when using the commutator of the

HCTL-1100 to drive a brushless

motor or step motor. The four

pins can be programmed to

energize each winding on a

multiphase motor.

2-153

MOTION SENSING

AND CONTROL

Figure 3. Register Block Diagram.

Operation of the

HCTL-1100

Registers

The HCTL-1100 operation is

controlled by a bank of 64 8-bit

registers, 35 of which are user

accessible. These registers

contain command and configuration information necessary to

properly run the controller chip.

The 35 user-accessible registers

are listed in Tables 1 and 2. The

register number is also the

address. A functional block

diagram of the HCTL-1100 which

shows the role of the useraccessible registers is also

included in Figure 3. The other 29

registers are used by the internal

CPU as scratch registers and

should not be accessed by the

user.

2-154

Table 1. Register Reference By Mode

Register

User

Hex Dec. Function Data Type

[1]

Access

General Control

R00H R00D Flag Register r/w

R05H R05D Program Counter scalar r/w

R07H R07D Status Register - r/w

[2]

R0FH R15D Sample Timer scalar r/w

R12H R18D Read Actual Position MSB 2’s Complement r

[4]

R13H R19D Read Actual Position 2’s Complement r

[4]/w[5]

R14H R20D Read Actual Position LSB 2’s Complement r

[4]

R15H R21D Preset Actual Position MSB 2’s Complement w

[8]

R16H R22D Preset Actual Position 2’s Complement w

[8]

R17H R23D Preset Actual Position LSB 2’s Complement w

[8]

Output Registers

R07H R07D Sign Reversal Inhibit - r/w

[2]

R08H R08D 8 bit Motor Command 2’s Complement+80H r/w

R09H R09D PWM Motor Command 2’s Complement r/w

Filter Registers

R20H R32D Filter Zero, A scalar r/w

R21H R33D Filter Pole, B scalar r/w

R22H R34D Gain, K scalar r/w

Commutator Registers

R07H R07D Status Register - r/w

[2]

R18H R24D Commutator Ring scalar

[6,7]

r/w

R19H R25D Velocity Timer scalar w

R1AH R26D X scalar

[6,7]

r/w

R1BH R27D Y Phase Overlap scalar

[6,7]

r/w

R1CH R28D Offset 2’s Complement

[7]

r/w

R1FH R31D Max. Phase Advance scalar

[6,7]

r/w

Position Control Mode

R00H R00D Flag Register - r/w

R12H R18D Read Actual Position MSB 2’s Complement r

[4]

R13H R19D Read Actual Position 2’s Complement r

[4]/w[5]

R14H R20D Read Actual Position LSB 2’s Complement r

[4]

R0CH R12D Command Position MSB 2’s Complement r/w

[3]

R0DH R13D Command Position 2’s Complement r/w

[3]

R0EH R14D Command Position LSB 2’s Complement r/w

[3]

2-155

MOTION SENSING

AND CONTROL

Table 1. (continued).

Register

User

Hex Dec. Function Data Type Access

Trapezoid Profile Control Mode

R00H R00D Flag Register - r/w

R07H R07D Status Register - r/w

[2]

R12H R18D Read Actual Position MSB 2’s Complement r

[4]

R13H R19D Read Actual Position 2’s Complement r

[4]/w[5]

R14H R20D Read Actual Position LSB 2’s Complement r

[4]

R29H R41D Final Position LSB 2’s Complement r/w

R2AH R42D Final Position 2’s Complement r/w

R2BH R43D Final Position MSB 2’s Complement r/w

R26H R38D Acceleration LSB scalar r/w

R27H R39D Acceleration MSB scalar

[6]

r/w

R28H R40D Maximum Velocity scalar

[6]

r/w

Integral Velocity Mode

R00H R00D Flag Register - r/w

R12H R18D Read Actual Position MSB 2’s Complement r

[4]

R13H R19D Read Actual Position 2’s Complement r

[4]/w[5]

R14H R20D Read Actual Position LSB 2’s Complement r

[4]

R26H R38D Acceleration LSB scalar r/w

R27H R39D Acceleration MSB scalar

[6]

r/w

R3CH R60D Command Velocity 2’s Complement r/w

Proportional Velocity Mode

R00H R00D Flag Register - r/w

R12H R18D Read Actual Position MSB 2’s Complement r

[4]

R13H R19D Read Actual Position 2’s Complement r

[4]/w[5]

R14H R20D Read Actual Position LSB 2’s Complement r

[4]

R23H R35D Command Velocity LSB 2’s Complement r/w

R24H R36D Command Velocity MSB 2’s Complement r/w

R34H R52D Actual Velocity LSB 2’s Complement r

R35H R53D Actual Velocity MSB 2’s Complement r

Notes:

1. Consult appropriate section for data format and use.

2. Upper 4 bits are read only.

3. Writing to R0EH (LSB) latches all 24 bits.

4. Reading R14H (LSB) latches data in R12H and R13H.

5. Writing to R13H clears Actual Position Counter to zero.

6. The scalar data is limited to positive numbers (00H to 7FH).

7. The commutator registers (R18H, R1CH, R1FH) have further limits which are discussed in the Commutator section of this data sheet.

8. Writing to R17H (R23D) latches all 24 bits (only in INIT/IDLE mode).

2-156

Table 2. Register Reference Table by Register Number

Register

User

Hex Dec. Function Mode Used Data Type Access

R00H R00D Flag Register All – r/w

R05H R05D Program Counter All scalar w

R07H R07D Status Register All – r/w

[2]

R08H R08D 8 bit Motor Command Port All 2’s complement

+ 80H r/w

R09H R09D PWM Motor Command Port All 2’s complement r/w

R0CH R12D Command Position (MSB) All except Proportional 2’s complement r/w

[3]

Velocity

R0DH R13D Command Position All except Proportional 2’s complement r/w

[3]

Velocity

R0EH R14D Command Position (LSB) All except Proportional 2’s complement r/w

[3]

Velocity

R0FH R15D Sample Timer All scalar r/w

R12H R18D Read Actual Position (MSB) All 2’s complement r

[4]

R13H R19D Read Actual Position All 2’s complement r

[4]/w[5]

R14H R20D Read Actual Position (LSB) All 2’s complement r

[4]

R15H R21D Preset Actual Position (MSB) INIT/IDLE 2’s complement w

[8]

R16H R22D Preset Actual Position INIT/IDLE 2’s complement w

[8]

R17H R23D Preset Actual Position (LSB) INIT/IDLE 2’s complement w

[8]

R18H R24D Commutator Ring All scalar

[6,7]

r/w

R19H R25D Commutator Velocity Timer All scalar w

R1AH R26D X All scalar

[6]

r/w

R1BH R27D Y Phase Overlap All scalar

[6]

r/w

R1CH R28D Offset All 2’s complement

[7]

r/w

R1FH R31D Maximum Phase Advance All scalar

[6,7]

r/w

R20H R32D Filter Zero, A All except Proportional scalar r/w

Velocity

R21H R33D Filter Pole, B All except Proportional scalar r/w

Velocity

R22H R34D Gain, K All scalar r/w

R23H R35D Command Velocity (LSB) Proportional Velocity 2’s complement r/w

R24H R36D Command Velocity (MSB) Proportional Velocity 2’s complement r/w

R26H R38D Acceleration (LSB) Integral Velocity and scalar r/w

Trapezoidal Profile

R27H R39D Acceleration (MSB) Integral Velocity and scalar

[6]

r/w

Trapezoidal Profile

R28H R40D Maximum Velocity Trapezoidal Profile scalar

[6]

r/w

R29H R41D Final Position (LSB) Trapezoidal Profile 2’s complement r/w

R2AH R42D Final Position Trapezoidal Profile 2’s complement r/w

R2BH R43D Final Position (MSB) Trapezoidal Profile 2’s complement r/w

R34H R52D Actual Velocity (LSB) Proportional Velocity 2’s complement r

R35H R53D Actual Velocity (MSB) Proportional Velocity 2’s complement r

R3CH R60D Command Velocity Integral Velocity 2’s complement r/w

Notes:

1. Consult appropriate section for data format and use.

2. Upper 4 bits are read only.

3. Writing to R0EH (LSB) latches all 24 bits.

4. Reading R14H (LSB) latches data in R12H and R13H.

5. Writing to R13H clears Actual Position Counter to zero.

6. The scalar data is limited to positive numbers (00H to 7FH).

7. The commutator registers (R18H, R1CH, R1FH) have further limits which are discussed in the Commutator section of this data sheet.

8. Writing to R17H (R23D) latches all 24 bits (only in INIT/IDLE mode).

2-157

MOTION SENSING

AND CONTROL

motor by using the commutator.

(See “Offset register” description

in the “Commutator section.”)

F5–Integral Velocity Control – set

by the user to specify Integral

Velocity Control. Also set and

cleared by the HCTL-1100 during

execution of the Trapezoidal

Profile mode. This is transparent

to the user except when the Limit

flag is set (see “Emergency Flags”

section).

Writing to the Flag Register

When writing to the flag register,

only the lower four bits are used.

Bit 3 indicates whether to set or

clear a certain flag, and bits

0,1,and 2 indicate the desired

flag. The following table shows

the bit map of the Flag register:

Bit Number Function

7-4 Don’t Care

3 1 = set

0 = clear

2 AD2

1 AD1

0 AD0

The following table outlines the

possible writes to the Flag

Register:

Flag SET CLEAR

F0 08H 00H

F1 - F2 0AH 02H

F3 0BH 03H

F4 0CH 04H

F5 0DH 05H

Reading the Flag Register

Reading register R00H returns

the status of the flags in bits 0 to

5. For example, if bit 0 is set

(logic 1), then flag F0 is set. If bit

4 is set, then flag F4 is set. If bits

0 and 5 are set, then both flags F0

and F5 are set.

The following table outlines the

Flag Register Read:

Flag

Bit (1 = set)

Number (0 = clear)

8-6 Don’t Care

5F5

4F4

3F3

2F2

1F1

0F0

Notes:

1. A soft reset (writing 00H to R05H) will

not reset the flags in the flag register. A

hard reset (RESET pin low) is required

to reset all the flags. The flags can also

be reset by writing the proper word to

the Flag register as explained above.

2. While in Trapezoid Profile Mode, Flag

F0 will be set, and Flag F5 may be set.

F5 is used for internal purposes. Both

flags will be cleared at the end of the

profile.

Program Counter Register

(R05H)

The Program Counter, which is a

write-only register, executes the

preprogrammed functions of the

controller. The program counter

is used along with the control

flags F0, F3, and F5 in the Flag

register (R00H) to change control

modes. The user can write any of

the following four commands to

the Program Counter.

Value

written

to R05H Action

00H Software Reset

01H Enter Init/Idle Mode

02H Enter Align Mode

(only from INIT/

IDLE Mode)

03H Enter Control Mode

(only from INIT/

IDLE Mode)

These Commands are discussed in

more detail in the “Operating

Modes” section.

Register Descriptions –

General Control, Output,

Filter, and Commutator

Flag Register (R00H)

The Flag register contains flags

F0 through F5. This register is a

read/write register. Each flag is

set and cleared by writing an 8-bit

data word to R00H. When writing

to R00H, the upper four bits are

ignored by the HCTL-1100, bits

0,1,2 specify the flag address, and

bit 3 specifies whether to set

(bit=1) or clear (bit=0) the

addressed flag.

Flag Descriptions

F0–Trapezoidal Profile Flag – set

by the user to execute Trapezoidal Profile Control. The flag is

reset by the controller when the

move is completed. The status of

F0 can be monitored at the Profile

pin and in Status register R07H

bit 4.

F1–Initialization/Idle Flag – set/

cleared by the HCTL-1100 to

indicate execution of the

Initialization/Idle mode. The

status of F1 can be monitored at

the Initialization/Idle pin and in

bit 5 of the Status register

(R07H). The user should not

attempt to set or clear F1.

F2–Unipolar Flag – set/cleared by

the user to specify Bipolar (clear)

or Unipolar (set) mode for the

Motor Command port.

F3–Proportional Velocity Control

Flag – set by the user to specify

Proportional Velocity control.

F4–Hold Commutator flag – set/

cleared by the user or automatically by the Align mode.

When set, this flag inhibits the

internal commutator counters to

allow open loop stepping of a

2-158

Motor Command Register

(R08H)

The 8-bit Motor Command Port

consists of register R08H. The

register is connected to external

pins MC0-MC7. MC7 is the most

significant bit. R08H can be read

and written to; however, it should

be written to only in the

Initialization/Idle mode. During

any of the four control modes, the

HCTL-1100 writes values to

register R08H.

The Motor Command Port

operates in two modes, bipolar

and unipolar, when under control

of internal software. Bipolar mode

allows the full range of values in

R08H (-128D to +127D). The

data written to the Motor

Command Port by the control

algorithms is the internally

computed 2’s-complement motor

command with an 80H offset

added. This allows direct interfacing to a DAC. Connecting the

Motor Command Port to a DAC,

Bipolar mode allows the full

voltage swing (positive and

negative).

Unipolar mode functions such

that with the same DAC circuit,

the motor command output is

restricted to positive values

(80H to FFH) when in a control

mode. Unipolar mode is used with

multi-phase motors when the

commutator controls the direction

of movement. (If needed, the Sign

pin could be used to indicate

direction). In Unipolar mode, the

user can still write a negative

value to R08H in INIT/IDLE

mode.

Unipolar mode or Bipolar mode is

programmed by setting or

clearing flag F2 in the Flag

Register R00H.

Internally, the HCTL-1100

operates on data of 24, 16 and 8bit lengths to produce the

8-bit motor command, available

externally. Many times the

computed motor command will be

greater than 8 bits. At this point,

the motor command is saturated

by the controller. The saturated

value output by the controller is

not the full scale value 00H

(00D), or FFH (255D). The

saturated value is adjusted to 0FH

(15D) (negative saturation) and

F0H (240D) (positive saturation).

Saturation levels for the Motor

Command port are in Figure 4.

Table 3. Status Register

Status Bit Function

0 PWM Sign Reversal Inhibit

0 = off

1 = on

1 Commutator Phase Configuration

0 = 3 phase

1 = 4 phase

2 Commutator Count Configuration

0 = quadrature

1 = full

3 Should always be set to 0

4 Trapezoidal Profile Flag F0

1 = in Profile Control

5 Initialization/Idle Flag F1

1 = in Initialization/Idle Mode

6 Stop Flag

0 = set (Stop triggered)

1 = cleared (no Stop)

7 Limit Flag

0 = set (Limit triggered)

1 = cleared (no Limit)

Status Register (R07H)

The Status register indicates the

status of the HCTL-1100. Each bit

decodes into one signal. All 8 bits

are user readable and are decoded

as shown below. Only the lower 4

bits can be written to by the user

to configure the HCTL-1100. To

set or clear any of the lower 4

bits, the user writes an 8-bit word

to R07H. The upper 4 bits are

ignored. Each of the lower 4 bits

directly sets/clears the corresponding bit of the Status register

as shown below. For example,

writing XXXX0101 to R07H sets

the PWM Sign Reversal Inhibit,

sets the Commutator Phase

Configuration to “3 Phase,” and

sets the Commutator Count

Configuration to “full.”

2-159

MOTION SENSING

AND CONTROL

PWM Motor Command

Register (R09H)

The PWM port outputs the motor

command as a pulse width

modulated signal with the correct

sign of polarity. The PWM port

consists of the Pulse and Sign

pins and R09H.

The PWM signal at the Pulse pin

has a frequency of External

Clock/100 and the duty cycle is

(–40D) gives a 40% duty cycle

signal at the Pulse pin and forces

the Sign pin high. Data outside

the 64H (+100D) to 9CH (–

100D) linear range gives 100%

duty cycle. R09H can be read and

written to. However, the user

should only write to R09H when

the controller is in the Initialization/Idle mode.

Figure 5 shows the PWM output

versus the internal motor

command.

Figure 4. Motor Command Port Output.

resolved into the 100 clocks. (For

example, a 2 MHz clock gives a

20 KHz PWM frequency.)

The Sign pin gives the polarity of

the command. Low output on Sign

pin is positive polarity.

The 2’s-complement contents of

R09H determine the duty cycle

and polarity of the PWM

command. For example, D8H

2-160

When any Control mode is being

executed, the unadjusted internal

2’s-complement motor command

is written to R09H. Because of the

hardware limit on the linear range

(64H to 9CH, ± 100D), the PWM

port saturates sooner than the 8bit Motor Command port (00H to

FFH, +127D to –128D). When

the internal motor command

saturates above 8 bits, the PWM

port is saturated to the full

± 100% duty cycle level. Figure 5

shows the actual values inside the

PWM port. Note that the Unipolar

flag, F2, does not affect the PWM

port.

For commutation of brushless

motors with the PWM port, only

use the Pulse pin from the PWM

port as the commutator already

contains sign information. (See

Figure 9.)

The PWM port has an option that

can be used with H-bridge type

amplifiers. The option is Sign

Reversal Inhibit, which inhibits

the Pulse output for one PWM

period after a sign polarity

reversal. This allows one pair of

transistors to turn off before

others are turned on and thereby

avoids a short across the power

supply. Bit 0 in the Status register

(R07H) controls the Sign Reversal

Figure 6. Sign Reversal Inhibit.

Figure 5. PWM Port Output.

2-161

MOTION SENSING

AND CONTROL

In Position Control, Integral

Velocity Control, and Trapezoidal

Profile Control the digital filter is

implemented in the time domain

as shown below:

MCn = (K/4)(Xn) –

[(A/256)(K/4)(X

n–1

) +

(B/256)(MC

n-1

)] [2]

where:

n = current sample time

n-1 = previous sample time

MCn = Motor Command Output

at n

MC

n-1

= Motor Command

Output at n-1

Xn = (Command Position –

Actual Position) at n

X

n-1

= (Command Position –

Actual Position) at n-1

In Proportional Velocity control

the digital compensation filter is

implemented in the time domain

as:

MCn = (K/4)(Yn) [3]

where:

Yn = (Command Velocity –

Actual Velocity) at n

For more information on system

sampling times, bandwidth, and

stability, please consult HewlettPackard Application Note 1032,

Design of the HCTL-1000’s

Digital Filter Parameters by the

Combination Method.

Inhibit option. Figure 6 shows the

output of the PWM port when Bit

0 is set.

Actual Position Registers

Read, Clear: R12H,R13H,R14H

Preset : R15H,R16H,R17H

The Actual Position Register is

accessed by two sets of registers

in the HCTL-1100. When reading

the Actual Position from the

HCTL-1100, the host processor

will read Registers R12H(MSB),

R13H, and R14H(LSB). When

presetting the Actual Position

Register, the processor will write

to Registers R15H(MSB), R16H,

and R17H(LSB).

When reading the Actual Position

registers, the order should be

R14H, R13H, R12H. These

registers are latched, such that,

when reading Register R14H, all

three bytes will be latched so that

count data does not change while

reading three separate bytes.

When presetting the Actual

Position Register, write to R15H

and R16H first. When R17H is

written to, all three bytes are

simultaneously loaded into the

Actual Position Register.

Note that presetting the Actual

Position Registers is only allowed

while the HCTL-1100 is in INIT/

IDLE mode.

The Actual Position Registers can

be simultaneously cleared at any

time by writing any value to

R13H.

Digital Filter Registers

Zero (A) R20H

Pole (B) R21H

Gain (K) R22H

All control modes use some part

of the programmable digital filter

D(z) to compensate for closed

loop system stability. The compensation D(z) has the form:

A

K z – –––

256

D(z) = ––––––––––– [1]

B

4 z + –––

256

where:

z = the digital domain operator

K = digital filter gain (R22H)

A = digital filter zero (R20H)

B = digital filter pole (R21H)

The compensation is a first-order

lead filter which in combination

with the Sample Timer T (R0FH)

affects the dynamic step response

and stability of the control

system. The Sample Timer, T,

determines the rate at which the

control algorithm gets executed.

All parameters, A, B, K, and T, are

8-bit scalars that can be changed

by the user any time.

As shown in equations [2] and

[3], the digital filter uses

previously sampled data to

calculate D(z). This old internally

sampled data is cleared when the

Initialization/Idle mode is

executed.

2-162

Sample Timer Register (R0FH)

The contents of this register set

the sampling period of the HCTL-

1100. The sampling period is:

t = 16(T+1)(1/frequency of the

external clock) [4]

where:

T = contents of register R0FH

The Sample Timer has a limit on

the minimum allowable sample

time depending on the control

mode being executed. The limits

are given in Table 4 below.

The minimum value limits are to

make sure the internal programs

have enough time to complete

proper execution.

The maximum value of T (R0FH)

is FFH (255D). With a 2 MHz

clock, the sample time can vary

from 64 µsec to 2048 µsec. With

a 1 MHz clock, the sample time

can vary from 128 µsec to 4096

µsec.

Digital closed-loop systems with

slow sampling times have lower

stability and a lower bandwidth

than similar systems with faster

sampling times. To keep the

system stability and bandwidth as

high as possible the HCTL-1100

should typically be programmed

with the fastest sampling time

Table 4.

R0FH Contents

Control Mode Minimum Limit

Position Control 07H(07D)

Proportional Velocity Control 07H(07D)

Trapezoidal Profile Control 0FH(15D)

Integral Velocity Control 0FH(15D)

possible. This rule of thumb must

be balanced by the needs of the

velocity range to be controlled.

Velocities are specified to the

HCTL-1100 in terms of

quadrature encoder counts per

sample time. The faster the

sampling time, the higher the

slowest possible speed.

Hardware Description

The Sample Timer consists of a

buffer and a decrement counter.

Each time the counter reaches

00H, the Sampler Timer Value T

(value written to R0FH) is loaded

from the buffer into the counter,

which immediately begins to

decrement from T.

Writing to the Sample Timer

Register

Data written to R0FH will be

latched into the internal buffer

and used by the counter after it

completes the present sample

time cycle by decrementing to

00H. The next sample time will

use the newly written data.

Reading the Sample Timer

Register

Reading R0FH gives the values

directly from the decrementing

counter. Therefore, the data read

from R0FH will have a value

anywhere between T and 00H,

depending where in the sample

time cycle the counter is.

Example –

1. On reset, the value of the timer

is pre-set to 40H.

2. Reading R0FH shows

3EH . . . 2BH . . . 08H . . .

3CH . . .

Synchronizing Multiple Axes

Synchronizing multiple axes with

HCTL-1100s can be achieved by

using the SYNC pin as explained

in the Pin Discussion section.

Some users may not only want to

synchronize several HCTL-1100s

but also follow custom profiles for

each axis. To do this, the user

may need to write a new

command position or command

velocity during each sample time

for the duration of the profile. In

this case, data written to the

HCTL-1100 has to be coordinated

with the Sample Timer. This is so

that only one command position

or velocity is received during any

one sample period, and that it is

written at the proper time within

a sample period.

At the beginning of each sample

period, the HCTL-1100 is

performing calculations and

executions. New command

positions and velocities should

not be written to the HCTL-1100

during this time. If they are, the

calculations may be thrown off

and cause unpredictable control.

The user can read the Sample

Timer Register to avoid writing

too early during a sample period.

Since the Sample Timer Register

continuously counts down from

its programmed value, the user

can check if enough time has

passed in the sample period to

insure the completion of the

internal calculations. The length

of time needed by the HCTL-1100

2-163

MOTION SENSING

AND CONTROL

to do its calculations is given by

the Minimum Limits of R0FH

(Sample Timer Register) as shown

in Table 4. For Position Control

Mode, the user should wait for the

Sample Timer to count down 07H

from its programmed value before

writing the next command

position or velocity. If the

programmed sample timer value

is 39H, wait until the Sample

Timer Register reads 32H.

Writing between 32H and 00H

will make the command information available for the next sample

period.

Commutator

Status Register (R07H)

Commutator Ring (R18H)

X Register (R1AH)

Y Phase Overlap (R1BH)

Offset (R1CH)

Max. Phase Advance (R1FH)

Velocity Timer (R19H)

The commutator is a digital state

machine that is configured by the

user to properly select the phase

sequence for electronic

commutation of multiphase

motors. The Commutator is

designed to work with 2, 3, and 4phase motors of various winding

configurations and with various

encoder counts. Along with

providing the correct phase

enable sequence, the Commutator

provides programmable phase

overlap, phase advance, and

phase offset.

Phase overlap is used for better

torque ripple control. It can also

be used to generate unique state

sequences which can be further

decoded externally to drive more

complex amplifiers and motors.

Phase advance allows the user to

compensate for the frequency

characteristics of the motor/

amplifier combination. By

advancing the phase enable

command (in position), the delay

in reaction of the motor/amplifier

combination can be offset and

higher performance can be

achieved.

Phase offset is used to adjust the

alignment of the commutator

output with the motor torque

curves. By correctly aligning the

HCTL-1100’s commutator output

with the motor’s torque curves,

maximum motor output torque

can be achieved.

The inputs to the Commutator are

the three encoder signals,

Channel A, Channel B, and Index,

and the configuration data stored

in registers.

Figure 7. Index Pulse Alignment to Motor Torque Curves.

The Commutator uses both

channels and the index pulse of

an incremental encoder. The

index pulse of the encoder must

be physically aligned to a known

torque curve location because it is

used as the reference point of the

rotor position with respect to the

Commutator phase enables.

The index pulse should be

permanently aligned during motor

encoder assembly to the last

motor phase. This is done by

energizing the last phase of the

motor during assembly and

permanently attaching the

encoder codewheel to the motor

shaft such that the index pulse is

active as shown in Figures 7

and 8. Fine tuning of alignment

for commutation purposes is done

electronically by the Offset

register (R1CH) once the complete control system is set up.

2-164

Figure 9. PWM Interface to Brushless DC Motors.

Each time an index pulse occurs,

the internal commutator ring

counter is reset to 0. The ring

counter keeps track of the current

position of the rotor based on the

encoder feedback. When the ring

counter is reset to 0, the

Commutator is reset to its origin

(last phase going low, Phase A

going high) as shown in

Figure 10.

Figure 10. Commutator Configuration.

Figure 8. Codewheel Index Pulse Alignment.

The output of the Commutator is

available as PHA, PHB, PHC, and

PHD. The HCTL-1100’s

commutator acts as the electrical

equivalent of the mechanical

brushes in a motor. Therefore, the

outputs of the commutator

provide only proper phase

sequencing for bidirectional

operation. The magnitude

information is provided to the

motor via the Motor Command

and PWM ports. The outputs of

the commutator must be combined with the outputs of one of

the motor ports to provide proper

DC brushless and stepper motor

control. Figure 9 shows an

example of circuitry which uses

the outputs of the commutator

with the Pulse output of the PWM

port to control a DC brushless or

2-165

MOTION SENSING

AND CONTROL

0, 1, or 2 are written to the Offset

register, phase A will be enabled.

When the values 3, 4 or 5 are

written to the Offset register,

phase B will be enabled. And,

when the values 6, 7, or 8 are

written to the Offset register,

phase C will be enabled. No

values larger than the value

programmed into the Ring

register should be programmed

into the Offset register.

Phase Advance Registers

(R19H, R1FH)

The Velocity Timer register and

Maximum Advance register

linearly increment the phase

advance according to the

measured speed for rotation up to

a set maximum.

The Velocity Timer register

(R19H) contains scalar data

which determines the amount of

phase advance at a given velocity.

The phase advance is interpreted

in the units set for the Ring

counter by bit #2 in R07H. The

velocity is measured in revolutions per second.

Advance = Nfv∆t [6]

16 (R19H + 1)

where: ∆t = –––––––––––– [7]

f external clk

Nf = full encoder counts/

revolution.

v = velocity (revolutions/

second)

The Maximum Advance register

(R1FH) contains scalar data

which sets the upper limit for

phase advance regardless of rotor

speed.

Figure 11 shows the relationship

between the Phase Advance

registers. Note: If the phase

advance feature is not used, set

both R19H and R1FH to 0.

stepper motor. A similar procedure could be used to combine

the commutator outputs PHAPHD with a linear amplifier

interface output (Figure 16) to

create a linear amplifier system.

The Commutator is programmed

by the data in the following

registers. Figure 10 shows an

example of the relationship

between all the parameters.

Status Register (R07H)

Bit #1- 0 =3-phase configura-

tion, PHA, PHB, and

PHC are active

outputs.

1 =4-phase configura-

tion, PHA – PHD

are active outputs.

Bit #2- 0 = Rotor position

measured in quadrature counts

(4x decoding).

1 = Rotor position

measured in full

counts (1 count = 1

codewheel bar and

space.)

Bit #2 only affects the commutator’s counting method. This

includes the Ring register

(R18H), the X and Y registers

(R1AH & R1BH), the Offset

register (R1CH), the Velocity

Timer register (R19H), and the

Maximum Advance register

(R1FH).

Quadrature counts (4x decoding)

are always used by the HCTL1100 as a basis for position,

velocity, and acceleration control.

Ring Register (R18H)

The Ring register is defined as 1

electrical cycle of the commutator

which corresponds to 1 torque

cycle of the motor. The Ring

register is scalar and determines

the length of the commutation

cycle measured in full or quadrature counts as set by bit #2 in the

Status register (R07H). The value

of the ring must be limited to the

range of 0 to 7FH.

X Register (R1AH)

This register contains scalar data

which sets the interval during

which only one phase is active.

Y Register (R1BH)

This register contains scalar data

which set the interval during

which two sequential phases are

both active. Y is phase overlap. X

and Y must be specified such that:

X + Y = Ring/(# of phases) [5]

These three parameters define the

basic electrical commutation

cycle.

Offset Register (R1CH)

The Offset register contains

two’s-complement data which

determines the relative start of

the commutation cycle with

respect to the index pulse. Since

the index pulse must be physically

referenced to the rotor, offset

performs fine alignment between

the electrical and mechanical

torque cycles.

The Hold Commutator flag (F4)

in the Status register (R07H) is

used to decouple the internal

commutator counters from the

encoder input. Flag (F4) can be

used in conjunction with the

Offset register to allow the user to

advance the commutator phases

open loop. This technique may be

used to create a custom commutator alignment procedure. For

example, in Figure 10, case 1, for

a three-phase motor where the

ring = 9, X = 3, and Y = 0, the

phases can be made to advance

open loop by setting the Hold

Commutator flag (F4) in the Flag

register (R07H). When the values

2-166

for a ring of 96 counts and a

needed offset of 10 counts,

numerically the Offset register

can be programmed as 0AH

(10D) or AAH (-86D), the latter

satisfying Equation 8.

If bit #2 in the Status register is

set to allow the commutator to

count in full counts, a higher

resolution codewheel may be

chosen for precise motor control

without violating the commutator

constraints equation (Equation 8).

Example: Suppose you want to

commutate a 3-phase 15 deg/step

Variable Reluctance Motor

attached to a 192 count encoder.

1. Select 3-phase and quadrature

mode for commutator by

writing 0 to R07H.

2. With a 3-phase 15 degree/step

Variable Reluctance motor the

torque cycle repeats every 45

degrees or 8 times/revolution.

3. Ring register

(4)(192) counts/revolution

= ––––––––––––––––––––––

8/revolution

= 96 quadrature counts

= 1 commutation cycle

4. By measuring the motor torque

curve in both directions, it is

determined that an offset of 3

mechanical degrees, and a

phase overlap of 2 mechanical

degrees is needed.

(4) (192)

Offset = 3°––––––––

360°

≅ 6 quadrature counts

Commutator Constraints

and Use

When choosing a three-channel

encoder to use with a DC brushless or stepper motor, the user

should keep in mind that the

number of quadrature encoder

counts (4x the number of slots in

the encoder’s codewheel) must be

an integer multiple (1x, 2x, 3x,

4x, 5x, etc.) of the number of

pole pairs in the DC brushless

motor or steps in a stepper

motor. To take full advantage of

the commutator’s overlap feature,

the number of quadrature counts

should be at least 3 times the

number of pole pairs in the DC

brushless motor or steps in the

stepper motor. For example, a

1.8°, (200 step/revolution)

stepper motor should employ at

least a 150 slot codewheel = 600

quadrature counts/revolution = 3

x 200 steps/revolution).

There are several numerical

constraints the user should be

aware of to use the Commutator.

The parameters of Ring, X, Y, and

Max Advance must be positive

numbers (00H to 7FH).

Additionally, the following

equation must be satisfied:

(-128D) 80H ≤ 3/2 Ring

+ Offset ± Max Advance

≤ 7FH (127D) [8]

In order to utilize the greatest

flexibility of the Commutator, it

must be realized that the

Commutator works on a circular

ring counter principle, whose

range is defined by the Ring

register (R18H). This means that

Figure 11. Phase Advance vs. Motor Velocity.

2-167

MOTION SENSING

AND CONTROL

To create the 3 mechanical

degree offset, the Offset

register (R1CH) could be

programmed with either A6H

(-90D) or 06H (+06D).

However, because 06H (+06D)

would violate the commutator

constraints Equation 8, A6H

(-90D) is used.

(2°) (4) (192)

Y = overlap = –––––––––– ≅ 4

360°

X + Y = 96/3

Therefore, X = 28

Y = 4

For the purposes of this example,

the Velocity Timer and Maximum

Advance are set to 0.

Operation Flowchart

The HCTL-1100 executes any one

of three setup routines or four

control modes selected by the

user. The three setup routines

include:

– Reset

– Initialization/Idle

– Align.

The four control modes available

to the user include:

– Position Control

– Proportional Velocity Control

– Trapezoidal Profile Control

– Integral Velocity Control

The HCTL-1100 switches from

one mode to another as a result of

one of the following three

mechanisms:

1. The user writes to the Program

Counter.

2. The user sets/clears flags F0,

F3, or F5 by writing to the Flag

register (R00H).

3. The controller switches automatically when certain initial

conditions are provided by the

user.

This section describes the function of each setup routine and

control mode and the initial

conditions which must be provided by the user to switch from

Figure 12. Operation Flowchart.

one mode to another. Figure 12

shows a flowchart of the setup

routines and control modes, and

shows the commands required to

switch from one mode to another.

2-168

From Reset mode, the HCTL-1100

goes automatically to

Initialization/Idle mode.

Initialization/Idle

Executed by:

- Writing 01H to R05H, or

- Automatically executed after a

hard reset, soft reset, or

- Limit pin goes low.

The Initialization/Idle mode is

entered either automatically from

Reset, by writing 01H to the

Program Counter (R05H) under

any conditions, or pulling the

Limit pin low.

In the Initialization/Idle mode, the

following occur:

– The Initialization/Idle flag (F1)

is set.

– The PWM port R09H is set to

00H (zero command).

– The Motor Command port

(R08H) is set to 80H (128D)

(zero command).

– Previously sampled data stored

in the digital filter is cleared.

It is at this point that the user

should pre-program all the

necessary registers needed to

execute the desired control mode.

The HCTL-1100 stays in this

mode (idling) until a new mode

command is given.

Align

Executed by:

- Writing 02H to R05H

The Align mode is executed only

when using the commutator

feature of the HCTL-1100. This

mode automatically aligns multiphase motors to the HCTL1100’s internal Commutator.

The Align mode can be entered

only from the Initialization/Idle

mode by writing 02H to the

Program Counter register (R05H).

Before attempting to enter the

Align mode, the user should clear

all control mode flags and set

both the Command Position

registers (R0CH, R0DH, and

R0EH) and the Actual Position

registers (R12H, R13H, and

R14H) to zero. After the Align

mode has been executed, the

HCTL-1100 will automatically

enter the Position Control mode

and go to position zero. By

following this procedure, the

largest movement in the Align

mode will be one torque cycle of

the motor.

The Align mode assumes: the

encoder index pulse has been

physically aligned to the last

motor phase during encoder/

motor assembly, the Commutator

parameters have been correctly

preprogrammed (see the section

called Commutator for details),

and a hard reset has been

executed while the motor is

stationary.

The Align mode first disables the

Commutator and with open loop

control enables the first phase

(PHA) and then the last phase

(PHC or PHD) to orient the motor

on the last phase torque detent.

Each phase is energized for 2048

system sampling periods (t). For

proper operation, the motor must

come to a complete stop during

the last phase enable. At this

point the Commutator is enabled

and commutation is closed loop.

The HCTL-1100 then automatically switches from the Align

mode to Position Control mode.

Control Modes

Control flags F0, F3, and F5 in

the Flag register (R00H) determine which control mode is

executed. Only one control flag

can be set at a time. After one of

Setup Modes

Hard Reset

Executed by:

-Pulling the RESET pin low

(required at power up)

When a hard reset is executed

(RESET pin goes low), the

following conditions occur:

– All output signal pins are held

low except Sign, Data bus, and

Motor Command.

– All flags (F0 to F5) are cleared.

– The Pulse pin of the PWM port

is set low while the Reset pin is

held low. After the Reset pin is

released (goes high) the Pulse

pin goes high for one cycle of

the external clock driving the

HCTL-1100. The Pulse pin then

returns to a low output.

– The Motor Command port

(R08H) is preset to 80H

(128D).

– The Commutator logic is

cleared.

– The I/O control logic is cleared.

– A soft reset is automatically

executed.

Soft Reset

Executed by:

- Writing 00H to R05H, or

- Automatically called after a

hard reset

When a soft reset is executed, the

following conditions occur:

– The digital filter parameters are

preset to

A (R20H) = E5H (229D)

B (R21H) = K (R22H) = 40H

(64D)

– The Sample Timer (R0FH) is

preset to 40H (64D).

– The Status register (R07H) is

cleared.

– The Actual Position Counters

(R12H, R13H, R14H) are

cleared to 0.

2-169

MOTION SENSING

AND CONTROL

these control flags is set, the

control modes are entered either

automatically from Align or from

the Initialization/Idle mode by

writing 03H to the Program

Counter (R05H).

Position Control Mode

Flags: F0 Cleared

F3 Cleared

F5 Cleared

Registers Used:

Register Function

R00H R00D Flag Register

R12H R18D Read Actual

Position MSB

R13H R19D Read Actual

Position

R14H R20D Read Actual

Position LSB

R0CH R12D Command

Position MSB

R0DH R13D Command

Position

R0EH R14D Command

Position LSB

Position Control performs pointto-point position moves with no

velocity profiling. The user

specifies a 24-bit position

Example Code to Program Position Moves

{ Begin }

Hard Reset { HCTL-1100 goes into INIT/IDLE Mode }

Initialize Filter, Timer, Command Position Registers

Write 03H to Register R05H

{ HCTL-1100 is now in Position Mode }

Write Desired Command Position to Command Position Registers

{ Controller Moves to new position }

Continue writing in new Command Positions

{ end }

command, which the controller

compares to the 24-bit actual

position. The position error is

calculated, the full digital lead

compensation is applied and the

motor command is output.

The controller will remain

position-locked at a destination

until a new position command is

given.

The actual and command position

data is 24-bit two’s-complement

data stored in six 8-bit registers.

Position is measured in encoder

quadrature counts.

The command position resides in

R0CH (MSB), R0DH, R0EH

(LSB). Writing to R0EH latches

all 24 bits at once for the control

algorithm. Therefore, the command position is written in the

sequence R0CH, R0DH and

R0EH. The command registers

can be read in any desired order.

The actual position resides in

R12H (MSB), R13H, and R14H

(LSB). Reading R14H latches the

upper two bytes into an internal

buffer. Therefore, Actual Position

Proportional Velocity Mode

Flags: F0 Cleared

F3 Set

F5 Cleared

Registers Used:

Register Function

R00H R00D Flag Register

R23H R35D Command

Velocity LSB

R24H R36D Command

Velocity MSB

R34H R52D Actual Velocity

LSB

R35H R53D Actual Velocity

MSB

Proportional Velocity Control

performs control of motor speed

using only the gain factor, K, for

compensation. The dynamic pole

and zero lead compensation are

not used. (See the “Digital Filter”

section of this data sheet.)

registers are read in the order of

R14H, R13H, and R12H for correct instantaneous position data.

The largest position move possible in Position Control mode is

7FFFFFH (8,388,607D) quadrature encoder counts.

2-170

The command and actual velocity

are 16-bit two’s-complement

words.

The command velocity resides in

registers R24H (MSB) and R23H

(LSB). These registers are

unlatched which means that the

command velocity will change to

a new velocity as soon as the

value in either R23H or R24H is

changed. The registers can be

read or written to in any order.

Integral Velocity Mode

Flags: F0 Cleared

F3 Cleared

F5 Set to begin move

Registers Used:

Register Function

R00H R00D Flag Register

R26H R38D Acceleration LSB

R27H R39D Acceleration MSB

R3CH R60D Command

Velocity

Integral Velocity Control performs

continuous velocity profiling

which is specified by a command

velocity and command acceleration. Figure 13 shows the capability of this control algorithm.

The user can change velocity and

acceleration any time to continuously profile velocity in time.

Once the specified velocity is

reached, the HCTL-1100 will

maintain that velocity until a new

command is specified. Changes

between actual velocities occur at

the presently specified linear

acceleration.

The command velocity is an 8-bit

two’s-complement word stored in

R3CH. The units of velocity are

The units of velocity are quadrature counts/sample time. To

convert from rpm to quadrature

counts/sample time, use the

formula shown below:

Vq = (Vr)(N)(t)(0.01667/rpm-sec) [9]

R24H R23H

IIII IIII IIII FFFF

COMMAND VELOCITY FORMAT

Where:

Vq = velocity in quadrature

counts/sample time

Vr = velocity in rpm

N = 4 times the number of slots

in the codewheel (i.e.,

quadrature counts).

Example Code for Programming Proportional Velocity Mode

{ Begin }

Hard Reset { HCTL-1100 goes into INIT/IDLE Mode }

Initialize Filter, Timer, Command Position Registers

Write 03H to Register R05H

{ HCTL-1100 is now in Position Mode }

Write Desired Command Velocity (if needed)

Set Flag F3 {Proportional Velocity Move Begins}

{ System ramps to Command Velocity }

Continue writing new Command Velocities

{end}

t = The HCTL-1100 sample time

in seconds. (See the section on

the HCTL-1100’s Sample Timer

register).

Because the Command Velocity

registers (R24H and R23H) are

internally interpreted by the

HCTL-1100 as 12 bits of integer

and 4 bits of fraction, the host

processor must multiply the

desired command velocity (in

quadrature counts/sample time)

by 16 before programming it into

the HCTL-1100’s Command

Velocity registers.

The actual velocity is computed

only in this algorithm and stored

in scratch registers R35H (MSB)

and R34H (LSB). There is no

fractional component in the actual

velocity registers and they can be

read in any order.

The controller tracks the command velocity continuously until

new mode command is given. The

system behavior after a new

velocity command is governed

only by the system dynamics until

a steady state velocity is reached.

2-171

MOTION SENSING

AND CONTROL

Figure 13. Integral Velocity Modes.

quadrature counts/sample time.

The conversion from rpm to

quadrature counts/sample time is

shown in equation 9. The

Command Velocity register

(R3CH) contains only integer data

and has no fractional component.

While the overall range of the

velocity command is 8 bits, two’scomplement, the difference

between any two sequential

commands cannot be greater than

7 bits in magnitude (i.e., 127

decimal). For example, when the

HCTL-1100 is executing a

command velocity of 40H

(+64D), the next velocity command must fall in the range of

7FH (+127D), the maximum

command range, C1H (-63D), the

largest allowed difference.

The command acceleration is a

16-bit scalar word stored in R27H

and R26H. The upper byte

(R27H) is the integer part and the

lower byte (R26H) is the

fractional part provided for

resolution. The integer part has a

range of 00H to 7FH. The

contents of R26H are internally

divided by 256 to produce the

R27H R26H

0IIIIIII FFFFFFFF/256

Command Acceleration Format

fractional resolution.

The units of acceleration are

quadrature counts/sample time

squared.

To convert from rpm/sec to

quadrature counts/[sample time]2,

use the formula shown below:

Aq = (Ar)(N)(t2)(0.01667/rpmsec) [10]

Where:

Aq = Acceleration in quadrature

counts/[sample time]

2

Ar = Acceleration in rpm/sec

N = 4 times the number of slots

in the codewheel (i.e.,

quadrature counts)

t = The HCTL-1100 sample time

in seconds. (See the section on

the HCTL-1100’s Sample Timer

register).

Because the Command Acceleration registers (R27H and R26H)

are internally interpreted by the

HCTL-1100 as 8 bits of integer

and 8 bits of fraction, the host

processor must multiply the

desired command acceleration (in

quadrature counts/[sample time]2)

by 256 before programming it

into the HCTL-1100’s Command

Acceleration registers.

Internally, the controller performs

velocity profiling through position

control.

Each sample time, the internal

profile generator uses the

information which the user has

programmed into the Command

Velocity register (R3CH) and the

Command Acceleration registers

(R27H and R26H) to determine

the value which will be automatically loaded into the Command

Position registers (R0CH, R0DH,

and R0EH). After the new

command position has been

generated, the difference between

the value in the Actual Position

registers (R12-R13H, and R14H)

and the new value in the

Command Position registers is

calculated as the new position

error. This new position error is

used by the full digital compensation filter to compute a new motor

command output by this sample

time. The register block in Figure

3 further shows how the internal

profile generator works in

Integral Velocity mode. In control

theory terms, integral compensation has been added and therefore, this system has zero steadystate error.

Although Integral Velocity Control

mode has the advantage over

Proportional Velocity mode of

zero steady state velocity error,

its disadvantage is that the closed

2-172

loop stability is more difficult to