Page 1

Honeywell

CT8611

Heat Pump

Thermostat Wiring Guide

Home and Building Control

Ploneywell Inc.

1985 Douglas Drive North

Golden Valley, Minnesota 55422

J. H. ■ Prinred in Tiuwnn * Furm NiiTflbcr 69-OE17 • [

Hone^ell

Helping You CotHrol Your World

Page 2

HOWTO USE THIS GUIDE

Before you disconnect the wires and remove your existing

thermostat, make certain this new thermostat, see Figs. 1

and 2, will replace it and that you understand how you will

reconnect the wiring. To do that, proceed as follows:

Step 1

Find the manufacturer of your heat pump in the Table of

Contents, and turn to the appropriate page.

Step 2

Expose the wiring on your current thermostat {the subbase)

and check that the terminals on your existing thermostat

coincide with the teminals shown in the second column

(Existing thermostat wiring).

if they do, read and follow the installation instructions provided

with the thermostat.

If they do not, call Honeywell Customer Assistance toll free at

1-800-468-1502, Monday-Friday, 7:00 a.m. - 5:30 p.m. Central

time, to make certain you can safely use this thermostat to

control your heat pump.

Before you call, please have the following information

available — thermostat model number and date code, heat

pump model number and manufacturer, and number of wires

connected to the thermostat. The date code is usually stamprid

on the back of the thermostat and is a four-digit number, e.g.,

9346.

NOTICE: ! his equipment is a Class B digital apparatus,

which complies with Canadian Radio Interference

Regulations, CRC c. 1374.

Page 3

TABLE OF CONTENTS

How to Use This Guide..................................................................... 3

Heat Pumps are Different................................................................ 6

Heat Pumps are Two Systems in One............................................ 7

Definitions of Terminal Functions.................................................8,9

Heat Pump Manufacturers.........................................................12-23

Amana........................................................................................12

American Standard .

Arcoaire................................................................................... 14

Bard...........................................................................................13

Borg Warner

B.D.P. (Bryant-Day/Night-Payne)............................................15

Carrier....................................................................................... 16

Comfortmaker...........................................................................14

Friedrich.................................................................................. 17

Heil Quaker

Janitrol..................................................................................... 13

Lennox...................................................................................... 19

Luxaire (Moncrief, Fraser, Johnston)......................

Rheem...

Ruud....................................................................................... 20

Snyder General.........................................................................14

Tappan.................................................................................... 13

Tempstar

Trane

Whirlpool

..........................................................................

................................................................................

.........

..................

.........

Williamson...

York..............................................................................................22,23

...........

..................................................

........................................................................

..............

..................................................................18

...................................

.......................................................................IS

.................!...............................................

.............................21

21

22,23

18

22

...20

13

Page 4

HEAT PUMPS ARE DIFFERENT

HEAT PUMPS ARE TWO SYSTEMS IN ONE

• Heat pun>p systems usually

have a supplemental,

“second stage" heating

system that operates only

when necessary. This heat

pump thermostat is designed

to minimize more expensive

second-stage operation,

indicated by the green AUX

light on your switching

subbase.

• With this thermostat, you will notice that your compressor

operates continuously during the recovery period. This may

appear to waste energy, but actually is more efficient.

Multiple ON-OFF cycles are neither necessary to achieve

comfort, nor are they as efficient for heat pump systems. By

reducing the number of cycles, you reduce the strain on

your system and extend equipment life.

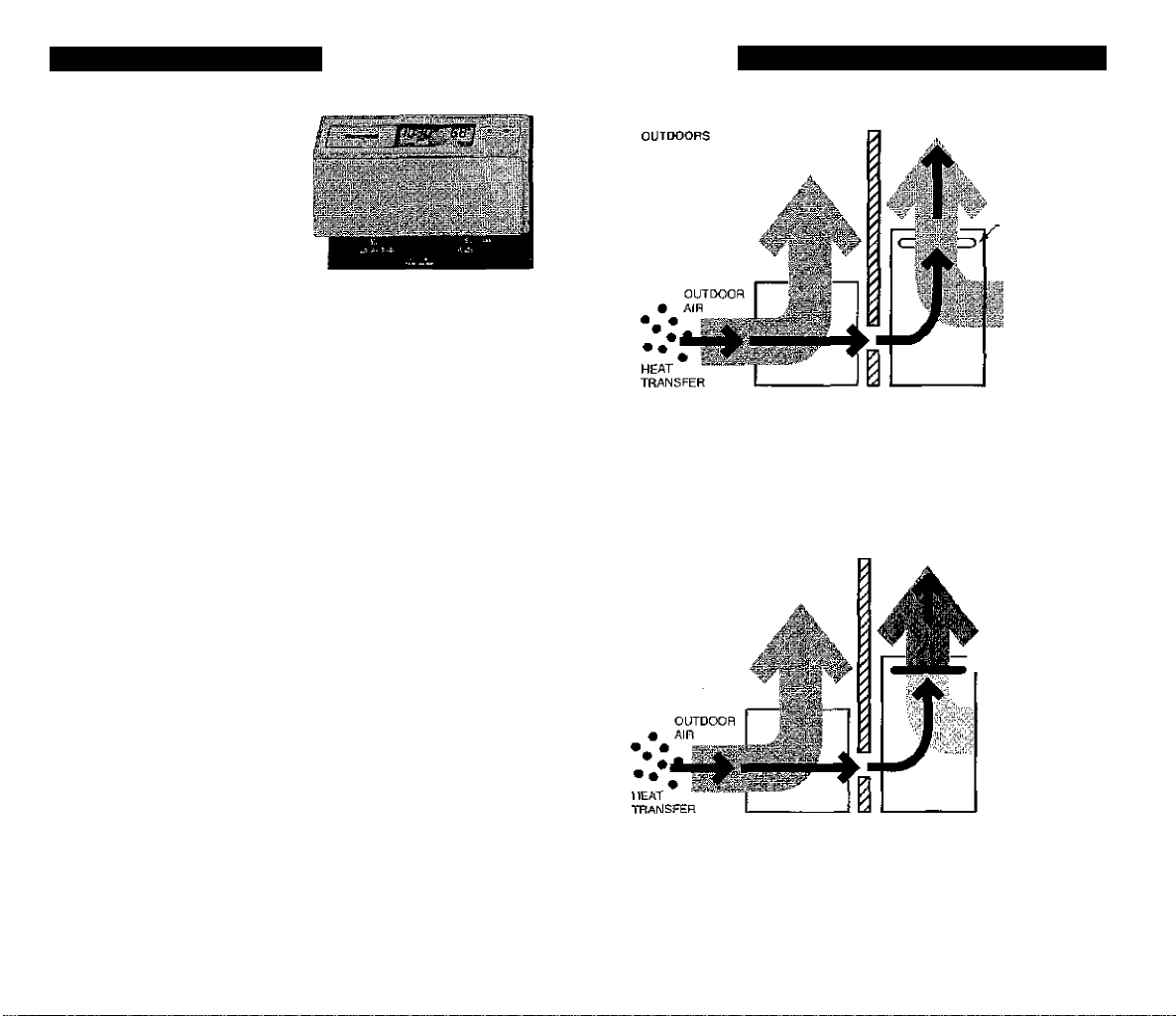

MILD WEATHER

INDOORS

■ AUXILIARY

HEATING

ELEMENT

OFF

INDOOR

AIR

In mild westher, virtuafiy all of the demand for heat in buildings

can be met by the heat pump compressor. This "First Stage"

process o\ moving heat indoors is very economical. As the

air becomes colder outside, the first stage may be unabfe to

deliver enough heat to maintain the desired comfort /evef

m the buiiding.

SEVERE WEATHER

OLrnKWRS

INDOORS

AUXILIARY

> HEATING

EUCMCNT

ON

i INDOOR

t AIR

During high heat demand, the thermostat wiU call for additiorm!

“Second Stage"power from the auxiliary heat system. This

auxiliary tieat is commonty electric “resistance" heat and is two

to three times more expensive to operate than the compressor.

If you have specific questions concerning the the operation of

your heat pump, please contact the equipment manufacturer.

Page 5

DEFINITIONS OF TERMINAL FUNCTIONS

Each terminal of the CT8611 controls a different heat pump

function. Here is a listing of the possible heat pump functions;

Function

STAGE HEAT:

Definition

When this terminal is activated, the

heat pump is on and providing heating

to the living space.

AUXILIARY HEAT:

When this terminal is activiatsd, the

auxiliary heating source is on because

the heat pump is unable to meet the

heating demand of the living space.

STAGE COOL;

When this terminal is activated, the

heat pump is on and providing

cooling to the iiving space.

COMPRESSOR;

When this terminal is activated, the

heat pump is on and providing either

heating or cooling to the living space,

depending on Ifie system switch

position.

C/0 VALVE HEAT:

Heating Changeover Valve. This

terminal is activated when the

system switch is in the HEAT position.

It provides changeover in heat pumps

that changeover in heating.

C/O VALVE COOL:

Cooling Changeover Valve. TTiis

terminal is activated when the

system switch is in the COOL position.

It provides changeover in heat pumps

tfiat changeover in cooling.

EM. HEAT:

Emergency Heat. This terminal is

activated when the system switch is

in the EM. HT position, in this situation,

the heat pump will not be activated.

FAN:

MULTIPLE

AUX. HEAT

LOADS:

OUTDOOR SENSOR:

OUTDOOR STAT:

POWER;

COMMON:

SYSTEM MONITOR:

When this terminal is activated, the

fan is on. With the fan switch in the

AUTO position, the tan cycles on and

off with the heat pump, VVith the fan

switch in the ON position, the fan is

on continuousty.

This terminal is activated when

additional auxiliary heat loads are

required. Since the CT86 M only has

provisions for one auxiliary heat load,

these loads must be connected to the

AUXILfARY HEAT terminal.

This terminal is not connected to the

CT8611. On your original thermostat,

this terminal was activated by an

outdoor sensor that controlled the

auxiliary heat source.

Outdoor Thermostat. This terminal is

activated when the system switch is in

the EM, HT. position. The outdoor

thermostat controls the amount of

auxiliary heat that will be activated.

This terminal connects to the power

side of the 24-volt transformer

This terminal connects to the common

side ot the 24-volt transformer.

Some heat pumps have the ability to

indicate when the heat pump is

malfunctioning. When this occurs, this

terminal is activated and the CHECK

LED is activated.

Page 6

AND OVERLOAD PROTECTION AS REQUIRED.

1\ POWER SUPPLY. PROVIDE DISCONNECT MEANS

A

AND OVERLOAD PROTECTION AS REQUIRED.

(HOT)

Fig. 1—Typical hookup of CT8611 with jumper intact.

10

Fig, 2—Typical hookup of CT8611 with jumper removed.

11

Page 7

BARD/JANlTROUTAPPAN/WILUAil/ISON

Notes

Q Jumper these two terminals if both are present.

This terminal must be connected to transformer common.

F lemove this factory-in stalled jumper for independent stage

1 heat and cool connection.

12

I '

Notes

[I This terminal musl be connected to transformer common.

B Leave factory-installed jumper in place.

El Connect muitiple second stage heating loads

to W2 terminals.

13

Page 8

ARCOAIRE/SNYDERGENERAUCOiFORTMAKER

B.D.P. (BRYANT-DAY/NIGHT-PAYNE)

Wiring

terminal

function

COMMON

POWER

COMPRESSOR

1ST STG.

HEAT

AUX. HEAT

FAN

C/O VALVE

HEAT

C/O VALVE

COOL

SYSTEM

MONITOR

EM. HEAT

MULTIPLE AUX.

HEAT LOADS El

Existing

thermostat

wiring

®—

©”©-

----

New

thermostat

wiring

®

-© .

®> /

Notes

O This terminal must be connected to transformer common.

0 Leave factoryanstalled jumper in place.

14

DEFROST

Notes

■®

□ This terminal must be connected to transformer common.

m Leave factory-installed jumper in place.

S Connect multiple second stage heating loads to

W2 terminals.

15

Page 9

CARRIER

FRIEDRICH

D This terminal must be connected to transformer common.

B Leave factoiY-instalted jumper in place.

16

Notes

D This terminal must be connected to transformer common.

n Leave factory-in stalled jumper in place.

B Tape off the end of the wire. Jumper is not required on

this thermostat (CT8611).

17

Page 10

LENNOX

Notes

□ This terminal must be connected to transformer common.

O Leave factory-installed jumper in place.

18

Notes

n This terminal must be connected to transformer common.

B Leave factory-installed jumper in place.

19

Page 11

RHEEM/RUUD

TRANE/AMERICAN STANDARD

Notes

D This terminal must be connected to transformer common.

0 Leave factory-installed jumper in place.

Notes

□ This terminal must be connected to transformer common.

0 Leave factory-installed jumper in place.

0 Tape off end. CT8611 replaces outdoor reset with improved

zero droop performance.

20 21

Page 12

YORK/BORG WARNER/LUXAIRE (IHONCRIEF, FRASER, JOHNSTON)

YORK/BORG WARNER

Notes

il This terminal must be connected to transformer common.

B Connect multiple second stage heating loads

to W2 terminals.

B Leave factory-installed jumper in place.

El If present on original equipment

22

Notes

n This terminal must be connected to transformer common.

B Remove factory-installed jumper.

23

Loading...

Loading...