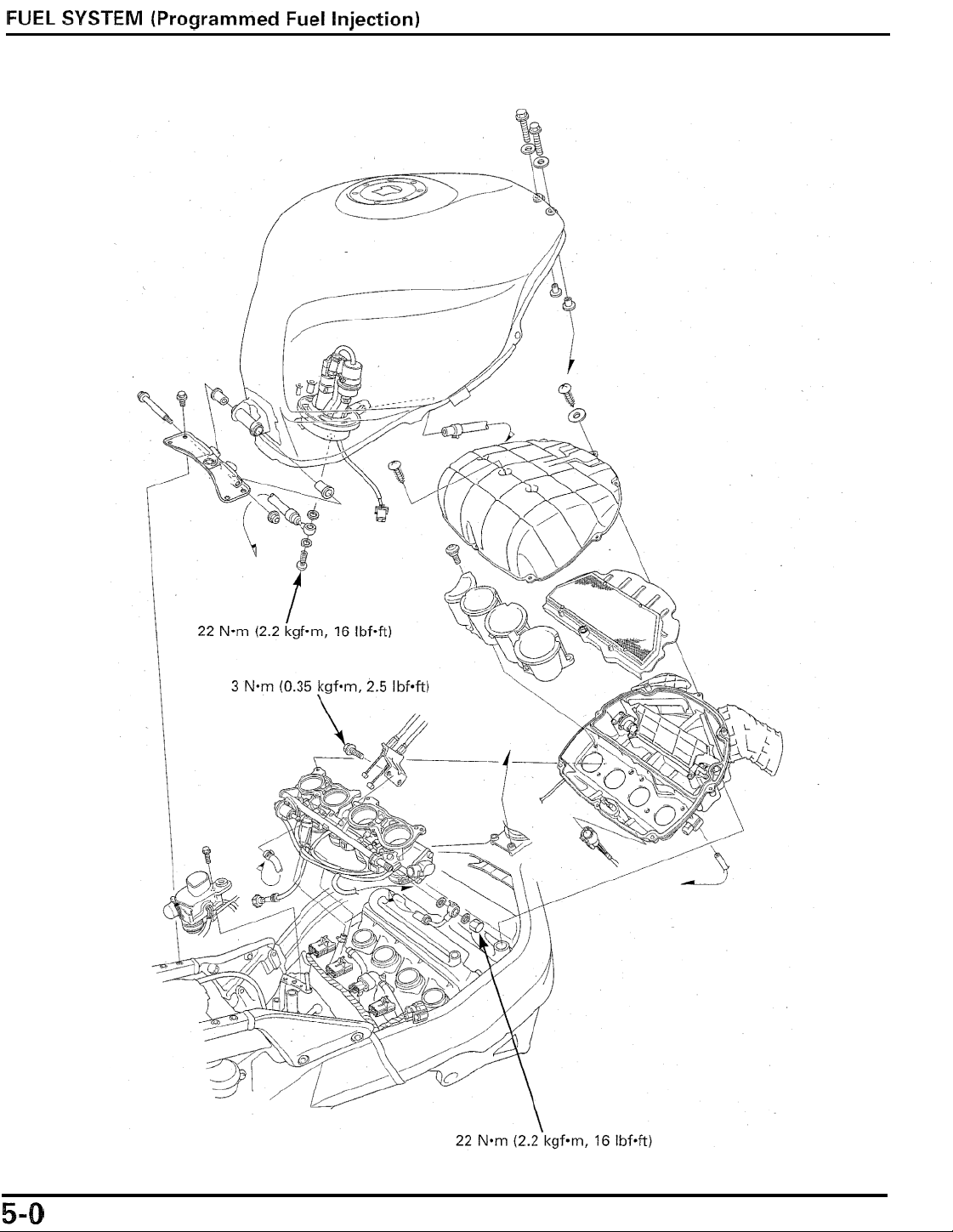

SERVICE INFORMATION

TROUBLESHOOTING

SYSTEM LOCATION

SYSTEM DIAGRAM

PGM

-

FI (PROGRAMMED FUEL

INJECTION) SYSTEM

PGM

-

FI SELF-DIAGNOSIS MALFUNC

TION INDICATOR LAMP (MIL)

FAILURE CODES

FUEL LINE INSPECTION

FUEL PUMP

FUEL CUT-OFF RELAY

FUEL TANK

AIR CLEANER HOUSING

THROTTLE BODY

INJECTORS

PRESSURE REGULATOR

FAST IDLE WAX UNIT

5-

1

5-3

5

-

4

-

5

5

MAP SENSOR

IAT SENSOR

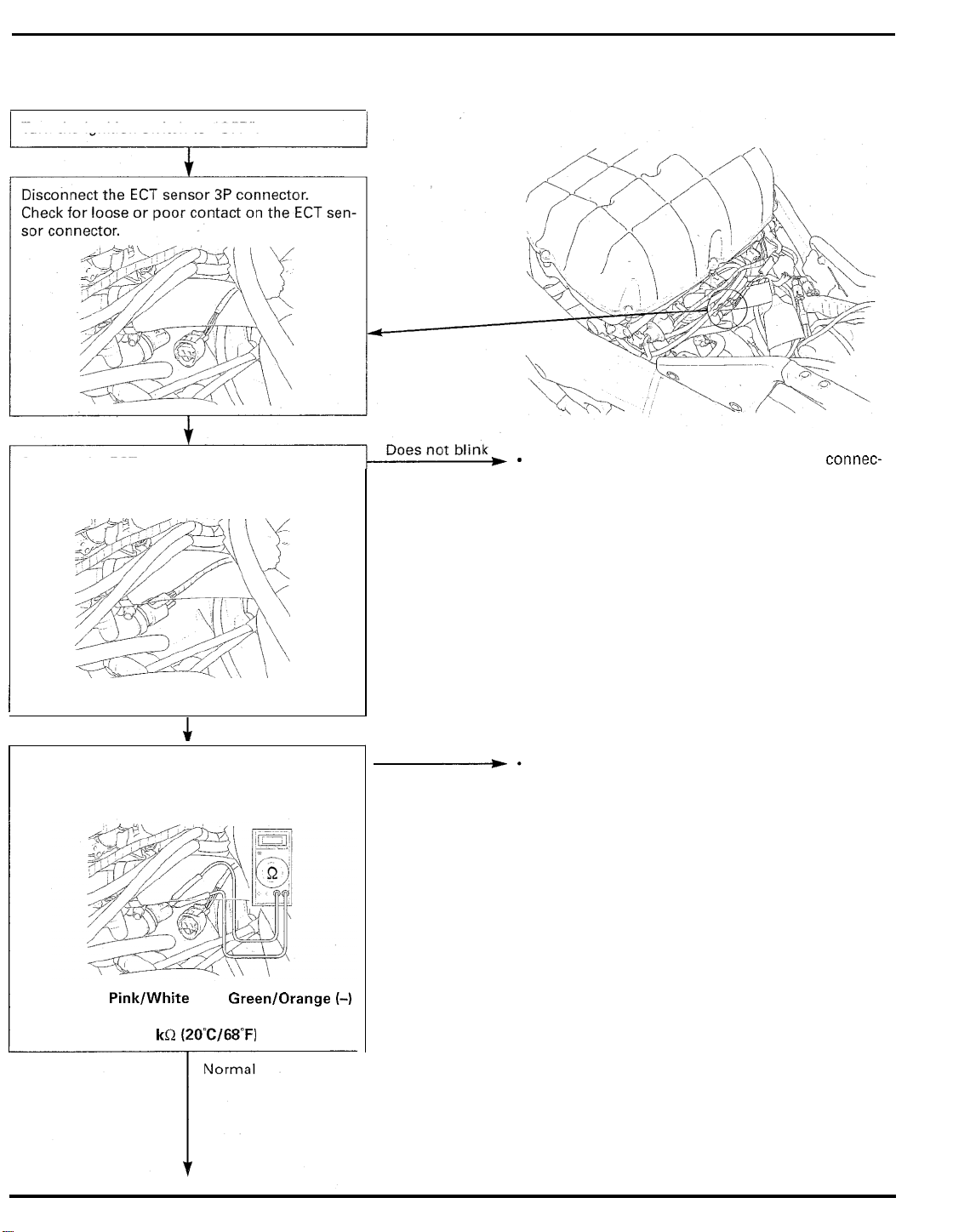

ECT SENSOR

CAM PULSE GENERATOR

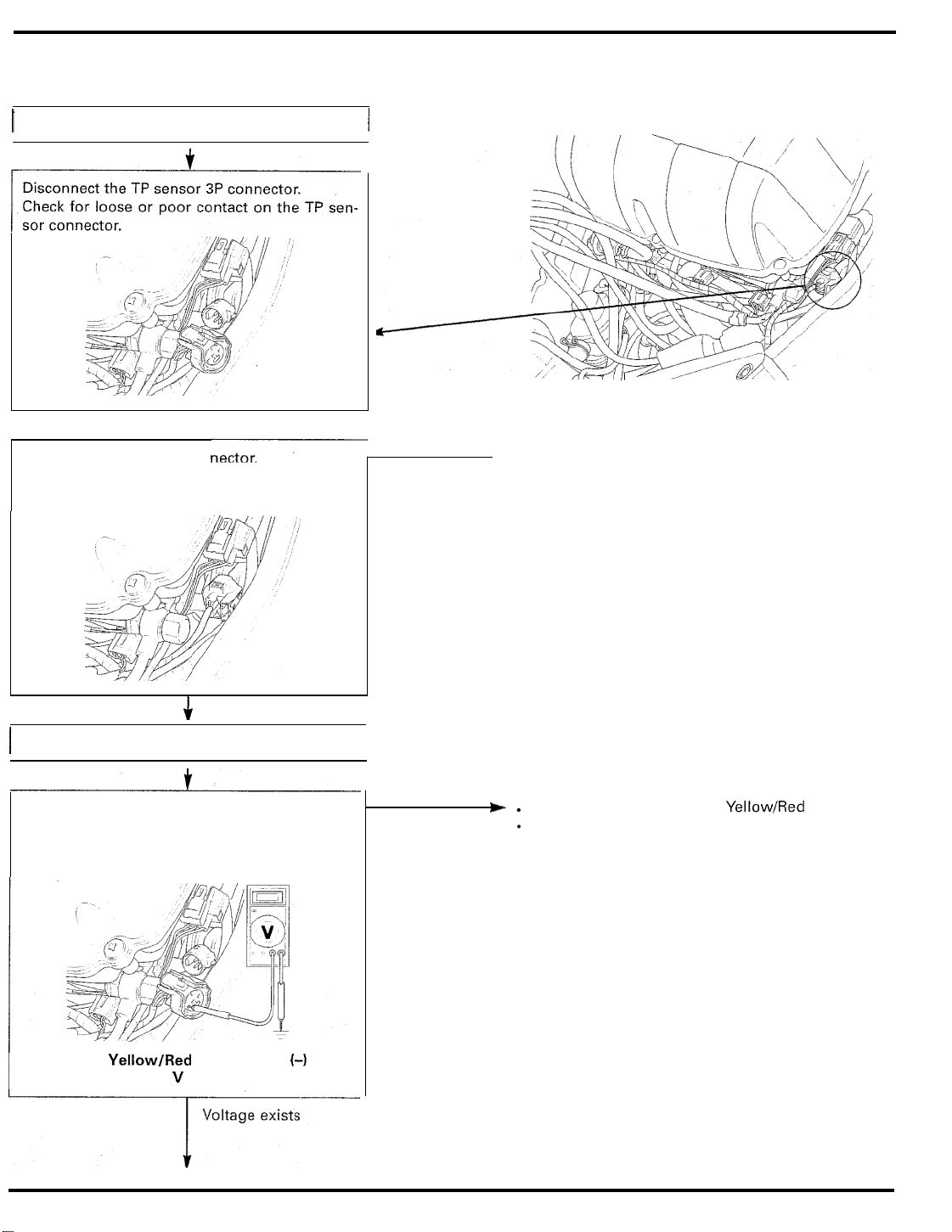

TP SENSOR

5

-

6

-

-

10

5

5

-

54

5

-

57

-

58

5

-

59

5

5

-

64

5

-

67

-

72

5

5

-

74

5

-

75

BANK ANGLE SENSOR

ENGINE STOP RELAY

ECM (ENGINE CONTROL MODULE)

PAIR SOLENOID VALVE

EVAP PURGE CONTROL SOLENOID

VALVE (California type only)

02

SENSOR (California type only)

EGCV AND AIR INTAKE VALVE

INSPECTION

EGCV AND AIR INTAKE VALVE

SERVO MOTOR

EGCV

VARIABLE AIR INTAKE VALVE

5-81

5

-

82

5

-

82

5

-

83

-

84

5

5

-

85

5

-

86

-

87

5

5

-

88

5

-

89

5

-

90

5

-

92

5

-

95

5

-

97

5

-

104

STARTER VALVE

-

76

5

STARTER VALVE

SYNCHRONlZATlON

SERVICE

INFORMATION

5

-

79

GENERAL

-

Be sure to relieve the fuel pressure while the engine

Bending or twisting the control cables will impair smooth operation and could cause the cables to stick or bind, resulting

loss

of vehicle control.

in

Work in a well ventilated area.

cause a fire or explosion.

Smoking or allowing flames or sparks in the work area or where gasoline

is

turned to

"

OFF".

is

stored can

5-1

FUEL

-

-

-

-

-

-

-

SYSTEM

Do

not apply commercially available carburetor cleaners to the inside of the throttle bore, which is coated with molybde

num.

Do not snap the throttle valve from full open to full closed after the throttle cable has been removed.

idle operation.

Seal the cylinder head intake ports with tape or a clean cloth to keep dirt and debris from entering the intake ports after the

throttle body has been removed.

Do not apply excessive force to the fuel pipe on the throttle body while removing or installing the throttle body.

Do not damage the throttle body.

Prevent

The throttle body is factory pre-set. Do not disassemble the throttle body

Do

throttle and idle valve synchronization failure.

Do

Always replace the packing when the fuel pump is removed.

The programmed fuel injection system is equipped with the Self-Diagnostic System described on page 5-6.

tion indicator lamp (MIL) blinks, follow the Self-Diagnostic Procedures to remedy the problem.

When checking the PGM-FI, always follow the steps in the troubleshooting flow chart (page 5-12 through 5-53).

The PGM

ble in the system. When any abnormality is detected

ing use of the numerical values of a situation preset in advance in the simulated program map.

however, that when any abnormality is detected in the four injectors and/or the ignition and cam pulse generator, the fail

safe function stops the engine to protect

For PGM-FI system location, see page 5-4.

A faulty PGM-FI system is often related to poorly connected or corroded connectors. Check those connections before pro

ceeding.

For fuel reserve sensor inspection, see section

The vehicle speed sensor sends digital pulse signals to the ECM (PGM-FI unit) for computation. For vehicle speed sensor

inspection, see section 19.

When disassembling the programmed fuel injection parts, note the location of the O-rings. Replace them with new ones

upon reassembly.

Before disconnecting the fuel hose, release the fuel pressure

Always replace the sealing washers when the fuel hose banjo bolt is removed or loosened.

Use a digital tester for PGM-FI system inspection.

EGCV is the abbreviation of Exhaust Gas Control Valve.

dirt

not loosen or tighten the white painted bolts and screws of the throttle body. Loosening or tightening them can cause

not push the fuel pump base under the fuel tank when the fuel tank is stored.

-

FI system is provided with a fail-safe function to secure a minimum running capability even when there is no trou

(Proarammed Fuel Iniection)

It

may cause incorrect

It

may cause incorrect throttle and idle valve synchronization.

and debris from entering the throttle bore, fuel hose and return hose, clean them using compressed air.

in

it

from damage.

19.

a way other than shown

by

the self-diagnosis function, running capability is secured by mak

by

loosening the fuel hose banjo bolt at the fuel tank.

in

this manual.

If

the malfunc

It

must be remembered,

-

-

-

-

-

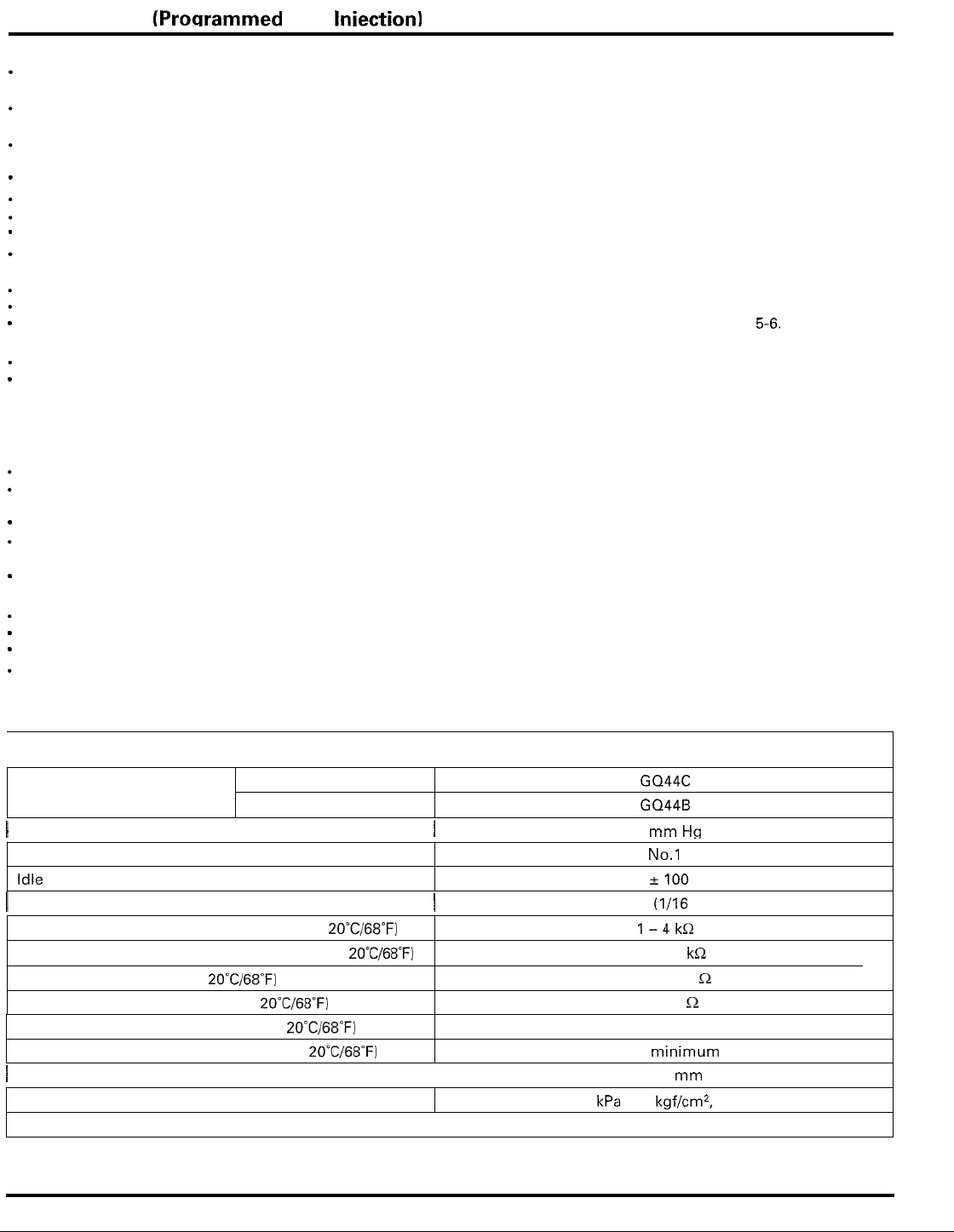

SPECIFICATIONS

I

Throttle body identification

number

I

Starter valve vacuum difference

Base throttle valve for synchronization

Idle speed

I

Throttle grip free play

Intake air temperature sensor resistance (at 2OoC/68"F)

Engine coolant temperature sensor resistance (at 20"C/68"F)

Fuel injector resistance (at 20"C/68"F)

PAIR solenoid valve resistance (at 20°C/68"F)

Cam pulse generator peak voltage (at 20"C/68"F)

Ignition pulse generator peak voltage (at 20"C/68"F)

/

Manifold absolute pressure at idle

Fuel pressure at idle

ITEM

Except California type

Ca I ifo rn ia type

I

I

I

I

SPECIFICATIONS

GQ44C

GQ44B

20

mm

Hn

No.1

1,200

f

100

rpm

2 - 6

mm

(1/16 - 1/4 in)

1-4kQ

2.3 - 2.6 kSZ

10.5

-

14.5

Q

20 - 24

0.7

0.7

150 - 250

343 kPa (3.5 kgf/cm2, 50 psi)

C2

V minimum

V minimum

mm

Hn

5-2

TORQUE VALUES

ECT (Engine Coolant Ternperature)/thermo sensor

Throttle body insulator band screw

Throttle cable bracket mounting screw

Fuel pipe mounting bolt

Pressure regulator mounting bolt

Starter valve synchronization plate screw

Fast idle wax unit link plate screw

Fast idle wax unit mounting screw

Starter valve lock nut

Fuel filler cap bolt

Fuel hose banjo bolt (fuel tank side)

Fuel hose sealing nut (throttle body side)

Fuel pump mounting nut

02

sensor (California type only)

EGCV mounting bolt (front)

(rear)

EGCV cover mounting bolt

EGCV pulley nut

EGCV pulley cover mounting bolt (lower)

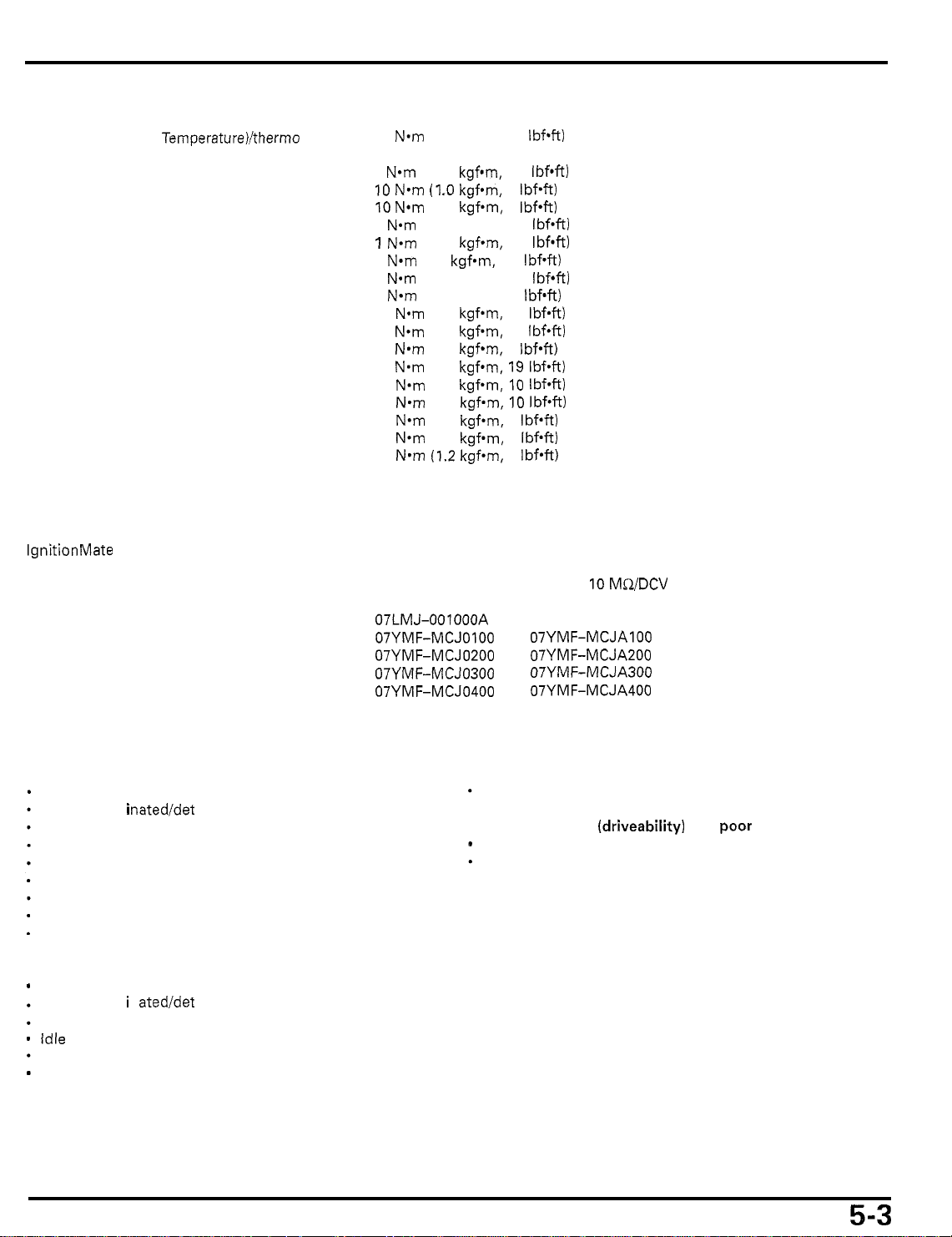

TOOLS

FUEL

N*m (2.3 kgf-m, 17 IbfW

23

See page 1-14

N-m

(0.35

3

10

Nm (1

10 N*m (1.0 kgf-m, 7 Ibf-ft)

1 N*m

7

N*m

5

N-m (0.6 kgf-m, 3.6 Ibf-ft)

2 N-m

2 N-m

22 N*m (2.2 kgf-m,

22

N-m

12 N*m

25 N.m (2.6 kgf-m,

14 N*m (1.4 kgfom, 10 IbfW

14

N*m

12 N*m (1.2 kgf-m, 9 IbfW

12 N-m (1.2 kgf-m,

12 N*m (1.2 kgf-rn, 9 Ibf-ft)

kgfom, 2.5 IbfW

.O

kgf*m, 7 Ibf-ft)

(0.09

kgf-m, 0.7 Ibf*ft)

(0.09

kgfm, 0.7 Ibf-ft)

(0.18

kgf-m, 1.3 IbfW

(0.2

kgf-m, 1.4 Ibf*ft)

(2.2 kgf-m,

(1.2

kgfom,

(1.4

kgf-m,

SYSTEM

16

IbfW

16

IbfW

9

IbfW

19

Ibf-ft)

10

Ibf-ft)

9

IbfW

(Programmed

See page

5-58

Fuel Injection)

for tightening sequence.

Fuel pressure gauge

IgnitionMate peak voltage tester (U.S.A. only) or

Peak voltage adaptor

ECM test harness, 26P

Vacuum gauge set

Installer shaft guide

Installer shaft

x

30

Installer shaft, 14

Remover, 14

x

16

mm

mm

TROUBLESHOOTING

Engine won’t to start

Intake

air

leak

Fuel conta

Pinched or clogged fuel hose

Faulty fuel pump

Clogged fuel filter

Clogged fuel injector filter

Sticking fuel injector needle

Faulty fuel pump operating system

Faulty pressure regulator

Engine stall, hard to start, rough idling

9

Intake air leak

F

ue I conta

Pinched

-

Idle speed misadjusted

Starter valve synchronization misadjusted

-

Faulty pressure regulator

m

i

natedidet e r io rated

m

i

n atedidet e riorat ed

or

clogged fuel hose

07406-0040003 or 07406-004000A (U.S.A. only)

07HGJ

-

0020100 (not available

digital multimeter (impedance

-

070MZ

07LMJ-001000A

07YMF-MCJ0100 or 07YMF-MCJA100 (U.S.A. only)

07YMF-MCJ0200 or 07YMF-MCJAPOO (U.S.A. only)

07YMF-MCJ0300 or 07YMF-MCJA300 (U.S.A. only)

07YMF-MCJ0400 or 07YMF-MCJA400 (U.S.A. only)

0010100 (two required)

Backfiring or misfiring during acceleration

Ignition system malfunction

Poor performance (driveability) and

Pinched or clogged fuel hose

Faulty pressure regulator

in

U.S.A.) with commercially available

10

MRiDCV minimum)

poor

fuel economy

5-3

FUEL

SYSTEM

(Programmed Fuel

Injection)

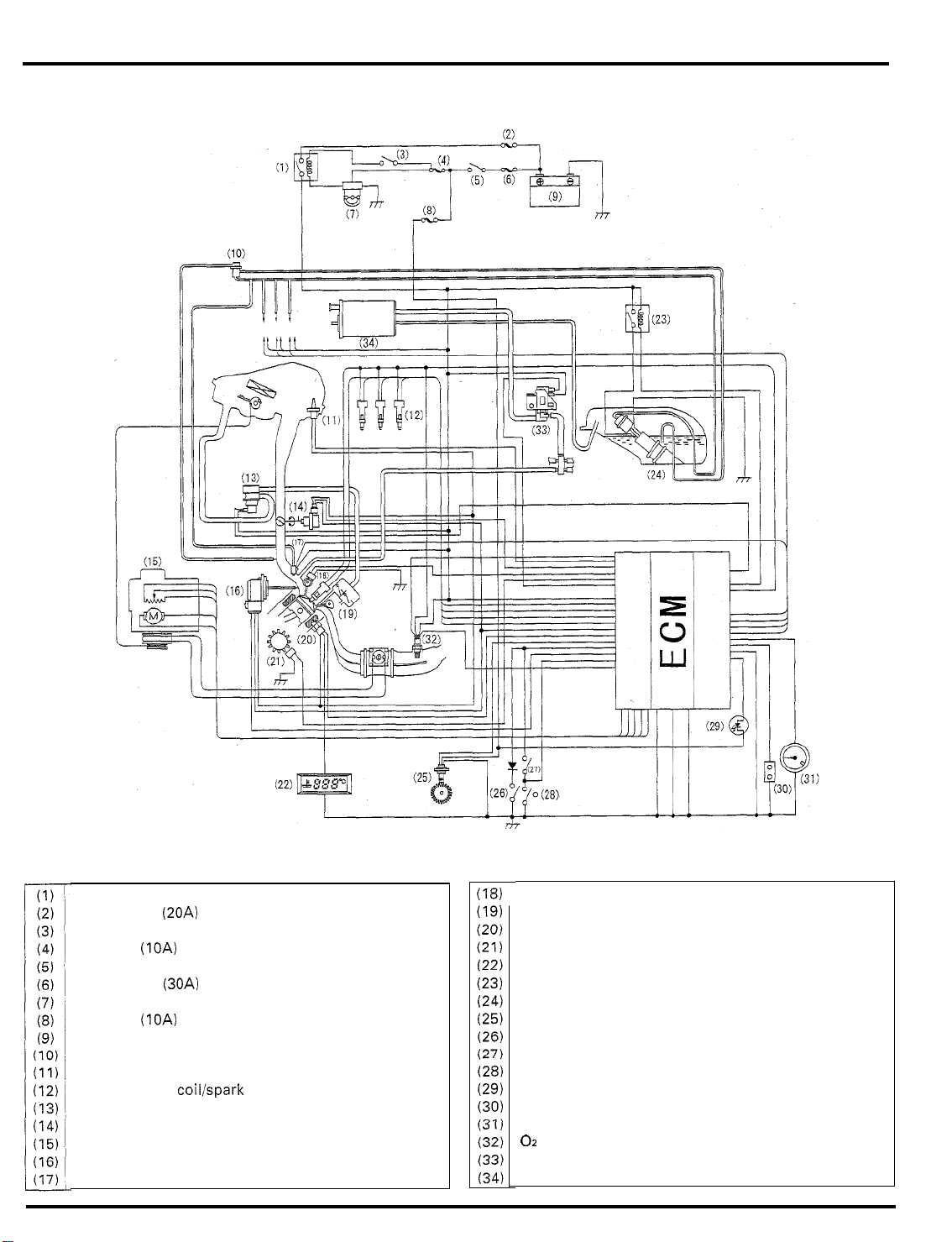

SYSTEM

LOCATION

PAIR

SOLENOID

I

VALVE

TP SENSOR

5-4

IGNITION PULSE GENERATOR

I

I

Manifold absolute Dressure sensor

1

Throttle position sensor

1

Intake air temperature sensor

1

Engine coolant temperature sensor

1

Engine control module

FULL

NAME

1

ABBREVIATIONS

I

se sensor

1

s sensor

1

se sensor

1

se sensor

I

ECM

I

I

I

I

I

I

FUEL

SYSTEM

(Programmed Fuel Injection)

SYSTEM

DIAGRAM

Engine stop relay

Main fuse

Engine stop switch

Sub

Ignition switch

Main fuse A

Bank angle sensor

Sub

Battery

Pressure regulator

IAT sensor

Direct ignition

PAIR solenoid valve

TP

sensor

EGCV and air intake valve servo motor

MAP sensor

Injectors

B

(20A)

-

fuse (10A)

-

fuse

(10A)

(30A)

coiI/spark plug

Cam pulse generator

PAIR check valve

ECT sensor

Ignition pulse generator

Water temperature

Fuel cut-off relay

Fuel pump

Vehicle speed sensor

Neutral switch

Clutch switch

Side stand switch

Malfunction indicator

Service check connector

Tach

o

meter

02

sensor (California type only)

EVAP purge control solenoid valve (California type only)

EVAP canister (California type only)

LCD

5-5

FUEL SYSTEM (Proclrarnrned Fuel

Iniection)

PGM-FI (PROGRAMMED FUEL

INJECTION) SYSTEM

SELF-DIAGNOSTIC PROCEDURES

Place the motorcycle on its side stand.

Start the engine and let

it

idle.

1

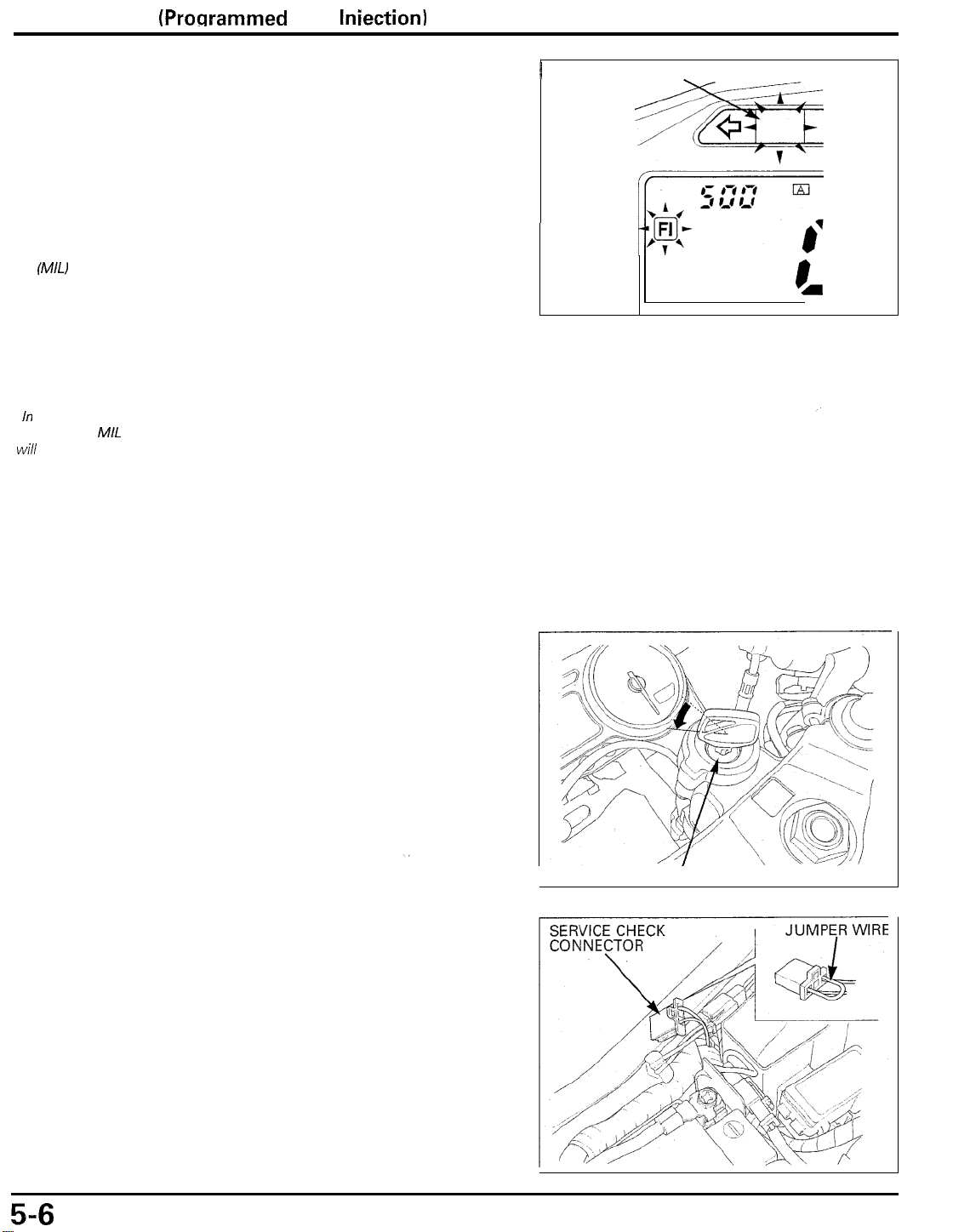

MALFUNCTION INDICATOR LAMP (MIL)

The malfunction

indicator lamp

(MlL)

blinking only with

switch in

below

wili illuminate and

will start

the side stand

down and with

the engine off

(engine stop

RUN)

engine revs are

5,000

In any other con

ditions, the

rpm

Mli

stay on

or

If

the malfunction indicator lamp (MIL) does not light

or blink, the system has no memory of problem data.

If

the malfunction indicator blinks, note how many

times the MIL blinks, and determine the cause

problem (page

-

If

you

wish to read the PGM-FI memory for trouble

data, perform the following:

Turn the ignition switch to

5-10

through

"

5-53).

OFF".

of

the

I

I,

,

5-6

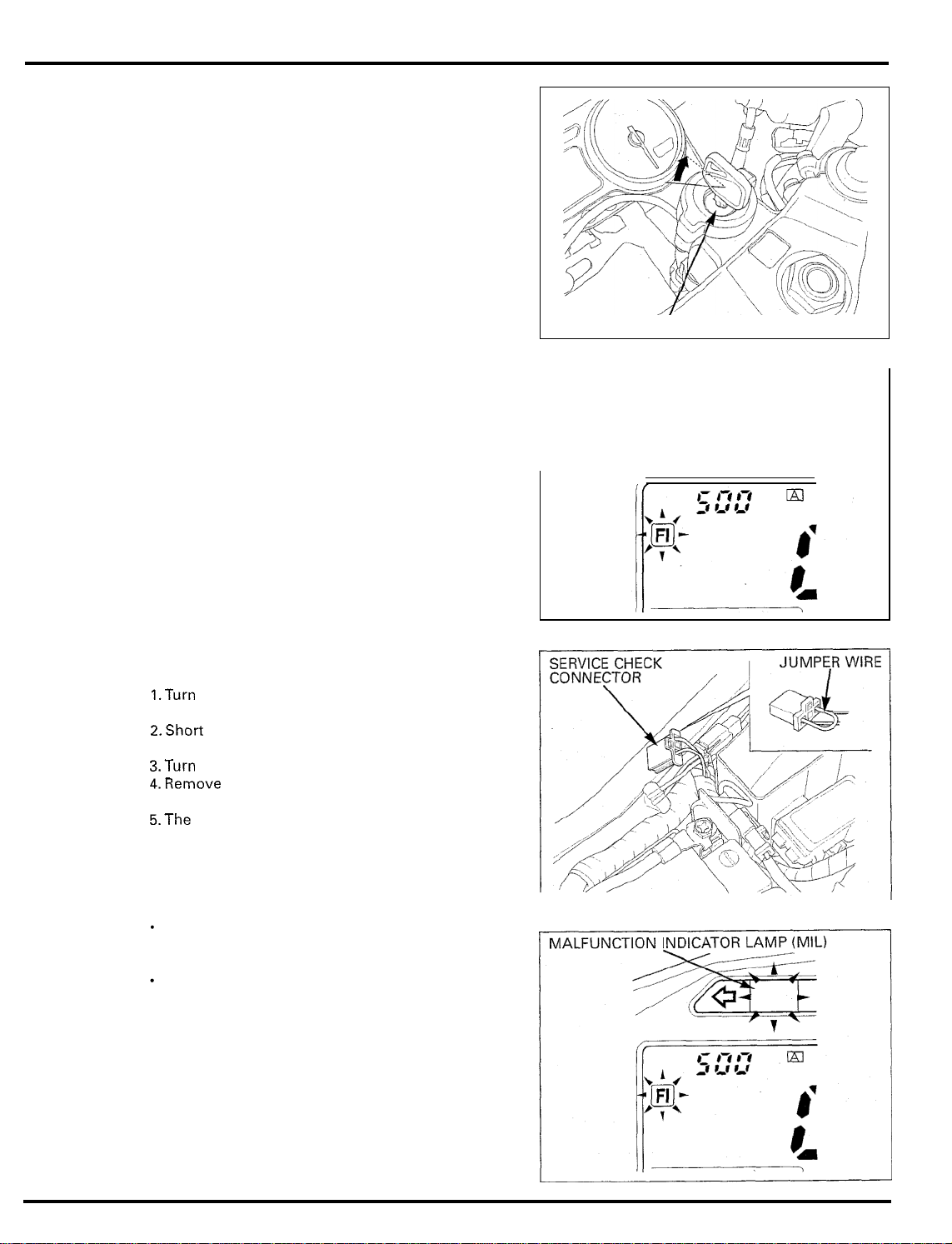

Remove the seat (page

Short the PGM-FI system service check connector ter

minals using a jumper wire.

2-2).

I

-

IGNITION SWITCH

FUEL

Turn the ignition switch to "ON" and engine stop

switch to

If the ECM has no self diagnosis memory data, the

MIL will illuminate, when you turn the ignition switch

to

If the ECM has self diagnosis memory data, the MIL

will start blinking, when you turn the ignition switch

to

Note how many times the malfunction indicator

blinks, and determine the cause of the problem (page

5

-

10 through 5-53).

Even if the PGM

not blink when the engine running.

"ON"

"ON"

"

.

.

RUN".

-

FI has memory data, the MIL does

SYSTEM

I

MALFUNCTION INDICATOR LAMP (MIL)

(Programmed Fuel Injection)

IGNITION'SWITCH

SELF-DIAGNOSIS

1.Turn the engine stop switch to "RUN" and ignition

switch to

2.Short

system using

3.Turn the ignition switch to "ON".

4.Remove the jumper wire from the service check

connector.

5.The MIL lights about 5 seconds. While the indicator

lights, short the service check connector again with

the jumper wire.

Self diagnosis memory data is erased if the MIL

turns

The service check connector must be jumped while

the indicator lights. If not, the MIL will not start

blinking.

Note that the self diagnosis memory data cannot be

erased if you turn

MIL starts blinking.

If

the

erased,

"

OFF".

the service check connector of the PGM-FI

a

off

and starts blinking.

MIL

blinks

so

try again.

RESET

jumper wire.

off

the ignition switch before the

20

times, the data has not

PROCEDURE

been

L

5-7

FUEL SYSTEM (Programmed Fuel Injection)

Avoldtouchmg

the teslerprobes

to

prevent electric

shock TOOLS:

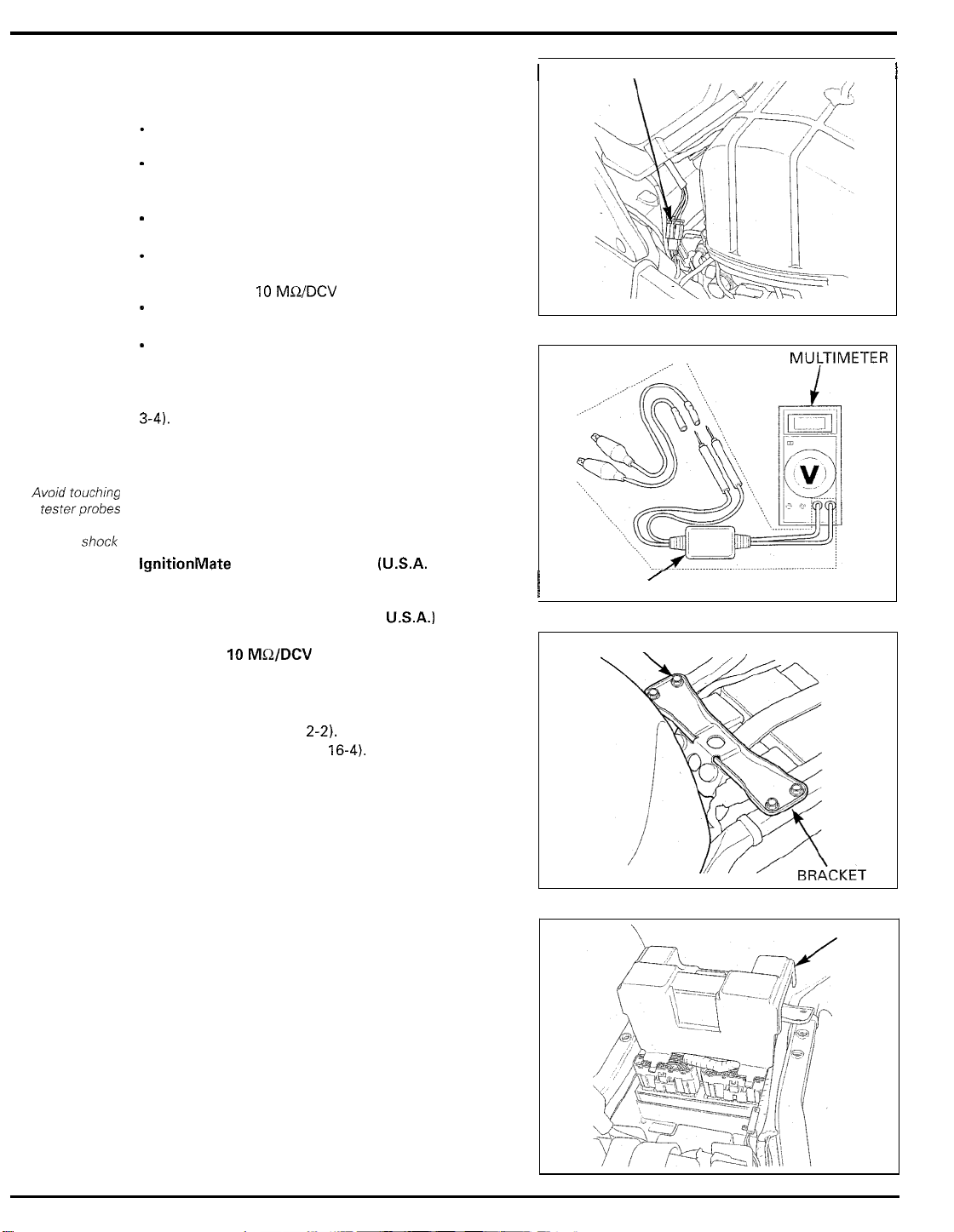

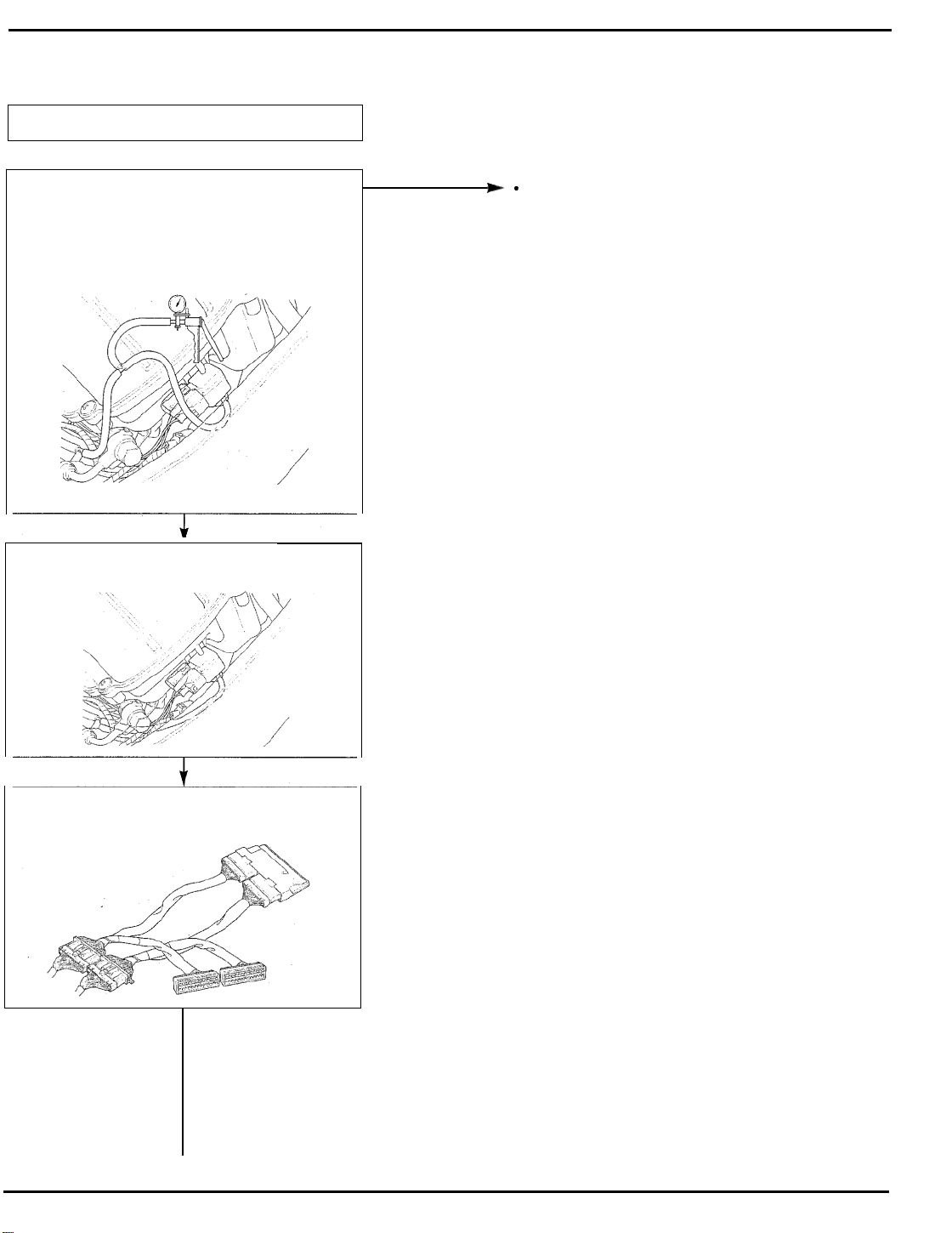

PEAK VOLTAGE INSPECTION PROCE

-

DURE

Use this procedure for the ignition pulse generator

and cam pulse generator inspection.

Check all system connections before inspection.

the system is disconnected, incorrect peak voltage

might be measured.

Check cylinder compression and check that all the

spark plugs are installed correctly.

Use the recommended digital muitimeter or a com

mercially available digital multimeter with an

10

impedance of

-

The display value differs depending upon the inter

nal impedance

Disconnect the fuel pump connector before check

ing the peak voltage.

Open and support the front end of the fuel tank (page

3-4).

Disconnect the fuel pump 3P (Black) connector.

Connect the peak voltage adaptor to the digital

multimeter.

IgnitionMate peak voltage tester

Peak voltage adaptor

with commercially available digital multimeter

(impedance

MR/DCV minimum.

of

the multimeter.

10

MCL/DCV minimum)

(U.S.A.

07HGJ-0020100

(not available

in

only)

U.S.A.)

If

or

I

3P (BLACK) CONNECTOR

-

-

-

I

I

PEAK VOLTAGE ADAPTOR

/

BOLTS

I

DIGITAL MULTIMETER

TEST HARNESS CONNECTION

Remove the seat (page

Remove the battery (page 16-4).

Remove the fuel tank rear bracket mounting bolts and

pull up the bracket.

Remove the ECM cover.

2-2).

I

I

\

ECM COVER

I

5-8

FUEL SYSTEM (Programmed

Fuel

Injection)

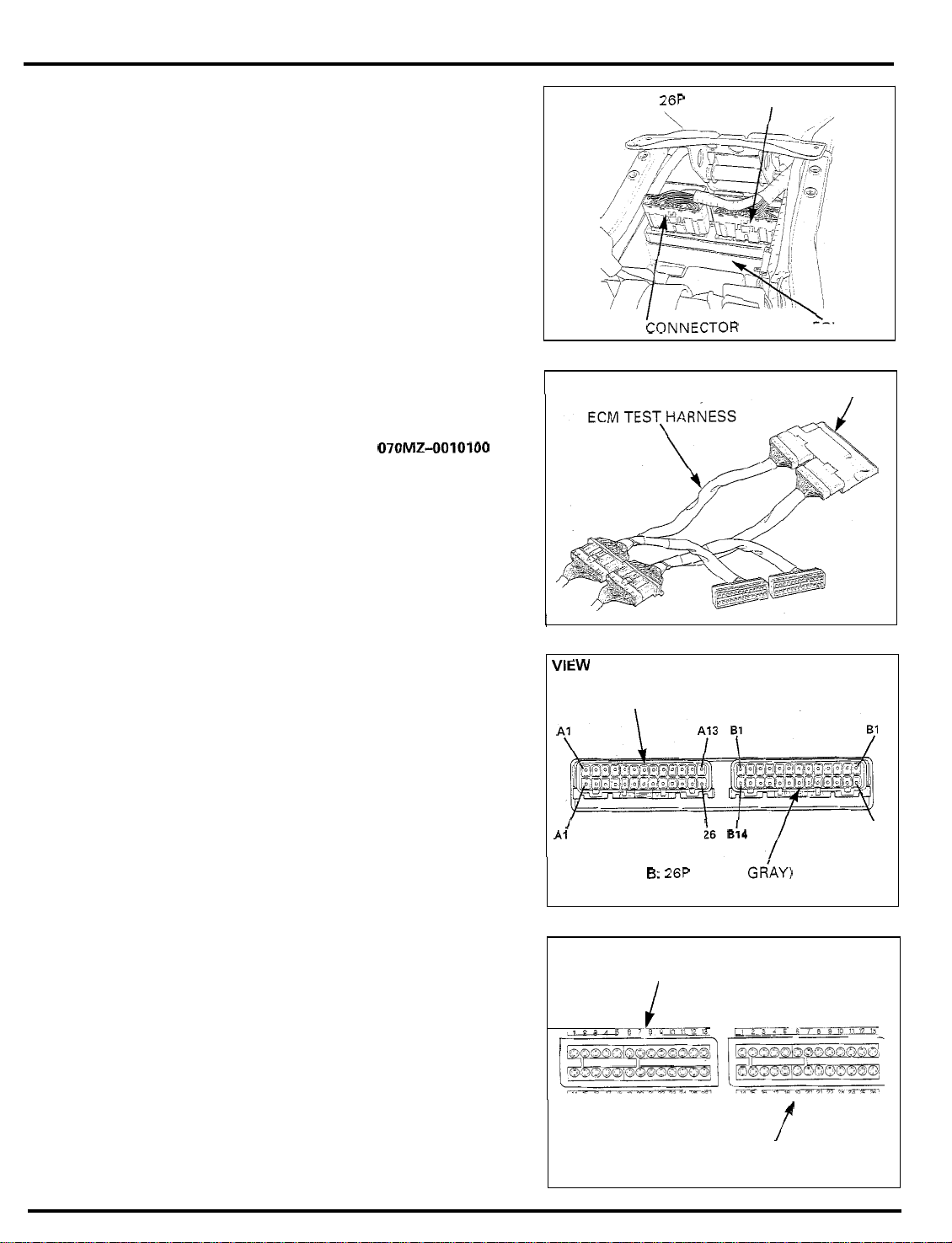

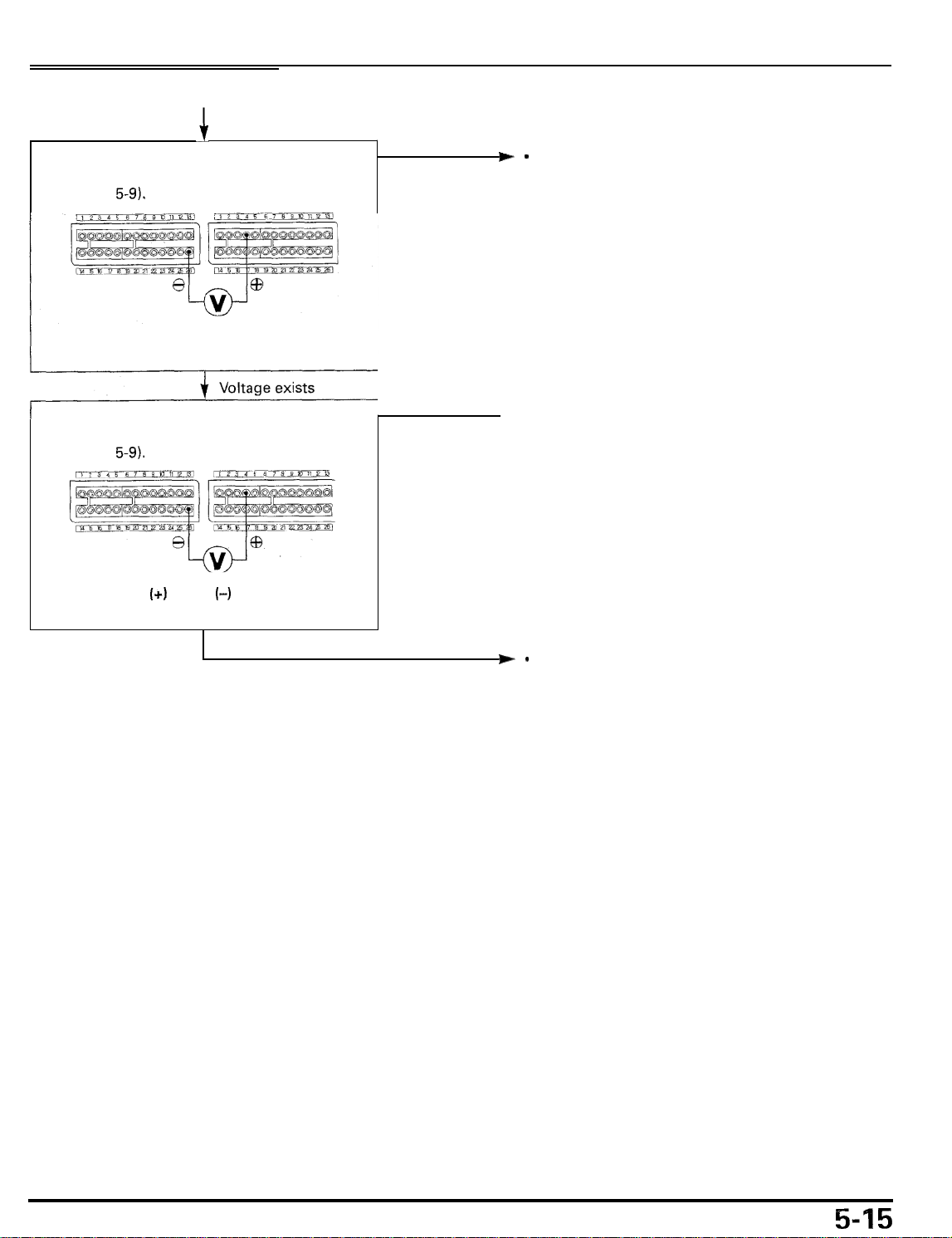

Disconnect the ECM

connectors from the unit.

Connect the ECM test harnesses between the main

wire harness and the ECM.

TOOL:

ECM

test

harness,

Install the battery and connect the positive terminal,

then connect the negative terminal.

26P

26P

(Black) and

070MZ-0010100

(two

26P

(Light gray)

required)

26p

26P

(BLACK) CONNECTOR

(LIGHT GRAY) CONNECTOR

ECM

TEST HARNESS TERMINAL LAYOUT

The ECM connector terminals are numbered as

shown in the illustration.

The test harness terminals are same layout as for the

ECM connector terminals as shown.

I

VIEW FROM WIRE HARNESS SIDE:

A:

26P

(BLACK) CONNECTOR

A1

I

4

A26

814

“I

B:

26~

(

LIGHT

G~AY)

26P

FOR

(BLACK) CONNECTOR

4

rr,Tn-l7FK

i

1

2

3

E-m

3

\

B26

CONNECTOF

I

F

f

O

R

26P

(

LIGHT

GRAY

)

CONNECTOR

5-9

FUEL

SYSTEM

(Programmed

Fuel

Iniection)

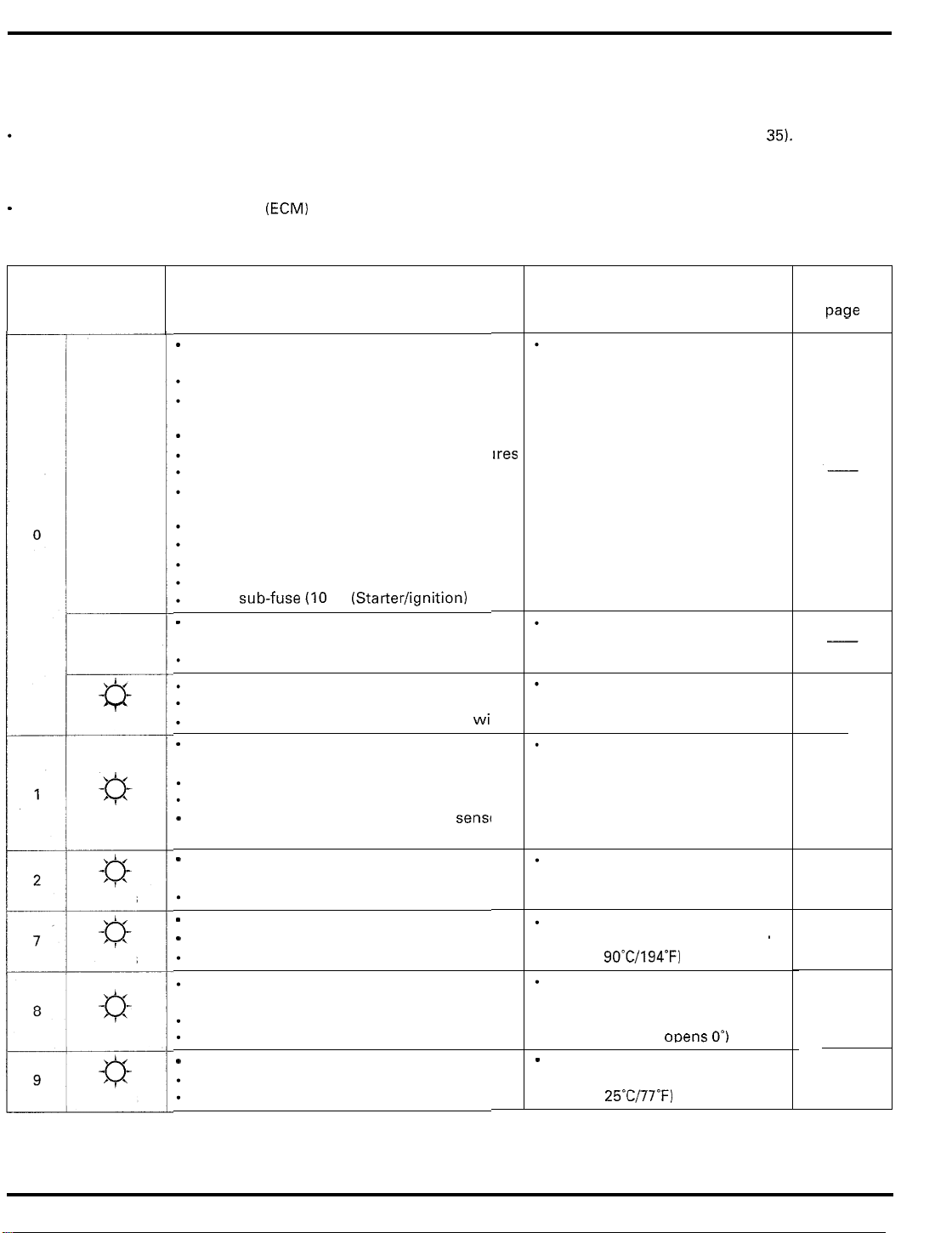

PGM-FI SELF-DIAGNOSIS MALFUNCTION INDICATOR LAMP (MIL)

FAILURE CODES

The PGM-FI malfunction indicator lamp (MIL) denotes the failure codes (the number of blinks from 0 to 35). The MIL has

two types of blinks, a long blink and short blink. The long blink lasts for

When two long blinks occur, and one short blink, that problem code is 21 (two long blinks

blink). Then, go to the flow chart and see problem code 21.

-

When the Engine Control Module (ECM) stores some failure codes, the MIL shows the failure codes in the order from the

lowest number to highest number. For example, when the MIL blinks once, then blinks seven times, two failures have

1

and

occurred. Follow the flow chart for failure codes

7.

1.3

seconds, the short blink lasts for 0.5 seconds.

=

20 blinks, one short blink

=

1

Number of PGM-FI

MIL blinks

0

No

blinks

0

No blinks

6-

'I'

Stays

lit

-0-

Blinks

-0-

Blinks

-0-

Blinks

-0-

Blinks

-0-

Blinks

Causes

Open circuit at the power input wire of the

ECM

Faulty bank angle sensor

Open circuit

circuit

*

Faulty engine stop relay

Open circuit in engine stop relay related

Faulty engine stop switch

Open circuit in engine stop switch related

wires

Faulty ignition switch

Faulty ECM

Blown PGM-FI fuse

Open circuit

Blown sub-fuse

*

Open or short circuit in malfunction indica

wire

Faulty ECM

Short circuit

Faulty ECM

Short circuit

-

Loose

connector

Open

Faulty MAP sensor

-

Wrong connection between the MAP sensc

and TP sensor connectors

-

Loose or poor connection of the MAP sen:

vacuum hose

Faulty MAP sensor

-

Loose

*

Open or short circuit in ECT sensor wire

Faulty ECT sensor

Loose or poor contact on TP sensor

connector

Open or short circuit

Faulty TP sensor

Loose or poor contact on IAT sensor

Open or short circuit

Faulty IAT sensor

in

bank angle sensor related

(20

A)

in

engine stop switch ground

(10

A) (Starter/ignition)

in

service check connector

in

service check connector

or

poor contacts on MAP sensor

or

short circuit in MAP sensor wire

or

poor contact on ECT sensor

in

TP sensor wire

in

IAT sensor wire

wi

w

Symptoms

-

safe contents)

(Fail

Engine does not start

Engine operates normally

Engine operates normally

Engine operates normally

Engine operates normally

Hard start at a low temperature

(Simulate using numerical

values:

Poor engine response when

operating the throttle quickly

(Simulate using numerical

values: Throttle

-

Engine operates normally

(Simulate using numerical

values;

90°C/194"F)

oDens

25"C/77"F)

0")

Refer to

Page

5

-

12

-

14

5

5-16

5

-

18

5-22

5-10

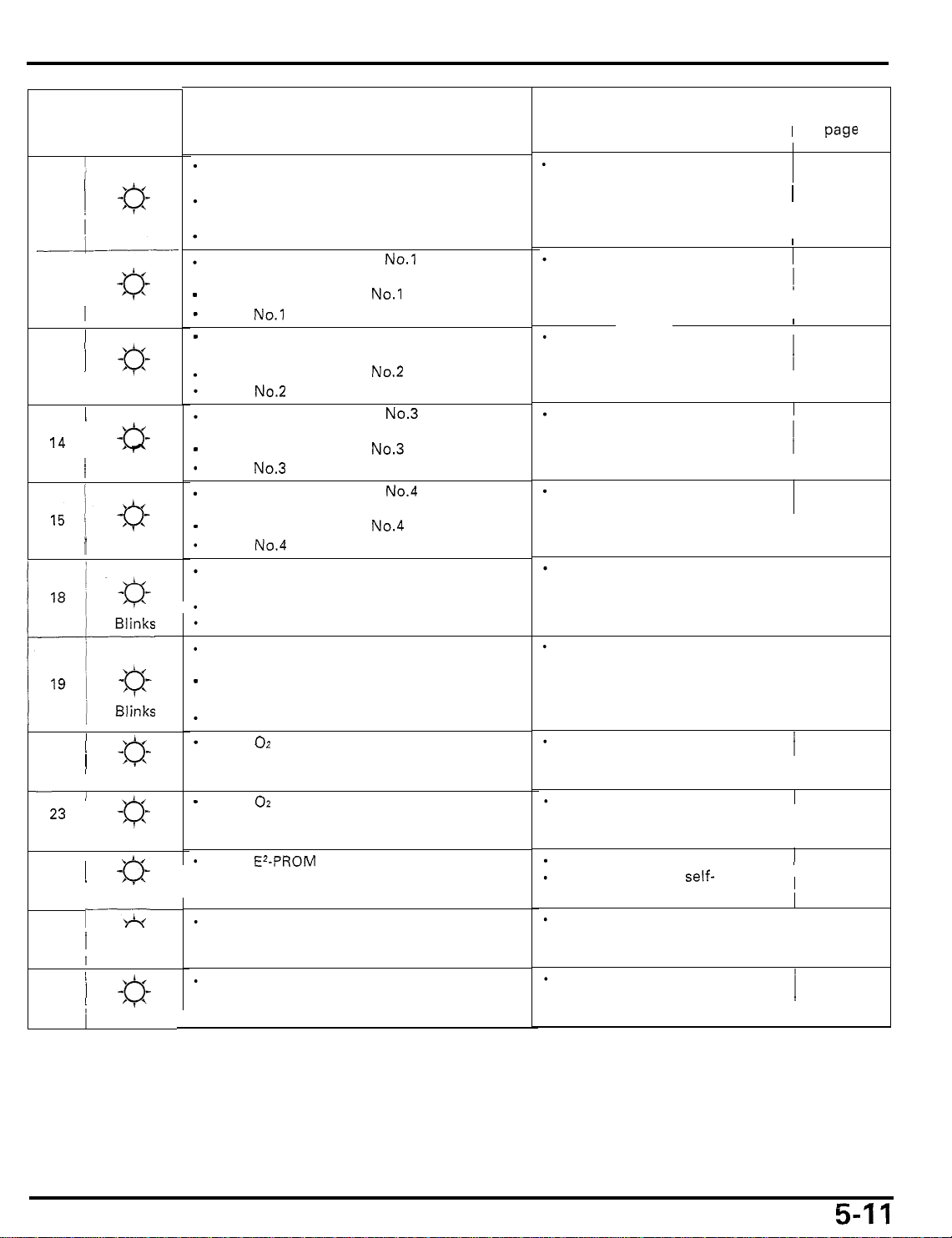

Number

MI L bli n ks

of

PGM-FI

Causes

FUEL

SYSTEM

(Fail

(Programmed Fuel

Symptoms

-

safe contents)

Injection)

1

Refer to

I

Page

A

-

11

13

14

21

23

33

34

35

1

1

-0-

I

Blinks

!

I

1

Blinks

i

-0-

!

Blinks

1

I

-36-

1'

~

Blinks

1

Blinks

I

;a-

I

I

,

Blinks

I

I

-0-

!

Blinks

1

-0-

1

Blinks

I

'

I

Blinks

1

;a-

i

Blinks

Loose or poor contact on vehicle speed

sensor connector

Open or short circuit

connector

Faulty vehicle speed sensor

Loose or poor contact on

connector

-

Open or short circuit in

Faulty

No.1

injector

-

Loose or poor contact on

connector

Open or short circuit

Faulty

No.2

injector

Loose or poor contact on

connector

-

Open or short circuit in

Faulty

No.3

injector

Loose or poor contact on

connector

-

Open or short circuit in

Faulty

No.4

injector

Loose or poor contact on cam pulse

generator

Open or short circuit in cam pulse generator

Faulty cam pulse generator

Loose or poor contact on ignition pulse

generator connector

-

Open or short circuit in ignition pulse

generator

Faulty ignition pulse generator

Faulty

02

sensor

-

Faulty

02

sensor heater

Faulty

E2-PROM

Faulty EGCV and air intake valve servo motor

voltage

Faulty EGCV and air intake valve servo motor

in

vehicle speed sensor

No.1

No.1

No.2

in

No.2

No.3

No.3

No.4

No.4

in

ECM

injector

injector wire

injector

injector wire

injector

injector wire

injector

injector wire

Engine operates normally

Engine does not start

Engine does not start

Engine does not start

Engine does not start

Engine does not start

Engine does not start

Engine operates normally

Engine operates normally

Engine operates normally

Does not hold the self-

diagnosis data

Engine operates normally

Engine operates normally

1

I

1

I

I

I

1

I

1

'

I

I

1

i

I

1

5-24

5-26

5-29

5-32

5-38

5-40

5-42

5-44

5-48

5-50

5-52

FUEL SYSTEM (Programmed Fuel Injection)

PGM-FI MIL

Connect the MAP sensor connector.

Place the motorcycle on its side stand.

Start the engine and check that the MIL blinks.

Turn the ignition switch to

1

BLINK

(MAP

4

1

"

I

SENSOR)

blink

OFF".

Does not blink

-

+

Loose or poor contact on the MAP sensor connec-

tor

Disconnect the MAP sensor 3P connector.

Turn the ignition switch to

Measure the voltage at the wire harness side

connector.

Connection: Yellow/Red

Standard: 4.75 - 5.25

Measure the voltage between the connector ter

minals

of

the-wire harness side.

"ON"

.

(+)

-

Ground

V

(-)

______)

-

-

t

Out

Out

of

of

range

range

-

Open or short circuit in Yellow/Red wire

Loose or poor contact on the ECM connectors

-

Open or short circuit in Greedorange wire

Loose or

poor

contact on the ECM connectors

Connection: Yellow/Red

5-12

(+)

-

Green/Orange

Voltage exists

(-1

FUEL

SYSTEM

(Programmed Fuel

Injection)

1

Measure the voltage between the terminals

the wire harness side.

Connection:

Light green/Yellow

Standard: 4.75

Turn the ignition switch to

Connect the MAP sensor

-

5.25

(c)

-

Greedorange

v

+

Voltage exists

"

OFF".

3P

connector.

(-1

of

Out

of

range

W

Open or short circuit in Light greenpellow wire

Loose or poor contact on the ECM connectors

Connect the test harness to ECM connectors.

"ON"

Turn the ignition switch to

Measure the voltage

nals (page 5-9).

Connection: B4

Standard: 2.7 - 3.1 V (760

(+)

at

the test harness termi

-

A26

.

(4

mm

Hg/1,013 kPa)

-

Voltage exists

w

Faulty MAPsensor

&

.

Replace the ECM with a new one, and inspect

again

it

5-13

FUEL SYSTEM (Programmed Fuel

Injection)

PGM-FI

Turn the ignition switch to

MIL 2 BLINKS (MAP SENSOR)

"

OFF".

t

Disconnect the vacuum hose from the MAP sen

sor.

Connect the vacuum gauge between the throttle

body and the MAP sensor using a 3

Start the engine and measure the manifold

absolute pressure

Standard:

150

-

250

at

idle speed.

mm

Hg

J.

Disconnect the vacuum gauge and connect the

hose to the MAP sensor.

-

way joint.

~~

Out

of

-

range

*

-

Check the hose installation

Disconnect the ECM connectors.

Connect the test harness

to

5-14

the ECM connector.

Turn the ignition switch

Measure the voltage at the test harness termi

nals (page

5-9).

to

"ON"

.

FUEL

Out

of

range

-

SYSTEM

F

-

Faulty MAPsensor

(Programmed

Fuel

Injection)

Measure the voltage at the test harness termi

nals (page

Connection:

Standard:

5-91.

B4

2.7

V

(+)

-

A26

maximum

I

[-I

-

Voltage exists

*

9

Replace the ECM

again

with

a new one, and inspect

it

5-45

FUEL

SYSTEM

(Programmed Fuel Injection)

PGM-FI

Turn the ignition switch to "OFF".

Connect the ECT sensor connector.

Place the motorcycle on its side stand.

Turn the ignition switch to

MIL 7 BLINKS (ECT

"ON"

.

SENSOR)

-

Loose or poor contact on the ECT sensor connec-

tor

I

Check that the MIL blinks.

7

blinks

"

Turn the ignition switch to

Disconnect the ECT sensor connector.

Measure the resistance at the ECT sensor termi

nals.

Connection: Pink/White

(sensor side terminals)

Standard:

2.3

-

2.6

kR

OFF".

(+)

-

Greedorange

(20"C/68"F)

-

(-1

Abnormal

-

Faulty ECT sensor

5-16

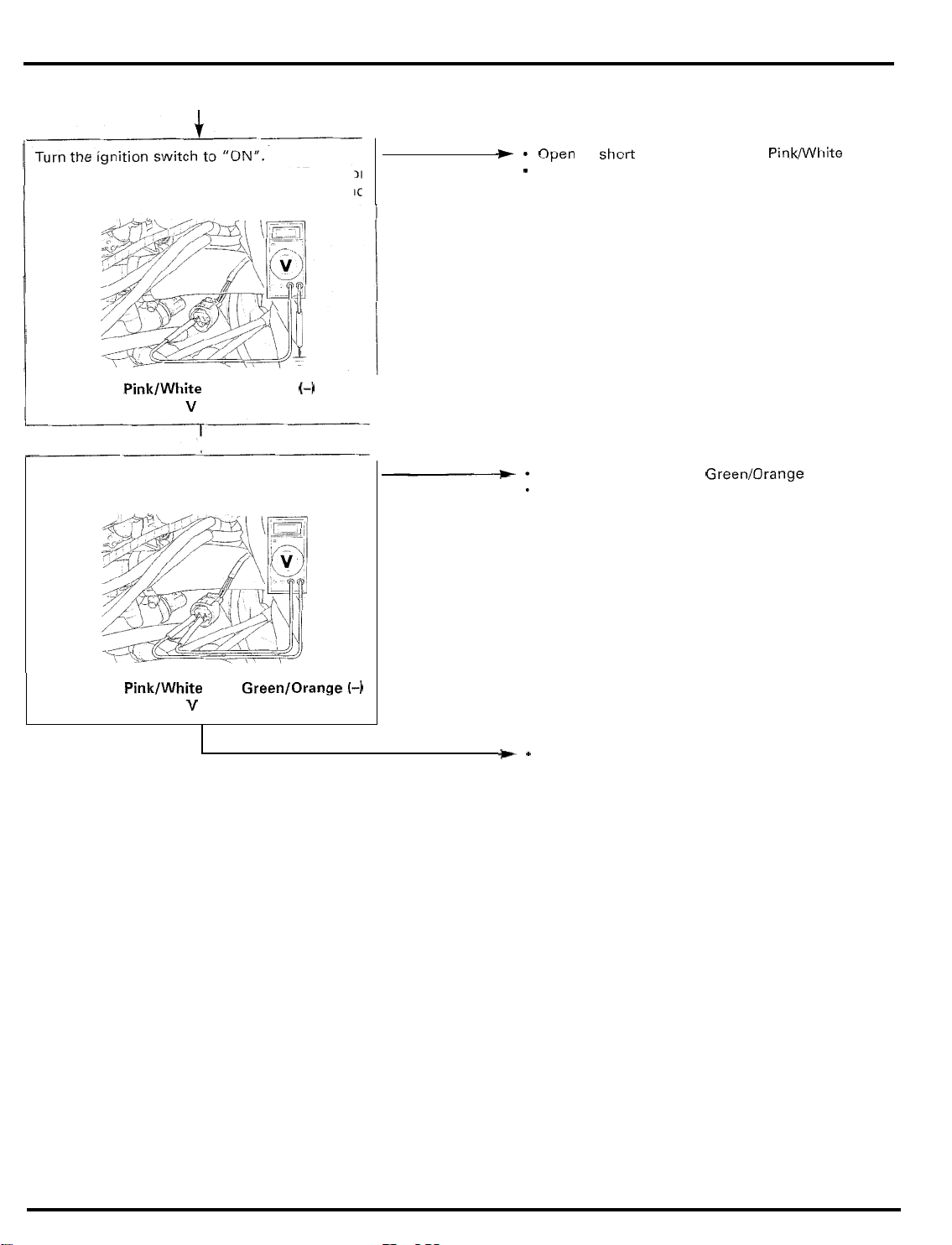

Measure the voltage between the ECT sensor

of

connector terminal

ground.

the wire harness side and

Out

of

range

FUEL

-

-

SYSTEM

Open or short circuit in Pink and Pinkwhite wire

Loose or poor contacts on the ECM connector

(Programmed

Fuel

Injection)

Connection:

Standard:

Measure the voltage at the ECT sensor connec

tor

of

Connection:

Standard:

Pink/White

4.75 - 5.25

the wire harness side.

Pink/White

4.75 - 5.25

(+)

V

Voltage exists

(+)

V

-

Ground

-

Greedorange

(-1

(-1

Out

-

___L

Voltage exists

of

range

Open or short circuit in Green/Orange wire

Loose or poor contacts on the ECM connector

+

*

Replace the ECM

again

with

a new one, and inspect

it

5-17

FUEL SYSTEM

(Programmed

Fuel

Injection)

PGM-FI MIL 8 BLINKS

I

Turn the ignition switch to "OFF".

Disconnect the TP sensor 3P connector.

Check for loose or poor contact on the TP sen

,

sor connector.

Place the motorcycle on its side stand.

Start the engine and check that the

(TP

SENSOR)

MIL

blinks.

I

-

4

8

blinks

I

Turn the ignition switch to "OFF".

'

Disconnect the TP sensor 3P connector.

Turn the ignition switch to

Measure the voltage between the wire harness

side connector terminal and ground.

Connection: Yellow/Red

Standard:

4.75

-

5.25

V

(+)

"ON"

-

Ground

.

(-)

I

Out of range

Open or short circuit in the YellowiRed wire

Loose or poor contact on the ECM connector

5-18

of the wire harness side.

Out

of

range

FUEL

-e

SYSTEM

Open or short circuit in Greedorange wire

Loose or poor contact on the ECM connectors

(Programmed

Fuel Injection)

Connection: Yellow/Red

Standard:

Turn the ignition switch to

Disconnect the ECM

4.75

-

5.25

(+)

V

”OFF”.

26P

connectors.

-

Green/Orange

t

Check for continuity between the

nector terminal

ground.

of

the wire harness side and

TP

sensor con

(-1

-

Continuity

*

Short circuit in Redh’ellow wire

Connection: Red/Yellow

Standard:

No

continuity

(+)

I

No

-

Ground

continuity

(-1

5-19

FUEL

SYSTEM

(Programmed

Fuel

.

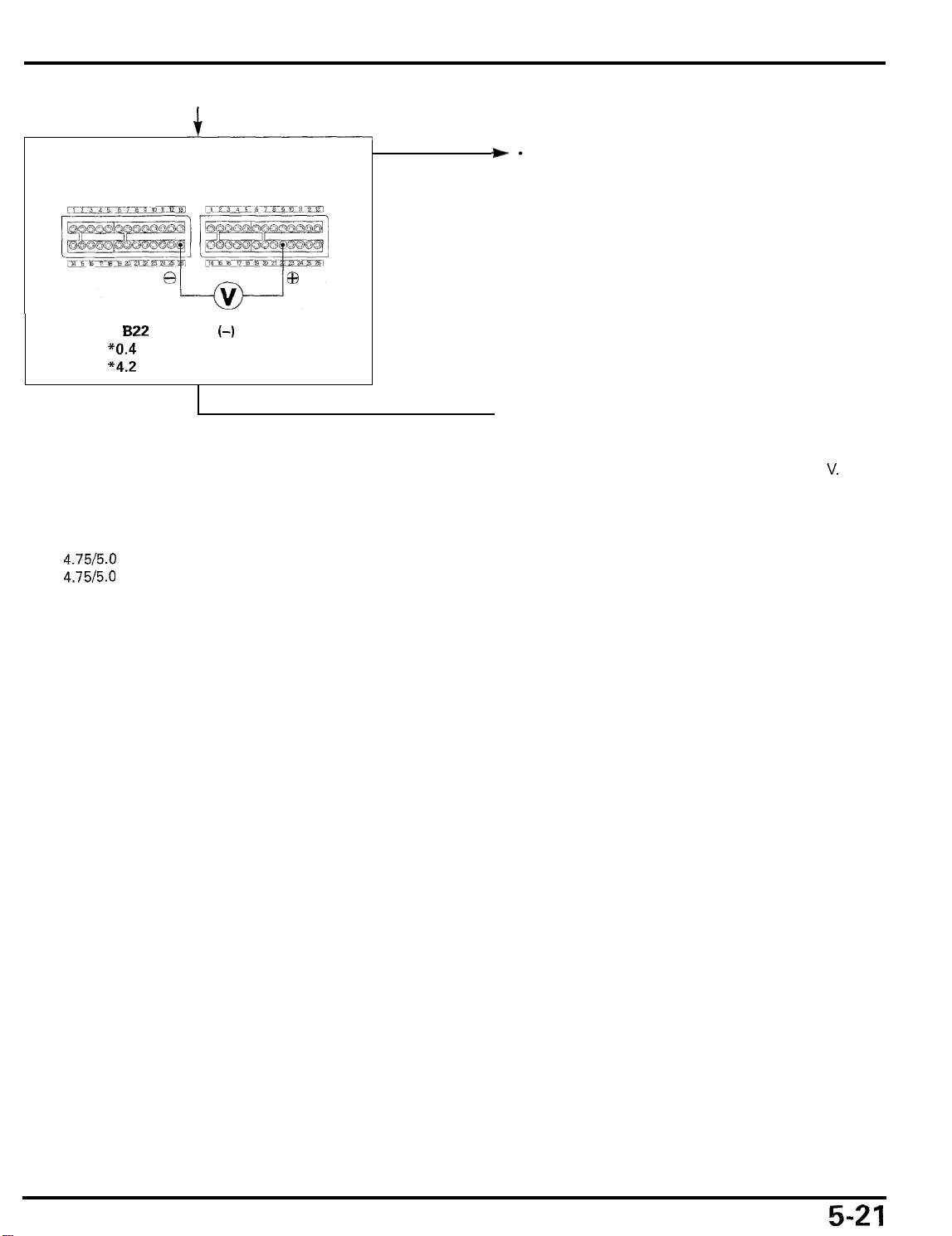

Connect the test harness to the

Check for continuity between the test harness

TP

terminal and the

sensor connector terminal.

ECM

connec-

Injectian)

+

-

Open or short circuit in Redflellow wire

Connection: Red/Yellow

Standard: Continuity

Connect the

TP

sensor

-

B22

3P

connector.

5-20

FUEL

SYSTEM

(Programmed

Fuel Injection)

Turn the ignition switch to "ON".

Measure the voltage at the test harness termi

nals.

Connection: B22

Standard:

A

voltage marked * refers to the value when the voltage reading at the TP sensor

When the reading

In the case of a voltage of 4.75

X

4.7515.0

0.4

0.6 X 4.7515.0 = 0.57

Thus, the solution is "0.38

Replace

0.4

(+)

*0.4

-

0.6

*4.2 - 4.8

shows

=

0.38

and

0.6

with

V

V

-

V

V

A26

(throttle

(throttle

(-)

fully

closed)

fully

open)

other than

-

0.57

4.2

and 4.8 respectively, in the above equations to determine the throttle fully open range.

V

at the

V

5

V,

derive a voltage at the test harness

TP

"

with

-

sensor

the throttle fully closed.

Normal

3P

connector:

+

Replace the

again

as

follows:

ECM

with

3P

connector (page

a new one, and inspect

5-19)

shows 5

V.

it

5-21

FUEL SYSTEM (Programmed Fuel Injection)

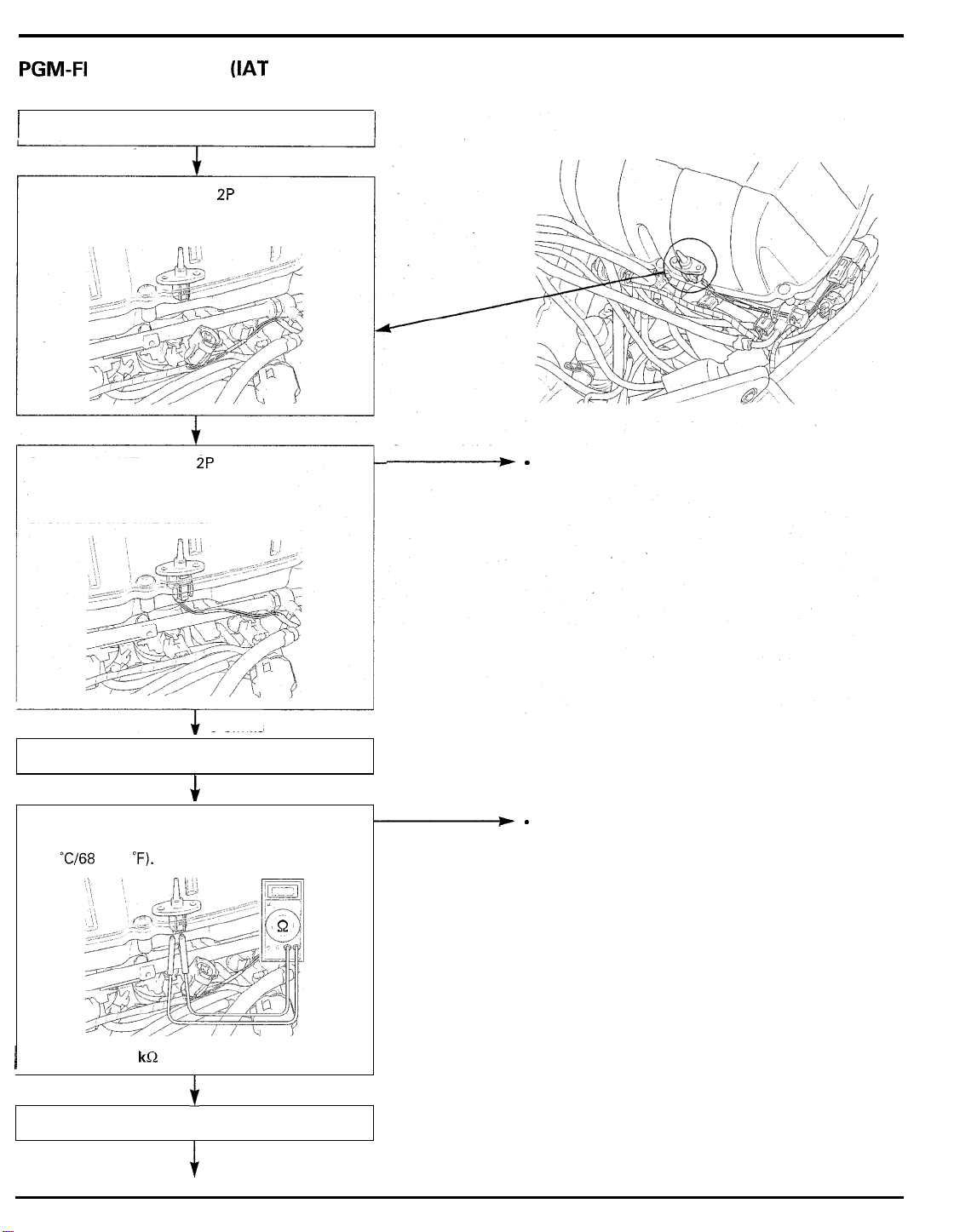

PGM-FI

I

Turn the ignition switch to "OFF

Disconnect the IAT sensor 2P connector.

Check for loose or poor contact on the IAT sen

sor connector.

Connect the IAT sensor

Place the motorcycle on its side stand.

Turn the ignition switch to

Check that the MIL blinks.

MIL 9 BLINKS

2P connector.

"ON"

(IAT

"

.

SENSOR)

-

Does not blink

-

-

Loose or poor contact on the IAT sensor connector

I

9

blinks

"

Turn the ignition switch to

OFF".

J-

Disconnect the IAT sensor 2P connector.

Measure the resistance

-

30

"C/68 - 86

1

Standard:

Turn the ignition switch to

1 - 4

OF).

kR

at

the IAT sensor

Normal

"ON"

.

(at

20

Abnormal

-

-

Faulty IAT

sensor

5-22

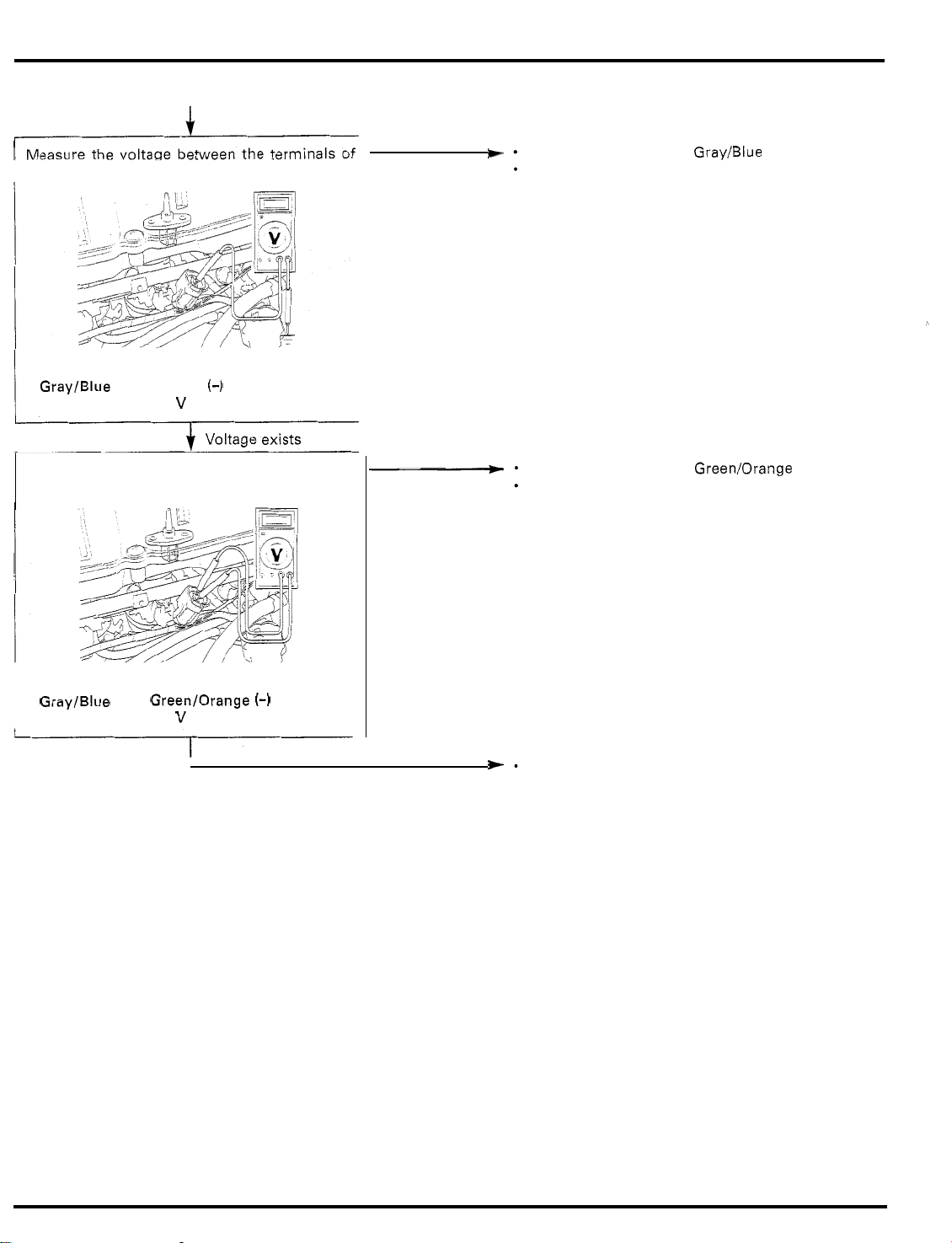

the wire harness side.

Connection:

Gray/Blue

Standard: 4.75

Measure the voltage between the terminals

the wire harness side.

(+)

-

Ground

-

5.25

(-1

V

of

Out

Out

-

of

of

range

range

FUEL

*

SYSTEM

Open or short circuit in GrayiBlue wire

Loose or poor contact on the ECM connectors

Open or short circuit in Greedorange wire

Loose or poor contact on the ECM connectors

(Programmed

Fuel Injection)

Connection:

Gray/Blue

Standard: 4.75

(+)

-

Green/Orange

-

5.25

V

I

(-1

Voltage exists

+

Replace the ECM with a new one, and inspect

again

it

5-23

FUEL SYSTEM

(Programmed

Fuel

Injection)

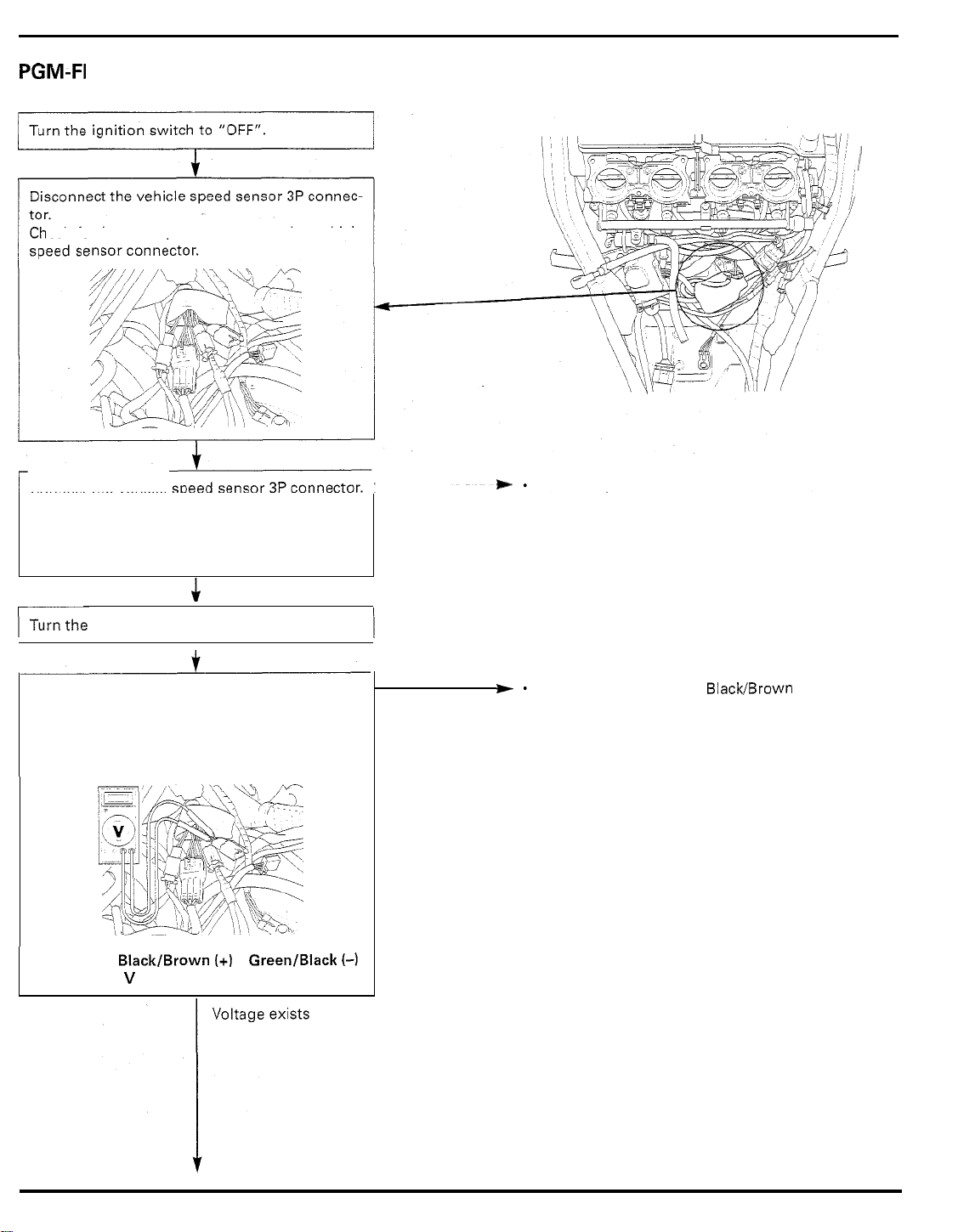

PGM-FI

Connect the vehicle

Start the engine.

With the side stand

more than 5,000 rpm about

Check that the

MIL

11

BLINKS

eck for loose or poor contact on the vehicle

UP

MIL

blinks.

(VEHICLE SPEED SENSOR)

and keep the engine rev

20

seconds or more.

Does not blink

*

Loose or poor contact on the vehicle speed sensor

connector

I

1

4

11

blinks

fi

ignition switch

to

"

OFF

"

f

Disconnect the vehicle speed sensor

tor.

Turn the ignition switch to

Measure the voltage at the wire harness side

con n ecto r.

Connection: Black/Brown

Standard:

12

V

"ON"

(+I

3P

.

-

Green/Black

connec

(-1

Out

of

range

k

-

Open or short circuit in Black/Brown wire

5-24

$

-

Connect the vehicle speed sensor

Disconnect the ECM connectors.

to

Connect the test harness

connectors.

the wire harness

3P

connector.

FUEL

SYSTEM

(Programmed

Fuel

Injection)

t

Support the motorcycle securely and place the

off

rear wheel

Shift the transmission into gear.

Measure the voltage at the test harness termi

nals with the ignition switch turned to

while slowly turning the rear wheel

L-6

CONNECTION:

STANDARD:

the ground.

7

rmriTTT5

-

B16

(+I

Repeat 0 to

LTzmn

-

Ground

(-1

5V

by

“ON”

hand.

ZI

-

-

Abnormal

Normal

Open or short circuit

in

Pink/Green wire

5-25

FUEL

SYSTEM (Programmed Fuel Injection)

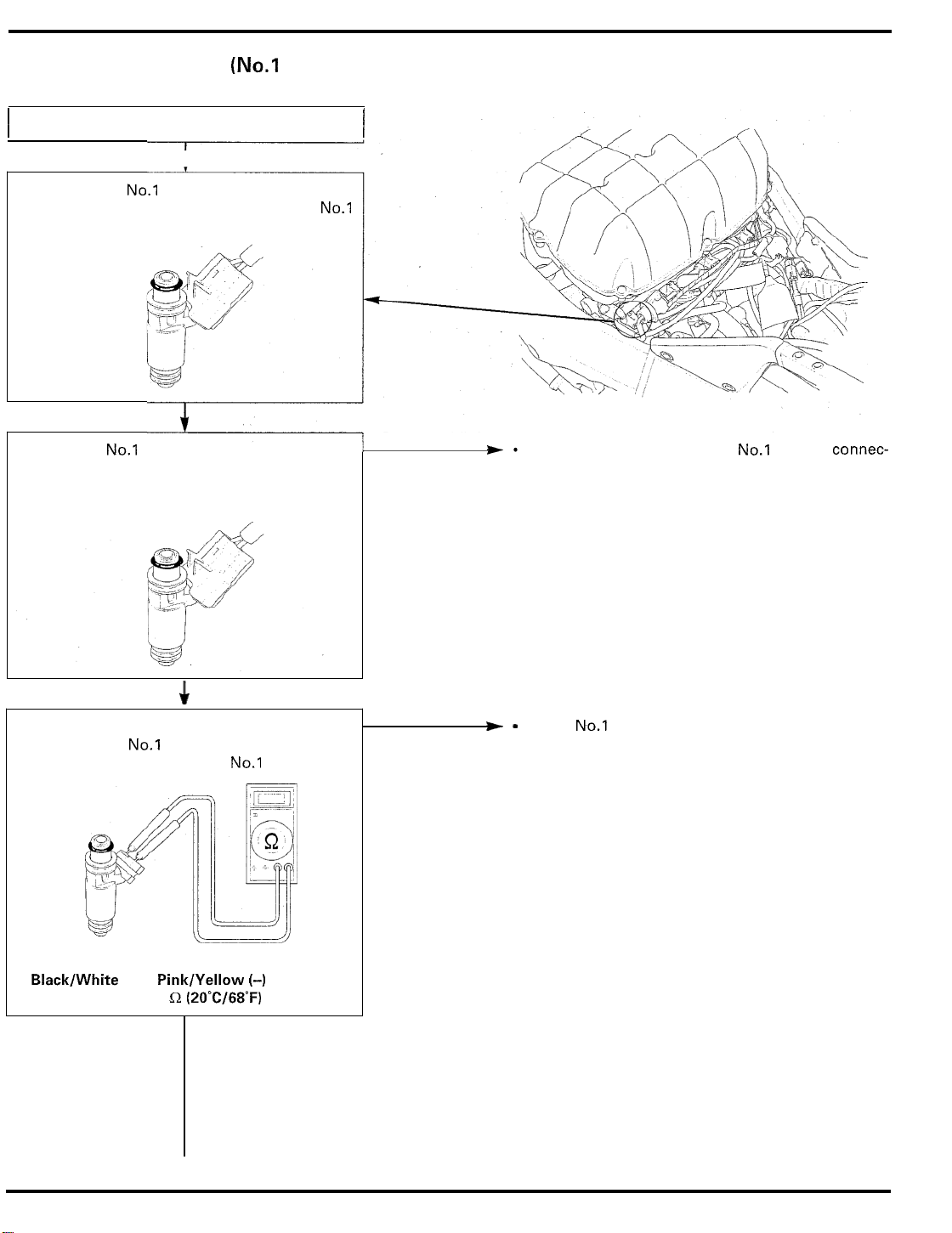

PGM-FI

I

Turn the ignition switch to "OFF".

Disconnect the

Check for loose or poor contact on the

injector 2P connector.

Connect the No.1 injector 2P connector.

Place the motorcycle on

Turn the ignition switch to

Check that the MIL blinks.

MIL

12 BLINKS (No.1 INJECTOR)

No.1 injector 2P connector.

its

side stand.

"ON"

.

No.1

I

e

Loose or poor contact on the No.1 injector connec-

tor

4

12 blinks

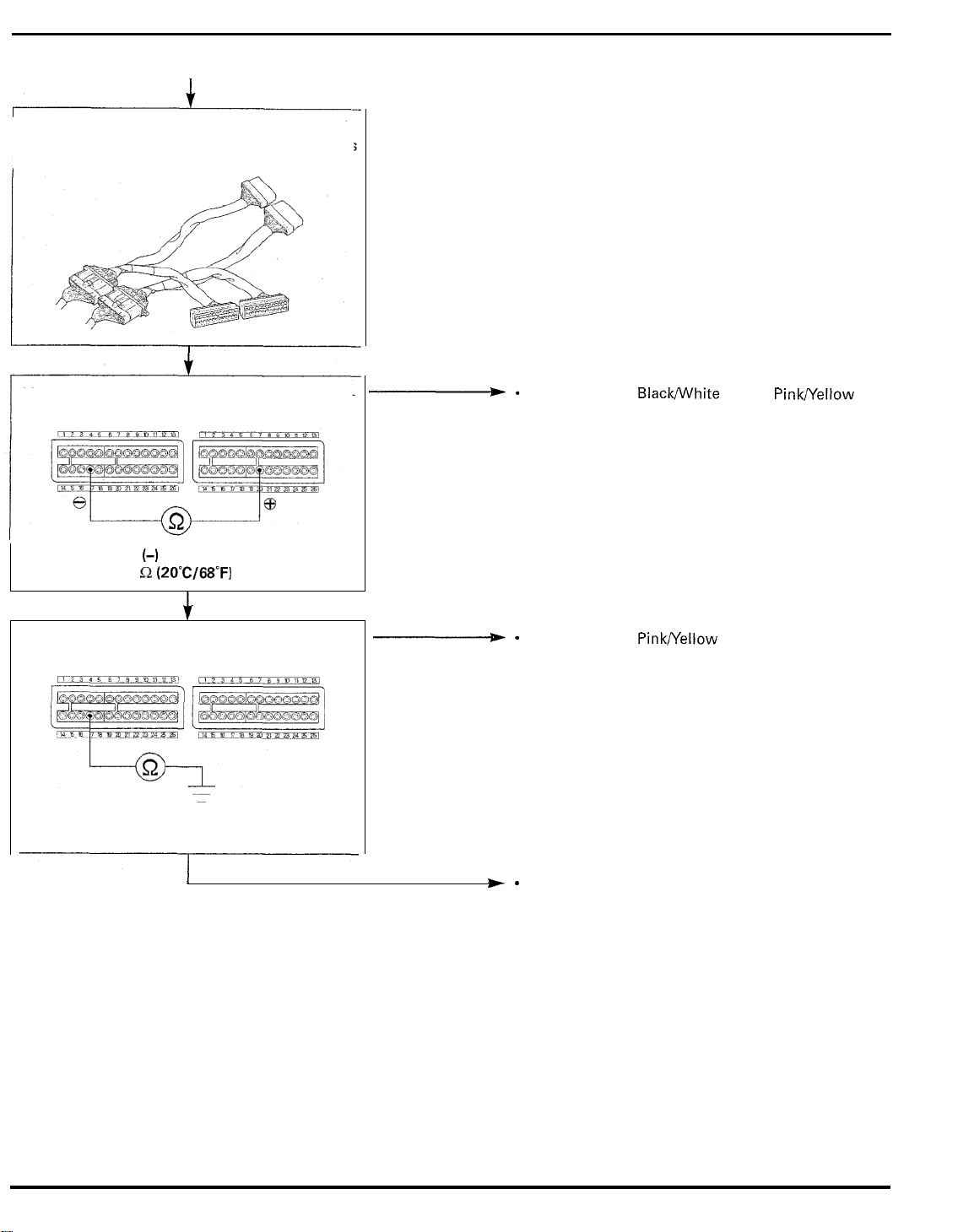

Turn the ignition switch to

Disconnect the No.1 injector

measure the resistance of the

Connection:

Black/White

Standard:

10.5

(+)

-

-

14.5

"

Pink/Yellow

Q

(20°C/68"F)

Normal

OFF".

2P

connector and

No.1 injector.

(-)

Abnormal

b

-

Faulty No.1 injector

5-26

FUEL

SYSTEM

(Programmed Fuel Injection)

+

Check for continuity between the No.1 injector

and ground.

-

~

Connection:

Black/White

Standard:

Turn the ignition switch to "ON".

Measure the voltage between the

connector

(+)

-

Ground

No

continuity

of

the wire harness side and ground.

(-1

No.1

injector

Continuity

Out

of

range

E

Faulty No.1 injector

Open or short circuit in Blackwhite wire

Connection:

Black/White

Standard: Battery voltage

Turn the ignition switch to

Connect the

(+)

-

Ground

No.1

injector connector.

(-1

Voltage exists

"

OFF".

5-27

FUEL

SYSTEM

Disconnect the ECM connectors.

Connect the test harness to the wire harness

connectors.

Measure the resistance at the test harness ter

minals.

(Programmed Fuel Injection)

-

-

Out

of

range

Open circuit in BlackWhite and/or PinWellow wire

Connection:

Standard:

Check for continuity between the test harness

terminal and ground.

Connection:

Standard:

I

A17

9

-

15

A17

No

continuity

(-1

-

B20

Cl

(20"C/68"F)

t

-

Ground

1

(+)

Normal

Continuity

_____9

No continuity

Short circuit in Pink/YeIlow wire

*

-

Replace the ECM with a new one,

again

and

inspect

it

5-28

FUEL SYSTEM

(Programmed Fuel Injection)

PGM-FI MIL

Check for loose or poor contact on the

injector 2P connector.

Connect the No.2 injector 2P connector.

Place the motorcycle on its side stand.

Turn the ignition switch to

Check that the

13

BLINKS (No.2 INJECTOR)

"ON"

.

MIL

blinks.

No2

Does not blink

-

Loose or poor contact on the No2 injector connec

tor

-

13

Disconnect the

measure the resistance of the

No2 injector 2P connector and

Normal

blinks

Abnormal

Faulty No.2 injector

No.2 injector.

Loading...

Loading...