Honda CBR 954RR Service Manual 13 front susp

FRONT

WHEEL/SUSPENSlQN/STEEWlNG

103

N*m

(10.5

kgf-m,

76

Ibf-ft)

30

78

N-m

N*n

EEL/SUS

SIONISTEE

SERVICE INFORMATiON

TROUBLESHOOTING

I

HANDLEBARS

13-1

-

3

13

13-4

FRONT WHEEL

FORK

STEERING STEM

13-9

13

-

1

13-26

SERVICE INFORMATION

GENERAL

*

When servicing the front wheel, fork or steering stem, support the motorcycle using a safety stand or hoist.

A contaminated brake disc or pad reduces stopping power. Discard contaminated pads and clean a contaminated disc

with a high quality brake degreasing agent.

-

After front wheel installation, check the brake operation

-

Refer to section 15 for brake system information.

-

Use only tires marked "TUBELESS" and tubeless valves on rims marked "TUBELESS TIRE APPLICABLE".

SPECIFICATIONS

ITEM

Minimum tire tread depth

Cold tire pressure Up to

Axle runout

Wheel

rim

runout

Wheel balance weight

Fork Spring free length

~

Steering head bearing pre-load

90

kg (200 Ib) load

Up to maximum weight capacity

Radial

Axial

Spring direction

Fork pipe runout

Recommended fork fluid

Fluid level

Fluid capacity

Pre

-

load adjuster initial setting

Tension adjuster initial setting

Compression adjuster initial setting

by

applying the brake lever.

Unit:

I

250

kPa (2.50 kgf/cmz, 36 psi)

250

kPa (2.50 kgf/cm2, 36 psi)

255.8 (10.07) 250.8 (9.87)

With the tapered end facing up

Pro Honda Suspension Fluid SS

(2.9)

73

513 2.5

18.1

2

0.09

7 turns from

2 turns from full hard

2 turns from full hard

11 - 16 N (1.1 - 1.6 kgf)

STANDARD

-

-

-

-

-

-

om3

(17.3 & 0.08 US

Imp

oz)

full

soft

-

oz,

1

SERVICE LIMIT

1.5 (0.06)

-

-

0.20 (0.008)

2.0 (0.08)

2.0 (0.08)

60 g (2.1

-

0.20 (0.008)

8

-

-

-

-

-

-

02)

mm

max.

5

(in)

1

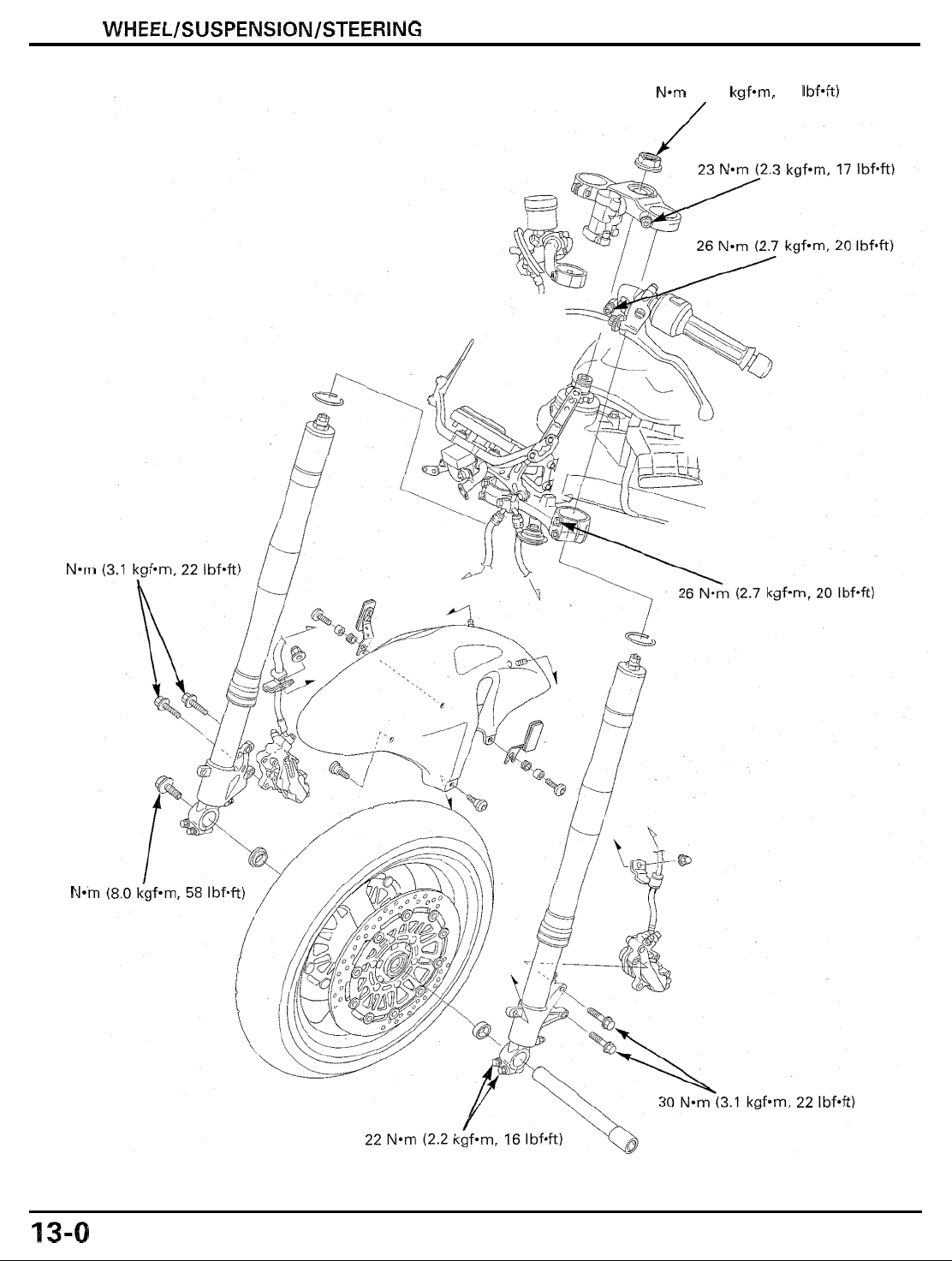

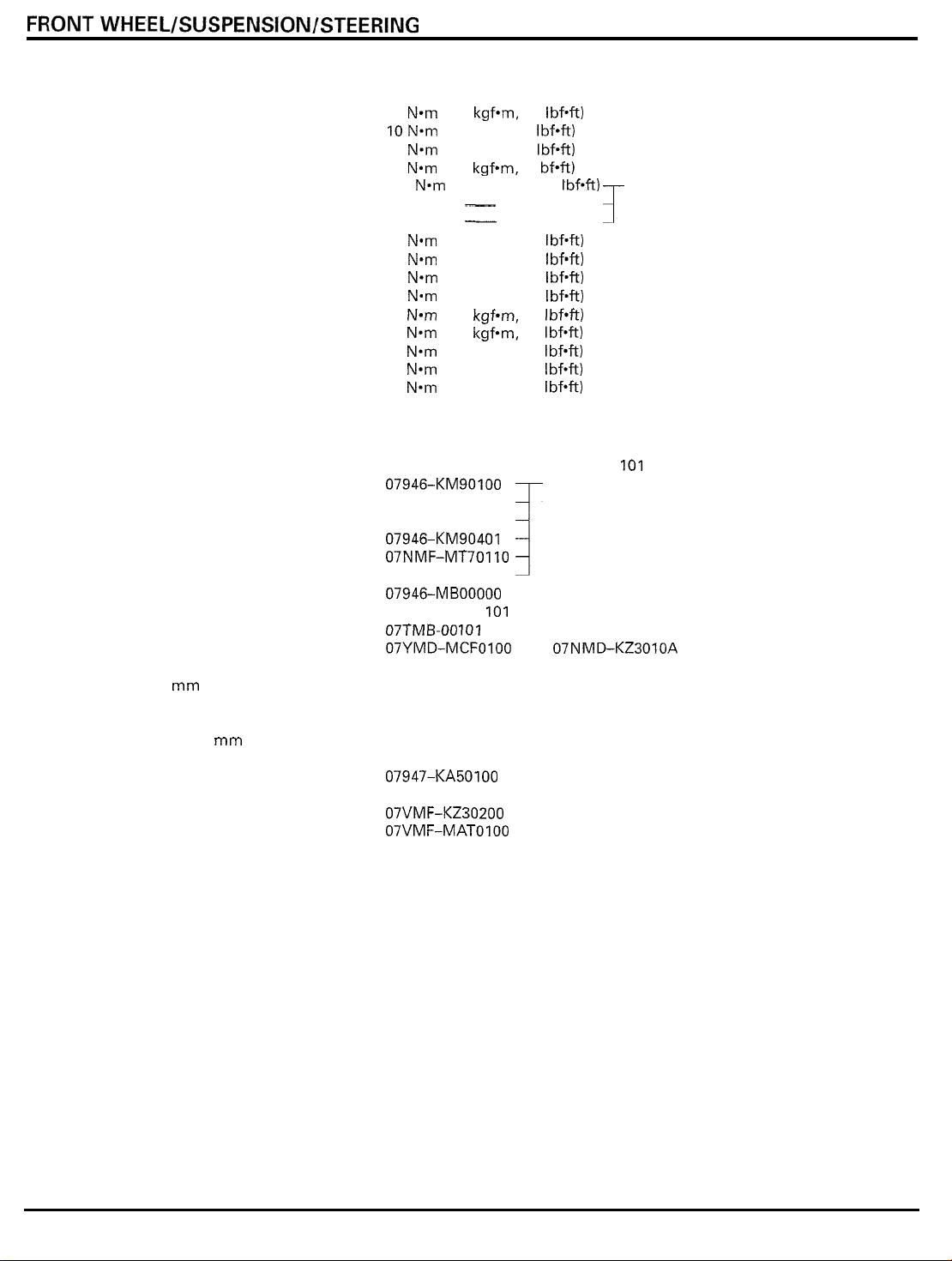

TORQUE

VALUES

Handlebar pinch bolt

Handlebar weight mounting screw

Front master cylinder holder bolt

Clutch lever bracket pinch bolt

Steering stem nut

Steering stem adjusting nut

Steering stem lock nut

Fork top bridge pinch bolt

Fork bottom bridge pinch bolt

Front axle bolt

Front axle holder pinch bolt

Front brake disc mounting bolt

Fork bolt

Fork socket bolt

Damper rod adjust case lock nut

Front brake caliper mounting bolt

TOOLS

Steering stem socket

Driver attachment, A

Driver attachment, B

Driver shaft assembly

Bearing remover, A

Bearing remover,

Assembly base

Steering stem driver

Fork damper holder

Fork damper holder handle

Oil seal driver

Driver

Attachment, 42

Pilot,

25 mm

Bearing remover shaft

Bearing remover head, 25

Main bearing driver attachment

Fork seal driver body

Oil seal driver

Installer shaft

Installer attachment A

Installer attachment

Remover attachment A

Remover attachment

B

x

47 mm

mm

B

B

26 N-m (2.7 kgfom, 20 ibfmft)

10 N-m (1.0 kgf-m, 7 Ibf*ft)

12 N-m (1.2 kgf-m, 9 IbfW

12 N*m (1.2 kgf-m, 9 I bf-ft)

103 N-m (10.5 kgf-m, 76 Ibf-ft)

ALOC bolt

See page 13

-

33

-

-

23 N-m (2.3 kgf-m, 17 Ibf-ft)

26 N-m (2.7 kgf-m, 20 IbfW

78 N-m (8.0 kgf-m, 58 Ibf-ft)

22 N-m (2.2 kgf-m, 16 Ibf-ft)

20

N-m (2.0 kgf-m, 14 Ibf-ft)

22 Nm (2.2 kgfom, 16 Ibf-ft)

34 N*m (3.5 kgf-m, 25 Ibf-ft)

25 N*m (2.6 kgf-m, 19 Ibf-ft)

30

Nm (3.1 kgf-m, 22 Ibf*ft)

0791 6-37101 01 or 0791 6-37 101

07946-KM90100

07 N M F-MT70 1

07946-KM90300

07946-KM90401

07NMF-MT70110

07946-KM90600

07946-MB00000

07Y

MB-MCFO 101

07TMB-00 101 OA

07YMD-MCF0100 or 07NMD-KZ301OA (U.S.A. only)

-

0010000

07749

-

0010300

07746

07746

-

0040600

07746

-

0050100

-

0050800

07746

-

ME90200

07946

07947-KA50100

07965-MA60000

07VMF-KZ30200

07VMF-MAT0100 (U.S.A. only)

07VMF

-

-

07VMF

-

07VMF

20

1

MAT0200 (U.S.A. only)

MAT0300 (U.S.A. only)

MAT0400 (U.S.A. only)

7

ALOC

bolt

Apply a locking agent

bolt

ALOC

00

(U.S.A. only)

Not available in U.S.A.

to

the threads.

13-2

TROUBLESHOOTING

FRONT

WHEEL/SUSPENSlON/STEERlNG

Hard steering

Faulty or damaged steering head bearings

-

Insufficient tire pressure

-

Steering head bearing adjustment nut too tight

Steers to one side

Unevenly adjusted right and left fork legs

Bent fork

Bent axle

Wheel installed incorrectly

-

Faulty steering head bearings

Bent frame

Worn wheel bearing

Worn swingarm pivot components

Front wheel wobbling

*

Bent rim

Worn front wheel bearings

Faulty tire

Unbalanced tire and wheel

or

does

not

track

straight

Wheel turns hard

Faulty wheel bearing

Bent front axle

-

Brake drag

Soft suspension

-

Insufficient fluid in fork

Weak fork springs

Tire pressure too low

Hard suspension

Incorrect fluid weight

Bent fork pipes

Clogged fork fluid passage

Front suspension noisy

Insufficient fluid in fork

Loose fork fasteners

FRONT

WHEEL/SUSPENSlON/STEERlNG

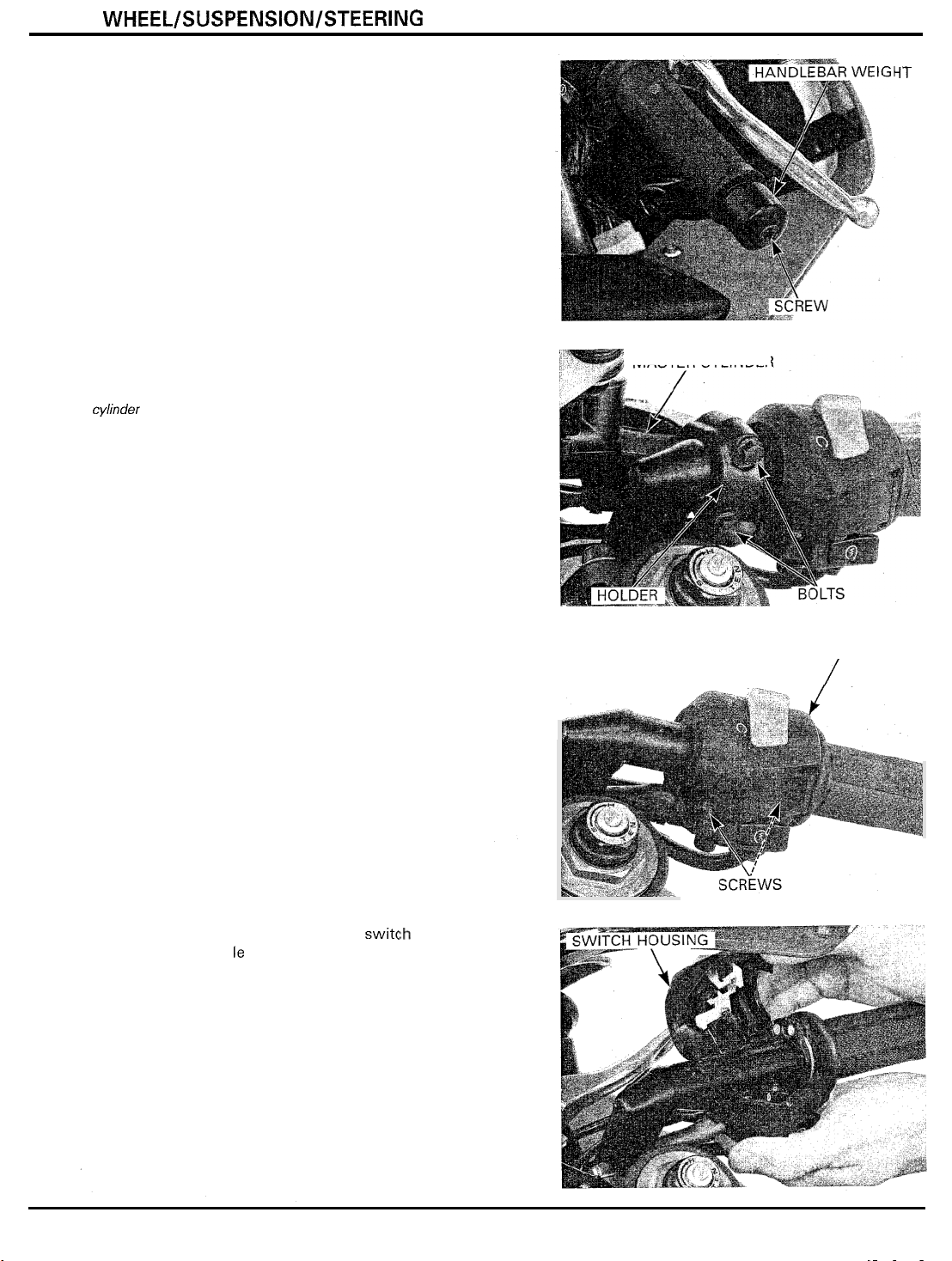

HANDLEBARS

REMOVAL

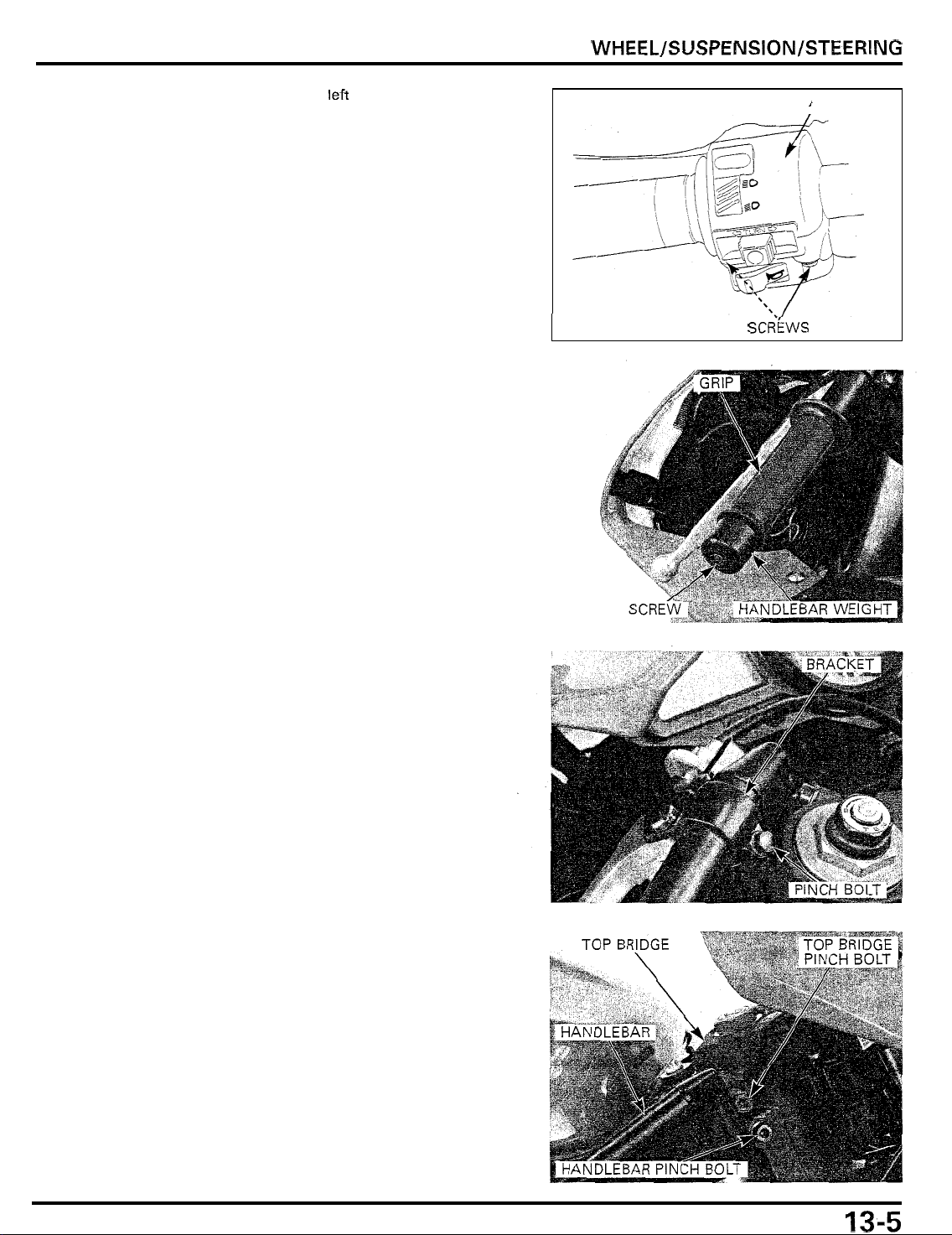

Remove the screw and right handlebar weight.

Disconnect the front brake switch wires connectors

from the switch.

Keep the brake

master

cylinder

upright

Remove the master cylinder holder bolts, holder and

master cylinder assembly.

-IT

MASTER CYLINDER

Remove the right handlebar switch housing screws.

Remove the right handlebar switc

right hand

le

ba r.

housing from the

SWITCH HOUSING

/

13-4

FRONT

WHEEL/SUSPENSlON/STEERlNG

Remove the screws and left handlebar switch housing

Remove the screw and handlebar weight.

Remove the handle grip from the handlebar.

SWITCH / HOUSING

scdiws

Loosen the clutch lever bracket pinch bolt

Loosen the top bridge pinch bolts and handlebar

pinch bolt.

Remove the steering stem nut and top bridge.

Remove the handlebars from the

Remove the throttle pipe from the right handlebar,

the

and also

bar.

clutch lever bracket

fork

from

sliders.

the

left

handle

-

13-5

FRONT

WHEEL/SUSPENSION/STEERlNG

INSTALLATION

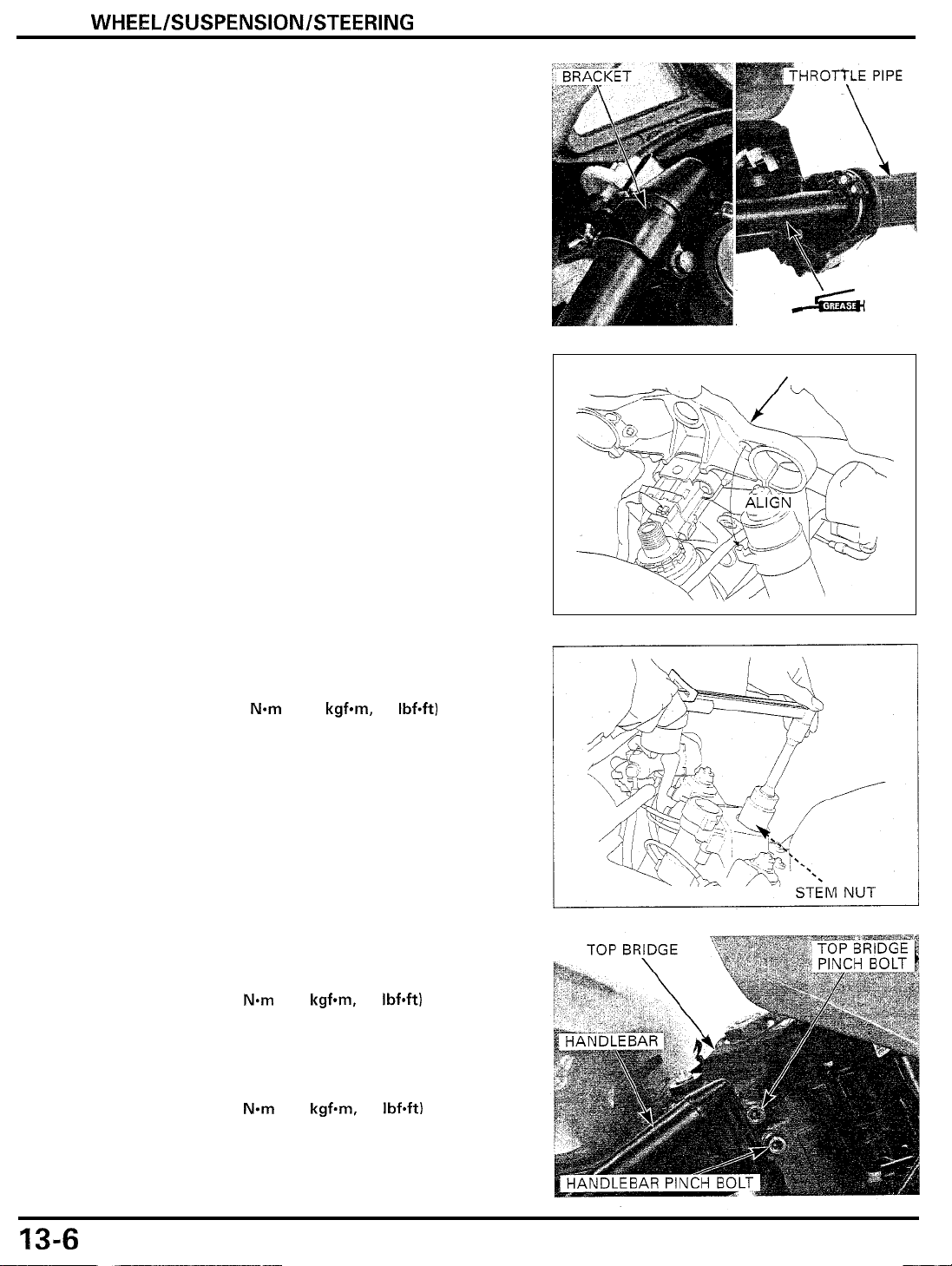

Apply grease to the sliding surface of the throttle

pipe.

Install the clutch lever bracket to the left handlebar,

and also the throttle pipe to the right handlebar.

Install the handlebars onto the fork sliders.

Install the top bridge while aligning its holes with the

handlebar stopper pins.

Install and tighten the steering stem nut to the speci

fied torque.

TORQUE: 103 N-m

(10.5

kgf-m, 76 Ibf-ft)

TOP

BRIDGE

-

13-6

Tighten the top bridge pinch bolts to the specified

torque.

TORQUE:

Seat the handlebar pivot upper surface with the top

bridge lower surface, then tighten the handlebar

pinch bolt to the specified torque.

TORQUE: 26 N-m (2.7 kgfam,

23

N-m (2.3 kgfom, 17 Ibfaft)

20

Ibf-ft)

FRONT

WHEEL/SUSPENSION/STEERlNG

Apply iubncant

splay

through rhe

tab

iocking

the rubber for

easy removal

hole

HANDLEBAR WEIGHT REPLACEMENT

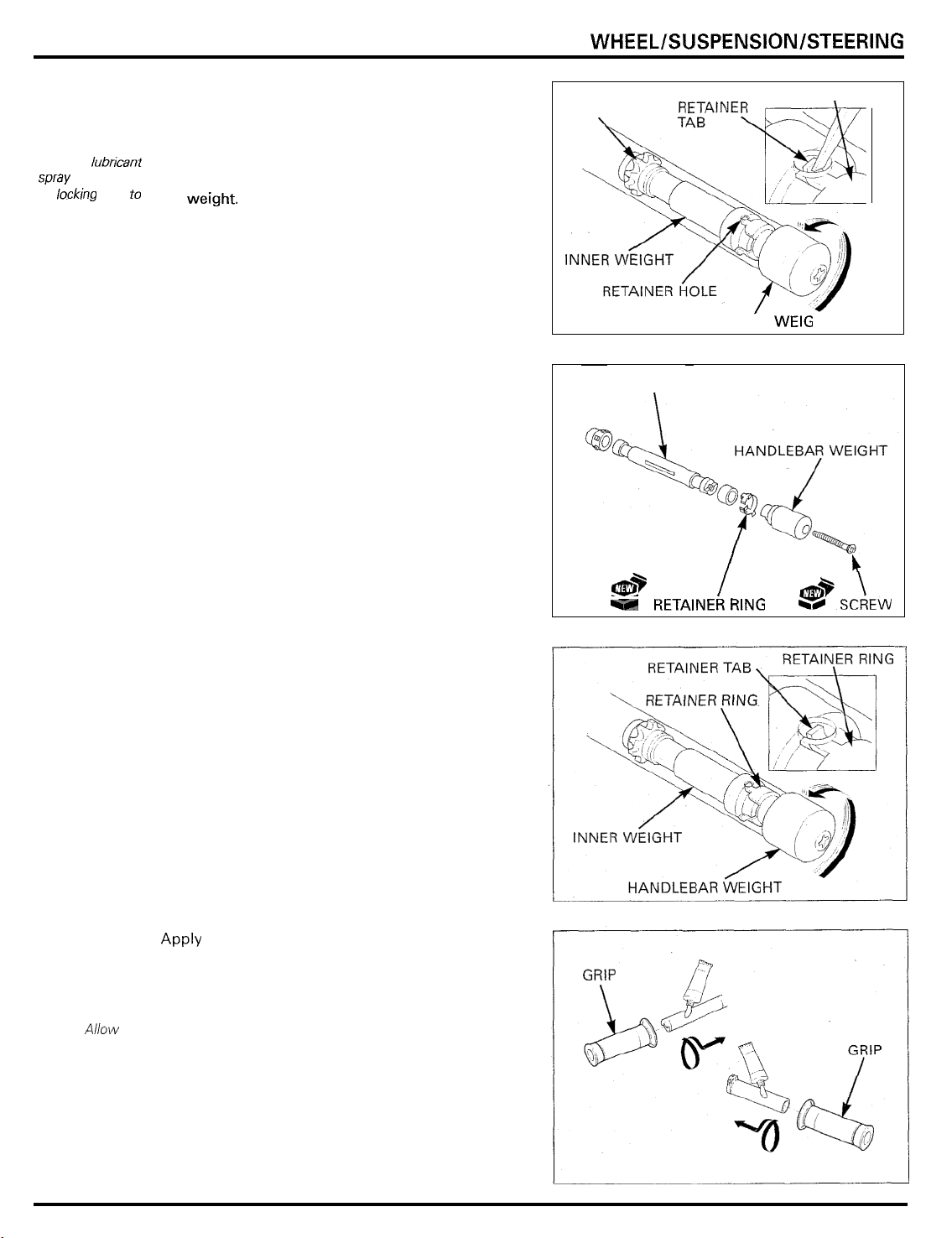

Remove the grip rubber from the handlebar.

Straighten the weight retainer tab by the screwdriver

or punch.

Temporarily install the handlebar weight and screw,

then remove the inner weight by turning the handle

to

bar weight.

Remove the handlebar weight from the inner weight.

Discard the retainer.

Install the new retainer onto the inner weight.

Install the handlebar weight onto the inner weight,

aligning the bosses and grooves each other.

Install a new mounting screw.

RUBBER RETAINER RING

CUSHION

-

HANDLEBAR

~ ~~~ ~

INNER WEIGHT

WElG HT

I

@!+

%@

RETAINERRING

/

x

NOW

adhesive

for approximately

1

the

to

dry

hour before

using

Insert the handlebar weight assembly into the

handlebar.

Turn the handlebar weight and hook the retainer tab

with the hole in the handlebar.

Apy./ londa Bond

the clean surfaces of the left handlebar and throttle

grip.

3

-

5

Wait

Rotate the grip for even application

minutes and install the grip.

A

to

the inside

the grip and

c

of

the adhesive

to

13-7

FRONT WHEEL/SUSPENSION/STEERl"

Tighten the clutch lever bracket pinch bolt by aligning

the punch marks on the left handlebar and clutch

lever bracket.

TORQUE:

Install the left handlebar switch housing aligning its

locating pin with the hole in the handlebar.

12

N-rn

(1.2

kgf-m, 9

Ibf-ft)

I

PIN

Tighten the forward screw first, then the rear screw.

Install the right handlebar switch housing by aligning

its locating pin with the hole in the handlebar.

SWITCH HOUSING

SCREWS

13-8

FRONT

WHEEL/SUsPEN$lON/sTEERlNG

Tighten the forward screw first, then the rear screw.

Install the master cylinder

master cylinder

bar.

Install the master cylinder holder with the

facing up.

Tighten the upper bolt first, the lower bolt.

TORQUE: 12

Connect the brake switch wires.

N.m

with

(1.2

by

aligning the end of the

the punch mark on the handle

"UP"

mark

kgf-m, 9 Ibf-ft)

SWITCH HOUSING

/

MASTER CYLINDER

-

/

FRQNT

Install the handlebar weight and tighten the new

mounting screw to the specified torque.

TORQUE:

10

N-m

(1.0

kgf-m, 7 Ibf-ft)

WHEEL

REMOVAL

Support the motorcycle securely and raise the front

off

wheel

Remove the brake hose clamp nuts, special bolts and

front fender (page

the ground using a safety stand or a hoist.

2-8).

13-9

FRONT WHEEL/SUSPENSION/STEERlNG

Do

not

the

after

operate

brake

the

brake

caiper

removed

Remove the mounting bolts and both brake calipers.

lever

Support the brake caliper with

I

S

does not hang from the brake hose.

a

piece of wire

Do

brake hose

Loosen the right axle pinch bolts.

Remove the axle bolt.

so

it

not twist the

Loosen the left axle pinch bolts.

Remove the axle and the front wheel.

Remove the side collars.

13-10

Loading...

Loading...