3.

MAINTE

SERVICE INFORMATION

MAINTENANCE SCHEDULE

FUEL LINE

THROTTLE OPERATION

AIR CLEANER

SPARK PLUGS

VALVE CLEARANCE

ENGINE

OIL/OIL

FILTER

ENGINE IDLE SPEED

RADIATOR COOLANT

COOLING SYSTEM

SECONDARY AIR SUPPLY SYSTEM

EVAPORATIVE EMISSION CONTROL

SYSTEM (California

SERVICE

IN

type

only)

FORMATION

3-1

-

3

3

3

-

4

3-5

3-6

3

-

6

3

-

10

3

-

15

3

-

17

3

-

18

-

18

3

3

-

19

3

-

19

DRIVE CHAIN

BRAKE FLUID

BRAKE PAD WEAR

BRAKE SYSTEM

BRAKE LIGHT SWITCH

HEADLIGHT AIM

CLUTCH SYSTEM

SIDE STAND

SUSPENSION

NUTS, BOLTS, FASTENERS

WHEELS/TIRES

STEERING HEAD BEARINGS

3-20

3

-

24

3

-

25

-

25

3

-

26

3

-

27

3

3

-

27

3

-

28

3

-

28

-

31

3

-

31

3

-

32

3

GENERAL

Place the motorcycle on level ground before starting any work.

is

Gasoline

Work in a well ventilated area. Smoking or allowing flames or sparks in the work area

can cause

If

the engine must be running

area.

The exhaust contains poisonous carbon monoxide gas that may cause

the engine in an open area

extremely flammable and

a

fire

or

explosion.

to

or

with an exhaust evacuation system in an enclosed area.

is

explosive under certain conditions.

do

some work, make sure the area

is

well ventilated. Never run the engine in an enclosed

loss

of consciousness and may lead to death. Run

or

where the gasoline

is

stored

3-1

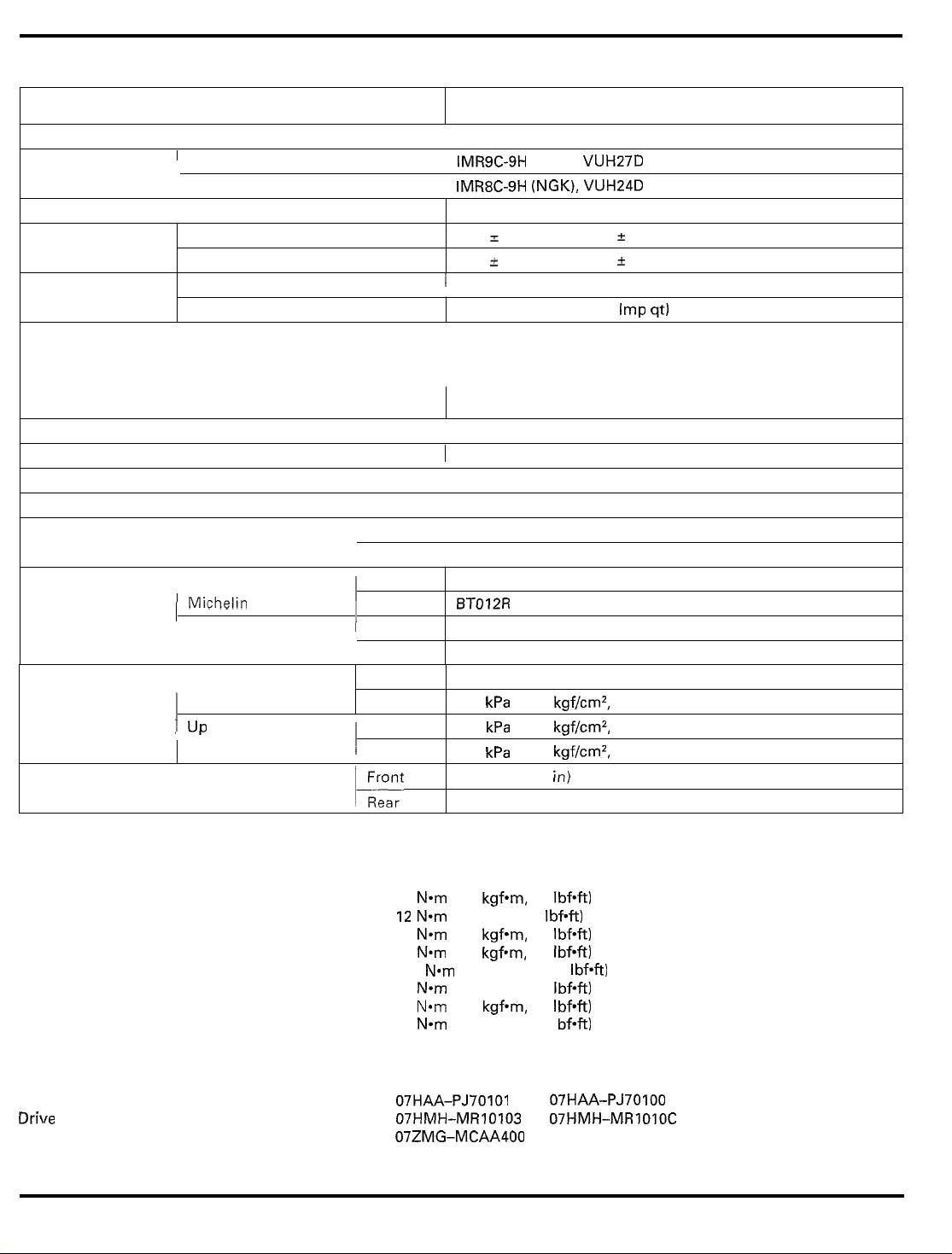

Spark plug

Spark plug gap

Valve clearance IN

Engine oil capacity

Drive chain slack

Recommended brake fluid

'

Standard

1

Optional

EX

At draining

At oil filter change

I

I

Michelin

1

Rear

Front

1

Rear

1

IMR9C-9H (NGK), VUH27D (DENSO)

1

IMR8C-9H (NGK), VUH24D (DENSO)

-

0.9 mm (0.03 - 0.04 in)

0.8

0.16

I

0.03 mm

0.27

2

0.03

i

3.5 liter (3.7 US qt, 3.1 Imp qt)

3.7 liter (3.9 US qt, 3.3

1

40 - 50

1

Honda DOT 4 Brake Fluid

BT012R RADIAL G

Pilot SPORT E

Pilot SPORT

mm

(0.006 L 0.001

mm

(0.01

1

(1.6 - 2.0 in)

E

L

0.001 in)

Imp qt)

in)

load

1

up

to

maximum

weight capacity

Minimum tire tread depth

TORQUE

Timing hole cap

Spark plug

Oil

drain bolt

Oil filter cartridge

Rear axle nut

Drive sprocket special bolt

Driven sprocket nut

Rear master cylinder push rod lock nut

VALUES

TOOLS

Oil

filter wrench

Drive chain tool set

Cam chain tensioner holder

Rear 290

1

Front

~

Rear

18

N-m (1.8 kgfom, 13 Ibf-ft)

12 N*m (1.2 kgf-m, 9 Ibf-ft)

29 N*m (3.0 kgfom, 22 IbfW

26 N-m (2.7 kgfmm, 20 Ibf-ft)

113 N-m (11.5 kgf-m, 83 Ibf-ft) U-nut

54

N*m (5.5 kgf-m, 40 Ibf*ft)

64 N*m (6.5 kgf*m, 47 Ibf-ft)

18 N*m (1.8 kgf-m, 13 I bf-ft)

07HAA-PJ70101 or 07HAA-PJ70100

07HMH-MR10103

07ZMG-MCAA400 (U.S.A. only)

kPa (2.90 kgf/cm2, 42 psi)

kPa (2.50 kgf/cm2, 36 psi)

250

290

kPa (2.90 kgf/cm2, 42 psi)

1.5

rnm

(0.06

in)

,

2.0 mm

(0.08

in)

or

07HMH-MRIOIOC (U.S.A. only)

Apply grease to the threads.

oil

Apply clean engine

to the O-ring.

3-2

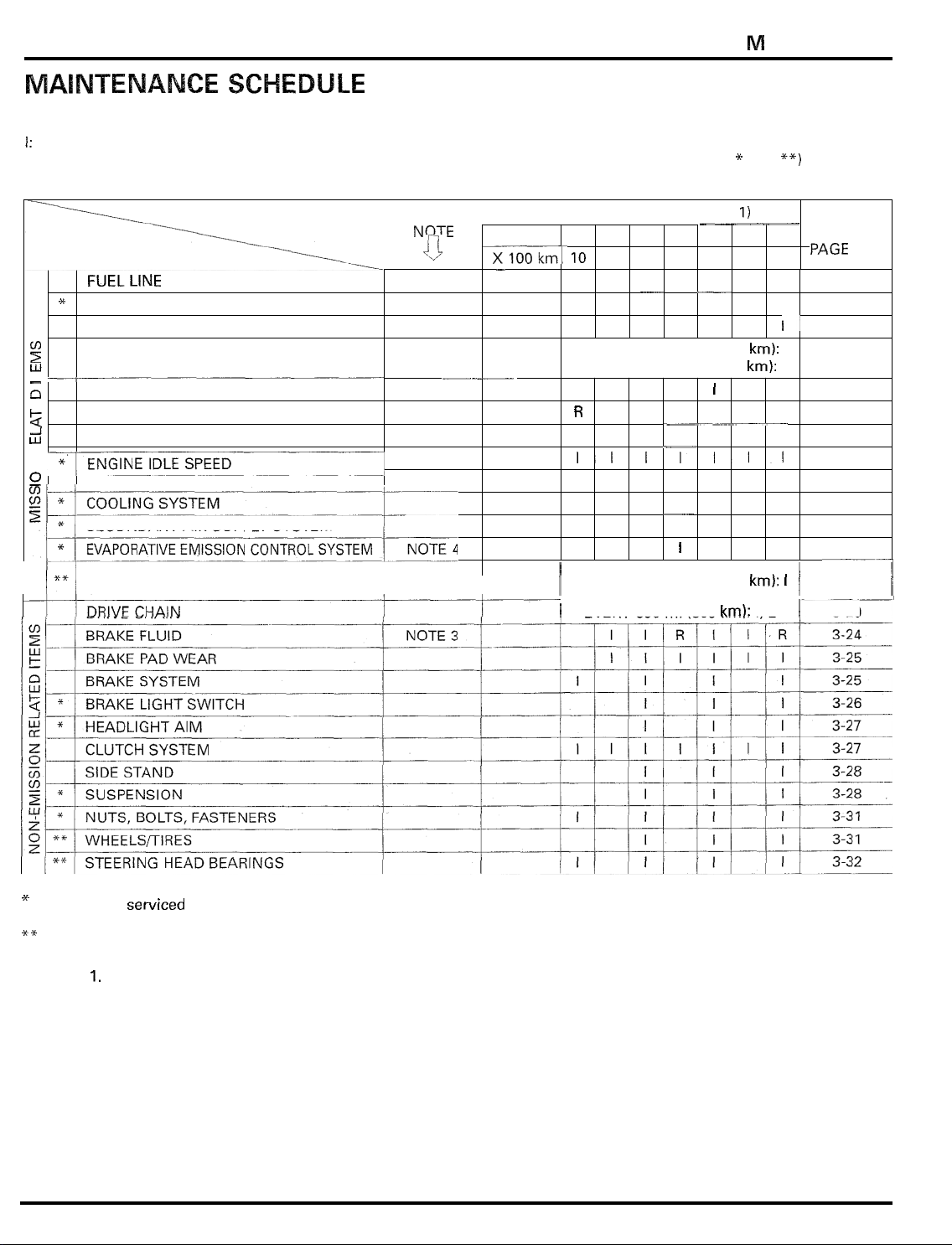

MAINTENANCE

Perform the Pre

I:

Inspect and Clean, Adjust, Lubricate

The following items require some mechanical knowledge. Certain items (particularly those marked

more technical information and tools. Consult their authorized Honda dealer.

ITEMS

*

*

!i

w

I

-

-I

-

a

*

W

2

-I

w

77

0

W

i

/**I

-

ride inspection in the Owner’s Manual at each scheduled maintenance period.

or

Replace

FREQUENCY

if

necessary. C: Clean.

NOTE

0

FUELLINE

THROTTLE OPERATION

AIR CLEANER

SPARK PLUGS

VALVECLEARANCE

ENGINE OIL

ENGINE OIL FILTER

RADIATOR COOLANT NOTE

SECONDARY AIR SUPPLY SYSTEM

EGCV (Exhaust Gas Control Valve)

CONTROL CABLE

NOTE

2

__-___

3

R:

Replace. A: Adjust. L: Lubricate.

ODOMETER READING (NOTE

,

X

1,000 mi

lookm~

-

0.6

10 64

4

I

EVERY

EVERY

R

R R

I

EVERY

I

1

16,000

32,000

IIIIIII

16,000

EVERY

8 12 16 20 24

128

I I

___

I

R

I

I

I

500

______

192

256

__

I

I

mi

(25,600

mi (51,200 km):

I

R R

-~~-

R R

___

I

I

__

I

I

mi

(25,600

mi

(800

*

and

1)

320 384

km):

km):

km):

I,

**I

I

I

I/

I

R

R

I

I

I

I

L

1

,

1

may require

REFER TO

PAGE

3-4

3-5

3-6

-

6

3

3-10

3-15

3-15

3-17

3-18

3-18

3-19

3-19

5-93

3-20

I

*

Should be serviced by an authorized Honda dealer, unless the owner has proper

cally qualified.

**

In the interest of safety, we recommend these items be serviced

NOTES:

1.

At higher odometer readings, repeat at the frequency interval established here.

2.

Service more frequently if the motorcycle

3.

Replace every 2 years,

mechanical skill.

4.

California

type

only

or

at the indicated odometer intervals, whichever comes first. Replacement requires

is

ridden in unusually wet

only

by an authorized Honda dealer.

tools

or

dusty areas.

and service data and

is

mechani

-

3-3

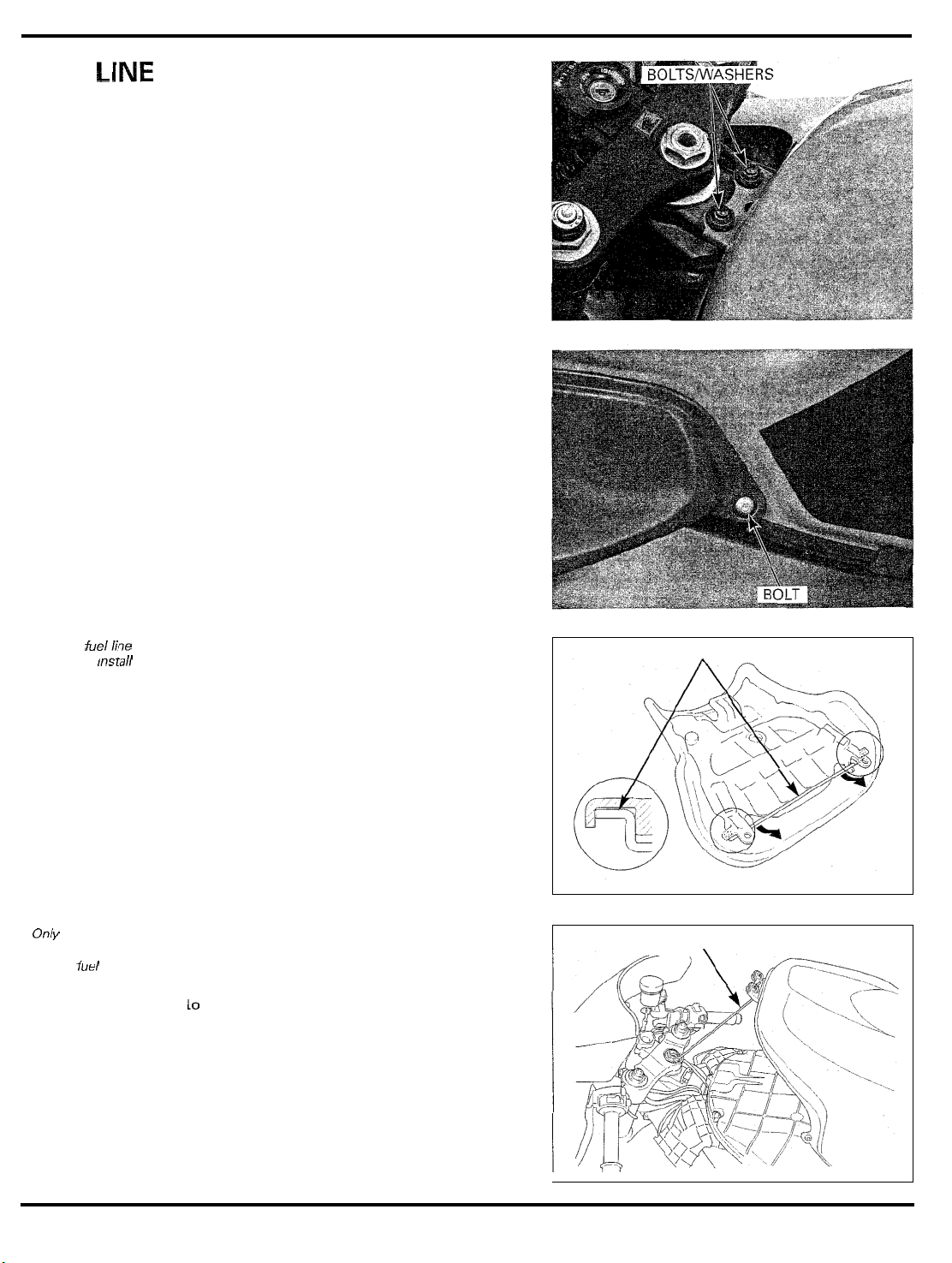

MAINTENANCE

FUEL

LINE

Remove the

washers.

Remove the right and left

front fuel

tank mounting bolts and

duct cover mounting bolts.

After fueiiine

inspection,

the rod ends into

the seat properly

Only use the rod

as

shown

to

support the

fuei tank

mstaii

Remove the seat and then remove the fuel tank sup

port rod from the seat.

Open and support the front end of fuel tank using the

as

support rod

Do

not

lift

sary

to

support

shown.

the front end of fuel tank more than neces

it.

-

-

FUEL

TANK SUPPORT

FUEL

TANK SUPPORT ROD

ROD

3-4

MAINTENANCE

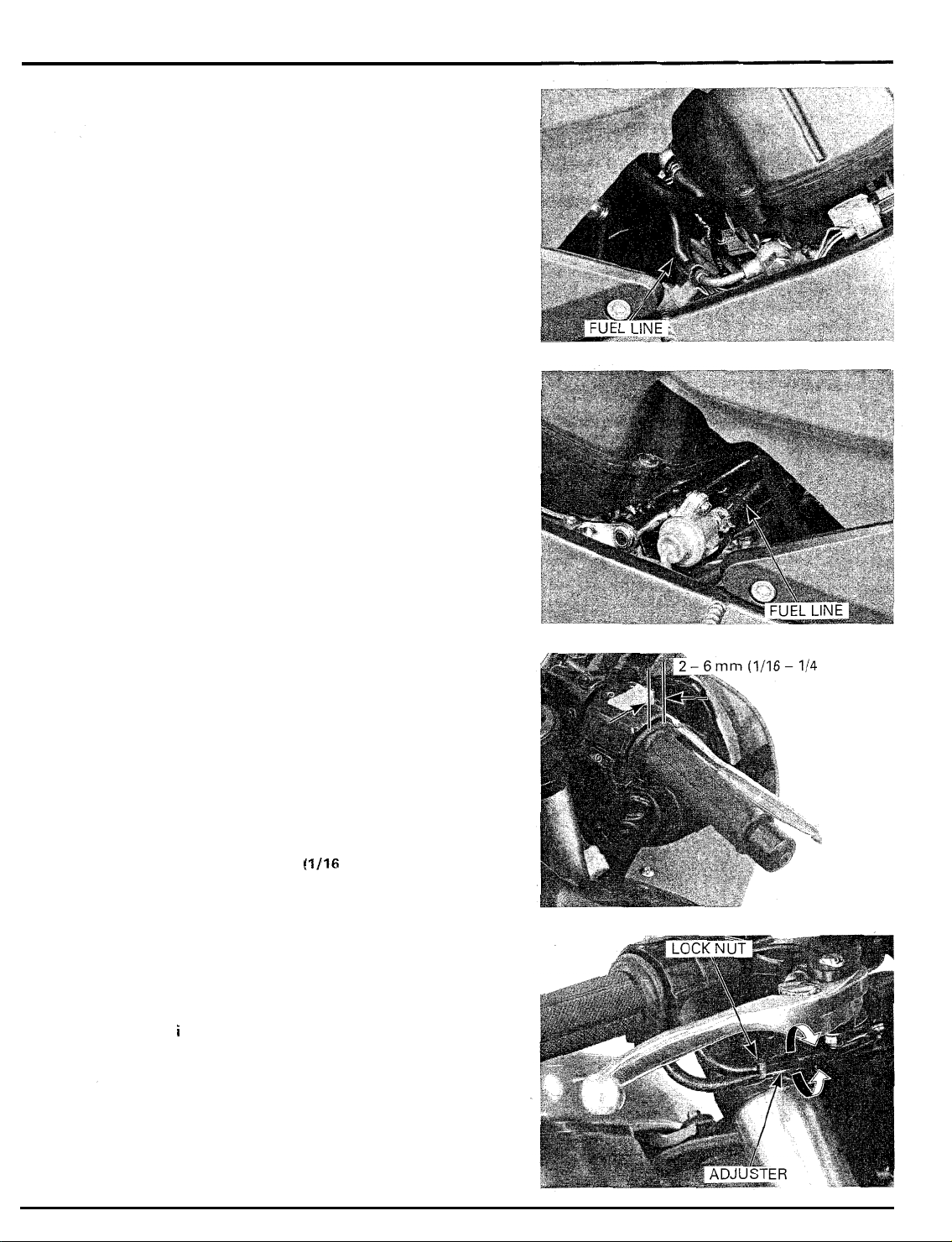

Check the fuel lines for deterioration, damage or leak

age. Replace the fuel line

Install the fuel tank in the reverse order of removal.

if

necessary.

-

THROTTLE OPERATION

Check for smooth throttle grip full opening and auto

matic full closing

the

Check

deteriorated, kinked or damaged.

Lubricate the throttle cables,

not smooth.

Measure the free play at the throttle grip flange.

FREE

Throttle grip free play can be adjusted at either end

the throttle cable.

Minor adjustments are made

Adjust the free play by loosening the lock nut and

t

u rn i ng the adjuster.

throttle cables and replace them

PLAY:

in

all steering positions.

2

-

6

mm

(1/16

if

throttle operation is

-

1/4

in)

with

the upper adjuster.

if

they are

of

‘4

in)

-

L

%

3-5

MAINTENANCE

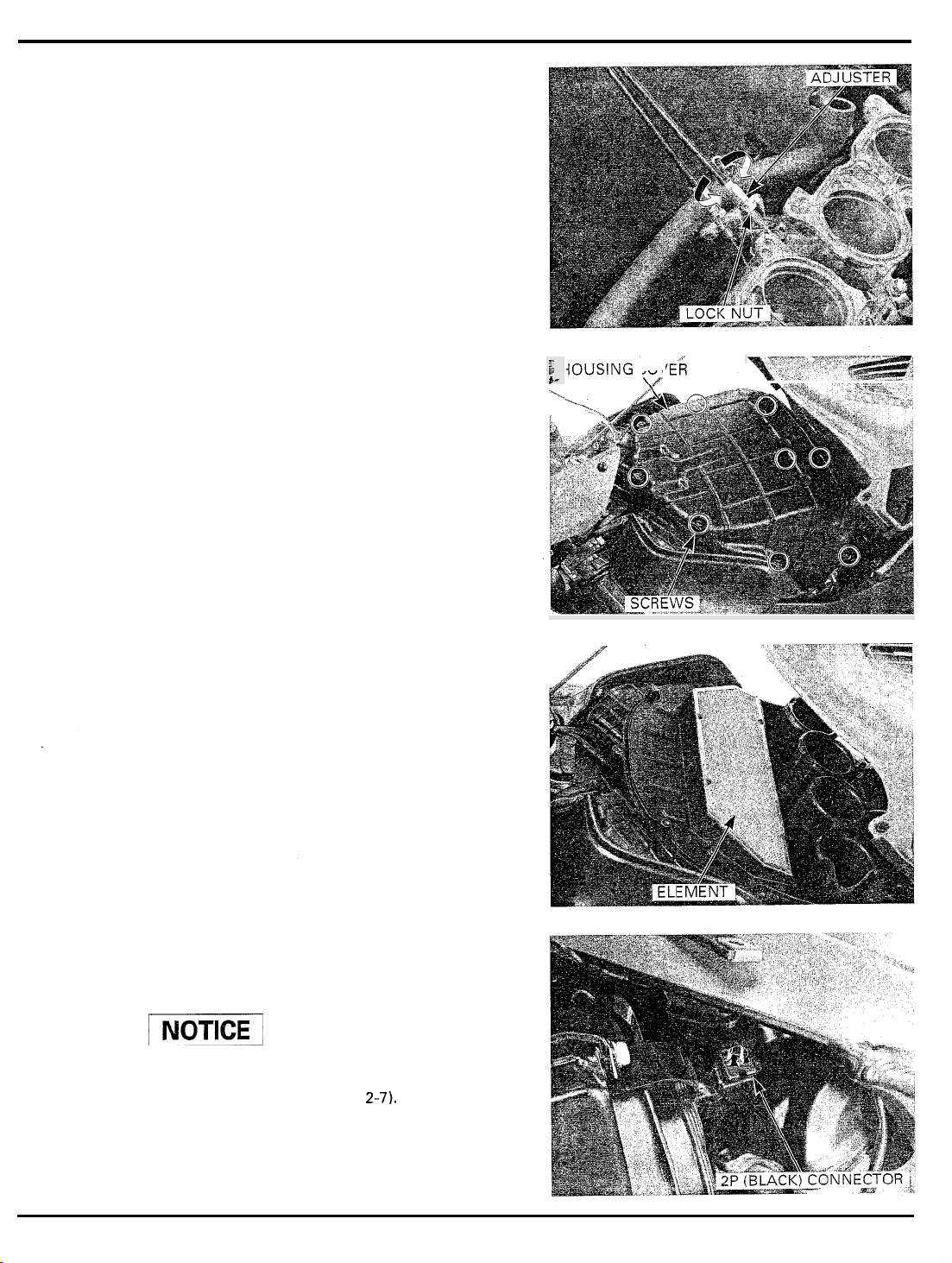

Major adjustments are made with the lower adjuster.

Remove the air cleaner housing (page

Adjust the free play

turning the adjuster.

After adjustment, tighten the lock nut securely.

Recheck the throttle operation.

Replace any damaged parts,

AIR CLEANER

Open and support the front end

3-4).

Remove the screws and air cleaner housing cover.

5-64).

by

loosening the lock nut and

if

necessary.

of

the fuel tank (page

1

HOUSING

e-

COVER

\/

Remove and discard the air cleaner element in accor

dance with the maintenance schedule (page 3Also replace the air cleaner element anytime it is

excessively dirty or damage.

Install the removed parts in the reverse order of

removal.

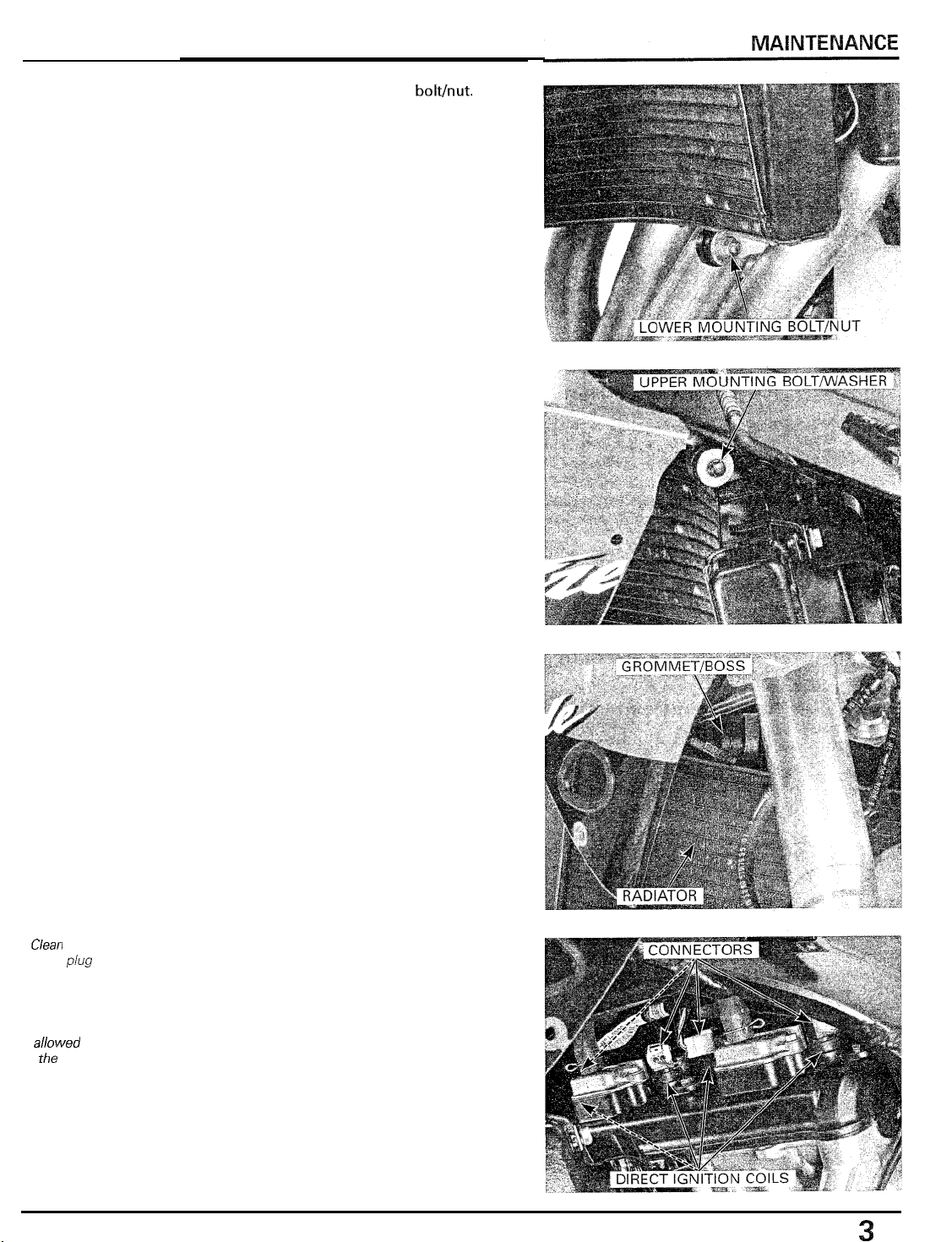

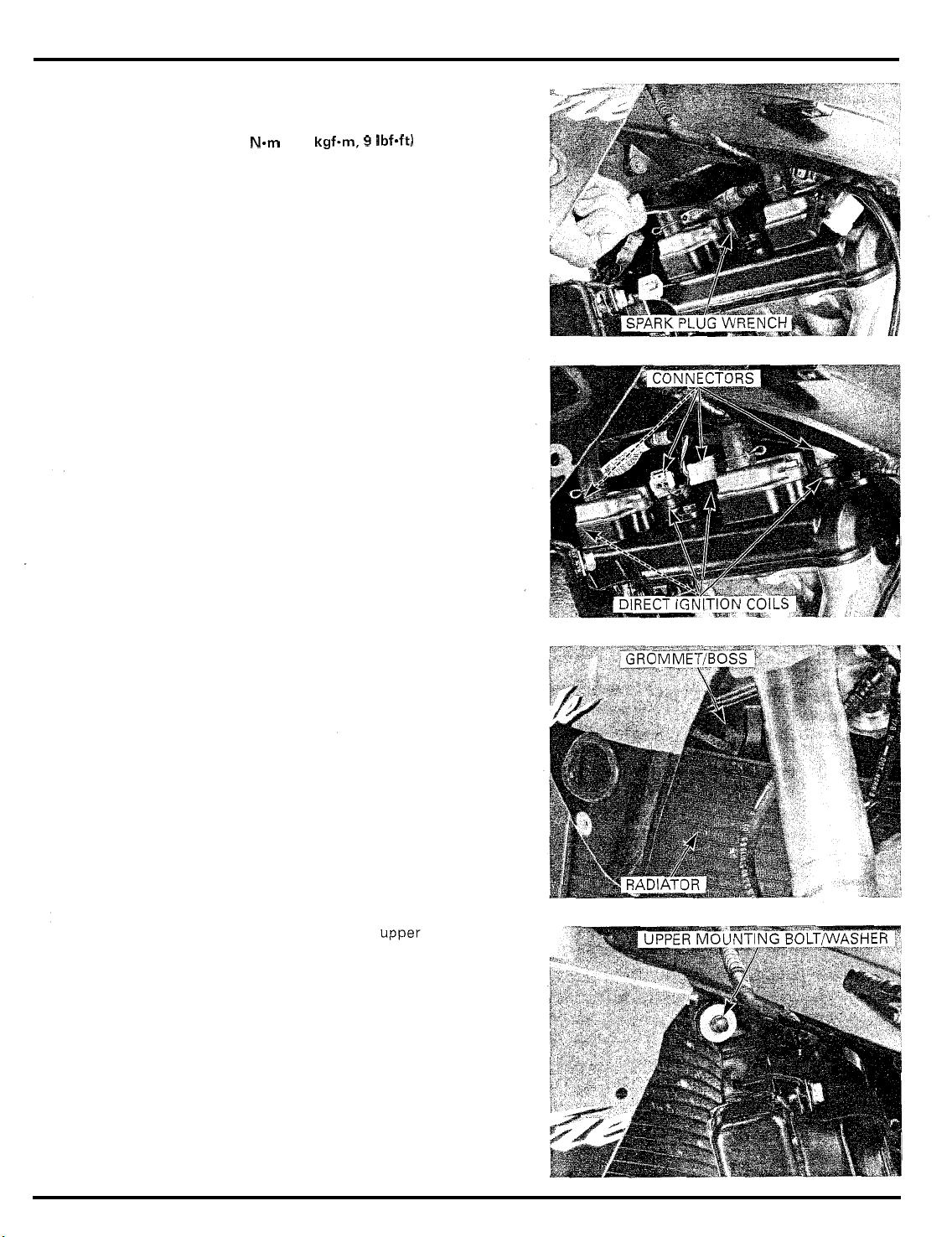

SPARK PLUGS

REMOVAL

/I

Be

careful not

Remove the lower cowl (page

Disconnect the fan motor wire

to

damage the radiator fins.

2-71.

2P

(Black) connector.

-

3).

3-6

Remove the radiator lower mounting bolthut.

Remove the radiator upper mounting bolt and

washer.

Ciean around the

spark

plug

with compressed

air before remov

ing, and be sure

that no debris

aiiowed to enter

the combustion

bases

chamber

Remove the radiator grommet from the frame

moving

Disconnect the direct ignition coil connectors.

Remove the direct ignition coils from the spark plugs.

-

I

S

it

to the right, then move the radiator forward.

boss

by

-

7

MAINTENANCE

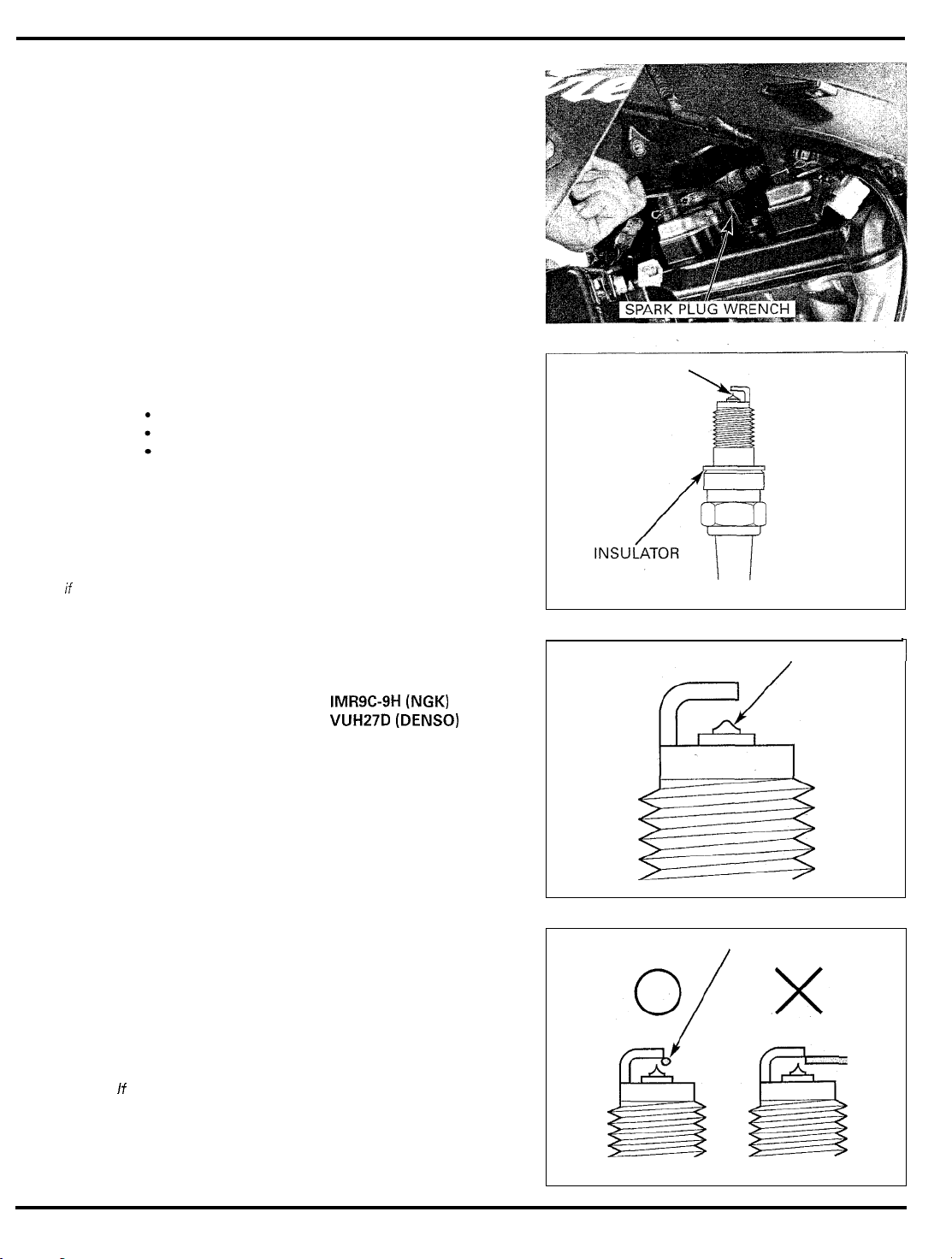

This motorcycle’s

spark plugs are

equipped with

iridium center

electrodes

Replace any spark

plug

If

the elec

trode is contami

nated

Remove the spark plug using the equipped spark

wrench or an equivalent.

Inspect or replace as described in the maintenance

schedule.

INSPECTION

Check the following and replace

mended spark plug: page

Insulator for damage

Electrodes for wear

Burning condition, coloration

If

the electrodes are contaminated with accumulated

objects or dirt, replace the spark plug.

-

-

Replace the plug if the center electrode

shown in the illustration.

3-2)

if

necessary (recom

is

rounded as

plug

-

ELECTRODE

La

ROUNDED ELECTRODE

1

Always use

the specified

spark plugs on

this motorcvcle.

To prevent

damaging the

iridium center

electrode, use a

wire type feeler

gauge to check the

spark plug gap

Do

not adjust the

spark plug gap

the gap is

replace the spark

plug with

out

a

of

new

one

specification,

SPECIFIED SPARK PLUG:

Check the gap between the center and side electrodes

with a wire type feeler gauge.

Make sure the

If

does not insert between the gap.

If the gauge can be inserted into the gap, replace the

plug with a new one.

1.0

mm

IMR9C-9H (NGK)

VUH27D (DENSO)

(0.04

in)

diameter plug gauge

WIRE TYPE FEELER GAUGE

/

3-8

Reinstall the spark plug in the cylinder head and hand

tighten, then torque

to

specification.

MAINTENANCE

TORQUE:

If

using the new plug, install as follows:

Install and hand tighten the new spark plug, then

tighten

tacts the seat of the plug hole.

Install the direct ignition coils.

Connect the direct ignition

12

it

about

N-m

(1.2

kgf-m,

9

IbfW

1/2

turn after the sealing washer con

coil

connectors.

-

Install the radiator grommet onto the frame boss.

Install the washer and

then tighten the bolt.

radiator

mounting bolt,

3-9

MAINTENANCE

Install and tighten

bolthut.

Connect the fan motor wire

Install the lower cowl (page

the

radiator

lower

2P

(Black) connector.

2-7).

mounting

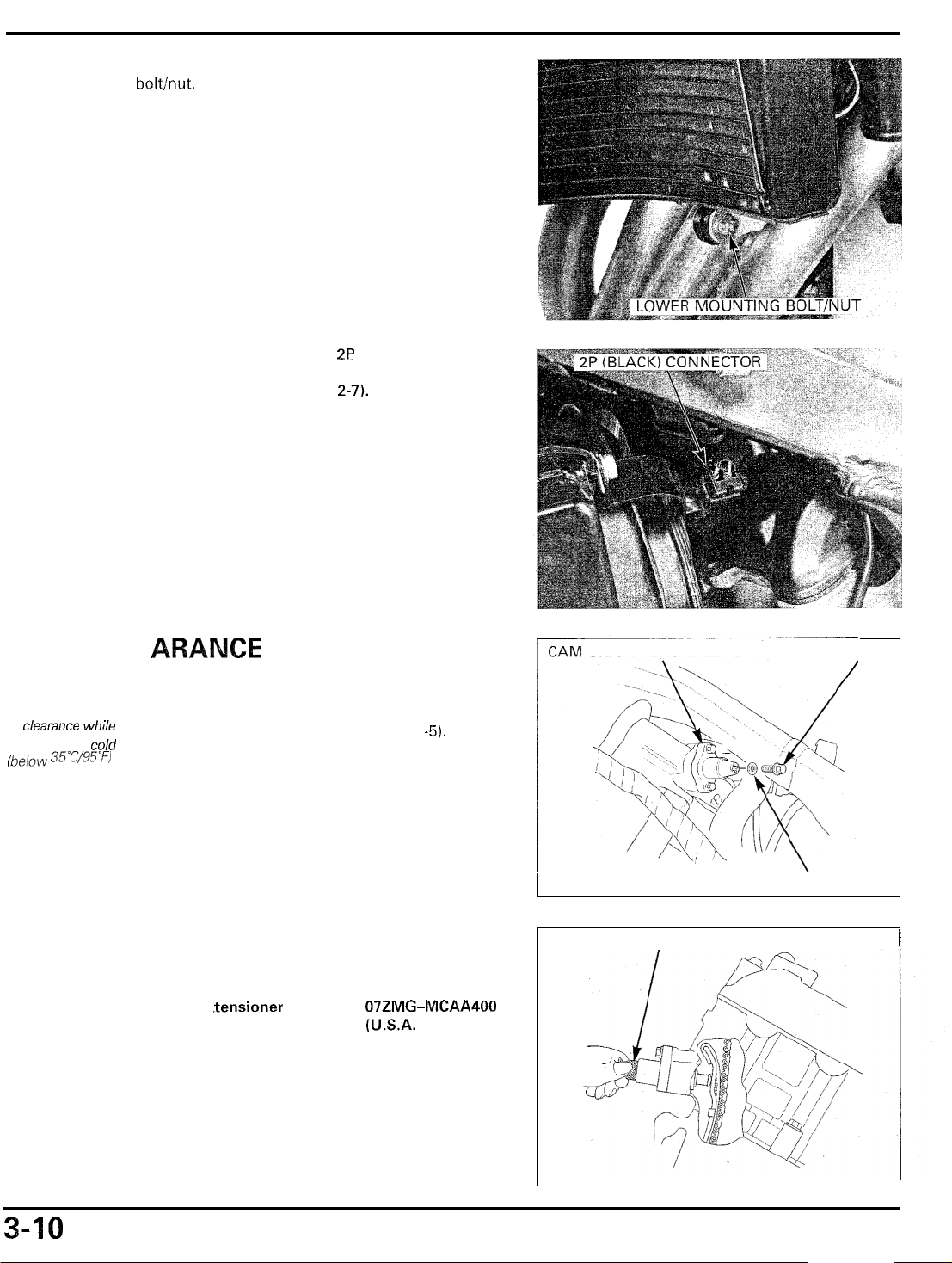

VALVE

inspect and adjust

ciearance whiie

the engine

35‘c’g5W

CLE

the valve

is

coid

INSPECTION

Remove the cylinder head cover (page

Remove the cam chain tensioner lifter

and sealing washer.

Turn the cam chain tensioner lifter shaft

wise) and secure

TOOL:

Cam chain tensioner holder 07ZMG-MCAA400

it

using the special tool.

(U.S.A. only)

-5).

8

sealing bolt

fully

in

(clock

CHAIN TENSIONER LIFTER BOLT

-

CAM CHAIN TENSIONER HOLDER

SEALING WASHER

I

3-70

Loading...

Loading...