Honda CBR 954RR Service Manual 01 general info

I

I

GENERAL INFORMATION

SERVICE RULES 1-1 LUBRICATION & SEAL POINTS 1-19

I

MODEL

DENT1 FlCATl ON 1-1 CABLE & HARNESS ROUTING 1-23

SPECIFICATIONS 1

TORQUE VALUES

TOOLS

-

3 EMISSION CONTROL SYSTEMS 1-37

1

-

12 EMISSION CONTROL INFORMATION

1

-

17

LABELS 1

-

40

SERVICE RULES

1.

Use genuine Honda or Honda-recommended parts and lubricants or their equivalents. Parts that

design specifications may cause damage to the motorcycle.

2.

Use the special tools designed for this product to avoid damage and incorrect assembly.

3.

Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with English

fasteners.

4.

Install new gaskets, O-rings, cotter

5.

When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6.

Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

7.

After reassembly, check all parts for proper installation and operation.

8.

Route all electrical wires as shown on pages

pins,

and lock plates when reassembling.

1-23

through

1-36,

Cable and Harness Routing.

do

not meet Honda's

MODEL IDENTIFICATION

1-1

GENERAL INFORMATION

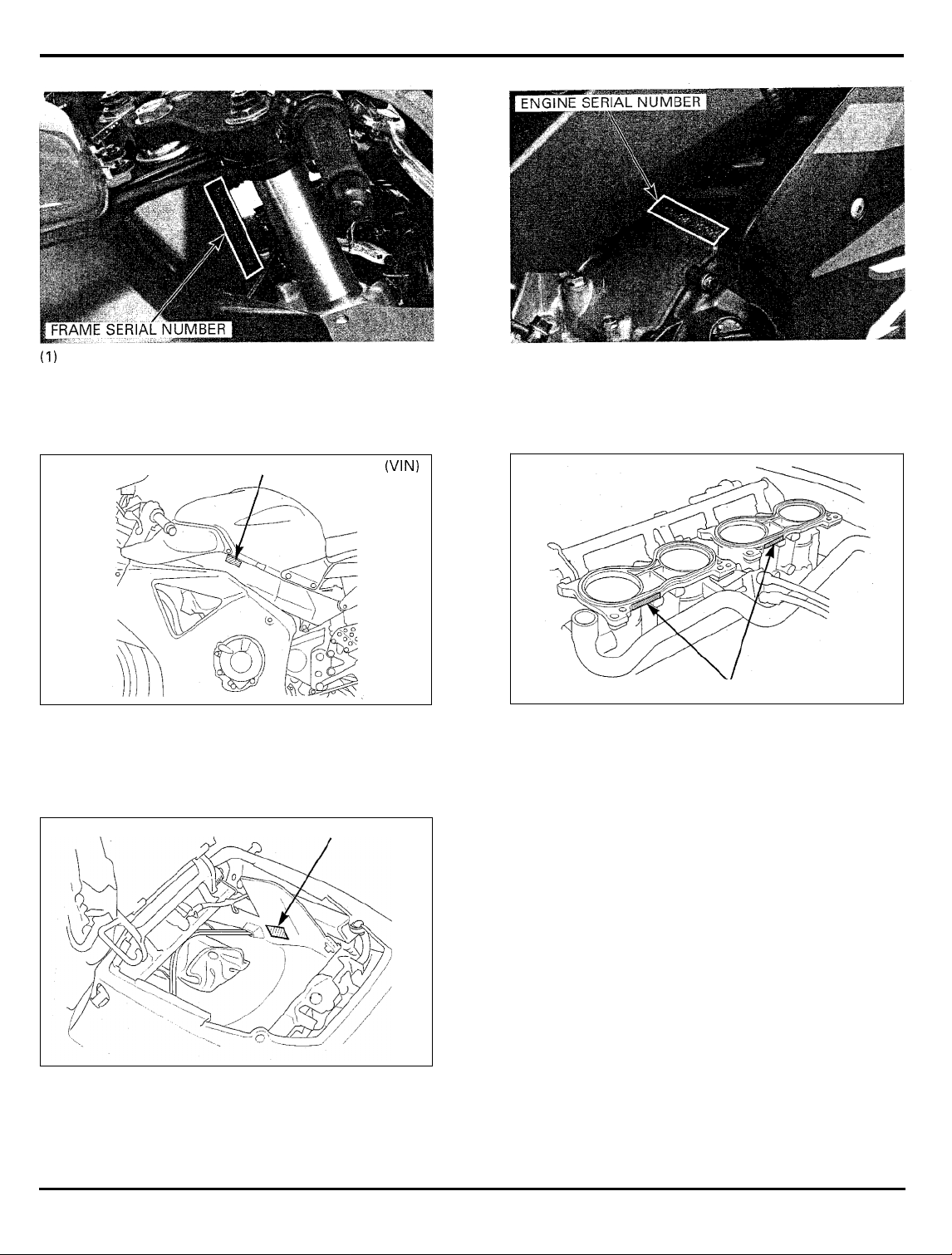

(1)

The frame serial number is stamped on the right side

of the steering head.

(2)

The engine serial number is stamped on the right

side of the upper crankcase.

VEHICLE IDENTIFICATION NUMBER

(3)

The Vehicle Identification Number (VIN) is located on

left side

Labels.

of

the main frame

on

the Safety Certification

COLOR LABEL

(VIN)

THROTTLE

(4)

The throttle body identification number is stamped

on the intake side of the throttle body as shown.

BODY

ID~NTIFICATION

NUMBER

(5)

The color label is attached as shown. When ordering

-

coded parts, always specify the designated

color

color code.

1-2

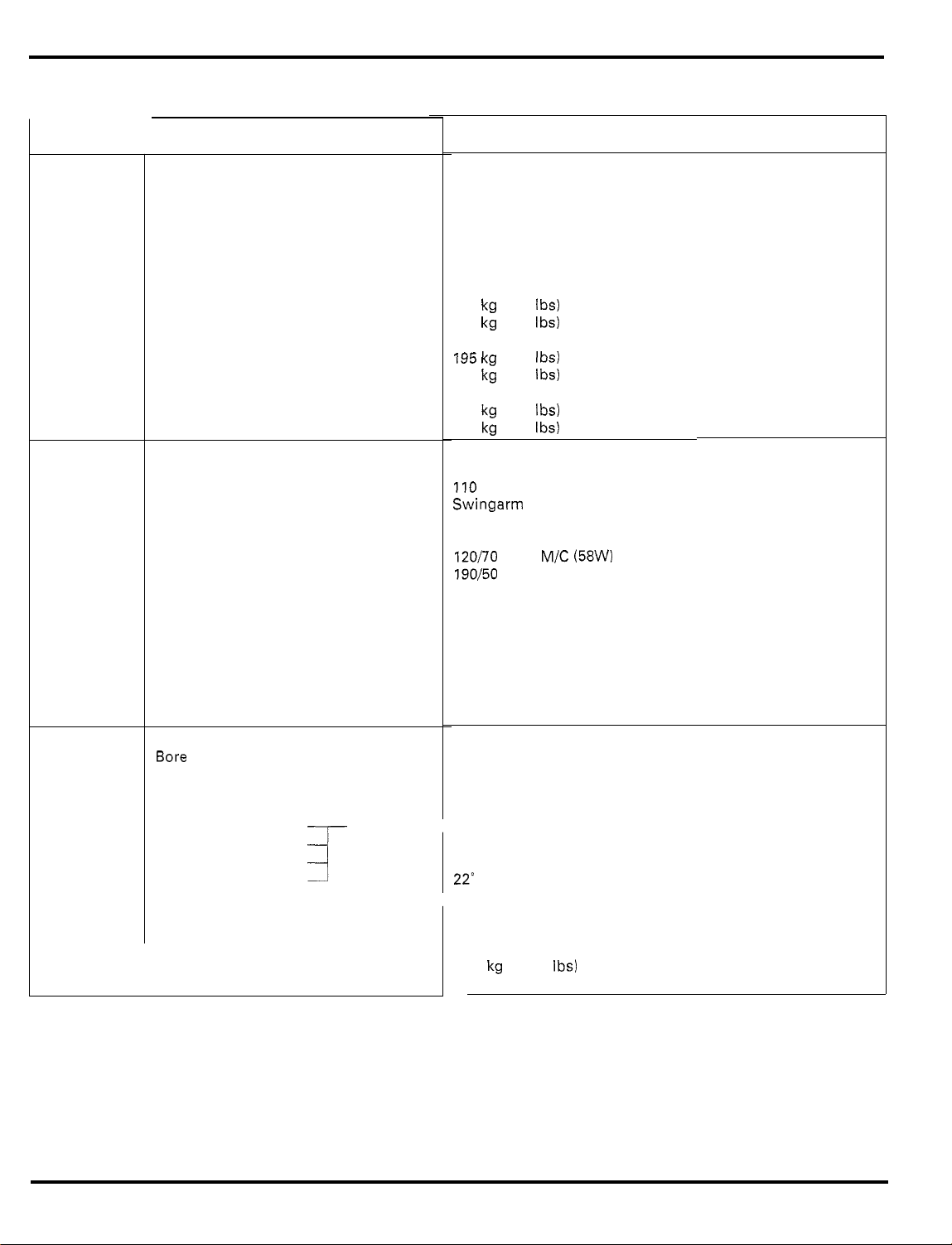

SPECIFICATIONS

GENERAL INFORMATION

GENERAL

DIMENSIONS

FRAME

ENGINE

ITEM

Overall length

Overail

Overal

Wheelbase

Seat height

Footpeg

Ground clearance

Dry weight

Curb weight

Maximum weight capacity

Frame type

Front suspension

Front wheel travel

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire

Tire brand

Front brake

Rear brake

Caster angle

Trail length

Fuel tank capacity

Cylinder arrangement

Bore and stroke

Displacement

Compression ratio

Valve train

Intake valve opens

Exhaust valve opens

Lubrication system

Oil pump type

Cooling system

Air filtration

Engine dry weight

Firing order

width

I

height

height

49 states, Canada type:

California type:

49 states, Canada type:

California type:

49 states, California type:

Canada type:

size

Bridgestone

Michelin

closes

closes

at 1

mm

(0.04 in) lift

SPECIFICATIONS

2,025

mm

(79.7 in)

mm

(26.8

680

1,135 mm (44.7 in)

1,395

mm

820

mm

mm

383

130

mm

kg (370 Ibs)

168

170 kg (375

195 kg (430 Ibs)

197 kg (434 Ibs)

160 kg (353 Ibs)

164 kg (362 Ibs)

Diamond

Inverted telescopic fork

110

mm

Swingarm

135

mm

Nitrogen gas filled damper

120170 ZR17 M/C (58W)

190/50 ZR17 M/C (73W)

Front: BT012F RADIAL G /Rear:

Front: Pilot SPORT E /Rear: Pilot SPORT E

Hydraulic double disc brake with 4 pots caliper

Hydraulic single disc brake with 1 pots caliper

23

"

45'

97

mm

18.0 liter (4.76

4 cylinders in

75.0

x

54.0

954 cm3 (58.2 cu-in)

11.5:

1

Chain driven, DOHC

25' BTDC

38

"

ABDC

41" BBDC

22O ATDC

Forced pressure and wet sump

Trochoid

Liquid cooled

Paper element

61.2

kg (134.9 Ibs)

1-2-4-3

in)

(54.9 in)

(32.3 in)

(15.1

in)

(5.1 in)

Ibs)

(4.3

in)

(5.3 in)

(3.8 in)

US

gal, 3.96 Imp gal)

-

line, inclined 30" from vertical

mm

(2.95 x 2.13

in)

BT012R

RADIAL G

1-3

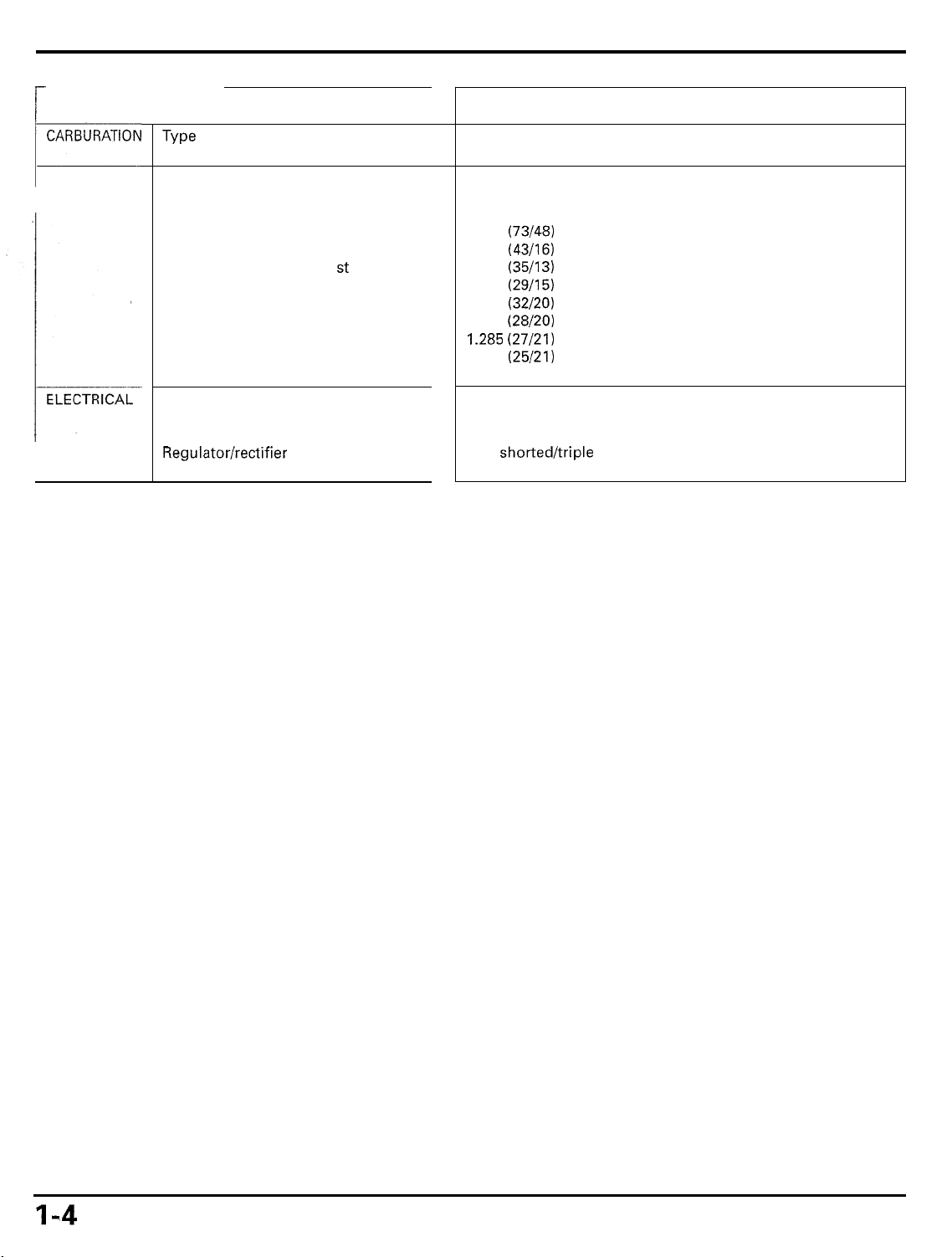

GENERAL INFORMATION

,--

GENERAL

DRIVE

TRAIN

I

(Cont’d)

ITEM

Type

Throttle bore

Clutch system

Clutch operation system

Transmission

Primary reduction

Final reduction

Gear ratio 1

Gearshift pattern

Ignition system

Starting system

Charging system

Regulator/rectifier

Lighting system

st

2nd

3rd

4th

5th

6th

SPECIFICATIONS

PGM-FI

42

Multi

Cable operating

Constant mesh, 6

1.520

2.687 (43/16)

2.692 (35/13)

1.933 (29/15)

1.600 (32/20)

1.400 (28/20)

1.285 (27/21)

1.190

Left

Computer

Electric starter motor

Triple phase output alternator

SCR

Battery

(Programmed Fuel Injection)

mm

(1.7 in)

-

plate, wet

-

speeds

(73/48)

(25/21)

foot operated return system,

-

controlled digital transistorized with electric advance

shorted/triple phase,

full

1

-

N

- 2 -

3

-

wave rectification

4

- 5 -

6

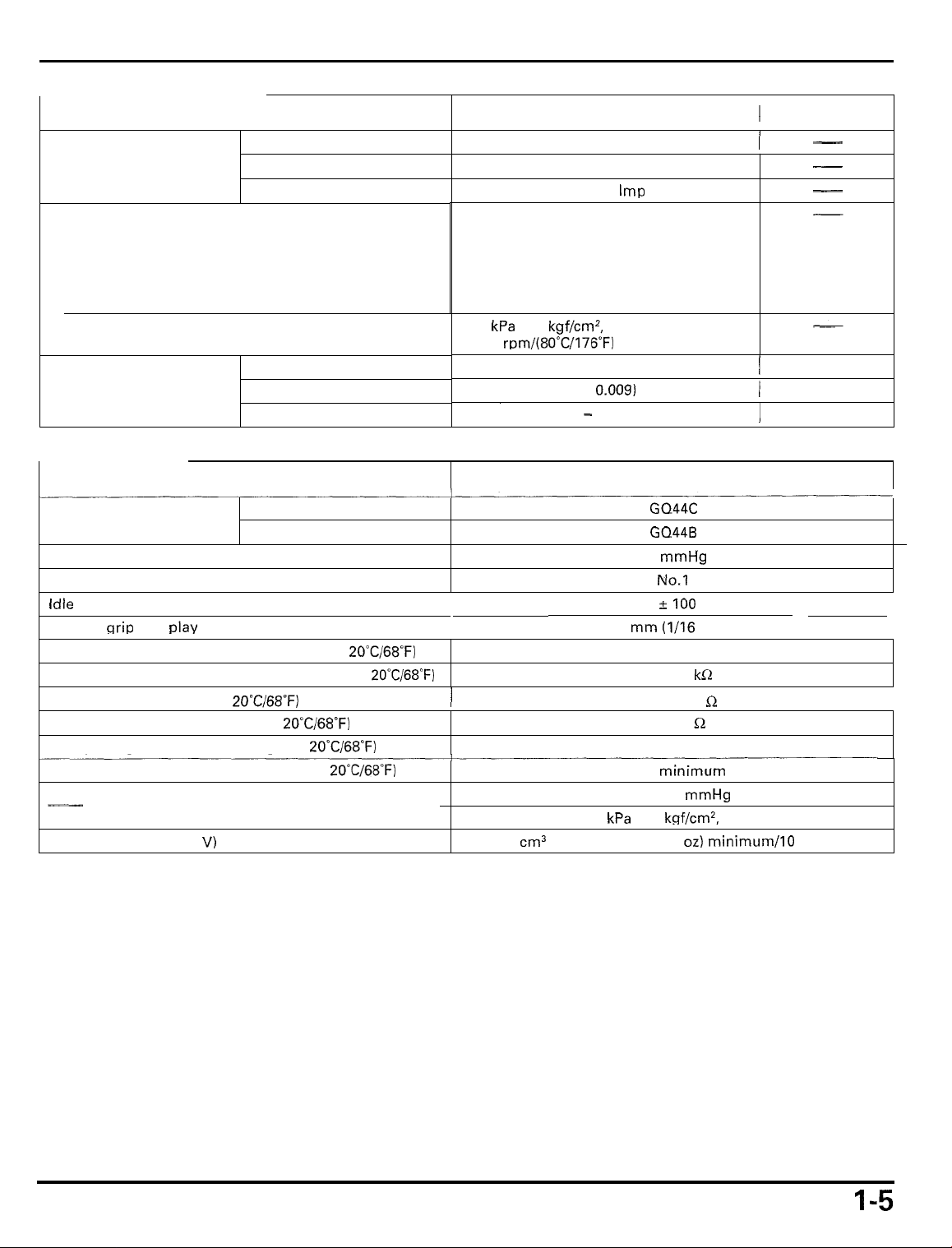

GENERAL INFORMATION

Unit:

mm

(in)

Engine oil capacity

Oil pump rotor

Throttle body identification

number

Starter valve vacuum difference

Base throttle valve for synchronization

Idle speed

Throttle

Intake air temperature sensor resistance (at

Enqine coolant temperature sensor resistance (at 20°C/68"F)

Fuel injector resistance (at 2OoC/68"F)

PAIR solenoid valve resistance (at

Cam pulse generator peak voltage (at 20"C/68"F)

Ignition pulse generator peak voltage (at

Manifold absolute pressure at idle

___

Fuel pressure at idle

Fuel pump flow (at 12

nrip

free play

At draining

At oil filter change

At disassembly

Tip

clearance

Body clearance

Side clearance

ITEM

Except California type GQ44C

California type GQ44B

20°C/68"F)

20"C/68"F)

20"C/68"F)

V)

STANDARD

3.5 liter (3.7 US

3.7 liter (3.9

4.0 liter (4.2

Pro Honda GN4 or HP4 (without molybde

num additives) 4-stroke

motor oil

API service classification: SG or higher

JASO T 903 standard: MA

Viscositv: SAE 1 OW

kPa

490

5,400

0.15

0.1

~~

0.02 - 0.07

(5.0

rr~m/(80"C/176"F)

(0.006)

5

-

0.22

I

188 cm3 (6.4

qt,

3.1 Imp qt)

US

qt,

3.3

Imp

qt)

US

qt,

3.5 Imp

-

kgf/cm2,

(0.006 - 0.009)

(0.001

-

0.003)

2

343 kPa (3.5 kqf/cm2, 50 psi)

US

qt)

oil

or equivalent

40

71

psi) at

SPECIFICATIONS

20 mmHg

No.1

1,200

f

100 rpm

-

6

mm

(1/16 - 1/4

1-4kR

2.3

-

2.6 kL2

10.5

-

14.5

20

-

24

0.7 V minimum

0.7 V minimum

150 - 250 mmHg

oz,

6.6

Imp

R

52

oz) minimum/lO seconds

I

SERVICE LIMIT

I

-

I

0.20 (0.008)

1

0.35

1

0.10 (0.004)

in)

-

__

-

(0.014)

I

1-5

GENERAL INFORMATION

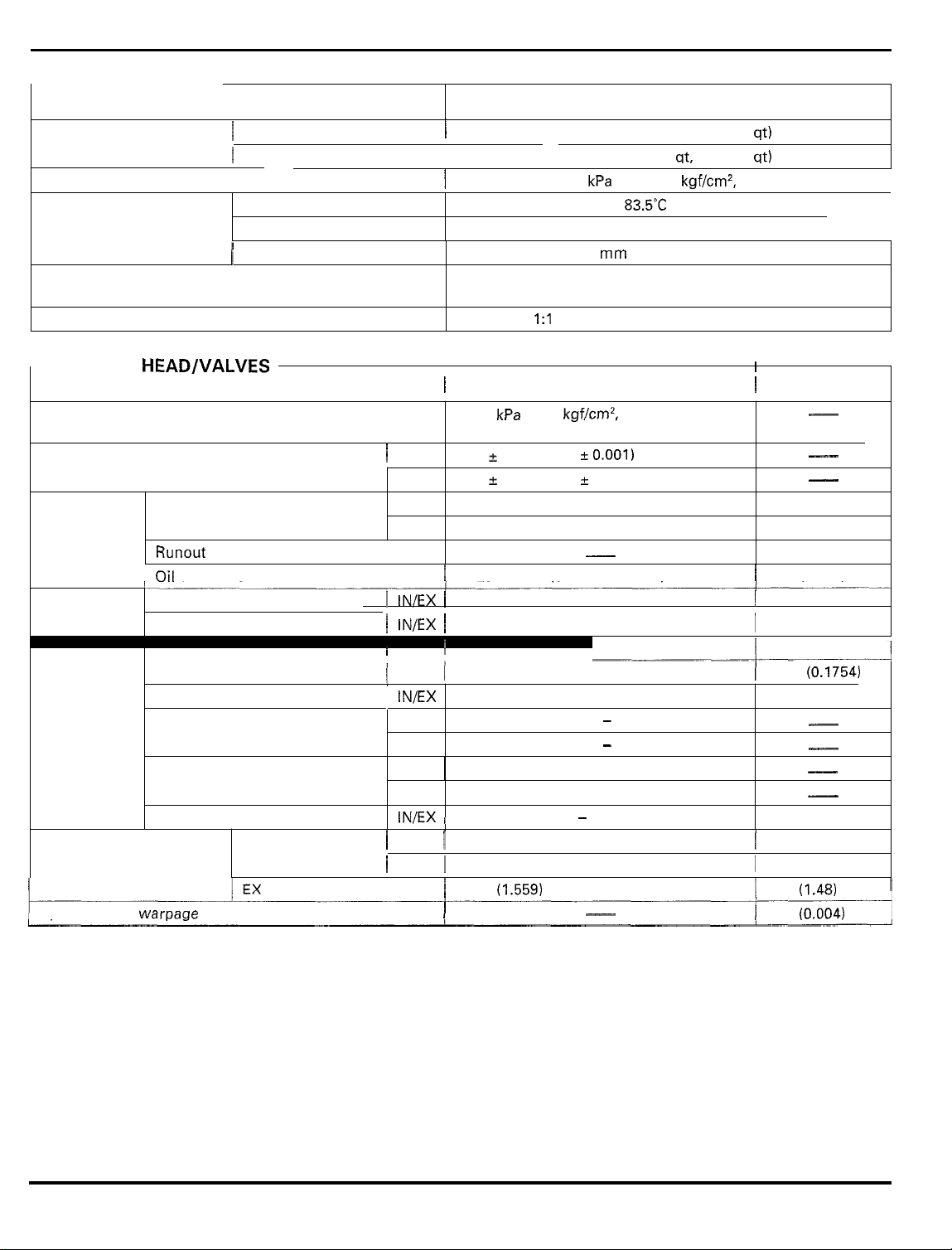

ITEM

Coolant capacity

Radiator cap relief pressure

Thermostat

Recommended antifreeze

Standard coolant concentration

1

Radiator and engine

1

Reserve tank

Begin to open

Fully

1

Valve

CYLINDER HEADNALVES

ITEM STANDARD

Cylinder compression

Valve clearance

Cam shaft Cam lobe height

Runout

I

oil

clearance

Valve lifter Valve lifter

Valve lifter bore

Valve,

valve guide

Valve spring free length

Cylinder head warpaqe

Valve stem

Valve guide

Stem-to-guide clearance

Valve guide projection above

cylinder head

Valve seat width

O.D.

O.D.

I.D.

IN

open

lift

I.D.

SPECIFICATIONS

I

i

I

Pro Honda HP Coolant or an equivalent high quality ethylene

glycol

I

I

1,196

at

1

IN

EX 0.27

IN

EX 36.45

I

IN/EX 1 25.978 - 25.993 (1.0228 - 1.0233)

i

IN/EX 1 26.010 - 26.026 (1.0240 - 1.0246)

I

IN

1

EX

1

IN/EX 4.500 - 4.512 (0.1722 - 0.1776) 4.540 (0.1787)

IN

EX

IN 14.3 - 14.6 (0.56 - 0.57)

EX 12.4 - 12.7 (0.49 - 0.50)

lN/EX

1

Inner

i

Outer

0.16 f 0.03 (0.006 f 0.001)

36.74 - 36.98 (1.446 - 1.456)

1

0.020 - 0.062 (0.0008 - 0.0024)

1

4.475 - 4.490 (0.1762 - 0.1768)

1

4.465 - 4.480 (0.1758 - 0.1764)

0.010 - 0.037 (0.0004 - 0.0015)

0.020 - 0.047 (0.0008 - 0.0019)

1

0.90

I

34.80 (1.370)

1

37.97 (1.495)

1

39.60 (1.559)

I

108 - 137

antifreeze containing corrosion protection inhibitors

1:l

kPa

(12.2

350

rpm

-c

0.03 (0.01 1

-

36.69 (1.435 - 1.444)

-

1.10 (0.035 - 0.043) 1.5 (0.06)

liter

(3.3

US

qt,

2.7

at,

0.4

kgf/cm2,

minimum

Imp

Imp

3.1

0.4

liter

(0.4

US

kPa

(1.1 - 1.4

80.5 - 83.5"C (177 - 182°F)

95°C (203°F)

8

rnm

(0.3

in)

mixture of antifreeze and

kgf/cm2,

-r-

0.001)

-

174

psi)

qt)

qt)

16 - 20

soft

psi)

water

I

I

SERVICE LIMIT

36.72 (1.446)

36.43 (1.434)

0.04 (0.002)

1

0.10 (0.004)

i

25.97 (1.022)

I

26.04 (1.025)

I

4.465 (0.1758)

1

4.455 (0.1754)

I

33.1 (1.30)

I

36.1 (1.42)

I

37.6 (1.48)

1

0.10 (0.004)

Unit:

-

-

-

-

-

-

-

mm

i

(in)

1-6

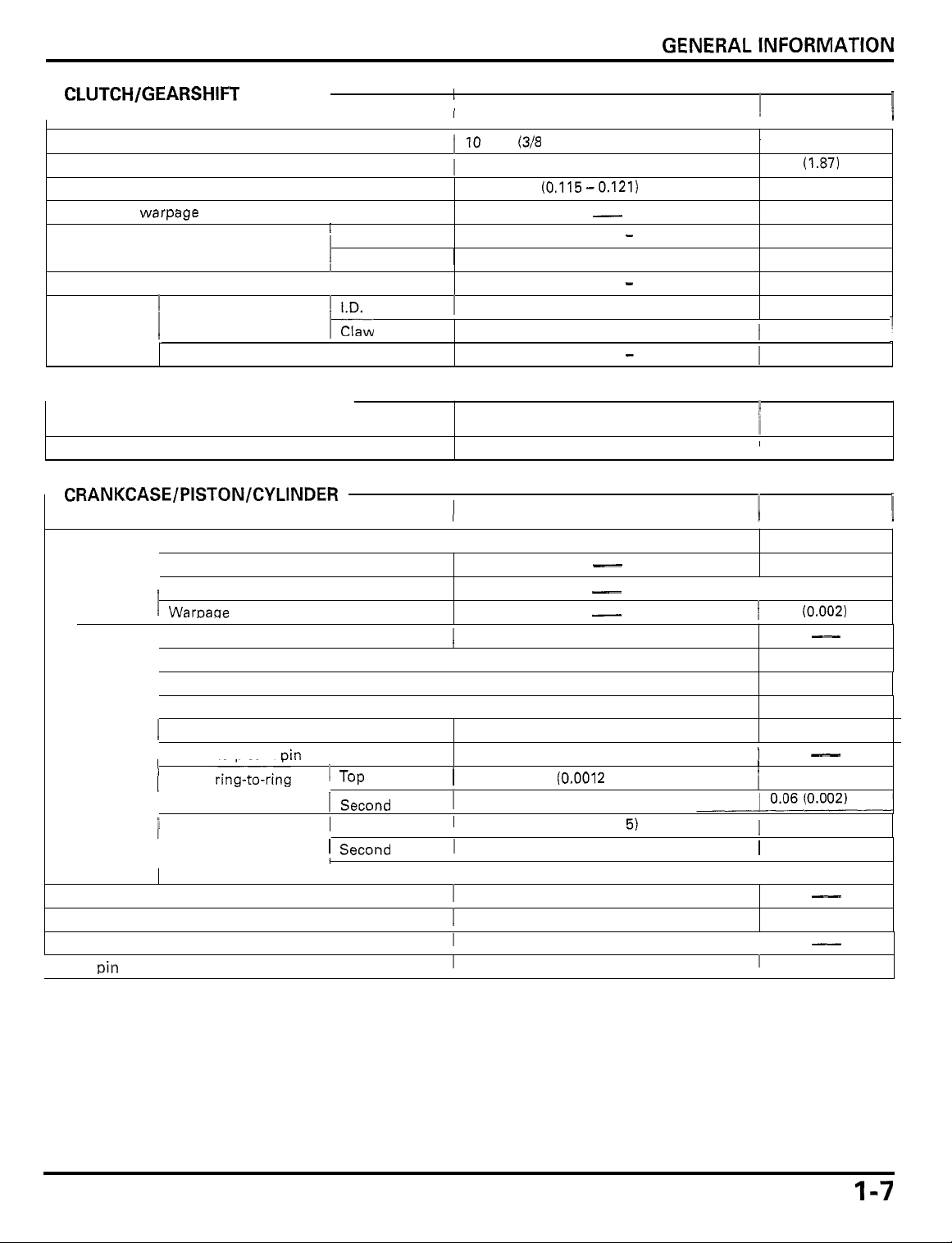

CLUTCH/GEARSHIFT LINKAGE

I

-

Clutch lever free play

Clutch spring free length

Clutch disc thickness 2.92

Clutch plate warpage

Clutch outer guide

Mainshaft

Shift fork,

forkshaft ~

O.D.

at clutch outer guide

I

Fork

Fork shaft

ITEM

O.D.

'

I.D.

~

O.D.

~

Ew

thickness

1

I

1

1

1

1

,

Unit: mm (in)

STANDARD

I0

-

20 (3/8 - 13/16)

48.8 (1.92) 47.4 (1.87)

-

3.08 (0.115-0.121) 2.6 (0.10)

-

25.000 - 25.021 (0.9843 - 0.9851) 25.03 (0.985)

34.975 - 34.991 (1.3770 - 1.3776)

24.980

-

24.993 (0.9835 - 0.9840)

12.000 - 12.018 (0.4724 - 0.4731) 12.03 (0.474)

5.93 - 6.00 (0.233 - 0.236)

11.957 - 11.968 (0.4707 - 0.4712)

1

SERVICE LIMIT

1

1

1

-

0.30 (0.012)

34.97 (1.377)

24.96 (0.983)

5.9 (0.23)

11.95 (0.470)

I

1

ITEM STANDARD

Starter driven sear boss

CRANKCASE/PISTON/CYLINDER

I

Taper

1

WarDase

Piston,

piston rings

Piston mark direction

1

Piston pin

i

Piston-to-oiston Din clearance

j

Piston rin$-to-rin'g

groove clearance

i

Piston ring end gap

i

Cylinder-to-piston clearance

Connecting rod small end

Connecting rod-to-piston pin clearance

Crank Din oil clearance

O.D.

ITEM

O

I.D.

.D.

I

I

1

1

I

TOP

Second

Top

Second

51.699 - 51.718 (2.0354 - 2.0361)

I

STANDARD

-

-

-

1

"0"

mark facing toward the intake side

16.994 - 17.000 (0.6691 - 0.6693)

0.002 - 0.014

i

0.030 - 0.065 (0.001 2 - 0.0026)

I

0.015 - 0.045 (0.0006 - 0.0018)

1

0.28 - 0.38 (0.01 1 - 0.01 5)

I

0.40 - 0.55 (0.016 - 0.022)

1

0.020 - 0.055 (0.0008 - 0.0022)

I

17.016 - 17.034 (0.6699 - 0.6706)

1

0.016 - 0.040 (0.0006 - 0.0016)

1

0.030 - 0.052 (0.0012 - 0.0020)

(0.0001

-

0.0006)

I

i

SERVICE LIMIT

i

51.684 (2.0348)

Unit: mm (in)

I

SERVICE LIMIT

0.10 (0.004)

,

,

0.10 (0.004)

~ 0.05

(0.002)

-

16.98 (0.669)

I

I

i

1

1

-

0.08 (0.003)

0.06 (0.002)

0.5 (0.02)

0.7

(0.03)

-

17.04 (0.671)

I

'

-

0.062 (0.0024)

I

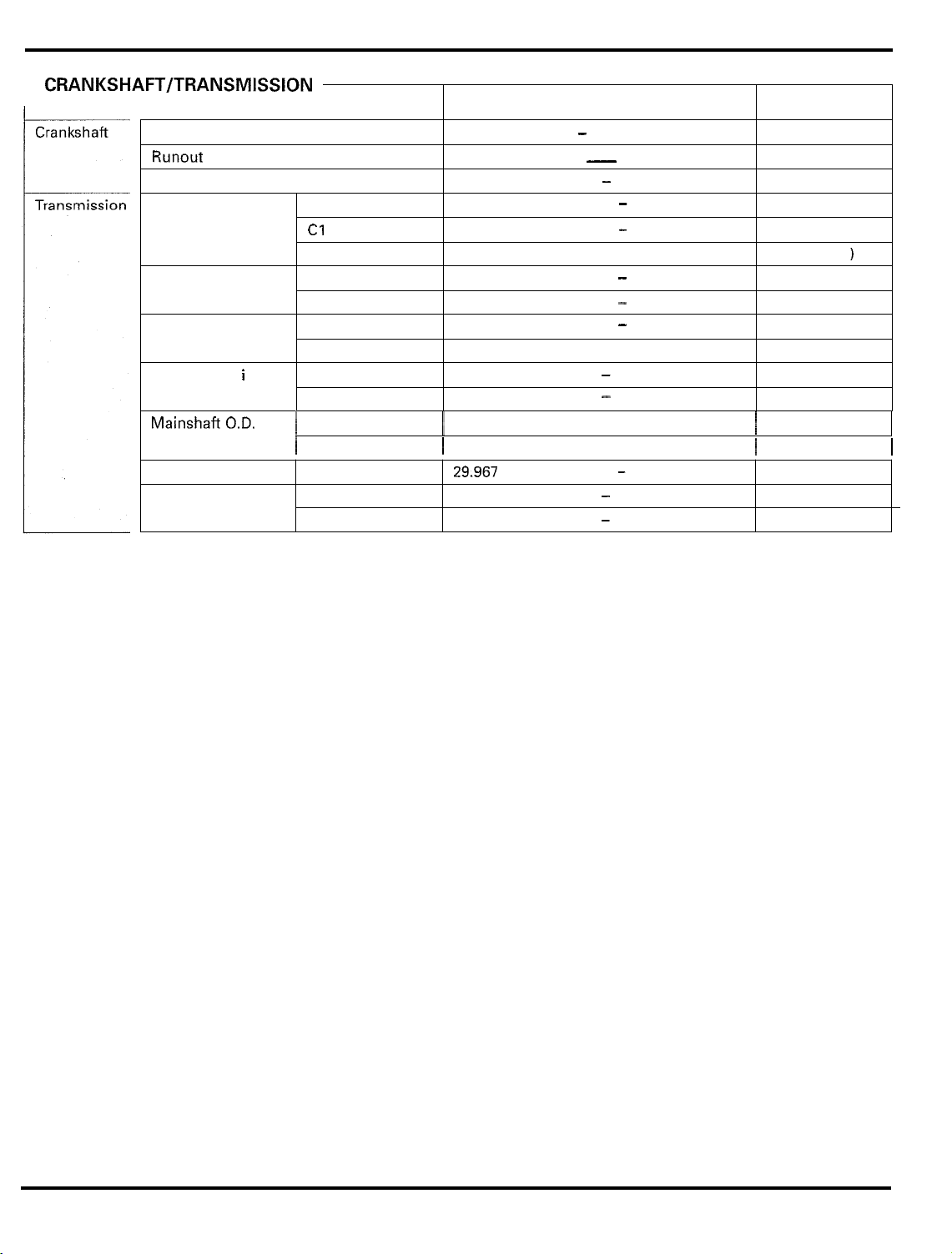

GENERAL INFORMATION

CRANKSHAFT/TRANSMISSlON

r

Side clearance

Runout

Main journal oil clearance

Gear I.D. M5, M6 31.000

Bushing O.D. M5, M6 30.950

Bushing

Gea r

clearance c3, c4 0.025

Mainshaft0.D.

Countershaft O.D.

Bushing

clearance

-to-

ITEM

I.D.

bus

-to-

h i ng

s haft

STANDARD

-

0.20 (0.002 - 0.008)

0.05

-

-

0.017

c1

c2, c3, c4

c3, c4

M5 27.985 - 28.006 (1.1018 - 1.1026)

c2

M5, M6

1

M5

1

Clutch outer guide I 24.980 - 24.993 (0.9835 - 0.9840)

C2 29.967 - 29.980 (1.1798 - 1.1803) 29.96 (1.180)

M5 0.005

c2 0.005 - 0.039 (0.0002 - 0.0015)

26.000

33.000

32.950

29.985

0.025

I

27.967 - 27.980 (1.1011 - 1.1016)

0.035 (0.0007 - 0.0014)

-

31.025 (1.2205 - 1.2215)

-

26.021 (1.0236 - 1.0244)

-

33.025 (1.2992 - 1.3002)

-

30.975 (1.2185 - 1.2195)

-

32.975 (1.2972 - 1.2982)

-

30.006 (1.1805- 1.1813)

-

0.075 (0.0010 - 0.0030)

-

0.075 (0.0010 - 0.0030)

-

0.039 (0.0002 - 0.0015)

SERVICE LIMIT

0.30 (0.012)

0.03 (0.001)

0.045 (0.0018)

31.04 (1.222)

26.04 (1.025)

33.04 (1.301

30.93 (1.218)

32.93 (1.296)

28.02 (1.103)

30.02 (1.182)

0.11 (0.004)

0.11 (0.004)

1

27.957 (1.1007)

1

24.96 (0.983)

0.08

(0.003)

0.08

(0.003)

)

I

1-8

Minimum tire tread depth

Cold tire pressure

Axle runout

Wheel rim runout Radial

Wheel balance weigh

Fork

Up to 90

Up to maximum weight capacity

Axial

Spring free length

Spring direction

Fork pipe runout

Recommended fork oil

Fluid level

Fluid

-

load adjuster initial setting

Pre

Rebound adjuster initial setting

Compression adjuster initial setting

kg

(200

capacity

Ib)

load

-

kPa (2.50 kgf/cm2, 36 psi)

250

kPa (2.50 kgf/cm2, 36 psi)

250

-

-

-

255.8

(10.07)

With the tapered end facing up

-

Pro Honda Suspension Fluid

73

(2.9)

513

k

2.5 cm3

18.1 2 0.09

7

turns from

2

turns from

2

turns from full hard

(17.3 * 0.08

Imp

02)

full

soft

full

hard

SS-8

US

02,

1.5 (0.06)

_____

-

-

0.20

(0.008)

2.0

(0.08)

2.0 (0.08)

250.8 (9.87)

-

0.20

(0.008)

-

-

-

-

-

-

Cold tire pressure

Axle runout

rim

Wheel

Wheel balance weight

Drive chain

Shock absorber

runout Radial

ITEM

Up to 90

Up

Axial

Size/l i n k DID

Slack

Spring adjuster standard position

Rebound adjuster initial setting

Compression adjuster initial setting

kg (200

to

maximum weight capacity 290 kPa (2.90 kgf/cm2, 42 psi)

Ib)

load

RK

kPa (2.90 kgf/cmz, 42 psi)

290

50VA8

50

(1.6 - 2.0)

C1/108

full

full

DID

RK

GB50HFOZ5/108

40

-

4th groove

2

turns from

2

turns from

STANDARD

-

-

-

-

-

hard

hard

SERVICE LIMIT

2.0 (0.08)

-

-

0.20

(0.008)

2.0

(0.08)

2.0

(0.08)

60 g (2.1

50

-

-

(2.0)

-

02)

max.

-

-

1-9

GENERAL INFORMATION

r

Front

Rear

ITEM STANDARD

1

Specified brake fluid

Brake disc thickness

Brake disc runout

1

Master cylinder I.D.

1

Master piston

Caliper cylinder I.D. ~ Upper

Caliper piston

Specified brake fluid

Brake disc thickness

Brake disc runout

Master cylinder I.D.

1

Master t7iston O.D.

Caliper cylinder I.D.

Caliper cylinder O.D.

O.D.

O.D.

Lower

Upper

I

Lower

SERVICE LIMIT

1

Honda

I

4.5 (0.18)

I

I

I

17.460 - 17.503 (0.6874 - 0.6891)

I

1

17.321 - 17.367 (0.6819 - 0.6837)

1

32.025 - 32.035 (1.2608 - 1.2612)

30.250 - 30.280 (1.1909 - 1.1921)

~

31,965 - 31.998 (1.2585 - 1.2598)

I

j

30.082 - 30.115 (1.1843 - 1.1856)

1

Honda

I

i

5.0 (0.20) 4.0 (0.16)

I

,

15.870 - 15.913 (0.6248 - 0.6265)

1

15.827 - 15.854 (0.6231 - 0.6242)

38.180 - 38.230 (1.5031 - 1.5051)

38.098

DOT 4

Brake Fluid

-

DOT

4

Brake Fluid

-

-

38.148 (1.4999 - 1.5019)

1

1

3.5 (0.14)

~

0.30 (0.012)

1

17.515 (0.6896)

I

I

17.309 (0.6815)

,

32.05 (1.262)

1

30.29 (1.193)

I

31.953 (1.2580)

i

30.074 (1.1840)

0.30 (0.012)

15.925 (0.6270)

1

15.815 (0.6226)

38.24 (1.506)

38.090 (1.4996)

-

-

I

1

1

I

Battery

Alternator

-

IGNITION SYSTEM

Spark plug Standard

Spark plug gap

Ignition coil peak voltage

Ignition pulse generator peak voltage

Ignition timing (

Capacity

Current leakage

Voltage

Charging current Normal

Capacity

Charging coil resistance

~

Optional

"F"

(2O"C/68'F)

ITEM

mark)

12V - 8.6

0.2

0.421

-

0.90

S

13.0 - 13.2

0.9

4.0

PECl

(NGK),

mm

100 V

0.7 V

13

"

Fully charged

Needs charging Below

1

Quick

(2O"C/68"F) 0.1 - 1.0

IMR9C-9H (NGK),

I

1

IMR8C-9H

0.80

Ah

mA max.

V

12.3 V

A/5

-

10

h

A10.5

h

kW/5,000

Fl

minimum

minimum

BTDC at idle

rpm

R

CAT1 ONS

VUH27D (DENSO)

VUH24D (DENSO)

(0.031 - 0.035

in)

7-70

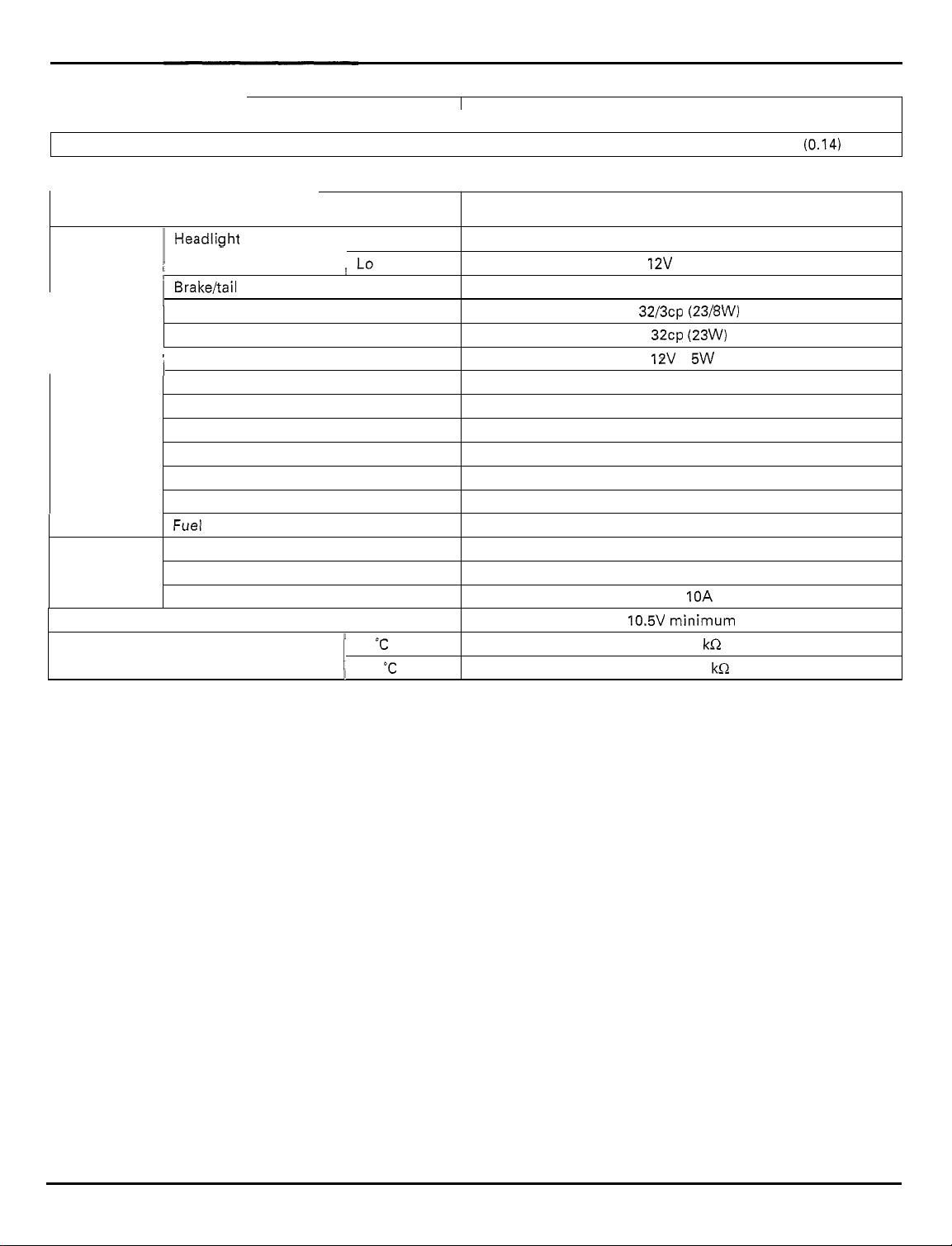

GENERAL INFORMATION

Starter motor brush length

Bulbs

1

1

Brakehail light

Front turn signal light

Rear turn

i

License light

Instrument light

Turn signal indicator

High beam indicator

Neutral indicator

Oil pressure indicator

PGM

-

FI warning indicator

Fuel reserve indicator

Fuse Main fuse

-

FI fuse

PGM

Sub fuse

Tachometer peak voltage

Thermo sensor resistance

ITEM

signal

light

Hi

!

Lo

80

"C

1

120

(176°F)

'C

(248°F)

1

10.0 - 10.5

(0.39

-

0.41) 3.5

SPECIFICATIONS

12v - 55w

12V - 55W

LED

12V - 32/3~p (23/8W)

12V - 32cp (23W) X 2

12V - 5W

LED

X

LED

LED

LED

LED

LED

LED

30 A

20

A

X

2, 10A X 3

20A

10.5V minimum

2.1 - 2.6

0.65 - 0.73 kQ

2

kQ

x

(0.14)

2

X

2

1-11

GENERAL INFORMATION

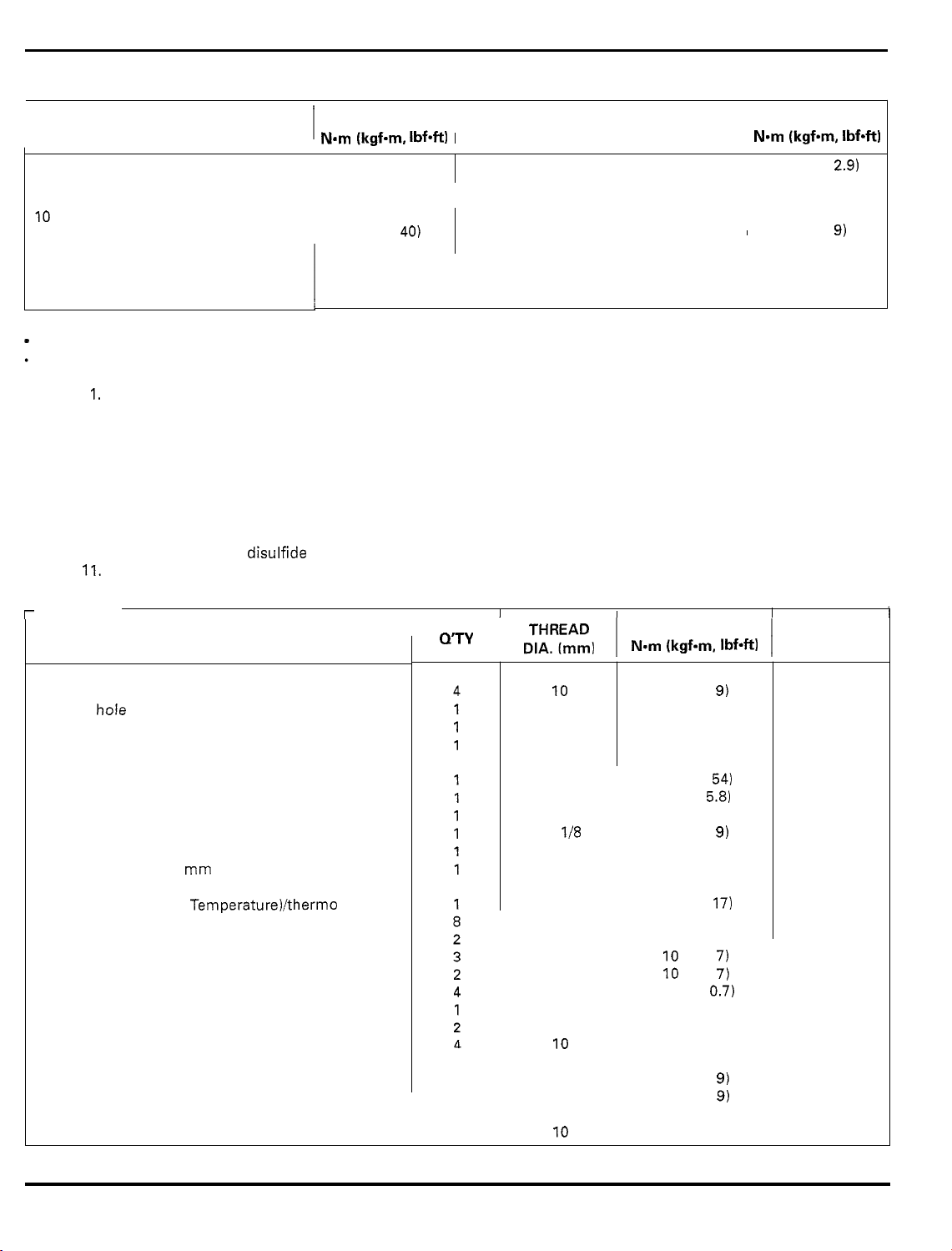

TORQUE

5

mm hex bolt and nut

10

mm hex bolt and nut

12

mm hex bolt and nut

-

Torque specifications listed below are for important fasteners.

Others should be tightened

NOTES:

3.

4.

5.

6.

7.

8.

9.

10.

11.

VALUES

I

FASTENER TYPE

to

standard torque values listed above.

1.

Apply sealant to the threads.

2.

Apply a locking agent to the threads.

Apply grease to the threads.

Stake.

Apply oil to the threads and flange surface.

Apply clean engine oil to the O-ring.

U-nut

ALOC bolt: replace with a new one.

CT bolt

Apply molybdenum disulfide oil to the threads and seating surface (after removing anti-rust oil additive).

One-way bolt

TORQUE

N-m (kgf-m, Ibf-ft)

5 (0.5, 3.6)

34 (3.5, 25)

54 (5.5,

40)

I

5

mm

screw

small flange)

6

mm

flange bolt

large flange)

FASTENER TYPE

(8

mm head,

TORQUE

~

N-m (kgf-m, Ibfbft)

4 (0.4, 2.9)

I

12 (1.2, 9)

r

ENGINE

ITEM

MAINTENANCE:

Spark plug

Timing

Oil drain bolt

Oil filter cartridge

LUBRICATION SYSTEM:

Oil cooler mounting bolt

Oil pump assembly flange bolt

Oil pump driven sprocket bolt

Oil pressure switch

Oil pressure switch wire terminal screw

Lower crankcase

FUEL SYSTEM (Programmed Fuel Injection):

ECT (Engine Coolant

Throttle body insulator band screw

Throttle cable bracket mounting bolt

Fuel pipe mounting bolt

Pressure regulator mounting bolt

Starter valve synchronization plate screw

Fast idle wax unit link plate screw

Fast idle wax unit mounting screw

Starter valve lock nut

COOLING SYSTEM:

Water pump cover flange bolt

Thermostat cover flange bolt

ENGINE MOUNTING:

Drive sprocket special bolt

hole cap

20

rnm

sealing bolt

Temperature)/thermo sensor

,

O'TY

1

;;RE:)

10

45

12

20

20

6

6

PT

118

4

20

12

5

5

6

6

3

3

6

10

2

2

1

6

6

10

I

TORQUE

~

N-m (kgf-m, IbfW

12 (1.2, 9)

18 (1.8, 13)

29 (3.0, 22)

26 (2.7, 20)

74 (7.5,

8

15 (1.5, 11)

2 (0.2, 1.4)

29 (3.0, 22)

23 (2.3,

See page

3 (0.35, 2.5)

1 (0.09,

1 (0.09, 0.7)

5 (0.5, 3.6)

2 (0.18, 1.3)

54 (5.5, 40)

54)

(0.8, 5.8)

12 (1.2,

10

10

12 (1.2,

12 (1.2, 9)

9)

17)

1-14

(1.0,

7)

(1.0, 7)

0.7)

9)

I

1

REMARKS

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

I

3

6

9

2

1

2

9

9

1-12