Page 1

HL600

HL662

ML-134297

ML-134298

Page 1 - English

Page 41 - French

Page 83 - German

INSTALLATION AND OPERATION MANUAL

MANUEL D’INSTALLATION ET D’UTILISATION

INSTALLATIONS UND BEDIENUNGSANLEITUNG

F34931 (April 2005)

Page 2

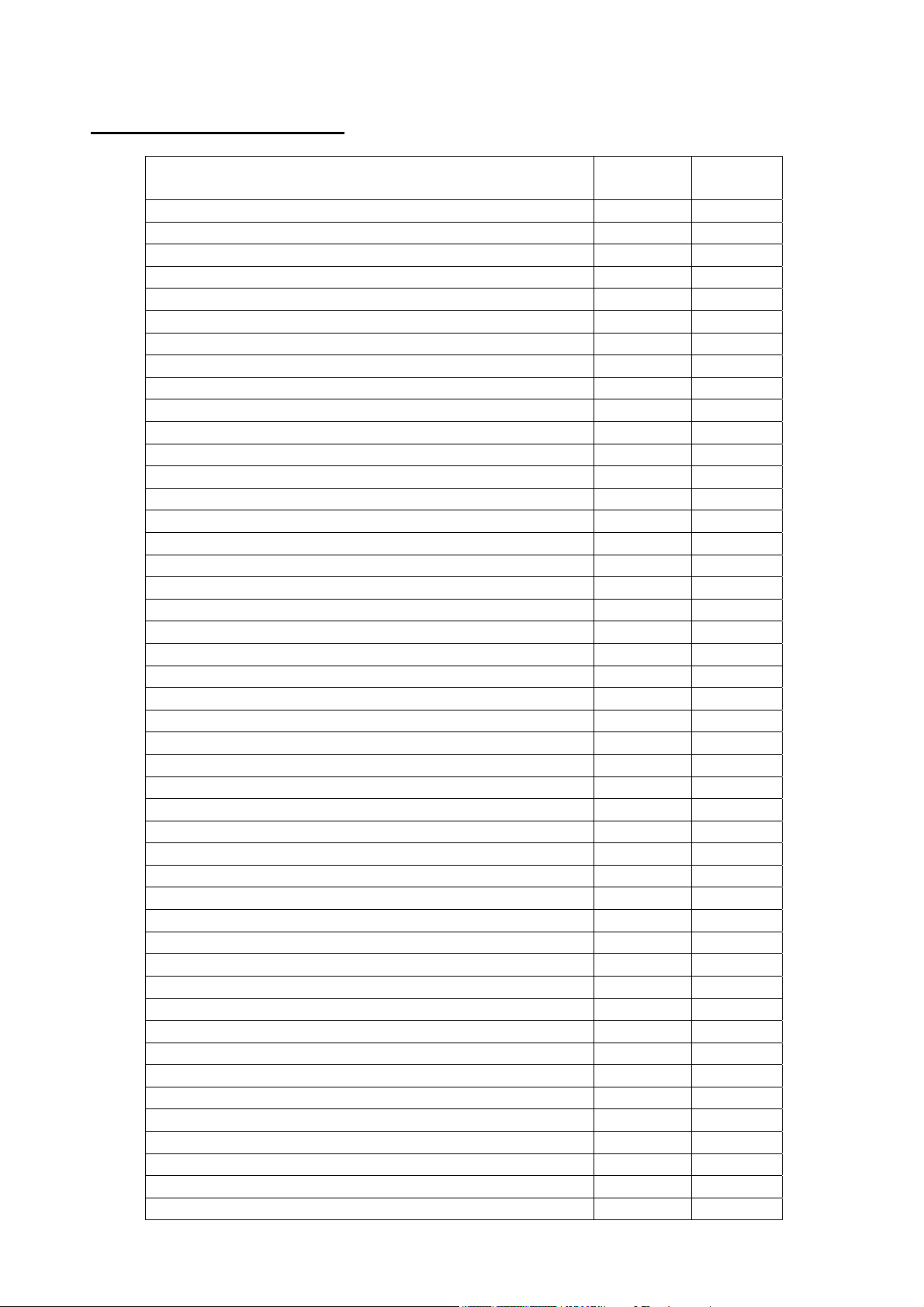

English / CONTENTS.

y

Safety information 1 3

Safety guidelines 1.1 3

Warning symbols 1.2 3

Liability 1.3 4

Foreword 2 4

General information 3 4

Caring for our environment 4 4

Packaging material 4.1 4

Disposal of your old appliance 4.2 4

Safety instructions 5 5

Dust hazard 5.1 5

Never 5.2 5

Always 5.3 6

Attachment safety instruction 5.4 6

Using the mixer 6 7

Operating for the first time 6.1 7

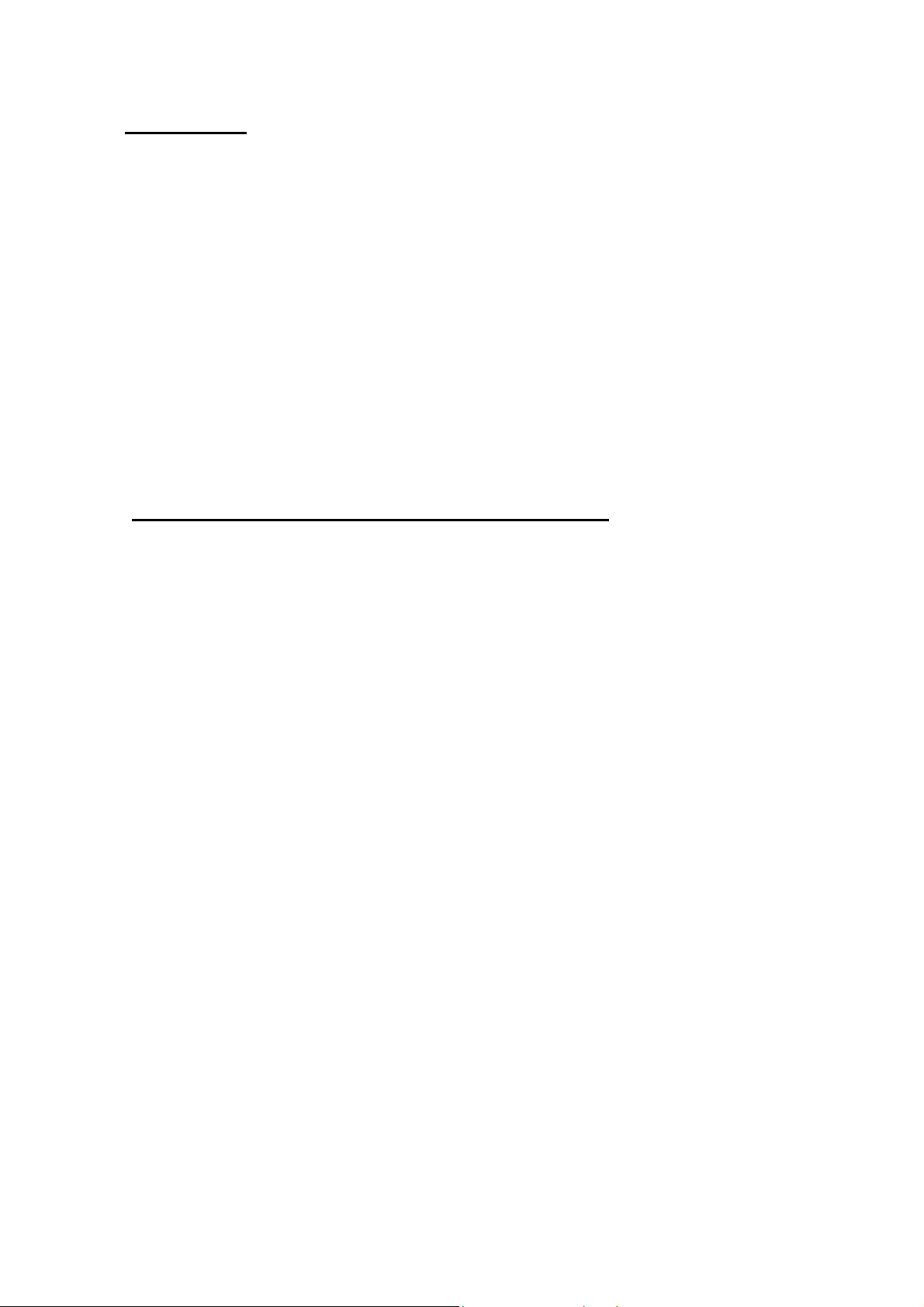

Mixer component identification. Figure 1 8

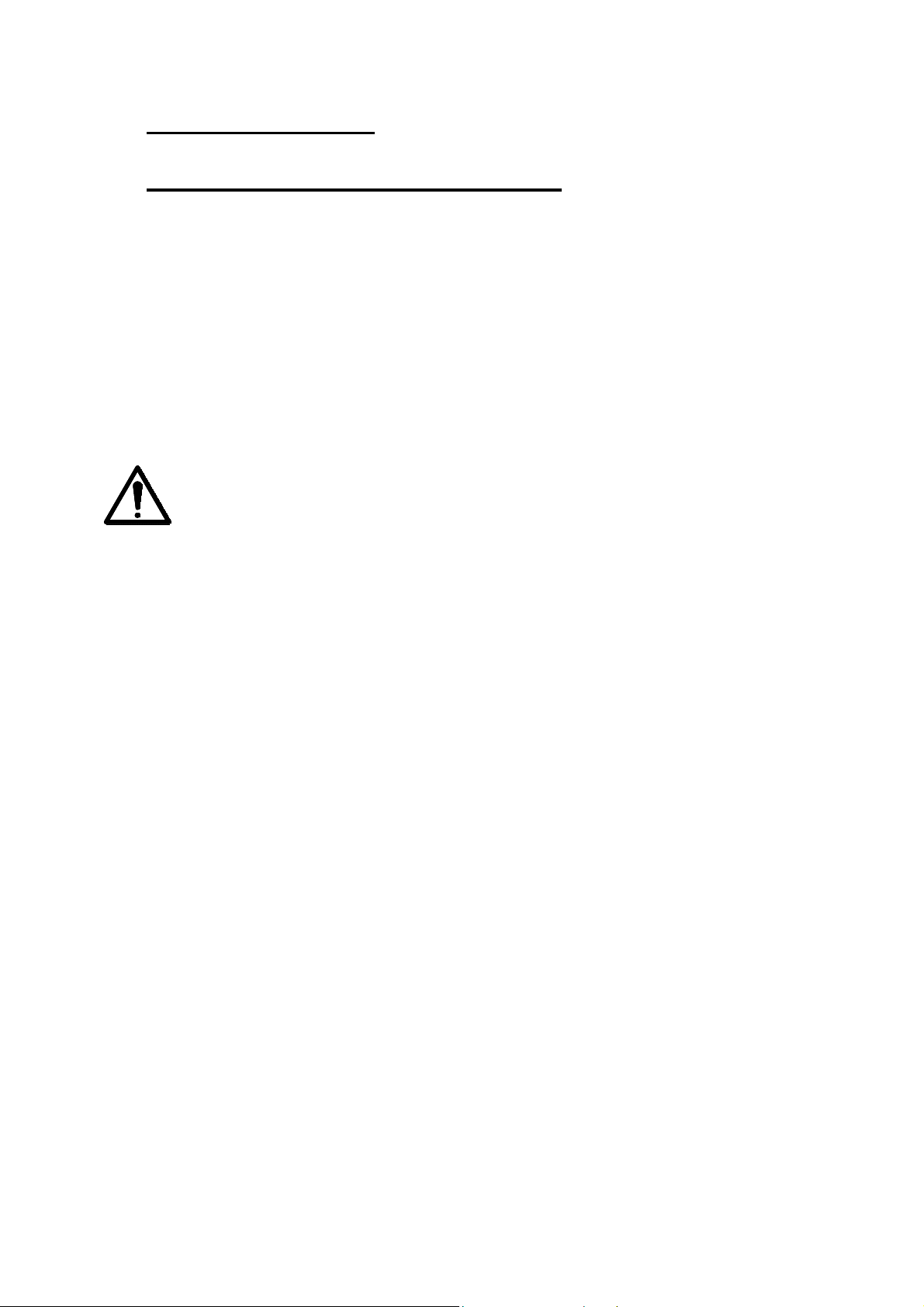

Controls, HL600 - Standard Controls 6.2 8

Controls, HL662 – Standard Controls 6.2 9

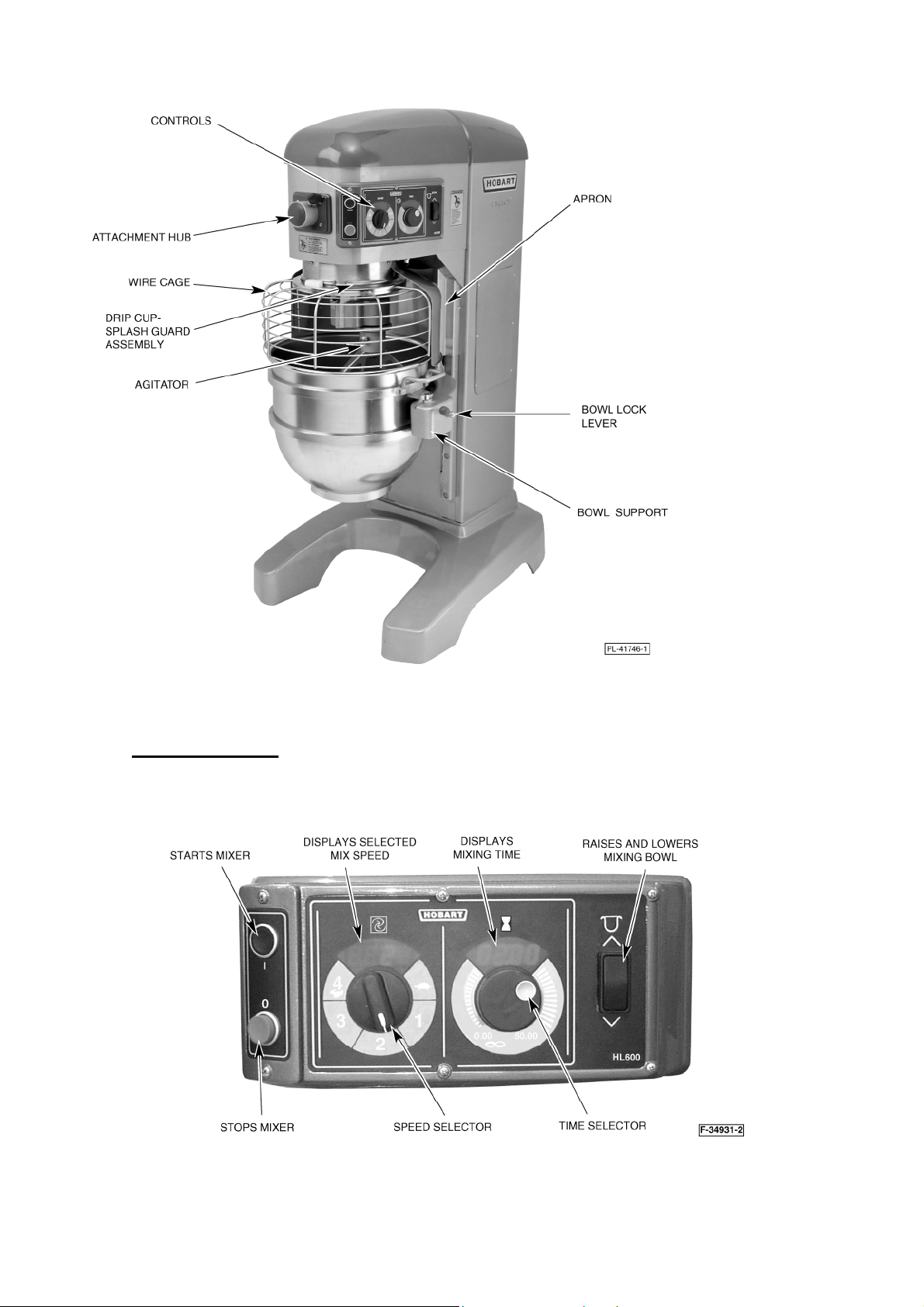

Controls, HL600 – Recipe Timer 6.2 10

Bowl placement 6.3 10

Agitator 6.4 11

Hold to run operation 6.5 11

Power bowl lift 6.6 11

Preparing for mixing 6.7 12

Operating notes 6.8 12

Timer operation 6.9 12

Recipe Mode — To Enter and Exit 6.9 14

Reviewing Recipe Steps 6.9 14

Running a Recipe 6.9 15

Interrupting a Recipe 6.9 15

Entering a Special Function 6.9 16

Enter the Access Code 6.9 16

Programming a Recipe [SEt ... rECP] 6.9 17

Programming a Pause 6.9 17

Making a Recipe Active or Inactive [Atth ... rECP] 6.9 18

Setting the Access Code [SEt ... CodE] 6.9 19

Unloading 6.10 20

Wire guard cage 6.11 20

Removing and cleaning the wire guard cage 6.12 21

Re-fitting the wire guard cage 6.13 21

Mixing capacity 7 21

Mixing capacity chart 7.1 24

Agitators and attachments 8 25

Mixer agitators 8.1 25

Using the attachment facilit

Section Page

8.2 26

1

Page 3

Splash cover and bowl extension ring 8.3 27

Bowl scraper attachment 8.4 27

Bowl truck 8.5 27

Cleaning 9 27

Cleaning after use 9.1 27

Installation and Commissioning 10 29

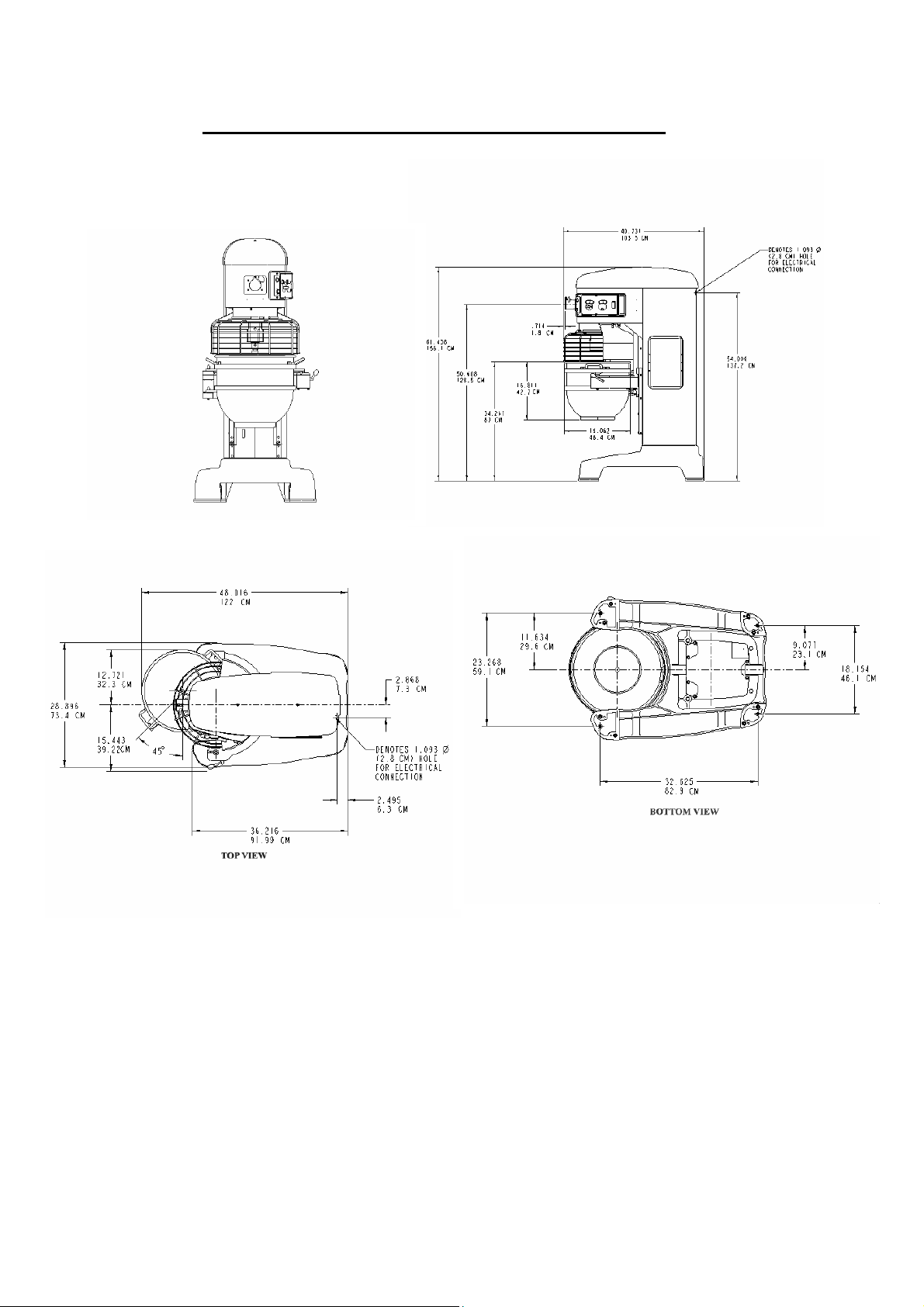

Mixer dimensions Figure 8 29

Technical information Table 1 30

Unpacking and handling 10.1 30

Location 10.2 31

Electrical installation 10.3 32

Electrical connection 10.4 32

Operator training 10.5 32

Mixer Maintenance 11 33

Lubrication 11.1 33

Slideways 11.1.1 33

Bowl lock mechanism 11.1.2 34

Planetary seal 11.1.3 34

Transmission oil 11.1.4 34

Adjustments 11.2 35

Agitator clearance 11.2.1 35

To measure agitator clearance 11.2.2 35

Interlock safety system 11.3 35

Transmission belt 11.4 36

Fault finding 12 36

Recommended spares 13 37

Notes 14 38

Service contact numbers 15 39

© Hobart 2005

2

Page 4

1.0 SAFETY INFORMATION.

The procedures and precautions contained in this manual are understood to apply to the

machinery only when it is used in the prescribed manner.

If the machinery is used other than in the recommended manner, the operator will be

responsible for his/her own safety and for the safety of the other persons who may be

involved.

The information in this manual has been prepared to assist the operator to understand,

maintain, and operate the mixer. In order to prevent accidents, read, understand and

follow all the precautions and warnings contained in this manual before installation or

operating for the first time. This manual must be studied to obtain a clear understanding

of the mixer and its capabilities.

1.1 SAFETY GUIDELINES.

Ensure sufficient precautions are observed during manual handling of the mixer

particularly when moving into position on installation. Reference must be made to

manual handling regulations. The mixer weights are given in Table 1.

• Do not hose or pressure clean this appliance. It is vital to adhere to the cleaning

instructions detailed in section 9 of this manual.

• Do not remove any covers or loosen any fittings whilst the machine is operating.

• Ensure this manual is kept in an easily accessible place for future reference near the

mixer.

• All operators must be trained in the safe operation of the mixer and attachments.

• Ensure the electrical supply has been isolated before attempting to service or move

the mixer.

• Rotating machinery and electricity are potentially hazardous and may cause injury if

sufficient precautions are not taken prior to operating or servicing the machine.

• Always have your mixer and attachments regularly serviced; at least twice a year,

depending on frequency of use.

• When mixing products that develop dust care must be taken. Mix the ingredients

using the STIR facility until the dust is eliminated.

• Exposure to dust (including flour) may be harmful to health causing rhinitis (running

noses), watering eyes and possibly occupational asthma.

1.2 WARNING SYMBOLS.

To identify the safety messages in this manual, the following symbols have been used

The "Warning" symbol is found primarily where the corresponding information

is important for the safe use of the machinery.

3

Page 5

The electrical hazard symbol is used when there are risks of an electrical

nature. Prior to servicing the machinery, always disconnect the power cable

from the mains supply.

1.3 LIABILITY.

Installations and repairs which are not carried out by Authorised technicians or the use

of other than original spare parts, and any technical alterations to the machine, may

affect the warranty set out in the standard conditions of sale.

2.0 FOREWORD.

Hobart reserves the right to alter the design of their products without prior notice. Whilst

every effort is made to ensure this publication reflects the latest design, the Company

cannot guarantee full compliance.

Take pride in your HL600/HL66 Mixer - keep it clean and in good mechanical and

electrical condition.

3.0 GENERAL INFORMATION.

The information and instructions contained in this manual may not cover all details or

variations in the equipment, not provide for every eventuality to arise with installation,

operation, or maintenance. If additional information is required, please contact your local

Hobart office.

The HL600 and HL662 Mixers are designed to mix food products as detailed on the

specification chart (Section 7.1, page 24).

The mixers are manufactured from epoxy powder painted castings, fabricated mild steel

pedestal, back panel & feet, with a plastic moulded top cover.

The machine is rated to operate on the electrical supplies shown in Table 1, page 30.

The Mixer is fitted with a "no volt release" safety feature to prevent automatic restarting

after a supply failure or disconnection from the mains. The bowl support and the guard

are interlocked so that when either is not in their correct operating positions, the mixer

will not work. The standard mixer is delivered with guard, bowl and agitators.

4.0 CARING FOR OUR ENVIRONMENT.

4.1

The pallet and protective polyethylene packing film have been selected

from materials that are environmentally friendly for disposal or can

normally be recycled. Instead of throwing them away, please ensure they

are recycled.

PACKAGING MATERIAL.

4.2

Old appliances contain materials that can be recycled. Please contact your local waste

collection centre; scrap merchant or local Hobart office about potential recycling

schemes.

DISPOSAL OF YOUR OLD APPLIANCE.

4

Page 6

5.0 SAFETY INSTRUCTIONS.

A FULLY TRAINED AND COMPETENT PERSON MUST ONLY USE THE

ATTACHMENT AND/OR MIXER.

The following instructions must be observed when using the mixer.

Note: The mixer must only be used for the purpose it was designed and inline with the

supplied operating instructions.

When maneuvering or lifting a bowl and contents with a total weight in excess of 25kg a

bowl truck must be used (Hobart part number 874361)

Only use attachments that comply with CE regulations (CE marked).

5.1 DUST HAZARD.

In order to minimise any dust hazard follow the instructions detailed below.

When mixing ingredients care must be taken to avoid the inhalation of dust particles e.g.

flour. Reference should be made to product supplier's data sheets to ensure adequate

precautions/protections are taken. Items such as flour must be added in such a manner

to avoid dust particles being dispersed into the local atmosphere. Carefully slit the bag

whilst holding in the lower part of the bowl. When mixing dry ingredient use the lowest

speed to minimise dust emission. Use a splash cover to reduce dust emissions (refer to

the recommended spare parts Section 13, page 37 for the cover part number). Mix the

ingredients in the bowl using the lowest speed until the risk of producing any dust is

eliminated. Fit suitable dust extraction equipment.

5.2 NEVER.

• Operate the mixer or attachments if a fault develops or the mixer is unsafe.

• Wear loose clothing.

• Attempt to reach into the bowl when mixing.

• Access rotating parts.

• Fit the agitator to the mixer without a bowl in place.

• Leave the agitator on machine without the bowl being fitted.

• Operate the mixer with attachments and agitator fitted.

• Use excessive force when operating which could affect the stability of the mixer.

• Operate the mixer if parts are disassembled.

• Over ride the safety switches fitted to the mixer.

• Open the guard to stop machine.

• Use the bowl lift to stop machine.

• Use the mixer in an unsafe condition.

• Clean the mixer with scouring powder or a scouring pad.

• Clean aluminium agitators in dishwashers.

• Inhale mixing ingredient dust particles.

5

Page 7

5.3 ALWAYS.

• Use the mixer in a well-lit area.

• Ensure the bowl, agitator, attachment and guard are correctly fitted to the mixer.

• Disconnect the mains electricity supply before cleaning the mixer.

• Clean the mixer daily.

• Remove agitator before using any attachments.

• Stop mixer before adding more ingredients.

• Use the stop button to stop machine.

• Clean the bowl, agitators and attachments after use.

• Clean the mixer using mild soap and water.

• Service the mixer and attachments at least twice a year depending on the

frequency of use.

• Use the mixer as intended and inline with the operating instructions.

• Use the correct reduced size equipment (bowl and agitators).

• Use attachments that are CE approved and CE marked.

5.4 ATTACHMENT SAFETY INSTRUCTIONS.

The following instructions must be observed when using the mixer with attachments.

Please also refer to the safety instructions in Section 6.0, page 7 and the instructions

provided with the attachment. Only CE marked and approved attachments must be

used.

A FULLY TRAINED AND COMPETENT PERSON SHOULD ONLY USE THE

ATTACHMENT AND/OR MIXER.

• Do not fit an attachment while the mixer is operating.

• Do not wear loose clothing.

• Do not use the mixer or attachment if a fault develops or the machine is unsafe.

• Do not access rotating parts.

• Do not use excessive force when operating the attachment, which could affect the

stability of the mixer.

• Do not operate the mixer if parts are disassembled.

• Always use the attachment and/or mixer in a well-lit area.

• Always ensure the attachment is operating at the correct speed.

• Always clean the attachments after use and refer to the attachment manufacture's

cleaning instructions.

• Always service your mixer and attachments regularly; at least twice a year

depending on the frequency of use.

6

Page 8

6.0 USING THE MIXER.

6.1

OPERATING FOR THE FIRST TIME.

Check Lubrication before use.

This mixer is shipped with oil in the transmission. Check the oil level before starting the

mixer.

• Electrically isolate the mixer.

• Remove the top cover.

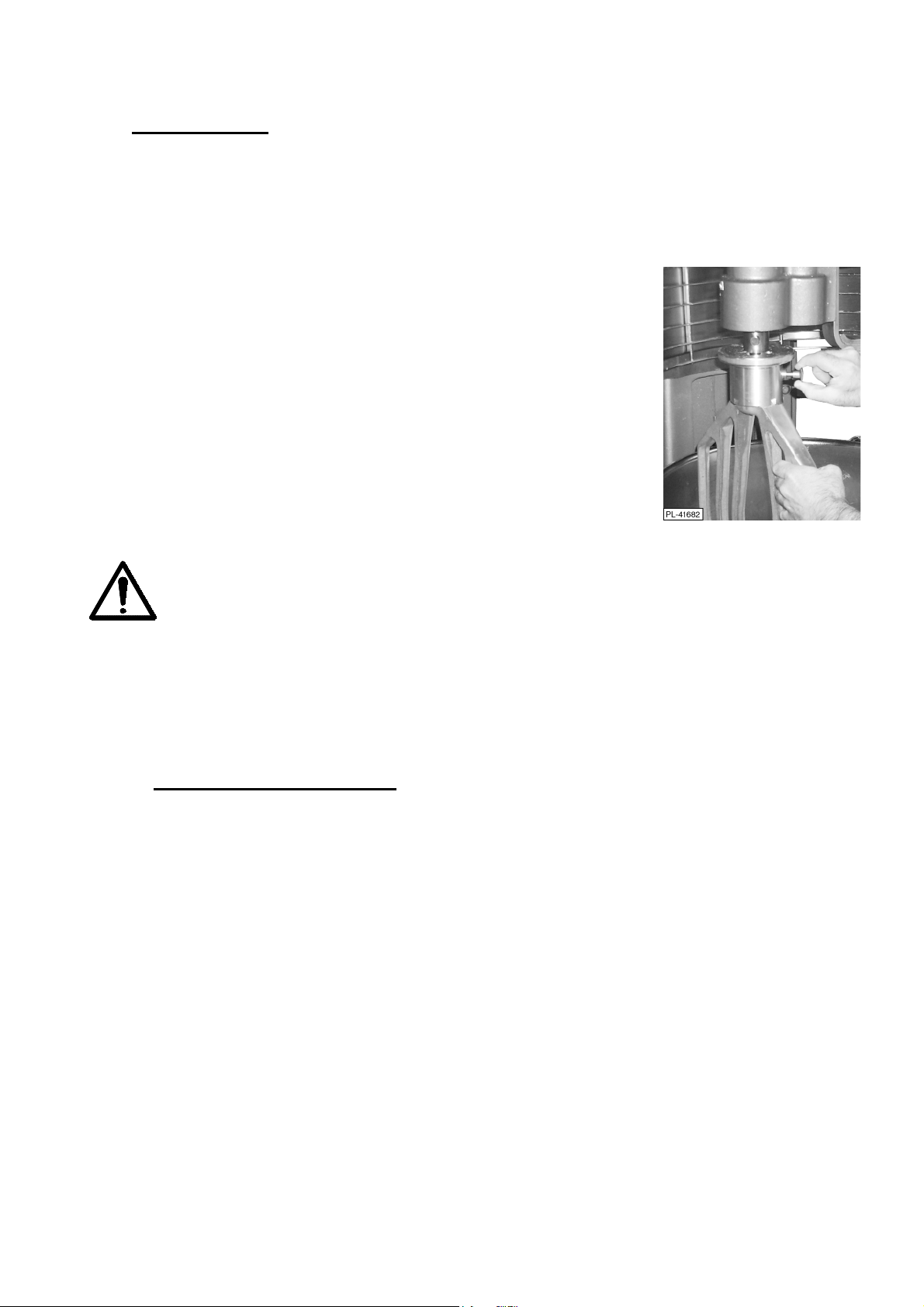

• Unscrew the dipstick using a 3/8” hexagon Allen key and check the oil level. The oil

level must be between the two grooves on the dipstick. Refer to figure 1 for the dip

stick position.

This food mixer is only for professional use by suitably trained

persons. Ensure operators have read and understood this manual

and have received adequate training. MOVING AGITATOR IN BOWL,

KEEP HANDS, CLOTHING AND UTENSILS OUT WHILE IN

OPERATION. DO NOT USE WITHOUT INTERLOCKED GUARD.

The Legacy mixer is equipped with Smart ™ Timer control and a power bowl lift. Other

operating parts (Fig.1, page 8) and their functions are described through out the

Operation section.

The Wire Cage guard must be in position or the mixer will not operate.

The bowl must stay in locked position on the Bowl Support or the mixer will not operate.

If the bowl support is not all the way up (mix position), the mixer will not operate unless

the START button is pressed and held.

If the bowl support is not in the mix position and the START button is pressed and held,

the mixer will operate only in Stir speed.

7

Page 9

MIXER COMPONENT IDENTIFICATION

6.2 CONTROLS.

Model HL600 (With Four Mix Speeds Plus Stir Speed)

Figure 2.

Figure 1.

8

Page 10

Model HL600 Mixer Speeds

STIR (Slow) STIR speed is for incorporating ingredients at the start

of each mixing process.

SPEED 1 (Low) This speed is for heavy mixtures such as pizza dough,

Heavy batters and potatoes.

SPEED 2 (Medium-Low) This speed is for mixing cake batters, mashing

potatoes and developing bread dough.

SPEED 3 (Medium-High) This speed is for incorporating air into light batches, as

well as finishing whipped items.

SPEED 4 (High) This speed is for maximum and accelerated air

incorporation into light batches.

Model HL662 (With Two Mix Speeds Plus Meat Grind, Cheese Shred, Vegetable

Slice Speeds)

Model HL662 Mixer Speeds

SPEED 1 (Slow) This speed is for heavy mixtures such as pizza dough.

SPEED 2 (Low) This speed is for developing pizza dough.

MEAT GRIND This speed is for grinding meat.

CHEESE SHRED This speed is for shredding cheese.

VEGETABLE SLICE This speed is for slicing vegetables.

Figure 3.

9

Page 11

PROGRAMMABLE RECIPE TIMER (OPTIONAL)

Timer Specifications

• Maximum number of programmable recipes: 9 recipes.

• Maximum number of steps allowed for each recipe: 6 steps.

• Maximum time allowed for each step in a recipe: 30 minutes.

For additional information on use of the programmable recipe timer, refer to pages

14 through 19.

6.3 BOWL PLACEMENT.

The bowl is heavy and must be correctly handled and lifted correctly to avoid personal

injury. If the total weight of the bowl and ingredient weights more than 25 kg a bowl truck

must be used. Refer to the recommended spare parts Section 13, page 37 for the bowl

truck part number. Table 1 (page 30) details the weights of bowls and agitators.

The bowl must be installed before the agitator is installed.

To install the bowl, fully lower the bowl support. Position the bowl so the alignment pins

on the left side of the bowl support fit in the holes in the bowl. Swing the bowl into the

locked position on bowl support.

10

Page 12

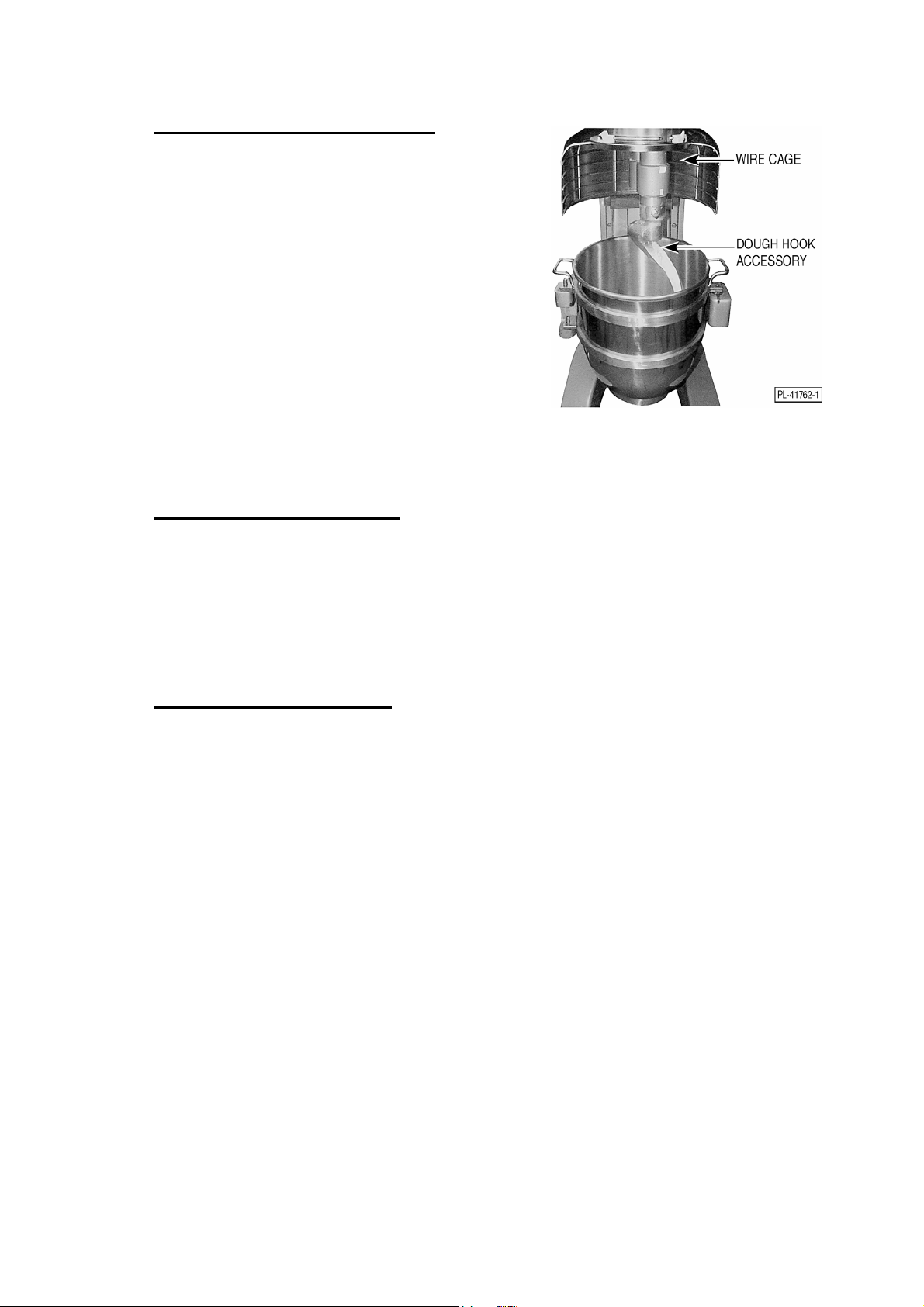

6.4 AGITATOR.

To install an agitator, the bowl must be on the bowl support and fully lowered.

To Install

1. Open the wire cage.

2. Place the agitator inside the bowl and line up the

horizontal slot on the agitator with the agitator shaft

pins.

3. Slide the agitator up the agitator shaft until it stops

and latches.

To Remove

1. Open the wire cage.

2. Lower the bowl by pressing and holding the down

arrow on the bowl switch.

3. Hold the agitator and pull the plunger of the

agitator out (Fig. 4). Slide the agitator down off

the agitator Shaft.

6.5 HOLD-TO-RUN OPERATION.

Use extreme caution whilst operating the hold to run facility when the bowl is

not in the upper position.

The Legacy mixer has a hold-to-run STIR feature that allows the mixer to be operated in

a STIR mode with the bowl in the down position. This allows the agitator to be gradually

engaged with the ingredients improving the blending and reducing the dust emission. The

start button must be continuously held to operate the mixer in the STIR mode. The bowl

can be raised or lowered at the same time whilst the agitator is rotating.

Figure 4.

6.6 POWER BOWL LIFT.

CAUTION: Before lowering the bowl onto a bowl truck, always unlock bowl and

swing bowl out slightly.

To raise the bowl, the bowl must be in the locked position. Push and hold the up arrow

on the bowl switch. To lower the bowl, push and hold the down arrow on the bowl switch.

To Raise the Bowl while Mixing

To raise the bowl while the agitator is mixing the product (when required by recipe or

when using the Bowl Scraper Attachment):

1. Close the wire cage, and then select a mixing speed on the SPEED dial.

2. Select a countdown time or HOLD for continuous count-up mixing.

3. While pressing and holding the up arrow on the bowl switch, press and hold the

START button.

4. When the bowl reached the mix position, release the START button. The mixer

automatically changes to the selected mixing speed.

11

Page 13

6.7 PREPARE FOR MIXING.

1. Place the mixing bowl on the bowl support.

2. Pour ingredients into the bowl.

3. Swing the bowl back to the locked position.

4. Place the agitator inside the bowl, then attach

it to the agitator shaft (Fig. 4, page 11).

5. Return the wire cage to front-centre position.

6. Push and hold the up arrow on the bowl switch

until the bowl reaches the mix position and

stops.

7. The mixer is now ready for mixing. (See Timer

Operation).

Figure 5.

6.8

OPERATING NOTES.

• Stir is to be used for incorporating ingredients. Do not use it to develop products.

• If the mixer is stopped during a mixing operation, the timer also stops. The timer

starts again where it left off when the START button is pressed.

• The SPEED window will display the SPEED dial's current speed selection. Turn

the TIME selector clockwise to take the mixer out of the hold mode.

6.9

Using the Count-Up Mode (Continuous Mixing)

TIMER OPERATION.

1. Turn the SPEED dial to select a mix speed (the SPEED setting can be changed at

any time during the mixing operation).

NOTE: STIR is to be used for incorporating ingredients. Do not use to develop

dough products.

2. Set the timer on hold by turning the TIME selector counter clockwise until "HOLD"

appears in the TIME window.

3. Press the START button to begin mixing. The timer starts counting forward from

00:00.

NOTE: If the wire cage is opened at any time, the mixing operation will stop. To

resume the mixing operation, close the wire cage and press the START button.

4. Use the STOP button to stop the mixer; the mixing time is displayed in the TIME

window.

5. Press the START button to resume mixing if needed.

NOTE: When the timer reached 50:00 minutes, it will rollover to 00:01 and

continue counting until the STOP button is pressed.

12

Page 14

Using the Count-Down Mode (Timed Mixing)

1. Turn the SPEED dial to select a mix speed.

a. If the count-up mode was used for the previous batch, the desired time

needs to be entered.

b. If the countdown mode was used for the previous batch, the previous time

will be displayed. If a different time is needed, turn the TIME selector to the

desired time.

2. Press the START button to begin mixing; the timer start counting down from the

set time.

a) To stop the mixer at any time, press the STOP button. To resume mixing,

press the START button. For example: the mixer is start at SPEED 1 for 30

seconds and is stopped after 10 seconds. Pressing the START button will

resume the mixing operation.

b) If the mixer is stopped and a new time setting is entered, pressing the START

button saves the new time setting on the current speed selection. For

example: The mixer is started at SPEED 1 for 30 seconds and is stopped after

10 seconds. Turning the TIME selector enters a new time. The new time will

replace the initial 30 seconds for SPEED 1 after the START button is pressed.

c) If the time is changed while mixing, the mixer will operate until the new time

expires. The adjustment to the time will not be stored.

d) If speed is changed while mixing, the time will change to the previous time for

the selected speed and count down.

Note: If the wire cage is opened at any time, the mixing operation will stop. To

resume the mixing operation, close the wire cage and press the START button.

3. When the timer reached 00:00, the mixer stops; a beeper sounds for 3 seconds.

The countdown timer displays the last-entered time.

13

Page 15

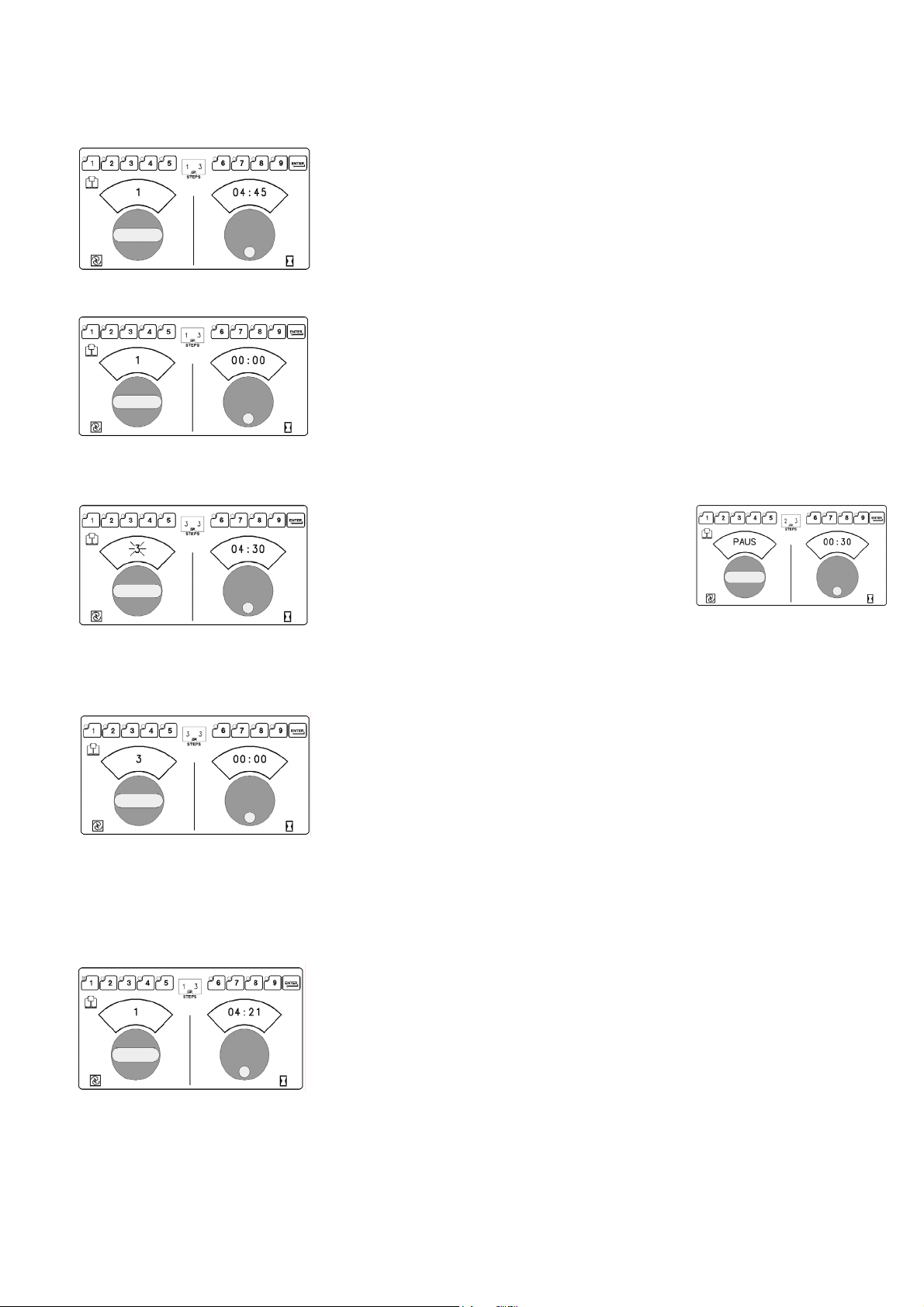

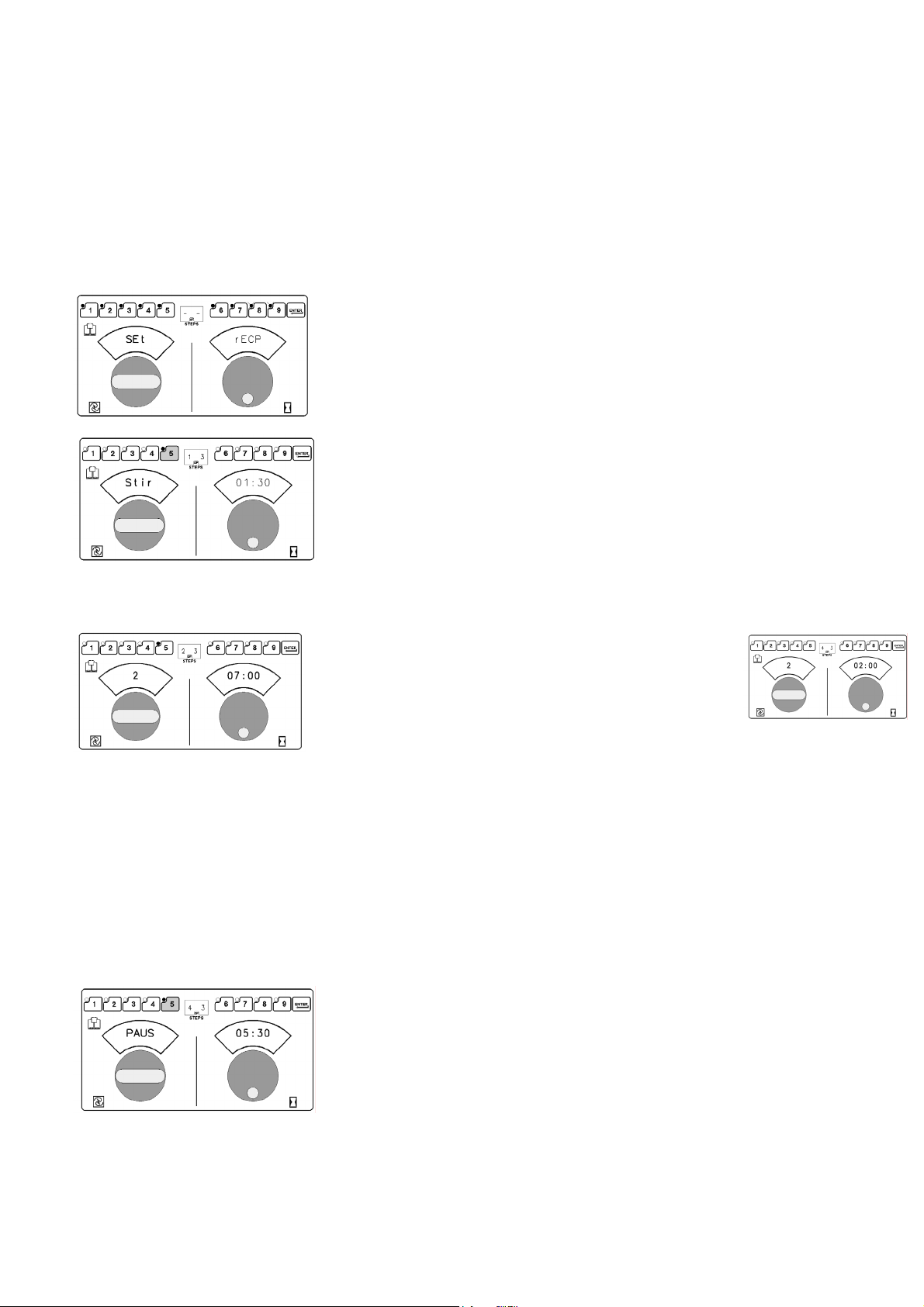

Recipe Mode — To Enter and Exit

• To enter recipe mode, press any recipe button. The

recipe button lights to indicate you are in Recipe Mode,

and the display shows the speed and time for the first

step of the recipe.

• If the recipe button light blinks, the recipe is inactive.

Refer to special functions to activate or de-activate

recipe buttons.

• To exit Recipe Mode, press the lighted Recipe Button.

The light on the recipe button goes off, indicating you are

in Standard Timer Mode. The previous time setting for

the shown speed will display.

This allows you to view a recipe without running the mixer.

For example, a three step recipe is shown.

• Select the recipe. The speed and time for the first step of

the recipe are displayed.

• Press the ENTER to display the next recipe step.

Repeatedly pressing the ENTER cycles through all the

recipe steps.

• Pressing START will begin mixing step 1 of the recipe,

regardless of the step displayed.

Reviewing Recipe Steps

14

Page 16

Running a Recipe

• Select the desired recipe by pressing the recipe

button. The button lights and step one of the

recipe displays.

• Press START.

• The mixer begins to run step one of the

programmed recipe. The timer display

indicates the mixer speed and counts down

the remaining time.

• When the time expires, the mixer

automatically switches to the speed and time

for the next recipe step and continues mixing.

Mixing steps run in succession at the

programmed speed and time.

• If a Pause step is

programmed in the

recipe, the mixer stops

and the time display

counts down the pause

time to 00:00 and beeps

Interrupting a Recipe

• After a Pause step, the

speed display for the next step flashes; press

START when ready to resume mixing.

• The mixer stops after the last step.

• The timer displays revert back to step one

for that recipe (as shown at the top of this

page). Run the same recipe again by

pressing START or select a different

recipe.

• Mixing can be stopped at any time by pressing

STOP.

• The speed display flashes to indicate the

program is interrupted, and the timer displays

the remaining time. Press START to resume

mixing

• If you do not wish to resume mixing, press the

recipe button twice until it is not lit — this

returns to Standard Timer Mode.

Timer will beep between steps and at end of step.

15

Page 17

FUNCTION USED BY

SEL . . . Unit Service Technician

LASt . . . Err Service Technician

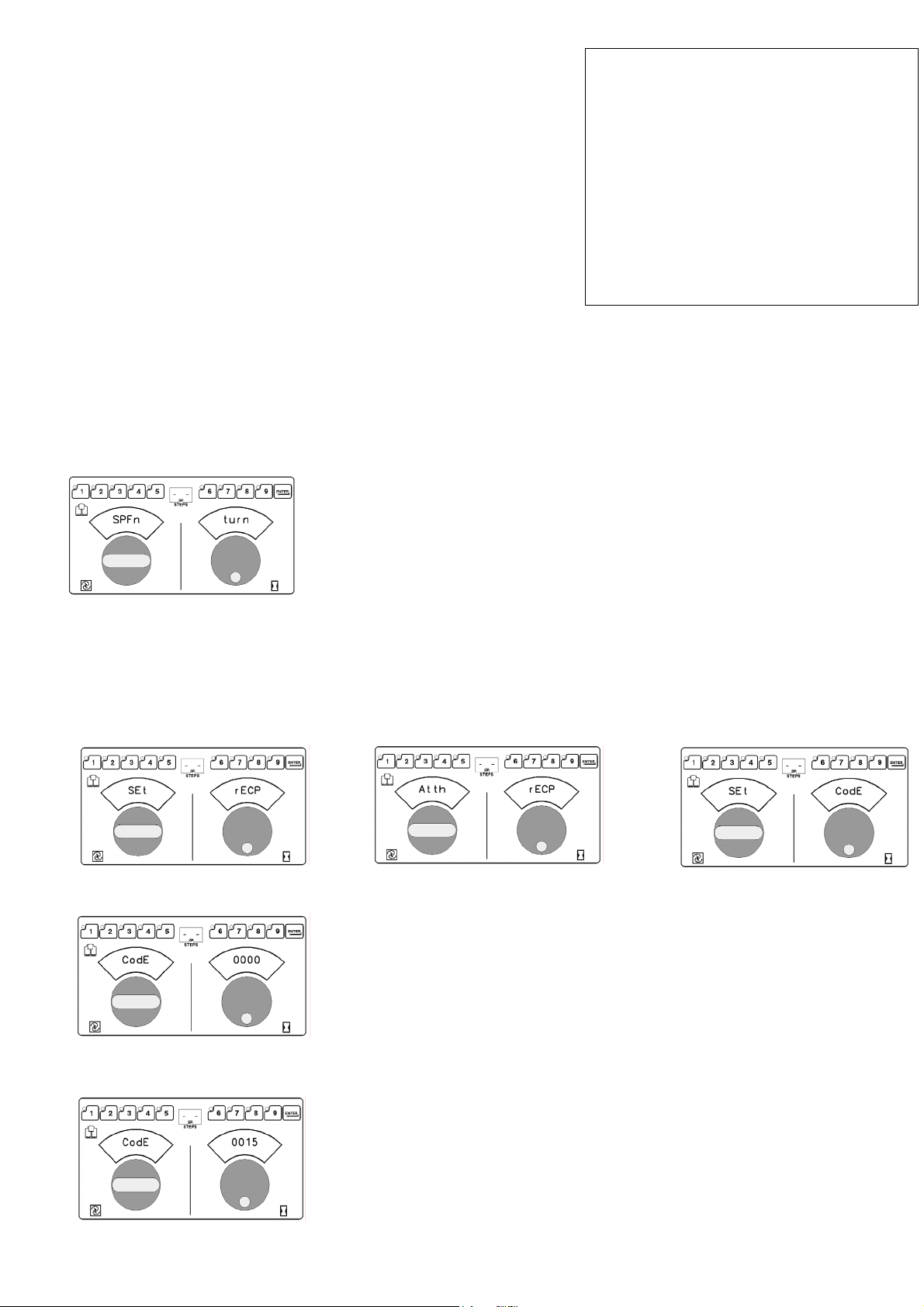

Entering a Special Function

Special Function Mode allows you to access three user

resettable parameters:

Err . . . Log Service Technician

totL . . . HrS Service Technician

LASt . . . HrS Service Technician

CAP . . . HrS Service Technician

RUN . . . DiAg Service Technician

SEt . . . CodE

SEt . . . rECP

Atth . . . rECP

Authorized Operator

Authorized Operator

Authorized Operator

• Programming Recipes, (SEt . . .rECP),

• Making Recipes Active or Inactive, (Atth . . .

rECP) and

• Setting the User Access Code (SEt . . . Code).

[There are also other parameters for service use viewable in Special Functions.]

Refer to the table.

• Begin from Standard Timer Mode . . . (If you are in

Recipe Mode, exit by pressing the lighted Recipe

button to return to Standard Timer Mode.)

• With no Recipe buttons lighted, press Enter for 5

seconds. SPFn . . . turn displays indicating

Special Functions.

• There is a one minute timeout in Special Functions

Mode: After one minute of inactivity the control will

automatically return to Standard Timer Mode.

• Turn the Timer Dial to select one of the special

functions: SEt . . .rECP, Atth . . .rECP or SEt . .

.CodE,.

Press ENTER.

Enter the Access Code

• You must enter the code to change any recipe

parameters.

• CodE . . . 0000 displays.

• Turn the timer dial to the applicable access code and

press ENTER. The default access code is 0015. Refer

to the next three pages for the applicable function.

• If the incorrect code has been entered, no is displayed

in the Step Display.

16

Page 18

Programming a Recipe [SEt . . . rECP]

This function allows you to program any of 9 mixer recipes with up to 6 steps in each recipe.

Follow instructions in Entering a Special Function on the previous page to enter SEt . .

.rECP.

After entering the Access Code, the display of SEt . . .

rECP indicates that you can now program a recipe.

All active recipe keys are lit continuously; inactive recipe

keys blink.

• Press the recipe key you want to program (1–9). It

stays lit.

• Set the speed and mix time for step one by turning the

speed and time dials; press ENTER to go to the next

step. If the recipe was previously programmed, step 1

of X displays to indicate the first of up to 6 steps

programmed for this recipe. The example shows that Stir

speed was previously programmed for 1 minute and 30

seconds.

• Set the speed and time for each step of the recipe, then

press ENTER to go to the next step. Repeat for each

step.

Programming a Pause

• If you add more steps than were previously

programmed, the step display does not update

until the recipe has been saved. The step display

can show step 4 of 3 during programming.

• Turn timer dial counterclockwise to End to terminate

the recipe. This sets the previous step as the last

step.

• Turn timer dial counterclockwise to End to terminate

the recipe. This sets the previous step as the last

step.

• To save the recipe, press the lit recipe button.

• Continue programming other recipes; or press ENTER

for 5 seconds to exit SEt . . . rECP and return to

standard Timer Mode.

• If you need to stop mixing to add ingredients or to rest

the dough, you can program a Pause step. Turn the

Speed dial to the top (PAUS displays); set the timer

dial for that amount of time; press ENTER.

• The mixer cannot be restarted while the pause step is

counting down. If programming a Pause to add

ingredients, its best to set the Pause Time for a short

amount of time.

• Pause cannot be entered in first or last step of a

recipe.

17

Page 19

NOTE: If a recipe step is programmed wrong, exit SEt . . . rECP and re-program the entire

recipe.

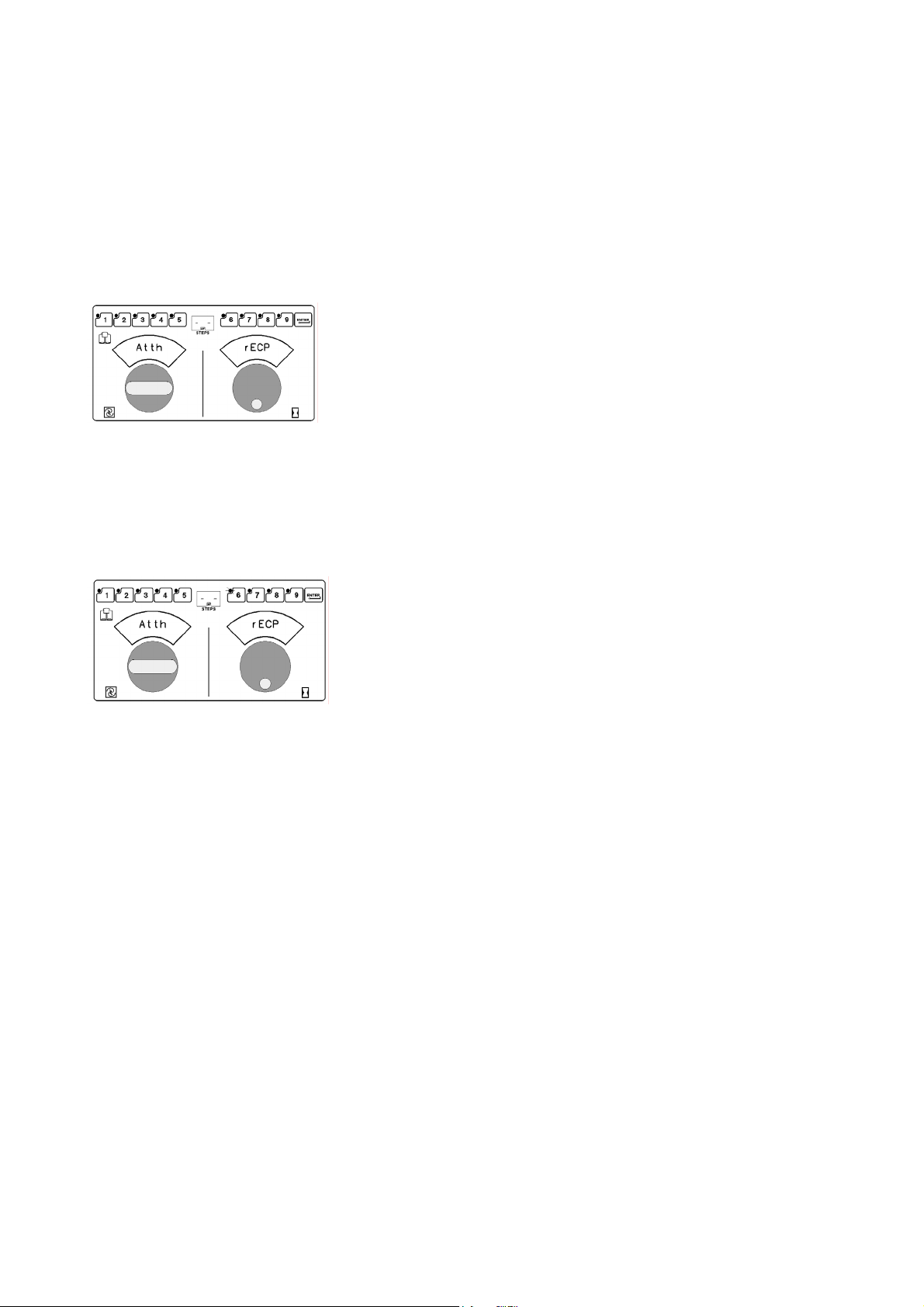

Making a Recipe Active or Inactive [Atth . . . rECP]

This function allows you to change the status of a recipe from Active to Inactive

or vice versa. A recipe that has inactive status will not run.

Follow instructions in Entering a Special Function

on page 16 to enter Atth . . .rECP.

After entering the Access Code, the display of Atth

. . . rECP indicates that you can change the status

of a recipe.

All active recipe buttons are lit continuously;

inactive recipe keys blink.

• Press any lighted recipe button to deactivate the

recipe; the recipe button blinks.

• Press any blinking recipe button to activate the

recipe; it becomes lit continuously.

• Press ENTER for 5 seconds to exit Atth . . .

rECP and return to Standard Timer Mode.

18

Page 20

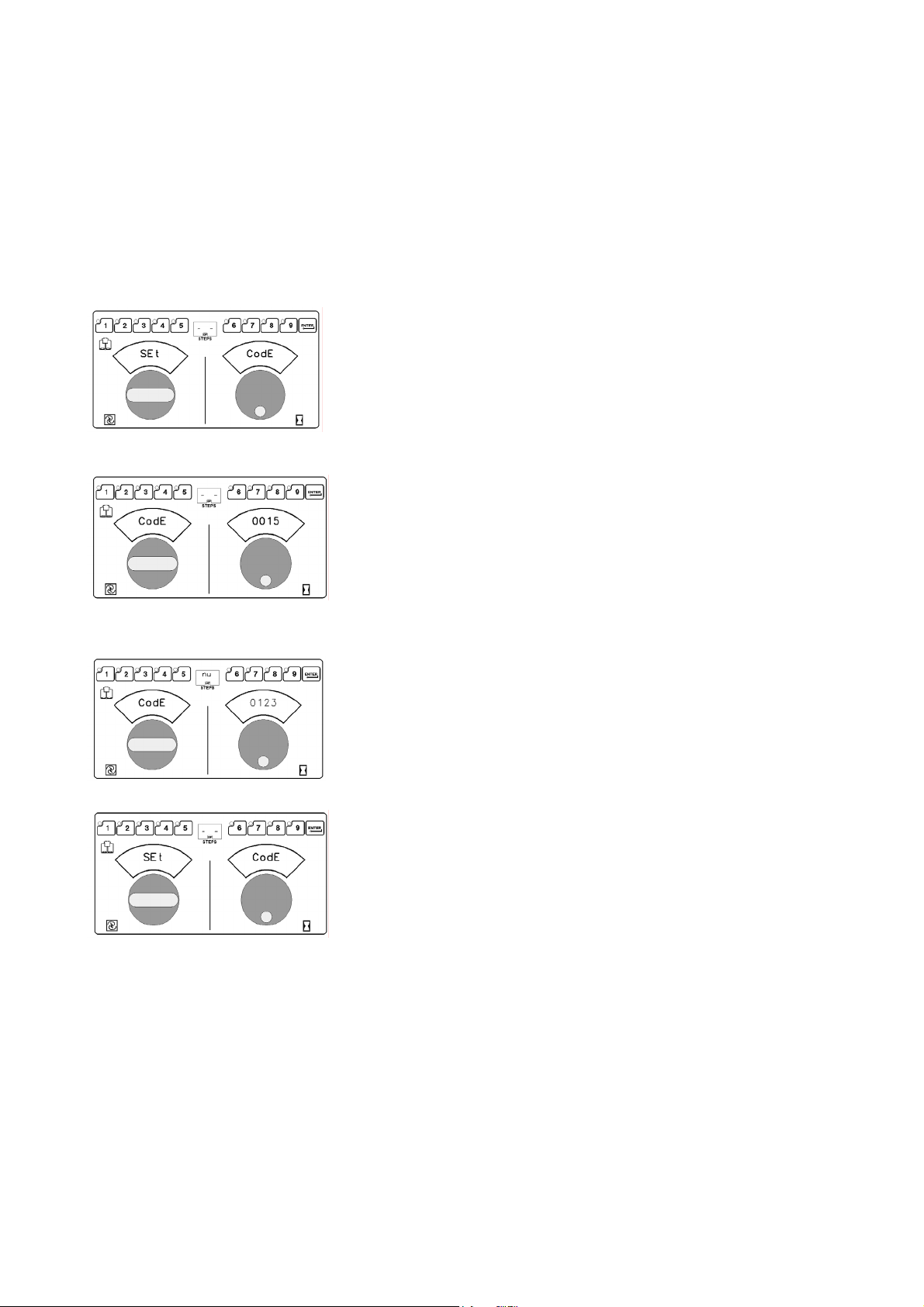

Setting the Access Code [SEt . . . CodE]

This function allows you to change the factory-set access code, 0015, to any

number from 0000 to 9999. We recommend that you keep the 0015 access code.

Follow instructions in Entering a Special Function on

page 16 to enter SEt . . .CodE.

• Turn the timer dial to the current code number

and press ENTER.

• The step display now reads nu..

• Turn the timer dial to the new code number and

press ENTER.

• Set…CodE displays. Press ENTER for 5

seconds to exit Set. . .CodE and return to

Standard Timer Mode.

• Make a record of the new access code.

If you lose the code, it can be restored to the factory-set default code 0015. Disconnect

power to the mixer. Press the enter key while powering up the mixer again. This

resets all factory defaults. Programmed recipes will be lost.

19

Page 21

6.10 UNLOADING.

1. Unlock the bowl and swing-out slightly. Press and hold the down arrow on the

bowl switch to lower the bowl

2. Open the wire cage assembly.

3. Remove the agitator from the agitator shaft.

4. Remove the bowl from the bowl support.

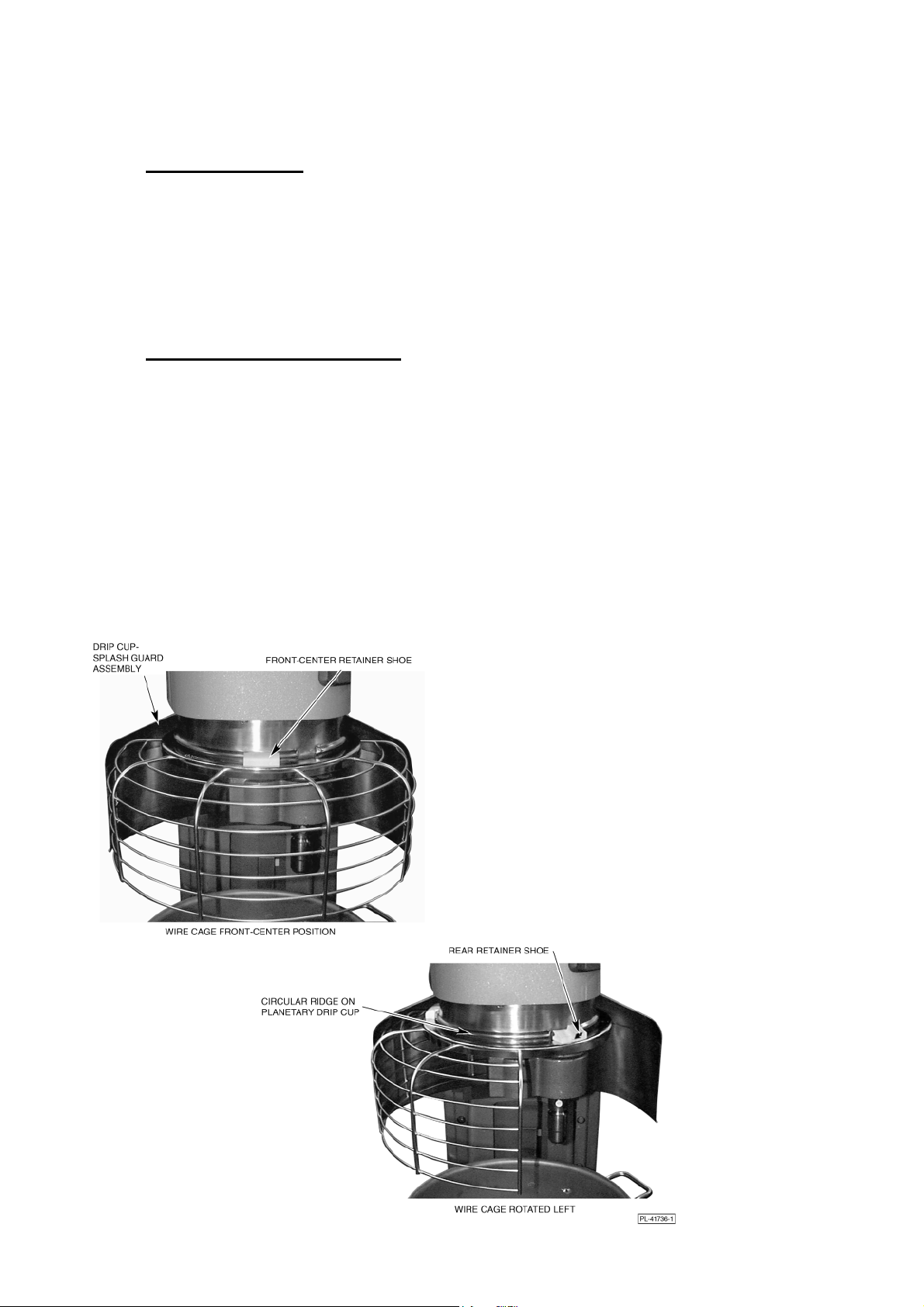

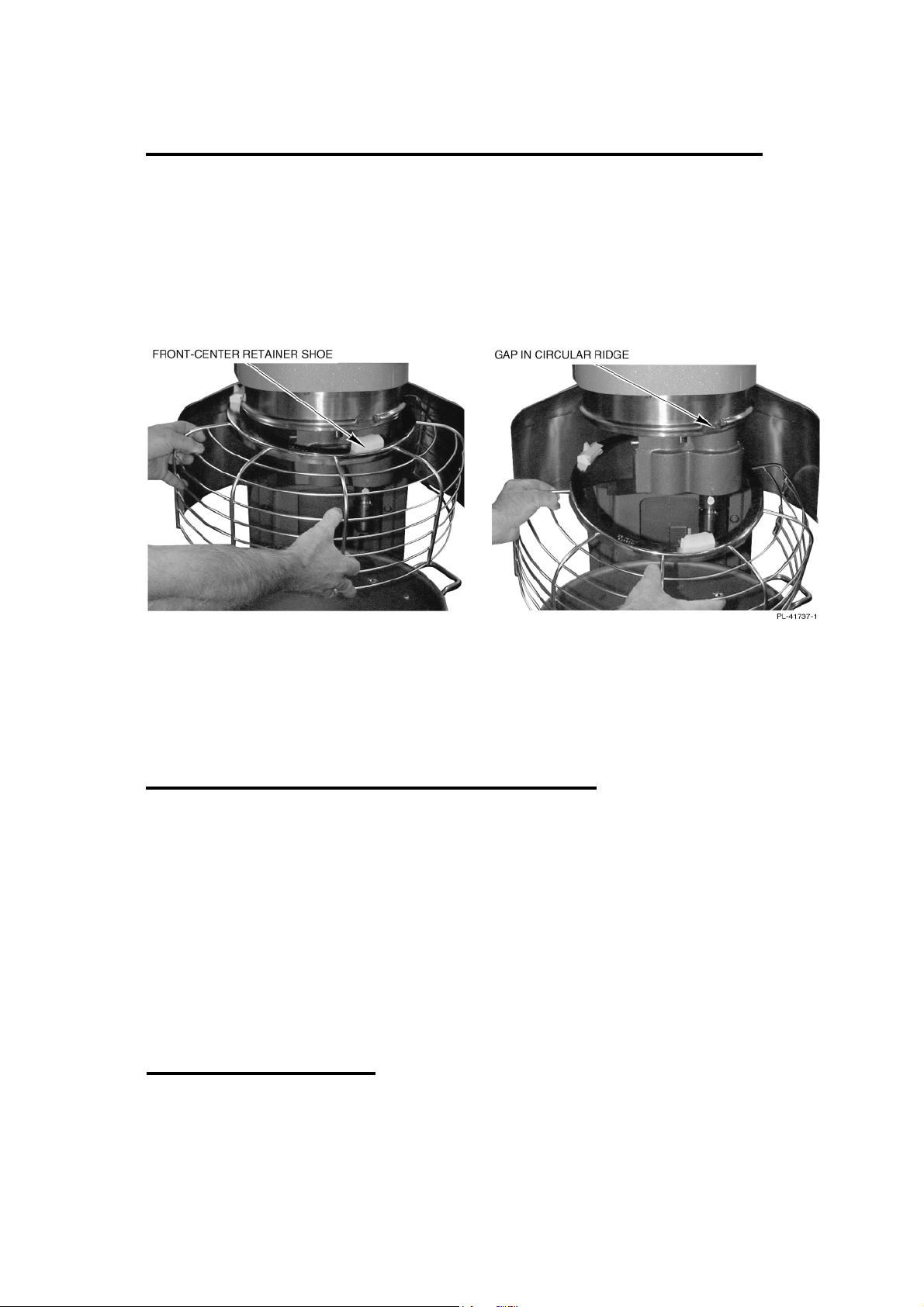

6.11 WIRE GUARD CAGE.

The wire cage can be rotated out of the way to add ingredients or to access the bowl and

agitator.

Note how the grooves on the nylon retainer shoes allow the Wire Cage to ride around the

circular ridge of the planetary drip cup.

• To open the wire cage, rotate it to your left.

• To close the wire cage, rotate it to your right until it stops in the front-centre,

closed position.

NOTE: The wire cage must be returned to the closed position for the mixer to operator.

Figure 6.

20

Page 22

6.12 REMOVE AND CLEANING THE WIRE GUARD CAGE.

1. Lower the bowl. Remove the agitator and bowl.

2. While holding the wire cage securely with both hands, rotate it to your left until the

front-centre retainer shoe reaches the gap in the circular ridge of the planetary

drip cup.

3. Lower the front of the wire cage and move the wire cage slightly to the rear so the

rear retainer shoes clear the ridge of the drip cup. The wire cage can now be

removed.

4. Wash the wire cage in a sink, rinse with clear water, and dry with a clean cloth.

5. The stainless steel splashguard can be wiped off and/or washed with a cloth or

sponge using warm, soapy water. Rinse with clear water and dry with a clean

cloth.

Figure 7.

6.13 RE-FITTING THE WIRE GUARD CAGE.

1. Position the ring of the wire cage so the front-centre retainer shoe is positioned

below the gap in the circular ridge of the planetary drip cup.

2. Position the grooves so the rear retainer shoes straddle the circular ridge on the

planetary drip cup.

3. Lift the front of the wire cage so the front-centre retainer shoe passes up through

the gap in the circular ridge on the planetary drip cup.

4. Rotate the wire cage to your right until all three-retainer shoes straddle the ridge

on the drip cup.

5. Continue rotating the wire cage so the opening is to the front of the mixer (to install

the agitators) or until it stops at the front-centre position.

7.0 MIXING CAPACITY.

MIXER CAPACITY

The Mixer Capacity Chart is a guide for controlling the batch sizes in your formulations.

The capacities listed take into account the amount of product, which can be contained in

the various sized bowls. The listed capacities are the maximum recommended batch

sizes. If the combined weight of the bowl and ingredients is greater than 25kg a bowl

21

Page 23

truck must be used. Recipes for dough used to establish the batch sizes in the Mixer

Capacity Chart are listed below:

Do not exceed the specified mix quantity.

The maximum capacity of the mixer bowls are:

HL600 (full size): 56.8 litres

HL600 (half size): 37.9 litres

HEAVY BREAD MEDIUM PIZZA RAISED DONUT

INGREDIENT DOUGH DOUGH DOUGH

Flour 100.0% 100.0% 100.0%

Water 55.0 50.0 65.0

Yeast 2.0 1.0 5.0

Salt 2.5 1.5 2.5

Sugar 5.0 - 0 - 15.0

Shortening 5.0 - 0 - 15.0

Oil -0- 2.0 -0-

Non-Fat Dry Milk 6.0 - 0 - 8.0

Total 175.5% 154.5% 210.5%

The ingredient percentages are based on a flour content of 100 percent to simplify using

the recipes to make various sized batches and compute the moisture absorption ratio.

The flour used in the recipes is hard wheat flour, enriched and bleached. It contains 11 to

12 percent protein content and 12 percent moisture content.

Flour, which has lower moisture content, will decrease the moisture absorption, cause

difficulty in proper gluten hydration, and make a heavier load on your mixer. Flours

containing high quality protein, such as high gluten flour, result in dough, which can be

very difficult to mix. If high gluten flour is used, reduce the batch quantity noted on the

Mixer Capacity Chart by 10 percent to prevent overloading of the mixer.

The temperature of the water used in the recipes is 18°C to 23.0°C. Cooler water

temperatures will cause the dough to be harder to mix. If you plan to mix doughs using

cold water, the batch size may need to be reduced by 15 to 20%.

Also considered and noted on the Mixer Capacity Chart is the moisture absorption ratio

(AR). This is the ratio of the weight of water to the weight of flour expressed as a

percentage.

AR = weight of water ÷ weight of flour ⋅ 100%

The absorption ratio gives an indication of the relative "heaviness" or "wetness"

of a batch. In fact, the capacities listed on the Mixer Capacity Chart for the

products listed below are based on the following absorption ratios:

22

Page 24

PRODUCT ABSORPTION RATIO

Heavy Bread Dough 55%

Medium Bread Dough 60%

Light Bread Dough 65%

Thin Pizza Dough 40%

Medium Pizza Dough 50%

Thick Pizza Dough 60%

Raised Donut Dough 65%

Whole Wheat Dough 70%

When mixing any of the above products with an absorption ratio lower than listed,

decrease the batch size proportionately to assure efficient mixing of the product and thus

eliminate the possibility of overloading your mixer. For example: An HL600 mixer has a

thin pizza dough capacity of 18.2 kg at first speed based on an AR of 40% according to

the Mixer Capacity Chart. If the batch has an AR of 30%, reduce the batch size to

compensate for the difference. Compute the size of the reduction as follows:

1. Divide the AR of the batch to be

mixed by the AR listed on the Mixer

Capacity Chart.

2. Multiply the rated batch size by the

percentage obtained in step 1. The

result is the maximum batch size of

the HL600 mixer for pizza dough with

30% AR.

Another factor often overlooked is the ability of your mixer to operate at a different

speed. To prevent overloading, use the recommended mix speed from the Mixer

Capacity Chart. Because of the toughness of a 40% AR thin pizza dough, a maximum

mix time of 5 minutes on first speed is recommended. Second speed should never be

used on 50% AR or lower products except on model HL662.

The speed of the mixer, length of mix time, room temperature and ingredient

temperatures all affect dough temperature. To achieve the desired final dough

temperature, you may need to adjust the water temperature.

For batch size capacities on other bread doughs not mentioned on the Mixer Capacity

Chart, follow the batch size recommendation for listed bread dough with a similar

absorption ratio.

18.2 kg. Rated Batch Size

x 75%

13.6 kg. Maximum Capacity

for 30% AR Dough

30% Actual AR

= 75%

40% Rated AR

23

Page 25

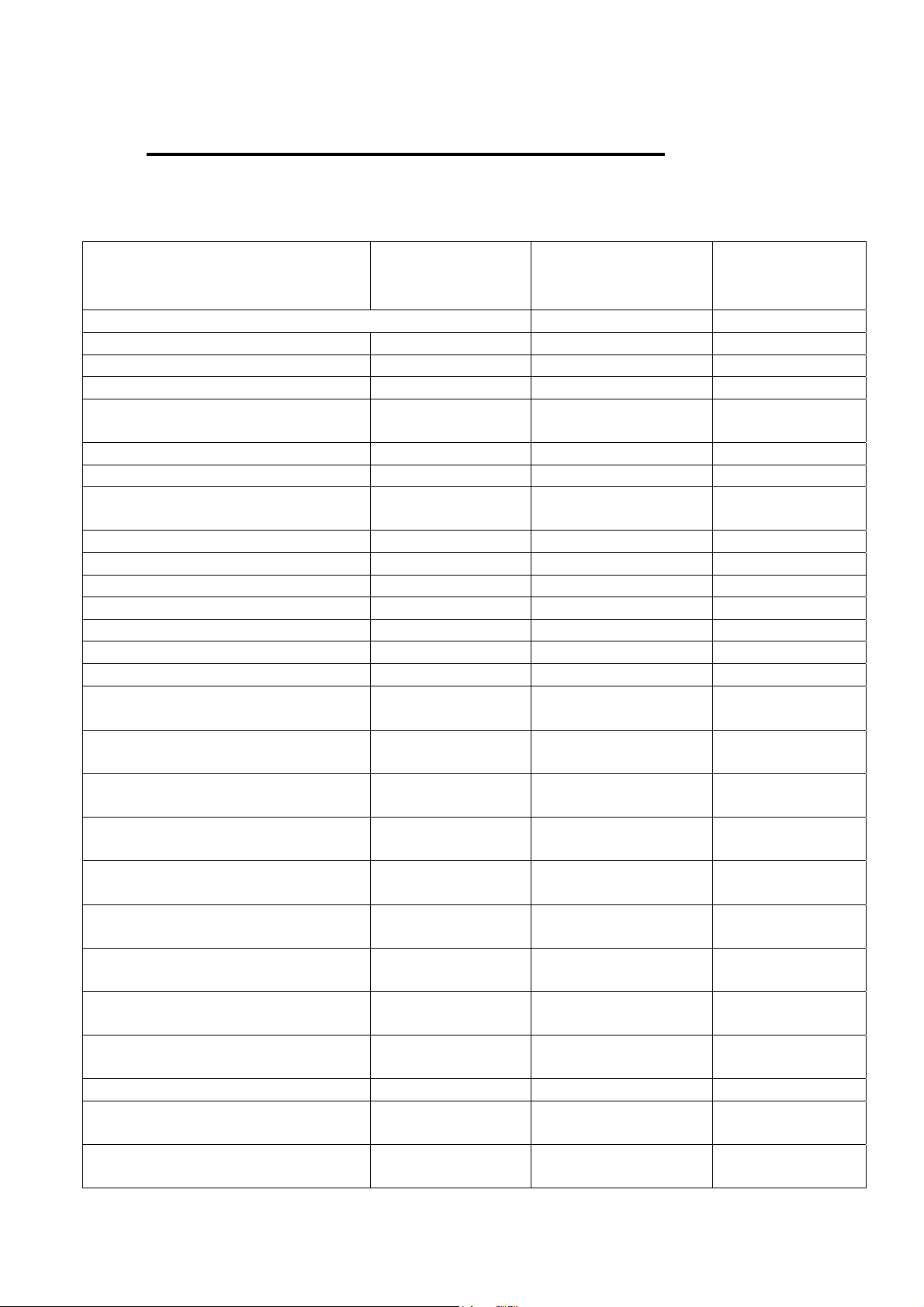

7.1 MIXING CAPACITY CHART- HL600 & HL662.

Recommended Maximum Capacities — dough capacities based on 21°C water and 12%

flour moisture.

PRODUCT

CAPACITY OF BOWL (LITRE LIQUID) 60 60

Egg Whites D 1.9 litre (2 qts) —

Mashed Potatoes B & C 18.2 kg (40 lbs.) —

Mayonnaise (Qts. of Oil.) B or C or D 17 litres (18 qts) —

Meringue (Qty. of Water) D 1.4 litre

Waffle or Hot Cake Batter B 22.7 litre (24 qts.) —

Whipped Cream D or C 12.9 litre (12 qts.) —

Cake, Angel Food (8-10 oz.

cake)

Cake, Box or Slab B or C 22.7 kg (50 lbs.) 75 lbs.

Cake, Cup B or C 27.3 kg (60 lbs.) 31.9 kg (70 lbs.)

Cake, Layer B or C 27.3 kg (60 lbs.) 31.9 kg (70 lbs.)

Cake, Pound B 25 kg (55 lbs.) 34.1 kg (75 lbs.)

Cake, Short (Sponge) C or I 20.5 kg (45 lbs.) --Cake, Sponge C or I 16.4 kg (36 lbs.) —

Cookies, Sugar B 18.2 kg (40 lbs.) 22.7 kg (50 lbs.)

Dough, Bread or Roll (Lt.-Med.)

60% AR§

Dough, Heavy Bread 55% AR§ ED 27.3 kg

Dough, Pie B & P 22.7 kg

Dough, Thin Pizza 40% AR §

(max. mix time 5 min.)

Dough, Med. Pizza 50% AR § . ED 31.9 kg

Dough, Thick Pizza 60% AR § . ED 31.9 kg

Dough, Raised Donut 65% AR ED 13.6 kg

Dough, Whole Wheat 70% AR ED 31.8 kg

Icing, Fondant

Icing, Marshmallow C or I 2.3 kg (5 lbs.) —

Shortening & Sugar, Creamed B 21.8 kg

Pasta, Basic Egg Noodle

(max. mix time 5 min.)

AGITATORS

SUITABLE FOR

OPERATION

C or I 20.5 kg

ED

ED

B 16.4 kg (36 lbs.) —

ED

HL600

(1- 1 /2 qts.)

(45 lbs)

36.4 kg

(80 lbs.*)

(60 lbs.*)

(50 lbs.)_

18.2 kg (40 lbs.)

(70 lbs.)

(70 lbs.*)

(30 lbs.†)

(70 lbs.)

(48 lbs.)

13.6 kg

(30 lbs.)

HL662

—

—

40.9 kg

(90 lbs.*)

38.6

(85 lbs.*)

27.3 kg

(60 lbs.)

27.3/18.2 kg

(60 /40 lbs.*)

40.9/31.9 kg

(90 /70 lbs.*)

40.9 kg

(90 lbs.*)

34.1 kg

(75 lbs.*)

40.9 kg

(90 lbs.*)

22.7

(50 lbs.)

18.2

(40 lbs)

24

Page 26

NOTE: %AR (% Absorption Ratio) = Water weight divided ABBREVIATIONS - AGITATORS

SUITABLE FOR OPERATION

B - Flat Beater

C - Wing Whip

D - Wire Whip

ED - Dough Hook

I - Wire Whip size by 10%.

P - Pastry Knife

1st Speed 2nd speed should never be used on 50% AR or lower

* 2nd Speed products with the exception of the HL662.

† 3rd Speed

by flour weight. Capacity depends on moisture content of

dough. Above capacities based on 12% flour moisture at

21.1°C water temperature.

§ If high gluten flour is used, reduce above dough batch

Use of ice requires a 10% reduction in batch size.

NOTE: Attachment hub should not be used while mixing.

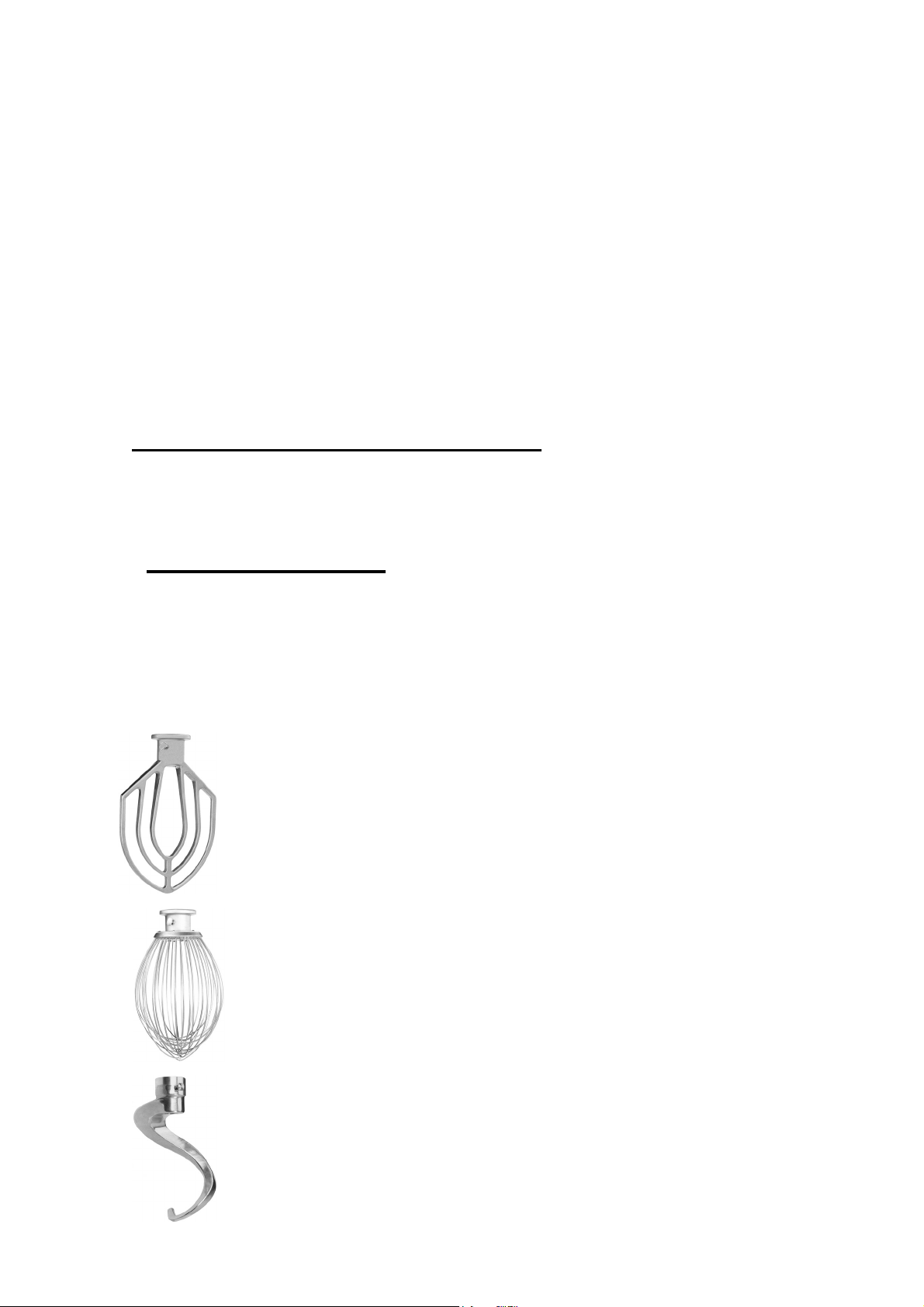

8.0

AGITATORS AND ATTACHMENTS.

Attachments for the attachment hub, agitators and accessories are detailed in the

following section.

8.1

AGITATORS AND THEIR USES

Hobart Quick Release ™ agitators are available for the Legacy mixers and for

the type of product that is being mixed.

MIXER AGITATORS.

The B Flat Beater is a multi-purpose agitator used for

mashing potatoes or other vegetables, and mixing cakes,

batters or icings. It is also used in industrial applications for

any product requiring a creaming or rubbing action and

uniform dispersion of ingredients. Use first speed for starting

most operations; medium speed for finishing.

The D Wire Whip is designed for maximum blending of air

into light products. Uses include: whipping cream, beating

egg whites, mixing very light icings, meringues and all similar

applications. The D Wire Whip is most commonly used in

third and fourth speed.

The ED Dough Hook is used for mixing most bread, roll and

pizza dough, which require folding, and stretching action for

best development. These agitators are suitable for use on all

yeast raised doughs and should be operated in first, second

or third speed.

25

Page 27

The C Wing Whip is used for whipping material that is too

heavy for the D Wire Whip. The heavy frame permits its use

for light creaming and beating. It is often used for whipping or

blending potatoes, butter, and mayonnaise or light icings. It is

generally used in first and second speed for whipping heavy

products like potatoes or in third or fourth speed for light

products such as mayonnaise or icings.

The P Pastry Knife combines shortening with flour, and is

ideal for light pastry shells (patty shells), flaky pie dough and

similar mixes. The cutting action of the knife practically

eliminates rubbing and allows delicate ingredients to be

combined without over development. The P Pastry Knife is

suitable for stirring operations in low speeds and for fast

cutting operations in medium speeds. You should not use the

P Pastry Knife at high speed if you want the pastry to have a

flaky texture.

The I Wire Whip makes sponge cakes and mixes

marshmallow and icing for heavy whipping.

8.2 USING THE ATTACHMENT FACILITY.

MEAT CHOPPER ATTACHMENT

The Meat Chopper Attachment allows you to prepare many additional foods with your

Hobart mixer. A plate having 4-mm holes comes with the Meat Chopper Attachment

when shipped from the factory. Other plates are available with hole sizes 2, 5, 6, 10, 13,

16 and 18 mm for fine to coarse chopping. The results are the same as produced by

Hobart commercial meat choppers. Operate Meat Chopper Attachments in second

speed on the HL600 or dedicated speed on the HL662 mixer. The feed pan should be

kept in place in the cylinder for ease of feeding. Cut meat into strips and feed it into the

chopper using the feed stomper only as needed. Substances that could become packed

tight in the chopper like breadcrumbs are not recommended. If material in the cylinder

stalls the mixer, push the STOP button at once. DO NOT attempt to restart at a slower

speed. Remove the adjusting ring, knife, plate and worm and clear the obstruction.

Always keep the drain hole on both the Attachment Hub and Meat Chopper clean, clear

and free of obstruction.

26

Page 28

8.3 SPLASH COVER AND BOWL EXTENSION RING

Splash Covers and Bowl Extension Rings provide a means for minimising dust

emissions and reducing splashing for certain mixes at higher speeds. Splash covers fit

under the Bowl Guard. The stainless steel Bowl Extension Ring is also available. Splash

Covers and Bowl Extensions, while convenient accessories, should not be used to

increase the mixing capacity beyond the recommended maximum. The best functioning

of Hobart mixers requires room at the top of the bowl for aeration and manipulation.

Follow the Hobart Mixer Capacity Chart of the best quality of mix. Splash Covers on

larger mixers have a smaller diameter opening at the top due to their inverted cone

shape. Overloading the mixer while a splash cover is in use reduces aeration because of

restriction in the area where air enters the batch.

8.4 BOWL SCRAPER ATTACHMENT.

The mixer Bowl Scraper Attachment is available for the HL600 Mixer full and half size

bowls. This attachment scrapes the sides of the bowl as the agitator rotates to reintroduce material into the mixture. The scraper must only be used with the whip or flat

beater agitators.

8.5 BOWL TRUCK.

When maneuvering or lifting a bowl and contents with a total weight in excess of 25 kg a

bowl truck must be used.

Bowl Trucks or dollies provide convenience, save time, and reduce effort in handling

large batches. Remove heavy batches of dough or batter from the mixer by unlocking the

bowl and lowering on to the Bowl Truck. Carefully roll the truck away to make room for

the next batch. Move the material to another location where it is to be used, or refrigerate

between mixing and further processing. Bowl Trucks save time, reduce handling, and

improve workflow. These are all valuable tools in a work place.

9.0 CLEANING.

CLEANING NEW MIXER BOWLS AND ACCESSORIES

Before using the first time, thoroughly wash new mixer bowls and agitators

(beaters, whips, dough hooks and pastry knives). Wash in hot water and a mild

detergent solution, rinsing with either a mild soda or vinegar solution, and

thoroughly rinse with clear water. Also follow this cleaning procedure for bowls and

agitators before whipping egg whites or whole eggs.

9.1 CLEANING AFTER USE.

After use, clean the mixing bowl, agitators and attachment with hot water, using a

suitable non-abrasive detergent and soft bristle brush. (Flushing the bowl with hot water

immediately after use will ease the cleaning).

Note: Do not clean the aluminium agitators in a dishwasher.

27

Page 29

Clean the mixer with a hot damp cloth; thoroughly wipe the bowl support arms and all

exterior surfaces. The guard should be cleaned as follows.

Cleaning the guard.

The guard should be cleaned at the end of each day. Once the guard is removed (see

Section 6.12 page 21) it can be cleaned with hot water, using a suitable non-abrasive

detergent and soft bristle brush. The stainless steel splashguard can be wiped off and/or

washed with a cloth or sponge them using warm soapy water. Rinse with clean water

and dry with a clean cloth.

28

Page 30

10.0 INSTALLATION AND COMMISSIONING.

OVERALL DIMENSIONS.

The Legacy series is available in two models:

• The HL600 is equipped with Stir, plus four mixing speeds.

• The HL662 is equipped with two mixing speeds.

A 40-litre bowl and agitators are also available.

A variety of attachments, agitators and accessories are available. These are described in Section

8 (page 25) of this manual.

Figure 8.

29

Page 31

Table 1. Technical information.

Description Units HL600 HL662

Motor power kW (hp) 2.0 (2.7) 2.0 (2.7)

Maximum speed of rotating part (50Hz) rpm 3975 3920

Nominal electrical supply 3 ph -- 400/50 400/50

Full load current at above voltage 3 ph -- 6.5 6.5

Locked rotor current at above voltage 3 ph Amps 16 16

Recommended fuse size 400v/3 ph/50Hz Amps 10 10

Minimum ambient temperature

Maximum ambient temperature

Transmission case lubricating oil capacity Litres 1.5 1.5

Attachment hub drive size -- # 12 # 12

Mixer weight (Bowl Included) Kg (Lbs) 411.4 (905) 411.4 (905)

Bowl weight (40 litre) Kg (Lbs) 15.9 (35.1) 15.9 (35.1)

Bowl weight (60 litre) Kg (Lbs) 18.8 (41.5) 18.8 (41.5)

Agitator weight (60 litre beater) Kg (Lbs) 2.8 (6.2) 2.8 (6.2)

Noise level dB (A)

Shipping weight (Bowl included) kg (Lbs) 434.1 (955) 434.1 (955)

Shipping dimensions (carton) LxWxH

Storage conditions. Temperature and

humidity.

Class of appliance

Enclosure IP rating IP45 IP45

Wiring terminal size; 3 phase 1.5/1.0 1.5/1.0

#

Refer to Section 10.3.

##

In accordance with EN-ISO 12001:1996.

o

C 0 0

o

C 40 40

Less than70

118.75 x 81.6

cm

o

C, +5 to +38, +5 to +38,

x 169.86

##

less than70

118.75 x 81.6

x 169.86

% RH 85 85

mm

Class 1

2

#

Class 1

#

##

10.1 UNPACKING AND HANDLING.

Wherever possible the food mixer should be transported to the

installation position in the packaging provided to avoid damage. Do

not use a sharp knife to cut into the box as damage to the machine

may occur. Check for possible shipping damage. If the unit is found to

be damaged, save the packaging material and contact your nearest

Hobart sales office.

Caution: The HL600 mixer is a heavy object and must be correctly handled

and lifted to avoid personal injury. Refer to Table 1, page 30 for weights and

dimensions. For UK installations refer to the ‘Manual Handling Operations

Regulations 1992 and HSE guidance notes for manual handling.

With the machine in the vicinity of its final position, remove from outer carton. Remove

mounting bolts under skid attached to mixer base. Remove mixer from skid forking from

the back of unit. When moving unit, always fork from back of unit.

30

Page 32

Care must be taken during this operation to ensure:

a) All required safety measures are taken to ensure correct lifting and handling to avoid

risk of injury through dropping, falling and tilting.

b) No damage occurs to the machine, which could impair the normal operation.

10.2 LOCATION.

The mixer is not suitable for outdoor installation and must not be installed

where a water jet could be used for cleaning. The mixer must only be

operated by trained staff and must be installed in an area where the use and

maintenance is restricted to trained personnel.

The mixer must be installed on a horizontal flat surface level to a minimum of 1mm in 1

metre side to side and front to back. Select a suitable flat level surface that can support

the weight of the mixer and bowl contents when full (refer to Table 1 for weights and

dimensions). In areas where stability may be an issue, the machine should be secured in

position. Refer to the recommended spare parts, Section 13, page 37 for a deck

mounting kit part number.

Once in position, the mixer must be levelled;

• Remove the two top cover screws and the top cover.

• Place a level on the top rim of the large pulley (refer to Fig. 9). Slide shims

under the base contact surface of the mixer as required levelling it front-toback and side-to-side.

• Do not replace the top cover until installation is completed.

Figure 9.

Ensure there is sufficient space around the mixer for the user to operate the controls and

to install and remove bowls. The area above and to the right side of the mixer should

allow the top and side covers to be removed for routine maintenance and servicing.

Servicing may be more difficult because of reduced clearances and you should always

check that equipment specifications permit the close proximity of other equipment. Refer

to Fig. 8, page 29 for the overall dimensions of the mixer and the clearance required to

accommodate the hinged bowl.

The mixer may be secured to floor by the use of deck plates. Each deck plate requires

two (2) ½" bolts. Bolts are to be supplied by customer. Refer to the recommended spare

parts Section 13, page 37 for a deck mounting kit part number.

31

Page 33

10.3 ELECTRICAL INSTALLATION.

The electrical installation of the mixer must conform to the local electricity board

regulations. When installed in the United Kingdom the installation must be in accordance

with the current edition of the IEE Regulations for electrical equipment in buildings and

the Electricity at work act.

A competent person must carry out the electrical installation.

The technical data shown in Table 1, page 30 details the electrical requirements for the

various mixer options.

The HL600 mixers are "class I" appliances where the protection against electric shock

does not rely solely on basic insulation. An external electrical isolator and MCB/fuses

(both items supplied by others) must be fitted to the incoming electrical supply to the

mixer. In addition a 30mA residual current device is strongly recommended to provide

extra protection.

Check that the impedance of the earth circuit is safe and operating at the

correct value.

The machine must be equipotentially bonded. The earthing screw is situated at

the rear of the machine and is identified by the symbol shown on the right.

Check the earth bonding resistance is less than 0.1Ω and the insulation resistance is

greater than 2 MΩ.

10.4 ELECTRICAL CONNECTION.

Refer to the wiring diagram supplied with the mixer and enclosed in the document

envelope. Note: Incoming power wires must be looped thru ferrite core before

connecting to terminal block TB1.

10.5 OPERATOR TRAINING.

Take time to explain the correct operation and cleaning of the Legacy mixer to the users

referring to this manual. Leave this manual with the operator and explain that it is

important to use it for further reference.

32

Page 34

11.0 MIXER MAINTENANCE.

A HOBART TRAINED AND COMPETENT PERSON SHOULD CARRY OUT

SERVICING.

Do not remove any covers or loosen any fittings while the mixer is operating.

Ensure the electrical supply has been isolated before attempting to service or

move the mixer.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND

FOLLOW LOCKOUT / TAGOUT PROCEDURES.

WARNING! THE ELECTRONIC DRIVE CONTROL IS FITTED WITH HIGH

VOLTAGE CAPACITORS. ISOLATE THE MIXER FROM THE MAINS AND ALLOW

THE CAPACITORS TO DISCHARGE FOR 5 MINUTES BEFORE REMOVING ANY

COVERS.

11.1 LUBRICATION

Figure 10.

11.1.1 SLIDEWAYS.

The slideways (Fig. 10) should be lubricated approximately twice a year. To reach

these areas, fully lower the bowl support and remove the apron, which is secured

by slotted screws. Wipe a thin coat of Lubriplate 630AA on the bowl pad area of

the bowl supports and on each slideway. Install the rear apron. Refer to the

recommended spare parts section for the Lubriplate oil part number.

33

Page 35

11.1.2 BOWL LOCKING MECHANISM.

Bowl Locking Mechanism should be lubricated after cleaning. Clean only if sticking or

hanging up.

11.1.3 PLANETARY SEAL.

Occasionally, the planetary seal (Fig. 10, page 33) may become dry and begin to

squeak. To correct this, work a little lubrication (mineral oil) under the lip of the

seal.

11.1.4 TRANSMISSION OIL.

Transmission oil should be checked once yearly or more depending on machine use. To

check the oil level, remove the top cover, which is secured by two screws. Remove the

Transmission Fill Plug (Fig. 11) and check the oil level. If the oil level is below the line

on the oil dipstick, add a small amount of the recommended transmission oil until it

returns to the proper level. Do not overfill the transmission, as leakage may result.

Contact your local Hobart Service Office for the recommended transmission oil.

Figure 11.

34

Page 36

11.2 ADJUSTMENTS

11.2.1 AGITATOR CLEARANCE.

The agitator clearance should be checked

periodically. The agitator must not touch the bowl and the maximum clearance between

the bottom of the bowl and the B flat beater is 1/8” (3 mm); the maximum clearance

between the bottom of the bowl and the ED dough is 5/16" (8 mm). Install a bowl and

agitator (e.g., beater) If the bowl and beater come into contact before the bowl support

reaches its stop, adjust the stop screw. Refer to Adjust the Bowl/Agitator Clearance,

Section 11.2.2.

11.2.2 TO MEASURE THE AGITATOR CLEARANCE.

Pour enough flour in the bowl to cover the bottom of the bowl where the beater

travels. With the bowl fully raised (beater should not touch the bottom of the

bowl), briefly run the mixer at the lowest speed.

Turn off the mixer, disconnect the electrical power supply, and measure the

depth of flour where the beater has traced a path. This measurement should be

taken at several points around the bowl to assure accuracy.

Adjust the Bowl/Agitator Clearance

• Remove the apron (which is secured by

slotted screws).

• Adjust the stop screw on right side.

• Loosen the bottom locking nut, (Fig. 12)

and turn the stop screw anti-clockwise to

increase the clearance or clockwise to

decrease the clearance. Tighten the

locking nut while holding the stop screw.

• After the adjustments are made, replace the

apron and secure it with the slotted screws.

• Reconnect the electrical power supply.

• Carefully operate the bowl lift several times to check the adjustments.

Figure 12.

11.3 INTERLOCK SAFETY SYSTEM.

Regular inspection of the mixer safety system is necessary to check the operation of the

bowl, guard and bowl support interlock switches. This must be performed no less than

once a year.

A spare parts manual is available on request from Hobart Spare Parts Distribution

Centre. For continued safe and reliable operation of this mixer, it is recommended that

servicing is only carried out by Hobart trained service personnel.

35

Page 37

11. 4 TRANSMISSION BELT.

The belt should be inspected yearly for wear. Replace if worn.

12.0 FAULT FINDING.

Fault Possible cause

Machine fails to start. Circuit protector is in open position – check fuse or

Agitator touches bowl. Bowl is not in closed (locked) position.

Planetary seal squeaks. Seal requires occasional lubrication – see Maintenance.

Time displays error code (Erxx) If the error code is flashing – wait for mixer to clear error

Alternated message of "b_in" on

SPEED display.

Alternated message of "b_up" on

SPEED display.

Alternated message of "b_gd" on

SPEED display

Message of "HI" and "LOAD" on

displays.

miniature circuit breaker.

Mixer is overloaded.

Wire cage is not in the closed position.

Bowl is not in closed (locked) position.

Improper agitator clearance – see Maintenance for

adjustment procedure.

Agitator is not installed properly.

condition.

If mixer continues to stop and timer displays flashing

error code, disconnect electrical power from mixer for 1

minute, and then reconnect.

If symptoms still exist, contact your local Hobart Service

office.

Bowl is not in all the way.

If message of "b_in" appears again after a corrective

action, disconnect electrical power from mixer for 1

minute, and then reconnect.

If symptoms still exist, contact your local Hobart Service

office.

Bowl is not up all the way.

If message of "b_up" appears after a corrective action,

disconnect electrical power from mixer for 1 minute, and

then reconnect.

If symptoms still exist, contact your local Hobart Service

office.

Wire cage is not closed completely.

If message of "b_gd" appears after a corrective action,

disconnect electrical power from mixer for 1 minute, and

then reconnect.

If symptoms still exist, contact your local Hobart Service

office.

Make sure you are not using STIR to develop dough

product.

36

Page 38

13.0 RECOMMENDED SPARES.

Part Number Description

0F-043069 Catalogue of replacement parts

873943-00001 Motor-Switch Reluctance (200-240/50/60/3/1)

873943-00002 Motor-Switch Reluctance (380-460/50/60/3)

873882 Top cover

478752-00001 Switch, Operator (Start)

478752-00002 Switch, Operator (Stop)

875588 PCB Assy (Timer Board)

874139 Bowl Lock Handle Assy

916005 Wire Cage

874123 Guard, Splash & Drip

294500-050-1 Transformer

087713-107-3 Contactor

FE-017-03 Fuse (125 volt, 2 Amp.)

114824-00001 Plug, Attachment

874351 Seal, Attachment Hub Cover

874029 Drive – Switch Reluctance (200-240/50/60/3/1)

874029-00002 Drive – Switch Reluctance (380-460/50/60/3)

874172 B Beater 60 Litre

874248 B Beater 40 Litre

873843 Bowl Assy 60 Litre

874207 Bowl Assy 40 Litre

874271 I Whip 60 Litre

874250 I Whip 40 Litre

874284 E Dough Arm 60 Litre

874278 C Six Wing Whip 60 Litre

874190 D Wire Whip 60 Litre

874249 D Wire Whip 40 Litre

874286 P Pastry Knife 60 Litre

874267 Bowl Scraper 60 Litre

874268 Bowl Scraper 40 Litre

874285 ED Dough Arm 60 Litre

874292 ED Dough Arm 40 Litre

874203 Bowl Truck

438082 Splash Cover 60 Litre

438081 Splash Cover 40 Litre

874622 Deck Plate Kit

501687 Lubriplate 630-AA

37

Page 39

14. NOTES:

38

Page 40

15.0 SERVICE CONTACT NUMBERS.

Hobart trained service technicians strategically throughout the UK are prepared to give

you fast, efficient and reliable service. Protect your investment by having a Hobart

inspection contract, which assures the continued, efficient operation of your Hobart

machines, spares and accessories. For disposal of mixer, contact Hobart Service Centre

for return details.

For further details please contact: -

Department Telephone Facsimile

SALES: 07002 101 101 02088 864 396

SERVICE 07002 202 202 01733 371 709

SPARES 07002 303 303 01733 371 332

Continued product improvement is a Hobart UK policy, specifications may change without notice.

Hobart UK

Hobart House, 51 The Bourne,

Southgate, London N14 6RT

Tel: 07002 101101 Fax 0208 886 4396

F34931 (April 2005)

Page 41

HL600

HL662

ML-134297

ML-134298

INSTALLATION AND OPERATION MANUAL

MANUEL D’INSTALLATION ET D’UTILISATION

INSTALLATIONS UND BEDIENUNGSANLEITUNG

F34931 (April 2005)

Page 42

Français / TABLE DES MATIERES.

Ag

Information sur la sécurité 1 42

Directives sur la sécurité 1.1 42

Symboles d'avertissement 1.2 43

Responsabilité 1.3 43

Avant-propos 2 44

Informations générales 3 44

Prendre soin de votre environnement 4 44

Les matières d'emballage 4.1 44

Pour éliminer votre ancien appareil 4.2 44

Instructions de sécurité 5 45

Danger de la poussière 5.1 45

Ne jamais 5.2 45

Toujours 5.3 46

Instructions de sécurité pour accessoires 5.4 46

Utilisation du mixer 6 47

Première utilisation 6.1 47

Identification des composants du mixer Figure 1 48

Commandes, HL600 – Commandes Standards 6.2 48

Commandes, HL662 – Commandes Standards 6.2 49

Commandes, HL600 – Temporisateur des recettes 6.2 50

Positionnement du bol 6.3 50

Agitateur 6.4 51

Fonctionnement “Maintien Manuel” 6.5 51

Levage mécanique du bol 6.6 51

Préparation pour mixage 6.7 52

Notes pour l'utilisation 6.8 52

Fonctionnement du temporisateur 6.9 52

Mode recettes – Entrée et sortie 6.9 54

Revue des étapes de recettes 6.9 54

Réalisation d’une recette 6.9 55

Interrompre une recette 6.9 55

Entrer une fonction spéciale 6.9 56

Saisir le code d'accès 6.9 56

Programmer une Recette [SEt ... rECP] 6.9 57

Programmer une Pause 6.9 58

Rendre une Recette Active ou Inactive [Atth ...

rECP]

Régler le Code d'Accès [SEt ... CodE] 6.9 59

Déchargement 6.10 60

Panier métallique de protection 6.11 60

Dépose et nettoyage du panier métallique 6.12 61

Remontage du panier métallique 6.13 62

Capacité de mélange 7 62

Tableau de capacité de mélange 7.1 65

Agitateurs et accessoires 8 66

itateurs du mixer 8.1 66

Section Page

6.9 58

41

Page 43

Utilisation du dispositif accessoire 8.2 68

Couvercle anti-projections et couronne d'extension

du bol

Dispositif racleur du bol 8.4 69

Chariot du bol 8.5 69

Nettoyage 9 69

Nettoyage après utilisation 9.1 69

Installation et mise en service 10 70

Dimensions du mixer Figure 8 70

Information technique Tableau

Déballage et manutention 10.1 71

Localisation 10.2 72

Installation électrique 10.3 73

Connexions électriques 10.4 74

Formation de l'opérateur 10.5 74

Maintenance du mixer 11 74

Lubrification 11.1 74

Glissières 11.1.1 75

Mécanisme de blocage du bol 11.1.2 75

Joint planétaire 11.1.3 75

Huile de transmission 11.1.4 75

Réglages 11.2 76

Dégagement de l'agitateur 11.2.1 76

Pour mesurer le dégagement de l'agitateur 11.2.2 76

Système de sécurité intrinsèque 11.3 77

Courroie de transmission 11.4 77

Dépannage 12 78

Pièces de rechange recommandées 13 79

Notes 14 80

Numéros de contact pour le service après-vente 15 81

8.3 68

71

1

1.0 INFORMATIONS SUR LA SECURITE.

Les procédures et précautions contenues dans le présent manuel ne s'appliquent qu'à la

machine lorsqu'elle est utilisée de la façon prescrite.

Si la machine est utilisée autrement que de la façon prescrite, l'opérateur sera

responsable de sa propre sécurité et de la sécurité des autres personnes qui peuvent

être concernées.

Les informations contenues dans le présent manuel ont été préparées pour aider

l'opérateur à comprendre, entretenir et utiliser le mixer. Afin d'éviter les accidents, il

convient de lire, assimiler et suivre toutes les précautions et avertissements contenus

dans le présent manuel avant installation ou première utilisation. Ce manuel doit être

étudié pour obtenir une compréhension claire du mixer et de ses capacités.

1.1 DIRECTIVES SUR LA SECURITE.

S'assurer que des précautions suffisantes sont observées au cours de la manipulation

manuelle du mixer, en particulier lors de la mise en place pendant l'installation. On se

42

Page 44

réfèrera aux réglementations de manipulations manuelles. Les poids du mixer sont

donnés au Tableau 1.

• Ne pas nettoyer cet appareil au jet d'eau ni au nettoyeur sous pression. Il est vital

d'adhérer aux instructions de nettoyage décrites en détail dans la section 9 du

présent manuel.

• Ne pas déposer de couvercle ni desserrer des accessoires pendant que la machine

est en marche.

• S'assurer que ce manuel est conservé dans un lieu facilement accessible à proximité

du mixer, pour référence ultérieure.

• Tous les opérateurs doivent être formés au fonctionnement du mixer et de ses

accessoires en toute sécurité.

• S'assurer que l'alimentation électrique a été coupée avant d'essayer d'entretenir ou

de déplacer le mixer.

• Les machines tournantes et l'électricité sont potentiellement dangereuses et peuvent

blesser si l'on ne prend pas suffisamment de précautions avant d'utiliser ou

d'entretenir la machine.

• Faire réviser régulièrement le mixer et les accessoires, au moins deux fois par an, en

fonction de la fréquence d'utilisation.

• Lorsqu'on mélange des produits qui produisent de la poussière, on prendra toutes les

précautions utiles. Mélanger les ingrédients en utilisant le dispositif STIR jusqu'à ce

que la poussière soit éliminée.

• L'exposition à la poussière (y compris la farine) peut être dangereuse pour la santé,

et sera la cause de rhinites, d'écoulement des yeux et peut-être d'asthme.

1.2 SYMBOLES D'AVERTISSEMENT.

Pour identifier les messages de sécurité dans le présent manuel, les symboles suivants

ont été utilisés.

Le symbole "Avertissement" se trouve essentiellement lorsque l'information

correspondante est importante pour la bonne utilisation de l'appareil en toute

sécurité.

Le symbole de danger électrique est utilisé lorsqu'il y a des risques de nature

électrique. Avant de réviser l'appareil, toujours débrancher le câble

d'alimentation électrique du secteur.

1.3 RESPONSABILITE.

Les installations et réparations qui ne sont pas effectuées par des Techniciens

Autorisés, ou l'utilisation de pièces de rechange autres que les pièces d'origine, et

43

Page 45

toutes modifications techniques de la machine, peuvent mettre en danger la garantie

fixée dans les conditions de vente standard.

2.0 AVANT-PROPOS.

Hobart se réserve le droit de modifier la conception de ses produits sans préavis. Bien

que tous les efforts nécessaires aient été faits pour que cette publication reflète la toute

dernière conception de l’appareil, la société ne peut pas garantir une totale conformité.

Prenez soin de votre mixer HL600 / HL662 – gardez-le propre et en bon état mécanique

et électrique.

3.0 INFORMATIONS GENERALES.

Les présentes informations et instructions contenues dans ce manuel peuvent ne pas

couvrir tous les détails ni les variations de l'équipement, ni tenir compte de toutes

possibilités pouvant de produire avec l'installation, l'utilisation ou la maintenance. Si des

informations supplémentaires sont requises, veuillez contacter votre bureau Hobart local.

Les mixers HL600 et HL662 sont conçus pour mélanger des produits alimentaires

comme détaillé dans le tableau de spécification (Section 7.1, page 65).

Les mixers sont fabriqués en pièces moulées époxy à peintures en poudre, avec socle,

panneau arrière et pieds en acier doux mécano-soudé, avec un couvercle supérieur

moulé en plastique.

La machine est prévue pour fonctionner sur les alimentations électriques indiquées au

Tableau 1, page 71.

Le mixer est équipé d'un dispositif de sécurité à "ouverture sans volt" pour éviter un

redémarrage automatique après panne de courant ou déconnexion du secteur. Le

support du bol et la protection sont à verrouillage intrinsèque de telle façon que si l'un ou

l'autre n'est pas dans sa position de fonctionnement correcte, le mixer ne fonctionne pas.

Le mixer standard est fourni avec protection, bol et agitateurs.

4.0 PRENDRE SOIN DE VOTRE ENVIRONNEMENT.

4.1 LESMATIERES D'EMBALLAGE.

Le film d'emballage de palette et protecteur en polyéthylène a été

sélectionné à partir de matières qui respectent l'environnement pour leur

élimination ou qui peuvent être normalement recyclées. Au lieu de les jeter,

veuillez vous assurer qu'ils sont recyclés.

4.2 POUR ELIMINER VOTRE ANCIEN APPAREIL.

Les anciens appareils contiennent des matières qui peuvent être recyclées. Veuillez

contacter votre centre local de collecte des déchets ; récupérateurs de métaux ou le

bureau Hobart local sur les systèmes de recyclage possibles.

44

Page 46

5.0 INSTRUCTIONS DE SECURITE.

SEULE UNE PERSONNE DUMENT FORMEE ET COMPETENTE DOIT UTILISER

L'ACCESSOIRE ET / OU LE MIXER.

Les instructions suivantes doivent être observées lorsqu'on utilise le mixer.

NB : Le mixer ne doit être utilisé que dans le but pour lequel il a été conçu et

conformément aux instructions d'exploitation fournies.

Lorsqu'on manœuvre ou qu'on soulève un bol et son contenu avec un poids total

dépassant 25 kg, il faut utiliser un chariot pour le bol (numéro de pièce Hobart 874361)

N'utiliser que des accessoires conformes aux réglementations CE (marqués CE).

5.1 DANGER DE LA POUSSIERE.

Pour réduire au minimum tout danger de poussière, suivre les instructions détaillées cidessous.

Lorsqu'on mélange des ingrédients, on prendra soin d'éviter de respirer les particules de

poussière, par exemple la farine. On se réfèrera aux fiches de données du fournisseur

de produit pour s'assurer que des précautions / protections adéquates sont prises.

Les articles tels que la farine doivent être ajoutés de façon à éviter la dispersion des

particules de poussières dans l'atmosphère locale.

Fendre soigneusement le sac tout en le maintenant dans la partie inférieure du bol. En

mélangeant des ingrédients secs, utiliser la vitesse la plus basse pour réduire au

minimum la propagation de poussière. Utiliser un couvercle anti-projections pour réduire

la production de poussière (voir la Section 13, Pièces de rechange recommandées, page

79 pour le numéro de pièce du couvercle). Mélanger les ingrédients dans le bol en

utilisant la vitesse la plus basse jusqu'à ce que le risque de production de poussière soit

éliminé.

Monter un équipement d'extraction de poussière approprié.

5.2 NE JAMAIS :

• Faire fonctionner le mixer ou les accessoires si un défaut apparaît ou si le mixer

ne fonctionne pas en sécurité.

• Porter des vêtements amples.

• Essayer de mettre la main dans le bol pendant le mélange.

• Accéder aux pièces tournantes.

• Monter l'agitateur sur le mixer sans bol en place.

• Laisser l'agitateur sur l'appareil sans monter le bol.

• Actionner le mixer avec les accessoires et l'agitateur montés.

• Utiliser une force excessive lors de l'utilisation, ce qui pourrait avoir un effet négatif

sur la stabilité du mixer.

• Faire fonctionner le mixer si des pièces sont démontées.

• Annuler les contacts de sécurité montés sur le mixer.

• Ouvrir la protection pour arrêter la machine.

• Utiliser le dispositif de levage du bol pour arrêter la machine.

• Utiliser le mixer dans un état contraire à la sécurité.

45

Page 47

• Nettoyer le mixer avec de la poudre décapante ou un tampon décapant.

• Nettoyer les agitateurs en aluminium dans un lave-vaisselle.

• Respirer les particules de poussière des ingrédients de mélange.

5.3 TOUJOURS :

• Utiliser le mixer dans une zone bien éclairée.

• S'assurer que le bol, l'agitateur, l'accessoire et la protection sont correctement

fixés au mixer.

• Débrancher l'alimentation électrique secteur avant de nettoyer le mixer.

• Nettoyer le mixer quotidiennement.

• Retirer l'agitateur avant d'utiliser des accessoires.

• Arrêter le mixer avant d'ajouter d'autres ingrédients.

• Utiliser le bouton d'arrêt pour arrêter la machine.

• Nettoyer le bol, les agitateurs et les accessoires après utilisation.

• Nettoyer le mixer en utilisant du savon doux et de l'eau.

• Réviser le mixer et les accessoires au moins deux fois par an en fonction de la

fréquence d'utilisation.

• Utiliser le mixer comme prévu et conformément aux instructions d'utilisation.

• Utiliser l'équipement de taille réduite correct (bol et agitateur).

• Utiliser des accessoires qui sont agréés CE et marqués CE.

5.4 INSTRUCTIONS DE SECURITE POUR LES ACCESSOIRES.

Les instructions suivantes doivent être observées lorsqu'on utilise le mixer avec ses

accessoires. Se référer également aux instructions de sécurité de la Section 6.0, page

47 et les instructions fournies avec l'accessoire. Seuls les accessoires marqués et

agréés CE doivent être utilisés.

SEULE UNE PERSONNE BIEN QUALIFIEE ET COMPETENTE DOIT UTILISER

L'ACCESSOIRE ET / OU LE MELANGEUR.

• Ne pas monter un accessoire quand le mixer fonctionne.

• Ne pas porter de vêtements amples.

• Ne pas utiliser le mixer ou l'accessoire si un défaut se produit ou si la machine

n'est pas sûre.

• Ne pas accéder aux pièces tournantes.

• Ne pas utiliser une force excessive en faisant fonctionner l'accessoire, car cela

pourrait affecter la stabilité du mixer.

• Ne pas utiliser le mixer si des pièces sont démontées.

• Toujours utiliser l'accessoire et / ou le mixer dans une zone bien éclairée.

• Toujours s'assurer que l'accessoire fonctionne à la vitesse correcte.

• Toujours nettoyer les accessoires après utilisation et se référer aux instructions

de nettoyage du fabricant d'accessoires.

• Toujours réviser votre mixer et ses accessoires régulièrement ; au moins deux

fois par an, en fonction de la fréquence d'utilisation.

46

Page 48

6.0 UTILISATION DU MIXER.

6.1 PREMIERE UTILISATION.

Vérifier la lubrification avant utilisation.

Ce mixer est expédié avec de l'huile dans la transmission. Vérifier le niveau d'huile avant

de faire démarrer le mixer.

• Isoler électriquement le mixer.

• Déposer le couvercle supérieur.

• Dévisser la jauge en utilisant une clé Allen hexagonale de 3/8” et vérifier le niveau

d'huile. Celui-ci doit être compris entre les deux encoches sur la jauge. Se référer à la