Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

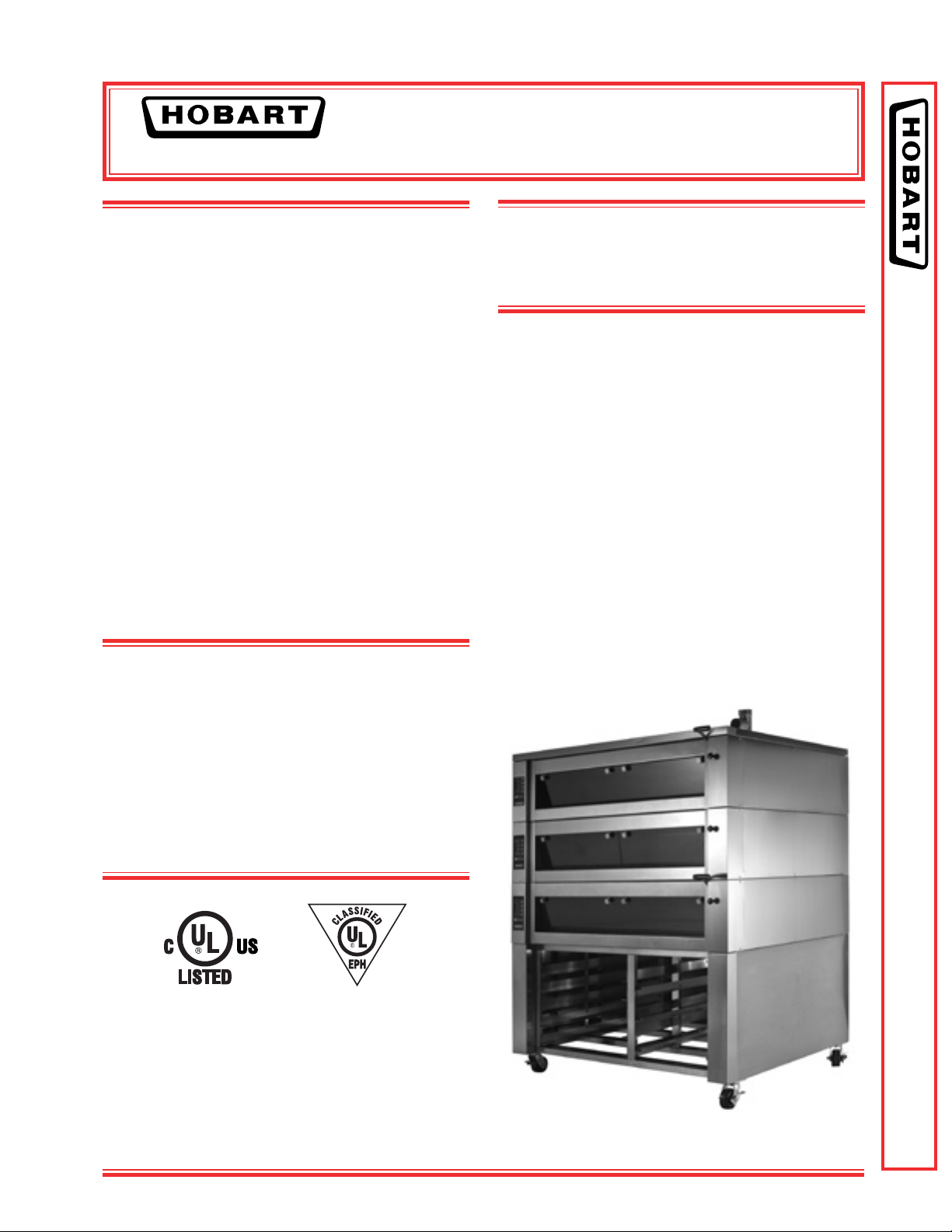

HWDO3D ELECTRIC

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ One to four decks in height

■ Each deck operates independently

■ Stainless steel exterior

■ Glazed stone baking surface

■ Separately controlled top and bottom elements

■ Easy-to-operate digital control

– Temperature

– Time

– Steam

■ Single point vent connection

■ Illuminated bake chamber

■ Glass loading door opens into the bake chamber

- minimal loading space required

■ Split glass in loading door for ease of cleaning

DECK OVEN

MODEL

❑ HWDO3D – Electric Deck Oven

Specifications, Details and Dimensions on Back.

■ Oven stand sold separately

OPTIONS & ACCESSORIES

❑ Deck oven accessory kit

– Includes 3 peels, 1 deck brush, 1 crevice

tools, and 1 dust pan

❑ 1-deck stand base, 48" high

❑ 2-deck stand base, 36" high

❑ 3-deck stand base, 31" high

❑ 4-deck stand base, 18" high

HWDO3D ELECTRIC DECK OVEN

Configuration shown includes 3 deck ovens

on a 3-deck stand base. Base sold separately.

F-40187 – HWDO3D Electric Deck Oven Page 1 of 2

Printed On Recycled Paper

HWDO3D ELECTRIC

DECK OVEN

SPECIFICATIONS:

UTILITIES

Power - 1 supply required per deck:

208V/60/3 33 amps, 10.7Kw

220-240V/60/3 28-33 amps, 10.3-12.2Kw

Water Connect Point - 1 supply required per deck:

3

⁄8" NPTF. Cold water @ 20-80 psi @ 0.5 GPM maximum

flow rate. NOTE: Water supply must have the proper

hardness, pH & chloride concentration. Consult your local

water company and/or water conditioner dealer before

installation.

Recommended water hardness range: 2-6 grains per gallon.

Recommended pH range: 7.0 to 8.0.

Acceptable range for chloride concentration: 0-50 ppm.

Drain Fitting: Drain tubing supplied from each deck to the

3

single

⁄4" NPT rear drain connection on the stand base.

Exact drain height varies with oven configuration. Route to

air-gap drain.

Steam Vent: 3

supply hood, duct and ventilator fan per local code. 500cfm

when steaming.

1

⁄2" diameter exhaust to hood. Customer to

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Consult local authorities to determine whether Type I

(grease) or Type II (vapor) duct will be required.

INSTALLATION

Floor should be level within

installation. Slope should not exceed

1

⁄8" per foot for proper

3

⁄4" in all directions

under the unit.

The purchaser is responsible for all installation costs and

for providing: Disposal of packing materials; labor to unload

oven upon arrival; installation mechanics; and all local

service connections including electricity, vents, water and

drain per local code. A factory technician or factory autho

rized installation technician must supervise and approve

any installation. In order to validate the warranty, start-up

must be performed by an authorized service company. All

services must comply with federal, state and local codes.

Minimum clearances to combustible construction:

1 inch from sides

1 inch from vent stack in back

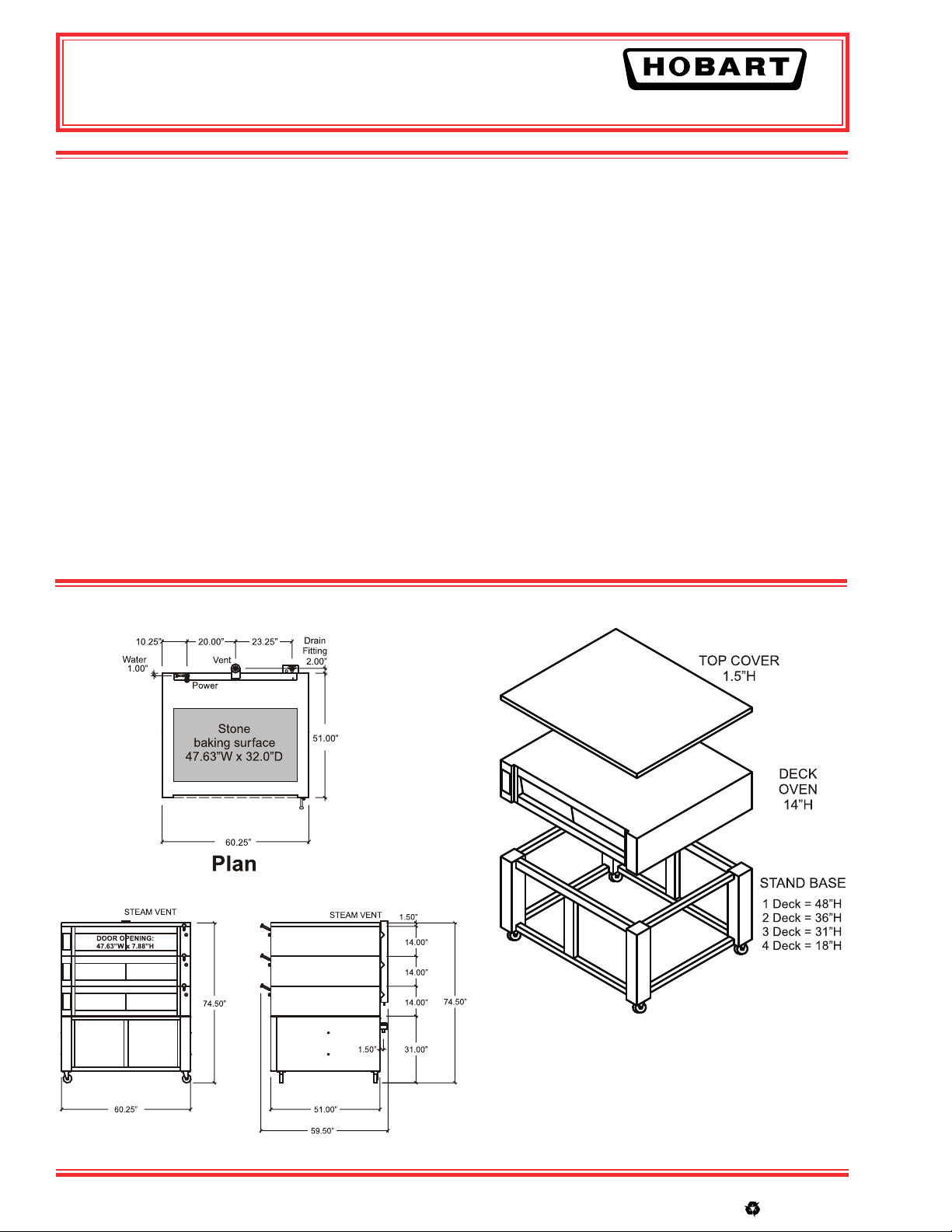

DETAILS AND DIMENSIONS

Note: Exact overall height and utility connection locations

will vary per your oven configuration. To determine exact

dimensions, add together the applicable dimensions above.

Example: a typical 3-deck oven configuration would include

1 top, 3 decks, and 1 stand - 1.5"+14"+14"+14"+31"=74.5"

As continued product improvement is a policy of Hobart, specifications are subject to change without notice.

Page 2 of 2 F-40187 – HWDO3D Electric Deck Oven

F-40187 (12/07) LITHO IN U.S.A. (H-01)

Loading...

Loading...