M

I

N

O

S

T

D

R

E

D

U

C

C

LXGe SERIES GLASSWASHER

LAVE-VERRE DE LA GAMME LXGe

’

E

I

M

O

LXGe SERIES

GLASSWASHER

LAVE-VERRE

DE LA GAMME LXGe

LAVAVAJILLAS DE

LA SERIE LXGe

P

L

N

E

S

O

I

LAVAVAJILLAS DE LA SERIE LXGe

MODELS

MODÈLES

MODELOS

LXGePR ML-130255

ML-130256

LXGeR ML-130257

ML-130258

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 47526 Rev. A (January 2015)

© HOBART CORPORATION, 2015

– 2 –

TABLE OF CONTENTS

GENERAL .........................................................................................................................................6

INSTALLATION .................................................................................................................................7

Unpacking ................................................................................................................................... 7

Location ......................................................................................................................................7

Leveling ....................................................................................................................................... 7

Water Requirements ...................................................................................................................7

Plumbing Connections ................................................................................................................ 8

Before First Use .........................................................................................................................8

Electrical Connection ..................................................................................................................9

Electrical Data ............................................................................................................................. 9

Connection Method ..................................................................................................................10

Detergent and Rinse Aid ...........................................................................................................11

Chemical Sanitizer (LXGePR) ...................................................................................................12

Checking Sanitizer Concentration ............................................................................................ 12

Deliming Solution ...................................................................................................................... 12

Priming Chemical Pumps .......................................................................................................... 13

Installation Diagram (LXGePR, short) ........................................................................................ 14

Installation Diagram (LXGePR, tall)............................................................................................15

Installation Diagram (LXGeR, short) ..........................................................................................16

Installation Diagram (LXGeR, tall) .............................................................................................. 17

PROGRAMMING.............................................................................................................................18

Manager Mode Programming ...................................................................................................18

Programming Instructions ......................................................................................................... 18

Menu Display Prompts .............................................................................................................. 18

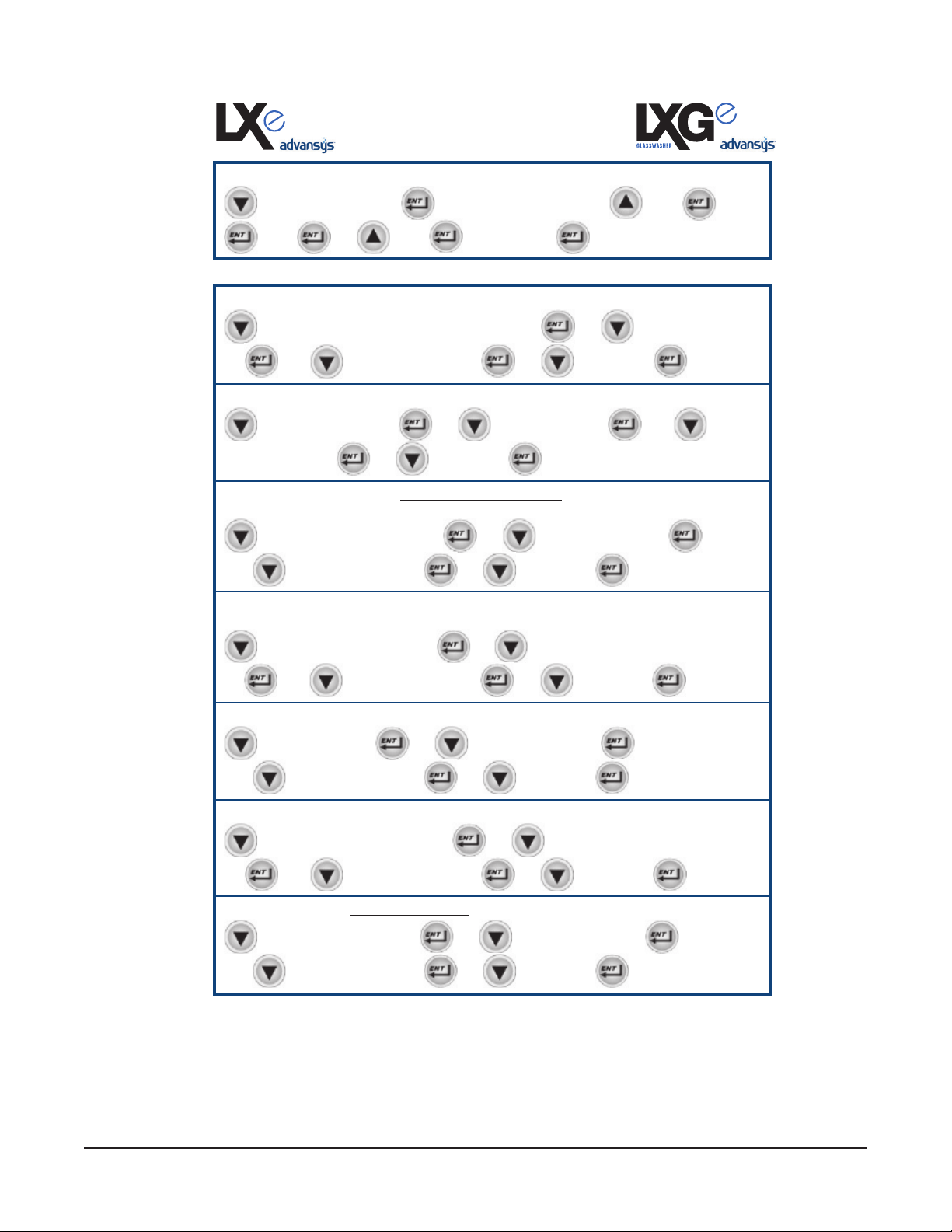

LXGe advansys Manager Mode Programming Card .................................................................19

Parameters Menu Table ............................................................................................................21

OPERATION ....................................................................................................................................23

Operating the LXGeR Glasswasher ........................................................................................... 23

Diagnostic/Error Messages .......................................................................................................24

Wash/Rinse Cycle Times (LXGePR and LXGeR) .......................................................................25

Preparation ..............................................................................................................................25

Do's and Don'ts For Your New Hobart Glasswasher ................................................................26

CLEANING ...................................................................................................................................... 27

MAINTENANCE ..............................................................................................................................28

Deliming .................................................................................................................................... 28

Lubrication ................................................................................................................................28

TROUBLESHOOTING ..................................................................................................................... 29

– 3 –

TABLE DES MATIÈRES

DESCRIPTION GÉNÉRALE ............................................................................................................. 31

INSTALLATION ............................................................................................................................... 32

Déballage .................................................................................................................................. 32

Emplacement ............................................................................................................................32

Mise de niveau .......................................................................................................................... 32

Besoins en eau ..........................................................................................................................32

Raccordements de plomberie ................................................................................................... 33

Avant la première utilisation ......................................................................................................34

Connexions électriques ............................................................................................................. 34

Données électriques .................................................................................................................34

Méthode de connexion .............................................................................................................35

Doseurs à détergent et aide au rinçage ....................................................................................36

Assainissement chimique (LXGePR) .........................................................................................37

Concentration de l’assainisseur chimique .................................................................................37

Solution de détartrage ..............................................................................................................37

Amorçage des doseurs chimiques ............................................................................................ 38

Schéma d’installation (LXGePR, petit) ......................................................................................39

Schéma d'installation (LXGePR, grand) ....................................................................................40

Schéma d’installation (LXGeR, petit) ......................................................................................... 41

Schéma d'installation (LXGeR, grand) .......................................................................................42

PROGRAMMATION ........................................................................................................................43

Programmation du mode de gestion ......................................................................................... 43

Instructions de programmation ................................................................................................. 43

Touches de navigation .............................................................................................................. 43

Carte de programmation du mode de gestion du modèle LXGe Advansys ..............................44

Grille du menu des paramètres ................................................................................................. 46

UTILISATION ..................................................................................................................................48

Faire fonctionner le lave-verre LXGeR ....................................................................................... 48

Messages de diagnostics et d’erreurs ......................................................................................49

Durée des cycles de lavage/rinçage (LXGePR et LXGeR) ......................................................... 50

Préparation ...............................................................................................................................50

Choses À FAIRE et NE PAS FAIRE avec votre nouveau lave-verre Hobart ............................... 51

NETTOYAGE ................................................................................................................................... 52

ENTRETIEN .....................................................................................................................................53

Détartrage .................................................................................................................................53

Lubrication ..............................................................................................................................53

DÉPANNAGE ..................................................................................................................................54

– 4 –

ÍNDICE

GENERAL .......................................................................................................................................56

INSTALACIÓN.................................................................................................................................57

Desempaque ............................................................................................................................. 57

Ubicación .................................................................................................................................. 57

Nivelación .................................................................................................................................57

Requisitos de agua ...................................................................................................................57

Conexiones de plomería ...........................................................................................................58

Antes del primer uso ................................................................................................................. 59

Conexión eléctrica ....................................................................................................................59

Datos eléctricos ........................................................................................................................59

Método de conexión .................................................................................................................60

Detergente y enjuague ..............................................................................................................61

Desinfectante químico (LXGePR) .............................................................................................62

Revisión de la concentración del desinfectante ....................................................................... 62

Solución para descalcicar ....................................................................................................... 62

Llenado de las bombas de químicos ........................................................................................63

Diagrama de instalación (LXGePR, pequeño) ...........................................................................64

Diagrama de instalación (LXGePR, grande) .............................................................................65

Diagrama de instalación (LXGeR, pequeño) .............................................................................. 66

Diagrama de instalación (LXGeR, grande) .................................................................................67

PROGRAMACIÓN ........................................................................................................................... 68

Programación en modo de Administrador ................................................................................68

Instrucciones de programación ................................................................................................. 68

Indicaciones en la pantalla del menú ........................................................................................68

Tarjeta de programación, modo de Administrador advansys LXGe ..........................................69

Tabla del menú de parámetros .................................................................................................. 71

OPERACIÓN ................................................................................................................................... 73

Operación del lavavajillas LXGeR ..............................................................................................73

Mensajes de error/diagnóstico .................................................................................................. 74

Tiempos del ciclo de lavado/enjuague (LXGePR y LXGeR) ....................................................... 75

Preparación ..............................................................................................................................75

Qué hacer y qué no hacer con su nuevo lavavajillas Hobart ..................................................... 76

LIMPIEZA ........................................................................................................................................ 77

MANTENIMIENTO ...........................................................................................................................78

Descalcicación ........................................................................................................................ 78

Lubricación ...............................................................................................................................78

SOLUCIÓN DE PROBLEMAS .........................................................................................................79

– 5 –

Installation, Operation and Care of

LXGe SERIES GLASSWASHERS

SAVE THESE INSTRUCTIONS

GENERAL

The LXGe Series glasswashers are fully automatic and front-loading. The LXGe series glasswashers

are capable of doing 24 to 38 racks per hour, depending on model.

All LXGe Series glasswashers shut down automatically 4 hours after last use to conserve energy.

The LXGeR glasswashers include Sense-A-Temp™ to insure proper hot water temperature during rinse.

Standard equipment includes one glass/wine rack, electronic controls, drain pump, rinse pump, chemical

pumps, ll hose, and drain hose.

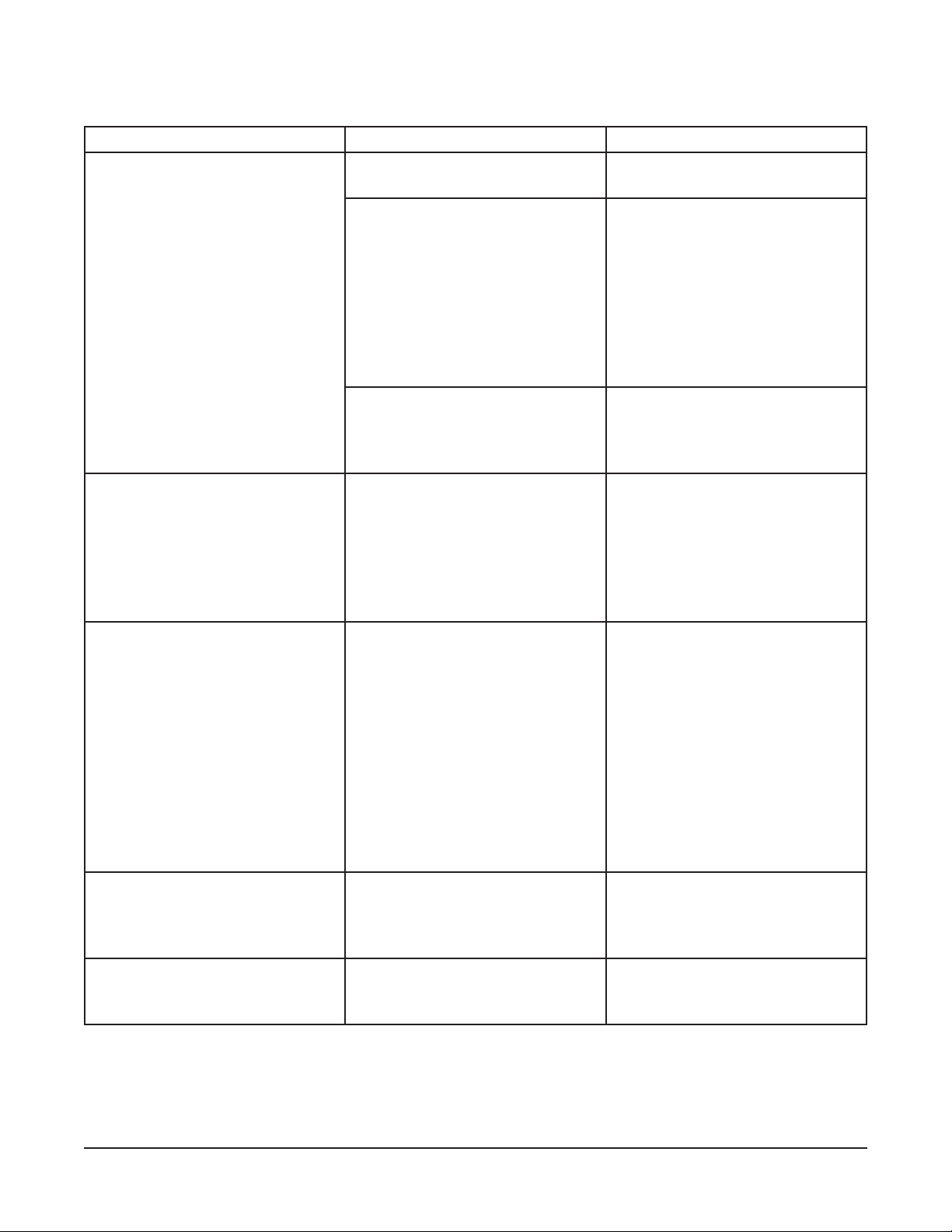

MODEL DESCRIPTION

LXGePR Fresh water rinse; low-temperature, chemical-sanitizing models for use

with 6% sodium hypochlorite solution (bleach) as the sanitizing agent*.

Note: If 8.40% bleach is to be used, contact Hobart Service or your

chemical supplier to change the sanitizer pump settings. (Charges may

apply)

LXGeR Fresh water rinse with an internal energy recovery unit and a built-in 70°F

rise booster heater. Recommended incoming water temperature 55°F to

80°F.

* - Sanitizing agent must be used in accordance with the EPA-registered label use instructions.

– 6 –

INSTALLATION

UNPACKING

Immediately after unpacking the glasswasher, check for possible shipping damage. If this machine

is found to be damaged, save packaging material and contact the carrier within 15 days of delivery.

LOCATION

Prior to installation, verify that the electrical supply agrees with the specications on the machine data

plate, which is located on the top of the door.

Steam generated from normal operation may escape from the door. Wood, laminates, veneers, etc. are

unsuitable materials for use in areas exposed to glasswasher steam and detergents. Stainless steel

or other moisture-resistant shields are recommended for surfaces adjacent to LXGe sides and top.

LEVELING

The machine must be level to operate properly. Place the glasswasher in its operating location. Level

the machine before any connections are made. Using a carpenter's level placed diagonally on the

rack tracks, level the machine front to back and side to side by threading the adjustable feet in or out.

WATER REQUIREMENTS

Proper water quality can improve glass washing performance by reducing spotting, enhancing

effectiveness of labor and extending equipment life. Water conditions vary from one location to another.

The recommended proper water treatment for effective and efcient use of this equipment will also

vary depending on the local water conditions. Ask your municipal water supplier for details about your

local water conditions prior to installation.

Recommended water hardness is 3 grains of hardness per gallon or less. Higher hardness may cause

excessive formation of lime scale. Water hardness above 3 grains per gallon requires water treatment.

Water treatment has been shown to reduce costs associated with machine cleaning, reduce deliming

of the glasswasher, and reduce detergent usage in the glasswasher.

High iron levels in the water supply can cause staining and may require an iron lter. High

chloride levels in the water supply can cause pitting and may require a chloride removal system. Contact

your local water treatment professional for proper water treatment.

Sediment may require a particulate lter. Dissolved solids may require water treatment such as a water

softener, reverse osmosis system, etc. Contact your local water treatment professional for proper water

treatment.

If an inspection of the glasswasher or booster heater reveals lime buildup after the equipment has been

in service, water treatment is recommended. If a water softener is already in place, ensure there is a

sufcient level of salt. Contact your local Hobart Service ofce for specic recommendations.

– 7 –

A water hammer arrestor (meeting ASSE-1010 Standard or equivalent) should be installed (supplied

by others) in the common water supply line at the service connection.

The plumber connecting this machine is responsible for making certain that water lines are THOROUGHLY

FLUSHED OUT BEFORE connecting to the glasswasher. This "ush-out" is necessary to remove all

foreign matter, such as chips (resulting from cutting or threading of pipes) pipe joint compound from the

lines; or, if soldered ttings are used, bits of solder or cuttings from the tubing. Debris, if not removed,

may lodge in the glasswasher's plumbing components and render them inoperative. Manual valves

or solenoid valves fouled by foreign matter and any expenses resulting from this fouling are NOT the

responsibility of the manufacturer and associated repair costs are not covered under warranty.

Water supply requirements are as follows:

MODEL TEMPERATURE

LXGePR 120°F Minimum

LXGeR 55°F Minimum, 85°F Maximum

NOTE: On LXGeR installations, if cold water supply temperature is consistently above 80°F or if excessive

water vapor or steam is entering the room after the condensing cycle is complete, contact Hobart Service

to increase condensing time.

Required owing water pressure to the glasswasher is 15-65 PSIG. If pressures higher than 65 PSIG are

present, a pressure regulating valve must be installed in the water line to the glasswasher (by others).

If owing pressure is less than 15 psi, improper machine operation may result. All LXGe glasswashers

are equipped with a pumped rinse system; therefore, a water pressure gauge is not required and is

not supplied with the machine.

The water pressure regulator must have a relief bypass. Failure to use the proper type

of pressure regulator may result in damage to the unit.

A manual shutoff valve (not supplied) should be installed upstream of the ll hose to accommodate

servicing the machine.

It is recommended that a line strainer (not supplied) be installed in the supply line between the manual

shutoff valve (not supplied) and the connection point on the machine. Make plumbing connections with

1

⁄2" minimum copper piping OD (3⁄4" recommended), with a 3⁄4" male garden hose tting (not supplied).

See installation diagrams, pages 14-17.

PLUMBING CONNECTIONS

Plumbing connections must comply with applicable sanitary, safety, and plumbing

codes.

Drain

5

A drain hose,

⁄8" inside diameter and 6' long, is provided. This should be securely plumbed into a

drain. Use care not to kink hose. See installation diagrams, pages 14-17. Drain must have a minimum

ow capacity of 5 gallons per minute.

BEFORE FIRST USE

This machine must be cleaned after installation and before being put into operation. (See Cleaning)

– 8 –

ELECTRICAL CONNECTION

Electrical and grounding connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical codes.

Disconnect the electrical power to the machine and follow lockout/tagout procedures.

ELECTRICAL DATA

Complied in accordance with the National Electrical Code NFPA-70, latest addition.

For supply connections, use copper wire only rated at 90°C minimum.

ledoM esahP/ztreH/stloV

LXGePR 1/06/021

LXGeR

tiucriCylppuSmuminiM

yticapmArotcudnoC

20 20

40 40120/208-240(3W)/60/1*

evitcetorPmumixaM

yticapmAeciveD

*The (3W) systems require three power wires that include a current carrying neutral. An additional

fourth wire must be provided for machine ground.

Refer to the top of the door of the machine and the electrical label on the back side of the lower front

panel for proper selection.

– 9 –

Connection Method

1. Remove the lower front panel by removing the two screws at the bottom of the panel (Fig. 1).

REMOVE TWO SCREWS

Fig. 1

2. Open door of glasswasher and remove the two left screws and the top right screw (Fig. 2). Pull

top of unit forward approximately 1” and remove the left side panel.

REMOVE THREE SCREWS

Fig. 2

– 10 –

3. A hole for 1” trade size conduit is supplied at the lower right in the back of the machine (Fig. 3).

If necessary due to space requirements, remove the knockout and use a 45° tting.

KNOCKOUT

Fig. 3

4. Install 1” trade size conduit and tting. Leave at least four feet of electrical line between wall

connection and machine. This allows machine to be pulled away from the wall for cleaning and/

or servicing.

5. Feed wires thru base of unit to front of unit. At least 24” and not more than 28” of the required

wire size must extend from the end of the conduit tting.

6. Make electrical connections according to wiring diagram supplied with the machine and secure

wires to the machine service connection. Keep excess wire in the base of the unit to a minimum.

7. Replace the left side panel, top of unit, and lower front panel. Re-install the three screws located

behind the door and the two screws at the bottom of the front panel.

DETERGENT AND RINSE AID

Use only commercial-grade detergents recommended by your chemical professional. Do not use

detergents formulated for residential glasswashers.

The detergent and rinse aid pump "ON" times are factory-set. If adjustments are required, contact your

local Hobart Service Ofce or your chemical supplier.

Place the detergent and rinse aid containers (which are obtained from an independent supplier) under

the glasswasher.

Remove the detergent bottle cap and put the red delivery tube in the detergent container by snapping

the bottle connector onto the container.

Remove the rinse aid bottle cap and place the blue delivery tube in the rinse aid container by snapping

the bottle connector onto the container.

Be sure to push the delivery tubes completely to the bottom of each container. Check to make sure

there are no obstructions or kinks in the delivery tubes.

– 11 –

CHEMICAL SANITIZER (LXGePR)

Items such as pewter, aluminum and silver will be attacked by sodium hypochlorite

(bleach). Therefore, chemical-sanitizing glasswashers should not be used to wash such items.

The LXGePR chemical sanitizer pump is factory-set for use with 6% sodium hypochlorite solution.

If 8.40% sodium hypochlorite solution is to be used, contact your local Hobart Service Ofce.

On LXGePR models, place a sanitizer approved for potable water rinse machines under the glasswasher

no higher than 10 inches off the oor. Do not pre-mix sanitizing solution with water or any other liquid.

Never premix a wetting agent with the sanitizing solution. Mixing may cause

hazardous gas to form.

Remove the sanitizer bottle cap and place the white delivery tube in the sanitizer container by snapping

the bottle connector onto the container. Be sure to push the delivery tube completely to the bottom of the

container. Check to make sure there are no obstructions or kinks in the delivery tube.

Frequently check your sanitizer bottle to make sure there is a sufcient chemical supply.

CHECKING SANITIZER CONCENTRATION

Verify there is sufcient chemical supply in the sanitizer bottle and that the delivery tube standpipe is

inserted completely to the bottom of the chemical container. Place a glass rack, with glasses, in the

machine.

On LXGePR models, the PuriRinse feature must be deactivated to properly check the sanitizer concentration.

To deactivate PuriRinse, press and hold the WASH key for ve seconds until wash cycle starts.

Follow the directions precisely that are on the litmus paper vial and test the water on the surface of the

bottom of the glasses. Concentration should be 50 p.p.m. minimum to 100 p.p.m. maximum.

If reading is incorrect, contact your local Hobart Service Ofce or chemical provider for adjustments.

DELIMING SOLUTION

All LXGePR and LXGeR models are equipped with an automatic deliming system. At installation, a

qualied Hobart Service technician or your chemical supplier must adjust the total water hardness

setting to properly set the delime intervals.

Remove the deliming agent bottle cap and put the black delivery tube in the container by snapping the

bottle connector onto the container.

Be sure to push the delivery tube completely to the bottom of the container. Check to make sure there

are no obstructions or kinks in the delivery tube.

– 12 –

PRIMING CHEMICAL PUMPS

When a chemical becomes empty, the priming operation starts automatically the next time the machine

is turned on or a wash cycle is started. Note that the initial prime time for all pumps (Detergent, Rinse

Agent, and Sanitizer) is 60 seconds. If the chemical is not sensed within 60 seconds, the add chemical

indicator will ash. After the chemical is sensed, the indicator in the display turns off; and the pump

continues to prime for 10 seconds to allow the chemicals to reach the machine. If all chemicals are

empty, the sanitizer will prime rst followed by detergent. Only one chemical pump will run at a time.

If chemicals are not sensed after three consecutive priming operations, the add chemical indicator will

ash and priming is cancelled. The next time a wash cycle is started, the add chemical indicator will

continue to ash. Verify that the chemical bottles are not empty and that the delivery tubes are inserted

completely to the bottom of the containers.

The priming operation can be reset by turning the glasswasher off, then back on.

If the chemical bottles are not empty and the delivery tubes are inserted correctly, then the chemical

sensor or pumps may have malfunctioned; contact your local Hobart Service Ofce.

– 13 –

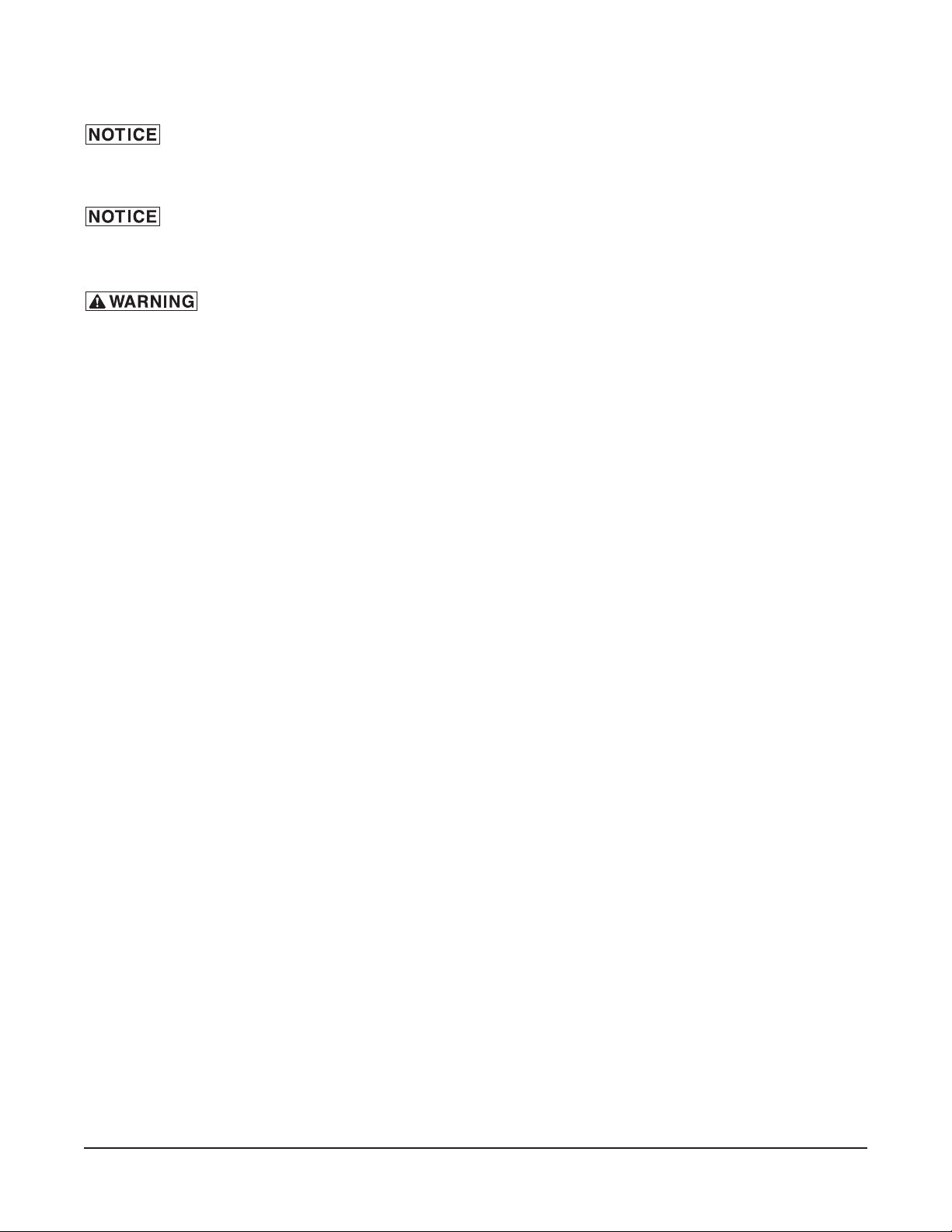

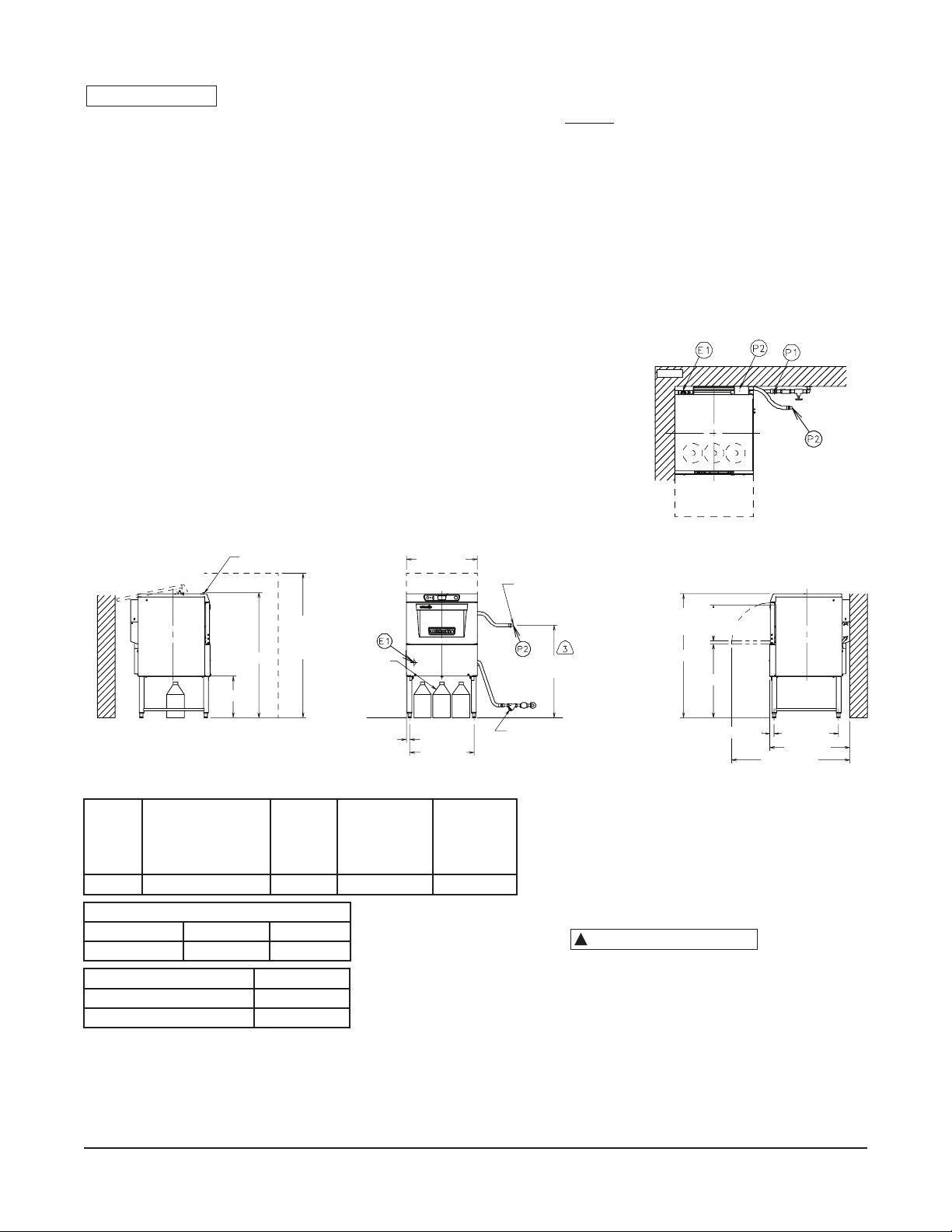

Mixing may cause hazardous gas to form.

Do not pre-mix other chemicals and sodium hypochlorite (liquid bleach).

Required owing water pressure to the dishmachine is 15-65 PSIG. If pressures

higher than 65 PSIG are present, a pressure regulating valve must be installed in the water line to the

dishmachine (by others).

Pressure guage not provided on pumped rinse machines.

Important: The chemical containers should be placed no higher than 16" above oor.

If chemical containers are to be placed in cabinet adjacent to machine, a 1/2" dia. hole is required in

the cabinet to run chemical supply line.

Use only 6% or 8.4% sodium hypochlorite (liquid bleach) as sanitizing chemical to insure proper

operation of dishmachine.

Certain materials including silver plate, aluminum and pewter are attacked by sodium hypochlorite

(liquid bleach).

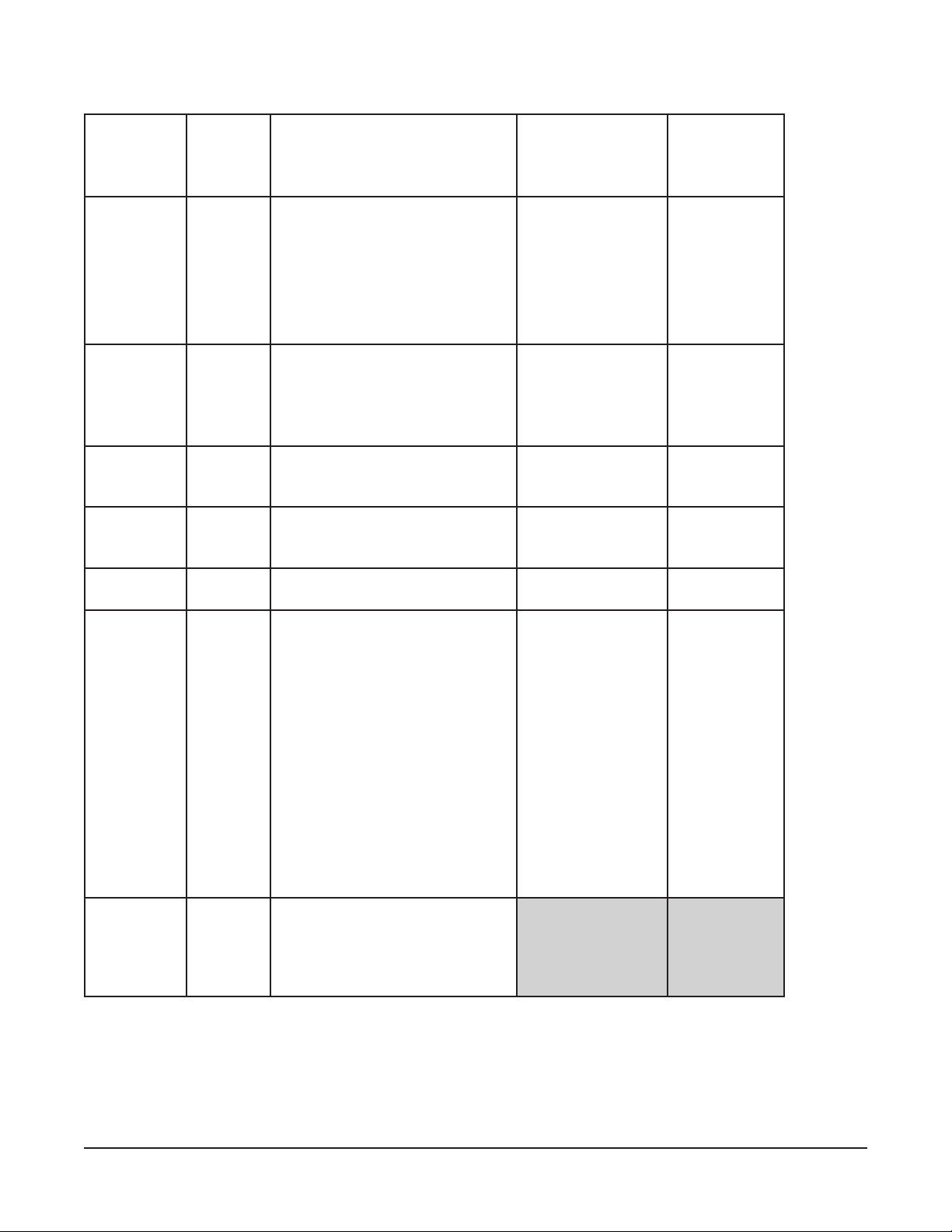

NOTES:

1. All vertical machine dimensions taken from oor may be increased by .875" or decreased by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine since it does not produce

excessive vapors.

PLUMBING NOTES:

1. Water hammer arrestor (meeting ASSE-1010 standard or equivalent) to be supplied (by others) in

common water supply line at service connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 44" AFF.

CONNECTION INFORMATION

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE

FOR 1" TRADE SIZE CONDUIT; 10-5/8" AFF.

P1 SINGLE FILL AND RINSE CONNECTION:

3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE;

120°F WATER MIN. FOR LXGePR, 140°F

RECOMMENDED.

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH

6' LONG HOSE SUPPLIED WITH MACHINE.

MODEL VOLTS/HERTZ/PHASE

LXGePR 120/60/1 15.4 20 20

HEAT OUTPUT, BTU/HR

MODEL LATENT SENSIBLE

LXGePR 1900 800

SHIPPING WEIGHTS LXGePR

NET WEIGHT OF MACHINE 150 LBS

DOMESTIC SHIPPING WEIGHT 170 LBS

RATED

AMPS

MIN SUPPLY

CKT CONDUCT

AMPACITY

MAX

PROTECTIVE

DEVICES

INSTALLATION DIAGRAM (LXGePR, short)

ACCESSORY CORD KITS AVAILABLE FOR ALL MACHINES

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE ONLY

RATED AT 90°C MINIMUM.

Electrical and grounding

connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical

codes.

Plumbing connections must comply with applicable

sanitary, safety and plumbing codes. Drain and ll line

congurations vary, some methods are shown on this

drawing.

– 14 –

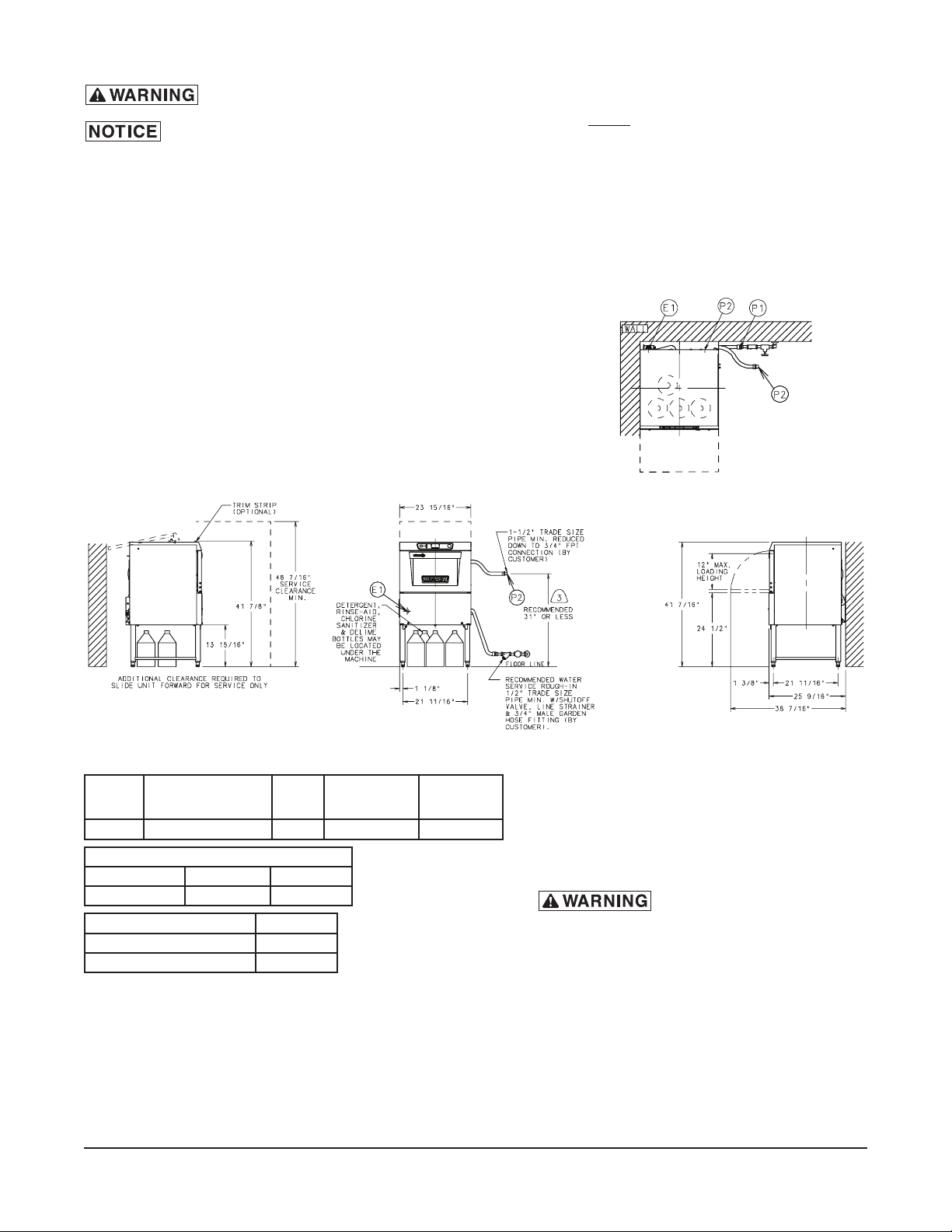

Mixing may cause hazardous gas to form.

Do not pre-mix other chemicals and sodium hypochlorite (liquid bleach).

Required owing water pressure to the dishmachine is 15-65 PSIG. If pressures

higher than 65 PSIG are present, a pressure regulating valve must be installed in the water line to the

dishmachine (by others).

Pressure guage not provided on pumped rinse machines.

Important: The chemical containers should be placed no higher than 24" above oor.

If chemical containers are to be placed in cabinet adjacent to machine, a 1/2" dia. hole is required in

the cabinet to run chemical supply line.

Use only 6% or 8.4% sodium hypochlorite (liquid bleach) as sanitizing chemical to insure proper

operation of dishmachine.

Certain materials including silver plate, aluminum and pewter are attacked by sodium hypochlorite

(liquid bleach).

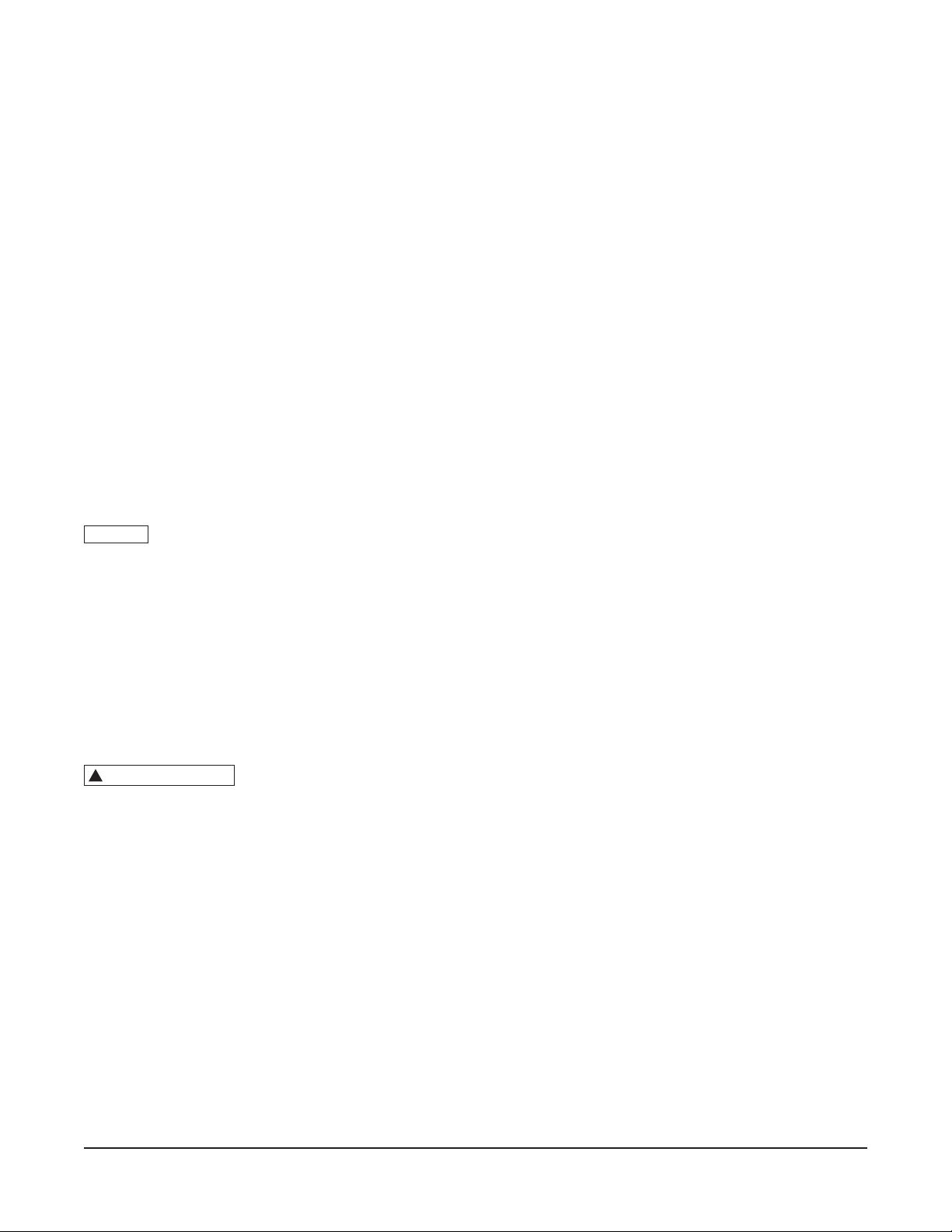

NOTES:

1. All vertical machine dimensions taken from oor may be increased by .875" or decreased by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine since it does not produce

excessive vapors.

PLUMBING NOTES:

1. Water hammer arrestor (meeting ASSE-1010 standard or equivalent) to be supplied (by others) in

common water supply line at service connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 51" AFF.

CONNECTION INFORMATION

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE

FOR 1" TRADE SIZE CONDUIT; 18-1/8" AFF.

P1 SINGLE FILL AND RINSE CONNECTION:

3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE;

120°F WATER MIN. FOR LXGePR, 140°F

RECOMMENDED.

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH

6' LONG HOSE SUPPLIED WITH MACHINE.

MODEL VOLTS/HERTZ/PHASE

LXGePR 120/60/1 15.4 20 20

HEAT OUTPUT, BTU/HR

MODEL LATENT SENSIBLE

LXGePR 1900 800

SHIPPING WEIGHTS LXGePR

NET WEIGHT OF MACHINE 150 LBS

DOMESTIC SHIPPING WEIGHT 170 LBS

RATED

AMPS

MIN SUPPLY

CKT CONDUCT

AMPACITY

MAX

PROTECTIVE

DEVICES

INSTALLATION DIAGRAM (LXGePR, tall)

– 15 –

ACCESSORY CORD KITS AVAILABLE FOR ALL MACHINES

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE ONLY

RATED AT 90°C MINIMUM.

Electrical and grounding

connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical

codes.

Plumbing connections must comply with applicable

sanitary, safety and plumbing codes. Drain and ll line

congurations vary, some methods are shown on this

drawing.

higher than 65 PSIG are present, a pressure regulating valve must be installed in the water line to the

Required owing water pressure to the dishmachine is 15-65 PSIG. If pressures

dishmachine (by others).

Pressure gauge not provided on pumped rinse machines.

If chemical containers are to be placed in cabinet adjacent to machine, a 1/2" dia. hole is required in

the cabinet to run chemical supply line.

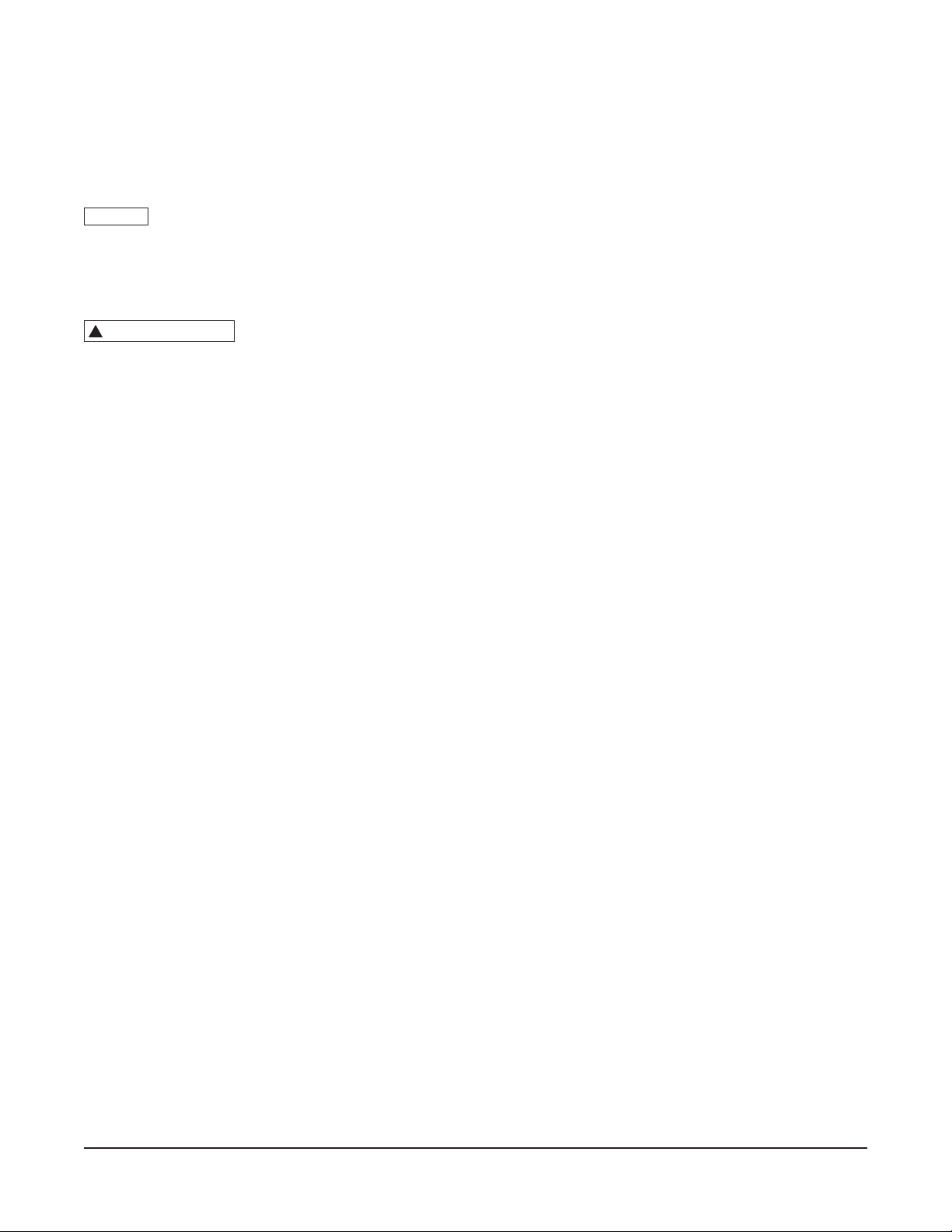

NOTES:

1. All vertical machine dimensions taken from oor may be increased by .875" or decreased by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine since it does not produce

excessive vapors.

PLUMBING NOTES:

1. Water hammer arrestor (meeting ASSE-1010 standard or equivalent) to be supplied (by others) in

common water supply line at service connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 44" AFF.

CONNECTION INFORMATION

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE

FOR 1" TRADE SIZE CONDUIT; 10-5/8" AFF.

P1 SINGLE FILL AND RINSE CONNECTION:

3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE;

55-85°F (COLD) RECOMMENDED FOR LXGeR.

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH

6' LONG HOSE SUPPLIED WITH MACHINE.

MODEL VOLTS/HERTZ/PHASE

LXGeR 120/208-240(3W)/60/1* 30.5 40 40

HEAT OUTPUT, BTU/HR

MODEL LATENT SENSIBLE

LXGeR 1100 2000

SHIPPING WEIGHTS LXGeR

NET WEIGHT OF MACHINE 165 LBS

DOMESTIC SHIPPING WEIGHT 185 LBS

RATED

AMPS

MIN SUPPLY

CKT CONDUCT

AMPACITY

PROTECTIVE

DEVICES

INSTALLATION DIAGRAM (LXGeR, short)

MAX

– 16 –

* THIS SYSTEM REQUIRES THREE POWER WIRES WHICH INCLUDES

A CURRENT CARRYING NEUTRAL, AN ADDITIONAL FOURTH WIRE

MUST BE PROVIDED FOR MACHINE GROUND.

ACCESSORY CORD KITS AVAILABLE FOR ALL MACHINES

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE ONLY

RATED AT 90°C MINIMUM.

Electrical and grounding

connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical

codes.

Plumbing connections must comply with applicable

sanitary, safety and plumbing codes. Drain and ll line

congurations vary, some methods are shown on this

drawing.

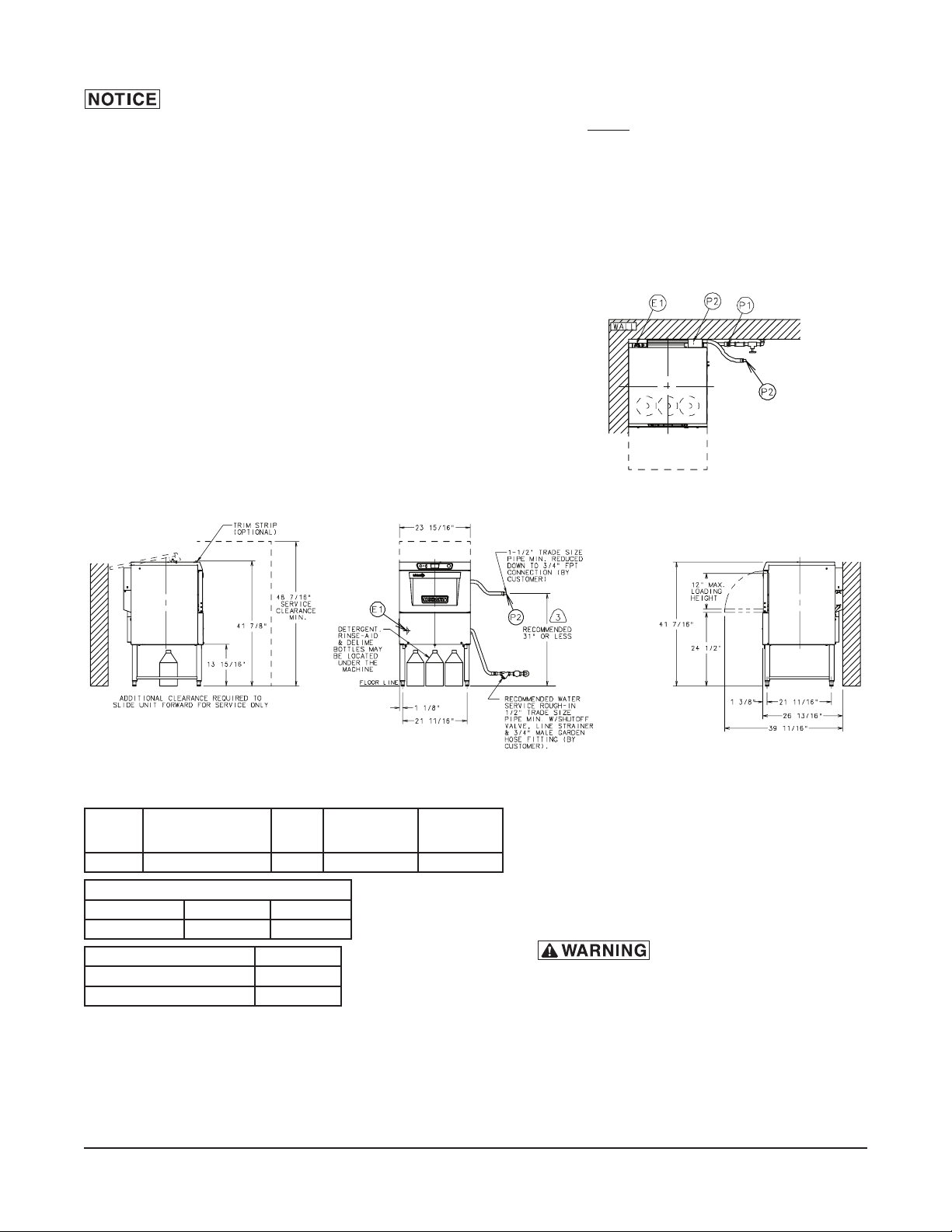

higher than 65 PSIG are present, a pressure regulating valve must be installed in the water line to the

Required owing water pressure to the dishmachine is 15-65 PSIG. If pressures

dishmachine (by others).

Pressure gauge not provided on pumped rinse machines.

If chemical containers are to be placed in cabinet adjacent to machine, a 1/2" dia. hole is required in

the cabinet to run chemical supply line.

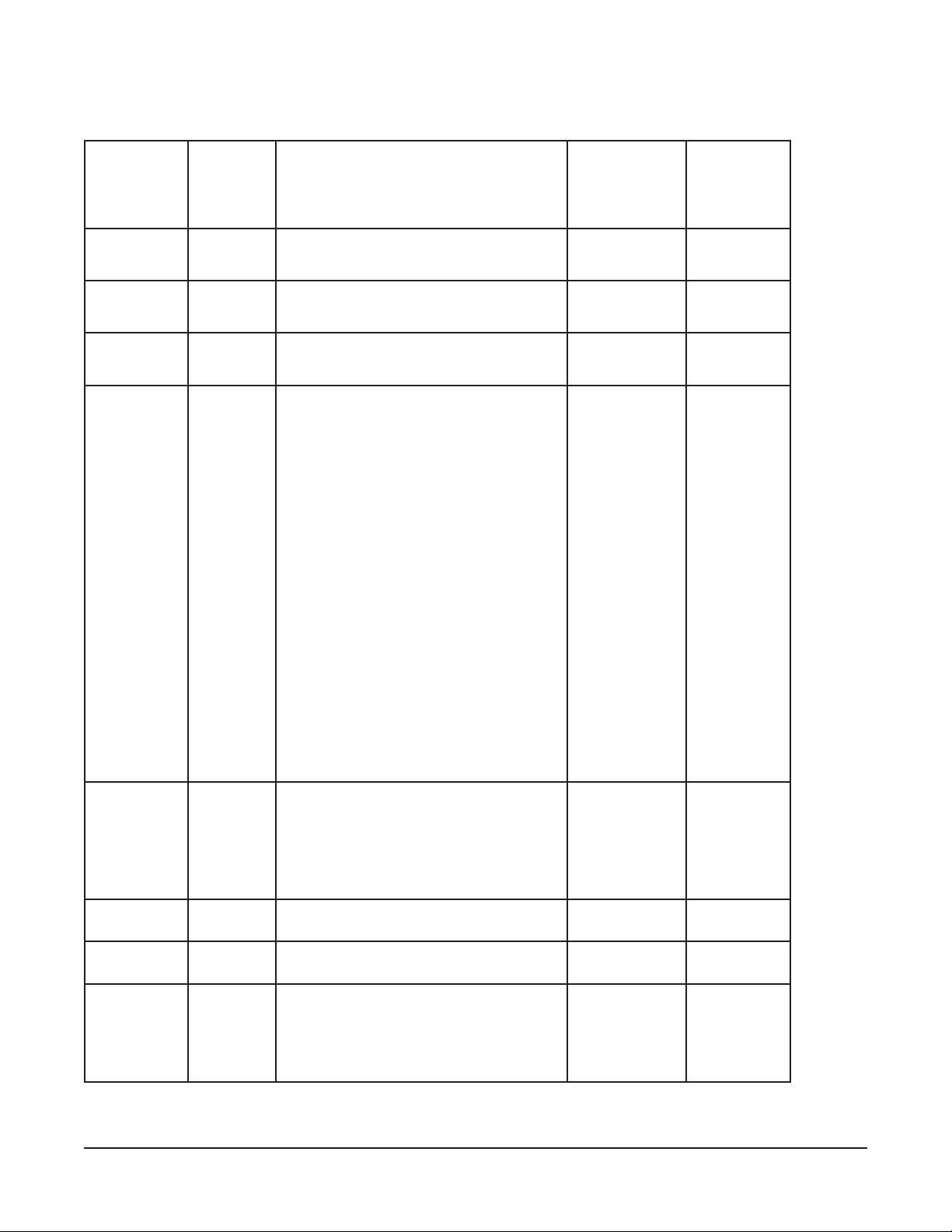

NOTES:

1. All vertical machine dimensions taken from oor may be increased by .875" or decreased by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine since it does not produce

excessive vapors.

PLUMBING NOTES:

1. Water hammer arrestor (meeting ASSE-1010 standard or equivalent) to be supplied (by others) in

common water supply line at service connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 51" AFF.

CONNECTION INFORMATION

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION: 1-3/8" DIA. HOLE

FOR 1" TRADE SIZE CONDUIT; 18-1/8" AFF.

P1 SINGLE FILL AND RINSE CONNECTION:

3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE;

55-85°F (COLD) RECOMMENDED FOR LXGeR.

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH

6' LONG HOSE SUPPLIED WITH MACHINE.

MODEL VOLTS/HERTZ/PHASE

LXGeR 120/208-240(3W)/60/1* 30.5 40 40

HEAT OUTPUT, BTU/HR

MODEL LATENT SENSIBLE

LXGeR 1100 2000

SHIPPING WEIGHTS LXGeR

NET WEIGHT OF MACHINE 165 LBS

DOMESTIC SHIPPING WEIGHT 185 LBS

RATED

AMPS

MIN SUPPLY

CKT CONDUCT

AMPACITY

PROTECTIVE

DEVICES

INSTALLATION DIAGRAM (LXGeR, tall)

MAX

– 17 –

* THIS SYSTEM REQUIRES THREE POWER WIRES WHICH INCLUDES

A CURRENT CARRYING NEUTRAL, AN ADDITIONAL FOURTH WIRE

MUST BE PROVIDED FOR MACHINE GROUND.

ACCESSORY CORD KITS AVAILABLE FOR ALL MACHINES

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE ONLY

RATED AT 90°C MINIMUM.

Electrical and grounding

connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical

codes.

Plumbing connections must comply with applicable

sanitary, safety and plumbing codes. Drain and ll line

congurations vary, some methods are shown on this

drawing.

PROGRAMMING

MANAGER MODE PROGRAMMING

The LXGe series glasswasher’s microprocessor allows customization options for machine operation.

To activate or change these features, the programming edit mode must be entered.

The manager programming mode requires a MANAGER CODE to be entered to access the options

listed in the PARAMETERS MENU. The manager code is 1001.

PROGRAMMING INSTRUCTIONS

All customization is performed through the on-screen menu using the UP Arrow, MENU/DOWN Arrow,

and the ENT keys located on the keypad at the top of the machine (Fig. 4).

Fig. 4

MENU DISPLAY PROMPTS

The following prompts are used inside the menus:

• The UP arrow and MENU/DOWN arrow keys are used to change parameter values and to navigate

the menu.

• The ENT key is used to accept a value, to perform a specied action, or to enter a submenu.

• The text just to the right of the '>' symbol on the display screen shows what action or command

will occur if the ENT key is pressed.

– 18 –

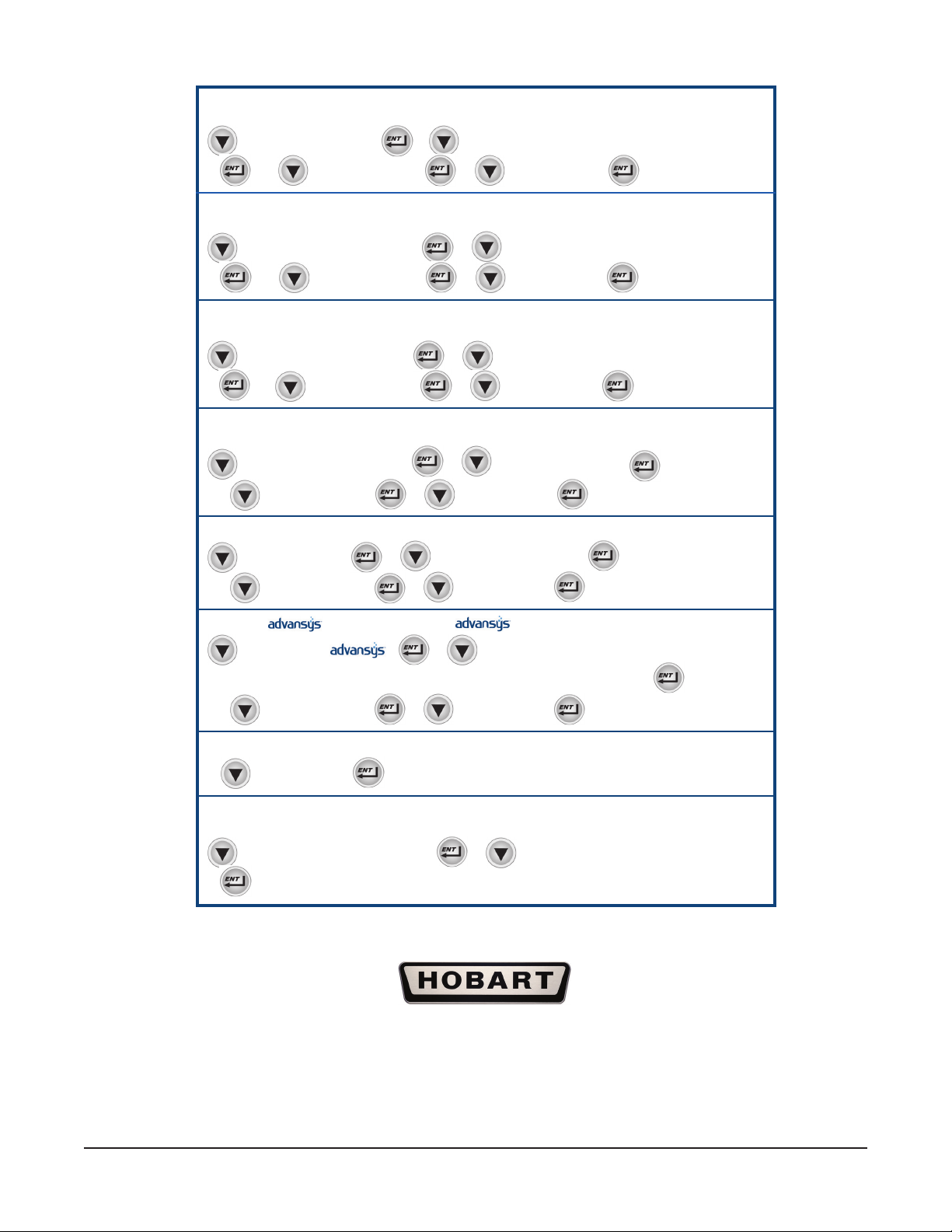

Manager Mode

UNDERCOUNTER

Programming Card

CHANGING PARAMETERS ENTER MANAGER SECURITY CODE: 1001

MANAGER MENU

➜

(for 0)

➜

➜ ➜

(for 1)

ENTER SECURITY CODE

Edit Parameters

➜

(for 1)

➜

CHANGING PARAMETERS IS REQUIRED TO CHANGE ALL CODES BELOW

CHEMICAL PUMP

until DETERGENT PUMP or RINSE AID PUMP

➜

➜

OR

➜

enable or disable the detergent pump or rinse aid pump.

➜ ➜

until EXIT MENU

➜ ➜

until EXIT

to enable or disable

➜

WASH CYCLE allows the customization of total run time.

until CYCLE TIME

➜

until EXIT MENU

➜ ➜

➜ ➜

until EXIT

to choose cycle,

➜

➜

OR

➜

LOW TEMP ALARMS for hot machines only: (parameter) enables or disables alert indicating

that the final rinse temperature has been below the minimum temperature for a period of time.

OR

➜

until LOW TEMP ALARMS

➜

until EXIT MENU

➜ ➜

➜ ➜

to enable or disable

until EXIT

➜

➜

WASH ARM ALARM enables or disables an alarm that alerts the operator that the wash arms

may be clogged or blocked.

➜

until WASH ARM ALARM

➜

OR

➜

➜ ➜

until EXIT MENU

➜ ➜

to disable, Visual, or Audio & Visual

until EXIT

➜

DELIME enables or disables the delime reminder alert.

OR

➜

until DELIME

➜

➜ ➜

until EXIT MENU

➜ ➜

to enable or disable

until EXIT

➜

➜

TEMPERATURE UNITS allows the choice of Fahrenheit or Celsius.

until TEMPERATURE UNITS

➜

➜

OR ➜

➜ ➜

until EXIT MENU

➜ ➜

to choose Fahrenheit or Celsius

until EXIT

➜

POTABLE RINSE for cold machines only enables or disables the potable water rinse option.

OR

➜

until POTABLE RINSE

➜

until EXIT MENU

➜ ➜

➜ ➜

to enable or disable

until EXIT

➜

➜

– 19 –

DIRTY WATER INDICATOR disables or gives a choice of how many cycles the machine will

run between dirty water alert and refresh cycles.

until DIRTY WATER INDICATOR

➜

➜ ➜

to Disable, 20 cycles, 40 cycles,

or 60 cycles

➜

OR ➜

until EXIT MENU

➜ ➜

until EXIT

➜

ENERGY SAVER MODE disables or gives choice of how many hours before the unit will

stay on before entering energy saving mode.

until ENERGY SAVING MODE

➜

➜

OR ➜

➜ ➜

until EXIT MENU

➜ ➜

to Disabled, 1 Hour, 2 Hours, or 3 Hours

until EXIT

➜

ADD CHEMICAL ALERT enable or disable the audio alert of missing chemicals.

OR

➜

until ADD CHEM AUDIO ALERT

➜

until EXIT MENU

➜ ➜

➜ ➜

to enable or disable

until EXIT

➜

➜

END CYCLE AUDIO ALERT enable or disable the unit creating an audio alert at the end of

each wash cycle.

OR

➜

until END CYCLE AUDIO ALERT

➜

until EXIT MENU

➜ ➜

➜ ➜

to enable or disable

until EXIT

➜

➜

LANGUAGE allows the choice of English, French or Spanish language.

OR

until LANGUAGE

➜

until EXIT MENU

➜

➜ ➜

➜ ➜

to English, French or Spanish

until EXIT

➜

➜

of options.

until BUTTON

➜

➜ ➜

One Normal Wash, One Heavy Wash (LXe only), Run Delime Cycle, or Energy Saver

OR

until EXIT MENU

➜

➜

➜

EXIT MENU TO MAIN MANAGER MENU

until EXIT MENU

➜

➜

to: Clean Sump, One Light Wash,

until EXIT

➜

➜

DELIME NOW allows for a single delime cycle to be run from the menu at anytime.

BUTTON allows the customization of the button to be used for a variety

Note: this operation takes 20-45 minutes depending on conditions.

until DELIME NOW

➜

➜ ➜

to YES or NO

➜

(this will exit menu)

701 South Ridge Avenue, Troy, OH 45374-0001

– 20 –

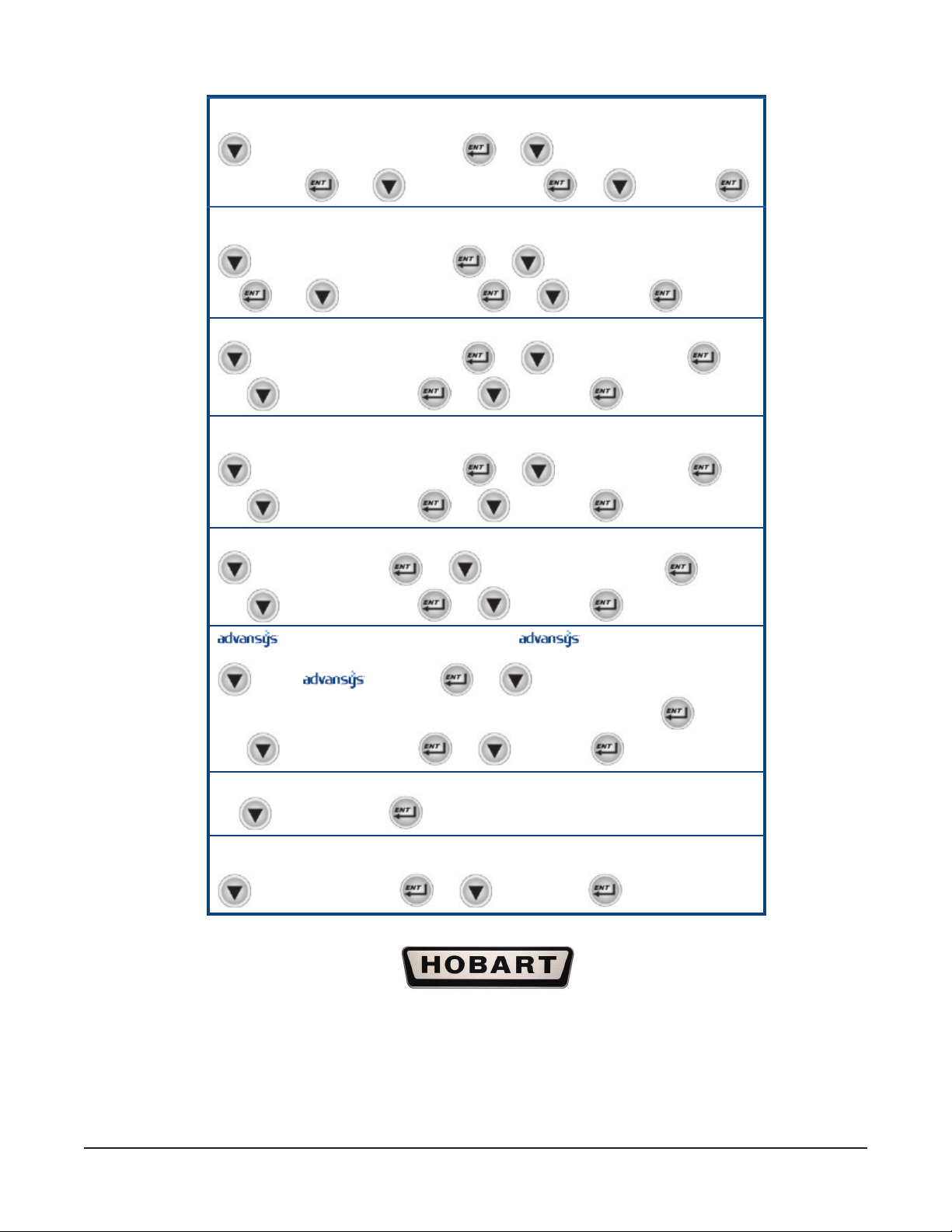

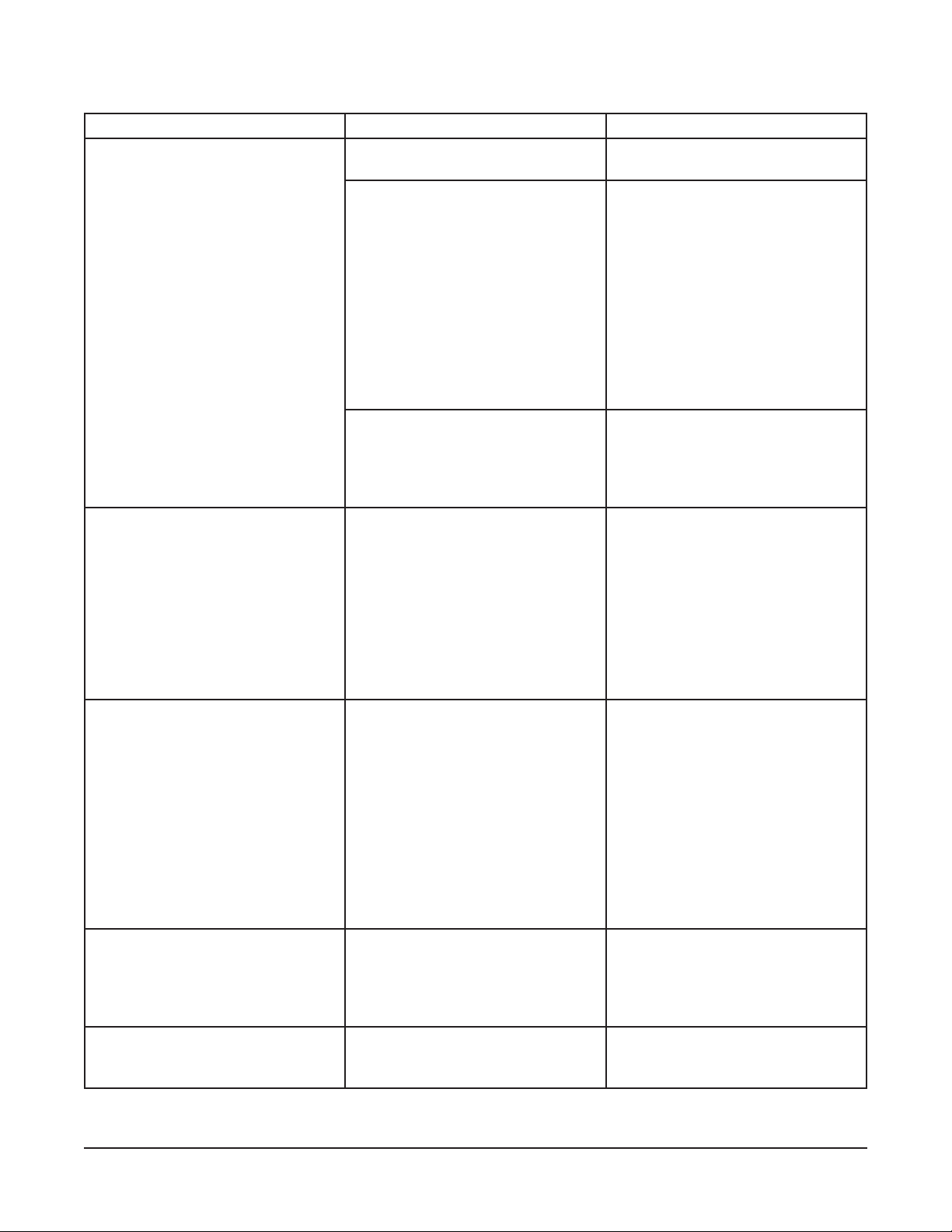

Parameter

Name

Advansys

Models

(LXGePR,

LXGeR)

PARAMETERS MENU TABLE

Description

Possible

Values

Default

Value

Detergent

Pump

Rinse Aid

Pump

Wash Cycle

Low Temp

Alarms

Wash Arm

Alert

Delime

Temperature

Units

Potable Rinse

✓

✓

✓

LXGeR

Only

✓

✓

✓

LXGePR

Only

Enables or disables the detergent pump.

Enables or disables the rinse aid pump.

Sets the cycle duration. Light or Normal Light

Enables or disables a visual alert on the

display that indicates that the Final Rinse water

temperature is below the required minimum of

180°F (82°C). When enabled, a message will

display notifying the user of this condition after

three consecutive cycles do not reach the required

nal rinse temperature. However, machine

operation will not change and ware will continue

to wash as expected. After the temperature

increases past the minimum, the message stops.

When disabled, there will be no extra message

indicating a low temperature event; however, the

temperature display will still show the current Final

Rinse water temperature.

Enables Visual Alert, Audio and Visual Alert,

or disables an alert that is displayed when the

machine detects a wash arm that is clogged or

blocked such that ware wash results could be

affected.

Enables or disables the alert to delime option.

Sets the display units to either Fahrenheit or

Celcius.

On LXGePR machines, this setting enables or

disables the PuriRinse option that sprays fresh

water after the sanitization cycle to remove the

sanitizer from the ware.

Disabled or

Enabled

Disabled or

Enabled

Disabled or

Enabled

Disabled,

Visual, or

Audio and

Visual

Disabled or

Enabled

Fahrenheit or

Celcius

Disabled or

Enabled

Enabled

Enabled

Disabled

Disabled

Enabled

Fahrenheit

Enabled

– 21 –

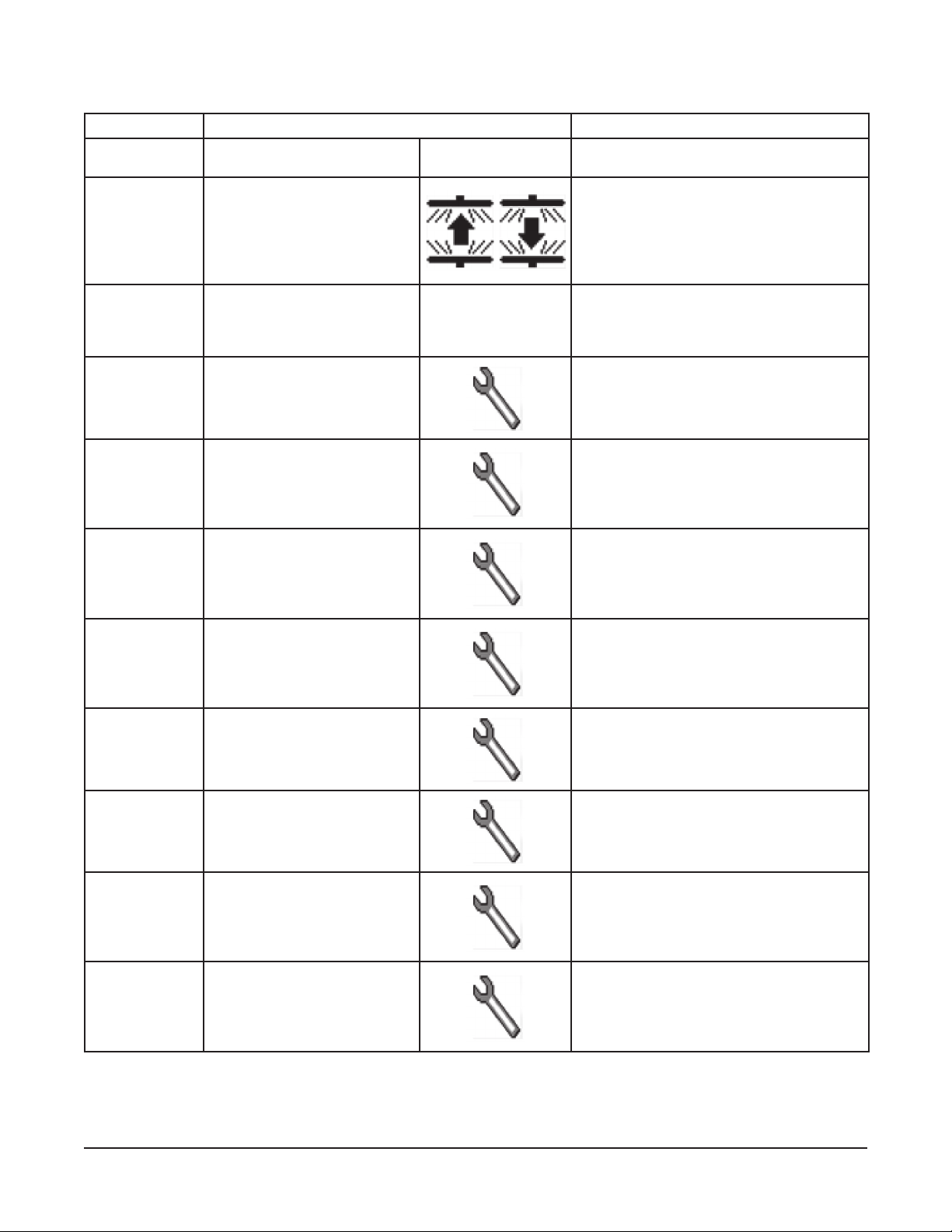

Parameter

Name

Dirty Water

Indicator

Energy Saver

Mode

Add Chemical

Alert

End Cycle

Audio Alert

Language

Advansys

Button

Advansys

Models

(LXGePR,

LXGeR)

✓

✓

✓

✓

✓

✓

Description

On Advansys machines, this setting allows for

a reminder for the operator to be notied that 20,

40, or 60 cycles have passed and a special water

refresh cycle is recommended. This cycle will

drain a portion of the wash water and refresh it

with fresh hot water.

On Advansys machines, this setting will control

when the machine will turn the heaters off in order

to save energy when not in use.

Enables or disables an audible alert if chemical is

not being detected.

Enables or disables an audible alert at the end of

a cycle.

Sets the language on the display to either English

or French.

Choose function for Advansys button.

Possible

Values

Disabled,

20, 40, or 60

cycles

Disabled, 1, 2,

or 3 hours

Disabled,

Visual, or

Audio and

Visual

Disabled or

Enabled

English (US)

or French

(Canada)

1. Not

programmed

2. Clean the

sump

3. One light

wash

4. One normal

wash

5. Run delime

cycle

6. Energy

saver

Default

Value

Disabled

2 hours

Audio and

Visual

Disabled

English (US)

Not

Programmed

From

Factory

Exit Menu

✓

Press ENT to exit the Parameters Menu and

return to the Manager Menu. Any settings that

were changed are saved.

– 22 –

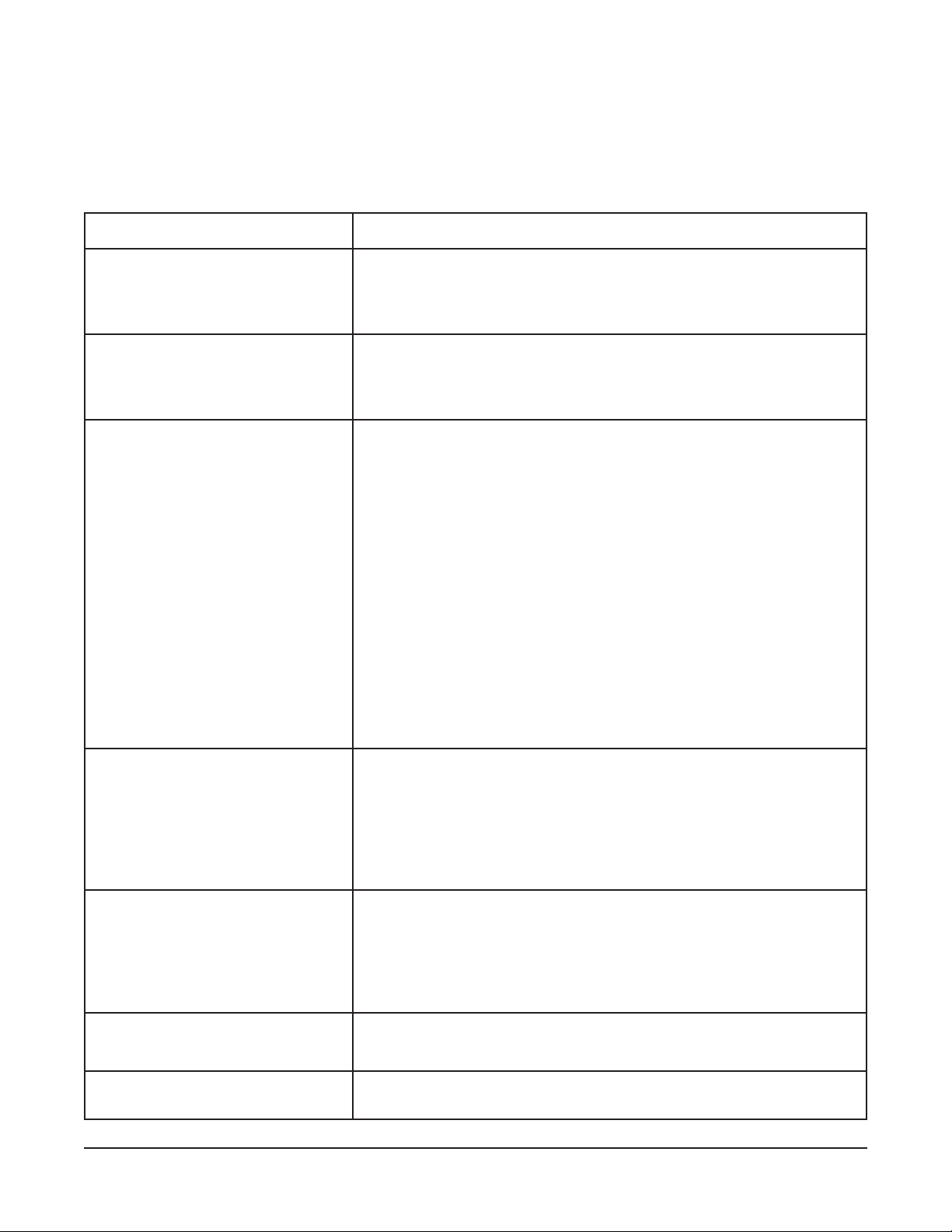

OPERATING THE LXGe GLASSWASHER

DO THIS DISPLAY SHOWS REMARKS

Press ON. Model number. Glasswasher performs self-

check. This takes 5 seconds.

FILL and ll icon lit; sump temperature displayed when ma-

chine is lling.

Glasswasher lls with water.

When lled, pump turns on for

10 seconds.

WARMING UP and warming up

icon are displayed when booster

is preheating on models LXGeR.

This preheat could take up to

15 minutes.

During ll, sump temperature is

displayed.

Open door; slide rack of dishes

into glasswasher. Close door.

Press WASH. WASH and wash icon lit; sump

READY lit and sump temperature displayed.

temperature displayed during

wash cycle.

RINSE and rinse icon lit; rinse

temperature displayed during

rinse cycle.

If door is opened during ll

cycle, ll will stop. After door is

closed, the process continues

where it stopped.

When lled, machine will maintain an idle state. Heat is maintained in both sump and/or

booster.

Detergent will be added automatically during wash cycle.

Rinse Aid and Sanitizer will be

added automatically during rinse

cycle. (NOTE: Sanitizer only

used on LXGePR models.)

Machine initiates a wash and

rinse cycle.

If door is opened during wash,

rinse, or drain cycle, cycle will

continue at point where door

was opened upon closing door.

When cycle is complete, reload

machine for next wash/rinse

cycle; or, if not in use, machine

will maintain idle mode.

At the end of the day, press

POWER.

READY lit and sump temperature displayed.

DRAIN and SHUTDOWN IN

PROGRESS are displayed; then

the display shuts down.

– 23 –

If POWER is pressed during

cycle, machine will drain and

shut down.

Machine will drain and shut

down if the four hour idle shutdown time is reached.

When POWER key is pressed,

machine will drain and shut

down.

DIAGNOSTIC/ERROR MESSAGES

Error Display Description

Door Open Door Open

WASH ARM ALERT

Clogged/

Blocked Wash

Arm

Low Rinse

Temperature

Low Rinse

Temperature

(10 In A Row)

Wash

Thermistor

Error

Booster

Thermistor

Error

Final Rinse

Thermistor

Error

- Remove & clean arm

- Check nozzles

- Replace arm

- Close door

LOW RINSE TEMP

LOW RINSE TEMP

Check Water Input

WASH TEMP SENSOR

Service Required

(Service Phone Number)

OPEN or SHORT

BOOSTER TEMP SENSOR

Service Required

(Service Phone Number)

OPEN or SHORT

RINSE TEMP SENSOR

Service Required

(Service Phone Number)

OPEN or SHORT

Displayed when the door of the machine

is opened.

Displayed if wash arm is blocked or

clogged which would result in poor wash

results. Follow on-screen instructions.

After two consecutive low temperatures,

if problem occurs on the third

consecutive cycle, the error will display.

The machine will continue to run cycles.

If the Low Rinse Temperature error

occurs for 10 consecutive cycles, the

error will change. The machine will

continue to run cycles.

Error displayed if wash temperature

probe is out of range. The machine will

continue to run cycles.

Error displayed if booster temperature

probe is out of range. The machine will

continue to run cycles. (LXGeR only)

Error displayed if nal rinse temperature

probe is out of range. The machine will

continue to run cycles.

Low Water In

Booster (Time

Out Within Any

Cycle)

Drain Error

Sump Level

Error

Booster Level

Error

FILL ERROR

Service Required

(Service Phone Number)

DRAIN ERROR

Service Required

(Service Phone Number)

SUMP LEVEL SENSOR

Service Required

(Service Phone Number)

OPEN or SHORT

BOOSTER LEVEL SENSOR

Service Required

(Service Phone Number)

OPEN or SHORT

Error displayed if the unit times out

before the unit is completely lled. The

machine will not operate and will only

allow power down.

Error displayed if the water level in the

unit will not come up. The machine will

not operate and will only allow power

down.

Error displayed if sump pressure switch

is out of range. The machine will not

operate and will only allow power down.

Error displayed if booster pressure switch

is out of range. The machine will not

operate and will only allow power down.

– 24 –

WASH/RINSE CYCLE TIMES (LXGePR) WASH/RINSE CYCLE TIMES (LXGeR)

COARSESTRAINER

FINESTRAINER

Wash 56 Seconds ** Wash 56 Seconds *, **

Drain 18 Seconds Max Drain 18 Seconds Max

Rinse 8 Seconds Rinse 8 Seconds

Dwell 10 Seconds Dwell 5 Seconds

PuriRinse 7 Seconds Condense 105 Seconds Max

* Maximum wash time may vary, depending on operation voltage and incoming water temperature

for 70

°F rise on LXGeR machines.

** Wash cycle time can be adjusted to a 56- or 85- second cycle.

PREPARATION

Make sure the coarse (Fig. 6) and ne (Fig. 7) strainers are in place and free of debris. Ensure that the

coarse strainer is installed with the handle towards the front of the machine. Check both wash arms

and rinse arms to make sure they spin freely and are not clogged.

Fig. 6 Fig. 7

– 25 –

Check to see if any detergent, rinse aid or sanitizer chemicals need to be replenished. Use only

commercial-type detergents, as prescribed by your chemical professional.

DO'S AND DON'TS FOR YOUR NEW HOBART GLASSWASHER

DO assure proper water hardness.

DO prescrape dishes thoroughly.

DO use only detergents recommended by your chemical professional.

DO at the end of the day, thoroughly clean the machine, rinse and dry. (Leave door open.)

DO use only products formulated to be safe on stainless steel.

DO NOT use detergents formulated for residential glasswashers.

DO NOT allow food soil to accumulate on the tank bottom.

DO NOT exceed chemical manufacturer's recommended concentrations for detergent, sanitizer, rinse

aid or lime scale remover.

DO NOT use steel wool to clean ware or glasswasher surface.

DO NOT allow foreign objects to enter the unit, especially metallic contaminants.

– 26 –

CLEANING

This machine must be cleaned at least once each working day. Use only products formulated to be safe

on stainless steel.

1. Press POWER. The machine will drain. When the display is no longer lit, open the door and remove

any debris from the bottom of the tank. Do not allow food soil to accumulate on the tank bottom.

2. Remove the lower rinse arm by pressing in on the buttons located on the sides of the center hub

and pull off (Fig. 8). Remove the lower wash arm by pulling the arm off the shaft. Remove the

upper rinse and wash arms in the same manner. Remove the coarse and ne strainers (see Figs.

6 and 7). Thoroughly clean these items in a sink. Remove debris from wash/rinse arm nozzles.

RINSE ARM

CENTER HUB

BUTTONS

LXGePR & LXGeR

Fig. 8

3. With a damp cloth, wipe the interior of the machine. DO NOT use steel wool. Wipe the exterior

of the machine. Remove any remaining debris with a mild cleanser formulated for stainless steel

and a soft cloth or brush.

4. Replace the ne and coarse strainers. Reinstall the lower wash arm by pushing it down on the

shaft. Press in on the buttons located on the sides of the center hub, place the rinse arm on the

shaft, and release. Spin arms to make sure they spin freely. Repeat this procedure with the upper

wash and rinse arms.

5. Use a soft, damp cloth or sponge and mild cleanser to clean the control keypad and display. DO

NOT use abrasive or harsh cleaners or scouring pads.

6. Leave the door ajar overnight to allow the interior to air out and dry. The door design allows for

the door to remain partially open and can be used to vent the machine at the end of the day.

– 27 –

MAINTENANCE

Maintenance and regular care is important to maintain optimal results with your Hobart glasswasher.

DELIMING

Deliming solution, rinse agents or any other kind of acid must not come in contact

with bleach or rinse solution containing bleach used in chemical-sanitizing machines. Mixing

may cause hazardous gas to form. This entire procedure must be followed step by step for safe

and satisfactory results.

Do not allow the deliming agent to remain in the machine longer than recommended by the

deliming agent manufacturer.

DELIME THE GLASSWASHER ON A REGULAR BASIS AS REQUIRED. The regularity will depend

on mineral content of the supply water. Deliming should be done when you can see clear signs of lime

deposits (a white, chalky substance) on the inside walls and on the wash arms. All LXGe glasswashers

are equipped with an automatic delime cycle reminder and are equipped with an internal delime pump

which will automatically pump the required amount of deliming agent into the unit.

If deliming is necessary, a deliming agent (such as Lime-A-Way ® or LSR ®) should be used for best results.

After the preprogrammed number of cycles has expired, the control will indicate the delime request

by displaying DELIME RECOMMENDED and will prompt ‘Would you like to delime now?’. You must

enter ‘Yes’ or ‘No’ to proceed with a delime cycle or to continue with normal machine operation. If ‘No’

is selected, the machine will continue to notify the operator at each start-up and power down until the

delime cycle is completed. To delime the unit:

1. Press the MENU/DOWN Arrow key until the ‘>’ symbol is shown to the left of ‘Yes’ and press the

ENT key.

2. Remove dish rack from machine.

3. Remove strainers from machine and clean. Replace strainer, empty rack and close door.

4. Ensure delimer chemical container is not empty. Be sure to push the delivery tube standpipe

completely to the bottom of the container. Check to make sure there are no obstructions or kinks

in the delivery tube.

5. Press ENT key to enter the delime mode. The machine will drain and rell with fresh water.

6. The unit will automatically enter the wash mode for 10 minutes, then will begin two rinse and drain

operations after the ll cycle is complete.

7. After the deliming operation is completed, power to the control will be turned off.

8. Inspect the interior of the machine for lime deposits. If necessary, another delime cycle can be

initiated by entering the Manager Programming Mode.

LUBRICATION

The pump motor has permanently sealed bearings and requires no lubrication.

– 28 –

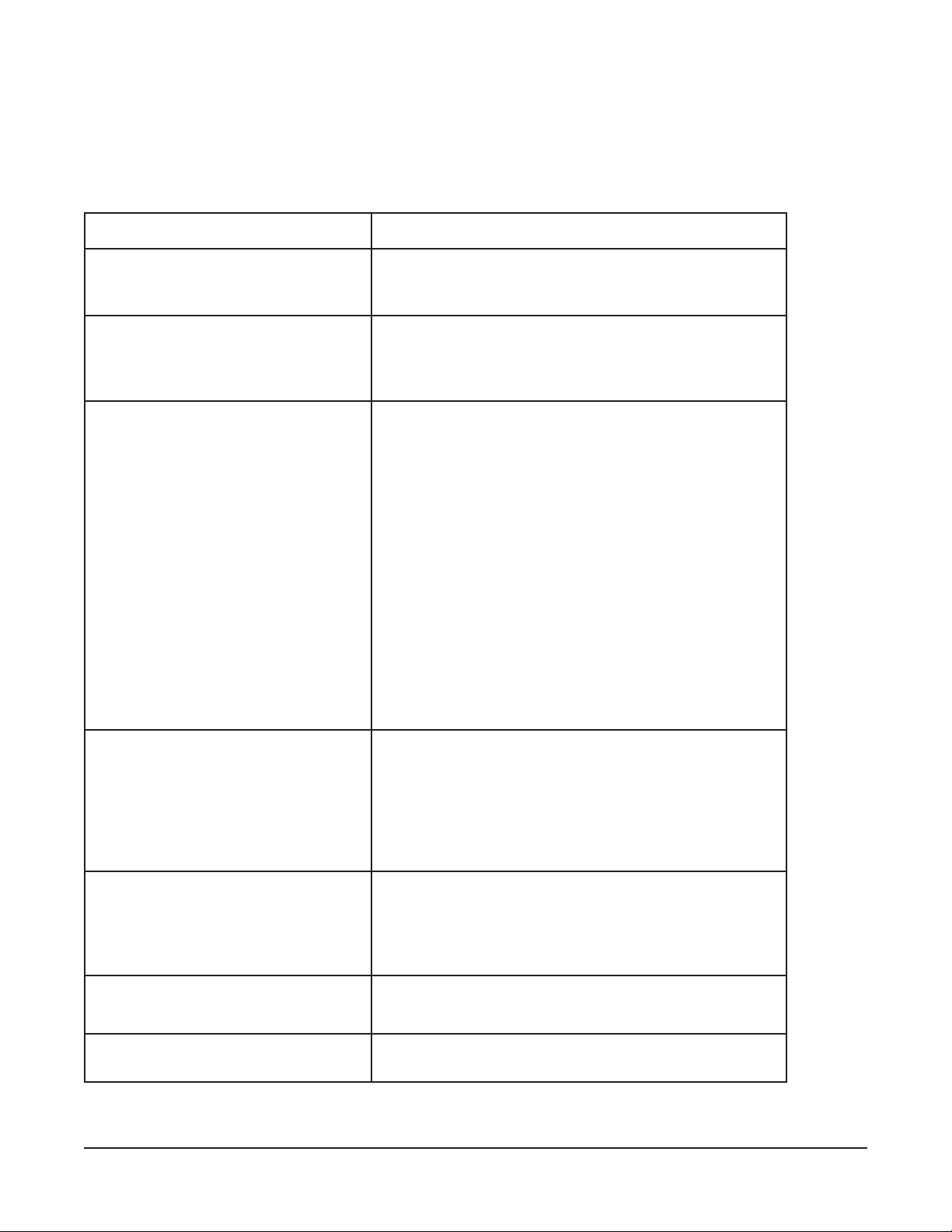

TROUBLESHOOTING

This section outlines various symptoms and possible causes that may be encountered in the event of

abnormal machine operation. If symptoms persist after possible causes have been checked, service

may be required.

Symptom Possible Causes

No machine operation (no display). 1. Machine OFF - turn machine ON.

2. Blown fuse or circuit breaker off at power supply.

3. Cord not plugged in (corded models only)

No machine operation (with display). 1. Display: "DOOR OPEN" - open and close door. If

problem persists, contact your local Hobart Service

Ofce.

2. See "Machine will not ll or will not ll high enough".

Glasses not clean. 1. Strainers clogged causing inadequate water supply

to pump - clean according to instructions. (See

CLEANING.)

2. Obstruction in wash arm(s) or wash arms will

not turn - clean according to instructions. (See

CLEANING.)

3. Wash and/or rinse arms will not turn - check that

they spin freely.

4. Detergent dispenser may be clogged.

5. Soil quantity - scrape dishes before cycle.

6. Improper rack loading. (See PREPARATION.)

7. Low water - check water supply.

8. Water temperature too low - note wash temperature

on display during WASH; should be above 120°F for

chemical sanitizing machines and above 150°F for

high temperature machines.

9. Incoming water supply turned off.

Spotting of silverware, glasses, or

dishes.

Chemicals not feeding. 1. Low on chemicals - check levels.

Food soils remain in glasswasher.

Appearance of rust in machine. 1. Ensure steel wool is not used to clean machine.

1. Improperly loaded racks.

2. Water temperature too low.

3. Improper type or concentration of detergent contact your chemical representative.

4. Hard water - install a water softener; use a rinse

agent.

5. Insufcient ll - check water supply.

2. Air leak at feeder hose connections - check insertion

of quick connect ttings and wire ties at tube to tube

connections.

3. Tubes kinked - check for smooth bends.

Follow daily cleaning instructions. (See CLEANING.)

2. May be due to high iron content in water supply.

– 29 –

Symptom Possible Causes

Unexpected results on

glasses or other ware.

Low temperature readings. 1. Low water supply temperature - make sure it meets

1. Etching - usually caused by any combination of high

temperatures, soft water, soft glass, or high alkaline

washing solutions.

2. Tarnishing - avoid washing silver, silver plates, and

pewter in chemical sanitizing machines.

3. Pitting - stainless steel may pit with lengthy contact

of foods containing salt, fruit juices, vinegar, etc.

Wash immediately.

4. Black or gray marks - may have been rubbed with

aluminum.

5. Brown stains - may be due to high iron content in

water supply.

6. Chipping - improper loading or glasses are too

delicate.

7. Wooden ware damage - avoid washing in glasswasher.

8. Rust on cast iron - seasoning is lost in glasswasher.

Avoid washing in glasswasher.

9. Plastic ware distortion - high temperatures. Check

plastic ware's instructions.

the recommended minimum temperature.

2. Rapid cycle use - if incoming water temperature is

low and cycle use rate is high, the hot water supply

may be insufcient to meet the demand.

3. Heavy ware load cools wash water - do not overload

racks.

4. Booster heater or sump heater set low - contact your

local Hobart Service Ofce.

Machine will not ll or will not

ll high enough.

Machine lls too high or

leaks from door.

Machine will not drain. 1. Drain pipes restricted - check glasswasher drain line

Some water occasionally drips out

of rinse arms (high temperature

glasswashers only).

1. Low water pressure - check for clogged hose

strainer; ensure the site water pressure meets

minimum ow pressures.

2. No water ow - main water supply valves may not be

working.

1. Machine not level. (see LEVELING.)

2. Fill solenoid valve leaking - power the glasswasher

OFF; if water continues to ow into the machine,

contact your local Hobart Service Ofce.

for kinks; ensure proper drain rate is allowed from

plumbing.

2. Power machine OFF. Wait several seconds and

then power back ON. Repeat this procedure twice

if necessary. If problem persists, contact your local

Hobart Service Ofce.

This is normal due to expansion of water being heated in

the booster tank.

– 30 –

Installation, fonctionnement et entretien des

LAVE-VERRE DE LA GAMME LXGe

CONSERVEZ CE MODE D’EMPLOI

DESCRIPTION GÉNÉRALE

Les lave-verre de la gamme LXGe sont entièrement automatiques à chargement frontal. Les lave-verres

de la série LXGe sont capables de traiter entre 24 et 38paniers à l’heure.

Dans le but de conserver l’énergie, tous les lave-verre de la gamme LXGe s’arrêtent

automatiquement 4 heures après la dernière utilisation.

Tous les lave-verre de la série LXGe sont équipés du surchauffeur Sense-A-Temp

température d’eau chaude adéquate lors du rinçage.

Les appareils sont livrés de série avec un panier pour verres à vin, des commandes électroniques,

une pompe de vidange, une pompe de rinçage, des doseurs de produits chimiques, un boyau de

remplissage et un boyau de vidange.

MODÈLE DESCRIPTION

LXGePR Ce sont des modèles à assainissement chimique fonctionnant à basse

température et dont le rinçage se fait à l’eau fraîche; l’agent d’assainissement

est une solution d'hypochlorite de sodium à 6% (javellisant). REMARQUE:

si vous devez utiliser un javellisant à 8,4%, veuillez contacter le Service de

l’entretien Hobart ou votre fournisseur de produits chimiques pour modier les

réglages du doseur d’assainissement (il se peut qu’il y ait des frais).

LXGeR Rinçage à l’eau fraîche avec un surchauffeur intégré capable d’élever

la température de 70°F (39°C). Cela permet une température d’eau de

distribution à 110°F (43°C)

MD

assurant une

* - L’agent d’assainissement doit être utilisé en conformité avec les directives de l’étiquette EPA enregistrée.

– 31 –

INSTALLATION

DÉBALLAGE

Aussitôt après avoir déballé le lave-verre, vériez si des dommages peuvent être survenus lors de

l’expédition. Si cet appareil a été endommagé, conservez le matériel d’emballage et contactez le

transporteur dans les 15jours suivant la livraison.

EMPLACEMENT

Avant l’installation, assurez-vous que la source électrique concorde avec les spécications de la

plaque signalétique de l’appareil qui se trouve au-dessus de la porte.

Pendant l’utilisation normale, il se peut que de la vapeur s’échappe par la porte. Les bois stratiés,les

placages, etc. sont des matériaux inadéquats pour utilisation dans des endroits exposés à lavapeur

d’un lave-verre et aux détergents. Il est recommandé d’utiliser de l’acier inoxydable ou un autre

bouclier résistant à l’humidité sur les surfaces à proximité des côtés et du dessus de l’appareil LXGe.

MISE DE NIVEAU

Pour bien fonctionner, l’appareil doit être mis de niveau. Placez le lave-verre à l’endroit où il doit

être utilisé. Mettez l’appareil de niveau avant de faire quelque raccordement que ce soit. À l’aide

d’un niveau de charpentier posé en diagonale sur les rails du panier, mettez l’appareil de niveau de

l’avant vers l’arrière et d’un côté à l’autre en vissant ou dévissant les pieds réglables.

BESOINS EN EAU

Une bonne qualité d’eau peut améliorer les performances de lavage en réduisant les taches, en

rehaussant l’efcacité du travail et en augmentant la durée de vie de l’appareil. Les conditions de

l’eau varient d’un endroit à l’autre. Le système de traitement d’eau approprié à recommander pour

une utilisation efcace et efciente de cet équipement variera lui aussi selon les conditions de l’eau

locale. Avant l’installation, demandez les détails sur la condition de l’eau locale à votre fournisseur

d’eau municipal.

La dureté d’eau recommandée est de 3grains par gallon US (20,58ppm) ou moins. Une dureté d’eau

plus élevée peut être cause d’une formation excessive de calcaire. Une dureté d’eau au-dessus de

3grains/gal US (20,58ppm) exige que l’eau soit traitée. Il a été démontré que le traitement de l’eau

réduit les coûts reliés au nettoyage du lave-verre, diminue le détartrage du lave-verre, de même que la

quantité de détergent utilisée.

ATTENTION Une source d’eau à haute teneur en fer peut causer des taches et peut rendre

nécessaire la mise en place d’un système de ltration du fer. Un niveau de chlorure élevé dans l’eau peut

être cause de piqûres et il peut être nécessaire d’installer un système de traitement des chlorures.

Pour une eau traitée adéquatement, consultez votre professionnel local de traitement de l’eau.

Les sédiments peuvent nécessiter un ltre spécial. Les matières dissoutes peuvent exiger un

traitement d’eau, tel qu’un adoucisseur, un système à osmose inversée, etc. Pour une eau traitée

adéquatement, consultez votre professionnel local de traitement de l’eau.

Si l’inspection du lave-verre ou du surchauffeur révèle une accumulation de calcaire après que

l’équipement ait été mis en service, le traitement de l’eau est recommandé. S’il y a déjà un

adoucisseur d’eau en place, assurez-vous que le niveau de sel est sufsant. Contactez le bureau

Hobart de votre région pour des recommandations particulières.

– 32 –

Un antibélier (conforme à la norme ASSE-10 ou équivalent) devrait être mis en place (par un tiers)

dans la conduite d’alimentation de l’eau générale au point de raccordement.

Le plombier qui raccorde cet appareil est responsable de s’assurer que les conduites d’eau SOIENT

PARFAITEMENT RINCÉES AVANT de les raccorder au lave-verre. Ce «rinçage» est nécessaire pour

retirer toutes les matières étrangères, telles que les copeaux provenant de la coupe ou du letage

des tuyaux et la pâte à joint dans les conduites; ou, si des joints soudés sont utilisés, les débris du

soudage ou du coupage des tuyaux. Les débris qui n’auraient pas été retirés peuvent venir se loger

dans les composants de la plomberie du lave-verre et les rendre inopérants. Les robinets manuels

ou électromagnétiques endommagés par des corps étrangers et tous les frais qui en résulteraient ne

sont PAS la responsabilité du fabricant et ne sont pas couverts par la garantie.

Les besoins en alimentation d’eau sont les suivants:

MODÈLE TEMPÉRATURE

LXGePR Minimale 120°F (49°C)

LXGeR Minimale 55°F (12,7°C), maximale 85°F (29°C)

REMARQUE: quand il s’agit d’une installation d’un appareil LXGeR et si la température de

l’alimentation d’eau froide se situe systématiquement au-dessus de 80°F (26,7°C) ou si des

vapeurs d’eau ou de la vapeur pénètrent dans la salle après la n du cycle de condensation,

contactez le Service de l’entretien de Hobart pour faire relever le temps de condensation.

La pression dynamique requise de l’eau au lave-verre est de 15 à 65lb/po² (103,4kPa à 448,1kPa).

Si des pressions supérieures à 65lb/po² (448,1kPa) sont présentes, il faut installer un régulateur de

pression sur la conduite d’eau de distribution au lave-verre (par un tiers). Si la pression dynamique est

inférieure à 15lb/po² (103,4kPa), un mauvais fonctionnement de l’appareil peut se produire. Tous les

lave-verre LXGe sont dotés d’un système de rinçage par pompage; un manomètre de pression n’est

donc pas nécessaire et n’est pas livré avec l'appareil.

ATTENTION Le régulateur de pression doit être équipé d’un dispositif de dérivation. La

non-utilisation d’un type de régulateur adéquat peut entraîner des dommages à l’appareil.

Un robinet d’arrêt manuel (non livré) devrait être installé en amont du boyau de remplissage pour

faciliter l’entretien de l'appareil.

Il est recommandé d’installer un ltre à tamis (non livré) sur la conduite d’alimentation d’eau

entre le robinet d’arrêt manuel (non livré) et le point de raccordement de l’appareil. Il faut faire les

raccordements avec un tuyau de cuivre d’un diamètre extérieur minimal de ½po (12,7mm) [¾po

(19mm) recommandé] et un raccord de boyau d’arrosage mâle de ¾po (19mm) (non livré). Voir les

schémas d’installation aux pages14 et 17.

RACCORDEMENTS DE PLOMBERIE

!

AVERTISSEMENT

Les raccordements de plomberie doivent se faire en conformité avec

les codes d’hygiène, de sécurité et de plomberie en vigueur.

Vidange

Un boyau de vidange d’un diamètre interne de 5/8po (15,8mm) et d’une longueur de 6pi (1829mm)

est livré avec l’appareil. Il devrait être raccordé solidement à un point de vidange. Faites attention de

ne pas entortiller le boyau. Voir les schémas d’installation aux pages14 et 17. Le système de vidange

doit avoir une capacité d’écoulement de 5gal US/minute (18,9l/m).

– 33 –

AVANT LA PREMIÈRE UTILISATION

Cette machine doit être nettoyée après l'installation et avant de la mettre en marche. (vous reporter

àNettoyage)

CONNEXIONS ÉLECTRIQUES

!

Les connexions électriques et de mise à la terre doivent être conformes

AVERTISSEMENT

aux sections pertinentes du Code national de l’électricité et de tous les autres codes électriques

en vigueur.

Déconnectez le courant électrique à l’appareil et observez les normes

!

AVERTISSEMENT

de verrouillage et d’étiquetage.

DONNÉES ÉLECTRIQUES

En conformité au Code national de l’électricité NFPA-70, édition la plus récente.

Pour les connexions à la source, n’utilisez que du l de cuivre d’une capacité

ATTENTION

nominale minimale de 90°C.

Modèle Volts/Hertz/Phase Courant minimal admissible du

circuit d’alimentation (Ampères)

LXGePR 120/60/1 20 20

LXGeR

120/208-240(3F)/60/1* 40 40

Courant maximal admissible du

dispositif de protection (Ampères)

*Les systèmes (3F) exigent 3ls d’alimentation comprenant un l neutre sous tension. Un quatrième

l supplémentaire est nécessaire pour la mise à la terre de l’appareil.

Pour une sélection adéquate, veuillez vous référer au dessus de la poignée de la porte de l’appareil

et à l’étiquette électrique se trouvant au dos du panneau inférieur avant.

– 34 –

Méthode de connexion

1. Enlevez le panneau inférieur avant en retirant les deux vis au bas du panneau (g.1).

REMOVE TWO SCREWS

RETIREZ LES DEUX VIS

Fig.1

2. Ouvrez la porte du lave-verre et retirez les deux vis de gauche et la vis en haut du côté droit

(g.2). Tirez le dessus de l’appareil vers l’avant pour qu’il sorte d’environ 1po (25,4mm) et

enlevez le panneau latéral gauche.

RETIREZ LES TROIS VIS

REMOVE THREE SCREWS

Fig.2

– 35 –

3. Un trou d’une grosseur commerciale de 1po (25,4mm) est percé du côté droit inférieur à

l’arrière de l'appareil (g.3). Si le manque d’espace l’exige, retirez la débouchure et utilisez un

raccord de 45°.

KNOCKOUT

DÉBOUCHURE

Fig.3

4. Installez un raccord de conduit de la taille commerciale de 1po (25,4mm). Laissez une longueur

de l d’au moins quatre pieds (1210mm) entre la connexion murale et l’appareil. L'appareil peut

ainsi être tiré du mur pour procéder au nettoyage ou à l'entretien.

5. Passez les ls à travers la base jusqu’à l’avant de l’appareil. À partir du raccord de conduit, la

longueur de l requise doit être d’au moins 24po (600mm) et ne pas dépasser 28po (710mm).

6. Faites les connexions électriques selon le schéma de câblage livré avec l’appareil et xez les

ls au point de connexion de l’appareil. L’excédent de l dans la base de l'appareil doit être le

plus court possible.

7. Remettez en place le panneau latéral gauche, le dessus et le panneau inférieur avant. Revissez

les trois vis situées derrière la porte et les deux vis au bas du panneau inférieur avant.

DÉTERGENT ET AGENT DE RINÇAGE