Page 1

SERVICE

MANUAL

KltchenAide

KD-18

MODEL

KDC-18

KDI-18

KDPKDS-18

(Dishwasher-Sink Combinations)

KDC-38 34076

KDS-38 34077

KDC-58

KDI-58

KDS-58

SERIES-AUTOMATIC

DISHWASHERS

ML

("Built-In"

34074

34073

34162

18

34072

(Convertible-Portable Models)

34112

34111

34110

DESCRIPTION

Models)

Custom

Imperial

Patrician /

Superba

Custom

Superba

Custom

Imperial

Superba

KITCHENAID

DIVISION

TROY,

OHIO

45374

Page 2

Air Gap & Fill Tube - - Constant Wash/Rinse System Control Panel -

--

Cycle Description (Operation)

Detergent Dispenser

Door Latch Mechanism

-------------------

----

--

- - -

------

--

-------

--

- -

------

---

--

---Door Seal Gasket

Door Springs

Drain Pump

Drain Valve

---

--

- -

- - -

--

--

--

--

----

--

-----

---

--

--

- -

--------

-----

------

----

- -

------

Electrical Cord

Evaporation Channel

Field Wiring

Fill Valve - -

Flo-Thru Drying Assy.

Grounding Screw

Reel

----

Compartment

----------

----

----------Indicator Light Assembly - Inner Door Assy.

Kickplate Adjustment

Lower Door Baffle Lower

Middle

Mo~r -----

Front

Wash

Panel

System ----

-------------

Outer Door Panel

------------

------

--

- -

--------

---

- Overfill Control Switch Overfill Protection Float Standpipe

Program Switch

-------

- - -----Pump and Shaft Seal Installation

Rinse Agent Dispenser

Self-Cleaning Filter Service Tips

Sheath Heater

----

--

- ----

Tank Seal Assembly

------

-----

------

-----

--

-------

- -

--

-----

- - - - -

----

Thermostat & Thermal Protector -

Timen - -

Timer Sequence Charts

Upper Rack Track

Wiring Harnesses Wuh

Wiring Diagrams

----

Pump--------

-

-----------

------------

---

-----

----

-------------

- -

---

--------

--

----------

---

- -

INDEX

--

- - - - - -

--

--

----

-

---------

- - -

-----

--

- - -

---------

-

--

- -

--

----

------

-------

--

--------

----

---

----------

- -

-----

- -

------

-

--

-------

--

--

-

--

- - -

-----

--------

-----

- -

------------

----

--------

- - - - - -

----

--

-------

--

- -

-----

--

---

----

-

--------

- -

--------

--

-

--

- - - -

- ---- - -

--

--

- - - - - - -

--------

---------------------

- - -

---

- - - - ---- -

- -

-----

-

--------

---

- -

---------

-------

------

---

---

- -

- -

- -

------------

- - - -

--

---

---

---

-

-----

- - - -

- -

-

--------

------

- - - - - -----

- -----

- - - -

- -

---------

-------

----

--

----

- -

----

- -

--

------

-------------

-------

----

---

- -

-----

--

- -

----

-----

------

- --------

----

-

-------------

------

---

- -

-

---

--

-

---

-

-----

- -

--

-

--

------

-----

--

---

--

--

--

---

---

- -

-----

--~---

-

--

- - - - - - -

---

--

--

-

----

--

------

- -

-

---

-----

--

-

---

---

-

---

-----

Page

21

20

12

10

23

22

23

15

18

14

24

-

-

14

14

15

17

14

22

-

22

15

23

12

20

20

12

16

16

22

18

23

21

-

27

21

24

-

16

12

36

23

21

18

32

Page 3

SELL

SfiWice

...

SERVICE

SeUb

Page 4

GENERAL

MODEL

This service

for

basic KD-18 dishwasher, designed

for which panels

may

lations (Fig.

vided

EXPLANATION

manual

the

KD-18 series dishwashers. This includes

be

ordered

I).

with

each

provides service

(with

various finishes)

and

added

Installation

of

these

options.

to

instructions

information

the

to

be

"Built-in";

and

kits

suit various instal-

are

pro-

INFORMATION

There

"convertible-portable"

built-in

instructions.

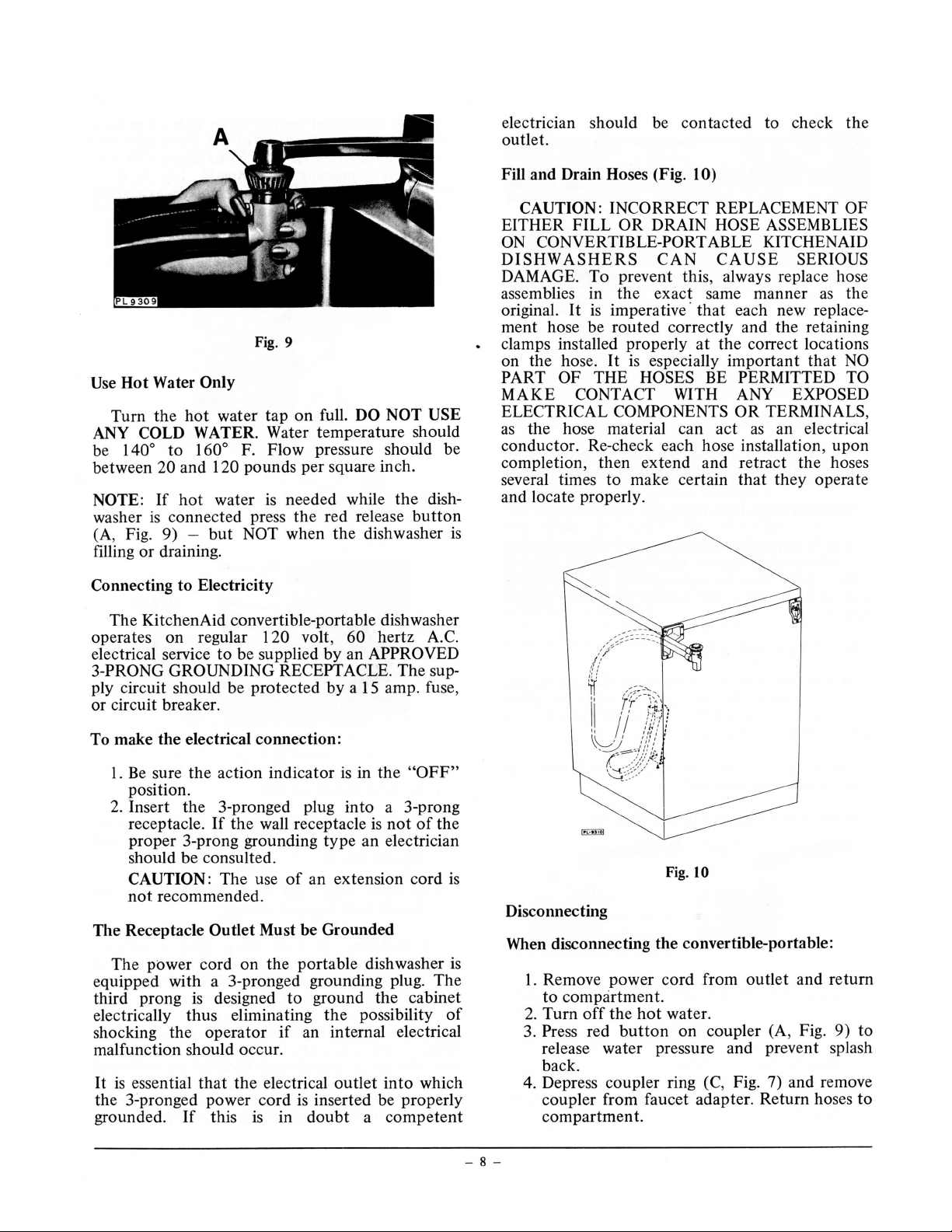

All KD-18 series dishwashers have

tergent

"Sanitized

separate

chamber

phase

are also KD-58 models (Fig.

at a later

dispensers,

Flo-

Thru

fan

and

circulate

of

each

cycle..

dishwashers. These

date,

using KD-18 conversion

pump-out

Drying"

heating

heated

element

air during

3),

which are

may

automatic

drain systems

systems (Fig. 4

outside

the

the

"Dry"

be

de-

and

).

A

wash

In

addition,

is

the

same

cabinet-sink

Fig.

1

there

is

a KD-38

KD-18 dishwasher installed in a

combination.

Fig. 2

model

(Fig. 2), which

Fig. 3

Th

e KDS

upp

er rack , with

both

Cycle as

A rinse agent dispenser may

KDI

optional

also

a

one

divide

upper

"Superba"

a rinse agent dispenser and a

standard

"Imperia

equipped

position

rs.

rack

l" and KDC

feature. The KDI

with a Soak'n

The

KDC

with

model

"stay-put" flex-a-divide

equipment.

"Custom"

upper

rack

"Custom"

fixed dividers.

has a

sixteen

be

added

"Imperial"

Wash Cycle

with

"stay

has a

I PL-139951

position

rs

and

Soak'n

models, as an

-put" fl

one

Scrub

to

both

the

models are

and

have

ex-a-

position

- 5 -

Page 5

A small items basket

"Superba"

the

Imperial and Custom models.

All

KD-18 models are equipped with energy saver

and KDP "Patrician".

is

standard with the KDS

It

is

optional

feature.

on

Protection against over filling

overfill control switch

that

shuts

is

provided by an ·

off

current

to

the

water fill valve when the water in the wash

chamber exceeds a predetermined level.

STARTING

INSTANT START - in all KD-18 series

KitchenAid front-loading dishwashers the cycle

selected and

1.

Oosing

the

the

unit

door.

is

started by:

is

Fig. 4

AUTOMATIC PROTECTION FEATURES

All

KD-18 series dishwashers are equipped with

KitchenAid designed motors, featuring overload

protection with

automatic

become overheated

automatically

...

. starting again when this con-

reset. Should

or

overloaded,

it

the

will

motor

stop

dition has been relieved.

The "Sanitized Flo-Thru Drying" system (Fig.

is

equipped with a thermal safety

prevent overheating. The sheath heater,

KDS

"Superba"

protection (a thermal

rarily open and

when

temperature

NOTE: The sheath

hot

water heater. Hot water, from 140°

models , has

automatic

protector

cut

off

all voltage

reaches a preset limit).

heater

is

NOT a

protector

(1,

which will

to

the

substitute

4)

to

Fig.

4)

overheat

tempo-

heater

for a

to

160°

F., must be supplied to the dishwasher for best

dish washing results.

2. Latching

the

door

by pushing the handle

down.

the

3. Pushing

All

built-in models start instantly. The SUPERB A

desired Cycle Selector Button.

and PATRICIAN models have Action Indicator

(1,

Lights

located

the dishwasher progresses through a cycl

will appear above the word indicating the part

the cycle in which

operating.

reason, such

dishwasher action may be resumed at this

closing and latching

originally selected Cycle Selector

dition,

have a "Rinsed

side

Fig. 5) (KDP). Once

been selected, this light will come

door

This light shows

NOT been washed,

Latching

ation will

handle remains in

Fig. 5) (KDS) and ( 4, Fig. 5) (KDP) are

on

the left side

If

the cycle

as

adding an additional item , the

of

the

the

door, then

the Control Panel.

dishwasher

is

interrupted

re-pushing the

Button

the

of

SUPERBA

Only"

the

Control Panel (2 , Fig. 5) (KDS) and (3,

and

PATRICIAN models

light, located

the

"Rinse-Hold" cycle has

on

is

unlatched until

the

the

handle, following "Rinse-Hold" oper-

tum

"Off'

the

another

operator

but

only rinsed and held.

the light,

cycle

that

the dishes have

as

latched position.

As

e,

a light

of

is

then

for any

point

by

. In ad-

on

the right

whenever the

is

selected.

long

as

the

The IMPERIAL model has an Indicator Light

on

the

located

shown)

On

both

that

the

right side

glows

IMPERIAL and CUSTOM models, the

Action Indicator

gresses and points

the dishwasher

is

to

knob

to

then

of

the Control Panel

indicate

rotates

the

part

operating.

"Power

of

On".

as

the

cycle pro-

the cycle in which

(not

STARTING CONVERTIBLE-PORT ABLE

MODELS

door

A built-in

of

the dishwasher until

interlock switch prevents operation

latched and a cycle

not

will

operate when

the

door

is

closed and

is

activated. The dishwasher

the

door

is

open.

l.

Load dishwasher, close and latch the door.

2. Connect hoses

to

grounded

to

sink faucet and power cord

outlet.

(See electrical in-

structions for detailed description). Allow a

-

6-

Page 6

Fig.

5

few seconds after plugging in power cord (for

timer

to

reset itself).

3.

Turn

on water.

3.

Pull

hoses and coupler from hide-away com-

partment

attach

7) by depressing

adapter

at

the

back

of

the

coupler (B, Fig. 7) to

outer

adapter

ring (C, Fig. 7).

and coupler are joined, release

ring which snaps upward for snug fit.

dishwasher and

(A, Fig.

Wh

en

outer

4. Then push the desired Cycle Selector

and

the

dishwasher will start instantly.

CONVERTIBLE-PORT

ABLES

Button

KD-58 convertible-portable models are essentially built-in dishwashers with portability features

added.

and an electrical outlet before

They

must be connected

to

they

the

sink faucet

can

"do

the

dishes".

Connecting

An

has an

necessary

with

external

If

the

other

Faucets

to Sink

adapter

aerator

to

adapter

adapters

with

Faucet

kit, furnished with

faucet

connect

or

internal threads.

cannot be used

the

adapter

coupler

on

as required.

External Threads (Fig.

the

dishwasher

with all parts

to

most

faucets

the

faucet , use

6)

Faucets

with Internal Threads (Fig. 8)

I. Remove faucet aerator.

2.

Screw faucet

(D

&

then

to

3.

Connect

F, Fig. 8)

adapter

faucet.

hoses and coupler

faucet with external threads.

Fig. 7

Fig. 8

(E, Fig. 8) with washers

to

adapter

(G, Fig. 8)

as

described for

and

PL9306

Fig. 6

I. Remove faucet aerator.

2. Screw

adapter

(A, Fig.

faucet.

6)

furnished in kit,

to

- 7 -

CAUTION:

IF

THE

ATTACHMENT, IT MAY

RESULT

LARLY

There

is

them in

that

this spray

and

the

obtained

hose

that

OF

BACK

IF

IT IS OLD.

no

need

to

pre-rinse dishes before placing

the

dishwasher.

attachment

hole closed with a chrome plug

locally.

Or

replace with a new and stronger

will withstand

SINK HAS A

BURST

SPRAY

AS A

PRESSURE, PARTICU-

It

is

suggested therefore ,

hose be disconnected

or

the

back pressure.

cap,

Page 7

electrician should be contacted to check

outlet.

the

Fig. 9

Only

Water

Hot

Use

Turn the

ANY COLD

to

140°

be

and

between

NOTE:

washer

20

hot

If

connected press

is

(A, Fig. 9) -

draining.

or

filling

water tap on full.

hot

WATER. Water temperature should

F. Flow pressure should be

160°

120 pounds per square inch.

needed while

water

is

the

when the dishwasher

NOT

but

DO NOT USE

the

red release

button

Connecting to Electricity

The KitchenAid convertible-portable dishwasher

operates on regular

electrical service

3-PRONG

GROUNDING RECEPTACLE. The sup-

to

120 volt , 60

be supplied by an

ply circuit should be protected

by

hertz A.C.

APPROVED

amp. fuse,

15

a

or circuit breaker.

dish-

is

CAN

0)

REPLACEMENT

HOSE

ASSEMBLIES

OF

ABLE KITCHEN AID

CAUSE

SERIOUS

Fill and Drain Hoses (Fig. 1

CAUTION:

EITHER

CONVERTIBLE-PORT

ON

INCORRECT

FILL

OR

DRAIN

DISHWASHERS

DAMAGE. To prevent this , always replace hose

th e

assemblies in the exa

imperative· that each new replace-

is

original.

It

same manner

ct

as

ment hose be routed correctly and the retaining

the correct locations

amps installed prop erly

cl

especially important that

is

on the hose.

PART OF

MAKE

ELECTRICAL

the hose material can act

as

It

HOSES

THE

CONTACT

COMPONENTS

at

BE

WITH

NO

PERMITTED TO

ANY EXPOSED

TERMINALS ,

OR

an electrical

as

conductor. Re-check each hose installation, upon

completion , then extend and retract the hoses

they operate

several times to make certain

that

and locate properly.

To make the electrical connection:

sure the action indicator

Be

1.

in the

is

"OFF"

position.

a 3-prong

Insert the 3-pronged plug

2.

the wall receptacle

receptacle.

If

into

is

not

of

the

proper 3-prong grounding type an electrician

should be consulted.

CAUTION:

recommended.

not

The use

an extension cord

of

is

The Receptacle Outlet Must be Grounded

The

power

cord on the portable dishwasher

equipped with a 3-pronged grounding plug. The

designed to ground the cabinet

third prong

electrically thus eliminating

shocking the operator

is

possibility

the

an internal electrical

if

of

malfunction should occur.

which

It

essential

is

that

electrical

the

the 3-pronged power cord

in

is

this

grounded.

If

outlet

inserted be properly

is

doubt

into

competent

a

is

Fig.lO

Disconnecting

When disconnecting the convertible-portable:

Remove power cord from outlet and return

I.

to compartment.

water.

hot

the

Press

off

red

button

on coupler

2. Turn

3.

release water pressure and prevent splash

back.

4. Depress coupler ring (C, Fig. 7) and remove

coupler from faucet adapter. Return hoses to

compartment.

8-

-

, Fig. 9) to

(A

Page 8

GENERAL SERVICING INSTRUCTIONS

All

models

especially designed

By

removing the lower front panel, the

panel , and

are accessible

its installed position.

These instructions cover all models

series dishwashers however, all the components

of

the KD-18 series dishwashers are

to

be serviced from the front.

outer

the

control panel, practically all parts

without

moving the dishwasher from

of

the KD-18

door

that

are listed, may

model.

NOTE:

(1)

(2) NEVER reuse gaskets or sealing

or

may

not

be used for each

CAUTION : ALWAYS DISCONNECT

ELECTRICAL POWER SUPPLY

FORE

COMPONENTS.

washers.

REMOVING ELECTRICAL

BE-

- 9 -

Page 9

CYCLE

DESCRIPTION

The following cycle descriptions (KDC-18 and

KD-38

(IMPERIAL),

KDS-18, KDS-38

dishwasher) are for

All

Selection

any

heating element during the dry portion

cycle. The fan in the drying system will continue

to operate. This will reduce the

used during the cycle. Under

you may find a few drops

silverware at the end

raise the

pop out. Any time

restart an interrupted cycle, you must again push

the Energy

(CUSTOM),

KDP-18

models have the energy saver feature.

of

the Energy

of

the

"wash

door

handle, the Energy Saver

Saver

the KDI-18 and KDI-58

(PATRICIAN) and the

and

KDS-58 (SUPERBA)

the

KD-18 5eries dishwashers.

Saver

button,

and

dry"

cycles, will shut

amount

certain conditions,

of

water on dishes and

of

the cycle. Every time you

you

start a new cycle,

button

to

save energy.

model

along with

off

the

of

the

of

energy

button

will

or

CUSTOM MODEL

heavily soiled loads, one

turned into a pre-wash by adding detergent to

both

compartments

Total: Time - 72 minutes plus automatic timer

advance- 2 minutes ; Water- 11.9 gallons.

SOAK'N

hard-to-clean pots, pans and casseroles along with

regular tableware. This cycle provides one prerinse, one wash with soak period, one rinse, one

wash and three after rinses and dry. This cycle

soaks and washes the ware approximately 22

minutes prior

load. Detergent should be added to

ments

food soils may

more abrasive action

minutes plus automatic 'timer advance - 2 minutes ;

Water- 13.7 gallons.

RINSE/HOLD CYCLE- Used

of

dishes which are to be held until dishwasher

filled. Keeps dishes moist until they are washed

and dried. Do

Total: Time - 1

advance-

WASH

of

the detergent dispenser.

71

CYCLE- Used to wash and dry

to

complete wash and dry

not

not

use detergent with this cycle .

rinse-

minutes;

of

the pre-rinses can be

of

the detergent dispenser.

of

both

compart-

Some incrusted

be completely removed

is

necessary. Total:

to rinse partial loads

3 minutes; Automatic timer

Water-

1.5 gallons.

Time-

the

as

72

is

a

NORMAL

daily loads including china and crystal with average soil. This cycle provides three pre-rinses, one

main wash, two

heavily soiled loads, the first pre-rinse can be

turned into a pre-wash by adding detergent to

both

Total: Time - 59 minutes plus automatic timer

advance- 2 minutes; Water-

RINSE/HOLD CYCLE - Used

of

dishes which are to be held

filled. Keeps dishes moist until they are washed

and dried. This cycle provides one rinse. Do

use detergent with this cycle. Total: Time - 3

minutes; Automatic timer advance - 58 minutes;

Water- 1.4 gallons.

WASH

compartments

CYCLE- Used

after

to

wash and dry

rinses and dry.

of

the detergent dispenser.

11

.8 gallons.

to rinse partial loads

up til

For

dishwasher

more

is

not

IMPERIAL MODEL

NORMAL

d

ai

ly loads including china and crystal with aver-

age

soil. This cycle provides three pre-rinses, one

main wash, two after rinses and dry.

WASH

CYCLE- Used

to wash and dry

For

more

PATRICIAN MODEL

NORMAL

daily loads including china and crystal with average

soil. This cycle provides three pre-rinses,

main wash, two after rinses and dry. For more

heavily soiled loads, one

turned

both

Total:

SOAK'N

hard to clean pots , pans and casserol

regular tableware. This cycle provides one prerinse, one wash with soak period, one rinse, one

wash, three after rinses and dr

and washes

prior to complete wash and dry

Detergent should be added to

of

the detergent dispenser.

soils may

abrasive action

minutes;

WASH

into

compartments

Time-

WASH

not

Water-

CYCLE- Used

a pre-wash by adding detergent to

67 minutes; Water- 1 2.9 gallons.

CYCLE- Used

th

e ware approximately

be completely removed

is

to wash and dry

of

the pre-rinses can be

of

the detergent dispenser .

to wash and dry

es

along with

y.

This cycle soaks

20 minutes

of

the load.

both

compartments

Some

necessary. Total: Time - 89

15.2

,gallons.

encrusted food

as

a more

one

-

10 -

Page 10

rinse partial loads

RINSE/HOLD

dishes which are

of

CYCLE- Used

be held until dishwasher

to

to

is

filled. Keeps dishes moist until they are washed

and dried. This cycle provides one rinse. Do

not

use detergent with this cycle. Total: Time - 7

minutes; Water- 2.2 gallons.

SHORT

WASH

lightly soiled loads

uystal.

and

two

wash,

right side

the

in

the detergent dispenser. Total: Time - 58

of

minutes;

Water-

CYCLE-

of

This cycle has one pre-rinse, one short

after rinses and dry.

the MAIN

of

8.4 gallons.

CANCEL/DRAIN CYCLE- Used

cycle in progress. When this

Used

glasses

plates, fine china

or

detergent only

Use

WASH

button

compartment

cancel

to

pushed, the

is

out

any

wash and dry

to

dishwasher will drain and automatically turn itself

off. To start a new cycle, wait until all indicator

lights have gone off, unlatch the door momentarily, relatch and select the desired new cycle.

be completely

If

not

of

there

timer when

the

too

is

much

The water in

drained because

the cancel

button

sump may

the

the

of

is

location

pushed .

water, lift latch, wait 3 to 5 seconds, close latch

and again press cancel /drain

button

.

approximately 46 minutes prior to a complete

the load. Detergent should be

wash and dry

added

tion

to

the detergent dispenser. A few incrusted or

of

burned on food soils may

removed

Total:

SANI

TimeCYCLE- Used

of

compartments and front indenta-

both

a more abrasive action

as

108 minutes;

Water-

when extra sanitizing

be completely

not

is

gallons.

15

necessary.

de-

is

sired. This cycle has three pre-rinses, one main

washes and

wash, three after rinses and dry.

dries daily loads with same sequence

wash cycle. In addition, the final rinse water

heated to approximately

180°

rinsing. For more heavily soiled loads, one

a pre-wash by adding

pre-rinses can be turned

both

detergent

to

into

compartments

It

the normal

as

F. before final

the

of

the detergent

of

is

dispenser. Total: Time - 67 minutes (plus time to

.5 gallons.

F.); Water-

heat water to

RINSE/HOLD

dishes which are to be held until dishwasher

of

180°

CYCLE- Used

13

rinse partial loads

to

is

filled. Keeps dishes moist until they are washed

and dried . This cycle provides one rinse. Do

use detergent with cycle. Total:

Time-

6 minutes;

not

Water- 1.5 gallons.

MODEL

to wash and dry

NORMAL

SUPERBA

WASH

CYCLE- Used

daily loads including china and crystal with aver-

age soil. This cycle provides three pre-rinses, one

more

after rinses and dry.

ee

main wash,

heavily soiled loa

turned

both

Total:

SOAK'N

hard-to-clean heavily

seroles along with r

soaking and scrubbing periods, one rinse, one

two

thr

, one

ds

a pre-wash by adding detergent to

into

compartments

Time-

67 minutes; Water- 13.5 gallons .

of

SCRUB CYCLE- Used

so

ular tablewa

eg

the pre-rinses can be

of

the det ergent dispenser.

to

ed pots, pans and cas-

il

re.

main wash, three after rinses and dry.

For

wash and dry

This cycle has

alter-

It

nately soaks and scrubs in preheated water for

wash and dry

SHORT

WASH

CYCLE

lightly soiled loads

of

-Used

glasses

to

plates, fine china

or

and crystal. This cycle has one pre-rinse, one short

detergent only

after rinses and dry.

wash,

in the right side

of

two

the MAIN

of

the detergent dispenser. Total: Time - 53

Use

WASH

compartment

minutes; Water- 7.5 gallons.

PLATE

WARM

be used for serving

CYCLE-Used

hot

throughout the wash chamber. Total: Time -

to warm dishes to

foods. Heated air flows

20

minutes.

any

CANCEL/DRAIN CYCLE- Used

to cancel

wash cycle in progress . When this

out

button

is

pushed, the dishwasher will drain and auto-

matically turn itself off. To start a new cycle, wait

, unlatch the

until

indicator lights have gone

all

off

door momentarily, re-latch and select the desired

be

new cycle. The water in the sump may

the location

completely drained because

timer when the cancel

much water, lift latch, wait 3 to 5 seconds,

too

of

button

pushed.

is

close lat ch and again press cancel/drain

not

there

If

button

of

the

is

.

-

11

-

Page 11

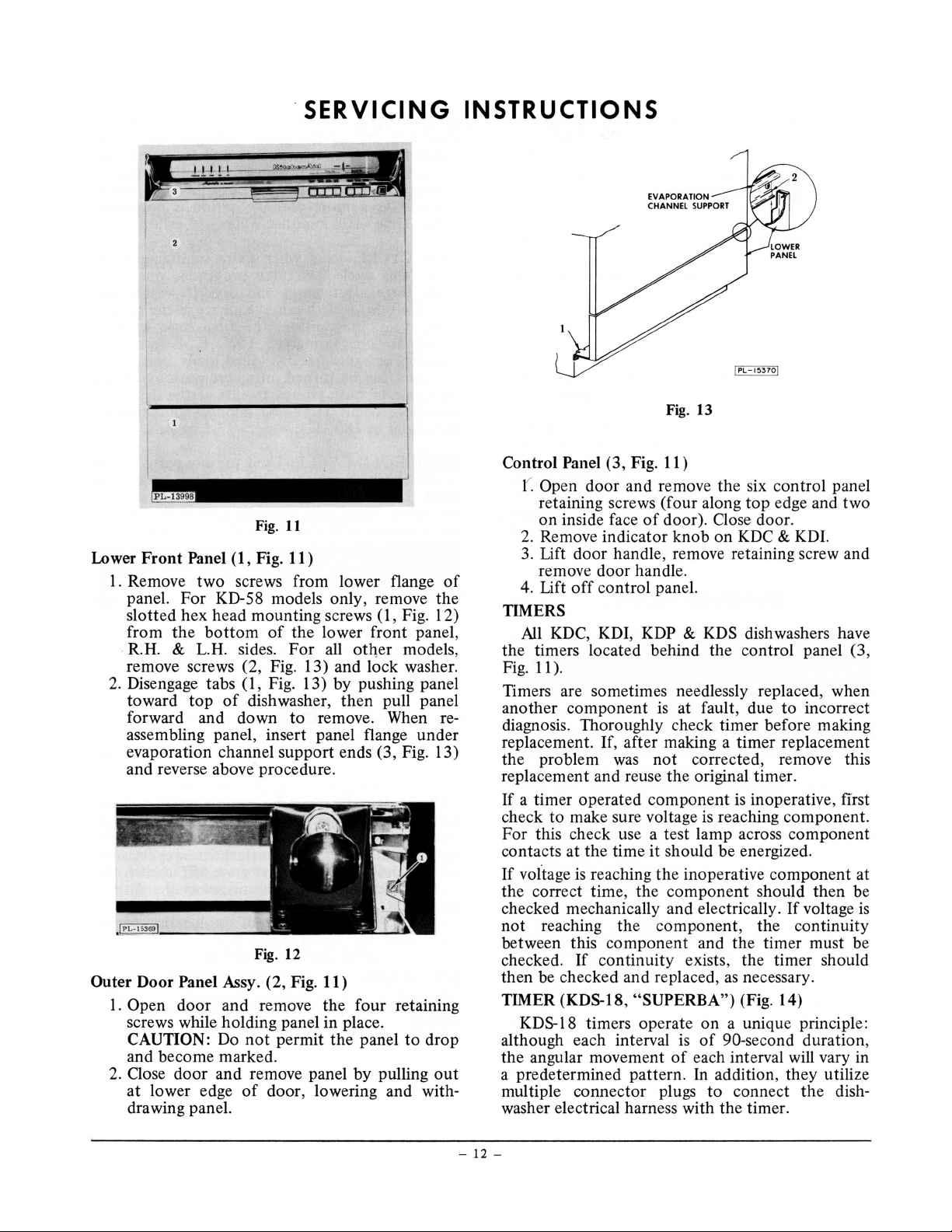

. SERVICING INSTRUCTIONS

Fig.

11

Lower

Outer Door Panel Assy. (2, Fig. 11)

Front

Panel (

I. Remove

1,

Fig.

11

)

two

screws from lower flange

panel. For KD-58 models only, remove the

slotted hex head mounting screws

from

the

R.H.

& L.H. sides.

bottom

of

the lower front panel,

For

all other models,

(I,

remove screws (2, Fig. 13) and lock washer.

2.

Disengage tabs ( 1, Fig. 13) by pushing panel

toward

forward and down

top

of

dishwasher,

then

to

remove. When reassembling panel, insert panel flange under

evaporation channel support ends (3, Fig. 13)

and reverse above procedure.

Fig. 12

1.

Open

door

and

remove the four retaining

screws while holding panel in place.

CAUTION: Do

not

permit the panel

and become marked.

2.

Close door and remove panel by pulling

at

lower edge

of

door, lowering and with-

drawing panel.

of

Fig. 12)

pull panel

to

drop

out

Fig.

13

Control Panel (3, Fig. 11)

door

( Open

retaining screws (four along

on

inside face

2.

Remove indicator knob on

3.

Lift door handle, remove retaining screw and

and remove the six control panel

top

edge and two

of

door). Close door.

KDC

& KDI.

remove door handle.

4. Lift

off

control panel.

TIMERS

All

KDC, KDI, KDP & KDS dishwashers have

the timers located behind the control panel (3,

Fig.

II).

Timers are sometimes needlessly replaced, when

another component

is

at fault, due to incorrect

diagnosis. Thoroughly check timer before making

replacement. If, after making a timer replacement

the problem

was

not

corrected, remove this

replacement and reuse the original timer.

is

If a timer operated component

check to make sure voltage

is

inoperative, first

reaching component.

For this check use a test lamp across component

contacts at the time it should be energized.

If

voftage

the correct time, the

checked mechanically and electrically.

not

between this compone

checked.

then be checked

is

reaching

reaching

If

the

inoperative component at

component

the

component, the continuity

nt

and the timer must be

should then be

If

voltage

is

continuity exists, the timer should

and

replaced ,

as

necessary.

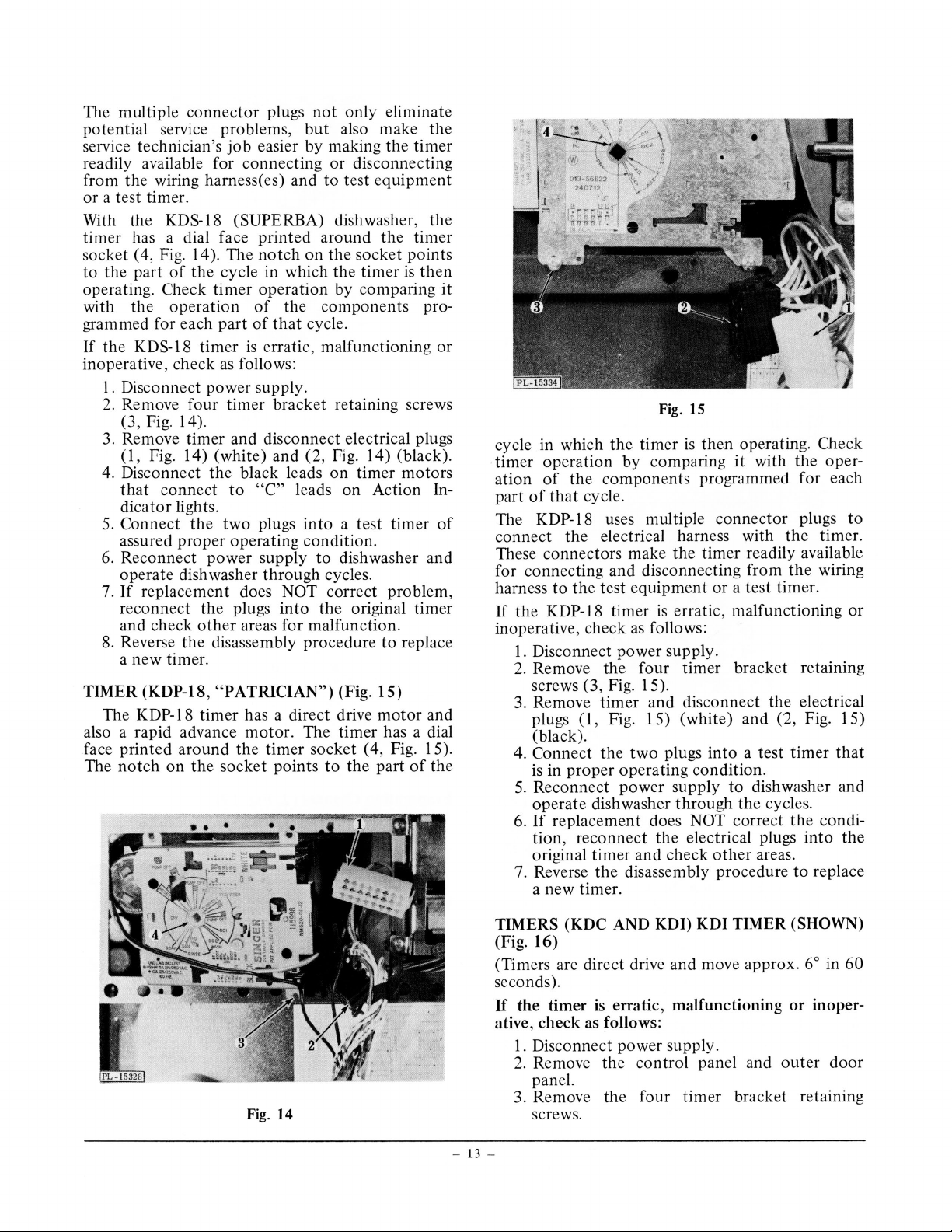

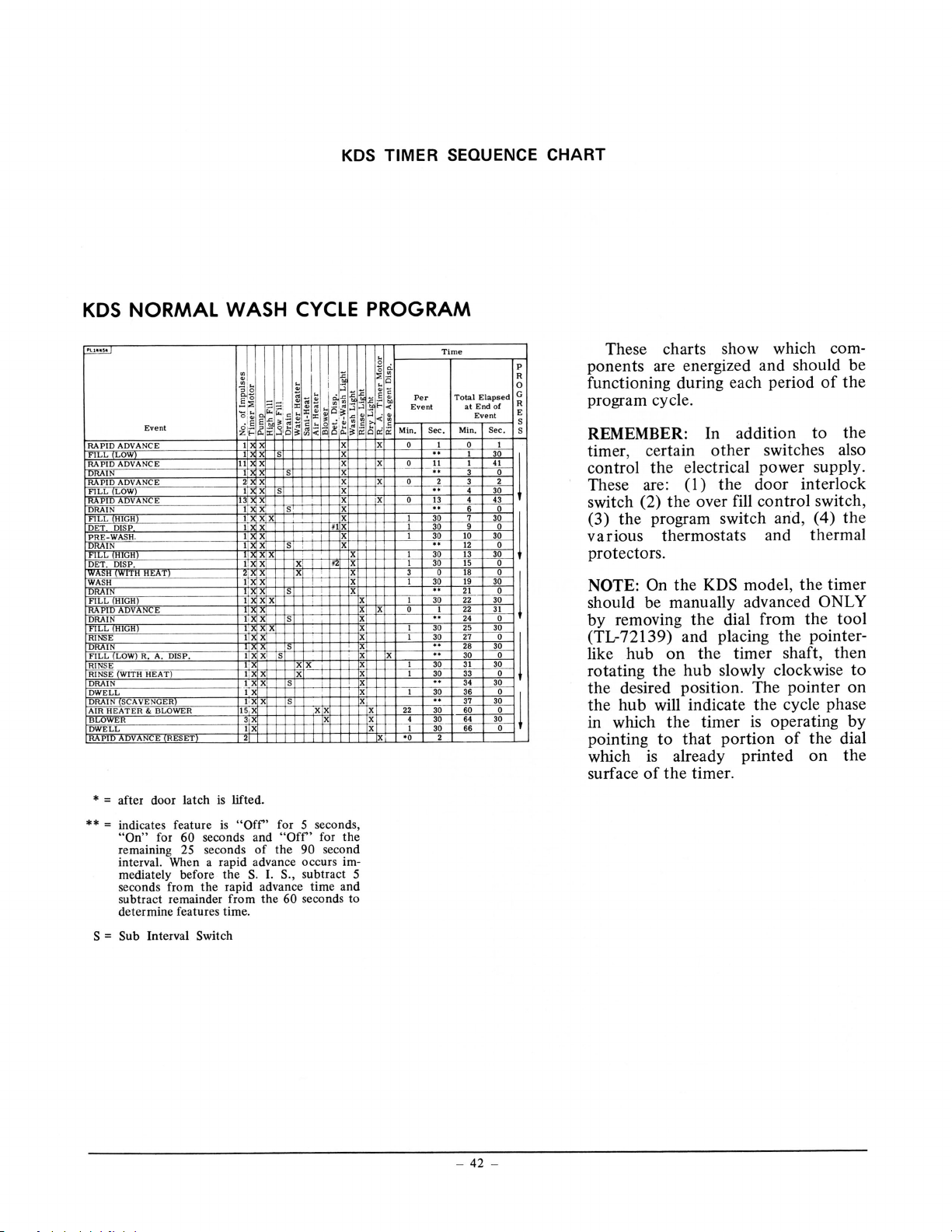

TIMER (KDS-18, "SUPERBA") (Fig. 14)

on

KDS-18 timers operate

although each interval

the angular movement

is

of

a unique principle:

of

90-second duration,

each interval will vary in

a predetermined pattern. In addition, they utilize

multiple connector plugs to connect the dishwasher electrical harness with the timer.

-

12-

Page 12

The multiple connector plugs

potential service problems,

service technician's

job

easier by making the timer

readily available for connecting

from the wiring harness(es) and

or

a test timer.

not

only eliminate

but

also make

or

disconnecting

to

test equipment

the

With the KDS-18 (SUPERBA) dishwasher, the

timer has a dial face printed around

).

The

socket ( 4, Fig. 14

to

the part

operating. Check

with

the

of

the

cycle in which the timer

timer

operation

grammed for each part

If the KDS-18 timer

inoperative, check

1.

Disconnect power supply .

as

follows:

notch

of

of

is

on

the

operation by comparing

the

components pro-

that

cycle.

erratic, malfunctioning

the

timer

socket points

is

then

it

or

2. Remove four timer bracket retaining screws

(3, Fig. 14).

3. Remove timer and disconnect electrical plugs

(1,

Fig. 14) (white) and (2, Fig. 14) (black).

on

4. Disconnect the black leads

that

connect

to

"C"

leads on Action In-

timer motors

dicator lights.

5.

Connect

the

two

plugs

into

a test timer

of

assured proper operating condition.

6.

Reconnect power supply

to

dishwasher and

operate dishwasher through cycles.

7.

If

replacement does NOT correct problem,

reconnect

and check

8.

Reverse

the

plugs

into

other

areas for malfunction.

the

disassembly procedure

the original timer

to

replace

a new timer.

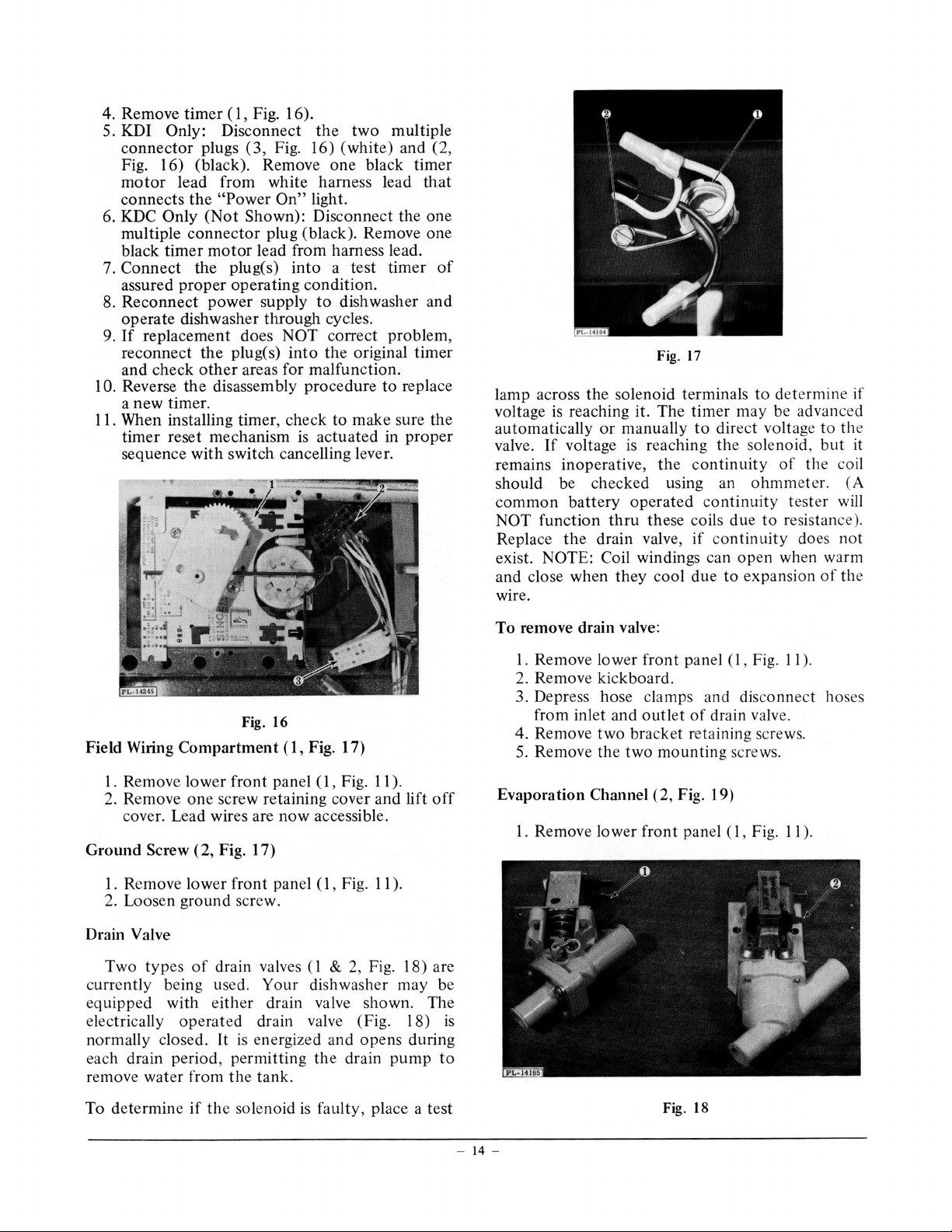

TIMER (KDP-18,

"PATRICIAN")

The KDP-18 timer has a direct drive

(Fig . 15)

motor

and

also a rapid advance motor. The timer has a dial

the

face printed around

The

notch

on

the

timer socket ( 4, Fig. 15).

socket points

to

the

part

of

the

Fig. 15

cycle in which the timer

timer operation by comparing

of

the

ation

part

of

that

components programmed for each

cycle.

The KDP-18 uses multiple connector plugs

connect

the

electrical harness with

is

then operating. Check

it

with the oper-

the

timer.

to

These connectors make the timer readily available

for connecting and disconnecting from

to

harness

If the KDP-18 timer

inoperative, check

1.

2.

the test equipment or a test timer.

is

erratic, malfunctioning

as

follows:

Disconnect power supply.

Remove the four timer bracket retaining

the

wiring

or

screws (3, Fig. 15).

3.

Remove timer and disconnect

plugs

(1

, Fig. 15) (white) and (2, Fig. 15)

the

electrical

(black).

4.

Connect

is

in proper operating condition.

5.

Reconnect power supply

operate dish washer through

If

replacement does NOT correct

6.

tion , reconnect

original timer and check

7.

Reverse

the

two plugs into a test timer

to

the

the

electrical plugs into

other

the

disassembly procedure

that

dishwasher and

cycles.

the

condi-

the

areas.

to

replace

a new timer.

Fig. 14

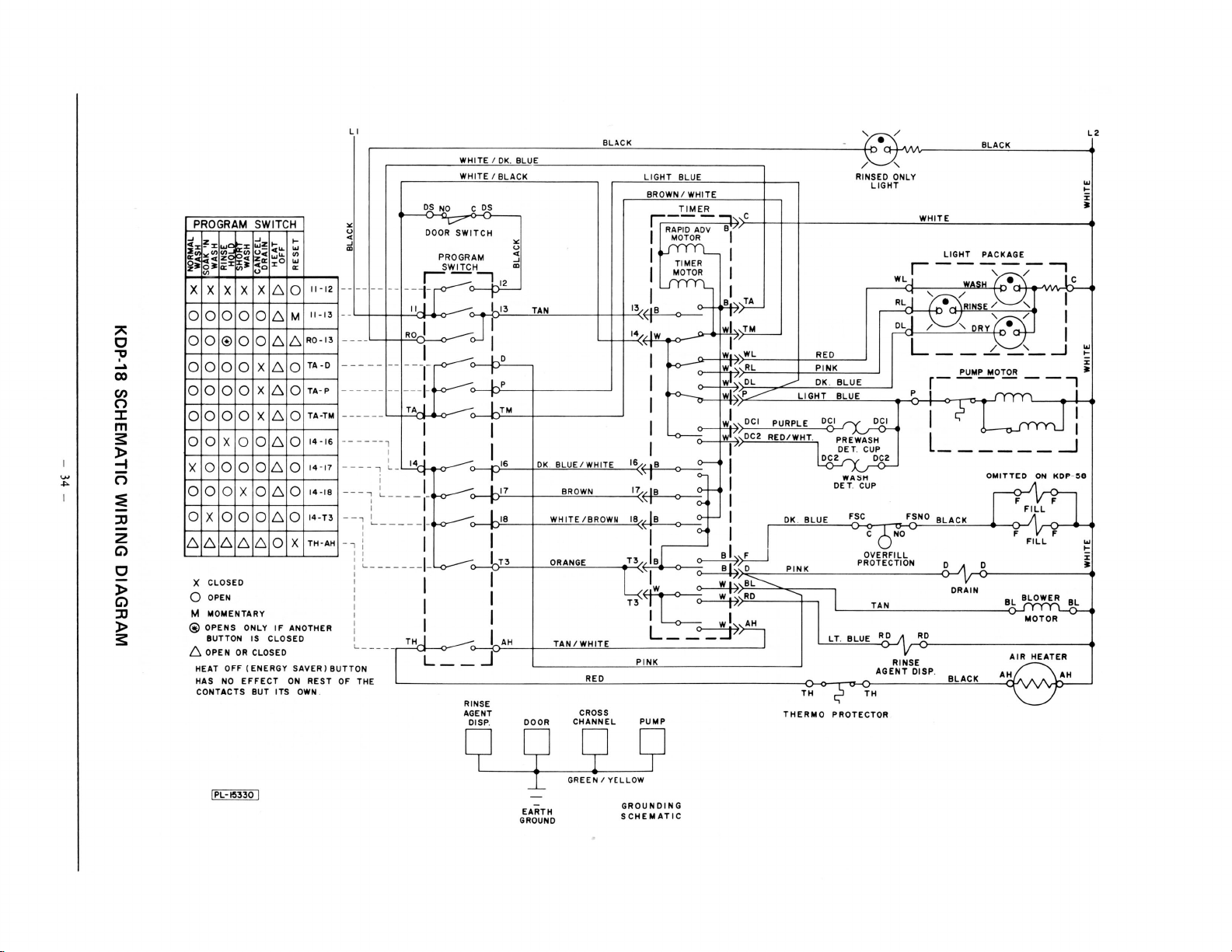

TIMERS (KDC AND KDI) KDI TIMER (SHOWN)

(Fig. 16)

(Timers are direct drive and move approx. 6° in 60

seconds).

If

the

timer

is

erratic, malfunctioning

ative, check

1.

Disconnect power supply.

2.

Remove

as

follows:

the

control panel and

panel.

3. Remove the four timer bracket retaining

screws.

-

13

-

or

outer

inoper-

door

Page 13

( 1, Fig. 16).

4. Remove

timer

5. KDI Only: Disconnect

connector

plugs

Fig. 16)

(3,

Fig. 16) (black) . Remove

motor

connects

6. KDC Only

multiple

black

Connect

7.

assured

Reconnect

8.

operate

If

9.

reconnect

and

10. Reverse

a

11. When installing

timer

sequence

lead from white harness lead

the

connector

timer

"Power

(Not

motor

On"

Shown): Disconnect

plug (black). Remove

lead from harness lead.

the plug(s)

proper

dishwasher

operating

power

supply

through

replacement does

plug(s)

the

areas for

other

check

disassembly

the

timer.

new

, check to make sure the

timer

reset mechanism

switch cancelling lever.

with

the

(white)

one

light.

a test

into

condition.

dishwasher a

to

cycles.

correct

NOT

the

into

malfunction.

procedure

actuated

is

multiple

two

black

timer

problem

original

to

in

and (2,

timer

that

e one

th

one

of

nd

timer

replace

proper

,

solenoid terminals

lamp across

voltage

automatically

valve.

the

reaching it.

is

voltage

If

manually

or

is

remains inoperative,

should be checked using an

common

function

NOT

Replace

battery

the

operated

thru

drain valve,

exist. NOTE: Coil windings can

and close when

they

wire.

17

Fig.

timer

e

Th

to

reaching

continuity

e

th

continuity

these coils

co

if

due

cool

determ

to

may be advanced

voltage

ect

dir

solenoid,

the

th

of

ohmmeter.

tester

resistance).

to

due

ntinuity

open

expansion

to

do

when warm

in

to

but

e co

es

of

e if

the

it

il

(A

will

not

th e

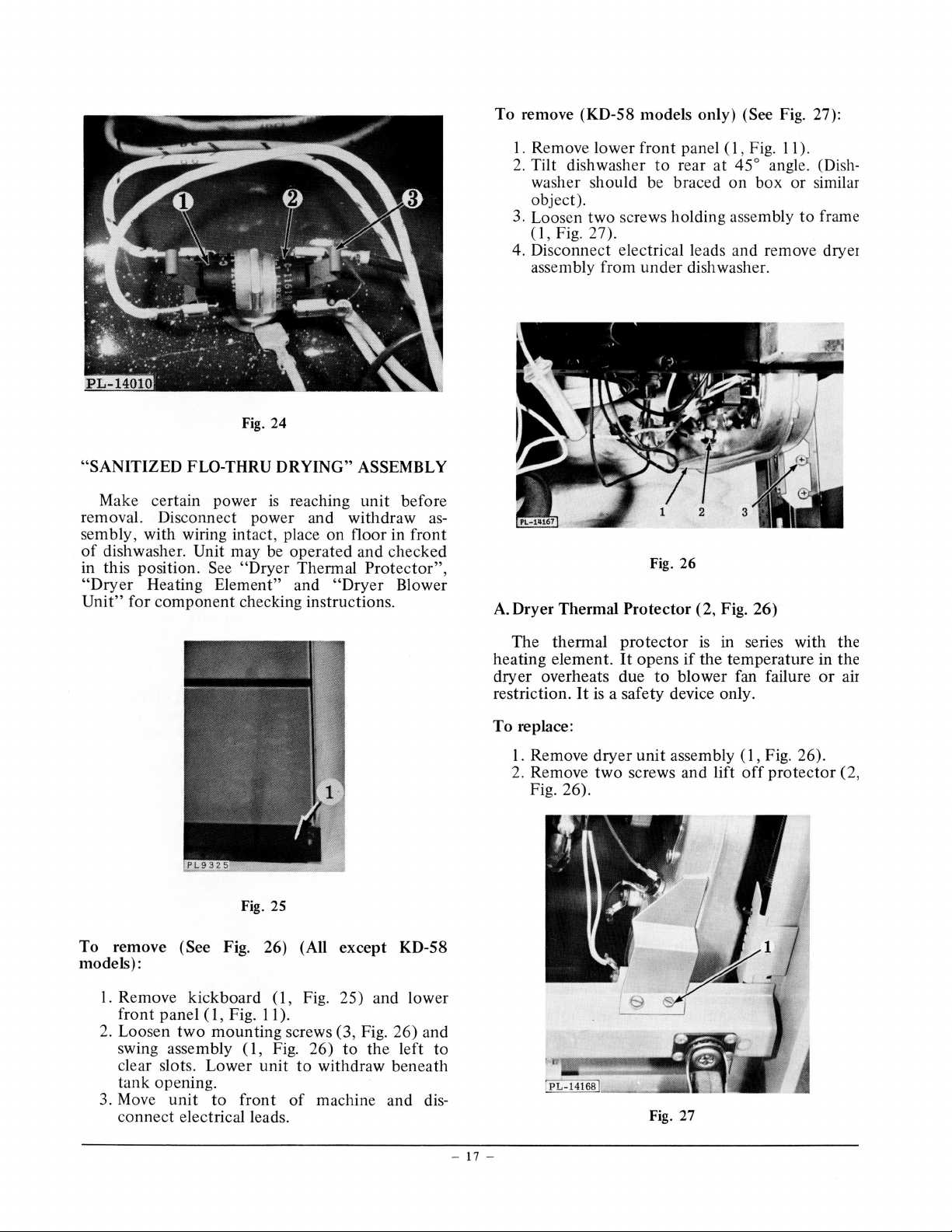

Field Wiring

Remove lower

1.

2. Remove

Compartment

front

screw retaining cover and

one

cover. Lead wires are

Ground

Screw (2, Fig. 17)

1. Remove lower

front

2. Loosen ground screw.

Drain Valve

drain valves ( l

of

types

Two

ly being used. Your

ent

urr

c

equipped with e

electrically

normally closed.

each drain period ,

remove water from

ith

operated

It

permitting

th

Fig. 16

( 1, Fig. 17)

panel

now

panel ( l , Fig.

dishwasher

n valve shown. Th e

ai

er dr

valve (Fig. 18)

in

dra

energized and

is

e tank.

ll

Fig.

(1 ,

accessible.

11

Fig. 18) are

2,

&

opens

drain

the

).

lift

).

may

during

pump

off

be

is

to

remove drain valve:

To

).

11

Fig.

,

(I

panel

Remove lower

l.

front

2. Remov e kickboard.

3. Depress hose clamps and disconnect hoses

drain valve.

from inlet and

4. Remove

Remove

5.

outlet

bracket retaining screws.

two

two

the

of

mounting

screws.

Evaporation Channel (2, Fig. 19)

Remove lower

1.

panel ( l, Fig.

front

II).

determine

To

if

th

e solenoid

faulty, place a test

is

Fig. 18

-

14

-

Page 14

2. Remove

end)

(3, Fig. 19).

3. Straighten

of

channel. Remove

two

retaining screws

conduit

tabs

(1

,

Fig. 19) in

evaporation

(one

at

channel.

each

center

NOTE: Wiring harness is sealed

conduit

Door

Springs

I. Make sure

2. Grasp

lift spring

3.

Adjustment

spring

the

and

must be pulled free.

( 4, Fig. 19)

power

top

hook

mounting

is

turned

portion

of

off

door

is

provided by changing

bracket

vertical frame member.

to

channe

OFF.

spring ( 4, Fig. 19)

stop

bracket.

(Fig.

20)

loc

ation

and

door

on

l

JPL-140061

DOOR

SPRING BRACKET

Fig.

20

between

the

closed.

the

certain it

the

timer

overfill

If

contro

the

solenoid

filter screen

is

not

and

fill valve

must

l switch, which

is

functioning

shou

ld

be removed

clogged. If th e

pass

through

is

normally

as it should,

to

va

lv

e still mal-

make

functions, it should be replaced.

To

replace fill valve:

1.

Shut

off

water

supp

ly valve.

2.

Remove low

3. Disconnect

4. Remove two

5. Disconnect electrical leads at valve coil

er

front

water

bracket

panel

inlet line

mounting

(I,

Fig.

at

fill valve.

11

).

screws.

(or

coils).

6. Depress hose clamp

and

disconnect fill line

hose.

Fig

Kickplate

The

kickplate

Fill Valve (Fig.

Two

Fig.

out

l

et

If

water

the

kickplate

sty

21)

(2, Fig.

is

fill

up

(for

period,

Adjustment

can

or

down.

21)

les

of

fill valves, single coil

convertible-portable)

21)

(for

not

passing

first

reaching each solenoid

operative.

viously

The

outlined

solenoid

under

. 19

be

adjusted

and

KD-18) are used.

through

make

and

the

certain voltage

that

may

be

"Drain

fill valve during

the

checked

Valve".

by

moving

outlet

dual coil

solenoid

as pre-

Voltage

(1,

is

is

CAUTION:

PARTS

ANY WAY

-

15

-

THE

SHOULD

OR

PARTS SUBSTITUTED.

VALVE,

NEVER

Fig

.

21

OR

COMPONENT

BE

ALTERED

IN

Page 15

4. Remove standpipe ( 4, Fig. 23) and gasket (3,

Fig. 23) from beneath tank.

5.

When reassembling standpipe, make sure

gasket

is

on stem before inserting stem

through the tank.

6. Using a tool, securely tighten standpipe

(2, Fig. 23

).

nut

Thermostat and Thermal Protector (KDS Only)

& 2, Fig. 24)

(1,

A thermostat

the water heater during the Sani Cycle.

the timer

motor

Fig. 24) (KDS only) controls

It

holds

circuit open (preventing timer

advancement) until the water reaches approximately 180° F.

closes, allowing the timer

at

which time the thermostat

to

advance.

(I

Fig. 22

Overfill Control Switch ( 1, Fig. 22)

The normally closed overfill control switch

is

an

electrically operated safety device in series with

the fill valve. This safety device will operate only

the timer stalls during fill cycle

washer fails to drain.

It

will

valve against a malfunction caused

material

or

a mechanical failure.

Excessive water in tank (approx.

of

hydro sweep) actuates the overfill control

not

or

if

protect

by

1/4"

below

the dish-

if

the fill

foreign

hub

switch, opening fill valve circuit.

is

This switch

permanently factory adjusted and

has automatic reset. DO NOT ATTEMPT TO

ADJUST.

To disassemble from dishwasher:

I.

Remove lower front panel

2.

Remove staple from cover.

(I,

Fig.

II)

.

3. Open cover and remove retaining screw.

4. Disconnect electrical lead wires to switch.

The automatic thermal

protector

normally closed safety device.

(2, Fig. 24)

If

for any reason

is

the sump temperature exceeds approximately

200° F. the

current flow

does

not

protector

to

the 1400 watt water heater.

contacts open , stopping

interrupt dishwasher cycle.

It

will auto-

It

matically reset at approx. 150° F.

To Service:

I.

Remove lower front panel

(l,

Fig.

II).

2. Remove thermostat cover.

3. Disassemble thermostat and thermal protector

by

rotating them

out

of

mounting

spring (3, Fig. 24).

a

Overfill Protection

Float

Standpipe (Fig. 23)

Should the tank reach an excessive level

(approx . 14 quarts), the overflow protection float

will prevent flooding by shutting

The float

is

located inside the left front

off

the fill valve.

comer

of

the tank.

To dissassemble from dishwasher:

I. Remove lower front panel ( 1, Fig.

2. Remove overfill control float

3.

Remove standpipe

nut

(2, Fig. 23) from

(I,

Fig. 23).

11

).

inside tank.

Fig. 23

-16-

Page 16

Fig. 24

"SANITIZED FLO-THRU DRYING" ASSEMBLY

To remove (KD-58 models only) (See

I. Remove lower front pan el ( 1, Fig.

2.

Tilt dishwasher

to

rear at 45° angle. (Dish-

Fig.

11

27):

).

washer should be braced on box or similar

object).

3.

Loosen two screws holding assembly to frame

(1,

Fig. 27).

4. Disconnect electrical leads and remove dryer

assembly from under dishwasher.

Make certain power

remova

l.

Disconnect power and withdraw

is

reaching unit before

assembly, with wiring intact, place on floor in front

of

dishwasher. Unit may

in this position.

"Dryer

Unit"

Heating Element" and

for component checking instructions.

See

be

operated and checked

"Dryer Thermal

"Dryer

Fig. 25

Protector"

Blower

To remove (See Fig. 26) (All except KD-58

models):

,

A.

Dryer Thermal Protector (2, Fig. 26)

The thermal

heating element.

dryer overheats due

It

restriction.

To

replace:

1.

Remove dryer

2.

Remove two screws and lift

is

Fig. 26

protector

It

opens

is

in series with the

if

the temperature in the

to

blower fan failure

a safety device only.

unit

assembly

(1,

off

or

Fig. 26).

protector

air

(2,

Fig. 26).

I. Remove kick board ( 1, Fig. 25) and lower

(1,

Fig.

11

front panel

2.

Loosen

two

mounting screws (3, Fig. 26) and

swing assembly

clear slots. Lower unit

).

(1 , Fig. 26)

to

withdraw beneath

to

the left

to

tank opening.

3. Move

unit

to

front

of

machine and dis-

connect electrical leads.

Fig. 27

- 17 -

Page 17

Fig. 28

B.

Dryer Heating Element (5, Fig. 28)

Should the dryer heating element become inoperative first check to make sure voltage

reaching element (during dry period).

not

reaching element, check for faulty energy

saver switch.

(thru thermal

If

voltage

protector)

is

reaching the element

(4, Fig. 28) next check

continuity using an ohmmeter.

If

voltage

If

no continuity

exists, replace element.

To replace:

I.

Remove dryer unit assembly (1 , Fig. 26).

2.

Disconnect electrical leads.

3. Remove the two retaining screws and lift

dryer heating element (5, Fig. 28).

4. Replace element and reassemble dryer unit.

is

is

out

WASH

PUMP, DRAIN PUMP AND MOTOR

SHAFT SEAL REPLACEMENT.

It

is

not

necessary

the dish washer

pump

or

motor

Wash

Pump (Figs. 29 & 30)

1.

Remove lower rack.

2.

Lift up and remove 4-Way Hydro Sweep

shaft seal.

to

remove the

to

install the wash pump, drain

motor

(wash arm).

3. Lift up and remove strainer.

4. Remove four retaining screws and lift

wash arm support

5.

Remove wash pump impeller retaining screw,

(1

, Fig. 29).

spring washer, cap washer, key washer and

wash pump impeller (2, Fig. 29).

Drain Pump (Figs. 29

1.

Remove wash pump components.

2.

Remove lower pump housing (3, Fig. 29).

3. Remove fine strainer seat

& 30)

(1

, Fig. 30).

4. Remove four retaining screws and lift

drain inlet cover (

top

(5, Fig. 29).

5.

Remove drain pump impeller (6, Fig. 29) and

4,

Fig. 29) and drain pump

shaft seal assembly (2, Fig. 30).

Pump and Shaft Seal Installation

1.

Proper spacing (working height)

pump impeller

is

important. Check shaft seal

of

working height with the shaft seal height

from

off

off

the drain

C.

Dryer Blower Unit ( 1 & 3 Fig. 28)

Should the dryer blower

to

operate , first check

make sure

inoperative, check

motor

shaft is free.

motor

ohmmeter. Replace

motor

the

winding continuity with

motor

if

(3, Fig. 28) fail

voltage supply. Next

If

motor

remains

tests prove negative.

To replace:

1.

Remove dryer unit assembly

(1,

Fig. 26) .

Note terminal location and replace in same

location.

2.

Disconnect electrical leads.

3. Loosen mounting screws and rotate unit

counterclockwise to clear mounting screws.

Lift

out

blower unit.

4. Loosen set screw and pull blower fan wheel

1,

Fig. 28) from

(

motor

shaft.

5. At reassembly, make sure dryer blower

cover (2, Fig. 28)

is

in place.

motor

Fig. 29

- 18 -

Page 18

Fig. 30

"touch"

31

).

to

Use the proper combination

on

dimension.

smaller I.D. and are

Limits

touch

top

or

and

of

"clear"

of

the

gauge (TL-91 043) (

the seal height gauge are

.631"

motor

to

clear. (See Fig.

of

shim washers

shaft to attain proper

NOTE: These shim washers have

NOT

the same washers

used for wash impeller spacing.

2.

The shaft seal assembly and drain

impeller are furnished

must be replaced

as

attemp a partial replacement. Use

as

a lubricant for assembling seal. Moisten the

as

a single unit and

a single unit only. Do

water only

bellows seal (stationary part) and press into

place in the drain housing cavity. Install the

drain pump impeller and rotating assembly a

the way down over the

motor

shaft. Make

sure no washers have stuck to the underneath

side

of

the impeller and the stationary part

completely seated in the drain pump body

for proper alignment. Firmly seat

Fig.

31

"0"

1,

Fig.

.606"

31

).

pump

not

ll

is

ring

around shaft into groove

of

drain pump

impeller.

3. Place

the drain pump top (stainless ste

el

soft

waste disposer) (5, Fig. 29) and inlet cover

( 4, Fig. 29)

into

position and securely fasten

with the four retaining screws.

4.

Position

upper spray supply hole

the lower pump housing

is

directly above the

so

the

rubber overhead connector. The recesses in

the lower pump housing must be in alignment

with the

the drain housing.

bearing spacers

32) furnished in the kit on top

motor

mounting plate bosses over

NOTE:

(Part

Assemble the four

No.

A-1

02652)

of

(1,

the lower

Fig.

pump housing with four retaining screws

removed in disassembling the wash arm

support.

5.

Assemble wash pump impeller making sure it

engages the drain pump impeller. Assemble

spring washer, cap washe

r,

key washer, and

retaining screw in proper sequence and

tighten screw.

NOTE: Check wash pump

impeller spacing with shim gauge (TL-91 042)

(2, Fig. 32) beneath vane

Fig. 32

impeller. The longest section

gauge should clear. The combination

sections (together) should

of

the

shim gauge are .0 15"

.025"

tion

to

"touch".

of

shim washers

Add the proper combina-

to

of

just

to

the top

wash

of

pump

the shim

of

both

touch. Limits

"clear"

of

and

the drain

impeller to attain the proper dimension.

Always use at least one shim washer.

6. After spacing wash pump impeller correctly,

remove the four bearing spacers.

7.

Install ring gasket to the lower pump housing.

Seat gasket properly. Make sure it

is

not

twisted in the groove.

8. Install the wash arm support and position it

with the word

dish washer with the four retaining scre

"FRONT"

to the front

of

the

ws.

Reassemble fine strainer seat, strainer, lower

-

19

-

Page 19

Fig. 33

wash arm, and lower rack in their correct

location. Check dishwasher for operation.

Motor ( 4, Fig. 32)

rotates

It

motor

The 1/2

operates

R.P.M.,

3450

H.P.,

wash and drain pumps.

both

single phase

counterclockwise, incorporates a centrifugal start

and integral

switch, ball bearing

mounted

rotor

automatic overload protector.

and

or

motor

pump

pry between gasket and tank

not

may be damaged.

p~t.

Pry to loosen

6. Withdraw complete

motor

from inside wash tank.

To reinstall

Motor and

I.

"arrow"

word

positioned to the front

Install

2.

motor:

pump

on

"FRONT"

motor

and

ed with

unit must be insta

motor

mounting plate and

ll

centered in the tank and

the dishwasher.

of

a complete

as

pump

unit

assembly from inside the tank.

Moisten the complete surface

3.

of

mounting plate gasket (7, Fig. 29) and area

inside tank where gasket fits with water to

aid installation.

4. Apply downward pressure on wash arm supsnap gasket in place in tank sump .

to

port

5. Make sure

motor

mounting plate ga

sk

Fig. 32) seals the tank.

enamel

from

.

unit

motor

et (3,

Always check

other

Check

components, before making replacement.

motor

motor

shaft

rotate. Apply 115

motor

white leads.

sources

other

If

trouble .

of

operation, independent

make certain

to

V.A.C.

across the black and the

it

starts and runs , check for

is

free

To remove:

Remove lower front panel and kickboard.

1.

Disconnect

2.

motor

electrical leads.

3. Remove drain and upper spray tubes from

motor

4. Unsnap and remove the three

mounting plate.

motor

retaining

clips.

Remove fine strainer seat from inside tank.

5.

Insert a screwdriver blade between

mounting plate and gasket. CAUTION: Do

of

to

motor

Fig. 35

6. Seat the fine strainer.

Install the three

7.

motor

retaining clips and

snap them in place.

flexible

motor

to

mounting

8. Connect

upper

spray supply tube

connector and drain tube to

plate and tighten. Make sure the drain hose

kinked.

not

9. Connect the

motor

electrical leads.

10. Check for leaks.

11. Assemble kickboard and lower front panel.

Constant Wash/Rinse System (Fig.

33)

is

Fig. 34

-

20 -

Remove the three nuts

I.

spray

upper

the

Remove

2.

upper

tube (3, Fig.

System (Fig. 34)

Remove

I.

Wash

two

Middle

that

(2, Fig. 33 ).

unit

,

(1

Fig. 33)

spray manifold from supply

.

33)

Fig. 34) and strap (2,

,

screws

(1

retain

Page 20

Fig. 36

Fig. 34)

that

holds the manifold to upper

rack.

2. Unsnap the four clips (4 , Fig. 34) and remove

middle wash arm guard (3, Fig. 34).

3. Pull complete assembly including manifold

tube (6, Fig. 34) from middle wash arm

receiver (5, Fig. 34).

Sheath Heater (1, Fig.

35)

(KDS Only)

To Replace:

1.

Remove lower front panel and kickboard.

2.

Disconnect electrical lead wires.

3.

Remove

from heating element

NOTE:

Always reassemble washer

4.

Lift and remove heating element from inside

of

tank.

Self-Cleaning Filter (Fig.

1.

Remove lower wash arm.

2.

Lift

3. Squeeze center section (2, Fig.

the

two

hex nuts and ring gaskets

on

underside

Use

new ring gaskets at reassembly.

and

ground lug!

36)

out

fine strainer assy. (1 , Fig. 36).

36)

of

of

strainer together and lift out.

4. Grasp rear and front

(1,

Fig. 30), lift up

out

.

Air Gap

& Fill Tube

The fill line air gap

of

tank. Do

dishwasher

not

is

removed. (Nut must be securely

tightened). · Tube must

gap

junction)

or

at fill valve.

Wiring Harness (KDP

1.

Remove

outer

tab

of

fine strainer seat

on

rear

tab

first, then lift

(1

& 2, Fig.

is

not

loosen

not

& KDS)

37)

accessible from inside

nut

at inlet unless

be kinked at

top

door panel, control panel and

lower front panel.

2. Remove

3.

Remove evaporation channel.

door

vapor shield.

4. Remove program switch bracket.

tank

coarse

(air

5.

Remove timer.

6.

Disconnect leads in door

lights, all switches, dispensers, door frame

ground, rinse agent dispenser ground, and

multiple connector plugs (one white (3, Fig.

38) and one black (4, Fig. 38)). On KDS and

KDP, also disconnect lead to rinse-only light.

7.

Disconnect all nonwhite leads to blower

motor

motor

also disconnect nonwhite leads

thermostat and sheath heater.

NOTE: Following removal

wiring harness, some electrical connections

still remain , such

fill valve, dryer heater and fan assembly

connections, fill valve connection. On the

KDS, there are also connections

thermal protector.

Wiring Harness (KDI

1.

Remove

lower front panel.

2. Remove door vapor shield.

3.

Remove evaporation channel.

4. Remove program switch bracket.

5. Remove timer .

6.

Disconnect leads in door

(KDI only), dispensers, and plug (KDC only) ,

or

door frame ground.

7.

.

Disconnect all nonwhite leads to blower

motor, heater thermostat, overfill control

switch, drain valve,

fill valve.

to

action indicator

, overfill control switch, drain valve,

and white lead

to

fill valve. On KDS,

to

of

the complete

as:

overfill control switch to

to

the

& KDC)

outer

door panel, control panel, and

to

switches, light

multiple plugs (KDI only)

motor

1

2

Fig. 37

to

timer and

and white lead to

heater

:#:87

-

21

-

Page 21

Fig. 38

Indicator Sequence Light Assy. (KDS & KDP) (3,

Fig. 40)

1.

Remove control panel.

2.

Remove indicating sequence light assembly

and disconnect leads.

1. Remove

2. Remove four retaining screws (with shim

outer

door panel and control panel.

washers when required).

NOTE: When replacing a door latch, program

switch

program switch cancel spring (

door handle latched and the normal cycle

depressed, check for correct clearance. The clea

ance between one side

switch cancel lever cap should be

(Fig. 38) with the

or

inner door panel , ALWAYS check the

1, Fig. 3 8). With th e

of

the cancel spring and the

1 /3

2"

to 3/3

other

side

of

the cancel spring

button

r-

2"

just contacting the program switch cancel bar. The

program switch cancel spring

is

removable for

adjustment by unsnapping it from the riveted

anchor. Pull

on tab

(1,

Fig. 39) with needle

out

nose pliers to disengage tab from detent, then pull

straight forward (see Fig. 39).

Door Latch Mechanism (2, Fig. 38)

is

The latch

actuates

the

a safety device

program push

each time the door handle

operates

the

interval timer line switch on KDC and

that

button

is

unlatched.

automatically

cancelling lever

It

also

KDI models and resets the timer.

The latch can be adjusted

to

increase the door seal

tension by adding shims between latch and inner

door mounting bracket.

Fig.

40

Program Switch Assy.

1.

Remove control panel and

2.

Remove switch bracket retaining screws,

(1,

Fig. 40) (KDS shown)

outer

grounding clip, lock washer and disconnect

electrical leads.

3.

Lift

switch assembly clear

reassembly be sure

to

reinstall grounding clip

of

and lock washer.

NOTE: Interlock switch (2 , Fig. 40)

accessible when control panel

is

removed.

door

door. At

panel.

is

also

Fig. 39

Inner Door Assy. (Fig. 40)

1.

Disconnect power supply.

2. Remove

panel.

-22

-

outer

door

panel and lower front

Page 22

3. Remove retaining screws and lift

off

vapor shield.

4. Unhook

5. Pull

door

springs.

off

action indicator

knob

(KDI

6. Remove control panel.

7.

Remove retaining screws from program

switch and bracket assembly.

8. Disconnect electrical wiring harness.

9. Remove timer.

I

0.

Disconnect electrical leads

dispenser

and

detergent dispenser.

11. Remove clips, push

at a

90°

angle and withdraw from hinges.

out

at

rinse agent

pins and lift

&

off

door

KDC).

door

Rinse Agent Dispenser (4, Fig. 40) (Optional

KDI

&

KDC)

on

Check by applying voltage to the dishwasher

and advancing timer thru two

or

three cycles;

observe rinse agent liquid on inner door assembly.

1. Remove

2.

Disconnect electrical lead wires.

3. Open

Lift

NOTE:

outer

door panel.

door

off

dispenser.

and remove

two

retaining nuts.

Avoid spilling concentrated rinse

agent liquid on counter top, floors, etc.

Fig.

41

Fig. 42

NOTE:

At reassembly use new detergent

dispenser gasket.

Upper Rack Track ( 2, Fig. 41)

1.

Pull

track forward to bumper stop. Lift tab

from detent hole and remove stop retaining

stud

(1,

Fig.

41

).

2. Pull track forward, releasing bumper. Withdraw track.

3.

Use

shim washers behind rollers for align-

ment, when required.

Door

Seal Gasket (1, Fig. 42)

The

door

seal

is

one piece wire

furnished

rod

in place. Retaining clips are

as

an assembly with a

included.

1.

Starting

clips from the

at

the

bottom,

tank

pry the seal retaining

by inserting a screwdriver

blade between wire rod and seal.

2.

Install the seal, starting at the top and

snapping new clips

into

holes in the tank.

Never reuse old clips.

3. Run dishwasher through a cycle and check

for leaks.

Detergent Dispenser (5, Fig.

CAUTION:

potential at

1.

Remove

2.

Disconnect electrical lead wires.

Bimetal units have voltage

all

times when

outer

door panel.

40)

motor

is

operating.

3. Remove bimetal and holder assembly (6, Fig.

40).

4. Remove retaining screws.

5.

Open

door

and lift out dispenser assembly.

6.

Reassemble bimetal unit

1/64"

clearance from stop on swing arm.

to

just

touch

or have

Lower Door Baffle

1.

Remove

2. Remove

3. Pull

4. Unhook

5. Remove hinge pin retaining clips and hinge

pins.

6. Lift

7. Remove three retaining screws holding lower

baffle

NOTE:

edges with

-

23

-

outer

door

panel.

door

vapor shield.

wiring harness from

door

springs.

off

door.

(I

, Fig. 43) to lower edge

When replacing

putty

to

prevent leaks.

slots

in the door.

door

of

the door.

baffle, seal

Page 23

5.

Remove tank seal (2, Fig. 43) by pulling on

end.

6. To reassemble tank seal, insert

se

al at one end

and pull it through.

DRAINING CONVERTIBLE-PORT ABLE

DISHWASHERS

Fig. 43

Tank Seal Assembly

I. Remove

2.

Remove hinge pin retaining clips and hinge

outer

door

panel.

pins.

3. Unhook

4. Lift

off

door

door.

springs.

Drain dish washer hoses before

serv1cmg

any

component which requires placing dishwasher on

its back

count

or

when making conversion to under-the-

er installation. Remove lower rack, wash arm

and strainer.

I.

Tilt dishwasher

to

rear at 45° angle.

(Diswasher should be braced on box or

similar object).

2.

Remove lower front panel.

Fig. 45

Fig. 44

3. Place suitable container under hose connections

(both

fill and drain hoses) at the fill

and drain valves.

4. Disconnect hoses from fill and drain valves.

5. Drain hoses

into

container.

Electrical Cord with Reel (KDI-58

Only) (2, Fig. 44)

To remove power cord with reel:

I.

Remove two mounting screws

from power cord housing.

2.

Remove power cord housing

push through slot opening, provided

housing.

3. With unit drained, lower rack, wash arm and

strainer removed, place dishwasher on back.

Protect fmish by laying it

object.

4. Remove lower front panel.

5. Disconnect electrical leads from reel.

6. Remove one mounting screw

slide cord reel

-

24-

to

the right and lift out.

& KDS-58

(1,

Fig. 45)

(I,

Fig. 46) and

on

a rug or similar

(1,

Fig. 44) and

in

the

Page 24

reassemble cord reel

To

KDS-58 Only)

dishwasher (KDI-58

on

&

1 2

/

__

Replace reel

1.

Fig.

(I,

screw

Extend

2.

corner

Pull

3.

corner

cord

mounting

Using

4.

reconnect

5. Make sure

Replace lower panel.

6.

power

dishwasher cabinet .

of

power

housing. Install cord housing with two

cord

cabinet. Replace cord in power

of

screws

nuts

wire

ground

there

frame with one

on

44).

cord up through left rear

through

(1 ,

connect

lead.

proper tension on the reel.

is

opening in top left

45).

Fig.

electrical leads and

mounting

I

I

PL-141281

\,

I

--

47

Fig.

WATER

(Fig. 48)

To

1.

2.

3. Remove hose clamp bracket (2, Fig. 48)

(FILL

remove:

See

PORTABLE DISHWASHER".

Remove anchor bracket (3, Fig.

guard ( 4, Fig. 48).

holding hoses

AND DRAIN) CONNECTIONS

"DRAINING

frame.

to

CONVERTIBLE

48)

and

-

ho~e

Fig. 46

Electrical

I. Remove

2. Remove

3. Locate

4. Disconnect

reassemble, reverse removal procedure

To

Power

from

from

cord housing slot.

washer

screw.

one

frame ground.

NOTE: Make sure

positioned in

and harness wire does

operation.

Cord (KDC-58)

two

housing.

cord

power

cabinet

cord

disassemble clamp by removing

and

power

mounting

cord housing

push end

and

clamp

cabinet

at

cord

power

for ease

not

screws (2, Fig. 4 7)

top

electrical leads and

interfere with cord

47)

Fig.

(1,

through

cord

of

dish-

corner

cord is properly

of

operation

of

Fig. 48

- 25 -

Page 25

4.

Stand

dishwasher upright and pull hoses

through hose coupler housing in top, right

dishwasher.

of

rear

To reassemble, reverse above procedures

NOTE:

especially careful

Be

that

dressed properly in loop in cabinet and

touch electrical components

hoses do

terminals,

not

hoses may

as

conductors under

as

act

some conditions.

hoses are

that

or

CONVERSION OF

Conversion

models

of

undercounter

to

KD-58

the KD-58 Convertible-Portable

MODELS

installation requires

special instructions. Complete instructions for

conversion and the undercounter

both

the

installation are provided.

REMOVAL OF TOP (Fig.

I. Remove retaining screws

49)

Fig. 49) from

(I,

49

Fig.

top anchor mounting brackets and front

wraparound housing.

2. Remove upper retaining screws

(I,

from hose coupler housing.

forward and lift off.

3. Slide

top

of

Fig. 48)

-

26

-

Page 26

CONDITION

SERVICE

POSSIBLE CAUSE

TIPS

REMEDY

Upper Rack binds.

Visible water vapor exhausting

from

under

door

N

__,

("steam").

1.

Binding due

not

center.

2. Binding

forced

3. Binding

tween

4. Binding

to

user's pushing from side,

due