Page 1

HC24EO SERIES STEAMER

MODEL ML

HC24EO3 ML-136006

HC24EO5 ML-136007

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 37491 (May 2010)

Page 2

HC24EO SERIES STEAMER

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL THIS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY

THIS MANUAL.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

© HOBART 2010

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

— 2 —

Page 3

HC24EO SERIES STEAMER

TABLE OF CONTENTS

INSTALLATION, OPERATION AND CARE OF MODEL HC24EO SERIES STEAMERS .................5

GENERAL ....................................................................................................................................5

INSTALLATION ............................................................................................................................5

UNPACKING................................................................................................................................5

INSTALLATION CODES AND STANDARDS ..............................................................................5

LOCATION...................................................................................................................................5

LEVELING FEET .........................................................................................................................6

LEVELING ...................................................................................................................................6

ANCHORING STEAMER ............................................................................................................6

STACKING STAND ......................................................................................................................6

ELECTRICAL CONNECTIONS ...................................................................................................7

ELECTRICAL DATA .....................................................................................................................8

SERVICE CONNECTIONS .........................................................................................................8

Water Connections ................................................................................................................8

Water Treatment ....................................................................................................................8

Water Requirements ..............................................................................................................8

Drain Connection ...................................................................................................................8

VENT HOOD ...............................................................................................................................9

INSTALLATION STARTUP PROCEDURE ..................................................................................9

Calibration Procedure ..........................................................................................................10

OPERATION ....................................................................................................................................12

CONTROLS ...............................................................................................................................12

OPERATING THE STEAMER ...................................................................................................12

LOW WATER ............................................................................................................................12

SHUTDOWN .............................................................................................................................13

EXTENDED SHUTDOWN .........................................................................................................13

CLEANING ......................................................................................................................................14

COOKING COMPARTMENT DRAIN .........................................................................................14

COMPARTMENT .......................................................................................................................14

DOOR GASKET ........................................................................................................................14

LEAVE COMPARTMENT DOOR OPEN....................................................................................14

STAINLESS STEEL EQUIPMENT CARE AND CLEANING ......................................................15

MAINTENANCE ..............................................................................................................................17

REMOVAL OF LIME SCALE DEPOSITS ..................................................................................17

DOOR GASKET ........................................................................................................................17

COOKING HINTS ............................................................................................................................18

ACCEPTABLE PAN SIZES ........................................................................................................18

— 3 —

Page 4

HC24EO SERIES STEAMER

COOKING GUIDELINES ...........................................................................................................18

Preparation ..........................................................................................................................18

Frozen Food Items ...............................................................................................................18

PRODUCTS TO BE COOKED IN SOLID PANS .......................................................................19

PRODUCTS TO BE COOKED IN PERFORATED PANS ..........................................................20

TROUBLESHOOTING ....................................................................................................................22

SERVICE AND PARTS INFORMATION ..........................................................................................23

— 4 —

Page 5

HC24EO SERIES STEAMER

INSTALLATION, OPERATION AND CARE OF

MODEL HC24EO SERIES STEAMERS

PLEASE KEEP THIS MANUAL FOR FUTURE USE

GENERAL

Vulcan convection steamers are produced

with quality workmanship and material. Proper

installation, usage and maintenance will result

in many years of satisfactory performance.

It is suggested that you thoroughly read this

entire manual and carefully follow all of the

instructions provided.

The HC24EO3 Steamer is rated at 8.0 kW and

the HC24EO5 Steamer is rated at 12.0 kW.

Model HC24EO3 can accommodate three 21/2"

deep (6.4 cm) steam pans. Model HC24EO5

can accommodate ve 21/2" deep (6.4 cm)

steam pans. The HC24EO3 and HC24EO5

electric convection steamers are designed for

cooking vegetables, eggs, and other foods,

in commercial kitchens. The steamer has a

0 to 60 minute timer. The steamers are

designed for installation on countertops or on

optional stands.

INSTALLATION

Before installing, verify that the electrical supply

agrees with the specications on the data plate

located on the front of the steamer in the lower

right hand corner. If the supply and equipment

requirements do not agree, do not proceed with

the installation. Contact your dealer or VulcanHart immediately.

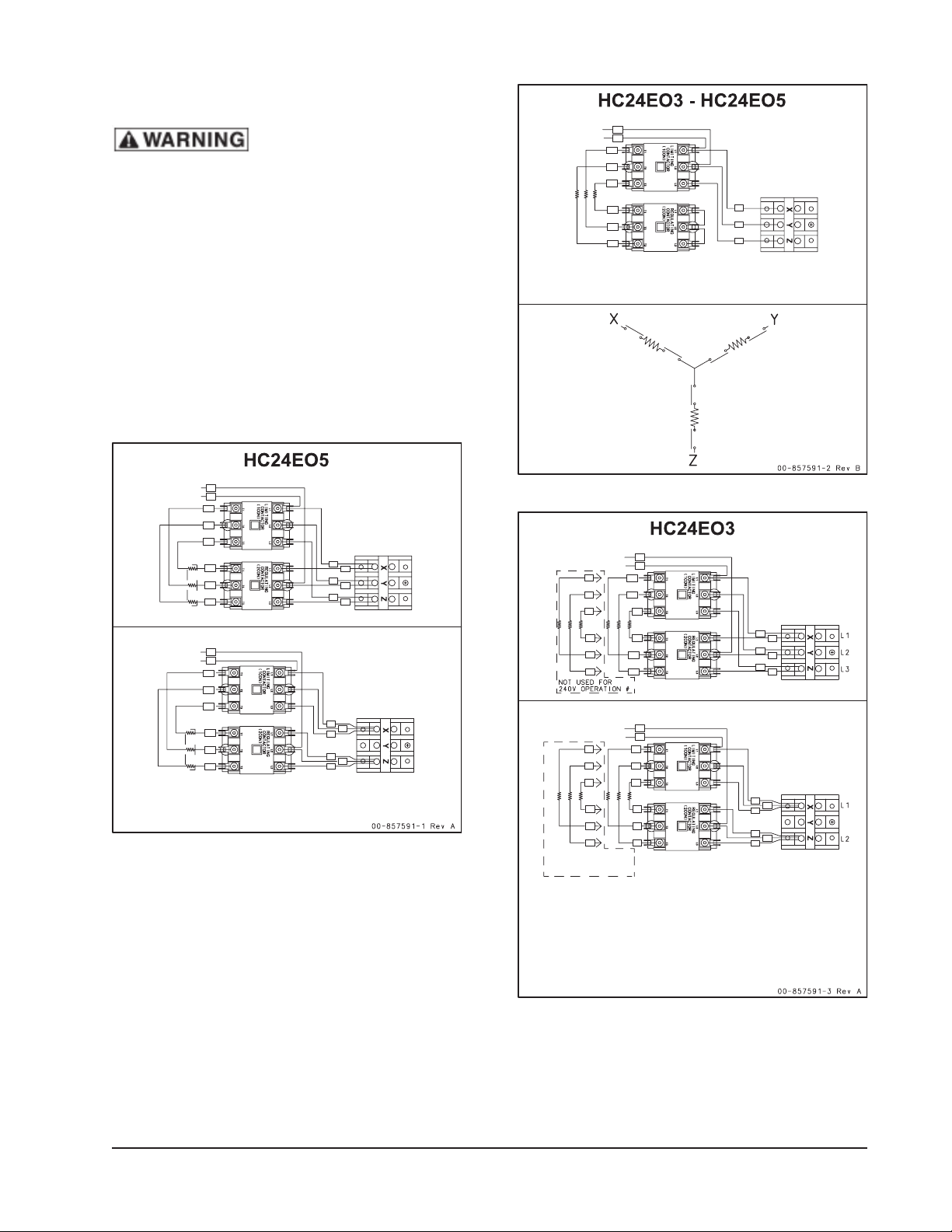

The HC24EO3 is shipped pre-wired for 208

V, 50 to 60 Hz, 3-phase. 240 V and single

phase operation require changes to the heater

connection 240 V, 50 to 60 Hz, 3-phase / 240 V,

50 to 60 Hz, 1-phase and 208 V, 50 to 60 Hz,

1-phase.

UNPACKING

This steamer was inspected before leaving the

factory. The transportation company assumes

full responsibility for safe delivery upon

acceptance of the shipment. Immediately after

unpacking, check for possible shipping damage.

If the steamer is found to be damaged, save

the packaging material and contact the carrier

within 15 days of delivery.

INSTALLATION CODES

AND STANDARDS

The steamer must be installed in accordance

with:

In the United States of America:

1. State and local codes.

2. National Electrical Code, ANSI/NFPA-70

(latest edition). Copies may be obtained from

The National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

3. Vapor Removal from Cooking Equipment,

(NFPA-96, latest edition) available from

NFPA.

In Canada:

1. Local codes.

2. Canadian Electric Code, CSA C22.2 (latest

edition). Copies may be obtained from

The Canadian Standard Association, 5060

Spectrum Way, Suite 100, Mississauga,

Ontario, Canada L4W 5N6.

LOCATION

The HC24EO5 is voltage specic. It is available

at 208 V, 50 to 60 Hz, 3-phase / 240 V, 50 to 60

Hz, 3-phase or 480 V, 50 to 60 Hz, 3-phase. It

can be eld converted to single phase.

The installation location must allow adequate

clearances for servicing and proper operation.

Minimum clearance for proper air circulation is

2" (5.1 cm) on the sides and 6" (15.2 cm) on

the back.

— 5 —

Page 6

HC24EO SERIES STEAMER

LEVELING FEET

This steamer is shipped with four 2" leveling

feet. Optional 4" leveling feet are available.

The 2" feet can be removed and the optional 4"

feet can be threaded into holes on the bottom

of the unit.

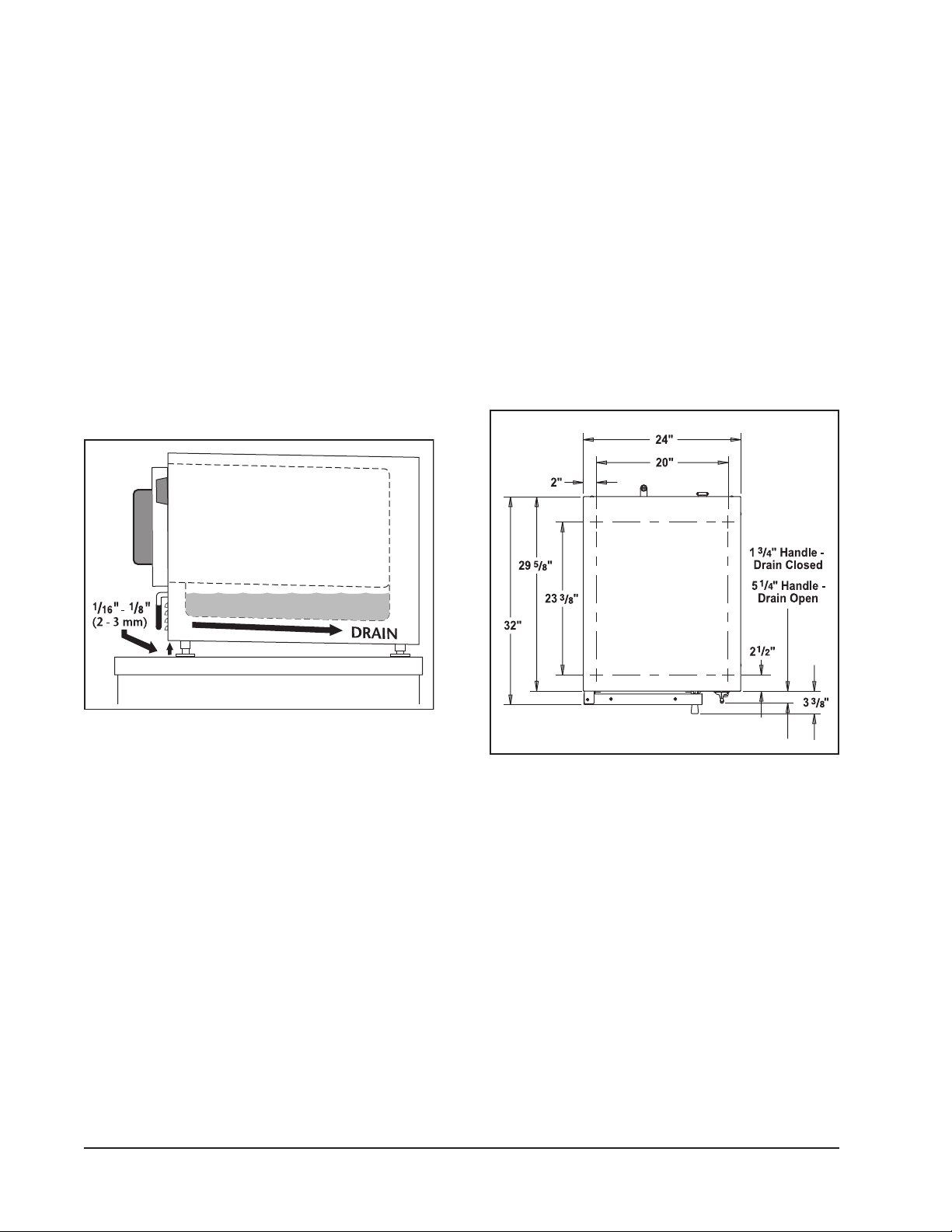

LEVELING

Position and level the unit using leveling feet.

Front of unit should be 1/16" to 1/8" higher than

the rear as indicated in Figure 1. Unit should

be level side to side.

Level the steamer front to back and side to side

by turning the adjustable feet.

ANCHORING STEAMER

1. Place steamer in the desired location on the

countertop and mark four corners. Remove

the steamer and drill 1/2" holes as indicated

in Figure 2.

2. Apply a bead of RTV or other NSF approved

sealant around the bottom edge of the

steamer. If anchoring the steamer, this

bottom seal is necessary to meet NSF

requirements.

3. Set steamer on countertop and bolt down

securely with 3/8" by 16" bolts (not supplied).

Screw length should be tabletop thickness

plus 1/2" for proper thread engagement.

Figure 1: Leveling Steamer

Figure 2: Anchoring Steamer

OPTIONAL ACCESSORIES

Optional accessories such as stands and stacking

kit will include directions for assembly.

— 6 —

Page 7

ELECTRICAL CONNECTIONS

To Control

Transformer *

To Control

Transformer *

3-PHASE, 208 V

3-PHASE, 240 V

1-PHASE, 208 V

1-PHASE, 240 V

B

BL

BR

YL

BL

BR

YL

21

24

21

22

23

24

25

26

22

25

23

26

BL

BR

YL

BL

BR

YL

A

B

A

*Primary taps of Control Transformer must be connected

according to the appliance data plate voltage marking and

actual connected supply.

To Control

Transformer *

3-PHASE, 380 V

3-PHASE, 415 V

3-PHASE, 480 V

B

BL

BR

YL

BL

BR

1CON L1 – T1

2CON T2 – L 2

1CON L2 – T2

2CON T3 –L3

2CON T1 –L1

1CON L3 - T 3

YL

21

22

23

A

*Primary taps of Control Transformer must be connected

according to the appliance data plate voltage marking and

actual connected supply.

To Control

Transformer *

To Control

Transformer *

3-PHASE, 208/240 V

1-PHASE, 208/240 V

B

BL

BR

YL

BL

BR

YL

21

24

21

22

23

24

25

26

22

25

23

26

BL

BR

YL

BL

BR

YL

GN

RD

OR

GN

RD

OR

GN

RD

OR

GN

RD

OR

A

B

A

*Primary taps of Control Transformer must be connected

according to the appliance data plate voltage marking and

actual connected supply.

** For operation from a 208 V supply, all 6 elements are to

be connected as shown. For 240 V supply, disconnect and

insulate element leads with Orange, Green and Red markers.

Not used for

240V operation **

: Electrical and grounding

connections must comply with the

applicable portions of the National

Electrical Code and/or other local

electrical codes.

When making electrical connections, use copper

wire suitable for at least 200°F (90°C). The

steamer must be grounded. The wiring diagram

is located on the inside of the right panel.

Steamers are wired for 3-phase and can be

converted to 1-phase by relocating the jumper

wires on the terminal block as shown on the

wiring diagram.

HC24EO SERIES STEAMER

— 7 —

Page 8

HC24EO SERIES STEAMER

ELECTRICAL DATA

Model Volts KW Amp @ Amp @

1 PH 3 PH

HC24EO3 208 8 38.5 22.2

240 8 33.3 19.2

HC24EO5 208 12 57.7 33.3

240 12 50.0 28.9

480 12 N/A 14.4

SERVICE CONNECTIONS

Water Connections

No water supply connections are required, as

the steamer is lled manually.

Water Treatment

A local water treatment specialist should

be consulted before installation of steam

generating equipment.

life. Water conditions vary from one location

to another. Ask your municipal water supplier

for details about your local water supply prior

to installation. Presence of sediment, silica,

excess chlorides or other dissolved solids may

lead to a recommendation for alternate form(s)

of water treatment. Test the water with the test

strip included with the steamer. Other factors

affecting steam generation are iron content,

amount of chloridation and dissolved gases.

Drain Connection

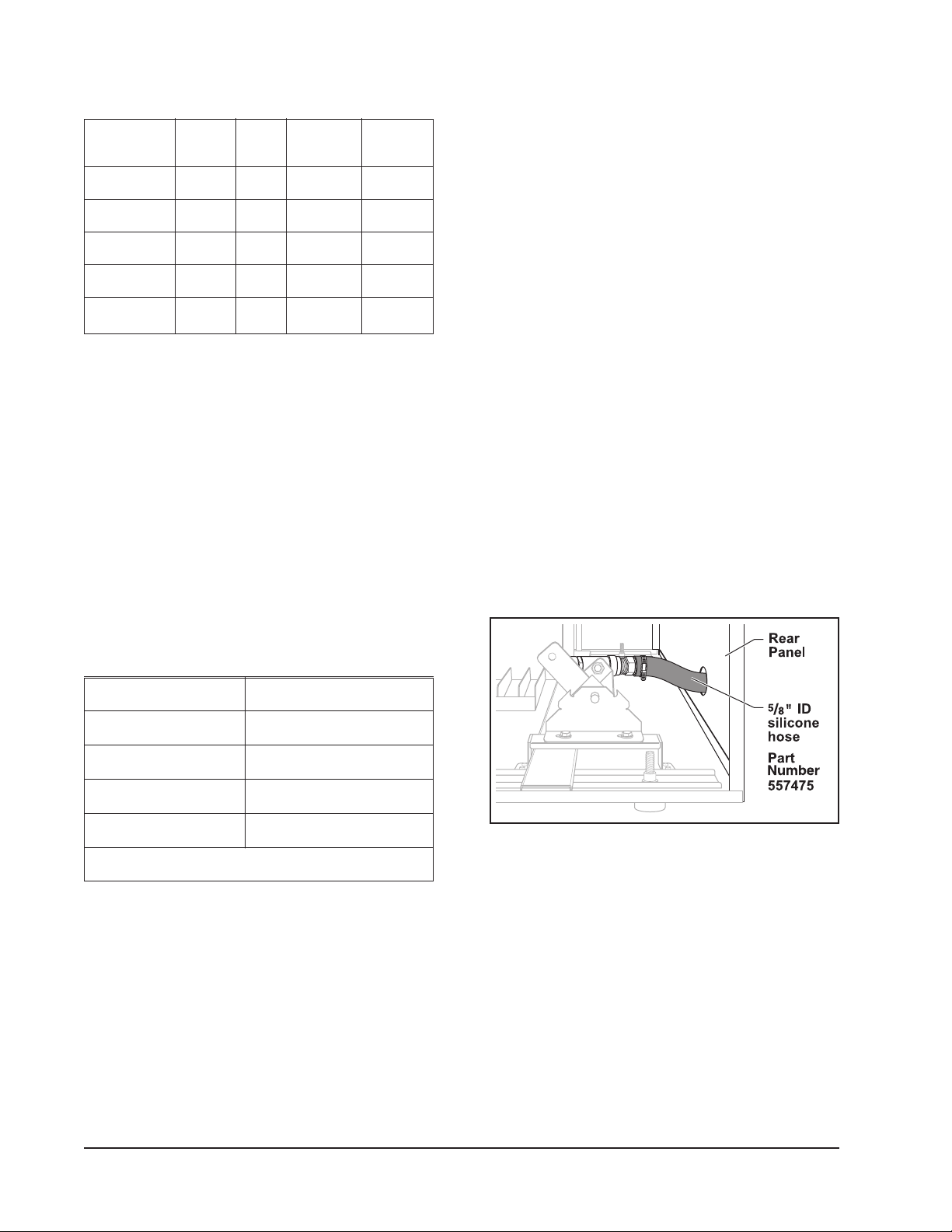

The C24EO can be congured to drain through

either the rear panel or through the bottom

base plate.

The unit is congured to be drained through the

rear panel from the factory. The unit is supplied

with a 12" length of 5/8" ID hose. If this length is

insufcient, remove the hose and install a new

hose ordered to the desired length. The factory

5

/8" ID silicone hose part number is 557475.

Hose is sold by the foot.

See Figure 3.

Hardness* No more than 3 grains

Silica less than 13 ppm

Total Chlorine less than 4.0 ppm

PH range 6.5 to 8

Undissolved Solids less than 5 microns

*17.1 ppm = 1 grain of hardness

If the water supply fails to meet these standards,

it will be necessary to install a water conditioner.

The use of strainers or lters will not remove

minerals from the water.

Water Requirements

Proper water quality can improve the taste of

the food prepared in the steamer, reduce liming

in the steam generator and extend equipment

Figure 3: Rear Panel Drain Connection

(Viewed with right side panel removed)

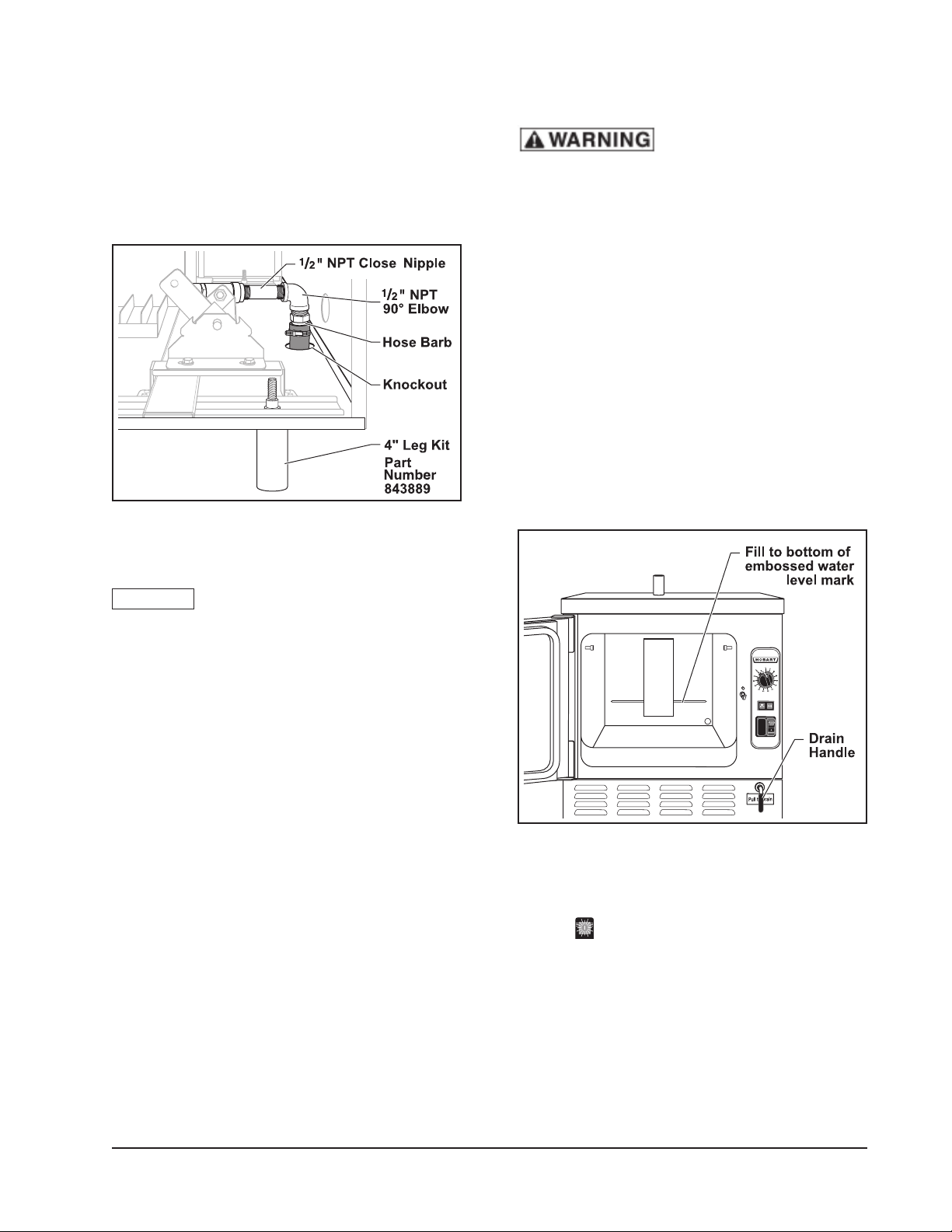

To eld congure the drain through the bottom

base plate, the 4" leg kit (part number 843889)

is required. Also required are a 1/2" NPT close

pipe nipple (11/8" long) and a 1/2" NPT 90°

elbow, which are available through local home

improvement or plumbing supply houses.

1. Remove right side panel.

2. Remove hose barb from drain.

3. Remove knockout from base plate.

— 8 —

Page 9

HC24EO SERIES STEAMER

4. Install the 1/2" NPT close nipple (11/8" long)

into drain.

5. Install 1/2" NPT 90° elbow onto pipe nipple.

6. Re-use hose barb.

7. Install hose barb into elbow with clamp, cut

to desired length or route to drain.

Figure 4: Bottom Panel Drain Connection

(Viewed with right side panel removed)

INSTALLATION STARTUP PROCEDURE

: The steamer and its

parts are hot. Use care when operating,

cleaning or servicing the steamer. The

cooking compartment contains live steam

and hot water. Stay clear when opening

the door.

Once the steamer is installed, thoroughly test

the steamer before operation.

1. Check that the proper electrical connections

have been made.

2. Close the drain valve by pushing the Drain

Handle in, located in the lower right hand

corner. Open the door and pour water

into the cooking compartment up to the

water level mark (the water level mark is

visible on the back wall of the steamer).

Do not overfill.

NOTICE Do not connect steamer drain

solidly to any drain piping. The steamer drain

must vent to the atmosphere to avoid creating

a back pressure and possible back siphoning

into the compartment.

VENT HOOD

Local codes may require the steamer to be

located under an exhaust hood. Information

on the c onstructi on and insta llation of

ventilating hoods may be obtained from

Vapor Removal from Cooking Equipment,

NFPA Standard No. 96 (latest edition).

BEFORE FIRST USE

Thoroughly clean the steamer before using

for the rst time. See the CLEANING section

in this manual.

Figure 5: Water Level Mark

3. Rotate the Timer to CONTINUOUS position.

Fully depress the Power Switch to the

ON

position. The Power Switch will turn

amber, indicating the unit is turned on.

4. With the door open, press in on the door

switch (small rod), located above the

door latch. The COOK light will come on.

Release the door switch and the COOK

light will turn off.

— 9 —

Page 10

HC24EO SERIES STEAMER

5. Close the compartment door and wait

approximately 10 minutes for unit to

preheat.

6. Rotate the Timer to 5 minutes. The Timer

will not start counting down until the cavity

has reached preheat temperature.

7. When the timer returns to 0, a buzzer will

sound signaling the end of the cooking

cycle. To silence the buzzer, turn the Timer

dial to the OFF position.

8. To turn the steamer off:

a. De pr es s th e Pow er Swi tc h to

the OFF

position.

b. Allow the steamer to cool.

c. Open the drain valve and drain the water

from the steamer.

d. Open the compartment door to allow

the inside to dry out.

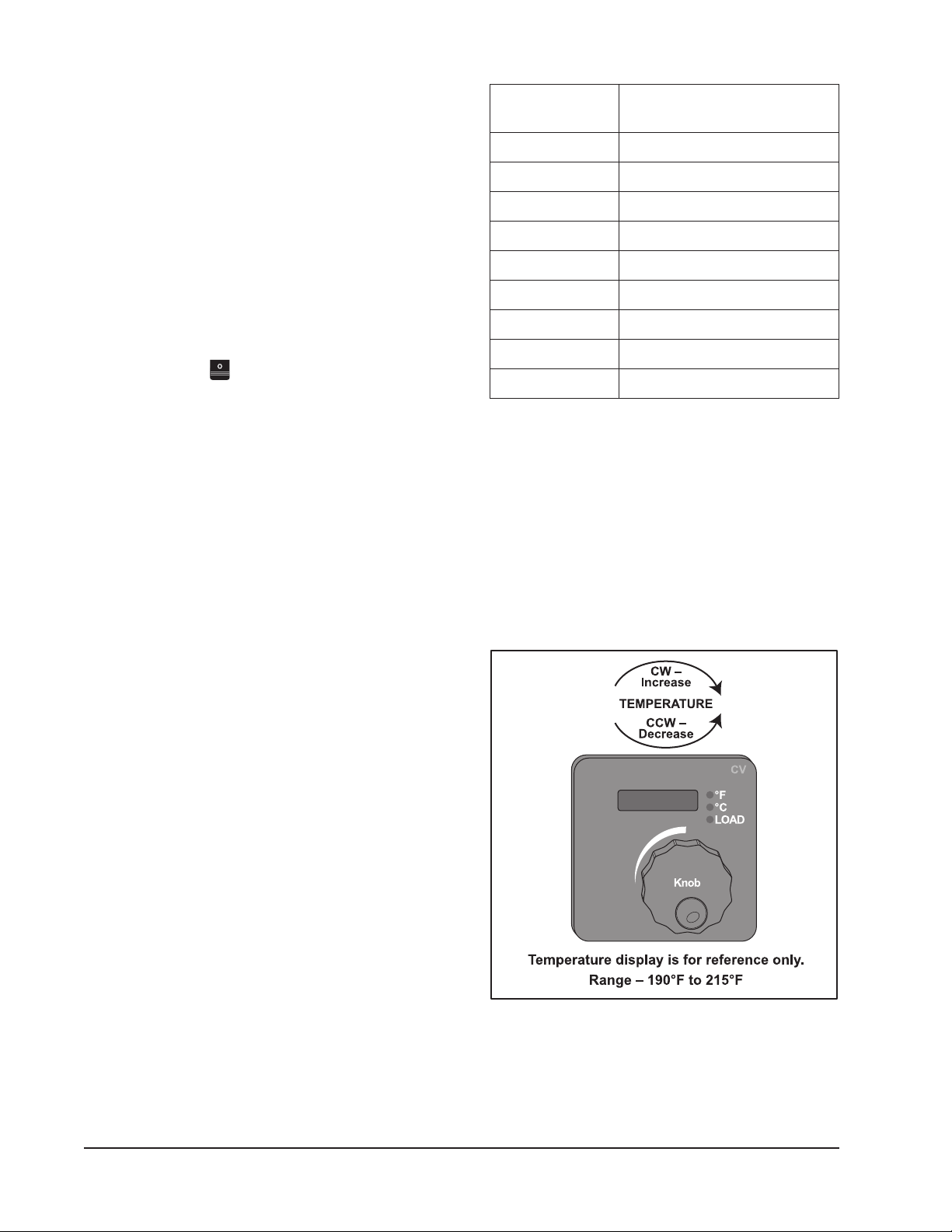

CALIBRATION PROCEDURE

ELEVATION DIGITAL

(FT) THERMOMETER - °F (C)

Sea Level 210 (99)

1,000 208 (98)

2,000 206 (97)

3,000 204 (96)

4,000 202 (94)

6,000 198 (93)

7,000 196 (91)

8,000 195 (90)

9,000 or above 194 (90)

1. Remove right side panel.

2. Place a temperature probe approximately

one inch down in the center of steam vent

pipe.

3. Turn steamer on by selecting CONTINUOUS

mode.

The right hand side panel must be removed

to access the temperature controller. To

achieve optimum steamer operation, rotate

the Temperature Control to the temperature

that corresponds to the elevation that it is

located at.

NOTE: The steamer is preset at the factory to

sea level.

A ha nd he l d d ig i ta l t he r mo m et er an d

thermocouple are required.

NOTE: If temperature setting is too high, the

boiling action will be excessive and cause

water droplets to exit the steam vent pipe

resulting in high water usage.

4. Using the table above, nd the corresponding

temperature for the elevation and set the

Temperature Control.

Figure 6: Temperature Control

— 10 —

Page 11

HC24EO SERIES STEAMER

NOTE: Temperature Control is configured

by vendor to Fahrenheit and cannot

be changed to Celsius. The display

indicates set point temperature only.

a. Wait 3 seconds after releasing the

knob for the selection to be saved in

memory. Display will blink momentarily

to indicate temperature is saved.

b. Allow temperature to stabilize by

completing two heating cycles with

door closed.

NOTE: Temperature display on control is for

reference only. When calibrating, use

the recorded temperature from meter.

5. Record temperature reading from meter

when load light goes out.

6. Compare recorded temperature to the

temperature from table.

a. If recorded temperature is correct, no

adjustment is necessary.

b. If recorded temperature is not correct,

adjust temperature setting and re-check

the temperature reading with meter.

NOTE: If unit cannot be calibrated call your

Authorized Vulcan Servicer.

7. If correct temperature reading is not attained

after 3 attempts, call your Authorized Vulcan

Servicer.

— 11 —

Page 12

HC24EO SERIES STEAMER

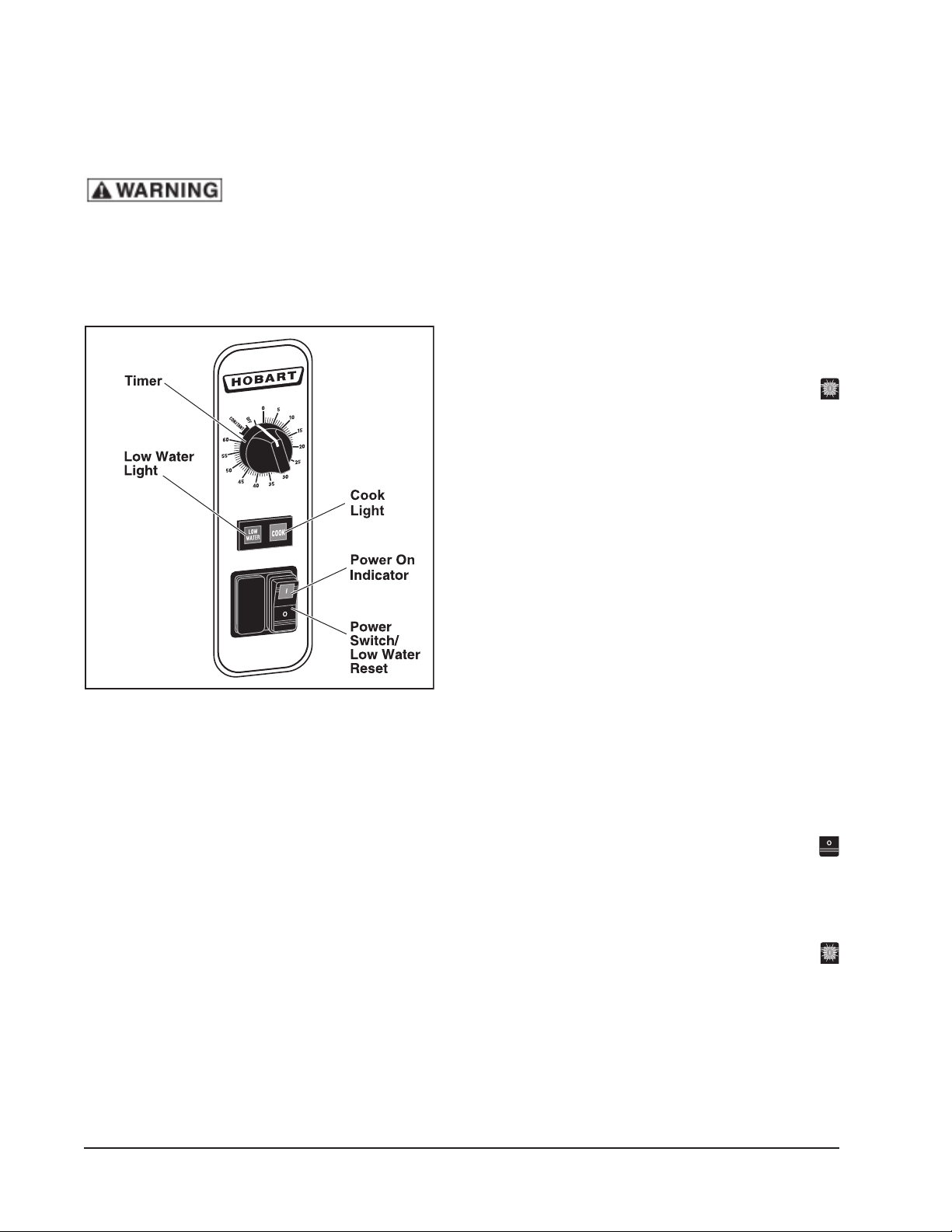

OPERATION

CONTROLS

: The steamer and its

parts are hot. Use care when operating,

cleaning or servicing the steamer. The

cooking compartment contains live steam

and hot water. Stay clear when opening

the door.

OPERATING THE STEAMER

1. Push the the drain lever in to close the drain

valve.

2. Open the door and pour water into the

cooking compartment up to the water level

mark. The water level mark is visible on the

back wall of the steamer. Unit capacity is 3

gallons. Do not overll.

3. Close door.

4. Verify Timer is in the OFF position.

5. Fully depress Power Switch to ON

position. Power light in switch will illuminate

amber.

6. Set timer to 5 minutes. In approximately 15

minutes unit will be preheated and ready to

cook.

7. Set timer to desired time (0 to 60 minutes)

or to CONTINUOUS position.

8. At the end of the timed cycle an audible

alarm will sound.

Figure 7: Controls

Power Switch/Low Water Reset: Turns

unit OFF/ON/RESETS LOW WATER LIGHT/

ALARM.

Low Water Light: When lit, indicates additional

water is required.

Timer: Selects the desired cooking time or

the CONTINUOUS position.

COOK Light: When lit, indicates the timer is

set and door is closed.

9. The unit returns to the idle temperature.

NOTE: Timer will not function until preheat has

been completed.

LOW WATER

1. When the Low Water light is illuminated

the unit needs to be relled with water. An

audible alarm will sound.

2. Fully depress Power Switch to OFF

position.

4. Rell unit with water.

5. Close door.

6. Fully depress Power Switch to ON

position to cancel Low Water alarm.

7. Timer will resume when steamer reaches

cooking temperature.

NOTE: Rell the unit when not in use or during

slow times to avoid running out of water.

Running out of water during a cooking

cycle will lengthen cook time.

— 12 —

Page 13

HC24EO SERIES STEAMER

SHUTDOWN

1. Rotate Timer to OFF position.

2. Fully depress Power Switch to OFF

position.

3. Allow steamer to cool.

4. Open the drain valve and drain the water

from steamer.

5. Open the compartment door to allow the

inside to dry.

6. Follow cleaning instructions in this

manual.

EXTENDED SHUTDOWN

1. Fully depress Power Switch to OFF

position.

2. Clean the interior and exterior of unit.

3. Leave door open.

4. Disconnect power.

— 13 —

Page 14

HC24EO SERIES STEAMER

CLEANING

COOKING COMPARTMENT DRAIN

Remove any particles or debris that may be

blocking the drain. Make a solution of warm

water with non-chloride detergent and pour

1

/2 gallon (1.9 liters) of it down the compartment

drain. Rinse by pouring 1/2 gallon (1.9 liters) of

hot water down the compartment drain.

Thoroughly clean the exposed surfaces

(sides, front, door and top) with a damp cloth

and polish with a clean cloth daily. To remove

discolorations, use a nonabrasive cleaner.

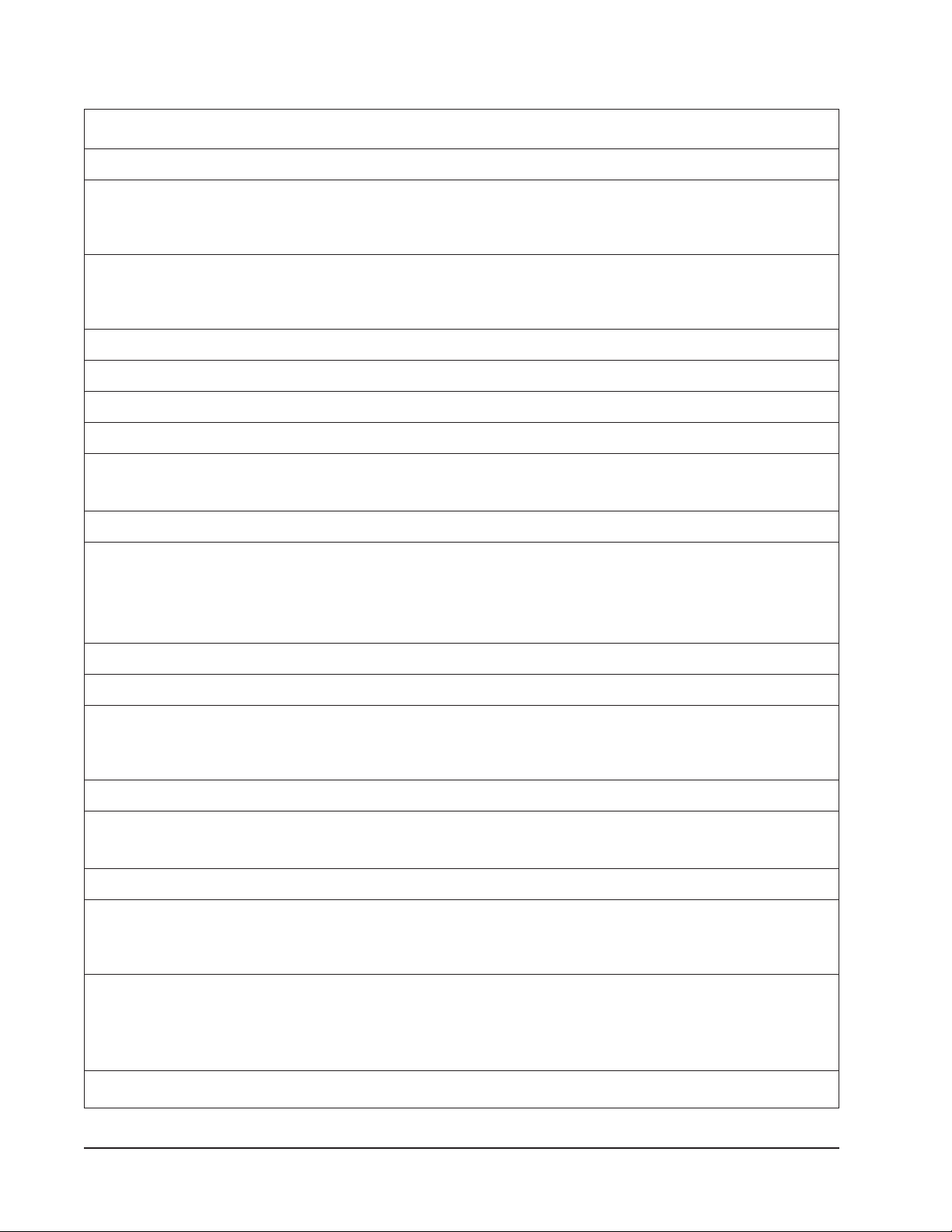

DOOR GASKET

Clean the gasket sealing surface of the

compartment door daily to remove food acids for

maximum gasket life. Do not use any solvents or

sharp instruments. Wash with a cloth moistened

in a solution of mild detergent and warm water.

Rinse with a fresh cloth moistened with warm

water to remove all traces of detergent.

Wipe dry with a clean cloth. Never apply food

oils or petroleum lubricants directly to the

door gasket. Petroleum-based solvents and

lubricants will reduce gasket life.

LEAVE COMPARTMENT DOOR OPEN

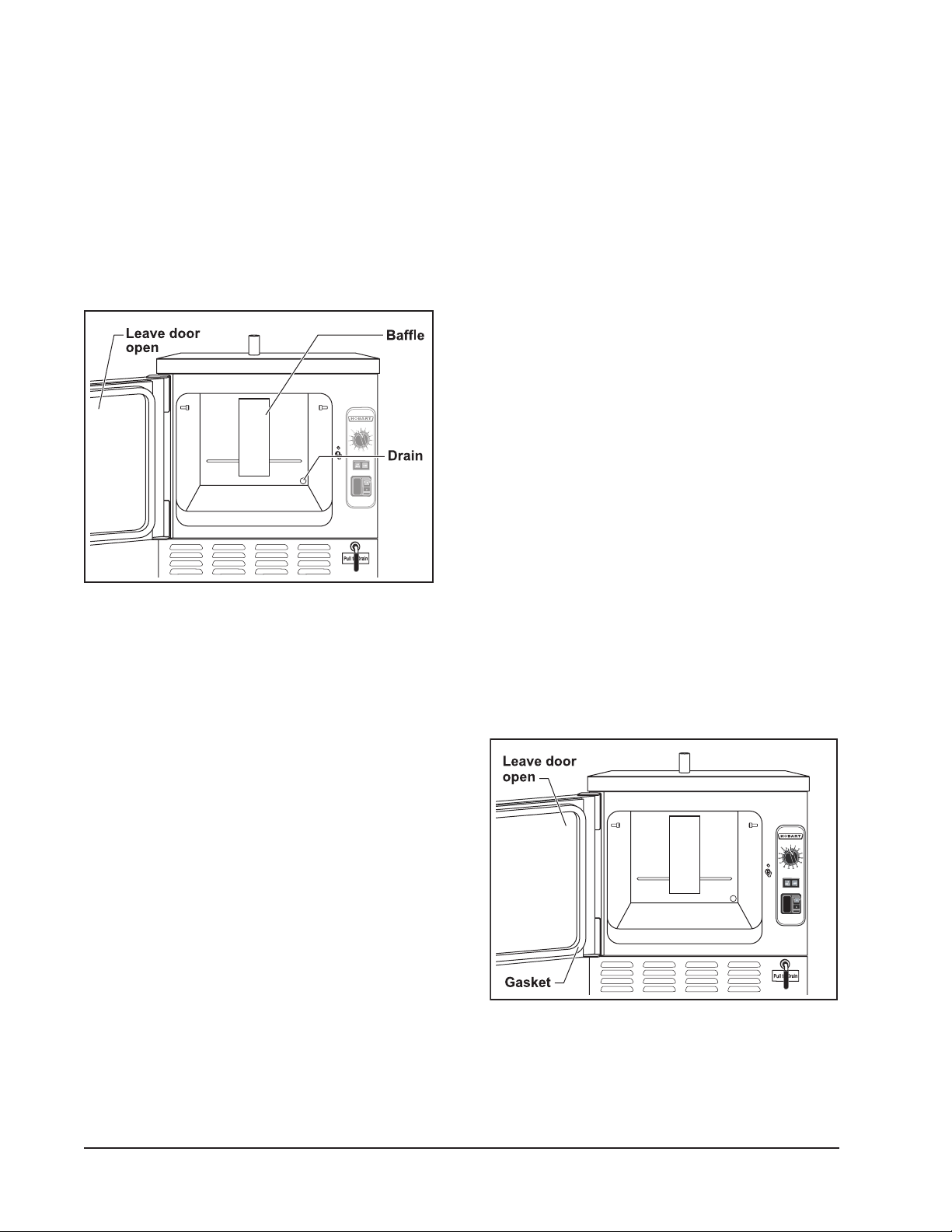

Figure 8: Oven Cavity

COMPARTMENT

The compartment, pan guides, and bafe

should be cleaned daily. The exterior should

be cleaned daily.

Remove the pan guides by lifting up and out.

Wash with a solution of warm water with nonchloride detergent. Rinse with warm water.

Remove the bafe from the compartment by

lifting up and out. Wash with a solution of warm

water with non-chloride detergent. Rinse with

warm water.

NOTE: Failure to reinstall bafe after cleaning

will affect cooking performance.

Wash the inside of the compartment with

a solution of warm water with non-chloride

detergent. Rinse with warm water.

Leave the compartment door slightly open

when the steamer is not in use. When the

compartment is idle, never latch the door and

apply pressure to the door gasket. Leaving the

gasket under pressure can cause permanent

deformation and reduce gasket life.

Figure 9: Leave Door Open

— 14 —

Page 15

HC24EO SERIES STEAMER

STAINLESS STEEL EQUIPMENT CARE

AND CLEANING

Contrary to popular belief, stainless steels

ARE susceptible to rusting.

Corrosion on metals is everywhere. It is

recognized quickly on iron and steel as unsightly

yellow/orange rust. Such metals are called

“active” because they actively corrode in a

natural environment when their atoms combine

with oxygen to form rust.

Stainless steels are passive metals because

they contain other metals, like chromium, nickel

and manganese, that stabilize the atoms.

400 series stainless steels are called ferritic,

contain chromium, and are magnetic; 300 series

stainless steels are called austenitic, containing

chromium and nickel; and 200 series stainless,

also austenitic, contains manganese, nitrogen

and carbon. Austenitic types of stainless are

not magnetic, and generally provide greater

resistance to corrosion than ferritic types.

With 12 to 30% chromium, an invisible passive

lm covers the steel’s surface acting as a shield

against corrosion. As long as the lm is intact

and not broken or contaminated, the metal is

passive and stainless. If the passive lm of

stainless steel has been broken, equipment

starts to corrode and starts to rust.

Enemies of Stainless Steel

There are three basic things which can break

down stainless steel’s passivity layer and allow

corrosion to occur.

1. Mechanical abrasion.

Water comes out of the faucet in varying degrees

of hardness. Depending on what part of the

country you live in, you may have hard or soft

water. Hard water may leave spots, and when

heated leaves deposits behind that if left to sit, will

break down the passive layer and rust stainless

steel. Other deposits from food preparation and

service must be properly removed.

Chlorides are found nearly everywhere. They

are in water, food and table salt. One of the

worst chloride perpetrators can come from

household and industrial cleaners.

So what does all this mean?

Don’t despair!

Here are a few steps that can help prevent

stainless steel rust.

1. Use the proper tools.

When cleaning stainless steel products,

use non-abrasive tools. Soft cloths and

plastic scouring pads will not harm steel’s

passive layer. Stainless steel pads also

can be used but the scrubbing motion must

be in the direction of the manufacturers’

polishing marks.

2. Clean with the polish lines.

Some stainless steel comes with visible

polishing lines or grain. When visible lines

are present, always scrub in a motion

parallel to the lines. When the grain cannot

be seen, play it safe and use a soft cloth or

plastic scouring pad.

3. Use alkaline, alkaline chlorinated or nonchloride containing cleaners.

2. Deposits and water.

3. Chlorides.

Mechanical abrasion means those things that

will scratch a steel surface. Steel pads, wire

brushes and scrapers are prime examples.

While many traditional cleaners are loaded

with chlorides, the industry is providing

an ever-increasing choice of non-chloride

cleaners. If you are not sure of chloride

content in the cleaner used, contact your

cleaning supplier. If your present cleaner

contains chlorides, ask your supplier if

they have an alternative. Avoid cleaners

containing quaternary salts; it also can

attack stainless steel and cause pitting

and rusting.

— 15 —

Page 16

HC24EO SERIES STEAMER

4. Treat your water.

Though this is not always practical,

softening hard water can do much to reduce

deposits. There are certain lters that can be

installed to remove distasteful and corrosive

elements. To insure proper water treatment,

call a treatment specialist.

5. Keep your food equipment clean.

Use alkaline, alkaline chlorinated or non-

chloride cleaners at recommended strength.

Clean frequently to avoid build-up of hard

stubborn stains. If you boil water in stainless

steel equipment, remember the single

most likely cause of damage is chlorides

in the water. Heating cleaners that contain

chlorides have a similar effect.

6. Rinse, rinse, rinse.

If chlorinated cleaners are used, rinse

and wipe equipment and supplies dry

immediately. The sooner you wipe off

standing water, especially when it contains

cleaning agents, the better. After wiping

equipment down, allow it to air dry; oxygen

helps maintain the stainless steel’s passivity

lm.

7. Never use hydrochloric acid (muriatic

acid) on stainless steel.

8. Regularly restore/passivate stainless

steel.

Recommended cleaners for specic

situations

Cleaning

Job

Routine

cleaning

Fingerprints

& smears

Stubborn

stains &

discoloration

Grease &

fatty acids,

blood, burnton-foods

Grease & oil

Restoration/

Passivation

Agent

Soap,

ammonia,

detergent,

Medallion

Arcal 20, LacO-Nu Ecoshine

Cameo, Talc,

Zud, First

Impression

Easy-off, DeGrease It Oven

Aid

Any good

commercial

detergent

Benet, Super

Sheen

Comments

Apply with cloth

or sponge

Provides barrier

lm

Rub in direction

of polish lines

Excellent

removal on all

nishes

Apply with

sponge or cloth

Review

1. Stainless steels rust when passivity (lm-shield) breaks down as a result of scrapes, scratches,

deposits and chlorides.

2 Stainless steel rust starts with pits and cracks.

3. Use the proper tools. Do not use steel pads, wire brushes or scrapers to clean stainless steel.

4. Use non-chlorinated cleaners at recommended concentrations. Use only chloride-free

cleaners.

5. Soften your water. Use lters and softeners whenever possible.

6. Wipe off cleaning agent(s) and standing water as soon as possible. Prolonged contact causes

eventual problems.

To learn more about chloride-stress corrosion and how to prevent it, contact the equipment

manufacturer or cleaning material supplier.

— 16 —

Page 17

HC24EO SERIES STEAMER

Developed by Packer Engineering, Naperville, Ill., an independent testing laboratory.

MAINTENANCE

: The steamer and its

parts are hot. Use care when operating,

cleaning or servicing the steamer. The

cooking compartment contains live steam

and hot water. Stay clear when opening

the door.

Steamer must be cleaned daily. See CLEANING

section.

REMOVAL OF LIME SCALE DEPOSITS

: Read and follow the

instructions on the deliming material

package. Avoid contact with skin and eyes.

Wear plastic or rubber gloves and safety

goggles when handling. Wash thoroughly

after handling. If deliming solution comes

in contact with the skin or eyes, rinse

thoroughly with clean water.

: The steamer and its

parts are hot. Use care when operating,

cleaning or servicing the steamer. The

cooking compartment contains live steam

and hot water. Stay clear when opening

the door.

The steamer should be delimed when scale

is present in the cavity well. Deliming may be

required frequently depending on water quality

and scale build up. This is in accordance with

the minimum preventive maintenance schedule

required by warranty.

2. Plastic or rubber gloves.

3. Safety goggles or face shield.

4. Spray bottle.

5. 1-gallon container for mixing the deliming

solution.

NOTE: Deliming solution may cause the surface

of aluminum measuring tools to tarnish

or etch.

Procedure:

1. Turn steamer off. Drain the steamer.

2. One bag will treat a C24EO3 or C24EO5

steamer.

• 1 bag to 2 gallons warm water

3. Spray cavity walls with solution. Pour

solution into cavity well.

• Maximum steamer capacity 3 gallons

4. Fully depress Power Switch to ON

position and set Timer for 5 min. After timer

sounds, rotate Timer dial to OFF position

and fully depress Power Switch to OFF

position.

5. Let delime solution soak for a minimum of

30 minutes, maximum 60 minutes. If scale

is still present, repeat steps 1 through 5.

6. Drain the steamer and rinse thoroughly with

warm clean water.

7. Dry with a clean dry cloth.

8. Leave steamer door open when not in use.

DOOR GASKET

Items required (not provided):

1. Deliming Solution – Scale Release™

Part Number 854893-13 (qty. 1).

• Contact the local Authorized Vulcan

Servicer or refer to website

www.hobartcorp.com

If the door gasket is leaking due to a nick or

cut, it must be replaced. Damage to the gasket

sealing surface will cause steam leakage.

— 17 —

Page 18

HC24EO SERIES STEAMER

COOKING HINTS

The steamer efficiently cooks vegetables and

other foods for immediate serving. Steam

cooking should be carefully time controlled.

Keep hot food holding-time to a minimum to

produce the most appetizing results. Prepare

small batches. Cook only enough to start

serving, then cook additional amounts to

meet demand.

ACCEPTABLE PAN SIZES

The steamer accommodates combinations

of full, half and one-third size pans, solid or

perforated.

Model Number of Pans Accommodated

Depth of Pan

1" 21/2" 4" 6"

C24EO3 6 3 2 1

PREPARATION

Prepare vegetables, fruits, meats, seafood and

poultry normally by cleaning, separating, cutting,

removing stems, etc. Cook root vegetables in

a perforated pan. Other vegetables may be

cooked in a perforated pan unless juices are

being saved. Liquids can be collected in a solid

12" x 20" pan placed under a perforated pan.

Perforated pans are used for frankfurters,

wieners and similar items when juices do not

need to be preserved. Solid pans are good

for cooking puddings, rice, and hot breakfast

cereals. Vegetables and fruits are cooked in

solid pans in their own juice. Meats and poultry

are cooked in solid pans to preserve their juice

or retain broth.

Canned foods can be heated in their opened

cans (cans placed in 12" x 20" solid pans) or

the contents may be poured into solid pans. DO

NOT place unopened cans in the steamer.

C24EO5 10 5 3 2

COOKING GUIDELINES

The steamer cooks vegetables, frankfurters,

eggs in their shells, and certain other meats

or food items at atmospheric pressure.

These cooking guidelines are suggestions only.

You should experiment with your food products

to determine the cooking times that will give you

the best results. Variables which affect cooking

time include size, weight, thickness of foods,

temperature, density, previous condition of

the foods (fresh, pre-blanched or frozen) and

degree of doneness desired.

Frozen Food Items

Separate frozen foods into smaller pieces to

allow more efcient cooking.

Use a pan cover for precooked frozen dishes

that cannot be cooked in the covered containers

in which they are packed if they require more

than 15 minutes of cooking time. When a cover

is used, approximately one-third additional

cooking time is necessary.

Cooking time for frozen foods depends on

the amount of defrosting required. If time

permits, allow frozen foods to partially thaw

overnight in a refrigerator. This will reduce

their cooking time.

— 18 —

Page 19

HC24EO SERIES STEAMER

PRODUCTS TO BE COOKED IN SOLID PANS

PRODUCT TIME (MINUTES) WEIGHT PER PAN

Eggs, Scrambled 9 to 12 8 doz.

Rice, Long Grain (Cover with 4 cups water/lb.) 23 to 25 2 lbs.

Pasta (Place perforated pan inside solid pan,

cover with cold water)

Spaghetti Regular/Vermicelli 10 to 15

Macaroni - Shells/Elbows 13 to 18

Noodles - 1/2" Wide 10 to 15

Lasagna Noodles 13 to 18

Frozen Casseroles, Lasagna 33 to 35 Full Pan

Meat Loaf, 3-5 Lb. Each 38 to 40 15 lbs.

Beef

Ground Chuck 19 to 25 10 lbs.

Sliced as Purchased 33 to 40 10 lbs.

Shrimp, Frozen, 10 Shrimp per Lb. 4 to 5 4 lbs.

Beans

Baked 8 to 9 10 lb. Can

Refried 8 to 9 10 lb. Can

Canned Vegetables 5 to 6 10 lb. Can

Prunes, Dried 11 to 15

— 19 —

Page 20

HC24EO SERIES STEAMER

PRODUCTS TO BE COOKED IN PERFORATED PANS

PRODUCT TIME (MINUTES) WEIGHT PER PAN

SEAFOOD

Clams

Frozen 9 to 12 3 doz.

Fresh, Cherrystone 4 to 6 3 doz.

King Crab, Frozen

Claws 3 to 4 21/2 lbs.

Legs 3 to 6 41/2 lbs.

Lobster Tail, Frozen 5 to 6 10 lbs.

Lobster, Live, 10" - 12" 4 to 5 4 Per Pan

Salmon Fillets, Frozen, 8 ounce each 4 to 5 71/2 lbs.

Scallops, Fresh 3 to 4 3 lbs.

Scrod Fillets, Fresh 3 to 5 4 lbs.

EGGS

Hard Cooked 14 to 15 4 doz.

Soft Cooked 8 to 10 4 doz.

Soft Yoke for Caesar Salad 5 to 8 4 doz.

MEATS

Chicken — Breasts, Legs, Thighs 19 to 20 15 lbs.

Turkey, Frozen

Breasts (2) 86 to 90 6 to 7 lbs. Each

Cut Lengthwise 53 to 55 20 to 25 lbs.

Corned Beef 40 to 75 6 to 8 lbs.

Hot Dogs and Wieners 2 to 3 80 to 100 Count

VEGETABLES

Asparagus Spears

Frozen 10 to 12 3 lbs.

Fresh 4 to 5 5 lbs.

Beans

Green 2" Cut, Frozen/Fresh 5 to 6 5 lbs.

Lima, Frozen 7 to 8 5 lbs.

Baby Lima, Frozen 4 to 5 5 lbs.

Brussel Sprouts, Frozen 5 to 6 5 lbs.

— 20 —

Page 21

HC24EO SERIES STEAMER

PRODUCT TIME (MINUTES) WEIGHT PER PAN

VEGETABLES (Cont’d.)

Broccoli

Spears, Frozen 6 to 8 4 lbs.

Spears, Fresh 4 to 6 5 lbs.

Flowerettes, Frozen 4 to 6 5 lbs.

Cabbage, Fresh, 1/6 Cut 6 to 8 5 lbs.

Carrots

Baby Whole, Frozen 6 to 8 7 lbs.

Crinkle Cut, Frozen 7 to 8 4 lbs.

Sliced, Fresh 9 to 11 9 lbs.

Cauliower, Flowerettes

Frozen 4 to 6 4 lbs.

Fresh 7 to 8 5 lbs.

Celery, 1" Diagonal Cut 5 to 7 5 lbs.

Corn

Yellow Whole Kernel, Frozen 3 to 5 5 lbs.

Cobbettes, Frozen 6 to 8 27 Ears

Corn-On-Cob, Fresh 16 to 18 80 Ears

16 to 18 54 Ears

10 to 12 18 Ears

Peas, Green 4 to 6 5 lbs.

Potatoes, Whole Russet 50 to 55 40 lbs.

Spinach

Chopped, Frozen 15 to 17 6 lbs.

Defrosted 4 to 5 6 lbs.

Fresh Cut 2 to 3 2 lbs.

Squash, Acorn Halves 22 to 25 10 Halves

Zucchini, Slices 6 to 8 10 lbs.

Frozen Mixed Vegetables 6 to 7 5 lbs.

FRUIT

Fruit, Blanch for Peeling

Grapefruit, Oranges 2 to 3

Pineapple, Whole for Cutting 2 to 4

— 21 —

Page 22

HC24EO SERIES STEAMER

TROUBLESHOOTING

SYMPTOMS

Steamer not steaming

Steamer not

steaming properly

Door leaks

Water does not drain

properly

Water foaming

POSSIBLE CAUSES

No main power source.

Door is open.

Power switch in OFF position.

Timer is off.

Needs water.

Excessive scale buildup in the

cavity well.

Not connected to correct voltage.

Damaged door gasket.

Damage to gasket sealing surface.

Blocked or obstructed steam vent.

Unit not level.

Drain clogged.

Cooking seafood without catch

pan.

REMEDY

Check the power source.

Close door.

Set power switch to ON.

Set Timer.

Add water.

Descale the steamer (see

REMOVAL OF LIME SCALE

DEPOSITS).

If voltage is not correct, contact

your Authorized Vulcan Servicer.

Check door gasket for damage.

If adjustment is needed, contact

your Authorized Vulcan Servicer.

Clear steam vent.

See leveling instructions in

the installation section of this

manual.

Unclog drain.

Use a catch pan. Drain and

replace water.

— 22 —

Page 23

HC24EO SERIES STEAMER

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Authorized Vulcan Servicer

in your area. Refer to our website, www.hobartcorp.com for a complete listing of Authorized Service

and Parts depots.

When calling for service, the following information (located on your machine data plate) must be

available:

Model Number

Serial Number

Manufacture Date (MD)

Voltage

— 23 —

Page 24

HC24EO SERIES STEAMER

(05-10)

— 24 —

PRINTED IN U.S.A.

Loading...

Loading...