Page 1

FRYER FILTER-IN-A-DRAWER

SUPPLEMENT TO INSTRUCTION MANUALS FOR:

Gas Fryer Models* Electric Fryer Models**

ML-135536 HG35F ML-126964 HFD40F

ML-135537 HG45F ML-126966 HFD50F

ML-135538 HG65F ML-126970 HFD85F

ML-135539 HG85F

ML-126965 HFC40F

ML-126953 HGD35F ML-126967 HFC50F

ML-126956 HGD45F ML-126971 HFC85F

ML-126959 HGD65F

ML-126962 HGD85F ML-126968 HD225F

ML-126954 HGC35F ML-126969 HC225F

ML-126957 HGC45F

ML-126960 HGC65F

ML-126963 HGC85F

* F-34085 and F-34086 Rev. A

** F-33637 Rev. B

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 34727 Rev. B (Jan. 2003)

Page 2

Table of Contents

GENERAL .............................................................................................................................................3

ASSEMBLY .....................................................................................................................................3

CONTROLS AND COMPONENT LOCATIONS — GAS FRYERS .................................................4

CONTROLS AND COMPONENT LOCATIONS — ELECTRIC FRYERS.......................................5

OPERATION.........................................................................................................................................6

FILTERING PROCEDURE WHEN USING LIQUID SHORTENING .........................................6

FILTERING PROCEDURE WHEN USING SOLID SHORTENING ...........................................7

FILTERING TIPS ............................................................................................................................8

PERIODICALLY REMOVE EXCESS DEBRIS FROM THE FILTER .........................................8

FLUSH AND DISCARD ................................................................................................................. 8

MAINTENANCE................................................................................................................................. 10

CLEANING THE FILTER DRAWER .......................................................................................... 10

FRYER BOIL-OUT INSTRUCTIONS......................................................................................... 11

TROUBLESHOOTING ...................................................................................................................... 12

SERVICE...................................................................................................................................... 12

© HOBART CORPORATION, 2003

–2 –

Page 3

OPERATION AND CARE OF

FRYER FILTER-IN-A-DRAWER

SAVE THESE INSTRUCTIONS

GENERAL

The Fryer Filter-In-A-Drawer filters the oil as it is pumped back to its respective tank. Valves inside the

doors under each fry tank must be set so only one tank is being drained, filtered and pumped back at

any one time.

The Fryer Filter-In-A-Drawer is used on the following Hobart Fryer Models:

Gas Fryers Electric Fryers

HG35F HGD35F HGC35F HFD40F HFC40F

HG45F HGD45F HGC45F HFD50F HFC50F

HG65F HGD65F HGC65F HFD85F HFC85F

HG85F HGD85F HGC85F HD225F HC225F

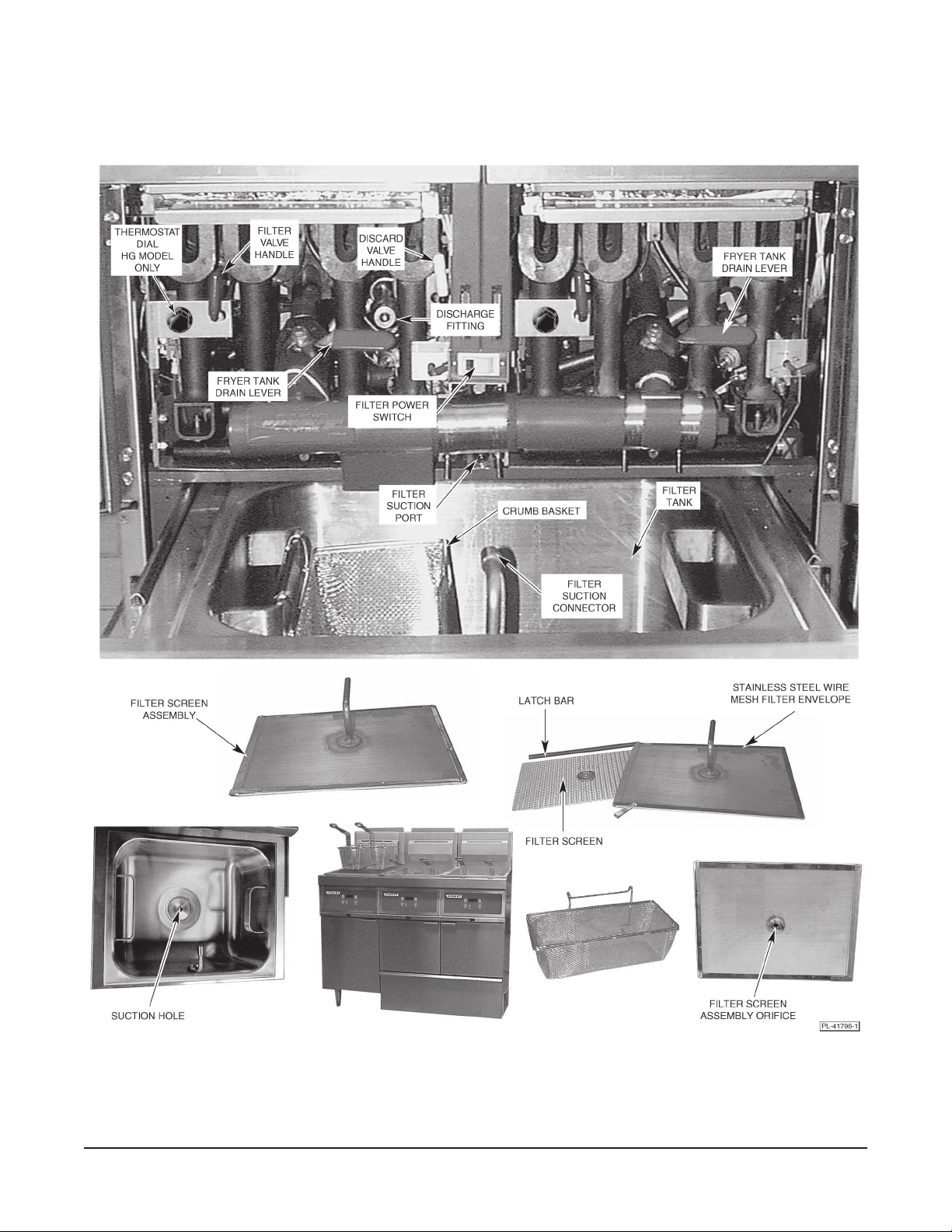

ASSEMBLY

1. After unpacking, wash the filter tank, crumb basket and filter screen. Use dishwashing

detergent and warm water, or clean the components in a dishwasher. Rinse the filter tank,

crumb basket and filter screen thoroughly. Wipe components dry with a clean cloth.

2. Pull the filter drawer out.

3. Place the filter tank in the filter drawer. Hang the crumb basket from the left tank handle inside

the filter tank (Figs. 1 and 2). Position the filter screen assembly flat on the bottom of the filter

tank so the filter orifice underneath the screen fits the suction hole in the bottom of the tank (Figs.

1 and 2). Close the drawer.

4. Make sure the two O-Rings are in place inside the filter suction port (Figs. 1 and 2). As the

drawer is closed, make sure the filter suction connector fits tightly into the filter suction port

(Figs. 1 and 2).

–3 –

Page 4

CONTROLS AND COMPONENT LOCATIONS — Gas Fryers

The filter tank cover is removed to show component locations.

Fig. 1

–4 –

Page 5

CONTROLS AND COMPONENT LOCATIONS — Electric Fryers

The filter tank cover is removed to show component locations.

Fig. 2

–5 –

Page 6

OPERATION

WARNING: HOT FRYING COMPOUND AND PARTS CAN CAUSE BURNS. USE CARE WHEN

OPERATING, CLEANING OR SERVICING THE FRYER. USE CARE WHEN FILTERING. DO NOT

LEAVE UNATTENDED.

WARNING: SPILLING HOT FRYING COMPOUND CAN CAUSE SEVERE BURNS. DO NOT

MOVE THE FRYER WITHOUT DRAINING ALL FRYING COMPOUND FROM THE TANK.

FILTERING PROCEDURE WHEN USING LIQUID SHORTENING

1. Turn the fryer's power OFF and open the doors (Fig. 3).

NOTE: HGC and HGD models have a drain valve interlock

system built in that will automatically shut the fryer off as soon

as the drain valve is opened.

2. Slowly turn the red fryer tank drain lever counterclockwise

(Fig. 5) until it stops. This allows the oil to drain into the filter

tank.

NOTE: Drain and filter only one fryer tank at a time.

Fig. 3

3. Pull the filter drawer out. Lift the filter tank cover up (Fig. 4). Make sure filter tank and parts are

properly assembled (pages 3 through 5).

4. Add 8 ounces of diatomaceous earth to the filter tank. Agitate to mix the diatomaceous earth

and shortening. Replace the filter tank cover. Slide the filter drawer back into place.

PL-41601

Fig. 4 Fig. 5

PL-41602

5. Turn the filter power switch ON (Fig. 6). The red pilot light in the filter power switch comes on.

PL-41603

Gas Fryer Electric Fryer

Fig. 6

–6 –

PL-41604

Page 7

6. To start filtering, pull out the red filter valve handle (Fig. 7) of the fryer tank to be filtered. Use

PL-41607

a brush to remove all the residue from the bottom of the tank into the drain tube. Let the oil recycle

for 1 to 3 minutes, flushing residue from the tank bottom into the filter.

PL-41605

Gas Fryer Electric Fryer

Fig. 7

7. Close the red fryer tank drain lever (Fig. 8) by turning

the lever clockwise until it stops. The fryer tank will now

refill.

8. After filtering is complete (all oil is removed from the

filter tank and air bubbles should appear in the fryer

tank), push in the red filter valve handle completely

(Fig. 9).

PL-41606

Fig. 8

PL-41608

Gas Fryer Electric Fryer

Fig. 9

9. Turn the filter power switch OFF (Fig. 6).

10. Close the fryer doors.

FILTERING PROCEDURE WHEN USING SOLID SHORTENING

1. Follow the fat melt procedure discussed in the

INSTRUCTION

2. Set the fryer thermostat at 350°F (177°C).

–7 –

PL-41609

manual supplied with your fryer.

Page 8

PL-41612

3. Once shortening has melted, stir oil to eliminate

COLD ZONE

- MIN -

- MAX -

COLD ZONE

PL-56013

- MIN -

- MAX -

solid shortening in the cold zone (Fig. 10). All

solid shortening must have melted completely.

4. Allow the fryer to idle at 350°F (177°C) for

10 minutes, if filtering from a cold start.

5. Turn the fryer off. Make sure filter tank and

parts are properly assembled (pages 3

through 5). Make sure the filter drawer is

completely closed before opening the drain

valve. Open the drain valve and drain the

shortening into the filter tank. Allow hot

Fig. 10

shortening to stand in the filter tank for

approximately 6 to 10 minutes. Then proceed

with steps 4 through 10 under Filtering

Procedure when Using Liquid Shortening on

pages 6 and 7.

FILTERING TIPS

• If filtering at the end of the day, make sure all the oil is returned to the fryer tank.

• Open the filter drawer approximately 1" to allow any oil in the return line to run back into the filter

tank. This will take about 30 seconds to complete.

• Close the filter drawer. If solid shortening is used, follow the "Melt" procedure the next morning.

PERIODICALLY REMOVE EXCESS DEBRIS FROM THE FILTER

The following operation is required after filtering one or more batches, as needed:

1. Pull the filter drawer out and remove the filter tank cover from the filter tank.

2. Remove the crumb basket and empty any debris into the trash.

3. Remove the filter screen assembly.

4. Scrape debris from the bottom of the filter tank and from the screen assembly into the trash.

NOTE: Scrape debris away from suction hole to avoid compacting debris in hole.

5. Reinstall the filter screen assembly and crumb basket.

6. Replace the filter tank cover. Close the drawer.

FLUSH AND DISCARD

1. Turn the fryer power OFF.

2. Make sure filter tank and parts are properly assembled

(pages 3 through 5). Open the fryer tank drain lever (Fig.

11) of the fryer tank that holds oil that is to be discarded.

Fig. 11

–8 –

Page 9

3. While holding the discard hose at the base of the fitting, use your free hand to slide the collar

away from the end of the female fitting (Fig. 12). Align the male and female parts of the quick

disconnect line and push the hose onto the male connector discharge fitting. Release the collar.

Pull the discharge hose away from the fryer to make sure discharge hose is fully inserted and

locked.

PL-41613

Gas Fryer Electric Fryer

Fig. 12

PL-41614

4. Turn the filter power switch ON (Fig. 13).

PL-41615

Gas Fryer Electric Fryer

Fig. 13

PL-41616

5. Place the nozzle in a suitable discharge container. To start the pump, pull the white discard

valve handle out (Fig. 14); the oil begins to flow through the discard hose. If the discharge

container is not large enough for the entire amount, stop the pump by pushing in the white

discard valve handle, empty the container and resume. When the last of the oil is in the

discharge container, stop the pump by pushing in the white discard valve handle, turn the filter

power switch OFF and disconnect the discharge hose (Fig. 15).

6. Clean the filter drawer following the instructions on page 10.

PL-41617

Fig. 14

–9 –

PL-41618

Fig. 15

Page 10

MAINTENANCE

PL-41621

PL-41622

PL-41619

PL-41620

WARNING: HOT FRYING COMPOUND AND PARTS CAN CAUSE BURNS. USE CARE WHEN

OPERATING, CLEANING OR SERVICING THE FRYER. USE CARE WHEN FILTERING.

WARNING: SPILLING HOT FRYING COMPOUND CAN CAUSE SEVERE BURNS. DO NOT

MOVE THE FRYER WITHOUT DRAINING ALL FRYING COMPOUND FROM THE TANK.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT/TAGOUT PROCEDURES.

CLEANING THE FILTER DRAWER

1. Pull the filter drawer out and remove the filter tank cover.

2. After filter parts have cooled, lift the filter tank out of the

drawer (Fig. 16). Set the filter tank aside.

3. Lift the drawer from the drawer slides (Fig. 17) and set

the drawer aside.

4. Lift the drawer slides up and off the slide guides (Fig. 18).

5. Carry the parts to the sink area for cleaning.

6. Remove the crumb basket from the filter tank.

7. Remove and disassemble the filter screen assembly for

cleaning (Fig. 19). The top left side of the assembly has

a metal latch and bar. Slide the metal latch off the bar. Lift

the bar up to allow access to the internal filter.

NOTE: The filter screen assembly should be cleaned daily. The

filter screen assembly parts may be placed in a dishwasher or

cleaned using a sink spraydown hose with dish detergent.

However, periodic fryer boil-out cleaning is recommended to

remove thick grease residue on the filter screen assembly. This

residue may hinder the filtration process. If you notice that the oil

filter return time is taking longer than 4 minutes to complete the

filter cycle, boil-out of the screen assembly is recommended.

This can be performed as part of the normal fry tank boil-out

procedure (see Fryer Boil-Out Instructions on page 11).

8. Wash all parts of the filter, including the drawer and

drawer guides, in normal dishwashing detergent. All

parts are dishwasher-safe and can be cleaned in a

commercial dishwasher instead of by hand.

Fig. 16

Fig. 17

Fig. 18

9. Rinse parts thoroughly and wipe dry with a clean cloth.

All parts must be completely dried before reuse.

10. Reinstall all removed filter parts before operating the filter

system.

11. The top cover must be replaced before operating this

system.

–10 –

Fig. 19

Page 11

FRYER BOIL-OUT INSTRUCTIONS

CAUTION: Do not run water or boil-out solution through the filter motor or pump. Do not use

the filter during boil-out or cleaning of the fryer.

Before cleaning the fryer, read the entire cleaning instructions provided by the cleaning product's

manufacturer. Some cleaners will require a boil-out procedure at boiling temperature, and some will not.

If your cleaning product company calls for a boil-out procedure, follow their procedures after performing

steps 1 through 5. If boil-out is required, but no procedures are stated, follow steps 1 through 23.

1. Turn off the fryer that is to be boiled out.

2. Remove and set aside the filter drawer assembly.

3. Drain all shortening from the fryer to be boiled out. Drain old shortening into a suitable disposal

container and discard.

4. Remove the filter screen assembly from the filter drawer vessel and separate the screen into

two parts (see page 10).

5. Place the two separated parts of the screen assembly into the fryer tank that is to be boiled out.

6. Following the cleaning instructions on page 10, clean the remaining

drawer assembly parts.

7. Place a stock pot under the drain manifold opening (Fig. 20).

8. Close the drain valve and fill the fryer tank with hot water to the

- Max - fill line.

9. Set the fryer thermostat to 210°F to 225°F (99°C to 107°C) and

turn the fryer on.

10. Allow water to come to a slow boil.

Fig. 20

PL-41623

11. Add boil-out solution and mix thoroughly. The water in the fryer tank must be near boiling for

the boil-out solution to dissolve completely and achieve maximum benefit.

CAUTION: Adding boil-out solution to boiling water can cause the fryer to boil over.

12. Allow the fryer to simmer or slowly boil for 10 to 15 minutes. Watch the fryer to make sure it does

not boil over. During the boil-out process, scrub the tank using the cleaning brush provided with

the fryer. To avoid damage to the tank finish, do not use a metal brush or scouring pad.

13. Turn the fryer off and allow the boil-out solution to remain in the fry

tank for another 10 to 15 minutes. The hot boil-out solution will

continue to break down oil residue at water temperatures as low as

180°F (82°C).

14. Open the drain valve.

15. Drain the boil-out compound into the stock pot below the drain

manifold opening (Fig. 21). Monitor the contents of the stock pot.

PL-41625

The full content of the fryer tank may not fit into the stock pot. If not,

close the drain valve when the stock pot is almost full and discard

Fig. 21

the boil-out solution.

16. Replace the emptied stock pot below the drain manifold opening, and repeat steps 14 and 15

as many times as needed.

17. Close the drain valve and fill the tank with clean, hot water to the - Max - fill line; drain and discard

as in steps 14 and 15.

–11 –

Page 12

18. After rinsing the tank, close the drain valve and refill the tank with hot water to the - Max - fill line.

19. Add 1 cup (0.2 L) of vinegar per 20 lb (9 kg) of fryer capacity to neutralize any caustic ingredients

remaining from the boil-out solution.

20. Turn the fryer on and slow boil for a few minutes with the thermostat set at 210°F to 225°F (99°C

to 107°C).

21. Turn the fryer off and drain the tank (see steps 14 and 15).

22. Close the drain valve and rinse the tank again with hot water.

23. Drain fryer tank (see steps 14 and 15) and remove. Dry and reassemble the filter screen

assembly. Thoroughly dry the fryer tank. Close the drain valve. Reinstall the entire filter drawer

assembly to the fryer. Fill the tank to the - Min - fill line with fresh oil or shortening.

TROUBLESHOOTING

NOTE: If using solid shortening, after all filtered oil has been returned to the fryer tank and the filter

power switch is off, open the filter drawer approximately 1 inch. This allows the remaining shortening

in the line to drain into the filter tank to prevent possible clogging as the shortening cools and solidifies.

MOTPMYSESUACELBISSOP NOITCAEVITCERROCDETSEGGUS

tonliO

rogniretlif

;gnidracsid

rotompmup

.nosi

.evitareponisipmuP.6

rotompmuP

tonsi

.gninnur

.yawehtlladesolctonrewarD.1

.deggulpsineercsretliF.2

.)s(enilmetsysretlifnigolC.3

.kcihtootdna)C°941(F°003wolebsigninetrohS.4

.evlavdracsidronruterhtiwmelborplacinahceM.5

.degagneylluftonnoitcennocesohdracsiD.7

.noitcennocrewopV021kcehC.1

.nodenruttonsihctiwsrewopretliF.2

.dednetxetonsieldnahevlavdracsiD.3

.gnikrowtonrotompmuP.4

.rewardehtesolC.1

.neercsretlifnaelC.2

.ecivresllaC.3

.ecivresllaC.5

.ecivresllaC.6

.esohehttcennocerdnaevomeR.7

.elcatpecerV021otnitinugulP.1

.nohctiwsnruT.2

.eldnahevlavdracsidtuolluP.3

.ecivresllaC.4

SERVICE

Contact your local Hobart Service Office for any repairs or adjustments needed on this equipment.

.)C°941(F°003evobaerutarepmetesaercnI.4

FORM 34727 Rev. B (Jan. 2003) PRINTED IN U.S.A.

–12 –

Loading...

Loading...