Page 1

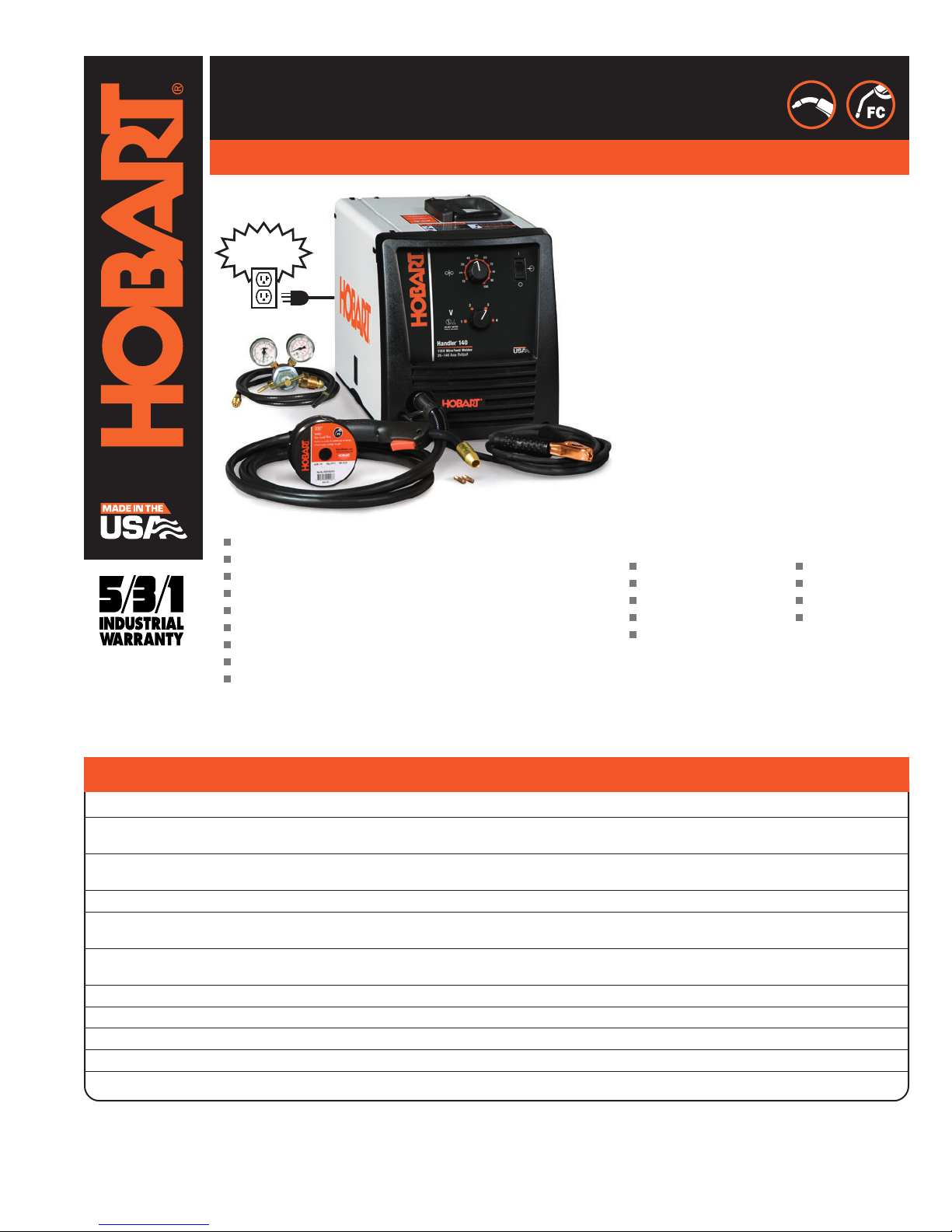

115 Vol t

Handler®140

115V Wire Feed Welder

Includes:

Comfortable 10-ft. (3 m) H100S2-10 gun

10-ft. (3 m) work cable with clamp

Built-in gas solenoid valve and dual-gauge regulator with gas hose

Spool hub assembly accommodates 4 or 8 in. spools

Sample spool of .030 in. (0.8 mm) self-shielding flux-cored wire

.030 in. (0.8 mm) contact tips

Power cord with plug

Weld set-up chart

Owner’s manual with parts lists, installation, operation and

maintenance guidelines

Stable arc with improved performance on thin gauge material.

Provides positive feed with adjustable tension. Easy access for threading wire.

Provides a broader operating window for each wire, with quick and easy adjustment for different thicknesses and joints.

Eases use and excellent safety feature which makes wire electrically “cold” until trigger is pulled.

Access makes it quick and easy to change polarity for solid or tubular wire. Includes convenient storage holes for

spare tips.

Makes it easy to change from one wire size to another. One knurled groove and one smooth groove for

.030–.035 in. (0.8 – 0.9 mm) wire.

Makes controls quickly visible and accessible.

Protects unit against current overload.

Protects power transformer to ensure reliability.

Protects wire feed system from overload, no fuses to change or circuit breaker buttons to reset.

Five-year warranty on transformers, three years on electronics (drive motors, rectifiers) and one year on guns.

Excellent arc performance

Proven built-in wire feeder with

quick-release tension lever

Four output voltage settings with

wire feed speed tracking

Built-in contactor

Convenient polarity changeover with

tip holder

Dual-groove quick-change drive roll

Sloped control panel

Short circuit protection

Self-resetting thermal overload

Self-resetting motor protection

Hobart's 5/3/1 Industrial Warranty

217919

March 2011

Features Benefits

B

uilt with Hobart quality and durability, the

Handler 140 is a wire welding package with

industrial performance capable of operating on

standard 115/120 volt, 20 amp home circuits.

The broad output range of 25 – 140 amps allows

you to weld 24 gauge up to 1/4 inch steel.

The Handler 140 is capable of running the following

wires: .023 – .035 in. (0.6 –0.9 mm) mild steel

or stainless steel, .030 – .035 in. (0.8 –0.9 mm)

flux-cored, and .030 in. (0.8 mm) aluminum. Four

output voltage settings with wire feed tracking

make the unit easy to set and adjust for different

materials and thicknesses.

#500500

Applications:

Home, farm and ranch and light fabrication projects.

Mower Decks/Brackets Grills/Smokers

Fences/Gates Firewood Racks

Kennels Metal Furniture

Signs Machinery and

Window Security Guards Auto Repair, etc.

Page 2

2

Flux Cored

E71T-11

(DCEN)

Solid Wire

ER70S-6

(DCEP)

Solid Wire

ER70S-6

(DCEP)

Stainless

Steel

(DCEP)

Aluminum**

(DCEP)

Good for windy or

outdoor applications

Produces less spatter.

Better bead appearance.

—

—

—

—

— 1/30 2/30

2/20

3/50

3/35

3/30

3/40

4/30

3/40

3/20

4/70

4/40

4/40

4/40

4/35

4/45

4/35

—

—

—

—

—

—

4/ 50*

—

—

—

—

4/30 —

—

—

—

—

2/30

2/20

—

—

1/25

—

3/40

2/30

3/25

3/30

3/20

4/25

—

4/503/402/30

——4/303/102/15

—4/ 90**3/ 90**

—

2/30

—

—

——

—

—

—

—

—

—

—

—

CFH

Settings are approximate. Adjust as required. Thicker materials can be

welded using proper technique, joint preperation and multiple passes.

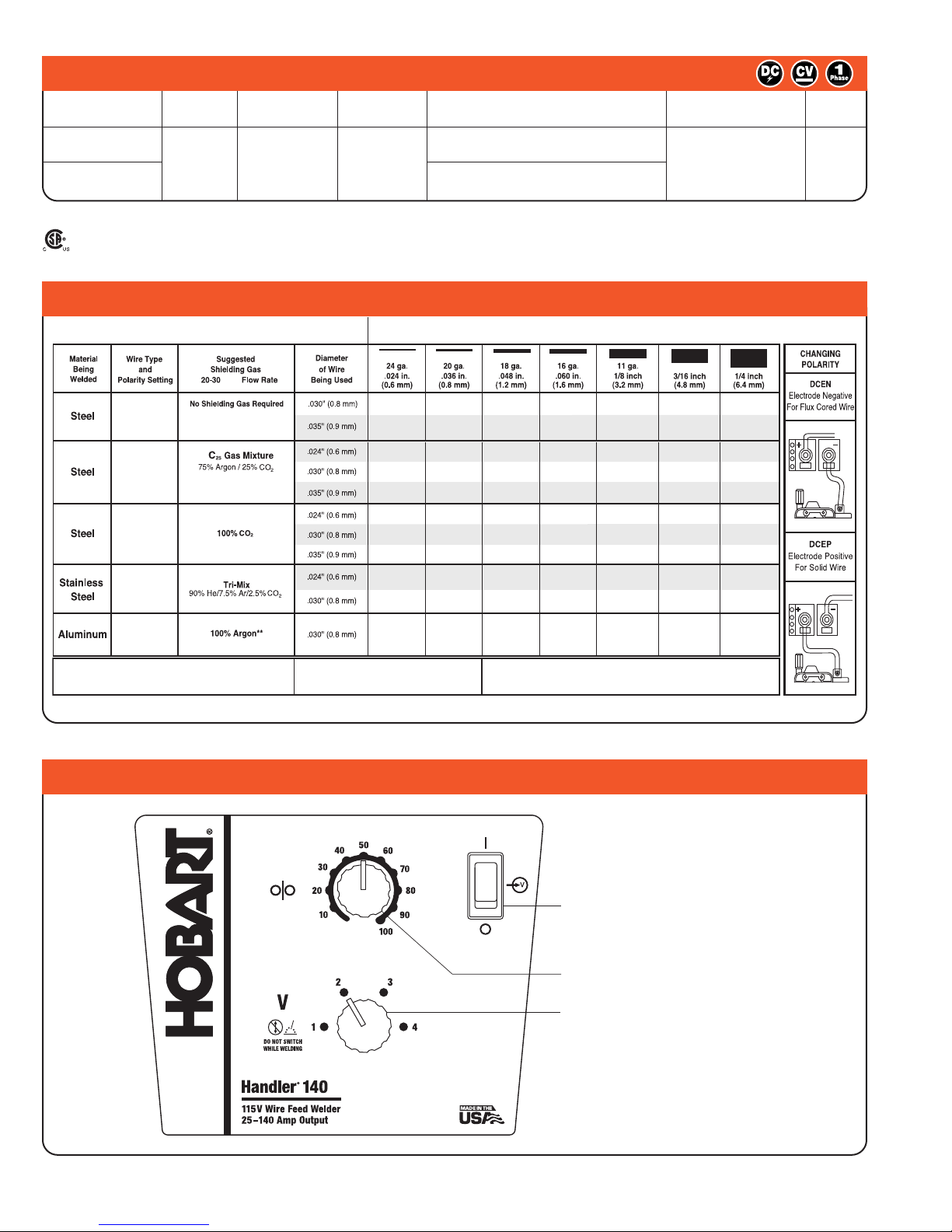

Recommended Voltage and Wire Speed Settings for thickness of metal being welded.

Number on left of slash is Voltage Setting/Number on right of slash is Wire Feed Setting.

*Multiple passes required. **Aluminum wire is soft so feedability is not as good. Make sure that hub tension is not too tight and keep the torch as straight as possible. A “push angle” for the torch is recommended.

Match feed roll groove to diameter of wire being used.

Set tension knob setting to 3 at start.

Adjust tension per instructions in the manual.

CAUTION! Do not change voltage switch

position while welding. See owners manual

for more information.

Wire speed listed is a starting value only. Wire speed setting can be

fine-tuned while welding. Wire speed also depends on other variables

such as stick out, travel speed, weld angle, cleanliness of metal, etc.

Handler 140 Welding Guide

Control Panel

1. Power Switch

2. Wire Speed Control

3. Voltage Control Switch

*

CSA rating.

Specifications

(SUBJECT TO CHANGE WITHOUT NOTICE.)

Rated Output

90 A, 19 VDC,

at 20% Duty Cycle

63 A, 21 VDC

at 20% Duty Cycle*

Max. OpenCircuit Voltage

28 V

Wire Feed

Speed Range

40–700 IPM

50–740 IPM

at no load

Current

Range

25 – 140 A

Amps Input at Rated Output, 60 Hz, 1-Phase

115 V KVA KW

20 2.9 2.5

15* 2.2* 1.77*

Dimensions

H: 12-3/8 in. (315 mm)

W: 10-5/8 in. (270 mm)

D: 19-1/2 in. (495 mm)

Net

Weight

57 lb.

(26 kg)

Certified by Canadian Standards Association to both the Canadian and U.S. Standards.

1

2

3

Page 3

Spool Gun 3035-20 #300143

20 ft. (6.1 m) cable and gas hose

Weld 14 gauge – 1/8 in. (1.9– 3.2 mm)

aluminum with the Handler 140

Threaded nozzle and contact tips

Spool gun conversion kit consisting of

control switch and gas diverter valve

Enclosed wire spool compartment with

internal spool hub tension adjustment

for 4 in. (102 mm) rolls of wire

For .030 – .035 in. (0.8– 0.9 mm) aluminum,

steel and stainless steel

Rated 150 amps, 60% duty cycle

SGA 100 Spool Gun Control #043856

Required to connect spool gun to the Handler

®

140. Includes 10 ft. (3 m) 115 VAC power cable

and plug, 6 ft. (1.8 m) interconnecting cable,

and 5 ft. (1.5 m) gas hose.

H100S2-10 Replacement MIG Torch

#245924

Comes in 10-ft. (3 m) length with liner for

.030 – .035 in. (0.8– 0.9 mm) diameter wire.

Portable CO

2 Cylinder

Kit #770626

Includes one 20 oz.

CO

2 cylinder (paintball

style), pre-set regulator

and gas hose, spare

“O” rings, and

mounting hardware.

Small Cart/Cylinder Rack #194776

Designed for portable MIG welders.

Accommodates large and small gas cylinders.

Running Gear/Cylinder Rack #770187

Heavy-duty construction. Accommodates large

and small gas cylinders.

Protective Cover #195186

Weather-resistant nylon resists stains and

mildew while protecting the finish of your welder.

Accessories

3

Performance Data

200

140

100

80

60

40

OUTPUT AMPERES

20

10

1 4 10 20 40 60 10026 808

DUTY CYCLE

DUTY CYCLE %

30

25

20

15

VOLTAGE

10

5

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

VOLT/AMP CURVE

AMPERAGE

RANGE 1

RANGE 2

RANGE 3

RANGE 4

Page 4

Hobart Welders An Illinois Tool Works Company hobartwelders.com

Hobart Welding Products Service 800-332-3281 Sales 800-626-9420

Litho in USA

Typical Installation for Optional Spool Gun 3035-20 to Handler®140

Item Hobart Package Part # Miller Package Part #

Contact Tips

.023/.025 in. (0.6 mm) #770174 (5 per package) #087 299 (10 per package)

.030 in. (0.8 mm) #770177 (5 per package) #000 067 (10 per package)

.035 in. (0.9 mm) #770180 (5 per package) #000 068 (10 per package)

MIG Nozzle (Standard) #770404 #169 715

Gasless Flux-cored Nozzle #770487 #226 190

Tip Adapter #770402 #169 716

Liners

.023/.025 in. (0.6 mm) #196139 #194 010

.030/.035 in. (0.8/0.9 mm) #196139 #194 011

.035/.045 in. (0.9/1.2 mm) #196140 #194 012

Power Source Drive Rolls

Dual-groove, V-smooth — #237338 —

For .023/.025 in. (0.6 mm) and

.030 – .035 in. (0.8– 0.9 mm) wire

Dual-groove, V-knurled — #202926 —

For .030 – .035 in. (0.8– 0.9 mm)

and .045 (1.2 mm) flux-cored wire

Dual-groove, V-knurled and V-smooth — #246565 —

For .030 – .035 in. (0.8– 0.9 mm)

flux-cored and solid wire

Consumables

For Handler®140, combine Spool Gun 3035-20 with SGA 100 to weld 14 gauge to 1/8 in. aluminum. To weld aluminum with comparable, competitive

power sources, the spool gun may also be used with the SGA unit.

Note: Refer to SGA Owner’s Manual for complete installation instructions.

Gas Hose to Gas Regulator

115 VAC Power Cord

Typical MIG welder

Interconnecting Cord

Spool Gun

SGA 100

Control Box

Spool Gun Trigger

Control Cord

Spool Gun Gas Hose

Spool Gun Weld Cable

Loading...

Loading...