Page 1

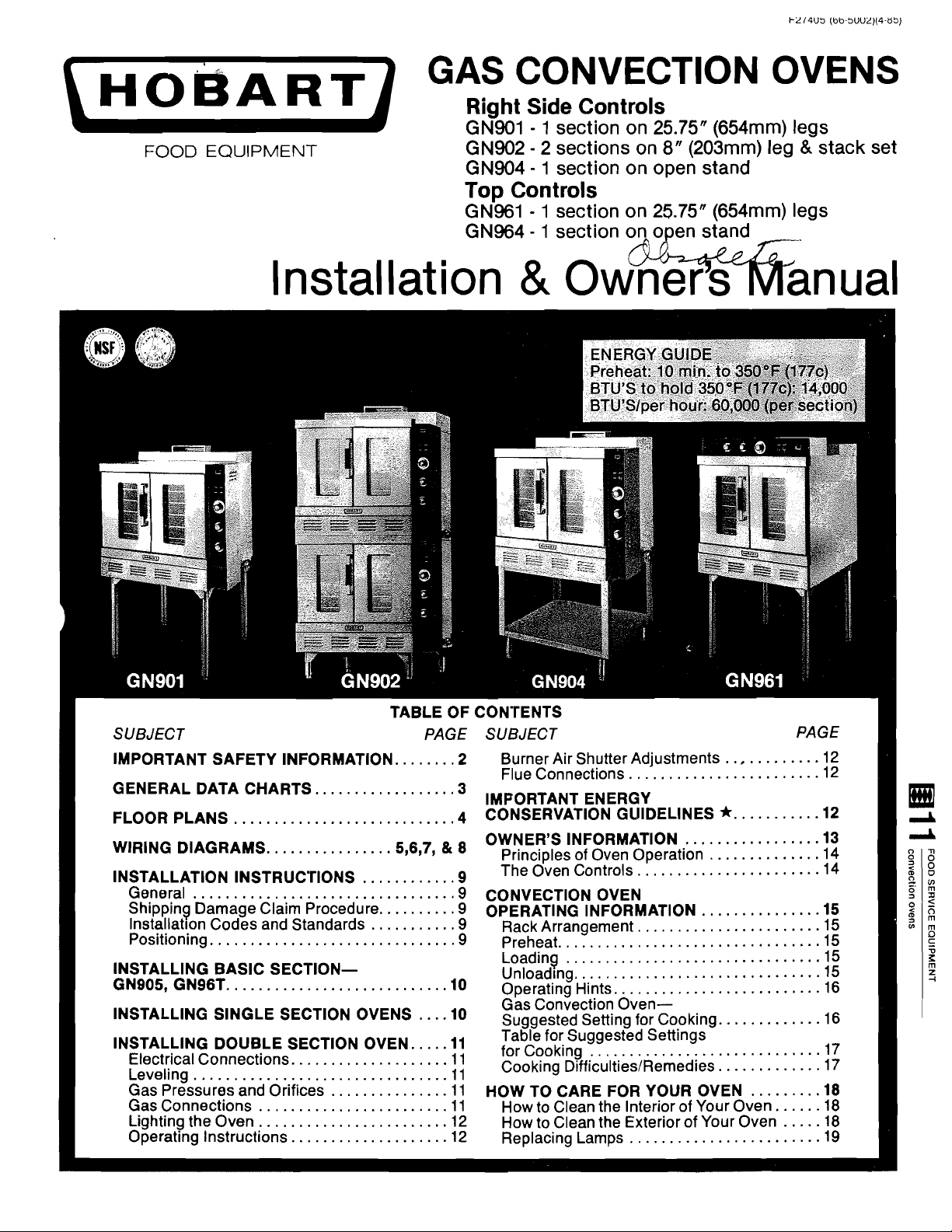

\HOBART]

FOOD

EQUIPMENT

GAS

Ria

GN901 - 1 section on 25.75" (654mm) leas

ON902 . 2

GN904 . 1 section on open stand

CONVECTION OVENS

ht

V-~

Side

...

Controls

sections on

8"

(203mm)

Top Controls

GN961 . 1 section on 25.75" (654mm) legs

GN964 . 1 section

leg

&-stack set

.

.

Installation

TABLE OF CONTENTS

SUBJECT

IMPORTANT SAFETY INFORMATION

GENERAL DATA CHARTS

FLOOR PLANS

WIRING DIAGRAMS 5.6.7. & 8

INSTALLATION

General

Shipping Damage Claim Procedure

lnstallatlon Codes and Standards

Positioning

INSTALLING BASIC SECTIONGNQOS. GN96T

INSTALLING SINGLE SECTION OVENS 10

INSTALLING DOUBLE SECTION OVEN

Electrical Connections

Leveling

Gas Pressures and Orifices

Gas Connections

Lighting the Oven

Operating Instructions

............................

................

INSTRUC'rIONS

.................................

...............................

............................

................................

........................

........................

..................

............

...........

....................

...............

....................

PAGE

........

..........

2

3

4

9

9

9

9

9

10

....

.....

11

11

11

11

11

12

12

&

0

SUBJECT

Burner Air Shutter Adjustments

Flue Connections 12

IMPORTANT ENERGY

CONSERVATION GLllDELlNES

OWNER'S INFORMATION 13

Principles of Oven Operation

The Oven Controls

CONVECTION OVEN

OPERATING INFORMATION 15

Rack Arrangement

Preheat

Loading 15

Unload~ng

Operating Hints 16

Gas Convection Oven-

Suggested Setting for Cooking 16

Table for Suggested Settings

for Cooking 17

Cooking

HOW TO CARE FOR YOUR OVEN

How to Clean the Interior of Your Oven

How to Clean the Exterior of Your Oven

Replacing Lamps 19

.................................

................................

...............................

Difficulties/Remedies

........................

.......................

.......................

..........................

.............................

........................

............

...........

*

.................

.............

...............

.............

.............

.........

n ual

PAGE

-14

......

.....

12

12

14

15

15

15

17

18

18

18

Page 2

THlS MANUAL HAS BEEN PREPARED FOR PERSONNEL AUTHORIZED, QUALIFIED, CERTIFIED OR LICENSED TO INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE

JUSTMENTS OF THE EQUIPMENT COVERED BY THlS MANUAL.

INITIAL FIELD STARTUP AND AD-

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

OF GAS IS DETECTED. THlS INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED

SHUT DOWN UNITS AT

AND CONTACT THE LOCAL GAS COMPANY OR

GAS SUPPLIER FOR SERVICE.

MAIN SHUT-OFF VALVE

SUPPI-IER.

THE SMELL

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY

OF THlS OR ANY OTHER APPLIANCE.

NOTE

IT IS IMPORTANT THAT YOU RETAIN THlS MANUAL FOR FUTURE REFERENCE.

Page 3

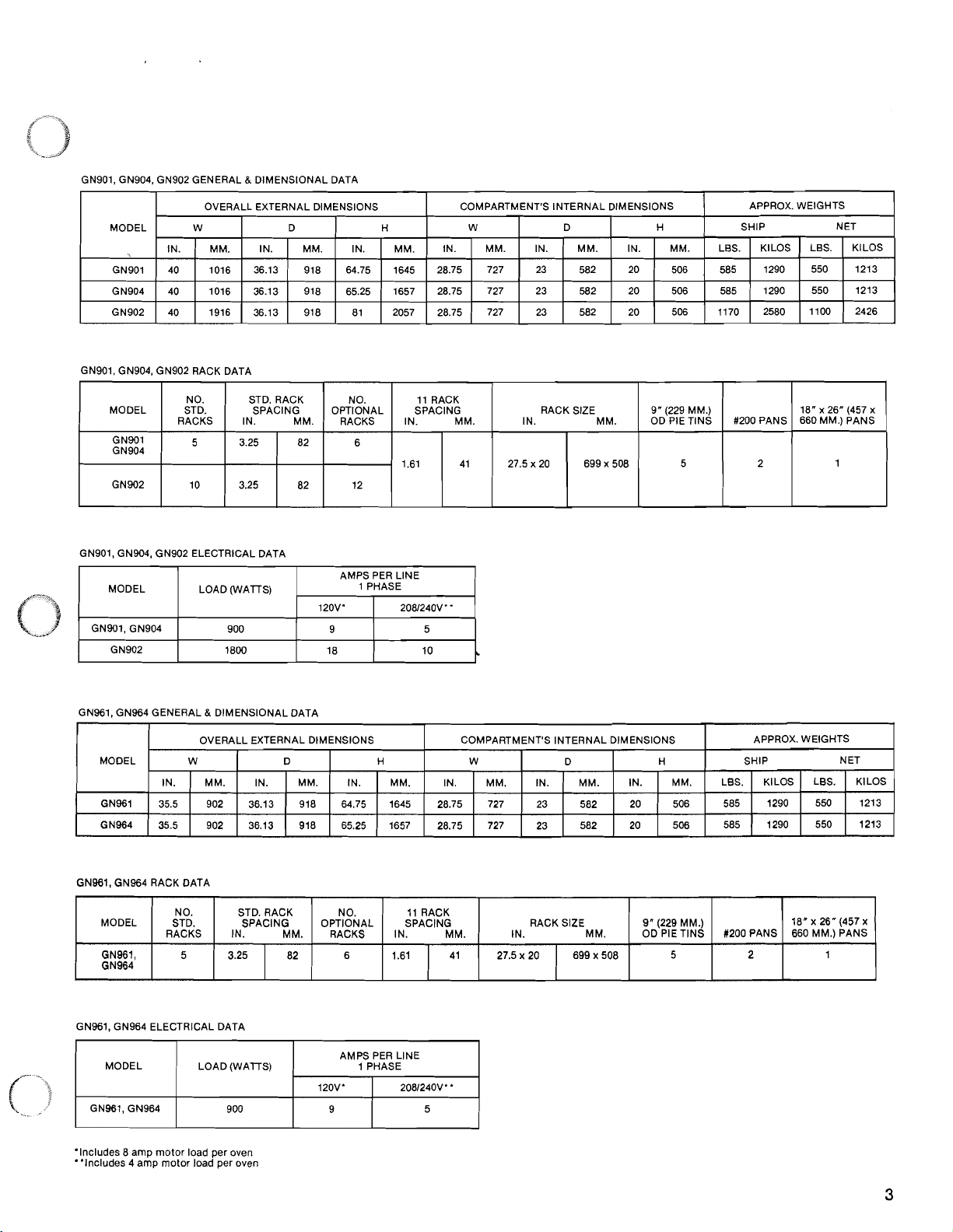

GN901. GN904, GN902 GENERAL & DIMENSIONAL DATA

GN901. GN904, GN902 RACK DATA

MODEL

GN901

GN904

GN902

NO.

STD.

RACKS

5

10

STD. RACK

SPACING

IN. MM.

3.25

3.25

82

82

OPTIONAL

GN901, GNW, GN902 ELECTRICAL DATA

MODEL LOAD (WATS) 1 PHASE

120'4' 2081240V~

GN901, GN904

GN961, GN964 GENERAL & DIMENSIONAL DATA

NO.

RACKS

6

12

AMPS PER

SPACING

IN.

1.61

LlNE

11 RACK

*

MM.

41 27.5

SIZE

RACK

IN. MM.

x

20

699 x 508

9"

(229 MM.)

OD PIE

TINS

5

#PO0 PANS

2

18" x 26" (457

660 MM.) PANS

1

x

GN961, GN964 RACK DATA

MODEL

GN961,

GN964

NO.

STD.

RACKS

5

STD. RACK

SPACING

IN. MM.

82

OPTIONAL

RACKS

GN961, GN964 ELECTRICAL DATA

MODEL LOAD (WATS) 1 PHASE

120'4' 2081240V*

GN961, GN964

'Includes 8 amp motor load per oven

"includes

4 amp motor load per oven

NO.

6 3.25

11 RACK

SPACING

IN. MM.

1.61 27.5 x 20 41 699 x 508

AMPS PER LlNE

RACK SIZE

IN. MM.

9" (229 MM.)

OD PIE TINS

5

U2OO PANS

2

18" x 26" (457

660 MM.) PANS

1

x

Page 4

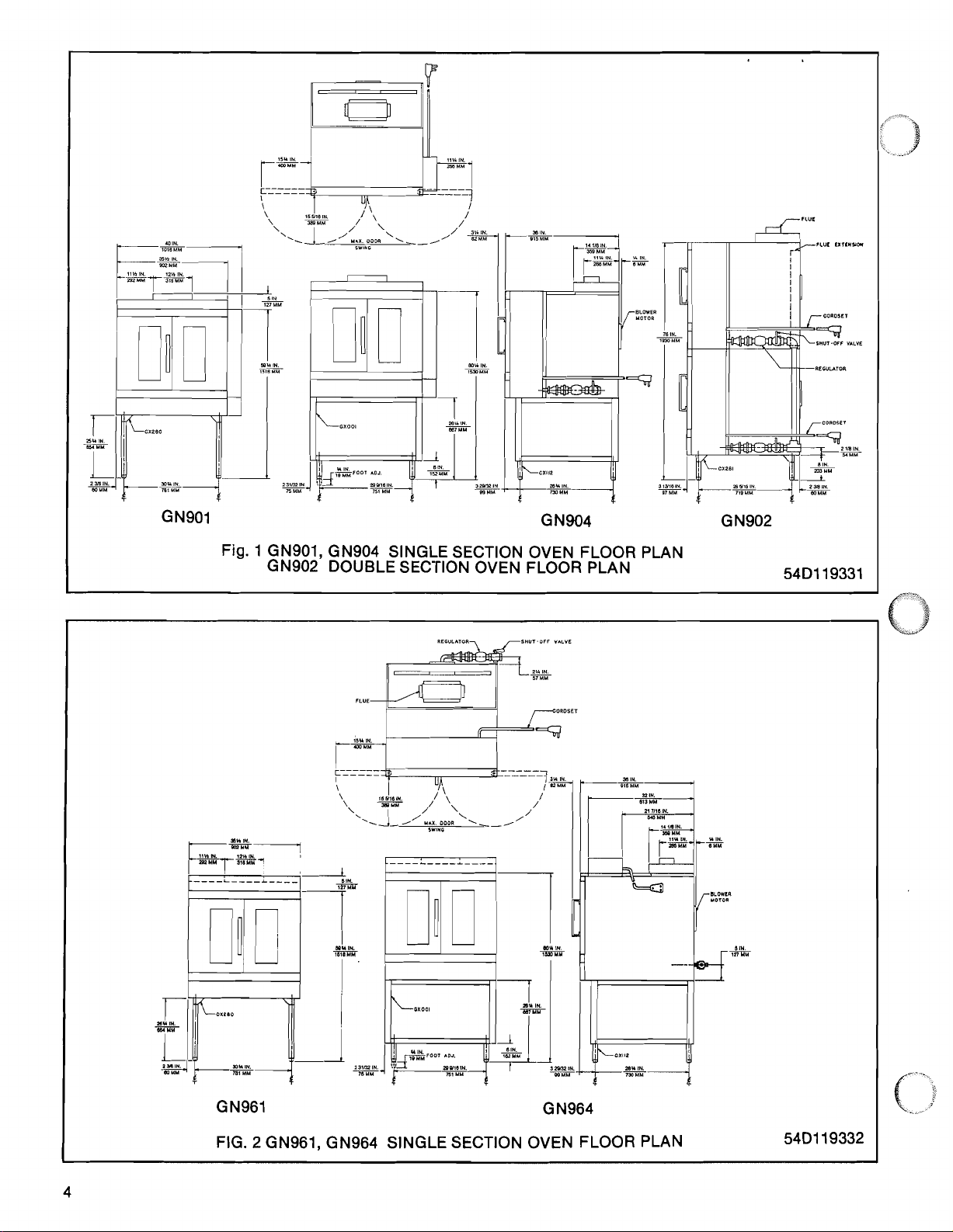

Fig. 1 GN901, GN904 SINGLE SECTION OVEN FLOOR PLAN

GN902 DOUBLE SECTION OVEN FLOOR PLAN

54D119331

GN961 G N964

FIG.

2

GN961, GN964 SINGLE SECTION OVEN FLOOR PLAN

5401 19332

Page 5

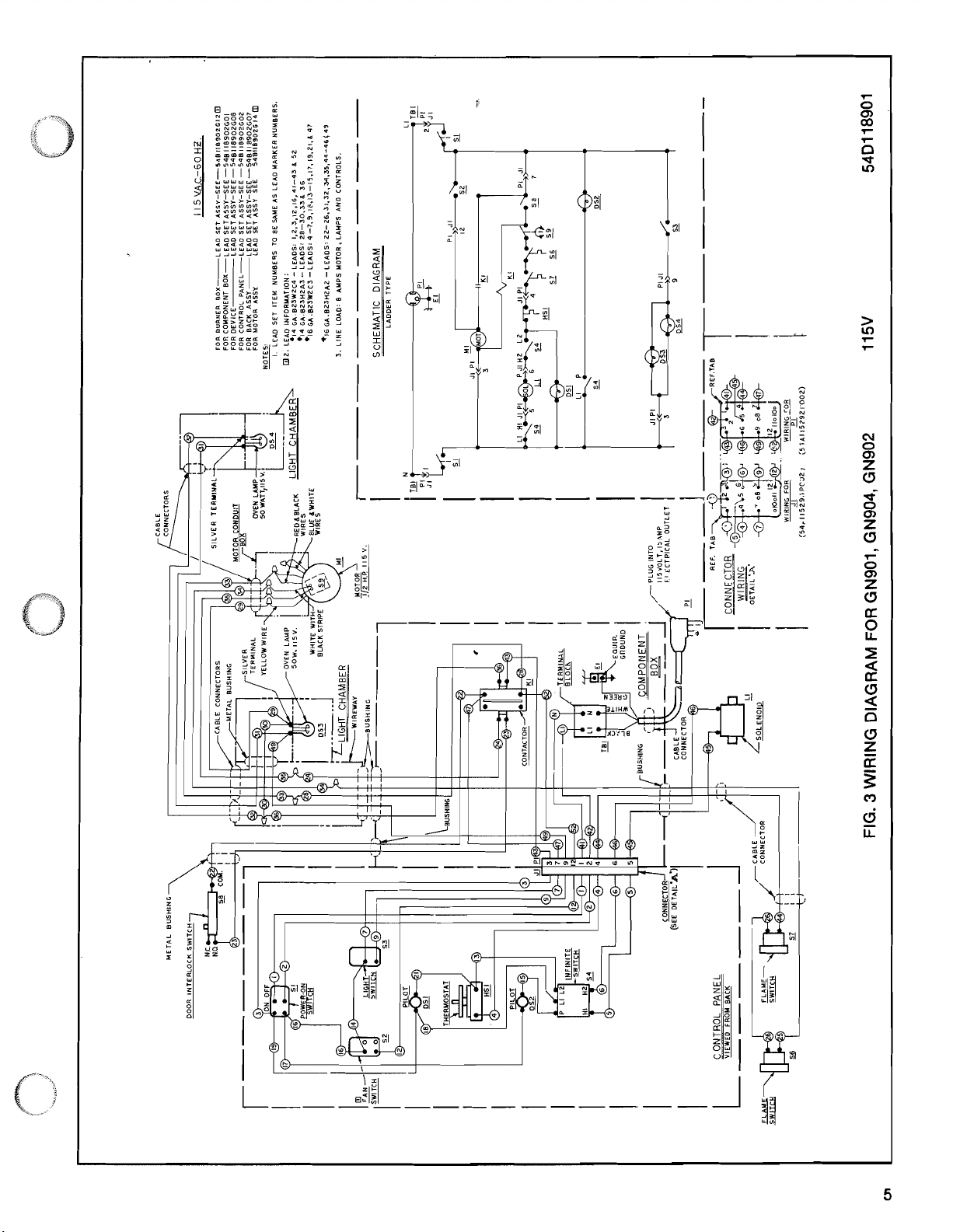

WIRING DIAGRAM FOR GN901, GN904, GN902 115V 54D118901

3

FIG.

Page 6

Page 7

V.AC -60HZ

5

11

NOTES:

ITEM NUYOERS ARE THE SAME AS

MARKER NUMBERS.

LEAD

I. LEAD

2. LEID

FOR

FMI

FOR

FOR

FOR

FOR

LINE 4 LEAD IHFORYATIOH:

3.

0231ZC4-LEADS: IJ.12.16.41-43 462

C*.

-14

-

-

SCHEMATIC DIAGRAM

1

(LADDER TYPE

--

I

SWITCH

DOOR INTERLOCK

ONNECTOR

%IRING -OETAIL~A~

I

-

--

WI:cING FOR WIFING FOR

JI~l54A115293POOZ~ ~-t54A115292P0021

-

I

EDGE

SWITCH

LCENTRIFUGAL

CHAMBER LIGHT CHAMBER

LIGHT

FIG. 5 WIRING DIAGRAM FOR GN961, GN964 115V 5401 19301

Page 8

Page 9

GENERAL

The Hobart gas oven you have purchased is a

quality product in the tradition of Hobart

fine

quality excellence. Properly installed and used it

will provide you with many years of service and

contribute to your profitable business environ-

ment.

codes or in the absence of local codes with

the National

70.1981. The 115 volt ovens are equipped with

a three-prong (grounding)

tection against shock hazard and should be

plugged directly into a

three-hole receptacle. DO NOT CUT OR REMOVE THE GROUNDING PRONG FROM

THIS PLUG.

Electrical Code ANSllNFPS No.

plug for your pro-

properly grounded

SHIPPING DAMAGE CLAIM PROCEDURE

The equipment you have received was carefully

inspected and packed by competent personnel

before leaving the factory. The company transporting the equipment assumes full responsibility

for safe delivery upon acceptance of the shipment. If the shipment is damaged:

1. Damage or Loss that is Visible

Make certain this is noted on the freight bill

or other shipping documents and signed by

\

7&&'

the person making

2. Damage Claims Should be Filed Immediately

This should be done regardless of extent of

damage. clear from combustibles.

Unnoticed Damage or Loss

If damage is noticed after the equipment is

unpacked, the transportation company or de-

livering carrier

and a concealed damage claim filed wlt

them within (15) days of date dellve

.made. The package should be kept or In

spectlon.

Hobart cannot assume responsibility for loss or

damage Incurred In transit.

INSTALLATION CODES AND STANDARDS

Hobart ovens

wlth:

1. State and local codes;

Natlonal Fuel Gas Code, ANSI-Z223.1-1980.

2.

Copies of this code may be obtained from

American Gas Assn.,

Arlington, Virginia 22209.

should be Installed In accordance

delivery.

b

should be notified lmmedlatel

i

y

Inc., 1515 Wllson Blvd.,

5. Check device nameplate to make sure that

the oven

that being

POSITIONING

Table 1 shows key general and dimensional data

all models. Consult floor plan on pages

of

for positioning and related information.

1. Combustibles in the Area

The equipment area should be kept free and

2. Clearances from Combustible

The ovens when installed should have the

followlng clearances from combustible construction:

The Flow of Combustion and Ventllatlon

The ovens must be Installed so that the flow

of

obstructed. Adequate

ings

provlded. Make sure there Is an adequate

su

p

qu

burners.

4.

Clearances for Servlclng

The lnstallatlon locatlon should also take lnto conslderatlon adequate clearances for

servlclng and proper operatlon.

voltage and type of gas agrees with

supplied.

4 & 5

Construction

Inches from the

inches from the back

combustlon and ventllatlon alr wlll not be

Into the combustlon chamber must be

ply of alr In the room to allow for that re-

red for

combustion

sldes - 6

-

6

clearance for alr open-

of the gas at the oven

Air

4-1

1%-

3. The ovens must be installed under a ventila-

-

tion hood and ventilation provided in accord-

ante

with NFPA Standard #96.

4.

The appliance when installed must be electrically grounded in accordance with local

1. Crating and packaging materials should be

removed with care.

2. The doors should not be used to

the oven.

lift or move

Page 10

These basic sections must be installed on legs

unless they are mounted on a Hobart modular

stand. Installations on concrete bases or other after being uncrated.

supports restricting air circulation on the bottom

-

will void the warranty. If a modular stand is ordered, the oven section must be set on the stand

A. Assembling the Legs to the Oven

1.

Unpack the oven and leg set.

2. Position the oven on its back, taking care

not to scratch or damage it. The motor

protrudes beyond the back; provide for

this when the oven is tipped back by resetting it on suitable spacers (2 x

3.

Attach each of the four leg assemblies to

the bottom of the oven with the

four bolts and lockwashers (6 bolts per

1

eg).

4. Place the oven in its normal attitude, on

its legs and lower it in the installing position.

5.

Attach the flue diverter over the flue vent

in the holes provided.

4's, etc.).

twenty-

Fig.

8

Installing lower flue extension

6. Attach flue trimpiece in front of the flue

diverter.

Assembling the Oven on the Stand

1.

Uncrate the oven and stand.

2. Screw two locating studs (found in stand

carton) into bottom of basic section (Fig.

7).

3.

Attach the four leg assemblies to the

bottom of the stand with the

furnished.

4. Mount basic section (Fig. 7).

5.

Attach flue diverter and flue trim to the

oven.

STAND

Fin. 7 Installation of basic oven on oDen stand

16

bolts

Fig.

9

sion.

Fig. 10 Attaching the upper flue extension

Installing middle piece of the flue exten-

Page 11

1. Unpack one oven and leg set.

2.

Rosition the oven on its back, taking care not

to scratch or damage it. The motor protrudes

beyond the back. Provide for this when the

oven is tipped back by resting it on suitable

spacers (2 x

4's, etc.).

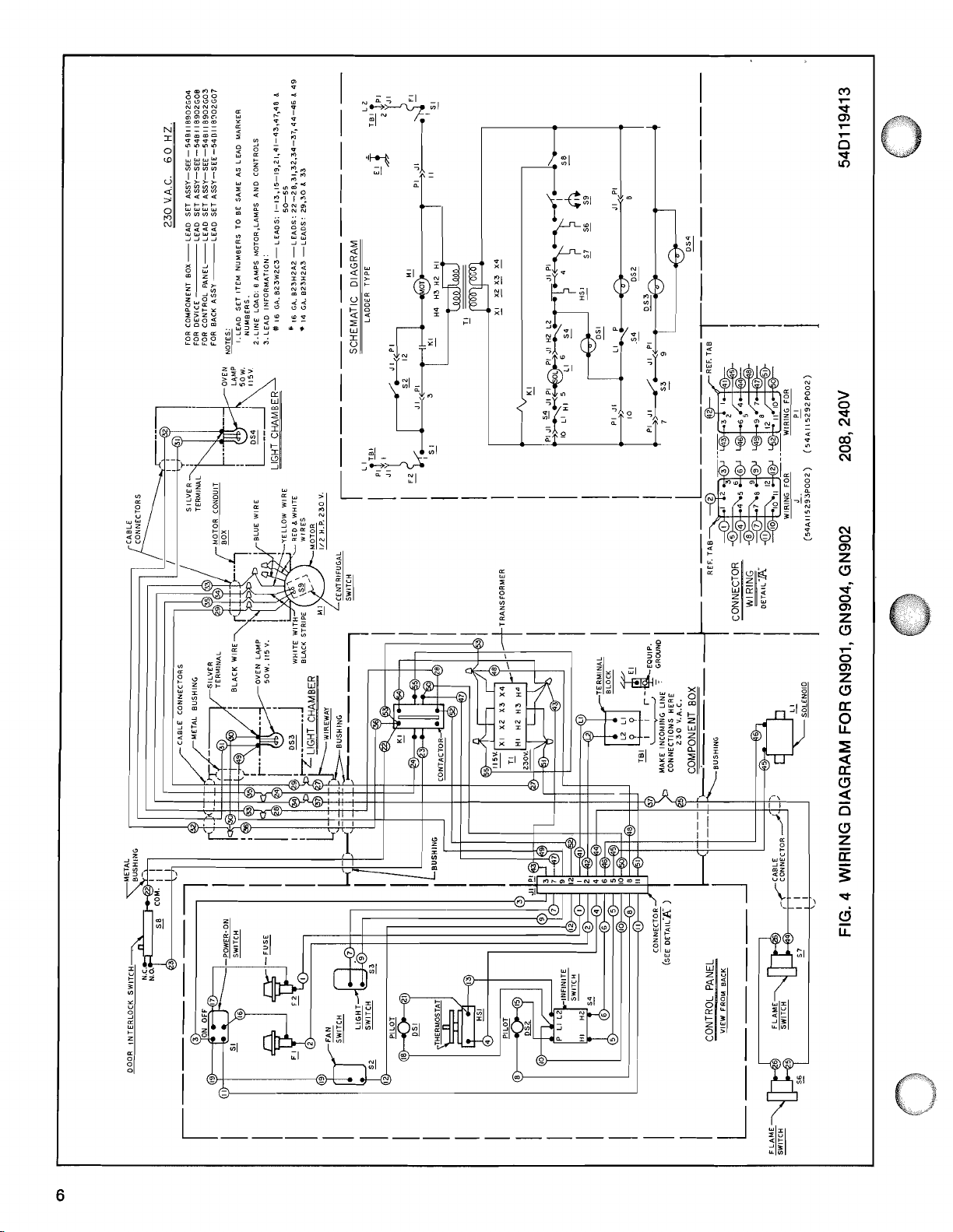

2. Refer to the appropriate wiring diagram Fig. 3,

4, 5, 6 and the information on it for making

proper line connections to the terminal block.

The 115 volt models have a cord and plug

attached and do not have to be wired. Each

of these ovens should be plugged into a

properly grounded 115 volt receptacle.

3. Attach each of the four leg assemblies to the

bottom of the oven with the twenty-four bolts

and lockwashers (6 bolts per leg).

4. Place the oven in its normal attitude, on its

legs, and lower it in the installing position.

5. Unpack the other oven, screw the two locking studs in the bottom of the oven Fig. 7.

6. Attach the flue diverter over the flue vent in

the holes provided. Screw in place.

7. Attach flue trimpiece in front of the flue

diverter.

8. Place top oven over bottom oven so that the

locating studs nest in the holes provided in

the bottom oven.

9.

Take the lower flue extension from the stack

kit and attach

oven Fig. 8.

10. Attach the middle piece of the flue extension

11. Attach upper flue extension to the upper

12. Connect the piping between the top oven

13. Leave

9.

Fig.

oven as shown in Fig. 10.

and bottom oven as shown on the floor plan

Fig. 1. Pipe compound must be suitable for

the gas being used. Check for gas leaks with

a soap and water solution.

gas valves closed until all the electrical

conne~tions are made and the ovens are

checked or used.

it to the bottom of the top

3. For 2081240 volt ovens the line leads must be

connected to the line terminal block which

may be reached by removing the wiring box

cover. Attach the ground lead to the terminal

provided.

4. Replace the wiring box cover.

5. Do not energize the power supply until after

the gas connections have been made.

LEVELING

Using a spirit level - adjust the legs to insure that

the oven racks are level in the final installed

position.

GAS PRESSLlRES AND ORIFICES

1.

"

Natural Gas

The standard orifices are set at 3.7 inch WC

(Water Column) pressure. A pressure regulator is supplied and must be installed when

the oven is connected to the gas supply.

Liquefied Propane Gas

2.

The standard orifices are set at 10 inches WC

(Water Column) pressure. A pressure regulator is supplied and must be installed when

the oven is connected to the gas supply.

GAS CONNECTIONS

1. The regulator supplied must be connected to

the manifold (note direction of gas flow

arrow).

2. The oven should be connected to the gas

line after leveling.

ELECTRICAL CONNECTIONS

1. Insure that the voltage stamped on the oven codes.

nameplate matches the available power

SUPP~Y.

WARNING

POWER AT THE MAIN CIRCUIT BOX. PLACE

A TAG ON THE CIRCUIT BOX INDICATING

ClRCLllT IS BEING WORKED ON.

THE

-

DISCONNECT THE ELECTRICAL

3. A gas shut-off valve should be installed in

the gas line ahead of the oven as required by

4. The gas supply lin'e must be at least the

equivalent of

5. Make sure the pipes are clean and free of

structions, dirt and piping compound.

3/4"

iron pipe.

ob-

Page 12

6.

IMPORTANT: All joints in the gas supply line

must be checked for leaks before lighting.

THE CHECK SHOULD BE MADE WITH SOAP

AND WATER SOLUTION (BUBBLES). AN

OPEN FLAME SHOULD NOT BE USED.

CAUTION: If burners do not light after the pilots

have been lit, check:

1.

Flame switch bulb should be hot (slightly

red).

LIGHTING THE OVEN

CAUTION: Prior to lighting, check all joints in the

as supply line for leaks. USE SOAP AND WATER

OLUTION. DO NOT USE AN OPEN FLAME.

D

OPERATING INSTRUCTIONS

1.

Open the manual valve and purge the gas

line to remove the air. Check for leaks with a

soap solution.

2. Light pilots (2) with a match or lighter rod.

1/2"

The flame should be approximately

The pilot flame will heat up the flame switch

sensing bulb.

3.

Turn on the electrical power, turn thermostat

to

max. and load control to "HI". After a brief

time the flame switch sensing bulb will heat

up and close the circuit to the

which will allow the gas to flow to the burners.

Oven door should be closed.

WARNING: Do not turn manual valves on unless

the pilots are to be lit. Before relighting pilot

lights, the manual valves must be OFF for a

minimum of five minutes.

BURNER AIR SHUTTER ADJUSTMENTS

1.

Burner air shutters should be adjusted as required. To adjust open the shutter until flame

leaves the burner port, then close slightly. Yellow

tipped flame should not be present.

2. The pilots wlll remain lit until the gas valves

are closed. If the oven

some time close the manual valve on the

oven. When the time comes to reuse the

oven, rellght the

pllots as described.

Is not to be used for

solonoid valve

high.

2. Thermostat setting.

3.

Load switch setting.

4.

Doors closed.

5.

Cool-down switch is off.

If burners still do not light, turn off the manual

valve and call a qualified servicer.

FLUE CONNECTIONS

Ventilation requirements will vary with each installation and must comply with applicable portions National Fire Protection Association Standard

#96

and with local codes. Considerations

to be kept in mind include:

1.

Flue connections should never be made directly to the oven.

2. The oven should be located under a hood

with an adequate connection to an exhaust

6

duct and having a

the oven sides.

3.

Clearance above the oven flue should be

adequate for the flue products to escape so

that there is no interference with the heat circulation In the ovens. Refer to the Standard

for the

moval of Smoke and

from Commerical Cooklng Equlpment, NFPA

Standard

4.

Conditions

the kitchen

wlndows next to the oven or fans blowing

dlrectly on the oven should not be allowed to

exlst.

5.

To prevent the oven function from belng

affected by a reduced atmospheric pressure,

adequate make up alr In the kltchen should

be

the ventllatlng system.

lnstallatlon of Equlpment for the Re-

#96.

resulting

-

such as wall type fans, or open

provided to replace the alr taken out by

inch extension beyond

Grease.Laden Vapors

In cross currents within

1.

Purchase properly sized equipment for your

operatlon; don't overslze or undersize.

2. Don't oversize ventilating system. Use the

size that will provide optimum air flow.

3.

Turn off unused equipment.

4.

Reduce thermostat settings In slack periods

slnce gas equipment heats up, recovers fast.

-

5.

Ad'ust menu patterns and cooking and baking

sc

A

edules: for optimum equipment use.

*Based on National Restaurant Association's

"Check-List for Energy Control and Conservation".

Page 13

Five standard racks per

section measure 27.5" x

"

(670 x 508 mm).

20

Cool to touch handle 200 pans. Six additional

Each rack holds two No.

opens both doors 180 racks optional for

non-

degrees, simultaneously. rising products.

Recycler recirculation system saves

approximately 40% in gas energy

costs by reusing already heated air.

INTERIOR: Porcelain panels over

stainless steel liner. Inner door liner

stainless steel.

Six-sided insulation (top, bottom,

sides, back and front) for high energy

efficiency.

Positive stops hold loaded racks securely when two-thirds withdrawn.

Automatic interlock switch shuts off

blower motor and burners when

doors are opened.

Two interior lights turned 'on by separate switch for in-process inspection.

Motor-driven blower fan constantly

circulates forced air for fast,

high-

loading, volume cooking.

cuts heat loss

for greater en-

ergy efficiency

and is more

sanitary and

virtually trouble-free.

M

Long-life energy-efficient

HP 1725rpm motor has sealed ball bearings,

needs no lubrication for 10 years.

Front-service access.

Fan switch allows operating the

blower when door is open for quick

cool down.

Interior temperature cycle varies

~t

only

10F.

Page 14

W

PRINCIPLES OF OVEN OPERATION

The heating of the oven involves the following:

1. Two tubular sheet

combustion chamber that is insulated.

2.

Above the combustion chamber is the flame

chamber which collects the heat coming

from the burners.

3.

The collected heat is directed through heat

exchanger tubes located in the cooking com-

partment. The oven compartment is first

heated indirectly by the heat from those

tubes.

4.

Heated flue products are then collected in a

chamber above the oven compartment,

drawn back into the oven and recirculated by

the blower wheel throughout the compartment.

5.

The fan distributes the heat throughout the

oven cavity.

W

THE OVEN CONTROLS

The control panel on the

mounted on the top and on the

section is mounted on the side. In both arrangements, the control functions are the same as

described

below.

metal burners operate in a

GN96T basic section is

GNSOS basic

Power

@

ON-OFF Switch. Energizes the oven controls

electrically.

@

Load Control. 'This is an infinite type control

which varies the input between

percent.

OFF

PERCENT OF

CONTROL SETTING FULL INPUT

HI-7

6

5

4

3

2

LO

-

1

OFF

@

Load Control Signal Light. When the light is

on, it indicates the

ing in the range between HI and LO settings.

@

Thermostat. This is a snapaction type control

of the temperature from

control

@

Thermostat Slgnal Llght. When the signal

light is "ON" it shows that the oven is preheating or is recovering to the termperature

dial settings

activatesldeactivates the burners.

while In a cooling cycle.

load control is function-

200'F

to

500'F.

and 100

This

I

CONTROL PANEL ON GN96T

I

CONTROL PANEL ON GN9OS

@

Tlmer. Any time interval can

one hour. The tlmer

val when the set time Is reached. The duration

of the timer rlng depends on how much the

tlmer has been wound.

@

Oven Llght Swltch. The oven lights are controlled by a rocker switch. To prolong

bulb Ilfe, use Ii hts only when loadlng the

oven, checking t

@

Automatlc Interlock Swltch (not vislble). Thls

switch shuts off the blower motor and burners

when the doors are opened except as noted

Item 9.

In

@

Cool Down Fan Switch. Thls swltch allows

the operatlon of the fan only (not the burners)

to cool down the oven

doors are o en. (See the para raph 1, page 18

Cool the &en to Clean un er the section

How to Care for Your Oven.)

will rlng for a short lnter-

1

e product or unloadlng.

be

selected up to

rapldly when the

8

llght

Page 15

6~

f@-)

k.

RACK ARRANGEMENT

The oven has eleven rack positions and five

racks are furnished with it. Additional racks are

available as optional accessories. The rack arrangement to be used for a cooking run will be

determined by the height of the particular product

being cooked. Thus the racks on which the product

will be placed may have one, two or more unused positions between them. For example,

cookies which have very little height can be

placed on 18 x 26 pans on each of the eleven

rack positions. Turkeys and other roasts with

considerable height would be placed on the

lowest positions

(#5

or #6).

PREHEAT

Followin are the steps to be followed in pre-

heating t e oven.

1.

2.

3. Set the thermostat dial to the temperature at

4.

5. Turn the Power Switch to "ON".

6.

R

The proper rack arrangement should be made

for the product to be cooked. (Refer to the

previous section.)

Your oven operates only when the doors are

closed. An electric interlock is provided that

de-energizes the blower and the burners

whenever the oven door is opened.

which the product will be cooked. Regarding

the temperature setting, the following Is

suggested. Since the oven chamber opening

is large and loading to capacity necessitates

keeping the doors open longer than Is usual

with standard ovens, temperature drops will

take place. To offset

while preheating, before the food is intro-

duced, the

the temperature at which the foo s

cooked.

Set the load control to HI.

The slgnal light will come on and stay on

until the set tem erature

preheat time is

350°F. The oven should be allowed to cycle

twice before loading for baklng to assure

good heat saturation of the oven chamber.

NOTE: Remember to set the thermostat to

desired cooking temperature if a higher

temperature was used to preheat the oven.

(#I) and the half-way position

this it Is suggested that

dial setting be 50°F hi her than

will be

B

1

g

mlnutes at a setting of

Is reached. Thls

7.

Under normal operating conditions, the

blower will continue to operate at all times

when the oven is on, except when the oven

doors are opened.

LOADING

With the oven preheated as noted above, it is

ready to proceed with the cooking.

1.

Open the doors (the fan will stop) and load

quickly. The pans should be centered on the

racks.

2.

When loading has been completed, close the

doors.

all cases, the oven should be loaded as

quickly as possible, keeping the door open

for the shortest possible period.

3. With the food in the oven chamber, reset the

temperature dial setting to what is appropriate

for the particular food product.

4.

Set the load control to the recommended

setting for the product and load to be cooked.

Refer to the Suggested Cooking Chart for

"

specifics.

5. Set the timer to the suggested time. A ain

refer to the Suggested Cooking Chart.

timer Is strict1 a mechanical one - IT IN NO

WAY

OVEN OR TURNS IT OFF. To insure that it

will ring when the time at which it was set

has elapsed, wind the timer to the maximum

setting. Then back-up to the desired setting

for the product. This will result in spring

tension sufficient to activate the alarm.

6.

When the cook time has elapsed, check for

proper doneness. If the food is done to your

satisfaction unload; if not set for additional

time and cooking as required.

UNLOADING

1.

Since convection ovens are high production

devices, consider the space that will be

needed to accommodate the food to be unloaded from the oven.

2.

Unloading should be fast to minimize the

heat loss while the doors are open

essential practice if consecutive cooking

loads are to be made.

3.

If consecutive loads are to be cooked, it is

suggested the doors be closed between each

load so the oven can recover to the preset

temperature.

'The blower will resume operation. In

%he

CONTR~LS

THE FUNCTION

OF THE

-

an

Page 16

OPERATING HINTS

Although some of the following points have been

touched on, they are mentioned again for their

significance.

1. When using the convection oven for the first

time with a particular food, check the degree

of doneness periodically before the suggested

time has elapsed, to make sure the desired

doneness is achieved.

2. Your own tables of temperature and times for

the various products should be completed,

as the oven is used, to reflect your own

operation.

3. Because the convection oven moves forced

heated air around in the oven chamber, the

temperature setting for the various products

are lower and the cook times are shorter than

in a conventional deck-type oven. Since recipes and foods are subject to many variations

and tastes, the recommendations about temperature settings and cooking times contained in this manual are SUGGESTIONS ONLY.

You, the operator, should do some experimenting in the beginning with your food products, since the oven may open up new vistas

of cooking for you, to find what temperatures

and times give you the best results.

4.

Do not open the doors unless it is necessary.

The windows on the doors allow product inspection without necessitating door opening.

There's adequate lighting, too

that go on when needed by turning the light

switch on the control panel.

-

two lights

In the table the temperatures are shown in

The indication on the dial is in both OF and "C as

shown in -Fig. 11.

Fig. 11 The temperature dial

'The load control varies from LO to HI as shown

in Fig. 12.

OF.

5. Load racks evenly and center the pans on

them. Keep them toward the front, to avoid

the possibility of light foods being thrown on

the motor fan.

6.

Use interior lights sparingly.

GAS CONVECTION OVEN - SUGGESTED SET-

TINGS FOR COOKING

The following Table 4 shows sug ested settings

of Temperature, Load Control and

products. These settings are intended as suggestions only since results depend on numerous

variables such as variations and content of the

food, recipes and preferences of the users.

In meat roasting it may be desirable to take

some steps to reduce shrinkage. In addition to

cooking meat at low temperatures (per the recommendations of USDA and the American Meat

Institute beef, lamb, and poultry should be cooked

at 225°F to

moisture in the cavity can be retained by placing

a shallow (1" deep) pan with water in the bottom

of the oven.

325"F, fresh pork at 325°F to 350°F)

7

ime,for various

4

MED

Fig. 12 Load Control

Page 17

TABLE 4 - SUGGESTED SETTINGS FOR COOKING

PRODUCT PRODUCT TEMPERATURE

CATEGORY PRODUCT DESCRIPTION

MEAT

FOWL

FISH

BREAD PRODUCTS

PASTRIES

Hamburger patties

Rolled rlb roasts

Standing rib roasts

Veal Roast

Steamship round Whole 6080 Lbs.

Meat Loaf 8-10 Lbs.

Turkeys

Chicken

2.2M Lbs.

Chicken

2.2112 Lbs. Backs 8 Wings

Fish stlcks 20.7. % X3"

Halibut steaks

Lobsters

Lobster tails

Bread-loaf 1 Lb.

(

Rolls

I

Rolls 2% Oz.

I

Biscuits

Muffins

Corn Bread

Sheet cakes

Angel cakes

Sugar cookies

Frult'pies (Frozen)

Apple pies (Fresh)

Pumpkin ples

Apple turnovers

2 Oz.

2.5 02.

4

02.

2022 Lbs.

15-20 Lbs. 300 3 Hr.

Breasts 8 Thighs 35

Breaded Fr

5 Oz. Fr.

1

M

Lb.

Y4

Lb.

Lbs118 x 2 6

7

26 Oz.

0.7.

20

x

1

Pan

(OF)

400-450

400450

375-400

1

?$

3M)

/

I I

I

335

56

7.10

8.12

1

l.%r. (Rare)

4-45 Hr. ,Me\

3 ~r. (~e'd)

1

45.60

33

i:

I

$:

TIME LOAD NO. OF

(MINUTES) CONTROL RACKS

4-6

6

5

283

6

46

5

283

7

46

5

283

7 3

1

'

1314

2

I

2

5

5

4

5

5 (24

5 (30 Pies)

5

5

2-PanlRack

Pies)

MISCELLANEOUS

Oven preheat Is proper but oven

never recovers from temperature

drop after food Is put In.

Edges of pans over-cooklng or very

uneven

browning.

Food

epllllng or

an

edge.

Overbrownlng or

Shrinkage very hlgh.

Melted cheese sand.

Pizza (Frozen)

Idaho potatoes

Frozen

TV

dinners

02. foil meals

Frozen 8

Frozen entrees (1" thick)

COOKING DIFFICULTIES AND SUGGESTED REMEDIES

DIFFICULTY PROBABLE CAUSE REMEDY

"running"

ahrlnklng.

towards

120 count150 Lbs.

100 count150 Lbs.

Count150 Lbs.

80

Load too big.

1.

Load control setting too high.

2.

Too many racks.

1.

Oven not leveled.

2.

Warped sheet pans.

Load control setting too high.

1.

Roasting temperature high

2.

Oven moisture low.

5 (120)

5

5

5

5

5

5

5

Check cooking chart for proper

loading.

Check Cooking Chart for proper

settings and loads.

1.

Level ovens on the racks both

front to back and side to side.

2.

Remove warped pans from the pan

set used for baking. Keep baking

pans separate from the others.

Lower the load control setting. Refer

to Cooking Chart.

1.

Reduce oven temperature.

2.

Put water in shallow pan

bottom.

on

oven

Page 18

W

HOW TO CLEAN THE INTERIOR OF YOUR

OVEN

Cool the Oven to Clean

Always allow oven to cool prior to cleaning.

To speed up the cooling, a Cool Down Fan

Switch is featured on the oven. In the Cool

Down position only, the blower will operate

when the doors are open. If the oven is still

hot make sure the fan is turned on with the

doors only slightly ajar to minimize the ex-

posure of the operator to the current of hot

air.

2.

Do Not Allow Large Accumulations

Keep the inside of the oven and racks wiped

clean. If food

so doors cannot be tightly closed, heat is

wasted and the oven will not operate properly.

Poorly closed doors permit a constant escape

of steam and vapor around the door.

causes a condensatioin which deteriorates

the finish around the oven front and door

lining.

3.

The Porcelain Liner Panels

Clean often when the oven in cold with mild

detergent or soa and water. This will prevent

food and dirt

frequently be all the cleaning that is necessary. Where soil resists soap-water clean-

ing, use a wooden tool to loosen

from the cold oven. Follow with a non-etching

cleaner which

procelaln enamel. Use clear water to rlnse;

for

d wlth a soft clean cloth. DO NOT USE

S~EEL

SOLUTIONS such as lye, soda ash, or

monla.

WOOL. WIRE BRUSHES and CAUSTIC

articles

P

rom "baking on" and will

Is specifically recommended

or carbon accumulate

splllage

'This

am-

foods and grease which resist simple

water cleaning, an abrasive cleaner such as

Bon Ami or Ajax, mixed into a paste, may be

employed. Apply with stainless steel wool or

sponge, always rubbing with the "grain".

This treatment is equally effective for "heat

tint" (slightly darkened areas caused by oxidation). Again, remember to rub in the direction of the polish lines. Rinse with clear wa-

ter, and dry with a soft cloth.

6.

The Recycler Tube

This tube should never be blocked. It should

be kept clean at all times for proper operation of the oven.

7.

Odors In The Oven

Low temperature cooking mayVresult in lingering odors. They can be eliminated by setting the thermostat at 500°F and the load

control at HI, and running the oven for half

an hour.

H

HOW TO CLEAN THE EXTERIOR OF YOUR

OVEN

Washln!

Wash al exterior surfaces at least once daily.

Use a cloth with warm water and a mild soap

or detergent. Where surfaces have been pol-

-

ished, use a cloth lightly

remove

dry. This simple beauty treatment not only

keeps your equlpment

but virtually ellminates the danger of grease

accumulation

remove stain

pollsh. Follow with a clear rlnse, then

-

which may form a hard-to-,

If left on too long.

hard rubbing will

dlrt-free and sparkling,

soap-

4.

The Llner Itself

The

porcelain

and should be removed periodically to check

for build-ups

air circulation and heat transfer, keep the

area around the heat exchange tubes clean.

The Stainless Steel Door Liner

5.

Soap or detergent and water will usually take

care of routine cleaning. Drying is accomplished with a soft clean cloth. For burnt-on-

liner side panels are removable

-

salt, batter, etc., For proper

Permalucent Flnlsh - Exterior Slde Panels

If rease has accumulated on the PERMALU 8 ENT flnlsh, remove It with any siliconbase polish, follow dlrectlons on the container. NEVER use a scouring pad-type

cleaner on the PERMALUCENT finish. If the

surface should be accidentally marred, it can

be quickly and easily restored to its original

beauty with a "PERMALUCENT Touch-Up-Kit",

available through your Hobart Chicago

Heights

each kit.

Servicer. Full instructions are in

Page 19

3.

Cleaning The Stainless Steel

To keep the stainless steel front bright and

gleaming at all times, just clean it regularly

with a damp cloth and polish with a soft, dry

cloth. To remove discolorations which may

have formed when regular

glected, use any detergent or plain soap and

water. For

a self-soaping scour

CAUTION: ALWAYS RUB WITH THE "GRAIN"

IN A HORIZONTAL DIRECTION.

4.

Plastlc Control Knobrr

Waah, d and pollsh with a soft cloth. Avoid

uslngl grl 7 ty soepsl or harah cleaners.

I

REPLACING

1.

Ctr@~k

2.

WARNING turn off electrlc aupply.

particular1 stubborn discolorations,

Y

ng pad may be used.

LAMPS

to

aneure

that the oven Is cool.

cleanlng was ne-

R~rnava

up

4,

ffcllm~v@

5.

Part1

6,

Rtaylace the burnt-out bulb,

7,

Replace the hardware by reversing the dls-

rrmombly procedure.

all rack5 by pulling forward, lifting

and

out.

screws from the llght window bezel.

out the bezel and wlndow.

b

Page 20

As

continued

changed without notlce.

product Improvement Is a pollcy of Hobart, speclflcatlons may

be

14th &Arnold Streets Chlcago Helghts, IL 60411

HOBART CORPORA'I'ION

PRINTED

IN

U.S.A.

Loading...

Loading...