Page 1

DDU38 DIRECT DRIVE UNLOADER

R-L OPERATION L-R OPERATION

ML-110564 ML-110565

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

FORM 33690 (6-97)

Page 2

Installation Instructions

DDU38 DIRECT-DRIVE UNLOADER

GENERAL

The DDU38 Unloader is connected to the unload end of a C-Line A, W, or AW dishwasher. It moves

the 20" x 20" rack in a 90 degree arc onto a dish table. The Unloader uses a direct linkage with the

dishwasher cradle to oscillate the rack-moving mechanism.

NOTE: The Unloader cannot be installed on dishwashers having either the Blower Dryer or the framemounted Electric Booster Heater options.

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the Unloader is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

LOCATION

CAUTION: Do not use a forklift to move or unskid machine.

Place Dishwasher and Unloader as close to their final positions as possible. Review all tags and labels

but do not remove any until installation is complete. Remove any packaging, tape, wire, and bracing.

ASSEMBLY

Leg Installation and Leveling

Insert the long legset into the two rear leg

sockets underneath the Unloader (Fig.1).

Insert the short legset into the two front leg

sockets. Fasten legs to leg sockets by

loosening and tightening the set screw in

each leg socket. Fill set screws with an NSF

approved silicone sealant.

Make sure adjoining parts of Dishwasher and

Unloader are exactly in line with each other.

Turn leveling feet (on bottom of legs) in or out

to adjust height and level machine. Also,

refer to Track Guide Leveling, page 6.

UNLOADER

LEG SOCKETS

DRAIN

LEVELING FEET

DISHWASHER

PL-52426

© HOBART CORPORATION, 1997

Fig. 1

– 2 –

Page 3

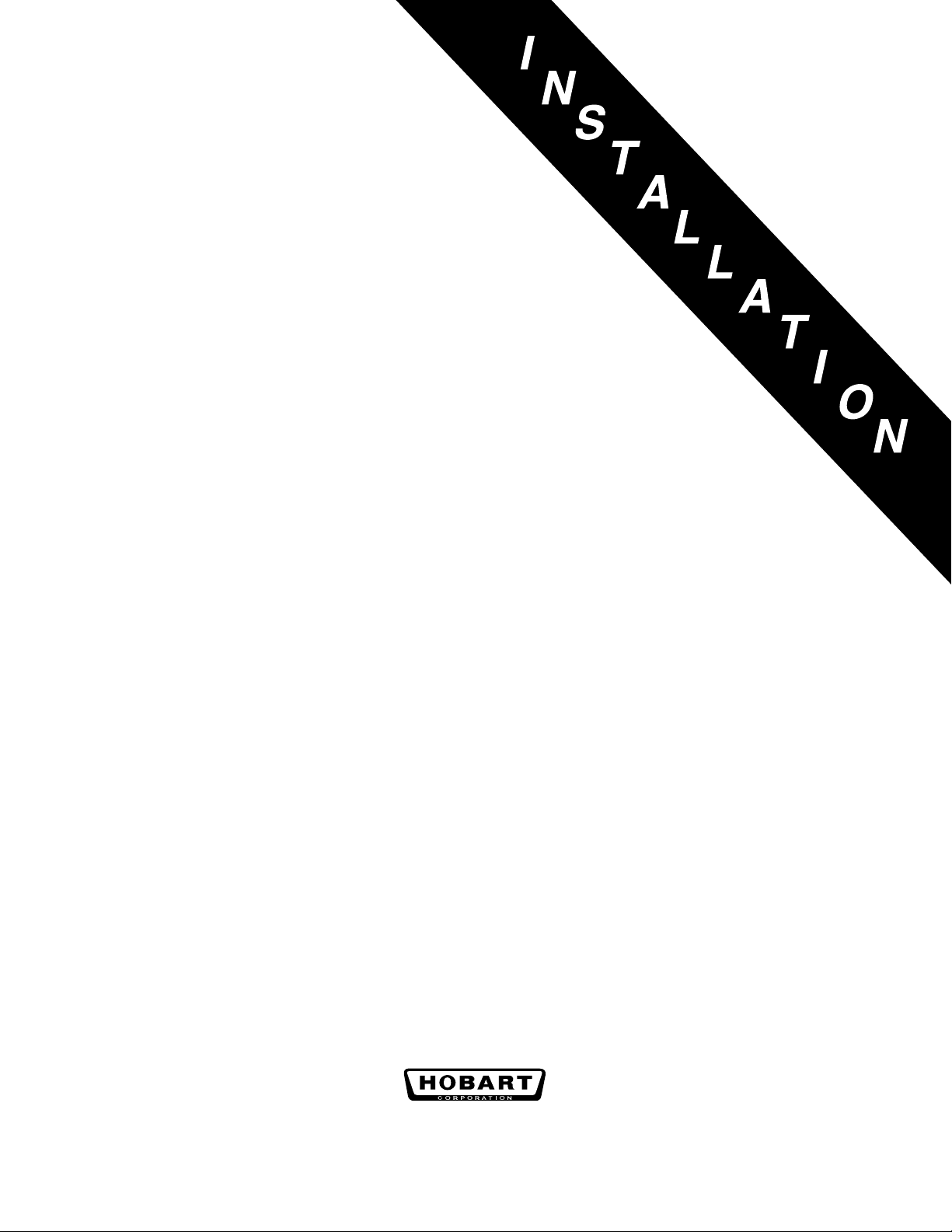

Drill Holes

If the Dishwasher was not specified for installation with a DDU38 Unloader, the mating holes may not

be present and must be drilled.

Refer to Figs. 2 & 3 for Right-to-Left Operation. Refer to Figs. 4 & 5 on page 4 for Left-to-Right

Operation. Templates are provided.

Right-to-Left Operation

23-11/16

7-9/32

5.000

4 PLC

1.000 DIA.

HOLE

2-5/8

1-17/32

2-1/4

5/16 DIA.

7 HOLES

2-11/16

2 PLC

4-1/8

3 PLC

4-7/8

2 PLC

15/32

3-15/16

18-3/16

INSIDE

REF.

11/32 DIA.

HOLE FOR

R-L OPER.

FRONT OF DISHWASHER

LEFT "UNLOAD" SIDE OF DISHWASHER

Fig. 2

CRADLE

PL-52428

BRACKET

TEMPLATE

CRADLE

FRONT

7

/8

11

/32 DIA.-2 HOLES

1 3/4

FRONT

PL-52758

PL-52427

1

3

/8

All C-Line A Models Except C54A-Series C54A-Series Only

Fig. 3

– 3 –

Page 4

Left-to-Right Operation

1-17/32

2-1/4

5/16 DIA.

7 HOLES

4-7/8

2 PLC

2-11/16

2 PLC

4-1/8

3 PLC

2-5/8

7-9/32

5.000

4 PLC

23-11/16

1.000 DIA.

HOLE

CRADLE

FRONT

18-3/16

INSIDE

REF.

11/32 DIA.

HOLE FOR

L-R OPER.

RIGHT "UNLOAD" SIDE OF DISHWASHER

Fig. 4

1

3

/8

15/32

3-15/16

PL-52429

11

/32 DIA.-2 HOLES

1 3/4

7

/8

TEMPLATE

CRADLE

FRONT OF DISHWASHER

PL-52430

FRONT

BRACKET

All C-Line A Models Except C54A-Series C54A-Series Only

Fig. 5

– 4 –

PL-52755

Page 5

Assemble Three Splash Guards, Apply Foam Tape, and Assemble Unloader-to-Dishwasher

1

Use 1

/2" foam tape (supplied) to make a watertight seal where the Unloader bolts to the Dishwasher

(Fig. 6). Assemble the unload end of the Dishwasher with the load end of the Unloader using six

1

/4" - 20 x 5/8" bolts, lockwashers, and nuts (provided). Refer to the paragraph after the next paragraph

regarding the seventh, upper-front, hole.

Three splash guards are provided in the bag of loose parts. Install the two splash guards with slotted

holes between dishwasher and unloader by bolting them to the end of the dishwasher chamber (Fig. 6).

1

Use the lowest hole on the chamber end as the bottom hole. Assemble using two

/4" - 20 x 5/8" screws,

lockwashers, and nuts (provided).

The smaller splash guard with round holes goes inside the unloader tank near the front corner (Fig. 6).

This splash guard uses the upper hole nearest the front of the seven holes that join the Unloader to

the Dishwasher. Assemble the smaller splash guard using one

1

/4" - 20 x 5/8" screw, lockwasher, and

nut (provided) — the screw goes through the bottom hole of the splash guard, the wall of the Unloader,

the Foam Tape, and the tank of the Dishwasher.

Right-to-Left Operation Left-to-Right Operation

FOAM TAPE

FRONT

FRONT

PL-52754

LEFT "UNLOAD" SIDE OF DISHWASHER RIGHT "UNLOAD" SIDE OF DISHWASHER

Fig. 6

– 5 –

Page 6

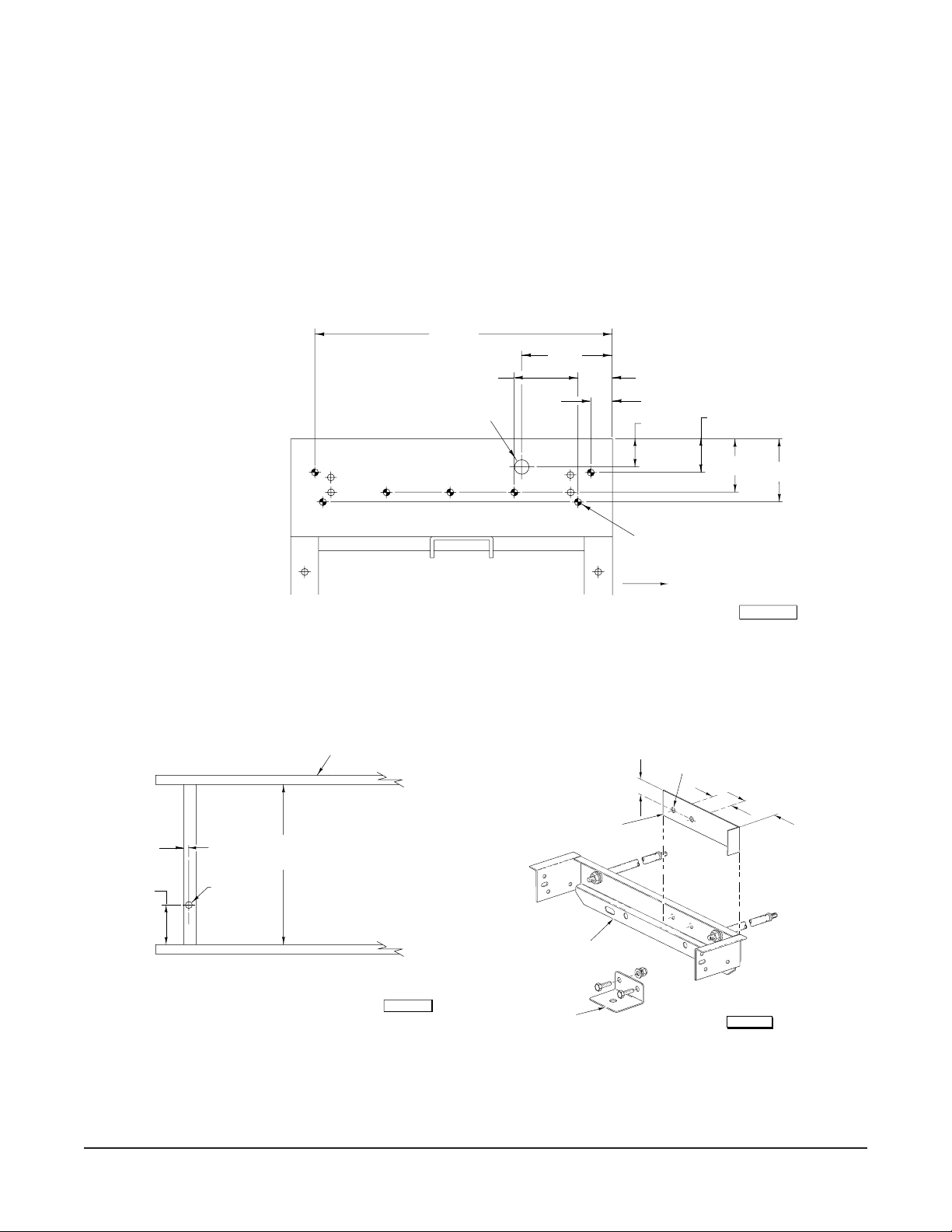

Direct Drive Linkage

Your Hobart service technician should assemble the linkage from the drive mechanism on the Unloader

to the Cradle of the dishwasher. The distance between the centers of the screws holding the drive rod

to the Unloader and the Cradle should be 113/32". If the 113/32" dimension is not present, turn the

Adjustable End on the Drive Rod until the dimension is present (Fig. 7). The bolt, washers, spacer, and

stopnut, (provided) should be assembled through the hole in the top of the Cradle and the Adjustable

End (Fig. 7) on all models except C54A Series. On C54A Series only, mount the bracket to the cradle

using two

5

/16" - 18 x 3/4" bolts, lockwashers, and nuts (provided) and assemble the Adjustable End to

the bracket with the bolt, washers, spacer, and stopnut (bottom view, Fig. 7). During assembly, your

Hobart service technician should apply a small amount of Neverseez graphite lubricant (not supplied)

on the spacer.

Right-to-Left Operation Shown

11-3/32"

ADJUSTABLE ENDDRIVE ROD

Fig. 7

Assemble Dish Table to Unloader

Assemble a suitable dish table (not included) to the discharge

end of the Unloader. Use suitable fasteners, such as two or

more stainless steel

5

/16"-18 x 5/8" machine screws,

lockwashers, and nuts (not provided) (Fig. 8). Use silicone

sealer or 1" foam tape between dish table and tank lip on

Unloader to make a watertight seal. The dish table should

tilt so it drains into the Unloader.

BRACKET

5/8"

CUSTOMER'S

TABLE

QUANTITY & LOCATION

OF MOUNTING HOLES

AND HARDWARE

BY OTHERS

BOLT

WASHER

SPACER

WASHER

STOPNUT

PL-52433

Fig. 8

CRADLE

C54A SERIES

CRADLE

7/8"

DDU38 TANK END

PL-52434

Track Guide Leveling

The track guides on which the rack rides should be even or slightly lower as the rack progresses from

the Dishwasher to the Unloader and from the Unloader to the dish table. Your Hobart service technician

can make any necessary adjustments.

– 6 –

Page 7

Assemble Table Limit Switch to Dishtable

The exact location of the Table Limit Switch (provided) is customer selectable. It may be mounted

either at the end or on the back of the dish table. When mounted on the back of the dish table, space

for at least three racks (60 inches) is usually provided.

Drill holes in the dish table at the proper location for mounting the Table Limit Switch. Refer to Fig. 9

for Right-to-Left operation. Refer to Fig. 10 for Left-to-Right operation.

Right-to-Left Operation Left-to-Right Operation

7/32" DIA.

2 HOLES

7/32" DIA.

2 HOLES

1/2" DIA.

2 HOLES

1-1/2"

3/4"

BOTTOM OF

DISH TABLE

1-1/2"

3/4"

1/2" DIA.

2 HOLES

BOTTOM OF

DISH TABLE

PL-52435

13/16"

PL-52439

13/16"

Fig. 9 Fig. 10

Disassemble actuator by removing two screws (Fig. 11). Save actuator and screws for reassembly

after switch is mounted.

Remove two screws, lockwashers, and nuts from switch bracket and reuse in mounting switch to dish

table through two

7

/32" diameter holes (Fig. 11). Reassemble actuator through two 1/2" diameter holes

in dish table. Reinstall actuator on hinge using two original screws (Fig. 11).

MOUNT SWITCH

REMOVE AND SAVE

TWO SCREWS,

LOCKWASHERS AND NUTS

ACTUATOR

REMOVE AND SAVE TWO

ACTUATOR SCREWS

USING TWO SCREWS,

LOCKWASHERS AND NUTS

THRU 7/32"DIA. HOLES

ACTUATOR

ASSEMBLE ACTUATOR

WITH TWO SCREWS

THRU 1/2" DIA. HOLES

SECURE WIRES WITH

STRAIN RELIEF AS SHOWN

RIGHT TO LEFT OPERATION SHOWN

(LEFT TO RIGHT OPPOSITE)

Fig. 11

– 7 –

PIGTAIL

LEADS

PL-52436

Page 8

PLUMBING CONNECTION

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY,

AND PLUMBING CODES.

Drain

The drain fitting (1

1

/2" NPT internal threads) underneath the Unloader (Fig.1) should be properly

connected to a suitable drain.

ELECTRICAL CONNECTION

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

1

Run

/2" conduit containing three #14 AWG insulated wires rated 90°C and 600 volt from the Table Limit

Switch to the control box on top of the dishwasher. Conduit and wires should be UL listed . When

routing conduit on gas heat dishwashers, provide a minimum clearance of 10 inches around the flue.

The installer should connect the Common, Normally Closed and Normally Open pigtails at the Table

Limit Switch; pigtail leads should be looped through strain relief to make secure (Fig. 13). The installer

should NOT connect the wires in the dishwasher control box. Only a properly trained Hobart service

technician should make the final wire connections in the dishwasher control box.

FORM 33690 (6-97) PRINTED IN U.S.A.

– 8 –

Loading...

Loading...