Page 1

MODEL 4822 CHOPPER

ML-136125

ML-136126

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

F-35109 (July 2005)

Page 2

Installation, Operation and Care of

MODEL 4822 CHOPPER

SAVE THESE INSTRUCTIONS

GENERAL

The 4822 Chopper uses a 11/2 horsepower motor. It will grind 16 lbs. per minute, first cutting, through

1

/8" plate.

a

The 4822 Chopper, with funnel-shaped cylinder, will grind 20 to 22 lbs. per minute, first cutting, through

1

/8" plate.

a

© HOBART, 2005

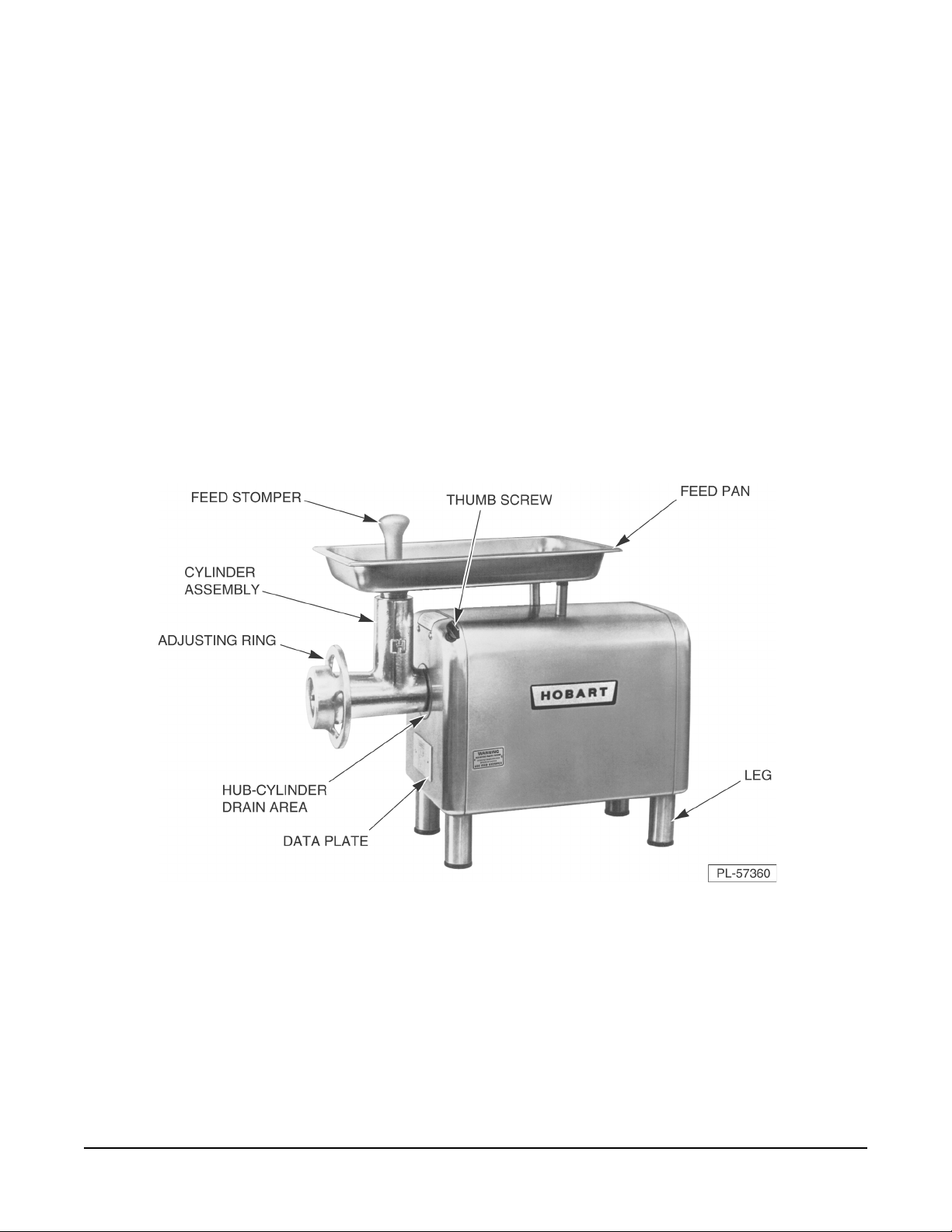

Fig. 1

– 2 –

Page 3

INSTALLATION

UNPACKING

Remove the carton from around the machine. Remove the four bolts holding the machine to the skid.

Unpack the chopper cylinder assembly.

Immediately after unpacking the chopper, check for possible shipping damage. If this machine is found

to be damaged after unpacking, save the packaging material and contact the carrier within 15 days of

delivery.

Prior to installation, test the electrical service to make sure that it agrees with the specifications on the

machine data plate.

The four leg assemblies (Fig. 1) are removed and packed in a separate carton for shipment. Unpack

and assemble these legs by screwing them into the four tapped holes of the frame. The rubber feet on

these legs cushion the machine. Under normal operation, the machine need not be bolted down.

ELECTRICAL CONNECTIONS

WARNING: THE ELECTRICAL CORD ON THIS MACHINE IS EQUIPPED WITH A GROUNDING-

TYPE PLUG WHICH MUST BE CONNECTED TO A PROPERLY GROUNDED RECEPTACLE. IF

THE RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

DO NOT REMOVE THE GROUNDING PRONG FROM THE PLUG.

Choppers with three phase motors should be connected so that the hub drive runs counterclockwise

facing the cylinder assembly.

A check must be made to verify correct direction of rotation. Energize machine momentarily by turning

switch ON then OFF.

If rotation is incorrect, disconnect plug from electrical outlet, disassemble the plug and interchange any

two power leads (not the green ground lead). Then reassemble the plug and recheck.

– 3 –

Page 4

CLEANING

WARNING: UNPLUG CHOPPER POWER CORD BEFORE CLEANING.

The chopper must be thoroughly cleaned and sanitized after installation and before being placed into

service.

Cleaning Supplies (Not Provided)

Recommended cleaning and sanitizing supplies include:

• A 12" handle nylon brush that will slide through the cylinder

• A two compartment pail for cleaning solutions

• A pail for sanitizing solution

• A scrap pail

• Clean cloths

• A spray bottle

NOTE: When using detergents and sanitizers, follow manufacturer's instructions. Rinse with clean

water.

Prepare a hot detergent solution in one side of the two compartment pail. Fill the other compartment with

warm potable rinse water.

Mix a sanitizing solution by adding one tablespoon of sodium hypochlorite bleach (5.25%) to one gallon

of water in a pail. This makes a 200 ppm solution. Use this solution to fill the spray bottle as well as the

pail for sanitizing.

Thoroughly clean and sanitize the feed pan, feed stomper, chopper cylinder assembly, worm

assembly, knife, plate, adjusting ring and machine housing. Refer to Fig. 1 for component identification.

NOTE: After cleaning, apply a light coat of food grade mineral oil to the cylinder, adjusting ring, knife,

plate and worm before reassembly.

– 4 –

Page 5

ASSEMBLY

Check to assure the hub and hub drive are clean and clear of any obstruction. Insert the cylinder

assembly with a slight twisting motion toward the left. The cylinder stop pin will contact the side of the

hole that receives it. Tighten the thumb screw.

NOTE: Upon disassembly it is only necessary to loosen the thumb screw about three turns. It should

never be removed.

Slide the worm into the cylinder and rotate until the square shank of the worm locks into the hub drive.

Install the knife with cutting edges facing out, and the plate, making sure the notch aligns with the pin

in the bottom of the cylinder. Thread the adjusting ring on hand tight. Install the feed pan and feed

stomper.

NOTE: On the model 4822 with funnel-shaped cylinder, tighten the feed pan thumb screw (Fig. 2),

holding the pan securely to the chopper cylinder assembly.

CAUTION: The knife and plate depend on meat for lubrication. Therefore, the chopper should

never be operated without meat.

Fig. 2

– 5 –

Page 6

OPERATION

Cut the meat into strips, turn the machine ON and feed the meat strips into the chopper, using the feed

stomper only as needed. If the strips are cut to proper size, they will feed without assistance from the

feed stomper, allowing both hands of the operator free to feed meat. When running meat through the

chopper a second time, more speed is attained by feeding small quantities at a time than by trying to

force large amounts with the feed stomper.

The feed pan should always be kept in place on the cylinder. It not only makes regular feeding easy,

but keeps the chopper attachment ready for immediate use. The fineness to which the meat is cut is

governed by the size of the holes in the perforated plate, not by the tension put on the adjusting ring.

Do not tighten the adjusting ring more than hand tight.

MAINTENANCE

WARNING: UNPLUG CHOPPER POWER CORD BEFORE CLEANING, SERVICING OR

REMOVING PARTS. REPLACE PARTS BEFORE USE.

MACHINE CLEAN UP

The machine should be thoroughly cleaned at the end of an operating day or after being idle for an

extended period of time. Refer to CLEANING for proper procedure.

HUB AND CYLINDER DRAIN

Hub Drain

A drain slot in the trim washer allows any meat juices to drain from the hub. This slot should be inspected

periodically to make sure that it is free of obstructions. A small brush can be used to remove any

material which may have accumulated.

Cylinder Drain

A drain hole at the bottom end of the cylinder allows any meat juices to drain. This hole should be

inspected periodically to make sure that it is free of obstructions. A small wire can be used to remove

any material which may have accumulated.

AIR INTAKE

Under normal operating conditions the motor air intake screen, located in the base of the chopper, will

need little or no attention. However, in some installations where sawdust or other foreign materials are

present in the air, this intake screen may become partially or completely covered. Where an adverse

dust condition does exist, periodically check the screen and wipe clean with a rag or brush as required.

STORAGE

The chopper should be completely cleaned and covered with a towel or other suitable cover when it is

not to be used in the immediate future.

SERVICE

Contact your local Hobart authorized service office for any repairs or adjustments needed on this

equipment.

– 6 –

Page 7

NOTES

– 7 –

Page 8

NOTES

FORM 35109 (July 2005) PRINTED IN U.S.A.

– 8 –

Loading...

Loading...