Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

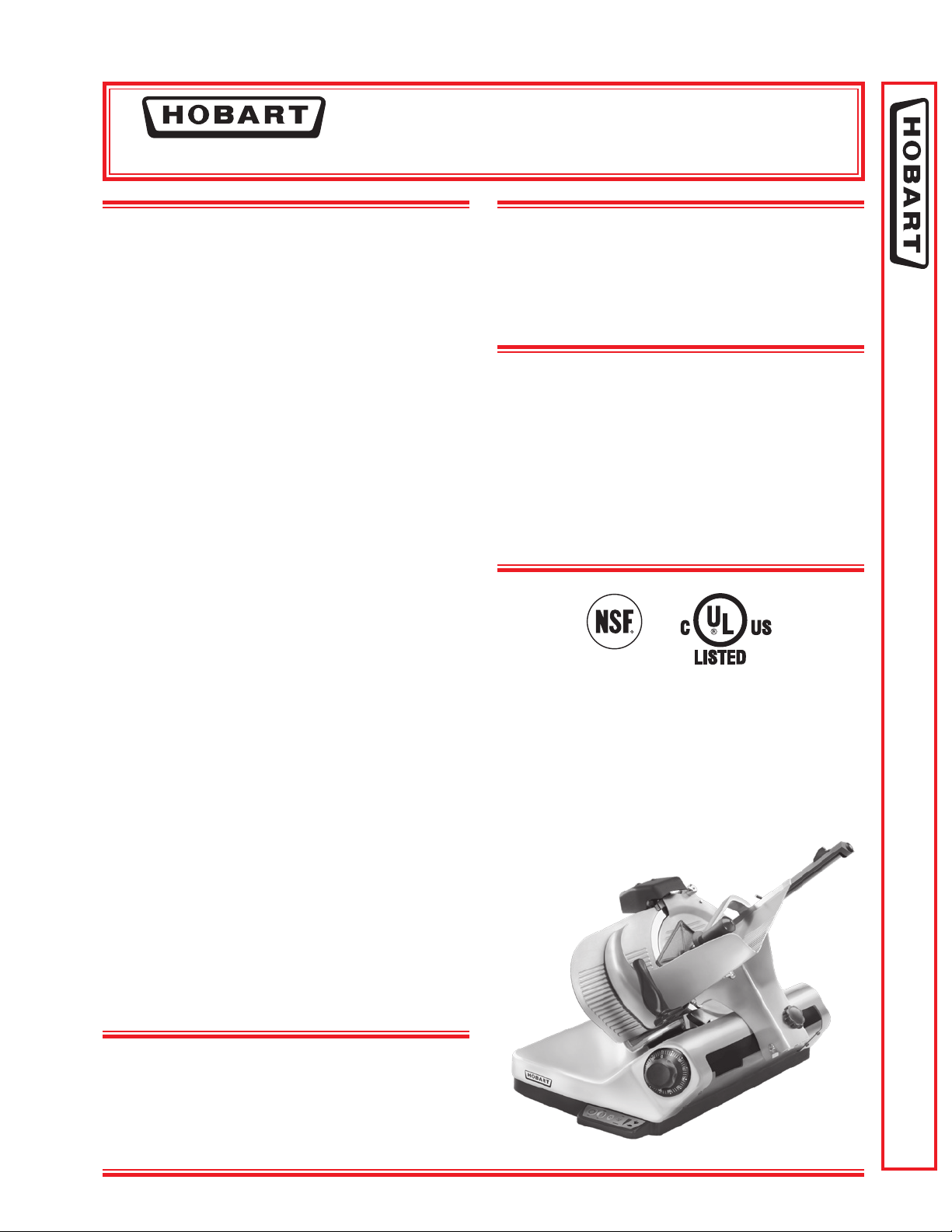

3913/3913N

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Low Prole, Linear Automatic Drive

■ Removable Knife (3913)

■ Non-Removable Knife (3913N)

■ Select-A-Stroke™ Custom Stroke Lengths

■ Removable Ring Guard Cover

■ Zero Knife Exposure

■ Three Automatic Speed Settings

■ Sharpen Knife Indicator Light

■ Manual Assist Mode

■ Enduralube™ Carriage Rail System

■ Tilting, Removable Carriage System

■ Knife Sharpen Button

■ Home Start Position

SLICER

MODEL

❑ 3913 – Full Featured Automatic Slicer with

Removable Knife and Tool

❑ 3913N – Full Featured Automatic Slicer with

Non-Removable Knife

ACCESSORIES

❑ Knife Removal Tool

❑ Full Fence

❑ Food Chute

❑ Product Deector

❑ 4" Legs

Specications, Details and Dimensions on Inside and Back.

■ 13" CleanCut™ Alloy Edged Knife

■ Top Mounted Borazon Stone Sharpener

■ Close To Stop

■ Glass Bead Finish on Gauge Plate, Top Knife

Cover and Product Tray

■ Auto Shutoff

■ Double-Action Indexing Barrel Cam

■ Gauge Plate Interlock

■ Lift Assist Cleaning Leg

■ No Volt Release

■ Rear Mounted Meat Grip

■ Ergonomic Style Handle

■ 1⁄2 H.P. PSC Knife Drive Motor

■ Sanitary Anodized Aluminum Base

■ 10 Rib Poly V-Belt Drive System

3913/3913N SLICER

F-40215 – 3913/3913N Slicer Page 1 of 4

Page 2

3913/3913N

SLICER

SOLUTIONS / BENEFITS

Linear Automatic Drive with Three Speeds

Labor savings, lower maintenance costs

■ Drive system uses magnets and electricity to move

product back and forth

■ Reduces moving parts and lowers prole of automatic

models

■ Three carriage speeds including 30, 42 and 52

strokes per minute

Removable Knife (3913)

Easier cleaning, labor savings

■ Knife easily removes with removal tool

■ Area within ring guard is open for faster cleaning

■ Knife and tool are warewasher safe for easy cleaning

and sanitation

Select-A-Stroke™ Custom Stroke Lengths

Ease of use, improved slicing performance

■ Operator sets stroke length with position of product

tray

■ Enables stroke lengths ideal for each product sliced

■ Reduces slicing time and wear on bearings

Removable Ring Guard Cover

Reduces labor, easier to clean

■ Catches product debris around the knife for easy

removal during cleaning

■ Reduces time to “oss” during cleaning

Zero Knife Exposure

Looking out for the operator

■ Knife edge is covered when sharpener is both

mounted, removed making cleaning easier

Manual Mode Assist

Ease of use, improved slicing performance

■ Reduces operator effort needed to move carriage

when slicing manually

Sharpen Knife Indicator Light

Improves performance, reduces cost

■ Indicates when to sharpen to reduce slicing with dull

knife

Enduralube™ Carriage Rail System

Performance, durability, lower maintenance

■ Smooth operation from continuous lubrication of

carriage rod

■ Replenish only twice a year to maintain performance

Exclusive Tilting, Removable Carriage System

Easier to clean, reduces labor

■ Tilt design allows for ease of midday cleaning

■ Removable for complete cleaning and sanitation

Sharpen Knife Button

Reduces cost of ownership, ease of use

■ Reduces over-sharpening and extends knife life

■ Eliminates guesswork on correct sharpening length

Home Start Position

Looking out for the operator

■ Carriage must be in “home position” before the slicer

will start, ensuring tray is in optimal loading position

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

CleanCut™ Knife

Reduces cost of ownership, improves yield

■ Super alloy edge stays sharp longer

Top Mounted Borazon Stone Sharpener

Ease of use, easier cleaning, reduces costs

■ Single action sharpens and hones in fteen seconds

■ Removable and warewasher safe for easy cleaning

and sanitation

■ Lifetime guaranteed Borazon sharpening stones

reduce maintenance costs

Close To Stop

Convenience, labor savings, energy savings

■ Closing of gauge plate turns off the slicer

Glass Bead Finish on Gauge Plate and Knife Cover

Ease of use, improves performance

■ Reduces drag for a smoother slicing motion

Automatic Shutoff

Energy savings

■ Knife shuts off after 30 seconds of inactivity to extend

motor life and save energy

Double-Action Indexing Barrel Cam

Increases reliability, easier to use

■ The rst full revolution of the indexing knob provides

precise control for shaving, chipping and thin slicing

■ The second revolution opens the gauge plate quickly

for thicker slicing

Gauge Plate Interlock

Ease of cleaning

■ Gauge plate must be closed to remove or tilt away

carriage for cleaning and cannot be opened when

product tray is tilted or removed

Lift Assist Cleaning Leg

Ease of use and cleaning

■ Gas assisted leg helps operator easily lift machine for

cleaning underneath

No Volt Release

Looking out for the operator

■ Slicer must be restarted if power fails or slicer is

unplugged

Rear Mounted Meat Grip

Slicing performance, ease of use

■ Opens up front of product tray for unobstructed

loading

■ Optimizes geometry and weight for better hold

1

⁄2 H.P. PSC Knife Drive Motor

Durability, cost savings

■ More efcient design reduces energy cost

Sanitary Anodized Aluminum Base

Easier cleaning, labor savings

■ Limited cracks/crevices or bolt holes where product

can lodge and bacteria may grow

■ Easy cleanup and durable nish

10 Rib Poly V-Belt Drive System

Reduces maintenance, improves efciency

■ Improves energy transfer from motor to knife

Page 2 of 4 F-40215 – 3913/3913N Slicer

Page 3

3913/3913N

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

SPECIFICATIONS

Linear Automatic Drive: Mounts directly on carriage rail to

deliver smooth, quiet carriage movement without moving

parts.

Removable Knife: Knife hub accepts Knife Removal Tool.

The tool covers the knife edge when removed (3913).

Non-removable knife can be ordered as 3913N.

Select-A-Stroke: Stroke length can be set to any point

along the carriage rail and remains in memory for 30

seconds after pausing.

Removable Ring Guard Cover: Cover ts on top of ring

guard to catch food debris. When removed, reveals a 0.12"

space between knife and guard for easier ossing.

Is durable Celcon™ plastic and can be washed in warewasher or three compartment sink.

Zero Knife Exposure: Knife edge is not exposed during

slicing or recommended cleaning procedures.

Manual Mode Assist: Linear drive assists as user pushes

and pulls carriage while slicing manually.

Sharpen Knife Indicator Light: Indicator light alerts

operator when to sharpen knife. A microprocessor counts

the optimal number of carriage strokes before activating an

LED on the control panel.

Enduralube™ Carriage Rail System: Enduralube™ ensures

optimal lubrication of carriage rail and bearings while

requiring only bi-annual oil replenishment.

Tilting, Product Tray Carriage System: Stainless steel

and aluminum product tray tilts easily for midday cleaning

and is removable for thorough cleaning and sanitation

procedures. The carriage has 121⁄2" manual travel.

Knife Sharpen Button: Sharpen button is preset for the

optimal sharpening duration to prevent both over and under

sharpening.

Home Start Position: Home-start ensures product tray is

in a convenient position before starting the slicer.

CleanCut™ 13" Knife: The knife is approximately 13 inches,

constructed of 304L stainless steel and high performance

Stellite™ alloy.

Top Mounted Borazon Stone Sharpener: Single action

operation utilizing two Borazon stones to sharpen and hone

in fteen seconds. Removable, top mounted and warewash

safe. When sharpener is removed for cleaning, knife edge

is completely shielded. Borazon stones have lifetime

guarantee.

Close To Stop: After slicing, a quick turn of the index knob

to the closed position turns off the slicer.

SLICER

Automatic Shutoff: Knife motor shuts off after 30 seconds

without carriage motion.

Double-Action Indexing Barrel Cam: First revolution

of index cam for precision slicing; second revolution for

thicker slicing selection.

Gauge Plate Interlock: Gauge plate interlock prevents tilt

or removal of the product tray when the gauge plate is open

and the knife is exposed.

Lift Assist Cleaning Leg: Gas piston helps to both lift and

then hold slicer in tilted position for cleaning beneath the

machine.

No Volt Release: In the event of power loss, slicer must be

restarted before operation can continue.

1

⁄2 H.P. PSC Knife Drive Motor: Permanently lubricated ball

bearings. Single Permanent Split Capacitor motor (PSC).

Sanitary Anodized Aluminum Base: One-piece base

inhibits growth of bacteria in seams, cracks and crevices.

Durable nish to withstand harsh cleaning products.

10 Rib Poly V-Belt Drive System: Knife is driven by a

Poly V belt with ten ribs for optimal efciency and power

transfer.

Finish: Stainless steel product tray, gauge plate and top

knife cover. Anodized aluminum base and product tray

support arm.

Meat Grip: Rear mounted grip is high strength thermoplastic. Swings out of way when not in use.

Product Deector: Deects large, thick slices off of motor

mount. Recommended when slicing product that is both

thicker than 3⁄8" and larger in diameter than 51⁄2".

Electrical Specication: 100-120/60/1.

Switch: Moisture protected membrane, operated by sealed

push-button switches.

Slice Thickness: Up to 1¼ inches.

Cord & Plug: 6-foot, three-wire power supply cord and at

plug. Plug not furnished on export models.

Capacity: The product tray will take food up to –

Rectangle: approximately 12" x 6" or

Round: approximately 8" diameter.

Warranty: All parts and service coverage for one year

including knife. Lifetime guarantee on Borazon stones in the

sharpening system.

Weight: Shipping 142 lbs., Net 110 lbs.

F-40215 – 3913/3913N Slicer Page 3 of 4

Page 4

3913/3913N

SLICER

DETAILS AND DIMENSIONS

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

Page 4 of 4 F-40215 – 3913/3913N Slicer

F-40215 (REV. 01/12) LITHO IN U.S.A. (H-01)

Loading...

Loading...