Hobart 3210-50, 3210, 3209-50 Operation And Maintenance Manual

:.

:

TM-318 /

020674 /

OPERATION AND MAINTENANCE MANUAL

with

ILLUSTRATED PARTS LIST

for

HOBART 400 HZ AC GENERATOR

Synchronous Motor Driven

with

Static Voltages Regulator

Manufactured by

MOTOR GENERATOR DIVISION

HOBART BROTHERS COMPANY

I

TROY, OHIO 45373

r

SAFETY INSTRUCTIONS AND WARNINGS FOR ELECTRICAL POWER EQUIPMENT

ELECTRIC SHOCK can kill. Do not touch live electrical parts.

FUMES AftID GASES can be fire and health hazards. Ventilate all fumes and exhaust gases to the outside.

ELECTRIC ARC FLASH can injure eyes, burn skin, cause equipment damage, and ignite combustible material. Do not

use power cables to break load and be sure tools don’t cause short circuits.

IMPROPER PHASE CONNECTION, PARALLELING, OR USE can damage this and attached equipment.

MOVING PARTS can cause serious injury. Keep clear of moving parts.

IMPORTANT - Protect yourself and others. Read and understand all the instructions in this Operating/Instruction

Manual before installing, operating, or servicing this equipment. Keep this manual available for future

use by all operators.

A. GENERAL

Equipment that supplies electrical power can cause serious injury or death, or damage to other equipment or

property, if the operator does not strictly observe all safety rules and take precautionary actions. Safe practices

have developed from past experience in the use of power source equipment. Certain of the practices below apply to

engine driven equipment.

B. SHOCK PREVENTION

Bare conductors, or terminals in the output circuit, or ungrounded, electrically-live equipment can fatally shock a

person. Have a competent electrician verify that the equipment is adequately grounded and learn what terminals

and parts are electrically HOT. Use proper safety clothing, procedures, and test equipment.

The electrical resistance of the body is decreased when wet, thus more easily permitting dangerous currents to flow

through it. When inspecting or servicing equipment, do not work in damp areas without being extremely careful.

Stand on dry rubber mat or dry wood, use insulating gloves that are effective when dampness or sweat cannot be

avoided. Keep your clothing dry and never work alone.

1. Installation and Grounding of Electrically Powered Equipment - Electrical equipment must be installed

and maintained in accordance with the National Electrical Code, ANSI/NFPA 70, and other applicable codes.

A power disconnect switch or circuit breaker must be located at the equipment. Check the nameplate for voltage,

frequency, and phase requirements. If only 3-phase power is available, connect any single-phase rated equipment to

only two wires of the 3-phase line. DO NOT CONNECT the equipment grounding conductor (lead) to the third live

wire of the 3-phase line, as this makes the equipment frame electrically HOT, which can cause a fatal shock.

---- --- ---

Be sure to connect the grounding lead, if supplied in a power line cable, to the grounded switch box or building

ground. If not provided, use a separate grounding lead. Be certain that the current (amperage) capacity of the

grounding lead will be adequate for the worst fault current situation. Refer to the National Electrical Code ANSI/

NFPA 70 for details. Do not remove plug ground prongs. Use correct mating receptacles.

2. Output Cables and Terminals - Inspect cables often for damage to the insulation and the connectors. Replace

or repair cracked or worn cables immediately. Do not overload cables. Do not touch output terminal while equipment is energized.

I

Instruction 910082

Nov 16182 Revised

Page 1

C.

FIRE AND EXPLOSION PREVENTION

Fire and explosion are caused by electrical short circuits, combustible material near engine exhaust piping, misuse

of batteries and fuel, or unsafe operating or fueling conditions.

1. Electrical Short Circuits and Overloads - Overloaded or shorted equipment can become hot enough to cause

fires either by self destruction or causing nearby combustibles to ignite. Provide primary input protection to remove short circuited or heavily overloaded equipment from the line.

2. Battery - Batteries may explode and/or give off flammable hydrogen gas. The acid and arcing from a ruptured

battery can cause fires and additional failures. When servicing, do not smoke, causing sparking, or use open flame

near the battery.

3. Encrine Fuel

- Use only approved fuel container or fueling system. Fires and explosions can occur if the fuel

tank is not grounded prior to and during fuel transfer. Shut unit DOWN before removing fuel tank cap. Do not

completely fill tank. Heat from the equipment may cause fuel expansion overflow. Remove all spilled fuel immediately including any that penetrates the unit. After cleanup, open equipment doors and blow fumes away with

compressed air.

D.

E.

F.

TOXIC FUME PREVENTION

Carbon Monoxide - Engine exhaust fumes can kill and cause health problems. Pipe or vent the exhaust fumes to a

suitable exhaust duct or outdoors. Never locate engine exhausts near intake ducts or air conditioners.

BODILY INJURY PREVENTION

Serious injury can result from contact with fans, belts, and pulleys inside the equipment. Shut DOWN equipment

for inspection and routine maintenance. When equipment is in operation use extreme care in doing necessary

troubleshooting and adjustment.

MEDICAL AND FIRST AID TRFATMFNT

First aid facilities and a qualified first aid person should be available for each shift for immediate treatment of all

injury victims. Electric shock victims should be checked by a physician and taken to a hospital immediately if any

abnormal signs are observed.

Call physician immediately. Seek additional assistance and use First Aid techniques recommended

by American Red Cross until medical help arrives.

IF BREATHING IS DIFFICULT, give oxygen, if available, and have victim lie down. FOR ELECTRICAL SHOCK, turn off power. Remove victim; if not breathing, begin artificial respiration,

preferably mouth-to-mouth. If no detectable pulse, begin external heart massage. Call Emergency

Rescue Squad immediately.

G.

EQUIPMENT PRECAUTIONARY LABELS

Inspect all precautionary labels on the equipment monthly. Order and replace all labels that cannot be easily read.

I

1

1

3. Service and Maintenance - This equipment must be maintained in good electrical and mechanical condition

to avoid hazards stemming from disrepair. Report any equipment defect or safety hazard to your supervisor and

discontinue use of the equipment until its safety has been assured. Repairs should be made by qualified personnel

only. Shut OFF all power at the disconnecting switch or line breaker before inspecting or servicing the equipment.

Lock switch OPEN (or remove line fuses) so that power cannot be turned ON accidentally. Disconnect power to

equipment i

I’ .

rt IS out of service. If troubleshooting must be done with the unit energized, have present another per-

son trained in turning off the equipment and providing or calling for first aid.

EMERGENCY FIRST AID

Page 2 Instruction 910082

Revised Nov 16182

FORART

B

$MOTOR GENERATOR DIVISION

a

“c

QD

!

HOBART BROTHERS COMPANY

%

z

Q. .q,+

TABLE OF CONTENTS

SUBJECT

CHAPTER/SECTION

PAGE

Introduction

Description/Operation

Description

General

Identification

Standard Unit and Variations

Canopy

Motor

Generator

Hobart Static Regulator

Data

Performance

Dimensions

Control Box Assembly

General

Controls and Instruments

Interior Pane I Assembly

General

Controls and Instruments

Motor Switch Box Assembly

Genera I

Components

1-O

l-1

I

Fe b 6/‘74

Contents

Page 1

FOBART

I

z

“0

B . B ,,d-

;MOTOR GENERATOR DIVISION

QD

:

2

HOBART BROTHERS COMPANY

TABLE OF CONTENTS (CONT’D)

SUBJECT

Power Module Assembly

General

Components

Preparation for Use

Genera I

Wiring

Motor Switch Overload Coils

Mounting Installation of Synchronous Motor-Driven

Generator Sets

Operation

Genera I

CHAPlER/SECTI,ON

l-l

l-2

l-3

PAGE

12

12

12

1

1

1

1

2

1

1

Remote Control

Variations

Servicing

Maintenance, Inspection/Check

Genera I

Inspection, Testing and Repair

Trouble Shooting

Trouble Shooting Procedures

General

Trouble Shooting Chart

Equipment for Trouble Shooting

2-o

2-l

3-O

3-l

2

2

1

1

1

1

1

1

1

1

1

Contents

Page 2

SUBJECT

CHA PTER/SECT ION

PAGE

FOBART

8

5

;MOTOR GENERATOR DIVISION

3

QD

3

HOBART BROTHERS COMPANY

%

4. 8ud

TABLE OF CONTENTS (CONT’D.)

Safety

’ Diagrams

Connections and Wiring

Chart

II lustrated Parts List

Introduction

Genera I

Purpose

Arrangement

Explanation of Parts List

Manufacturer ‘s Codes

Explanation of Manufacturer’s (Vendor) Code List

Parts List

Explanation of Parts List Arrangement

Symbols and Abbreviations

Feb 6/;74

May 12/75 Revised

3-l

4-o

4-l

4-2

4-3

1

2

2

3 thru 8

1

1

1

1

1

1

1

I

Contents

Page 3

Con tents

Page 4

GENERATOR DIVISION

HOBART BROTHERS COMPANY

Fe b 6/74

HOBART

z

J

QD

$MOTOR GENERATOR DIVISION

:

z

HOBART BROTHERS COMPANY

“0

b. B,,\6

INTRODUCTION

This manual contains operation and service information and instructions for Hobart 400-Hz

Ground Power Generating hit, driven by a synchronous motor. Specification numbers

and model numbers for each model covered by this manual are listed below. See Data,

sub-seption 8, page 2, this Section,

for complete details on various units.

Specs. 4576A (S-4576A) Mode I 32 1 O-50

Specs. 4713A (S-4713A) Model 3210

Specs. 4820A (S-4820A) Mode I 3209-50

Specs. 4910B (S-4910B) Model 3209

In addition to the standard unit,, the manual also covers variations to the basic specifications,

which are designated by a numerical suffix to the specification number, on the nameplate.

A sub-section entitled “Variations” in Chapter 1 explains these variations, and will include

any such new variations as they are added in the future.*

The manual is in no way presented as a text book on electricity or electronics. Its primary

purpose is to provide information and instructions to experienced operators, electricians

and mechanics who have never seen nor operated this particular generator set. It is the

intent of the manual to guide and assist operators and maintenance personnel in the proper

use and care of the equipment.

Use of the manual should not be put off until a trouble or need for help develops. Read the

instructions before starting the unit. Learn to use the manual and to locate information con-

tained in it. Each page is identified in the lower outside corner by the chapter and section

number in which it appears. Each new section starts with page 1. The figure numbers within the’manual are numerically consecutive throughout the manual, regardless of the section

in which they appear.

In addition to operation and maintenance instructions,

the manual containsan Illustrated

Parts List in Chapter 4.

A collection of manufacturer’s I iterature is supplied as part of the

information package;

* From time-to-time, specialized use of this equipment may require the addition of

other appropriate instructions and parts lists (VARIATIONS) to the basic manual.

Individual pages that specifically describe ‘the variation are inserted at the front of this

manual as ADDENDUM SHEETS.

I

Introduction

Page 1

FOBART

e

a

QD

gMOTOR GENERATOR DIVISION

i

HOBART BROTHERS COMPANY

“0

b. ,,,I++

CHAPTER 1. DESCRIPTION/OPERATION

SECTION 1. DESCRIPTION

1.

The 400-Hz AC generator set is a self-contained motor generator set, complete with

all controls, instruments and protective devices necessary for manual or fully automatic

0 ration.

I=

It is designed to utilize standard line power (either 50 or 60 hertz) to

generate power for providing ground service to aircraft, requiring 400-Hz power.

The’ motor and generator rotors are mounted on a common shaft supported at the ends

by ball bearings.

A centrifugal fan is mounted on the shaft between the motor and

generator rotors. In operation,

the fan draws air in axial ly from the outer ends of the

housing, over the rotor and stator windings, and discharges it radially through a duct

at the center of the housing. The housing is of two-piece construction, bolted together

circumferentia-lly at the middle to facilitate removal when necessary for service or repair of enclosed parts.

The entire unit is mounted on a welded structural stee I frame.

2.

Identification

A nameplate bearing SPECS, MODEL and SERIAL numbers of the unit is located

on or near the generator control pane I.

Parts orders or inquiries regarding this

equipment must refer to these numbers. Direct all parts orders and correspondence

to:

MOTOR GENERATOR DIVISION

HOBART BROTHERS COMPANY

TROY , OH IO 45373

U.S.A.

3.

Standard lktit and Variations

As stated above, the standard 400-Hz AC generator is a self-contained, stationary

unit identified by one of the specification (S) numbers listed in lntroductioni

Page 1. Variations to the standard models are identified by VAR. numbers. A

variation provides for motor switch 220-V input power on some models which are

380-volt standard, and a variation provides for mounting the unit on a trailer for

portable use. See the sub-section on VARIATION S, Section 1-3, page 2.

If other variations become available, or if changes are made, new information will

be added at the end of the sections in which the information would normally be located.

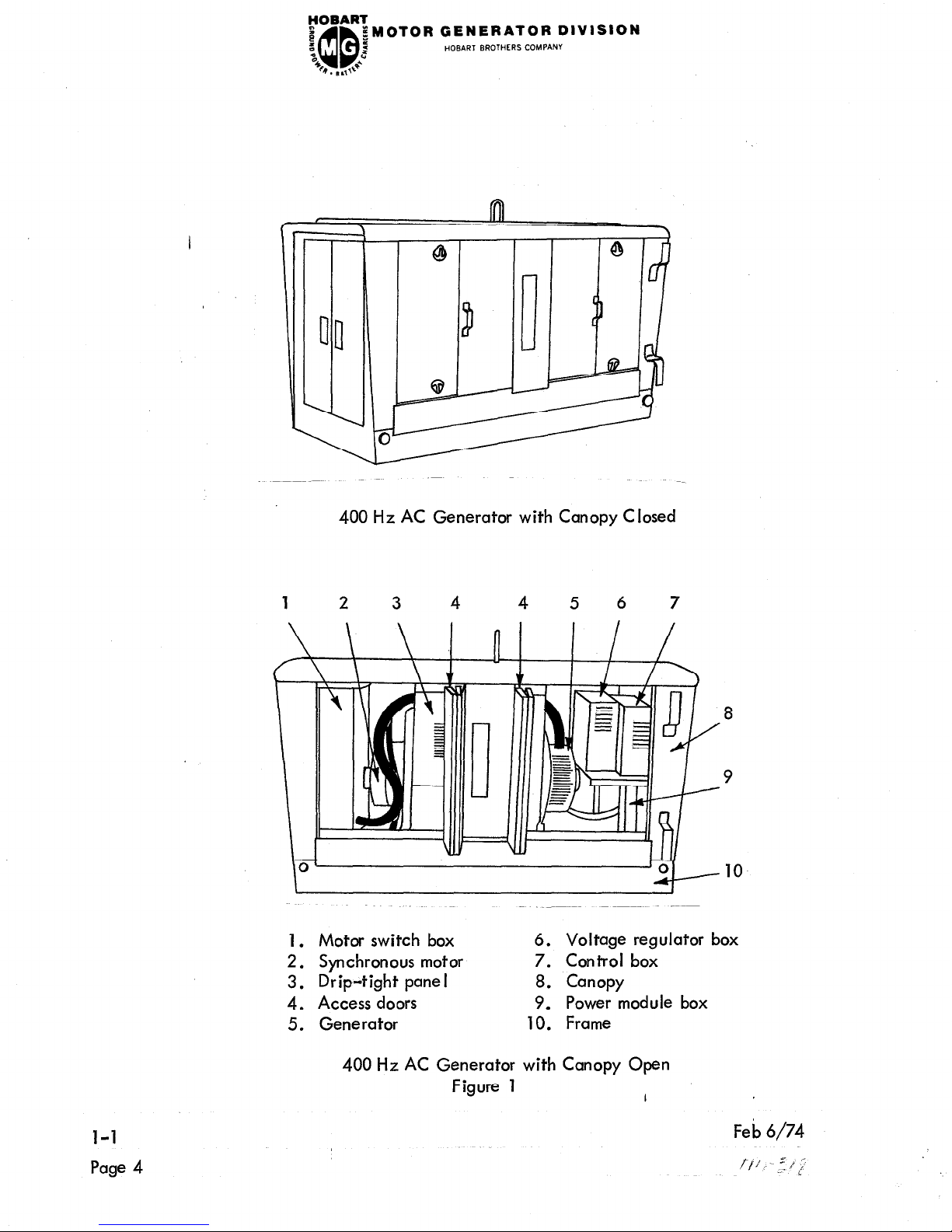

4. Canopy

A sheet metal enclosure, identified as a canopy, provides protection for the electric

motor, generator and electrical controls.

It is equipped with two large (four panels)

hinged doors on each side to provide easy access for service and maintenance. Doors

I

l-l

Page 1

FOBART

I

z

“0

QD

B . II ,+”

gMOTOR GENERATOR DIVISION

2

HOBART BROTHERS COMPANY

at each end of the canopy provide access to the motor switch box on the one end, and the

control box and power module box on the other end.

See Figure 1 for location of these

items .

5. Motor

The drivel motor is 50 or 60 Hz synchronous motor. Field excitation is provided by a rotary

brush less exciter, and is set to provide approximate unity power factor on the input.

6. Generator

The generator is a 3-phase, 4000hertz, synchronous AC generator, or alternator, of the

rotating field type, having output terminals for connection to a 4-wire, grounded neutral,

external circuit. Fie Id excitation is provided by an automatically regulated brush less

rotary exe iter .

7. Hobart Static Regulator

The voltage regulator is designed to maintain the set voltage of the generator within f 1%.

See the regulator manual furnished with this equipment for detailed instructions on installation,

operation and maintenance.

8. Data

A. Performance

Mod. 32 1 O-50

(S-4576A)

Mod. 3210

(S-4713A)

Mod. 3209-50

(S-4820A)

Mod. 3209

(S-4910B)

Motor

Volts

Amperes

Hertz

Phase

Power Factor

RPM

HP

Generator

(2

380

94

50

3

1 .O

1500

75

230/460

154/77

60

3

1.0

1200

75

380

63

50

3

1.0

1500

50

230/460

103/52

60

3

1.0

1200

50

Volts

115/200

Amperes 173

KVA

Duty Cycle 100%

Power Factor 0.8

60

115/200

174

60

48

100%

0.8

400

3

1200

115/200

108

37.5

30

100%

0.8

400

3 ’

1500

115/200

108

37.5

30

100%

0.8

400

3 ’

1200

Fe b 6/74

GENERATOR DIVISION

HOBART BROTHERS COMPANY

B.

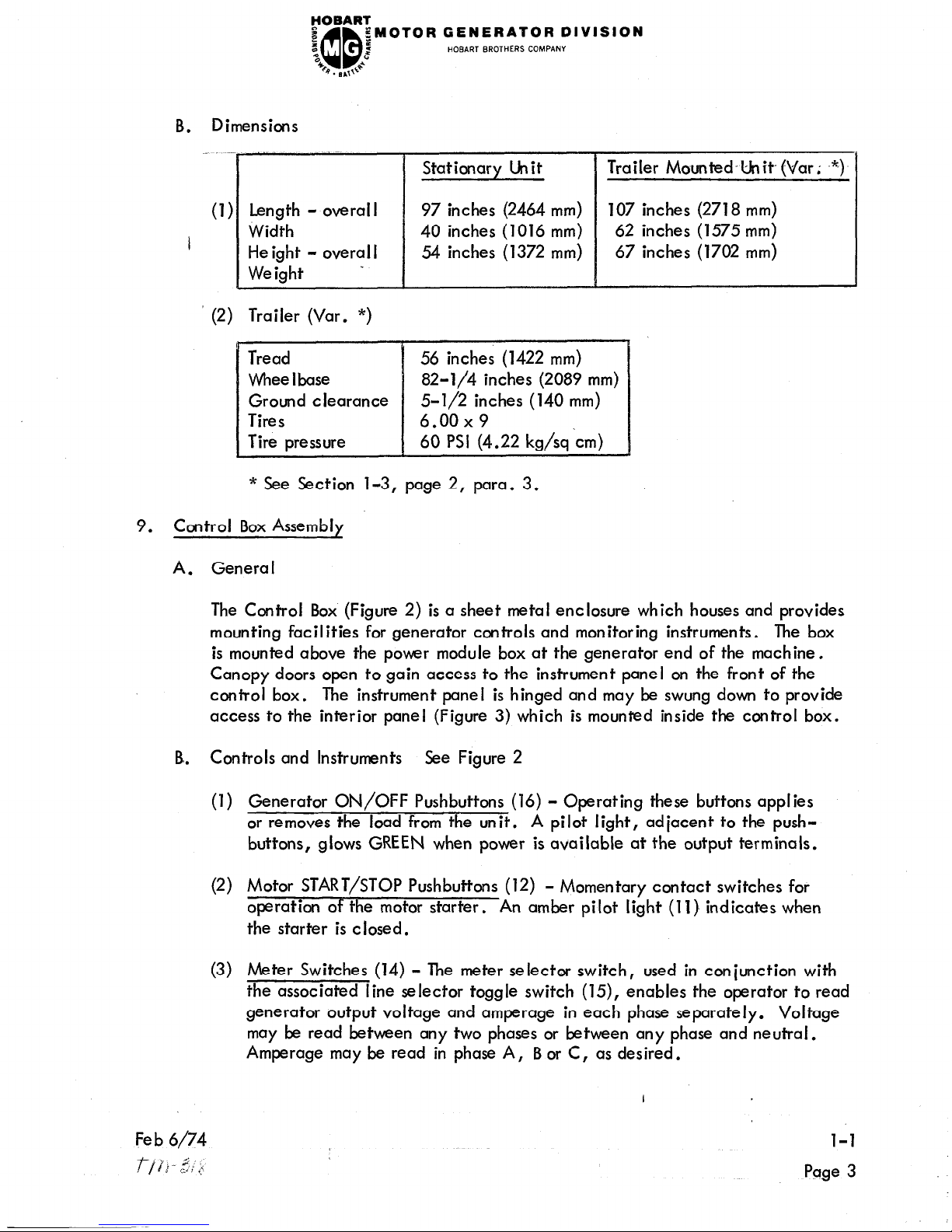

Dimensions

Stationary Unit

Trailer Mounted’Unit- (Var; -*)

(1) Length - overall

97 inches (2464 mm)

107 inches (2718 mm)

I

Width 40 inches (1016 mm)

62 inches (1575 mm)

He ight - overal I

54 inches (1372 mm)

67 inches (1702 mm)

Weight

(2) Trailer (Var. *)

Tread 56 inches (1422 mm)

Whee I base 82-l/4 inches (2089 mm)

Ground clearance

5-l/2 inches (140 mm)

Tires 6.00x9

Tire pressure 60 PSI (4.22 kg/sq‘cm)

* See Section 1-3, page 2, para. 3.

9. Control Box Assembly

A. General

The Control Box (Figure 2) is a sheet metal enclosure which houses and provides

mounting facilities for generator controls and monitoring instruments. The box

is mounted above the power module box at the generator end of the machine.

Canopy doors open to gain access to the instrument panel on the front of the

control box.

The instrument panel is hinged and may be swung down to provide

access to the interior panel (Figure 3) which is mounted inside the control box.

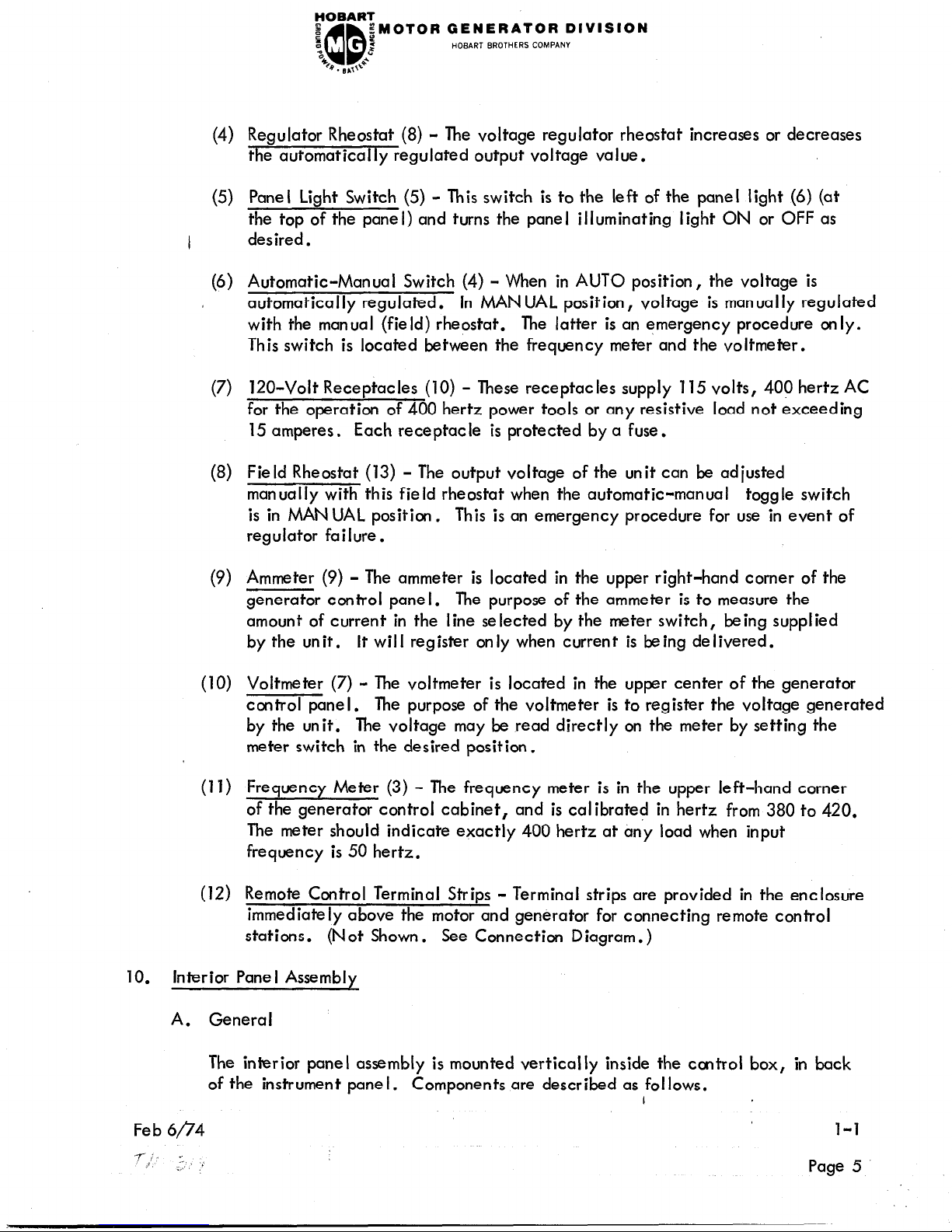

B. Controls and Instruments See Figure 2

(1) Generator ON/OFF Pushbuttons (16) - Operating these buttons applies

or removes the load from the unit. A pilot light, adjacent to the push-

buttons, glows GREEN when power is available at the output terminals.

(2) Motor START/STOP Pushbuttons (12) - Momentary contact switches for

operation of the motor starter.

An amber pilot light (11) indicates when

the starter is closed.

(3) Meter Switches (14) - The meter selector switch, used in conjunction with

the associated line selector toggle switch (15), enables the operator to read

generator output voltage and amperage in each phase separately. Voltage

may be read between any two phases or between any phase and neutral.

Amperage may be read in phase A, B or C, as desired.

l-l

Page 3

rOBART_

e

QD

gMOTOR GENERATOR DIVISION

B

:

z

HOBART BROTHERS COMPANY

“c

b. sa+e

400 Hz AC Generator with Canopy Closed

3

4 5 6 7

8

10

1. Motor switch box

6. Voltage regulator box

2. Synchronous motor

7. Control box

3. Drip-tight panel

8. Canopy

4. Access doors

9. Power module box

5. Generator

10. Frame

400 Hz AC Generator with Canopy Open

Figure 1

I

l-l

Feb

6/74

Page 4

-tr-c p;

FOBART

:

;MOTOR GENERATOR DIVISION

‘:

“0

QD

=i

HOBART BROTHERS COMPANY

%

z

.9. ,q,1”

(4)

(5)

I

(6)

(7)

(8)

(9)

(10)

(11)

(12)

Regulator Rheostat (8) - The voltage regulator rheostat increases or decreases

the automatically regulated output voltage value.

Panel Light Switch (5) - Th is switch is to the left of the panel light (6) (at

the top of the panel) and turns the pane I illuminating light ON or OFF as

desired.

Automatic-Manual Switch (4) - When in AUTO position, the voltage is

automatically regulated.

In MANUAL position, voltage is manually regulated

with the manual (field) rheostat. The latter is an emergency procedure only.

This switch is located between the frequency meter and the voltmeter.

120-Volt Receptacles (10) - These receptacles supply 115 volts, 400 hertz AC

for the operation of 400 hertz power tools or any resistive load not exceeding

15 amperes. Each receptacle is protected by a fuse.

Field Rheostat (13) - Th e output voltage of the unit can be adjusted

manually with this field rheostat when the automatic-manual toggle switch

is in MANUAL position,

This is an emergency procedure for use in event of

regulator failure.

Ammeter (9) - Th e ammeter is located in the upper right-hand corner of the

generator control pane I.

The purpose of the ammeter is to measure the

amount of current in the line selected by the meter switch, being supplied

by the unit. It will register only when current is being delivered.

Voltmeter (7) - The voltmeter is located in the upper center of the generator

control pane I. The purpose of the voltmeter is to register the voltage generated

by the unit. The voltage may be read directly on the meter by setting the

meter switch in the desired position.

Frequency Meter (3) - The frequency meter is in the upper left-hand corner

of the generator control cabinet, and is calibrated in hertz from 380 to 420.

The meter should indicate exactly 400 hertz at any load when input

frequency is 50 hertz.

Remote Control Terminal Strips -

Terminal strips are provided in the enclosure

immediately above the motor and generator for connecting remote control

stations. (Not Shown.

See Connection Diagram.)

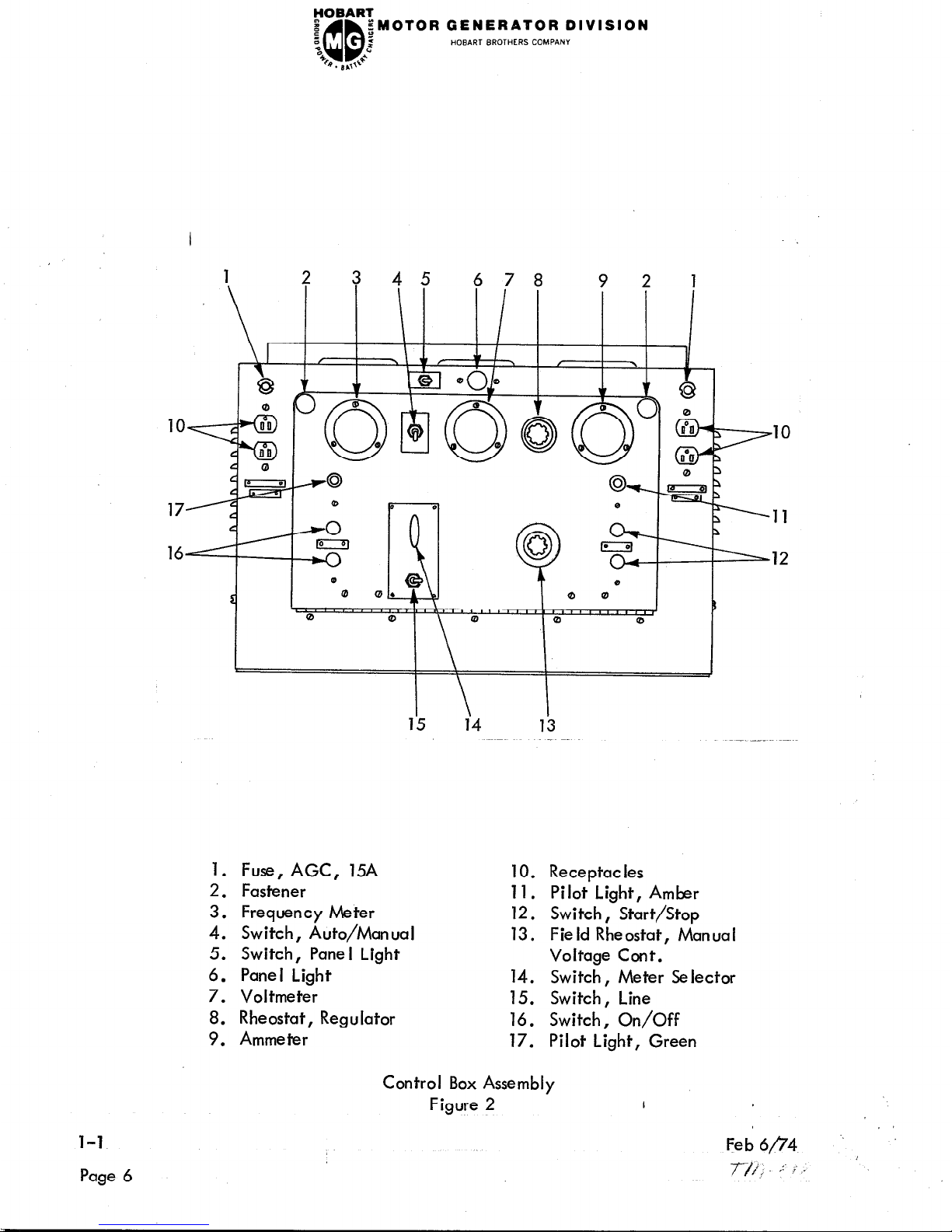

10.

Interior Pane I Assembly

A. General

The interior panel assembly is mounted vertically inside the control box, in back

of the instrument pane I.

Components are described as follows.

I

Feb 6/74

l-l

Page 5

FOBART

e

s

QD

iMOTOR GENERATOR DIVISION

d

HOBART BROTHERS COMPANY

%

4F,. s,,l’*’

1. 3 45 6 7 8

9 2 1

k

53

0

10

II0

16

t-:

1. Fuse, AGC, 15A

10. Receptacles

2. Fastener

11. Pilot Light, Amber

3. Frequency Meter

12. Switch, Start/Stop

4. Switch, Auto/Manual

13. Field Rheostat, Manual

5. Switch, Pane I Light

Voltage Cont.

6. Panel Light

14. Switch, Meter Selector

7. Voltmeter

15. Switch, Line

8. Rheostat, Regulator

16. Switch, On/Off

9. Ammeter

17. Pilot Light, Green

,lO

,ll

.12

l-l

Page 6

Control Box Assembly

Figure 2

I

rOBART_

I

z

QD

:MOTOR GENERATOR DIVISION

:

“0

E

HOBART BROTHERS COMPANY

48

6

9. 8.0

B. Controls and Instruments

(1)

, (2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

Rectifier, Load Contactor (10) - Furnishes direct current to the operating

coil of the load contactor.

Relay, Time De lay (11) (hdervoltage Timer) - This relay is set for a 5-second

time delay in the undervoltage circuit.

This relay provides time de lay when

abnormal loads are encountered for a short period of time. If an undervoltage

persists for a period longer than 5 seconds,

the main contactor circuit will be

opened.

Manual Range Limiting Resistor (6) - This 250-ohm resistor is set to limit

voltage when the AUTO-MAN UAL Switch is in MAN UAL position, and the

manual rheostat is turned all the way clockwise.

Undervoltage Relay (2) - This relay is set to close its set of contacts when

the line-to-neutral voltage falls to 93-103 volts; this is equivalent to a

line-to-line output voltage of 161-178.5 volts. The closing of these contacts

energize a 5-seccnd time delay relay switch Gee (2) above], which in turn

opens the main contactor, protecting the load from effects of low voltage.

hderfrequency Relay (4) - Th

ese contacts open if the frequency drops to

approximately 360 hertz and ret lose when the frequency recovers to 375 hertz.

The purpose of this relay is to open the main contactor and protect the load

from the effects of operating at too low a frequency.

Overvoltage Relay (1) - Th

is relay has a normally closed set of contacts

which open if the voltage exceeds 130 to 134 volts, line-to-neutral, or

225 to 232 volts, I ine-to-l ine .

This opens the main contactor to remove the

load from the generator.

Plug Interlock Relay (13) - The 28 volts DC from the aircraft, through

terminals E and F and Neutral causes the interlock relay to close, as well

as the contactor in the aircraft. With the interlock relay closed, power is

maintained to the rectifier, holding the contactor closed when the ON button

is released.

Plug Interlock Switch (or Test Bank Switch) (12) - This toggle switch should be

OFF when feeding an aircraft with control leads on E and F, or ON for feeding

a load bank or other non-aircraft load without the plug interlock system.

Current Limiting Resistor (3) - This 1000ohm, 250watt resistor is in series

with the plug interlock relay to limit the amount of load current drawn through

the plug interlock relay contacts, in case phase “C” of the load contactor

does not close when the generator “ON ” pushbutton is actuated.

I

l-l

Page 7

YOBART

e

QQ

EMOTOR GENERATOR DIVISION

s

:

z

HOBART BROTHERS COMPANY

3

b . n ,,+**

2

3

4

5

6 7

I

I

I

t

0

I

t

I

A

13

9 12

I r

II IO 9

8

J

1. Overvoltage Relay

2. Undervoltage Relay

3. Resistor, 100 Ohm 25 W

4. Underfrequency Relay

5. Overload Relay

6. Resistor, 250 Ohm 100 W (Gen . Ext. Field)

7. Resistor, 50 Ohm 100 W (Overload Adjust)

8. Rectifier, Generator Exciter Field

9. Terminal Strips

10. Rectifier, Load Contactor

11. Undervoltage Timer

12. Test Bank Switch

13. Interlock Relay

l-l

Page 8

Interior Panel Assembly

Figure 3

FOBART

e

QQ

;MOTOR GENERATOR DIVISION

I

z

e

HOBART BROTHERS COMPAN”

“0

s. B,,+a

(10)

(11)

I

Overload Relay (OL) (5) - This thermally operated relay serves to protect the

generator set from the effects of any induced overload (grounding or shorting

of exciter or generator, or exce,ssive load).

Overload Adjustment Resistor (7) - This resistor, connected in parallel with

the overload relay, serves to regulate the tripping time of the overload relay.

It is set to trip the overload relay at 25% overload in 4-5 minutes.

If nuisance

overload tripping becomes a problem, trip point may be increased by moving

the resistor adjusting slide away from the end to which the jumper wire is

attached.

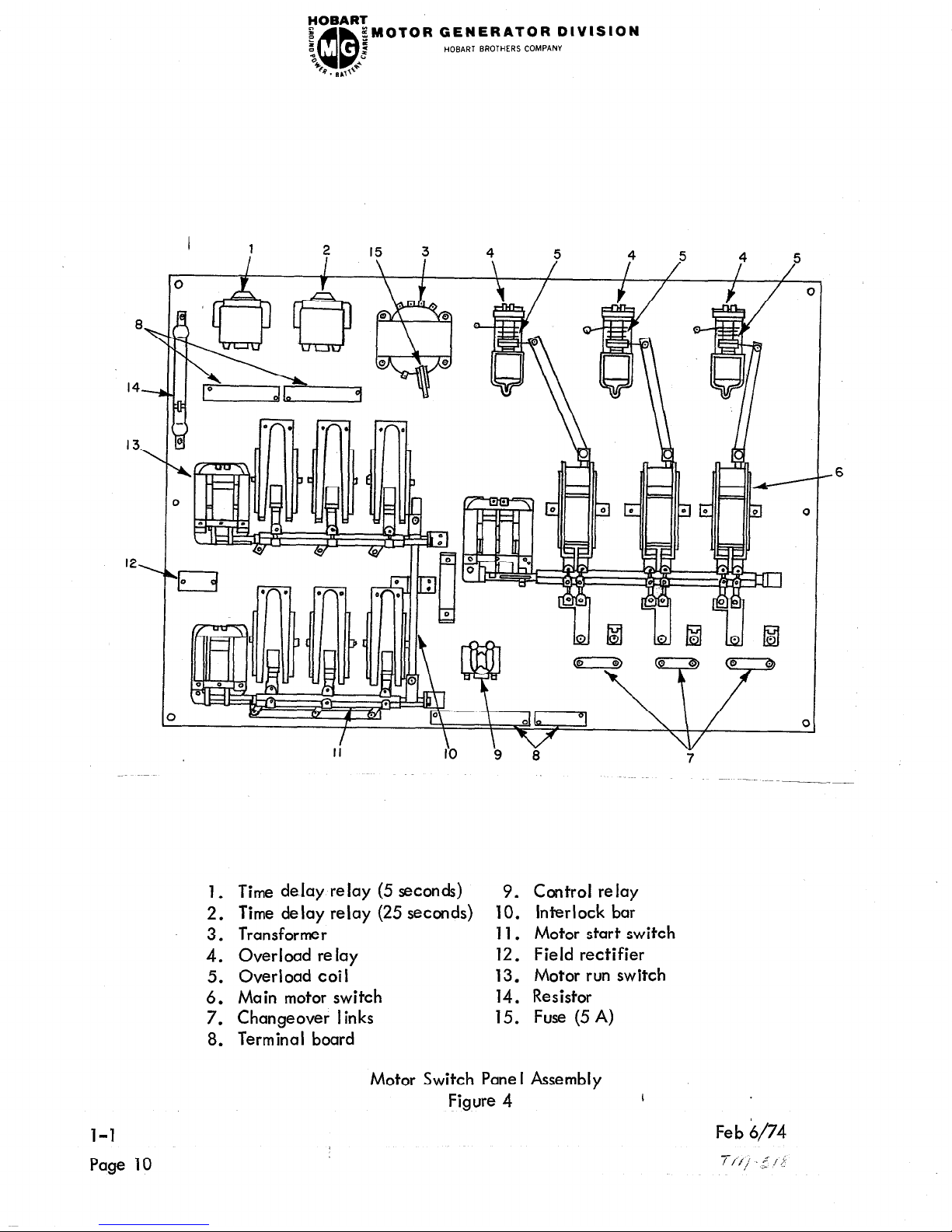

11.

Motor Switch Box Assembly

A. General

The motor switch furnishes primary control for the drive motor.

It is located in the

motor end of the canopy, with doors opening to gain access to the motor switch box.

N OTE :

The motor STOP/START

pushbutton switch is located on the control

panel at the opposite end of the unit. The non-manual components

for stop/start, time delay, voltage changeover, etc., are located

on a panel in the motor switch box assembly.

B. Components

(1)

(2)

(3)

Transformer

- This transformer (3) reduces input line voltage from 380-V AC to

115-V AC for operation of the time delay relays, motor switch coils, control

relay, etc.

A 5-ampere fuse (15) protects the 115-V AC control circuit. The transformer

is functional at all times when input power is connected to the input terminals

and the overload relay (4) contacts are closed.

?TP%

- The control relay (9) applies power to the “main” motor switch

COI w en t e START pushbutton is pressed. The relay also by-passes the

START and STOP pushbutton switches to prevent the relatively high switch-coil

currents from passing through them. All power for operation of switches, timers,

etc., must pass through this relay.

Main Motor Switch - The “main” switch (6) consists of three pairs of stationary

contacts and three pairs of movable contacts. Movable contacts are clamp

mounted on a bearing supported shaft.

A core is attached to the shaft, so that

when the magnetic switch coil is energized,

the center of the coil.

it attracts the core and pulls it into

to close the contacts.

The core is thus moved to rotate the shaft sufficiently

The contacts are held in the closed position as long as

the switch coil is energized.

When the coil circui,t is broken, the contacts

l-l

Page 9

FOBART

D

;

n

“0

QQ

;MOTOR GENERATOR DIVISION

:

2

HOBART BROTHERS COMPANY

B , B ,,J

ll

1. Time delay relay (5 seconds) 9. Control relay

2. Time delay relay (25 seconds)

10. Interlock bar

3.

Transformer

11. Motor start switch

4.

Overload relay

12. Field rectifier

5.

Overload coil

13. Motor run switch

6.

Main motor switch

14. Resistor

7.

Changeover links

15. Fuse (5 A)

8. Terminal board

1-l

Page 10

Motor Switch Panel

Figure 4

Assembly

I

Feb $74

T/i,/ .,‘/;

-6

IVISION

FOBART

e

,QQ

EMOTOR GENERATOR D

z

2

HOBART BROTHERS COMPANY

3

2

4

0. B&l>

‘a

are opened immediately by gravity and spring loading. Stationary contacts

are equipped with blowout coils and arc shields to “blowout”, “dampen”,

and minimize arcing which results from opening the contacts. A small set

of contacts mounted on the “main ” contact shaft are closed when the “main ”

contacts are closed.

These contacts apply a holding current to the switch

I

coil circuitry and allow the START switch button to be released after the

main switch closes.

(4) Motor “Start” Switch

- The motor “start” switch (11) is very similar to the

“main” motor switch (6) described above.

Mechanical and electrical operating

characteristics are the same. The “start” switch is energized to close at the

same time the “main” switch is closed to provide a “wye” starting connection

to the motor‘stator windings.

(5)

Time Delay Relay (25 Second) - This is a double-pole, double-throw,

120-V AC relay (2). It has an adjustable time delay range of from 5 seccnds

to 50 seconds. For this application it is adjusted for a time delay of 25 seconds

between energization of the coil and actuation of the contacts. The coil is

energized as soon as the control relay (9) contacts close. After a delay of

25 seconds, the time delay relay functions to open the “start” switch (11)

and close the “run” switch (13). At the same time it supplies power to the

5-second time delay relay (1)

and also supplies 115-V AC power to the

voltage regulator for flashing the generator field. The 25-second delay

allows the motor to reach operating speed.

(6) Time De lay Re lay (5 Seconds) - This re lay (1)

is identical to the time delay

relay (2) described above , except it is adjusted for a 5-second time delay.

It is energized at the same time the “run” switch is closed. The function

of this relay is to connect 115-V AC to the field application relay and

disconnect flashing current from the generator field, 5 seconds after the

“run” switch closes.

(7) Motor Run Switch - The motor “run” switch is identical to the “start” switch.

After the motor reaches operating speed with the stator windings in “wye”

connection, the “start” switch opens and the “run” switch closes to connect

the motor stator windings in

“delta” connection for synchronous running.

The “main” switch remains closed during this operation.

(8) Start-Run Interlock Bar - The interlock bar is designed to mechanically pre-

vent the motor “start” switch and “run” switch from closing or being closed at

the same time.

(9) Field Rectifier - This rectifier converts 115-V alternating current to direct

current for excitation of the motor exciter fields. The rectifier becomes

functional five seconds after the motor run switch is closed.

I

Feb 6/74

l-l

71,; -5 : [;

Page 11

(10)

(11)

(12)

(13)

(14)

FOBARZ

z

QQ

$MOTOR GENERATOR DIVISION

s

2

z

HOBART BROTHERS COMPANY

“0

B . B ,‘,++

Overload Relay - These solenoid operated, dashpot type relays (4) protect the

motor against overload.

Under a continuous overload condition, the coils

(5), which carry the motor input current, provide a magnetic force sufficiently

strong to pull the dashpot plunger upward against the retaining force of the

dashpot piston to OPEN the relay contacts which supply input power to the

trsformer (3). Thus, all operating power is removed from the controls and

all normally open switches return to OPEN position.

The resistive force of the dashpot on the movement of the plunger prevents

nuisance tripping of the relay contacts when the motor is overloaded for short

periods of time,

such as in starting, etc.

Overload Coil - These coils (5), which are connected in series with input power

cables, provide magnetic force for operating the overload plungers.

Changeover Links - The connector links (7) provide a means of quickly changing

the motor stator connections for other applications.

Terminal Board - Four terminal boards (8) provide connection facilities for

electrical components interconnecting wiring.

Resistor - This 250-ohm, loo-watt resistor (14) functions to discharge voltage

induced in the revolving fields when the motor starts.

12. Power Module Assembly

A.

B.

l-l

Page 12

Genera I

The power module assembly provides a terminal point for the output power terminals,

and input power junction box.

It supports the following components as described

below.

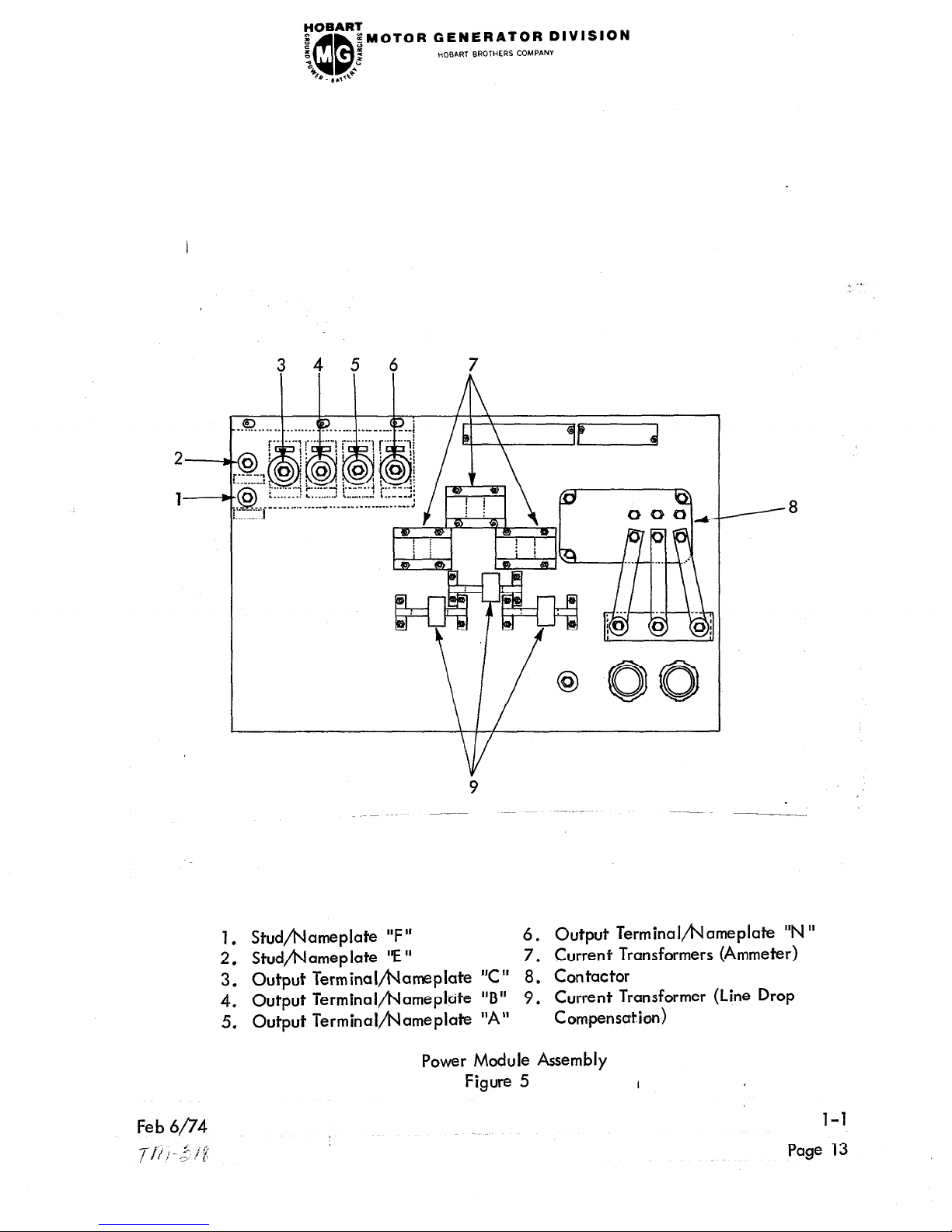

Components

(1)

(2)

(3)

Current Transformers (Ammeter) (7) - These transformers are used together with

the ammeter to indicate the amount of load current at any time.

Current Transformers (Line Drop Compensation) (9) - These transformers are

used with the regulator for line drop compensation.

Load Contactor (8) - The contactor connects and disconnects the generator

and the load. The contactor is furnished DC voltage by the rectifier on the

inter ior pane I .

The generator ON/OFF switch (item 16, Figure 2) on the

control pane I, controls the opening and closing of the contactor.

Fed 6/74

YOBARI

e

a

QQ

;MOTOR GENERATOR DIVISION

,,oB,WT BROTHERS COMPANY

z

I

CI

b . @ ,,k-

3 4 5

6

7

1. Studfiameplate “F”

6. Output Terminal~ameplate “N ”

2. Stud/hJameplate “E” 7. Current Transformers (Ammeter)

3. Output Terminalbameplate “C” 8. Contactor

4. Output TerminaI/t\lameplcite

“B” 9. Current Transformer (Line Drop

5. Output Terminalfiameplate “A” C om-pensation)

Power Module Assembly

Figure 5

I

1-l

Page 13

FOBART

@

QQ

2MOTOR GENERATOR DIVISION

z

2

2

HOBART BROTHERS COMPANY

“0

b . I ,,+*

(4) Output Power Terminals: Phase “A” (6)

Phase “B” (5)

Phase “C” (4)

Neutral “N” (3)

Stud “F” (2)

Stud “E ” (1)

l-l

Feb 6p4

Page 14

. -:

,/ -,.;,* :

FOBART

e

z

“0

% . B ,,+”

Genera I

1.

When installing or storing this ground power unit, avoid locations exposed to high

huTidity or dust. Moisture condenses on generator parts and electrical controls, caus-

ing corrosion which can seriously affect operation and efficiency. Dust and dirt cause

needless extra wear on al I moving parts.

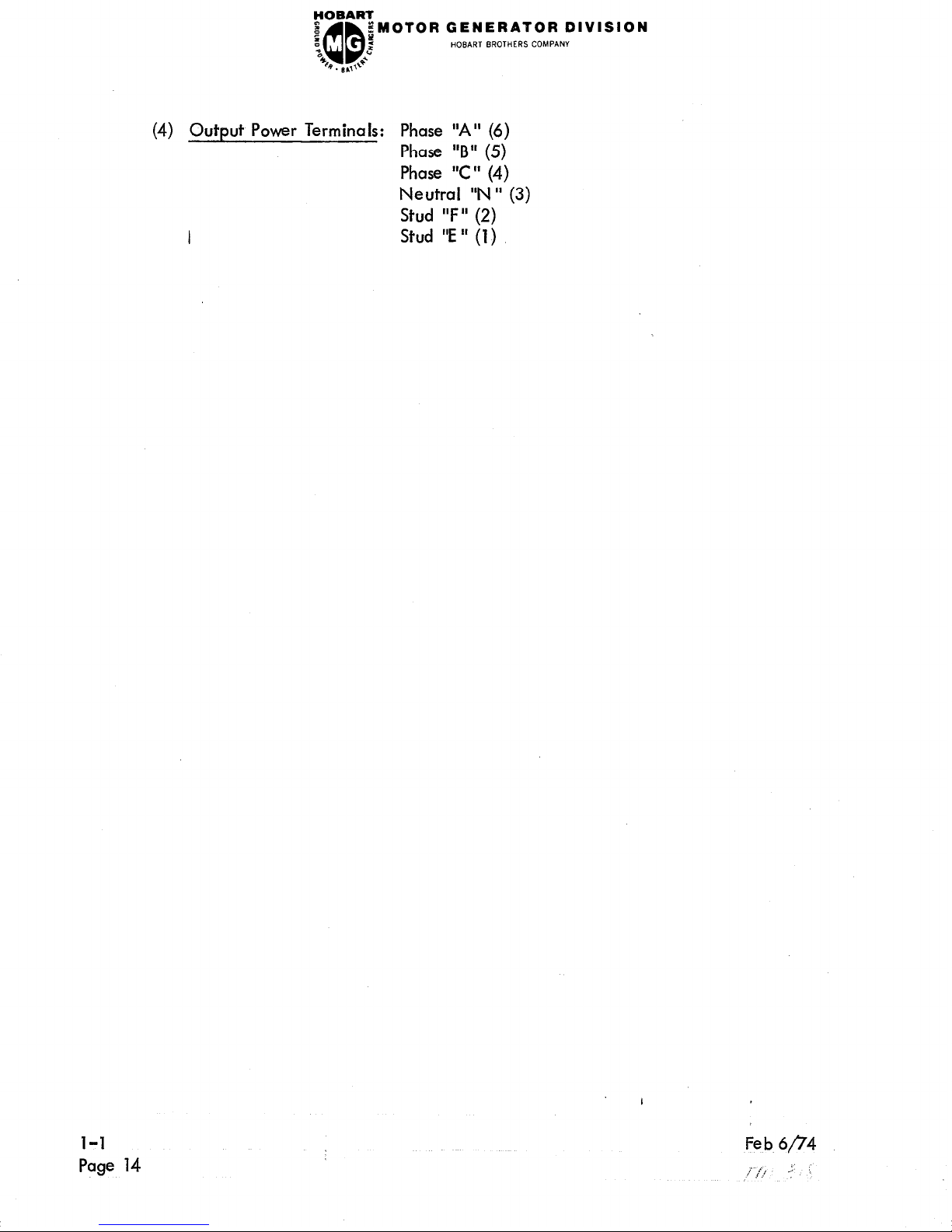

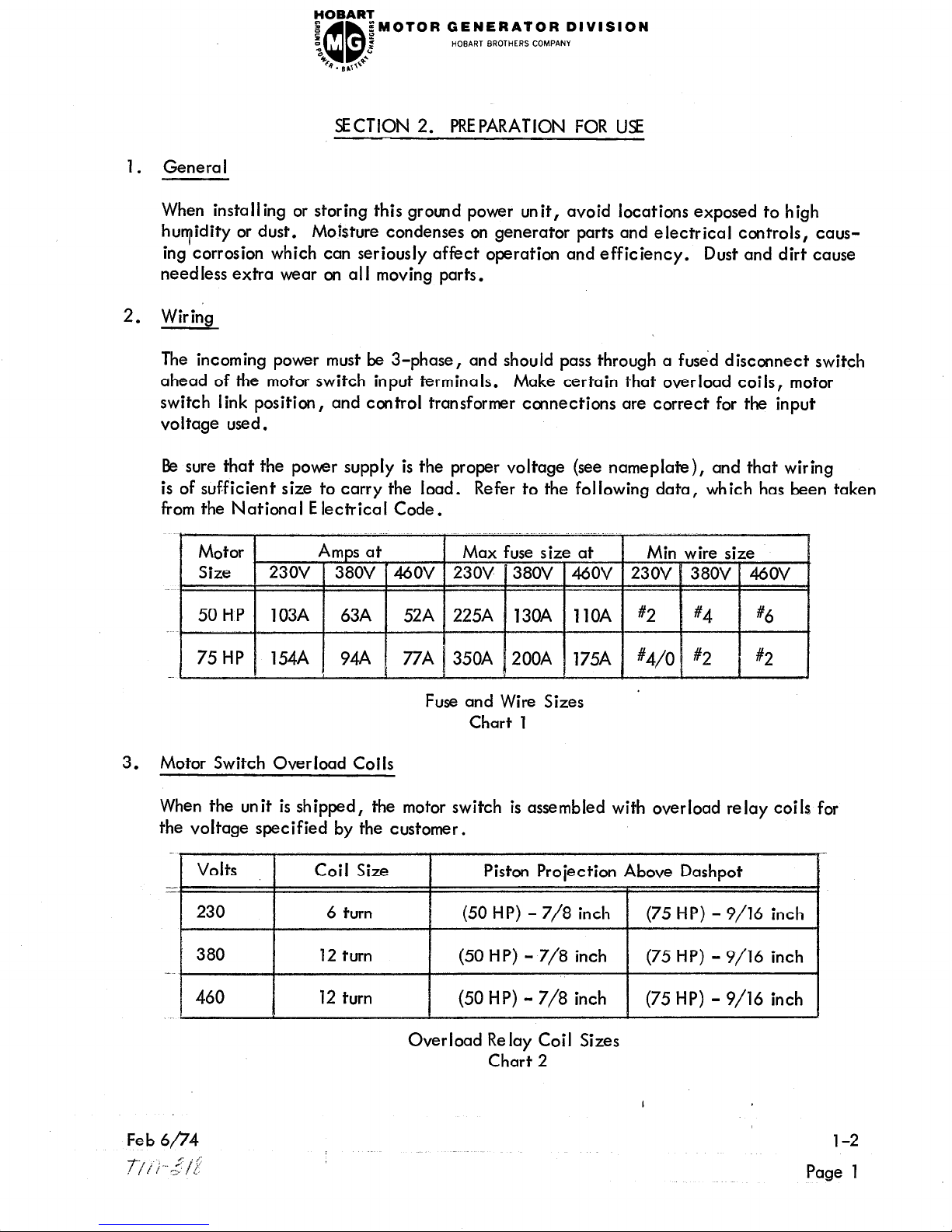

2. Wiring

The incoming power must be 3=phase, and should pass through a fused disconnect switch

ahead of the motor switch input terminals. Make certain that overload coils, motor

switch link position, and control transformer connections are correct for the input

voltage used.

;MOTOR GENERATOR DIVISION

s

z

QQ

SECTION 2. PREPARATION FOR USE

HOBART BROTHERS COMPANY

Be sure that the power supply is the proper voltage (see nameplate), and that wiring

is of sufficient size to carry the load. Refer to the following data, which has been taken

from the National E lectrical Code.

Fuse and Wire Sizes

Chart 1

3. Motor Switch Overload Coils

When the unit is shipped, the motor switch is assembled with overload relay coils for

the voltage specified by the customer.

Overload Relay Coil Sizes

Chart 2

l-2

Page 1

FOBART

I

f

“0

B . B ,+”

CAUTION: IF A 3-CONDUCTOR, RUBBER-COVERED, INPUT POWER CABLE

IS USED, IT IS NECESSARY TO GROUND THE EQUIPMENT WITH

A WIRE OF MINIMAL COMPARATIVE SIZE TO THE WIRE- IN THE

INPUT POWER CABLE. THIS WIRE MAY BE BARE OR INSULATED

AND OF ANY COLOR, BUT IT MUST MAKE GOOD ELECTRICAL

CONTACT WITH A METALLIC PART OF THE GENERATOR FRAME,

I

OF THE SHEET METAL CABINET, OR OF THE CONTROL BOX AND

A WATER PIPE OR THE FUSED DISCONNECT SWITCH BOX.

WHEN 4-CONDUCTOR, RUBBER-COVERED CABLE IS USED, THE

GROUNDING WIRE MUST BE GREEN IN COLOR. WHEN FLEXIBLE

ARMORED CABLE OR CONDUIT IS REQUIRED BY LOCAL CODES,

INSTALL IT IN SUCH A MANNER THAT ADEQUATE GROUNDING

OF THE EQUIPMENT IS INSmED.

WITH THE MACHINE FRAME GROMDED, THE OPERATOR IS

ALWAYS ASSURED MAXIMUM PROTECTION EVEN IN THE UN-

LIKELY EVENT OF INSULATION FAILURE OR ACCIDENTAL

GROUNDING OF THE POWER SUPPLY.

;MOTOR GENERATOR DIVISION

z

z

QQ

HOBART BROTHERS COMPANY

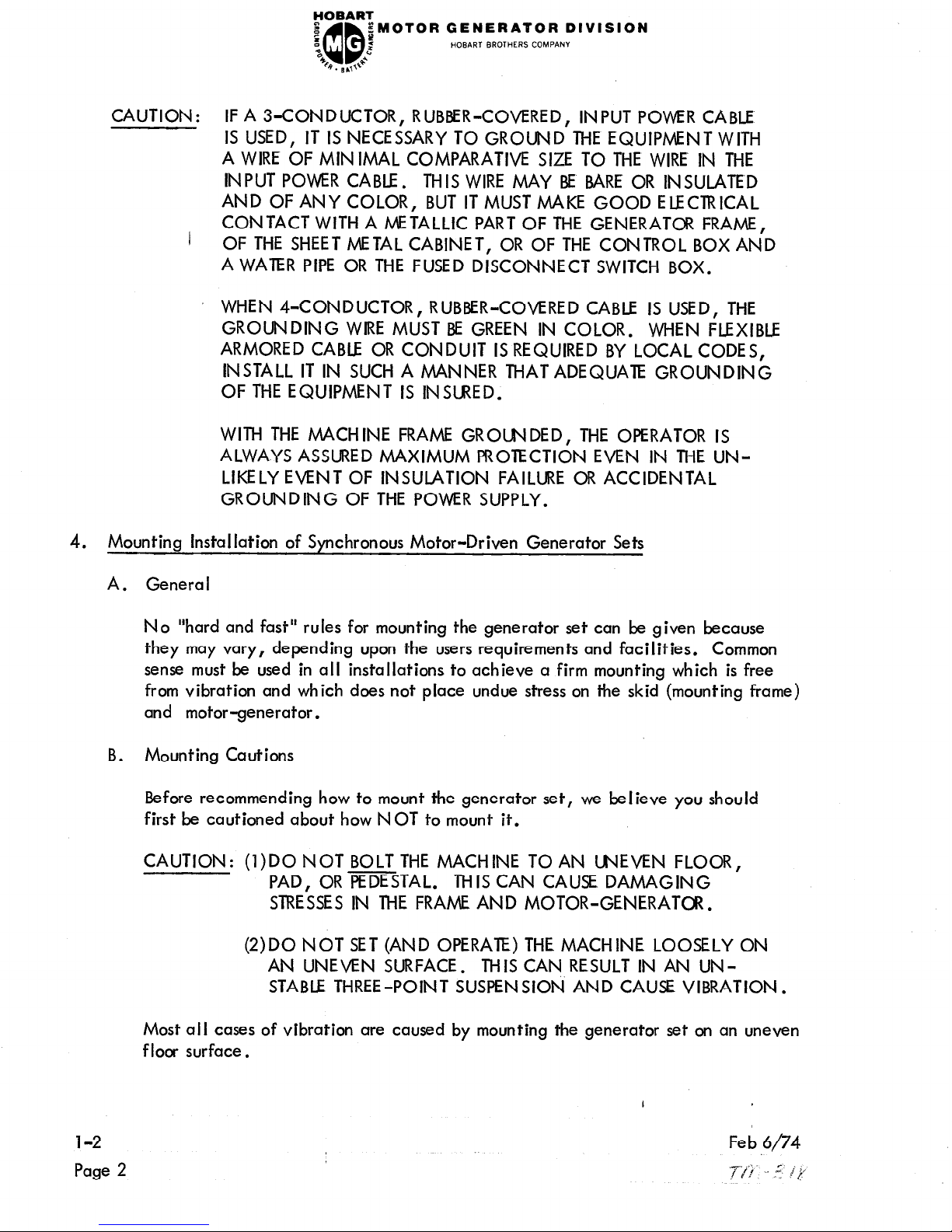

4. Mounting Installation of Synchronous Motor-Driven Generator Sets

A. General

No “hard and fast” rules for mounting the generator set can be given because

they may vary, depending upon the users requirements and facilities. Common

sense must be used in all installations to achieve a firm mounting which is free

from vibration and which does not place undue stress on the skid (mounting frame)

and motor-generator.

Mounting Cautions

B.

Before recommending how to mount the generator set, we believe you should

first be cautioned about how NOT to mount it.

CAUTION: (l)DO NOT BOLT THE MACHINE TO AN U\IEVEN FLOOR,

PAD, OR PEDESTAL. THIS CAN CAUSE DAMAGING

STRESSES IN THE FRAME AND MOTOR-GENERATOR.

(2)D0 NOT SET (AND OPERATE) THE MACHINE LOOSELY ON

AN UNEVEN SURFACE. THIS CAN RESULT IN AN UN-

STABLE THREE-POINT SUSPENSION AND CAUSE VIBRATION.

Most all cases of vibration are caused by mounting the generator set on an uneven

floor surface.

l-2

Page 2

I

Feb 6/74

,7;l’j .3 “2

$iOBARl

z

a

‘c

‘c,

C. Recommended Mounting Instructions

qMOTOR GENERATOR DIVISION

2

QQ

d

0. @*1x

HOBART BROTHERS COMPAN”

(1) Mounting surface -

is the mounting surface. Whether the machine is mounted on a cement

floor, or on a pedestal, the mounting surface should be even and smooth

so that the full length of the skid can contact the cement.

The single most important thing in generator mounting

I

(2) Pad mounting -

between the skid and mounting surface in all installations.

Resilient pads placed between the skid and the floor may help to compensate

for slight unevenness in the mounting surface, and also insulate the skid

from-floor to reduce vibration . .

with or without bolts from skid to floor.

(3) Leveling pads - An alternate method to the plain pad installation described

above is one involving the use of self-contained leveling mounts such

as “Unisorb Level-Rites” or equivalent. These mounts will compensate

for a greater degree of floor unevenness than plain insulating pads.

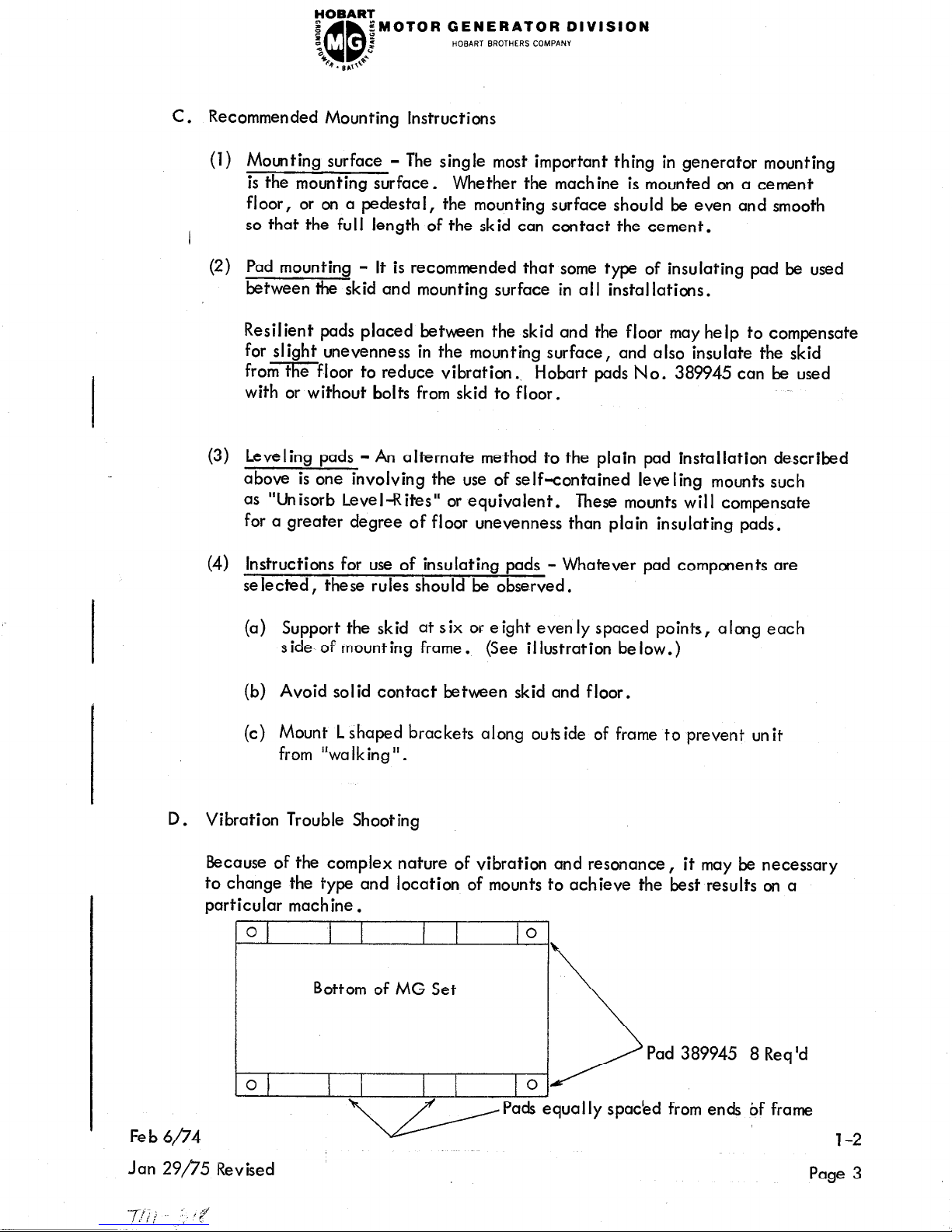

(4) Instructions for use of insulating pads - Whatever pad components are

selected, these rules should be observed.

It is recommended that some type of insulating pad be used

Hobart pads No. 389945 can be used

(a) Support the skid at six or eight evenly spaced points, along each

side of mounting frame.

(b) Avoid solid contact between skid and floor.

(c) Mount Lshaped b

from “walking”.

D. Vibration Trouble Shooting

Because of the complex nature of vibration and resonance, it may be necessary

to change the type and location of mounts to achieve the best results on a

particular machine.

rackets along outside of frame to prevent unit

(See illustration below.)

Pad 389945 8 Req ‘d

Fe b 6/74

Jan 29/?‘5 Revised

Pads equally spaced from ends of frame

l-2

Page 3

FOBART

z

QQ

;MOTOR GENERATOR DIVISION

z

5

HOBART BROTHERS COMPANY

“ss.

2

64

c

. BAT+

l-2

Page 4

Feb ~$74

FOBART

e

z

“0

44@. g,,++*

1. General

Determine that the machine is properly installed (see Section 1, sub-section 12, para.

11 2 and 3). Connect a 3-phase load to terminals N, A, B, C, E and F at the upper

left-hand side of the power module panel.

service. Also see Section 2, sub-section 4, l-2, page 2.

A. Starting

To start the unit, place the motor circuit breaker, if so equipped, in ON position,

momentarily push the motor START button (12, Fig. 2) and release it. The armature

should rotate in the direction indicated by the arrow on the housing.

not, wait until the motor is up to speed, stop the machine (see paragraph D below),

and reverse any two of the incoming power lines. This change will cause the

armature to rotate in the correct direction. Armature rotation should be in a

counterclockwise direction when the operator is facing the generator control

pane I, where the START-STOP push buttons are located.

$MOTOR GENERATOR DIVISION

:

z

QQ

SECTION 3, OPERATION

HOBART BROTHERS COMPANY

E and Fare interlock leads for aircraft

If it does

With the motor running ,

to full speed, adjust the voltage regulator rheostat until the voltmeter indicates

120 volts line to neutral.

B. Applying Load

Press the generator ON button to apply the load. The GREEN pilot light will

glow when the generator output contactor is closed. The voltage regulator will

automatically maintain the set voltage.

The voltage between any two phases (A-B, B-C, C-A) or line to neutral can be

read directly on the voltmeter by setting the meter selector switch and associated

toggle switch to the desired position.

The current on any phase can be read directly on the ammeter by placing the

meter selector switch on the desired phase (A, B, or C).

C. To Disconnect Load

To stop the supply of current to the load, push the generator OFF pushbutton.

D. To Stop Motor

the AMBER pilot light will glow. After the machine is up

Disconnect generator load, if any, push the motor STOP pushbutton momentarily,

and release it.

I

l-3

Page 1

FOBART

e

QQ

;MOTOR GENERATOR DIVISION

t

2

HOBART BROTHERS COMPANY

“0

2

b . B ,,,J-

2. Remote Control

Remote stations may be connected to the terminal strips above the motor and generator

housings in accordance with the connection diagram furnished with the equipment. When

adding remote control, note that it is necessary to remove the jumpers from the terminals

used in cknecting the remote station.

3.

Variations

As stated in Section 1, Description, paragraph 3, l-l, page 1; when variations to the

basic specifications occur,

information will be added at the end of the section in which

information would normally be located.

Variation numbers assigned to the different specs (S numbers) covered by this manual,

vary from one to the other.

Each spec (S number) is listed below, with variations shown

as they apply to the particular spec number.

A. S-4576A:

(1) Var. 1 - not used

(2) Var. 2 - not used

(3) Var. 3 - 220-Volt Input Power

(a) Explanation

- Motor switch designed for 220-volt rather than

380-volt input voltage.

(b) Data - Data listed in Section 1, l-1, page 2 is changed by

Var. 3 as follows:

Motor

Volts

220 v AC

Amperes 161 A

(c) Fuse and Wire Size Change:

Amps at 220 Volt Max Fuse Size

Min Wire Size

161 A 350 A #4/o

(d) Motor Switch Overload Coil Change:

Volts

Coil Size

_Y

Piston Projection Above Dashpot

220

6 turns

1 9/16 inch p

l-3

Feb

6/74

Page 2

7-/j)

2, ;k

Loading...

Loading...