Hobart 3100 Owner’s Manual

MODEL

3100

&

3100C

STACKING SLICER

ML-104493 3100

ML-104494

3100e

\ H

'?@!,~.~

701

S. RIDGE AVENUE

TROY, OHIO 45374-0001

T I

Form 19234 Rev. B (11-98)

TABLE OF CONTENTS

GENERAL 3

INSTALLATION 3

UNPACKING 3

ASSEMBLy 5

TEST SLICER OPERATION 10

ELECTRiCAL 10

TRAII\JING 10

OPERATION

SAFETY

BEFORE FIRST USE

CONTROLS ;

SELECTING LAYOUT OPTIONS 13

THE KEYPAD 15

BASIC LAYOUTS - RECTANGULAR TRAY 16

MULTIPLE LAYOUTS - RECTANGULAR TRAY 18

BASIC LAYOUTS - ROUND PLATTER 19

MULTIPLE LAYOUTS - ROUND PLATTER 20

SANDWICH PACKAGE LAYOUTS 20

EXAMPLES

SLICING 22

MANUAL

AUTOMATIC 23

11

11

11

12

21

22

..

RECLAMPING '

REPROGRAMMING FACTORY PRESET VALUES 25

CLEANII\JG 27

MAINTENANCE 30

SHARPENING THE KNIFE 30

LAYOUT PROBLEMS

LUBRICATIOI\I

WEAR ADJUSTMENT

© HOBART CORPORATION 1993

-2-

24

32

32

32

Installation, Operation and Care of

MODEL 3100

& 3100C STACKING SLICER

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

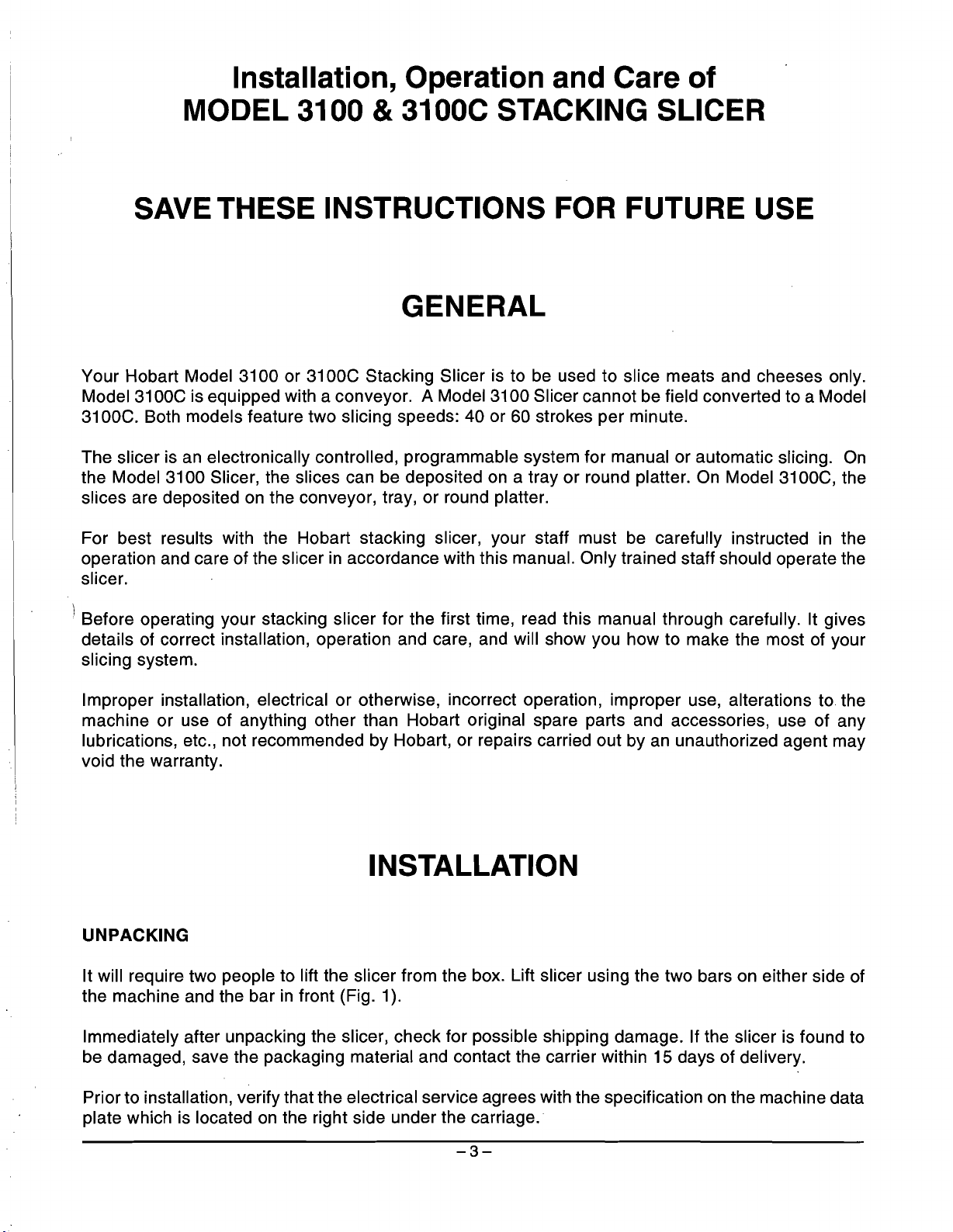

Your Hobart Model 3100 or

Model

31

The slicer is

the Model 3100 Slicer, the slices can be deposited

slices are deposited

For best results with the Hobart stacking slicer, your staff must be carefully instructed

operation and care of the slicer

slicer.

31

DOC

is equipped with a conveyor. A Model 3100 Slicer cannot be field converted to a Model

DOC.

Both models feature two slicing speeds: 40 or

an

electronically controlled, programmable system for manual or automatic slicing.

on

31

DOC

Stacking Slicer is to be used to slice meats and cheeses only.

60

strokes per minute.

on

a tray or round platter.

the conveyor, tray, or round platter.

in

accordance with this manual. Only trained staff should operate the

On

Model

31

DOC,

in

On

the

the

) Before operating your stacking slicer for the first time, read this manual through carefully. It gives

details of correct installation, operation and care, and will show you how to make the most of your

slicing system.

Improper installation, electrical or otherwise, incorrect operation, improper use, alterations to the

machine or use of anything other than Hobart original spare parts and accessories, use of any

lubrications, etc., not recommended by Hobart, or repairs carried out by

void the warranty.

an

unauthorized agent may

INSTALLATION

UNPACKING

It will require two people to lift the slicer from the box. Lift slicer using the two bars on either side of

the machine and the bar

Immediately after unpacking the slicer, check for possible shipping damage. If the slicer is found to

be damaged, save the packaging material and contact the carrier within 15 days of delivery.

in

front (Fig. 1).

Prior to installation, verify that the electrical service agrees with the specification

plate which is located

on

the right side under the carriage

-3-

..

on

the machine data

I PL-22038]

Fig. 1

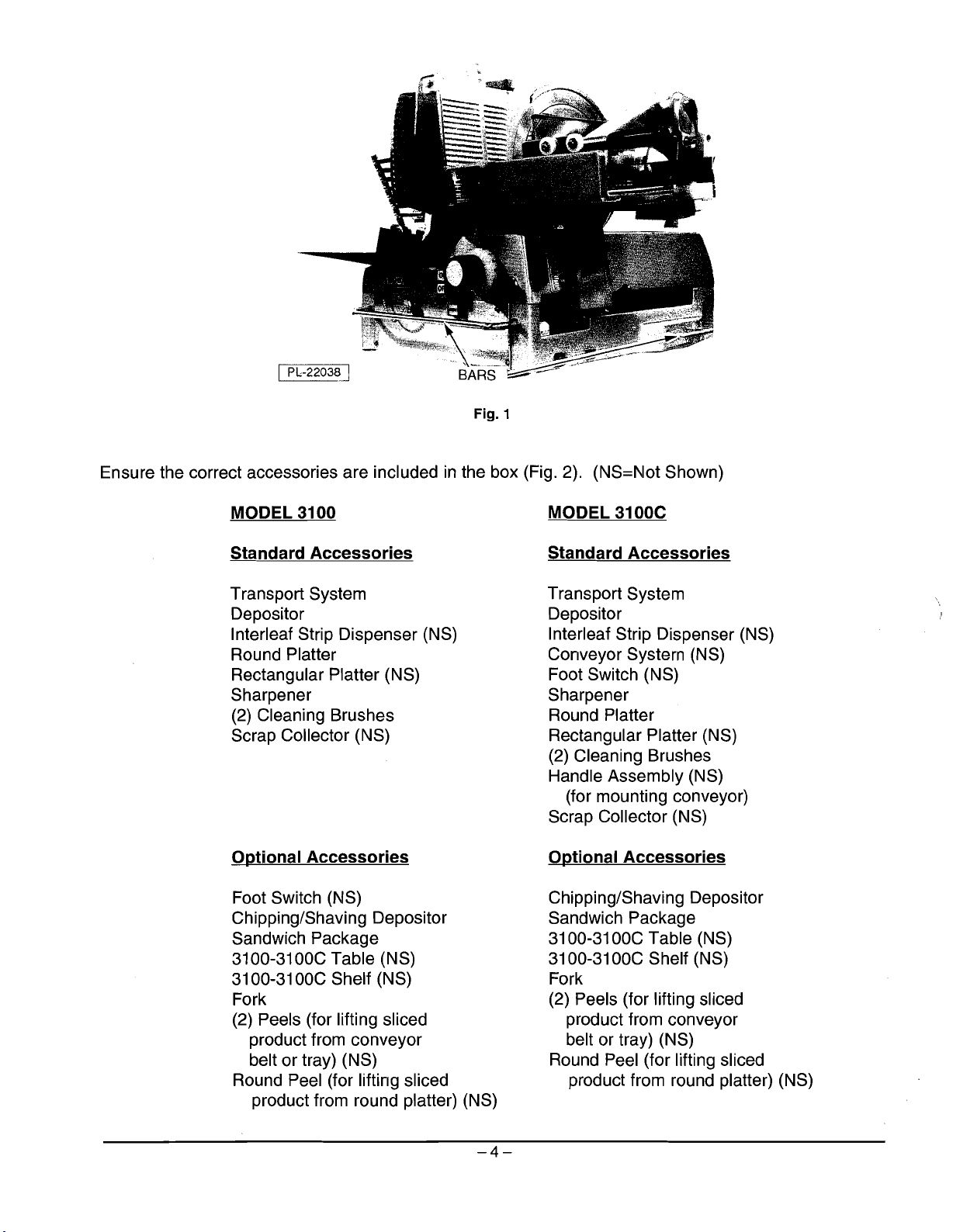

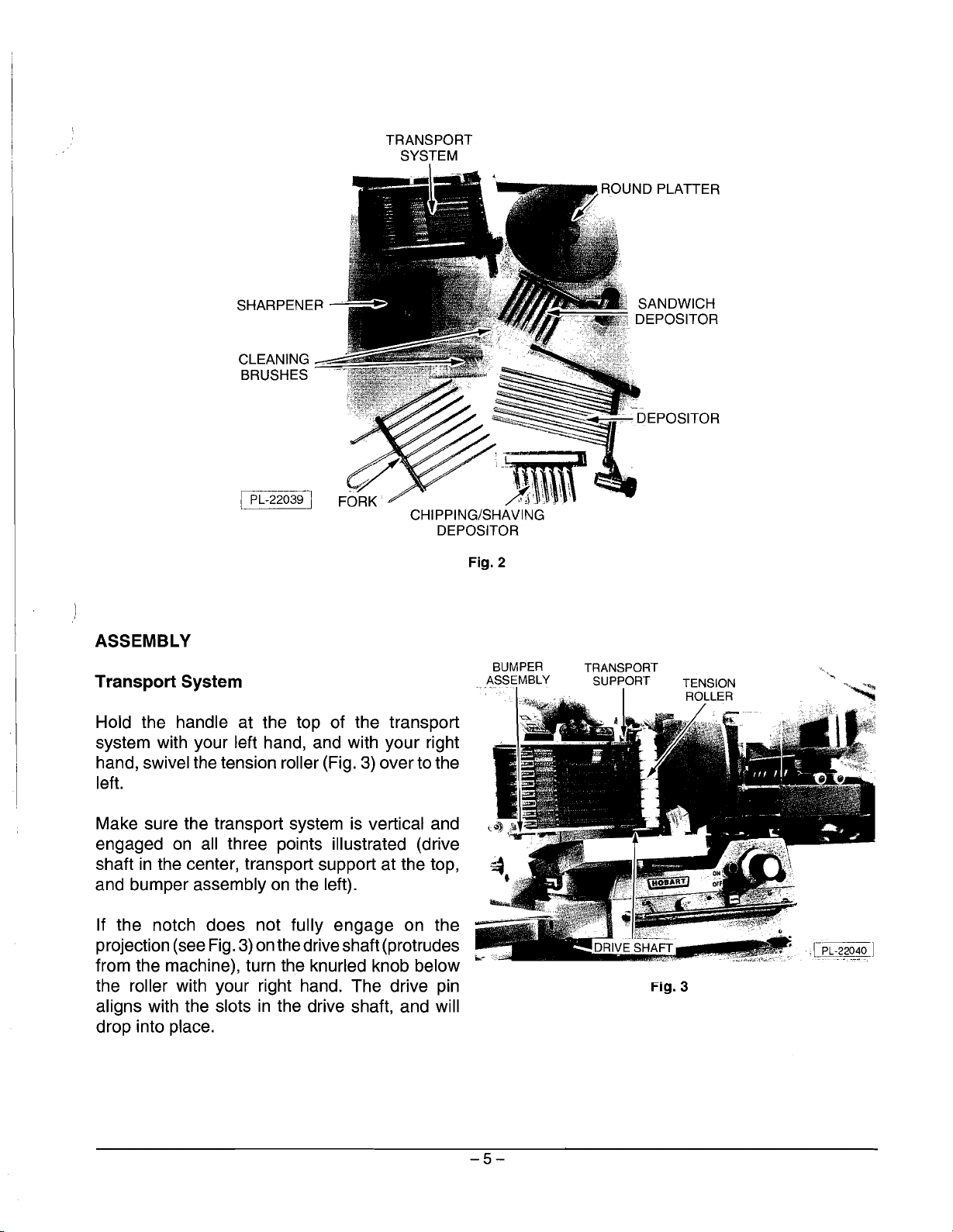

Ensure the correct accessories are included

MODEL 3100

Standard Accessories

Transport System

Depositor

Interleaf Strip Dispenser (NS)

Round Platter

Rectangular Platter (NS)

Sharpener

(2) Cleaning Brushes

Scrap Collector (NS)

Optional Accessories

Foot Switch (t\lS)

Chipping/Shaving Depositor

Sandwich Package

31

00-31

OOC

Table (NS)

31

00-31

OOC

Shelf (NS)

Fork

(2) Peels (for lifting sliced

product from conveyor

belt or tray) (NS)

Round Peel (for lifting sliced

product from round platter) (NS)

in

the box (Fig. 2). (NS=t\lot Shown)

MODEL 3100C

Standard Accessories

Transport System

Depositor

Interleaf Strip Dispenser (NS)

Conveyor System (NS)

Foot Switch (NS)

Sharpener

Round Platter

Rectangular Platter (NS)

(2) Cleaning Brushes

Handle Assembly (NS)

(for mounting conveyor)

Scrap Collector

(t\lS)

Optional Accessories

Chipping/Shaving Depositor

Sandwich Package

31

00-31

OOC

Table (NS)

31

00-31

OOC

Shelf (NS)

Fork

(2) Peels (for lifting sliced

product from conveyor

belt or tray) (t\lS)

Round Peel (for lifting sliced

product from round platter) (NS)

-4-

SHARPENER

CLEANING

BRUSHES

---I

'PL:~22039

1_

ASSEMBLY

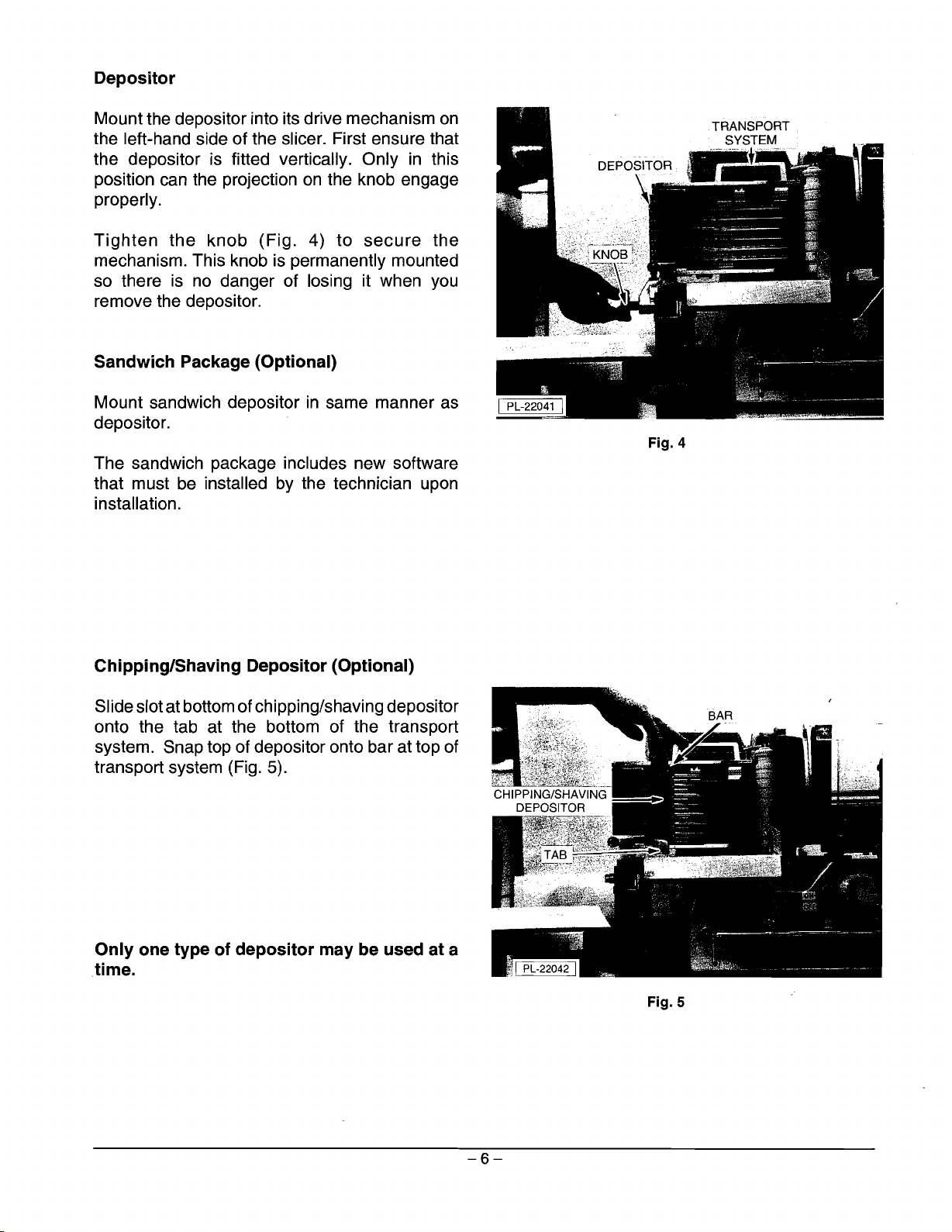

Transport System

Hold the handle at the top of the transport

system with your left hand, and with your right

hand, swivel the tension roller (Fig.

left.

Make sure the transport system

engaged

shaft

and bumper assembly

If the notch does not fully engage on the

projection (see

from the machine), turn the knurled knob below

the roller with your right hand. The drive pin

aligns with the slots

drop into place.

on

all three points illustrated (drive

in

the center, transport support at the top,

Fig.

3)

on

in

J

CHIPPING/SHAVING

DEPOSITOR

3)

over to the

is

vertical and

on

the left).

the drive shaft (protrudes

the drive shaft, and will

Fig. 2

-

•.

".:."'.\'\.\

/;!J \ ':-

,~l

\

TRANSPORT

SUPPORT

;JDRivE'SHA,,~

•.

Fig. 3

,J,lll1;":

·,l~~]

'

.....

-5-

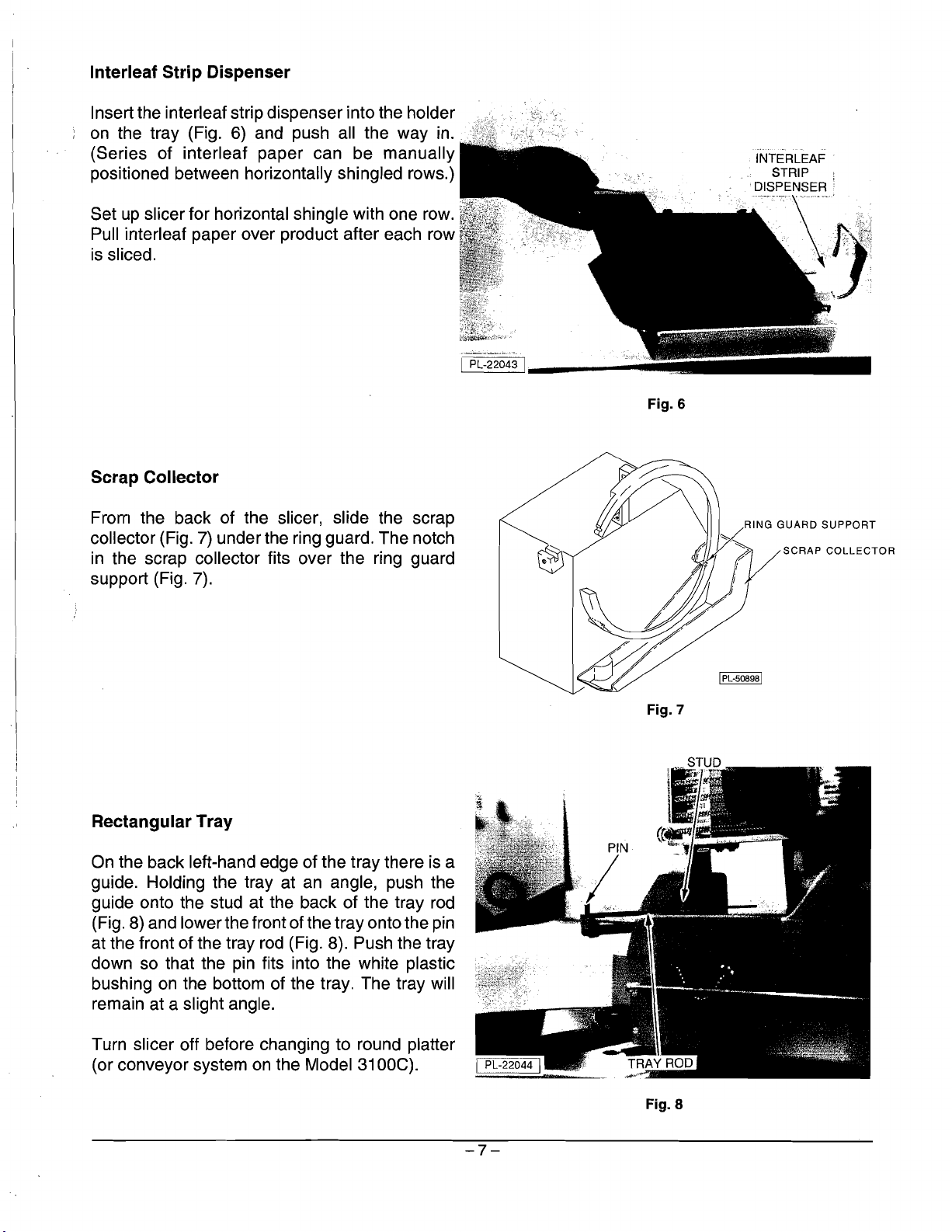

Depositor

Mount the depositor into its drive mechanism

on

the left-hand side of the slicer. First ensure that

the depositor is fitted vertically. Only

position

can

the projection

on

the knob engage

in

this

properly.

Tighten

the knob (Fig. 4) to

secure

the

mechanism. This knob is permanently mounted

so

there

is

no

danger of losing it when

you

remove the depositor.

Sandwich Package (Optional)

Mount sandwich depositor

in

same manner as

depositor.

The sandwich package includes new software

that must

be

installed

by

the technician upon

installation.

Fig. 4

Chipping/Shaving Depositor (Optional)

Slide slot at bottom of chipping/shaving depositor

onto the tab at the bottom of the transport

system. Snap top of depositor onto bar at top of

transport system (Fig. 5).

Only one type of depositor may be used at a

time.

Fig. 5

-6-

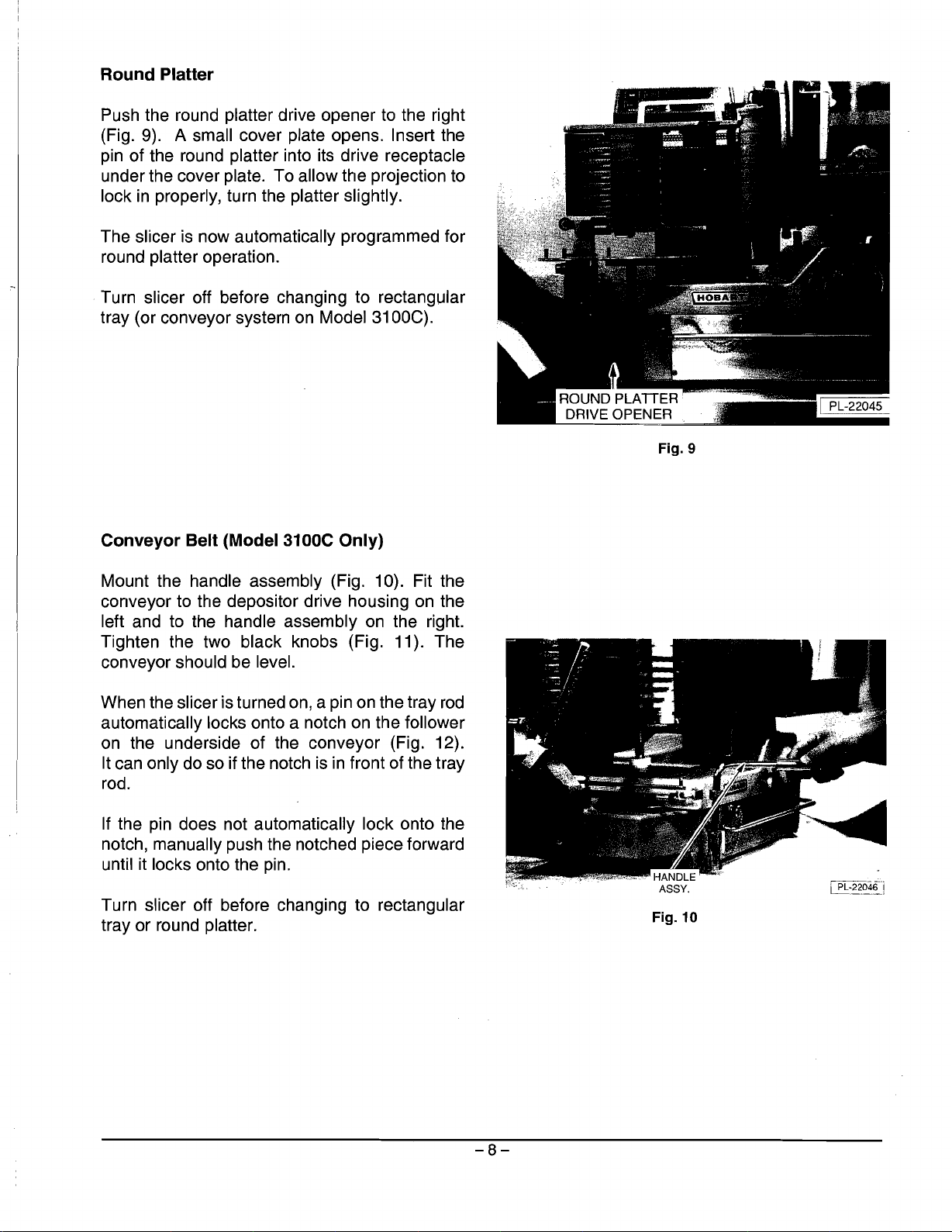

Interleaf Strip Dispenser

Insert the interleaf strip dispenser into the holder

on

the tray (Fig.

(Series of interleaf paper can be manually

positioned between horizontally shingled rows.)

up

Set

Pull irrterleaf paper over product after each row

is

Scrap Collector

slicer for horizontal shingle with one

sliced.

6)

and push all the way in.

row.

I PL-22043 I

Fig. 6

INTERLEAF

STRIP

DISPENSER

.

....

,T'.\

..

' ''

. .

II..

!;-t"c,::\.

fr··;it~)

~;

.• ' -"c'

..

',r

..

'-","

".i,

.

,j

..•••.•'..••.•

.

From the back of the slicer, slide the scrap

7)

collector (Fig.

in

the scrap collector fits over the ring guard

support (Fig. 7).

Rectangular Tray

On

the back left-hand edge of the tray there

guide. Holding the tray at

guide onto the stud at the back of the tray

(Fig.

8)

and lower the front of the tray onto the pin

at the front of the tray

down so that the pin fits into the white plastic

bushing

remain at a slight angle.

on

under the ring guard. The notch

is

an

angle, push the

rod

rod

(Fig. 8). Push the tray

the bottom of the tray. The tray will

a

Fig. 7

RING

IPL-50898 I

GUARD

SUPPORT

Turn slicer off before changing to round platter

on

(or conveyor system

the Model

31

DOC).

Fig. 8

-7-

Round Platter

Push the round platter drive opener to the right

(Fig. 9). A small cover plate opens. Insert the

pin of the round platter into its drive receptacle

under the cover plate. To allow

lock

in

properly, turn the platter slightly.

the projection to

The slicer is now automatically programmed for

round platter operation.

Turn slicer off before changing to rectangular

tray (or conveyor system on Model 3100C).

~'

III

ROUND

DRIVE OPENER

PLAlTER

Fig. 9

Conveyor Belt (Model 3100C Only)

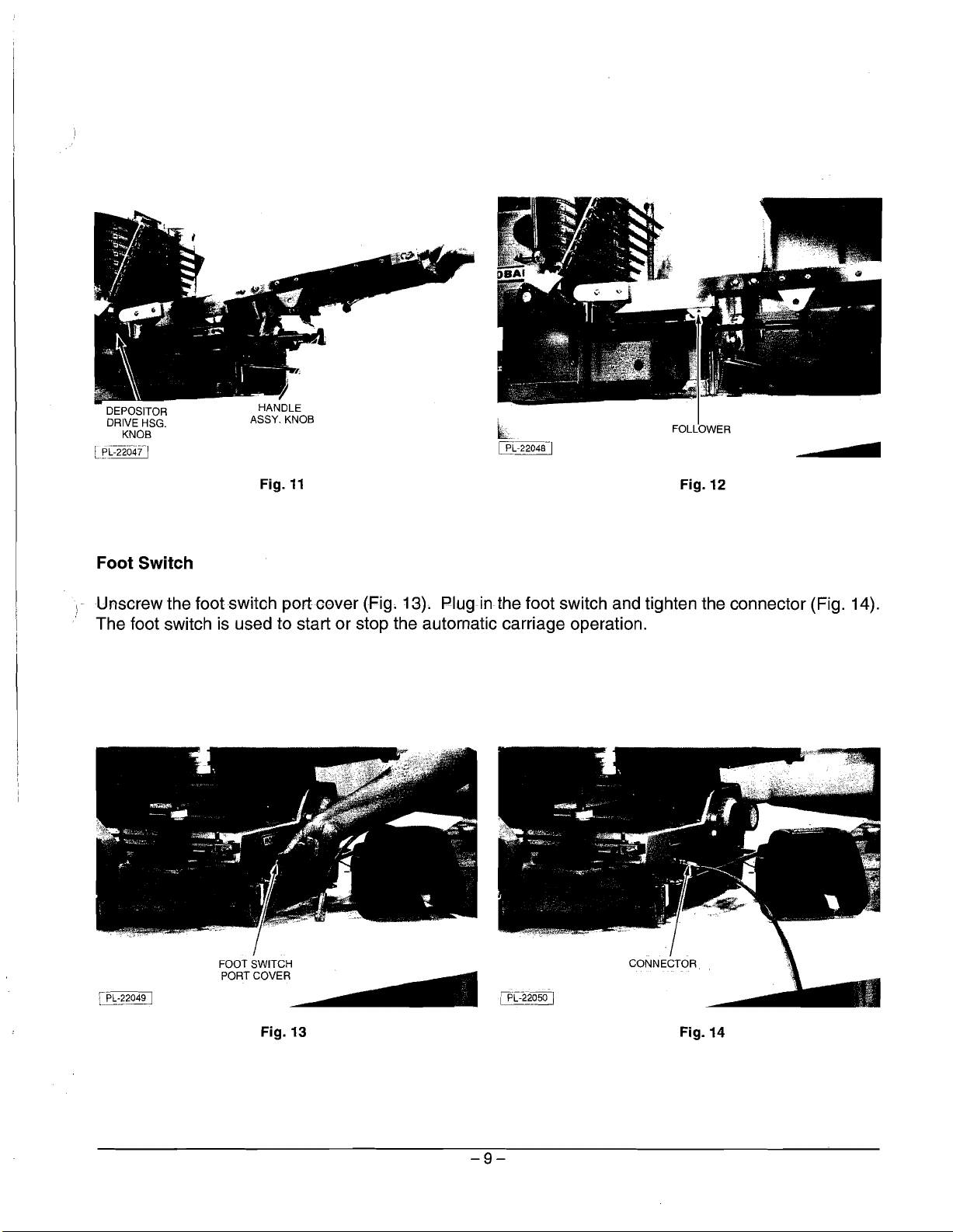

Mount the handle assembly (Fig. 10). Fit the

conveyor to the depositor drive housing on the

left and to the handle assembly on the right.

Tighten the two black knobs (Fig. 11). The

conveyor should be level.

When the slicer is turned on, a pin on the tray

rod

automatically locks onto a notch on the follower

on the underside of the conveyor (Fig. 12).

It can only do so if the notch is

in

front of the tray

rod.

If the pin does not automatically lock onto the

notch, manually push the notched piece forward

until it locks onto the pin.

Turn slicer off before changing to rectangular

tray or round platter.

ili:~186-i

Fig. 10

-8-

DEPOSITOR

DRIVE HSG.

KNOB

[1'L-=-22047"/

Foot Switch

Fig.

11

~L

lli

-22048-1

FOLLOWER

Fig.

12

•

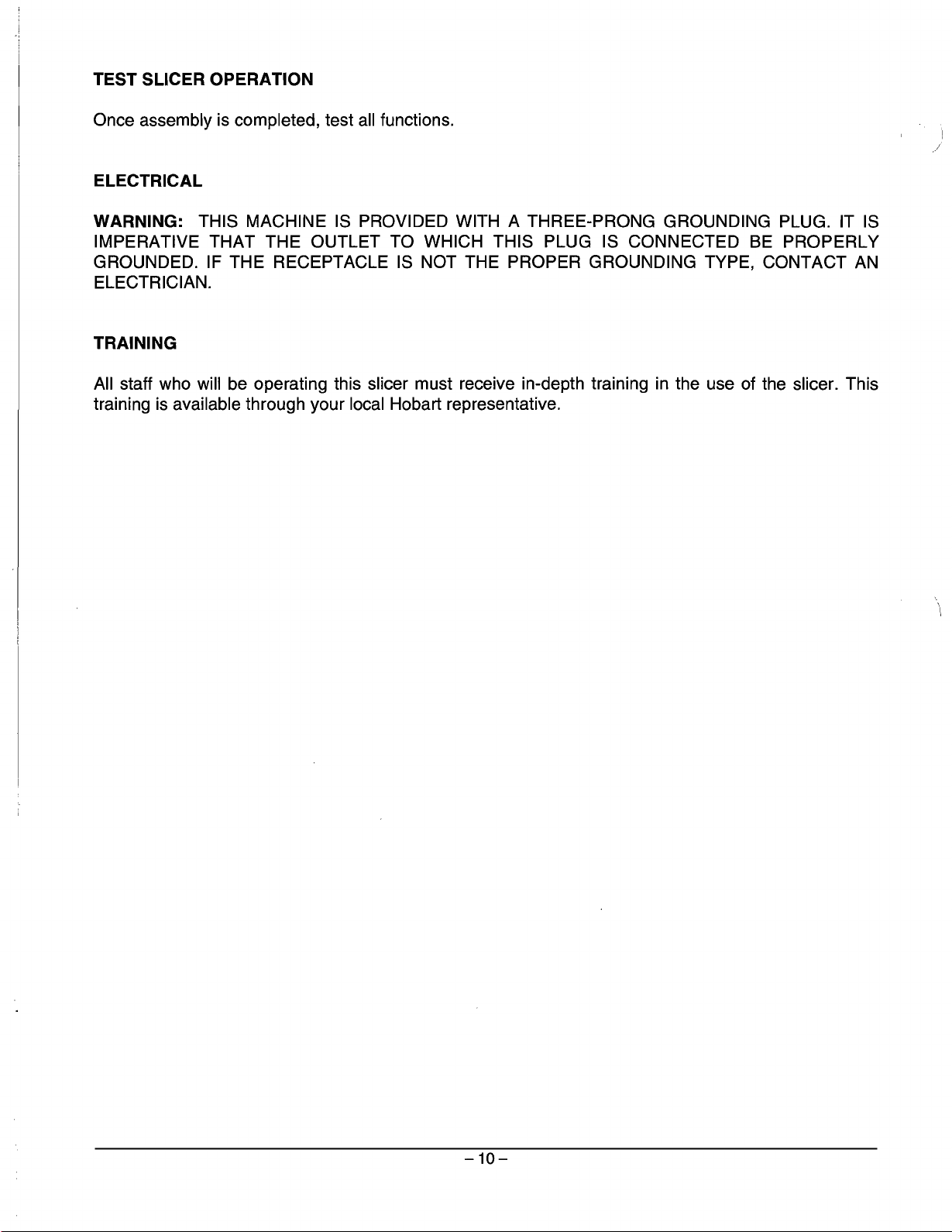

i" Unscrew the footswitoh port"oever (Fig. 13). Plug

in

the foot switch and tighten the connector (Fig. 14).

, The foot switch is used to start or stop the automatic carriage operation.

CONNECTOR

lPL:~204~

FOOT SWITCH

PORTCOVER~

Fig.

13

1P[:2-2_~

Fig.

14

-9-

TEST SLICER OPERATION

Once assembly is completed, test

ELECTRICAL

WARNING:

THIS MACHINE

all

functions.

IS

PROVIDED WITH A THREE-PRONG GROUNDING PLUG.

IMPERATIVE THAT THE OUTLET TO WHICH THIS PLUG

GROUNDED.

IF

THE RECEPTACLE

IS

NOT THE PROPER GROUNDING TYPE, CONTACT

ELECTRICIAN.

TRAINING

All staff who will

training

is

available through your local Hobart representative.

be

operating this slicer must receive in-depth training

IS

CONNECTED

in

the use of the slicer. This

BE

PROPERLY

IT

IS

AN

-10-

Loading...

Loading...