Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

2912

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Variable Six-Speed Automatic Carriage with

Front Mounted Controls

■ Home Position Start

■ Close To Stop

■ Gauge Plate Interlock

■ Carriage System Interlock

■ No Volt Release

■ Exclusive Tilting, Removable Carriage System

■ CleanCut™ Knife

■ Top Mounted Borazon Stone Sharpener

■ Hobart Poly V-Belt Drive System

■ Sanitary Anodized Aluminum Base

■ Double-Action Indexing Cam

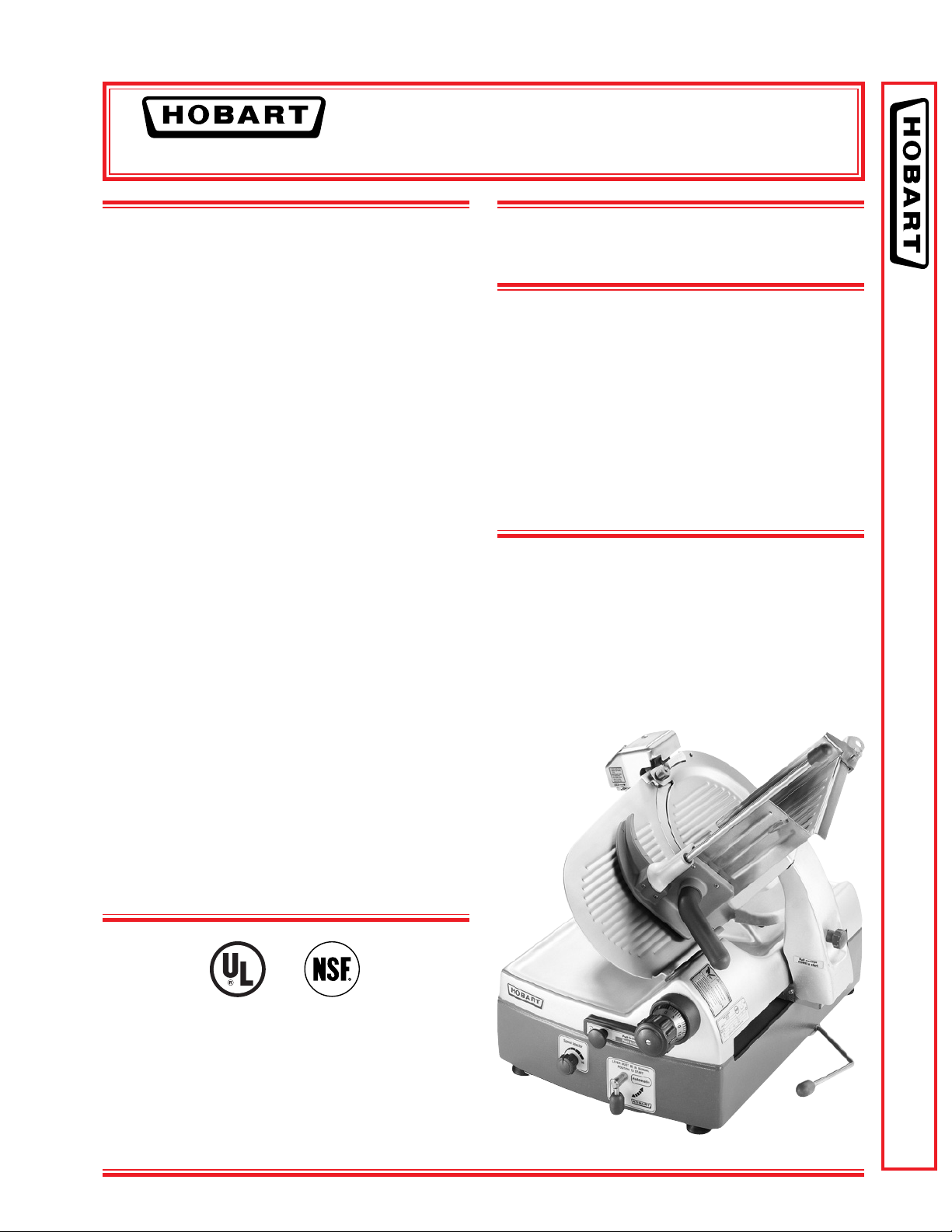

SLICER

MODEL

❑ 2912 – Smart Feature Automatic Slicer

ACCESSORIES

❑ Low Fence

❑ High Fence

❑ Food Chute

❑ Heavy Meat Grip

❑ Tall Legs

❑ Product Tray

Specications, Details and Dimensions on Inside and Back.

■ Permanently Mounted Ring Guard

■ Heavy Gauge Stainless Steel Knife Cover

■ Lift Lever

■ Removable Rear Deector

■ 1⁄2 H.P. Knife Drive Motor

■ Nylon Carriage Roller

■ Electroless Nickel Plated Single Slide Rod with

Reservoir Wick

■ Stainless Steel Carriage

■ Ergonomic Style Handle

■ Low Fence

2912 SLICER

F39688 – 2912 Slicer Page 1 of 4

Page 2

2912

SLICER

SOLUTIONS / BENEFITS

Variable Six-Speed Automatic Carriage with Front

Mounted Controls

Improved yield, labor savings

■ Greater exibility for all slicing needs

■ Six speed choices for 28, 33, 38, 42, 47, and 52

strokes per minute

Home Start Position

Maximizes yield

■ Carriage must be in “home position” before the slicer

will start

Close To Stop

Convenience, labor savings, energy savings

■ Closing of gauge plate turns off the slicer

Gauge Plate Interlock

Supports use of proper cleaning procedures, easier to

clean

■ Gauge plate must be closed to remove carriage for

cleaning and cannot be opened when removed

Carriage System Interlock

■ Will not tilt away or remove if gauge plate indicator is

not closed

No Volt Release

Protects against unintentional starting of slicer

■ Slicer must be restarted if power fails or slicer is

unplugged

Exclusive Tilting, Removable Carriage System

Reduces labor, improves sanitation

■ Tilt design allows for ease of midday cleaning

■ Removable for complete cleaning and sanitation

procedures

CleanCut™ Knife

Reduced cost of ownership, improved yield

■ Thin edge design improves yield

■ Super alloy edge lasts longer

■ Fewer and shorter sharpenings required

Top Mounted Borazon Stone Sharpener

Ease of use, improved sanitation, reduced costs

■ Single action sharpens and hones in just ve

seconds

■ Removable and submersible for easy cleaning and

sanitation

■ Lifetime guaranteed Borazon sharpening stones

provide maximum performance with reduced

maintenance costs

Poly V-Belt Drive System

Performance, durability, reduced maintenance

■ Patented design extends belt life while producing

optimum slicing results

■ Quieter operating slicer

Sanitary Anodized Aluminum Base

Improved sanitation, labor savings

■ One piece base protects against possible growth of

bacteria

■ No cracks/crevices or bolt holes where product can

lodge and bacteria may grow

■ Easy cleanup and durable nish

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Double-Action Indexing Cam

Increases reliability, easier to use, increased yield

■ The rst full revolution of the indexing knob provides

precise control for shaving, chipping and thin slicing

■ The second revolution opens the gauge plate quickly

for thicker slicing

■ Gauge plate holds position for consistent, precision

slicing

Permanently Mounted Ring Guard

Protection

■ Protects knife during operation and cleaning

Heavy Gauge Stainless Steel Knife Cover

Durability, ease of use, sanitation

■ Twelve-gauge stainless steel maintains shape to

ensure consistent t

■ Spring loaded knob for quick removal and easy

cleanup

■ One piece design for simplistic usage

Lift Lever

Improved sanitation, ease of use

■ Props machine for easy cleaning underneath slicer

Removable Rear Deflector

Improved sanitation, ease of use

■ Allows access for thorough cleaning

■ No tools required means easy removal during

cleaning

1

⁄2 H.P. Knife Drive Motor

Durability, performance

■ Reserve power runs at 400 rpm for optimum results

Nylon Carriage Roller

Performance

■ Easy movement for manual operation

Electroless Nickel Plated Single Slide Rod with

Reservoir Wick

Performance, durability, lower maintenance

■ Smooth operation with continuous lubrication of

carriage rod

■ Resistant to rust

Stainless Steel Carriage

Improved sanitation, durability

■ Maximum sanitation with minimum cleanup time

■ Corrosion resistant, impact resistant

Ergonomic Style Handle

Operator satisfaction

■ Comfortable manual operation

Meat Grip Options

Multiple choices for improved yield and consistency

■ Front meat grip standard

■ Heavy front meat grip available

Page 2 of 4 F39688 – 2912 Slicer

Page 3

2912

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

SPECIFICATIONS

VARIABLE SIX-SPEED AUTOMATIC CARRIAGE WITH

FRONT MOUNTED CONTROLS: Choice of six speeds -

28, 33, 38, 42, 47, 52 strokes per minute. Carriage can be

disengaged from power drive whether slicer is in operation

or not. Automatic engagement and speed selector controls

located in front of machine. Speed can be changed with

slicer motor on or off. Carriage driven by DC gear-reduction

motor and 4 bar synchronous linkage.

HOME POSITION START: Home-start ensures carriage is

in a convenient position before starting the slicer.

CLOSE TO STOP: After slicing, a quick turn of the index

knob to the closed position turns off the slicer.

GAUGE PLATE INTERLOCK: Gauge plate interlock

protects knife edge when indicator is at zero.

CARRIAGE SYSTEM INTERLOCK: Carriage will not tilt

away or remove if gauge plate indicator is not closed.

NO VOLT RELEASE: In the event of power loss, slicer

must be restarted before operation can continue.

SLICER

PERMANENTLY MOUNTED RING GUARD: Permanently

mounted ring guard with integrated product deector

protects knife.

HEAVY GAUGE STAINLESS STEEL KNIFE COVER: One

piece design made of 12 gauge stainless steel, durable to

maintain shape and ensure consistent t. Spring loaded for

quick removal and replacement.

LIFT LEVER: Lift lever facilitates raising slicer to tilted

position for cleaning beneath the machine.

REMOVABLE REAR DEFLECTOR: No tools are required

for removal of the deector for thorough cleaning of the

slicer.

KNIFE MOTOR: 1⁄2 H.P., permanently lubricated ball

bearings. Single phase capacitor-start, induction run.

ELECTROLESS NICKEL PLATED SINGLE SLIDE ROD

WITH RESERVOIR WICK: Transport slide rod is E-Nickel

electroless plated. Slide rod bearings feature an oil

reservoir/oil wick.

TILTING REMOVABLE CARRIAGE SYSTEM: Positive

angle carriage design enables operator to slice without

manual feed. The stainless steel carriage system tilts back

easily for midday cleaning and is removable for thorough

cleaning and sanitation procedures. The carriage has

121⁄2" manual travel.

CLEANCUT™ KNIFE: Another Hobart exclusive, the knife

is constructed of 304L stainless steel and high performance

super alloy. Knife is protected by a permanently mounted

ring guard with integrated product deector. The stainless

steel knife cover provides easy access for cleaning. Gauge

plate protects knife edge when indicator is closed. Knife

cover is quickly removed with a quarter turn of the spring

loaded locking knob.

TOP MOUNTED BORAZON STONE SHARPENER: One

lever operation utilizing two Borazon stones to sharpen and

hone in ve seconds. Removable and top mounted. When

sharpener is removed for cleaning, knife edge is shielded.

Borazon stones have lifetime guarantee.

HOBART POLY V-BELT DRIVE SYSTEM: Knife is driven

by a Hobart Poly V belt and runs at 400 rpm for optimal

performance.

SANITARY ANODIZED ALUMINUM BASE: One-piece

base protects against possible growth of bacteria. All

surfaces are durable and smooth, presenting no holes or

crevices in which food can lodge.

DOUBLE-ACTION INDEXING CAM: First revolution of

index cam for precision slicing; second revolution for

thicker slicing selection. Indexing cam holds true to setting

during slicing operation.

FINISH: Stainless steel carriage, gauge plate and knife

cover. Anodized aluminum base.

ERGONOMIC STYLE HANDLE: Specially designed for

ease of use during manual operation.

MEAT GRIP: Front mounted grip is high strength

thermoplastic. Swings out of way when not in use.

ELECTRICAL SPECIFICATIONS: 120/60/1 – U L Listed.

Also available in 100/50/60/1, 240/60/1 (3 amps) and

230/50/1 (3 amps) – not submitted for U L Listing.

SWITCH: Moisture protected toggle type, operated by a

push-pull rod.

CORD & PLUG: 6-foot, three-wire power supply cord and

plug. Plug not furnished on export models.

CAPACITY: The carriage will take food up to 12" in width

or 71⁄2" in diameter.

GAUGE PLATE: Gauge plate is a heavy aluminum

casting with ribbed laminated stainless steel face for

smooth feeding. Adjustable to cut any thickness of slice

up to 1".

WARRANTY: All parts and service coverage for one year

including knife. Lifetime guarantee on Borazon stones in

the sharpening system.

WEIGHTS FOR THE FOLLOWING ITEMS: Tubular Chute

9.1 lbs.; Swing Arm .61 lbs.; Heavy Front Meat Grip 2.76

lbs.; Heavy Handle 2.7 lbs.; Standard Meat Grip 2.34 lbs.

WEIGHT: Shipping 182 lbs., Net 140 lbs.

F39688 – 2912 Slicer Page 3 of 4

Page 4

2912

SLICER

DETAILS AND DIMENSIONS

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

LEGEND

LEGEND

E1-ELECTRICAL CONNECTION,

E1-ELECTRICAL CONNECTION,

APPROX 61⁄2" ABOVE

APPROX 61⁄2" ABOVE

COUNTER TOP

COUNTER TOP

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

Page 4 of 4 F39688 – 2912 Slicer

F39688 (REV. 08/12) LITHO IN U.S.A. (H-01)

Loading...

Loading...