HIT HA13561F Datasheet

HA13561F

Combo (Spindle & VCM) Driver

ADE-207-182 (Z)

1st Edition

July 1996

Description

This COMBO Driver for HDD application consists of Sensorless Spindle Driver and BTL type VCM Driver.

Bipolar Process is applied and a “Soft Switching Circuit” for less commutation noise and a “Booster Circuit’

for smaller Saturation Voltage of Output Transistor are also implemented.

Features

• Soft Switching Driver

Small Surface Mount Package: FP-80E (QFP80 Pin)

Low thermal resistance: 35°C/W with 6 layer multi glass-epoxy board

• Low output saturation voltage

Spindle 0.8 V Typ (@1.0 A)

VCM 0.8 V Typ (@0.8 A)

Functions

• 1.8 A Max/3-phase motor driver

• 1.2 A Max BTL VCM Driver

• Auto retract

• Soft Switching Matrix

• Start up circuit

• Booster

• Speed Discriminator

• Internal Protector (OTSD, LVI)

• POR

• Power monitor

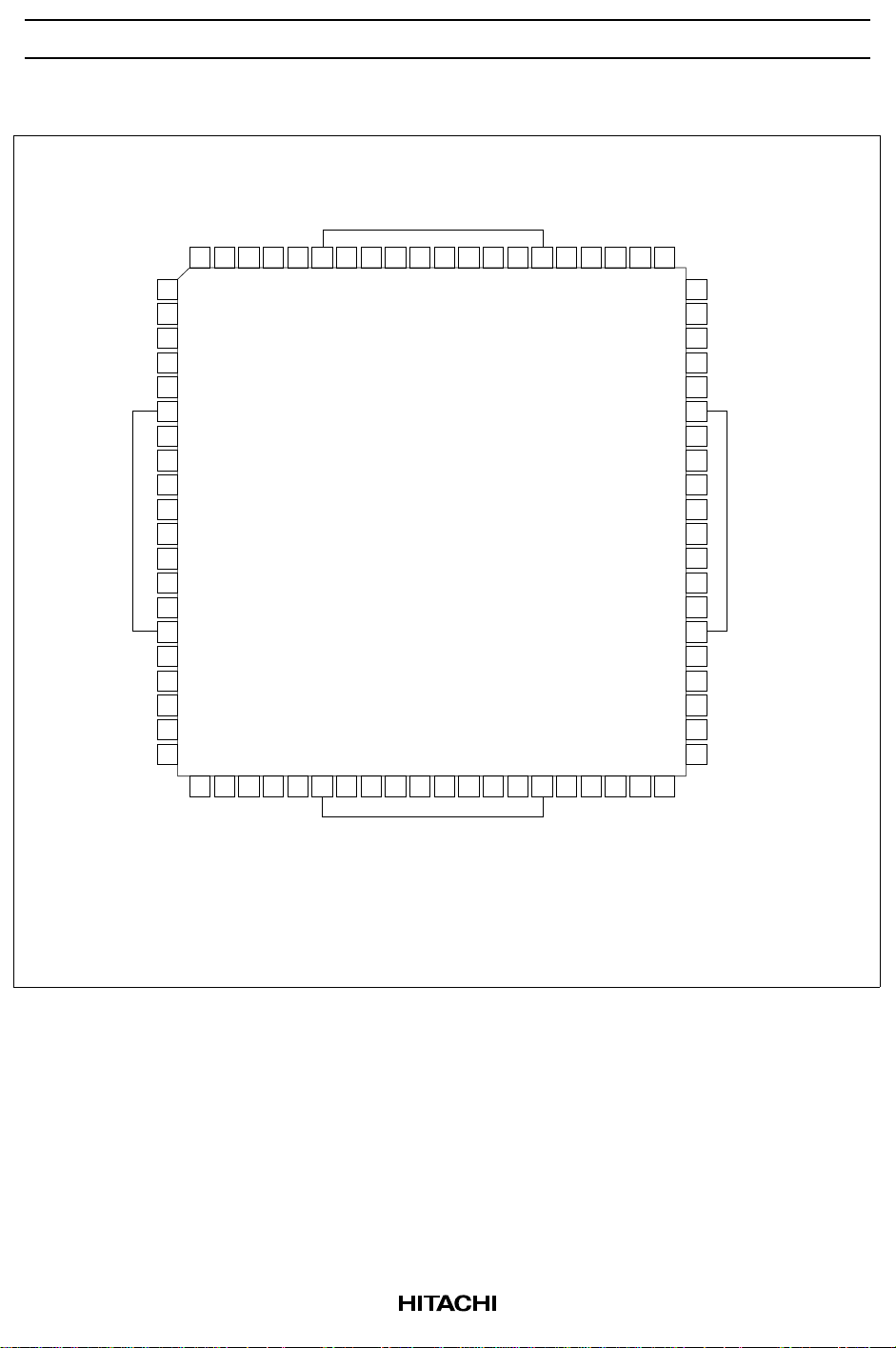

HA13561F

Pin Arrangement

)

+

TAB

RS

RETON

RETPOW

Vpsv

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 6162

LVI2

OPIN(-)

VCTL

OPIN(

RESINH

VREF1

1

VBST

BC2

BC1

W

RNF

CT

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

V

21 22 23 24 25 26 272829 30 31 32 33 34 35 36 37 38 39 40

U

R1

CLREF

C-PUMP

Vpss

TAB

VCMP

VCMN

TAB

PCOMP

*NC : No internal connection

Please note that there is no isolation check between pin 58 and pin 59

at the testing of this IC.

(Top View)

Vss

LVI1

COMM

DELAY

60

COMPOUT

59

NC*

58

NC*

57

GAIN

56

VCMENAB

55

54

53

52

51

50

49

48

47

46

45

POR

44

SPNENAB

43

READY

42

CLOCK

41

CNTSEL

POLSEL

TAB

2

HA13561F

Pin Description

Pin Number Pin Name Function

1 VBST Boosted voltage output to realize the low output saturation voltage

2 VCMP Output terminal on VCM driver

3 VCMN Output terminal on VCM driver

4 BC2 To be attached the external capacitor for booster circuitry

5 BC1 ditto

6 to 15 GND Ground pins

16 W W phase output terminal on spindle motor driver

17 RNF Sensing input for output current on spindle motor driver

18 PCOMP To be attached the external capacitor for phase compensation of spindle

motor driver

19 CT To be attached the center tap of the spindle motor for B-EMF sensing

20 V V phase output terminal on spindle motor driver

21 U U phase output terminal on spindle motor driver

22 C-PUMP To be attached the external integral constants for speed control of spindle

motor

23 CLREF Reference voltage input for current limiter of spindle motor driver

24 R1 To be attached the external resistor for setting up the oscillation frequency of

start-up circuitry and the gain of speed control loop of spindle motor driver

25 Vpss Power supply for spindle motor driver

26 to 35 GND Ground pins

36 V

37 LVI1 Sensing input for power monitor circuitry

38 DELAY To be attached the external capacitor to generate the delay time for power on

39 COMM To be attached the external capacitor for setting up the oscillation frequency

40 POLSEL To be selected the input status corresponding to the pole number of spindle

41 CNTSEL To select the count Number of Speed Discriminator

42 CLOCK Master clock input for this IC

43 READY Output of speed lock detector for spindle motor

44 SPNENAB To select the status of spindle motor driver

45 POR Output of power on reset signal for HDD system

46 to 55 GND Ground pins

56 VCMENAB To select the status of VCM driver

57 GAIN To select the Transfer conductance gm of VCM driver

SS

Power supply for small signal block

reset signal

motor

3

HA13561F

Pin Description (cont)

Pin Number Pin Name Function

58 NC No function

59 NC ditto

60 COMPOUT Comparator output to detect the direction of output current on VCM driver

61 VREF1 Regulated voltage output to be used as reference of peripheral ICs

62 RESINH Used for inhibiting the restart function of the spindle motor driver after power

down

63 OPIN (+) Non inverted input of OP.Amp. to be used for filtering the signal on PWMOUT

64 VCTL OP. Amp. output, this signal is used as control signal for VCM driver output

65 OPIN (–) Inverted input of OP.Amp. to be used for filtering the signal on PWMOUT

66 to 75 GND Ground pins

76 LVI2 Sensing input for power monitor circuitry

77 Vpsv Power supply for VCM driver

78 RETPOW Power supply for retract circuitry

79 RETON To be attached the base terminal of external transistor for retracting

80 RS Sensing input for output current on VCM driver

4

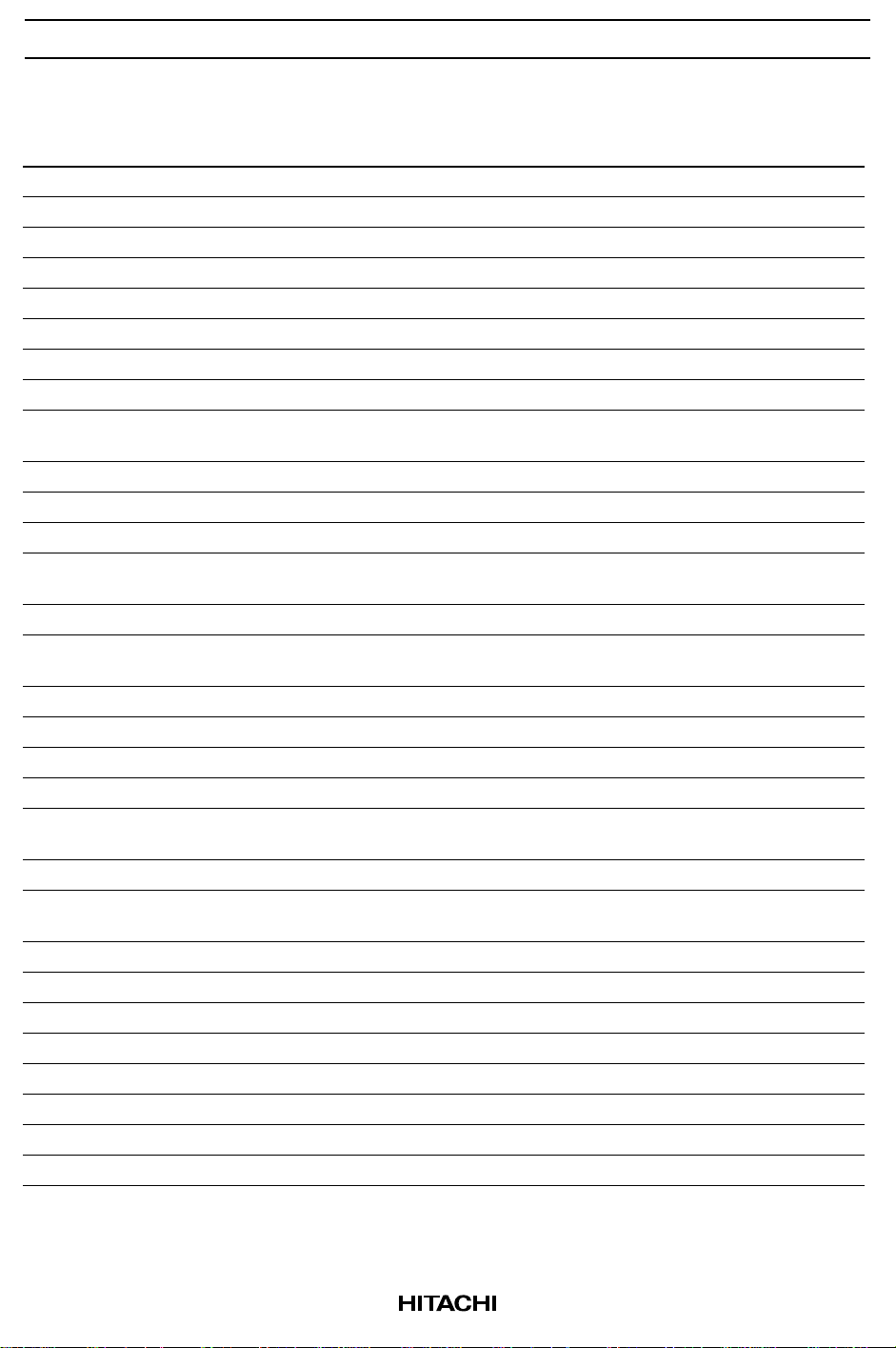

Block Diagram

HA13561F

RESINH

COMM

C103

C-PUMP

C2

C1

CLREF

R1b

SPNENAB

POLSEL

CLOCK

(5MHz Typ)

CNTSEL

READY

VCTL

OPIN(–)

OPIN(+)

Vref1

GAIN

VCM ENAB

C104

C105

R1

R1a

NC

NC

BC1

BC2

V

VSS (+5V)

V

SS

36 25

C102

B-EMF

AMP.

SOFT

SWITCHING

MATRIX

62

39

START-UP

CIRCUIT

COMMUTATION

LOGIC

22

23

CHARGE

PUMP

CURRENT

CONTROL

24

44

40

(D1)

SPEED DISCRI.

42

1/32

(CNT)

41

43

SPEED

READY

V

BST

64

–

65

63

61

59

58

+

OPAMP.

Vref1

(=4.6V)

OTSD

+

VCM

DRIVER

–

57

56

5

4

1

BST

BOOSTER

Vss

(+5V)

V

BST

Vss

37 76 38

LVI1

R101

POWER

MONITOR

LVI2

R103

Vps

R102 R104

Vps

(+12V)

POR

Delay

DELAY

C106

V

BST

Vpss

SPINDLE

DRIVER

RETRACT

DRIVER

P

N

COMPARATOR

Vps(+12V)

U

V

W

PCOMP

Vpsv

RETPOW

RETON

VCMP

VCMN

–

+

GND

6 to 15,26 to 35

46 to 55,66 to 75

C101

CT

19

21

U

20

V

16

W

17

18

77

78

79

2

3

80

RS

COMP

60

OUT

R105

45

POR

(L:RESET)

R

C110

C111

D1

R108

C

R

NF

Qret

X

X

Vss(+5V)

C109

R

S

R

L

D2

5

HA13561F

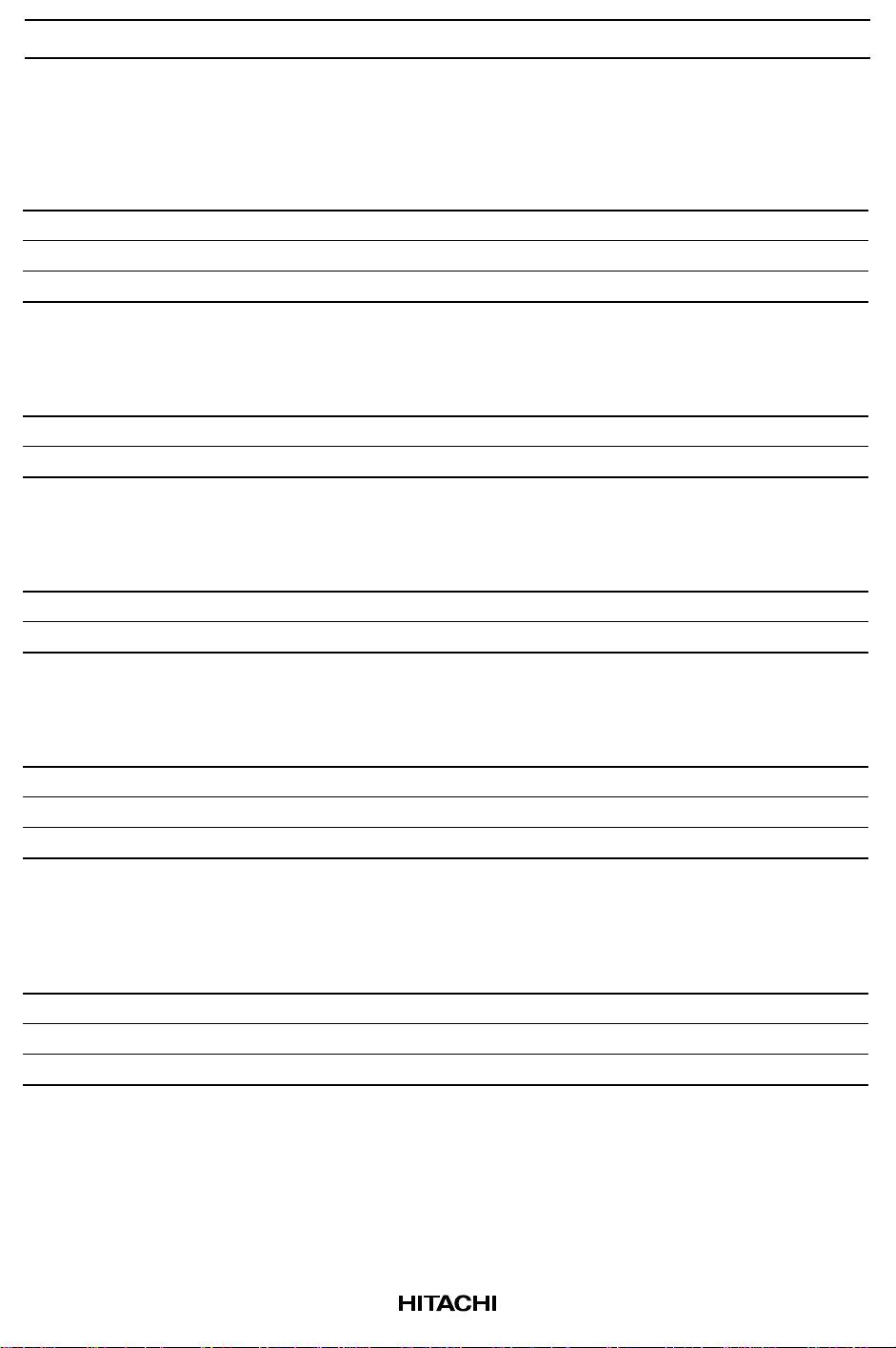

Truth Table

Table 1 Truth Table (1)

SPNENAB Spindle Driver

HON

Open Cut off

L Braking

Table 2 Truth Table (2)

VCMENAB VCM Driver

HON

L Cut off

Table 3 Truth Table (3)

OTSD Spindle Driver VCM Driver Retract Driver

not Active See table 1 See table 2 Cut off

Active Cut off Cut off ON

Table 4 Truth Table (4)

POLSEL (D1) Comment

H — Test Mode

Open 1/12 for 8 poles motor

L 1/18 for 12 poles motor

Table 5 Truth Table (5)

Rotation Speed

CNTSEL CNT

H 2605 3,600 rpm

Open 2084 4,500 rpm

L 1736 5,400 rpm

(at CLOCK = 5 MHz)

6

Table 6 Truth Table (6)

RESINH Spindle Driver

H Inhibiting the restart after power down

L Not inhibiting the restart after power down

Table 7 Truth Table (7)

GAIN VCM Driver

H High Gain Mode

L Low Gain Mode

HA13561F

7

HA13561F

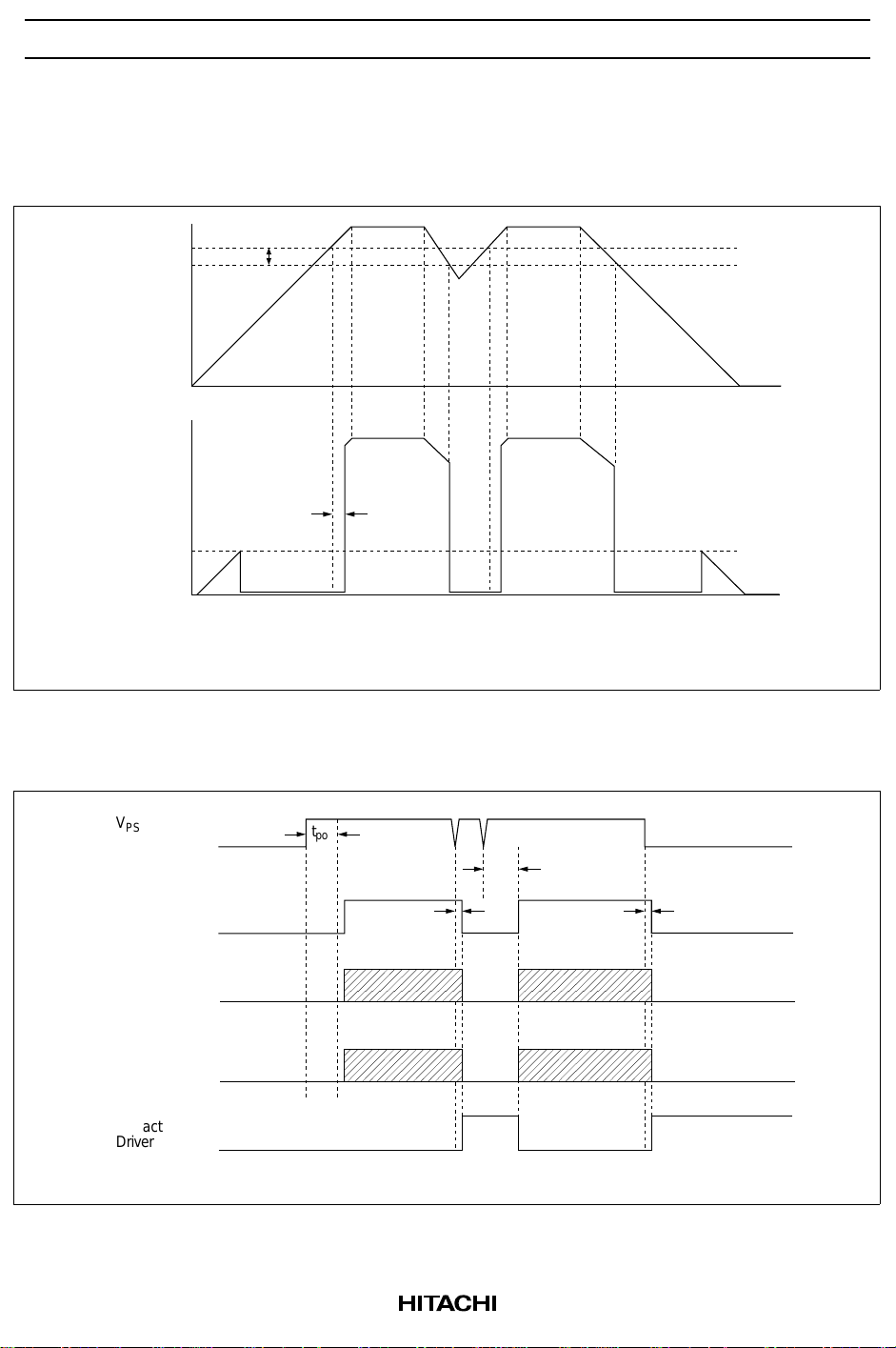

Timing Chart

1. Power on reset (1)

Vsd

Vps and

V

SS

Vhys

t

POR

1.0V

MAX

0

t

DLY

Note: 1. How to determine the threshold Voltage Vsd and the delay time t

external components table.

2. Power on reset (2)

VPS or

V

SS

POR

Spindle

Driver

ON

OFF

t

por

t

por

<1µs <1µs

t

both are shown in the

DLY

VCM

Driver

Retract

Driver

ON

OFF

Note: 2. Retract driver need B-EMF voltage or another power supply.

8

Retract

Loading...

Loading...