Page 1

7 8

Hilti Corporation

LI-9494 Schaan

Tel.:+ 423/ 23421 11

Fax: +423 / 23429 65

www.hilti.com

PD 42

Operating instructions en

Brugsanvisning da

Bruksanvisning sv

Bruksanvisning no

Käyttöohje fi

Инструкция по зксплуатации ru

Lietoßanas pamåcîba lv

Instrukcija lt

Kasutusjuhend et

Hilti = registered trademark of Hilti Corp., Schaan W 3399 0307 00-Pos. 2 1 Printed in Liechtenstein © 2007

Right of technical and programme changes reserved S. E. & O.

320299 / B

*320299*

320299

Page 2

12

6

+Ç34+“+±+≠

+#

+[+{

+]

+|

5798

1

2

1

3

4

5

6

1

2

1

2

3

5 6

4

Page 3

PD 42 laser range meter

It is essential that the operating instructions

are read before the tool is operated for the

first time.

Always keep these operating instructions

together with the tool.

Ensure that the operating instructions are

with the tool when it is given to other

persons.

Contents Page

1. General information 25

2. Description 26

3. Insert tools, accessories 30

4. Technical data 30

5. Safety rules 31

6. Before use 33

7. Operation 37

8. Care and maintenance 44

9. Troubleshooting 45

10. Disposal 46

11. Manufacturer’s warranty ಣ tools 47

12. EC declaration of conformity 47

1. General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that could lead

to serious bodily injury or fatality.

1 These numbers refer to the corresponding illustrations. The illustrations can be found on the foldಣout

cover pages. Keep these pages open while studying

the operating instructions.

In these operating instructions, the designation “the

tool” always refers to the PD 42 laser range meter.

Parts, operating controls and indicators 1

On/off button

@

Side measure button

;

Graphic display

=

Measure button

%

Delete (clear) button

&

Horizontal bubble

(

FNCಣbutton

)

Folding spike

+

{/" thread for PDA 71 measuring extension

§

Rear contact points

/

Minus button

:

Plus button

·

{/" thread on the underside

$

Reference button

£

Optical sight

|

Laser exit lens

¡

Receiving lens

Q

Vertical bubble

W

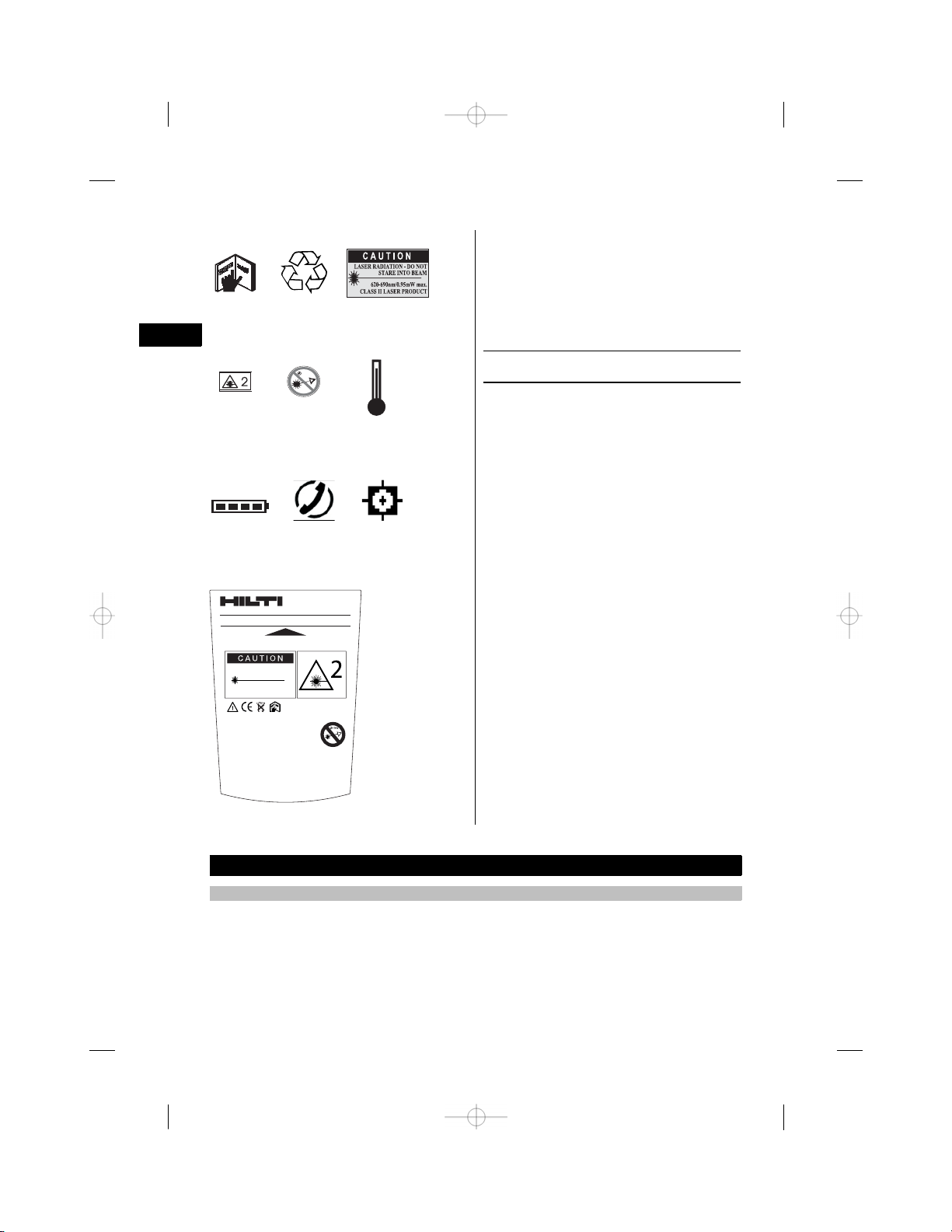

1.2 Explanation of the pictograms and other

information

Warning signs

en

WARNING

Draws attention to a potentially dangerous situation

that could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation

that could lead to slight personal injury or damage to

the equipment or other property.

NOTE

Draws attention to an instruction or other useful

information.

General

warning

25

Page 4

en

Symbols

Read the

operating

instructions

before use.

Return waste

material for

recycling.

Laser class II according

to CFR 21, § 1040 (FDA)

Location of identification data on the tool

The type designation and serial number can be found

on the type identification plate on the tool. Make a

note of this data in your operating instructions and

always refer to it when making an enquiry to your

Hilti representative or service department.

Type:

>1/4s

Laser class 2

in accordance

with

EN 60825ಣ

1:2003

Battery status

indicator

Do not look

into the beam.

Hardware

errors

Type identification plate

AVOID EXPOSURE

DIN EN 60825-1:2003

PD 42

Made in Germany

Hilti = trademark of Hilti Corp., Schaan, LI

Serial number

Laser radiation is emitted from this aperture

LASER RADIATION - DO NOT

STARE INTO BEAM

620-690nm/0.95mW max.

CLASS II LASER PRODUCT

This device complies with part 15 of

the FCC Rules. (1) This device may not

cause harmful interference, and (2) this

device must accept any interference received, including inter-

ference that may cause undesired operation.

Item No.: 30673 Power: 3V nom/400 mA

Manufactured:

PD 42

Temperature

indicator

Unfavorable

operating

conditions

01

Serial no.:

2. Description

2.1 Use of the product as directed

The tool is designed for measuring distances, adding and subtracting distances and offers many practical

functions such as a timer, area and volume measurement, min/max calculation, setting out, painter’s area

measurement, Pythagoras function and data memory.

Do not use the tool as a leveling tool.

Measurements taken from plastic foam materials such as polystyrene foam, from snow or from highly reflective

surfaces (mirrors, glass, etc.) may produce inaccurate results.

26

Page 5

The tool and its ancillary equipment may present hazards when used incorrectly by untrained personnel or

when used not as directed.

Take the influences of the surrounding area into account. Do not use the appliance where there is a risk of fire

or explosion.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

To avoid the risk of injury, use only genuine Hilti accessories and additional equipment.

Modification of the tool is not permissible.

NOTE

Observe the permissible operating and storage temperatures.

2.2 Display

The measurements, settings and tool status are shown in the display. When the tool is in measuring mode,

the measurements taken are shown at the bottom of the display area (the result line). When using a function,

e.g. area measurement, the distances measured are shown in the intermediate result line and the calculated

result is shown at the bottom of the display (the result line).

2.3 Display illumination

In low light conditions, the display is illuminated automatically as soon as a button is pressed. The display

illumination intensity is reduced to 50% after 10 seconds. If no button is pressed over a period of 20 seconds,

the display illumination switches off automatically.

NOTE

Illumination of the display consumes battery power. Shorter battery life is therefore to be expected when this

feature is used frequently.

2.4 Basic principle

The distance is measured along a laser beam emitted by the tool to the point at which the beam strikes

a reflective surface. The target from which the measurement is taken is clearly identified by the red laser

measuring spot. The range of the tool depends on the reflectance and structure of the target surface from

which measurements are taken.

en

2.5 Measuring principle

The tool emits a visible laser beam carrying signal pulses which are reflected by the target. The time between

reflected pulses is used as a basis for determining the distance.

This measuring principle permits highly accurate and reliable measurement of distances to objects without

need for special reflectors.

2.6 Standard measuring display mode

Standard measuring display mode is always activated when the “On/off” or “Measure” button is pressed to

switch the tool on.

27

Page 6

2.7 Symbols in the display

Temperature Temperature too high

Unfavorable operating

conditions

(>+50°C) / too low (<ಣ

10°C).

Insufficient reflected

laser light.

en

General hardware error Switch the tool off and on again. If the fault persists,

2.8 Control panel

Measure button Activates the laser beam.

Plus button Initiates distance, area and volume addition.

Minus button Initiates distance, area and volume subtraction.

FNCಣbutton Always activates the previously used function.

Delete (clear) button

The Cತbutton has various

functions depending on

operating mode.

Allow the tool to cool down or warm up.

Observe the minimum measuring distance (50 mm

from the front edge of the tool); clean the lenses;

take measurements from a different surface or use a

target plate.

please contact Hilti Service.

Begins distance measurement.

Activates continuous measuring mode (long press,

approx. 2 sec.).

Stops continuous measuring mode.

Adds distances in standard measuring and painter’s

measuring modes.

Adds areas and volumes in the relevant modes.

Subtracts distances in standard measuring and

painter measuring modes.

Subtracts areas and volumes in the relevant modes.

Press the button repeatedly to activate or select the

functions one after the other (when no measurements

have been taken).

When measurements have been taken: Deletes all

measurements and restarts the function.

Stops continuous measuring (tracking).

Stops continuous measuring (tracking).

Clears the standard measurement display.

Clears the last measurement and returns to

“Functions”.

Clears data memory (long press when data memory

is displayed).

Ends the function if no measurements have been

taken.

28

Page 7

On/off button When the tool is switched off, press the button

briefly to switch it on.

When the tool is switched off, press and hold the

button to activate the menu.

When the tool is switched on, press the button

briefly to switch it off.

Reference button Switches between the various measuring reference

points (front, tripod thread on the underside, rear).

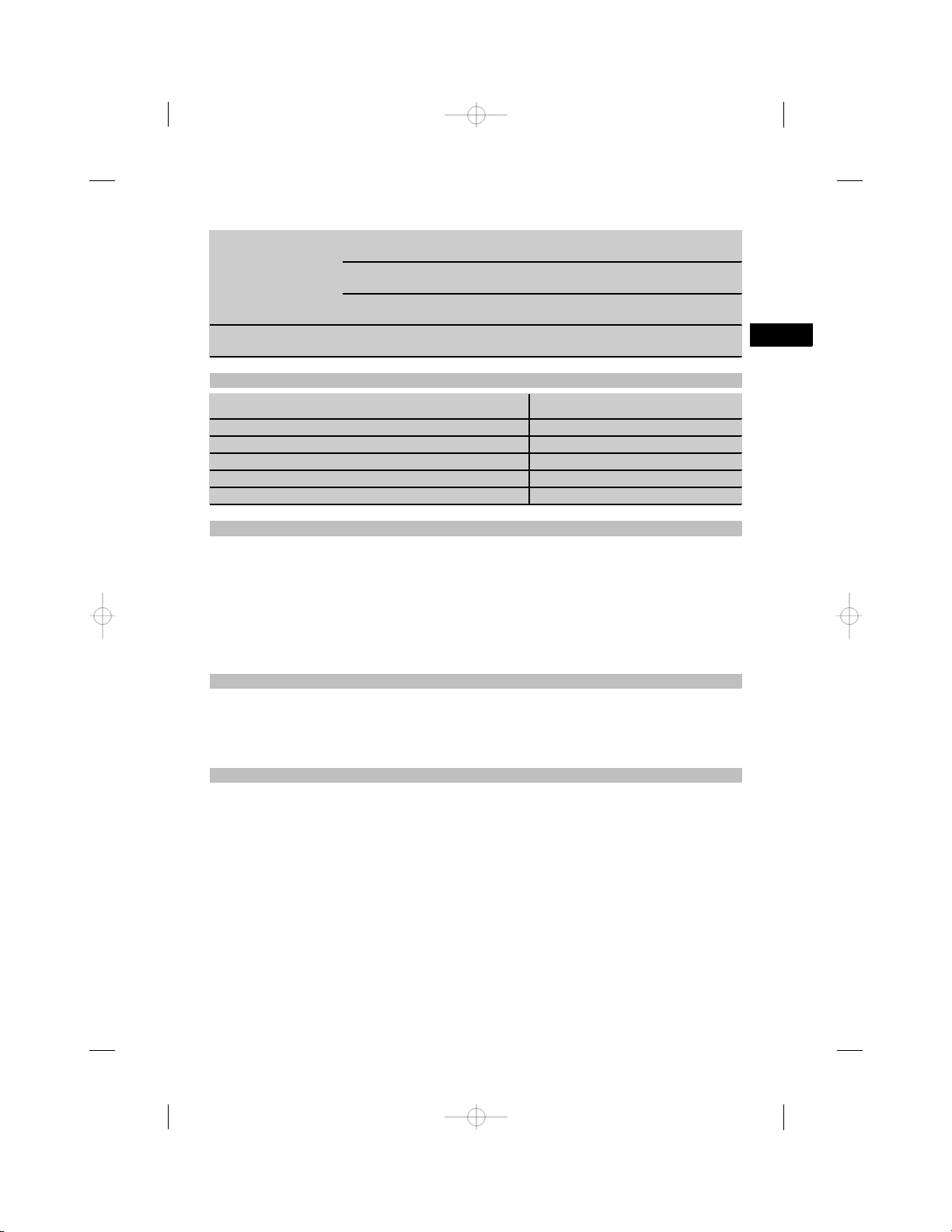

2.9 Battery condition indicator

Number of segments shown Charge status in %

4 = 100 % capacity

3 = 75 % capacity

2 = 50 % capacity

1 = 25 % capacity

0 Fully discharged

2.10 Items supplied as standard

1 PD 42 laser range meter

1 Hand strap

1 PDA 50 target plate

2 Batteries

1 Battery compartment key

1 Operating instructions

1 Manufacturer’s certificate

2.11 PUA 60 laser visibility glasses

The laser visibility glasses have no protective function and thus do not protect the eyes from laser beams. As

these glasses limit color vision they must not be worn by persons driving on a public road and must not be

used to look directly into the sun.

The PUA 60 laser visibility glasses improve laser beam visibility considerably.

en

2.12 PDA 50 / 51 / 52 target plate

The PDA 50 target plate is made of durable plastic with a special reflective coating. Use of the target plate is

recommended at distances greater than 10 m in poor light conditions.

The PDA 51 target plate has no reflective coating and its use is recommended in poor light conditions and at

short distances. The PDA 52 target plate is equipped with the same reflective coating as the PDA 50 but is

considerably larger in size (A4 format, 210 x 297 mm). This makes it much easier to aim the tool at the target

plate over long distances.

NOTE

For reliable distance measurements, care should be taken to ensure that the laser beam strikes the target plate

at right angles as far as possible. The laser spot on the target plate and the measuring reference point (starting

point) may otherwise be in different planes (parallax error).

29

Page 8

NOTE

When the target plate is used and very high accuracy is required, 1.2 mm should be added to the measurement

obtained.

2.13 PDA 71 measuring extension

The measuring extension is made from aluminium and is equipped with a nonಣconductive plastic grip. The

screw on the measuring extension should be screwed into the threaded bush on the rear contact surface of

en

the PD 42. When the measuring extension is screwed onto the tool, the rear reference is then relocated to the

tip of the measuring extension, i.e. the rear reference is extended by 1270 mm (50 inches).

3. Insert tools, accessories

Target plate PDA 50

Target plate PDA 51

Target plate PDA 52

Measuring extension PDA 71

Hand strap PDA 60

Soft pouch

Laser visibility glasses PUA 60

PDA 65

4. Technical data

Right of technical changes reserved.

Technical data Values

Power supply

Battery condition check Battery condition indicator with 4 segments showing

Measuring range 0.05…200 m

Typical measuring range without target plate Drywall panel, white: 100 m

Accuracy

Smallest unit displayed

Beam diameter Beam length 10 m: Max. 6 mm

Basic operating modes

Display Illuminated dotಣmatrix display with permanent

3V DC AAಣsize batteries

100%, 75%, 50%, 25% charge : No segments

shown: The batteries are exhausted

Concrete, dry: 70 m

Brick, dry: 50 m

Typically ±1.0 mm for single and continuous

measurement

1mm

Beam length 50 m: Max. 30 mm

Beam length 100 m: Max. 60 mm

Single measuring, continuous measuring, calculation/functions

indication of operating mode and battery condition

30

Page 9

Technical data Values

Laser

Optical sight Sideಣmounted, with laser reference

Automatic cutಣout Laser: 1 min

Battery life Max. number of measurements with laser

Operating temperature range -10…+50°C

Storage temperature -30…+70°C

Protection class (except battery compartment) IP 54 protection against dust and water jets

Weight without batteries 170 g

Dimensions 120 mm x 55 mm x 28 mm

Menu / units Distance Area Volume

m

cm

mm

In Inches, decimal Inchest Inchesu

In {/೩{/೩ inch Inchest Inchesu

In {/ೢ೧ {/ೢ೧ inch Inchest Inchesu

In {/ೣ {/ೣ inch Inchest Inchesu

Ft Feet, decimal Feett Feetu

Ft {/೩ Feetಣinchesಣ{/೩ Feett Feetu

Ft {/ೢ೧ Feetಣinches

Ft {/ೣ Feetಣinchesಣ{/ೣ Feett Feetu

Yd Yards, decimal Yardst Yardsu

Meters

Centimeters

Millimeters

ಣ{/ೢ೧ Feett Feetu

Visible 635 nm, Output power less than 1 mW: Laser

class 2

IEC 825ತ 1:2003CFR 21 § 1040 (FDA)

Tool: 10 min

beam switched on for a time of 10 s Alkaline 8,000…10,000 NiMH 6,000…8,000

IEC 529

mt mu

mt mu

mt mu

en

5. Safety rules

In addition to the information relevant to safety

given in each of the sections of these operating

instructions, the following points must be strictly

observed at all times.

5.1 Basic information concerning safety

a) Do not render safety devices ineffective and do

not remove information and warning notices.

b) Keep laser tools out of reach of children.

c) Failure to follow the correct procedures when

opening the tool may cause emission of laser

radiation in excess of class 2. Have the tool

repaired only at a Hilti service center.

d) Check that the tool functions correctly each time

before use.

e) Operation of the tool in the proximity of pregnant

women is not permissible.

f) Measurements taken from surfaces with low re-

flectivity in highly reflective surroundings may be

inaccurate.

g) Measurements taken through panes of glass or

other objects may be inaccurate.

h) Rapid changes in the conditions under which

the measurement is taken, e.g. persons walking

through the laser beam, may lead to inaccurate

results.

31

Page 10

i) Do not point the tool toward the sun or other

ಣ

ಣ

powerful light sources.

5.2 Proper organization of the workplace

a) Avoid unfavorable body positions when working

on ladders or scaffolding. Make sure you work

from a safe stance and stay in balance at all

en

times.

b) Check the measuring reference setting before

taking the measurement.

c) When the tool is brought into a warm environ-

ment from very cold conditions, or vice

allow it to become acclimatized before use.

d) As a precaution, check the previous settings and

adjustments you have made.

e) When setting up the tool with the aid of the

bubble level, view the bubble level at a slight

angle.

f) Secure the area in which you are working and

take care to avoid directing the beam towards

other persons or towards yourself when setting

up the tool.

g) Use the tool only within its specified limits.

h) Observe the accident prevention regulations ap-

plicable in your country.

5.3 Electromagnetic compatibility

Although the tool complies with the strict requirements of the applicable directives, Hilti cannot entirely rule out the possibility of the tool being subject

to interference caused by powerful electromagnetic

radiation, leading to incorrect operation. Check the

accuracy of the tool by taking measurements by other

means when working under such conditions or if you

are unsure. Likewise, Hilti cannot rule out the possibility of interference with other devices (e.g. aircraft

navigation equipment). The tool complies with the

requirements of class A; The possibility of interference occurring in a domestic environment cannot be

excluded.

5.4 General safety rules

a) Check the condition of the tool before use. If the

tool is found to be damaged, have it repaired at

a Hilti service center.

versa,

b) The user must check the accuracy of the tool

after it has been dropped or subjected to other

mechanical stresses.

c) Although the tool is designed for the tough con-

ditions of jobsite use, as with other measuring

instruments it should be treated with care.

d) Although the tool is protected to prevent entry

of dampness, it should be wiped dry each time

before being put away in its transport container.

5.5 Electrical

a) Keep the batteries out of reach of children.

b) Do not allow the batteries to overheat and do not

expose them to fire. The batteries may explode or

release toxic substances.

c) Do not charge the batteries.

d) Do not solder the batteries into the tool.

e) Do not discharge the batteries by short

ing. This may cause them to overheat and present

a risk of personal injury (burns).

f) Do not attempt to open the batteries and do not

subject them to excessive mechanical stress.

5.6 Laser classification

Depending on the version purchased, the tool complies with Laser Class 2 in accordance with IEC825ಣ

1:2003 / EN60825ಣ1:2003 and Class II in accordance

with CFR 21 § 1040 (FDA). This tool may be used

without need for further protective measures. The

eyelid closure reflex protects the eyes when a person looks into the beam unintentionally for a brief

moment. This eyelid closure reflex, however, may be

negatively affected by medicines, alcohol or drugs.

Nevertheless, as with the sun, one should not look

directly into sources of bright light. Do not direct the

laser beam toward persons.

5.7 Transport

Always remove the batteries before shipping the

tool.

circuit-

32

Page 11

6. Before use

6.1 Inserting the batteries 2

CAUTION

Do not use damaged batteries.

CAUTION

Always replace the complete set of batteries.

DANGER

Do not mix old and new batteries. Do not mix

batteries of different makes or types.

1. Unscrew the battery compartment cover from the

rear of the tool.

2. Remove the batteries from the packaging and

insert them in the tool.

NOTE Take care to observe correct polarity (see

symbols in battery compartment).

3. Check to ensure that the battery compartment

cover is closed securely.

6.2 Switching the tool on / off

1. The tool can be switched on by pressing either

the “On / off” button or the “Measure” button.

2. When the tool is switched off, press the “On / off”

button: The tool switches on.

The laser beam is switched off.

3. When the tool is switched on, press the “On / off”

button: The tool switches off.

4. Whenthe tool is switched off, press the “Measure”

button: The tool and the laser beam switch on.

6.3 First distance measurements

1. Press the “Measure” button once.

If switched off, the tool will be switched on and

the laser beam activated.

If the tool is already switched on, the laser beam

will be activated.

2. Aim the tool by positioning the visible laser spot

on a white surface at a distance of approx. 3 ಣ 10

m.

3. Press the “Measure” button again.

The distance will be displayed in less than a

second, e.g. 5.489 m.

You have just taken your first measurement with

the tool.

6.4 Settings menu

MENU

m

1. With the tool switched off, press the “On / off”

button for approx. 2 seconds to enter menu mode.

2. Press the “Plus” button to switch the beep signal

on or off.

3. Press the “Minus” button repeatedly to scroll

through the choice of units.

4. Press the “On / off” button briefly to close the

menu.

The tool is switched off and all the settings shown

will be saved.

6.5 Measuring references

NOTE

The tool can take measurements from 5 different

reference (contact) points. The “Reference” button on

the top left on the front of the tool is used to switch

between the front and rear references (front or rear

edge of the tool). The reference is set automatically

to the tip of the spike when the spike is folded

out through 180°. When the measuring extension

is screwed onto the tool at the rear (at the battery

compartment), this is detected automatically by the

tool and indicated by the long extension symbol in the

en

33

Page 12

display. The PDA 71 measuring extension can also be

fitted to the underside of the tool, but is not detected

automatically when in this position.

en

Front edge

Thread on underside

Rear edge

Spike

1. Press the “Measure” button to switch the laser

beam on and then aim the tool at the target.

2. Pressthe “Measure” button or the side “Measure”

button and aim the tool at the target until the laser

spot disappears from the optical sight.

The distance is shown in the display.

6.7 Measuring distances

NOTE

When the spike is folded back in, the measuring

reference is always reset to the rear edge of the tool

irrespective of how far the spike was folded out or to

which point on the tool the measuring reference was

previously set.

Distances can be measured from all stationary targets

without a highly reflective surface, i.e. concrete, stone,

wood, plastic, paper, etc. The use of prisms or other

highly reflective targets is not permissible and, if

attempted, may falsify the results.

6.7.1 Measuring distances step by step

NOTE

The range meter measures distances in a very short

time and simultaneously shows various information

in the display.

Switch the tool on by pressing the “On / off” button.

PDA 71 measuring extension screwed on at the rear

6.6 Optical sight 3

NOTE

The optical sight is useful when measuring distances

greater than 10 meters.

The builtಣin optical sight is particularly helpful outdoors and in situations where the laser spot is otherwise difficult to see or no longer visible. With the aid

of the optical sight, the tool can be aimed accurately

at targets even at great distance. When the tool is

switched on, the laser spot can be seen in the optical

sight. If the laser spot cannot be seen in the optical

sight, either the measurement has been successfully

completed or the laser beam has switched itself off

after the corresponding time interval. The axis of the

optical sight lies parallel to the axis of the laser beam.

34

----------

Press the “Measure” button once. The laser beam is

switched on and is visible in the form of a spot on the

target surface. This aiming mode is indicated in the

display by a blinking laser symbol.

m

Page 13

----------

Aim at the target. Press the “Measure” button once

again to measure the distance. The result usually

appears in the result line in less than a second and

the laser beam then switches off.

5.489

If further measurements are taken, up to three previously determined distances are shown in the intermediate result lines, i.e. a total of the last four measured

distances are shown.

5.489

12.349

m

m

m

m

The tool can, of course, be switched on again at any

time by pressing the “Measure” button. Pressing the

Cಣbutton clears all currently displayed values.

6.7.2 Measuring modes

Distances can be measured using two different measuring modes, i.e. single distance measuring or continuous measuring. Continuous measuring mode is

used for setting out given distances or lengths and

can also be used where distance measurement is

otherwise difficult, e.g. at corners, edges or in niches,

etc.

6.7.2.1 Single distance measuring (“Measure”

button)

1. Switch the laser beam on by pressing the “Measure” button.

2. Press the “Measure” button again.

The measured distance will be shown in the result

line at the bottom of the display in less than a

second.

6.7.2.2 Single distance measuring (“On /off”

button)

1. Switch the laser beam on by pressing the “On /

off” button.

2. Press the “Measure” button to switch the laser

beam on and then aim the tool at the target.

3. Press the “Measure” button again.

The measured distance will be shown in the result

line at the bottom of the display in less than a

second.

6.7.2.3 Continuous measuring (tracking)

NOTE

Continuous measuring is possible in all situations

where individual distances can be measured. This

applies also to functions, such as areas.

en

24.634

27.317

m

m

35

Page 14

1. Press the “Measure” button for about 2 seconds

to activate the continuous measuring mode.

NOTE When doing so, it doesn’t matter whether

the tool or the laser beam is switched on or

off. The tool will always switch to continuous

measuring mode.

During continuous measuring, distances are up-

en

dated in the result line at the rate of approx. 6 ಣ

10 measurements every second. The measuring

rate depends on reflectivity of the target surface.

If the beep signal is active, continuous measuring

is indicated by a beep signal approx. 2 ಣ 3 times

per second.

2. Measuring is stopped by pressing the “Measure”

button once again.

The last valid measurement is then shown in the

result line in the display.

6.7.3 Measuring from corners 45

The spike is used when measuring diagonally across

rooms or from inaccessible corners.

1. Fold out the spike through 180°.

The measuring reference is then set automatically

to the end of the spike. The range meter takes

the extended reference point into account and

corrects the measured distances accordingly.

2. Position the range meter with the spike at the

desired starting point for the measurement and

aim toward the target.

3. Press the “Measure” button.

The measured distance is shown in the display.

6.7.4 Measuring with the aid of target

objects 67

When taking measurements to outside corners (e.g.

on outside walls of buildings, perimeter fences, etc.),

boards, bricks or other suitable objects can be held

against the corner and used as the target. Use of

the PDA 50, PDA 51 or PDA 52 target plate is

recommended for long distances and in unfavorable

light conditions, e.g. in strong sunlight.

6.7.5 Measuring in bright conditions

We recommend use of the PDA 50, PDA 51 or PDA 52

target plate for long distances and in very bright light

conditions.

6.7.6 Taking measurements to rough surfaces 8

When measuring to rough surfaces, e.g. rough plaster

etc., an average distance value is measured with the

center of the laser spot weighted higher than the

edges of the laser spot.

6.7.7 Taking measurements to curved or

inclined surfaces

If the laser beam strikes the target surface at a very

narrow angle, the light reflected may be inadequate.

Conversely, too much light may be reflected toward

the tool in situations where the laser beam strikes

the target perpendicularly. We recommend use of the

PDA 50, PDA 51 or PDA 52 target plate in both of

these situations.

6.7.8 Taking measurements to wet or shiny

surfaces

As long as the range meter can be aimed directly at

the surface, the distance to the target will be reliably

measured. With highly reflective surfaces, a reduction

in range must be expected and the distance to the

actual point of reflection may be measured.

6.7.9 Taking measurements to transparent

surfaces

It is generally possible to measure distances to transparent or semiಣtransparent materials, e.g. liquids,

polystyrene foam, etc. Light penetrates these materials, however, and measuring errors may therefore

occur. Measuring errors may also occur when measurements are taken through glass or if objects are

present within the line of the laser beam.

6.7.10 Measuring range

6.7.10.1 Increased range

The range of the tool is generally increased when

measurements are taken in the dark, at dawn or dusk

and when the target and/or the tool is shaded from

bright light.

Use of the PDA 50, PDA 51 or PDA 52 target plate

also increases the range of the tool.

6.7.10.2 Reduced measuring range

Measuring range may be reduced in bright conditions,

e.g. in bright sunlight or when working under very

powerful floodlights.

The range of the tool may be reduced when measurements are taken through glass or when objects lie

within the path of the laser beam.

The range of the tool may be reduced when measurements are taken to mat green, blue or black surfaces

or to wet or shiny surfaces.

36

Page 15

7. Operation

NOTE

The direct control buttons are used for adding and

subtracting distances. All other functions are activated

by pressing the FNCಣbutton.

7.1 Distance measurements

NOTE

With all functions of the tool, each step in the operation is always indicated in the display.

NOTE

Continuous measuring mode can be used with all

functions in which individual distance measurement

is possible.

NOTE

If measuring errors occur during continuous measuring, and continuous measuring mode is canceled

by pressing the “Measure” button again, the last valid

measurement will be displayed.

7.2 Adding distances

1. Press the “Measure” button (the laser beam will

switch on).

2. Aim the range meter at the target.

3. Press the “Measure” button.

The first distance will be measured and displayed

(the laser then switches off).

4. Press the “Plus” button. The first distance is then

displayed in the middle result line and a plus sign

appears in the lower (intermediate) result line (the

laser beam switches on).

5. Aim the range meter at the target.

6. Press the “Measure” button.

The second distance is then measured and displayed in the lower (intermediate) result line. The

result of the addition is shown in the result line.

The current total of the distances is always shown

in the result line.

The procedure can be repeated until all distances

have been added.

7. To terminate the addition of distances, simply

measure a distance without first pressing the

“Plus” button.

All previous measuring and calculation results are

shown in the intermediate results lines.

8. Press the Cಣbutton to clear the display.

7.3 Subtracting distances

en

12.349

+ 5.489

17.838

Individual distances can be conveniently added. This

is useful, for example, for determining the total length

of the inner face of door or window openings or

for adding several individual distances that form a

perimeter.

m

m

m

3.947

- 3.322

0.625

Individual distances can be conveniently subtracted

from each other, e.g. in order to determine the distance between the underside of a pipe and the ceiling.

m

m

m

37

Page 16

This can be done by subtracting the distance between

the floor and the underside of the pipe from the

distance between the floor and the ceiling. If the

pipe diameter is subtracted, the result is the distance

between the top of the pipe and the ceiling.

1. Press the “Measure” button (the laser beam

switches on).

en

2. Aim the range meter at the target.

3. Press the “Measure” button. The first distance

will be measured and displayed (the laser then

switches off).

4. Press the “Minus” button. The first distance is

then displayed in the middle result line and a

minus sign appears in the lower (intermediate)

result line (the laser beam switches on).

5. Aim the range meter at the target.

6. Press the “Measure” button.

The second distance is then measured and displayed in the lower (intermediate) result line.

The result of the subtraction is shown in the result

line.

The current difference in distance is always shown

in the result line.

The procedure can be repeated until all distances

have been subtracted.

7. To terminate the subtraction of distances, simply

measure a distance without first pressing the

“Minus” button.

All previous measuring and calculation results are

shown in the intermediate results lines.

8. Press the Cಣbutton to clear the display.

7.4 Timer

10s

4.347

m

button. A beep sound is emitted every second up to

about 4 seconds before the timer triggers the tool.

The last 4 seconds are counted down by a double

beep every second.

7.5 Measuring areas

m

5.489

5.489

12.349

12.349

67.784

67.784

Each step of the area measurement operation is

indicated graphically in the display. For example,

to determine the floor area of a room, proceed as

follows:

1. Pressthe FNCಣbutton to activate the area function.

NOTE When the area function is activated, the

laser beam is already switched on.

2. Aim the range meter at the target.

3. Press the “Measure” button.

The width of the room is measured and the value

displayed.

The graphic display automatically prompts you to

measure the length of the room.

4. Aim the tool at the next target to obtain the length

of the room.

5. Press the “Measure” button.

The second distance is then measured, the area

calculated immediately and the result is displayed

in the result line.

Both distances used for the area calculation are

shown in the intermediate result lines and can

be noted down conveniently at the end of the

operation.

m

m

m

m

m

3

2

The timer function works like the selfಣtimer on a

camera. The “Plus” and “Minus” buttons can be used

to adjust the timer interval to one of the three settings:

5, 10 or 20 seconds. To activate the timer, press the

“Measure” button. To stop the timer, press the Cಣ

38

Page 17

6. The Cಣbutton can be pressed at any time to

stop the measuring operation. Each measurement

can then be cleared, one after the other, and

measuring restarted.

NOTE If the Cಣbutton is pressed several times

or the FNCಣbutton is pressed, the function will be

canceled or, respectively, restarted.

NOTE If the second distance is measured using

continuous measuring mode (tracking), the result

of the area calculation is updated continuously.

This allows parts of the area to be included/

excluded.

NOTE After calculation of an area, the “Plus”

button can be pressed to add another area or,

respectively, the “Minus” button used to subtract

an area.

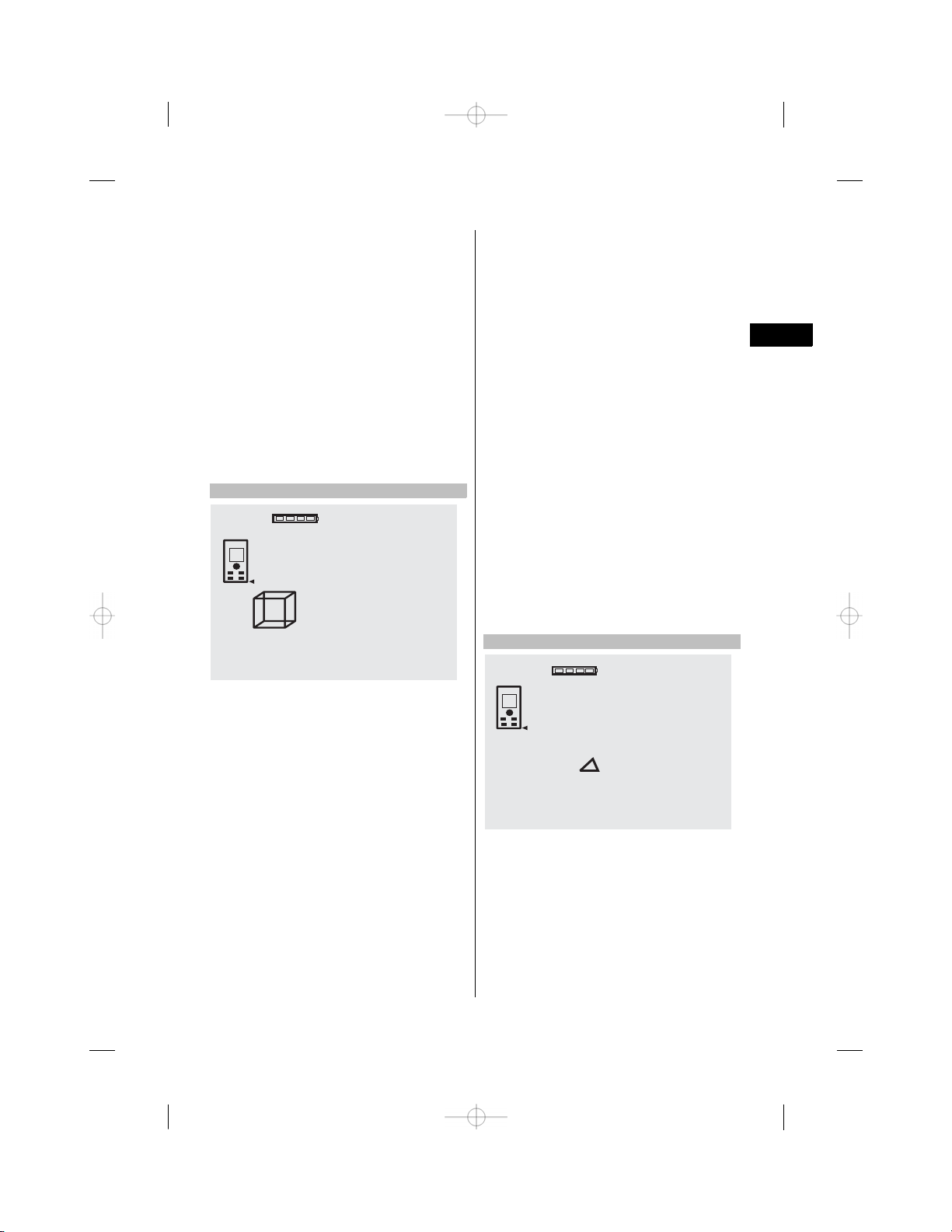

7.6 Measuring volumes

5.489

12.349

24.634

m

m

m

8. Aim the tool at the next target to obtain the height

of the room.

9. Press the “Measure” button.

The volume is calculated and shown in the result

line in the display as soon as the height of the

room has been measured.

All three distances used for the volume calculation

are shown in the intermediate result lines and can

be noted down conveniently at the end of the

operation.

10. The Cಣbutton can be pressed at any time to

stop the measuring operation. Each measurement

can then be cleared, one after the other, and

measuring restarted.

NOTE If the Cಣbutton is pressed several times

or the FNCಣbutton is pressed, the function will be

canceled or, respectively, restarted.

NOTE If the third distance is measured using

continuous measuring mode (tracking), the result

of the volume calculation is updated continuously.

This allows parts of the volume to be included/

excluded.

NOTE After calculation of a volume, the “Plus”

button can be pressed to add another volume or,

respectively, the “Minus” button used to subtract

a volume.

en

3

1669.783

Each step of the volume measurement operation is

indicated graphically in the display. For example, to

determine the volume of a room, proceed as follows:

1. Press the FNCಣbutton to activate the volume function. A volume can be determined in a single

measuring operation.

NOTE When the volume function is activated, the

laser beam is already switched on.

2. Aim the range meter at the target.

3. Press the “Measure” button.

The width of the room is measured and the value

displayed.

4. The graphic display automatically prompts you to

measure the length of the room.

5. Aim the tool at the next target to obtain the length

of the room.

6. Press the “Measure” button.

The length of the room is measured and the value

displayed.

7. Press the “Measure” button.

m

7.7 Measuring using the “Min/max” function

MAX 8.642

MIN 5.123

3.519

4.347

The “Maximum” function is used mainly to determine

the length of diagonals, while the “Minimum” function

is used to check parallels and set up objects parallel

to each other, or to take measurements in situations

where access is difficult. The “Maximum” function

makes use of continuous measuring mode. The value

shown in the display is updated whenever the measured distance increases. The “Minimum” function

also makes use of continuous measuring mode. The

value shown in the display is updated whenever

m

m

m

m

39

Page 18

the measured distance decreases. By combining the

“Maximum” and “Minimum” functions, differences in

distance can be determined very quickly, easily and

reliably. The distance between a pipe and ceiling, or

the distance between two objects even in inaccessible

locations, can thus be easily and reliably determined.

1. Press the FNCಣbutton to activate the “Min/max”

en

function.

NOTE When the “Min/max” function is activated,

the laser beam is already switched on.

2. Aim the range meter at the target.

3. Press the “Measure” button.

Continuous measuring then begins.

The values shown in the MIN and MAX display

areas are then updated whenever the measured

distance increases or decreases.

4. Press the “Measure” button to stop measuring.

The maximum distance, minimum distance and

the difference between minimum and maximum

are then shown in the display.

5. The Cಣbutton can be pressed at any time to stop

the last measuring operation, clear the result and

restart measuring.

NOTE If the Cಣbutton is pressed several times

or the FNCಣbutton is pressed, the function will be

canceled or, respectively, restarted.

NOTE Further “Undo” steps are not possible.

If the Cಣbutton is pressed several times or the

FNCಣbutton pressed once, the function will be

canceled.

7.8 Measuring / setting out

5.123

+ 3.519

1.604

The tool can be used to indicate given distances, e.g.

when setting out and marking the position of drywall

framing.

7.8.1 Setting out using a measured distance

1. Press the FNCಣbutton to activate the “Setting out”

function.

NOTE When the “Setting out” function is activated, the laser beam is already switched on.

2. Aim the range meter at the target.

3. Press the “Measure” button.

The initial distance, i.e. the distance to be transferred, is then measured and shown in the uppermost intermediate result line.

4. Press the “Measure” button.

The tool begins measuring in continuous measuring mode.

The difference between the currently measured

distance (see result line) and the initial distance

is shown in the lowest intermediate result line.

5. Move the tool back and forth until the difference

shown is as close to zero as is required for your

purpose.

6. The Cಣbutton can be pressed at any time to stop

the last measuring operation, clear the result and

restart measuring.

NOTE Further “Undo” steps are not possible.

If the Cಣbutton is pressed several times or the

FNCಣbutton pressed once, the function will be

canceled.

7.8.2 Setting out given distances

1. Press the FNCಣbutton to activate the “Setting out”

function.

NOTE When the “Setting out” function is activated, the laser beam is already switched on.

2. Enter the initial distance by pressing the “Plus”

button.

m

m

m

NOTE Pressing the “Plus” button briefly causes

the last digit to change (increase) by 1. Pressing

and holding the “Plus” button causes the digits to

change at a faster rate. The longer the button is

pressed, the faster the digits change. The “Minus”

button functions in the same way as the “Plus”

button, except that the digits decrease.

3. Press the “Measure” button.

The tool begins measuring in continuous measuring mode.

The difference between the currently measured

distance (see result line) and the initial distance

is shown in the lowest intermediate result line.

40

Page 19

4. Move the tool back and forth until the difference

shown is as close to zero as is required for your

purpose.

5. The Cಣbutton can be pressed at any time to stop

the last measuring operation, clear the result and

restart measuring.

NOTE Further “Undo” steps are not possible.

If the Cಣbutton is pressed several times or the

FNCಣbutton pressed once, the function will be

canceled.

7.9 Painter’s area

+

27.317

5.489

12.349+

m

m

m

2

6. Once all wall lengths have been added together,

press the “Measure” button again after taking

the last measurement and when the total of all

measurements is shown in the result line at the

bottom of the display.

The total length is transferred to the top intermediate result line and a multiplication symbol is

shown in the line below.

7. Now measure the height of the walls (= height of

the room).

The total wall area of the room is shown in the

result line at the bottom of the display.

8. The Cಣbutton can be pressed at any time to stop

the last measuring operation, clear the result and

restart measuring.

NOTE Further “Undo” steps are not possible.

If the Cಣbutton is pressed several times or the

FNCಣbutton pressed once, the function will be

canceled.

NOTE The “Minus” button can be used to subtract

certain distances, e.g. dimensions of windows or

doors. The “Plus” and “Minus” buttons can be

used alternately at any time.

en

The painter’s area function is used, for example, to

determine the surface area of the walls in a room.

This is done by determining the total length of all

walls and multiplying this figure by the height of the

room.

1. Press the FNCಣbutton to activate the painter’s area

function.

NOTE When the painter’s area function is activated, the laser beam is already switched on.

2. Measure the length of the first wall.

The length is shown in the top intermediate result

line.

3. Press the “Plus” button and measure the next

length.

The sum of the two lengths is shown in the results

line.

4. Press the “Plus” button again to make the tool

ready to measure the next length.

The total length is then displayed in the top

intermediate result line.

5. Measure the third length and, if necessary, any

further lengths.

7.10 Indirect measurements

A distance can be measured indirectly by taking

several measurements and the result then calculated

using the Pythagoras rule. The indirect measurement

functions are accessed by pressing the FNCಣbutton.

Three functions are available for use:

The “Single Pythagoras” function using a triangle with

two measured distances.

The “Double Pythagoras” function with 2 adjoining

triangles.

The “Combined Pythagoras” function using 2 part

triangles.

NOTE

A reduced level of accuracy, much lower than the

level of accuracy of the tool itself, must generally

be expected when the indirect measuring method is

used. In order to obtain the best results, care must

be taken regarding the geometry of the situation (i.e.

right angles and triangle relationships). Best results

are obtained when the tool is aimed carefully at the

corners of the object, when all points are within the

41

Page 20

same plane and when the measurements are taken

from a location not too far away from the object.

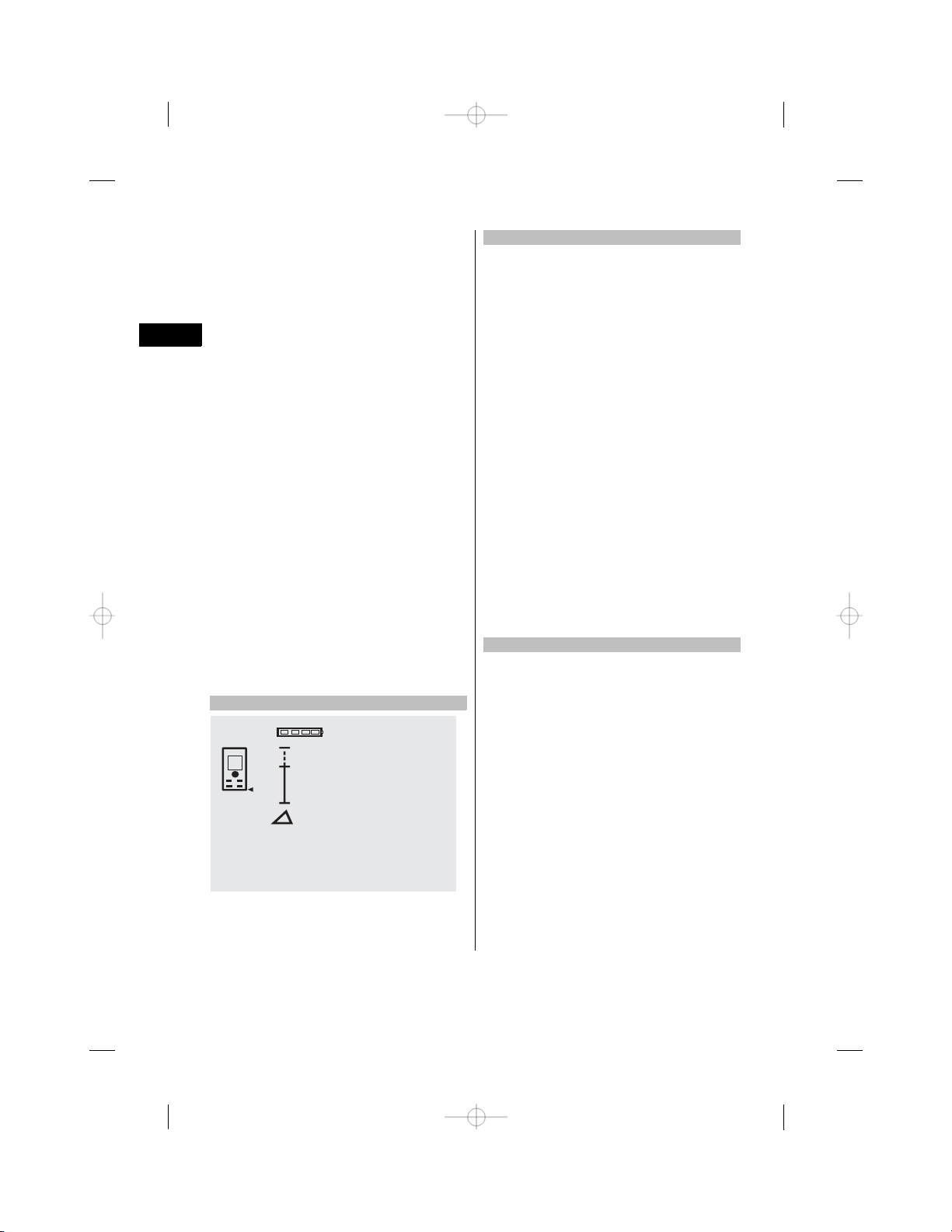

7.10.1 The “Single Pythagoras” method

en

8.642

5.123

7.10.2 The “Double Pythagoras” method

8.642

m

m

5.123

5.430

m

m

m

6.962

Follow the symbols in the display. The blinking side

of the triangle indicates the measurement to be taken.

When the 2 required distances have been measured,

the result is then calculated and shown in the result

line in the lower area of the display.

1. Press the FNCಣbutton to activate the “Single Pythagoras” function.

NOTE When the “Single Pythagoras” function is

activated, the laser beam is already switched on.

2. Aim the tool at the target as indicated by the

symbol in the display.

Press the “Measure” button.

3. The graphic display automatically prompts you to

measure the shorter distance.

4. Aim the laser spot at the target and press the

“Measure” button.

NOTE Please note that this distance is measured

in continuous measuring mode in order to ensure

that the shortest distance to the target (at right

angles) is measured reliably.

When the second measurement has been taken,

the tool then immediately calculates the opposite

“indirect distance”.

The system checks whether the geometric relationship allows a result to be calculated. An

invalid result, due to inappropriate geometry, is

indicated by the result line blinking (broken line).

In this case, one or both of the distances must be

remeasured.

m

8.76

Follow the symbols in the display. The blinking side

of the triangle indicates the measurement to be taken.

When the 3 required distances have been measured,

the result is then calculated and shown in the result

line at the bottom of the display.

1. Press the FNCಣbutton to activate the “Double

Pythagoras” function.

NOTE When the “Double Pythagoras” function is

activated, the laser beam is already switched on.

2. Aim the tool at the target as indicated by the

symbol in the display.

Press the “Measure” button.

3. The graphic display automatically prompts you to

measure the middle distance.

NOTE Please note that this distance is measured

in continuous measuring mode in order to ensure

that the shortest distance to the target (at right

angles) is measured reliably.

4. Sweep the laser spot slowly over the target at the

point where the distance is shortest and then stop

measuring by pressing the “Measure” button.

After the last distance has been measured, the

tool immediately calculates the opposite “indirect

distance”.

The system checks whether the geometric relationship allows a result to be calculated. An

invalid result, due to inappropriate geometry, is

indicated by the result line blinking (broken line).

In this case, one or more of the distances must

be remeasured.

m

42

Page 21

7.10.3 The “Combined Pythagoras” method

7.11 Saving the current measurement

7.823

4.762

3.894

4.044

Follow the symbols in the display. The blinking side

of the triangle indicates the measurement to be taken.

When the 3 required distances have been measured,

the result is then calculated and shown in the result

line at the bottom of the display.

1. Press the FNCಣbutton to activate the “Combined

Pythagoras” function.

NOTE When the “Combined Pythagoras” function

is activated, the laser beam is already switched

on.

2. Aim the tool at the target as indicated by the

symbol in the display.

Press the “Measure” button.

3. The graphic display automatically prompts you to

measure the middle distance.

4. The graphic display prompts you to measure the

last distance.

NOTE Please note that this distance is measured

in continuous measuring mode in order to ensure

that the shortest distance to the target (at right

angles) is measured reliably.

After the last distance has been measured, the

tool immediately calculates the opposite “indirect

distance”.

The system checks whether the geometric relationship allows a result to be calculated. An

invalid result, due to inappropriate geometry, is

indicated by the result line blinking (broken line).

In this case, one or more of the distances must

be remeasured.

m

m

m

m

5.489

12.349

24.634

27.317

If several distance measurements have been taken,

up to 3 previous measurements are shown in the

intermediate result lines in the standard display, i.e.

in total, the 4 previous measurements are shown and

saved. The last measurement taken is shown in the

lowest line of the display.

7.12 Data memory

+

5.489

12.349+

m

m

m

m

m

m

M

4

27.317

The tool saves measurements and the results of

calculations continuously while in operation. A total

of up to 30 values, including graphic symbols, are

saved in this way. The complete set of information

displayed is saved in the following situations:

A function provides a valid result when:

m

2

en

43

Page 22

A valid distance is measured and shown in the standard display:

Distances are added using the “Plus” button – the

last total is saved in each case.

Distances are subtracted using the “Minus” button –

the last total is saved in each case.

NOTE

en

When data memory is already filled with the 30

previous sets of displayed data, the “oldest” set of

data is deleted when a new set of displayed data is

saved.

7.12.1 Clearing data memory

Data memory can be completely cleared by pressing

the Cಣbutton for approx. 2 seconds while data memory

is displayed.

---------

---------

M

---------

m

m

m

1

---------

m

8. Care and maintenance

8.1 Cleaning and drying

1. Blow dust off the lenses.

2. Do not touch the glass or the filter with the fingers.

3. Use only a clean, soft cloth for cleaning. If necessary, moisten the cloth slightly with pure alcohol

or a little water.

NOTE Do not use any other liquids as these may

damage the plastic components.

4. The temperature limits for storage of your equipment must be observed, especially in winter /

summer.

8.2 Storage

Remove the tool from its case if it has become wet.

The tool, its carrying case and accessories should

be cleaned and dried (at maximum 40°C / 104°F).

Repack the equipment only once it is completely dry.

Check the accuracy of the equipment before it is used

after a long period of storage or transportation.

Remove the batteries from the tool before storing it

for a long period. Leaking batteries may damage the

tool.

8.3 Transport

Use the Hilti toolbox or packaging of equivalent quality

for transporting or shipping your equipment.

CAUTION

Always remove the batteries before shipping the

tool.

8.4 Calibration and adjustment

8.4.1 Calibration

Monitoring of measuring equipment for users certified in accordance with ISO 9000X: As specified

in ISO 900X, you may carry out the inspection and

testing of the PD 42 laser range meter yourself (see

ISO 17123ಣ4: Field Process for Accuracy Examination

44

Page 23

of Geodetic Instruments: Part 6, Closeಣrange Optoಣ

electrical Range Meters).

1. Select a readily accessible measuring distance of

a known length (approx. 1 to 5 meters / 3 to

15 feet) which does not change over time and

measure the same distance 10 times.

2. Determine the mean deviation from the known

distance. This value should be within the specified

accuracy tolerance for the tool.

3. Keep a record of this value and note the date when

the next test is due.

Repeat this test at regular intervals as well as

before and after important measuring tasks.

Apply a test and inspection confirmation sticker

to the PD 42 and keep a record of the entire

monitoring, test and inspection procedure and

the results.

Please refer to the technical data contained in

the operating instructions and the information

concerning measuring accuracy.

8.4.2 Adjustment

To ensure that the laser range meter is adjusted

correctly, we recommend that it is returned to a Hilti

Service Center for calibration. Accurate adjustment of

the tool will be confirmed by a calibration certificate.

8.4.3 Hilti calibration service

We recommend that the tool is checked by the Hilti

calibration service at regular intervals in order to

verify its reliability in accordance with standards and

legal requirements.

Use can be made of the Hilti calibration service

at any time, but checking at least once a year is

recommended.

The calibration service provides confirmation that the

tool is in conformance, on the day it is tested, with

the specifications given in the operating instructions.

The tool will be readjusted if deviations from the

manufacturer’s specification are found. After checking and adjustment, a calibration sticker applied to

the tool and a calibration certificate provide written

verification that the tool operates in accordance with

the manufacturer’s specification.

Calibration certificates are always required by companies certified according to ISO 900x.

Your local Hilti Center or representative will be pleased

to provide further information.

9. Troubleshooting

Fault Possible cause Remedy

The tool can’t be switched on.

No distances displayed by the

tool.

Frequent error messages or

the tool doesn’t measure.

Measuring reference not set

to the spike.

The batteries are exhausted. Replace the batteries.

Incorrect battery polarity. Insert the batteries correctly and

The button is faulty. Return the tool to Hilti for repair.

“Measure” button was not pressed. Press the “Measure” button.

Faulty display.

The target surface is too brightly lit

by the sun.

The target surface is too shiny. Take measurements from less shiny

The target surface is too dark.

Bright sunlight towards the tool. Use the PDA 50/ PDA 51/ PDA 52

The spike is not folded out fully. Fold the spike out fully.

The spike is faulty. Return the tool to Hilti for repair.

close the battery compartment

cover.

Return the tool to Hilti for repair.

Measure from the other direction –

sun from behind.

surfaces.

Use the PDA 50/ PDA 51/ PDA 52

target plate.

target plate.

en

45

Page 24

Fault Possible cause Remedy

Measuring reference not set

to the extension.

No result obtained using

en

Pythagoras function.

No result obtained using

functions.

The measuring extension is not

screwed in fully.

Dirt or foreign matter in the threaded

bush.

A distance is missing. Measure the missing distance(s).

The difference between the dis-

tances is insufficient.

The result cannot be calculated

(geometry incorrect).

Distance measurements are missing.

Numerical value of the result is too

high (cannot be displayed).

Screw the measuring extension in

fully.

Clean the threaded bush.

The distance to be calculated should

be greater than {/ of the distances

measured.

Move as close as possible to the

object to be measured. Triangles

are possibly too small.

Measure the missing distance(s).

Change to a larger unit.

10. Disposal

WARNING

Improper disposal of the equipment may have serious consequences:

The burning of plastic components generates toxic fumes which may present a health hazard.

Batteries may explode if damaged or exposed to very high temperatures, causing poisoning, burns, acid burns

or environmental pollution.

Careless disposal may permit unauthorized and improper use of the equipment. This may result in serious

personal injury, injury to third parties and pollution of the environment.

Most of the materials from which Hilti tools or appliances are manufactured can be recycled. The materials must

be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements

for taking back old tools and appliances for recycling. Ask Hilti customer service or your Hilti representative

for further information.

For EC countries only

Disposal of electric tools together with household waste is not permissible.

In observance of European Directive 2002/96/EC on waste electrical and electronic equipment

and its implementation in accordance with national law, electric tools that have reached the end

of their life must be collected separately and returned to an environmentally compatible recycling

facility.

Dispose of the batteries in accordance with national regulations.

46

Page 25

11. Manufacturer’s warrantyಣtools

Hilti warrants that the tool supplied is free of defects

in material and workmanship. This warranty is valid

so long as the tool is operated and handled correctly,

cleaned and serviced properly and in accordance with

the Hilti Operating Instructions, and the technical

system is maintained. This means that only original

Hilti consumables, components and spare parts may

be used in the tool.

This warranty provides the freeಣofಣcharge repair or

replacement of defective parts only over the entire

lifespan of the tool. Parts requiring repair or replacement as a result of normal wear and tear are not

covered by this warranty.

12. EC declaration of conformity

Designation: Laser range meter

Type: PD 42

Year of design:

We declare, on our sole responsibility, that this

product complies with the following directives and

standards: EN 50081ತ1, EN 61000ತ6ತ2, 89/336/EEC.

2006

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental

or consequential damages, losses or expenses in

connection with, or by reason of, the use of, or

inability to use the tool for any purpose. Implied

warranties of merchantability or fitness for a particular purpose are specifically excluded.

For repair or replacement, send the tool or related

parts immediately upon discovery of the defect to

the address of the local Hilti marketing organization

provided.

This constitutes Hilti’s entire obligation with regard

to warranty and supersedes all prior or contemporaneous comments and oral or written agreements

concerning warranties.

Hilti Corporation

Bodo Baur Tassilo Deinzer

Quality Manager Head BU Measuring Systems

BA Electric Tools & Accessories BU Measuring Systems

01 2007 01 2007

en

47

Loading...

Loading...