Henny Penny SCR-6, SCR-8 General Manual

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT: Any part of a new appliance, except lamps and fuses, which proves to be defective

in material or workmanship within two (2) years from date of original installation, will be repaired or replaced

without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To validate this warranty, the

registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

REPLACEMENT PARTS: Any appliance replacement part, except lamps and fuses, which proves to be

defective in material or workmanship within ninety (90) days from date of original installation will be repaired

or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new

frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to install

the new frypot as well as the cost of any other parts replaced, such as insulation, thermal sensors,

high limits, fittings, and hardware, will be the responsibility of the owner.

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If

damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse;

(b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED. HENNY

PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Henny Penny SCR-6/8

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ..................................................................................................... 1-1

1-1 Henny Penny Rotisserie ................................................................................. 1-1

1-2 Features .......................................................................................................... 1-1

1-3 Assistance ...................................................................................................... 1-1

1-4 Safety ............................................................................................................. 1-2

1-5 Proper Care .................................................................................................... 1-2

Section 2. INSTALLATION ...................................................................................................... 2-1

2-1 Introduction .................................................................................................... 2-1

2-2 Location ......................................................................................................... 2-1

2-3 Stacking Instuctions ....................................................................................... 2-2

2-4 Unpacking ...................................................................................................... 2-3

2-5 Leveling of Unit ............................................................................................. 2-4

2-6 Electrical Requirements .................................................................................2-4

Section 3. OPERATION ............................................................................................................ 3-1

3-1 Introduction .................................................................................................... 3-1

3-2 Controls and Switches.................................................................................... 3-1

3-3 Installation of Discs, Rods, and Spits ............................................................ 3-5

3-4 Procedure for Angled Spits............................................................................ 3-6

3-5 Procedure for Meat Forks or Spits ................................................................ 3-6

3-6 Use of Optional Accessories .......................................................................... 3-7

3-7 Program Mode Operation .............................................................................. 3-7

3-8 Preheat Control .............................................................................................. 3-8

3-9 Cooking Control............................................................................................. 3-8

3-10 Door Switch ................................................................................................... 3-8

3-11 Hold Control .................................................................................................. 3-8

3-12 Cleaning Procedures ...................................................................................... 3-9

Section 4. PROGRAMMING..................................................................................................... 4-1

4-1 Introduction .................................................................................................... 4-1

4-2 Programming for Cook and Hold .................................................................. 4-1

4-3 Special Programming Mode .......................................................................... 4-3

4-4 Tech Mode.....................................................................................................4-5

Section 5. COOKING PROCEDURES .................................................................................... 5-1

5-1 Program Cook Parameters ............................................................................. 5-1

5-2 Loading the Rotisserie ................................................................................... 5-1

5-3 Removing Spits from the Rotisserie .............................................................. 5-1

5-4 Removing Cooked Meat from Spits .............................................................. 5-1

5-5 Seasonings and Barbecue Sauce .................................................................... 5-2

5-6 Basic Rules of Safe Food Preperation ........................................................... 5-2

5-7 Minimum Temperature Requirements for Hot and Cold Food Storage ........ 5-3

5-8 Testing for Doneness ..................................................................................... 5-3

5-9 Basic Cooking Procedures ............................................................................. 5-4

5-10 Cooking Guidlines ......................................................................................... 5-5

698 i

Henny Penny SCR-6/8

TABLE OF CONTENTS

Section Page

Section 6. TROUBLESHOOTING ............................................................................................ 6-1

6-1 Introduction .................................................................................................... 6-1

6-2 Troubleshooting ............................................................................................. 6-1

Error Codes ................................................................................................... 6-3

Section 7. MAINTENANCE ...................................................................................................... 7-1

7-1 Introduction .................................................................................................... 7-1

7-2 Maintenance Hints ......................................................................................... 7-1

7-3 Halogen Lamp Replacement .......................................................................... 7-1

7-4 Blower Replacement ...................................................................................... 7-2

7-5 Thermal Sensor Replacement ........................................................................ 7-3

7-6 Contactor ........................................................................................................ 7-4

7-7 Drive Motor Replacement ............................................................................. 7-5

7-8 Rotation Control Switch ................................................................................ 7-6

7-9 Capacitor Replacement - Blower Motor ........................................................ 7-7

7-10 Capacitor Replacement - Drive Motor........................................................... 7-8

7-11 Door Sensor Replacement ............................................................................. 7-8

7-12 Socket - Halogen Lamp ................................................................................. 7-9

7-13 Power Switch ................................................................................................. 7-10

7-14 Radiant Heaters .............................................................................................. 7-10

7-15 “Speaker” Replacement ................................................................................. 7-11

7-16 Meat Probe Receptacle Replacement ............................................................ 7-12

7-17 Transformer.................................................................................................... 7-12

7-18 Control Board Replacement ........................................................................... 7-13

7-19 Relays ............................................................................................................. 7-13

7-20 High Limits .................................................................................................... 7-16

Section 8. PARTS INFORMATION.......................................................................................... 8-1

8-1 Introduction .................................................................................................... 8-1

8-2 Genuine Parts ................................................................................................. 8-1

8-3 How To Order ................................................................................................ 8-1

8-4 Prices .............................................................................................................. 8-1

8-5 Delivery.......................................................................................................... 8-1

8-6 Warranty ........................................................................................................ 8-1

Distributors List - Domestic and International

ii 698

Henny Penny SCR-6/8

SECTION 1. INTRODUCTION

1-1. HENNY PENNY The Henny Penny Rotisserie, SCR-6 or 8 , combines

ROTISSERIE rotating convection heat with rotating disks so that food

browns more evenly and cooks faster. It can also be used as a

display unit for displaying of product while in the cooking or

holding mode.

1-2 FEATURES

!!

! Distinctive compact design

!!

! Preselected automatic controls

! Integrated Solid State Controls

! Combination hot air convection and infrared cooking

! Rotating disk movement

! LED readout control panel

! Tempered glass doors

! Removable drip pan

! Removable rotor disk

! Stainless steel construction

! Removable vent panels for easy cleaning

1-3. ASSISTANCE

Should you require assistance, just call your local independent distributor (refer to the distributor list in the rear of this

manual).

In addition, feel free to contact our corporate headquarters in

Eaton, Ohio by dialing our toll free number 1-800-417-8405,

or 937-456-8405.

500 1-1

Henny Penny SCR-6/8

1-4. SAFETY To ensure safe operation of the Henny Penny Rotisserie, the

proper procedures for installation, operation, and maintenance should be followed and properly understood. Where

information is of particular importance or is safety related,

the words WARNING, CAUTION, and NOTE are used.

Their usage is as follows:

The word WARNING is used to alert you to a procedure

that if not performed properly, may cause personal injury.

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the unit.

NOTE

The word NOTE is used to highlight especially important information.

1-5. PROPER CARE As with any of our equipment, the Rotisserie does require

care and maintenance, which are discussed in this manual.

The careful use of the recommended procedures, coupled

with the regular preventive maintenance, will result in few

repairs to the equipment.

1-2 698

Henny Penny SCR-6/8

SECTION 2. INSTALLATION

2-1. INTRODUCTION This section provides the installation instructions for the Henny

Penny Rotisserie.

NOTE

The installation of this unit must conform to all local, state,

and federal codes.

Do not puncture the Rotisserie with any objects such as drills

or screws as electrical shock, or component damage could

result.

NOTE

Installation of this unit should be performed by a qualified

service technician.

2-2. LOCATION The proper location of the unit is very important for operation and

convenience. Choose a location which will provide easy loading

and unloading without interfering with the final assembly of food

orders.

NOTE

The SCR-6/8s rotisseries must be 2 inches from any rear wall.

No minimum spacing is required for the sides of the units.

After the Henny Penny Rotisserie has been placed on a table,

run a bead of silicone (silicone or equivalent sealant must be a

NSF listed material) around the perimeter of the unit sealing it

to the table top. You are now ready to make the electrical

connection.

The SCR series rotisserie is a commercial appliance, and many

surfaces could be hot. To prevent burns it is recommended that

the unit be located in an area that cannot be accessed by the

public.

500 2-1

Henny Penny SCR-6/8

2-3. STACKING

INSTRUCTIONS NOTE

A Stacking Kit

must be used to stack rotisseries, or to stack a

rotisserie on a display. This kit ensures 3 inches clearance

from a rear wall. The part numbers of the stacking kits are

02664, for use on the SCR-6 and SCD-6, and 02665 is used

on the SCR-8 and SCD-8.

1. Lay unit on it’s side and bolt locking casters or legs, to

the control side of unit.

2. Using the bolts provided for the non-locking casters, or

legs, bolt both the stacking spacer (provided in the kit)

and the non-locking caster, or legs, to the front side of the

unit. The stacking spacer should extend out the front of

the unit about three inches.

3. Carefully lift the rotisserie and place it on top of the

display, or bottom rotisserie, with the controls on the

same side.

The SCR-8 weighs approximately 500 lbs. (230 Kg) and

the SCR-6 weighs 380 lbs. (172 Kg). Extreme care

should be taken when lifting the rotisserie to prevent

personal injury.

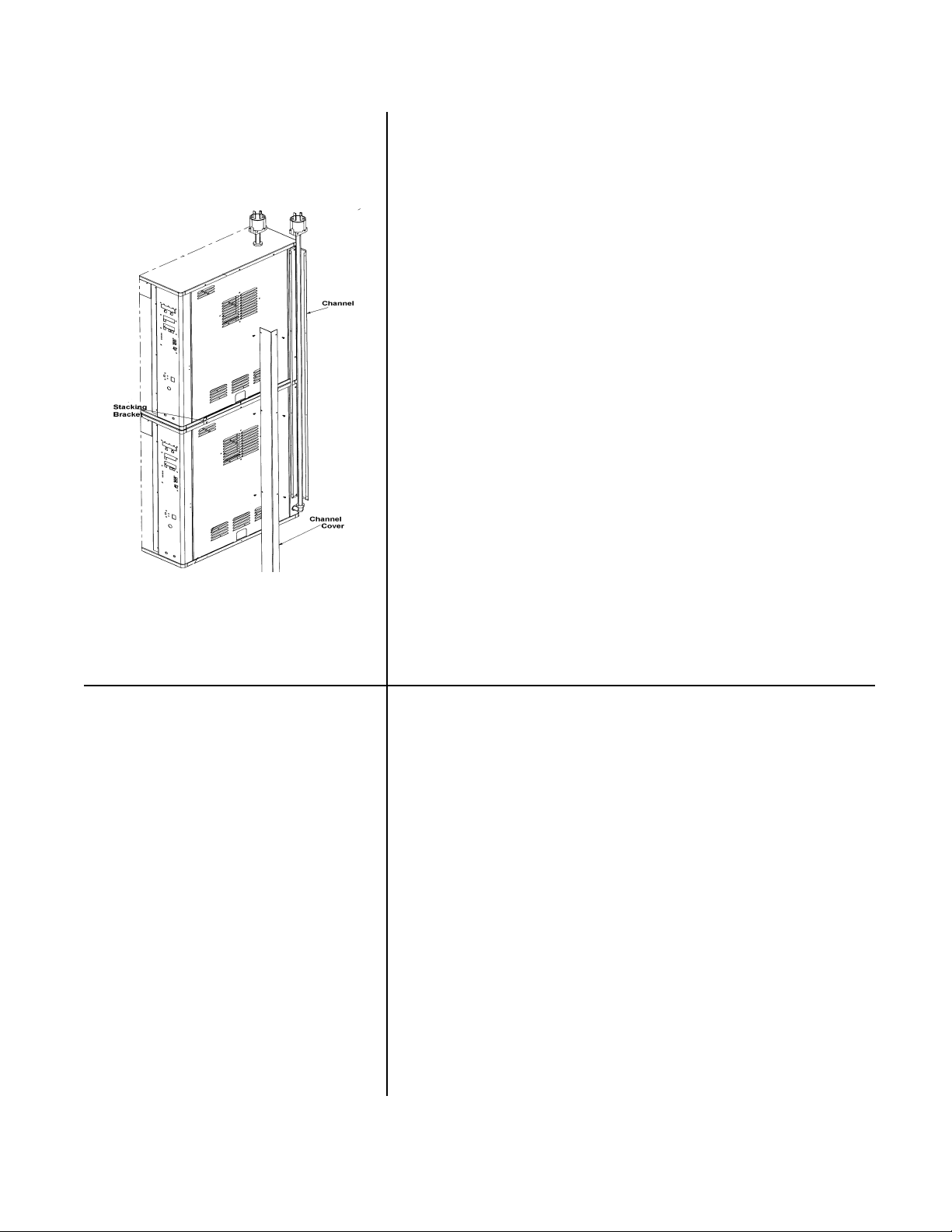

Figure 2-1 4. Remove the three side panel screws from the top unit

and remove the three top side panel side screws from

the bottom unit.

5. Mount the stacking brackets to each side of the units, as

shown in Figure 2-1, using the screws removed in step 4.

6. Unit is now ready for use.

NOTE

For units being installed in Canada, for Price Costco,

proceed with the following steps:

7. Remove the black plug button from the top of the upper

unit.

2-2 698

Henny Penny SCR-6/8

2-3. STACKING 8. Remove the screws from the channel assembly and take

INSTRUCTIONS (continued) the top two parts apart.

9. Remove the screws along the corners of both top and

bottom units.

10. Mount one side of the channel to the units, using the

screws previously removed in step 9. See Figure 2-2.

11. Route the power cord up through the mounted channel

and attach the cover to the channel, using the screws

previously removed in step 8. See Figure 2-2.

12. Unit is now ready for use.

Figure 2-2

2-4. UNPACKING The Henny Penny Rotisserie has been tested, inspected, and

expertly packed to insure arrival at its destination in the best

possible condition. The unit is packed inside a heavy

cardboard carton with sufficient padding to withstand normal

shipping treatment.

NOTE

Any shipping damages should be noted in the presence of

the delivery agent and signed prior to his or her departure.

To remove the Henny Penny Rotisserie from the carton you

should:

1. Carefully cut banding straps.

2. Remove packing from around the unit.

3. Lift carton from unit.

4. Remove brackets securing unit to skid.

5. Remove unit from skid.

6. Your Rotisserie is now ready for setup.

698 2-3

Henny Penny SCR-6/8

2-5. LEVELING OF UNIT For proper operation, the Rotisserie should be level from side to

side and front to back. This will ensure proper door operation.

2-6. ELECTRICAL The Henny Penny rotisserie is available from the factory

REQUIREMENTS wired 208 or 240 volt, 220-380 volt, 240-415 volt, 230-400

volt, 1 or 3 phase, 50/60 hertz service.

The cabinet must be adequately and safely grounded according to local electrical codes to prevent the possibility

of electrical shock.

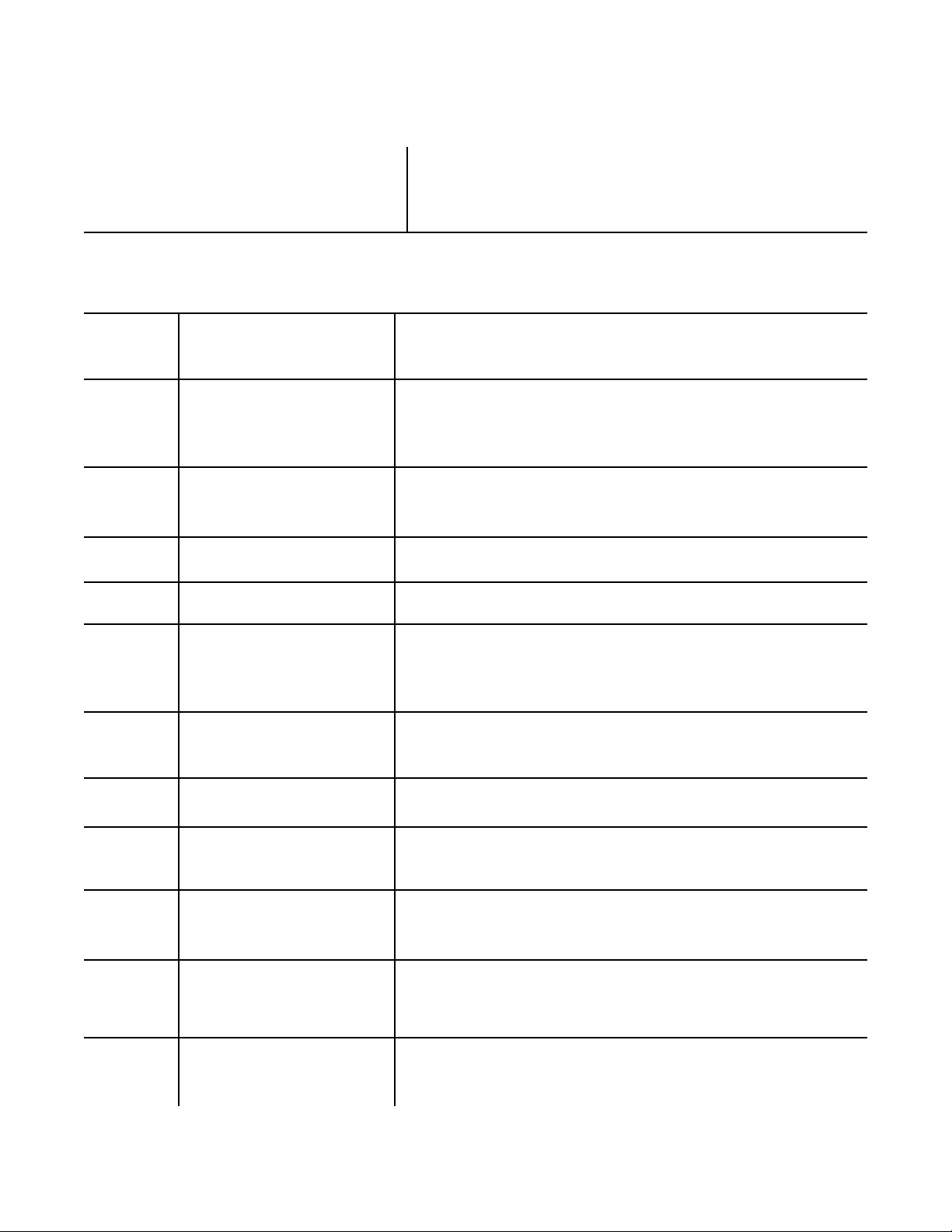

Model Product Volts Phase Amps Watts Wire

No. No.

SCR-8 02639 208 3 33.6 11,100 3+G

02638 208 1 50.5 11,100 2+G

02645 240 3 29.1 11,100 3+G

02638 240 1 46 11,100 2+G

SCR-6 02634 208 3 22.8 6800 3+G

02630 208 1 32.5 6800 2+G

02637 240 3 19.7 6800 3+G

02630 240 1 28.3 6800 2+G

2-4 500

Henny Penny SCR-6/8

SECTION 3. OPERATION

3-1. INTRODUCTION The Henny Penny Rotisserie is computer controlled. The

computer control regulates the cabinet temperatures and

provides timing and program functions of the rotisserie.

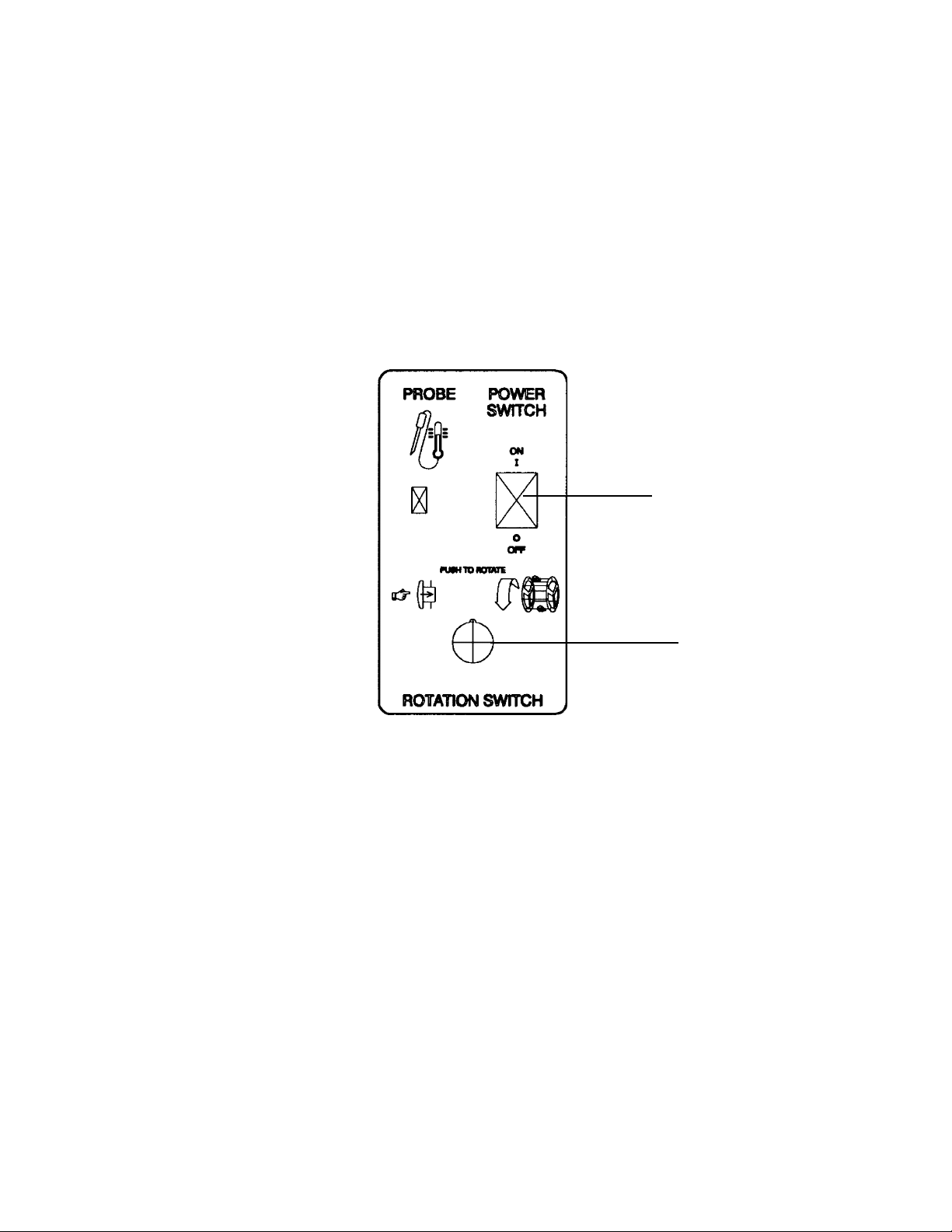

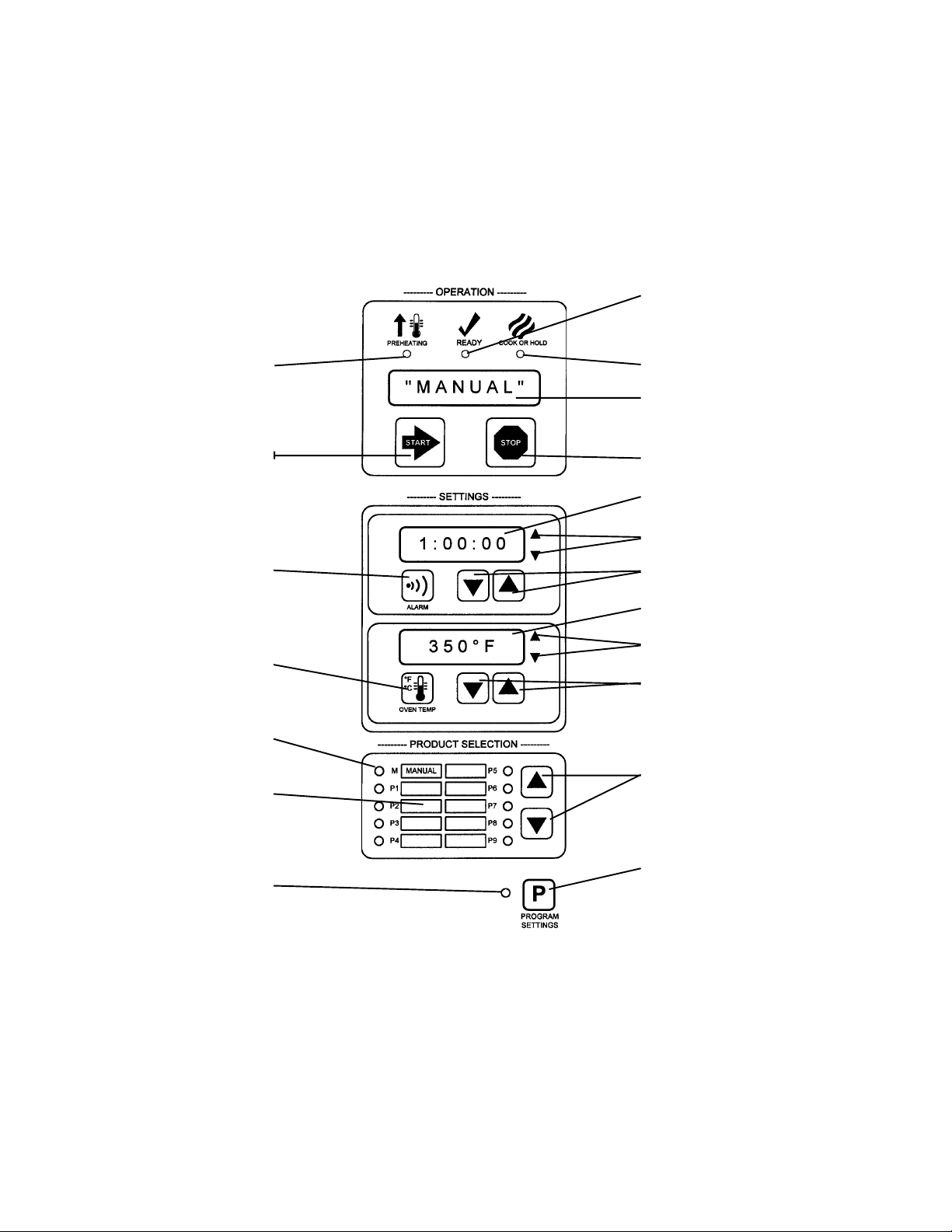

3-2. CONTROLS AND SWITCHES (Refer to Figures 3-1 and 3-2)

Item Description Function

1 Power Switch This two position rocker switch controls power to the rotisserie

and the control.

2 Rotor Switch The rotor switch is pressed to bypass the computer control and

turns the rotor motor on. A rotor switch may be located on

both and the operator side and customer side.

3 Meat Probe The meat probe is plugged into this receptacle, then inserted into

the product and the temperature displays.

4 Preheating LED This LED turns on during a preheating mode.

5 Program LED This LED flashes during a program mode.

6 Product LED A product LED is located above each product button. It turns

on when a product is selected and during programming. The

LED flashes during cook and hold cycles.

7 Product Up and Down The ten product selections, labeled M through P9, are

Buttons selected by pressing the Up and Down buttons.

8 Cook or Hold LED This LED turns on during a cook cycle and during the hold cycle

9 Program Button The program button is pressed to access the program and

special program modes.

10 Menu Board The menu board displays the product names. The menu items

can be changed.

11 Digital Displays The three digital displays are LED displays which show

temperature, time, and messages associated with the

operation.

12 Ready LED This LED turns on during preheat when the temperature nears

the programmed set point temperature. It turns off during a

cook cycle

the

control

698 3-1

Henny Penny SCR-6/8

3-2. CONTROLS AND SWITCHES (Refer to Figures 3-1 and 3-2)

(continued)

.

Item Description Function

13 Start Button The start button is pressed to begin the unit preheating or begins

a cook cycle.

14 Stop Button The stop button is pressed to end a cook or hold cycle.

15 Alarm Button The alarm button is pressed to view or change the alarm

settings. The settings can be changed at any time.

16 Oven Temperature The temperature button is pressed to view the current oven

Button temperature.

17 Set Temperature Up These buttons are pressed to change the temperature setpoint.

and Down Buttons

18 Set Time Up and These buttons are pressed to change the time settings.

Down Buttons

3-2 698

Henny Penny SCR-6/8

1

2

Figure 3-1

698 3-3

Henny Penny SCR-6/8

12

4 8

11

13 14

11

19

15 18

11

20

16

17

6

7

10

9

5

Figure 3-2

3-4 401

Henny Penny SCR-6/8

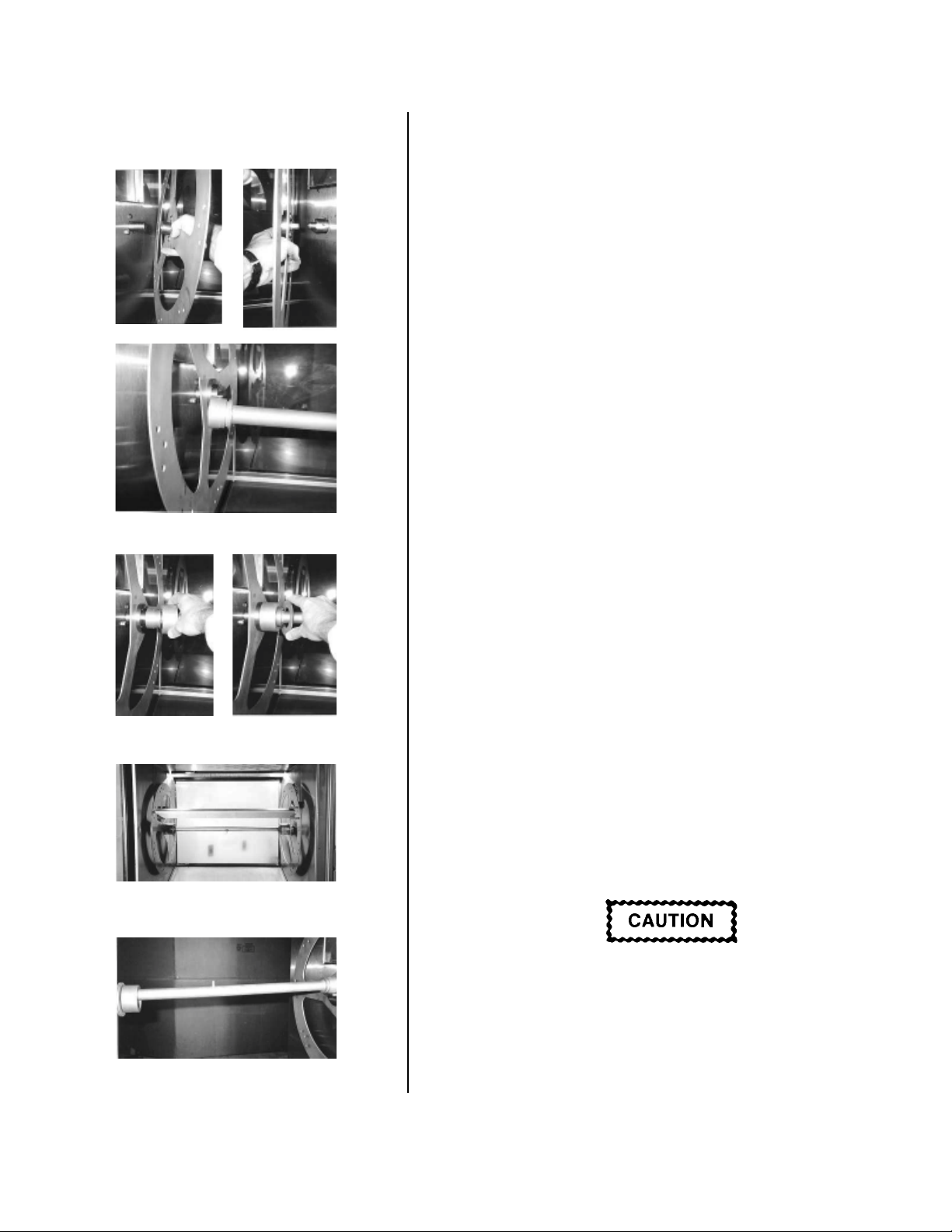

3-3. INSTALLATION OF DISCS,

ROD AND SPITS

1. Fit discs up to appropriate disc support on each side

of unit.

2. Place each end of the rod assembly into the hubs on

each disc.

3. Slide the collars onto each hub of discs.

4. Slide retention rings over hubs and into slot on rod.

5. Slip angled spits onto discs, with the “V” of the angled

spits towards the rod.

NOTE

Fit the spit with the “V” towards the rod. Reversing the spit will result in spits tilted at an angle.

When removing the rod assembly make sure

indicator is pointed up towards top of unit. If it is

pointed down, the rod assembly will fall.

698 3-5

Henny Penny SCR-6/8

3-4. PROCEDURE FOR The angled spits are the standard accessory for the Henny

ANGLED SPITS Penny rotisseries. Some of the advantages of the angled spits,

compared to the meat forks, are the ease and speed in which whole

chickens can be placed on the spits. Also, cooking on spits

compared to baskets and pans is superior as the meat cooks more

uniformly and is basted by itself as it rotates. It is important to place

meat on the spit evenly for even cooking results.

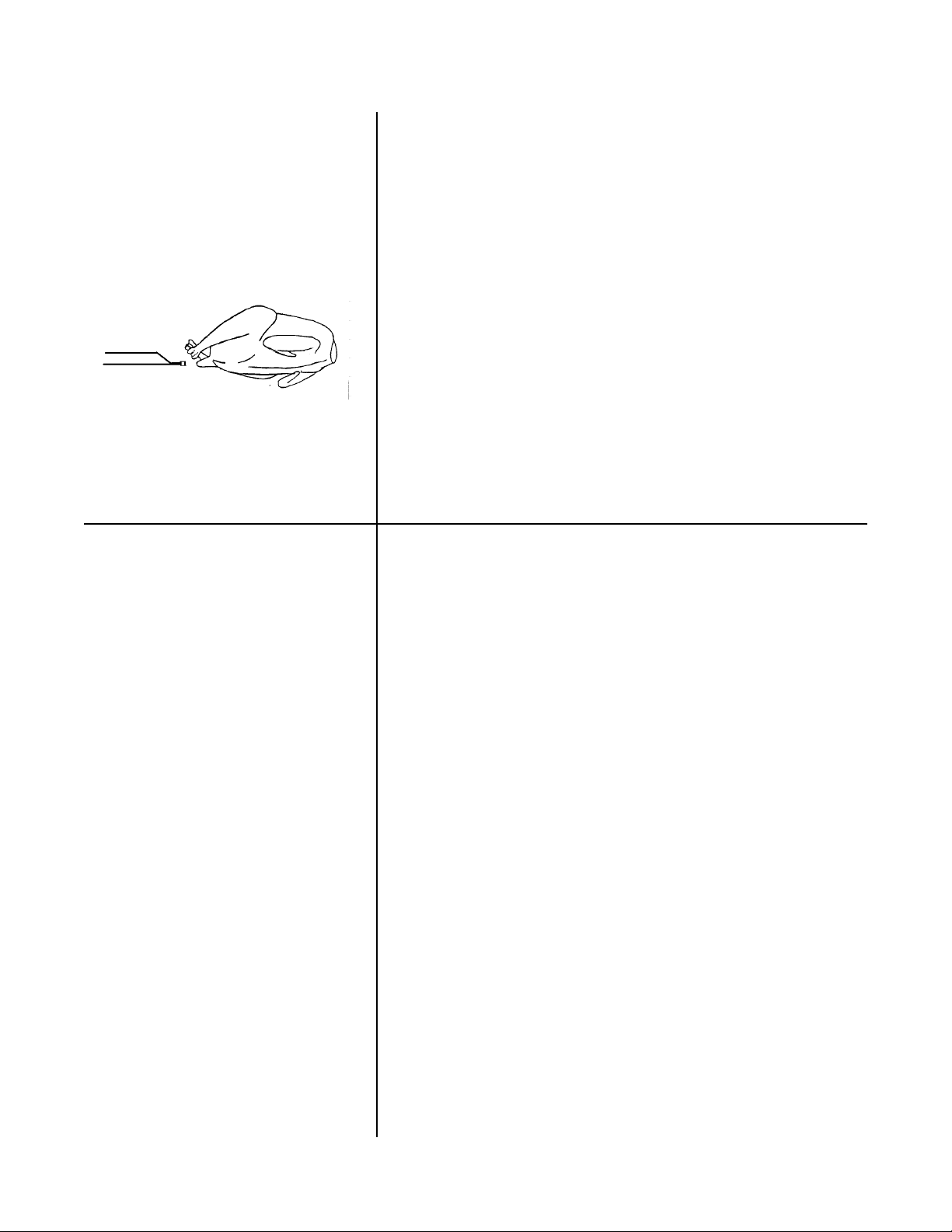

Place the chicken on its back. Cut a small slit in the extra skin at the

tail end of the chicken. Place one, then the other leg through the slit,

so the legs are in a crossed fashion. Fold the wings up behind the neck.

Hold the spit with the opening of the “V” shape facing upwards

and the angle of the “V” towards the table. Slide the spit

lengthwise through the body cavity of the chicken, tail cavity

Figure 3-1 first, with the breast up (see Figure 3-1).

3-5. PROCEDURE FOR MEAT The double spits or meat forks are optional accessories. Some

FORKS OR SPITS of the advantages of cooking on spits compared to baskets or

(OPTIONAL) pans are that the meat cooks more uniformly and is basted

by itself as it rotates. It is important to place meat on the spit

evenly for even cooking results.

Place chicken and small poultry on spits in a vertical position

for maximum capacity (see diagram). Place chicken on its back.

Gently push legs and thighs toward the back. This gives the

chest a more plump appearance and positions the drumsticks

better for insertion of the spit. Run one point of the spit

through the chest at the height of the wings. Run the other

point through the large part of the drumstick and lower body.

Push the spit through to the other side of the chicken. Wings

can either be pinned by the spit or folded behind the neck.

If turkey or large poultry is cooked, it may be necessary to

place them horizontally on spits so they do not touch the top

of the oven or interfere with adjacent spits. In this case, run

the spits lengthwise through the breast and thighs.

Whole roasts - beef, lamb, pork and ham, should be centered

on the spits evenly. Most roasts will have to be placed on spits

lengthwise due to their size and shape. However, if small roasts

are cooked, they can be placed vertically on spits, provided

they do not touch the top of the oven or interfere with adjacent spits.

3-6 698

Henny Penny SCR-6/8

3-5. PROCEDURE FOR MEAT Pork ribs - spare or baby racks should be weaved on the spits

FORKS OR SPITS like an accordion. Both tines of the meat fork should pierce

(continued) the slab.

Best results are obtained if poultry or roasts are not crowded

together. Leave adequate space between products for best

browning.

3-6. USE OF OPTIONAL Baskets are available as an option for food products too

ACCESSORIES small or impractical to put on spits.

Meatloaf, fish, stuffed bell peppers, and frozen pastries are examples of products that can be baked in the baskets.

If baskets are used instead of spits to bake whole chicken or

roasts, keep in mind these products will require more time to

cook and the browning will not be as uniform.

Coated accessories are available. For more information contact your local distributor.

3-7. OPERATION MODE The control has ten product cook cycles which may be pro-

grammed for specific products. Each cycle may consist of up

to four Cook steps and a Hold Parameter.

1. Press the Up or Down button, under PRODUCT SELECTION, to select the desired product. Then press the START

button and the unit will begin to preheat to the temperature appropriate for that product.

NOTE

The Manual Mode is not programmed and a cook time and

temperature must be programmed once this product is selected. Use the Up or Down button, under PRODUCT SELECTION, to select Manual mode (M). Press the START

button to begin preheat. Use the time and temperature Up

and Down buttons to program this mode.

2. Once the “Ready” LED flashes, the product can now be

loaded into the unit. “READY TO LOAD” message

scrolls in top display.

698 3-7

Henny Penny SCR-6/8

3-7. OPERATION MODE 3 Open the door and load the product into the unit. Press the

(continued) rotate knob as needed to rotate the discs to help in loading.

Close the door, then press the START button to begin cook

cycle.

NOTE

The middle display shows the time remaining and the bottom

display shows the set point temperature. The actual temperature shows when the Oven Temperature button is pressed.

4. At the end of the cook cycle an alarm will sound, the

middle display shows “0:00” and the top display flashes

“DONE”. Press the STOP button to end the cook cycle.

NOTE

If a hold time is not programmed, the cycle is ended and

alarm turned off by pressing the STOP button. If a hold

time is programmed, the unit will sound an alarm and

automatically go into the hold cycle. Hold time remaining

and temperature will be displayed.

5. At the end of the hold cycle, the middle display flashes

“0:00” and the top display flashes “END”. Pressing the

STOP button stops the alarm and rotor, and all outputs are

off.

NOTE

To abort a Cook or Hold cycle, press and hold the STOP button for 2 seconds. The cook cycle can also be paused by pressing and releasing the STOP button. If power is removed at any

time, the control will resume the operation that was active at

power down, whether it was in a cook cycle, hold cycle, or

preheat.

3-8. PREHEAT CONTROL During preheat, the air heat and radiant heat are both turned

on to regulate the air temperature to the programmed

preheat/cook setpoint. Both air and radiant heat are

turned off when the air temperature is above the setpoint.

The blower runs continuously, but the rotor is off.

3-9. COOKING CONTROL Normally during a cook cycle, the air heating elements and

the radiant elements are regulated to the programmed air

temperature set point.

3-10. DOOR SENSOR If either door is opened during a cook cycle, all functions are

turned off, and remain off until both doors are closed. The top

display shows “DOOR IS OPEN”. But, if the meat probe is

plugged into the unit and the control side door is open, the top

display will show meat probe temperature.

3-11. HOLD CONTROL The hold mode can be programmed for time and temperature.

3-8 698

Henny Penny SCR-6/8

3-12. CLEANING 1. Turn all controls to OFF and disconnect the electrical

PROCEDURES power supplied to the unit.

Allow the unit to cool before cleaning, as the exterior and

interior of the cabinet may be hot enough to cause burns.

2. Remove the discs and rod assembly and take to a sink to

clean them thoroughly. (See Section 3-3).

NOTE

If door of unit is partially open it is designed to close

automatically. To keep door open, position door fully

open.

Be sure to keep groove in the rod clean of debris. The

retaining ring must fit securely in the groove to keep rod

assembly from falling and damaging unit, or causing

personal injury.

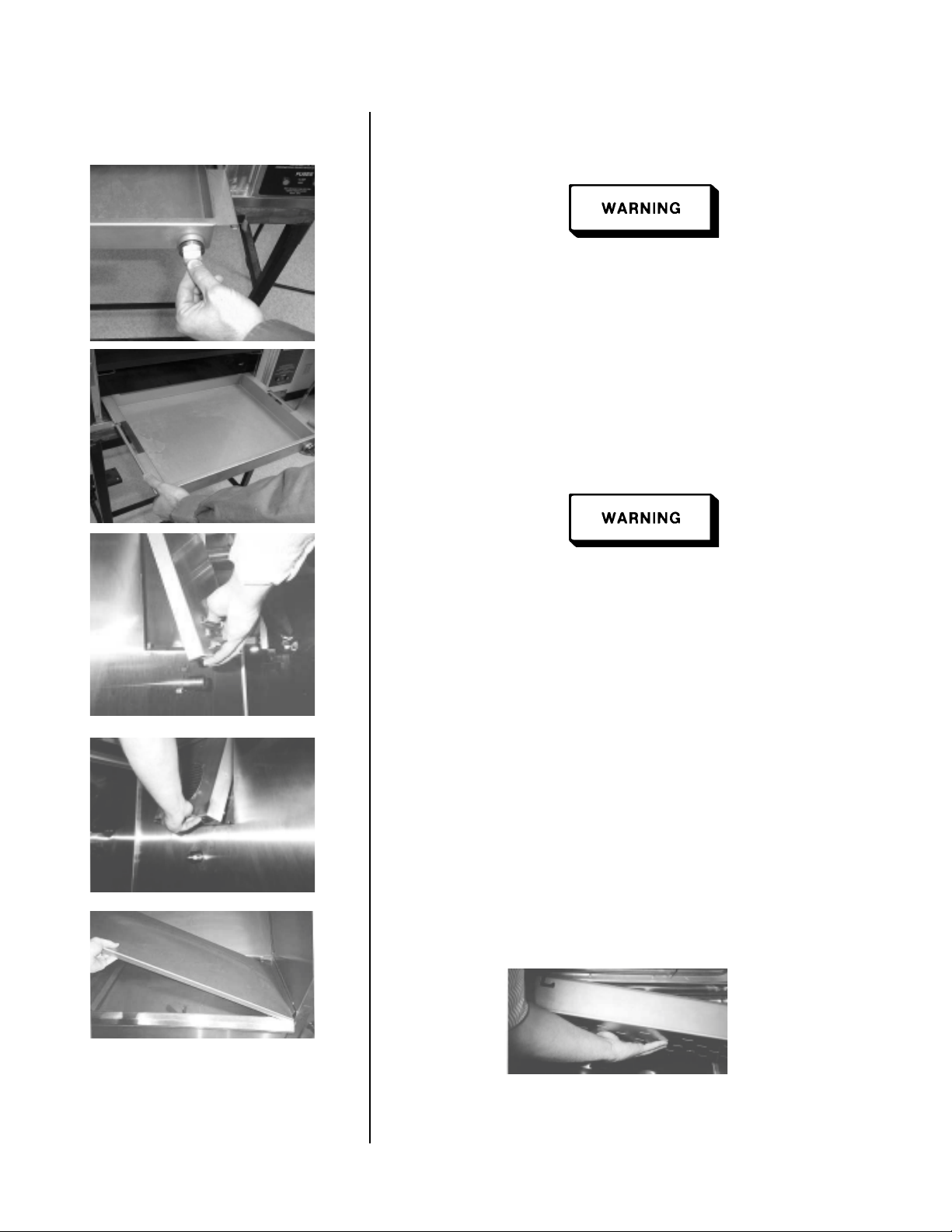

3. Pull grease pan partially out and unscrew drain plug to

discard grease into another container.

4. Remove grease pan, vent panels (side vents first), back

panel, and grease trays from unit, and take to a sink to

clean thoroughly.

NOTE

The top vent panel (covering air heaters), is slotted to the

right on the SCR-8 and to the left on the SCR-6.

500 3-9

Henny Penny SCR-6/8

3-12. CLEANING 5. Loosen the thumb screw on the blower fan blade and pull

PROCEDURES blade from shaft. Then take fan blade to a sink to clean

(continued) thoroughly.

When reinstalling fan blade, be sure the offset shaft

matches up, and the thumb screw is tightened snug, but

not too tight. If the fan is not installed properly the fan

could hit the vent cover and damage to the fan could

result.

Do not use abrasive cleaners or cleaners/sanitizers con taining clorine, bromine, iodine, or ammonia chemicals.

These abrasives and chemicals will deteriorate the

stainless steel material and shorten the life of the unit.

Futhermore, when cleaning the coated parts, Do Not

use any abrasive cloth, degreaser, oven cleaner, or any

type of corrosive cleanser. Hot soapy water is all that is

needed to clean these parts. Any of the other cleaners

mentioned above will greatly reduce the life of the

coating.

3-10 698

Henny Penny SCR-6/8

SECTION 4. PROGRAMMING

4-1. INTRODUCTION The controls can be preset at the factory, or the desired

functions can be programmed in the field. The Program

Settings (“P”) button is used to program the following

functions: Cooking(steps), alarms, and hold.

NOTE

An exception is the Manual mode. Cook time and temperature

can be programmed into this slot without entering the program

mode.

4-2. PROGRAMMING FOR 1. Press and hold the Program Settings (“P”) button until

COOK AND HOLD the control beeps and the display shows “PROG”, then

release the “P” button.

2. Enter the access code 1-2-3 by pressing the button under the

digit. The Alarm button is under the 1, the Down button is

under the 2, the Up button is under the 3.

The control will sound three quick beeps, the word “STEP”

lights up above the “P” button and the settings for the

currently selected product are shown. The product, (P1

through P9), flashes then “COOK-1” shows in the top

display.

NOTE

If the incorrect access code is entered, the Programing

mode is denied. A “BAD CODE” message shows

on the display and a warning tone is generated. After

approximately 10 seconds the control returns to normal

operation and the access code may be tried again.

3. Select the product to be programmed, P1 through P9, using

the Up and Down buttons under PRODUCT SELECTION

NOTE

Once the desired product is selected, each press of the Program (“P”) button advances to the next cook or hold step. The

parameters are described below.

4. Once the product is selected the preheat/cook temperature can

be entered. Press the Up and Down buttons under the temperature display until the desired temperature shows in the display.

5. The time can be programmed by pressing the Up and Down

buttons under the time (middle) display.

Example: “1:30:00” is 1 hour, 30 minutes, and 0 seconds.

NOTE

Up to four times and temperatures

can be programmed per cook cycle

698 4-1

Loading...

Loading...