Page 1

Henny Penny

Pressure Fryer

Model PFE-590

Model PFE-592

OPERA TOR’S MANUAL

Page 2

Page 3

LIMITED WARRANTY FOR HENNY PENNY EQUIPMENT

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original

purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT : Any part of a new appliance, except baskets, lamps, and fuses, which proves to be defective in

material or workmanship within two (2) years from date of original installation, will be repaired or replaced without

charge F .O.B. factory , Eaton, Ohio, or F .O.B. authorized distributor . Baskets will be repaired or replaced for ninety (90)

days from date of original installation. Lamps and fuses are not covered under this Limited W arranty. To validate this

warranty, the registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

FIL TER SYSTEM: Failure of any parts within a fryer filter system caused by the use of the non-OEM filters or

other unapproved filters is not covered under this Limited Warranty.

REPLACEMENT P A R TS: Any appliance replacement part, except lamps and fuses, which proves to be defective in

material or workmanship within ninety (90) days from date of original installation will be repaired or replaced without

charge F .O.B. factory , Eaton, Ohio, or F .O.B. authorized distributor .

The warranty for new equipment covers the repair or replacement of the defective part and includes labor charges and

maximum mileage charges of 200 miles round trip for a period of one (1) year from the date of original installation.

The warranty for replacement parts covers only the repair or replacement of the defective part and does not include any

labor charges for the removal and installation of any parts, travel, or other expenses incidental to the repair or replacement of

a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or workmanship

issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover any frypot that fails due to

any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new frypot at no cost or

provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for the frypot only . Any freight charges and labor costs to install the new frypot as

well as the cost of any other parts replaced, such as insulation, thermal sensors, high limits, fittings, and

hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No

allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If damage occurs during

shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FOR TH THE SOLE REMEDY AGAINST HENNY PENNY FOR ANY BREACH

OF W ARRANTY OR OTHER TERM. BUYER AGREES THA T NO OTHER REMEDY (INCLUDING CLAIMS FOR ANY INCIDENT AL OR CONSEQUENTIAL DAMAGES) SHALL BE AV AILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the

equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED WARRANTY IS EXPRESSL Y IN LIEU OF ALL OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANT ABILITY AND FITNESS, AND ALL OTHER W ARRANTIES ARE EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY

PERSON TO ASSUME FOR IT ANY OTHER OBLIGA TION OR LIABILITY.

Revised 01/01/07

FM05-032-G

Revised 8-6-10

Page 4

HENNY PENNY

8 HEAD ELECTRIC PRESSURE FRYER

SPECIFICA TIONS

Height 61" (155 cm)

Width 24" (61 cm)

Depth 41¾" ( 107 cm)

Floor Space Approximately 7 sq. ft. (.65 sq. m.)

Pot Capacity 8 head of chicken - 22 lbs. (9.9 kg)

100 lbs. shortening (45 Kg.)

Electrical 208 VAC, 3 Phase, 50/60 Hz, 17 KW, 47.2 Amps

240 VAC, 3 Phase, 50/60 Hz, 17 KW, 40.9 Amps

200 VAC, 3 Phase, (Delta), 50/60 Hz, 17 KW , 49.1 Amps

240 VAC, 3 Phase, (Delta), 50 Hz, 17 KW , 40.9 Amps

380 VAC, 3 Phase, 50 Hz, 17 KW, 25.8 Amps

415 VAC, 3 Phase, 50 Hz, 17 KW, 23.7 Amps

400 VAC, 3 Phase, 50 Hz, 17 KW, 24.6 Amps

Heating Two 8,500 watt electric immersion elements

Shipping W eight Approximately 758 lbs. (344 kg.)

A data plate, located on the back shroud behind the lid, gives the information of the type of

fryer, serial number , warranty date, and other information pertaining to fryer . Also, the serial

number is stamped on the outside of the frypot. See figure below .

Page 5

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION.................................................................................................... 1-1

1-1 Pressure Fryer ...............................................................................................1-1

1-2 Proper Care ................................................................................................... 1-1

1-3 Assistance ..................................................................................................... 1-1

1-4 Safety ............................................................................................................1-2

Section 2. INSTALLATION ...................................................................................................... 2-1

2-1 Introduction....................................................................................................2-1

2-2 Unpacking .....................................................................................................2-1

2-3 Selecting the Fryer Location ......................................................................... 2-5

2-4 Leveling the Fryer ......................................................................................... 2-5

2-5 V entilation of Fryer........................................................................................ 2-6

2-6 Electrical Requirements ................................................................................2-6

2-7 International Electrical Requirements ...........................................................2-7

Section 3. OPERATION ............................................................................................................ 3-1

3-1 Operating Components .................................................................................. 3-1

3-2 Lid Operation................................................................................................. 3-3

3-3 Melt Cycle Operation .................................................................................... 3-4

3-4 Switches and Indicators ................................................................................3-5

3-5 Filling or Adding Shortening...........................................................................3-8

3-6 Basic Operation............................................................................................. 3-9

3-7 Care of Shortening ........................................................................................ 3-11

3-8 Filtering Instructions ...................................................................................... 3-11

3-9 Changing the Filter Envelope.........................................................................3-13

3-10 Cleaning the Frypot ....................................................................................... 3-14

3-11 Filter Pump Motor Protector-Manual Reset ................................................. 3-15

3-12 Regular Maintenance Schedule..................................................................... 3-15

3-13 Preventive Maintenance................................................................................3-16

3-14 Programming .................................................................................................3-19

3-15 Special Program Mode .................................................................................. 3-21

Section 4. TROUBLESHOOTING.............................................................................................4-1

4-1 Troubleshooting Guide .................................................................................... 4-1

4-2 Error Codes .................................................................................................... 4-2

GLOSSARY .......................................................................................................................G-1

1203 i

Page 6

Page 7

SECTION 1. INTRODUCTION

Model PFE- 590/592

1-1. PRESSURE FRYER

P-H-T A combination of pressure, heat, and time is automatically

Pressure Pressure is basic to this method of food preparation. The pres-

Heat Heat generated is another important factor of the pressure fryer.

Time Time is important because the shorter time involved in frying

The Henny Penny pressure fryer is a basic unit of food processing equipment which is used only in institutional and commercial

food service operations.

controlled to produce the optimum in a tasty , appealing

product.

sure is developed from the natural moisture of the food. The

patented lid traps this moisture and uses it as steam. Because

the steam builds rapidly , a greater part of the natural juices

are retained within the food. An operation valve vents excess

steam from the pot and maintains constant live steam

pressure.

Energy savings is realized due to the unit’ s short frying time,

low temperature, and heat retention of the stainless steel

frypot.

foods results in additional economies for the user. Foods are

table ready in less time than it would take to fry them in a conventional open-type fryer.

As of August 16, 2005, the Waste Electrical and Electronic Equipment directive went into effect for the European Union. Our

products have been evaluated to the WEEE directive. We have

also reviewed our products to determine if they comply with the

Restriction of Hazardous Substances directive (RoHS) and have

redesigned our products as needed in order to comply. T o continue

compliance with these directives, this unit must not be disposed as

unsorted municipal waste. For proper disposal, please contact

your nearest Henny Penny distributor.

1-2. PROPER CARE

As in any unit of food service equipment, the Henny Penny

pressure fryer does require care and maintenance. Requirements for the maintenance and cleaning are contained in this

manual and must become a regular part of the operation of the

unit at all times.

1-3. ASSISTANCE

207 1-1

Should you require outside assistance, call your local distributor in

your area, or call 1-800-417-8405 or 1-937-456-8405.

Page 8

Model PFE- 590/592

1-4. SAFETY

The Henny Penny pressure fryer has may safety features

incorporated. However, the only way to ensure a safe operation

is to fully understand the proper installation, operation, and

maintenance procedures. The instructions in this manual have

been prepared to aid you in learning the proper procedures.

Where information is of particular importance or safety related,

the words DANGER, WARNING , CAUTION, and NOTICE are

used. Their usage is described below .

SAFETY ALER T SYMBOL is used with DANGER,

W ARNING, or CAUTION which indicates a personal injury

type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICA TES AN IMMINENTL Y

HAZARDOUS SITUA TION WHICH, IF NOT

AVOIDED, WILL RESUL T IN DEA TH OR SERIOUS

INJURY.

1-2 403

Page 9

1-5. SAFETY

(Continued)

Model PFE- 590/592

Equipotential Ground Symbol

W aste Electrical and Electronic Equipment (WEEE) Symbol

Shock Hazard Symbols

OR

OR

Hot Surface Symbols

908 1-3

Page 10

SECTION 2. INST ALLA TION

Model PFE- 590/592

2-1. INTRODUCTION

2-2. UNP ACKING

INSTRUCTIONS

This section provides the installation and unpacking instructions for

the Henny Penny PFE-590.

Installation of this unit should be performed only by a qualified

service technician.

Do not puncture the fryer with any objects such as drills

or screws as electrical shock or component damage

could result.

Any shipping damage should be noted in the presence of the

delivery agent and signed prior to his or her departure.

1. Cut and remove the plastic bands from the main box.

2. Remove the box lid and lift the main box off the fryer .

3. Remove corner packing supports (4).

4. Cut the stretch film from around the carrier/rack box and

remove it from the top of the fryer lid.

5. Cut and remove the metal bands holding the fryer to the

pallet.

All counterweights must be loaded before unlatching

lid, or personal injury could result.

6. Remove the fryer from the pallet.

T ake care when moving the fryer to prevent personal

injury . The fryer weighs approximately 758 lbs.

(344 Kg).

2-1 803

Page 11

Model PFE- 590/592

2-2. UNP ACKING

INSTRUCTIONS

(Continued)

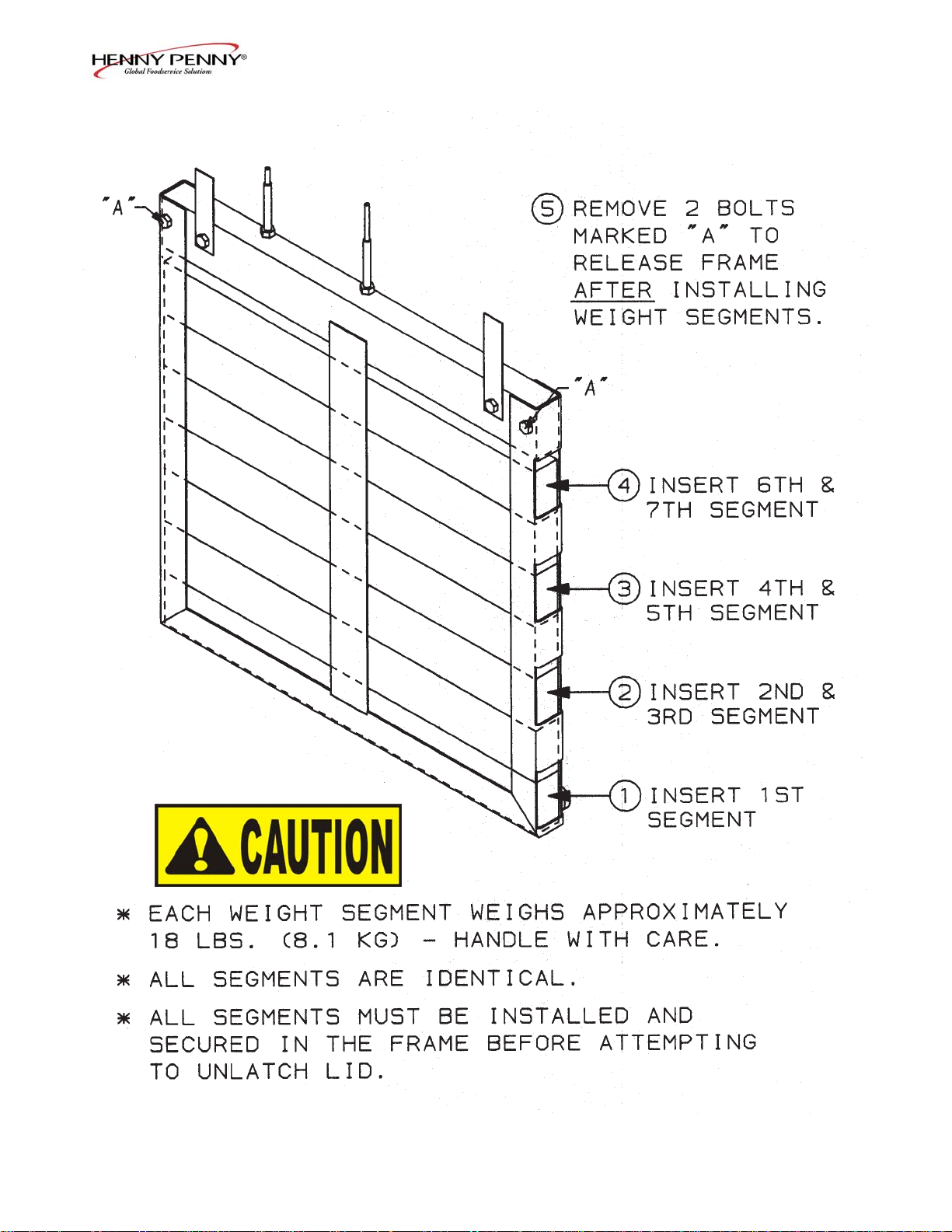

7. Remove the counterweights from the pallet, which are

strapped to the pallet, under the fryer.

Do not drop. The counterweights weigh approximately

18 lbs. (8.1 kg.) each. Handle with care, or personal

injury could result.

8. Remove rear service cover .

9. Load the seven weights into the counterweight assembly . See

page 2-4.

10. Replace rear service cover.

T o avoid personal injury and assur e safe operation of

unit, rear service cover must be in place.

11. Cut warning tags from the lid assembly. The lid may now

be unlatched.

12. Remove the accessories from inside the filter drain pan.

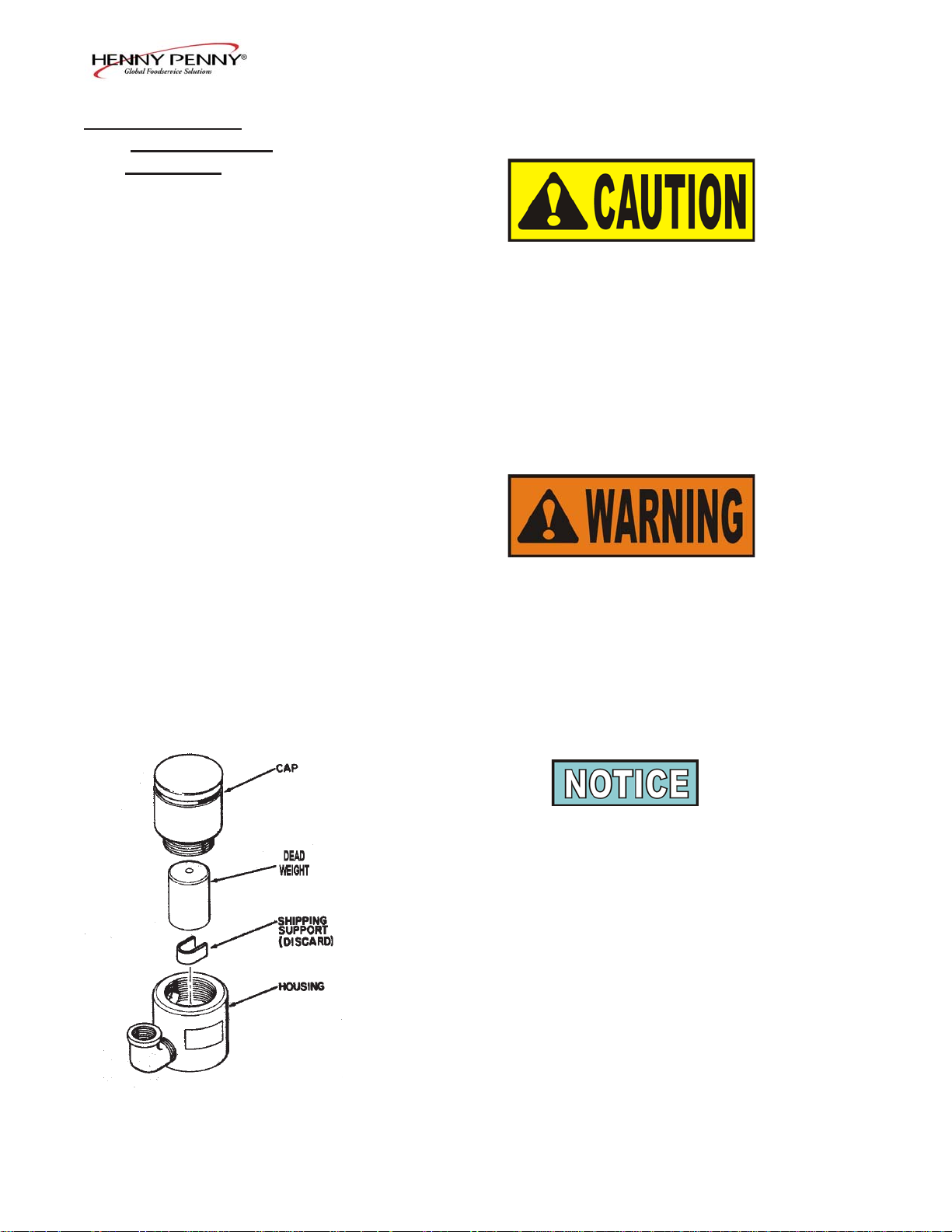

13. Prepare the deadweight valve for operation

The metal shipping support is placed within the deadweight

assembly housing to protect the deadweight orifice and deadweight during shipment. This support must be removed prior

to installation and start-up.

A. Unscrew the deadweight cap.

B. Remove the deadweight.

C. Remove and discard the metal packing support.

D. Clean the deadweight orifice with a dry cloth.

E. Carefully place deadweight over deadweight orifice.

Replace deadweight cap, finger tight.

13. Remove the protective paper from the fryer cabinet.

Clean exterior surface with a damp cloth.

404 2-2

Page 12

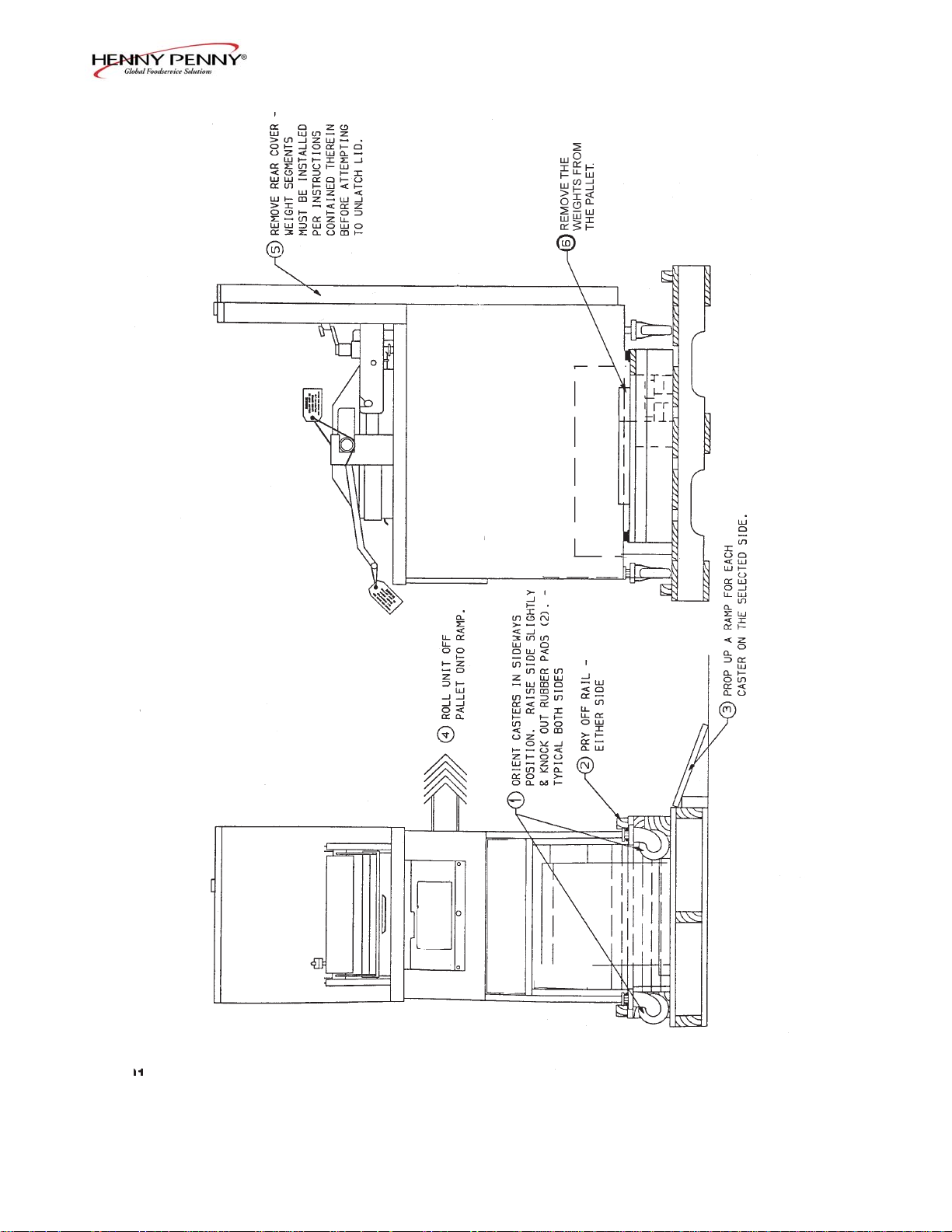

Optional Ramp Unloading

Model PFE- 590/592

2-3 1103

Page 13

Model PFE- 590/592

404 2-4

Page 14

Model PFE- 590/592

2-3. SELECTING THE

LOCATION

The proper location of the fryer is very important for operation,

speed, and convenience. Choose a location which will provide

easy loading and unloading without interfering with the final assembly of food orders. Operators have found that frying from raw to

finish, and holding the product in a warmer provides fast continuous

service. Landing or dumping tables should be provided next to at

least one side of the fryer. Keep in mind the best ef ficiency will be

obtained by a straight line operation, i.e. raw in one side and finish

out the other side. Order assembly can be moved away with only

a slight loss of efficiency . T o properly service the fryer, 24 inches

(60.96 cm) of clearance is needed on all sides of the fryer. Access

for servicing can be attained by removing a side panel.

To avoid fire and ruined supplies, the area under the

fryer should not be used to store supplies.

2-4. LEVELING THE FRYER

T o prevent sever e burns from splashing hot shortening,

position and install fryer to prevent tipping or movement. Restraining ties may be used for stabilization.

For proper operation, level the fryer from side to side and front to

back, using level on the flat areas around the frypot collar.

FAILURE TO FOLLOW THESE LEVELING

INSTRUCTIONS CAN RESUL T IN SHOR TENING

OVERFLOWING THE FRYPOT WHICH COULD

CAUSE SERIOUS BURNS, PERSONAL INJUR Y ,

FIRE AND/OR PROPERTY DAMAGE.

2-5 703

Page 15

Model PFE- 590/592

2-5. VENTILATION OF FR YER The fryer should be located with provision for venting into

adequate exhaust hood or ventilation system. This is essential

to permit efficient removal of steam exhaust and frying odors.

Special precaution must be taken in designing an exhaust canopy to

avoid interference with the operation of the fryer. W e recommend

you consult a local ventilation or heating company to help in designing an adequate system.

V entilation must conform to local, state, and national codes.

Consult your local fire department or building authorities.

2-6. ELECTRICAL The electric fryer requires 208 or 240 volt, three phase, 50/60

REQUIREMENTS Hertz service. The power cord may be already attached to the

fryer, or provided at installation. Check the data plate mounted just

above the lid, on the left side of the back shroud, to determine the

correct power supply .

This fryer must be adequately and safely grounded

(earthed) or electrical shock could result. Refer to local

electrical codes for correct grounding (earthing) procedures or in absence of local codes, with The National

Electrical Code, ANSI/NFPA No. 70-(the curr ent edition). In Canada, all electrical connections are to be

made in accordance with CSA C22.1, Canadian Electrical Code Part 1, and/or local codes.

T o avoid electrical shock, this appliance must be

equipped with an external circuit breaker which will

disconnect all ungrounded (unearthed) conductors. The

main power switch on this appliance does not disconnect

all line conductors.

A separate disconnect switch with proper capacity fuses or breakers must be installed at a convenient location between the fryer and

the power source. It should be an insulated copper conductor

rated for 600 volts and 90o C. For runs longer than 50 feet

(15.24 m), use the next larger wire size.

706 2-6

Page 16

Model PFE- 590/592

2-7. INTERNA TIONAL Units being used outside the United States may not be shipped

ELECTRICAL with the power cord attached to the unit because of the different

REQUIREMENTS wiring codes. The fryers are available from the factory wired for

208, 240, 380 and 415 volts, 3 phase, 50 Hertz service. A terminal

block is mounted inside the fryer for the cable wiring. A decal on

the inside of the right side panel will help in the wiring of the unit.

CE units require a minimum wire size of 4mm to be wired to

the terminal block. If a flexible power cord is used, it must be

HO7RN type.

T o install the power cord, follow these procedures:

1. Remove the right side panel of the unit.

2. Install the cord, with a strain relief, to the junction box.

3. Attach the wires to the terminal block according to the wiring

diagram on the side panel.

4. Pull the slack out of the cord and thread it down through the

the clamp on the frame, at the rear, left leg of fryer . Then run

the cable under the frame and out the rear of the fryer, so it

doesn’t interfere with the filter drain pan.

The filter drain pan must be as far back under fryer as

it will go, and the cover in place. Be sure the hole in the

cover lines up with the drain before opening the drain.

Failure to follow these instructions causes splashing of

shortening and could result in personal injury .

5. Wiring the fryer is now complete.

2-7 703

Page 17

2-7. INTERNA TIONAL

ELECTRICAL

REQUIREMENTS

(Continued)

Model PFE- 590/592

• The supply power cords shall be oil-resistant, sheathed flexible

cable, no lighter than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord.

• It is recommended that a 30 mA rated protective device such as

a residual current circuit breaker (RCCB), or ground fault

circuit interrupter (GFCI), be used on the fryer circuit.

(FOR EQUIPMENT WITH CE MARK ONL Y!)

T o prevent electric shock hazard this appliance must be

bonded to other appliances or touchable metal surfaces in

close proximity to this appliance with an equipotential

bonding conductor . This appliance is equipped with an

equipotential lug for this purpose. The equipotential lug is

marked with the following symbol .

908 2-8

Page 18

Model PFE- 590/592

BOIL-OVER PREVENTION IN HENNY PENNY COOKERS

F AILURE TO FOLLOW THESE INSTRUCTIONS CAN RESUL T IN SHOR TENING

OVERFLOWING THE FR YPOT WHICH COULD CAUSE SERIOUS BURNS,

PERSONAL INJUR Y . FIRE AND/OR PROPERTY DAMAGE.

• THE SHORTENING MA Y BE STIRRED ONLY DURING THE MORNING

ST ART UP PROCEDURE. DO NOT STIR THE SHORTENING AT ANY

OTHER TIME.

• FIL TER THE SHORTENING A T LEAST TWICE A DA Y .

• FIL TER ONL Y WHEN “COOL” IS DISPLA YED.

• BRUSH ALL CRACKLINGS FROM FR YPOT SURF ACES AND THE COLD

ZONE DURING THE FILTERING PROCESS.

• MAKE SURE THE FRYER IS LEVEL.

• BE CERT AIN THE SHOR TENING IS NEVER ABOVE THE UPPER FR YPOT

LEVEL INDICA T OR LINE.

• BE CERT AIN THA T THE GAS CONTROL VALVE AND BURNERS ARE

PROPERL Y ADJUSTED. (GAS UNITS ONLY)

• USE RECOMMENDED PRODUCT LOAD SIZE

FOR ADDITIONAL INFORMA TION ON THESE INSTRUCTIONS, REFER TO THE

HENNY PENNY OPERA TOR MANUAL AND THE KFC ST ANDARDS LIBRARY.

FOR ASSIST ANCE CALL THE HENNY PENNY SERVICE DEPARTMENT AT

1-800-417-8405.

or

1-937-456-8405

2-9 703

Page 19

Model PFE- 590/592

Page 20

Model PFE- 590/592

SECTION 3. OPERA TION

3-1. OPERA TING COMPONENTS

POWER/PUMP Switch A three way switch with center OFF position; move the switch to

the position marked POWER to operate the fryer; move the switch

to the position marked PUMP to operate the filter pump; certain

conditions must be met prior to operation of the filter pump; these

conditions are covered later in this section

Frypot This reservoir holds the cooking shortening, and is designed to

accommodate the heating elements, 8 head of product and an

adequate cold zone for collection of cracklings

Carrier This stainless steel carrier consists of five racks, containing the food

product during and after frying (4 cook racks and 1 cover rack)

Lid Gasket Provides the pressure seal for the frypot chamber

Deadweight assembly The deadweight style operating pressure relief valve is used to

maintain a constant level of steam pressure within the frypot;

any excess steam pressure is vented through the exhaust stack;

remove the deadweight cap, and clean the cap, weight, and

deadweight orifice once a day . See Preventive Maintenance

Section.

Failure to clean the deadweight assembly daily could

result in the fryer building too much pressure. Severe

injuries and burns could result.

Safety Relief Valve An ASME approved spring loaded valve set at 14.5 psi

(999 mbar); in the event the operation valve becomes obstructed,

this safety valve releases excess pressure, keeping the frypot

chamber at 14.5 psi (999 mbar); if this occurs, turn the COOK/

PUMP switch to the OFF position to release all pressure from the

frypot

If safety relief valve activates, turn main power switch

to the OFF position. To avoid serious burns and

injuries, have fryer serviced before next use.

3-1 703

Page 21

Model PFE- 590/592

3-1. OPERA TING COMPONENTS

(Continued)

Safety Relief Valve Ring

DO NOT PULL THIS RING. SEVERE BURNS FROM

THE STEAM WILL RESUL T .

Pressure Gauge Indicates the pressure inside the frypot.

Solenoid V alve An electromechanical device that causes pressure to be held in the

frypot

The solenoid valve closes at the beginning of the Cook Cycle and

opens automatically at the end of the Cook Cycle; if this valve

becomes dirty or the teflon seat nicked, pressure will not build and

it must be repaired per the Maintenance Section of the T echnical

Manual

Drain V alve A two-way ball valve, normally in the closed position; turn the han-

dle to drain the shortening from the frypot into the filter drain pan

DO NOT OPEN THE DRAIN VALVE WHILE

FRYPOT IS UNDER PRESSURE. HOT SHORTENING WILL EXHAUST , AND SEVERE BURNS WILL

RESULT.

Drain Interlock Switch A microswitch that provides protection for the frypot in the event an

operator inadvertently drains the shortening from the frypot while

the main switch is in the COOK position; the switch is designed to

automatically shut off the heat when the drain valve is opened

Condensation Drain Pan The collection point for the condensation formed within the steam

exhaust system; it must be removed and emptied periodically ,

usually daily

Shortening Mixing System The unit is equipped with a shortening mixing capability to ensure

the shortening is properly mixed to prevent an accumulation of

moisture, causing boiling action in the frypot; the filter pump is

activated by the controls, at preset intervals, to mix the shortening

Lid Latch The fryer lid is equipped with a mechanical catch on the front

of the lid which engages a bracket on the front of the frypot; this

device holds the lid down while the lid is being locked into

place, but is not meant to hold pressure in the frypot

703 3-2

Page 22

Model PFE- 590/592

3-1. OPERA TING COMPONENTS (Continued)

High T emperature Limit This is a safety component that senses the temperature of the

shortening; if the temperature of the shortening exceeds 420°F

(212°C), this control opens and shuts off the heat to the frypot;

when the temperature of the shortening drops to a safe operation

limit, the control must be manually reset by pressing the red reset

button, located under the control panel, in the right, front of the

fryer

Figure 3-1

Air V alve Pumps air into the shortening, periodically , to keep the shortening at

a uniform temperature; this only functions when the unit has been

sitting idle for a period of time, and when heating from a cold start

Filter Drain Pan The removable pan that houses the filter and catches the shortening

when it is drained from the frypot; also used to remove anddiscard

old shortening

When hot shortening is in this pan, use extreme care to

avoid burns.

Filter Union Connects the filter to the filter pump, and allows easy removal of the

filter and drain pan

Fuses A protective device which breaks the circuit when the current

exceeds the rated value

3-2. LID OPERA TION T o close lid:

1. Lower the lid until gasket comes into contact with the

frypot and lock the lid in place with the lid latch.

2. Pull lid handle forward until it stops.

3. Lift up on the lid handle until it stops.

4. Bring lid handle out towards you until it stops.

5. Push lid handle down, locking lid in place.

LID MUST BE LA TCHED PROPERL Y OR PRESSURIZED SHORTENING AND STEAM MAY

ESCAPE FRYPOT . SEVERE BURNS WILL RESUL T .

3-3 703

Page 23

3-2. LID OPERA TION Continued)

Model PFE- 590/592

DO NOT LIFT HANDLE OR FORCE LID LA TCH

OPEN BEFORE PRESSURE GAUGE READS “0”

PSI. ESCAPING STEAM AND SHOR TENING WILL

RESUL T IN SEVERE BURNS.

TO AV OID SERIOUS PERSONAL INJUR Y , DO NOT

OPERA TE WITHOUT LID COVER IN PLACE AND

ALL COMPONENTS INST ALLED.

TO AV OID SERIOUS PERSONAL INJUR Y , DO NOT

T AMPER WITH ANY COMPONENT OF LID

LOCKING MECHANISM.

T o open lid:

1. Gently raise handle until it stops.

2. Push handle back until it stops.

3. Lower handle.

Lower the handle before attempting to raise the lid, or

damage to the lid could result.

4. Push handle back.

5. Unlatch the front lid latch.

3-3. MEL T CYCLE OPERA TION If the shortening is below 185o F (85o C), with the POWER/PUMP

switch in the POWER position, the fryer will enter the Melt Cycle.

The shortening heats slowly to prevent scorching of the shortening.

The heat cycles on and off to slowly melt the shortening. At 185o F

(85o C), the heat stays on until 250o F (121o C), the Cool Mode,

is reached. T o exit the Cool Mode, press the EXIT COOL button.

See Filling and Adding Shortening Section.

703 3-4

Page 24

Model PFE- 590/592

3-4. SWITCHES AND Refer to image at end of this section.

INDICATORS

EXIT COOL Button After cooking, or filtering the shortening, the temperature automati-

cally goes into the Cool Mode, which keeps shortening at a lower

temperature; this temperature extends the shortening life and

minimizes the time to heat the shortening for the next Cook Cycle;

EXIT COOL button must be pressed to heat up to setpoint temperature

AL THOUGH THE DISPLA Y WILL READ “COOL”

DURING THE STANDBY MODE, THE SHOR TENING IS HOT AND WILL CAUSE BURNS.

Product Selection Buttons Select the number of heads, or product, to be cooked by pressing

the button below the menued item; shortening will then heat to

drop temperature of that item

Pressing the same button again will begin the Cook Cycle; the

indicator will change from “DROP” to counting down the cook

time in minutes and seconds

At the end of the Cook Cycle, the alarm sounds and the indicator

reads “DONE”; press the cycle button that is flashing, and the

alarm will cease; the fryer will then reset to the Cool Mode

A Cook Cycle can be aborted at any time by pressing and

holding the product button.

Time/T emperature Display This is a 4 digit LED type display which shows the remaining cook

time during Cook Cycles and also the shortening temperature on

demand from the operator

Heat Indicator Illuminates whenever the control calls for heat; when shortening

temperature is reached, the heat light goes off

3-5 703

Page 25

Model PFE- 590/592

3-4. SWITCHES AND

INDICA TORS (Continued)

HI T emperature Indicator The display reads “HI” if the shortening temperature is 40° F above

the setpoint

Drop Indicator The display reads “DROP” when the shortening has reached

the setpoint temperature (will read “DROP” 2° before setpoint and

4° above setpoint )

Done Indicator The display reads “DONE” at the end of the Cook Cycle

T emperature Button Allows the operator to read the temperature of the shortening while

in a Cook Cycle

SCAN Button Allows the operator to toggle through any running multiple timers

FUNCTION Button Used in the programming of the controls

EXIT FILL Button After filtering the fryer, if in the Filter Lockout Mode, the display

reads “FILL” and the EXIT FILL button must be pressed

Multiple Timers The control has the capability to run multiple timers; if more than

one product is being cooked, a timer can be started by pressing

more than one product button per Cook Cycle

The products must have the same setpoints, and the pressure

must be programmed off. See Programming Section.

703 3-6

Page 26

3-4. SWITCHES AND

INDICA TORS (Continued)

Model PFE- 590/592

TEMPERA TURE BUTTON DIGITAL DISPLAY

PRODUCT BUTTONS

Figure 3-2

3-7 403

Page 27

3-5. FILLING OR ADDING

SHORTENING

Model PFE- 590/592

The shortening level must always be above the heating

elements when the fryer is heating and at the frypot level

indicators on the rear of the frypot (Figure 3-3). Failure

to follow these instructions could result in a fire and/or

damage to the fryer.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source befor e placing it in the frypots. The heating elements must be

completely submerged in shortening. Fir e or damage to

the frypot could result.

1. It is recommended that a high quality frying shorteningbe used

in the pressure fryer. Some low grade shortenings have a high

moisture content and cause foaming and boiling over .

Figure 3-3

T o avoid severe burns when pouring hot shortening into

frypot, wear gloves and take care to avoid splashing.

2. The electric model requires 100 lbs. (45 kg.) of shortening.

The frypot has 2 level indicator lines inscribed on the rear

wall of the frypot which show when the heated shortening is at

the proper level. Figure 3-3.

3. Cold shortening should be filled to the lower indicator.

BE CERT AIN THE SHORTENING IS NEVER

ABOVE THE UPPER LEVEL INDICA TOR LINE.

FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESUL T IN SHOR TENING OVERFLOWING

THE FRYPOT CAUSING SERIOUS BURNS, PERSONAL INJUR Y , FIRE AND/OR PROPERTY

DAMAGE.

For complete instructions, refer to KFC’s S tandards Library .

703 3-8

Page 28

Model PFE- 590/592

3-6. BASIC OPERA TION Follow the procedure below on the initial start-up of the fryer , and

each time the fryer is brought from a cold, or shut down condition,

back into operation. These are basic, general instructions. Be sure

to follow KFC’ s Standards Library when operating the fryer.

1. Make sure the frypot is filled to the proper level with shortening, to the lower level indicator.

DO NOT OVERLOAD, OR PLACE PRODUCT WITH

EXTREME MOISTURE CONTENT INTO THE

RACKS. 22 LBS. (9.9 KG.) IS THE MAXIMUM

AMOUNT OF PRODUCT PER FRYPOT . FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN RE

SUL T IN SHOR TENING OVERFLOWING THE

FRYPOT WHICH COULD CAUSE SERIOUS

BURNS, PERSONAL INJUR Y , FIRE AND/OR

PROPERTY DAMAGE.

2. Turn the POWER/PUMP switch to the POWER position and

press the appropriate product button to select the amount

of product to be cooked.

3. Stir the shortening as it’ s heating up from a cold start.

Be sure to stir down into the cold zone.

DO NOT STIR THE SHORTENING A T ANY OTHER

TIME EXCEPT A T MORNING ST AR T -UP . FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN RESUL T IN SHOR TENING OVERFLOWING THE

FRYPOT WHICH COULD CAUSE SERIOUS

BURNS, PERSONAL INJUR Y , FIRE, AND/OR

PROPERTY DAMAGE.

3-9 703

Page 29

Model PFE- 590/592

3-6. BASIC OPERA TION 4. Allow fryer to heat until digital display shows “DROP”.

(Continued) (Press the EXIT COOL button if the display shows COOL”)

The heat cycles on and off approximately 10 degrees before

the setpoint temperature, to help prevent overshooting the

setpoint temperature. (proportional control)

5. Before loading product onto the racks, lower racks into the

hot shortening to keep the product from sticking to the racks.

6. Slide racks of breaded product into carrier on the lid, starting

with the bottom tier, to prevent damaged product.

7. Lower and lock the lid down and press the appropriate

product button (2, 4, 6, or 8 head).

8. At the end of the cycle, pressure begins venting automatically,

alarm sounds, and the display shows “DONE”. At this time,

press the appropriate product button (2, 4, 6, or 8 head).

9. W ait for the pressure gauge to show “0” pressure in the

frypot before attempting to open the lid.

DO NOT LIFT HANDLE OR FORCE LID LA TCH

OPEN BEFORE PRESSURE GAUGE READS “0”

PSI. ESCAPING STEAM AND SHOR TENING WILL

RESUL T IN SEVERE BURNS.

10. Unlock and raise the lid cautiously.

11. Using the rack handles, remove the racks of product from

the carrier, starting with the top rack.

703 3-10

Page 30

3-7. CARE OF THE

SHORTENING

Model PFE- 590/592

FOLLOW THE INSTRUCTIONS BELOW TO A V OID

SHORTENING OVERFLOWING THE FR YPOT ,

WHICH COULD RESUL T IN SERIOUS BURNS,

PERSONAL INJUR Y , FIRE, AND/OR PROPERTY

DAMAGE.

1. T o protect the shortening when the fryer is not in immediate

use, the fryer should be put into the Cool Mode.

2. Frying breaded products requires filtering to keep the

shortening clean. The shortening should be filtered at

least twice a day: after lunch rush and at the end of the day .

3. Maintain the shortening at the proper cooking level. Add

fresh shortening as needed.

4. Do not overload the racks with product (22 lbs. (9.9 kgs.)

maximum), or place product with extreme moisture content

into racks.

WITH PROLONGED USE, THE FLASHPOINT OF

SHORTENING IS REDUCED. DISCARD SHORTENING IF IT SHOWS SIGNS OF EXCESSIVE

SMOKING OR FOAMING. SERIOUS BURNS,

PERSONAL INJUR Y , FIRE, AND/OR PROPERTY

DAMAGE COULD RESUL T .

3-8. FIL TERING The Henny Penny electric 8 head pressure fryer, Model 590, should

INSTRUCTIONS be cleaned and the shortening filtered and polished at least twice

daily; after lunch rush and at the end of the day . Refer to KFC’s

Standards Library .

Filter shortening immediately following a Cook Cycle when the

shortening temperature is in the Cool Mode.

Drain the shortening at 250° F (121° C) or less. Higher

temperatures cause cracklings to burn on the steel frypot

surfaces after the shortening has drained.

3-11 703

Page 31

3-8. FIL TERING

INSTRUCTIONS

(continued)

Model PFE- 590/592

ONLY FILTER WHEN “COOL” IS DISPLAYED.

FAILURE TO DO SO CAN RESULT IN SHORTENING

OVERFLOWING THE FRYPOT, CAUSING SERIOUS

BURNS, PERSONAL INJURY, FIRE,AND/OR

PROPERTY DAMAGE.

High volume cooking could cause the cold zone to fill quicker with

cracklings and cleaning may be required more often. Part of the

filtering process involves removing cracklings from the cold zone of

the frypot.

1. Turn POWER/PUMP switch to OFF position.

2. Make sure filter drain pan is under fryer and the filter union

is fastened to the filter standpipe, coming out of the pan.

Shortening Stirrer

Drain Cleanout Small White

Rod Brush

The filter drain pan must be as far back under fryer as

it will go, and the cover in place. Be sure the hole in the

cover lines up with the drain before opening the drain.

Failure to follow these instructions causes splashing of

shortening and could result in personal injury.

Surfaces of fryer and racks will be hot. Use care when

filtering to avoid getting burned.

3. Remove cooking racks, carrier and wipe bottom of lid. Tilt

lid out of the way to clean frypot.

4. Pull drain handle towards you to open drain valve. The handle

should point straight out to the front of the fryer. Use large

white brush to clean cracklings from the elements and from

sides and bottom of frypot as shortening drains. Use the drain

cleanout rod to push cracklings through drain opening in bottom

of frypot if necessary. Using the small straight white brush,

clean between the elements and the frypot wall.

BRUSH ALL CRACKLINGS FROM FRYPOT SURFACES AND THE COLD ZONE DURING THE FILTERING PROCESS. FAILURE TO DO SO CAN

RESULT IN SHORTENING OVERFLOWING THE

FRYPOT, WHICH COULD CAUSE SERIOUS BURNS,

PERSONAL INJURY, FIRE AND/OR PROPERTY

703 3-12

DAMAGE.

Page 32

Model PFE- 590/592

3-8. FIL TERING 5. Scrape cracklings and crackling ring from frypot and discard.

INSTRUCTIONS Do not let cracklings drain into filter drain pan. These crack-

(Continued) lings can cause a burned taste in gravy . Wipe all surfaces with

a clean damp towel. If water drops into cold zone, dry with

towel before pumping shortening back into the frypot.

Do not bang the pot scraper, or other cleaning utensil, on

the frypot rim. Damage to the frypot rim could result and

the lid may not seal properly during a cook cycle.

6. Return drain handle to the closed position to close the drain.

7. Turn POWER/PUMP switch to PUMP , and when all shortening has been pumped into frypot swing drain handle to

the closed position to close the drain.

IF THERE ARE AIR BUBBLES COMING UP IN THE

SHORTENING, IT’S POSSIBLE THA T THE FIL TER

CONNECTION A T THE UNION ON THE FILTER

TUBE IS NOT TIGHTENED PROPERL Y. IF SO,

TURN OFF THE PUMP AND USE PROTECTIVE

CLOTH OR GLOVE WHEN TIGHTENING THE

UNION. THIS UNION WILL BE HOT AND SEVERE

BURNS WILL RESULT .

3-9. CHANGING THE FIL TER The filter envelope should be changed after 10-12 filterings, or

ENVELOPE whenever it becomes clogged with crumbs. Refer to KFC’s

Standards Library .

Use protective cloth or glove when disconnecting the

filter union or severe burns could result.

If the filter pan is moved while full of shortening, use

care to prevent splashing, or severe burns could result.

Be sure that the filter screens, crumb catcher, filter clips

and the standpipe are thoroughly dry before assembly of

the filter envelope or water will dissolve the filter paper.

3-13 605

Page 33

Model PFE- 590/592

3-10. CLEANING THE FRYPOT After the initial installation of the fryer, as well as before every

change of shortening, the frypot should be thoroughly cleaned as

follows:

1. Turn the POWER/PUMP switch to OFF positioin, and

unplug unit from wall receptacle.

Moving the fryer or filter drain pan while containing

hot shortening is not recommended. Hot shortening can

splash out and severe burns could result.

The filter drain pan must be as far back under fryer as

it will go, and the cover in place. Be sure the hole in the

cover lines up with the drain before opening the drain.

Failure to follow these instructions causes splashing

of shortening and could result in personal injury .

2. If hot shortening is present in the frypot, it must be

drained by slowly pulling the drain handle out towards you.

3. Close the drain valve and discard the shortening.

4. Raise lid, remove the racks and carrier from lid, and tilt lid

back, so that the lid won’t interfere with cleaning.

5. Refer to KFC’ s Standard’ s Library on cleaning instructions.

DO NOT CLOSE LID WITH WA TER AND/OR

CLEANER IN FRYPOT . WA TER UNDER PRESSURE BECOMES SUPERHEA TED. WHEN LID IS

OPENED, ESCAPING WA TER AND STEAM WILL

RESUL T IN SEVERE BURNS.

If the cleaning solution in the frypot starts to foam and

boil over , immediately turn the power switch to OFF

and do not try to contain it by closing the fryer lid

or severe burns could result.

703 3-14

Page 34

Model PFE- 590/592

3-10. CLEANING THE FRYPOT

(Continued)

Do not use steel wool, other abrasive cleaners or cleaners/sanitizers containing chlorine, bromine, iodine or

ammonia chemicals, as these will deteriorate the stainless steel material and shorten the life of the unit.

Do not use a water jet (pressure sprayer) to clean the

unit, or component damage could result.

Make sure the inside of the frypot, the drain valve opening,

and all parts that come in contact with the new shortening are

as dry as possible.

3-11. FIL TER PUMP MOT OR The filter pump motor is equipped with a manual reset button,

PROTECTOR-MANUAL located on the rear of the motor, in case the motor overheats. If

RESET motor won’t run, wait about 5 minutes before attempting to reset

this protective device to allow motor to cool. Remove the access

panel on the left side panel of the unit to reset the button. It takes

some effort to reset, and a screwdriver can be used to help reset

the button.

T o prevent burns caused by splashing shortening, turn

the unit’s main power switch to the OFF position before

resetting the filter pump motor’ s manual reset

protection device.

3-12. REGULAR As in all food service equipment, the Henny Penny pressure fryer

MAINTENANCE does require care and proper maintenance. The table below

SCHEDULE provides a summary of scheduled maintenance. The following

paragraphs provide preventive maintenance procedures to be

performed by the operator .

Procedure Frequency

Filtering of shortening See KFC’ s Standards Library

Changing of shortening See KFC’s S tandards Library

Changing the filter envelope See KFC’s S tandards Library

Cleaning the deadweight assy . Daily-see Preventive

Maintenance Section

Cleaning the frypot See KFC’ s Standards Library

Cleaning the Nylatrons Monthly-see Preventive

Maintenance Section

Reversing lid gasket Every 90 Days-see Preventive

Maintenance Section

Lubricate rear lid rollers Annually-see Preventive

Maintenance Section

Cleaning safety relief valve Annually-see Preventive

Maintenance Section

3-15 810

Page 35

3-13. PREVENTIVE Cleaning Deadweight Assembly - Daily

MAINTENANCE

DO NOT A TTEMPT T O REMOVE DEADWEIGHT

CAP WHILE FRYER IS OPERA TING. SEVERE

BURNS OR OTHER INJURIES WILL RESUL T .

At the end of each day’ s usage of the fryer, the deadweight

1.

assembly must be cleaned. The fryer must be off and the

pressure released. Open the lid and then remove the

deadweight valve cap and deadweight.

ORIFICE CAP DEADWEIGHT

Deadweight cap may be hot. Use protective cloth or

glove, or burns could result.

Model PFE- 590/592

EXHAUST TUBE

Failure to clean the deadweight assembly daily could

result in the fryer building too much pressure. Severe

injuries and burns could result.

2. Wipe both the cap and deadweight with a soft cloth. Make

certain to thoroughly clean inside cap, the deadweight seat,

and around deadweight orifice.

3. Clean the exhaust tube with stainless steel brush (Henny

Penny part number 12147).

4. Dry parts and replace right away to prevent damage or loss.

Cleaning Nylatrons - Monthly

1. Spray Henny Penny biodegradable, food safe, foaming

degreaser (part no. 12226) on Nylatrons.

2. Raise lid up and down several times to spread the degreaser.

3. Wipe Nylatrons to remove food soil, grease, and degreaser

residue.

Reversing Lid Gasket - Every 90 Days

Reversing the lid gasket helps to prevent early failure of lid gasket

and the loss of pressure during a cook cycle.

1. Raise the lid and remove racks and carrier.

2. Grasping the lid handle, lift the front of the lid up until it

stops in an upright position.

810 3-16

Page 36

3-13. PREVENTIVE Reversing Lid Gasket (Continued)

MAINTENANCE

Continued)

Be sure the metal arm on the left side of the lid is in the

vertical position holding the lid upright, or severe

injuries could result. (See photo at left.)

3. Using a thin blade screwdriver, pry out the gasket at the

corners. Remove the gasket.

Check the gasket for any tears or nicks. If the gasket is

damaged, it needs to be replaced.

Model PFE- 590/592

4. Clean the gasket and gasket seat with hot water.

5. Rotate the gasket with the opposite side facing out.

Install the 4 corners of the lid gasket. Smooth the

gasket into place, working from the corners towards the

middle of each side.

Lubricating Lid Rollers - Annually

The lid rollers, in the back of the fryer, should be lubricated at

least once a year, to allow the lid easy movement.

1. Remove the back shroud of the fryer .

2. Using spindle lube, part number 12124, place a small amount

of lube on both top and bottom rollers. Make sure to lube

both left and right rollers.

3-17 703

Page 37

3-13. PREVENTIVE Cleaning Safety Relief V alve-Annually

MAINTENANCE

Continued)

SAFETY V AL VE

DO NOT A TTEMPT T O REMOVE SAFETY VAL VE

WHILE FRYER IS OPERA TING, OR SEVERE BURNS

OR OTHER INJURIES WILL RESUL T .

DO NOT DISASSEMBLE OR MODIFY THIS SAFETY

V AL VE. TAMPERING WITH THIS V AL VE COULD

CAUSE SERIOUS INJURIES AND WILL VOID

AGENCY APPROV ALS AND APPLIANCE

WARRANTY .

1. Use a wrench to remove pressure gauge.

2. Use a wrench to loosen the valve from the pipe tee, turn

counterclockwise to remove.

Model PFE- 590/592

3. Clean the inside of the pipe tee with hot water.

Turn the safety relief valve towards the rear of the fryer when

reinstalling the relief valve.

4. Immerse the safety relief valve in a soapy water solution for 24

hours. Use a 1:1 dilution rate. The valve cannot be disassembled. It is factory preset to open at 14-1/2 pounds of

pressure. If it does not open or close, it must be replaced.

703 3-18

Page 38

Model PFE- 590/592

3-14. PROGRAMMING 1. Press and hold the FUNCTION button for two seconds.

“REG PROGRAM” shows in the display , followed by

“CODE”.

2. Press the code 1,2,3. “SELECT PRODUCT” scrolls

across the display .

If no buttons are pressed, within approximately 1 minute

while in the Program Mode, the controls will revert back

to the Cook Mode.

3. Press the appropriate product button, (1-0), to identify

what product you want to program.

4. “INT1” and “TIME” flashes on the left side of the display .

The right side shows the starting time of the Cook Cycle and

can be changed by pressing the appropriate numbers. Ex:

Press 1,0,0,0 and 10:00 flashes on the right side of the

display , setting the start time at 10 minutes.

5. After the time is set, press and release the FUNCTION

button and “INT1” and “TEMP” flashes on the left side

of the display . The right side shows the starting

temperature and can be changed by pressing the appropriate

numbers. Ex: Press 2,5,0 and “250° F” will show on

the right side of the display , setting the start temperature

at 250° Fahrenheit.

6. After the temperature is set, press and release the FUNC-

TION button and “INTI” and “PRESS” flashes on the

left side of the display . Press any of the product buttons,

(1-0), to turn the pressure on or off.

7. After the pressure is set, press and release the FUNCTION

button and “INTI”, “LOAD”, and “COMP” flashes on the

left side of the display . The factory preset load compensation

value shows in the right side of the display .

3-19 703

Page 39

Model PFE- 590/592

3-14. PROGRAMMING 8. After the load compensation, press and release the

(Continued) FUNCTION button. “PROP” and “CONTROL” shows on

the left side of the display and the factory preset proportional

control temperature shows on the right side of the display .

9. After the proportional control, press and release the

FUNCTION button. “ALM 1” and “TIME” flashes in

the left side of the display , and the first alarm time shows

on the right side of the display . T o change the time the

alarm sounds, press the appropriate product buttons to set

the time. Ex: Press 1,0,0,0. 10:00 flashes on the right

side of the display , which means when the timer counts

down to 10 minutes, an alarm will sound.

10. After alarm is set, press and release the FUNCTION

button. “ALM 1”, “SELF-’ ’, and “CANCEL” flashes

in the left side of the display and “YES” or “NO” shows

on the right side of the display . The yes and no can be

toggled by pressing any of the product buttons, (l -0).

“YES” means the alarm tone automatically stops after

several beeps. “NO” means someone must manually

press the appropriate product button to stop the alarm

tone.

11 . Repeat steps 9 and 10 for alarms 2 and 3.

12. After alarm 3 is set, press and release the FUNCTION

button. “FIL TER” and “CYCLES” shows on the left side

of the display and the filter cycle value is on the right side

of the display . The value is the number of Cook Cycles

that must completed before the control signals the operator

that the shortening needs filtered

403 3-20

Page 40

Model PFE- 590/592

3-14. PROGRAMMING 13. After the filter value is set, press and release the FUNCTION

(Continued) button. “EOC” and “EXIT” flashes on the left side

of the display , and “COOL” shows on the right side of the

display . The end-of-cycle (EOC), exit point can be set to

COOL, SETP , or FLTR, by pressing any of the product

buttons (EOC). At the end of a Cook Cycle, the controls

can be set to return to: COOL, the setpoint temperature, or

to signal the operator to filter the shortening.

14. After the end-of-cycle setpoint is set, press and release the

FUNCTION button. “HEAD” and “COUNT” flashes on

the left side of the display and a number shows on the

right side of the display . The number on the right, is the

number of head of chicken to be cooked when that product

button is pressed. The number can be changed by

pressing the appropriate product button.

Another product can be programmed while in the Program

Mode by following these procedures:

Press and hold the SCAN button at any time while in the

Program Mode, and the display scrolls “SELECT

PRODUCT”. Then press any of the product buttons,

(1-0), and now that product can be programmed.

15. T o program second interval, press and release the SCAN

button while in the Time Mode, of the first mode. “INT2”

and “TIME” flashes on the left side of the display . Then

follow the steps above, starting with step 4.

3-15. SPECIAL PROGRAM MODE Review Usage

1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 1 time until “REVIEW USE” shows

in the display .

2. “DAIL Y” shows in the display . Press any of the product

buttons to view the usage of that product. Press and hold the

FUNCTION button to exit Special Program Mode.

3-21 403

Page 41

Model PFE- 590/592

3-15. SPECIAL PROGRAM MODE Reset Usage

(Continued) 1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as “REG

PROGRAM” shows in the display , press and release the

FUNCTION button 2 times until “RESET USE” shows in

display .

2. When “CODE” shows in the display , press 1-3-5. “DAIL Y

will show in the display , and press any of the product buttons

to reset them to 0.

Factory Presets (F/C, Gas/Electric, Speaker Volume,

Speaker Frequency , Codes, Initialize System)

1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 3 times until “F AC PRESET” shows

in the display .

2. When “CODE” shows on the display , enter 2-9-5-7. “DEG”

and “MODE” flashes in the display . Press any of the product

buttons to toggle from ºF to ºC, and vice versa.

3. Press and release the FUNCTION button and “TYPE”

and “FR YR” flashes in the display. Press any of the product

buttons to toggle from “GAS” to “ELEC”, or vice versa.

4. Press and release the FUNCTION button twice, and

“SPKR” and “VOL” flashes in the display . The volume can

be changed from 01 to 10, 10 being the loudest.

5. Press and release the FUNCTION button 3 times, and

“SPKR” and “FREQ” flashes in the display . The frequency

can be set from 100 to 2000.

6. Press and release the FUNCTION button 10 times, and

“INITIALIZE SYSTEM” scrolls across the display . Press

and hold any of the product buttons and the display counts

down from 5. Once the display counts down, release the

product button, and the control sets factory preset parameters into the controls.

Before attempting to change the other modes in the Factory

Preset Mode, please call the Henny Penny T echnical Service

Department at 1-800-417-8405, or 1-937-456-8405.

403 3-22

Page 42

3-15. SPECIAL PROGRAM MODE T ech I/O Mode

(Continued) 1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 4 times until “TECH I-O” shows in

the display .

2. When “CODE” shows in the display , press 2-4-6 (1-7-7-6

for CE units). “HEA T’, “PRESSURE”, and “PUMP”

shows alternately in the display . Also, the LEDs over 1, 2

and 3 flashes alternately .

3. T o test the heat circuit, press and hold the 1 button.

4. T o test the pressure system, press and hold the 2 button.

5. T o test the pump system, press and hold the 3 button.

Model PFE- 590/592

3-23 403

Page 43

Model PFE- 590/592

3-15. SPECIAL PROGRAM Heat Control

MODE (Continued) 1. Press and hold the FUNCTION button for two seconds until

“REG PROGRAM” shows in the display . As soon as

“REG PROGRAM” shows in the display , press and release

the FUNCTION button 6 times until “HEA T CNTRL” shows

in the display .

2. When “CODE” shows in the display , press 1-2-3-4.

“MEL T”, “EXIT”, and “TEMP” flashes in the display , along

with the shortening temperature at which the unit exits the

Melt Cycle. This should be set at 180º F (82º C), and should

not be changed until the factory is consulted.

3. Press and release the FUNCTION button and ”MEL T”,

“CYCLE”, and “100s” shows alternately in the display , along

with the period (pulse) length of 4000. This should not be

changed until the factory is consulted.

4. Press and release the FUNCTION button twice and

“MEL T”, “ON-”, “TIME”, and “100s”, shows alternately in

the display , along with the length of time the heat is on. This

should be set at 1700, and should not be changed until the

factory is consulted.

5. Press and release the FUNCTION button three times and

“COOL”, “SET -”, and “POINT” shows alternately in the

display , along with the temperature at which the control exits

the Melt Cycle. This is set at 250º F (121º C), and should

not be changed until the factory is consulted.

6. Press and release the FUNCTION button four times and

“AUTO”, and “IDLE” shows alternately in the display , along

with “OFF”. This should not be changed until the factory is

consulted.

7. Press and release the FUNCITON button five times and

“AUTO”, “IDLE”, and “MMSS” shows alternately in the

display , along with “0:00”. This should not be changed until

the factory is consulted.

8. The last 3 functions in the Heat Control Mode are used by the

factory only , and should not be changed.

403 3-24

Page 44

Model PFE- 590/592

SECTION 4. TROUBLESHOOTING

4-1. TROUBLE SHOOTING GUIDE

Problem Cause Correction

Power switch on but fryer

completely inoperative

• Open circuit

• Fryer plugged in

• Check breaker or fuse at wall

Pressure not exhausting at

end of Cook Cycle

Operating pressure too high

• Solenoid or exhaust line clogged

• Deadweight clogged

• Turn off and allow fryer to cool to

release the pressure in frypot; have

all lines, solenoid and exhaust tank

cleaned

• Turn off and allow fryer to cool to

release the pressure in frypot; clean

deadweight; see Preventive Mainte-

nance Section

DO NOT OPERATE UNIT IF PRESSURE GAUGE SHOWS HIGH PRESSURE CONDITIONS.

SEVERE INJURIES AND BURNS WILL RESULT. IMMEDIATELY PLACE THE POWER/

PUMP SWITCH IN THE OFF POSITION, WHICH RELEASES THE PRESSURE BY ALLOWING THE UNIT TO COOL. DO NOT RESUME USE OF UNIT UNTIL CAUSE OF HIGH

PRESSURE HAS BEEN FOUND AND CORRECTED.

Pressure does not build

• Not enough product in frypot

• Metal shipping spacer not

removed from deadweight assy.

• Place full capacity product in frypot

when using fresh shortening.

• Remove shipping spacer; see

Unpacking Instructions Section

Shortening not heating

Foaming or boiling over

Shortening not draining

Filter motor won’t run

• Pressure not programmed

• Lid gasket leaking

• Drain valve open

• High temperature limit tripped

• See Boil-Over chart on fryer

and beginning of Operation

Section in this manual

• Drain valve clogged

• Motor overheated

• Check programming

• Reverse or replace lid gasket

• Close drain valve.

• Reset high temperature limit; see

Operating Components Section

• Follow Boil-Over procedures from

chart

• Push cleaning rod through open

drain valve

• Reset motor; see Filter Pump Motor

Protector-Manual Reset Section

More detailed troubleshooting information is available in the T echnical Manual, available at www .hennypenny .com,

or 1-800-417-8405 or 1-937-456-8405.

4-1 703

Page 45

Model PFE- 590/592

4-2. ERROR CODES In the event of a control system failure, the digital display will

show an “Error Message”. These messages are coded: “E04”,

“E05”, “E06”, “E41”. A constant tone is heard when an error code

is displayed, and to silence this tone, press any of the product

buttons.

DISPLAY CAUSE PANEL BOARD CORRECTION

“E04” Control board overheating Turn switch to OFF position, then turn

switch back to ON; if display still shows

“E04”, the board is getting too hot; check for

signs of overheating behind the control

panel; once panel cools down the controls

should return to normal; if “E04” persists,

replace the control

“E05” Shortening overheating Turn switch to OFF position, then back to

ON; if display shows “E05”, the heating

circuits and temperature probe should be

checked; once the unit cools down, the

controls should return to normal; if “E05”

persists, replace the controls

“E06” T emperature probe failure Turn switch to OFF position, then back to

ON; if the display shows “E06”, the temperature probe should be checked; once the

temperature probe is repaired, or replaced, the

controls should return to normal; if “E06”

persists, replace the controls

“E41” Programming Failure Turn switch to OFF position, then back to

ON. If display shows “E41”, the control

should be re-initialized (see programming

section); if the error code persists, replace

the control panel.

“E71” Pump motor relay failure or Replace relay if contacts are stuck closed;

wiring problem check wiring on POWER/PUMP switch, or at

wall receptacle; L1 and N may be reversed

403 4-2

Page 46

Model PFE- 590/592

Page 47

Model PFE- 590/592

G L O S S A R Y

HENNY PENNY PRESSURE FRYERS

air valve a valve that allows air into the filter lines when the pump is on in the mixing

mode on eight head fryers

airflow switch a switch that senses the amount of airflow coming from the blower; if the airflow

falls below a certain level, the switch cuts power to the gas control valve that

shuts down the burners on gas eight head fryers

blower located on the rear of a gas eight head fryer, the blower pulls flue gases out of

the flue and provides the proper amount of air to the burner tubes for efficient

combustion

breading a flour and seasoning mixture used to coat the product prior to frying

burner assembly an assembly on gas fryers that houses the pilot light which ignites the gas that

(gas fryers only) heats the fryer

burner chamber the area on four head fryers in which the gas combustion that heats the

(gas fryers only) shortening takes place

burner tubes the tubes in eight head fryers through which heated air is forced to heat the

(gas fryers only) shortening

carrier a wire frame inside the eight head frypot that holds five racks of product during the

cook cycle

casters the wheels on bottom of the fryer that allow the unit to roll; casters should be

locked when unit is in use and not being moved; casters may be adjusted to help

level the fryer

cleaning solution an agent used to clean the frypot; see recommended cleaning procedures

cold zone an area in the bottom of the frypot where shortening is cooler than the area

above; the zone allows the crumbs to settle without burning

condensation drain pan a pan located at the bottom of the fryer that collects condensation from the steam

exhaust system; the pan should be removed and emptied periodically

cook cycle a programmed cycle that cooks a particular product at a preselected temperature

and for a preselected time

cooking load the amount of product cooked during a cook cycle

cool a preset temperature, usually 250° F (121° C) or less, which can be manually or

automatically switched to, to save the life of the shortening, when not cooking.

counterweight the weights shipped with the fryer that, when installed in the counterweight

assembly , enable the eight head fryer lid to lift easily

403 G-1

Page 48

Model PFE- 590/592

counterweight assembly an assembly of weights and cables that enable the eight head fryer lid to lift

easily

cracklings the crumbs of breading that come off the product during a cook cyclecrumb

catcher the part of the filter assembly on four head fryers that filters crumbs out

of the shortening before the shortening is pumped back into the frypot

crumb catcher the part of the filter assembly on four head fryers that filters crumbs out of the

shortening before the shortening is pumped back into the frypot

data plate a label or plate located on the right side panel of the fryer that indicates the fryer

type, serial number, warranty date, and other information

deadweight a metal cylinder that works with the orifice to regulate the amount of steam

entering the deadweight assembly

deadweight valve assembly an assembly that controls pressure inside the frypot; the entire deadweight

assembly should be cleaned according to the recommended procedures; the

assembly is made up of the deadweight, the deadweight cap, the deadweight

orifice, the deadweight valve, and the deadweight body

deadweight cap a threaded cap that screws onto the deadweight valve housing

deadweight orifice an opening that regulates the amount of steam entering the deadweight assembly

deadweight body a container that holds the deadweight assembly

deadweight seat indentation on both ends of deadweight

dilution box a metal air intake device on the rear of the fryer to pull in fresh air for the blower

drain interlock switch a microswitch that automatically shuts off the fryer heat in the event the drain

valve is inadvertently opened while the fryer power switch is in the ON position

drain valve a valve that allows the shortening to drain from the frypot into the filter drain

pan; the fryer power switch should be in the OFF position before the drain valve

is opened; the drain valve should remain closed at all other times

drop temperature the starting, preset cooking temperature, at which product is placed in the

shortening

dumping table a table onto which the cooked product is dumped after removal from the fryer

frypot

exhaust hose a hose used to vent steam from the frypot on eight head fryers

fill lines the lines marked on the interior real wall of the frypot that show the proper

shortening level (also referred to as level indictor lines)

filter clips the clips are the part of the filter screen assembly that holds the filter envelope

closed

filter union the threaded connection between the fryer and the filter system that can be

connected or released without tools

G-2 403

Page 49

Model PFE- 590/592

filter drain pan a pan that rolls or slides under the fryer into which shortening is drained

filter envelope a fiber envelope into which the filter screen is placed; the end of the envelope is

folded and held closed with filter clips; a part of the filter screen assembly

filter quick disconnect an optional connection on the fryers allowing the filter rinse hose to be con-

nected or released without tools

filter screen assembly an assembly that filters the shortening as it is pumped from the frypot; the

assembly is made up of two filter screens, a filter envelope, and two filter clips

(Note: four head fryers have three filter screens that includes a crumb catcher)

flame sensors the sensors that shut off the gas supply to eight head gas fryers if the pilot lights

(gas fryers only) go out or do not light

flashpoint the temperature at which shortening ignites

frypot the interior portion of the fryer that holds the shortening and the product while

cooking

frypot collar the top flat surface area around the fryer lid

gas control valve an automatic dual controller that controls gas to both pilot lights and gas

(gas fryers only) pressure to burners on fryers; if either pilot light goes out, the controller shuts

off the gas to the other pilot light

gas valve knob the knob that opens and closes the gas control valve

(gas fryers only)

gas pressure regulator a device located on the gas control valve that regulates the gas pres-

sure; the

(gas fryers only) pressure specifications are preset at the factory

heat indicator the light that illuminates when the shortening is being heated; the light goes off

when the preset shortening temperature has been achieved

heating elements the coils located inside the frypot on electric fryers that heat the shortening

high limit a temperature control that opens and shuts off the heat to the frypot if it senses

shortening temperature in excess of 420°F (212°C) on eight head fryers and 450°F

(232°C) on four head fryers

idle a preset temperature, usually 250° F (121° C) or less, which can be manually or

automatically switched to, to save the life of the shortening, when not cooking.

ignition modules two modules that send electrical energy to the spark igniters that ignite the pilot

lights on eight head gas fryers

L-shaped brush a brush included with the fryer that is used to clean around the burner tubes and

heating elements

landing table another name for a dumping table (see dumping table)

level indicator lines lines marked on the interior real wall of the frypot that show the proper

shortening level (also referred to as fill lines)

403 G-3

Page 50

Model PFE- 590/592

lid assembly an assembly comprised of lid, lid handle, lid latch, and lid gasket (Note: on four

head fryers. the lid assembly includes spindles)

lid gasket the gasket around the lid that creates a seal when the lid is properly latched

lid handle a handle that is attached to the lid and is used to lower the lid into contact with

the frypot; the handle is then pulled forward and pushed down to lock the lid in

place (see lid latch)

lid latch a mechanical catch on the front of the fryer lid that engages a bracket located on

the front of the frypot; the latch holds the lid down while it is being locked into

place

manual shutoff valve a valve located between the fryer and the wall that shuts off the flow of gas from

(gas fryers only) the supply line; this is not the main shutoff valve for the store

P-H-T the automatic control of pressure, heat, and time to produce appealing food

product

pilot orifice a controlled opening for the pilot light located on the burner assembly

(gas fryers only)

pilot light a small flame that remains burning even when the fryer is not in use; the flame

(gas fryers only) ignites the gas when the fryer is turned on

poker brush a brush that is included with the fryer that is used to clear the drain in the bottom

of the frypot. (also referred to as straight brush)

power/pump switch a three-way switch located on the front control panel of the fryer that serves as

an off/on switch and a filter switch

pressure gauge the gauge located on the left rear corner of the frypot that shows the pressure

inside the frypot

pressure pad a piece of plastic on eight head fryers located between the lid locking arm and the

lid casting that helps create the seal for the lid; only a service technician should

perform maintenance or repair on the pressure pad

product a food item cooked in the fryer

ready the starting, preset cooking temperature, at which product is placed in the

shortening

safety relief valve a spring loaded valve that automatically releases excess pressure if the operating

valve becomes obstructed; if the safety release valve activates, turn the Power/

Pump switch to “OFF” to release all pressure from the frypot

setpoint a preset cooking temperature; the setpoint is a programmable feature

shipping spacer a spacer located in the deadweight assembly for protection during shipment

shortening mixing system an automatic system on eight head fryers that periodically uses the filter pump to

mix the shortening in the frypot to prevent an accumulation of moisture to

minimize the boiling action in the frypot

G-4 403

Page 51

Model PFE- 590/592

sift breading the process of removing clumps from breading

solenoid valve a valve used to generate or release pressure for the cook cycle

spark igniters the igniters that create a spark to ignite the pilot lights on eight head gas fryers

(gas fryers only) (see ignition modules)

standpipe the pipe through which oil is pumped back into the frypot after the filtering

process is complete

standpipe assembly the pipe and fittings that are part of the shortening filtering process

straight brush a brush that is included with the fryer that is used to clear the drain in the bottom

of the frypot

temperature probe a round probe that is located in the inside of the frypot that measures the

temperature of the oil in the frypot; the probe communicates with the control

panel

403 G-5

Page 52

*FM05-032-G* Henny Penny Corp., Eaton, Ohio 45320, Revised 8-6-10

Henny Penny Corporation

P .O.Box 60

Eaton,OH 45320

1-937-456-8400

1-937-456-8402 Fax

Toll free in USA

1-800-417-8417

1-800-417-8434 Fax

www.hennypenny.com

Loading...

Loading...