Page 1

Global Foohrvice Sohtiom

Henny Penny --

Pressure Fryer _

ode1 581 .

Page 2

Page 3

Henny Penny Model 581

FM01-322

Revised 04-16-07

Page 4

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Page 5

e

Section 1.

Section 2.

Section 3.

INTRODUCTION

l-l.

l-2.

l-3.

PressureFryer

ProperCare

Assistance

l-4. Safety

INSTALLATION

2-l.

2-2.

2-3.

2-4.

2-5.

2-6.

2-7.

2-8.

Unpacking Instructions

Selecting the Fryer Location

LevelingtheFryer

Ventilation of Fryer’ ........................................

Electrical Requirements

Testing the Fryer ...........................................

Operational Checks

International Electrical Requirements

OPERATION

...............................................

.............................................

..............................................

...............................................

...................................................

...............................................

.................................................

3-1. Operating Controls

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

3-8.

3-9.

3-10.

3-l 1.

3- 12.

3-l 3.

LidOperation

Filling or Adding Shortening

CareoftheShortening

Start-Up (Preheat) Procedures

Frying Procedures

Filtering

Changing the Filter Envelope

Filter Pump Problem Prevention

Cleaning the Frypot

Seasonal Shutdown

Cleaning the Operating Valve

Night Closing Procedures ...................................

.............................................

.................................................

.....................................

.................................

.........................................

.....................................

........................................

..........................

.........................................

.................................

......................................

................................

.........................................

................................

..............................

........................................

........................................

................................

l-l

l-l

l-l

l-l

1-2

2-1

2-l

2-4

2-4

2-4

2-4

2-5

2-5

2-6

3-l

3-l

3-6

3-8

3-8

3-9

3-10

3-12

3-14

3-16

3-17

3-19

3-19

3-20

Section 4.

TROUBLESHOOTING

4-l.

Introduction

4-2. Troubleshooting

Section 5. MAINTENANCE

5-l.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. Arrangement

5-3. Maintenance Hints

5-4.

5-5.

Removing Complete Panel Assy.

High Temperature Limit Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6. Fuse Holders

5-7.

Cook/Pump Switch

5-8. Contactors

5-9.

Heating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

...........................................

..............................................

...........................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . ; . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-l

4-l

4-l

5-l

5-l

5-l

5-l

5-l

5-2

5-4

5-4

5-6

5-8

.

Page 6

Henny Penny Model 581

TABLE OF CONTENTS

Section Page

5-10. Drain Switch ............................................................................................ 5-10

5-11. Temperature Probe Replacement............................................................. 5-11

5-12. Control Panel Replacement...................................................................... 5-12

5-13. Switchboard Replacement ....................................................................... 5-13

5-14. Heat Relay................................................................................................ 5-14

5-15. Pressure Relay.......................................................................................... 5-15

5-16. “E10” Relay ............................................................................................. 5-16

5-17. Keyswitch ................................................................................................ 5-17

5-18. Transformer.............................................................................................. 5-18

5-19. Reversing the Lid Gasket......................................................................... 5-19

5-20. Lid Counterweight ................................................................................... 5-20

5-21. Pressure Pads ........................................................................................... 5-21

5-22. Lid Adjustment ........................................................................................ 5-22

5-24. Adjusting the Magnet Plate (SN: GG015JJ and below) ......................... 5-23

5-25. Solenoid Valve......................................................................................... 5-23

5-26. Operating Control Valve.......................................................................... 5-25

5-27. Removal & Cleaning of Safety Relief Valve........................................... 5-27

5-28. Pressure Gauge......................................................................................... 5-27

5-29. Drain Valve Removal .............................................................................. 5-28

5-30. Nylatron Slides......................................................................................... 5-28

Section 6. PROGRAMMING ............................................................................................... 6-1

6-1. Introduction.............................................................................................. 6-1

6-2. Programming............................................................................................ 6-1

6-3. Load Compensation ................................................................................. 6-4

6-4. Load Anticipation .................................................................................... 6-4

6-5. Proportional Control ................................................................................ 6-4

6-6. Filter Cycle Count.................................................................................... 6-5

6-7. Idle Mode................................................................................................. 6-5

6-8. Melt Mode................................................................................................ 6-6

6-9. Programming 1

6-10. One Button Henny Penny Parameters...................................................... 6-7

6-11. Timing Through Power Interruptions ...................................................... 6-7

6-12. Clean-Out Mode....................................................................................... 6-8

Section 7. PROGRAMMING ............................................................................................... 7-1

7-1. Introduction.............................................................................................. 7-1

7-2. Genuine Parts........................................................................................... 7-1

7-3. When Ordering Parts................................................................................ 7-1

7-4. Prices........................................................................................................ 7-1

7-5. Delivery.................................................................................................... 7-1

7-6. Warranty .................................................................................................. 7-1

7-7. Recommended Spare Parts for Distributors............................................. 7-1

Exploded Views ....................................................................................... 7-2 to 7-19

Wiring Diagrams

Distributor Lists – Domestic and International

ii 206

st

Cycle ............................................................................ 6-7

Page 7

Henny Penny Model 581

SECTION 1. INTRODUCTION

1-1. PRESSURE FRYER The Henny Penny Pressure Fryer is a basic unit of food pro-

cessing equipment which is used only in institutional and

commercial food service operations.

P-H-T A combination of Pressure, Heat, and Time is automatically

controlled to produce the optimum in a tasty, appealing

product.

Pressure Pressure is basic to this method of food preparation. The pres-

sure is developed from the natural moisture of the food. The

patented lid traps this moisture and uses it as steam. Because

the steam builds rapidly, a greater part of the natural juices

are retained within the food. An operation valve vents excess

steam from the pot and maintains constant live steam pressure.

Heat Heat generated is another important factor of the pressure fryer.

Energy savings is realized due to the unit’s short frying time,

low temperature, and heat retention of the stainless steel

cookpot.

Time Time is important because the shorter time involved in frying

foods results in additional economies for the user. Foods are

table ready in less time than it would take to fry them in a conventional open-type fryer.

1-2. PROPER CARE As in any unit of food service equipment, the Henny Penny

Pressure fryer does require care and maintenance. Requirements for the maintenance and cleaning are contained in this

manual and must become a regular part of the operation of the

unit at all times.

1-3. ASSISTANCE Should you require outside assistance, call your local

distributor in your area, or call 1-800-417-8405 or

937-456-8405.

201 1-1

Page 8

The Henny Penny Pressure Fryer has many safety features

incorporated. However, the only way to ensure a safe operation

is to fully understand the proper installation, operation, and

maintenance procedures. The instructions in this manual have

been prepared to aid you in learning the proper procedures.

Where information is of particular importance or safety

related, the words DANGER, WARNING, CAUTION, and

NOTE are used. Their usage is described below.

The word DANGER indicates an imminent hazard

which will result in highly serious injury such as second

or third degree burns, loss of sight, and other permanent injuries.

The WARNING is used to alert you to a procedure,

that if not performed properly, might cause personal

injury, such as burns and/or loss of sight, and damage

to the fryer.

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the fryer,

or product.

The word NOTE is used to highlight especially important information.

Page 9

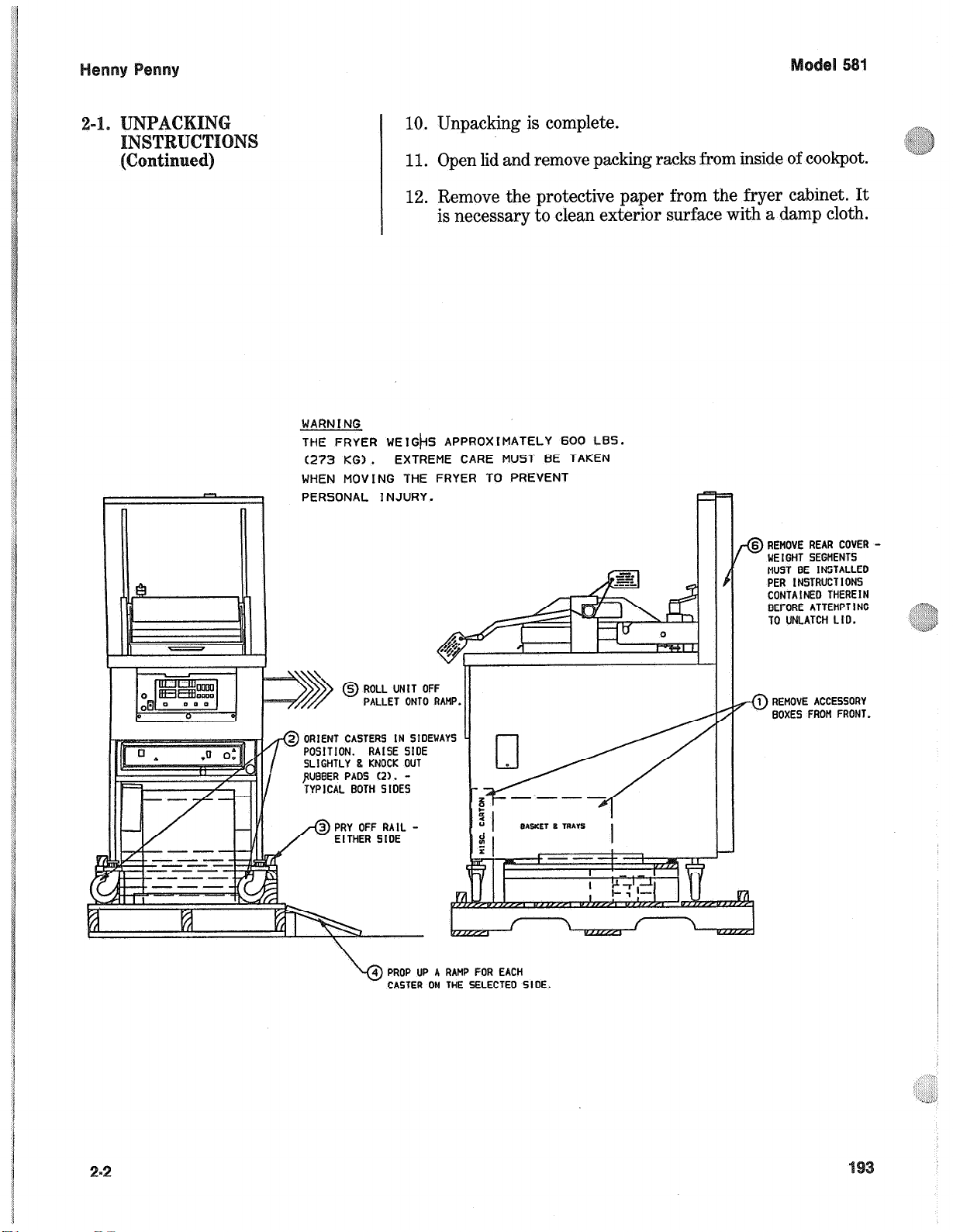

1. Cut and remove the metal bands from the carton.

2. Remove the carton lid and lift the main carton off the

fryer.

3. Remove corner packing supports (4).

4. Cut and remove the metal bands holding the fryer to the

pallet.

Do not unlatch the lid before completion of steps 5, 6,

and 7.

5. Remove the fryer from the pallet. See page 2-2.

The fryer weighs approximately 600 lbs. (273 KG).

Extreme care should be taken when moving the fryer

to prevent personal injury.

6. Load the Counterweight Assembly. See page 2-3.

7. Replace rear cover.

8. Cut warning tags from the lid assembly. The lid may now

be unlatched.

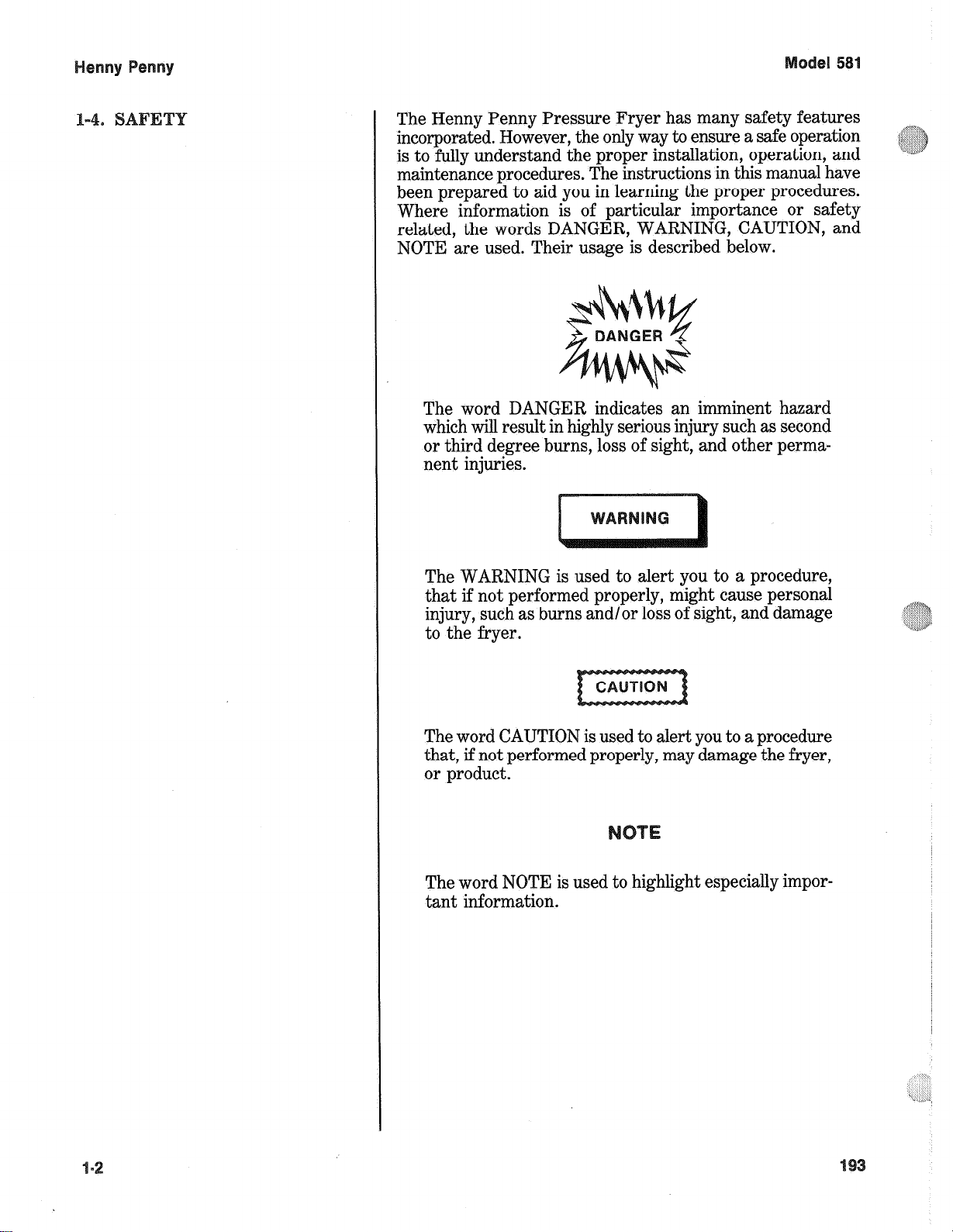

9. Prepare the deadweight valve for operation.

The metal shipping support is placed inside the

deadweight valve housing to protect the orifice and

weight during shipment. This support must be removed

prior to installation and start-up.

A. Unthread the top cap.

B. Remove the round weight.

C. Remove and discard the shipping support.

D. Clean the orifice with a dry cloth.

m

E. Replace the weight and secure the top cap.

Page 10

10. Unpacking is complete.

a:‘,‘:!:,!>j)

4S$~@b

11. Open lid and remove packing racks from inside of cookpot.

12. Remove the protective paper from the fryer cabinet. It

is necessary to clean exterior surface with a damp cloth.

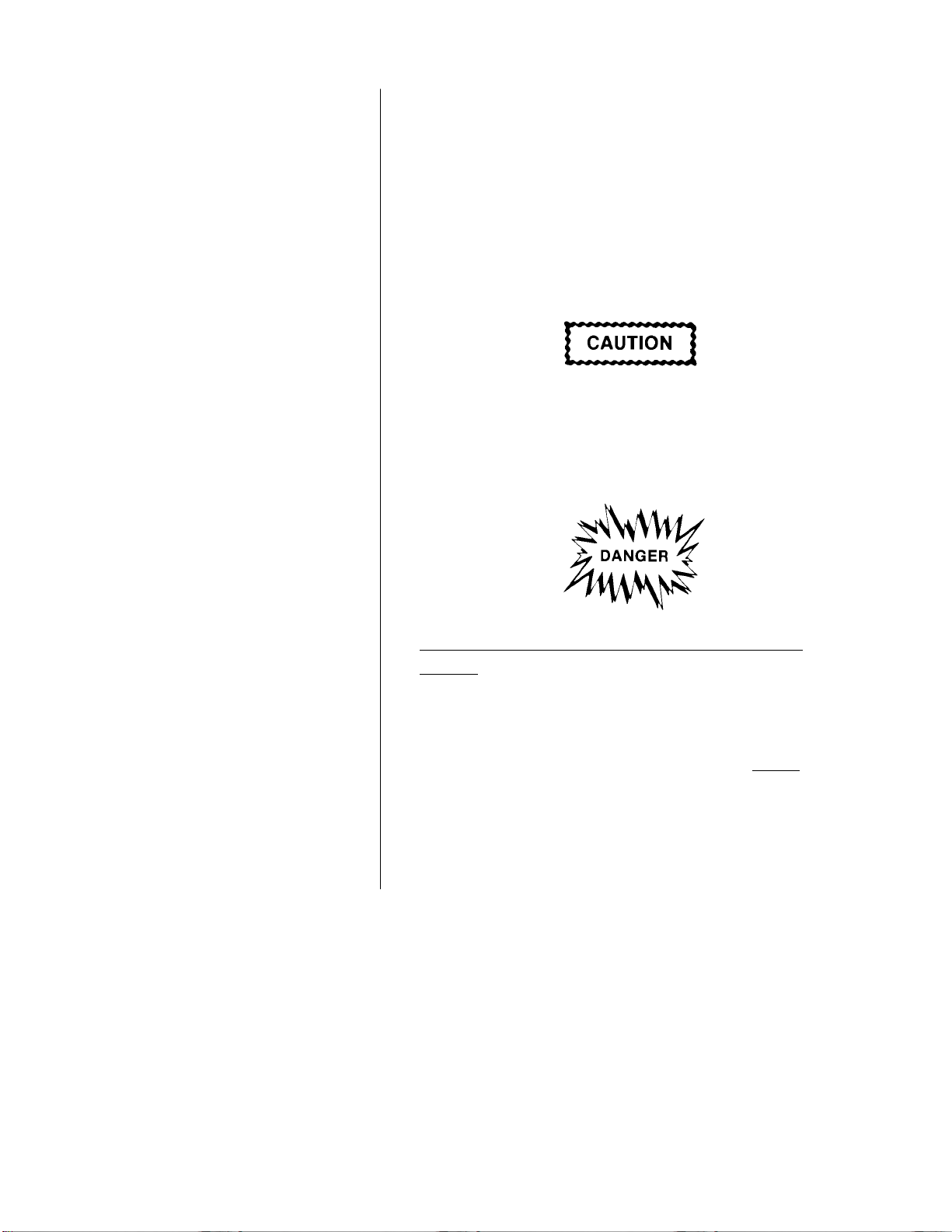

WARN I NG

THE FRYER WEI+S APPROXlMATELY 600 L6S.

(273 KG).

WHEN MOVING THE FRYER TO PREVENT

PERSONAL INJURY.

EXTREME CARE MUST BE TAKEN

-@REMOVE REAR COVER UEIGHT SEGMENTS

MUST BE INSTALLED

PER INSTRUCTIONS

CONTAINED THEREIN

BEFORE ATTEMPTING

TO UNLATCH LID.

A%

;,,, ::&

‘{

”

@ ROLL UNIT OFF

PALLET ONTO RAMP

ORIENT CASTERS IN SlOEWAYS

POSITION.

SLIGHTLY 8 KNOCK OUT

JIUBSER PADS (2). -

TYPICAL BOTH SIDES

RAISE SIDE

EITHER SIOE

PROP UP 4 RAMP FOR EACH

CASTER ON THE SELECTEO SIDE.

1 REMOVE ACCESSORY

f-0

BOXES FRON FRONT.

Page 11

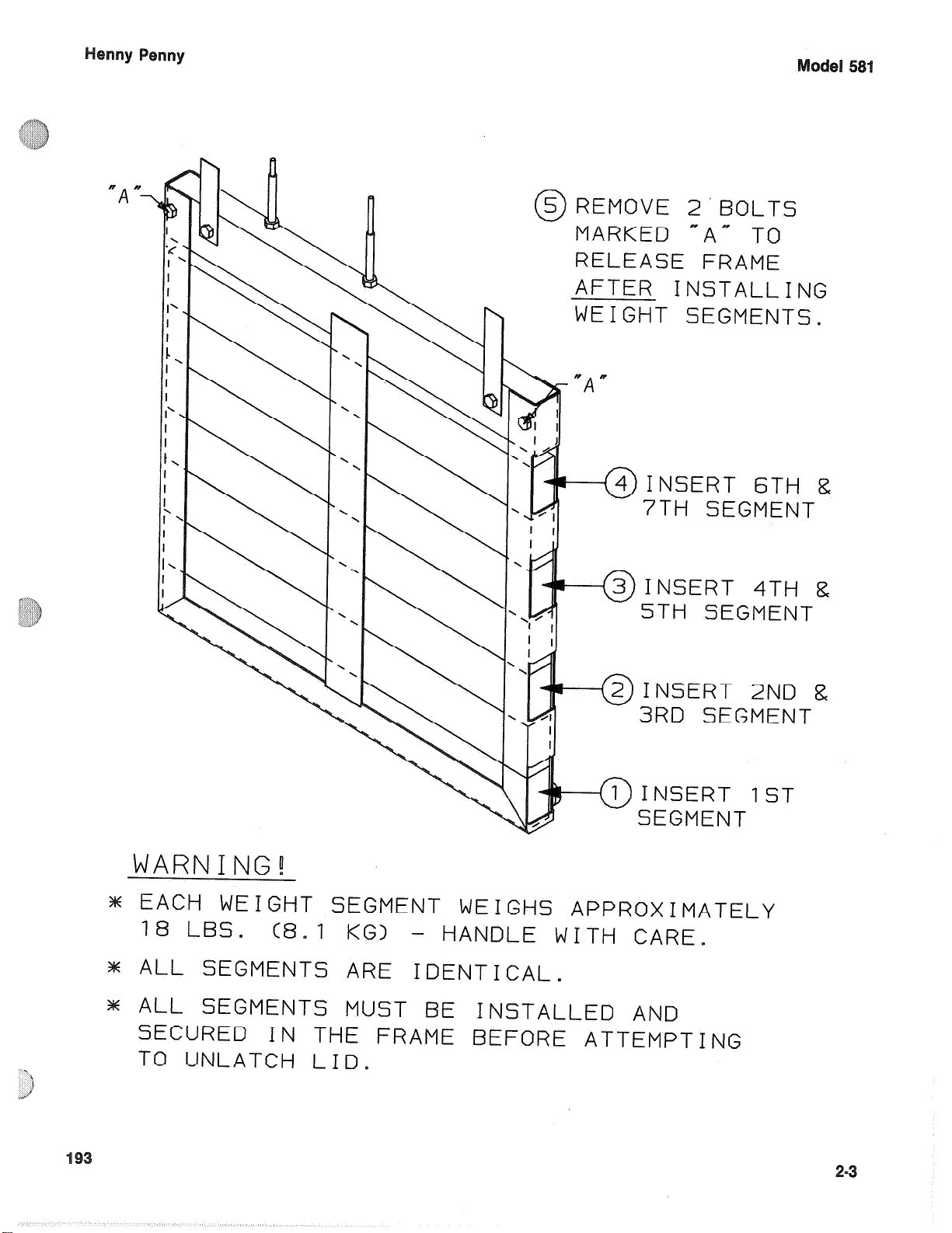

5 REMOVE 2’BOLTS

0

MARKED “A” TO

RELEASE FRAME

AFTER INSTALLING

WEIGHT S

EGMENTS.

INSERT 6TH &

7TH SEGMENT

I

C3J INSERT 4Tti 8

\

\

Y

Y \ .

\

5TH SEGMENT

2 INSERT 2ND &

0

3RD SEGMENT

' 9

.,I

--(~)INsE

SEGMENT

WARNING!

m EACH

18 LBS.

m ALL SEGMENTS ARE

m ALL SEGMENTS MUST BE INSTALLED AND

SECURED

TO UNLATCH

WEIGHT SEGMENT WEIGHS

(8.1 KG> - HANDLE WITH CARE.

IDENTICAL.

IN

THE FRAME BEFORE ATTEMPTING

LID.

APPROXIMATELY

RT IST

Page 12

58

The proper location of the fryer is very important for operation, speed, and convenience. Choose a location which will

provide easy loading and unloading without interfering with

the final assembly of food orders. Operators have found that

frying from raw to finish, and holding the product in a warmer

provides fast continuous service. Landing or dumping tables

should be provided next to at least one side of the fryer. Keep

in mind the best efficiency will be obtained by a straight line

operation, i.e. raw in one side and finished out the other side.

Order assembly can be moved away with only a slight loss of

efficiency.

For proper operation, the fryer must be level from side to side

and front to back. Using a level placed on the flat areas around

the frypot collar, adjust the casters until the unit is level.

The fryer should be located with provision for venting into adequate exhaust hood or ventilation system. This is essential to

permit efficient removal of the steam exhaust and frying odors.

Special precaution must be taken in designing an exhaust

canopy to avoid interference with the operation of the fryer.

Make certain the exhaust hood is designed high enough to allow

for proper opening of the fryer lid. We recommend you con-

sult a local ventilation or heating company to help in designing an adequate system.

The electric fryer is available from the factory wired for

2081120 or 240/120 volts, three phase 60 Hz. service. The power

cord may be already attached to the fryer, or provided at

installation. Check the data plate on the right side of the fryer

to determine the correct power supply.

This fryer must be adequately and safely grounded.

Refer to local electrical codes for correct grounding

procedures. If fryer is not adequately grounded,

electrical shock could result.

A separate disconnect switch with proper capacity fuses or

breakers must be installed at a convenient location between

the fryer and the power source. It should be an insulated copper

conductor rated for 600 volts and 90 “6. For runs longer than

50 feet, use the next, larger size wire.

Page 13

Each Henny Penny pressure fryer was completely checked and

tested prior to shipment. However, it is good practice to check

the unit again after installation.

1. Cook a round of product.

2. Check to see that the indicator needle in the pressure

gauge is reading in the “Operating Zone”.

Should the pressure gauge read beyond the “Operating

Zone” turn the Power/Pump switch to the “OFF” position and refer to the Operation Control Valve Section.

Continued use of the unit at this high pressure could

result in serious injuries and severe burns.

3. Make sure lid gasket is not leaking, and no steam is coming

from safety relief valve.

4. Cheek the drain valve and fill line check valve

5. At the end of the cook cycle:

* The control will sound off by beeping.

The fryer will automatically depressurize.

6. Push the timer button.

7. When all the pressure has exhausted (observe pressure

gauge) open the lid.

DO NOT ATTEMPT TO OPEN LID UNTIL THE

PRESSURE DROPS TO ZERO. Opening the lid when

the cookpot is pressurized will allow hot shortening and

moisture to escape from the cookpot, resulting in severe

burns.

8. Let rack hang for 3-5 seconds, then proceed to take out

racks of chicken and place onto a bun pan.

Page 14

If all the above functions have been performed satisfactorily

the fryer is ready for operation.

All operators, as well as maintenance and management

personnel, must throughly read and understand the

Operation Section prior to putting the fryer into operation. Failure to adhere to these instructions could result

in serious bodily injury or property damage.

2-8. INTERNATIONAL

ELECTRICAL

~~REMENT~

Units being used outside the United States may not be shipped

with the power cord attached to the unit because of the

different wiring codes. The fryers are available from the

factory wired for 208240,380 and 415 volts, 3 phase, 50 Hertz

service. A terminal block is mounted inside the fryer for the

cable wiring. A decal on the inside of the right side panel will

help in the wiring of the unit.

To install the power cord, follow these procedures:

1. Remove the side panel from the right side of the unit.

2. Remove the front panel, behind the filter knob and quick

disconnect.

3. Thread the cable through the strain relief on the junction

box.

4. Attach the wires to the terminal block according to the

wiring diagram on the side panel.

5. Pull the slack out of the cable and tighten the screws on

the strain relief.

6. Pull the slack out of the cable and secure it with.the clamp

on the back of the cookpot.

Be sure the cable doesn’t sag, or it could interfere with

the use of the portable filter.

Page 15

7. Pull the slack out of the cable and secure it with the clamp

on the frame, at the rear, right leg of fryer.

Be sure enough slack is out of the cable so it doesn’t

extend out past the portable filter stop bracket at the

bottom of the fryer frame. The cable could interfere

with the portable filter, not allowing it to be pushed

all the way in. This could cause hot shortening to spill

onto the floor.

8. Wiring the fryer is now complete.

Page 16

Henny Penny Model 581

BOIL-OVER PREVENTION

IN HENNY PENNY FRYERS

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN SHORTENING

OVERFLOWING THE FRYPOT, WHICH COULD CAUSE SERIOUS BURNS,

PERSONAL INJURY, FIRE AND/OR PROPERTY DAMAGE.

• THE SHORTENING MAY BE STIRRED ONLY DURING THE MORNING

START UP PROCEDURE. DO NOT STIR THE SHORTENING AT ANY

OTHER TIME

• FILTER THE SHORTENING AT LEAST TWICE A DAY

• FILTER ONLY AFTER POWER SWITCH IS OFF

• BRUSH ALL CRACKLINGS FROM FRYPOT SURFACES AND THE COLD

ZONE DURING THE FILTERING PROCESS

• MAKE SURE THE FRYER IS LEVEL

• BE CERTAIN THE SHORTENING IS NEVER ABOVE THE UPPER FRYPOT

“FILL” LINE

• USE RECOMMENDED PRODUCT LOAD SIZE, 22lbs. (9.9 kg)

FOR ADDITIONAL INFORMATION ON THESE INSTRUCTIONS REFER TO THE

HENNY PENNY SERVICE.

FOR ASSISTANCE CALL THE HENNY PENNY SERVICE DEPARTMENT AT

1-800-417-8405, or1-937-456-8405.

2-8 203

Page 17

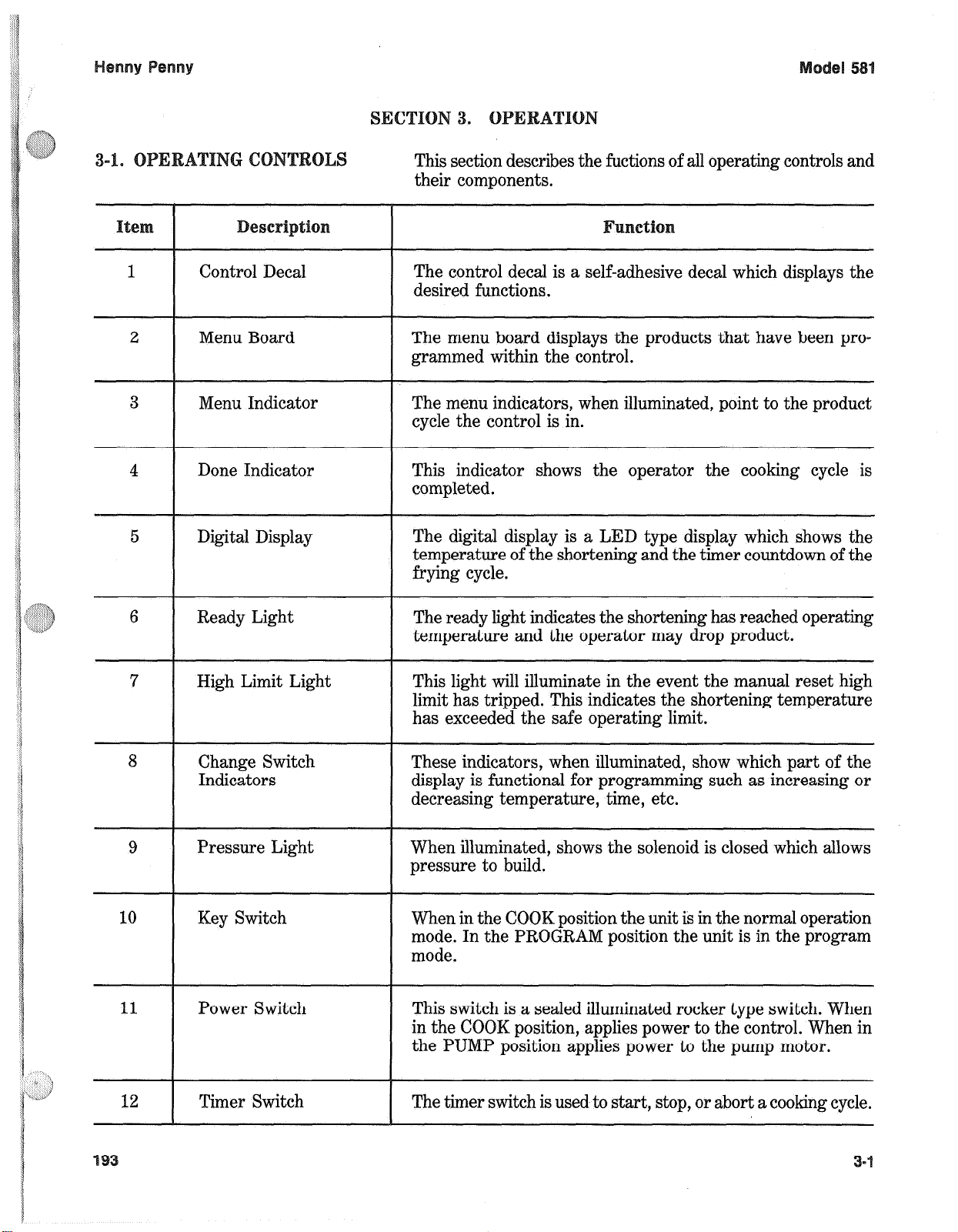

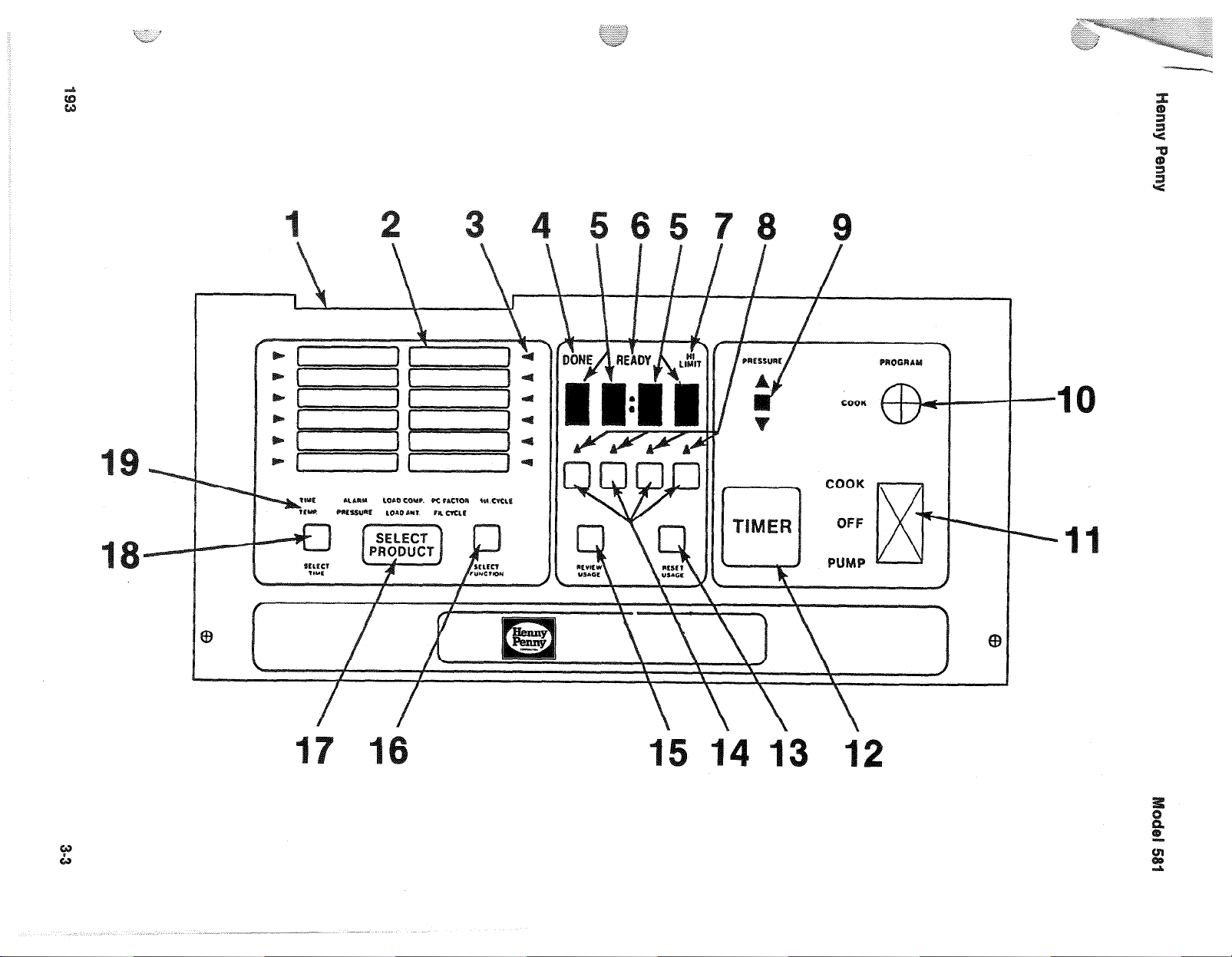

This section describes the fuctions of all operating controls and

their components.

1

Control Decal

Menu Board

Menu Indicator

Done Indicator

Digital Display

Ready Light

High Limit Light

The control decal is a self-adhesive decal which displays the

desired functions.

The menu board displays the products that have been programmed within the control.

The menu indicators, when illuminated, point to the product

cycle the control is in.

This indicator shows the operator the cooking cycle is

completed.

The digital display is a LED type display which shows the

temperature of the shortening and the timer countdown of the

frying cycle.

The ready light indicates the shortening has reached operating

temperature and the operator may drop product.

This light will illuminate in the event the manual reset high

limit has tripped. This indicates the shortening temperature

has exceeded the safe operating limit.

Change Switch

Indicators

Pressure Light

Key Switch

Power Switch

Timer Switch

These indicators, when illuminated, show which part of the

display is functional for programming such as increasing or

decreasing temperature, time, etc.

When illuminated, shows the solenoid is closed which allows

pressure to build.

When in the COOK position the unit is in the normal operation

mode. In the PROGRAM position the unit is in the program

mode.

This switch is a sealed illuminated rocker type switch. When

in the COOK position, applies power to the control. When in

the PUMP position applies power to the pump motor.

The timer switch is used to start, stop, or abort a cooking cycle.

Page 18

Itx?

I

escriptio

I

~u~~tiQ~

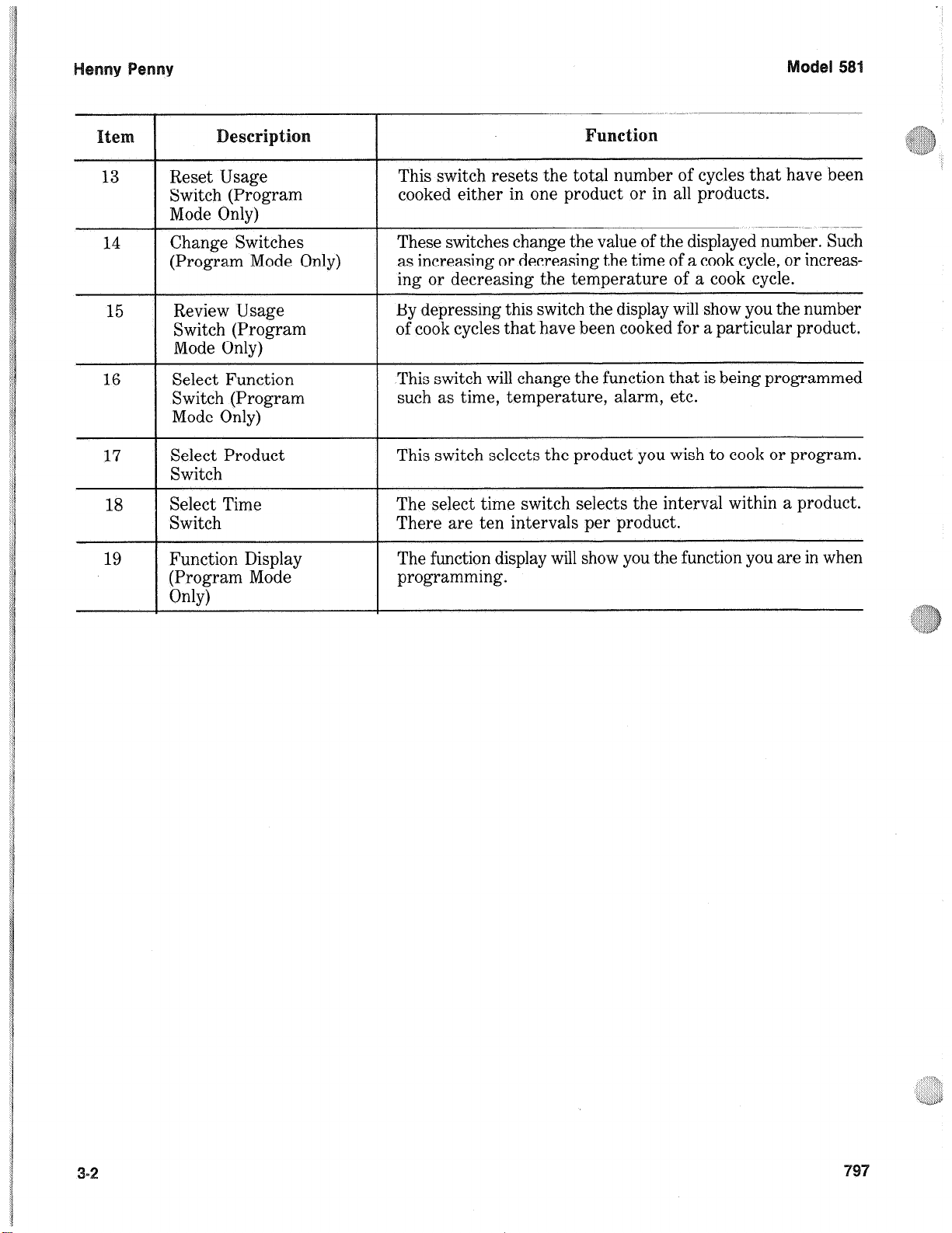

13 Reset Usage

Switch (Program

Mode Only)

14

15

16 Select Function

17

18

19 Function Display

Change Switches

(Program Mode Only)

Review Usage

Switch (Program

Mode Only)

Switch (Program

Mode Only)

Select Product

Switch

I

Select Time

Switch

(Program Mode

Only)

This switch resets the total number of cycles that have been

cooked either in one product or in all products.

These switches change the value of the displayed number. Such

as increasing or decreasing the time of a cook cycle, or increasing or decreasing the temperature of a cook cycle.

By depressing this switch the display will show you the number

of cook cycles that have been cooked for a particular product.

This switch will change the function that is being programmed

such as time, temperature, alarm, etc.

This switch selects the product you wish to cook or program.

I

The select time switch selects the interval within a product.

There are ten intervals per product.

The function display will show you the function you are in when

programming.

Page 19

COOK

PROGRlU

Page 20

Henny Penny Model 581

3-1. OPERATING CONTROLS (Continued)

1. Cook/Pump Switch This is a three-way switch with center “OFF” position. Move

the switch to the position marked “POWER” to operate the

fryer. Move the switch to the position marked “PUMP” to

operate the filter pump. Certain conditions must be met prior

to operation of the filter pump. These conditions are covered

later in this section.

2. Cookpot This reservoir holds the cooking shortening, and is designed to

accommodate the Heat Exchanger, 8 head of product and an

adequate cold zone for collection of cracklings.

3. Cooking Rack This stainless steel rack consists of five baskets that contain

the food product during and after frying.

4. Lid Gasket The lid gasket provides the pressure seal for the cookpot

chamber.

5. Operating Valve The dead weight style operating pressure relief valve is used to

maintain a constant level of steam pressure within the cookpot.

Any excess steam pressure is vented through the exhaust stack.

NOTE

Remove the dead weight cap, and clean the cap, weight, and

orifice, once a day to prevent over pressurization of the

cookpot

6. Safety Relief Valve The safety relief valve is an ASME approved spring loaded

valve set at 14.5 psi (999 mbar). In the event the operation

valve becomes obstructed, this safety valve will release excess

pressure, keeping the cookpot chamber at 14.5 psi (999 mbar).

If this occurs, turn the Power/Pump switch to the “OFF”

position to release all pressure from the cookpot.

7. Safety Relief Valve Ring THE RING IS NOT TO BE PULLED.

Severe burns from the steam will result.

8. Gauge The pressure gauge indicates the pressure inside the cookpot.

3-4 201

Page 21

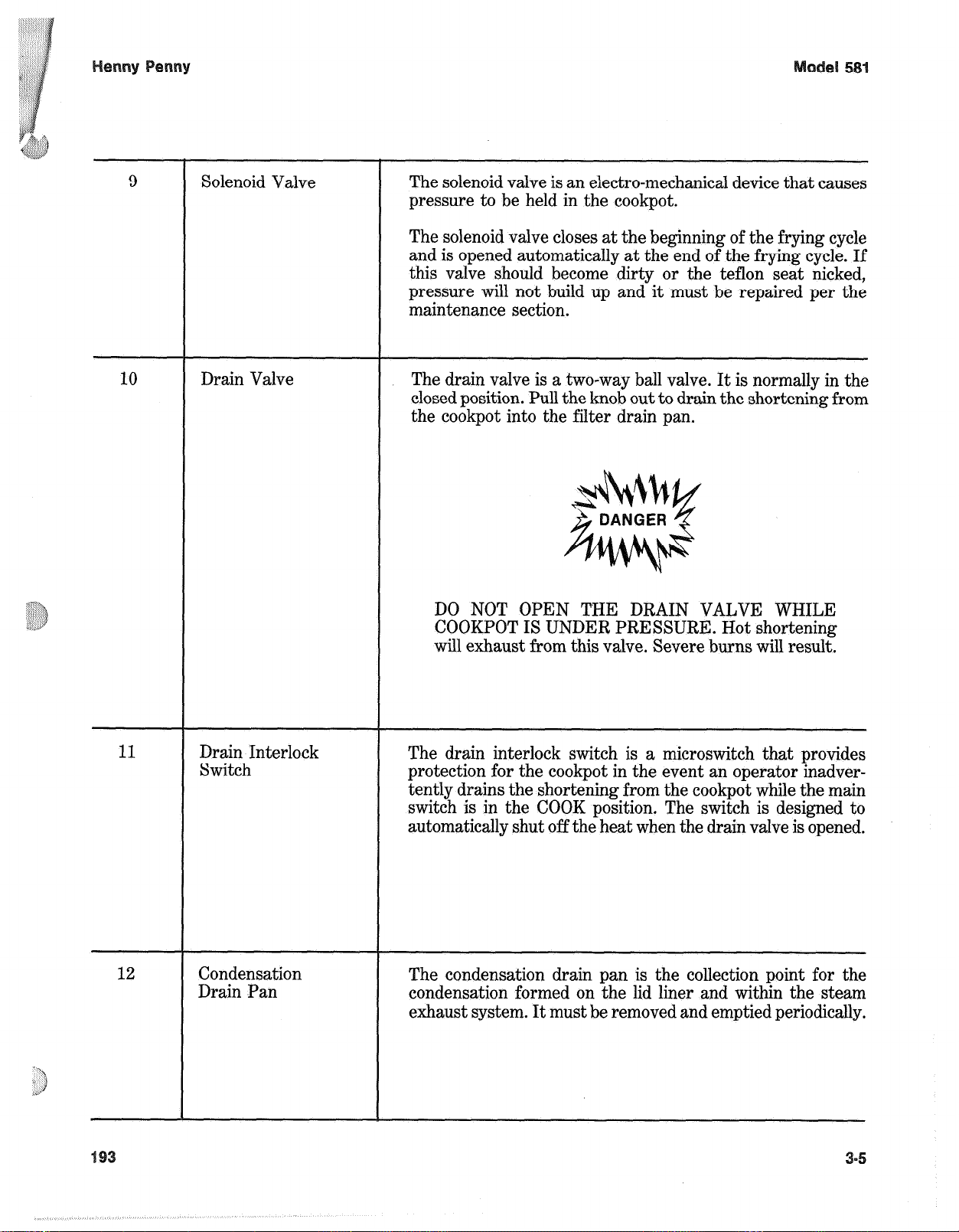

9

Solenoid Valve

The solenoid valve is an electro-mechanical device that causes

pressure to be held in the cookpot.

The solenoid valve closes at the beginning of the frying cycle

and is opened automatically at the end of the frying cycle. If

this valve should become dirty or the teflon seat nicked,

pressure will not build up and it must be repaired per the

maintenance section.

10

11

Drain Valve

Drain Interlock

Switch

The drain valve is a two-way ball valve. It is normally in the

closed position. Pull the knob out to drain the shortening from

the cookpot into the filter drain pan.

DO NOT OPEN THE DRAIN VALVE WHILE

COOKPOT IS UNDER PRESSURE. Hot shortening

will exhaust from this valve. Severe burns will result.

The drain interlock switch is a microswitch that provides

protection for the cookpot in the event an operator inadvertently drains the shortening from the cookpot while the main

switch is in the COOK position. The switch is designed to

automatically shut off the heat when the drain valve is opened.

Condensation

Drain Pan

The condensation drain pan is the collection point for the

condensation formed on the lid liner and within the steam

exhaust system. It must be removed and emptied periodically.

Page 22

Henny Penny Model 581

3-2. LID OPERATION

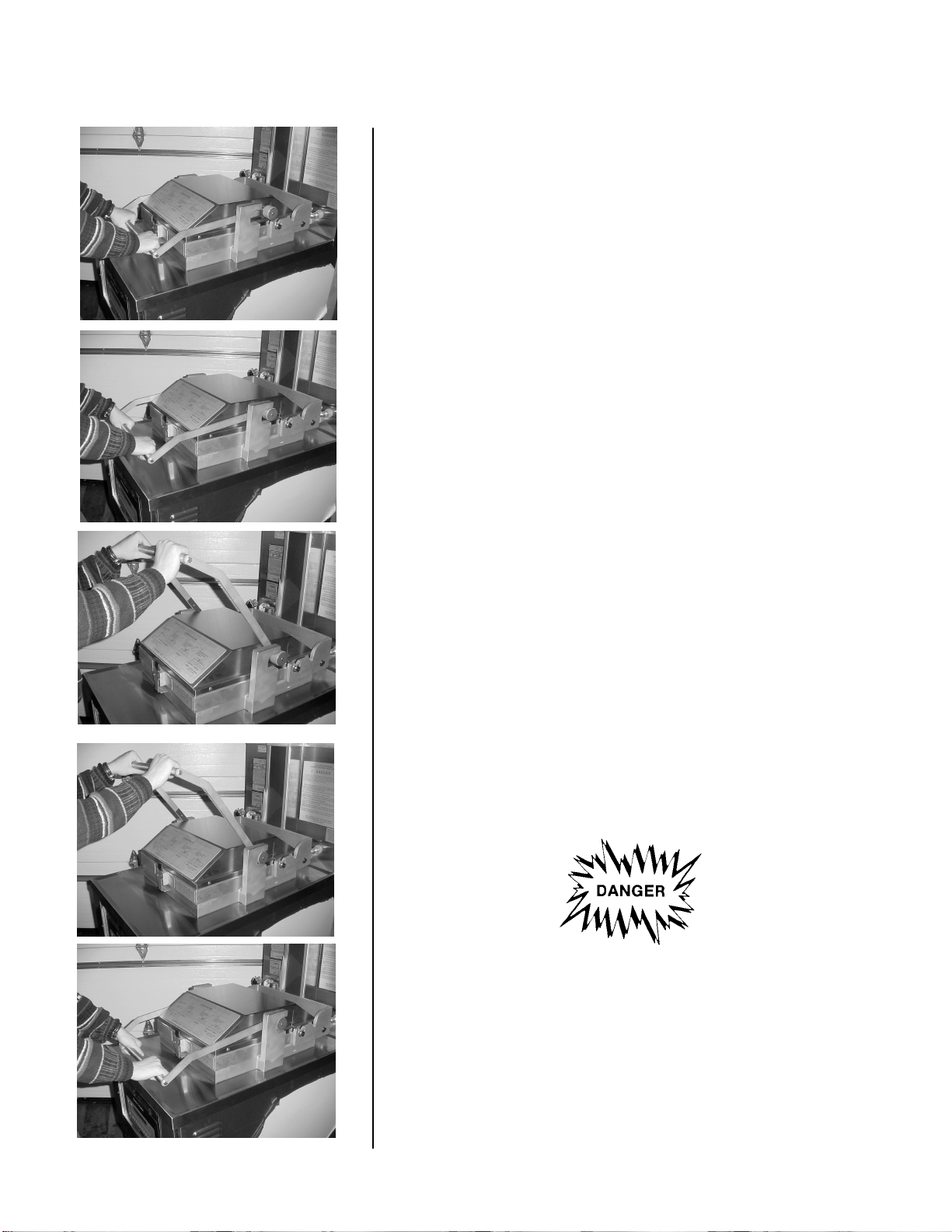

To close lid:

1. Lower the lid until lid latches into place.

1

2. Pull lid handle forward until it stops.

2 3. Lift up on the lid handle until it stops.

4. Bring lid handle out towards you until it stops.

3

5. Push lid handle down, locking lid in place.

4

DO NOT ATTEMPT TO OPEN LID UNTIL THE

PRESSURE DROPS TO ZERO. Lid is locked when fryer

is under pressure. Do not attempt to force the lid latch or

open the lid while under pressure. Opening the lid when

the cookpot is pressurized will allow hot shortening and

moisture to escape from the cookpot, resulting in severe

burns.

5

3-6 201

Page 23

Henny Penny Model 581

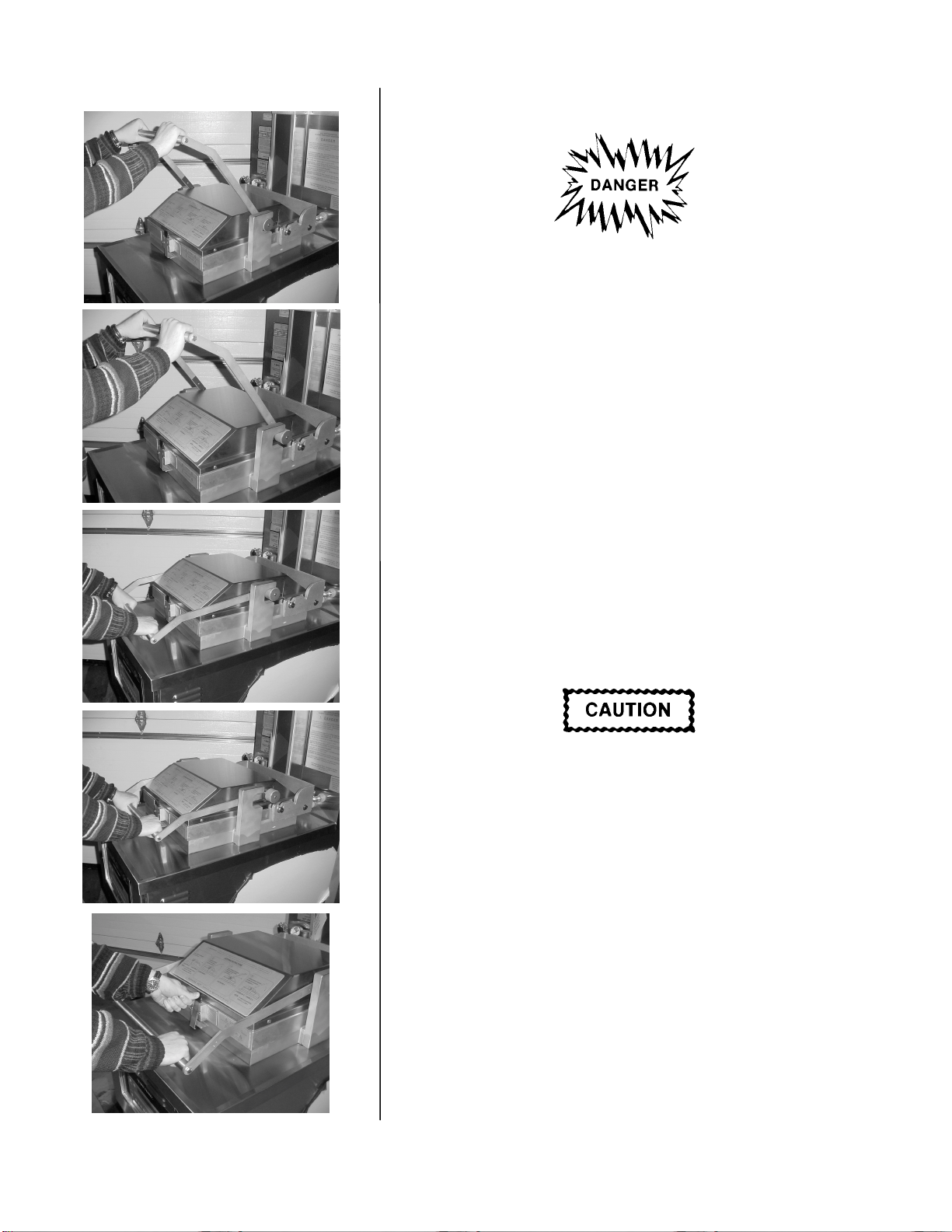

3-2. LID OPERATION (Continued) To open lid:

DO NOT ATTEMPT TO OPEN LID UNTIL THE

1 PRESSURE DROPS TO ZERO. Lid is locked when fryer

is under pressure. Do not attempt to force the lid latch or

open the lid while under pressure. Opening the lid when

the cookpot is pressurized will allow hot shortening and

moisture to escape from the cookpot, resulting in severe

burns.

1. Gently raise handle until it stops.

2

2. Push handle back until it stops.

3. Lower handle.

3

DO NOT raise the lid with the handle in the up position.

Lower the handle before attempting to raise the lid, or

damage to the lid could result.

4

4. Push handle back.

5. Unlatch the front lid latch and raise lid with handle.

5

201 3-7

Page 24

Henny Penny Model 581

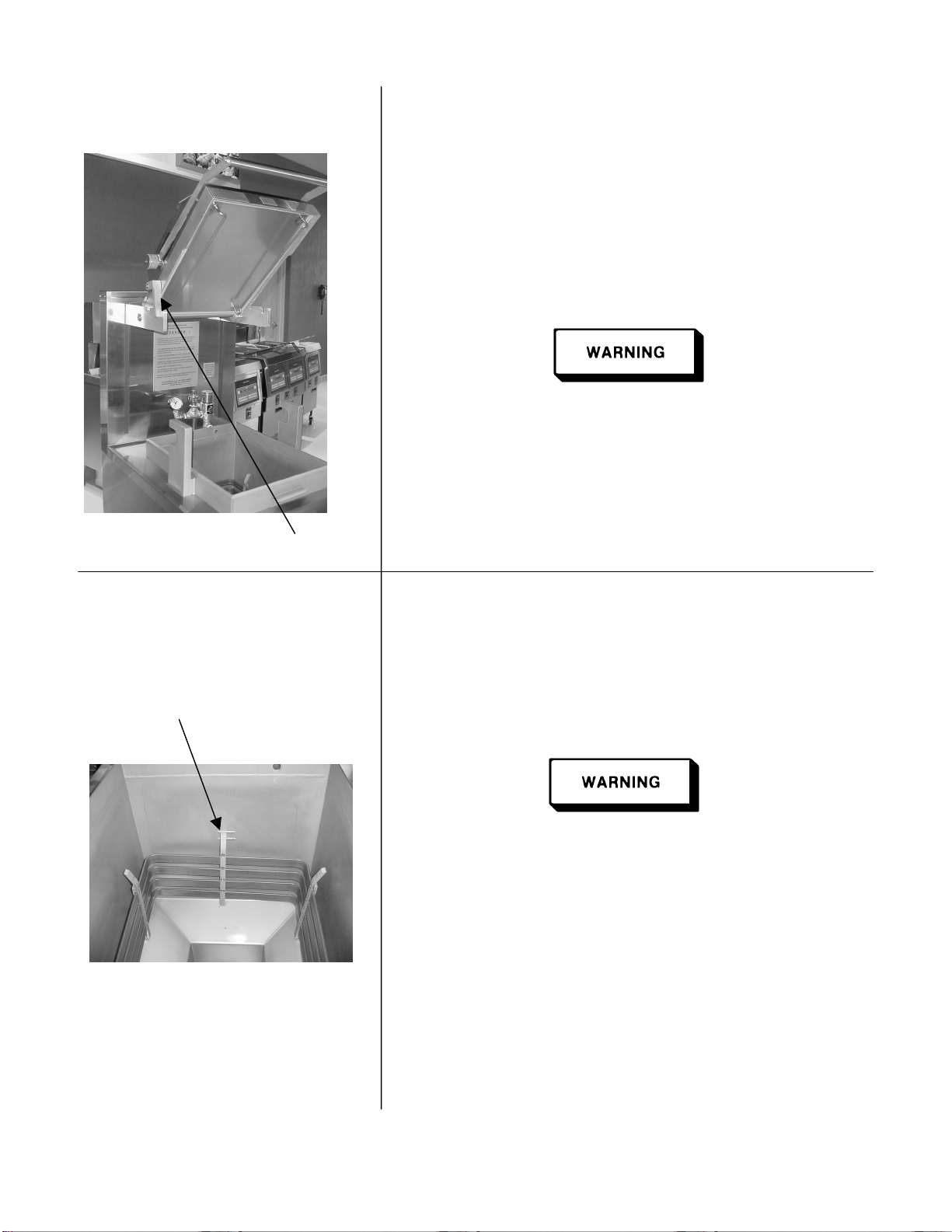

3-2. LID OPERATION Tilt the lid back for ease of filtering or servicing.

(Continued)

1. With the lid completely raised, remove the Cooking Rack

from lid.

2. Using the handle, tilt lid back until the metal “kickstand”

fits in the groove in the lid support. (See photo).

Make sure the “kickstand” is secure in the groove of the lid

support, or severe injuries could result.

Kickstand

3-3. FILLING OR ADDING 1. It is recommended that a high quality frying shortening be

SHORTENING used in the pressure fryer. Some low-grade shortenings

have high moisture content and will cause foaming and

boiling over.

2. If a solid shortening is used, it can be melted into a liquid

level Indicator lines

first, then poured into the cookpot. Attempting to melt solid

shortening in the cookpot may cause burning or scorching

of the fresh shortening.

GLOVES SHOULD BE WORN AND CARE MUST

BE TAKEN WHEN POURING HOT SHORTENING.

Severe burns could result. Also, when adding fresh

shortening to existing shortening, care must be taken to

avoid splashing or severe burns could result.

3. The electric model requires 100 lbs. The pot has two level

indicator lines inscribed on the rear wall of the frypot

which show when the heated shortening is at the proper

level. Maintain hot shortening at the upper level indicator

line. Add fresh shortening as needed.

4. Cold shortening should be filled to 1/2 inch below lower

level indicator line.

3-8 203

Page 25

Henny Penny Model 581

3-4. CARE OF THE

SHORTENING 1. To protect the shortening when the fryer is not in imme-

diate use, the fryer should be put into the Idle Mode.

2. Frying breaded products requires filtering to keep the

shortening clean. The shortening should be filtered at least

twice a day; after lunch rush and at the end of the day.

3. Maintain hot shortening at the upper level indicator line.

Add fresh shortening as needed.

The shortening level must always be above the heating

elements when the fryer is heating, and up to the upper

level indicator line on the frypot. Failure to follow these

instructions could result in a fire and/or damage to the

fryer.

With prolonged use, the flashpoint of shortening is

reduced. Discard shortening if it shows signs of excessive

smoking or foaming. Serious burns, personal injury, fire,

and/or property damage could result.

To avoid shortening overflowing the frypot, do not

overload the basket with product, or place product with

extreme moisture content into basket. The recommended

product load size is 22 lbs (9.9 kg.) Serious burns, personal

injury, fire and/or property damage could result.

203 3-9

Page 26

The following procedures should be followed on the initial startup of the fryer each time the fryer is brought from a cold, or

shut down, condition back into operation.

1. Check to see that all of the control switches are turned off.

2. Be sure the drain valve is CLOSED.

3. Remove carrier and baskets from lid and tilt lid back (see

section 3-2).

4. Fill the cookpot to a level at

l/2

inch below the bottom fill

line (see section 3-3).

5. Connect power to fryer.

6. Move the Cook/Pump switch to the “COOK” position.

7. Select the desired product using the Select Product switch.

The red indicator will be illuminated beside the product.

8. When the desired temperature has been reached the Ready

Light will illuminate. Stir the shortening at this time to

stabilize the temperature. Be sure to agitate the shortening in the “cold zone”

in the bottom of the cookpot.

Do not stir the shortening at any other time except at

initial “cold” start-up. Failure to follow these instructions can result in shortening overflowing the cookpot

which could cause serious burns, personal injury, fire,

and/or property damage.

9. After the shortening temperature has stabilized for a

minimum of 30 minutes, check the shortening temperature

using a good deep fat thermometer (Henny Penny part

number 12106). If off more than 5”F, refer to the

maintenance section.

10. If the shortening was not filtered the night before at shutdown, it should be filtered now, after the shortening

reaches the frying temperature (325°F) and before the

fryer is used.

Page 27

If the shortening temperature exceeds 420°F immediately shut off the power at the main circuit breaker

and have the fryer repaired. If shortening

(temperature) exceeds its flashpoint, fire will occur,

resulting in severe burns and/or property damage.

11. Raise the lid up and place carrier and baskets onto lid.

12. Lower lid and emerse baskets into shortening, then raise

lid. This will keep the product from sticking to the baskets.

You are now ready to start frying.

Do not permit the fryer to set for an extended period

of time at high temperature (325 “F or above), because

the shortening will break down much sooner. When the

fryer is not being used for frying, put the controls to

the “IDLE” position.

1. Take the chicken parts, 2,4,6, or 8 cut-up chickens, from

the cooler and place in a scullery sink. Wash the chicken

and at this point break the thigh from the joint of the

backbone.

2. Remove any excess fat from the thigh.

I

3. Remove the chicken from the water and drain slightly but

allow the parts to remain moist.

4. If a breading machine is used, fill the breading drum with

approximately 8 to 10 pounds of PHT Fryer Mix. Feed

the moist but drained pieces into the chute at one end of

the breader.

Page 28

5. Allow the breaded pieces to fall onto a tray as they come

out of the breader drum. (More breading may be needed

if a large amount of product is to be breaded.)

6. If a breading machine is not used, the food should be placed

in the dry mix and hand tumbled so that each piece of food

is completely covered.

7. Knock off any excess breading and place the breaded

product on a tray for cooler storage. Place a damp cloth

over the breaded food to retain moisture. The breaded food

should be held for a minimum of 30 minutes before frying, so that it can absorb spices from the breading and

so that breading can better adhere to the product.

8. Prepare fryer as per start-up procedures.

9. Be sure the product selector is on chicken.

10. Lower the lid and baskets into shortening, then raise them

to grease the baskets.

11. Remove baskets and place product into baskets - the larger

pieces to the outside edge of baskets.

12. Place the baskets onto carrier, starting with the bottom

rack and working up.

13. Place cover grid on top rack to prevent pieces from

floating.

14. Lower lid and baskets and lock lid down.

15. Push the timer switch.

16. Within a few minutes, the pressure gauge should increase

to the operation zone. If it does not, recheck the procedures

and then refer to the troubleshooting section.

17. When the timer reaches zero the fryer will automatically

depressurize and the control will beep. Push the timer

switch to reset the controls.

Check the pressure gauge reading. Do not attempt to

open the lid until the pressure drops to zero. Opening

the lid when the cookpot is pressurized will allow hot

shortening and moisture to escape from the eookpot

resulting in severe burns to the operator.

Page 29

18. After the pressure drops to zero, open the lid.

19. Let baskets hang for approximately 15 seconds before

removing the baskets.

20. Place the product into a warming cabinet immediately.

21. Before frying the next load, allow time for the shortening to reheat. (Wait until the ready light comes on.)

Frying breaded food requires frequent filtering. Taste the cold

shortening every day for flavor. Watch the shortening for

foaming during frying cycles. Discard the shortening as soon

as it shows signs of foaming. Clean the frypot as follows each

time the shortening is changed or filtered.

1. Turn the power switch to the “OFF” position.

The best results are obtained when the shortening is

filtered at the normal frying temperature.

2. Remove carrier from lid of the fryer.

I

Rack may be hot. Burns could result.

3. Lower the lid to the lid stop bracket and tilt the lid back

and into an upright position (see section 3-2).

4. Use a metal spatula to scrape any build-up from the sides

of the frypot. Do not scrape heating element.

5. Roll the filter unit under the fryer, until the latch located

on the front, right leg of the fryer, secures the filter unit

in place.

The filter unit must be in the proper position beneath

the drain valve. This will prevent the splashing of

shortening on the floor. This splashing could result in

severe burns.

NING

Page 30

6. Open the drain valve fully by pulling the drain valve knob

all the way out.

7. As the shortening drains from the cookpot, use brushes

(Henny Penny part number 12105 includes both brushes)

to scrape and clean the side of the cookpot and the heating

elements. If the drain fills with breading, use the white

brush to push the breading into the filter pan.

8. When all of the shortening has drained, scrape or brush

the sides and the bottom of the cookpot.

9. Rinse the frypot as follows:

A. Close the drain valve.

B. Connect hose of filter unit to the fryer.

C. Plug filter unit into the fryer.

Lower the lid so that the very first surge of shorten- Lower the lid so that the very first surge of shortening will not splash up or over the top of the cookpot,

causing severe burns.

D. Turn the cook/pump switch to the “PUMP” position.

Carefully open lid to see if shortening is returning pro-

perly. Fill cookpot

l/3

full, then turn pump off.

If there are air bubbles coming up in the shortening,

it is possible that the filter connection union on the filter

tube line is not tightened properly. If so, turn off the

pump. Use gloves to tighten the union. Severe burns

could result.

E. Wash down and scrub the sides of cookpot. Use “L”

brush to clean the heating elements.

F. After the sides and bottom are cleaned, open the drain

valve and let shortening drain out, then close drain

valve.

Page 31

10. Lower the lid down to the lid stop bracket during the first

surge of pumping and pump all the shortening out of the

filter pan and back into the frypot.

11. When the pump is pumping air only, the shortening in the

cookpot will appear to be boiling. Move the main power

switch to the “OFF” position.

When the appearance of boiling occurs, immediately

turn the pump off. This will prevent aeration of the

shortening, therefore increasing shortening life.

12. Check the level of the shortening in the eookpot. Add fresh

shortening if necessary, until it reaches the point between

the level indicators.

13. After completing the filtering operation, empty and

replace the condensation drain pan.

14. If frying is to be continued at this time, move the main

power switch back to the “COOK” position, and allow time

for reheating of the shortening.

The filter envelope should be changed after lo-12 filterings

or whenever it becomes clogged with crumbs. Proceed as

follows:

1. Unplug portable filter (PF-180) from cooker and roll filter

unit out from under the cooker.

2. Remove back cover from filter unit and remove crumb

basket. Discard crumbs and clean thoroughly with soap

and water. Rinse thoroughly with hot water.

3. Unscrew dairy union from standpipe and remove filter

head assembly from filter pan.

This union will be hot. Use protective glove or cloth,

or severe burns will result.

397

3-15

Page 32

4. Lift the screen assembly from the drain pan.

5. Wipe the shortening and crumbs from the drain pan. Clean

the drain pan with soap and water. Thoroughly rinse with

hot water.

6. Unthread the suction standpipe from the screen assembly.

7. Remove filter clips and discard the filter envelope.

8. Clean the top and bottom filter screen with soap and

water. Rinse thoroughly with hot water.

Be sure that the filter screens, crumb catcher, filter

clips, and the suction standpipe are thoroughly dry

before assembly of filter envelope, as water will dissolve

the filter paper.

9. Assemble the top filter screen to the bottom filter screen.

10. Slide the screens into a clean filter envelope.

11. Fold the corners in, then double fold the open end.

12. Clamp the envelope in place with the two filter retaining

clips.

13. Place large washer on top of filter paper and screw on the

suction standpipe assembly.

14. Place complete filter screen assembly back into filter drain

pan.

15. Place filter assembly over suction standpipe assembly, and

connect filter union by hand. Do not use a wrench to

tighten.

16. Place crumb basket into position in the back of the filter

pan and place cover over it.

17. Portable filter is now ready to be slid under the cooker

for filtering.

Page 33

The following steps will help prevent filter pump problems:

1. Make certain the filter paper envelope is properly installed

over the filter screens. Make sure the open end of the

envelope is properly folded over and clamped in place with

the retaining clips, so that the envelope is sealed and

crumbs cannot enter.

2. Make sure the filter valve is kept closed at all times during

frying.

3. Make sure all the shortening has been pumped from the

filter lines and the pump by allowing the filter pump motor

to run until the shortening in the cookpot appears to be

bubbling or boiling.

The filter motor is equipped with a manual reset button in the

event the motor’s thermal protector actuates. This reset button

is located on the front of the filter head assembly, behind a

hinged circular door. Wait approximately 5 minutes before

attempting to reset this protector device.

Use steady, hard pressure on the reset button until a

definite “click” is heard. The button takes some force

to reset.

To prevent burns caused by splashing shortening, the

unit’s power cord must be unplugged before resetting

the filter pump motor’s manual reset protection device.

Page 34

After the initial installation of the fryer, as well as before every

change of shortening, the cookpot should be thoroughly cleaned

as follows:

1. Turn the main power switch OFF.

The filter drain pan must be in position under the drain

valve to prevent splashing or spilling of hot liquids.

Failure to do so will result in splashing and severe

burns.

2. If hot shortening is present in the cookpot, it must be

drained by slowly pulling the drain valve knob.

3. Close the drain valve. Discard the shortening in the filter

pan. Roll the empty filter pan under the fryer.

4. Lower the lid to the lid stop bracket and tilt lid back, so

that the lid won’t interfere with cleaning.

5. Fill the cookpot to the level indicators with hot water. Add

8 to 10 ounces of fryer cleaner (Henny Penny part number

12101) to the water and mix thoroughly.

Always wear safety goggles or face shield and protective rubber gloves when cleaning the cookpot, as the

cleaning solution is highly alkaline. Avoid splashing or

other contact of the solution with eyes or skin. Severe

burns or blindness could result. Carefully read the

instructions on the cleaner. If solution comes in contact with eyes, rinse thoroughly with cool water and

see a physician immediately.

6. Enter Boil Out mode. (See page 6-8.)

NEVER PRESSURIZE FRYER TO CLEAN. Leave

lid open. Water under pressure is super heated and will

cause severe burns if it comes in contact with skin.

Page 35

Henny Penny Model 581

3-11. CLEANING THE FRYPOT

(Continued)

DO NOT let the cleaning solution boil. If the cleaning

solution in the cookpot starts to foam and boil over, DO

NOT TRY TO CONTAIN IT BY CLOSING THE

FRYER LID or severe burns could result.

7. Using the fryer brush (Henny Penny part number 12105)

scrub the inside of the cookpot, the lid liner, and around

the counter-top of the fryer.

Do not use steel wool, other abrasive cleaners or cleaners/sanitizers containing chlorine, bromine, iodine or

ammonia chemicals, as these will deteriorate the

stainless steel material and shorten the life of the unit.

Do not spray the unit with water, such as, with a garden

hose. Failure to follow this caution could cause component

failure.

8. After cleaning, turn off the main power switch. Open

the drain valve and drain the cleaning solution from the

cookpot into the drain pan and discard.

9. Close the drain valve and refill the cookpot with hot

water to proper level.

10. Add approximately 16 ounces of distilled vinegar and

heat the solution to no more than 195ºF (91ºC).

11. Using a clean brush, scrub the interior of the cookpot and

lid liner. This will neutralize the alkaline left by the

cleaning compound.

12. Drain the vinegar rinse water and discard.

13. Rinse down the cookpot, using clean hot water.

14. Thoroughly dry the drain pan, and the cookpot interior.

NOTE

Make sure the inside of the cookpot, the drain valve

opening, and all parts that come in contact with the

new shortening are as dry as possible.

15. Refill the fryer with fresh shortening

203 3-19

Page 36

1. Drain and clean the frypot.

Turn the main circuit breaker off and unplug the electrical

2.

cord if possible.

3. Close the lid.

4. Remove and clean condensation drain pan.

At the end of each day, the operating valve must be cleaned

as follows:

1. Turn the COOK/PUMP switch to OFF. Be sure all

pressure has been released and open the lid.

2. Unscrew the valve cap and remove the cap and weight.

Use gloves. Valve cap may be very hot and burns could

result.

3. Clean the cap and weight in hot detergent water. Make

certain to thoroughly clean the inside of the valve cap and

the weight.

4. Clean the exhaust tube with stainless steel brush (Henny

Penny part number 12147).

Clean orifices and the inside of the valve body with a clean

5.

lint free cloth.

6. Dry the weight and valve cap.

7. Replace weight and valve cap. Hand tighten the cap.

Page 37

el 5

At the end of each day or shift, perform the following

procedures:

1. Move the COOK/PUMP switch to the OFF position.

2. Filter the shortening.

3. Place racks and carrier in sink for cleaning.

4. Clean operating valve per previous paragraph.

3-21

Page 38

Page 39

This section provides troubleshooting information in the form

of an easy to read table.

If a problem occurs during the first operation of a new fryer,

recheck the installation per the Installation Section of this

manual.

Before troubleshooting, always recheck the operation procedures per Section 3 of this manual.

To isolate a malfunction, proceed as follows:

1. Clearly define the problem (or symptom) and when it

occurs.

2. Locate the problem in the Troubleshooting table.

3. Review all possible causes. Then, one-at-a-time work

through the list of corrections until the problem is solved.

4. Refer to the maintenance procedures in the Maintenance

Section to safely and properly make the checkout and

repair needed.

If maintenance procedures are not followed correctly,

injuries and/or property damage could result.

Page 40

Product Color Not

Correct:

A. Too Dark

Temperature too high.

Check temperature setting

in the program mode. See

section on programming.

Remove and replace defective probe.

B. Too Light

Shortening too old.

Shortening too dark.

Breading product too far

in advance.

Wrong cook button

pushed.

Temperature too low.

Fryer incorrect preheat.

Slow fryer heat-up/

recovery.

Wrong cook button

pushed.

Change shortening.

Filter shortening.

Change shortening.

Bread product closer to

actual frying period.

Be sure to select the

correct product to be

cooked.

e Check temperature setting.

a Remove and replace defec-

tive probe.

Allow proper preheat time.

Refer to heating elements

in the maintenance section.

Be sure to select the

correct product to be

cooked.

C. Product

Greasy

Shortening old.

Temperature too low.

Wrong cook button

pushed.

Cookpot overloaded.

Product not removed from

cookpot immediately after

depressurization.

Replace shortening.

Check temperature setting.

Temperature not recovered

when product was dropped

in cookpot.

Remove and replace defective probe.

Be sure to select the

correct product to be

cooked.

Reduce cooking load.

Remove product

immediately after

depressurization of the

eookpot.

Page 41

B. Too Light

Temperature too low.

Check temperature setting.

Remove and replace defec-

tive probe.

C. Product

Greasy

Fryer incorrect preheat.

Slow fryer heat-up/

recovery.

Wrong cook button

pushed.

0 Shortening old.

Temperature too low.

0 Cookpot overloaded.

Product not removed from

cookpot immediately after

end of cycle.

0 Allow proper preheat time.

* Refer to heating elements

in the maintenance section.

@ Be sure to select the

correct amount of product

to be cooked.

e Replace shortening.

@ Check temperature setting.

e Temperature not recovered

when product was dropped

in cookpot.

e Remove and replace defec-

tive probe.

0 Reduce cooking load.

0 Remove product

immediately after end of

cycle.

D. Spotted

Product

Improper separation of the

product.

Breading not uniform on

the product.

Burned breading particles

on product.

Product sticking together.

Load product into basket

properly.

Sift breading regularly.

Separate product during

breading.

Filter the shortening more

frequently.

Separate product prior to

pressure cooking.

Page 42

E. Dryness of

Product

Moisture loss prior to

cooking.

Product Flavor

(Taste):

A. Salty Taste

Overcooking the product.

Low operating pressure.

Wrong cook button pushed.

Breading mixture is too

salty.

Incorrect choice of

breading.

Reduce cooking time.

Reduce cooking

temperature.

Cheek pressure gauge

reading, check for pressure

leaks.

Be sure to select the

correct product to be

cooked.

Sift breading after each

use.

Incorrect breading mixture.

Discard old breading.

Use breading designed for

the desired product.

urned Taste

6. Bland Taste

Burned shortening flavor.

Cookpot not properly

cleaned.

aw product not fresh.

Breading mixture incorrect

for product (spice content

too low).

Cooking temperature too

high (spice flavors lost).

Replace shortening.

Drain and clean cookpot.

Use fresh raw products.

Use breading designed for

desired product.

Check temperature.

Page 43

D. Rancid Taste

Shortening too old.

Replace shortening, and

follow recommended care

and use of shortening.

General:

A. Meat

Separation

From Bone

B. Bone Color

Not Proper

Non compatible products

cooked within the same

shortening.

Infrequent filtering.

Raw product not fresh.

Incorrect meat cut.

Overcooking.

Product not fresh.

Using frozen product (black

bone).

Improper processing of

product (black bone).

Replace shortening.

Use compatible products,

and follow recommended

care and use of shortening.

Replace shortening, and

follow recommended care

and use of shortening.

Use fresh product.

Use correct meat cutting

procedures.

Check cooking time.

Use fresh product.

Use fresh product.

Use proper processing

procedure for product.

6. Breading Falh

Off

D. Product

Sticking

Together

Product not thoroughly

cooked (red bone).

Incorrect breading

procedures.

Product partially frozen.

Product breaded too long

prior to cooking.

Improper loading

procedure.

Wrong cook button pushed.

Check cooking time.

Check cooking temperature.

Use correct breading

procedure.

Thoroughly thaw the

product, before breading.

Refer to breading and

frying instructions.

Properly load product per

loading procedures.

Be sure to select the

correct product to be

cooked.

Page 44

With switch in

POWER position,

the fryer is completely inoperative

(NO POWER)

Open circuit.

Check to see that unit is

plugged in.

Check the breaker or fuse

at supply box.

Check control panel fuses

(electric model only).

Check voltage at wall

receptacle.

Check MAIN POWER

switch. Replace if defective.

Check cord and plug.

Pressure will not

exhaust at end of

cooking cycle.

Operating

pressure too high

Exhaust line from solenoid

valve to condensation tank

clogged.

Solenoid valve clogged.

Dead weight clogged.

Turn unit off and allow

fryer to cool to release

pressure from cookpot;

clean all pressure lines,

exhaust stacks, and condensation tank.

Check and clean solenoid

valve per Maintenance

Section on Solenoid Valve.

Turn unit off and allow

fryer to cool to release

pressure from cookpot;

remove dead weight and

clean.

Page 45

Henny Penny Model 581

Problem Cause Correction

LID/PRESSURE SECTION (Continued)

• Exhaust line to stack clogged • Clean exhaust line to stack.

DO NOT OPERATE UNIT

IF HIGH PRESSURE

CONDITIONS EXIST,

SEVERE INJURIES AND

BURNS WILL RESULT.

Place the Power/Pump

switch in the “OFF”

position immediately. Release

the pressure by allowing unit

to cool. The pressure will

then drop. Do not resume use

of unit until cause of high

pressure has been found

and corrected.

Pressure does not • Not enough product in fryer • Place proper quantity of

build or product not fresh. fresh product within

cookpot to generate steam.

• Metal shipping spacer not • Remove shipping spacer.

removed from dead weight. See Unpacking Section.

• Lid open or not latched. • Close and latch lid.

• Solenoid valve leaking or • Check or clean solenoid

not closing. valve per maintenance

section on the solenoid

valve.

• Dead weight valve leaking. • Repair per maintenance sec tion on operating valve.

• Pressure not programmed. • Check programming.

• Lid gasket leaking. • Reverse gasket or lid needs

adjusted. See Sections 5-10

& 5-13.

1201 4-7

Page 46

Henny Penny Model 581

Problem Cause Correction

LID/PRESSURE SECTION (Continued)

• Safety relief valve leaking. • Check and replace if

necessary per maintenance

section on the relief valve.

• Pressure pad broken or crushed. • Replace pressure pads.

Lid won’t move • Cable on Counterweight • Put cable on Counterweight

up or down loose or broken per section on

Counterweight Cable.

• Check operation of • Make proper adjustments.

counterweight carriage in

rear of cooker.

HEATING OF SHORTENING SECTION

Shortening will • Blown fuse or tripped • Reset breaker or replace

not heat circuit breaker at supply fuse.

box or control panel.

• Blown fuse at control panel. • Check fuse per Main tenance Section on fuses

• Faulty Cook/Pump switch. • Check Cook/Pump switch

per Maintenance Section on

Cook/Pump switch.

• Faulty Cord and Plug. • Check cord and plug and

power at wall receptacle.

• Faulty contactor. • Check contactor per

Maintenance Section on

contactors.

• Faulty Drain Switch. • Check drain switch per

Maintenance Section on

Drain Switches.

• Faulty PC board. • Remove and replace control

panel.

• Faulty high limit control • Check high limit control

switch. switch per Maintenance

Section on High Limits.

4-8 1201

Page 47

Heating of

shortening too

slow (Electric

Model)

Low or improper voltage.

Weak or burnt out

element(s).

Use a meter and check the

receptacle against data

plate.

Check heating element(s)

per Maintenance Section on

Heating Elements.

Shortening

overheating

(Electric Model)

Points in contactor bad.

Wire(s) loose.

Burnt or charred wire

connection.

Check shortening

temperature.

Check contactor for not

opening.

Faulty PC Board.

Faulty probe.

Check contactor per

Maintenance Section on

Contactors.

Tighten.

Replace wire and clean

connectors.

Check temperature setting

in the program mode.

Check faulty contactor per

Maintenance Section on

Contactors.

Remove and replace control

panel.

Remove and replace probe.

Foaming or boil-

ing o,ver of

shortening

Water in shortening.

Condensation line stopped

up.

Improper or bad

shortening.

Improper filtering.

At end of cooking cycle,

drain shortening and clean

cookpot. Add fresh

shortening.

Remove and clean condensation line.

Use recommended

shortening.

Refer to the procedure

covering filtering the

shortening.

Page 48

Cold zone full of cracklings.

Filter shortening.

Shortening will

not drain from

cookpot

Shortening leaking

through drain

valve.

Improper rinsing after

cleaning the fryer.

Too much stirring.

Drain valve clogged with

crumbs.

Drain valve will not open by

pulling the knob.

Obstruction in drain.

Faulty drain valve.

Clean and neutralize the

cookpot. Rinse with vinegar

to remove the alkaline, then

rinse with hot water and

dry cookpot.

Only stir on initial heat-up.

Open valve - push cleaning

brush through drain open-

ing from inside of cookpot.

Replace cotter pins in valve

coupling.

Remove obstruction.

Replace drain valve.

Page 49

The following guide requires voltage to be present when troubleshooting the control. When

the guide refers to connecting pins on the power connection, unplug the power connector

from the board and refer to the attached illustration. These are numbered 1 through 9.

Using a strand of #16 gauge wire, connect the pins as numbered in the troubleshooting

guide. Extreme caution must be taken when connecting these pins to avoid control board

damage or electrical shock.

With switch in COOK position, the fryer is

completely inoperative (no power switch light).

With switch in COOK position, the fryer is

completely inoperative (power switch light on,

pump works).

Control operative - all lights on - primary

contactor engages - no heat or pressure.

Control operative -

pressure - primary contactor does NOT

engage.

Control operative - all lights on - has pressure

- no heat.

all lights on - no heat or

Check to see if unit has voltage.

Check fuses.

Defective power switch.

+S Check voltage on pins 1 and ‘7 on the power

connector, 10 VAC.

If voltage is present, check fuse on control

board.

@ If fuse is defective, replace fuse.

Check 5 amp fuse located on heat shroud fuse OK.

Check voltage from center of fuse to ground

- 208/240 VAC.

Defective transformer.

Connect pins 4 and 6 on the power

connector.

If contactor engages - replace control boarcJ

If contactor does not engage, replace

contactor.

Control operative - all lights on - heat on - no

pressure - pressure light OFF.

Control operative pressure - pressure light ON.

all lights on - heat on - no

Connect pins 3 and 6 on the power

connector.

If solenoid engages - defective control

board.

If solenoid does not engage - defective

solenoid coil - 2081240 VAC.

Check programming

Page 50

Error message E-5 display reads HI.

Read display temperature - if display

temperature reads HI, unplug power

connector from control board. If secondary

contactor stays engaged, change contactor if secondary contactor disengages, change

control board. If shortening temperature

reads normal - defective thermal sensor replace.

Error message E-6.

Error message E-10.

Error message E-41.

Defective thermal sensor.

Replace thermal sensor.

Reset manual high limit thermostat.

Depress timer switch.

Control must be completely reprogrammed.

If the power connector is making poor contact onto the board, an error message could be

read, or it might disable other components. When removing connector, look down into power

connector to see if the ramp connectors, inside the power connector, are not flat. If so,

they can be removed from the power connector, and bent back into proper position.

Page 51

This section provides procedures for the checkout and replacement of the various parts used within the fryer. Before replacing any parts, refer to the Troubleshooting section. It will aid

you in determining the cause of the malfunction.

This section is arranged in groupings of the components that

work together within the fryer. The general groups are listed

below.

Removing the Control Panel

Probe

Electrical Components

Control Board

Pressure System

1. You may want to use a multimeter to check the electric

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter will read infinity.

The complete control panel can be easily removed for repair

on the panel itself, or for access to the area behind the control

panel.

1. Remove electrical power supplied to the fryer.

Place the Cook/Pump Switch in the “OFF” position,

and unplug the power cord and/or turn the wall circuit

breaker off or electrical shock could result.

2. Remove the two screws securing the Control Panel and

lift panel up and out.

3. Unplug the g-pin connector and the probe connection at

the Control Board. Then remove complete panel from unit.

Page 52

This high temperature control is a manual reset control which

senses the temperature of the shortening. If the shortening

temperature exceeds 420 “F (215 “C), this control switch will

onen and shut off the heat to the cooknot. When the

temperature of the shortening drops to a safe-operation limit,

the control must be manually reset. The reset button is located

above the filter knob in the front of the cooker. This will allow

heat to be supplied to the cookpot.

Before replacing a high temperature limit control, check to

see that its circuit is closed.

The shortening temperature must be below 380°F

(193°C) to accurately perform this check.

1. Remove electrical power supplied to the fryer.

Remove electrical power supplied to the fryer by

unplugging the unit, or by turning off the wall circuit

breaker or electrical shock could result.

2. Remove the control panel.

3. Remove the two electrical wires from the high

temperature limit control.

4. Manually reset the control, then check for continuity

between the two terminals after resetting the control. If

the circuit is open, replace the control, then continue with

this procedure. (If the circuit is closed, the high lmit is not

I

defective. Reconnect the two electrical wires.)

Page 53

Remove electrical power supplied to the fryer by

unplugging the unit, or by turning off the wall circuit

breaker or electrical shock could result.

1. If the tube is broken or cracked, the control will open, shutting off electrical power. The control cannot be reset.

2. Drain shortening from the cookpot and discard. A

substance in the tube could contaminate the shortening.

3. Remove control panel.

4. Loosen small inside screw nut on capillary tube.

5. Remove capillary bulb from bulb holder inside the cookpot.

6. Straighten the capillary tube.

7. Remove larger outside nut that threads into pot wall.

8. Remove the two nuts securing the high limit bracket at

the front of the fryer, and remove bracket.

9. Loosen the three screws that secure high limit to the high

limit bracket.

10. Remove defective control from control panel area.

11. Insert new control and replace screws.

12. Uncoil capillary line, starting at capillary tube, and insert

through cookpot wall.

To avoid electrical shock or other injury, the capillary

line must run under and away from all electrical power

wires and terminals. The tube must NEVER be in such

a position where it could accidentally touch the electrical power terminals.

13. Carefully bend the capillary bulb holder on heating

elements.

Page 54

14. Slip capillary bulb into bulb holder located on heating

elements. Pull excess capillary line from pot and tighten

nut into cookpot wall.

Be sure capillary bulb of high limit is positioned as not

to interfere with basket or when cleaning the cookpot

wall, or damage to capillary tube could result.

15. With excess capillary line pulled out, tighten smaller nut.

16. Replace front panel.

17. Refill with shortening.

There are two fuse holders on each model of the electric fryers.

Remove electrical power supplied to the fryer by

unplugging the unit, or turning off the wall circuit

breaker or electrical shock could result.

CONTROL PANEL FUSES 3 Phase Check from #54 to #55

and #68 to #69 on fuse assembly, or the fuse can be removed

to check for a closed circuit. If not, replace the fuse (HP#

EFOZ-007).

The Cook/Pump Switch is a three way rocker switch with a

center “OFF” position. With the switch in the “COOK”

position the fryer will operate. With the switch in the “PUMP”

position the filter pump will operate, but the heating unit will

not.

Remove electrical power supplied to the fryer by

unplugging the unit, or turning off the wall circuit

breaker or electrical shock could result.

Page 55

1. Remove Control Panel.

2. “OFF” Position - should be open circuit anywhere on the

switch.

3. “COOK” Position - Check from:

#5 to #6 closed circuit

#l to #2 closed circuit

4. “PUMP” Position - Check from:

#4 to #5 closed circuit

#3 to #2 closed circuit

Check across the jumpers on the wires of the

Cook/Pump Switch. These jumpers have resistors and

capacitors which may be faulty.

1. With control panel removed and wires off of the switch,

push in on tabs on the switch to remove from the panel.

2. Replace with new switch, and reconnect wires to switch

following the wiring diagram.

3. Replace the control panel.

Page 56

The electric fryer requires two switching co&actors:

contactor and a heat contactor. The primary contactor

energizes (contacts close) any time the Cook/Pump Switch

is in the “COOK” position and the temperature of the pot is

below 420°F (215°C). The high limit will cut the power at the

primary contactor if temperatures in the cookpot exceed 420 “F

(215°C). The primary contactor supplies power to one side of

the heat eontactors.

The heat contactor (mercury contactor) is controlled by the

computer controller. When the controller calls for heat, the

heat contactor applies power to one side of the heating

elements. When the heat contactor and the primary eontactor are energized (contacts closed), the electric heating

elements heat the shortening.

1. Remove electrical power supplied to the fryer.

a primary

Remove electrical power supplied to the fryer by

unplugging the unit, or turning off the wall circuit

breaker or electrical shock could result.

2. Remove the control panel.

3. Perform a check on both contactors as follows:

Open Circuit

Open Circuit

Open Circuit

4. Check across the coil terminals:

Standard Contactor - 415 ohms

Mercury Contactor - 1500 ohms

Page 57

The following checks are performed with the wall cir-

cuit breaker on, and the Cook/Pump Switch in the

“COOK” position. Extreme caution should be taken.

Make connections before applying power, take reading,

and remove power by unplugging the power cord, or

by turning off the wall circuit breaker, before remov-

ing meter leads or electrical shock could result.

5. With power re-applied and in a heat-up mode, check the

power going to both contactor coils. This is to be sure

power is going to the contactors.

If no voltage is found going into the coils, check wiring, high-

limit, and drain switch for the primary contactor. (See

Maintenance Section). For the heat contactor, check wiring

and connection at the P.C. Board.

If either contactor is defective it must be replaced as follows:

Remove electrical power supplied to the fryer by

unplugging power cord or turning off the wall circuit

breaker, or electrical shock could result.

1. Remove only those wires directly connected to the contactor being replaced. Label the wires.

2. Remove the two mounting nuts on the base plate and

remove standard contactor (primary), proceed to step 5,

if this is the contactor to be replaced.

3. Remove the two mounting nuts securing the mercury contactor bracket to the base plate and remove bracket.

4. Remove the two screws securing the mercury contactor

to the bracket and remove contactor.

5. Install new contactor in reverse order of previous steps.

6. Install control panel.

7. Reconnect power to fryer and test the fryer for proper

operation.

Page 58

Each electric fryer uses two heating elements.

Heating elements are available for 208 or 220/240,380