Page 1

Solutions

M

Page 2

Page 3

Henny Penny Model 520

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT: Any part of a new appliance, except lamps and fuses, which proves to be defective

in material or workmanship within two (2) years from date of original installation, will be repaired or replaced

without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To validate this warranty, the

registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

REPLACEMENT PARTS: Any appliance replacement part, except lamps and fuses, which proves to be

defective in material or workmanship within ninety (90) days from date of original installation will be repaired

or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new

frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for the frypot only . Any freight charges and labor costs to install

the new frypot as well as the cost of any other parts replaced, such as insulation, thermal sensors,

high limits, fittings, and hardware, will be the responsibility of the owner.

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If

damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE

ABOVE LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER W ARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANT ABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGA TION OR LIABILITY.

FM01-344

Revised 02-16-06

Page 4

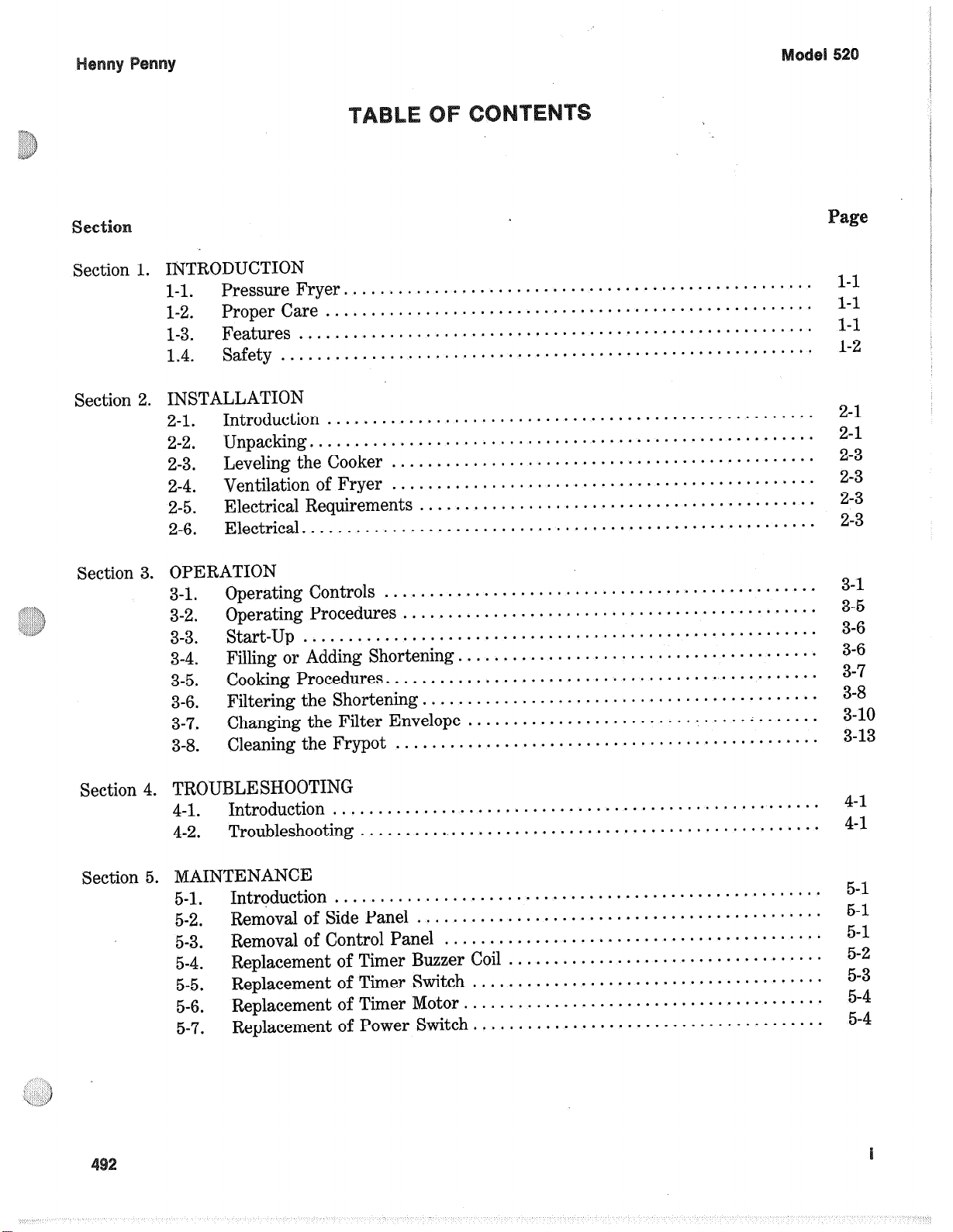

Section 1. INTRODUCTION

l-l.

1.2.

l-3.

1.4.

PressureFryer ....................................................

Proper Care..

Features

Safety

...........................................................

....................................................

.........................................................

l-l

&t

l-2

Section 2. INSTALLATION

2-l.

Introduction

......................................................

2-2. Unpacking ........................................................

2-3. Leveling the Cooker

2-4.

2-5.

2-6.

Ventilation of Fryer

Electrical Requirements

Electrical .........................................................

Section 3. OPERATION

3-l.

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

3.8.

Operating Controls

Operating Procedures

Start-Up

.........................................................

Filling or Adding Shortening.

Cooking Procedures

Filtering the Shortening.

Changing the Filter Envelope

Cleaning the Frypot

Section 4. TROUBLE SHOOTING

4-l.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. Troubleshooting . . . . . . . . . ., . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-l

2-l

............................................... 2-3

............................................... 2-3

............................................ 2-3

2-3

................................................

i-l5

..............................................

i-66

.......................................

................................................

...........................................

......................... .,

...............................................

.............

3-7

3-8

3-10

3-13

-

-

4-l

4-l

Section 5.

AINTENANCE

5-l.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

Introduction

Removal of Side Panel

Removal of Control Panel

Replacement of Timer Buzzer Coil

Replacement of Timer Switch

Replacement of Timer Motor

Replacement of Power Switch

......................................................

.............................................

..........................................

...................................

.......................................

........................................ 5-4

.......................................

5-l

5-l

5-l

i-E

-

5-4

Page 5

Henny Penny Model 520

TABLE OF CONTENTS (Continued)

Section Page

5-8. Replacement of Thermostat .............................................................................. 5-5

5-9. Calibration of Thermostat ................................................................................. 5-6

5-10. Replacement of High Limit................................................................................ 5-8

5-11. Replacement of Heating Element ....................................................................... 5-10

5-12. Replacement of Contactors .............................................................................. 5-11

5-13. Replacement of Lid Hinge Spring...................................................................... 5-12

5-14. Replacement of Lid Gasket .............................................................................. 5-14

5-15. Lid Latch Lubrication ....................................................................................... 5-14

5-16. Deadweight V alve Assembly............................................................................. 5-15

5-17. Removal and Cleaning of Safety Relief V alve..................................................... 5-16

Wiring Diagrams............................................................................................... 5-17

Section 6. P ARTS INFORMATION

6-1. Introduction ..................................................................................................... 6-1

6-2. Genuine Parts................................................................................................... 6-1

6-3. How to Find Parts............................................................................................ 6-1

6-4. How to Order .................................................................................................. 6-1

6-5. Recommended Spare Parts for Distributors ...................................................... 6-1

Section 7. ELECTRONIC CONTROLS

7-1. Introduction ..................................................................................................... 7-1

7-2. Control Panel Layout ....................................................................................... 7-1

7-3. Usage Review Operation.................................................................................. 7-2

7-4. Usage Review/Reset Operation ........................................................................ 7-2

7-5. Programming in General ................................................................................... 7-2

7-6. Regular Program Mode .................................................................................... 7-3

7-7. Special Program Mode .................................................................................... 7-4

7-8. Basic Operations Instructions ........................................................................... 7-4

Henny Penny Distributor List

ii 206

Page 6

I 52

The Henny Penny Pressure Fryer Model 520 is a basic unit

of food processing equipment. It has found wide application

in institutional and commercial food service operations.

A combination of Pressure, Heat, and Time is automatically

controlled to produce the optimum in a tasty, appealing

product.

Pressure is basic to this method of food preparation. The

pressure is developed from the natural moisture of the food.

The patented lid traps this moisture and uses it as steam.

Because the steam builds rapidly, the greater part of the

natural juices are retained within the food. An operation valve

vents excess steam from the pot and maintains constant live

steam pressure.

eat

e

Heat generated is another important factor of the pressure

fryer. Energy savings is realized due to the unit’s short frying

time, low temperature, and heat retention of the stainless steel

cookpot.

Time is important because the shorter time involved in frying

foods results in additional economies for the user. Foods are

table ready in less time than it would take to fry them in a

conventional open-type fryer.

As in any unit of food service equipment, the Henny Penny

Pressure Fryer Model 520 does require care and maintenance.

Requirements for the maintenance and cleaning are contained

in this manual and must become a regular part of the operation

of the unit at all times.

@ Easy to use timer and thermostat controls set in recessed

panel to protect from spills.

Pump switch for optional built-in automatic filter system.

Easy access to drain valve and filter valve handles for

manual filtering.

Page 7

1-3. FE

One piece cast aluminum lid with stainless steel liner for

easy cleaning.

Single-action front lid latch allows one-handle opening and

closing.

Latch mechanism locks lid in closed position when under

pressure.

Automatic pressure release valve.

Removable side panels provide easy access for servicing.

1-4. SAF

The Henny Penny Pressure Fryer has many safety features

incorporated. However, the only way to ensure safe operation

is to fully understand the proper installation, operation, and

maintenance procedures. The instructions in this manual have

been prepared to aid you in learning the proper procedures.

Where information is of particular importance or safety

related, the words DANGER, WARNING, CAUTION, and

NOTE are used. Their usage is described below.

The word DANGER indicates an imminent hazard

which will result in highly serious injury such as second

or third degree burns, loss of sight, and other permanent injuries.

I

The word WARNING is used to alert you to a

procedure, that if not performed properly, might cause

personal injury, such as burns and/or loss of sight, and

damage to the fryer.

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the fryer,

or product.

The word NOTE is used to highlight especially important information.

Page 8

This section provides the installation instructions for the Model

520 Electric Henny Penny Pressure Cooker.

The Henny Penny Model 520 has been tested, inspected, and

expertly packed to insure arrival at its destination in best

possible condition. The unit is packed inside a heavy cardboard

carton with sufficient padding to withstand normal shipping

treatment.

Any shipping damages should be noted in the presence

of the delivery agent and signed prior to his or her

departure.

To remove the Henny Penny Model 520 from the carton, you

should:

1. Cut the bands from the carton.

2. Lift the carton from the cooker.

3. Open the lid of the unit and remove the basket and all

accessories.

4. Remove the filter drain pan and remove all accessories.

Page 9

Step 5

Step 6

5. Slide cooker from skid.

The cooker weighs approximately 275 pounds (124.9

kg). Care should be taken when lifting to prevent

personal injury.

6. Unthread the cap from the operating valve.

A metal shipping support is placed within the operating

valve housing to protect the orifice and weight during

shipment. This support must be removed prior to

installation and start-up.

7. Remove the weight.

8. Remove and discard the metal shipping support.

9. Clean the orifice with a dry cloth.

10. Replace the weight and cap.

11. Remove any protective paper and cardboard from the

cooker and clean with a soft cloth and detergent water.

Page 10

odd

520

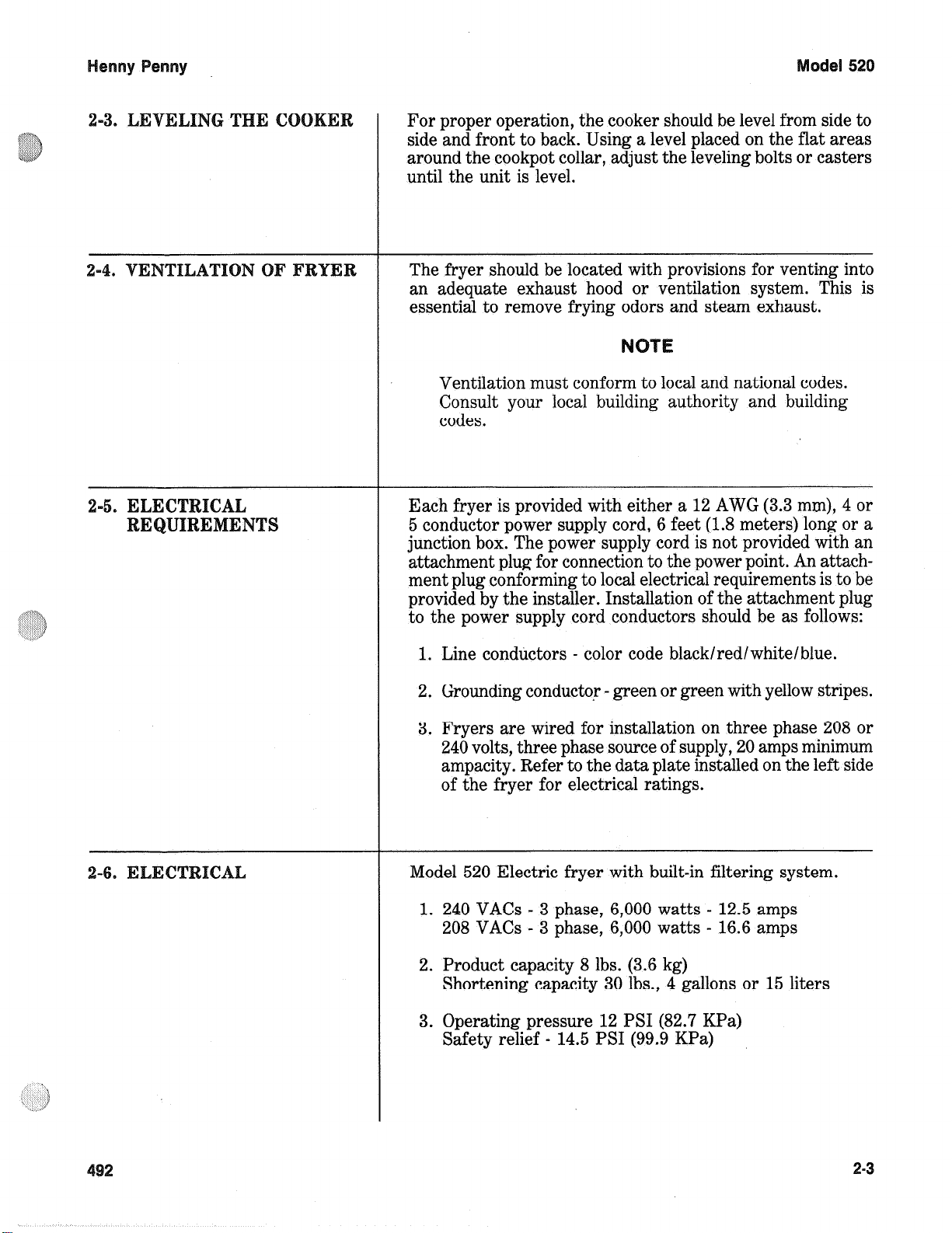

For proper operation, the cooker should be level from side to

side and front to back. Using a level placed on the flat areas

around the cookpot collar, adjust the leveling bolts or casters

until the unit is level.

-4. VE

The fryer should be located with provisions for venting into

an adequate exhaust hood or ventilation system. This is

essential to remove frying odors and steam exhaust.

Ventilation must conform to local and national codes.

Consult your local building authority and building

codes.

Each fryer is provided with either a 12 AWG (3.3 mm), 4 or

5 conductor power supply cord, 6 feet (1.8 meters) long or a

junction box. The power supply cord is not provided with an

attachment plug for connection to the power point. An attachment plug conforming to local electrical requirements is to be

provided by the installer. Installation of the attachment plug

to the power supply cord conductors should be as follows:

1. Line conductors - color code black/red/white/blue.

2. Grounding conductor - green or green with yellow stripes.

3. Fryers are wired for installation on three phase 208 or

240 volts, three phase source of supply, 20 amps minimum

ampacity. Refer to the data plate installed on the left side

of the fryer for electrical ratings.

Model 520 Electric fryer with built-in filtering system.

1. 240 VACs - 3 phase, 6,000 watts - 12.5 amps

208 VACs - 3 phase, 6,000 watts - 16.6 amps

2. Product capacity 8 lbs. (3.6 kg)

Shortening capacity 30 lbs., 4 gallons or 15 liters

3. Operating pressure 12 PSI (82.7 KPa)

Safety relief - 14.5 PSI (99.9 KPa)

2-3

Page 11

Y

et

52

\

Page 12

Henny Penny Model 520

SECTION 3. OPERA TION

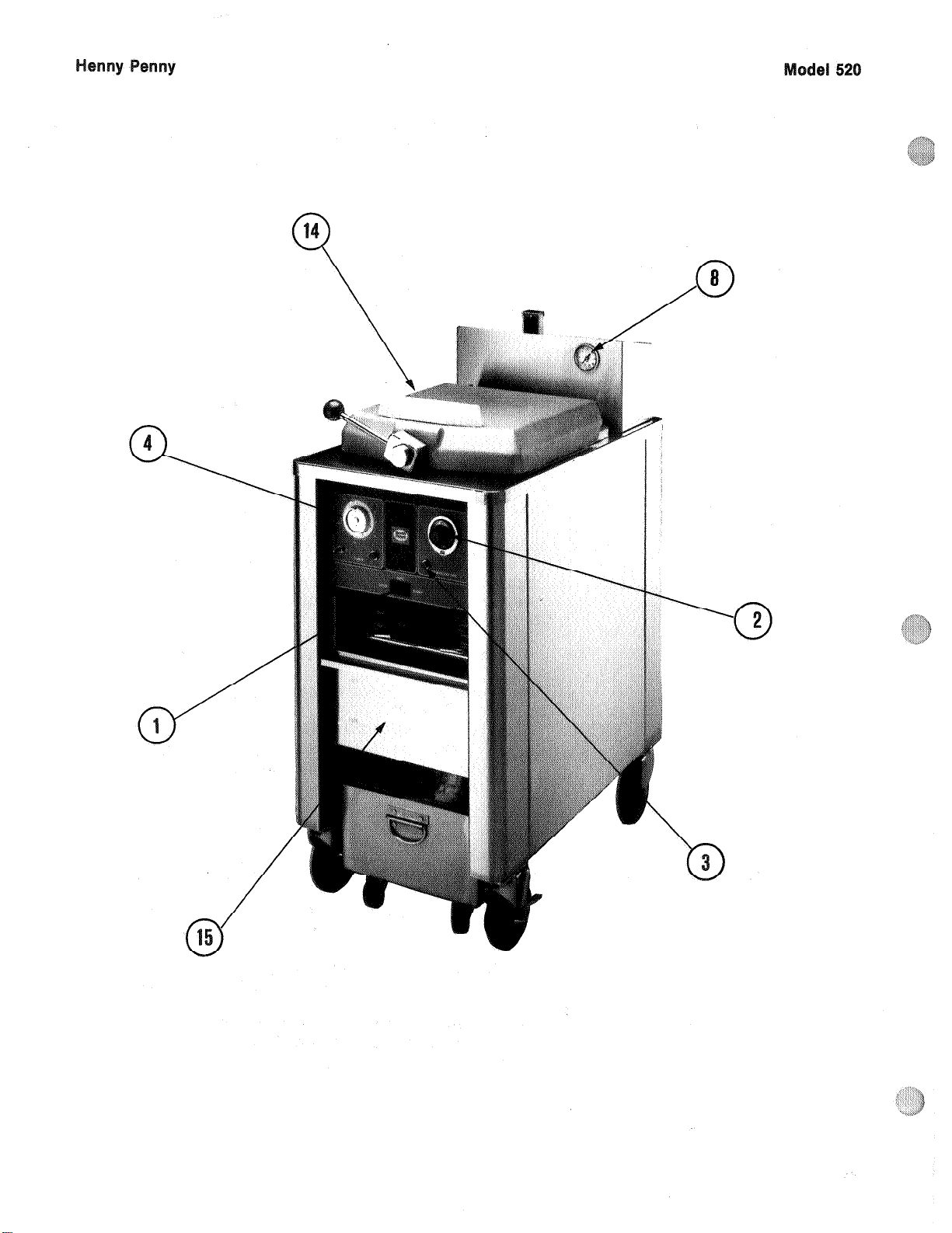

3-1. OPERA TING CONTROLS

Item Description Function

1 Main Power Switch A three way rocker switch with a center off position. Pressing

with Built- In Indicator the left side of the rocker switch (COOK position) operates the

Lights fryer, and the amber light illuminates. No light is visible when

the switch is in the OFF position. T o filter, press the right side

of the rocker switch (PUMP position) to operate the pump

motor, and the red light illuminates.

2 Single Stage An electromechanical device used to regulate temperature.

Thermostat To set the desired cooking temperature, turn the thermostat

knob clockwise.

3 Temperature Light Illuminates when the shortening temperature is below the

set-point temperature. The light goes off when the shortening

reaches the set-point temperature.

4 Timer An electromechanical device that controls the length of the

cooking cycle. The timer controls the operation of the solenoid

valve and automatically resets at the end of the cooking time.

Set the desired cooking time by turning the grayknob clockwise

until the arrow points at the desired cooking time. Pushing on

the red button, activates the timing cycle and closes the solenoid. The red arrow times down to zero (0), while the black

arrow remains at the preset time. When the red arrow reaches

zero (0), it automatically goes back to the preset time. Also, the

solenoid opens, releasing the pressure inside the frypot.

A. Set gray knob to desired time.

B. Push red button to start timing cycle and build pressure.

C. When red arrow reaches zero (0), it resets to preset time

and pressure is released.

5 End of Cooking Cycle A. The timer buzzer sounds, the solenoid valve opens to

release pressure, and the timer resets.

B. Move the timer switch to the OFF position.

6 Dead W eight V alve Maintains a constant level of steam pressure within the frypot.

Assembly Excessive steam pressure is vented through the exhaust stack.

NOTE

Remove the dead weight cap, and clean the cap, weight,

and orifice once a day to prevent over-pressurization inside

the frypot. See section 5-16.

402 3-1

Page 13

Henny Penny Model 520

Item Description Function

7 Safety Relief V alve The safety relief valve is set at 14.5 PSI (99.9 KPa). In the

event that the dead weight valve becomes clogged, the safety

valve releases excessive pressure, keeping the frypot at a

maximum of 14.5 PSI (99.9 KPa). If this occurs, turn the main

power switch to the OFF position to release all pressure from

the frypot. Also, clean the dead weight valve at this time.

DO NOT pull the Safety Relief Valve Ring, or severe burns

will result.

8 Pressure Gauge Indicates nominal pressure within the frypot. This gauge is not

used to calibrate the dead weight assembly . Operating pressure

of the dead weight assembly is preset at the factory .The gauge

is used as an indication of pressure build up within the frypot.

9 Solenoid V alve An electromechanical device that causes pressure to be held in

the frypot. The solenoid valve closes at the beginning of the

cooking cycle and automatically opens at the end of the cooking

cycle.

10 Drain V alve A two way ball valve, normally in the CLOSED position. T o

open the drain, pull the handle slowly outward, away from the

fryer . This releases the oil from the frypot into the filter drain

pan. Push it back in to close the valve.

DO NOT open the drain valve while frypot is under

pressure. Hot shortening exhausts from this valve.

Severe burns will result.

11 Drain Interlock Switch A microswitch that provides protection for the frypot in case the

operator drains shortening from the frypot while the main

switch is in the POWER position. The switch is designed to

automatically remove power from the heating elements when

the drain valve is open.

12 Filter V alve A two way ball valve which operates in conjunction with the

filtering system. W ith the handle in the open position (handle

facing vertical by turning it counterclockwise) and the main

power switch in the PUMP position, this valve directs the

filtered shortening from the drain pan back to the frypot. T o

close the filter valve, turn it clockwise to the horizontal position.

3-2 402

Page 14

el

520

ke

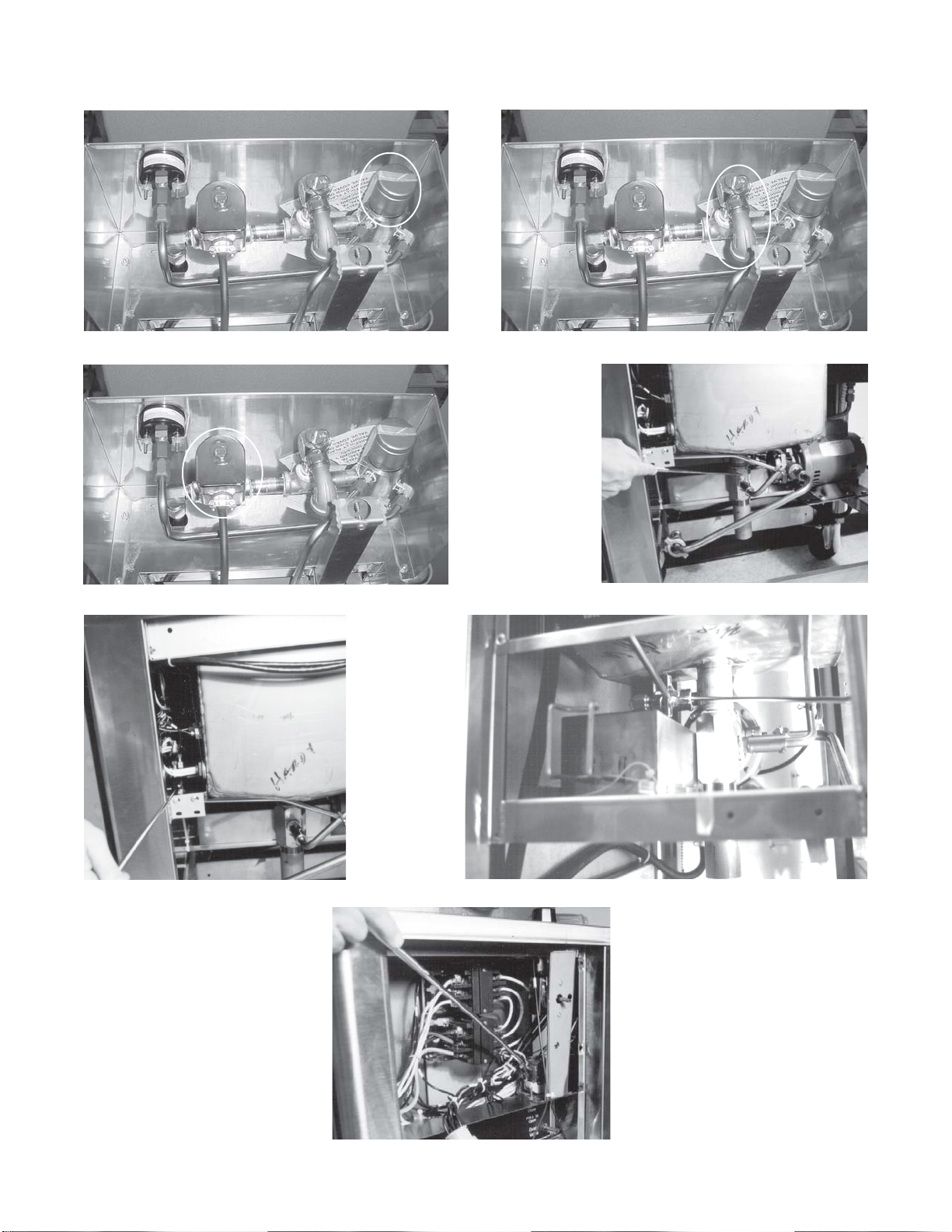

High Temperature

Control

Lid/Locking Assembly

Fun~tio~

The high temperature thermostat is a manual reset control

which senses the temperature of the shortening. If the shorten-

ing temperature exceeds the safe operating limit, this control

will remove power from the contactors, thus removing heat

to the cook pot. When the temperature of the shortening drops

to preset safe operating limit, the control must be manually

reset. The reset button is located on the upper surface of the

recess in the front panel below the regulating thermostat.

Before pressure will build in the cook pot, the lid must be closed

and locked. To close the lid, push the lid down with one hand

by using the plastic handle on top of the lid. While holding the

lid closed with one hand,. turn the handle on the latch

counterclockwise 160 o (until it contacts the stop) to lock the lid.

DO NOT place your free hand on top of the lid during

the latching procedure. The surface may be hot and

burns could result.

15

Condensate Drain Pan

The lid will not latch or pressure build unless the handle is fully

latched. As pressure builds within the cook pot, the handle will

be locked in place. As long as the locking assembly is engaged,

it will prevent the handle from being moved clockwise and

opening the lid. The locking assembly disengages when the

internal pressure falls below 1 PSI (6.8 KPa).

The condensate drain pan is located behind the panel, below

the drain and filter valve handles. Remove the panel and the

condensate pan is located on the left. It can be easily removed

by grasping the handle and pulling out carefully. The condensation pan should be emptied daily.

3-3

Page 15

Henny Penny Model 520

Item 6 Item 7

Item 9 Item 10

Item 11 Item 12

Item 9

3-4 101

Page 16

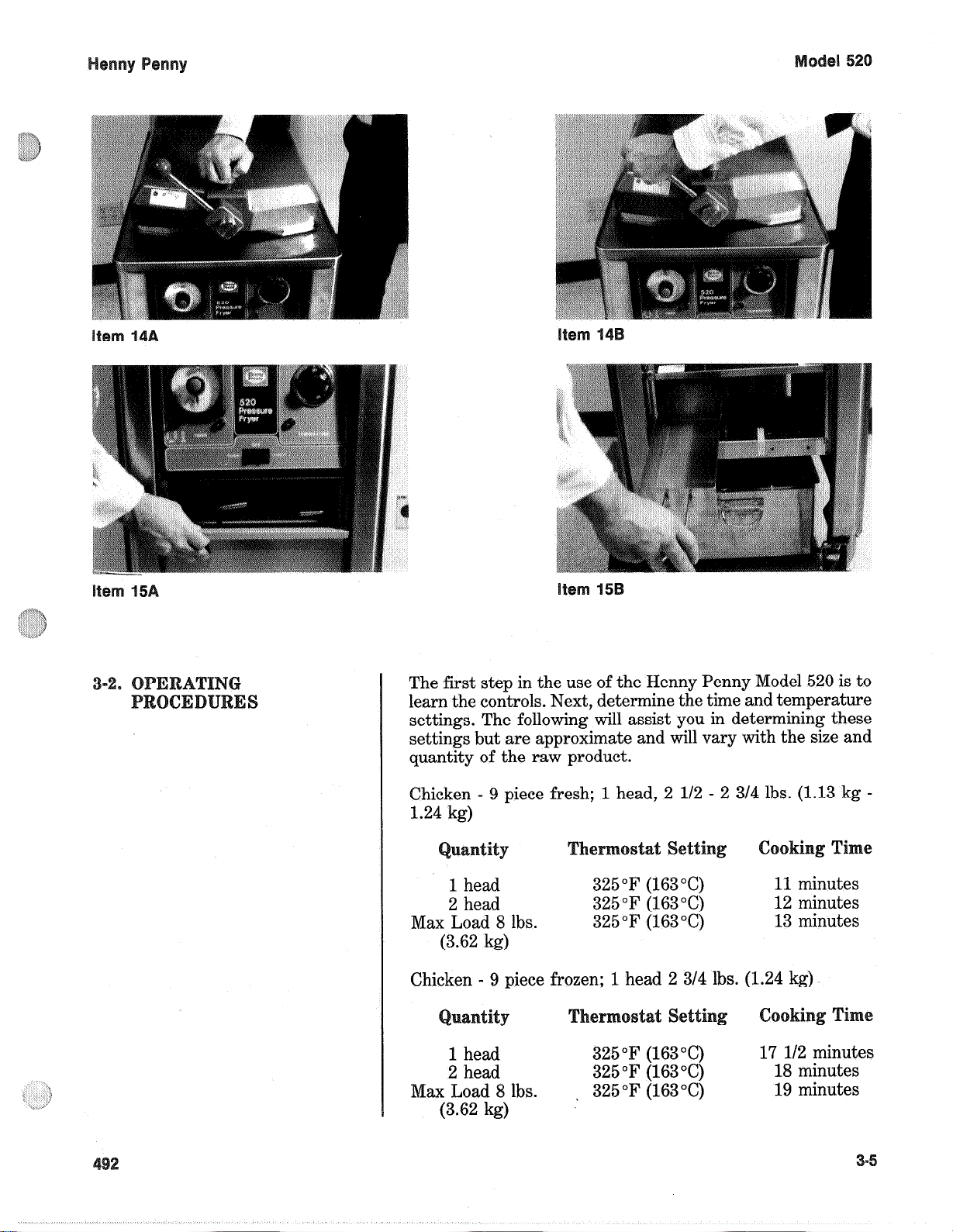

The first step in the use of the Henny Penny Model 520 is to

learn the controls. Next, determine the time and temperature

settings. The following will assist you in determining these

settings but are approximate and will vary with the size and

quantity of the raw product.

Chicken - 9 piece fresh; 1 head, 2 l/2 - 2 3/4 lbs. (1.13 kg -

1.24 kg)

1 head

2 head

Max Load 8 lbs.

(3.62 kg)

Chicken - 9 piece frozen; 1 head 2 3/4 lbs.

tit

1 head

2 head

Max Load 8 lbs.

(3.62 kg)

325°F (163°C)

325 “F (163 “C)

325 “F (163 “C)

T

325 “F (163 “C)

325 “F (163 “6)

325 “F (163 “C)

,’

etti

11 minutes

12 minutes

13 minutes

(1.24 kg)

c

17 l/2 minutes

18 minutes

19 minutes

Page 17

del

52

The following procedures should be followed in the initial

start-up of the fryer and each time the fryer is brought from

a cold or shut down condition back into operation.

1. Check to see that all control switches are turned OFF.

2. Be sure that the drain valve and filter valve are closed.

3. Remove the wire basket from the cook pot and leave the

lid open.

4. Fill the cook pot with shortening to level indicated. The

level indication is the maximum shortening level when hot.

5. Connect the power to the fryer.

6. Move the main power switch to the COOK position.

7. Turn the thermostat knob to the desired cooking

temperature. The temperature light will go on.

8. When the shortening has reached the desired cook

temperature, the temperature indicating light will be off.

9. Thoroughly stir the shortening to stabilize’the temperature

throughout. Make sure that the shortening at the bottom

of the pot is agitated and evenly heated.

10. After the shortening temperature has stabilized for a

minimum of 30 minutes, check the shortening temperature

using a good deep fat thermometer (Henny Penny part

no. 121006).

11. Lower the empty basket into the cook pot (food will be

added later).

12. Select the desired cooking time. You are ready to start

cooking.

NOTE: The overall operation of the 520 Fryer is no

different than our present Model 500 or Model

600 Pressure Fryers.

1. It is recommended that a high quality liquid frying shortening be used in the pressure fryer. Some low grade shortenings have a high moisture content and will cause foaming

and boiling over.

2. If a solid shortening is used, it must be melted to a liquid

first, then poured into the frypot. Attempting to melt a

shortening in the frypot may cause burning or scorching

of the fresh shortening.

“I

‘+I

Page 18

Step 3

el 520

Gloves should be worn and care must be taken when

pouring hot shortening into the unit. Severe burns could

result. Also, when adding fresh shortening to existing

shortening, care must be taken to avoid splashing.

3. Cold shortening should be filled approximately 112 inch

below the bottom level of the level indicator line. The

shortening will expand when heated.

3-5. COOKING

1. Before dropping the product into the basket, make certain

that the shortening is at the correct cooking temperature

for the type of product. Also, check that the temperature

light is OFF. Once the product has been prepared, you are

ready to cook. Place the basket in the cook pot a few

seconds before placing the product in the basket.

2. Place the product into the submerged basket by first

dropping in the larger pieces. This gives the larger and

more difficult pieces a few .extra seconds to cook in the

shortening. Continue to place the remaining product in

the basket.

3. Lift the basket slightly out of the shortening and shake

it, causing the pieces to separate. Return the basket to

the shortening. Doing this will prevent white spots on the

finished product.

4. Remove the basket handle and close the lid quickly. Latch

the lid as previously described.

5. Activate the time as previously described. Within a few

minutes, the pressure gauge will increase to the operating

zone.

6. At the end of the cooking cycle, the fryer will automatically

depressurize. Also the timer light will go off and the timer

will automatically reset.

7. After the pressure drops to 0, open the lid latch assembly

by turning the handle clockwise 160 O.

Page 19

Henny Penny Model 520

3-5. COOKING PROCEDURES 8. Raise the lid promptly to allow most of the condensation

(Continued) on the lid to drain down and out through the drain channel.

Do not let the lid slam up against the back stop. This could

damage the hinge assembly . This will also allow condensation to

drop back into the shortening.

NOTE: The condensation opening behind the pot needs to be

kept clear of obstructions. Failure to do so will cause the

moisture to back up onto the countertop.

9. Insert the handle into the basket, lift the basket out of the

shortening, and hang it on the side of the cook pot to drain.

Allow the product to drain approximately 15 seconds before

placing it into the tray .

10. The fryer will automatically recover to the preset cooking

temperature. Once the thermostat indicator light goes out, you

can begin the next cook cycle. If filtering of shortening is

desired at this time, refer to the next section.

NOTE: When no additional cooking is intended within 30 minutes

of the previous cook cycle, it is recommended to reduce

the shortening temperature (by turning the thermostat

knob counterclockwise) to 275

o

F (135o C).

Four product controls, use the “C” (up and down)

buttons and select Idle. The controls will automatically

o

reduce the temperature to 250

F (121o C).

3-6. FIL TERING THE Cooking breaded products requires frequent filtering to keep

SHORTENING the shortening clean. The shortening should be filtered after

every three to six cooking cycles. For the best quality product, do

not exceed six cook cycles without filtering.

1. Turn the thermostat and the main power switch to the OFF

position. Remove and clean the fry basket in soap and water .

Rinse thoroughly .

NOTE: For best results, filter shortening at normal cooking

temperature.

2. Use a metal spatula to scrape build up from sides of the frypot.

When using the pot scraper, do not damage the capillary line on

the thermostat, or the high limit control. Also, do not scrape the

heating elements, or damage to elements could result.

3-8 600

Page 20

el 520

The filter pan must be in the

the drain valve. This will prevent the splashing of the

hot shortening as it drains into the filter drain pan

which would cause burns.

3. Open the drain valve by pulling it forward slowly. This

will prevent excessive splashing of the hot shortening as

it drains into the filter drain pan.

4. As the shortening drains from the fry pot, use bushes

(Henny Penny part no. 12105) to scrape and clean the sides

of the fry pot and the heating elements. If the drain fills

with breading, use the white brush to push the breading

into the filter pan.

5. When all of the shortening has drained, scrape or brush

the sides and the bottom of the cook pot.

6. Rinse the cook pot as follows:

A. Close the drain valve by pushing the handle inward.

B. Open the filter valve by turning the handle counter-

clockwise.

proper position beneath

Hold the lid closed so that the very first surge of the

shortening will not splash up or over the top of the cook

pot’. Severe burns will result.

C. Move the main power switch to the PUMP position.

Carefully open the lid to see if shortening is returning properly. Fill cook pot l/3 full, then turn off the

mum. . .

If there are air bubbles coming up in the shortening,

it is possible that the filter connecting union on the filter

tube line is not tightened properly. If so, turn off the

pump and use gloves to tighten the union. *This union

will be hot and severe burns will result.

Page 21

el

520

3-6. FILTERING THE

S TENING (Co~ti

D. Wash down and scrub the sides of the cook pot. Use

“L” brush to clean the heating elements.

E . After the sides and bottom are cleaned, open the drain

valve.

7. Pump all the shortening out of the filter pan and back into

the cook pot. Close the lid during the first surge of

pumping.

8. When the pump is pumping air only, the shortening in the

fry pot will appear to be boiling. Close the filter valve first

and then move the main power switch from PUMP to

OFF. This will keep the filter pump and lines from filling

up with shortening.

Note: When the appearance of boiling occurs, immediately

close the filter valve, then turn the pump off. This will

prevent aeration of the shortening, therefore increasing

shortening life.

9. Check the level of the shortening in the cook pot. Add fresh

shortening, if necessary, until it reaches the level indicator

line on the rear wall of the cook pot.

GING T

ENVELOPE

F~LTE

NOTE: Approximately 10 to 12 filterings can be made with

one filter paper envelope, depending on several

conditions; the quantity and type of product fried and

filtered, the type of breading used, and the amount

of crumb accumulation left inside the filter drain pan.

When the filter screen assembly and filter paper

become clogged and pumping flow rate slows down,

clean the screen assembly and change the filter

envelope. See procedure on page 3-11.

10. After completing the filtering operation, empty and

replace the condensation drain pan.

11. If cooking is to be continued at this time, move the main

power switch back to the COOK position and allow time

for reheating of the shortening.

The filter envelope should be changed after lo-12 filterings

or whenever it becomes clogged with crumbs. Proceed as

follows:

1. Move the main power switch to the OFF position.

2. Remove and empty the condensation drain pan.

3. Disconnect the filter union and remove the filter drain pan

from beneath the fry pot. The filter drain pan is provided

with casters for ease of movement.

Page 22

Step 3

FILTE

ti~~e~)

This union will be hot. Use protective glove or cloth

to prevent burns.

4. Lift the screen assembly from the drain pan.

5. Wipe the shortening and crumbs from the drain pan. Clean

the drain pan with soap and water. Thoroughly rinse with

hot water.

Step 6

6. Unthread the suction standpipe from the screen assembly.

7. Remove the crumb catcher. Clean thoroughly with soap

and water. Rinse thoroughly with hot water.

Page 23

ENVELOPE (Co~ti~~ed)

Step 8

Step 10

8. Remove filter clips and discard the filter envelope.

9. Clean the top and bottom filter screen with soap and

water. Rinse thoroughly with hot water.

Be sure that the filter screens, crumb catcher, filter

clips, and the suction standpipe are thoroughly dry

before assembly of filter envelope, as water will dissolve

the filter paper.

Assemble the top filter screen to the bottom filter screen.

10.

11. Slide the screens into a clean filter envelope.

tep 11

tep 12

12. Fold the corners in and then double fold the open end.

Clamp the envelope in place with two filter retaining clips.

13.

Replace the crumb catcher screen on top of the filter paper.

14.

Screw on the suction standpipe assembly.

Place complete filter screen assembly back into filter drain

15.

pan. Slide pan back into place beneath the fryer.

Connect the filter union by hand. Do not use a wrench to

16.

tighten.

Slide the condensation drain pan back into place. The fryer

17.

is now ready to operate.

Page 24

Henny Penny Model 520

3-8. CLEANING THE FR YPOT T aste the cold shortening every day for flavor. Watch the shortening

for foaming during the cook cycle. Discard the shortening as soon

as it shows signs of foaming. Drain and clean the frypot as follows:

1. Turn the power switch to OFF .

Place the filter drain pan under the drain valve to prevent

splashing or spilling of hot liquids. Failure to do so, results in

splashing and severe burns.

2. Pull out drain valve handle to drain hot shortening from frypot.

3. Close the drain valve, and discard the shortening in filter pan.

Install the filter drain pan under the fryer, leaving out the filter

screen assembly .

4. Fill the frypot to the level line with hot water. Add 2 to 4

ounces (6 to 12 ml) of fryer cleaner (Henny Penny part no.

12101) to the water and mix thoroughly . The fry basket can be

placed inside the frypot for cleaning.

Always wear safety goggles or face shield and rubber gloves

when cleaning the frypot. The highly alkaline cleaning solution

should not contact eyes or skin, or severe burns will result.

Carefully read the instructions on the cleaner . If solution

contacts your eyes, rinse thoroughly with cool water and see a

physician immediately .

5. Standard Controls: Set thermostat to 195

o

F (91o C) and turn

the power switch to POWER position.

Electronic Controls: Use the up and down buttons to select

the Clean mode. The controls will automatically heat the

solution up to 190

o

F (88o C).

NEVER PRESSURIZE TO CLEAN. Leave the lid open.

W ater under pressure is super heated and causes severe burns.

600 3-13

Page 25

Henny Penny Model 520

3-8. CLEANING THE FR YPOT 6. When the set temperature is reached, turn unit off.

(Continued)

Watch cleaning solution constantly to make sure it does NOT

boil over causing damage to controls.

If the cleaning solution starts to foam and boil over, DO NOT

CLOSE THE FRYER LID, severe burns could result.

7. Let the cleaning solution stand for 15 to 20 minutes, with the

unit turned off.

8. Use fryer brush (Henny Penny part no.12105), to scrub the

inside of the frypot, the lid liner, and the counter top of the fryer.

Never use steel wool, it deteriorates the stainless steel.

Do not use the cleaning solution on the lid or the lid hinge.

These aluminum parts will corrode if the PHT cleaner contacts

them. Also, Do not use abrasive cleaners, or cleaner containing

chlorine, bromine, iodine, or ammonia chemicals on the stainless

steel. Deterioration of the stainless steel will result.

9 Open the drain valve and drain the cleaning solution from the

frypot into the drain pan and discard.

10. Replace the empty drain pan, close the drain valve, and refill the

frypot with hot water to proper level.

1 1. Add approximately 4 ounces of distilled vinegar and reheat the

vinegar solution to 195

o

F (91o C), or use the Clean mode on

electronic controls.

12. Using a clean brush, scrub the interior of the frypot and lid liner.

This neutralizes the alkaline left by the cleaning compound.

13. Drain the vinegar rinse water and discard.

14. Rinse down the frypot, using clean hot water .

15. Thoroughly dry the drain pan, and the frypot interior .

NOTE: Make sure the inside of the frypot, the drain valve

opening, and all the parts that will come in contact with the

new shortening, are as dry as possible.

16. Replace the clean filter screen assembly in the drain pan and

install under fryer .

17. Refill the fryer with fresh shortening.

3-14 700

Page 26

TING

el 52

4-1.

4-2. T

UCTI

This section provides troubleshooting information in the form

of an easy to read table.

If a problem occurs during the first operation of a new fryer,

recheck the installation section of this manual.

Before troubleshooting, always recheck the operating

procedures.

To isolate a malfunction, proceed as follows:

1. Clearly define the problem (or sympton) and when it

occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes. Then, one-at-a-time, work

through the list of corrections until the problem is solved.

WARNING

I

Refer to the maintenance procedures section to safely

and properly make the checkout and repair needed. If

maintenance procedures are not followed correctly,

injuries and/or property damage could result.

Page 27

Y

el- 520

roble

Product Color Not

Correct:

A. Too Dark

B. Too Light

cause‘

Temperature too high.

Shortening too old.

@ Shortening too dark.

* Dip solution too strong for

product.

e Breading product too far in

advance.

@ Temperature too low.

I

Correction

e Reduce thermostat setting.

e Check thermostat calibration.

e Remove and replace defective

thermostat.

0 Change shortening.

0 Filter shortening.

0 Taste shortening.

@ Change shortening.

@ Use correct dip solution or

shorten product immersion

time.

@ Bread product closer to actual

frying period.

8 Increase temperature.

Check calibration of

thermostat.

0 Remove and replace defective

thermostat.

6. Product Greasy

Dip solution too weak.

Fryer incorrect preheat.

Frypot overloaded with

product.

Slow fryer heatuplrecovery.

Temperature too low.

Frypot overloaded.

Product not removed from

frypot immediately after

depressurization.

0 Correct dip solution.

@ Allow proper preheat time.

@ Stir shortening prior to

dropping product into frypot.

Reduce cooking load.

@ Refer to heating elements in

the maintenance section.

Replace shortening.

@ Increase thermostat setting.

@ Temperature not recovered

when product was dropped in

frypot basket.

Check thermostat calibration.

Replace thermostat if needed.

Reduce cooking load.

Remove product immediately

after depressurization of the

fryer.

Page 28

Y

el 520

D. Spotted Product

E. Dryness of

Product

Improper separation of the

product.

Product was incorrectly

dipped.

Breading not uniform on the

product.

6 Burned breading particles on

product.

0 Product sticking together.

@ Moisture loss prior to cooking.

Over cooking the product.

Drop product into basket

properly and shake basket

before closing lid.

@ Agitate product during the

dipping procedure.

c Sift breading regularly.

a Separate product during

breading.

@ Filter the shortening more

frequently.

e Separate product prior to

pressure cooking.

0 Use fresh product.

0 Keep product covered with a

moist cloth to reduct

evaporation.

0 Reduce cook time.

* Reduce cook temperature.

Product Flavor

(Taste):

A. Salty taste

B. Burned Taste

Low operating pressure.

Too small of a load being

cooked.

Breading miirture is too salty.

Marination mixture too

concentrated.

Incorrect choice of breading.

@ Burned shortening flavor.

Shortening needs filtering.

0 Check pressure gauge reading,

check, for pressure leaks.

e Increase quantity to obtain

correct operating pressure and

product quality.

Sift breading after each use.

0 Incorrect breading mixture.

e Discard old breading.

e Reduce the concentration of

the marination mixture.

@ Use breading designed for the

desired product.

e Replace shortening.

Filter shortening more

frequently.

Frypot not properly cleaned.

Drain and clean frypot.

Page 29

ode1

520

C. Bland Taste

D. Rancid Taste

Raw product not fresh.

@ Breading mixture incorrect

for product (spice content too

low).

0 Cooking temperature too high

(spice flavor lost).

Breading does not adhere to

product.

@ Shortening too old.

8 Non compatible products

cooked within the same

shortening.

Infrequent filtering.

Use fresh raw products.

Use breading designed for

desired product.

@ Use correct temperature for

breading used.

@ Use correct dip and breading

and use correct procedure for

the product.

0 Replace shortening and follow

recbmmended care and use of

shortening.

@ Replace shortening.

* Use compatible products and

follow recommended care and

use of shortening.

0 Replace shortening and follow

recommended care and use of

shortening.

General:

A. Meat separation

from bone

B. Bone color not

proper

Raw product not fresh.

Incorrect meat cut.

Overcooking.

Raw product contains too

much water.

Product not fresh.

Using frozen product (black

bone).

Improper processing of

product (black bone).

Product not thoroughly

cooked (red bone).

@ Use fresh product.

Use correct meat cutting

procedures.

Reduce cooking time.

Allow product to drain after

marinating.

Use fresh product.

Use fresh product.

Use proper processing

procedure for product.

Increase cooking time.

Page 30

el 520

C. Breading falls

off

D. Product sticking

together

Incorrect breading

procedures.

Product partially frozen

during breading.

@ Improper handling of cooked

product.

* Excessive stirring of product

prior to closing the lid.

Product breaded too long

prior to cooking.

Improper separation

procedures prior to closing the

lid.

Frypot overloaded with

product.

Use correct breading

procedure.

@ Thoroughly thaw the product

before breading.

Handle cooked product

carefully.

0 Separate the product.

Refer to breading and frying

instructions.

0 Separate the product.

@ Reduce the cooking load.

With switch in

POWER position the

fryer is completely

inoperative (NO

POWER)

Improper loading procedure.

Open circuit.

0 Load product in frypot.

Check to see that unit is

plugged in.

Check breaker for fuse at

supply box.

@ Check control panel fuses.

e Check voltage at wall

receptacle.

Check MAIN POWER switch.

Replace if defective.

Check cord and plug.

Check circuit breaker.

Page 31

ode1 520

Pressure will not

exhaust at end of

frying cycle

Operating pressure

too high

Pressure does not

build

Exhaust line from solenoid

valve to expansion tank

clogged.

* Solenoid valve clogged.

* Dead weight clogged.

* Exhaust line to stack clogged.

* Not enough product in fryer

or product not moist.

Metal shipping spacer not

removed from dead weight.

Lid open or not latched.

* Solenoid valve leaking or not

closing.

Dead weight valve leaking.

* Release pressure from frypot;

clean all pressure lines.

* Check and clean solenoid valve.

* Release pressure from frypot;

remove dead weight and clean.

* Clean exhaust line to stack.

* Place proper quantity of moist

product within frypot to

generate steam.

Remove shipping spacer.

* Close and latch lid.

* Check or clean solenoid valve.

* Repaid dead weight valve, per

maintenance section.

Filter motor runs but

pumps shortening

slowly

Main timer not closing

solenoid.

Safety relief valve leaking.

Filter valve not open.

Pump clogged.

Filter screens not properly

assembled.

Filter line connections loose.

Solidified shortening in lines.

I

Filter paper clogged.

Check main timer.

Check and replace if necessary.

Open filter valve.

Remove and clean pump.

Reassemble filter screens.

Tighten all filter line

connections.

Clear all filter lines of solidified

shortening.

Change filter paper.

Page 32

el

52

Motor hums but will

not pump

Shortening will not

heat

Ca~ee

CTIQN (Continued)

Defective motor.

Motor

thermal protector

* Clogged lines or pump.

TENING SEC

Blown fuse or tripped breaker

at supply box or control panel.

Blown fuse at control panel.

Faulty main switch.

correction

Check/replace motor.

* Reset thermal switch.

* Remove and clean pump lines.

* Replace pump seal, rotor and

rollers.

* Reset breaker or replace fuse.

* Check fuse.

* Check main switch.

eating of shortening

too slow

Shortening

overheating

Check cord and plug. Check

power at receptacle.

Faulty contactor.

Faulty thermostat.

Faulty high limit control

switch.

Low or improper voltage.

Weak or burnt out elements.

Points in contactor bad.

Wires loose.

Burnt or charred wire

connection.

Check thermostat

Check cord and plug and power

at wall receptacle.

* Check contactor.

* Check thermostat’.

Check high limit control switch.

Use a meter and check the

receptacle against data plate.

Check heating elements.

Check contactor.

* Tighten.

Replace wire and clean

contactors.

* Calibrate thermostat

* Check faulty thermostat

Check contactor for not

opening.

Check faulty contactor.

Page 33

ING SECTIQN

Foaming or boiling

over of shortening

Shortening will not

drain from fry-pot.

Water in shortening.

Condensation line stopped up.

Improper or bad shortening.

Improper filtering.

* Improper rinsing after

cleaning the fryer.

Drain valve clogged with

crumbs.

Drain valve will not open by

turning handle.

* At the end of frying cycle,

drain shortening and clean

frypot. Add fresh shortening

and check procedure for raising

lid.

* Remove and clean condensation

line.

Use recommended shortening.

* Refer to the procedure

covering filtering the

shortening.

Clean and neutralize the frypot.

Rinse with vinegar to remove

the alkaline then rinse with hot

water and dry frypot.

* Open valve - force cleaning

brush through drain opening.

Replace cotter pins in valve

coupling.

Timer fails to run

Buzzer continues to

buzz

Buzzer will not buzz

Timer will not reset

Timer light out

No power input

Timer set at zero.

Faulty microswitch.

Possible faulty buzzer.

Timer indicator not returning

to zero.

Faulty timer.

Faulty lamp.

Check timer switch

Check timer motor

Set timer indicator to a setting

other than zero.

Check and replace faulty

microswitch.

Check buzzer, replace if. faulty.

* Replace timer.

* Replace timer.

Replace lamp.

Page 34

.

UCTI This section provides procedures for the replacement of the

various parts used within the pressure fryer. Before replacing

parts, refer to the troubleshooting section of this manual. It

will aid you in determining the cause of the malfunction.

WARNING

I

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

1. Remove two 318” nuts from bottom of side panel,

2. Using a straight blade screwdriver, gently pry side panel

straight up.

3. Slide side panel from unit.

I

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

Page 35

Step lb

1. Remove four screws securing control panel to unit and

also thermostat knob.

2. Unplug the nine pin connector.

3. Remove two wires from thermostat (wire number 13 &

16) and remove control panel.

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

1. Follow steps 1, 2 and 3 in

emoval of Control Panel.

emove two screws from the buzzer coil bracket.

‘”

.,,,*i

Page 36

move screw mounting buzzer coil to bracket.

4. Cut wires on old buzzer. (Note: Mark wires before

cutting.)

5. Install new buzzer and splice cut wires.

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

1. Follow steps 1, 2 and 3 in Removal of Control Panel.

2. Unplug wires from old timer switch. (Note: Mark wires

before unplugging.)

3. Loosen the 9116” retainer nut behind timer switch.

Remove front retainer nut of timer switch and install new

4.

switch.

Page 37

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

2

1. Follow steps 1,

and 3 in Removal of Control Panel.

2. Remove the two screws securing motor to timer.

3. Cut wires on old motor. (Note: Mark wires before cutting.)

4. Install new motor and splice cut wires.

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

1. Follow steps 1, 2 and 3 in Removal of Control Panel.

2. Unplug wires from old power switch. (Note:

ark wires

before removing.)

3. Depress retainers on rear of switch and push switch out

towards front of control panel.

. Install new power switch.

Page 38

2a

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failme to do so could result

in electrical shock.

1. Follow steps 1, 2 and 3 in Removal of Control Panel.

2. Remove two 3/V nuts securing thermostat bracket to

control area.

3. Remove two screws holding thermostat to bracket.

4. On the inside of pot, loosen screws on bracket securing

thermostat bulb.

emove 11116” nut from pot wall and remove thermostat.

6. Install new thermostat in reverse order.

Page 39

el

52

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

Whenever the thermostat fails to maintain the selected

temperature within f 5 “F (- 15 “C) of the thermostat setting,

it should be calibrated.

To calibrate the thermostat, it is necessary to perform step

increases in the temperature of shortening. Follow this

procedure:

1. Place the main power switch in the POWER position. Be

sure there is shortening in the frypot.

2. Set the thermostat knob to 250°F (121” C).

3. Allow enough time for the shortening to heat. When the

shortening reaches the set temperature on the thermostat,

the indicator light will go off. Usually, it will take no longer

than 15 minutes for the shortening to heat to the set

temperature.

4. Remove the fry basket from the shortening.

5. Stir the shortening with the basket handle.

6. Measure the temperature of the shortening using an

accurate, mercury tube type, deep fat thermometer

capable of measuring temperatures in the 250 “F to 400 “F

(121 “C to 204°C) range. (Henny Penny part number

12106.)

7. Insert the thermometer near the center of the frypot to

a depth of about 3 inches below the level of shortening.

8. Carefully stir the shortening with the thermometer.

9. Allow the mercury in the thermometer to rise to the

temperature of the shortening. Hold the thermometer

straight up and down.

The temperature reading is to be taken just as the

TEMP indicator light goes off. This will give the correct

temperature rather than an override temperature.

10. If the temperature is within 5°F (- 15°C) of the

temperature set on the thermostat, increase the thermostat setting approximately 25 “F (- 4°C). Wait until the

indicator light goes off, then again check the temperature

Page 40

el 520

of the shortening. If it is again within 5 “F (- 15%), the

thermostat does not require calibration.

If the thermometer is accidentally broken, and mercury

and pieces of broken glass fall into the shortening,

discard the shortening and clean the frypot thoroughly.

Mercury is highly poisonous.

11. If the temperature indicated on the thermometer differs

more than 5 “F (- 15 “C), remove the thermostat knob by

pulling it off its stem.

Do not rotate the knob while removing it.

12. Turn the adjustment screw in the center of the hollow

stem, using a small blade screwdriver. If the thermometer

reading was higher than the setting, rotate the screw

clockwise. If lower, counter-clockwise. For example:

setting:

reading:

adjustment:

After adjusting the screw, install the knob and reset the

13.

thermostat to 250°F (121 “C). Again, measure the

temperature of the shortening with the deep fat thermometer. Wait a few moments for the shortening to reach

the 250 “F (121 “C) temperature setting, indicated on the

thermometer. The indicator light should go off when the

temperature reaches 250 “F (121 “C). Readjust screw if

necessary.

14. Set the thermostat to 275°F (135 “6).

250 “F (121 “C)

275 “F (135 “C)

114 turn clockwise.

I

15. Check the temperature of the shortening when the

indicator light goes off.

16. If the temperature measured on the thermometer is not

within 5 “F (- 15 “C) of the thermometer setting, adjust

for the correct temperature as in steps 12 and 13 of this

procedure.

Once the thermostat has been calibrated and set at the

desired cooking temperature, do not use the thermostat

to turn the fryer ‘off. Use the ON-OFF switch.

Page 41

This high temperature control is a manual reset control

which senses the temperature of the shortening. If the

shortening temperature exceeds the safe operating

limit, this control switch will open and shut off the heat

to the frypot. When the temperature of the shortening drops to the safe operating limit, the control must

manually be reset.

Before replacing a high temperature limit control, check to

see that its circuit is closed.

The shortening temperature must be below 330°F

(192°C) to accurately perform this check.

1. Remove electrical power supplied to the fryer.

Place POWER/OFF/PUMP switch in the OFF

position, and unplug the power cord or open the wall

circuit breaker, or electrical shock could result.

2. Remove the control panel.

3. Remove the two electrical wires from the high

temperature limit control.

4. Check for continuity between the two terminals after

resetting the control. If the circuit is open, replace the

control, then continue with this procedure. (If the circuit

is closed, the high limit is not defective. Reconnect the two

electrical wires.)

Before following these steps,

POWER/OFF/P~P switch in the OFF position, and

unplug the power cord or open the wall circuit breaker,

or electrical shock could result.

place

1. If the tube is broke&i or cracked, the control will open,

shutting off electrical power. The control cannot be reset.

Page 42

2. Drain shortening from the frypot.

3. Remove control panel.

4. Loosen small inside screw nut on capillary tube.

5. Remove capillary bulb from bulb holder inside the fry-pot.

6. Straighten the capillary tube.

I

7. Remove larger outside nut that threads into pot wall.

8. Remove the two screws that secure the high limit to the

high limit bracket.

9. Remove defective control from control panel area.

10. Insert new control and replace screws.

11. Uncoil capillary line, starting at capillary tube, and insert

through frypot wall.

To avoid electrical shock or other injury, the capillary

line must run under and away from all electrical power

wires and terminals. The tube must never be in such

a position where it could accidentally touch the

electrical power terminals.

Page 43

Step 3

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

1. Drain the shortening.

2. Remove the thermostat and high limit bulb holder from

the heating element inside the frypot.

3. Remove the heating element wires from the contactor.

Label each so it can be replaced in the same position on

the new element.

4. Slide the element spreaders to the center of the heating

element.

Remove the brass nut and washer, which secure the ends

5.

of the element through the frypot wall.

Remove the heating element from the frypot by lifting the

6.

far end and sliding it up and out toward the rear of the

frypot.

Always install new rubber 0 rings (2) when installing

heater elements.

7. Install new heating element with new rubber 0 rings (2)

mounted on terminal ends, and spreaders loosely mounted

in the center of the stacked elements.

8. Replace the heating elements, terminal end first at

approximately 45” angle, slipping the terminal ends

through the front wall of the frypot.

Replace the brass nut and washer on the heating element

9.

terminals. Tighten the brass nuts to 30 foot lbs. of torque.

10. Move the element spreaders from the center of the

element, and tighten.

11. Replace the thermostat and high limit bulb holder and

tighten screw which holds the bulb in place.

econnect the wires to the appropriate terminal as labeled

when they were removed.

13. Replace the front control panel.

Page 44

14. Conned the power cord to the wall receptacle or close wall

circuit breaker.

Heating element should never be energized without

shortening in the frypot, or damage to element could

result.

15. Replace the shortening in the fry-pot.

If either contactor is defective it must be replaced as follows:

WARNING

I

Remove electrical power supplied to the fryer, by

unplugging or opening the wall circuit breaker, or

electrical shock could result.

1. Remove only those wires directly connected to the

contactor being replaced. Label the wires.

2. Remove the two mounting screws on the base plate and

remove contactor.

3. Install the new contactor and tighten the two mounting

screws.

4. Connect the labeled wires to their respective positions.

5. Install the control panel.

connect power to the fryer and test the fryer for proper

operation.

Page 45

Place power switch in the OFF position, shut off power

at the fuse or breaker box. Failure to do so could result

in electrical shock.

1. Remove retaining ring from hinge pin.

I

2. Using a punch and hammer, drive hinge pin out from

spring.

3. Remove old spring.

4. Remove stops from cam.

oosen 318” nuts from rear shroud, remove nut from

pressure gauge, and remove shroud.

Page 46

5-13.

Step

EPLA

INGE

(CQntin~e~)

5b

6. Position new spring as shown in illustration at left.

tep 6a

Spring must be in this position to accurately install lid

hinge spring.

7. Open lid to rear of unit as far as possible.

8. Using a punch and hammer, drive hinge pin back into lid

and spring.

9. Reattach lid stops and rear shroud.

Page 47

Henny Penny Model 520

5-14. REPLACEMENT OF LID

GASKET

Place power switch in the OFF position, pull fuse or turn off

wall circuit breaker, or electrical shock could result.

1. Using a straight blade screwdriver, pry one corner of gasket

out from liner.

2. Pull gasket from lid.

Step 1

3. Clean gasket and gasket seat with soap and hot water .

4. Reinstall lid gasket with “good” side facing out, or install new

gasket.

NOTE

Reverse lid gasket every 90 days to keep gasket in good

Step 2

condition.

5-15. LID LA TCH The cam shaft and latch plate should be lubricated every 90 days to

LUBRICATION prevent early wear and failure of latch parts.

1. Using spindle lube, part number 12124, place a small amount of

spindle lube in the top portion of the latch plate. See Figure 1.

Figure 1

2. Using spindle lube, part number 12124, place a small amount of

spindle lube on the cam shaft. See Figure 2.

Figure 2

5-14 101

Page 48

Henny Penny Model 520

5-16. DEADWEIGHT VALVE

ASSEMBLY

Do not attempt to remove the valve cap while the fryer is in

operation, or severe burns or other injuries could result.

The deadweight valves are located behind the lid. The valve, left of

th e pressure gauge, is a 14 1/2 lb. (999 mbar) safety relief valve, and

the one on the right is the operating valve.

V alves are working properly , when the pointer on the gauge is in the

Deadweight Valve “OPERA TING ZONE” (green area). The gauge pointer should

not normally exceed the operating zone. If the pressure builds to

14-1/2 lbs.(999 mbar), the safety relief valve will open to release

steam pressure from inside cookpot.

CAP ORIFICE WEIGHT

DO NOT MANUALL Y ACTIVA TE THE SAFETY

RELIEF VAL VE. Hot steam will be released from valve

when ring is pulled. Keep away from safety valve exhaust,

or severe burns could result.

1. A T THE END OF EACH DAY’S USAGE OF THE

FR YER, THE OPERA TING VAL VE MUST BE

CLEANED. The fryer must be OFF and the pressure

released. Open the lid and then remove the dead weight

valve cap and dead weight.

Failure to clean the operating control valve daily could

result in the fryer building too much pressure. Severe

injuries and burns could result.

2. Wipe both the cap and weight with a soft cloth. Make

certain to thoroughly clean inside cap, the weight seat, and

around valve orifice.

3. Dry the parts and replace immediately to prevent damage

or loss.

402 5-15

Page 49

Henny Penny Model 520

5-17. REMOVAL & CLEANING The safety relief valve should be cleaned once a year.

OF SAFETY RELIEF VALVE

SAFETY VALVE

DO NOT ATTEMPT TO REMOVE V AL VE WHILE

FR YER IS OPERA TING, or severe burns or other injuries

could result.

1. Using 3/8” socket, remove the 4 nuts securing back shroud.

2. Loosen nut on pressure gauge, and pull the back shroud from

fryer .

Step 1

Step 2

3. Unscrew Deadweight cap and remove cap and weight.

4. Use a wrench to loosen the valve from the pipe tee, turn

counterclockwise to remove.

5. Clean the inside of the pipe tee with hot water.

6. Immerse the safety relief valve in a soapy water solution

for 24 hours. Use a 1 to 1 dilution rate. The valve cannot

be disassembled. It is factory preset to open at 14 1/2

pounds of pressure. If it does not open or close, it must

be replaced.

DO NOT DISASSEMBLE OR MODIFY THIS VAL VE.

T ampering with this valve could cause serious injuries and also

voids agency approvals and appliance warranty .

Step 3

5-16 402

Page 50

MODEL 52OC

HENNY PENNY CORP.

EATON, OH 45320

MOTOR

PUMP

~-~-

I I ‘II I-

I I

CONNECTORS

-- !A

I- I

I

11

I I

12131415161718191

I I I I I

1A 2A 3A 4A 5A 6A 7A 8A 9A

I

I I I I

I

I

I

I

HI-LIMIT

THERMOSTAT

I

I

I

I

ER

2001360 V

2201380 V

240/415 V

3 PH

4 WIRE + GND

RTD PROBE

I/O BOARD

I--

(-‘ONTROL PANEL - - ___ - - - ~ - ____ ~ - - ____ - -

40249

Page 51

22 6

MODEL 520C

HENNY PENNY CORP.

EATON, OH 45320

---------I

I I

I

I

[11213141516171819]

1A 2A 3A 4A 5

I I

I I I I

23

P

231

I I

I I

I I

6A 7A 8 9A

HI-LIMIT

THERMOSTAT

I I I

I I

208V 3 PH 50 HZ (601

240V 3 PH 50 HZ (601

3 WIRE + GND

DELTA

l/O BOARD

P13

RTD PROBE

n

I I

.

--

I

CONTROL PANEL __ - -.,-e!- __ - - - - - - ~ - - -

Ii

-J

38860

Page 52

MODEL 520C

HENNY PENNY CORP.

EATON, OH 45320

NEUT

lNCTx1 1

FILTER

MOTOR

PUMP

77

26

I

-

7

II

7AI

MOV

44669

28 SECONDARY

R/C F;;TER ! 1

t-

1

22 CONTACTOR

1

1

I

11 21

12$ 11

1 1

PRIMARY

r

I I

31

-

8'

'

1

I

DRAII\

SWITCI

I I

23

”

I

HI-LIMIT

THERMOSTAT

FILTER

l/O BOARD

208V - 240V

1 PH

2 WIRE + GND

RTD PROBE

-

KEY

---I

” I S\IILI

LOAD

I’// I

I

I

L----.-p- CONTROL PANEL - - -.m.-! - - - - v - - - - - - -

:2”0”

240 24ov

2OEV

2OEV

L

PlO

p5 "7-l.. ilDISPLAY CONTROL

BOARD

P N 4

BOARD

II

38852

Page 53

:+

I I I

-1

FILTER 26

MOTOR

PUMP

200/360 V

220/380 V

240/415 v

50 HZ 3 PH

4 WIRE + GND

7

9 PIN CONNECTOR

we--

I

I

l-

MALE 21

FEMALE .!. I 2. I m?. I 4.

I I-

II I

II ,

I’ I

I

I

‘1 1

1

lv\ ,?A +I 4A

f

I

31 41

2 1 3 1 4

I

I

IQ++-

POWER SWITCH

- -CONTROL PANEL- -

MODEL 520

HENNY PENNY CORP.

EATON, OH 45320

I

I

1

--l

DRAIN SWITCH

HI-LIMIT

THERMOSTAT

T I MER MOTOR u

“I

VEAT LIGHT1

1

Page 54

JU

HEATERS

-

I

- -CONTROL PANEL-

208V 3 PH 50

240V 3 PH 50 HZ (60)

3 WIRE + GND

DELTA

+

HZ (601

1A

POWER SWITCH

MODEL 520

HENNY PENNY CORP.

EATON, OH 45320

-

1

I

8 1

s

r6171619111 I I

--_--------I

91 r,-- THERMOSTAT

---I- -; I,, 7 - -

------

HER SW I TCHES

1 I II4

I

TIMER MOTOR

I

36453

1

I

I

+

Page 55

Page 56

Henny Penny Model 520

SECTION 6. PARTS INFORMATION

6-1. INTRODUCTION This section lists the replaceable parts of Henny Penny Model

520 Compact Pressure Fryer.

6-2. GENUINE P ARTS Use only genuine Henny Penny parts in your fryer . Using a

part of lesser quality or substitute design may result in cabinet

damage or personal injury .

6-3. HOW TO FIND PARTS T o find items you want to order from the Parts List, proceed

as follows:

1. Referring to the illustration in this section, find the part item

number of the part needed.

2. Find the item number in the parts list, which shows the Henny

Penny part number, a description of the part, any model or

usage limitations, and the quantity of parts used.

6-4. HOW TO ORDER Once the parts you want to order have been found in the

Parts List, write down the following information:

Example:

Item number 31

Part number 17308

Description Filter V alve

From the date plate list the following information:

Example:

Product number 02571

Serial number 00179

Phase 3

Voltage 208

6-5. RECOMMENDED

SPARE PARTS FOR

DISTRIBUTORS

Recommended replacement parts, stocked by your distributor, are

indicated with

√√

√ in the parts lists. Please use care when ordering

√√

recommended parts, because all voltages and variations are

marked. Distributors should order parts based upon common

voltages and equipment sold in their territory .

206 6-1

Page 57

Henny Penny Model 520

6-2 101

Page 58

Henny Penny Model 520

520 FRYER PAR TS LIST

PART

NO. NUMBER DESCRIPTION Qty.

37956 LID ASSEMBL Y , Complete .............................................. 1

√√

√ 1 19475 TORSION SPRING, Lid .................................................. 1

√√

2 37955 LID, Machined Casting...................................................... 1

3 32227 KNOB .............................................................................. 1

4 16165 SPRING, LockPin ............................................................. 1

5 37505 RETAINER, Pin. ............................................................... 2

6 37751 LOCKING LEVER ARM ASSEMBL Y ............................ 1

7 SC01-049 SCREW #6-32 x 3/8 PH-RHD C ..................................... 6

8 19471 LINER, Lid ....................................................................... 1

√√

√ 9 19472 GASKET, Lid ................................................................... 1

√√

10 SC01-152 SCREW #6-32 x 3/8 PH-FHD SS.................................... 8

11 36146 CAMSHAFT , Machined ................................................... 1

12 RR01-008 RING , Ret.1 1/2 Shaft ....................................................... 1

13a 29070 ELEMENT SPREADER-BAR.......................................... 3

13b 29359 ELEMENT SPREADER ................................................... 3

13c SC01-055 ELEMENT SPREADER-SCREW .................................... 3

14 36177 EXTRACTION CAM ...................................................... 1

√√

√ 15 29224 HEATING ELEMENT, 6KW, 208V ................................. 1

√√

√√

√ 36072 HEATING ELEMENT , 6KW , 220V................................. 1

√√

√√

√ 48436 HEATING ELEMENT , 6KW , 230V................................. 1

√√

16 RR01-009 RING , Ret. 1 1/8 Shaft ...................................................... 1

17 36562 PIN, Cam ......................................................................... 1

18 29339 SLEEVE, Fryer ................................................................. 1

19 36094 HANDLE, Finished ........................................................... 1

20 29397 SPRING ........................................................................... 1

21 29341 NUT, Handle ..................................................................... 1

22 38231 SHAFT, Handle (units built before 1993 use 38231 & 36094) 1

23 16102 KNOB, Spindle (Red)....................................................... 1

24 16855 SEAL, “O” Ring ................................................................ 2

25a 29295 BRACKET , High Limit Thermocouple - BAR .................... 2

25b 29297 BRACKET , High Limit Thermocouple ............................... 2

25c SC01-055 BRACKET , High Limit Thermocouple -SCREW ............... 6

26 36079 SCREW , 5/16-24 x 1 Flat HD .......................................... 2

27 36145 LATCHPLA TE, Machined................................................. 1

28 36163 POT & COUNTERT OP WELDMENT ............................ 1

29 36056 SHIM, Latch .005 ............................................................. 1

30 17255 COTTER PIN................................................................... 4

√√

√ 31 17308 FILTER V AL VE................................................................ 1

√√

32 19739 ROD, Filter V alve Extension .............................................. 1

√√

√ recommended parts

√√

206 6-3

Page 59

Henny Penny Model 520

520 FRYER PAR TS LIST (Continued)

PART

NO. NUMBER DESCRIPTION Qty.

33 WA01-005 W ASHER, AM. S td. 10 x 1-5/16 OD, T ype A, Series N.. 2

34 NS01-017 NUT, Hex 5/8-18 Brass I ................................................. 2

35 19193 SIDE P ANEL ASSEMBL Y.............................................. 2

36 NS03-031 #8 TINNERMAN F ASTENER ....................................... *

37 SC04-002 SCREW , #8-32 X 3/8 PH THD C ................................... *

√√

√ 38 16738 TEMPERA TURE CONTROL, High Limit ........................ 1

√√

39 29285 BRACKET , Contactor ..................................................... 1

√√

√ 40 19405 CONTACTOR ................................................................ 2

√√

√√

√ 41 36067 TIMER, 240 v, 60 HZ...................................................... 1

√√