Page 1

Electronic Controls Retrofit

FM01-875 - D

Page 2

Electronic Controls Retrofit

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s

written consent. If damage occurs during shipping, notify the sender at once so that a claim may be

filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse;

(b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED.

HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY

OTHER OBLIGATION OR LIABILITY.

Page 3

Electronic Controls Retrofit

SECTION 1. INSTALLATION

1-1. INTRODUCTION

This section provides instructions for the removal of the

existing controls, and the installation of the new Henny

Penny Electronic Control Retrofit.

Installation of the kit should be preformed only by a

qualified service technician.

Do not puncture the unit with any objects such as

drills or screws as component damage or electrical

shock could result.

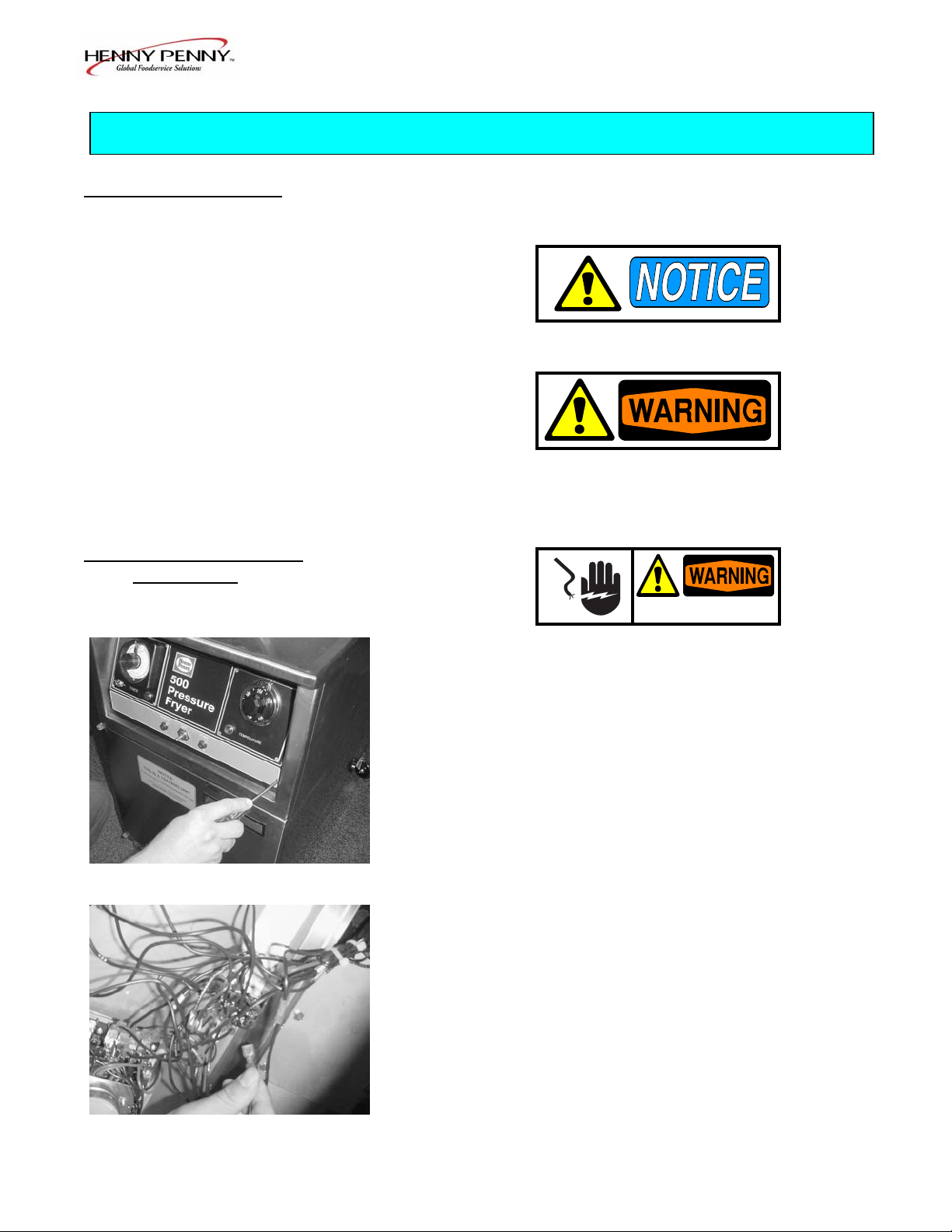

1-2. REMOVING “OLD”

CONTROLS

shock

To avoid electrical shock or property damage, move

the power switch to “OFF” and disconnect main

circuit breaker, or unplug cord at wall receptacle.

1. Drain shortening from frypot.

2. Remove the Phillip’s head screws from the control

Figure 1-1 panel. Figure 1-1.

3. Cut wire ties and mark the wires to the pump(connected

to the power switch) and unplug them. Figure 1-2.

Hint: A 500/600/561 Manual may help in referring to the

original wiring diagram.

.

Figure 1-2

602 1-1

Page 4

Electronic Controls Retrofit

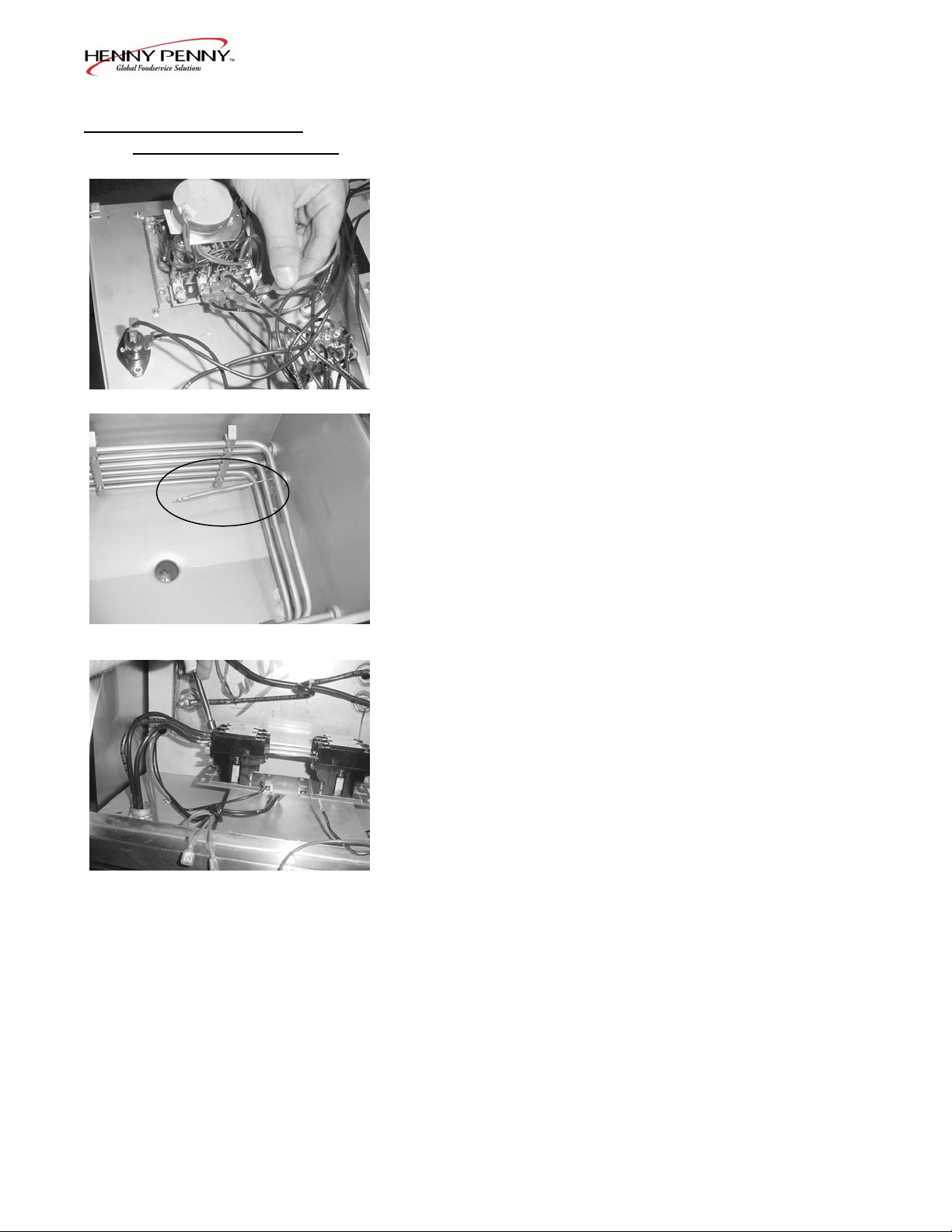

1-2. REMOVING “OLD”

CONTROLS (Continued)

4. Mark and disconnect the wires to the pressure solenoid,

at the N/C terminals on the timer. Figure 1-3.

Figure 1-3 5. Remove thermostat bulb, capillary, and bracket from

the elements and pull from frypot. Figure 1-4.

6. Disconnect and remove the remaining control wires and

connectors.

a. Disconnect remaining power switch wires.

Figure 1-4 b. Disconnect indicator light, drain switch and high

limit wires.

c. Disconnect 15 amp fuse holder wires from Primary

Contactor.

7. Pull “old” control from unit.

Figure 1-5

8. Remove L1, L2, & L3 from Primary Contactor.

Figure 1-5.

1-2 602

Page 5

Electronic Controls Retrofit

1-2. REMOVING “OLD”

CONTROLS (Continued)

9. Remove the 3 wires from the heating elements.

Figure 1-6.

If element terminals look heavily corroded, remove the

wires at the contactor instead of the elements. Remove

the wires from the mercury contactor, from the kit, and

pull the amp rings from the wires. Slide the appropriate

Figure 1-6 colored ring over the line wire and attach to mercury

contactor. See below. Black=L1 Red=L2 Orange=L3 Using a wire tie, fasten each ring up on the line wire, so it doesn’t slide down against the contactor terminal.

Black

Red

Orange

Figure 1-7

10. Remove the 2 bolts securing the contactor bracket and

remove entire contactor assembly. Figure 1-7.

11. Remove pressure solenoid coil. Figure 1-8.

Figure 1-8

602 1-3

Page 6

Electronic Controls Retrofit

1-3. INSTALLING “NEW” 1. Install new temperature probe. See instruction below.

CONTROLS

Figure 1-9

1-4 602

Page 7

Electronic Controls Retrofit

1-3. INSTALLING “NEW” 2. Install the 24 VAC solenoid coil from kit.

CONTROLS (Continued)

3. Install 2 sheets of insulation against frypot wall, thin

sheet first. Figure 1-10.

Figure 1-10

4. Locate the wire harness with the 6-pin red connector.

a. Connect the yellow wires to high limit wires using

wire nuts.

b. Connect the white wires to the drain switch wires

using wire nuts. Figure 1-11.

Figure 1-11

5. Install contactor assembly from kit. Figure 1-12.

6. Connect the solenoid wires to the red wires in positions

1 & 2 of the 12-pin connector.

Figure 1-12

Insure these are not connected to the pump by accident.

602 1-5

Page 8

Electronic Controls Retrofit

1-3. INSTALLING “NEW” 7. Locate the harness with the 2-pin white connector and

CONTROLS (Continued)

connect the wires to the pump wires.

Be sure to connect these to the pump wires and NOT

the pressure solenoid wires, or the 24V pressure

solenoid coil will be damaged when the pump is

turned on.

8. Install the two threaded standoffs in the lower holes,

where the front panel mounting screws were removed.

Tighten the nuts on the threads on the back side of the

sheet metal to prevent the standoffs from turning.

Figure 1-13.

Figure 1-13 9. Wire tie the wires to keep them from interfering with

the components, except for the probe and amp

monitoring connector. Pull the wires to the left side of

the controls, but don’t bundle the power switch wires

with the others for ease of panel removal.

10. Plug all connectors, including the probe and new

transformer harness into the back of the control.

The connector from the transformer can plug into two

connectors on the control. This is to select the voltage

tap on the transformer for 208V or 240V. Determine

the proper voltage and insert the plug into that

connector.

11. Secure the panel into place with screws previously

removed.

12. Supply power to the fryer and program the low amp

setting in Special Program Mode. (Power switch off)

Computron 8000 installations see next page, Chick-

fil-A installations see page 1-8.

1-6 602

Page 9

Electronic Controls Retrofit

1-3. INSTALLING “NEW”

CONTROLS (Continued)

For Computron 8000 Retrofits Only!

The Computron 8000 controls monitors the amperage

to the elements. The nominal amp setting must be

programmed after installation and before operation, or

a constant warning shows on the display when the

controls are turned on.

a. Press and hold for 5 seconds until

"L-2" and "LEVEL 2", followed by, “SP PROG"

and “ENTER CODE shows in the display.

b. Enter code 1, 2, 3, and "SP- 1 ", "TEMP, UNITS"

shows in the display.

c. Press until “SP-12”, “AMPS RDG,

NOMINAL” shows in display.

d. Check the amp reading on the right side of display

(ex: “37 A”) with the amp reading on the data

plate. If readings are different, use to

change display to match data plate.

e. Press and hold to exit Special Program Mode

and unit is now ready for operation.

602 1-7

Page 10

Electronic Controls Retrofit

1-3. INSTALLING “NEW”

CONTROLS (Continued)

For Chick-fil-A Retrofit Only!

Upon initial start-up “CLOCK SET” shows in display. Set

the clock to your time, following prompts on the display, or

see section 2-2 in Operating Instructions for help.

Then display asks if the peanut oil is NEW or OLD. The

controls automatically adjust the peanut oil temperature to

the age of the peanut oil. If the oil is old, use to set

the number of days of old peanut oil.

Set Nominal Voltage

The controller continually monitors the line voltage supplied

to the fryer (when the fryer is on). If the line voltage drops

below [90%] of its nominal value, the controller signals a

“LOW VOLTAGE” alarm. Also, once the voltage is set, the

controls automatically set the nominal amperage value. This

nominal voltage value must be programmed after retrofit

installation to avoid nuisance alarms.

1. Press and hold for 5 seconds until “L 2 LEVEL 2”

shows in the display. Then release 5 times until

“TECH” shows in the display.

2. Enter code 1, 1, 2, 2, 1, 1, 2, 2.

3. Press and release 10 times until “T-11” shows in

the display.

4. Use to match the displayed value with the

voltage showing on the data plate, on the door of the

fryer.

1-8 902

Page 11

1-8 703

Electronic Controls Retrofit

Page 12

Electronic Controls Retrofit

Parts List:

Item Part

Number Number Description Qty

1 32633 Card – C8000 Std. Product Menu 1

1 32634 Card – C8000 Blank Menu 1

1 61725 Card – CFA Menu – Pressure Fryer 1

2 29898 Power Switch 1

3 27303 Decal – Control –Bent – C8000 1

3 61576 Decal – Control – Bent – CFA 1

4 55167 Assembly – Probe/Compression Fitting 1

5 16738 High Limit – 450 degree F. 1

6 29521 Assembly – Transformer 1

7 18364 Assembly – Fuse Holder – 15 amp 2

7 EF02-007 Fuse – 15 amp 2

8 29510 Contactor – Mercury – 24 VAC 1

9 51795 Contactor – 24 VAC 1

10 32613RB Assembly – Control 8000 Bent Panel (SN: KB020JJ and below) 1

10 24319RB Assembly – Control CFA – Bent Panel (SN: KB020JJ and below) 1

11 26974 Assembly – Speaker 1

12 29515 Solenoid – 24 Volt – 60 Hz. 1

12 29698 Solenoid – 24 Volt – 50 Hz. 1

12 29547 Solenoid Coil – 24 Volt – 50/60 Hz. 1

13 63294 Insulation – Fryer Pot – ¼” 1

14 63295 Insulation – Fryer Pot – 1/8” 1

15 24347 Assembly – Current Sense Xformers 1

802 1-9

Loading...

Loading...