Henny Penny

Open Fryer

Model OFG-390

OPERA TOR’S MANUAL

LIMITED WARRANTY FOR HENNY PENNY EQUIPMENT

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original

purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT : Any part of a new appliance, except baskets, lamps, and fuses, which proves to be defective in

material or workmanship within two (2) years from date of original installation, will be repaired or replaced without

charge F .O.B. factory , Eaton, Ohio, or F .O.B. authorized distributor . Baskets will be repaired or replaced for ninety (90)

days from date of original installation. Lamps and fuses are not covered under this Limited W arranty. To validate this

warranty, the registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

FIL TER SYSTEM: Failure of any parts within a fryer filter system caused by the use of the non-OEM filters or

other unapproved filters is not covered under this Limited Warranty.

REPLACEMENT P A R TS: Any appliance replacement part, except lamps and fuses, which proves to be defective in

material or workmanship within ninety (90) days from date of original installation will be repaired or replaced without

charge F .O.B. factory , Eaton, Ohio, or F .O.B. authorized distributor .

The warranty for new equipment covers the repair or replacement of the defective part and includes labor charges and

maximum mileage charges of 200 miles round trip for a period of one (1) year from the date of original installation.

The warranty for replacement parts covers only the repair or replacement of the defective part and does not include any

labor charges for the removal and installation of any parts, travel, or other expenses incidental to the repair or replacement of

a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or workmanship

issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover any frypot that fails due to

any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new frypot at no cost or

provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for the frypot only . Any freight charges and labor costs to install the new frypot as

well as the cost of any other parts replaced, such as insulation, thermal sensors, high limits, fittings, and

hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No

allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If damage occurs during

shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FOR TH THE SOLE REMEDY AGAINST HENNY PENNY FOR ANY BREACH

OF W ARRANTY OR OTHER TERM. BUYER AGREES THA T NO OTHER REMEDY (INCLUDING CLAIMS FOR ANY INCIDENT AL OR CONSEQUENTIAL DAMAGES) SHALL BE AV AILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the

equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED WARRANTY IS EXPRESSL Y IN LIEU OF ALL OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANT ABILITY AND FITNESS, AND ALL OTHER W ARRANTIES ARE EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY

PERSON TO ASSUME FOR IT ANY OTHER OBLIGA TION OR LIABILITY.

Revised 01/01/07

FM05-031-E

Revised 8-6-10

Model OFG- 390

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the rear shroud cover of the control panel.

Post in a prominent location, instructions to be followed if user smells gas. This information

should be obtained by consulting the local gas supplier.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance must be left all

around appliance for sufficient air to the combustion chamber .

The Model OFG-390 open fryer is equipped with a continuous pilot. But fryer can not be operated

with out electric power . Fryer will automatically return to normal operation when power is restored.

Keep appliance area fr ee and clear fr om combustibles.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. FIRE OR

EXPLOSION COULD RESUL T .

703

Technical Data for CE Marked Products

Nominal Heat Input: Natural (I

) = 26,4 kW (90,000 Btu/h)

2H

(Net) Natural (I2E) = 26,4 kW (90,000 Btu/h)

Natural (I2S) = 23,75 kW (81,000 Btu/h)

Liquid Propane (I

) = 27,0 kW (92,000 Btu/h)

3P

Model OFG- 390

Nominal Heat Input: Natural (I

) = 29,3 kW (100,000 Btu/h)

2H

(Gross) Natural (I2E) = 29,3 kW (100,000 Btu/h)

Natural (I2S) = 26,4 kW (90,000 Btu/h)

Liquid Propane (I

Supply Pressure: Natural (I

) = 20 mbar

2H

) = 29,3 kW (100,000 Btu/h)

3P

Natural (I2E) = 20 mbar

Natural (I2S) = 25 mbar

Liquid Propane (I

Test Point Pressure: Natural (I

) = 8,7 mbar

2H

) = 37/50 mbar

3P

Natural (I2E) = 8,7 mbar

Natural (I2S) = 8,7 mbar

Liquid Propane (I

Injector Size: Natural (I

) = 2,51 mm

2H

) = 25 mbar

3P

Natural (I2E) = 2.51 mm

Natural (I2S) = 2.85 mm

Liquid Propane (I

) = 1,04 mm

3P

This appliance must be installed in accordance with the manufacturer’s instructions and the regulations in force and

only used in a suitable ventilated location. Read the instructions fully before installing or using the appliance.

Datos Tecnicos Para Products CE

Consumo Calorico Nominal: Gas Natural (I

) = 26,4 kW (90,000 Btu/h)

2H

(Neto) Gas Natural (I2E) = 26,4 kW (90,000 Btu/h)

Gas Natural (I2S) = 23,75 kW (81,000 Btu/h)

Propano Licuado (I

) = 27,0 kW (92,000 Btu/h)

3P

Consumo Calorico Nominal: Gas Natural (I

) = 29,3 kW (100,000 Btu/h)

2H

(Bruto) Gas Natural (I2E) = 29,3 kW (100,000 Btu/h)

Gas Natural (I2S) = 26,4 kW (90,000 Btu/h)

Propano Licuado (I

Presion De Alimentacion: Gas Natural (I

) = 29,3 kW (100,000 Btu/h)

3P

) = 20 mbar

2H

Gas Natural (I2E) = 20 mbar

Gas Natural (I2S) = 25 mbar

Propano Licuado (I

Presion En Ez Punto De Prueba: Gas Natural (I

) = 37/50 mbar

3P

) = 8,7 mbar

2H

Gas Natural (I2E) = 8,7 mbar

Gas Natural (I2S) = 8,7 mbar

Propano Licuado (I

Diámetro Boquilla: Gas Natural (I

) = 25 mbar

3P

) = 2,51 mm

2H

Gas Natural (I2E) = 2.51 mm

Gas Natural (I2S) = 2.85 mm

Propano Licuado (I

) = 1,04 mm

3P

Este equipo debe instalarse únicamente en un recinto adecuadameute ventilado y conforme a las indicaciones del

fabricante y a las normas vigentes. Lea completamente las instrucciones antes de instalar o usar este equipo.

HENNY PENNY

6 HEAD GAS OPEN FRYER

SPECIFICA TIONS

Height 61" (155 cm)

Width 24" (61 cm)

Depth 41¾" ( 107 cm)

Floor Space Approximately 7 sq. ft. (.65 sq. m.)

Pot Capacity 6 Head of chicken - 20 lbs. (9 kg.)

130 lbs. shortening (46 Kg.)

Electrical 120 VAC, 1 Phase, 50/60 Hz, 10 Amp, 2 W ire + Ground

230 VAC, 1 Phase, 50/60 Hz, 5 Amp, 2 W ire + Ground

Heating Propane or Natural Gas; 100,000 BTU/Hr .(29.3 kw)

Shipping W eight Approximately 670 lbs. (304 kg.)

A data plate, located on the back shroud behind the lid, gives the information of the type of

fryer, serial number , warranty date, and other information pertaining to fryer . Also, the serial

number is stamped on the outside of the frypot. See figure below .

703

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION.................................................................................................... 1-1

1-1 Introduction....................................................................................................1-1

1-2 Proper Care ................................................................................................... 1-1

1-3 Assistance ..................................................................................................... 1-1

1-4 Safety ............................................................................................................1-2

Section 2. INSTALLATION ...................................................................................................... 2-1

2-1 Introduction....................................................................................................2-1

2-2 Unpacking .....................................................................................................2-1

2-3 Selecting the Fryer Location ......................................................................... 2-4

2-4 Leveling the Fryer ......................................................................................... 2-4

2-5 V entilation of Fryer........................................................................................ 2-5

2-6 Gas Supply..................................................................................................... 2-5

2-7 Gas Leak Test ............................................................................................... 2-8

2-8 Gas Pressure Regulator Setting ....................................................................2-8

2-9 Electrical Requirements ................................................................................2-9

Section 3. OPERATION ............................................................................................................ 3-1

3-1 Operating Components .................................................................................. 3-1

3-2 Lid Operation................................................................................................. 3-3

3-3 Melt Cycle Operation .................................................................................... 3-3

3-4 Switches and Indicators ................................................................................3-3

3-5 Filling or Adding Shortening...........................................................................3-6

3-6 Basic Operation............................................................................................. 3-7

3-7 Care of Shortening ........................................................................................ 3-9

3-8 Filtering Instructions ...................................................................................... 3-9

3-9 Changing the Filter Envelope.........................................................................3-11

3-10 Lighting and Shutdown of Burners ................................................................ 3-1 1

3-11 Cleaning the Frypot ....................................................................................... 3-12

3-12 Filter Pump Motor Protector-Manual Reset ................................................. 3-13

3-13 Regular Maintenance Schedule..................................................................... 3-13

3-14 Preventive Maintenance................................................................................3-14

3-15 Programming .................................................................................................3-16

3-16 Special Program Mode .................................................................................. 3-18

Section 4. TROUBLESHOOTING.............................................................................................4-1

4-1 Troubleshooting Guide .................................................................................... 4-1

4-2 Error Codes .................................................................................................... 4-2

GLOSSARY .......................................................................................................................G-1

Distributors List - Domestic and International

306 i

Model OFG- 390

SECTION 1. INTRODUCTION

1-1. INTRODUCTION The Henny Penny open fryer is a basic unit of food processing

equipment. This unit is used only in institutional and commercial

food service operations.

As of August 16, 2005, the W aste Electrical and Electronic Equipment directive went into effect for the European Union. Our

products have been evaluated to the WEEE directive. W e have

also reviewed our products to determine if they comply with the

Restriction of Hazardous Substances directive (RoHS) and have

redesigned our products as needed in order to comply . T o continue

compliance with these directives, this unit must not be disposed as

unsorted municipal waste. For proper disposal, please contact

your nearest Henny Penny distributor .

1-2. PROPER CARE As in any unit of food service equipment, the Henny Penny

open fryer does require care and maintenance. Requirements for

the maintenance and cleaning are contained in this manual and must

become a regular part of the operation of the unit at all times.

1-3. ASSISTANCE Should you require outside assistance, call your local independent

distributor in your area, or call Henny Penny Corp. at

1-800-417-8405 or 1-937-456-8405.

1-1 207

Model OFG- 390

1-4. SAFETY

Henny Penny open fryer has may safety features incorporated.

However, the only way to ensure a safe operation is to fully under

stand the proper installation, operation, andmaintenance proce

dures. The instructions in this manual have been prepared to aid you

in learning the proper procedures. Where information is of particu

lar importance or safety related, the words DANGER, W ARNING,

CAUTION, and NOTICE are used. Their usage is described

below .

SAFETY ALER T SYMBOL is used with DANGER,

W ARNING, or CAUTION which indicates a personal injury

type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICA TES AN IMMINENTL Y

HAZARDOUS SITUA TION WHICH, IF NOT

AVOIDED, WILL RESUL T IN DEA TH OR SERIOUS

INJURY.

306 1-2

SECTION 2. INST ALLA TION

Model OFG- 390

2-1. INTRODUCTION

2-2. UNP ACKING

INSTRUCTIONS

This section provides the installation and unpacking instructions for

the Henny Penny OFG-390, open fryer .

Installation of this unit should be performed only by a qualified

service technician.

Do not puncture the unit with any objects such as drills

or screws as component damage or electrical shock

could result.

Any shipping damage should be noted in the presence of the

delivery agent and signed prior to his or her departure.

1. Cut and remove the metal bands from the carton.

2. Remove the carton lid and lift the main carton off the fryer .

3. Remove corner packing supports (4).

4. Cut the stretch film from around the carrier/rack box and

remove it from the top of the fryer lid.

4. Cut and remove the metal bands holding the fryer to the

pallet.

All counterweights must be loaded before unlatching the

lid, or personal injury could result.

5. Remove the fryer from the pallet.

T ake care when moving the fryer to prevent personal

injury . The fryer weighs approximately 670 lbs.

(304 kg).

803 2-1

Model OFG- 390

2-2. UNP ACKING

INSTRUCTIONS

(Continued)

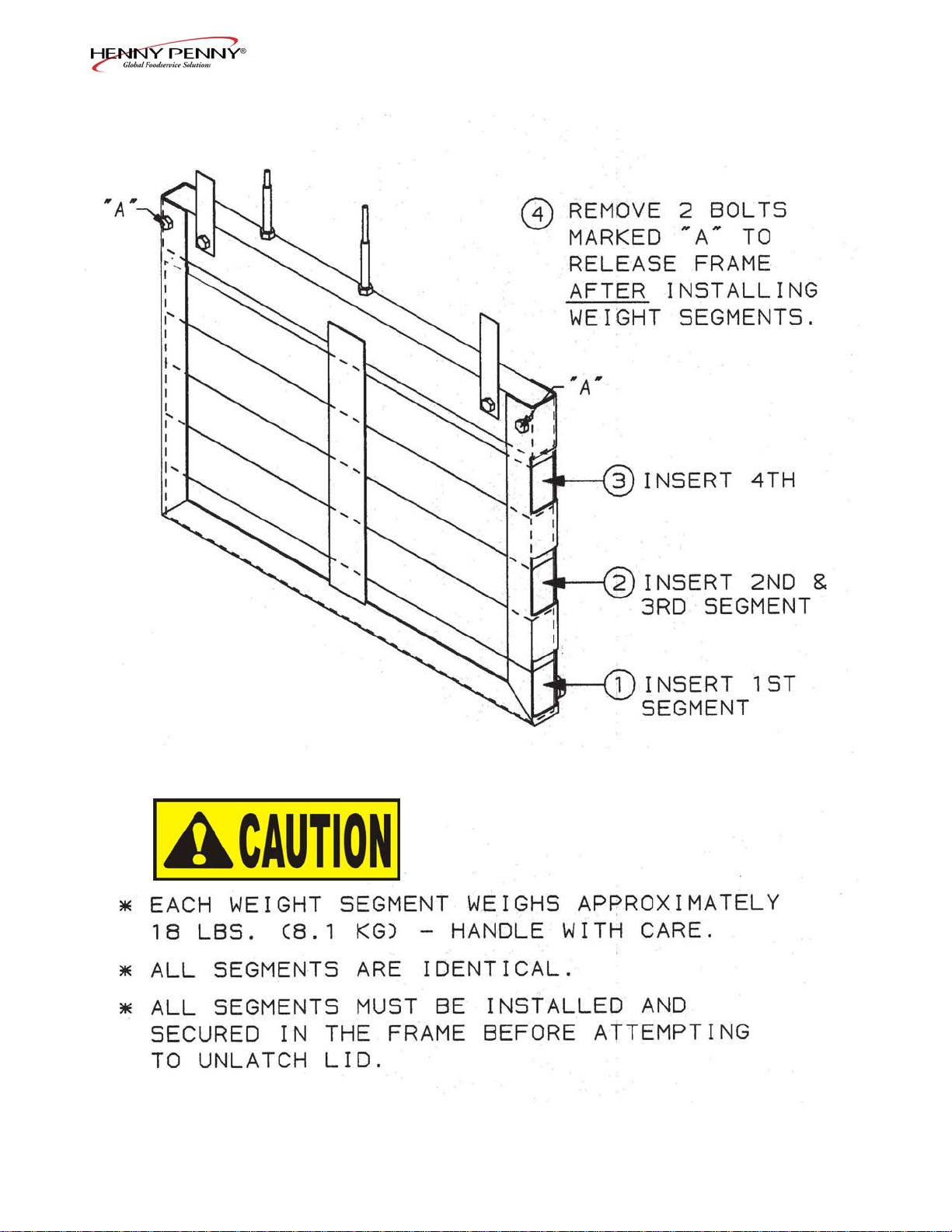

7. Remove the counterweights from the pallet, which are

strapped to the pallet, under the fryer .

Do not drop. The counterweights weigh approximately

18 lbs. (8.1 kg.) each. Handle with care, or personal

injury could result.

8. Remove rear service cover.

9. Load the 4 weights into the counterweight assembly.

10. Replace rear service cover .

T o avoid personal injury and assure safe operation of

unit, rear service cover must be in place.

11. Cut warning tags from the lid assembly. The lid may now

be unlatched.

12. Remove the accessories from inside the filter drain pan.

The fittings for installing the gas line are in a separate box,

along with the accessories, in the filter drain pan.

13. Remove the protective paper from the fryer cabinet. Clean

exterior surface with a damp cloth.

2-2 803

Optional Ramp Unloading

Model OFG- 390

703 2-3

Model OFG- 390

2-4 908

Model OFG- 390

2-3. SELECTING THE The proper location of the fryer is very important for operation,

LOCATION speed, and convenience. Choose a location which provides easy

loading and unloading without interfering with the final assembly of

food orders. Operators have found that frying from raw to finish,

and holding the product in warmer provides fast continuous service.

Landing or dumping tables should be provided next to at least one

side of the fryer. Keep in mind the best ef ficiency will be obtained

by a straight line operation, i.e. raw in one side and finish out the

other side. Order assembly can be moved away with only a slight

loss of efficiency. To properly service the fryer, 24 inches (61.96cm)

of clearance is needed on all sides of the fryer. Access for servicing

can be attained by removing a side panel. Also, at least 6 inches

(15.24 cm) around the base of the unit is needed for proper air supply

to the combustion chamber.

To avoid a fire, install the fryer with minimum clearance

from all combustible and noncombustible materials,

6 inches (15.24 cm) from side and 6 inches (15.24 cm)

from back. If installed properly, the gas fryer is designed

for operation on combustible floors and adjacent to

combustible walls.

To avoid fire and ruined supplies, the area under the

fryer should not be used to store supplies.

T o prevent sever e burns from splashing hot shortening,

position and install fryer to prevent tipping or movement. Restraining ties may be used for stabilization.

2-4. LEVELING THE FRYER For proper operation, the fryer must be level from side to side and

front to back. Using a level placed on the flat areas around the

frypot collar, adjust the leveling bolt or casters until the unit is level.

FAILURE TO FOLLOW THESE LEVELING

INSTRUCTIONS CAN RESULT IN SHORTENING

OVERFLOWING THE FRYPOT WHICH COULD

CAUSE SERIOUS BURNS, PERSONAL INJURY,

FIRE AND/OR PROPERTY DAMAGE.

703 2-5

Model OFG- 390

2-5. VENTILATION OF FRYER The fryer should be located with provision for venting into

adequate exhaust hood or ventilation system. This is essential

to permit efficient removal of the flue gases and frying odors.

Special precaution must be taken in designing an exhaust

canopy to avoid interference with the operation of the fryer.

W e recommend you consult a local ventilation or heating company

to help in designing an adequate system.

V entilation must conform to local, state, and national codes.

Consult your local fire department or building authorities.

2-6. GAS SUPPL Y The gas fryer is factory available for either natural or propane gas.

Check the data plate on the right side panel of the cabinet to determine the proper gas supply requirements. The minimum supply for

natural gas is 7 inches water column, and 10 for propane.

Do not attempt to use any gas other than that specified

on the data plate. Incorrect gas supply could cause a

fire or explosion resulting in severe injuries and/or

property damage.

Please refer below for the recommended hookup of the fryer to

main gas line supply .

T o avoid possible serious personal injury:

• Installation must conform with local, state, and

national codes, and be in accordance with Canadian Gas Authority S tandard CSA B149-& 2,”

Installation Codes - Gas Burning Appliances” and

Australian Gas Authority Rule AG601-2000

Section AS5601.

• The fryer and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.45 KPA)

(34.47 mbar).

2-6 703

Loading...

Loading...