TECHNICAL MANUAL

Henny Penny

Open Fry Station

Model OFE/OFG-323

Model OFE/OFG-322

Model OFE/OFG-321

Model OFE/OFG-324

Model OEA/OGA-323

Model OEA/OGA-322

Model OEA/OGA-321

Model OEA/OGA-324

Model ODE/ODG-323

Model OFE/OFG-321,322,323,324

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the inside of the right side panel.

Post in a prominent location, instructions to be followed in event user smells gas. This information shall

be obtained by consulting the local gas supplier.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance must be left all around

appliance for sufficient air to the combustion chamber.

The Model OFG/OGA-32X open fryer is equipped with a continuous pilot. But the open fryer can not be

operated without electric power. The unit will automatically return to normal operation when power is

restored.

To avoid a fire, keep appliance area free and clear from combustibles.

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

FM06-008

Revised 06-04-2012

Model OFE/OFG-321,322,323,324

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING ...................................................................................................1-1

1-1. Introduction .............................................................................................................1-1

1-2. Safety ......................................................................................................................1-1

1-3. Troubleshooting ......................................................................................................1-2

1-4. Error Codes .............................................................................................................1-5

Section 2. MAINTENANCE .............................................................................................................2-1

2-1. Introduction .............................................................................................................2-1

2-2. Maintenance Hints ..................................................................................................2-1

2-3. High Temperature Limit Control (Gas Units) .........................................................2-1

2-4. Complete Control Panel Replacement ...................................................................2-4

2-5. Power Switch ..........................................................................................................2-4

2-6. Temperature Probe Replacement ............................................................................2-5

2-7. Flame Sensor (Gas Units) .......................................................................................2-8

2-8. Pilot/Ignitor Assembly ............................................................................................2-9

2-9. Ignitor Module ........................................................................................................2-10

2-10. Transformer Replacement .......................................................................................2-10

2-11. I/O Power Supply Boards Assembly .......................................................................2-11

2-12. Vacuum Switch .......................................................................................................2-11

2-13. Speaker Assembly (Gas Units) ...............................................................................2-12

2-14. Drain Microswitch ..................................................................................................2-13

2-15. Filter Switch ............................................................................................................2-13

2-16. Gas Control Valve Assembly ..................................................................................2-14

2-17. Blower Motor Assembly .........................................................................................2-16

2-18. Heating Elements (Electric Only) ...........................................................................2-18

2-19. Heating Contactors (Electric Only) .........................................................................2-21

2-20. Speaker Assembly (Electric Units) .........................................................................2-23

2-21. High Temperature Limit Control (Electric Units) ..................................................2-24

2-22. Autolift Actuator (motor) Replacement (if Applicable) .........................................2-25

2-23. Autolift Transformer Replacement (if Applicable) ................................................2-28

2-24. Autolift PC Board Replacement (if Applicable) .....................................................2-28

Wiring Diagrams

Section 3. PARTS INFORMATION .................................................................................................3-1

3-1. Introduction .............................................................................................................3-1

3-2. Genuine Parts ..........................................................................................................3-1

3-3. When Ordering Parts ...............................................................................................3-1

3-4. Prices .......................................................................................................................3-1

3-5. Delivery ...................................................................................................................3-1

3-6. Warranty ..................................................................................................................3-1

3-7. Recommended Spare Parts for Distributors ............................................................3-1

i 109

Model OFE/OFG-321,322,323,324

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, WILL RESULT IN DEATH OR

SERIOUS INJURY.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTICE is used to highlight especially important

information.

SAFETY ALERT SYMBOL is used with DANGER,

WARNING or CAUTION which indicates a personal

injury type hazard.

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION This section provides troubleshooting information in the form of

an easy to read table.

If a problem occurs during the first operation of a new fryer,

recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation Section of

the Operator’s Manual.

1-2. SAFETY Where information is of particular importance or is safety related,

the words DANGER, WARNING, CAUTION, or NOTE are used.

Their usage is described on the next page:

203 1-1

Model OFE/OFG-321,322,323,324

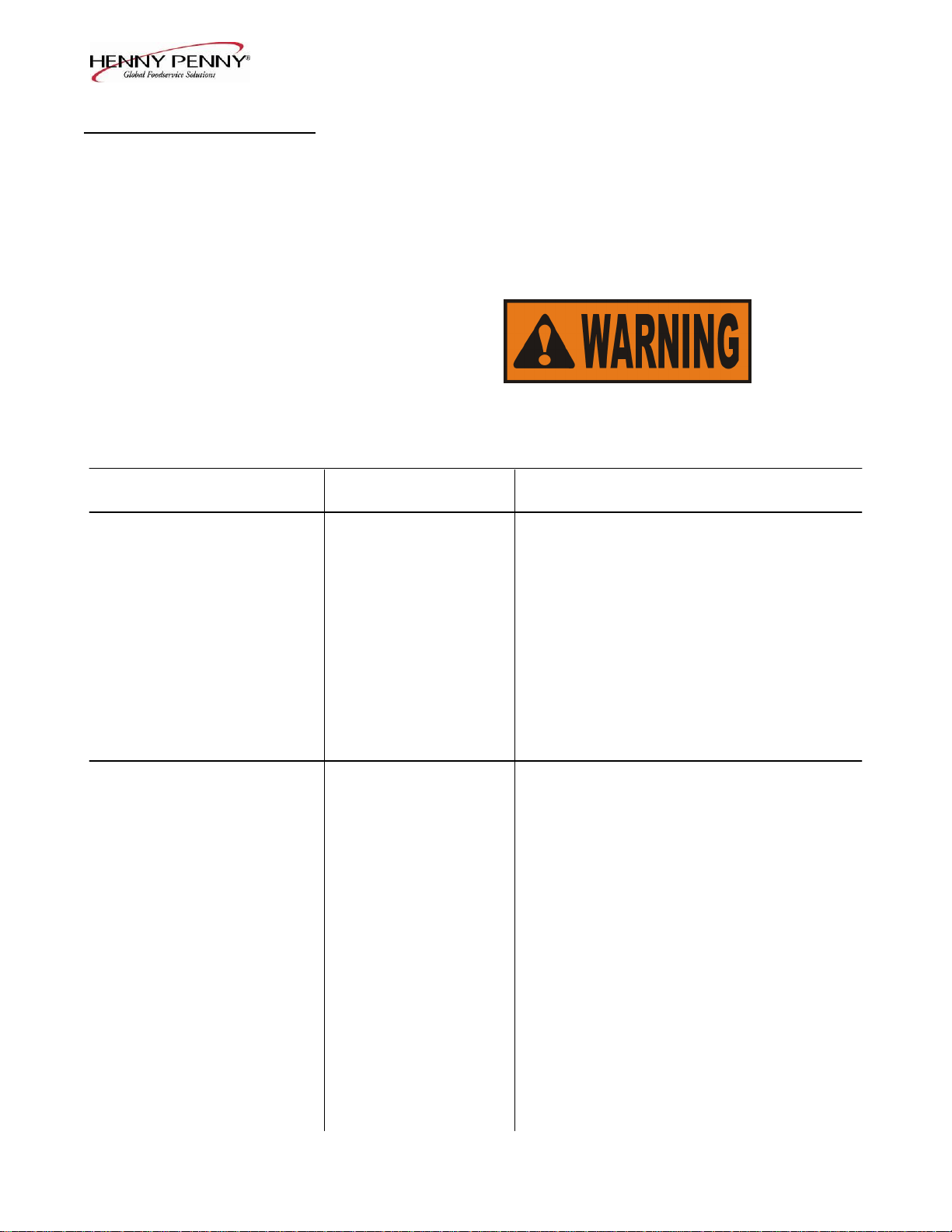

1-3. TROUBLESHOOTING To isolate a malfunction, proceed as follows:

1. Clearly define the problem, or symptom and when it

occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes, then one at a time, work

through the list of corrections until the problem is solved.

If maintenance procedures are not followed correctly,

injuries and/or property damage could result.

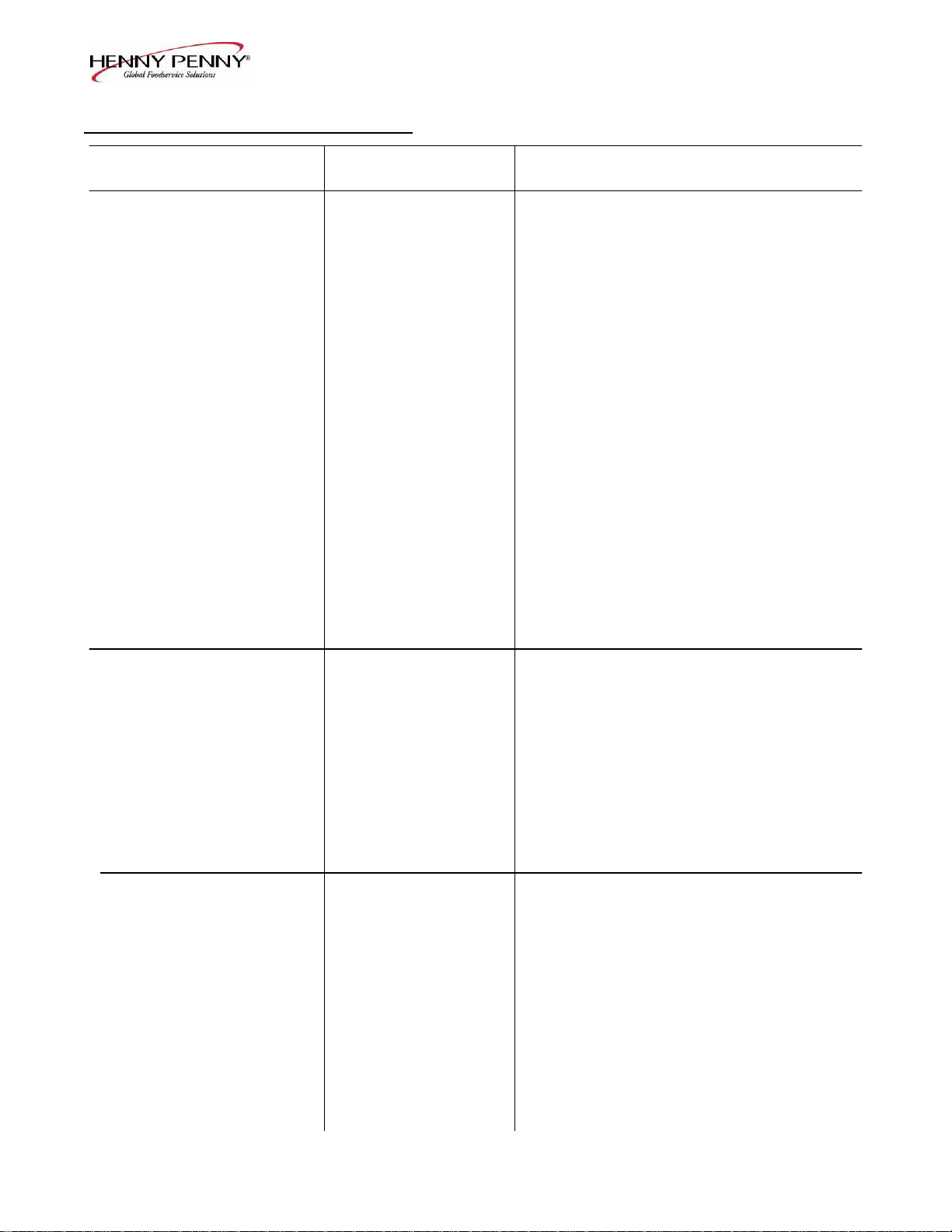

PROBLEM CAUSE CORRECTION

With the switch in Open circuit Check to see if unit is plugged in

the POWER position,

fryer is completely Check breaker or fuse at supply box

inoperative

Check POWER switch per Power Switch

Section; replace if defective

Check voltage at wall receptacle

Check cord and plug

Shortening will not Faulty contactor Check contactor per Heating Contactors

heat but lights are on (elec. model) Section

Faulty gas control Check gas control valve per Gas Control

valve (gas model) Valve Assembly Section

Faulty temperature Check temperature probe per Temperature

probe Probe Replacement Section; “E-6A or B”

Faulty high limit Check high limit per the appropriate High

Temperature Limit Control Section; “E-10”

Faulty drain switch Check drain switch per Drain Microswitch

Section; “E-15"

1-2 203

Model OFE/OFG-321,322,323,324

1-3. TROUBLESHOOTING(Continued)

PROBLEM CAUSE CORRECTION

Heating of Low or improper Use a meter and check the receptacle

shortening too voltage (elec. unit) voltage against the data plate

slow

Weak or burnt out Check heating elements per Heating

elements (elec. unit) Elements Section

Wire(s) loose Tighten

Burnt or charred Replace wire and clean connectors

wire connection

Faulty contactor Check contactor per Heating Contactors

Section

Supply line too small Increase supply line size; refer to

- low gas volume Installation Section of Operator’s Manual

(gas unit)

Improper ventilation Refer to Installation Section of Operator’s

Manual

Shortening Temperature probe Calibrate temperature probe if 10 off;

overheating needs calibration if more than 10 off, replace temperature

probe

Mercury contactor Check mercury contactor for not opening;

stuck closed replace if necessary (elec. unit)

Bad control board Replace control board if heat indicator stays

on past ready temperature

Foaming or boiling Water in shortening At end of cook cycle, drain shortening and

over of shortening clean

Improper or bad Use recommended shortening

shortening

Improper filtering Refer to the Filtering the Shortening

Section in Operator’s Manual

Improper rinsing Clean and rinse the frypot; then dry

after cleaning fryer thoroughly

203 1-3

Model OFE/OFG-321,322,323,324

1-3. TROUBLESHOOTING

(Continued)

PROBLEM CAUSE CORRECTION

Shortening will not Drain valve clogged Open valve, force cleaning brush through

drain from frypot with crumbs drain

Drain valve will not Replace cotter pins in valve coupling

open by turning

handle

Filter motor runs Pump clogged Remove pump cover and clean

but pumps shortening

slowly Filter line connection Tighten all filter line connections

loose

Solidified shortening Clear all filter lines of solidified shortening

in lines

Filter switch on but Defective switch Check/replace switch per Filter Switch

motor does not run Section

Defective motor Check/replace motor

Motor thermal Reset thermal switch on filter motor

protector tripped

Motor hums but Clogged lines or Remove and clean pump and lines

will not pump pump

Replace pump seal, rotor and rollers

1-4 203

Model OFE/OFG-321,322,323,324

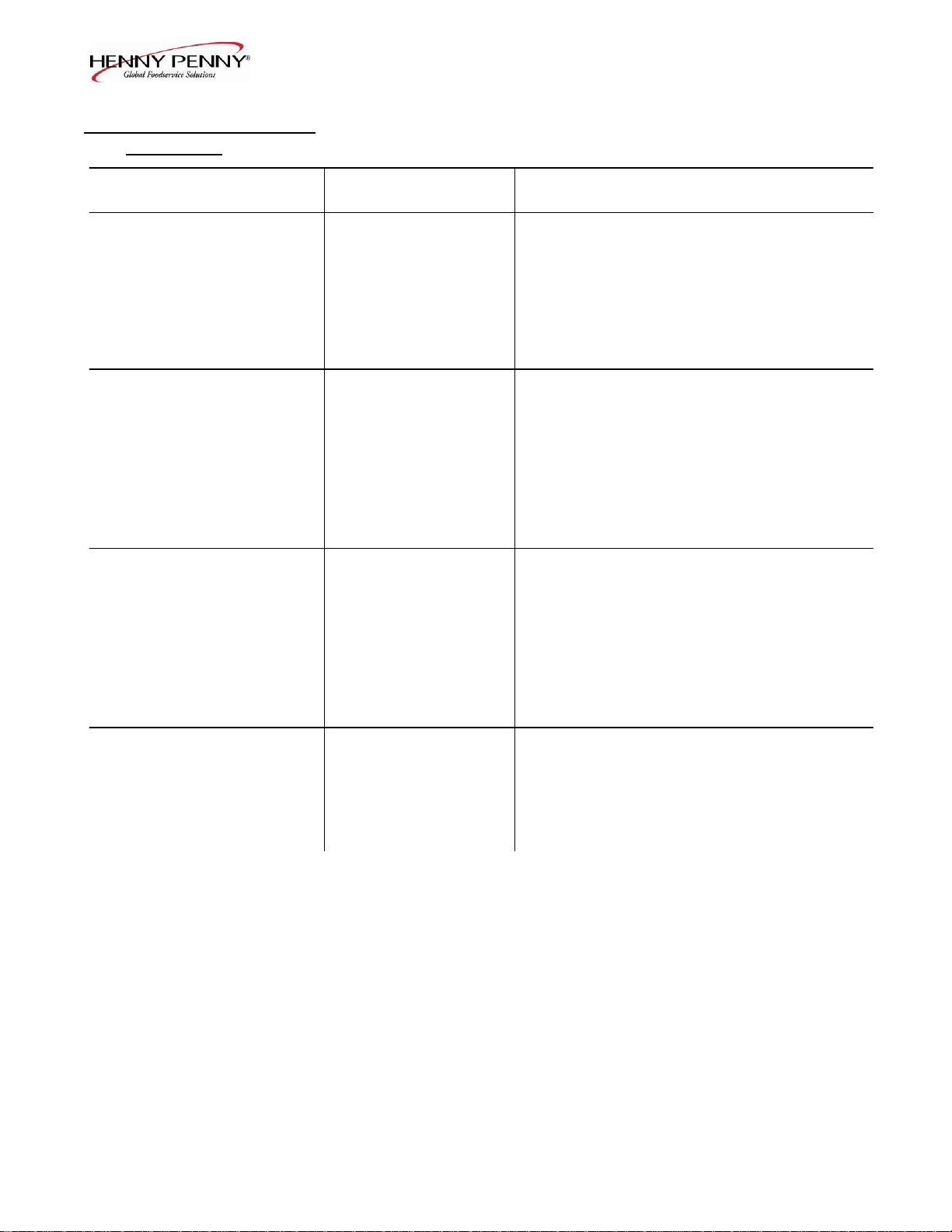

1-4. ERROR CODES In the event of a control system failure, the digital display shows

an error message. These messages are coded: “E-4”, “E-5”, “E-

6A”, “E-6B”, “E-10”, “E-15”, “E-20”, “E-31”, “E-41”, “E-46”,

and “E-92”. A constant tone is heard when an error code is

displayed, and to silence this tone, press any button.

DISPLAY CAUSE PANEL BOARD CORRECTION

“E-4” Control board Turn switch to OFF position, then turn switch back to ON;

overheating if display shows “E-4”, the control board is getting too hot;

check the louvers on each side of the unit for obstructions

“E-5” Shortening Turn switch to OFF position, then turn switch back to ON;

overheating if display shows “E-5”, the heating circuits and temperature

probe should be checked

“E-6A” Temperature Turn switch to OFF position, then turn switch back to ON;

probe open if display shows “E-6A” the temperature probe should be

checked

“E-6B” Temperature Turn switch to OFF position, then turn switch back to ON;

probe shorted if display shows “E-6B” the temperature probe should be

checked to replace, per Temperature Probe Replacement

Section

“E-10” High limit Reset the high limit by manually pushing up on the red

reset button; if high limit does not reset, high limit must be

replaced per High Limit Temperature Control Section

“E-15” Drain switch Close drain, using the drain valve handle; if display still

failure shows “E-15”, check the drain microswitch per Drain

Microswitch Section

“E-41”, Programming Turn switch to OFF, then back to ON. If display shows any

“E-46” failure of the error codes, try to reinitialize the control (Special

Program Mode Section of Operator’s Manual). If error

Code persists, replace the control panel per Complete

Control Panel Replacement Section

203 1-5

Model OFE/OFG-321,322,323,324

1-4. ERROR CODES

(Continued)

DISPLAY CAUSE PANEL BOARD CORRECTION

“E-20A” Vacuum Press the timer button to try the ignition process again,

switch failure and if “E-20A” persists, check the air switch per Vacuum

(stuck closed) Switch Section

“E-20B” Draft fan or Press the timer button to try the ignition process again,

vacuum and if “E-20B” persists, check the vacuum switch per

switch failure Vacuum Switch Section or the blower motor per Blower

(stuck open) Motor Assembly Section

“E-20C” Ignition modules Press the timer button to try the ignition process again; if

not responding “E-20C” persists, check the ignition module per Ignitor

Module Section or the spark ignitor per Pilot/Ignitor

Assembly Section, or the I/O board per I/O Power Supply

Boards Assembly Section

“E-20D” Pilots not lit or Press the timer button to try the ignition process again; if

no flame sense “E-20D” persists, check the ignition module per Ignitor

Module Section, or the I/O board per I/O Power Supply

Boards Assembly Section, or the flame sensor per Flame

Sensor Section

“E-31” Fan switch jumper Check for jumper wire on 12-pin connector & add if

wire missing missing

“E-47” Analog converter Turn switch to OFF, then back to ON; if “E-47” persists,

chip or 12 volt replace the I/O board, or the PC board; if speaker

supply failure tones are quiet, probably I/O board failure

“E-48” Input system Replace PC board

error

“E-70” Faulty POWER Check POWER switch checked, along with its wiring;

switch or switch replace input/output board if necessary

wiring; faulty I/O

board

“E-92” 24 VAC fuse Check for shorted component in 24 volt circuit;

on I/O open (i.e., high limit, drain switch, vacuum switch)

1-6 109

Model OFE/OFG-321,322,323,324

SECTION 2. MAINTENANCE

2-1. INTRODUCTION This section provides procedures for the checkout and replacement

of the various parts used within the fryer. Before replacing any

parts, refer to the Troubleshooting Section. It will aid you in

determining the cause of the malfunction.

2-2. MAINTENANCE HINTS 1. You may need to use a multimeter to check the electric

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter will read infinity.

2-3 HIGH TEMPERATURE

LIMIT CONTROL The high temperature limit control is a safety, manual reset control

(Gas Units) that senses the temperature of the shortening. If the shortening

temperature exceeds 425F (218C), this switch will open

and shut off heat to the frypot. When the temperature of the

shortening drops to a safe operation limit, the control must be

manually reset by pressing the red reset button. The red reset

button is located under the control panel, in the front of the fryer.

This will allow heat to be supplied to the frypot once again.

Checkout Before replacing a high temperature limit control, check to see

that its circuit is closed.

The shortening temperature must be below 380F

(193C) to accurately perform this check.

Checkout:

1. Remove electrical power supplied to fryer.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel.

203 2-1

Model OFE/OFG-321,322,323,324

2-3 HIGH TEMPERATURE

LIMIT CONTROL

(Continued)

3. Remove the two nuts securing the high limit bracket to the unit

and pull the bracket from the unit.

4. Remove the two screws securing the high limit to the bracket,

and remove the high limit from the bracket.

5. Remove the two electrical wires from the high temperature

limit control.

6. Manually reset the control, then check for continuity between

the two terminals after resetting the control. If the circuit is

open, replace the control, then continue with this procedure.

(If the circuit is closed, the high limit is not defective. Reconnect the two electrical wires.)

Replacement:

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

1. If the tube is broken or cracked, the control will open, shutting

off electrical power to the heat circuit. The control cannot be

reset, and it will continuously click when pushed.

2. Drain the shortening from the frypot and discard. A substance

in the tube could contaminate the shortening.

3. Remove the control panel.

4. Loosen small inside screw nut on capillary tube.

2-2 203

2-3 HIGH TEMPERATURE

LIMIT CONTROL

(Continued)

Model OFE/OFG-321,322,323,324

5. Remove the bracket from the heat tube covering the high limit

bulb.

6. Straighten the capillary tube behind the pot wall.

7. Pull the high limit bulb through the retainers on the heat tube.

8. Remove the larger outside nut that threads into the pot wall.

9. Remove the defective high limit from the control panel area.

10. Insert new high limit into bracket and replace wires.

11. Uncoil capillary line, starting at capillary tube, and insert

through frypot wall.

To avoid electrical shock or other injury, run the capillary

line under and away from all electrical power wires and

terminals. The tube must never be in such a position where

it could accidentally touch the electrical power terminals.

12. Insert capillary line through brackets on heat tube, and then

pull back through pot wall until capillary bulb is secure in

brackets.

13. Pull excess capillary line from pot and tighten nut into

frypot wall.

14. With excess capillary line pulled out, tighten smaller nut.

15. Replace bracket on heat tube covering the high limit bulb.

16. Replace front panel.

17. Refill frypot with shortening.

203 2-3

Model OFE/OFG-321,322,323,324

2-4. COMPLETE CONTROL

PANEL REPLACEMENT Should the control board become inoperative, follow these

instructions for replacing the board.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the four screws securing the control panel and lift

out.

3. Unplug the wire connectors going to the control board.

4. Install new control panel in reverse order.

When plugging connectors onto new control panel, be sure

the connectors are inserted onto all of the pins, and that the

connectors are not forced onto the pins backwards. If not

connected properly, damage to the board could result.

2-5. POWER SWITCH 1. Remove electrical power supplied to fryer.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove control panel.

3. Label and remove the wires from the switch. With test

instrument, check across the terminals of the switch with

the switch in the ON position, then in the OFF position.

With the switch in the ON position, the circuit should be

closed. With the switch in the OFF position, the circuit

should be open. If the switch checks defective, replace by

continuing with this procedure.

2-4 203

Model OFE/OFG-321,322,323,324

2-5. POWER SWITCH

(Continued) 4. With control panel removed, and the wires off the switch, push

in on tabs on the switch to remove from panel.

5. Replace with new switch, and reconnect wires to switch.

6. Replace the control panel.

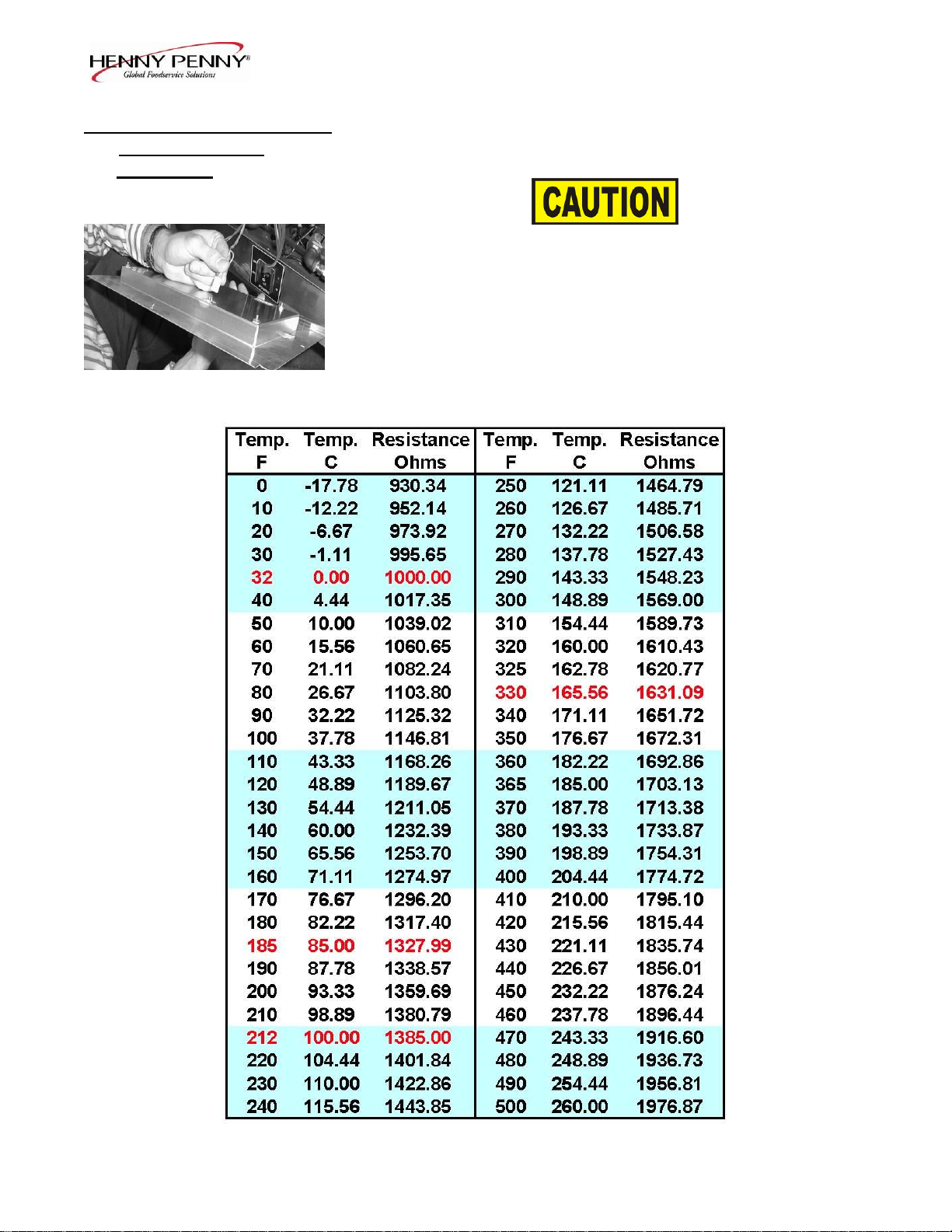

2-6. TEMPERATURE PROBE The temperature probe relays the actual shortening temperature to

REPLACEMENT the control board. If it becomes disabled, “E-6B” will show in the

display. Also, if the shortening temperature is out of calibration by

more than 10°F or C°, the temperature probe should be replaced.

An Ohm check can be performed also. See chart on page 2-7.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

Electric breaker, or unplug cord at wall receptacle.

2. Drain the shortening from the frypot.

3. Remove the control panel.

Gas

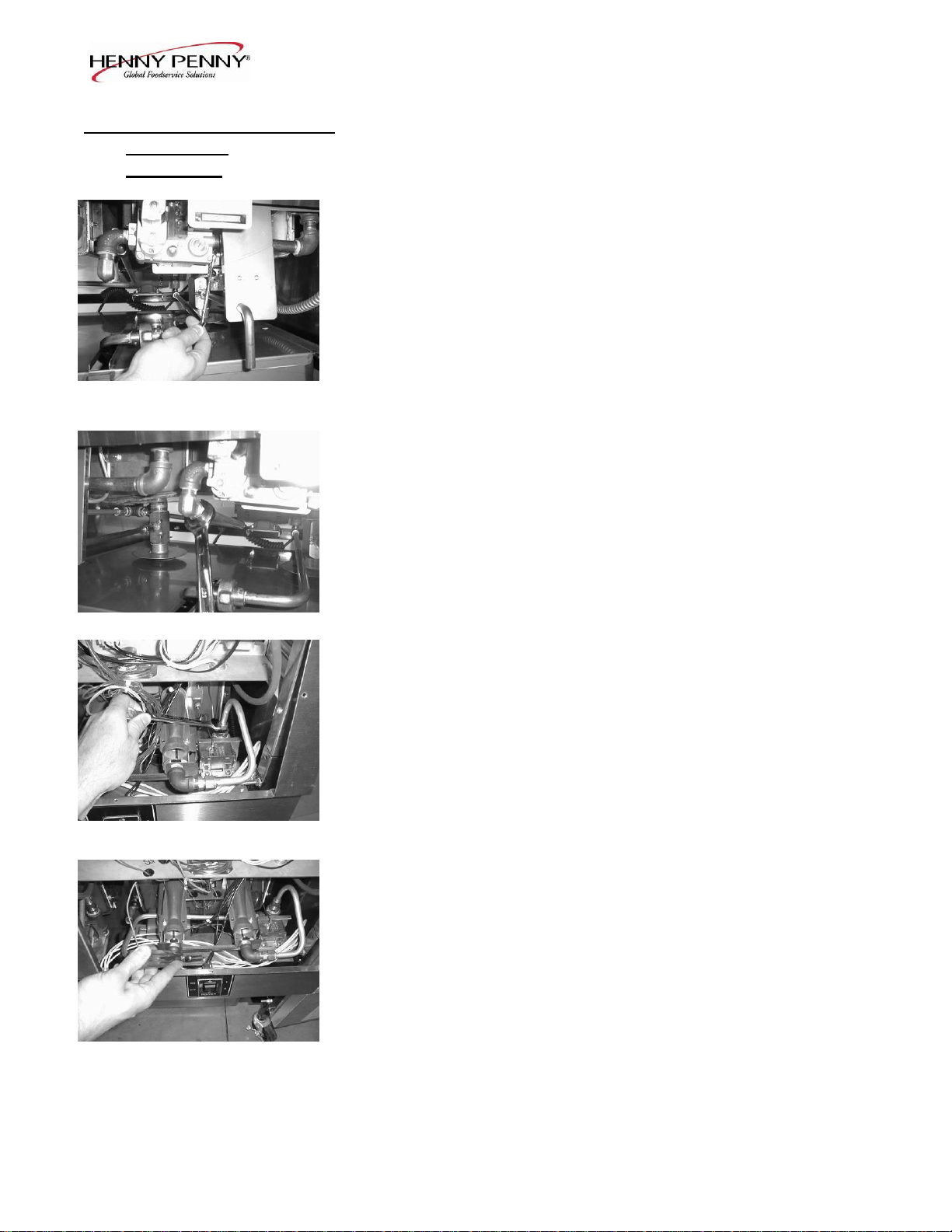

4. Using a 1/2" wrench, remove the nut on the compression

fitting.

5. Remove the temperature probe from the frypot.

6. Follow the appropriate instructions, on the following page,

depending upon the type of fryer, gas or electric.

606 2-5

2-6. TEMPERATURE PROBE

REPLACEMENT

(Continued) ELECTRIC

Model OFE/OFG-321,322,323,324

GAS

2-6 606

Model OFE/OFG-321,322,323,324

2-6. TEMPERATURE PROBE 7. Tighten the compression nut hand tight and then a half turn

REPLACEMENT with wrench.

(Continued)

Excess force will damage temperature probe.

8. Connect new temperature probe to PC board and replace

control panel.

9. Replace shortening.

10. Turn power on and check out fryer.

606 2-7

Model OFE/OFG-321,322,323,324

2-7. FLAME SENSOR The flame sensor recognizes the pilot flame and allows gas to

(Gas Units) continue to the pilot. The flame sensor must send a minimum of

two (2) micro amps to the ignition module. The pilot flame should

be split in two by the flame sensor, causing the flame sensor to be

bright red in color.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle..

2. To access flame sensor, open the filter doors in the front of the

unit. Follow the small gauge yellow wire running to the sensor

behind the pilot assembly.

3. Disconnect the flame sense wire from the flame sensor.

4. Using a pair of needle nosed pliers, pull the flame sensor out

of the pilot assembly bracket.

5. Insert new flame sensor and reconnect flame sensor wire.

6. Turn power on and check fryer.

2-8 203

Model OFE/OFG-321,322,323,324

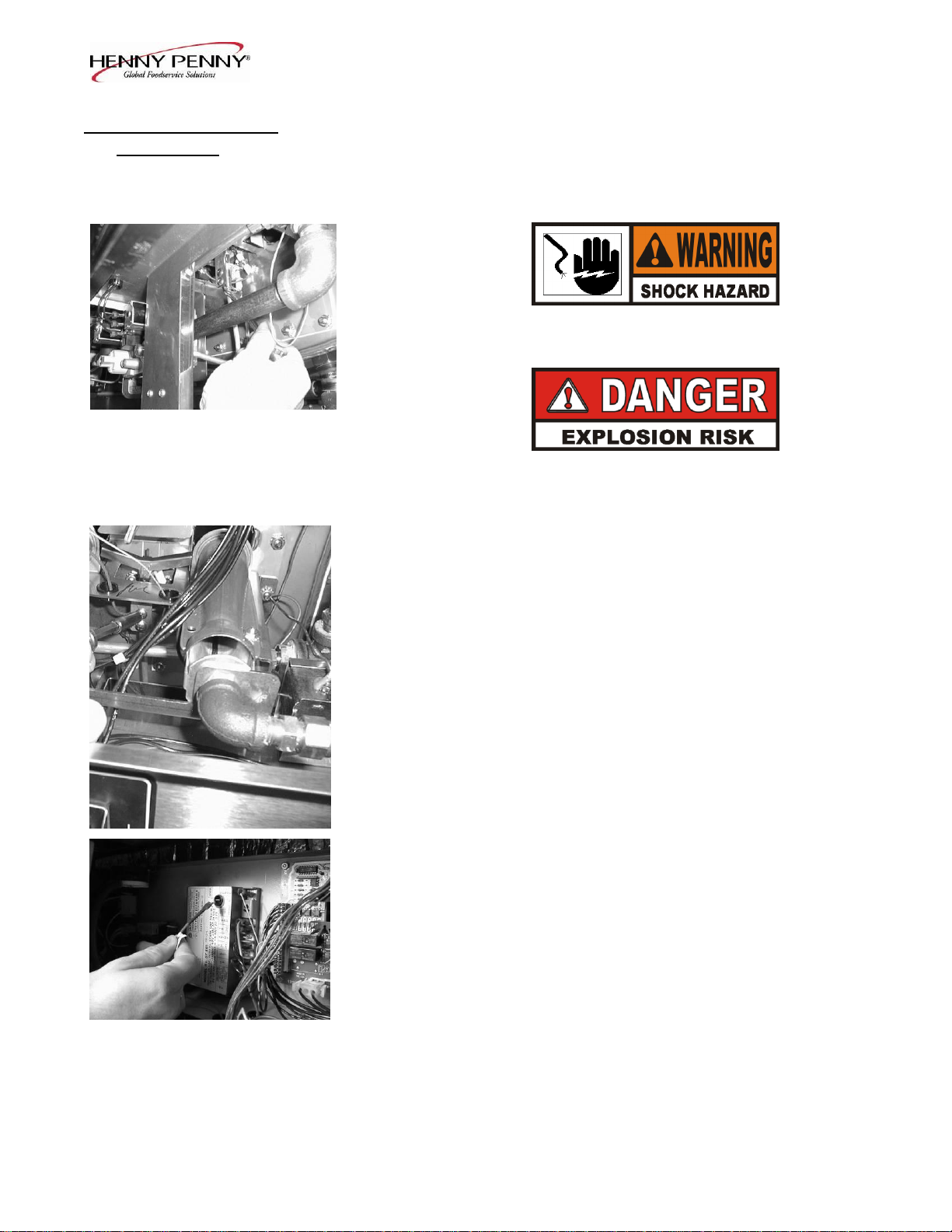

2-8. PILOT / IGNITOR The Henny Penny open fryer (gas) has electronic spark ignition

ASSEMBLY that lights a standing pilot. The gap between the spark electrode

and the pilot hood should be set at 1/8 of an inch.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

TO AVOID PERSONAL INJURY OR PROPERTY

DAMAGE, BEFORE STARTING THIS

PROCEDURE, MOVE THE MAIN POWER SWITCH

TO THE OFF POSITION. DISCONNECT THE MAIN

CIRCUIT BREAKERS AT THE CIRCUIT BREAKER

BOX OR UNPLUG SERVICE CORD FROM WALL

RECEPTACLE. TURN OFF THE MAIN GAS

SUPPLY TO THE FRYER AND DISCONNECT AND

CAP THE MAIN SUPPLY LINE TO FRYER, OR

POSSIBLE EXPLOSION COULD RESULT.

2. Remove the control panel as discussed in Complete Control

Panel Replacement Section.

3. Disconnect the pilot gas line fitting at the pilot assembly with

a ½ inch wrench.

4. With a Phillips head screwdriver, remove the two screws

securing the pilot assembly to the mounting bracket.

5. Remove the flame sensor wire from the flame sensor.

6. Follow the wire from the spark ignitor back to the module, and

remove wire from module.

7. After removing assembly from unit, pull the flame sensor out

of the bracket as discussed in section 6-7. Insert flame sensor

into new pilot/ignitor assembly.

8. Reinstall the new pilot/ignitor assembly in reverse order. Be

extremely careful not to cross thread the pilot gas line fitting.

203 2-9

Model OFE/OFG-321,322,323,324

2-9. IGNITOR MODULE During normal operation, the ignition modules send 24 volts to the

ignitors and gas control valve. If a module does not sense a pilot

flame, the module starts the ignition process again. But, if a pilot

light goes out for longer that 10 seconds, or it goes out 3 times within

10 seconds, the module keeps the 24 volts from reaching the gas

control valve. The burners shut down.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel as discussed in Complete Control Panel

Replacement Section.

3. Label and remove the wires at module.

4. Using a 3/8 inch nut driver, remove the keps nuts securing the

module to the shroud.

5. Install new module in reverse order.

2-10. TRANSFORMER The transformer reduces voltage down to accommodate those

components with low voltage.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel as discussed in Complete Control Panel

Replacement Section.

3. Squeeze on the wire connector at the I/O board assembly to

disconnect the wires from the transformer.

4. Using a Phillips head screwdriver, remove the two screws

securing the transformer to the shroud.

5. Install the new transformer in reverse order.

2-10 203

Model OFE/OFG-321,322,323,324

2-11. I/O POWER SUPPLY

BOARD ASSEMBLY The input/output power supply board assembly distributes

voltage to the various components in the fryer. The board also

receives information from components in the fryer.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel as discussed in Complete Control

Panel Replacement Section.

3. Disconnect the wire assemblies from the board.

4. Using a nut driver or wrench, remove the four keps nuts

securing the board to the shroud.

5. Install the new I/O board assembly in reverse order.

2-12. VACUUM SWITCH The vacuum switch senses the airflow from the induction blower.

If the airflow is reduced below a set amount, the switch will open

and the I/O board will cut power to the gas control valve, which

will shut the pilot flame off.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel as discussed in Complete Control

Panel Replacement Section.

3. Remove the air hose from the vacuum switch.

4. Label and remove wires from vacuum switch.

203 2-11

Model OFE/OFG-321,322,323,324

2-12. VACUUM SWITCH

(Continued) 5. Using a Phillips head screwdriver, remove the screws securing

the vacuum switch to the shroud.

6. Install the new vacuum switch in reverse order.

To avoid property damage, do not tamper with, or disas semble this component. It is set and sealed from the

factory and is not to be adjusted.

2-13. SPEAKER ASSEMBLY The speaker assembly emits audible signals to let the operator

(Gas Units) know when cooking and hold times are finished.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel as discussed in Complete Control

Panel Replacement Section.

3. Using a Phillips head screwdriver, remove the four screws

securing the speaker to the shroud.

4. Install new speaker in reverse order. When plugging connector

into control board, be sure to align pins into connector

correctly.

2-12 203

Model OFE/OFG-321,322,323,324

2-14. DRAIN MICROSWITCH Upon turning the drain handle, the drain microswitch circuit

should open, cutting off the pilot flame. This will prevent the fryer

from heating while shortening is being drained from the frypot.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. The following check should be made to determine if the drain

microswitch is defective.

a. Remove the two screws securing the microswitch to the

drain rod valve bracket.

b. Remove wires from the switch.

c. Check for continuity across the two outside terminals of the

drain switch. If the circuit is open, the drain switch is

defective. The circuit should only be opened by pressing on

the actuator of the drain switch.

3. Replace switch in reverse order.

2-15. FILTER SWITCH

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

203 2-13

Model OFE/OFG-321,322,323,324

2-15. FILTER SWITCH

(Continued) 2. Remove the control panel above the switch.

3. Label and remove the wires from the switch. With test

instrument, check across the terminals of the switch with the

switch in the ON position, and then in the OFF position. With

the switch in the ON position, the circuit should be closed.

With the switch in the OFF position, the circuit should be open.

If the switch checks defective, replace it by continuing with this

procedure.

4. With wires removed from the switch, push in on tabs on the

switch and remove switch from the panel.

5. Push new switch into panel and reconnect wires.

2-16. GAS CONTROL VALVE

ASSEMBLY The gas control valve assembly controls the flow of gas to the pilot

and the main burner. The valve has two 24 volt coils, which are

regulated by terminals P and M on the valve. The C terminal is the

common terminal. For gas flow to the pilot, 24 VAC must be

present between the P and C terminals. For gas flow to the main

burner, 24 VAC must be present between the M and C terminals.

TO AVOID PERSONAL INJURY OR PROPERTY

DAMAGE, BEFORE STARTING THIS

PROCEDURE, MOVE THE MAIN POWER SWITCH

TO THE OFF POSITION. DISCONNECT THE MAIN

CIRCUIT BREAKERS AT THE CIRCUIT BREAKER

BOX OR UNPLUG SERVICE CORD FROM WALL

RECEPTACLE. TURN OFF THE MAIN GAS

SUPPLY TO THE FRYER AND DISCONNECT AND

CAP THE MAIN SUPPLY LINE TO FRYER, OR

POSSIBLE EXPLOSION COULD RESULT.

1. Remove control panel assembly.

2. Remove wires from gas control valve.

2-14 203

Model OFE/OFG-321,322,323,324

2-16. GAS CONTROL VALVE

ASSEMBLY

(Continued)

3. Using a 7/16 inch wrench, remove the pilot line from the gas

control valve.

4. Using a 1 inch wrench, loosen the nut securing the main gas

inlet line to the gas control valve.

5. Using 5/8 inch wrench, remove the two burner gas line fittings

at the black tee fitting, located behind the control panel area.

6. Using a Phillips head screwdriver, remove the three screws

securing the gas control valve bracket to the frame of the fryer

behind the control panel area.

203 2-15

Model OFE/OFG-321,322,323,324

2-16. GAS CONTROL VALVE

ASSEMBLY

(Continued)

7. With the bracket dropped down, remove the two screws behind

the bracket securing the gas control valve to the bracket.

8. Install the new gas control valve in reverse order.

2-17. BLOWER MOTOR

ASSEMBLY The blower motor assembly induces the draft for the burners. If the

blower motor fails, the air switch will fail to close, causing an

“E-20B” error code in the display.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

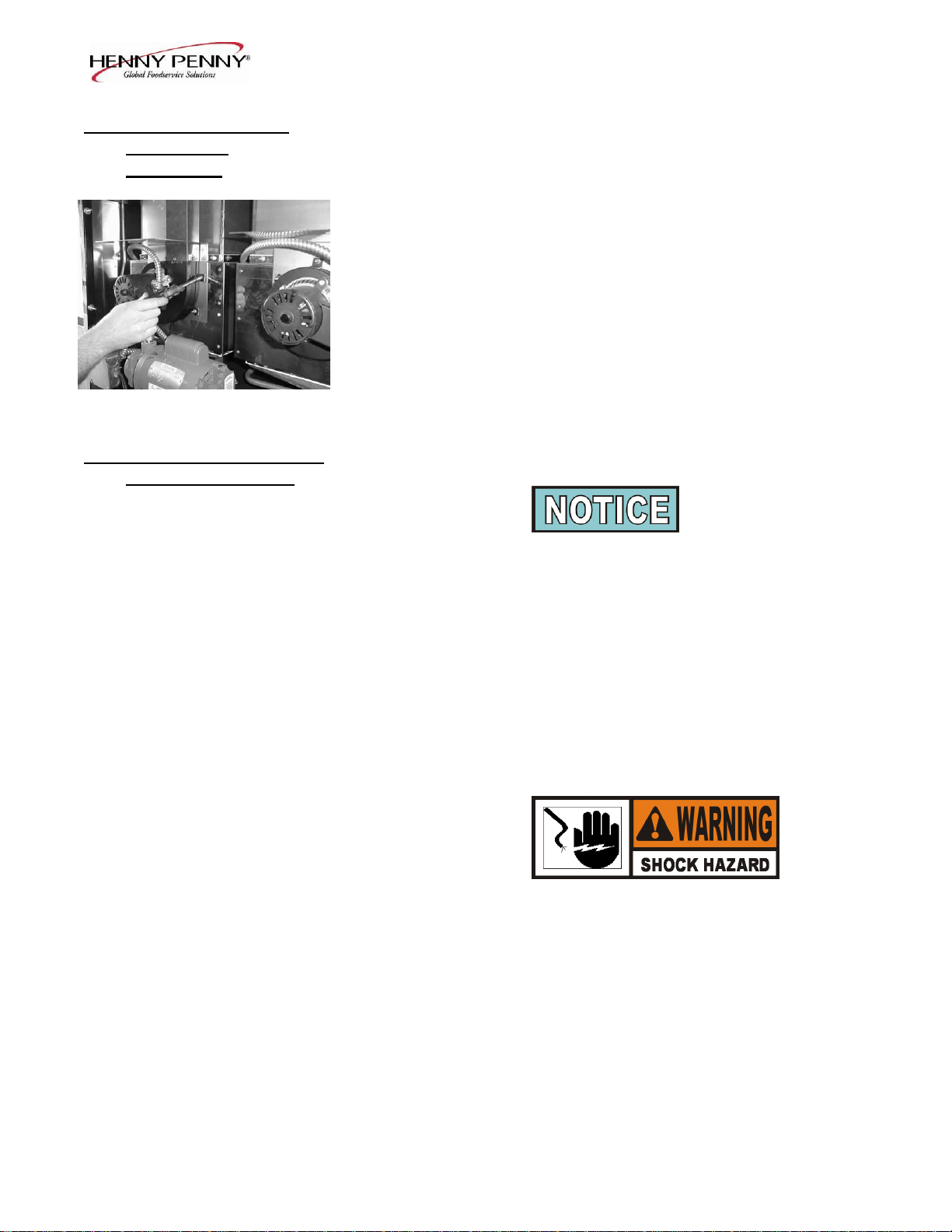

2. Remove screws securing the two rear covers to the unit.

3. Remove the wire cover from the blower motor housing.

2-16 203

Model OFE/OFG-321,322,323,324

2-17. BLOWER MOTOR

ASSEMBLY

(Continued)

4. Remove wire nuts connecting blower motor wires to wires in

conduit.

5. Loosen conduit from blower motor.

6. Remove screws connecting flue to bracket in upper frame.

7. Remove screws connecting flue to blower.

203 2-17

Model OFE/OFG-321,322,323,324

2-17. BLOWER MOTOR

ASSEMBLY

(Continued)

8. Using 3/8 inch nut driver, remove nuts securing blower to the

unit. Pull blower from unit.

9. Install new blower in reverse order.

2-18. HEATING ELEMENTS

(ELECTRIC ONLY)

Heating elements are available for 208 and 230 volts. Check

data plate to determine correct voltage.

Checkout:

If the shortenings temperature recovery is very slow or at a slower

rate than required, this may indicate defective heating element(s).

An ohmmeter will quickly indicate if the elements are shorted or

open.

1. Remove electrical power supplied to the frypot to be worked on.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle, to the frypot

to be worked on. Be aware the other controls will have

power.

2. Remove control panel.

2-18 203

Model OFE/OFG-321,322,323,324

2-18. HEATING ELEMENTS

(ELECTRIC ONLY)

(Continued) 3. Perform an ohm check on one element at a time, with wires

disconnected from element. If the resistance is not within

tolerance, replace the element.

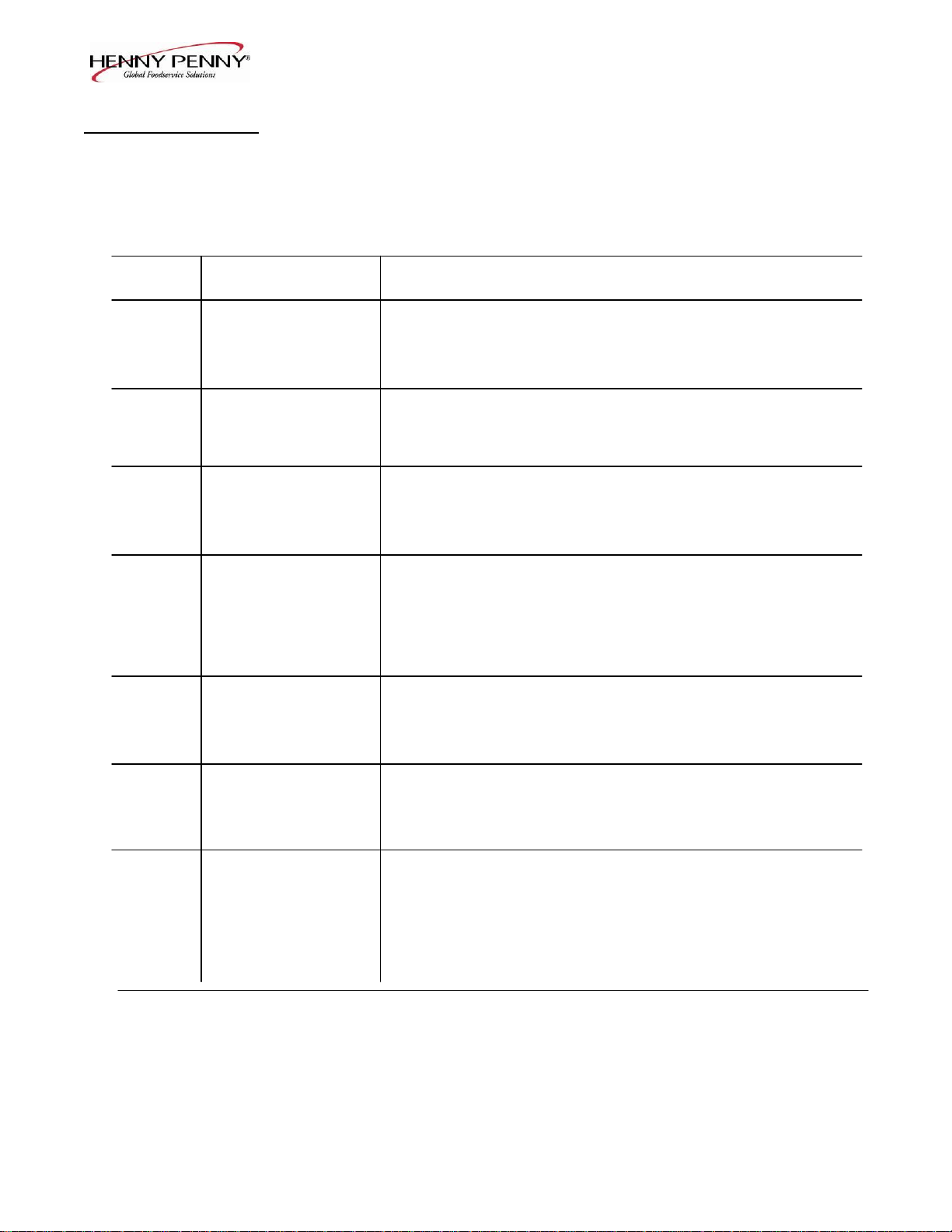

Voltage Wattage Resistance Ohms (cold)

208 4800 9

230 4800 11

Replacement:

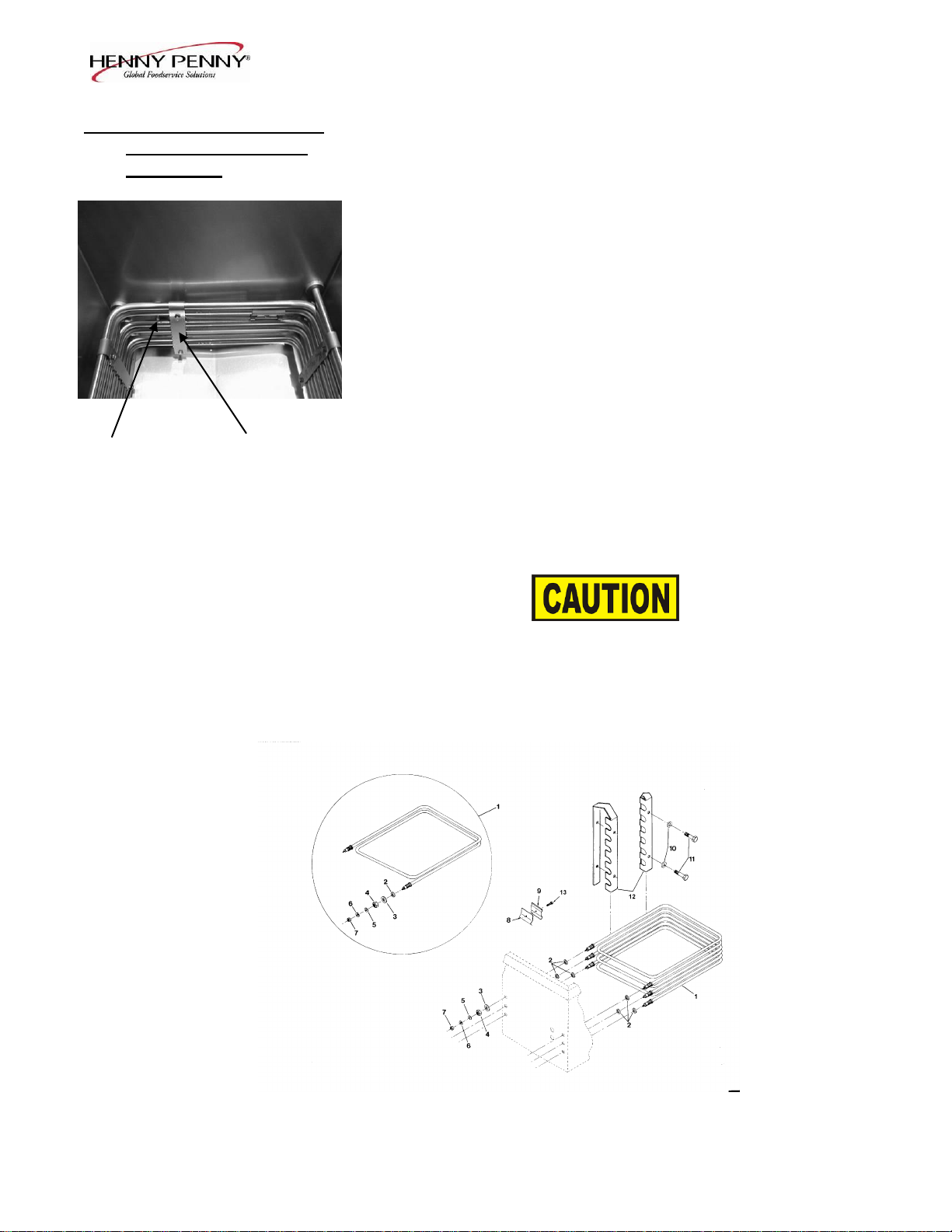

Refer to figure 2-2.

1. Drain the shortening from the frypot.

2. Remove the high limit bulb holder from the heating element

inside the frypot.

3. Remove the heating element wires from the terminals by

removing the nuts and washers. Label each so it can be

replaced on the new element in the same position.

4. Remove the bolts from the five element spreaders. The

element spreaders will now pull off the elements.

5. Remove the brass nuts and washers which secure the ends of

the elements through the frypot wall.

6. Remove the heating elements from the frypot as a group by

lifting the far end and sliding them up and out toward the

rear of the frypot.

Always install new rubber O-rings when installing heater

elements.

7. Install new heating elements with the new O-rings, terminal

end first at approximately a 45 angle, slipping the terminals

through the front wall of the frypot.

8. Replace the brass nuts and washers on the element terminals.

Tighten the brass nuts to 30 foot lbs. of torque.

203 2-19

Model OFE/OFG-321,322,323,324

2-18. HEATING ELEMENTS

(ELECTRIC ONLY)

(Continued) 9. Evenly space the element spreaders on the sides of the

elements and reinstall bolts. Place the fifth spreader in the

front of the elements as to protect the temperature probe.

(Fig.6-1

10. Replace the high limit bulb holder on the top element, and

position the bulb between the top and second element

midway from side to side, and tighten screw that holds the

bulb in place.

11. Reconnect the wires to the appropriate terminal as labeled

when they were removed.

Temperature Spreader

Probe

Fig. 2-1 12. Replace the front control panel.

13. Connect the power cord to the wall receptacle or close wall

circuit breaker.

Heating elements should never be energized without

shortening in the frypot, or damage to the elements could

result.

14. Replace the shortening in the frypot.

Fig. 2-2

2-20 203

33

37

Electromechanical

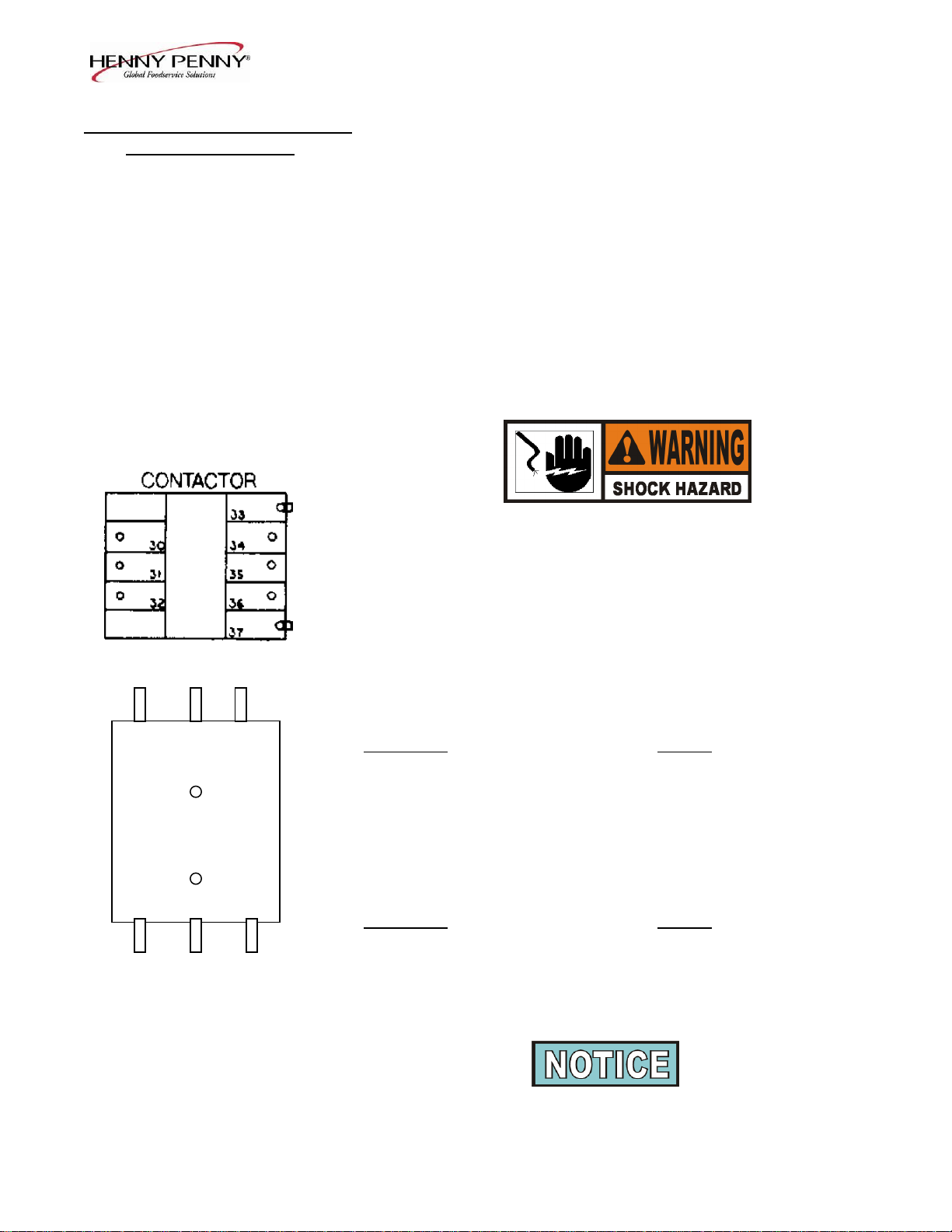

2-19. HEATING CONTACTORS

(ELECTRIC ONLY)

Each well of an electric fryer requires two switching contactors.

The first in line is the primary contactor and the second in line is

the heat contactor. When open, the primary contactor does not

allow power to flow to the heat contactor. When closed, the

primary supplies voltage to the heat contactor. When the heat

contactor is open, no voltage is supplied to the heating elements.

When the heat contactor closes, voltage is supplied to the heating

elements.

Checkout (Power Removed)

1. Remove electrical power supplied to the frypot to be worked on.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle, to the frypot

to be worked on. Be aware the other controls will have

power.

2. Remove the control panel.

30 31 32 3. Perform a check on the contactor as follows:

ELECTROMECHANICAL CONTACTOR

Test Points Results

From 30 to 34 open circuit

From 31 to 35 open circuit

From 32 to 36 open circuit

From 33 to 37 ohm reading 5 to 6

MERCURY CONTACTOR

Test Points Results

34 35 36 From 30 to 34 open circuit

Mercury Contactor From 31 to 35 open circuit

From 32 to 36 open circuit

From 33 to 37 ohm reading 1700

109 2-21

Wires should be removed and labeled to obtain an accurate check

of contactors.

Model OFE/OFG-321,322,323,324

Loading...

Loading...