Henny Penny OFE-322, OFE-321, OFE-324, OFE-323, OFG-321 User Manual

...

Model OFE/OFG-321,322,323,324

SECTION 2. MAINTENANCE

2-1. INTRODUCTION

of the various parts used within the fryer. Before replacing any

parts, refer to the Troubleshooting Section. It will aid you in

determining the cause of the malfunction.

2-2. MAINTENANCE HINTS

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter will read infinity.

2-3 HIGH TEMPERATURE

LIMIT CONTROL The high temperature limit control is a safety, manual reset control

(Gas Units)

that senses the temperature of the shortening. If the shortening

temperature exceeds 425°F (218°C), this switch will open

and shut off heat to the frypot. When the temperature of the

shortening drops to a safe operation limit, the control must be

manually reset by pressing the red reset button. The red reset

button is located under the control panel, in the front of the fryer.

This will allow heat to be supplied to the frypot once again.

Checkout Before replacing a high temperature limit control, check to see

that its circuit is closed.

This section provides procedures for the checkout and replacement

1. You may need to use a multimeter to check the electric

The shortening temperature must be below 380°F

(193°C) to accurately perform this check.

Checkout:

1. Remove electrical power supplied to fryer.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel.

203 2-1

Model OFE/OFG-321,322,323,324

2-3 HIGH TEMPERATURE

LIMIT CONTROL

(Continued)

3. Remove the two nuts securing the high limit bracket to the unit

and pull the bracket from the unit.

4. Remove the two screws securing the high limit to the bracket,

and remove the high limit from the bracket.

5. Remove the two electrical wires from the high temperature

limit control.

6. Manually reset the control, then check for continuity between

the two terminals after resetting the control. If the circuit is

open, replace the control, then continue with this procedure.

(If the circuit is closed, the high limit is not defective. Reconnect the two electrical wires.)

Replacement:

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

1. If the tube is broken or cracked, the control will open, shutting

off electrical power to the heat circuit. The control cannot be

reset, and it will continuously click when pushed.

2. Drain the shortening from the frypot and discard. A substance

in the tube could contaminate the shortening.

3. Remove the control panel.

4. Loosen small inside screw nut on capillary tube.

2-2 203

2-3 HIGH TEMPERATURE

LIMIT CONTROL

(Continued)

Model OFE/OFG-321,322,323,324

5. Remove the bracket from the heat tube covering the high limit

bulb.

6. Straighten the capillary tube behind the pot wall.

7. Pull the high limit bulb through the retainers on the heat tube.

8. Remove the larger outside nut that threads into the pot wall.

9. Remove the defective high limit from the control panel area.

10. Insert new high limit into bracket and replace wires.

11. Uncoil capillary line, starting at capillary tube, and insert

through frypot wall.

To avoid electrical shock or other injury, run the capillary

line under and away from all electrical power wires and

terminals. The tube must never

be in such a position where

it could accidentally touch the electrical power terminals.

12. Insert capillary line through brackets on heat tube, and then

pull back through pot wall until capillary bulb is secure in

brackets.

13. Pull excess capillary line from pot and tighten nut into

frypot wall.

14. With excess capillary line pulled out, tighten smaller nut.

15. Replace bracket on heat tube covering the high limit bulb.

16. Replace front panel.

17. Refill frypot with shortening.

203 2-3

Model OFE/OFG-321,322,323,324

2-4. COMPLETE CONTROL

PANEL REPLACEMENT

Should the control board become inoperative, follow these

instructions for replacing the board.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the four screws securing the control panel and lift

out.

3. Unplug the wire connectors going to the control board.

4. Install new control panel in reverse order.

When plugging connectors onto new control panel, be sure

the connectors are inserted onto all of the pins, and that the

connectors are not forced onto the pins backwards. If not

connected properly, damage to the board could result.

2-5. POWER SWITCH 1. Remove electrical power supplied to fryer.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove control panel.

3. Label and remove the wires from the switch. With test

instrument, check across the terminals of the switch with

the switch in the ON position, then in the OFF position.

With the switch in the ON position, the circuit should be

closed. With the switch in the OFF position, the circuit

should be open. If the switch checks defective, replace by

continuing with this procedure.

2-4 203

Model OFE/OFG-321,322,323,324

2-5. POWER SWITCH

(Continued)

4. With control panel removed, and the wires off the switch, push

in on tabs on the switch to remove from panel.

5. Replace with new switch, and reconnect wires to switch.

6. Replace the control panel.

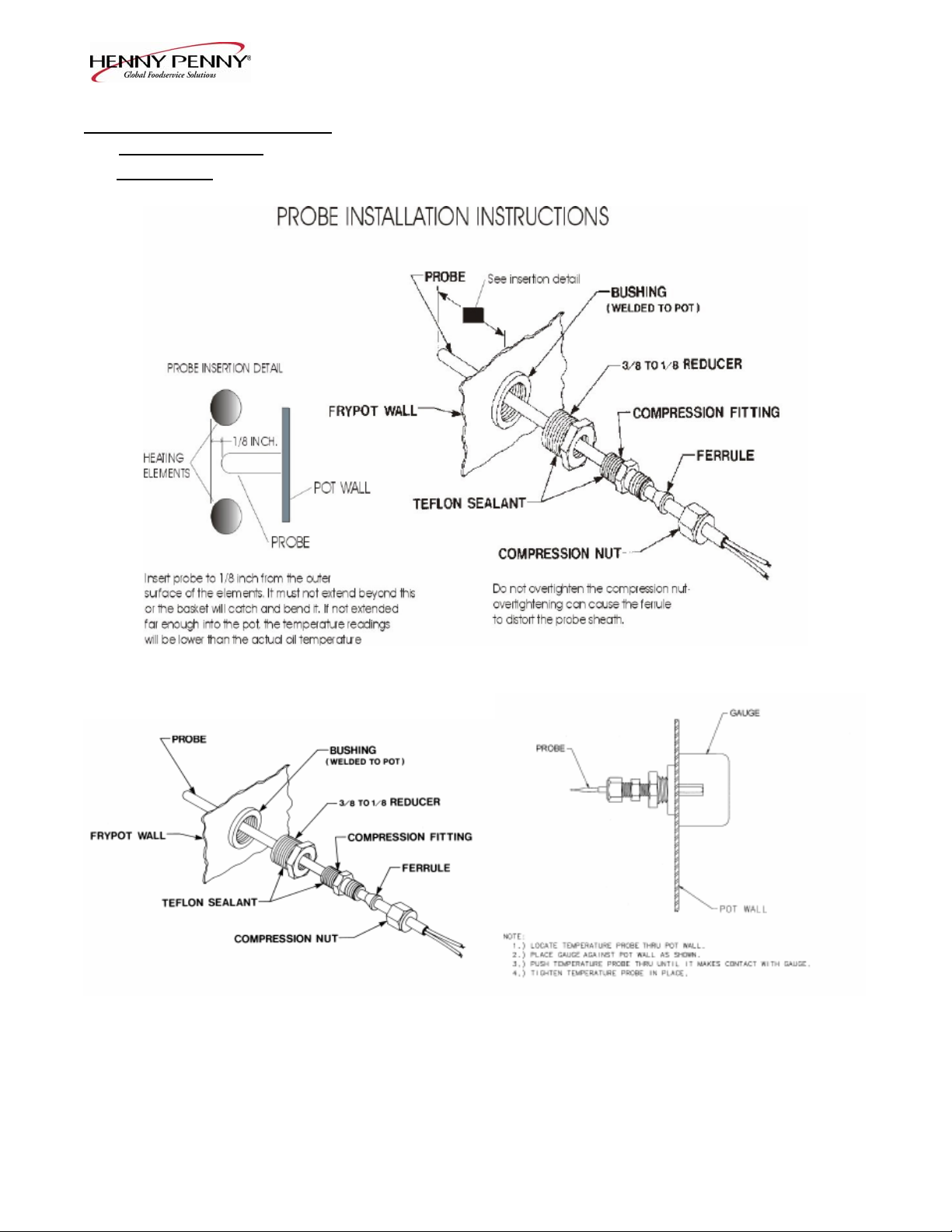

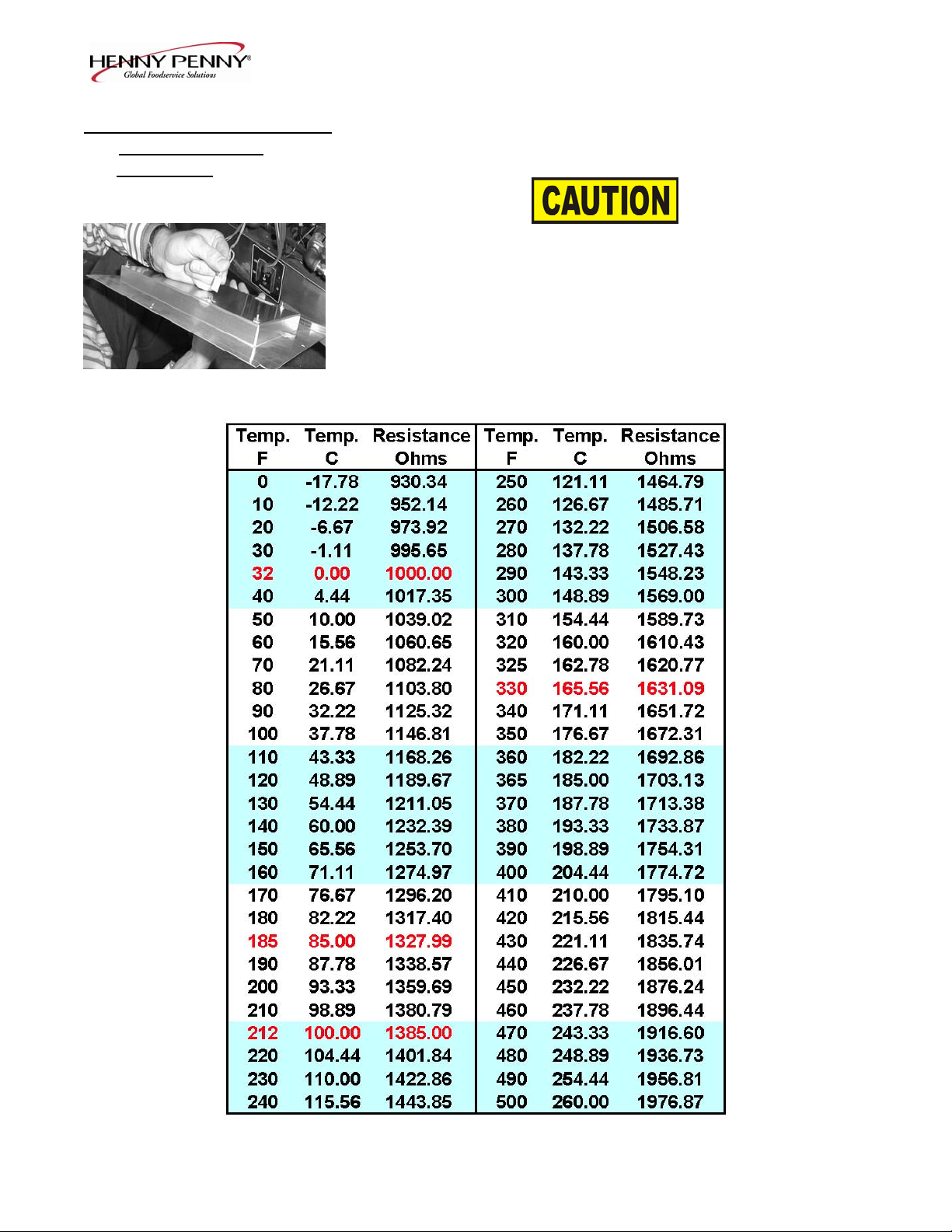

2-6. TEMPERATURE PROBE

REPLACEMENT

the control board. If it becomes disabled, “E-6B” will show in the

The temperature probe relays the actual shortening temperature to

display. Also, if the shortening temperature is out of calibration by

more than 10°F or C°, the temperature probe should be replaced.

An Ohm check can be performed also. See chart on page 2-7.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

Electric breaker, or unplug cord at wall receptacle.

2. Drain the shortening from the frypot.

3. Remove the control panel.

Gas

4. Using a 1/2" wrench, remove the nut on the compression

fitting.

5. Remove the temperature probe from the frypot.

6. Follow the appropriate instructions, on the following page,

depending upon the type of fryer, gas or electric.

606 2-5

2-6. TEMPERATURE PROBE

REPLACEMENT

(Continued)

ELECTRIC

Model OFE/OFG-321,322,323,324

GAS

2-6 606

Model OFE/OFG-321,322,323,324

2-6. TEMPERATURE PROBE 7. Tighten the compression nut hand tight and then a half turn

REPLACEMENT

(Continued)

with wrench.

Excess force will damage temperature probe.

8. Connect new temperature probe to PC board and replace

control panel.

9. Replace shortening.

10. Turn power on and check out fryer.

606 2-7

Model OFE/OFG-321,322,323,324

2-7. FLAME SENSOR

(Gas Units)

continue to the pilot. The flame sensor must send a minimum of

The flame sensor recognizes the pilot flame and allows gas to

two (2) micro amps to the ignition module. The pilot flame should

be split in two by the flame sensor, causing the flame sensor to be

bright red in color.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle..

2. To access flame sensor, open the filter doors in the front of the

unit. Follow the small gauge yellow wire running to the sensor

behind the pilot assembly.

3. Disconnect the flame sense wire from the flame sensor.

4. Using a pair of needle nosed pliers, pull the flame sensor out

of the pilot assembly bracket.

5. Insert new flame sensor and reconnect flame sensor wire.

6. Turn power on and check fryer.

2-8 203

Model OFE/OFG-321,322,323,324

2-8. PILOT / IGNITOR The Henny Penny open fryer (gas) has electronic spark ignition

ASSEMBLY

that lights a standing pilot. The gap between the spark electrode

and the pilot hood should be set at 1/8 of an inch.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

TO AVOID PERSONAL INJURY OR PROPERTY

DAMAGE, BEFORE STARTING THIS

PROCEDURE, MOVE THE MAIN POWER SWITCH

TO THE OFF POSITION. DISCONNECT THE MAIN

CIRCUIT BREAKERS AT THE CIRCUIT BREAKER

BOX OR UNPLUG SERVICE CORD FROM WALL

RECEPTACLE. TURN OFF THE MAIN GAS

SUPPLY TO THE FRYER AND DISCONNECT AND

CAP THE MAIN SUPPLY LINE TO FRYER, OR

POSSIBLE EXPLOSION COULD RESULT.

2. Remove the control panel as discussed in Complete Control

Panel Replacement Section.

3. Disconnect the pilot gas line fitting at the pilot assembly with

a ½ inch wrench.

4. With a Phillips head screwdriver, remove the two screws

securing the pilot assembly to the mounting bracket.

5. Remove the flame sensor wire from the flame sensor.

6. Follow the wire from the spark ignitor back to the module, and

remove wire from module.

7. After removing assembly from unit, pull the flame sensor out

of the bracket as discussed in section 6-7. Insert flame sensor

into new pilot/ignitor assembly.

8. Reinstall the new pilot/ignitor assembly in reverse order. Be

extremely careful not to cross thread the pilot gas line fitting.

203 2-9

Loading...

Loading...