Page 1

Model OFE/OFG/OEA/OGA-341, 342

TECHNICAL MANUAL

Model OFE/OFG-341

Model OFE/OFG-342

Model OEA/OGA-341

Model OEA/OGA-342

High Volume Open Fryer

Henny Penny

Page 2

Model OFE/OFG/OEA/OGA-341, 342

Page 3

Model OFE/OFG/OEA/OGA-341, 342

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the inside of the right side panel.

Post in a prominent location, instructions to be followed in event user smells gas. This information shall

be obtained by consulting the local gas supplier.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance must be left all around

appliance for sufficient air to the combustion chamber.

The Model OFG/OGA-34X open fryer is equipped with a continuous pilot. But the open fryer can not be

operated without electric power. The unit will automatically return to normal operation when power is

restored.

To avoid a fire, keep appliance area free and clear from combustibles.

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

FM06-030

Revised 12-30-09

Page 4

Model OFE/OFG/OEA/OGA-341, 342

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING ...................................................................................................1-1

1-1. Introduction .............................................................................................................1-1

1-2. Safety ......................................................................................................................1-1

1-3. Troubleshooting ......................................................................................................1-2

1-4. Error Codes .............................................................................................................1-4

Section 2. MAINTENANCE .............................................................................................................2-1

2-1. Introduction .............................................................................................................2-1

2-2. Maintenance Hints ..................................................................................................2-1

2-3. High Temperature Limit Control (Gas Units) ........................................................2-1

2-4. Complete Control Panel Replacement ...................................................................2-4

2-5. Power Switch ..........................................................................................................2-4

2-6. Temperature Probe Replacement (Gas) ..................................................................2-5

2-7. Temperature Probe Replacement (Electric) ............................................................2-6

2-8. Flame Sensor/Pilot/Ignitor Assembly (Gas) ...........................................................2-7

2-9. Ignition Module ......................................................................................................2-9

2-10. Transformer Replacement .......................................................................................2-10

2-11. Control & I/O Boards Replacement ........................................................................2-10

2-12. Vacuum Switch Replacement .................................................................................2-11

2-13. Drain Microswitch Replacement ............................................................................2-12

2-14. Filter Switch Replacement ......................................................................................2-12

2-15. Gas Control Valve Replacement .............................................................................2-13

2-16. Blower Motor Replacement ....................................................................................2-15

2-17. Heating Elements (Electric) ....................................................................................2-17

2-18. Heating Contactors (Electric) .................................................................................2-19

2-19. Speaker Assembly ...................................................................................................2-22

2-20. High Temperature Limit Control (Electric) ............................................................2-23

2-21. Filter Pump and Motor Removal ............................................................................2-26

2-22. Autolift Transformer Replacement (if applicable) .................................................2-27

2-23. Autolift PC Board Replacement (if applicable) ......................................................2-28

2-24. Autolift Actuator (Motor) Replacement (if applicable) ..........................................2-28

Wiring Diagrams

Section 3. PARTS INFORMATION .................................................................................................3-1

3-1. Introduction .............................................................................................................3-1

3-2. Genuine Parts ..........................................................................................................3-1

3-3. When Ordering Parts...............................................................................................3-1

3-4. Prices .......................................................................................................................3-1

3-5. Delivery ..................................................................................................................3-1

3-6. Warranty .................................................................................................................3-1

3-7. Recommended Spare Parts for Distributors ............................................................3-1

ii 106

Page 5

Model OFE/OFG/OEA/OGA-341, 342

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION This section provides troubleshooting information in the form of

an easy to read table.

If a problem occurs during the first operation of a new fryer,

recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation Section of

the Operator’s Manual.

1-2. SAFETY Where information is of particular importance or is safety related,

the words DANGER, WARNING, CAUTION, or NOTE are used.

Their usage is described on the next page:

SAFETY ALERT SYMBOL is used with DANGER,

WARNING or CAUTION which indicates a personal

injury type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, WILL RESULT IN DEATH OR

1003 1-1

SERIOUS INJURY.

Page 6

Model OFE/OFG/OEA/OGA-341, 342

1-3. TROUBLESHOOTING To isolate a malfunction, proceed as follows:

1. Clearly define the problem or symptom and when it

occurs.

2. Locate the problem in the Troubleshooting table.

3. Review all possible causes, then one at a time work

through the list of corrections until the problem is solved.

If maintenance procedures are not followed correctly,

injuries and/or property damage could result.

PROBLEM CAUSE CORRECTION

With the switch in • Open circuit • Check to see if unit is plugged in

the ON position,

fryer is completely • Check breaker or fuse at supply box

inoperative

• Check power switch per Power Switch

Section; replace if defective

• Check voltage at wall receptacle

• Check cord and plug

Shortening will not • Faulty contactor • Check contactor per Heating Contactors

heat but lights are on (elec. model) Section

• Faulty gas control • Check gas control valve per Gas Control

valve (gas model) Valve Assembly Section

• Faulty temperature • Check temperature probe per Temperature

probe Probe Replacement Section; “E6”

• Faulty high limit • Check high limit per the appropriate High

Temperature Limit Control Section; “E10”

• Faulty drain switch • Check drain switch per Drain Microswitch

Section; “E15"

1-2 1003

Page 7

Model OFE/OFG/OEA/OGA-341, 342

1-3. TROUBLESHOOTING(Continued)

PROBLEM CAUSE CORRECTION

Heating of • Low or improper • Use a meter and check the receptacle

shortening too voltage (elec. unit) voltage against the data plate

slow

• Weak or burnt out • Check heating elements per Heating

elements (elec. unit) Elements Section

• Wire(s) loose • Tighten

• Burnt or charred • Replace wire and clean connectors

wire connection

• Faulty contactor • Check contactor per Heating Contactors

Section

• Supply line too small • Increase supply line size; refer to

- low gas volume (gas Installation Section of Operator’s Manual

unit)

• Improper ventilation • Refer to Installation Section of Operator’s

Manual

Shortening • Temperature probe • Calibrate temperature probe if ± 10° off;

overheating needs calibrated if more than ± 10° off, replace temperature

probe

• Mercury contactor • Check mercury contactor for not opening;

stuck closed replace if necessary (elec. unit)

• Bad control board • Replace control board if heat indicator stays

on past ready temperature

Foaming or boiling • Water in shortening • At end of cook cycle, drain shortening and

over of shortening clean

• Improper or bad • Use recommended shortening

shortening

• Improper filtering • Refer to the Filtering the Shortening

Section in Operator’s Manual

• Improper rinsing after • Clean and rinse the frypot; then dry

cleaning the fryer thoroughly

1003 1-3

Page 8

Model OFE/OFG/OEA/OGA-341, 342

1-2. TROUBLESHOOTING

(Continued)

PROBLEM CAUSE CORRECTION

Shortening will not • Drain valve clogged • Open valve, force cleaning brush through

drain from frypot with crumbs drain

• Drain valve will not • Replace cotter pins in valve coupling

open by turning

handle

Filter motor runs • Pump clogged • Remove pump cover and clean

but pumps shortening

slowly • Filter line connection • Tighten all filter line connections

loose

• Solidified shortening • Clear all filter lines of solidified shortening

in lines

Filter switch on, • Defective switch • Check/replace switch per Filter Switch

motor does not run Section

• Defective motor • Check/replace motor

• Motor thermal • Reset thermal switch on filter motor

protector tripped

Motor hums but • Clogged lines or • Remove and clean pump and lines

will not pump pump

• Replace pump seal, rotor and rollers

1-4 1003

Page 9

Model OFE/OFG/OEA/OGA-341, 342

1-4. ERROR CODES In the event of a control system failure, the digital display shows

An error message. These messages are coded: “E4”, “E5”, “E6”,

“E10”, “E15”, “E20”, “E31”, “E41”, “E46”, and “E92”. A

Constant tone is heard when an error code is displayed, and to

silence this tone, press any button.

DISPLAY CAUSE PANEL BOARD CORRECTION

“E4” Control board Turn switch to OFF position, then turn switch back to ON;

overheating if display shows “E4”, the control board is getting too hot;

check the louvers on each side of the unit for obstructions

“E5” Shortening Turn switch to OFF position, then turn switch back to ON;

overheating if display shows “E5”, the heating circuits and temperature

probe should be checked

“E6-A” Temperature Turn switch to OFF position, then turn switch back to ON;

probe open if display shows “E6” the temperature probe should be

checked

“E6-B” Temperature Turn switch to OFF position, then turn switch back to ON;

probe shorted if display shows “E6” the temperature probe should be

checked to replace, per Temperature Probe Replacement

Section

“E10” High limit Reset the high limit by manually pushing up on the red

reset button; if high limit does not reset, high limit must be

replaced per High Limit Temperature Control Section

“E15” Drain switch Close drain, using the drain valve handle; if display still

failure shows “E-15”, check the drain microswitch per Drain

Microswitch Section

“E31” Elements not Check to make sure the elements are hinged all way down

hinged all the into the frypot; check for obstructions under elements

way down

“E41”, Programming Turn switch to OFF, then back to ON; if display shows any

“E46” failure of the error codes, try to reinitialize the control (Special

Program Mode Section of Operator’s Manual); if error

code persists, replace the control panel per Complete

Control Panel Replacement Section

1003 1-5

Page 10

Model OFE/OFG/OEA/OGA-341, 342

1-4. ERROR CODES

(Continued)

DISPLAY CAUSE PANEL BOARD CORRECTION

“E-20 A” Vacuum Press the timer button to try the ignition process again,

switch failure and if “E-20 A” persists, check the air switch per Vacuum

(stuck closed) Switch Section

“E-20 B” Draft fan or Press the timer button to try the ignition process again,

vacuum and if “E-20 B” persists, check the vacuum switch per

switch failure Vacuum Switch Section or the blower motor per Blower

(stuck open) Motor Assembly Section

“E-20 C” Ignition modules Press the timer button to try the ignition process again; if

not responding “E-20 C” persists, check the ignition module per Ignitor

Module Section, the spark ignitor per Pilot/Ignitor

Assembly Section, or the I/O board per Control & I/O

Boards Section

“E-20 D” Pilots not lit or Press the timer button to try the ignition process again; if

no flame sense “E-20 D” persists, check the ignition module per Ignition

Module Section, the I/O board per Control & I/O Boards

Section, or the flame sensor per Flame Sensor Section

“E-47” Analog converter Turn switch to OFF, then back to ON; if “E47” persists,

chip or 12 volt replace the I/O board, or the PC board; if speaker

supply failure tones are quiet, probably I/O board failure

“E-48” Input system Replace PC board

error

“E-70” Faulty power Check power switch, along with its wiring;

switch or switch replace I/O board if necessary

wiring; faulty I/O

board

“E-92” 24 VAC fuse Check for shorted component in 24 volt circuit;

on I/O open (i.e., high limit, drain switch, vacuum switch)

1-6 1003

Page 11

Model OFE/OFG/OEA/OGA-341, 342

SECTION 2. MAINTENANCE

2-1. INTRODUCTION This section provides procedures for the check out and

replacement of the various parts used within the fryer. Before

replacing any parts refer to the Troubleshooting Section. It will aid

you in determining the cause of the malfunction.

2-2. MAINTENANCE HINTS 1. You may need to use a multimeter to check the electric

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter will read infinity.

2-3. HIGH TEMPERATURE

LIMIT CONTROL This high temperature control is a safety, manual reset control,

(Gas Units) which senses the temperature of the shortening. If the short-

ening temperature exceeds 425°F (218°C), this switch opens

and shuts off heat to the frypot. When the temperature of the

shortening drops to a safe operation limit, the control must be

manually reset by pressing the red reset button. The red reset

button is located under the control panel, in the front of the fryer.

(Figure 2-1). This allows heat to be supplied to the frypot.

Before replacing a high temperature limit control, check to see

that its circuit is closed.

Figure 2-1

The shortening temperature must be below 380°F (193°C)

to accurately perform this check.

Checkout

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

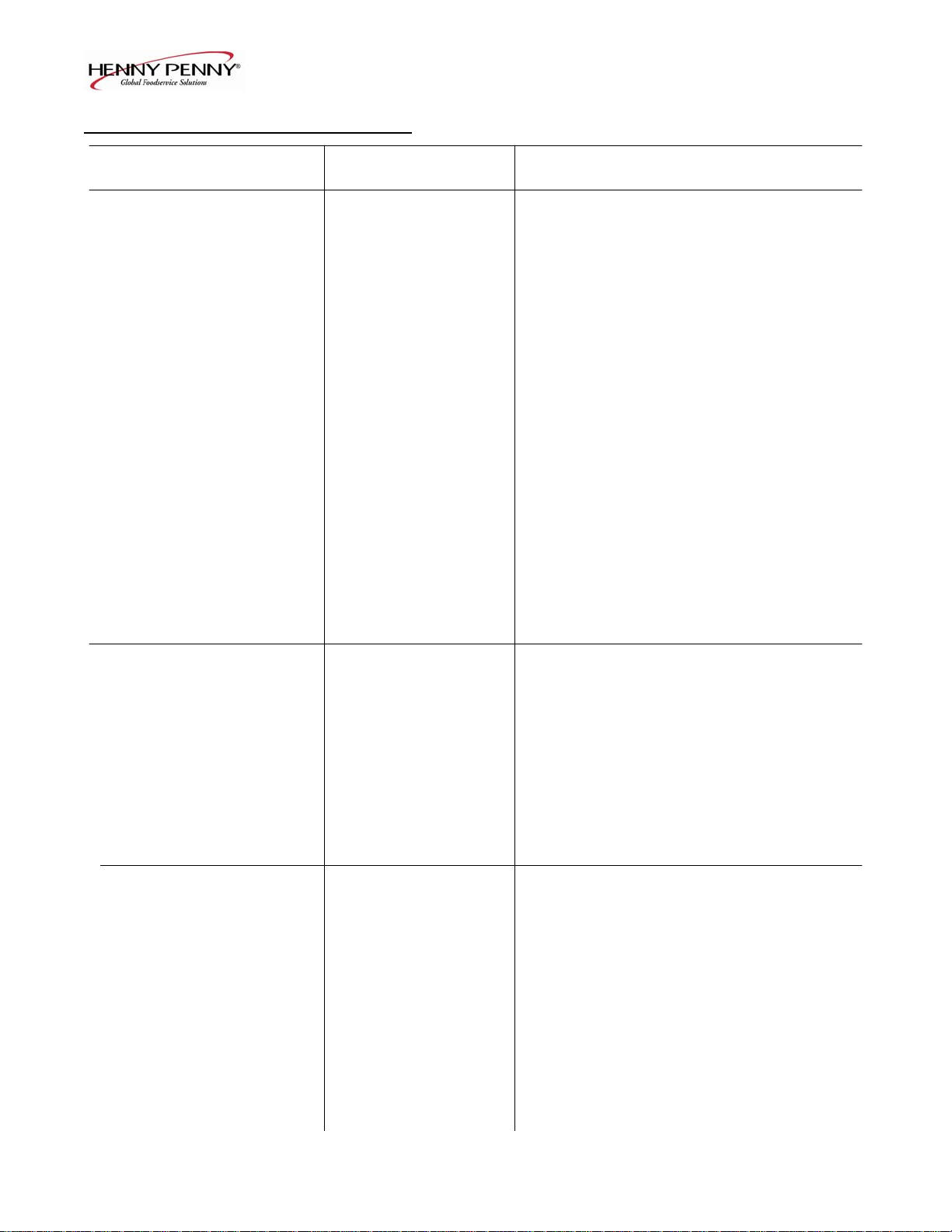

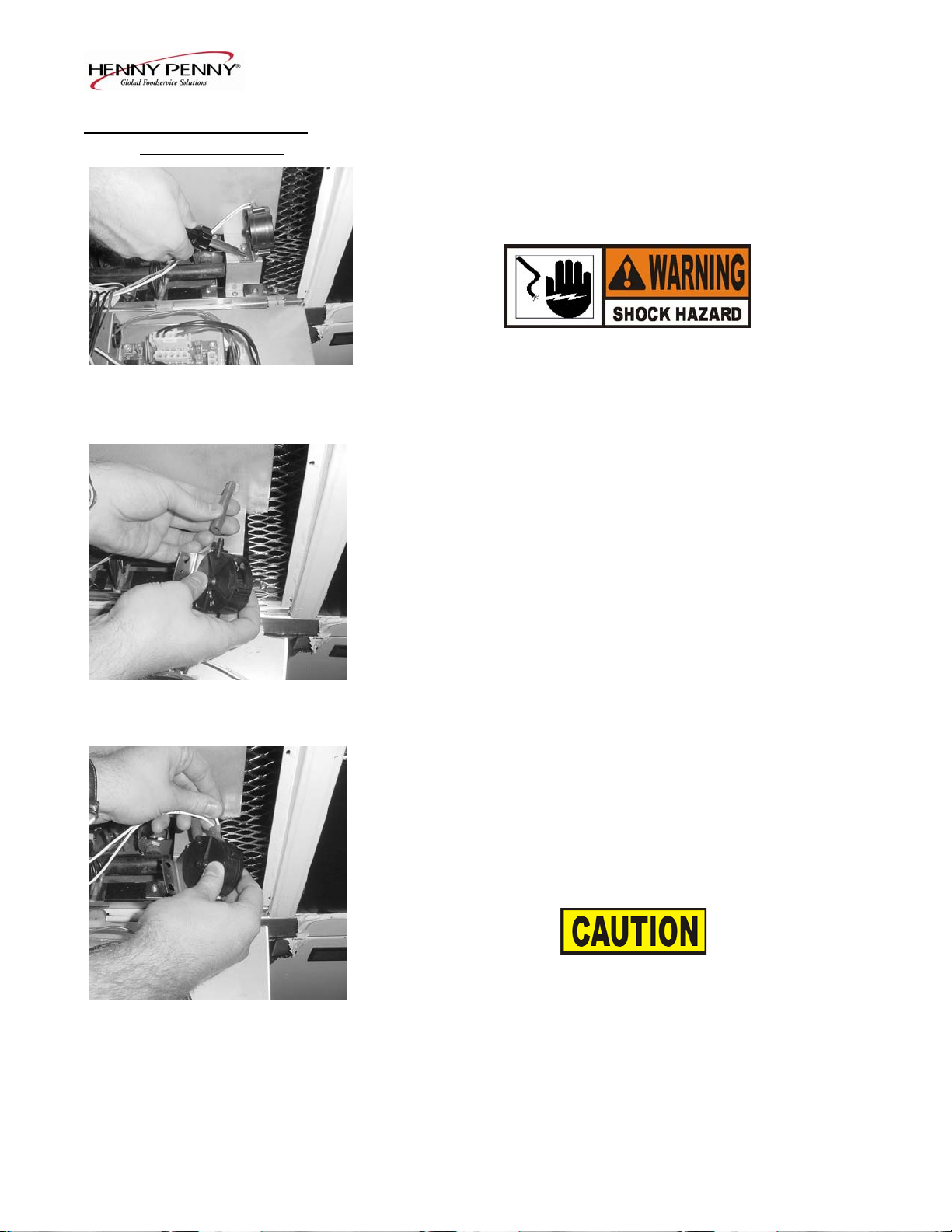

1. Remove the control panel. Figure 2-2.

Figure 2-2

1003 2-1

Page 12

Model OFE/OFG/OEA/OGA-341, 342

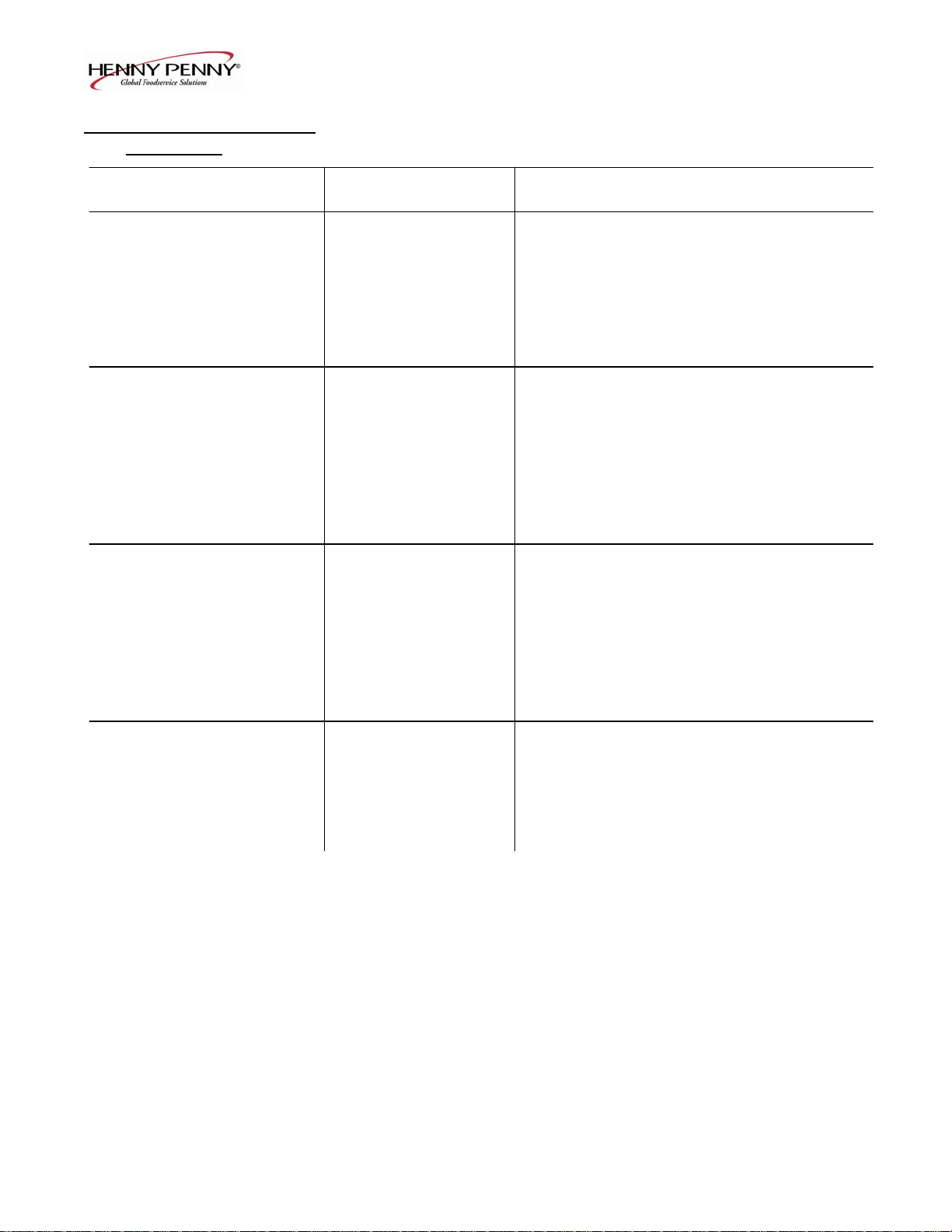

1-3. HIGH TEMPERATURE 2. Using a Phillip’s head screwdriver, remove the screws securing

LIMIT CONTROL the inner heat shield and remove from unit. Figure 2-3.

(Gas Units) (Continued)

Figure 2-3 3. Remove the screw securing the high limit bracket to the frame

and remove the high limit and bracket from unit. Figure 2-4.

Figure 2-4 4. Remove the two screws securing the high limit to the bracket

and remove the high limit from bracket.

5. Remove the two electrical wires from the high temperature

limit control. Figure 2-5.

Figure 2-5

6. Manually reset the control, then check for continuity between

the two terminals after resetting the control. If the circuit is

open, replace the control, then continue with this procedure.

(If the circuit is closed, the high limit is not defective. Re connect the two electrical wires.)

2-2 1003

Page 13

Model OFE/OFG/OEA/OGA-341, 342

2-3. HIGH TEMPERATURE

LIMIT CONTROL

(Gas Units) (Continued)

Replacement To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

1. If the tube is broken or cracked, the control opens, shutting

off electrical power to the heat circuit. The control cannot be

reset, and it continuously clicks when pushed.

2. Drain the shortening from the frypot and discard. A substance

from the tube could contaminate the shortening.

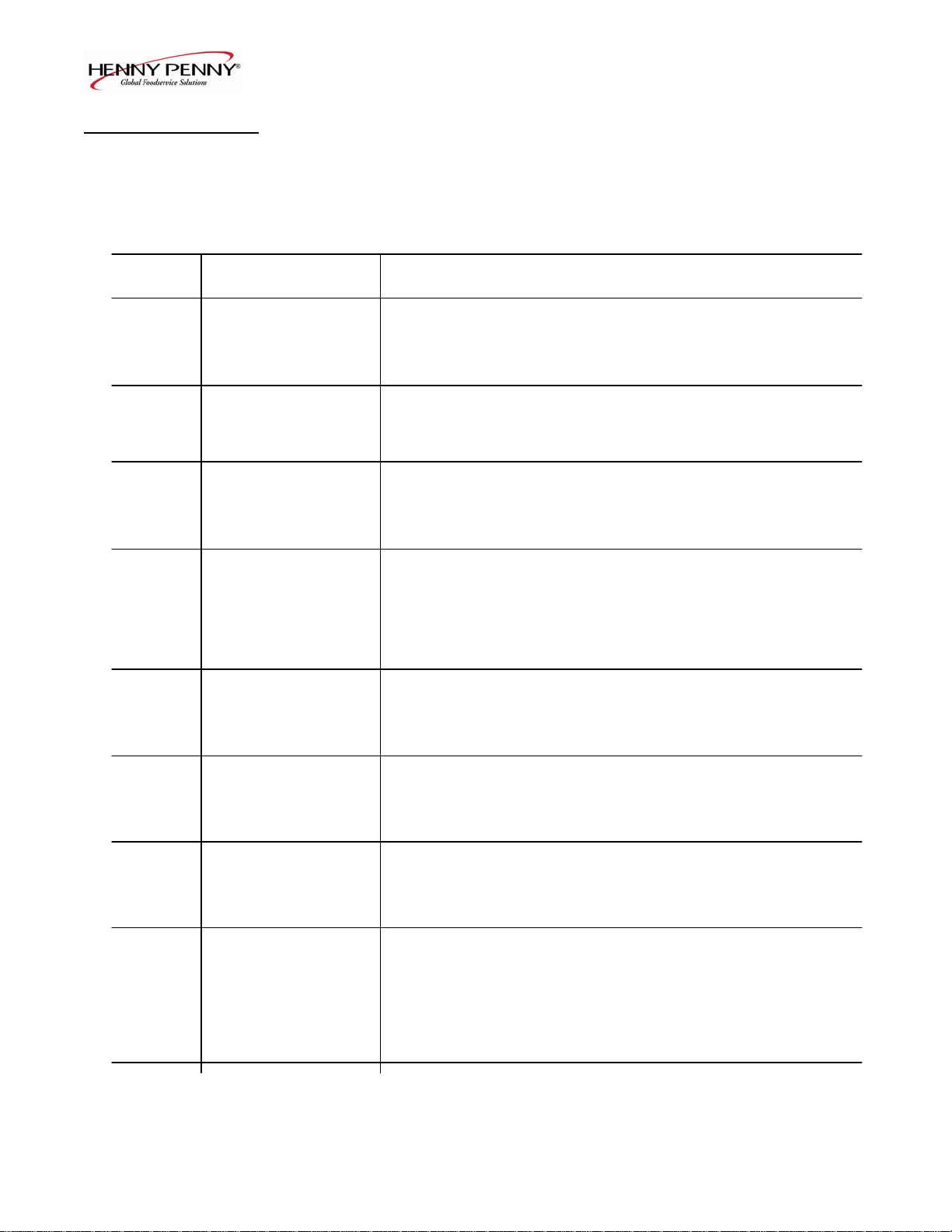

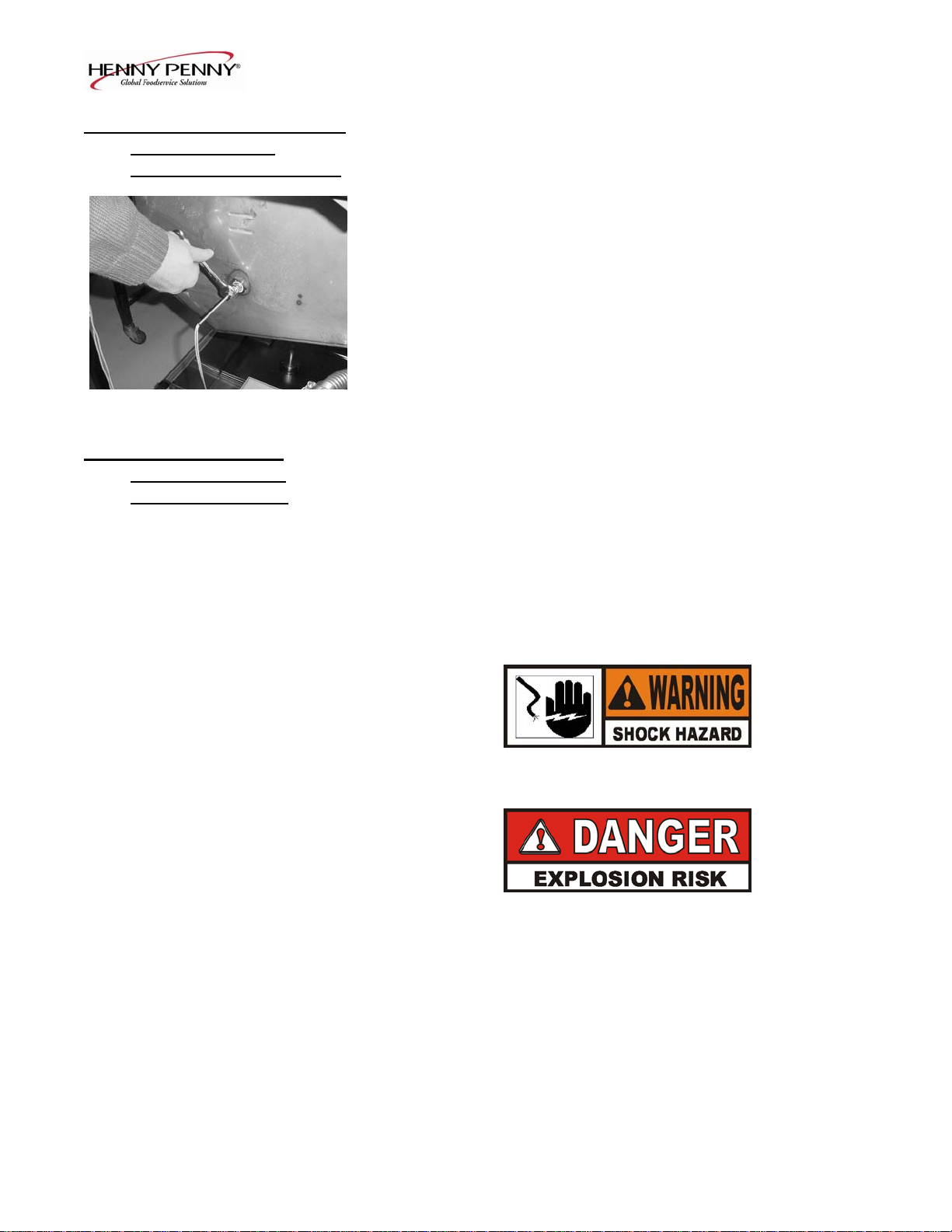

Figure 2-6 3. Remove the control panel.

4. Using a 5/16” wrench, loosen small inside screw nut on

capillary tube. Figure 2-6.

5. Using a 11/16” crows-foot, remove the larger nut securing the

capillary tube to the pot. Figure 2-7.

6. Remove the two screws securing the high limit guard and

Figure 2-7 remove guard. Figure 2-8

7. Straighten the capillary tube inside the frypot, and pull the

capillary tube through the frypot, from behind the control

panel. Remove the defective high limit from the control panel

area.

8. Replace new high limit in reverse order.

Figure 2-8

To avoid electrical shock or other injury, run the

capillary line under and away from all electrical power

wires and terminals. The tube must never

be in such a

position where it could accidentally touch the electrical

power terminals.

1003 2-3

Page 14

Model OFE/OFG/OEA/OGA-341, 342

2-4. COMPLETE CONTROL Should the control board become inoperative, follow these

PANEL REPLACEMENT instructions for replacing the board.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the two screws securing the control panel and lift out.

Figure 2-9 Figure 2-9.

3. Unplug the wire connectors going to the control panel.

Figure 2-10.

4. Remove transformer(s) from control panel. They must be

installed on the replacement panels.

5. Install new control panel in reverse order.

When plugging connectors onto new control panel, be sure the

connectors are inserted onto all of the pins, and that the

connectors are not forced onto the pins backwards. If not

Figure 2-10 connected properly, damage to the board could result.

2-5. POWER SWITCH 1. Remove electrical power supplied to fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove control panel.

3. Label and remove wires from the switch. With test instrument

Figure 2-11 check across the terminals of the switch with switch in the on

position, and the circuit should be closed. In the off position,

the circuit should be open. If the switch checks defective,

replace by continuing with this procedure. Figure 2-11.

2-4 504

Page 15

Model OFE/OFG/OEA/OGA-341, 342

2-5. POWER SWITCH (Continued)

4. With control panel removed, and the wires off the switch, push

in on tabs on the switch to remove from panel. Figure 2-12.

5. Replace with new switch, and reconnect wires to switch.

6. Replace the control panel.

Figure 2-12

2-6. TEMPERATURE PROBE The temperature probe relays the actual shortening temperature

REPLACEMENT (Gas) to the control board. If it becomes disabled, “E06” shows in the

display. Also, if the shortening temperature is out of calibration

more than 10°F or C°, the probe should be replaced. An Ohm check

can be performed also. See chart below.

1. Remove electrical power supplied to the fryer.

Figure 2-13

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Drain the shortening from the frypot.

3. Remove the control panel and heat shield from control area.

Figure 2-13.

4. Using a ½ inch wrench, remove the nut on the compression

Figure 2-14 fitting. Figure 2-14.

806 2-5

Page 16

Model OFE/OFG/OEA/OGA-341, 342

2-6. TEMPERATURE PROBE 5. Remove the probe from the frypot, and disconnect wire

REPLACEMENT (GAS) connector from the control panel. Figure 2-15.

(Continued)

6. Place the nut and new ferrule on the new probe and insert the

probe into the compression fitting until it extends one (1) inch

(2.54cm) into the frypot. Figure 2-16.

7. Tighten hand tight and then a half turn with wrench.

Figure 2-15

Excess force will damage probe.

8. Connect new probe to PC board and replace control panel.

9. Replace shortening, and turn power on to check out fryer.

Figure 2-16

2-7. TEMPERATURE PROBE The temperature probe relays the actual shortening temperature

REPLACEMENT (Gas) to the control board. If it becomes disabled, “E06” shows in the

REPLACEMENT display. Also, if the shortening temperature is out of calibration

(ELECTRIC) more than 10°F or C°, the probe should be replaced. An Ohm check

can also be performed. See chart on page 2-5.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Drain the shortening from the frypot.

Figure 2-17 3. Remove screws securing rear cover of fryer, and remove rear

cover. Figure 2-17.

2-6 1209

Page 17

Model OFE/OFG/OEA/OGA-341, 342

2-7. TEMPERATURE PROBE 4. Using a ½ inch wrench, remove the nut on the compression

REPLACEMENT fitting. Figure 2-18.

(ELECTRIC) (Continued)

5. Remove the probe from the frypot, and disconnect probe.

6. Place the nut and new ferrule on the new probe and insert the

probe into the compression fitting until it extends one (1) inch

(2.54cm) into the frypot.

7. Reconnect new probe onto wires, replace rear cover, and fryer

Figure 2-18 is now ready for use.

2-8. FLAME SENSOR/ The Henny Penny open fryer (gas) has electronic spark ignition

PILOT / IGNITOR that lights a standing pilot. The gap between the spark electrode

ASSEMBLY (GAS) and the pilot hood should be1/8 of an inch (3.18 mm). The

flame sensor recognizes the pilot flame and allows gas to continue

to the pilot. The flame sensor must send a minimum of two (2)

micro amps to the ignition module. The pilot flame should be split

in two by the flame sensor, causing the flame sensor to be bright

red in color.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

TO AVOID PERSONAL INJURY OR PROPERTY

DAMAGE, BEFORE STARTING THIS

PROCEDURE, MOVE THE MAIN POWER SWITCH

TO THE OFF POSITION. DISCONNECT THE MAIN

CIRCUIT BREAKERS AT THE CIRCUIT BREAKER

BOX OR UNPLUG SERVICE CORD FROM WALL

RECEPTACLE. TURN OFF THE MAIN GAS

SUPPLY TO THE FRYER AND DISCONNECT AND

CAP THE MAIN SUPPLY LINE TO FRYER, OR

POSSIBLE EXPLOSION COULD RESULT.

1003 2-7

Page 18

Model OFE/OFG/OEA/OGA-341, 342

2-8. FLAME SENSOR/

PILOT / IGNITOR

ASSEMBLY (Gas)

(Continued)

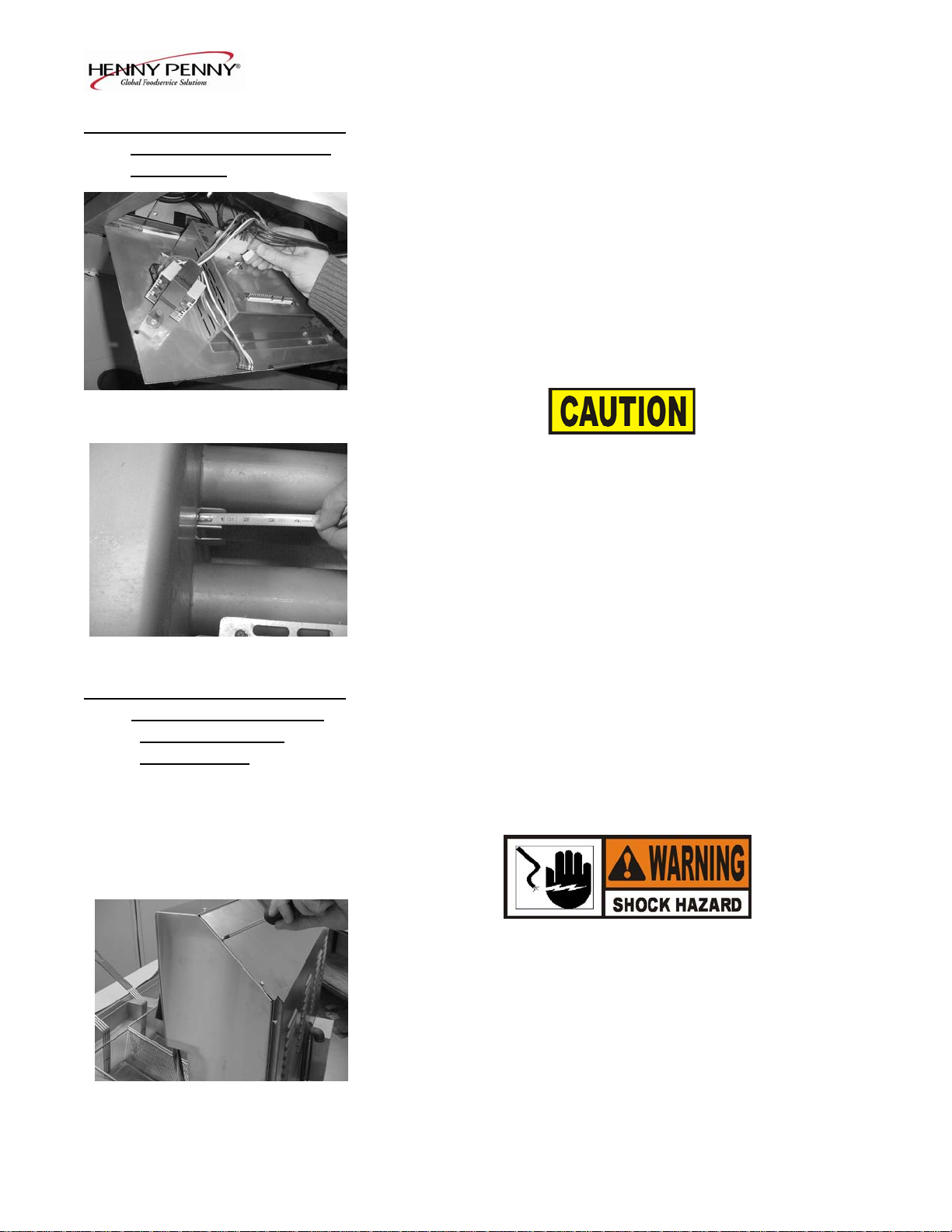

2. Remove the control panel and heat shield from control area.

Figure 2-19.

Figure 2-19

3. Disconnect the flame sense wire from ignition module.

Figure 2-20.

Figure 2-20

4. Using a 7/16” wrench, loosen the nut on the pilot tube and pull

tube from assembly. Figure 2-21.

Figure 2-21

5. Remove the two screws securing the assembly and pull

assembly from unit. Figure 2-22.

6. Now the flame sensor or or pilot assembly can be removed

from bracket.

Figure 2-22

2-8 1003

Page 19

Model OFE/OFG/OEA/OGA-341, 342

2-9. IGNITION MODULE During normal operation, the ignition modules send 24 volts to the

ignitors and gas valve. If a module does not sense a pilot flame,

the module starts the ignition process again. But, if a pilot light

goes out for longer that 10 seconds, or it goes out 3 times within 10

seconds, the module keeps the 24 volts from reaching the gas

valve. The burners shut down.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

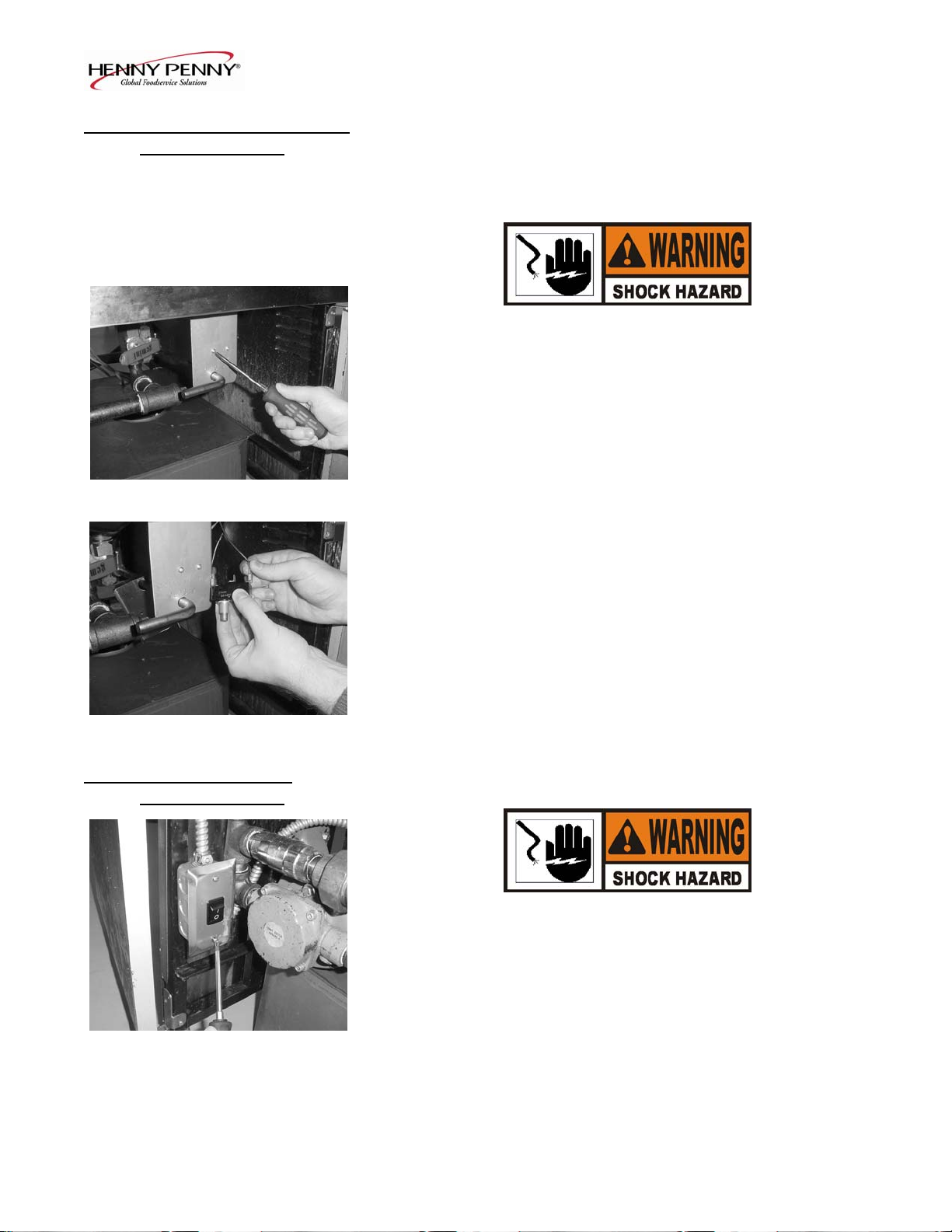

Figure 2-23 2. Remove the control panel and heat shield from control area.

Figure 2-23.

3. Using a 3/8 inch socket, remove the two nuts securing the

module. Figure 2-24.

Figure 2-24

4. Label and remove the wires at module. Figure 2-25.

5. Install new module in reverse order.

Figure 2-25

1003 2-9

Page 20

Model OFE/OFG/OEA/OGA-341, 342

2-10. TRANSFORMER The transformer reduces voltage down (to 24V) to accommodate

REPLACEMENT those components with low voltage.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel

Figure 2-26

3. Remove the two wire connectors to disconnect transformer

From panel. Figure 2-26.

4. Using a 3/8” nut-driver, remove the two nuts securing the

transformer to the panel and remove transformer. Figure 2-27.

5. Install the new transformer in reverse order.

Figure 2-27

2-11. CONTROL & I/O 1. Remove electrical power supplied to the unit.

BOARDS

REPLACEMENT

I/O Power Supply Control

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control.

3. Using a 5/16” nut-driver or wrench, remove the 4 nuts securing

the PC shield and remove shield. Figure 2-28.

4. Disconnect the wire assemblies from the appropriate board.

Figure 2-28

5. Using a 5/16” nut-driver or wrench, remove the 4 nuts securing

the appropriate board to the shroud.

6. Install the new board in reverse order.

2-10 1003

Page 21

Model OFE/OFG/OEA/OGA-341, 342

2-12. VACUUM SWITCH This switch senses the airflow from the induction blower. If

REPLACEMENT the airflow is reduced below a set amount, the switch opens and

the I/O board cuts power to the gas control valve, which shuts the

pilot flame off.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

Figure 2-29 breaker, or unplug cord at wall receptacle.

2. Remove the control panel.

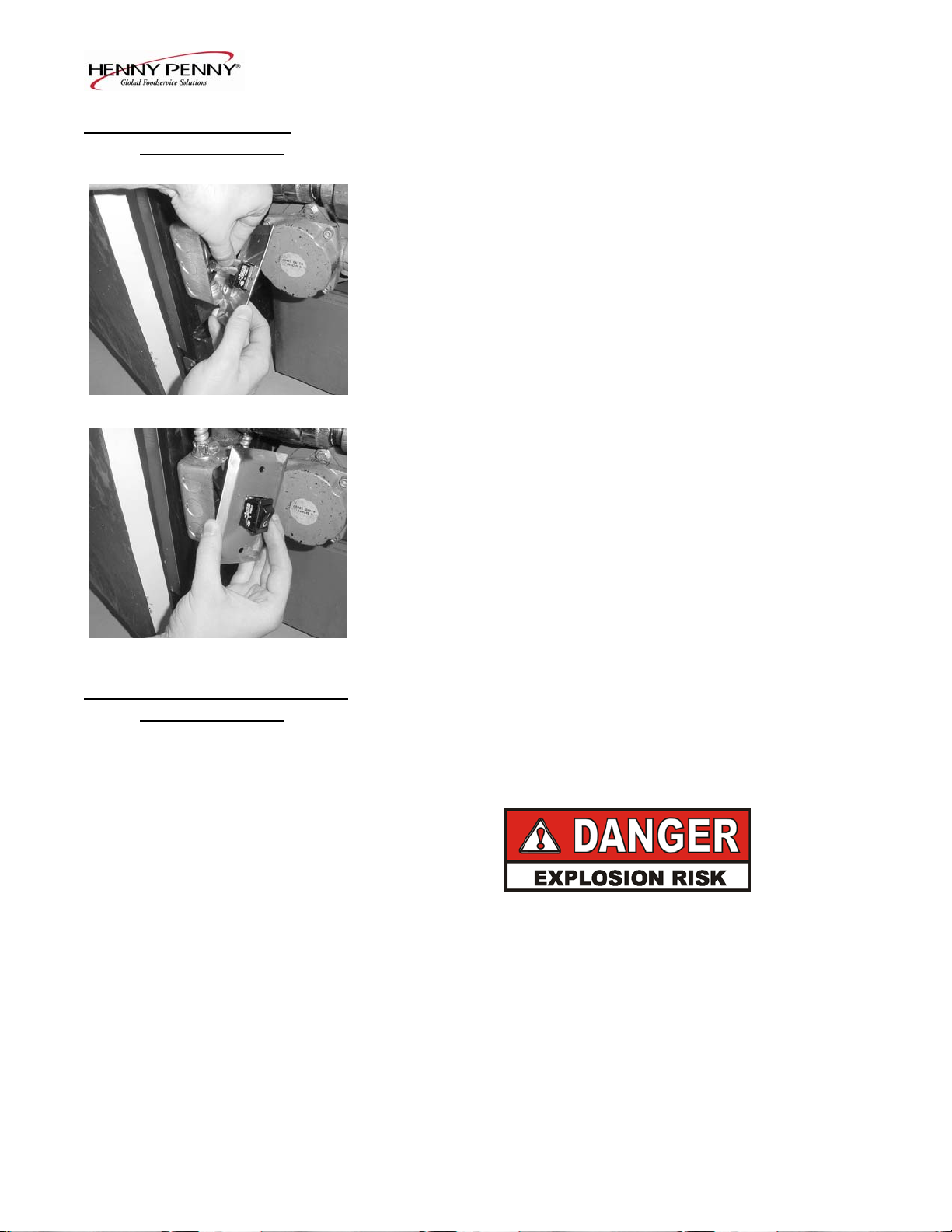

3. Remove the 2 screws securing the switch to the heat shield.

Figure 2-29.

4. Remove the air hose from the air switch. Figure 2-30.

Figure 2-30

5. Label and remove wires from air switch. Figure 2-31.

6. Install new vacuum switch in reverse order.

To avoid property damage, do not tamper with, or disas semble

this component. It is set and sealed from the factory and is not

Figure 2-31 to be adjusted.

1003 2-11

Page 22

Model OFE/OFG/OEA/OGA-341, 342

2-13. DRAIN MICROSWITCH Upon turning the drain handle, the drain microswitch should

REPLACEMENT “open”, cutting off the pilot flame. This will prevent the fryer

from heating while shortening is being drained from the frypot.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. The following check should be made to determine if the drain

microswitch is defective.

a. Remove the two screws and nuts securing the microswitch

Figure 2-32 to the drain rod valve bracket, and remove microswitch.

Figure 2-32.

b. Remove wires from the switch. Figure 2-33.

c. Check for continuity across the two outside terminals of the

drain switch. If the circuit is open, the drain switch is

defective. The circuit opens by pressing on the actuator of

the microswitch.

3. If defective, replace switch in reverse order.

Figure 2-33

2-14. FILTER SWITCH

REPLACEMENT

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Open the door (left door on 2 well units), and remove the 2

Figure 2-34 screws securing the switch box cover. Figure 2-34.

2-12 1003

Page 23

Model OFE/OFG/OEA/OGA-341, 342

2-14. FILTER SWITCH 3. Label and remove the wires from the switch. With test

REPLACEMENT instrument check across the terminals of the switch. With the

(Continued) switch in the on position, the circuit should be closed. With the

switch in the off position, the circuit should be open. If the

switch is defective, replace by continuing with this

procedure. Figure 2-35.

Figure 2-35

4. With wires removed from the switch, push in on tabs on the

switch and remove switch from front of switch box cover.

Figure 2-36.

5. Push new switch into panel and reconnect wires.

Figure 2-36

2-15. GAS CONTROL VALVE The gas valve assembly controls the flow of gas to the pilot and the

REPLACEMENT main burner. The valve has two 24-volt coils, which are regulated

by the P and M terminals on the valve. The C terminal is the

common terminal. For gas flow to the pilot, 24 VAC must be

present between the P and C terminals. For gas flow to the main

burner, 24 VAC must be present between the M and C terminals.

TO AVOID PERSONAL INJURY OR PROPERTY

DAMAGE, BEFORE STARTING THIS

PROCEDURE, MOVE THE MAIN POWER SWITCH

TO THE OFF POSITION. DISCONNECT THE MAIN

CIRCUIT BREAKERS AT THE CIRCUIT BREAKER

BOX OR UNPLUG SERVICE CORD FROM WALL

RECEPTACLE. TURN OFF THE MAIN GAS

SUPPLY TO THE FRYER AND DISCONNECT AND

CAP THE MAIN SUPPLY LINE TO FRYER, OR

POSSIBLE EXPLOSION COULD RESULT.

1003 2-13

Page 24

Model OFE/OFG/OEA/OGA-341, 342

2-15. GAS CONTROL VALVE

REPLACEMENT

(Continued)

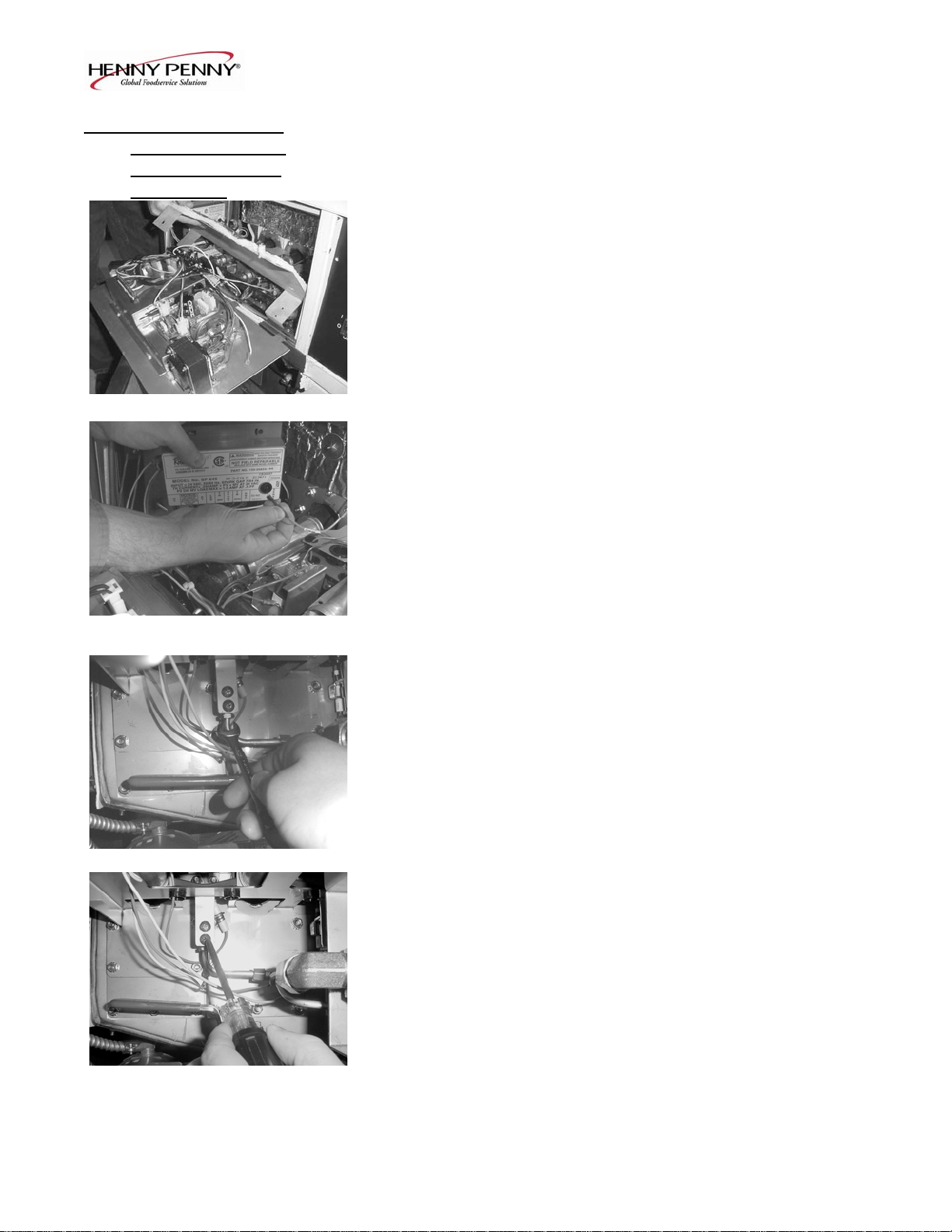

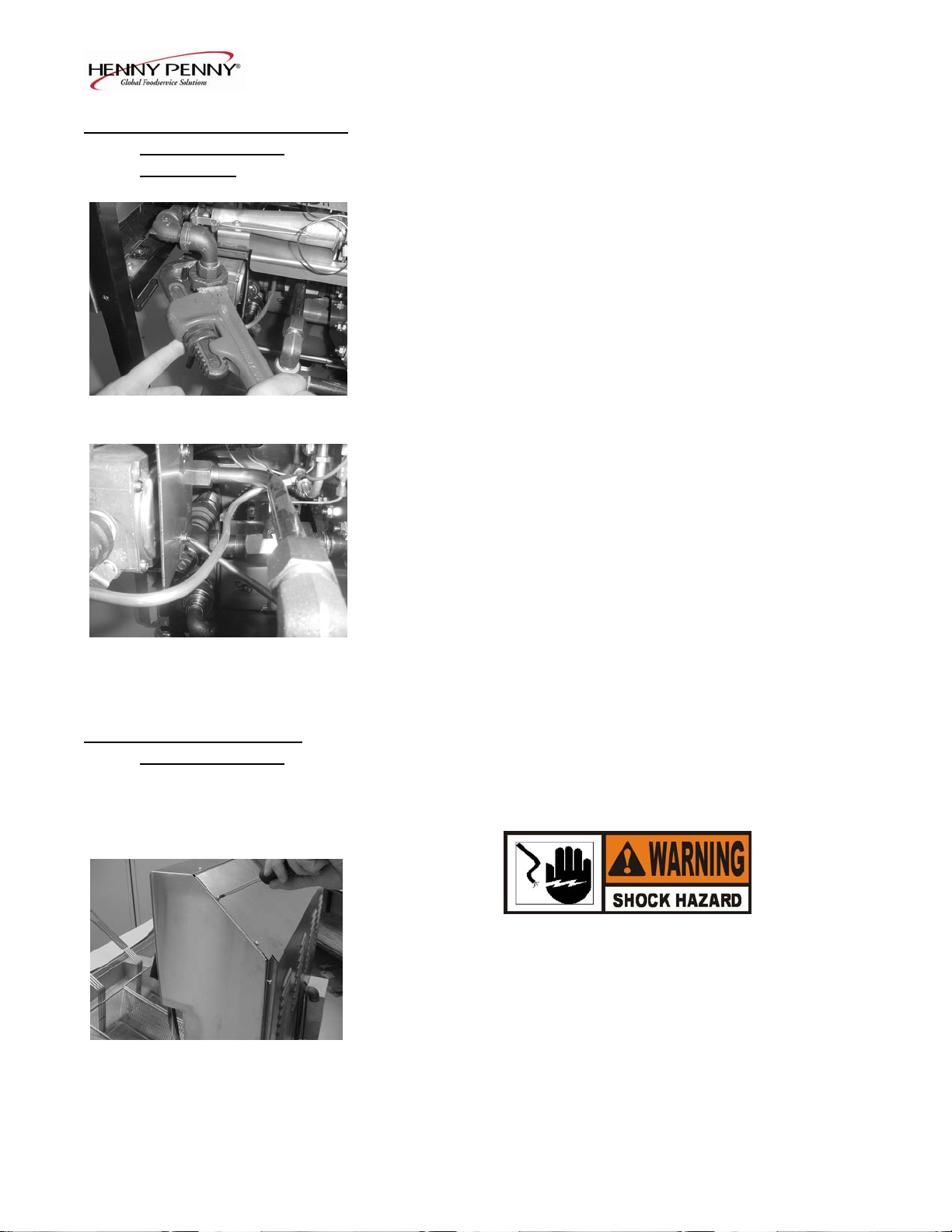

1. Remove right side panel. Figure 2-37.

Figure 2-37

2. Label and remove wires from gas valve. Figure 2-38

Figure 2-38

3. Using a 7/16 wrench, remove the pilot line from the gas valve.

Figure 2-39.

Figure 2-39

4. Using a 1-inch wrench, loosen the nut securing the main gas

inlet line to the gas valve. Figure 2-40.

Figure 2-40

2-14 1003

Page 25

Model OFE/OFG/OEA/OGA-341, 342

2-15. GAS CONTROL VALVE

REPLACEMENT

(Continued)

5. Using a pipe wrench, loosen the outlet fitting to the burner.

Figure 2-41.

Figure 2-41

6. Using a Phillips screwdriver, remove the 2 screws securing

the gas valve to the bracket and remove gas valve from unit.

Figure 2-42.

7. Remove the fittings from the gas valve and install in new gas

valve.

Figure 2-42

8. Install the new gas valve in reverse order.

2-16. BLOWER MOTOR The blower motor assembly induces the draft for the burners. If the

REPLACEMENT blower motor fails, the air switch will fail to close, causing an

“E-20B” error code in the display.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove screws securing the rear cover to the unit.

Figure 2-43 Figure 2-43.

106 2-15

Page 26

Model OFE/OFG/OEA/OGA-341, 342

2-16. BLOWER MOTOR

REPLACEMENT

(Continued)

3. Remove the wire cover from the blower motor housing.

Figure 2-44.

Figure 2-44

4. Remove wire nuts connecting blower motor wires to wires in

conduit. Figure 2-45.

Figure 2-45

5. Loosen conduit from blower motor. Figure 2-46.

Figure 2-46

7. Remove screws connecting flue to blower. Figure 2-47.

Figure 2-47

2-16 1003

Page 27

Model OFE/OFG/OEA/OGA-341, 342

2-16. BLOWER MOTOR

REPLACEMENT

(Continued)

8. Using 3/8 inch nut driver, remove nuts securing blower to the

unit. Figure 2-48. Pull blower from unit.

Figure 2-48 9. Install new blower in reverse order.

2-17. HEATING ELEMENTS

(ELECTRIC)

Heating elements are available for 208 and 230 voltage. Check

data plate to determine correct voltage.

Checkout If the shortening temperature recovery is very slow or at a slower

rate than required, this may indicate defective heating element(s).

An ohmmeter quickly indicates if the elements are shorted or open.

1. Remove electrical power supplied to the frypot to be checked

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle, to the frypot

to be worked on. Be aware the other control on 2-frypot

Figure 2-49 units will have power.

2. Remove rear cover. Figure 2-49.

3. Using a flat-head screwdriver, remove the appropriate wires

from the terminal blocks. Figure 2-50.

Figure 2-50

106 2-17

Page 28

Model OFE/OFG/OEA/OGA-341, 342

2-17. HEATING ELEMENTS 4. Perform an ohm check on one element at a time, with wires

(ELECTRIC) disconnected. The 2 elements actually have 3 small heating

(Continued) elements inside the outer plate. It’s important to check

between the correct wires to obtain an accurate ohm reading.

The wires are labeled for your convenience. If the resistance

is not within tolerance, replace the element.

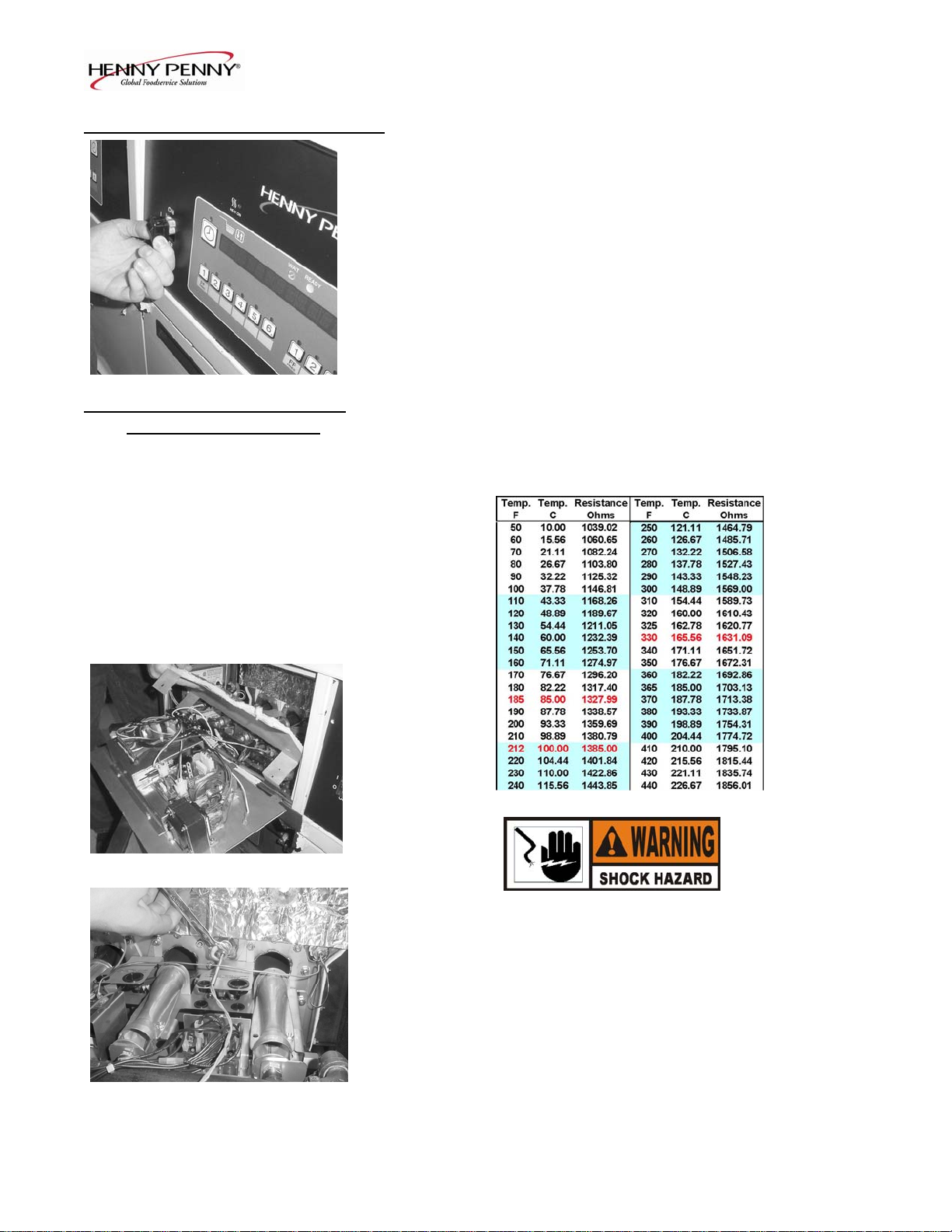

Wire Nos. Voltage Wattage Ohms (cold)

1L1 to 1L1 208 11000 11.7

1L2 to 1L2 208 11000 11.7

1L3 to 1L3 208 11000 11.7

1L1 to 1L1 240 11000 15.7

1L2 to 1L2 240 11000 15.7

1L3 to 1L3 240 11000 15.7

Replacement 1. Drain the shortening from the frypot

2. Remove the high limit bulb holder from the heating

element inside the frypot. See High Limit Temperature

Control-Electric Section.

3. Using a Phillip’s-head screwdriver, remove the screws

securing the element to the element hinges. Figure 2-51.

4. Pull element from fryer and replace with new element,

following steps in reverse order.

5

. Connect the power cord to the wall receptacle or close wall

Figure 2-51 circuit breaker.

Heating elements should never be energized without

shortening in the frypot, or damage to the elements could

result.

6. Replace the shortening in the frypot, and unit is ready for

operation.

2-18

1003

Page 29

Model OFE/OFG/OEA/OGA-341, 342

2-18. HEATING Each well of an electric fryer requires two switching contactors.

CONTACTORS The first in line is the primary contactor and the second in line is

(ELECTRIC) the heat contactor. When open, the primary contactor does not

allow power to flow to the heat contactor. When closed, the

primary supplies voltage to the heat contactor. When the heat

contactor is open, no voltage is supplied to the heating elements.

When the heat contactor closes, voltage is supplied to the heating

elements.

Checkout (Power Removed) 1. Remove electrical power supplied to frypot to be worked on.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle, to the frypot

to be worked on. Be aware the other control on 2-frypot

Heat Contactor units will have power.

(Mercury)

2. Remove the control panel.

30 31 32

3. Perform a check on the contactor as follows:

From 23 to 29 open circuit

From 24 to 28 open circuit

From 25 to 27 open circuit

33

37

Test Points Results

From 30 to 34 open circuit

From 31 to 35 open circuit

From 32 to 36 open circuit

34 35 36 From 33 to 37 ohm reading 1700

Figure 2-52 From 22 to 26 ohm reading 415

Wires should be removed and labeled to obtain an accurate

check of contactors.

Figure 2-53

1003 2-19

Page 30

Model OFE/OFG/OEA/OGA-341, 342

2-18. HEATING

CONTACTORS

(ELECTRIC)

(Continued)

To avoid electrical shock, make connections before

applying power, take reading, and remove power before

removing meter leads. The following checks are

performed with the wall circuit breaker closed and the

main power switch in the ON position.

1. Re-apply power to unit and turn power switch to ON.

2. Using illustrations from previous page, check voltage as

follows:

Test Points Results

Heat Contactor

From terminal 34 to 35 The voltage should read

From terminal 35 to 36 the same at each terminal

From terminal 34 to 36

Test Points

Primary Contactor

From terminal 27 to 28 It should correspond to the

From terminal 28 to 29 voltage stated on the data

From terminal 27 to 29 plate.

Replacement If neither contactor is defective it must be replaced as follows:

(Heat Contactor)

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle, to the frypot

to be worked on. Be aware the other control on 2-frypot

units will have power.

1. Remove only the wires directly connected to the contactor

Figure 2-54 being replaced. Label the wires for replacement. Figure 2-54.

2-20 1003

Page 31

Model OFE/OFG/OEA/OGA-341, 342

2-18. HEATING

CONTACTORS

(ELECTRIC)

Continued)

2. Remove the screws securing the contactor to the shroud, and

remove contactor. Figure 2-55.

3. Install new contactor, and see steps 4 and 5.

Figure 2-55

Replacement

(Primary Contactor)

1. Remove only the wires directly connected to the contactor

being replaced. Label the wires for replacement. Figure 2-56.

2. Remove screws securing contactor to unit and remove

contactor. Figure 2-57.

Figure 2-56

3. Install new contactor.

4. Reinstall the control panel.

1003 2-21

Figure 2-57

5. Reconnect power to the fryer and test for proper operation.

Page 32

Model OFE/OFG/OEA/OGA-341, 342

2-19. SPEAKER ASSEMBLY The speaker assembly emits audible signals to let the operator

know when cooking and hold times are finished.

1. Remove electrical power supplied to unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

Figure 2-58 breaker, or unplug cord at wall receptacle.

2. Remove control panel.

3. Pull the power switch connector from back of panel.

Figure 2-58.

Figure 2-59

4. Pull the transformer connectors from back of panel.

Figure 2-59.

Figure 2-60 5. Using a 5/16” nutdriver or wrench, remove the 4 nuts securing

the PC board shield and pull shield from studs. Figure 2-60.

6. Pull the speaker connector from control board. Figure 2-61.

Figure 2-61

7. Using a 5/16” nut-driver or wrench, remove the 2 nuts securing

the speaker to the shield and remove speaker from panel.

Figure 2-62

8. Install new speaker in reverse order.

Figure 2-62

2-22 1003

Page 33

Model OFE/OFG/OEA/OGA-341, 342

2-20. HIGH TEMPERATURE This high temperature control is a safety, manual reset control,

LIMIT CONTROL which senses the temperature of the shortening. If the short (ELECTRIC) ening temperature exceeds 425°F (218°C), this switch opens

and shuts off heat to the frypot, and E10 shows in control display.

When the temperature of the shortening drops to a safe operation

reset the high limit by pressing the reset button. The reset

button is located behind the frypot, in the element hinge. A small

instrument, such as a Phillip’s head screwdriver, or Allen wrench

must be used to reset the high limit. This allows heat to be

supplied to the frypot once again. See Figure 2-63.

Before replacing a high temperature limit control, check to see

that its circuit is closed.

Figure 2-63

The shortening temperature must be below 380°F (193°C)

to accurately perform this check.

1. Remove electrical power supplied to fryer.

Checkout To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove rear cover of fryer. Figure 2-64.

Figure 2-64

3. Remove the two screws securing the high limit to the bracket

and pull high limit from bracket. Figure 2-65.

Figure 2-65

106 2-23

Page 34

Model OFE/OFG/OEA/OGA-341, 342

2-20. HIGH TEMPERATURE

LIMIT CONTROL

(ELECTRIC)

(Continued)

4. Pull back cardboard cover and remove the two electrical wires

from the high temperature limit control. Figure 2-66.

Figure 2-66 5. Manually reset the control, then check for continuity between

the two terminals after resetting the control. If the circuit is

open, replace the control, then continue with this procedure.

(If the circuit is closed, the high limit is not defective. Re connect the two electrical wires.)

Replacement

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle, to the frypot

to be worked on. Be aware the other control on 2-frypot

units will have power.

1. Drain the shortening from the frypot.

Figure 2-67

2. Remove capillary from brackets on upper part of element.

Figure 2-67.

3. Remove capillary bulb from bulb holder inside the frypot.

Figure 2-68

2-24 1003

Page 35

Model OFE/OFG/OEA/OGA-341, 342

2-20. HIGH TEMPERATURE

LIMIT CONTROL

(ELECTRIC)

(Continued)

4. Straighten the capillary tube, and pull capillary tube through

the hole in the element hinge, from the rear of the fryer.

5. Remove the defective control from the fryer.

Figure 2-69 6. Straighten the capillary tube on the new high limit, and thread

the capillary tube through the hole in the element hinge.

Figure 2-69.

7. Reattach the capillary to the brackets on the upper and lower

parts of the elements.

DO NOT crimp or kink the capillary tube during installation.

Also, keep capillary tube behind element to protect from

damage from the basket or during cleaning. Damage to the

capillary tube reduces the life of the high limit, or causes the

high limit to fail.

8. Connect wires to new high limit body and fasten to bracket,

using the two screws removed in the checkout part of this

section.

Make sure red reset button of high limit lines up with the

plunger that inserts into the element hinge.

To avoid electrical shock or other injury, run the capillary

line under and away from all electrical power wires and

terminals. The tube must never be in such a position

where it could accidentally touch the electrical power

terminals

9. Re-install the rear cover and unit is now ready for use.

1003 2-25

Page 36

Model OFE/OFG/OEA/OGA-341, 342

2-21. FILTER PUMP AND 1. Remove electrical power supplied to unit.

MOTOR REMOVAL

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Open the door (left door on 2 well units), and remove the 2

screws securing the switch box cover and pull filter motor

wires from filter switch. Figure 2-70.

Figure 2-70

3. Remove the 2 screws securing the switch box to the frame.

Figure 2-71

Figure 2-71

4. Loosen screws on conduit connector and pull conduit from the

connector. Figure 2-72.

5. Disconnect filter union to filter in drain pan.

Figure 2-72

6. Using a pipe wrench, disconnect the outlet pipe to frypot.

Figure 2-73.

Figure 2-73

2-26 1003

Page 37

Model OFE/OFG/OEA/OGA-341, 342

2-21. FILTER PUMP AND 7. Remove left side panel.

MOTOR REMOVAL

(Continued)

8. Using 9/16” socket or wrenches, remove the bolts and nuts

securing the motor to the bracket and pull pump, motor, and

piping from unit. Figure 2-74.

Figure 2-74

2-22. AUTOLIFT 1. Remove electrical power supplied to unit.

TRANSFORMER

REPLACEMENT

(if applicable)

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove control panel.

3. Label and remove wires from transformer. Figure 2-75.

Figure 2-75

4. Using 3/8” nut-driver or wrench, remove nuts securing

transformer to panel and remove transformer from panel.

Figure 2-76.

5. Install new transformer in reverse order.

Figure 2-76

1003 2-27

Page 38

Model OFE/OFG/OEA/OGA-341, 342

2-23. AUTOLIFT PC BOARD 1. Remove electrical power supplied to unit.

REPLACEMENT

(if applicable)

Autolift PC Board

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove control panel

3. Disconnect connectors from PC board.

4. Using 5/16” nut-driver or wrench, remove the 4 nuts securing

Figure 2-77 the autolift PC board to the panel and remove PC board from

panel.

5. Install new panel in reverse order.

2-24. AUTOLIFT

1. Remove electrical power supplied to unit.

ACTUATOR (MOTOR)

REPLACEMENT

(if applicable)

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Drain shortening from frypot.

Figure 2-78 3. Remove basket and knock pin from basket hanger. Figure 2-78.

4. Remove rear cover. Figure 2-79.

Figure 2-79

2-28 106

Page 39

Model OFE/OFG/OEA/OGA-341, 342

2-24. AUTOLIFT

ACTUATOR (MOTOR)

REPLACEMENT

(if applicable)

5. Disconnect actuator connector. Figure 2-80.

Figure 2-80

6. Remove female connector from plate. Figure 2-81.

Figure 2-81

Figure 2-82 7. Using 7/16” socket, remove the 4 nuts securing the support

plate. 2 nuts are behind the insulation. Figures 2-82 & 2-83.

Figure 2-83

1003 2-29

Page 40

Model OFE/OFG/OEA/OGA-341, 342

2-24. AUTOLIFT

ACTUATOR (MOTOR)

REPLACEMENT

(if applicable)

8. Remove the 2 top screws securing the support plate and

remove the plate from the unit. Figure 2-84.

Figure 2-84

9. Using a 15T torx driver, remove the 2 torx screws from

the back shroud, and pull the actuator from the unit.

Figure 2-85.

Figure 2-85 10. Install new actuator in reverse order.

2-30 1003

Page 41

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/C

106 2-31

Page 42

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/C

2-32 106

Page 43

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/C

106 2-33

Page 44

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/C

2-34 106

Page 45

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/C

106 2-35

Page 46

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/C

2-36 106

Page 47

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/C

106 2-37

Page 48

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/C

2-38 106

Page 49

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/O

106 2-39

Page 50

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/O

2-40 106

Page 51

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/O

707 2-41

Page 52

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/O

2-42 106

Page 53

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/O

707 2-43

Page 54

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/O

2-44 707

Page 55

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/O

707 2-45

Page 56

Model OFE/OFG/OEA/OGA-341, 342

Drain switch wired N/O

2-46 106

Page 57

Model OFE/OFG/OEA/OGA-341, 342

SECTION 3. PARTS INFORMATION

3-1. INTRODUCTION This section list the replaceable parts of the Henny Penny

OFE/OFG- 32X Open Fryers.

3-2. GENUINE PARTS Use only genuine Henny Penny parts in your fryer. Using a part of

lesser quality or substitute design may result in damage to the unit

or personal injury.

3-3. WHEN ORDERING

PARTS Once the parts that you want to order have been found in the parts

list; write down the following information:

Item number 3

Part number 60783 example:

Description Vacuum Switch

From the data plate, list the following information:

Product number OFG341.0

Serial number 0001 example:

Voltage 120

3-4 PRICES Your distributor has a price parts list and will be glad to inform

you of the cost of your parts order.

3-5 DELIVERY Commonly replaced items are stocked by your distributor and will

be sent to you when your order is received. Other parts will be

ordered, by your distributor, from Henny Penny Corporation.

Normally, these will be sent to your distributor within three

working days.

3.6 WARRANTY

All replacement parts (except lamps and fuses) are warranted for

90 days against manufacturing defects and workmanship. If

damage occurs during shipping, notify the carrier at once so that

a claim may be properly filed. Refer to warranty in the front of this

manual for other rights and limitations.

3.7 RECOMMENDED Recommended replacement parts, stocked by your distributor, are

SPARE PARTS FOR

indicated with √ in the parts lists. Please use care when ordering

DISTRIBUTORS recommended parts, because all voltages and variations are

marked. Distributors should order parts based upon common

voltages and equipment sold in their territory.

106 3-1

Page 58

Model OFE/OFG/OEA/OGA-341, 342

1 2 3 4 5

Item No. Part No. Description Qty. per Well

√ 1 60207 Transformer – 120-24V 1

√ 1 60536 Transformer – 230-24V 1

√ 2 50290 Autolift PC Board 1

√ 3 54561 Speaker Assy. 1

√ 4 72515 Vacuum Switch (Gas Only) 1

√ 5 TS22-012 Transformer-Autolift 1

√ recommended parts

3-2 807

Page 59

Model OFE/OFG/OEA/OGA-341, 342

Gas Components

1 2 3 4 5

Item No. Part No. Description Qty. per Well

√ 1 77602

Ignition Module – CE (OFG-SN: BR0804001 & Above) 2

(OGA-SN: BS0805001 & Above)

√ 1 77839 Ignition Module – Non -CE

(OGA-SN: BS0805001 & Above)

(OFG-SN: BR0804001 & Above)

2

√ 1 14933 Kit - Ignition Module – Non-CE 1

(OGA-SN: BS0804002 & Below)

(OFG-SN: BR0803010 & Below)

√ 1 14920 Kit - Ignition Module – CE 1

(OGA-SN: BS0804002 & Below)

(OFG-SN: BR0803010 & Below)

√ 2 60241 High Limit 1

√ 3 60818 Relay – 10A-24V 2

√ 4 14849 Temperature Probe Assy. 1

5 60202 Vacuum Switch Hose 1

6* 32792 Assy – Gas Line (Flex) – 342 1

√ recommended parts/*not shown

1109 3-3

Page 60

Model OFE/OFG/OEA/OGA-341, 342

Gas Burner Assembly

Item No. Part No. Description Qty. per Well

1 FP01-091 Union – ½ NPT Female - BI 1

2 FP01-088 Elbow – Street ½ x 90 BI 2

3 NS03-067 Nut – Locking ½-20 x 3/16 LON 3

4 23389 Weldment - Manifold 1

5 64055-03 Orifices – Burner - LP 3

5 64055-16 Orifices – Burner – Nat. 3

6 21629 Bracket – High Limit Mounting 1

7 60032 Burner – Inshot 3

8 23118 Stud Assy – Burner Bracket – 34X 1

3-4 106

Page 61

Model OFE/OFG/OEA/OGA-341, 342

Electric Components

1 2 3 4 5

Item No. Part No. Description Qty. per Well

√ 1 29510 Mercury Contactor – 24V 1

√ 2 51795 Standard Contactor – 24V 1

√ 2 65075 Assy.-240v E/M Heat Contactor-CE-240V (UK) 1

√ 2 65074 Assy.-240v E/M Heat Contactor-CE-230V 1

√ 3 18364 Fuse and Holder Assembly (SN: BC0707002 & below) 2

√ 3 EF02-007 Fuse – 15 Amp 2

√ 3 EF02-006 Fuse Holder – 15 Amp 2

√ 3 EF02-125 Breaker – Push Button Reset (SN: BC0707003 & above)2

√ 3 EF02-105 Fuse – 15 Amp – CE 2

√ 3 EF02-104 Fuse Holder – 20 Amp – CE 2

√ 4 14970 Fuse-Class “G” – 60 Amp (Set of 3) 1

5 60722 Block-Fuse – 60 Amp 1

6* 19923 Transformer – Large – 480V 1(per unit)

7* 60838 Transformer-.05 KVA, 480-240V 1(per 342)

√ recommended parts/*not shown

707 3-5

Page 62

Model OFE/OFG/OEA/OGA-341, 342

1 2

Item No. Part No. Description Qty. per Well

1 60367 Guard - High Limit 1

√ 2 14849 Temperature Probe Assembly (Gas units) 1

√ recommended parts

3-6 806

Page 63

Model OFE/OFG/OEA/OGA-341, 342

806 3-7

Page 64

Model OFE/OFG/OEA/OGA-341, 342

Item No. Part No. Description Qty. per Unit

1 14671 Screen Assembly, Filter 1

2 65211 Crumb Catcher 1

3 use 14671 Top Filter Screen 1

4 use 14671 Bottom Filter Screen - SN: BR0502006 & below) 1

4 65447 Bottom Filter Screen - SN: BR0502007 & above) 1

5 17505 Filter Envelope Clips 2

√ 6 12102 Filter Envelope Paper (100 per Carton) 1

7 24769 Drain Pan Cover - 341-Before Jan. 1, 2006 1

7 70491 Drain Pan Cover - 341-Jan. 1, 2006 & After 1

7 24770 Drain Pan Cover - 342-Before Jan. 1, 2006 1

7 70493 Drain Pan Cover - 342-Jan. 1, 2006 & After 1

7 36223 Cover-Single Capacity Pan-342-Before Jan. 1, 2006 1

7 70587 Cover-Single Capacity Pan-342-Jan. 1, 2006 & After 1

8 24297 Drain Pan/Handle Assy. - 341-Before Jan. 1, 2006 1

8 70378 Drain Pan/Handle Assy. - 341-Jan. 1, 2006 & After 1

8 24298 Drain Pan/Handle Assy. - 342-Before Jan. 1, 2006 1

8 70245 Drain Pan/Handle Assy. - 342-Jan. 1, 2006 & After 1

8 36225 Assy.–342 Single Well Capacity Pan-Before Jan. 1, 2006 1

8 70581 Assy.–342 Single Well Capacity Pan-Jan. 1, 2006 & After 1

9 14656 Kit - Tube - Pick-up - 341-Before Jan. 1, 2006 1

9 14726 Kit-Tube-Pick-up-341-Short-Jan. 1, 2006 & After 1

9 14657 Kit - Tube - Pick-up - 342-Before Jan. 1, 2006 1

9 14727 Kit-Tube-Pick-up-342-Short-Jan. 1, 2006 & After 1

√ 10 use 69289 Union - Female Fitting 1

11 67799 Tube - Pick-up - 341-Before Jan. 1, 2006 1

11 70382 Tube - Pick-up - 341-Short-Jan. 1, 2006 & After 1

11 21044 Tube - Pick-up - 342-Before Jan. 1, 2006 1

11 70384 Tube - Pick-up – 342-Short-Jan. 1, 2006 & After 1

12 65208 Nut - Filter 1

13 74320 Cover - Frypot – Gas & Electric 1(per well)

14 21039 Rack - Electric 1(per well)

14 21040 Rack - Gas 1(per well)

15 32794 Handle – Wire Rack Removal 1

16 03498 Filter Pan Dolly – 341 - Before Jan. 1, 2006 1

16 03551 Filter Pan Dolly – 341-Short - Jan. 1, 2006 & After 1

16 03499 Filter Pan Dolly – 342 - Before Jan. 1, 2006 1

16 03552 Filter Pan Dolly – 342-Short - Jan. 1, 2006 & After 1

17 03003 Assy - Filter Rinse Hose 1

√ recommended parts

3-8 607

Page 65

Model OFE/OFG/OEA/OGA-341, 342

1 2 3 4 5 6 7 8 9 15 10 14 11 12 13

Item No. Part No. Description Qty. per Unit

1 52064 Caster-4 inch – swivel w/brake 2

√ 2 43768 Switch - Power DPST 125-250V (Filter) 1

√ 2 52224 Covered Power Switch - CE 1

3 17334 Quick Disconnect – Male - 341 1

3 17333 Quick Disconnect – Female - 342 1

4 21800 Valve-3/4 inch Check 1

5 67589 Assy. - 5 GPM Pump & Motor - 4/1/06 & After 1

5 69357 Assy. - 8 GPM Pump & Motor - Before 4/1/06 1

5 64218 Filter Pump Assy. – 8 GPM - Before 4/1/06 1

5 17437 Filter Pump Assy. – 5 GPM - 4/1/06 & After 1

6 67583 Filter Pump Motor – ½ hp 1

√ * 17476 Seal Kit 1

7 21816 Rod - Drain Valve (normally closed) 1

7 66124 Rod - Drain Valve - Elec. (normally open) 1

7 68558 Rod - Drain Valve - Gas (normally open) 1

7 70963 Rod - Drain Valve - Gas (normally open) - CE 1

√ 8 18227 Microswitch – Drain (behind bracket) 1 (per well)

9 60312 Caster-4 inch 2

√ 10 17432(use 69289) Union - Handle Fitting 1

11 55152 Drain Valve and Coupling Assy. 1 (per well)

√ recommended parts/*not shown (Continued)

607 3-9

Page 66

Model OFE/OFG/OEA/OGA-341, 342

Item No. Part No. Description Qty. per Unit

√ 12 52129 Gas Valve - 24V - Nat. 1 (per well)

√ 12 60632 Gas Valve - 24V - Nat. - CE 1 (per well)

√ 12 21332 Gas Valve - 24 V - LP 1 (per well)

√ 12 60633 Gas Valve - 24V - LP - CE 1 (per well)

13 23443 Weld Assy. – Drain Extension – Elec. 1 (per well)

13 24420 Weld Assy. – Drain Extension – Gas 1 (per well)

14 17431(use 69289) Union - Male Fitting 1

15 32734 Flexible Hose (before 4-26-04) 1

15 67621 341 Pump Tube (SN: BR0406001 & after) 1

15 67622 342 Pump Tube (SN: BR0405001) 1

15 68378 342 Pump Tube (SN: BS0406002 & after) 1

16* 14416 Kit – Nat. to LP Conversion 1 (per well)

16* 14417 Kit – LP to Nat. Conversion 1 (per well)

√ recommended parts

*not shown

3-10 707

Page 67

Model OFE/OFG/OEA/OGA-341, 342

1 2 3 4 5 6 7 8 9

Item No. Part No. Description Qty. per Well

√ 1 60207 Transformer – 120-24V 1

√ 1 60536 Transformer – 230-24V 1

√ 2 74127RB Control Panel Assy. less transformers 1

√ 3 71029RB Control Board Assy – China 1

√ 4 58790RB I/O Board w/Power Supply Assy. 1

5 21645 Assy -Wire-Temp Interconnect - 2 pin 1

6 60810 Power Cable - I/O to Control - 4 pin 1

7 21643 Wire Assembly - I/O to Control - 14 pin 1

8 59565 Menu Card 1

√ 9 TS22-012 Transformer-Autolift (when applicable) 1

√ recommended parts

607 3-11

Page 68

Model OFE/OFG/OEA/OGA-341, 342

6 1 2 3 4 5

Item No. Part No. Description Qty. per Unit

1 33501 Gas Line – ¾ in. w/Double Swivel – 341 1

1 33167 Gas Line – 1 in. w/Double Swivel – 342 1

√ 2 64197 Blower Motor Assy – 120V 1 (per well)

√ 2 21037 Blower Motor Assy – 220V-50 Hz 1 (per well)

3 33353 120V Coiled Power Cord 1

4 63602

4 80091

Actuator-Auto-lift (when applicable-Below SN: BS0812001) 2(per well)

Actuator-Auto-lift (when applicable-SN: BS0812001 & Above) 2(per well)

5 21006 Panel – Left Side - before 4/27/05 1

5 67854 Panel – Left Side - 4/27/05 to Dec. 31, 2005 1

5 70225 Panel – Left Side - Jan. 1, 2006 & After 1

6 21005 Panel – Right Side - Before Jan. 1, 2006 1

6 70226 Panel – Right Side -Jan. 1, 2006 & After 1

7* 31421 Bearing – Auto-Lift (when applicable) 4(per well)

√ recommended parts/*not shown

3-12 1209

Page 69

Model OFE/OFG/OEA/OGA-341, 342

5 6 1 2 3 7 4 10 8 9

Item No. Part No. Description Qty. per Well

√ 1 43768 Power Switch 1

√ 1 52224 Covered Power Switch - CE 1

2 21687 Decal - Control - 34X 1

3 21008 Door Assembly - 341- Before Jan. 1, 2006 1

3 70207 Door Assembly - 341-Jan. 1, 2006 & After 1

3 21086 Door Assembly - LH - 342 - Before Jan. 1, 2006 1 (per unit)

3 70238 Door Assembly - LH - Jan. 1, 2006 & After 1 (per unit)

4 41836 Pocket Pull 1

5 17618 Hinge Assembly - Top - LH 1

6 21034 Hinge Assembly - Bottom - LH 1

7 21426 Door Assembly - RH - 342 - Before Jan. 1, 2006 1 (per unit)

7 70240 Door Assembly - RH-342-Jan. 1, 2006 & After 1 (per unit)

4 41836 Pocket Pull 1

8 17620 Hinge Assembly - Top - RH 1

9 21433 Hinge Assembly - Bottom - RH 1

10 21036 ½ Size Basket 2

10 21038 1/3 Size Basket 3

10 64211 Full Size Basket 1

10 81584 Basket, 1/2 Size, Reduced Weight 2

11* 23850 Skimmer - Square Mesh 1

12* 14784 Kit – Joining (Non-Auto-Lift fryers only!) 1

√ recommended parts/

410 3-13

*not shown

Page 70

Model OFE/OFG/OEA/OGA-341, 342

1 2 3 4 5 6 7 8

Item No. Part No. Description Qty. per Well

√ 1 64210-01 Element – OFE34X – 208V 2

√ 1 64210-02 Element – OFE34X – 220V 2

√ 1 64210-03 Element – OFE34X – 230V 2

√ 1 64210-04 Element – OFE34X – 240V 2

√ 1 64210-07 Element – OFE34X – 480V 2

2 24194 Spreader - Front - 34X 1

3 21978 Strap - Spreader - 34X 10

4 24176 Weldment - Spreader - 34X 2

5 23929 Strap - Vertical - Rear 1

6 23928 Strap - Brace Vertical - Rear 1

7 23507 Strap - Capillary Tube 2

7 23854 Guard - Position Hi Limit 1

√ recommended parts

3-14 106

Page 71

Model OFE/OFG/OEA/OGA-341, 342

1 3 2

Item No. Part No. Description Qty. per Well

√ 1 60266 Pilot - Tee Style & Ignitor Assy. 1

23735 Orifice – Pilot – Nat. 1

60614 Orifice – Pilot – LP 1

√ 2 60292 Sensor - Flame - Pilot 1

3 21827 Tube – Pilot 1

3 67817 Tube – Pilot – CE 1

√ recommended parts

106 3-15

Page 72

Model OFE/OFG/OEA/OGA-341, 342

Electric Components

1 2 3 4

Item No. Part No. Description Qty. per Well

1 60241 High Limit - 425º F 1

2 23823 Assy-Heater Terminal Block 1

3 14973 Temperature Probe Assembly 1

4 18227 Microswitch 1

5* 32497 EMC Filter Board - CE 1

6* 32498 Assy – 4 Inch Terminal Block 1

recommended parts/*not shown

3-16 607

Page 73

Model OFE/OFG/OEA/OGA-341, 342

OFG/OGA-341 OFG/OGA-342

Item No. Part No. Description Qty. per Unit

1 16336 Elbow – Male 1

2 FP02-050 Nipple – ½ x 24 LG BI 1

3 FP01-090 Elbow – ½ NPT x 90 Female - BI 4

4 FP02-051 Nipple – ½ x 17 LG BI 1

5 FP02-052 Nipple – ½ x 4 LG BI 1

6 16335 Male Connector – 37 Flare 2

7 FP01-089 Bushing – Reducing – 3/4M to 1/2F BL 2

8 FP01-097 Tee – ¾ NPT – Female Pipe – BI 1

9 FP01-100 Elbow – Street – ¾ NPT BI 1

10 FP02-040 Nipple – ¾ x 24 LG BI 1

11 FP02-032 Nipple – ¾ x 17 LG BI 1

12 FP01-098 Elbow – ¾ NPT x 90 Female - BI 3

13 FP02-023 Pipe – ¾ NPT x 19-1/4 LG BI 1

14 21801 Tube Assy – Valve Inlet – 34X 341- 1 342- 2

15* FP01-200 Fitting – Gas Inlet BSPT 1

*not shown

607 3-17

Page 74

Model OFE/OFG/OEA/OGA-341, 342

Item No. Part No. Description Qty. per Well

1 24809 Hook – Basket Hanger – ½-Size

1 70102 Hook – Basket Hanger – ½-Size

(before 06/01/05) 1

(06/01/05 & after) 1

2 36030 Bracket – 1/3-Size Basket 1

3 38912 Bracket – 1/2-Size Basket

(before 06/01/05) 1

3-18 106

Page 75

Model OFE/OFG/OEA/OGA-341, 342

OFG/OFE ELECTRO MECHANICAL PARTS LIST

PART NUMBER DESCRIPTION

√ 60816 Adjustable Relay Base

√ 60817 Adjustable Time Delay Relay

√ 60818 24VAC Coil Relay

√ 60765 24V Dual Face Timer

√ 14851 Thermostat Kit

60814 E/M Bulb Mounting Clip (Gas)

√ 35916 Transformer 120V to 24V (Gas)

√ 60536 Transformer 24V/230V (Electric)

√ 60792 Indicator Light – 24 V

√ 51795 24v Mechanical Contactor (Elec. Only)

√ 65098 Assy. - Heat Contactor – 24V - CE

√ 65567 Assy. – Timer Buzzer Coil-24V

36224 Decal – E/M Controls – 34X

607 3-19

Page 76

Model OFE/OFG/OEA/OGA-341, 342

OVER-THE-TOP PUMBING W/O D.C. PARTS (March 1, 2006 & After)

Item No. Part No. Description Qty.

1 73370 HANGER-ACTUATOR CONDUIT 1

2 SC06-013 U BOLT 1/4-20 FOR 3/4 DIA 3

3 71185 BRACKET-TUBE 1

4 SC03-001 SCREW #10 X 1/2 PH PHD TEK 2 C 4

5 71139 ASSY-TUBE RETURN LINE 1

6 16807 FITTING CONNECTOR MALE 2

7 FP01-090 ELBOW-1/2NPT X 90 FEMALE BI 2

8 FP02-018 NIPPLE-1/2 NPT X 2.00L BI 1

9 71063 ASSY-PUMP RETURN TUBE 1

10 71142 BRACKET-TUBE REAR SUPPORT 1

3-20 806

Page 77

Model OFE/OFG/OEA/OGA-341, 342

OVER-THE-TOP FAUCET ASSY. (March 1, 2006 & After)

Item No. Part No. Description Qty.

1 71899 ASSY. – 341 FAUCET 1

17333 FEMALE DISCONNECT 1

1 71665 ASSY. – 342 FAUCET 1

17334 MALE DISCONNECT 1

2 71830 HANDLE – DIVERTER VALVE (

Direct-Connect units) 1

1209 3-21

Page 78

Model OFE/OFG/OEA/OGA-341, 342

341 DIRECT-CONNECT PARTS LIST (Before March 1, 2006)

Part No. Description Qty.

16282 NIPPLE 3/4 X CLOSE 1

21611 DISCONNECT-MALE 1

21612 DISCONNECT-FEMALE 1

21753 HOSE-SHORTENING DISCARD 1

21800 VALVE-3/4 CHECK 1

23430 VALVE-3/4 INLET-E34X 1

67850 BRACKET-34X D/C REAR SUPPORT 1

FP01-140 PLUG-3/4 PIPE-BI 2

FP01-142 CROSS-3/4 NPT BI 1

FP02-039 NIPPLE-3/4 X 6 LG-BI 1

FP02-059 NIPPLE-3/4 X 27 LG-BI 1

SC03-001 SCREW #10 X 1/2 PH PHD TEK 2 C 2

342 DIRECT-CONNECT PARTS LIST (Before March 1, 2006)

Part No. Description Qty.

16282 NIPPLE 3/4 X CLOSE 1

21611 DISCONNECT-MALE 1

21612 DISCONNECT-FEMALE 1

21753 HOSE-SHORTENING DISCARD 1

21800 VALVE-3/4 CHECK 1

67850 BRACKET-34X D/C REAR SUPPORT 1

FP02-059 NIPPLE-3/4 X 27 LG-BI 1

SC03-001 SCREW #10 X 1/2 PH PHD TEK 2 C 2

FP01-140 PLUG-3/4 PIPE-BI 1

FP02-033 NIPPLE-3/4 NPT X 4 IN LONG BI 1

FP02-039 NIPPLE-3/4 X 6 LG-BI 1

3-22 806

Page 79

Model OFE/OFG/OEA/OGA-341, 342

341 W/DIRECT-CONNECT PARTS LIST (March 1, 2006 & After)

Item No. Part No. Description Qty.

1 71139 ASSY-TUBE RETURN LINE 1

2 73370 HANGER-ACTUATOR CONDUIT 1

3 SC06-013 U BOLT 1/4-20 FOR 3/4 DIA 3

4 71070 ROD – EXTENSION FILTER VALVE 1

5 SC03-001 SCREW #10 X 1/2 PH PHD TEK 2 C 4

6 71185 BRACKET-TUBE 1

7 17255 COTTER PIN 1

8 17407 CONNECTOR – ½ MALE ELBOW 2

9 21613 VALVE – DIVERTER 1

10 16807 FITTING CONNECTOR MALE 1

11 71063 ASSY – PUMP RETURN TUBE 1

12 71142 BRACKET-TUBE REAR SUPPORT 1

13 67492 STOP – D/C EXTENSION ROD 1

806 3-23

Page 80

Model OFE/OFG/OEA/OGA-341, 342

341 AUTO-LIFT W/DIRECT-CONNECT PARTS LIST (March 1, 2006 & After)

Part No. Description Qty.

16807 FITTING CONNECTOR MALE 3

17255 PIN-COTTER 1

19811 1/2" 90 STRT ELL,S.S. 1

21613 VALVE-DIVERTER 1

21800 VALVE-3/4 CHECK 1

67492 STOP-D/C EXTENSION ROD 1

71063 ASSY-PUMP RETURN TUBE 1

71142 BRACKET-TUBE REAR SUPPORT 1

71185 BRACKET-TUBE 1

71652 ASSY-TUBE RETURN LINE A/LIFT 1

71653 ASSY-DIV TUBE RS A/LIFT 1

71830 HANDLE-DIVERTER VALVE 1

71921 ROD-EXTENSION A/LIFT FLTR V 1

FP01-018 1/2 STR PIPE COUPLING CONDUIT 1

FP01-029 REDUCER 1/2NPT M-3/8NPT F SS*S 1

FP01-089 BUSHNG-REDUCNG 3/4M TO 1/2F BL 1

FP01-090 ELBOW-1/2NPT X 90 FEMALE BI 1

FP02-018 NIPPLE-1/2 NPT X 2.00L BI 2

SC01-209 #10-32 X3/8 PH THD SS 2

SC03-001 SCREW #10 X 1/2 PH PHD TEK 2 C 4

SC06-013 U BOLT 1/4-20 FOR 3/4 DIA 2

17333 RINSE HOSE DISCONNECT FEMALE 1

17334 RINSE HOSE DISCONNECT MALE 1

FP02-001 NIPPLE 3/8 CLOSE 1

60610 RETURN LINE - UPPER 1

71462 WELD ASSY-TUBE COUPLING PLATE 1

341 AUTO-LIFT W/O DIRECT-CONNECT PARTS LIST (March 1, 2006 & After)

Part No. Description Qty.

71185 BRACKET-TUBE 1

71652 ASSY-TUBE RETURN LINE A/LIFT 1

71653 ASSY-DIV TUBE RS A/LIFT 1

FP01-018 1/2 STR PIPE COUPLING CONDUIT 1

FP01-029 REDUCER 1/2NPT M-3/8NPT F SS 1

FP01-090 ELBOW-1/2NPT X 90 FEMALE BI 3

FP02-018 NIPPLE-1/2 NPT X 2.00L BI 1

SC03-001 SCREW #10 X 1/2 PH PHD TEK 2 C 4

SC06-013 U BOLT 1/4-20 FOR 3/4 DIA 2

17333 RINSE HOSE DISCONNECT FEMALE 1

17334 RINSE HOSE DISCONNECT MALE 1

FP02-001 NIPPLE 3/8 CLOSE 1

60610 RETURN LINE - UPPER 1

71462 WELD ASSY-TUBE COUPLING PLATE 1

3-24 806

Page 81

Model OFE/OFG/OEA/OGA-341, 342

342 AUTO-LIFT W/DIRECT-CONNECT PARTS LIST (March 1, 2006 & After)

Part No. Description Qty.

16807 FITTING CONNECTOR MALE 4

17255 PIN-COTTER 2

17407 CONNECTOR 1/2 MALE ELBOW 3

19811 1/2" 90 STRT ELL,S.S. 1

21613 VALVE-DIVERTER 2

21800 VALVE-3/4 CHECK 1

67492 STOP-D/C EXTENSION ROD 2

71063 ASSY-PUMP RETURN TUBE 1

71142 BRACKET-TUBE REAR SUPPORT 1

71185 BRACKET-TUBE 1

71652 ASSY-TUBE RETURN LINE A/LIFT 1

71653 ASSY- DIV TUBE RS A/LIFT 1

71670 TUBE-LINE OIL RETURN 1

71740 ASSY-DIV TUBE LS A/LIFT 1

71777 LABEL-OIL RETURN 34X 1

71790 ROD-EXTENSION DIVERTER 1

71830 HANDLE-DIVERTER VALVE 1

71921 ROD-EXTENSION A/LIFT FLTR V 1

FP01-018 1/2 STR PIPE COUPLING CONDUIT 2

FP01-089 BUSHNG-REDUCNG 3/4M TO 1/2F BL 1

FP01-090 ELBOW-1/2NPT X 90 FEMALE BI 1

FP02-018 NIPPLE-1/2 NPT X 2.00L BI 2

SC01-209 #10-32 X3/8 PH THD SS 2

SC03-001 SCREW #10 X 1/2 PH PHD TEK 2 C 4

SC06-013 U BOLT 1/4-20 FOR 3/4 DIA 2

17333 RINSE HOSE DISCONNECT FEMALE 1

17334 RINSE HOSE DISCONNECT MALE 1

FP02-001 NIPPLE 3/8 CLOSE 2

60610 RETURN LINE - UPPER 1

71462 WELD ASSY-TUBE COUPLING PLATE 2

73188 ASSY-DIV TUBE A/LIFT - GAS 2

806 3-25

Page 82

Model OFE/OFG/OEA/OGA-341, 342

342 AUTO-LIFT W/O DIRECT-CONNECT PARTS LIST (March 1, 2006 & After)

Part No. Description Qty.

16807 FITTING CONNECTOR MALE 4

17255 PIN-COTTER 1

17407 CONNECTOR 1/2 MALE ELBOW 1

21613 VALVE-DIVERTER 1

71063 ASSY-PUMP RETURN TUBE 1

71142 BRACKET-TUBE REAR SUPPORT 1

71185 BRACKET-TUBE 1

71652 ASSY-TUBE RETURN LINE A/LIFT 1

71670 TUBE-LINE OIL RETURN 1

71740 ASSY-DIV TUBE LS A/LIFT 1

71777 LABEL-OIL RETURN 34X 1

71790 ROD-EXTENSION DIVERTER 1

FP01-018 1/2 STR PIPE COUPLING CONDUIT 2

FP01-090 ELBOW-1/2NPT X 90 FEMALE BI 1

FP02-018 NIPPLE-1/2 NPT X 2.00L BI 2

SC03-001 SCREW #10 X 1/2 PH PHD TEK 2 C 4

SC06-013 U BOLT 1/4-20 FOR 3/4 DIA 2

17333 RINSE HOSE DISCONNECT FEMALE 1

17334 RINSE HOSE DISCONNECT MALE 1

FP02-001 NIPPLE 3/8 CLOSE 2

60610 RETURN LINE - UPPER 1

71462 WELD ASSY-TUBE COUPLING PLATE 2

73188 ASSY-DIV TUBE A/LIFT - GAS 2

3-26 1209

Loading...

Loading...