Hellwig 7636 User Manual

559-734-7451 800-367-5480 FAX 559-734-7460

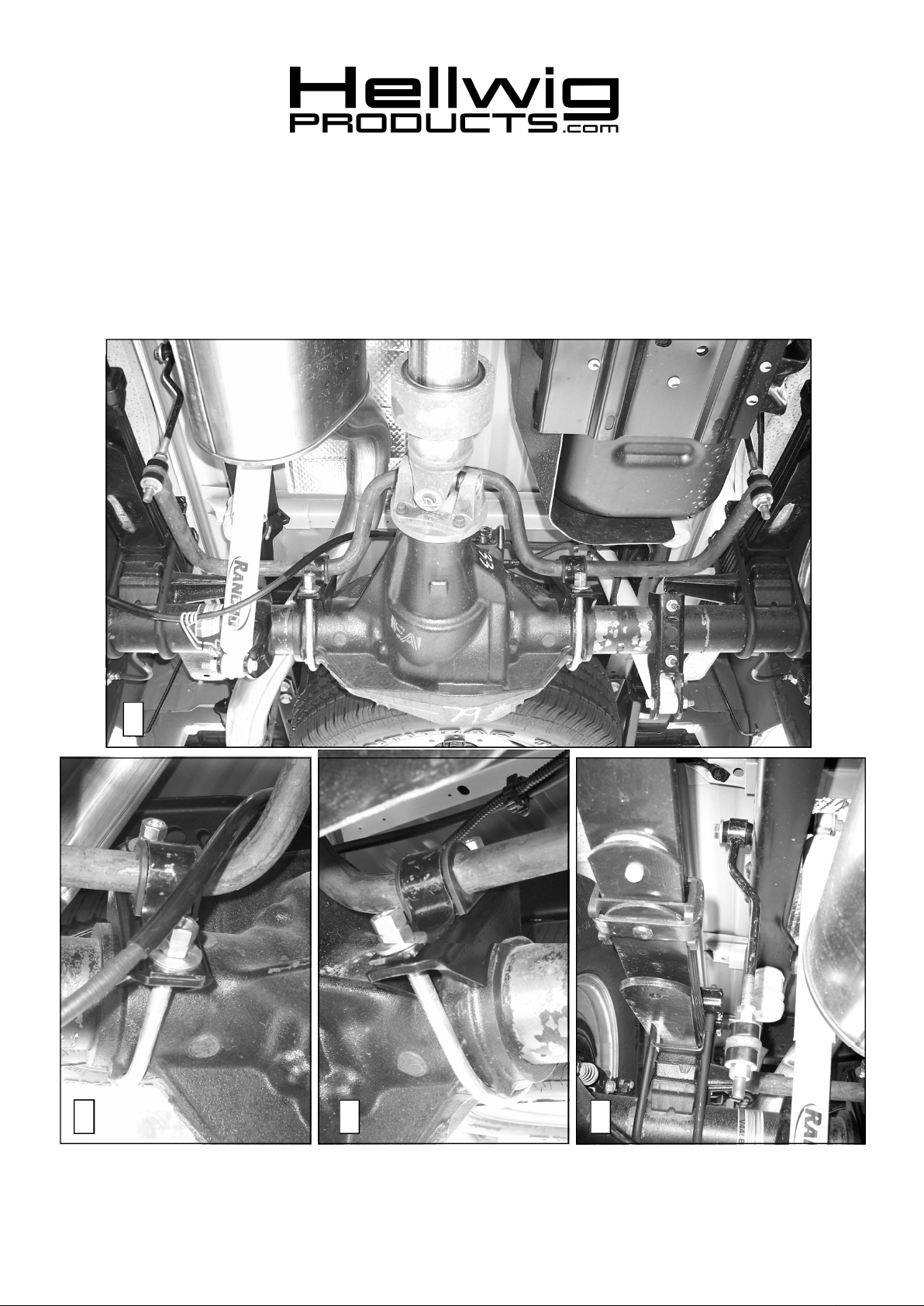

INSTALLATION INSTRUCTIONS

Rear Stabilizer Bar

2005+ 2WD & 4WD F-250/F-350 Super Duty Except Dual Wheels

Thank youfor purchasing a quality Hellwig Product.

1 2 3

1

2 3 4

7636, 7677, 7687 ( R-7677 )

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

Rear Stabilizer Bar

2005+ 2WD & 4WD F-250/F-350 Super Duty Except Dual Wheels

Thank youfor purchasing a quality Hellwig Product.

TORQUETABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – ½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.

SAFETY: BEFORE STARTING YOUR INSTALLATION, BE SURE TO SET PARKINGBRAKE AND CHOCK THE WHEELS.

NOTE: TO EASE INSTALLATIONAND TO PROPERLY ADJUST BAR, THEWEIGHT OF THE VEHICLE MUST BE ON THE SUSPEN-

SION, AS IF DRIVING DOWNTHE ROAD. DO NOT RAISE THE VEHICLEBY FRAME.

NOTE: THISUNIT IS DESIGNED TOREPLACETHEFACTORYINSTALLEDREAR ANTI-SWAYBAROR ASAN ADDITION IF THE

REAR ANTI-SWAY IS NOT FACTORY SUPPLIED.

NOTE: THISKIT INCLUDES LOCK NUTS WHICH REQUIRE TIGHTENING WITH A WRENCH AFTER BEING STARTED BY HAND.

1. Remove the factoryinstalled rear anti-sway bar (if equipped) and all factory supplied hardware.

2. Locate the half round cast lugs on the differential housing at each side near the axle tubes. Install the U-bolts on the axle betweenthese

lugs and install the saddles over the legs of the U-bolts. Orient the saddle brackets as shown in photos two(2) and three(3).

3. Place the D-shaped poly-bushings ontothe straight areas of the baron each side of the center clearance hump. Place the U-plates over the

bushings on the bar, positionthe U-plates and ploy-bushings as close as possible to the center of the hump. To avoid any possible bushing

noise, apply a thin layer greaseto the inside of the bushings( automotive grease can be used ).

4. Disconnect the emergency cable bracket located on the passenger side shock mount. Save bolt to reattach the bracket later. Move emergency brake cable out of the way to ease sway bar installation.

5. Place the bar with the bushings and U-plates up over the top of the differential housing. Align the bushings and U-plates so that they align

with the U-bolts on the differential. Place the bar bushings and U-plates onto the U-boltsand saddles , attach them with the flat washers

and nuts provided. Leaveloose at this time to allow for adjustmentlater.

6. Locate the end links and assemble with the poly bushings as in photo (4). Insert the hour glass polybushingsthrough the welded ends of

the end links. Insert the steel sleeves through the hour glass poly bushings. ( To ease installation lightly grease the steel sleeve and the

hour glass bushingbefore assembling ).

7. Attach the end links to the frame rail as shown in photo four (4). Install jam nut and hex nut on end link in position shown in photo four

(4).

8. Raise the arms of the sway bar and install the end link bushings on the arms of the sway bar as shown in the photos with the locknut on

the bottom of the end link. Tighten the nuts until the poly bushings start to bulge. Do not over tighten or damagecan occur to the poly

bushings.

9. Align the bar to be as centered on the differential as possible , and so that the arms are as level as possible. Move the bar axle, axle

mounting hardware and the frame brackets so the bar is aligned properly. The bar should have clearance on all undercarriage components.

Tighten all of the mounting hardware to the specified rates. Be sure to move any lines, wires or hoses on the axle or the inside of the

frame to avoid any damage. Double nutthe axle U-bolts.

10. Bounce the vehicle checking for clearance on all undercarriage components shocks, exhaust etc… test drive the vehicle and recheck your

installation. Recheck periodically on a regular basis thereafter.

ATTENTION INSTALLER: BE SURE THE CUSTOMER RECEIVES THIS INSTRUCTION SHEET, ALL WARNING

AND NOTE CARDS AND THE WARRANTY FORM.

7636, 7677, 7687 ( R-7677 )

Loading...

Loading...