Hellwig 55816 User Manual

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

REAR STABILIZER BAR

70-81 CAMARO & FIREBIRD

Thank you for purchasing a quality Hellwig Product.

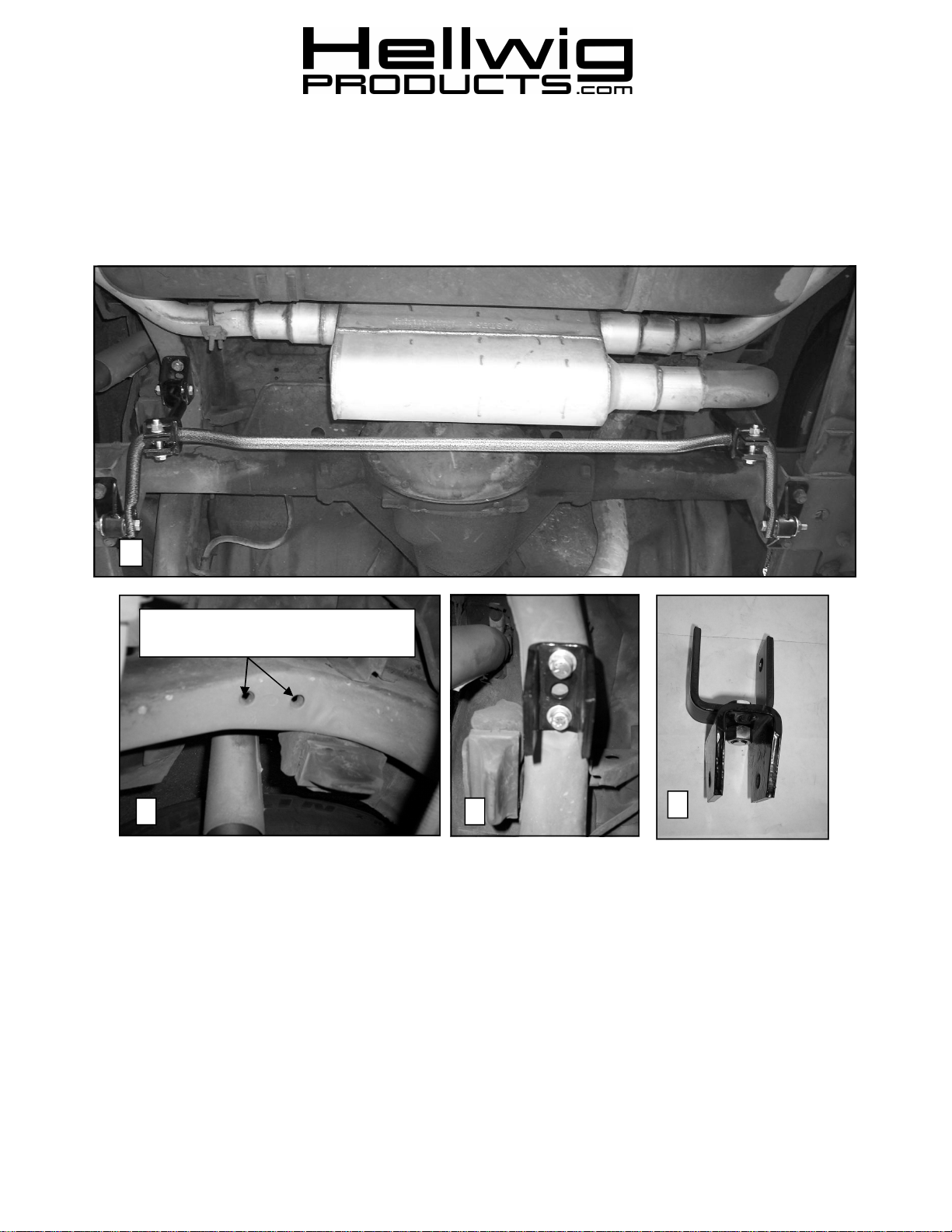

1

Locate holes in frame to mount frame

bracket using supplied 3/8-16 X 1” bolts.

2 3

TORQUE TABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – ½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.-5/8”=120 ft. lbs

SAFETY: BEFORE STARTING YOUR INSTALLATION, BE SURE TO SET PARKING BRAKE AND CHOCK

TIRES.

NOTE: THIS UNIT IS DESIGNED TO REPLACE THE FACTORY INSTALLED REAR ANTI-SWAY BAR. OR AS

AN ADDITION IF THE VEHICLE WAS NOT EQUIPPED WITH A FACTORY REAR SWAY BAR.

NOTE: THISKIT INCLUDES LOCKNUTS WHICH REQUIRE TIGHTENING WITH A WRENCH AFETR BE

ING STARTED BY HAND.

4

5816 ( R-5816) 02/15/07

559-734-7451 800-367-5480 FAX 559-734-7460

559-734-7451 800-367-5480 FAX 559-734-7460

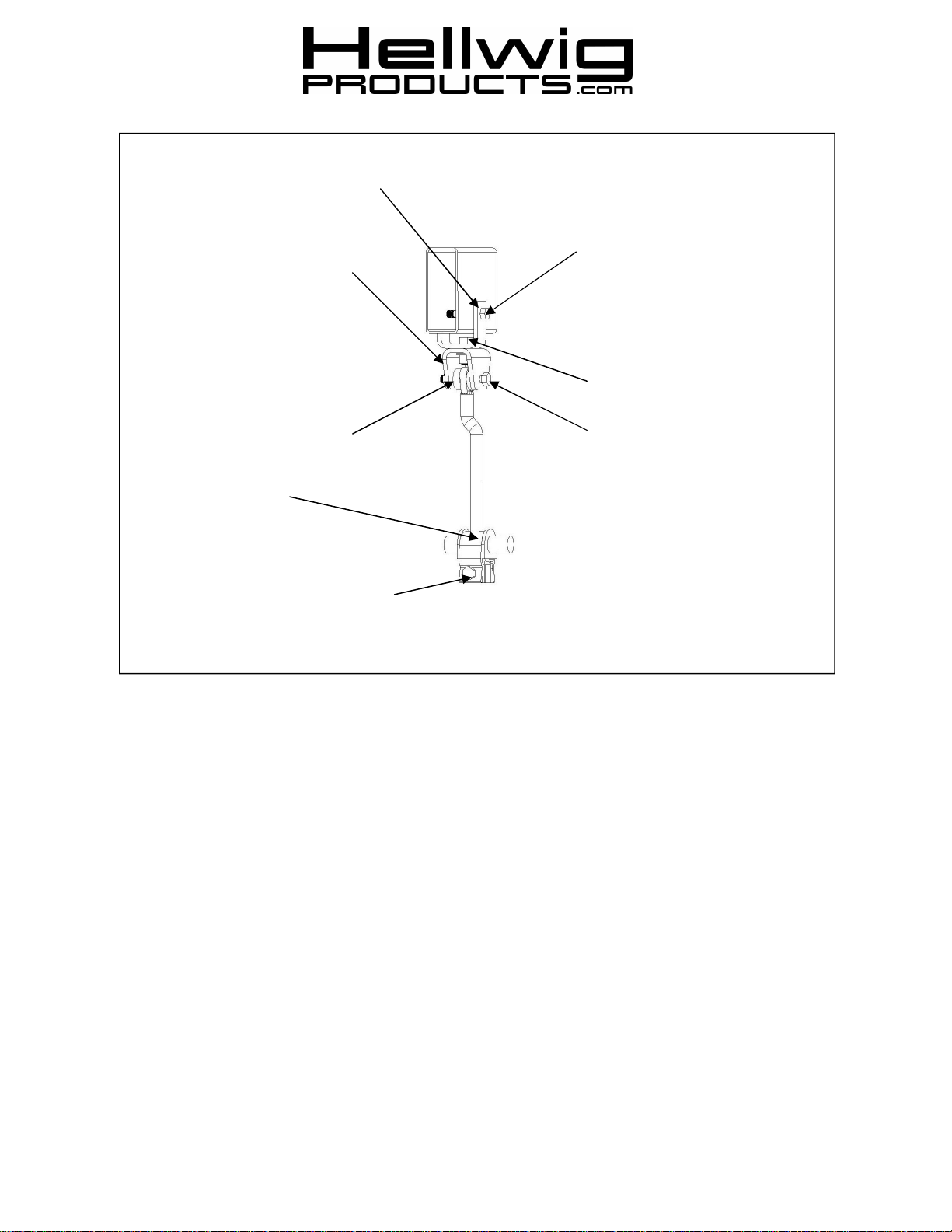

This bracket not required if predrilled holes exist in frame.

Mount this bracket to frame

with 3/8 x 1” bolts if pre-drilled

holes exist in frame. If holes

not present, mount to ubracket with 1/2” bolt as

shown.

Hourglass Bushings and

sleeves (lubricate and install

hourglass bushings before

sleeves)

D-Bushing

3/8 x 3-1/4” bolt and locknut

through subframe requires .468 dia clearance hole.

Fully mount sway bar to vehicle to determine location of

hole. Torque to 25 ft-lb

1/2 x 1” bolt and locknut.

Torque to 50 ft-lb

7/16 x 2 1/4 bolt and locknut.

Torque to 35 ft-lb

3/8 x 2 1/2 bolt, lockwasher,

and nut. Tighten until hanger

contacts bushing support.

1. If equipped, remove factory sway bar.

2. Locate the pre-drilled holes in the subframe as shown in photo (2). Attach frame bracket

to subframe using factory hardware if equipped with factory sway bar. If pre-drilled

holes are not threaded, use a 3/8-16 tap to thread holes and attach bracket using 3/8 X 1”

bolts, washers and lockwashers. See photo (3) for attachment of frame bracket. Torque

bolts to 20 ft-lb.

3. If your vehicle does not have these holes see diagram above and photo (4) for assembly

of frame bracket and end link. FULLY MOUNT SWAY BAR BEFORE DRILLING

HOLES IN SUBFRAME FOR CORRECT ALIGNMENT OF SWAY BAR AND END

LINKS. Make sure all fuel and brake lines, brake hoses, and brake cables are protected

before drilling any holes in subframe.

4. Assemble end links by inserting hourglass bushing and then inner sleeve into outer

sleeve of end link. Fully lubricate bushings before installation. Attach end link to

frame bracket using 7/16 x 2 3/4” bolt and locknut. See photo (5) and diagram. Leave

loose at this time at this time to allow for adjustment.

5. Lubricate the D-bushings and locate on sway bar as shown in photo (1).

6. Position D-bushings in hanger of end link as shown in diagram and photo (6). Insert ushaped bushing support into hanger and attach with 3/8 x 2 1/2” bolt, washer and nut.

Tighten bolt until hanger contacts bushing support.

5816 ( R-5816) 02/15/07

Loading...

Loading...